Alto Shaam ASG-4G Installation Manual

US A/CA NA DA

U.S.A. O NL Y

Convection Oven

Gas

Model:

ASC-4G

Electronic

Control

•InstallatIon

•operatIon

•MaIntenance

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744

p ri n te d i n u. s. a.

FAX: 262.251.7067 • 800.329.8744

www.alto-shaam.com

MN-28663 • 02/11

Delivery .................................. 1

Unpacking ................................1

Safety Procedures and Precautions............. 2

Installation

Site Installation..........................3

Clearance Requirements ..................3

Installation Requirements .................. 4

Leveling ...............................4

Dimension Drawings ...................... 4

Gas Specifications ......................5-7

Electrical Connection .....................8

Ventilation .............................9

Stacking Instructions...................10-11

Oven Stand Assembly Option .............. 12

Operating Instructions

User Safety Information .................. 13

Capacity ..............................13

Options & Accessories ................... 13

Start-Up Operation . . . . . . . . . . . . . . . . . . . . . . 14

Electronic Control Operation and Features ..15-18

Chef Operating Tips .....................19

Care and Cleaning

Cleaning and Preventive Maintenance ....... 20

Protecting Stainless Steel Surfaces ......... 20

Cleaning Agents ........................ 20

Cleaning Materials ...................... 20

Equipment Care ........................ 21

Clean Daily............................ 21

Exterior............................... 21

Motor Care ............................ 21

Service

Troubleshooting Guide ................... 22

Full Assembly View......................23

Interior Oven Compartment View ........... 24

Electrical View ......................... 24

Leg Assembly .......................... 25

Service Parts List .......................26

Wire Diagrams

ASC-4G, Electronic, 120V ................ 27

Warranty

Transportation Damage and Claims ..Back Cover

Limited Warranty ................Back Cover

i

DELIVERY

UNPACKING

This Alto-Shaam appliance has been

thoroughly tested and inspected to ensure only

the highest quality unit is provided. Upon

receipt, check for any possible shipping damage

and report it at once to the delivering carrier.

See Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered

in one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to ensure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood

by all people using or installing the equipment

model. Contact the Alto-Shaam Tech Team Service

Department if you have any questions concerning

installation, operation, or maintenance.

NOTE: All claims for warranty must include the

full model number and serial number of

the unit.

1. Carefully remove the

appliance from the

carton or crate.

®

NOTE: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

Tech Team Service Department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

ASC-4G Gas Convection Oven - Electronic Control • 1

SAFETY PROCEDURES

AND PRECAUTIONS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

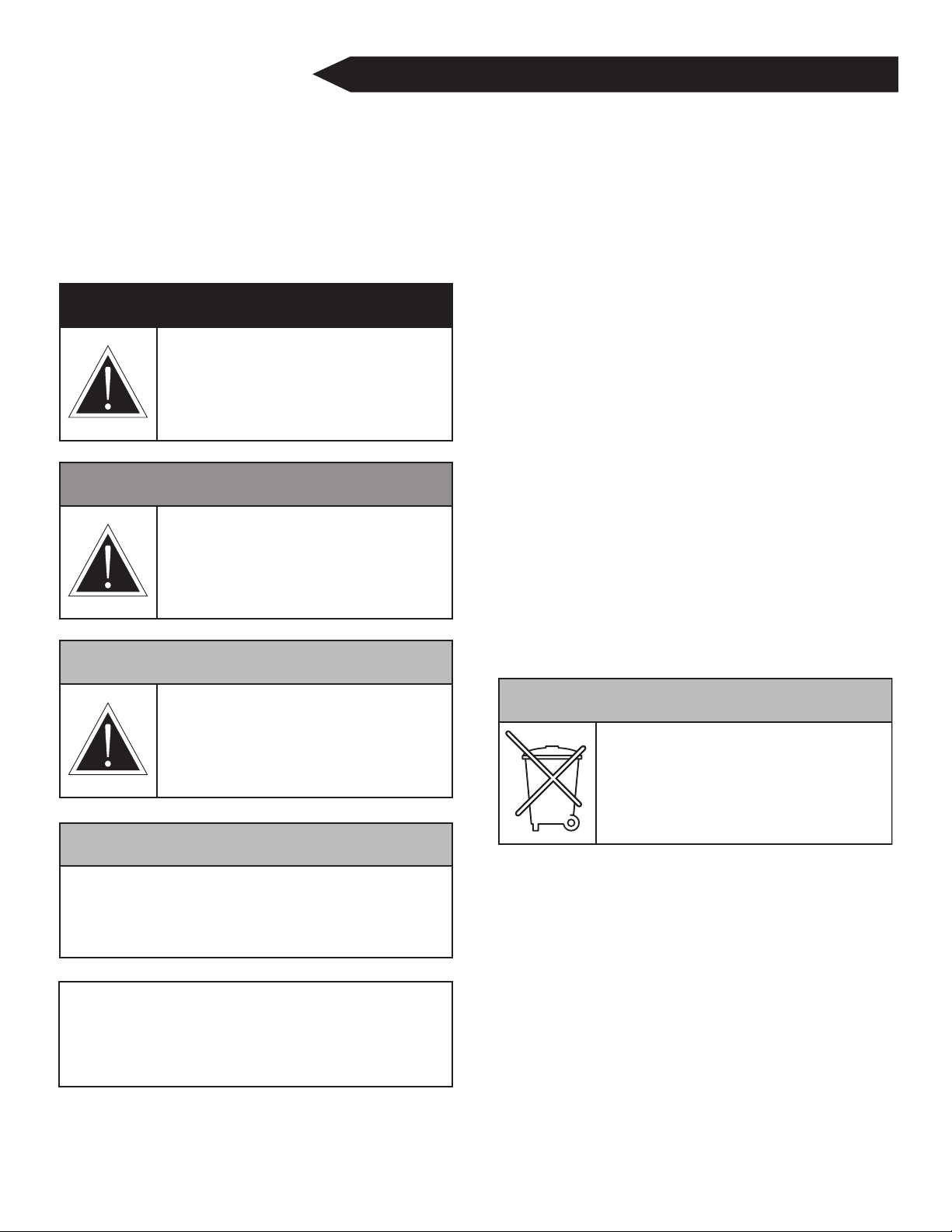

DANGER

Used to indicate the presence of

a hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

WARNING

Used to indicate the presence of

a hazard that CAN cause personal

injury, possible death, or major

property damage if the warning

included with this symbol is ignored.

1. This appliance is intended to cook, hold

or process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are

familiar with the purpose, limitations, and

associated hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

CAUTION

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

CAUTION

Used to indicate the presence of a hazard that

can or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

NOTE: Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

NOTE

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

ASC-4G Gas Convection Oven - Electronic Control • 2

INSTALLATION

CAUTION

(C HE CK LOCAL CO DE S.)

NE T

SH IP PING

CR AT E 45" L X 53" W X 49" H

DI ME NSION S:

MI NI MU M EN TRY CL EAR AN CE

) UN CRA TED

EX TE RI OR

IN TE RI OR

CO MB US TIB LE

SU RF AC ES

NO N

-C OM BU STI BL E

SU RF AC ES

BA CK

LE FT S ID E

RI GH T SI DE

FROM GREASE

PRODUCING EQUIPMENT

EN TR Y C LE AR AN CE :

UN CR ATED

RE CO MM END ED

SE RV IC E

AC CE SS :

RIG HT CON TR OL S ID E

DANGER

IMPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH,

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

DO NOT LIFT OR MOVE THE

OVEN BY USING THE DOORS

OR THE DOOR HANDLES.

SITE INSTALLATION

®

The Alto-Shaam convection

oven must be installed in

a location that will permit

the oven to function for its

intended purpose and to

allow adequate clearance for

ventilation, proper cleaning,

and maintenance.

1. Hood installation is required.

2. The oven must be installed on a stable and

level surface. A non-combustible, heat

resistant, and fireproof surface is highly

recommended. If the oven is to be installed

on a combustible surface, factory supplied

legs or oven stand MUST be used.

3. DO NOT install this oven in any area where

it may be affected by any adverse conditions

such as steam, grease, dripping water, high

temperatures, etc.

4. This appliance must be kept free and clear of

any combustible materials.

5. This appliance must be kept free and clear

of any obstructions blocking access for

maintenance or service.

ASC-4G Gas Convection Oven - Electronic Control • 3

CAUTION

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN

IN OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

DANGER

DO NOT store or use gasoline or other

fl ammable vapors or liquids in the

vicinity of this or any other appliance.

WEIGHT

420 lb (191 kg)

465 lb (211 kg)

(1143mm x 1346mm x 1245mm)

DIMENSIONS H x W x D:

: 58-1/2" x 38" x 44-1/2"

(1486mm x 964mm x 1130mm)

: 24" x 29-1/8" x 25"

(610mm x 740mm x 635mm)

MINIMUM CLEARANCE REQUIREMENTS

31-1/2" (800mm

0" (0mm) 0" ( 0mm)

2" (51mm) 0" ( 0mm)

2" (51mm) 2" (51mm)

6" (152mm) 6" (152mm)

31-1/2" (800mm)

20" (508mm)

INSTALLATIONINSTALLATION

INTENDED FOR

MA XIM UM

FU LL -SIZE SH EET P ANS

INSTALLATION REQUIREMENTS

The oven must be mounted on the factory equipped

oven legs or on an optional oven stand. Installation

on a solid or concrete base that in any way restricts

air flow may void the warranty.

All clearances for a proper ventilation air supply

must be maintained to minimize fire hazard. Do

not locate the oven immediately adjacent to any

other heat-generating appliance.

WARNING

Inadequate ventilation, or failure to

ensure an adequate supply of fresh

air will result in a high ambient

temperature at the rear of the

appliance. An excessive ambient

temperature can cause the thermaloverload protection device on the

blower motor to trip resulting in

severe damage to the blower motor.

A number of adjustments are associated with

initial installation and start-up. Adjustments

must be conducted by a qualified service

technician. Installation and start-up adjustments

are the responsibility of the dealer or user.

These adjustments include but are not limited to

thermostat calibration, door adjustment, leveling,

and gas pressure verification. The Platinum series

oven burners are factory-adjusted with fixed air

openings and require no field adjustment.

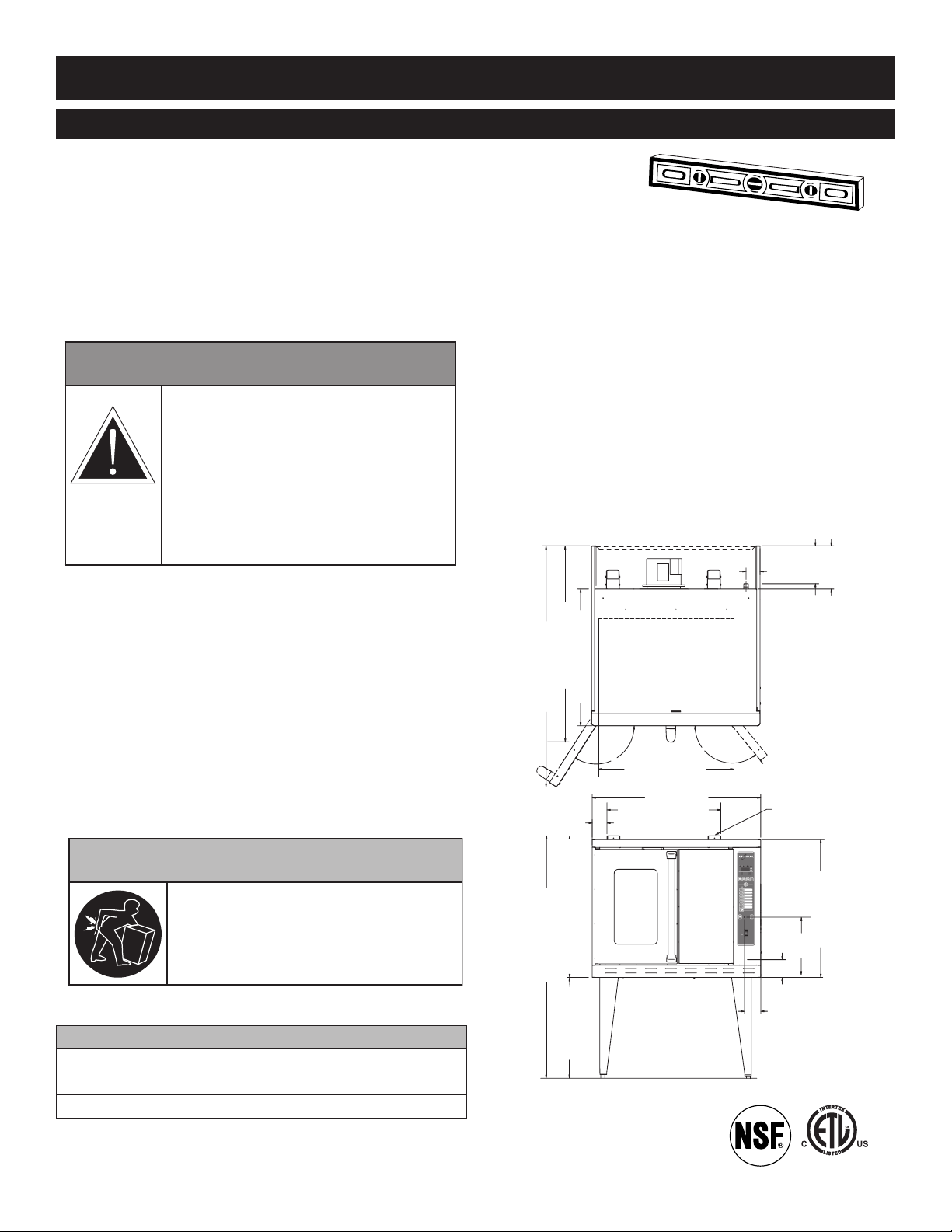

LEVELING

The oven should be

leveled before the gas

supply is connected. Level the oven from

side-to-side and front-to-back with the use of a

spirit level. For ovens installed on a mobile stand,

it is important that the floor surface be level due to

the probability of frequent oven repositioning.

We recommend checking the level of the oven

periodically to make certain the floor has not

shifted or the oven moved.

NOTE: Failure to properly level this oven can

cause improper function as a result

of erratic burner combustion and will

result in the uneven baking of products

consisting of semi-liquid batter.

1/2"

GAS INLET

3-5/32"

(80,1mm)

6-15/16" (176mm)

9-15/16" (252mm)

44-1/2" (1130mm)

30-5/8" (778mm)

54-5/8" (1387mm)

123°

3-5/16" (84,4mm)

29-1/8" (740mm)

CAVITY WIDTH

38" (965mm)

25-11/16" (652mm)

129°

EXHAUST

VENT

LINE CORD ENTRANCE

CAUTION

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

PRODUCT\PAN CAPACITY

72 lb (33 kg)

45 qts (43 liters)

12 (twelve): 18" x 26" x 1"

ASC-4G Gas Convection Oven - Electronic Control • 4

31-15/16" (810mm)

58-1/2" (1486mm)

26-1/2" (673mm)

MODEL ASC-4G

Electronic Control

(329mm)

12-15/16"

4" (102mm)

1/2" GAS INLET

3-11/16" (93mm)

6' (1828mm)

LINE CORD ENTRANCE

31-1/16" (789mm)

3107173

GAS SPECIFICATIONS

F UE L TY P E O RI FI C E SI Z E O RI FI C E P/ N MA N IF OL D PR E SS UR E

C ON VE R SI O N SP RI N G KI T S

GA S CO NNECTI ON:

CH EC K PL UM BIN G C ODE S FO R PR OP ER S UP PLY LI NE SI ZIN G TO

AT TA IN B UR NER MA NIF OL D

DANGER

CONNECTING TO THE WRONG GAS

SUPPLY COULD RESULT IN FIRE OR

AN EXPLOSION CAUSING SEVERE

INJURY AND PROPERTY DAMAGE.

GAS SUPPLY & INSTALLATIONGAS SUPPLY & INSTALLATION

INSTALLATION REQUIREMENTS

3/4" NP T

NOTE: If a flexible gas line is used, it must be AGA

approved, commercial type and at least 1" I.D.

GAS PRESSURE CHART

The gas valve and burner have been fitted

according to the gas type specified on the

identification name plate.

TECHNICAL SPECIFICATIONS

Natural Gas

Min. connected pressure 7.0" W.C. 1.74 kPa

Max. connected pressure 14.0" W.C. 3.48 kPa

OrificeSize 1/8

Manifold pressure 5.0" W.C. 1.25 kPa

Gross thermal output

Propane Gas

Min. connected pressure 11.0" W.C. 2.74 kPa

Max. connected pressure 14.0" W.C. 3.48 kPa

OrificeSize 2.1mm

Manifold pressure 10.0" W.C. 2.49 kPa

Gross thermal output

50,000 Btu/hr

50,000 Btu/hr

WARNING

TO AVOID SERIOUS PERSONAL

INJURY, installation of this appliance

must conform to local, state, and

national codes; the current edition

of the American National Standard

Z223.1, National Fuel Gas Code, and

all local municipal building codes.

In Canada, installation must be in

accordance with Standard CAN/CSA

FIELD CONVERSION OF FUEL TYPE

To convert from either fuel type, replace the orifice

located at the burner inlet with the desired orifice.

Replace the spring kit located on the front left side of

the valve. Remove the cap and nylon screw, replace

spring and nylon screw with desired kit. Set the

manifold pressure to the corresponding values

located under technical specifications.

Natural 1/8 OR-29172 5.0 IN/WC

Propane* 2.15mm OR-29451 (male) 10.0 IN/WC

B 149.1 and Installation Codes - Gas

Burning Appliances, and local codes.

# 43 OR-29054 (male) 10.0 IN/WC

# 43 OR-26430 (female) 10.0 IN/WC

Natural VA-28821 Propane VA-28444

* Contact Factory with serial number

ASC-4G Gas Convection Oven - Electronic Control • 5

GAS SUPPLY & INSTALLATION

GAS REQUIREMENTS

GAS CONNECTION

Installation

DANGER

Installation, air adjustment and/or

service work must be in accordance

with all local codes and must be

performed by a certifi ed service

technician qualifi ed to work on

gas appliances.

The gas inlet is located at the back of the oven.

Code requires the installation of a manual gas

shutoff valve to be installed in the gas line ahead

of the oven. This oven is also equipped with

fixed burner orifices determined by the elevation

specified as the initial installation location.

The oven is furnished with a regulator integral

to the operation of the gas solenoid valve

and may not require an additional external

regulator. To ensure safe and proper operation,

the gas pressure regulator installed in the oven

is required for use with both natural gas and

propane. If the connected pressure exceeds

14.0" W.C. (3.48 kPa), a step-down regulator

is required. A step-down regulator is not the

responsibility of the manufacturer.

Use an approved pipe sealant at all connections.

Do not use Teflon® tape. Gas supply connections

and pipe joint compound must be resistant to the

action of propane gases. Pipes must be clean, free

of obstructions and pipe joint compound.

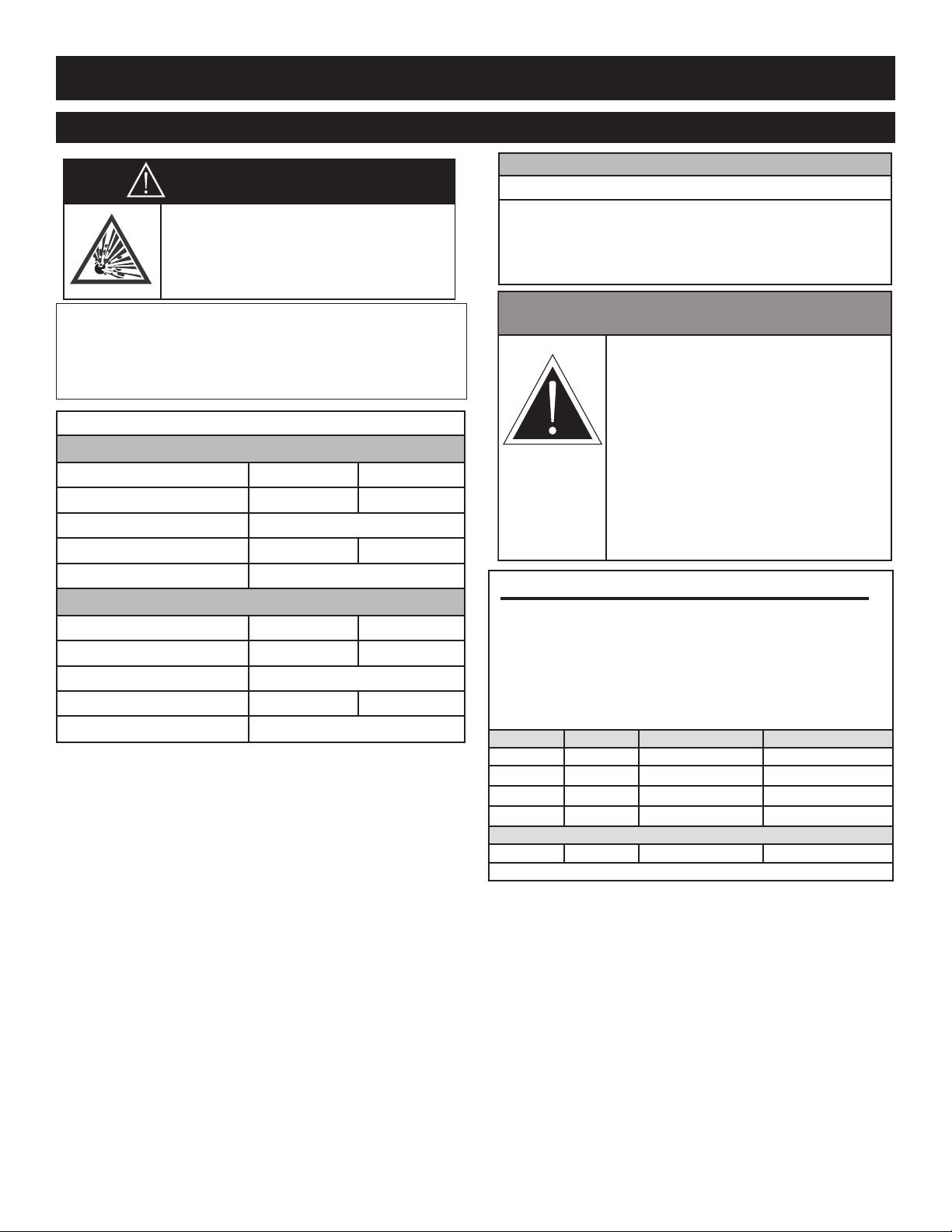

INCORRECT CORRECT

In the U.S.A., installation must conform to local

codes or, in the absence of local codes, with the

current edition of the National Fuel Gas Code,

NFPA-54 and ANSI Z223.1-1980 (latest edition).

In Canada, installation must be in accordance

with local codes, CAN/CGA-B149.1,

for Natural Gas Burning Appliances and

Equipment (latest edition) or CAN/CGA-B149.2

Installation for Propane Burning Appliances

and Equipment (latest edition).

The inlet supply line must be properly sized

to accommodate all individual appliances

simultaneously used on the same line but

must never be smaller than 3/4" NPT.

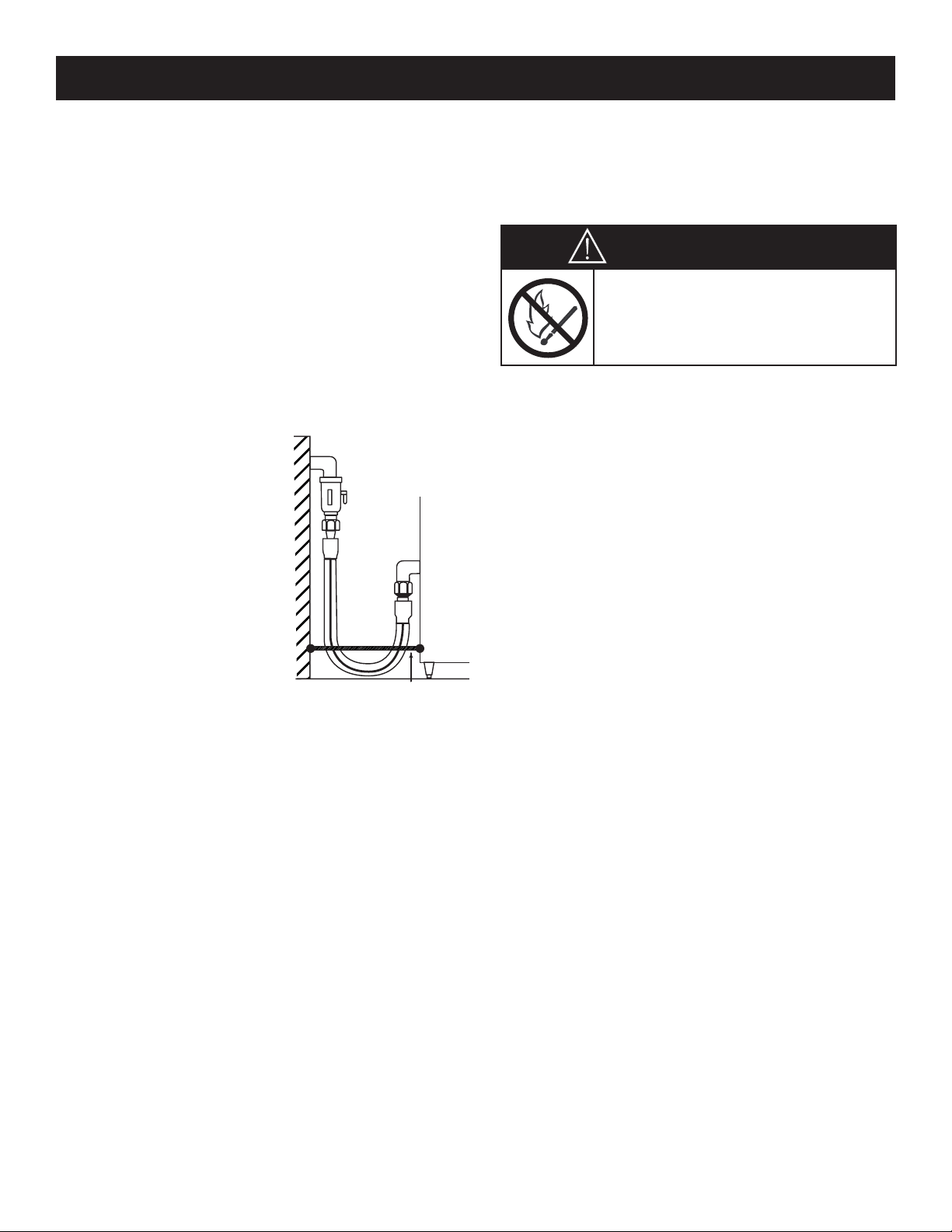

A

B

C

E

G

D

F

H

GAS INTAKE

A-G Installation elbow

B Wall Valve

C-D Three-piece union fi tting

(minimum 1 per installation)

E-F End connector for the fl exible tube

H Marking line

ASC-4G Gas Convection Oven - Electronic Control • 6

GAS SUPPLY & INSTALLATION

GAS CONNECTION

O FF

LEAK TESTING

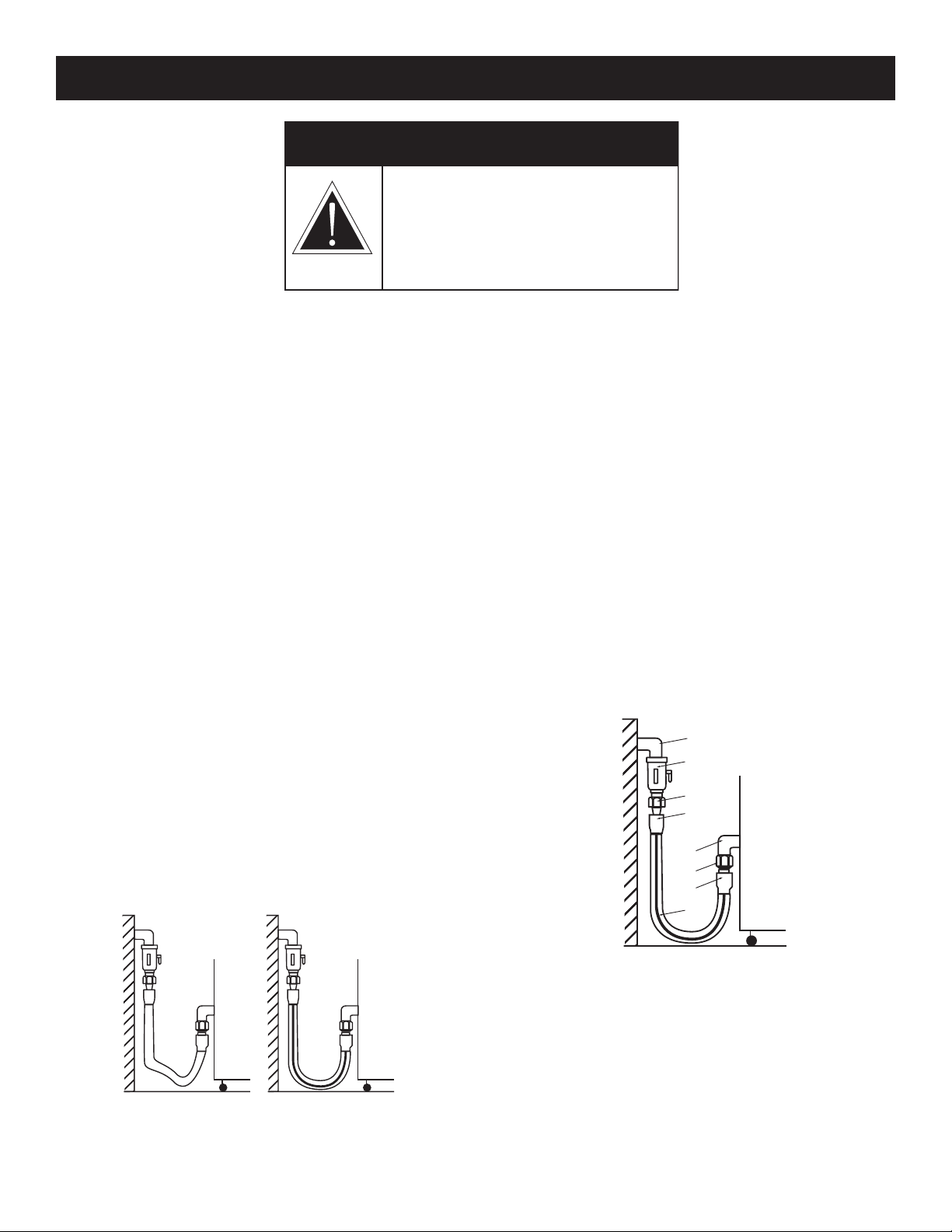

� FOR OVENS ON CASTERS

The oven must be supplied with a flexible

connector that complies with The Standard for

Connectors for Movable Gas Appliances, ANSI

Z21.69, CGA 6.16 and addenda Z21.69a (latest

editions). A quick disconnect device must be

installed to comply with The Standard for Quick

Disconnect Devices for Use with Gas Fuel, ANSI

Z21.41 and CAN1-6.9 (latest editions). A flexible

connector is not supplied by the factory.

Adequate means must be

provided to limit the

movement of the appliance.

Limitation of movement

must be made without

depending on the connector,

the quick disconnect device,

or the associated piping

designed to limit oven

movement. Mounting holes

for a restraining device are

located on the lower back

flange of the oven chassis.

CORRECT

RESTRAINT

Use a soap and water solution on all gas supply

line connections.

DANGER

NEVER USE AN OPEN

FLAME TO LEAK TEST.

Shut the gas supply

necessary to disconnect the restraint.

Reconnect the restraint immediately

following the return of the oven to its

original position. Turn the gas supply ON

after the restraint has been reconnected.

if it becomes

ASC-4G Gas Convection Oven - Electronic Control • 7

Loading...

Loading...