Page 1

combitherm®

GAS

Technical Service Manual

Page 2

How to Use this Technical Service Manual

This manual has been compiled as a complete resource for a technician working on Combitherm Gas models. It includes

necessary product information and drawings, along with helpful troubleshooting procedures.

Introduction gives a quick overview of the Combitherm Gas line to aid in model identification.

Sections 1 through 5 contain information applying to Combitherm Gas models:

– CONTROL PANEL IDENTIFICATION includes information on using the controllers and operating instructions. It is

the same material supplied to the customer.

– PREVENTIVE MAINTENANCE includes procedures for cleaning. This information is also supplied to the customer.

– SERVICE MODE AND ERROR CODES explains the special programming available to you as a technician to view

status, make adjustments and test functions on models equipped with Standard and Deluxe Controllers. Information is

also included on the use of displayed error codes to resolve problems and on the functions that can be operated under

fault conditions.

– TROUBLESHOOTING TREES are provided for the most common conditions you will be required to address.

– COMBITHERM PARTS has drawings and lists of available parts that apply to the electric models.

Section 6 contains Wiring Diagrams that are specific to each model.

Printing

From this CD, you may print the Current Page or any range of pages. If you would like to print out a complete manual

for a specific model, print pages 1 – 102 (Sections 1 – 5) along with the pages in that model’s section (7.14 ESG, for

example). Here’s a tip: Because printers vary in their capacity to handle large drawings, make a test print of one of the

Wiring Diagrams before printing the model’s section.

C O MB I T H E RM GA S T EC H nI CA l SE R vI C E MA nu Al

Page 3

TABLE OF CONTENTS

How to Use this Technical Service Manual ..................................... 2

Introduction ................................................................................. 4

1 — Control Panel Identification ................................................. 5

2 — Preventive Maintenance ...................................................... 49

3 — Service Mode and Error Codes ............................................ 63

4 — Troubleshooting Trees ........................................................ 68

5 — Combitherm Parts .............................................................. 78

6 — Wiring Diagrams ................................................................ 115

C O MB I T H E RM El E C TR I C T E CH n IC A l SE Rv IC E MA nu Al

C O MB I T H E RM GA S T EC H nI CA l SE R vI C E MA nu Al • 3

Page 4

INTRODUCTION

MODEL NUMBERS

This manual covers the following gas models:

Boiler-Free Models

6.10ESG

10.10ESG

7.14ESG

12.18ESG

10.20ESG

20.20ESG

CONTROLLERS

•Standardisatouchkeycontroller.

•DeluxeisatouchkeycontrollerwithprogrammableRapid-Touch™keys.

•S-Controlisrotarydialcontroller.

FEATURES AND OPTIONS

•RecessedDoorisavailableonallmodels.

MODES

•SmokerModeisavailableonboiler-freegasmodels.

•CoreTempProbe(singlepoint)isoptionalonS-controlmodels.

The Combitherm combination oven/steamer is a multipurpose oven used for:

STEAM MODE

COMBINATION MODE

CONVECTION MODE

RETHERM MODE

CORE TEMPERATURE MODE

C O MB I T H E RM El E C TR I C T E CH n IC A l SE Rv IC E MA nu AlC O MB I T H E RM GA S T EC H nI CA l SE R vI C E MA nu Al • 4

Page 5

Standard and Deluxe Control......................................................... 6

S-Control ..................................................................................... 45

Return to Main Table of Contents .................................................. 3

S ECTION 1 – CONTROL PANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 5

1

CONTROL PANEL IDENTIFICATION

Page 6

S ECTION 1 – CONTROL PANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 6

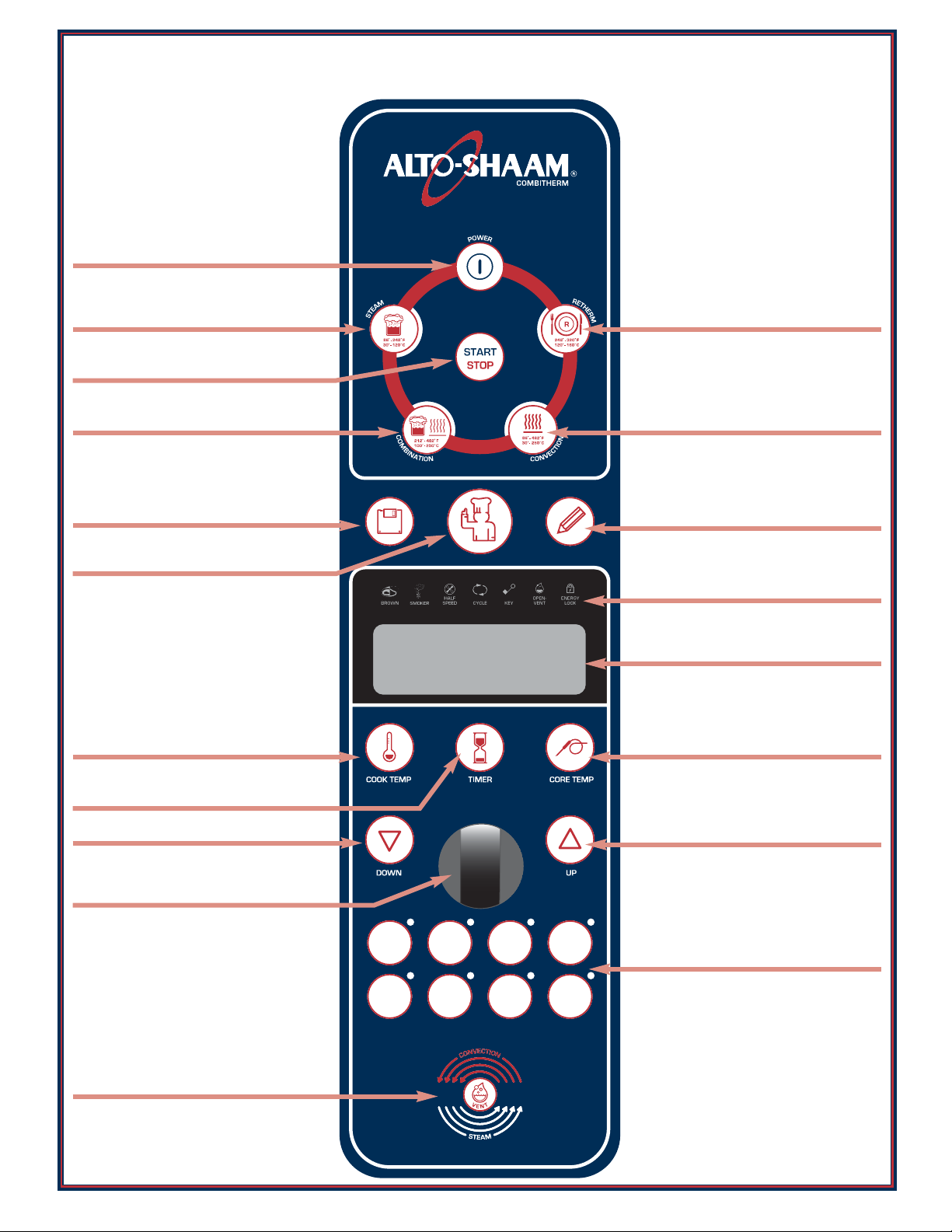

POWER ON/OFF KEY

STEAM MODE KEY

PROGRAMMED MENU KEY

COOKING TEMPERATURE KEY

DOWN ARROW KEY

MOISTURE VENT KEY

START/STOP KEY

CHEF FUNCTION KEY

TIME KEY

COMBINATION MODE KEY

RETHERM MODE KEY

CONVECTION MODE KEY

PROGRAM INSTALL/EDIT KEY

FUNCTION & OPERATING

CONTROL PANEL DISPLAY

CORE TEMPERATURE KEY

UP ARROW KEY

RAPID-TOUCH KEYS

INDICATORS

DELUXE MODELS ONLY

DELUXE MODELS ONLY

DELUXE MODELS ONLY

ELECTRIC MODELS ONLY

CONTROL PANEL IDENTIFICATION

STANDARD

AND PROGRAMMABLE DELUXE MODELS

ADJUSTMENT KNOB

Page 7

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 7

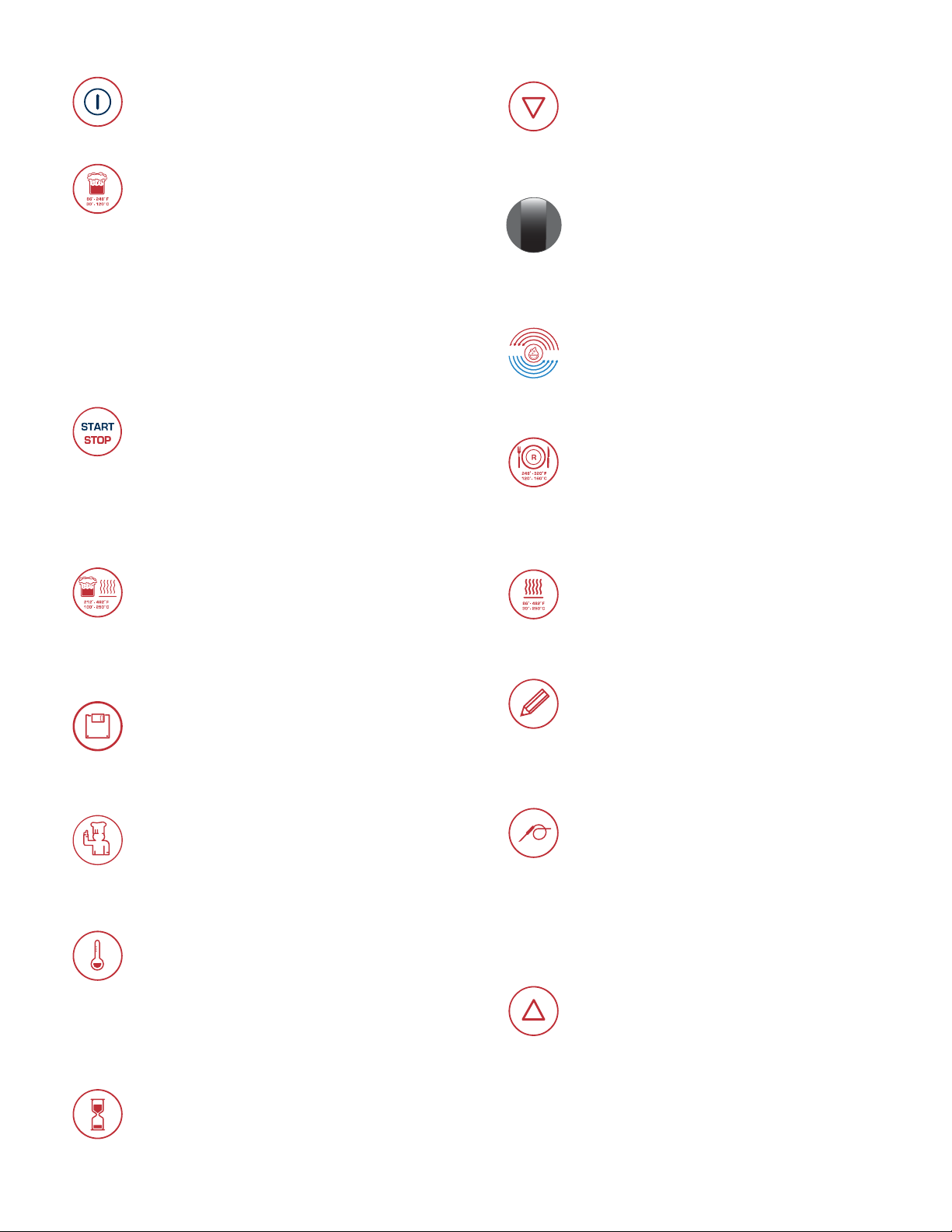

STANDARD & DELUXE CONTROL PANEL BASIC FUNCTION

POWER ON/OFF KEY

Activates power to the oven.

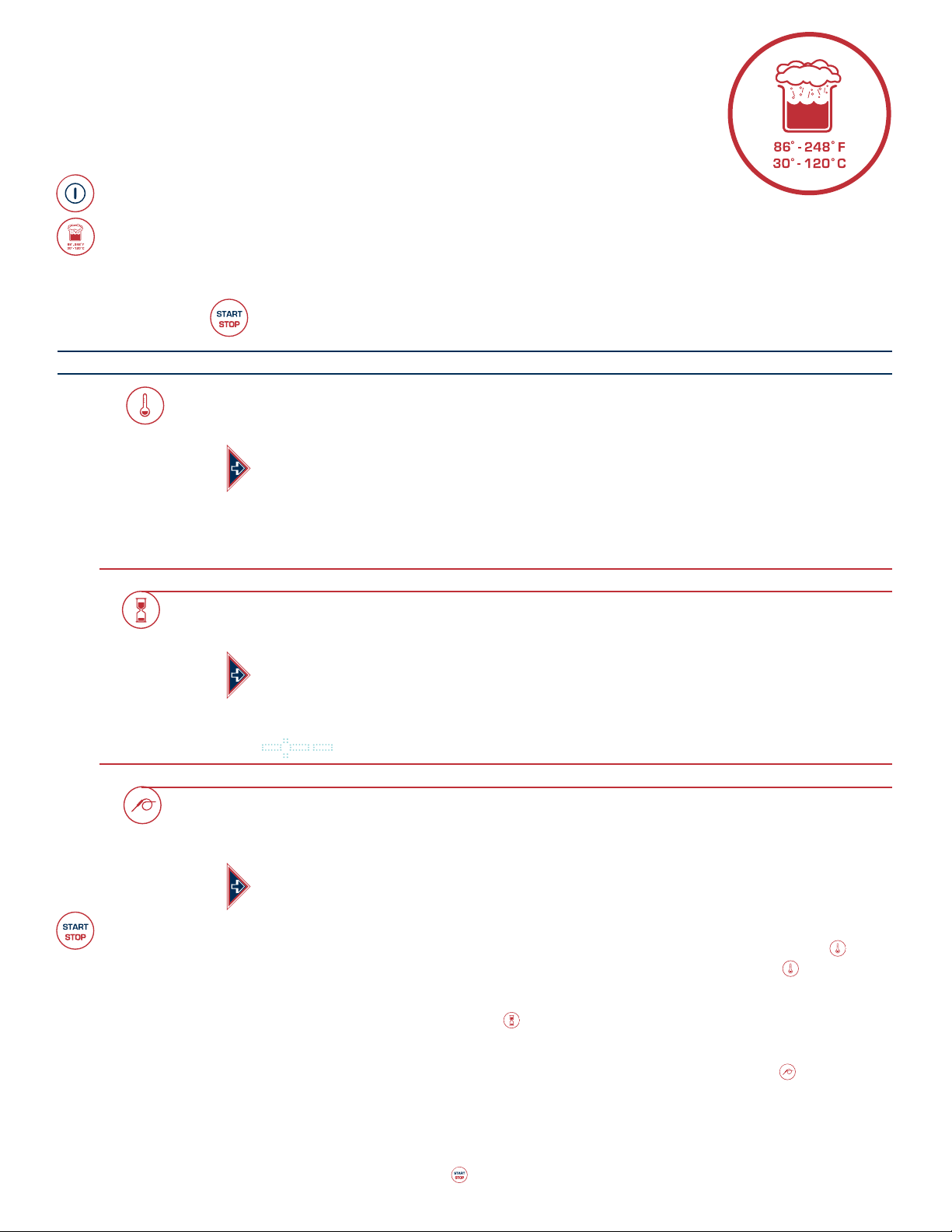

STEAM MODE KEY

The oven will operate in the steam mode at a

temperature range of 86°F to 248°F

(30°C to 120°C).

• Automatic steaming at 212°F (100°C)

FACTORY-SET DEFAULT.

• Quick steaming between 213°F and 248°F

(101°C and 120°C).

• Low Temperature Steaming between

86°F and 211°F (30°C and 99°C).

START/STOP KEY

Initiates all cooking mode functions and

programmed procedures stored in memory.

Stops an activated cooking mode or

programmed procedure currently in progress,

and exits the Chef function key .

COMBINATION MODE KEY

Selection key for cooking with a combination

of steam and convection heat that can be set

within a temperature range of 212°F to 482°F

(100°C to 250°C).

PROGRAMMED MENU KEY

Used to access and exit a menu list of all

stored cooking programs that can be reviewed

in display .

DELUXE MODELS ONLY

CHEF FUNCTION KEY

Used to select programmed menu functions,

various auxiliary functions, and several chef

help instructions.

COOKING TEMPERATURE KEY

Used to set the required cooking temperature,

to recall the set cooking temperature, or to

check the actual oven temperature in

conjunction with the down arrow key , the

up arrow key or the adjustment knob .

TIME KEY

Used to set the required cooking time or recall

the set cooking time in conjunction with the

down arrow key , the up arrow key , or

the adjustment knob .

DOWN ARROW KEY

Used to decrease displayed cook temperature

, time , or core temperature and as a

scrolling key for programming functions.

ADJUSTMENT KNOB

Displays oven functions. Serves the same

function as the up and down arrow keys to

increase or decrease the displayed cook

temperature , time , or core temperature .

MOISTURE VENT KEY

Immediately vents steam and condensate from the

oven compartment while cooking in the Convection

mode or in the Combination mode .

RETHERM MODE KEY

Food rethermalization or reheating mode will

operate with automatic steam injection at a

temperature range of 248°F to 320°F

(120°C to 160°C).

CONVECTION MODE KEY

Selection key for convection cooking without

steam at a temperature range of 86°F to 482°F

(30°C to 250°C).

PROGRAM INSTALL AND EDIT KEY

Used to create, change, duplicate, and delete

programmed menus.

DELUXE MODELS ONLY.

• • • • • • • CONTROL PANEL DISPLAY

CORE TEMPERATURE KEY

Used to set the required internal product

temperature, to recall the internal product

temperature set by the operator, or to display

the current internal temperature of the product

in conjunction with the down arrow key , the

up arrow key , or the adjustment knob .

UP ARROW KEY

Used to increase displayed cook temperature

, time , or core temperature and as a

scrolling key for programming functions.

• • • • • • • RAPID-TOUCH KEYS DELUXE MODELS ONLY.

One-touch cooking for immediate access to

frequently used operator set programs including

cooking modes, cleaning, and other oven functions.

CONTINUED

Page 8

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 8

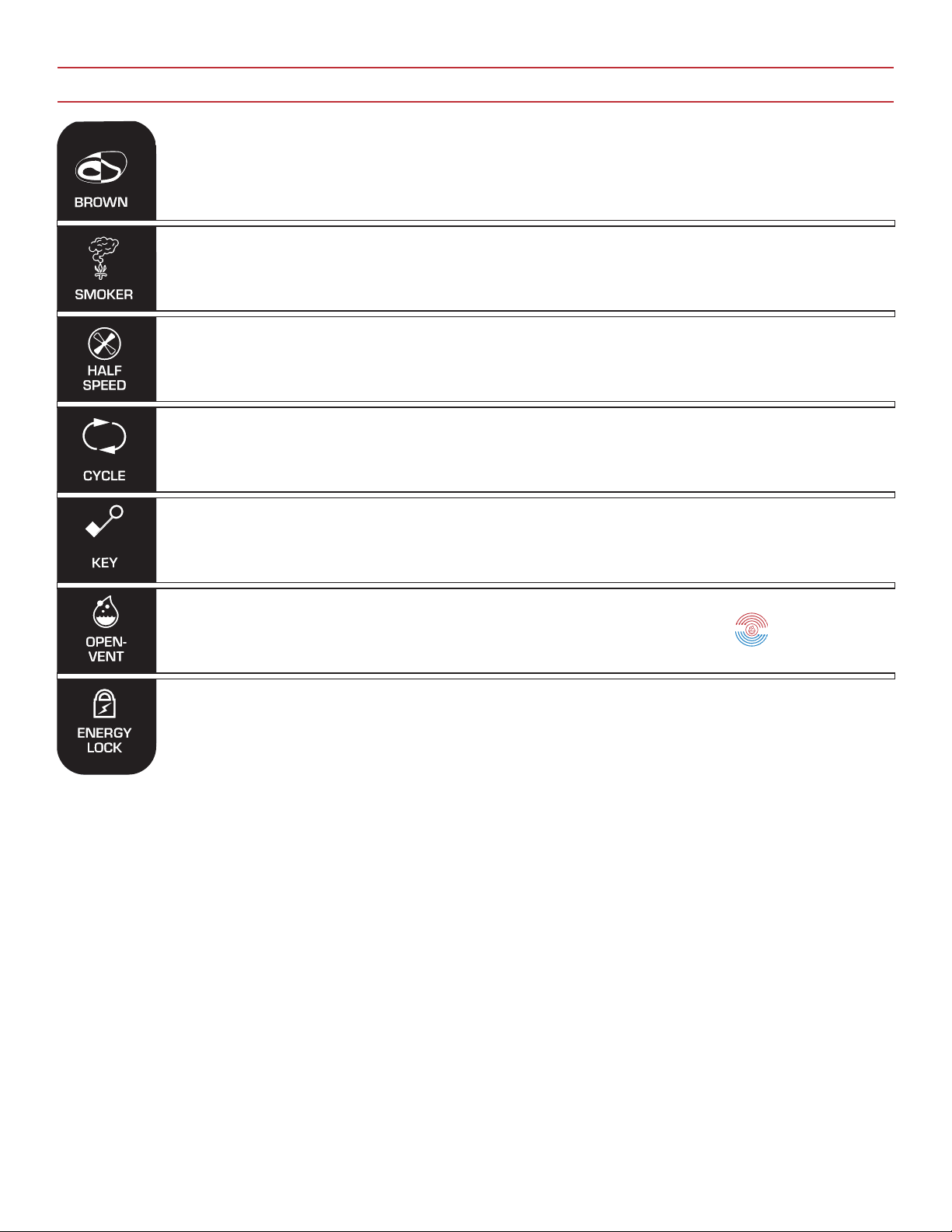

FUNCTION & OPERATING INDICATORS

A. GOLD-N-BROWN FEATURE

This indicator will illuminate when the browning function is set by the operator in a

timed or programmed cooking cycle in either convection mode or combination mode.

B. COMBI SMOKER (ON EQUIPPED MODELS)

This indicator will illuminate when the smoking function is set by the operator in a

timer, probe or programmed cooking cycle in either convection mode or combination

mode.

C. REDUCED FAN SPEED

This indicator will illuminate whenever the operator sets a reduced fan speed to

protect products affected by high-velocity air movement.

D. CONFIRMATION OF OVEN OPERATION

This indicator illuminates whenever the oven is operating in any mode.

E. KEY LOCK

This indicator will illuminate when operator has locked any mode key or function to

prevent unauthorized or accidental changes.

F. MOISTURE VENT

This indicator will illuminate whenever the Moisture Vent Key

is pressed by the operator to eliminate excessive moisture.

G. ENERGY LOCK

FOR USE WITH OVENS INSTALLED UNDER AN ALTO-SHAAM VENTLESS HOOD.

This indicator is a safety feature that will illuminate and prevent the oven from being

operated unless the ventless oven hood is operating.

STANDARD & DELUXE CONTROL PANEL BASIC FUNCTIONS

Page 9

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 9

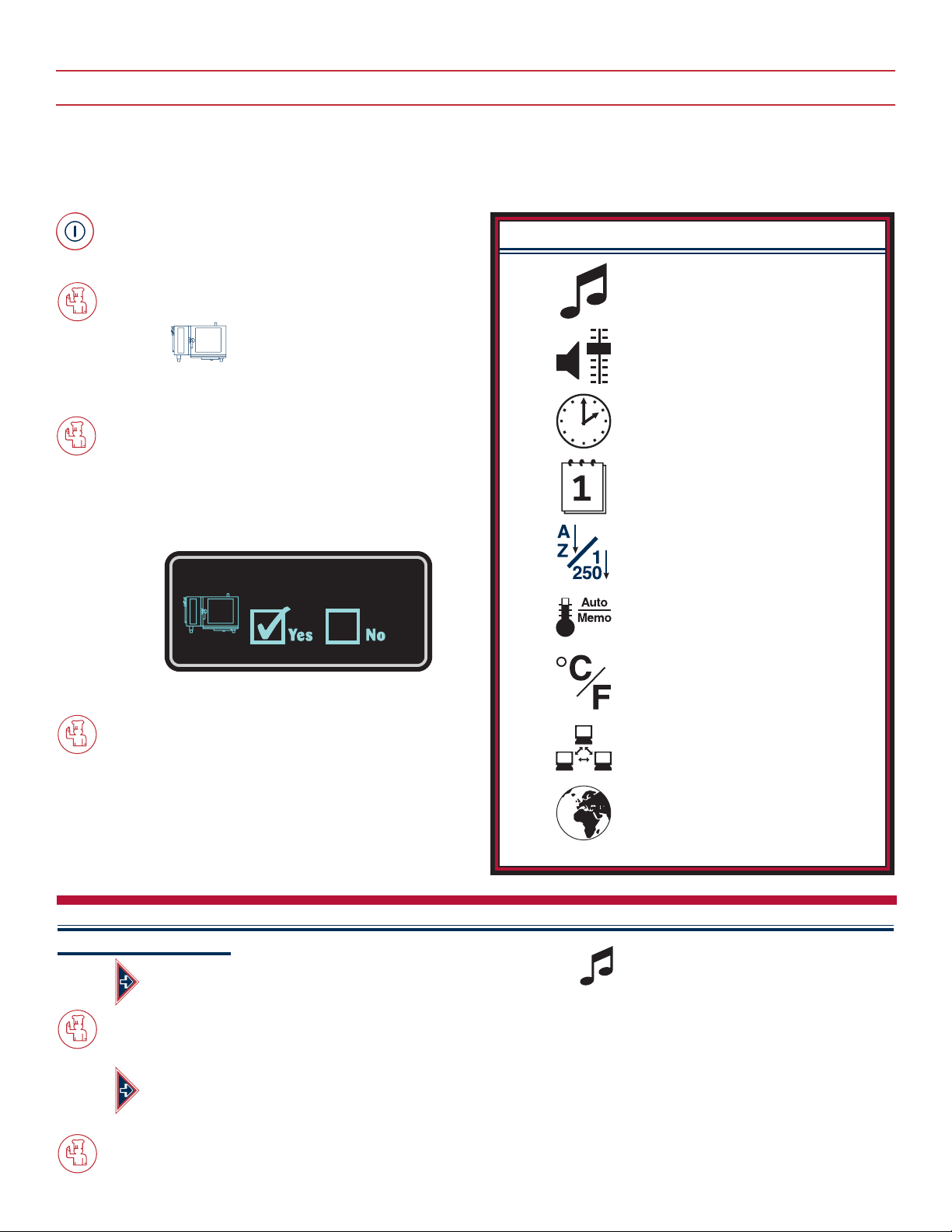

SET UP MENU

Following installation, the control should be set with the date and time. In addition to the date and time,

the set-up function provides the operator with the ability to adjust a number of other Combitherm

operating conditions to conform with the needs of the individual installation.

SET-UP PROCEDURES

PRESS THE ON/OFF POWER KEY

TO THE ON POSITION.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob

until the set up symbol is

highlighted within the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys

or rotate the adjustment knob to select

“YES” for the set up function.

PRESS THE CHEF FUNCTION KEY TO

CONFIRM THE SET UP FUNCTION.

Press the up and down arrow keys

or rotate the adjust

ment knob to

highlight one of the following

adjustment functions:

SET UP ADJUSTMENT CHOICES

SIGNAL TONE

VOLUME

TIME

DATE

PROGRAM INDEX

DEFAULT/MEMO SETTINGS

TEMPERATURE DISPLAY

NETWORK ADDRESS

LANGUAGE

SIGNAL TONE

Rotate the adjustment knob until the signal tone symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SIGNAL TONE SELECTION.

Press the up and down arrow keys or rotate the adjustment knob to select each tone offered.

Stop rotation at each individual setting to hear an audio playback. Select the tone desired.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SELECTED SIGNAL TONE SETTING.

Set up

Page 10

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 10

ALWAYS BEGIN SET UP ADJUSTMENTS FROM THE SET UP MENU .

VOLUME

Rotate the adjustment knob until the volume symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE VOLUME SELECTION.

Press the up and down arrow keys or rotate the adjustment knob to select each volume level

offered. Stop rotation at each individual setting to hear an audio playback. Select the volume

desired with consideration of the noise level within the kitchen during peak production periods.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE VOLUME SETTING.

TIME

Rotate the adjustment knob until the time symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE TIME SELECTION.

Press the up and down arrow keys to alternate between hours and minutes and rotate the

adjustment knob in each to adjust the numbers to the correct time.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SET TIME.

DATE

Rotate the adjustment knob until the date symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE DATE SELECTION.

Rotate the adjustment knob to select the preferred date format.

Press the up and down arrow keys to alternate between day, month and year, and rotate the

adjustment knob in each to adjust the numbers to the correct settings.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SET DATE.

PROGRAM INDEX

Rotate the adjustment knob until the program index symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE PROGRAM INDEX SELECTION.

Press the up and down arrow keys or rotate the adjustment knob to select the preferred index format:

“YES” for a listing of programs entered alphabetically with the program install/edit key.

“NO” for a listing of programs entered numerically with the program install/edit key.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE PROGRAM INDEX SETTING.

SET-UP PROCEDURES

Page 11

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 11

SET-UP PROCEDURES

ALWAYS BEGIN SET UP ADJUSTMENTS FROM THE SET UP MENU .

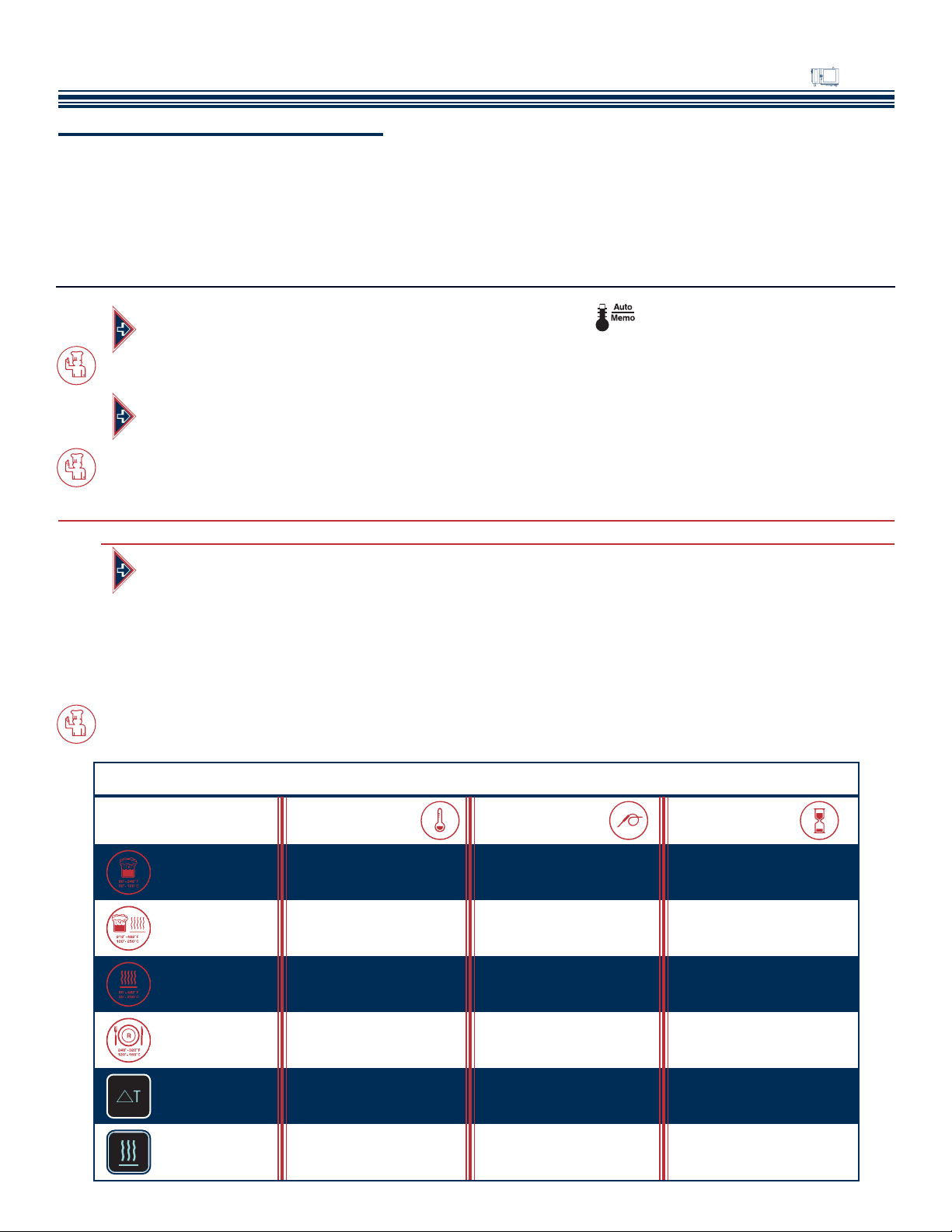

DEFAULT/MEMO SETTING

Rotate the adjustment knob until the default/memo symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE DEFAULT/MEMO SELECTION.

Rotate the adjustment knob to “NO” for memo. This setting will display the last operator set values for

time and temperature in each cooking mode.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE MEMO SETTING.

TO CHANGE THE DEFAULT SETTINGS

Rotate the adjustment knob to select “YES”.

A numbered list of default descriptions will appear in the display. Rotate the adjustment knob

until the setting to be changed is highlighted. Press the up arrow key to highlight the time or

temper

ature to be changed. Rotate the adjustment knob to change the default to the setting

desired. Press the down arrow key to save the new default setting.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE NEW DEFAULT SETTINGS.

COOKING

MODE

OVEN

TEMPERATURE

CORE

TEMPERATURE

COOKING

TIME

COMBITHERM FACTORY SET DEFAULT SETTINGS

DELTA-T 122°F 172°F

FREE

MODE (50°C) (77°C)

RETHERM 275°F 158°F

5 MINUTES

MODE (135°C) (70°C)

PREHEAT 374°F

FREE —

MODE (140°C)

CONVECTION 338°F 158°F

30 MINUTES

MODE (170°C) (70°C)

COMBINATION 302°F 158°F

70 MINUTES

STEAM MODE (150°C) (70°C)

STEAM 212°F 158°F

25 MINUTES

MODE (100°C) (70°C)

The default/memo setting allows the operator to choose

between a display showing the factory set defaults for

time and temperature or the last operator set values for

time and temperature in each cooking mode. This

adjustment function also allows the operator to change

the defaults from those set at the factory to settings that

better meet the needs of the individual operation.

Cooking product with operator set defaults for time and

temperature can help reduce operator error. Cooking

with the oven in the memo setting is particularly useful

when several batches are cooked in succession. The

memo setting eliminates the necessity to set time and

temperature for each batch.

Page 12

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 12

ALWAYS BEGIN SET UP ADJUSTMENTS FROM THE SET UP MENU .

TEMPERATURE DISPLAY

Rotate the adjustment knob until the temperature display symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE TEMPERATURE DISPLAY SELECTION.

Press the up and down arrow keys or rotate the

adjustment knob to select either Fahrenheit or Celsius.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE TEMPERATURE DISPLAY SETTING.

NETWORK ADDRESS

Press the up and down arrow keys or rotate the adjustment knob until the network address

symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE NETWORK ADDRESS SELECTION.

The current network address will appear in the display.

Rotate the adjustment knob to select 1 through 99 and assign

a different network number for each PC to be connected.

PRESS THE CHEF FUNCTION KEY TO CONFIRM EACH NETWORK ADDRESS.

LANGUAGE

Press the up and down arrow keys or rotate the adjustment knob

until the language symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE LANGUAGE PROGRAM SELECTION.

Rotate the adjustment knob to select the required language.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE LANGUAGE SETTING.

CHINESE

DUTCH

ENGLISH*

FRENCH

GERMAN

ITALIAN

JAPANESE

KOREAN

POLISH

PORTUGUESE

RUSSIAN

SPANISH

SWEDISH

*U.S. FACTORY SETTING

NOTE

: SOME OF THE LANGUAGE SELECTIONS SHOWN ABOVE MAY NOT BE AVAILABLE ON ALL MODELS.

SET-UP PROCEDURES

Page 13

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 13

DO NOT USE THE ATTACHED HAND-

HELD HOSE TO SPRAY ANYTHING OTHER

THAN THE INTERIOR OF THE COMBITHERM

OVEN COMPARTMENT.

DO NOT USE THE SPRAY HOSE

ON THE SURFACE OF A HOT COOKING

COMPARTMENT. ALLOW THE OVEN TO

COOL TO A MINIMUM OF 150°F (66°C).

NOTE: USE AUTHORIZED COMBITHERM OVEN CLEANER ONLY.

UNAUTHORIZED CLEANING AGENTS MAY DISCOLOR OR HARM INTERIOR SURFACES OF THE

OVEN. READ AND UNDERSTAND LABEL AND MATERIAL SAFETY DATA SHEET BEFORE USING

THE OVEN CLEANER.

FOR OPERATOR SAFETY

NOTE AND OBSERVE ALL SAFETY PRECAUTIONS LOCATED THROUGHOUT THIS GUIDE.

IMPORTANT SAFETY PRECAUTIONS

NOTE: Automatic steam venting is a standard

safety feature built into all Combitherm

oven models. This feature vents all

steam from the oven compartment

IMMEDIATELY BEFORE COOKING

TIME EXPIRES.

This function is provided in all

programmed and timed production

when operating in any Steam,

Combination, Convection, and Retherm

cooking mode. Automatic steam

venting does not function if the oven

door is opened before time expires or

when the oven has been set to

continuous operation.

HOT STEAM CAUSES BURNS

ROTATE THE DOOR HANDLE TO THE

FIRST OPEN ROTATION POSITION ONLY.

WAIT UNTIL THE STEAM IS VENTED BEFORE

FULLY OPENING THE DOOR.

DO NOT

HANDLE PANS CONTAINING LIQUID

OR SEMILIQUID PRODUCTS POSITIONED

ABOVE THE EYE LEVEL OF THE OPERATOR.

SUCH PRODUCTS CAN SCALD AND CAUSE

SERIOUS INJURY.

AT NO TIME SHOULD THE INTERIOR OR

EXTERIOR BE STEAM CLEANED, HOSED

DOWN, OR FLOODED WITH WATER OR

LIQUID SOLUTION OF ANY KIND. DO NOT

USE WATER JET TO CLEAN.

SEVERE DAMAGE OR

ELECTRICAL HAZARD COULD RESULT.

WARRANTY BECOMES VOID IF APPLIANCE IS FLOODED.

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

Page 14

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 14

The Steam mode provides the operator with the ability to steam, poach, or blanch.

This mode will automatically steam at the boiling point of water; quick-steam above the

boiling point for faster cooking results; or low temperature steam, below the boiling point,

for more delicate products such as pâté, mousse, seafood, or custard.

PRESS THE ON/OFF POWER KEY TO THE ON POSITION.

PRESS THE STEAM MODE KEY.

Automatic Steam temperature of 212°F (100°C) will appear in the display.

The last set time or oven control default setting for time will appear in the display.

PRESS THE START KEY TO STEAM AT THE SETTINGS SHOWN.

TO CHANGE THE SETTINGS SHOWN:

PRESS THE TEMPERATURE KEY.

The cooking temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to select

the desired cooking temperature.

• Automatic Steaming 212°F (100°C)

• Quick-steaming 213°F to 248°F (101°C to 120°C)

• Low Temperature Steaming 86°F to 211°F (30°C to 99°C)

TO COOK BY TIME:

PRESS THE TIME KEY.

The cooking time will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to

select the time desired…

or

Set control for continuous operation by rotating the adjustment knob to the right until

appears in the display.

TO COOK BY INTERNAL PRODUCT TEMPERATURE:

PRESS THE CORE TEMP KEY.

The previously set core temperature or oven control default setting will appear

highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to

select the internal temperature desired and insert the product probe.

PRESS THE START KEY TO BEGIN COOKING IN THE STEAM MODE.

• The set cooking temperature will appear in the display. To adjust the set temperature, press the key

once and make corrections as required. To display the actual oven temperature, press the key twice.

• The remaining cooking time will appear in the display. To display the set time or to change the set

values for time during operation, press the time key once and make corrections as required.

• The actual internal product temperature will appear in the display. To display the set internal product

temperature or to change the set values for core temperature during operation, press the key once

and make corrections as required.

When the cooking time has expired or the operator set internal temperature has been reached, a buzzer

will sound indicating the end of the operating mode.

• To stop the buzzer, press the start/stop key or open the oven door.

STEAM MODE

STEAM G LOW TEMPERATURE STEAM G QUICK STEAM

Page 15

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 15

This mode will steam a full or partial load of a single product, or multiple products

without transfer of flavors. When steaming multiple products, however, individual

product cooking times must be taken into consideration. The non-pressurized

atmosphere of the Combitherm also provides the ability to open the door during the

steam mode in order to monitor products more closely throughout the steaming process.

STEAM

Perforated, 2-1/2" deep pans

(65mm) are particularly suitable

for use in this program mode.

These pans will provide a shorter

cooking time and will prevent

product over-cooking at the

bottom of the pan.

Separate ice-encased vegetables

before steaming to assure more

even cooking.

A variety of products can be

steamed at the same time but

attention must be paid to the

different cooking times required

for each food product.

Butter and season vegetables

after steaming.

Steam long-grain rice using

approximately 1-part rice to

approximately 1-1/2-parts water

or seasoned liquid.

Steam durum wheat noodles in

unperforated pans using 1-part

noodles to 5-parts cold water.

QUICK STEAMING

Quick steaming is suitable

for hearty, root-type vegetables

such as potatoes, legumes,

and cabbage.

Quick steaming provides a

cooking time which is

approximately 10-percent shorter

than the regular steam mode

temperature of 212°F (100°C).

Set the steam cooking

temperature between 221°F

(105°C) and 230°F (110°C) for

small loads and between 230°F

(110°C) and 248°F (120°C) for

full loads.

LOW TEMP STEAM

The low temperature steam mode

will function whenever the oven

compartment temperature is

below 212°F (100°C).

Proof yeast dough at a

temperature setting of 90°F to

110°F (32°C to 43°C).

It will take longer to steam

products using the low

temperature steam mode.

Steaming sausages in low

temperature steam prevents

cracked or peeling skins.

Use low temperature steam for

delicate foods such as shrimp,

fish, seafood, and crème caramel.

For best results, low temperature

steam all delicate food items at a

temperature of 210°F (99°C)

or below.

STEAM MODE

CHEF OPERATING TIPS

Page 16

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 16

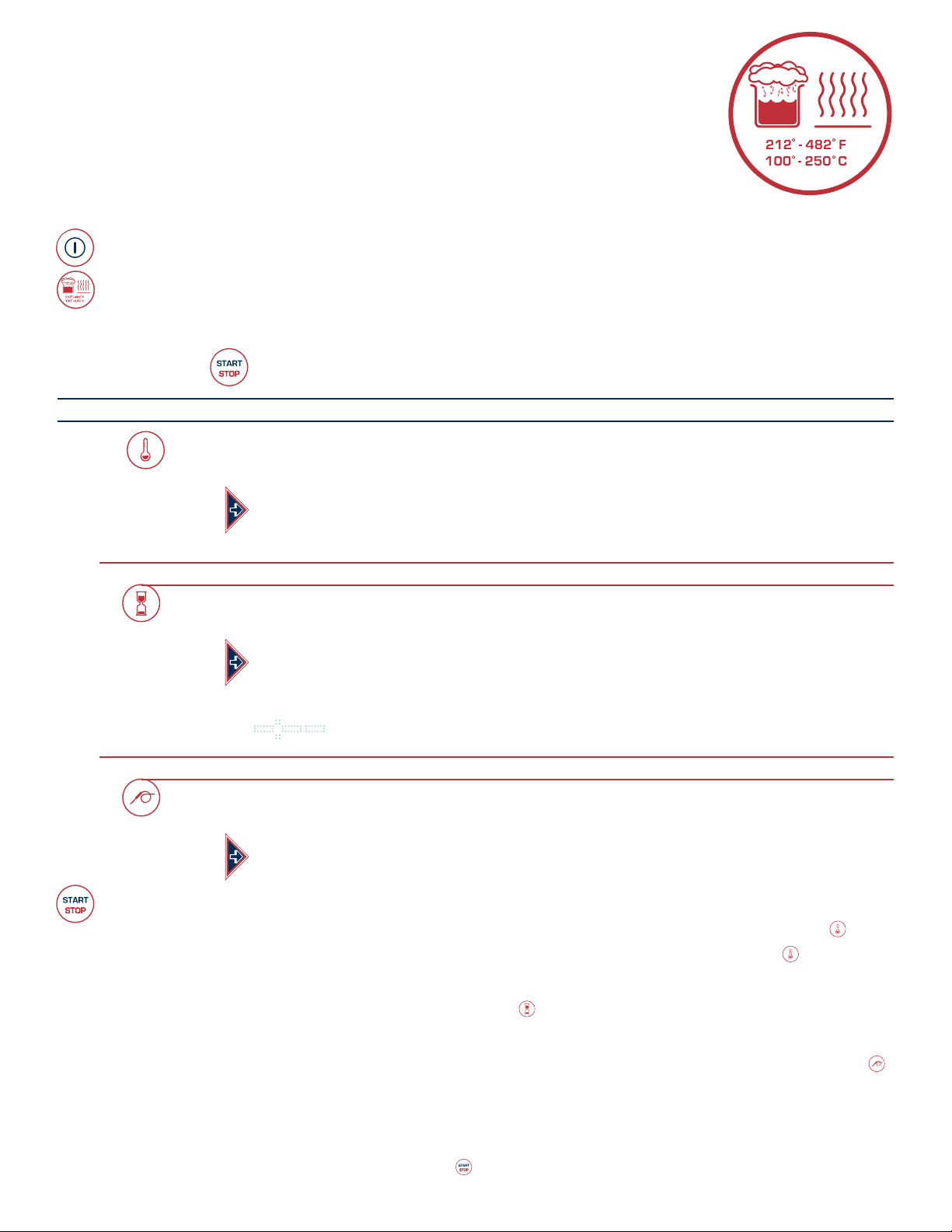

The Combination mode will prove to be the most versatile and widely used mode

the Combitherm oven has to offer. It will produce the best possible results on the

widest variety of products — all within the shortest period of time. The unique control

function of this mode enables the operator to roast or bake with a combination of

steam and convection heat. In addition to shorter cooking times, this combination of

steam and heat offers less product shrinkage and more moisture retention than obtained

in a standard convection oven.

PRESS THE ON/OFF POWER KEY TO THE ON POSITION.

PRESS THE COMBINATION MODE KEY.

The last set values or oven control default setting for temperature will appear in the display.

The last set time or oven control default setting for time will appear in the display.

PRESS THE START KEY TO COOK AT THE SETTINGS SHOWN.

TO CHANGE THE SETTINGS SHOWN:

PRESS THE TEMPERATURE KEY.

The cooking temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to

select the desired cooking temperature.

• 212°F to 482°F (100°C to 250°C)

TO COOK BY TIME:

PRESS THE TIME KEY.

The cooking time will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to select

the time desired…

or

Set control for continuous operation by rotating the adjustment knob to the right until

appears in the display.

TO COOK BY INTERNAL PRODUCT TEMPERATURE:

PRESS THE CORE TEMP KEY.

The core temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to

select the internal temperature desired and insert the product probe.

PRESS THE START KEY TO BEGIN COOKING IN THE COMBINATION MODE.

• The set cooking temperature will appear in the display. T

o adjust the set temperature, press the key

once and make corrections as required. To display the actual oven temperature, press the key twice.

• The remaining cooking time will appear in the display. To display the set time or to change the set

values for time during operation, press the time key once and make corrections as required.

• The actual internal product temperature will appear in the display. To display the set internal

product temperature or to change the set values for core temperature during operation, press the

key once and make corrections as required.

When the cooking time has expired or the operator set internal temperature has been reached, a

buzzer will sound indicating the end of the operating mode.

• To stop the buzzer, press the start/stop key or open the oven door.

COMBINATION MODE

Page 17

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 17

Due to the automatic steam adjustment, the

door can be opened at any time during a

cooking operation. Be certain to observe the

safety warning when opening the oven door.

The Combination mode is particularly efficient

when used for baking, broiling, grilling, stewing,

braising, and roasting.

When using the Combination mode, cooking

temperatures can be reduced 10- to 20-percent

below the temperatures used for conventional

cooking methods.

Cooking time will be reduced approximately

40-percent when cooking at the same temperature

used for convection oven cooking and up to 50- to

60-percent less time when cooking at the same

temperature used for a conventional oven.

Food browning in the Combitherm begins

at a cooking temperature of approximately

248°F (120°C).

A higher cooking temperature results in heavier

browning but also results in greater product

weight loss. To achieve additional browning use

the Moisture Vent Key or set Gold-n-Brown into

the product procedure. Gold-n-Brown is

particularly useful for adding color to high moisture

products such as chicken and other poultry items

or for additional browning of full loads and other

moist products.

The Combination mode provides even browning

without the necessity to turn the pans.

For more even cooking, do not cook in pans

deeper than 4-inches (100mm).

The Combination mode injects the optimum amount of steam

automatically. There is no need to select moisture levels. Foods do not

dry out. Flavors are retained with no transfer of flavors when mixing

product loads.

COMBINATION MODE

CHEF OPERATING TIPS

Page 18

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 18

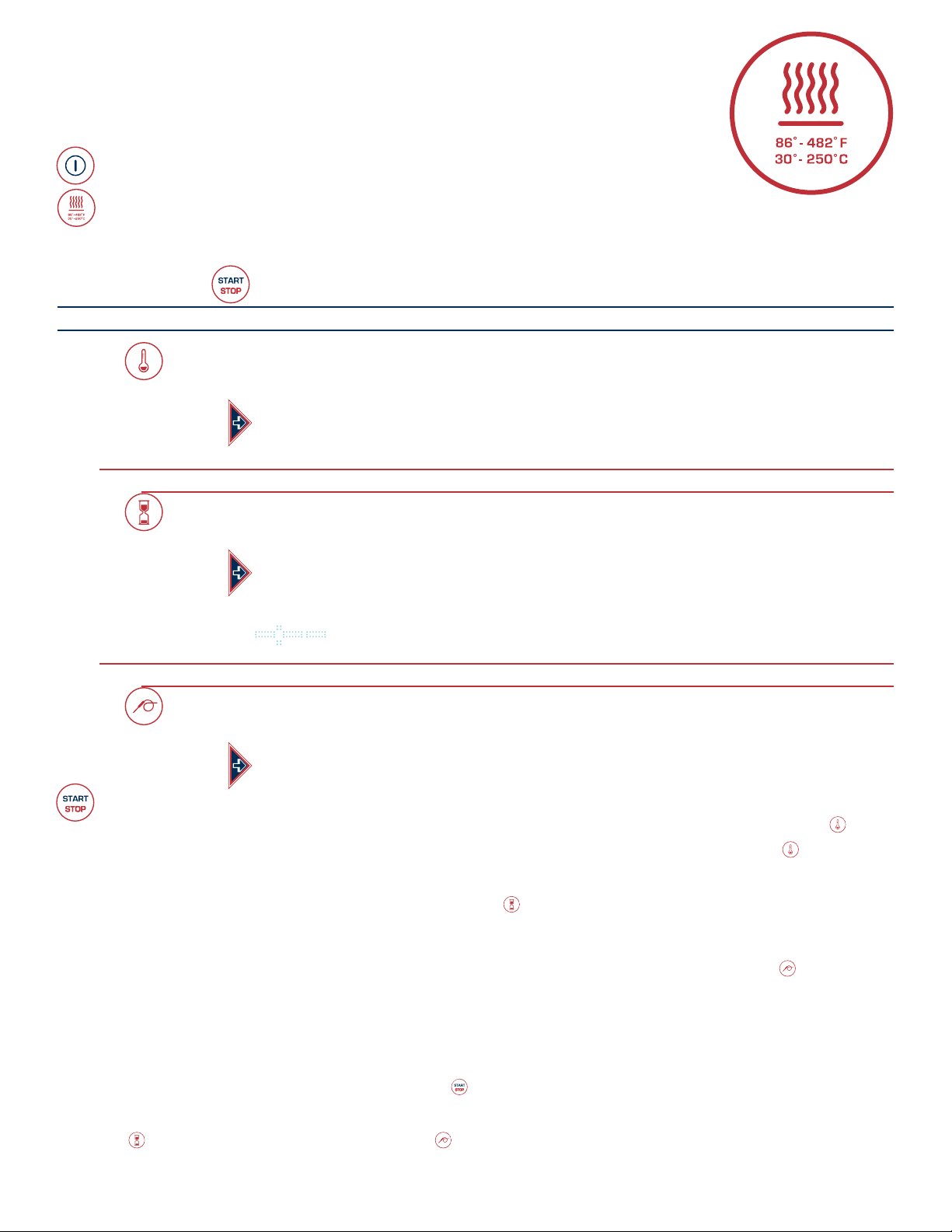

The Convection mode operates with hot circulated air within a temperature range

of 86° to 482°F (30° to 250°C). For many applications, better results may be

achieved with the Combination mode; therefore, the operator may want to consider

using the Convection mode on a more limited basis.

PRESS THE ON/OFF POWER KEY TO THE ON POSITION.

PRESS THE CONVECTION MODE KEY.

The last set values or oven control default setting for temperature will appear in the display.

The last set time or oven control default setting for time will appear in the display.

PRESS THE START KEY TO COOK AT THE SETTINGS SHOWN.

TO CHANGE THE SETTINGS SHOWN:

PRESS THE TEMPERATURE KEY.

The cooking temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob

to select the desired cooking temperature.

• 86° to 482°F (30° to 250°C)

TO COOK BY TIME:

PRESS THE TIME KEY.

The cooking time will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to select the

time desired…

or

Set control for continuous operation by rotating the adjustment knob to the right until

appears in the display.

TO COOK BY INTERNAL PRODUCT TEMPERATURE:

PRESS THE CORE TEMP KEY.

The core temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to

select the internal temperature desired and insert the product probe.

PRESS THE START KEY TO BEGIN THE COOKING MODE.

• The set cooking temperature will appear in the display. To adjust the set temperature, press the

key

once and make corrections as required. To display the actual oven temperature, press the key twice.

• The remaining cooking time will appear in the display. To display the set time or to change the set

values for time during operation, press the time key once and make corrections as required.

• The actual internal product temperature will appear in the display. To display the set internal product

temperature or to change the set values for core temperature during operation, press the key once

and make corrections as required.

When the cooking time has expired or the operator set internal temperature has been reached, a buzzer

will sound indicating the end of the operating mode.

• To stop the buzzer, press the start/stop key or open the oven door.

To check the length of time the product has been operating in the core temperature mode, press and hold the

time key along with the core temperature key . The time period will appear at the top of the display.

CONVECTION MODE

Page 19

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 19

The Convection mode works best with foods

containing little moisture or for very moist food

which require a dryer finished product.

For baking, preheat the Combitherm at a

temperature of 36°F to 54°F (20°C to 30°C) above

the baking temperature required. Once preheated,

reset the temperature as required.

A higher cooking temperature results in heavier

browning but also results in greater product weight

loss. To achieve additional browning use the

Moisture Vent Key or set the Browning Feature

into the product procedure.

To prevent the surface of food from excessive

drying, the fan will not engage if the internal

oven temperature is above 212°F (100°C)

and the set oven temperature is below

212°F (100°C).

The Convection Mode can be used to roast or bake products needing very

short cooking times or for high moisture products such as muffins, cakes,

and cookies, or for browning the surface of the product.

CONVECTION MODE

CHEF OPERATING TIPS

Page 20

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 20

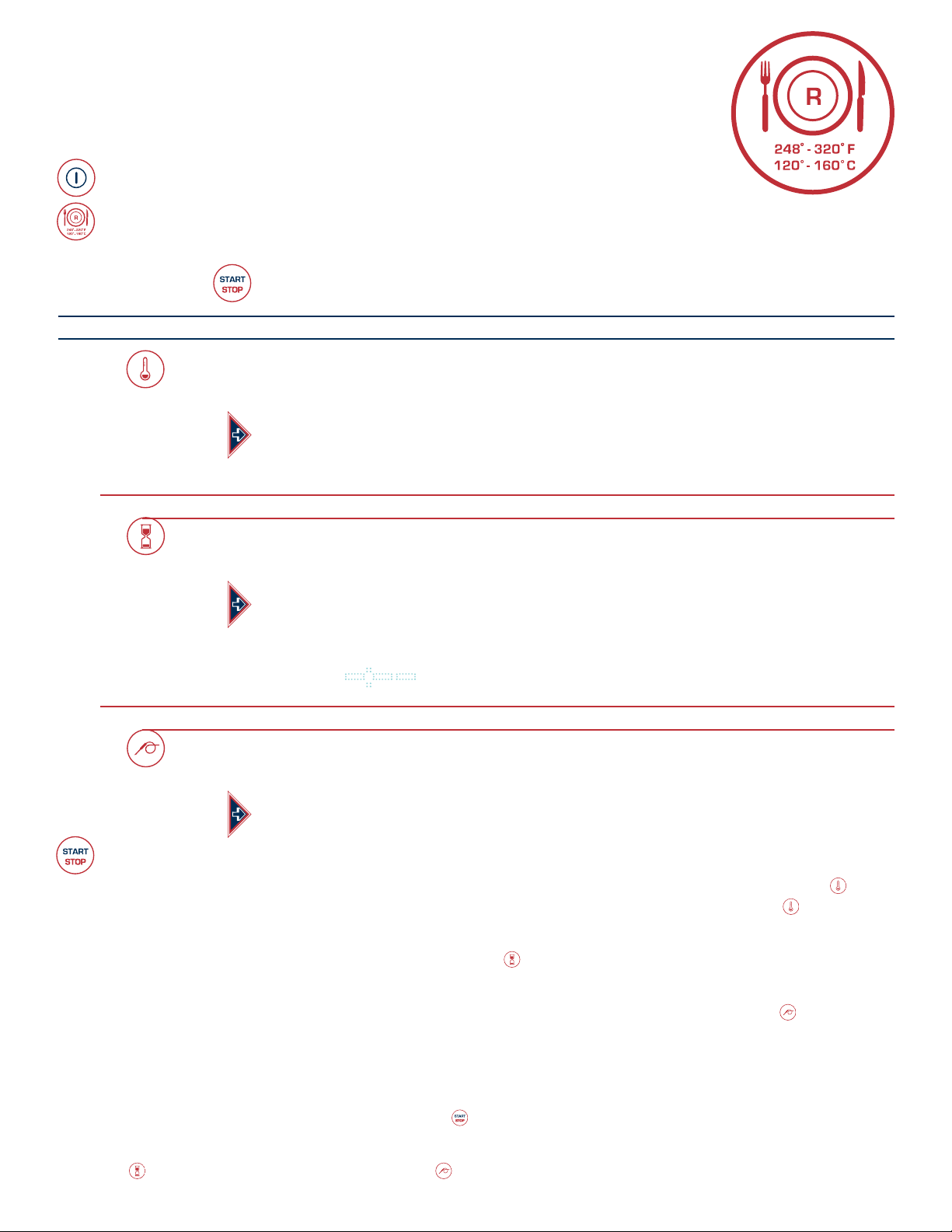

The Retherm mode can be used to rethermalize (regenerate) portioned food on

plates, trays, or platters within a short period of time. Steam is automatically injected

into the oven compartment as required. Items are brought up to proper serving

temperatures without dry edges or condensate forming on the plates.

PRESS THE ON/OFF POWER KEY TO THE ON POSITION.

PRESS THE RETHERM MODE KEY.

The last set values or the default settings will appear in the display.

PRESS THE START KEY TO COOK AT THE SETTINGS SHOWN.

TO CHANGE THE SETTINGS SHOWN:

PRESS THE TEMPERATURE KEY.

The cooking temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob

to select the desired cooking temperature.

• 248° to 320°F (120° to 180°C)

TO COOK BY TIME:

PRESS THE TIME KEY.

The cooking time will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to select the

time desired…

or

Set control for continuous operation by rotating the adjustment knob to the

right until appears in the display.

TO COOK BY INTERNAL PRODUCT TEMPERATURE:

PRESS THE CORE TEMP KEY.

The core temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to

select the internal temperature desired and insert the product probe.

PRESS THE START KEY TO BEGIN THE RETHERM MODE.

• The set cooking temperature will appear in the display. To adjust the set temperature, press the key

once and make corrections as required. To display the actual oven temperature, press the key twice.

• The remaining cooking time will appear in the display. To display the set time or to change the set

values for time during operation, press the time key once and make corrections as required.

• The actual internal product temperature will appear in the display. To display the set internal product

temperature or to change the set values for core temperature during operation, press the key once

and make corrections as required.

When the cooking time has expired or the operator set internal temperature has been reached, a buzzer

will sound indicating the end of the operating mode.

• To stop the buzzer, press the start/stop key or open the oven door.

To check the length of time the product has been operating in the core temperature mode, press and hold the

time key along with the core temperature key . The time period will appear at the top of the display.

RETHERM MODE

Page 21

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 21

Since plated meals consist of dissimilar products, there are several important factors

to consider in order to produce the finest results. Product density (compactness),

thickness, quantity of product on each plate, and quantity of plates all relate to the

length of time necessary to reheat. Again, experience is the best method to

determine reheating time. Once the time has been determined and recorded for a

specific meal, the results will be consistent for future reheating times.

HELPFUL HINTS FOR REHEATING ON THE PLATE

•

ALL FOOD COMPONENTS ON THE PLATE SHOULD BE OF SIMILAR DENSITIES.

•

ALL FOOD COMPONENTS ON THE PLATE SHOULD BE SIMILAR IN THICKNESS.

•

ARRANGE ALL FOOD COMPONENTS EVENLY ON THE PLATE.

•

AVOID EXCESSIVE OVERLAPPING OF PRODUCT.

•

SAUCES MUST BE HEATED AND ADDED TO PRODUCT AFTER REHEATING.

•

A MIXED VARIETY OF MEALS CAN BE REHEATED AT THE SAME TIME.

• À LA CARTE RETHERMALIZATION

À la carte rethermalization is designed to take

a single plate from a refrigerated temperature to

serving temperature for immediate service. Plates

are prepared in advance, covered, and refrigerated.

Preheat the Combither

m oven. Remove plate from

refrigeration and place in the oven at 275°F (135°C)

for an uncovered plate or 300°F (150°C) for a

covered plate. Plates with meat components will

take more time than plates containing all vegetable

components. Follow internal temperature

requirements for reheating and allow for override

time. After reheating, remove the plate from the

oven, add any sauces, garnish, and serve. This

process can be repeated as required.

For the most efficient continuous service, it is

suggested that the Combitherm oven be dedicated to

the rethermalization process during serving hours.

• BANQUET RETHERMALIZATION

Banquet rethermalization is designed for high

volume, full or partial load (multiple plate) reheating.

For maximum efficiency, it is essential that volume

rether

malization be used in conjunction with the

utilization of holding cabinets to keep rethermalized

food at proper temperatures.

Plates are assembled in advance, covered, and

refrigerated or loaded on the roll-in cart and

refrigerated. Preheat the Combitherm oven at

275°F (135°C) for uncovered plates or 300°F (150°C)

for covered plates. Remove plates or the roll-in cart

from refrigeration, load in the oven and set timer as

required. Follow internal temperature requirements

for reheating and allow for override time. Remove

the plates or roll-in cart from the Combitherm and

roll into the companion holding cabinet. Relocate

the holding cabinet to the banquet service area.

• RETHERMALIZING PREFABRICATED AND

VACUUM-PACKED FROZEN FOODS

For bulk product rethermalization, completely

defrost product bags in walk-in cooler. DO NOT

REMOVE PRODUCT FROM THE BAG. Load

thawed bags in preheated oven and rethermalize in

the Low Temperature Steam mode until the required

internal temperature is reached. Place rether

malized

bags in a preheated holding cabinet set at

140° to 165°F (60° to 74°C) until ready for service.

For large volume on-the-plate regeneration,

defrost bags in walk-in cooler. Open bags and plate

per menu requirements in a (

MAXIMUM) 55°F (13°C)

refrigerated room. Cover plates, place on Alto-Shaam

roll-in cart (trolley), and roll into Combitherm oven

preheated at 275°F (135°C).

Regenerate in the Convection mode for 3 to 5

minutes. Switch to the Retherm mode for an

additional 3 minutes or more if required. Transfer

full trolley to a preheated holding cabinet set at

160°F (71°C) until ready for service. In the case of

meat cooked to rare, set the cabinet at 140°F (60°C).

RETHERM MODE CHEF OPERATING TIPS

PLATE COVERS MUST BE USED FOR ON-THE-PLATE REGENERATION.

Page 22

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 22

CORE TEMPERATURE PROBE MODE

As an alternative to timer operation, the Core Temperature Probe mode can

be used in conjunction with any program mode to cook by sensing internal

product temperature. For a more accurate internal temperature, a

specialized Combitherm product probe senses temperature from four strategic

points and displays a temperature average.

PRESS THE ON/OFF POWER KEY TO THE ON POSITION.

INSERT THE PRODUCT PROBE.

The probe must be inserted so that the tip is positioned in the center of the food mass.

For liquid or semiliquid foods, suspend the probe in the center of the product and

secure the probe wire to the container edge.

SELECT AND PRESS THE REQUIRED COOKING PROGRAM.

PRESS THE TEMPERATURE KEY.

The cooking temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to

select the desired cooking temperature within the temperature range of

the cooking mode selected.

PRESS THE CORE TEMP KEY.

The core temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to

select the internal product cutoff temperature.

PRESS THE STAR

T KEY TO BEGIN THE COOKING MODE.

• The actual internal product temperature will appear in the display. To display the set internal product

temperature or to change the set values for core temperature during operation, press the key once

and make corrections as required.

When the operator set internal temperature has been reached, a buzzer will sound indicating the end of

the operating mode.

• To stop the buzzer, press the start/stop key or open the oven door.

To check the length of time the product has been operating in the core temperature mode, press and hold the

time key along with the core temperature key . The time period will appear at the top of the display.

CHEF OPERATING TIPS

To prevent over-cooking, remove product from the oven as soon as the required internal

temperature is reached in either the Core Temperature mode or the Core Temperature Delta-T

mode. The Core Temperature mode should not be used for cooking thin product items.

DO NOT USE THE PROBE WHEN COOKING THIN PRODUCTS.

Page 23

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 23

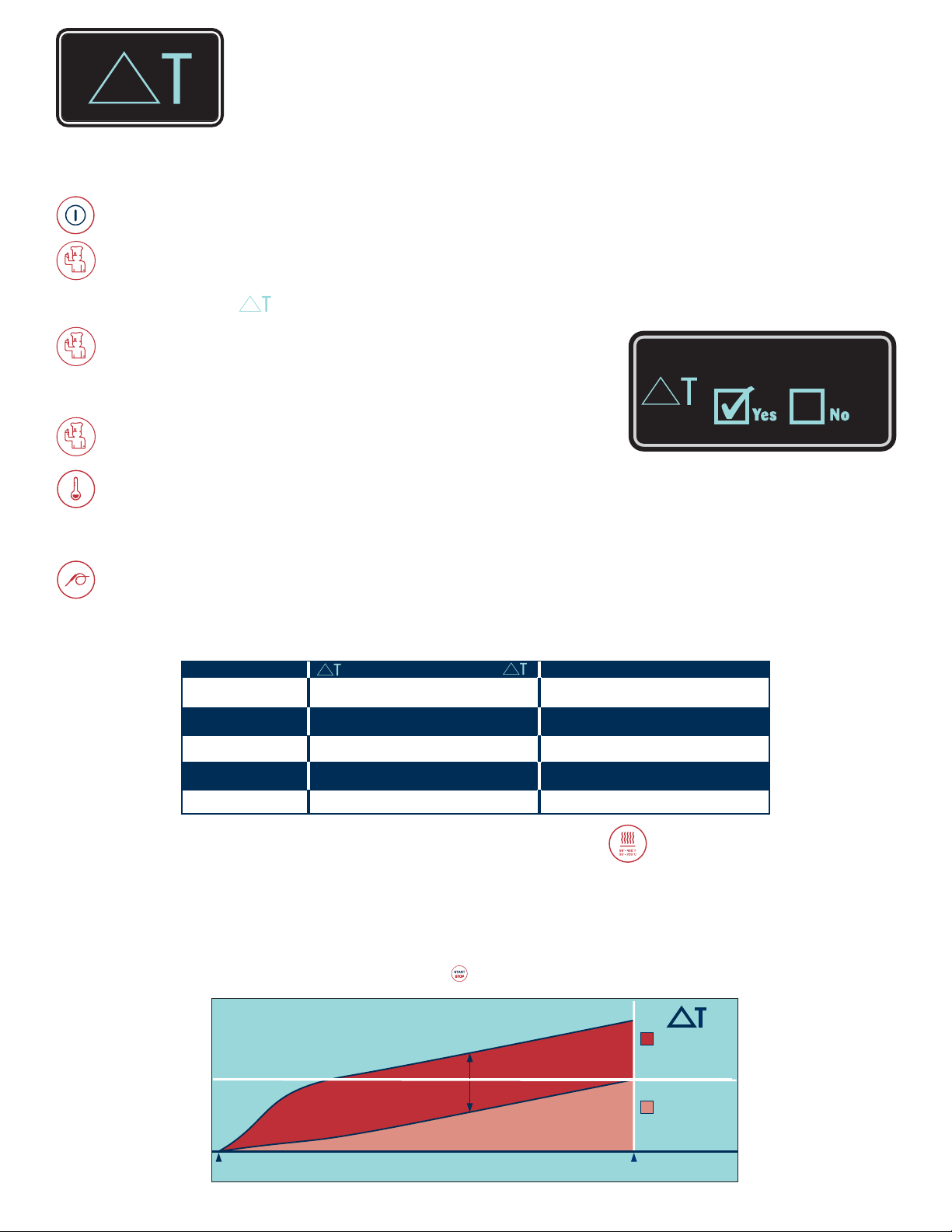

DELTA-T CORE TEMPERATURE COOKING

This special program function cooks by internal product temperature with the use of

the probe. Unlike the standard core temperature mode, however, the Delta-T oven

temperature automatically increases in direct proportion to the internal temperature

of the product. The Delta-T mode cooks with convection heat but provides a more

gentle method of cooking. Browning occurs toward the end of the cooking cycle.

PRESS THE ON/OFF POWER KEY TO THE ON POSITION.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate the adjustment knob until the

Delta-T symbol is highlighted in the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate the

adjustment knob to select “

YES” for the Delta-T function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SETTING.

PRESS THE TEMPERATURE KEY.

Press the up and down arrow keys or rotate the adjustment knob to select the desired

Delta-T cooking temperature within the cooking temperature ranges shown below.

PRESS THE CORE TEMP KEY.

Press the up and down arrow keys or rotate the adjustment knob to select the

internal product cutoff temperature within the temperature ranges shown below.

THE OVEN WILL BEGIN THE DELT

A-T CONVECTION COOKING MODE.

The set Delta-T temperature will appear in the display.

The actual internal product temperature will appear in the display.

When the operator set inter

nal temperature has been reached, a buzzer will sound indicating

the end of the operating mode.

• To stop the buzzer, press the start/stop key or open the oven door.

DELTA -T TEMPERATURE

122°F to 131°F (50°C to 55°C)

122°F to 140°F (50°C to 60°C)

122°F to 158°F (50°C to 70°C)

122°F to 158°F (50°C to 70°C)

122°F to 140°F (50°C to 60°C)

CORE TEMPERATURE SETTING

118°F to 136°F (48°C to 58°C)

122°F to 140°F (50°C to 60°C)

172°F (78°C)

172°F (78°C)

172°F (78°C)

PRODUCT

BEEF ROAST

TENDERLOIN

VEAL & LAMB

PORK ROAST

HAM

Delta-T

DIFFERENCE BETWEEN COOKING COMPARTMENT TEMPERATURE

AND INTERNAL PRODUCT TEMPERATURE.

PRODUCT AND OVEN

TEMPERATURE START

INTERNAL PRODUCT

TEMPERATURE REACHED

COOKING

COMPARTMENT

TEMPERATURE

INTERNAL

PRODUCT

TEMPERATURE

Page 24

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 24

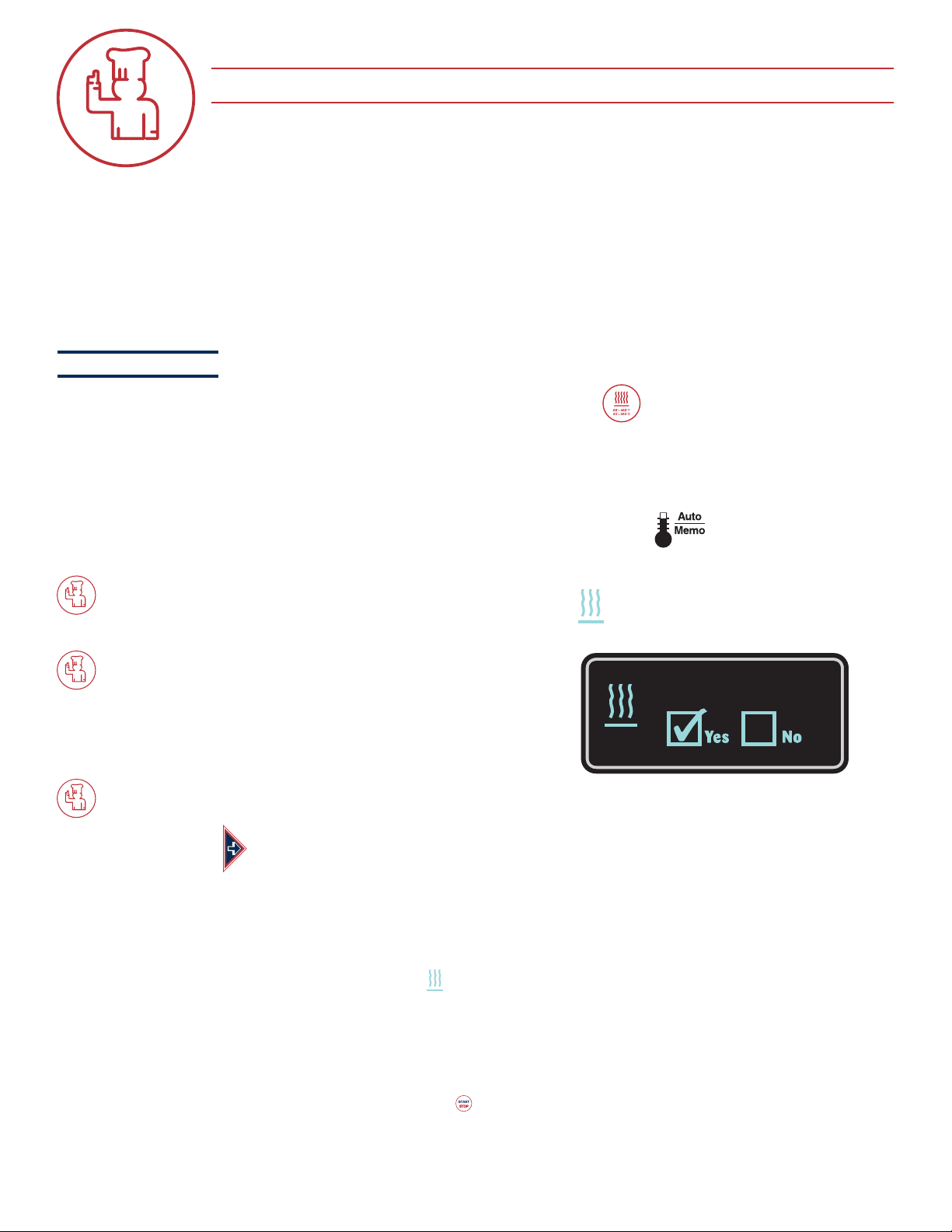

CHEF FUNCTION KEY

There are several auxiliary functions available through the use of the Chef Function Key.

With the exception of the ability to add additional moisture to the oven compartment, that

can only be used during the convection mode, all additional functions can be engaged at any time during any

cooking mode. Chef Functions can also be programmed into a cooking procedure in oven models that

include the deluxe programmable feature. At the end of a cooking mode or program, the oven automatically

disengages all operator-set chef functions. These functions, however, do remain programmed and will

reengage the next time the programmed procedure is used.

PREHEATING

THE PREHEATING FUNCTION IS ENGAGED IN THE CONVECTION MODE AT A FIXED

TEMPERATURE AND TIME. BOTH THE TEMPERATURE AND TIME CAN BE ADJUSTED BY THE

OPERATOR TO COMPLY WITH THE REQUIREMENTS OF THE INDIVIDUAL OPERATION.

SEE START UP PROCEDURES UNDER DEFAULT/MEMO SETTING .

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the preheat symbol is highlighted in the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys

or rotate the adjustment knob to select

“YES” for the Preheat function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SETTING.

THE OVEN WILL BEGIN THE PREHEAT FUNCTION.

• The set preheat temperature will appear in the display.

• The set preheat time will appear in the display.

• The preheat symbol will appear in the display.

When the set time and temperature has been reached, a buzzer will sound indicating

the end of the preheat function.

• To stop the buzzer, press the start/stop key or open the oven door.

AUXILIARY FUNCTIONS

Preheating

Page 25

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 25

CHEF FUNCTION KEY

GOLD-N-BROWN

The browning feature is an automatic function designed to regulate humidity for additional color

to products as needed. This feature is particularly useful for adding color to high moisture

products such as chicken and other poultry items or for additional browning of full loads and

other moist products. In addition, this feature may be used to add texture to fried items such as

French fries or breaded chicken. Gold-n-Brown can be used in both the combination mode and

the convection mode and can be programmed into a cooking procedure.

Browning can be used for any product with a set cooking time more than 5-minutes. Depending

on the type of product and product load, the browning feature may also slightly increase the set

cooking time in order to fully complete the browning function. This is a standard operating

condition of this feature.

SELECT AND PRESS THE REQUIRED COOKING MODE AND SET MODE FUNCTIONS.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the browning symbol is highlighted within

the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate the

adjustment knob to select “

YES” for the browning function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SETTING.

The browning indicator light will illuminate directly above the display.

PRESS THE START KEY.

The oven will engage the browning feature in the Combination or Convection mode set

by the operator.

AUXILIARY FUNCTIONS

Brown

Page 26

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 26

CHEF FUNCTION KEY

COOL-DOWN FEATURE

The cool-down feature provides the operator with the ability to lower the temperature of the

oven compartment at an accelerated pace. This function is useful when it is necessary to immediately

change from a high temperature cooking function to a lower temperature function or to the steam program.

This function is also useful to help cool the oven compartment in preparation for cleaning.

CHEF OPERATING TIP

When using the cool-down feature in preparation for cleaning, it is important to remember

the temperature in the display indicates the air temperature inside the oven compartment

and not the interior walls of the oven. Always make certain to allow the oven walls to cool

to a minimum of 140°F (60°C) before spraying the compartment with oven cleaner.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the cool-down symbol is highlighted in the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys

or rotate the adjustment knob to select

“YES” for the cool-down function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SETTING.

OPEN THE OVEN DOOR.

The display will indicate the current temperature of the oven.

ROTATE THE ADJUSTMENT KNOB TO SELECT A COOL-DOWN TEMPERATURE WITHIN A

RANGE OF 212°F TO 68°F (100°C TO 20°C).

THE FACTORY SET DEFAULT IS 122°F (50°C).

The displayed temperature will continue to decline until it reaches the operator set

temperature or factory default temperature if not selected by the operator.

AUXILIARY FUNCTIONS

Cool Down

Page 27

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 27

CHEF FUNCTION KEY

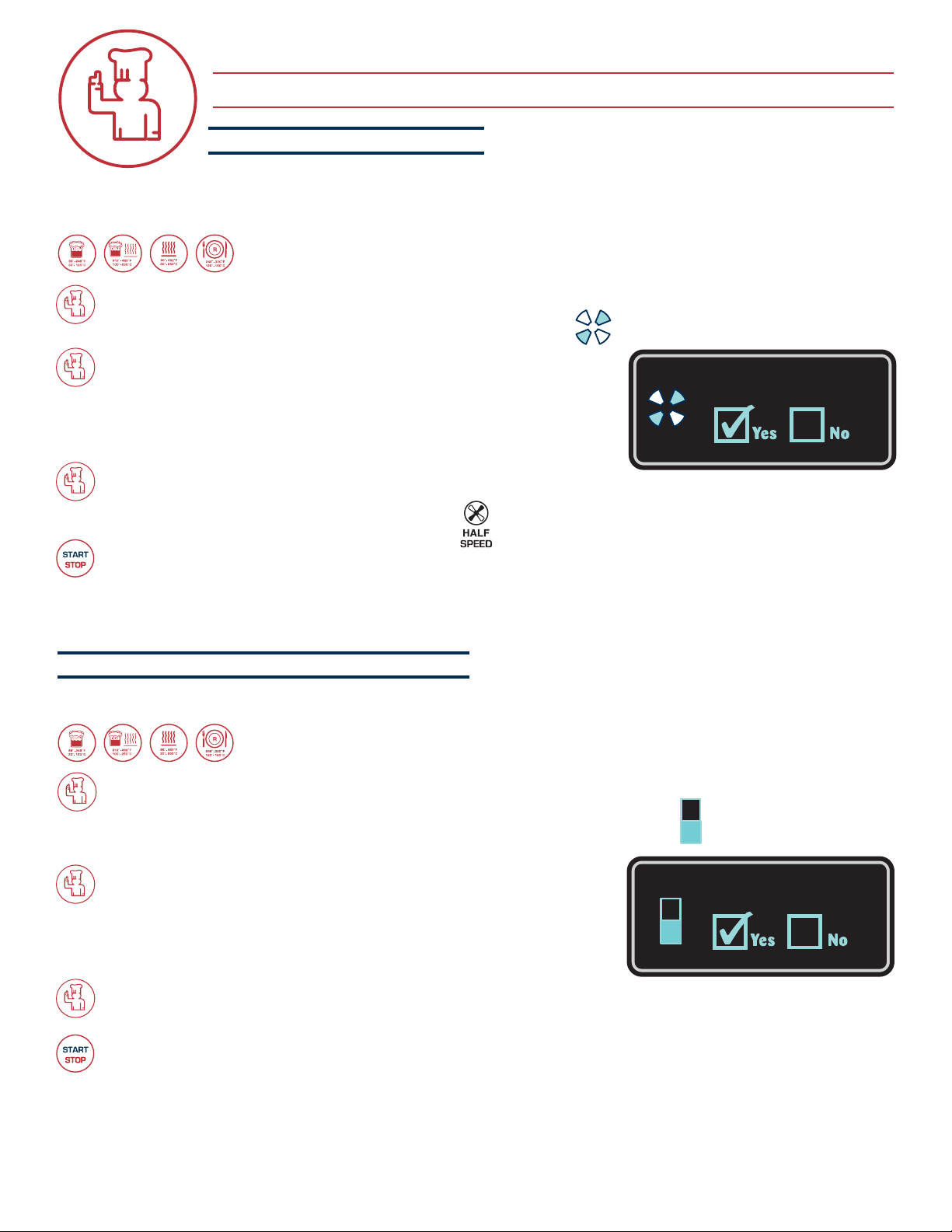

REDUCED FAN SPEED

The reduced fan speed function is useful for flow-sensitive products such as soufflês and

meringues, or any products affected by a high velocity of air movement.

SELECT AND PRESS THE REQUIRED COOKING MODE AND SET MODE FUNCTIONS.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the fan symbol is highlighted in the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate

the adjustment knob to select “

YES” for the reduced

fan speed function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SETTING.

The reduced fan speed indicator light will illuminate directly above the display.

PRESS THE START KEY.

The oven will start at a reduced fan speed in whatever cooking mode set by the operator.

REDUCED POWER ELECTRIC MODELS ONLY

The reduced power function can be used to reduce kitchen power peaks and energy consumption.

SELECT AND PRESS THE REQUIRED COOKING MODE AND SET MODE FUNCTIONS.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the reduced power symbol is highlighted

in the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate

the adjustment knob to select “

YES” for the reduced

power function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SETTING.

PRESS THE START KEY.

The oven will operate with reduced power in whatever cooking mode set by the operator.

REDUCED POWER WILL RESULT IN LONGER COOKING TIMES.

Redcʼd fan speed

Redcʼd power

AUXILIARY FUNCTIONS

Page 28

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 28

AUXILIARY FUNCTIONS

CHEF FUNCTION KEY

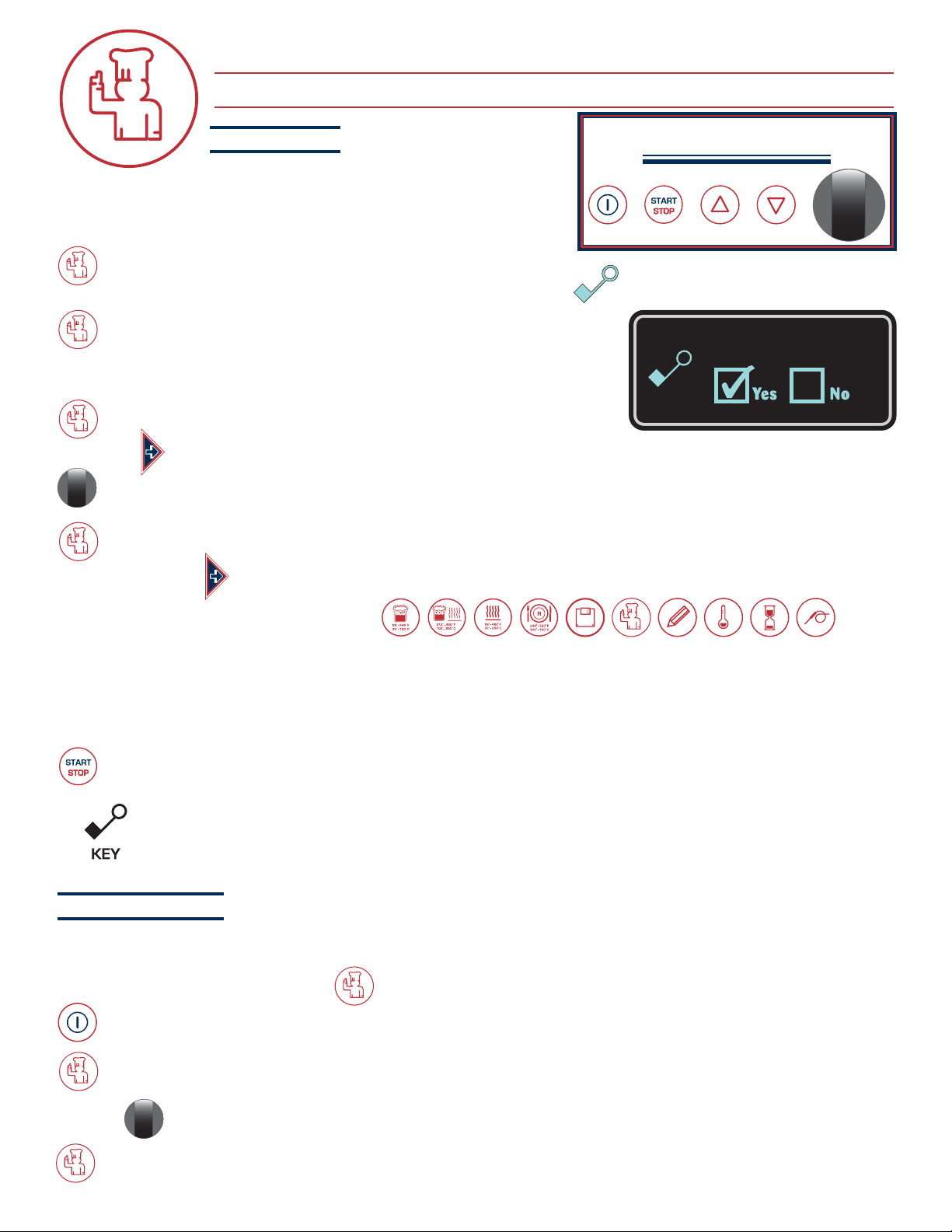

KEY LOCK

Except as noted, all of the mode keys and

functions available on the Combitherm can be

locked to prevent unauthorized or accidental

changes to the settings.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the key symbol is highlighted within the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate the

adjustment knob to select “YES” for the key lock function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM THE SETTING.

The display will indicate PIN 000.

ROTATE THE ADJUSTMENT KNOB TO PIN 000.

¶ PIN 000 is the factory set default to prevent an accidental lock or unlock of the control functions.

PRESS THE CHEF FUNCTION KEY.

THE DISPLAY WILL INDICATE “ALL KEYS UNLOCKED.”

SELECT AND PRESS THE FIRST

CONTROL FUNCTION TO BE LOCKED.

The display will indicate “LOCK.”

If the wrong key has been selected and locked in error, press the same control key again and

“UNLOCK” will appear in the display.

Continue in this manner until all desired control functions are locked.

PRESS THE START KEY TO CONFIRM THE LOCKING FUNCTION.

Whenever any control function has been locked, the key lock symbol will be illuminated within the display.

Whenever any locked control function is pressed, the key lock symbol will flash and an

audible signal will sound.

KEY UNLOCK

FOLLOW THE SAME PROCEDURE AS ABOVE UNTIL THE DISPLAY INDICATES “ALL KEYS UNLOCKED.”

To unlock the Chef Function key.

PRESS THE POWER KEY TO TURN THE OVEN OFF.

PRESS THE CHEF FUNCTION KEY

ROTATE THE ADJUSTMENT KNOB TO PIN 000 TO DISENGAGE ALL LOCK FUNCTIONS.

PRESS THE CHEF FUNCTION KEY. THE DISPLAY WILL INDICATE “ALL KEYS UNLOCKED.”

Key lock

OPERATING ELEMENTS THAT

CANNOT BE LOCKED

Page 29

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 29

CHEF FUNCTION KEY

STEAM INJECTION

Additional steam can be added to the cooking compartment at any time when cooking in the

convection mode.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the steam injection symbol is highlighted within

the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate

the adjustment knob to select “

YES” for the steam

injection function.

PRESS THE CHEF FUNCTION KEY TO ACTIVATE THE STEAM INJECTION FUNCTION.

Additional steam is injected into the oven compartment for a time period of

approximately 15 seconds.

NOTE: Steam injection cannot be programmed through the control keypad, but can

be programmed through optional Kitchen Management software.

AUXILIARY FUNCTIONS

Add moisture

Page 30

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 30

AUXILIARY FUNCTIONS

GENERAL SMOKER OPERATION

SMOKING FUNCTION

LOAD WOOD CHIPS.

G

Measure one container full of dry wood chips.

G

Soak dry chips in water for 5 minutes.

G

Shake excess water off wood chips.

G

Place moistened chips back into the container

and position the container securely on the two prongs

located on the interior back panel of the oven.

A full container of wood chips will produce smoke

for an approximate period of one to two hours

depending on the cooking temperature being used

for the selected product. The tested procedures in

this manual for many of the products that are appropriate

for smoking provide complete product smoke penetration

and full smoke flavor.

CHEF OPERATING TIP

Products such as ribs that require heavier smoke penetration to reach full smoke flavor

should remain in the oven after cooking has been completed. Do not open the oven door.

Set the oven in the Low Temperature Steam Mode at 140° to 160°F (60° to 71°C) and allow

the product to remain in the oven for a period of one hour.

If you would like assistance, you are invited to contact an Alto-Shaam corporate chef for recommendations.

NOTE: Always keep the OVEN DOOR CLOSED

whenever operating the smoking function.

The Combitherm Smoker can be operated without using the smoking function. After using the oven as a

smoker, however, it is necessary to clean the oven in order to prevent a transfer of smoke flavor to nonsmoked products. Cleaning instructions are provided in this manual.

AVAILABLE FROM ALTO-SHAAM

WOOD CHIPS 20 POUND BULK PACKS

APPLE WC-22543

HICKORY WC-2829

CHERRY WC-22541

SUGAR MAPLE WC-22545

THE TOTAL WEIGHT OF WOOD CHIP

BULK PACKS MAY VARY DUE TO HIGH

MOISTURE CONTENT WHEN PACKAGED

.

THE USE OF IMPROPER MATERIALS FOR THE

SMOKING FUNCTION COULD RESULT IN DAMAGE,

HAZARD, EQUIPMENT FAILURE, OR COULD

REDUCE THE OVERALL LIFE OF THE OVEN.

DO NOT USE SAWDUST FOR SMOKING.

DO NOT USE WOOD CHIPS SMALLER THAN

THUMBNAIL SIZE.

DO NOT OPEN THE OVEN DOOR DURING

THE SMOKING FUNCTION. The introduction

of outside air in the oven compartment may

cause the wood chips to flame.

ON EQUIPPED MODELS

Page 31

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 31

CHEF FUNCTION KEY

SMOKER FEATURE

The ability to smoke product, hot or cold, is offered on all boiler-free electric models and on all

gas models with the exception of the 10•20ESGAS, the 12•18ESGAS, and the 20•20ESGAS. The

smoking function can be engaged in either the Combination mode or the Convection mode of

operation. The smoking function cannot be operated when the oven is operating in the steam

mode or the retherm mode.

SELECT AND PRESS THE REQUIRED COOKING MODE (CONVECTION OR COMBINATION).

TO SET COOK TEMPERATURE:

PRESS THE TEMPERATURE KEY.

The cooking temperature will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to select the desired

cooking temperature.

TO SET COOK TIME:

PRESS THE TIME KEY.

The cooking time will appear highlighted within the oven display.

Press the up and down arrow keys or rotate the adjustment knob to select the time

desired.

or

Set control for continuous operation by rotating the adjustment knob to the right until desired

time appears in the display.

TO ACTIVATE SMOKER:

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the smoker symbol is highlighted

within the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate the

adjustment knob to select “YES” for the Smoker function.

PRESS THE CHEF FUNCTION KEY TO CONFIRM

THE SETTING.

PRESS THE START KEY TO ACTIVATE THE SMOKER FUNCTION.

AUXILIARY FUNCTIONS

Smoker

ON EQUIPPED MODELS

U.S . PAT. 7,157,668

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

Page 32

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 32

CHEF FUNCTION KEY

ENERGY LOCK

FOR USE WITH OVENS INSTALLED UNDER A VENTLESS HOOD.

Energy lock is a safety feature to prevent the oven control from being operated unless the ventless

oven hood is in operation. The energy lock indicator light will illuminate in the control display if this

situation occurs and the oven control will be inoperable until the oven hood is reset and operating.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the energy lock symbol is highlighted within the

display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate

the adjustment knob to select “

YES” for the energy

lock function.

PRESS THE CHEF FUNCTION KEY TO ACTIVATE THE ENERGY LOCK FUNCTION.

The oven control will not operate when power is engaged until the ventless hood

is reset and operating.

Press the “Combi Reset” button on the ventless hood to energize the hood and

r

eturn the oven control to normal operation.

ENERGY PROTECTION FURNISHED UPON REQUEST AS A FACTORY INSTALLED OPTION

In locations where the electric service is regulated with a device installed on site, this function will

protect full power to the Combitherm for the duration of the next operator set program or cooking mode.

This function cannot be set during an active cooking mode or program. Power interruption may affect all

other electric service within the regulated location.

FOR USE ONLY IN THOSE COUNTRIES WHERE THE LOCAL ELECTRIC

UTILITY PROVIDES AN ENERGY OPTIMIZATION SYSTEM INSTALLED ON SITE.

PRESS THE CHEF FUNCTION KEY.

Rotate the adjustment knob until the program protection symbol is highlighted

within the display.

PRESS THE CHEF FUNCTION KEY.

Press the up and down arrow keys or rotate

the adjustment knob to select “

YES” for the energy

protection function.

PRESS THE CHEF FUNCTION KEY TO ACTIVATE THE PROGRAM PROTECTION FUNCTION.

AUXILIARY FUNCTIONS

Energy Lock

Program protection

Page 33

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 33

MOISTURE VENT KEY

This function provides the operator with the ability to eliminate excessive moisture from

the oven compartment and the exterior surface of the foods being cooked. The moisture

vent key is designed to operate in both the Combination mode and in the Convection

cooking mode. On deluxe models, this function can also be made part of a cooking program.

PRESS THE MOISTURE VENT KEY TO REDUCE STEAM AND MOISTURE LEVELS IN THE OVEN.

The illuminated, blue portion of the Moisture Vent Key will go out. Open vent symbol will illuminate

within the display.

PRESS THE MOISTURE VENT KEY TO DISENGAGE THE MOISTURE VENT KEY FUNCTION.

The blue portion of the Moisture Vent Key will illuminate. Open vent symbol within the display

will extinguish.

AT THE END OF A COOKING MODE, THE MOISTURE VENT KEY WILL AUTOMATICALLY DISENGAGE.

ADVANCE FEATURES

Page 34

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 34

QUICK PROGRAMMING

This quick programming function provides the operator with the ability to temporarily program a cooking

procedure using multiple cooking modes, along with any auxiliary functions desired. Quick programming is

particularly useful when cooking several batches of the same product back-to-back and will remain

programmed until any new cooking mode key is pressed.

PRESS AND HOLD THE FIRST REQUIRED COOKING MODE FOR A PERIOD OF 3-SECONDS.

01/01 will appear at the top of the display indicating STEP ONE.

The temperature and time will appear directly below 01/01.

PRESS THE TEMPERATURE KEY.

The temperature will become highlighted within the display.

ROTATE THE ADJUSTMENT KNOB TO SELECT THE REQUIRED TEMPERATURE.

PRESS THE TIME KEY OR THE CORE TEMP KEY .

The time or core temperature will become highlighted within the display.

ROTATE THE ADJUSTMENT KNOB TO SELECT THE REQUIRED SETTING.

PRESS AND HOLD THE SECOND REQUIRED COOKING MODE FOR A PERIOD OF 3-SECONDS.

Follow the above directions until all steps have been entered.

PRESS THE START KEY.

The oven will begin cooking as programmed, automatically switching to each cooking

mode entered. Each step entered will be indicated in the display as the oven cycles from

mode to mode. EXAMPLE: 01/05 = STEP ONE OF FIVE

02/05 = STEP TWO OF FIVE

PRESS THE STOP KEY OR OPEN THE OVEN DOOR WHEN THE BUZZER SOUNDS AT THE END

OF THE PROGRAM.

THIS PROGRAM WILL REMAIN IN TEMPORARY MEMORY UNTIL ANY NEW

COOKING MODE KEY IS PRESSED. QUICK PROGRAMMING CAN BE SAVED AND

STORED IN MEMORY ON DELUXE MODELS ONLY.

ADVANCE FEATURES

Page 35

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 35

Auxiliary Functions are made part of the control as an additional convenience to the operator, however,

these functions are not necessary for the general operation of the Combitherm oven.

START TIME PRESELECT

Start time preselect provides the operator with the ability

to program a fixed start time for oven operation. This

function can be operated when cooking in any mode and

is offered as a convenience to set an advanced start-up of

the preheating function prior to the beginning of the

production day. It can also be used for advance start-up

for non-refrigerated items such as baked potatoes.

SELECT AND PRESS THE REQUIRED COOKING MODE.

Set all mode functions such as temperature, time, core temperature, etc.

The time entered in the initial operational mode setup will automatically be

reflected on the start time preselect display.

PRESS AND HOLD THE TIME KEY WHILE TURNING THE ADJUSTMENT KNOB.

The display will indicate the current programmed settings in 24-hour (military) time.

The cooking time shown (

UPPER RIGHT) indicates automatic oven operation for a period of one hour and

appears only when cooking by time as entered in the initial operational mode setup.

TO CHANGE THE STARTING TIME, PRESS AND HOLD THE TIME KEY AND TURN THE

ADJUSTMENT KNOB.

Rotate the adjustment knob to select the starting time desired. As the starting time is

changed, the countdown for oven start (

LEFT) and the ending time will automatically

adjust accordingly.

RELEASE THE TIME KEY AFTER THE REQUIRED STARTING TIME HAS BEEN SELECTED.

The oven preselect start time display will immediately begin a countdown and will

automatically start the oven when zero is reached.

THIS FUNCTION CAN BE CANCELLED AT ANY TIME BY PRESSING THE START/STOP KEY .

ADVANCE FEATURES

01:00

00:48 10:23 11:23

1-HOUR TOTAL

COOKING TIME

OVEN START

IN

48 MINUTES

STARTING TIME

10:23 A.M.

ENDING TIME

11:23 A.M.

1:00

2:00

3:00

4:00

5:00

6:00

7:00

8:00

9:00

10:00

11:00

12:00

1:00

2:00

3:00

4:00

5:00

6:00

7:00

8:00

9:00

10:00

11:00

12:00

1:00

2:00

3:00

4:00

5:00

6:00

7:00

8:00

9:00

10:00

11:00

12:00

13:00

14:00

15:00

16:00

17:00

18:00

19:00

20:00

21:00

22:00

23:00

24:00

A.M. P.M.

To prevent food spoilage, this feature

is not recommended for use with any

raw product that requires temperature

maintenance at or under 40°F (4°C).

Page 36

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 36

COMBITHERM PROGRAMMING SYMBOLS

PROGRAM FUNCTION

RECORDING A COOKING PROCEDURE

Recording a cooking procedure provides the operator with the ability to test and

verify all set operating parameters for the selected cooking modes and to make any

necessary adjustments before saving and storing the procedure into memory.

PRESS THE PROGRAM INSTALL AND EDIT KEY.

Press the up and down arrow keys or rotate the adjustment

knob until the record symbol is highlighted in the display.

PRESS THE PROGRAM INSTALL KEY TO CONFIRM THE SELECTION.

The display will indicate “Recorder ON” and the record symbol will appear in the display.

SELECT AND PRESS THE FIRST REQUIRED COOKING MODE.

Set all cooking mode parameters for temperature, time, or internal product temperature

plus auxiliary functions, and advanced features for the first step to be recorded.

PRESS THE START KEY TO BEGIN THE FIRST RECORDED STEP.

When the cooking time has expired or the operator set internal temperature has been reached, a buzzer will

sound indicating the end of the operating mode.

• To stop the buzzer, press the start/stop key or open the oven door.

SELECT AND PRESS THE SECOND REQUIRED COOKING MODE.

Set all cooking mode parameters for temperature, time, or internal product temperature

plus auxiliary functions, and advanced features for the second step to be recorded.

PRESS THE START KEY TO BEGIN THE SECOND RECORDED STEP.

Continue to record cooking modes as indicated for up to 20 steps.

All cooking mode steps entered with “Recorder ON” will remain in memory, in the order entered, until the recorder is

turned off. Recorded procedures will not be lost or affected by pressing the stop/start key .

RECORD

COPY PROCEDURE

INSERT STEP

SAVE

DELETE PROCEDURE

APPEND STEP

NEW PROCEDURE

EDIT PROCEDURE

DELETE STEP

Page 37

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 37

TO CANCEL THE RECORDING FUNCTION

WITH THE “Recorder ON” FUNCTION ACTIVATED, PRESS THE PROGRAM INSTALL AND EDIT KEY.

Press the up and down arrow keys or rotate the adjustment knob until the record

symbol is highlighted in the display.

PRESS THE PROGRAM INSTALL KEY TO CONFIRM THE SELECTION.

“Recorder OFF” will appear in the display and the oven can be operated normally.

SAVING A RECORDED COOKING PROCEDURE

When the previous cooking mode steps recorded produce satisfactory results, the recorded

cooking procedure can be saved in memory for future use.

PRESS THE PROGRAM INSTALL/EDIT KEY.

Press the up and down arrow keys or rotate the

adjustment knob until the save symbol is highlighted in the display.

PRESS THE PROGRAM INSTALL/EDIT KEY TO CONFIRM THE SELECTION.

Name the procedure. Rotate the adjustment knob to select the first letter

of the procedure name. Press the up and down arrow key to select

second letter position and rotate the adjustment knob to select the second

letter

. Continue this procedure for each subsequent alpha character,

number, or symbol required.

PRESS THE PROGRAM INSTALL AND EDIT KEY TO CONFIRM THE PROCEDURE NAME.

The display will indicate the first unoccupied memory location within the programmed menu.

If an alternate location is desired, rotate the adjustment knob to highlight another unoccupied,

numbered memory location within the programmed menu. If an occupied location is selected,

the existing procedure will be replaced by the new procedure.

PRESS THE PROGRAM INST

ALL/EDIT KEY TO CONFIRM THE PROCEDURE LOCATION.

The display will indicate “please wait” and will return to the main menu display.

The procedure has now been saved in the selected location and can be verified by rotating the

adjustment knob to the saved procedure.

To review the set operating parameters of any programmed procedure, press the programmed menu key

and rotate the adjustment knob until the procedure to be reviewed is highlighted in the display. Press the chef

function key. The cooking mode key for the first step will illuminate and the program mode, temperature,

time, or core temperature will appear in the display. Rotate the adjustment knob to review each step.

——————

—

A

PROGRAM FUNCTION

Page 38

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 38

CREATING A NEW COOKING PROCEDURE

Cooking procedures for items prepared on a regular basis can be stored in memory.

PRESS THE PROGRAM INSTALL/EDIT KEY.

Press the up and down arrow keys or rotate the adjustment knob until the new procedure

symbol is highlighted in the display.

PRESS THE PROGRAM INSTALL/EDIT KEY TO CONFIRM THE SELECTION.

All cooking mode keys will begin to flash and 01/01 will appear at the top of the

display indicating the first cooking step.

SELECT AND PRESS THE FIRST REQUIRED COOKING MODE.

Set cooking mode functions for temperature and time, or internal core temperature. Add any auxiliary functions

along with the moisture venting feature. Follow the basic operating instructions located in this booklet. Auxiliary

functions can be added by pressing the chef function key after entering the operating mode parameters for

each individual step and pressing the up and down arrow keys or rotating the adjustment knob to select the

auxiliary function required. Press the chef function key to confir

m the auxiliary function setting(s) for each step.

PRESS THE PROGRAM INSTALL/EDIT KEY TO CONFIRM THE FIRST STEP.

SELECT AND PRESS THE SECOND REQUIRED COOKING MODE.

The display will indicate 02/02 indicating the second cooking mode step.

Set all cooking mode functions as indicated above.

PRESS THE PROGRAM INSTALL/EDIT KEY TO CONFIRM THE SECOND STEP.

CONTINUE WITH THE ABOVE INSTRUCTIONS UNTIL ALL MODE STEPS AND FUNCTIONS ARE ENTERED.

UP TO 20 COOKING MODE STEPS CAN BE SAVED IN A SINGLE PROCEDURE.

AFTER ALL FUNCTIONS ARE ENTERED,

PRESS THE PROGRAM INSTALL/EDIT KEY TO CONFIRM THE NEW PROCEDURE.

Name the procedure. Rotate the adjustment knob to select

the first letter of the procedure name. Press the up and

down arrow key to select second letter position and rotate

the adjustment knob to select the second letter. Continue for

each subsequent alpha character, number, or symbol required.

PRESS THE PROGRAM INSTALL AND EDIT KEY TO CONFIRM THE PROCEDURE NAME.

Rotate the adjustment knob to highlight an unoccupied, numbered memory location within the

programmed menu. If an occupied location is selected, the existing procedure will be

replaced by the new procedure.

PRESS THE PROGRAM INSTALL AND EDIT KEY TO CONFIRM THE PROGRAM INST

ALLATION.

The display will indicate “please wait” and will return to the main menu display.

——————

—

A

PROGRAM FUNCTION

Page 39

S ECTION 1 – CONTROL P ANEL I DENTIFICATION • COMBITHERM GAS TECHNICAL S ERVICE M ANUAL • 39

START A PROGRAMMED PROCEDURE

PRESS THE PROGRAMMED MENU KEY.

All stored procedures are listed alphabetically or numerically as selected by the

operator in the initial oven start up procedures under the program index category.

Rotate the adjustment knob until the required procedure is highlighted in the display.

PRESS THE START KEY.

To review the set parameters of any programmed procedure, press the

programmed menu key and rotate the adjustment knob until the procedure to

be reviewed is highlighted in the display. Press the chef function key. The

cooking mode, temperature, time, or core temperature will appear in the display.

COPY A PROGRAMMED PROCEDURE

PRESS THE PROGRAMMED MENU KEY.

Rotate the adjustment knob until the procedure to be copied is highlighted in the display.

PRESS THE PROGRAM INSTALL AND EDIT KEY.

Press the up and down arrow keys or rotate the adjustment knob until the copy»

procedure symbol is highlighted in the display.

PRESS THE PROGRAM INSTALL AND EDIT KEY.

The display will select an empty, numbered location to insert the duplicate copy.

PRESS THE PROGRAM INSTALL AND EDIT KEY TO CONFIRM THE DUPLICATION.

The display will indicate “please wait” and will retur

n to the main menu display.

An exact duplicate of the selected procedure has been inserted in the new location under the same name as the

original procedure. The duplicate can be renamed and edited as required. See additional editing instructions.

DELETE A PROGRAMMED PROCEDURE

PRESS THE PROGRAMMED MENU KEY.