Alto-Shaam ASF-60G User Manual

W164 N9221 Water Street • P.O. Bo x 450 • M en om on ee Fa ll s, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744

US A/CA NA DA FAX: 262.251.7067 • 800.329.8744 U.S .A . ONLY

www.alto-shaam.com

®

ASF-60G shown with

ptional automatic

o

basket lifts

G A S F R Y E R

F r y Te c h S e r i e s

ASF-60G and

ASF-75G

Gas Fryers

ASF-75G shown with

optional automatic

basket lifts

with

Deluxe Control

• I NSTALLATION

• OPERATION

• MAI NTENANCE

P RI N TE D I N U .S . A.

M N- 28 85 6 • 0 3/ 09

D E L I V E R Y

T

his Alto-Shaam appliance has been

t

horoughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and report

it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

N O T E: All claims for warranty must include the

full model number and serial number of

the unit.

U N P A C K I N G

1. Carefully remove the

appliance from the

carton or crate.

N O T E: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner or

manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

®

W A R N I N G

In the event of loss of power to the

appliance, turn the “burner control

knobs” to the OFF position. Remove

food product from the unit. If burner

control fails to extinguish the flame,

shut off main gas valve located in

rear of unit.

D A N G E R

BEFORE STARTING THE

APPLIANCE, MAKE CERTAIN

YOU DO NOT DETECT THE

ODOR OF GAS.

IF THE ODOR OF GAS IS DETECTED:

• DO NOT attempt to light any appliance.

• DO NOT touch any electrical switches.

• Extinguish any open flame.

• Use a telephone OUTSIDETHE

PROPERTY & IMMEDIATELY

contact your gas supplier.

• If unable to contact your gas supplier,

contact the fire department.

KEE P THIS MANUAL IN A CONV ENIEN T LOCATION FOR R EFERE NCE.

Gas Fryer O p e r a t i o n & C a r e M a n u a l • 1

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated

hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

N O T E : Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

C A U T I O N

Used to indicate the presence of a hazard that can

or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

C A U T I O N

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

D A N G E R

Used to indicate the presence of a

hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

W A R N I N G

Used to indicate the presence of a

hazard that CAN cause personal injury,

possible death, or major property

damage if the warning included with

this symbol is ignored.

SAF E TY PROCE D URES

AND PREC AUTI O NS

K

nowledge of proper procedures is essential to the

s

afe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

N O T E

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

I N S T A L L A T I O N

Gas Fryer O p e r a t i o n & C a r e M a n u a l • 2

61-5/8" (1564mm)

Doo

r o

pen

s

12

0°

Electrical

Gas

Connection

1/2" NPT

24-13/16" (630mm)

31-9/16" (802mm)

12-7/16" (315mm)

2-7/8"

(72mm)

31-13/16" (808mm)

50-7/16" (1280mm) LIFT UP

44-7/16" (1128mm) LIFT DOWN

38-11/16" (983mm)

OIL

TROLLEY

I N S T A L L A T I O N

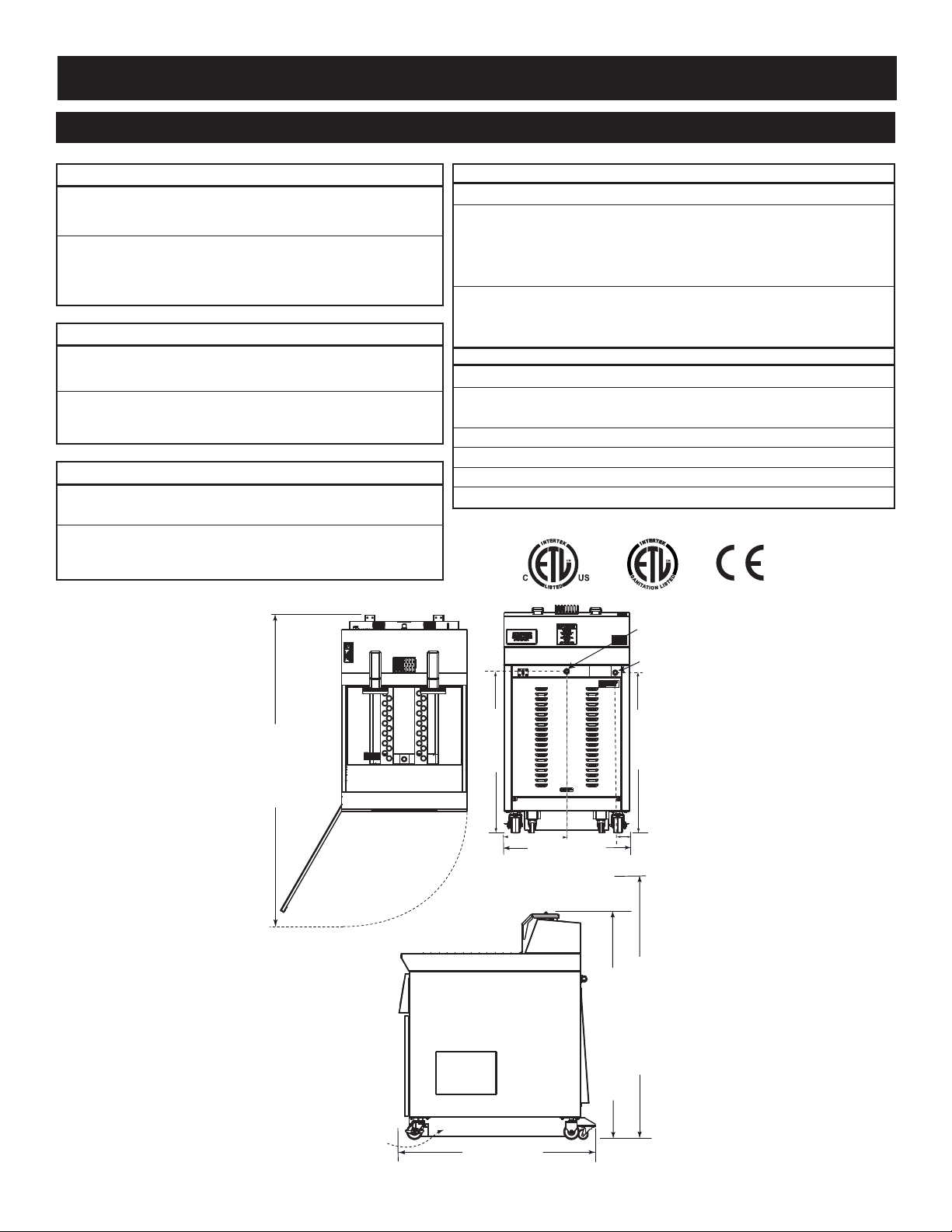

A S F - 7 5 G S P E C I F I C A T I O N S

DI MENSI ONS EX TERIOR H x W x D:

45-5/16" x 24-13/16" x 37-7/8"

(1150mm x 630mm x 961mm)

BASKE T DIMEN SIONS (H X W X D)

11-1/2" x 12-3/4" x 21-3/4"

(292mm x 324mm x 552mm)

C A PA C I T Y

SHORTENING/OIL:

73 lb (33 kg) MA XIMUM

LOAD CAPACITY:

13 lb (6 kg)

MA XIMUM

WE IGHT EST.

NE T WE IGHT: 360 lb (163 kg)

SHIP WEIGHT: 520 lb (236 kg)

CA RTON DIMENSIONS: H x W x D

57" x 34" x 47"

(1448mm x 864mm x 1194mm)

STA NDARD ACCES SORIE S

■■

asket, Half-Size

B

Brush Set

■■

■■

■■

Filter, Paper

■■

■■

(ONE3-B

AN GLE BR USH BH-28692

SC RUB BR USH BH-28693

ST RAIGHT B RUSH BH-28691

(7 PAPER FILTE RS INCLUDED AS STAN DARD)

7 COU NT RE FILL PAC KAGE FI-27791

100 COUN T REF ILL PACKA GE FI-27794

(2 I NCL UDED A S STAND ARD) B

RU SH SE T I NCLU DED AS STAND ARD

)

S-27140

O P T I ON S

■■

Basket, Full-Size (48 C HICKE N P IECE CAPACITY) BS-26998

■■

FILTERS

Fry Pot Cover 5005136

■■

Mobile Drawer Cover 5006073

■■

Strainer/Skimmer CE-27400

■■

■■

Oil Discard Hose HO-27686

Charcoal/Carbon (30 COU NT P KG.) FI-27648

■■

Reusable Mesh (S

INGL E F ILTER

) FI-27014

Gas F r y e r O p e r a t i o n & Care M a n u a l • 3

33-5/8" (854mm)

23-3/8"

(592mm)

47-1

/2

"

(1

206mm

)

6-5/8"

(168mm)

5-7/16"

(142mm) Gas Connection

31-1/2" (802mm)

Electrical Connection

2-7/8"

(72mm)

1

50

°

15-3/4"

(400mm)

4

4

-

3

/

8

"

(

1

1

2

7

m

m

)

5

0

-

3

/

8

"

(

1

2

8

0

m

m

)

l

if

t

u

p

I N S T A L L A T I O N

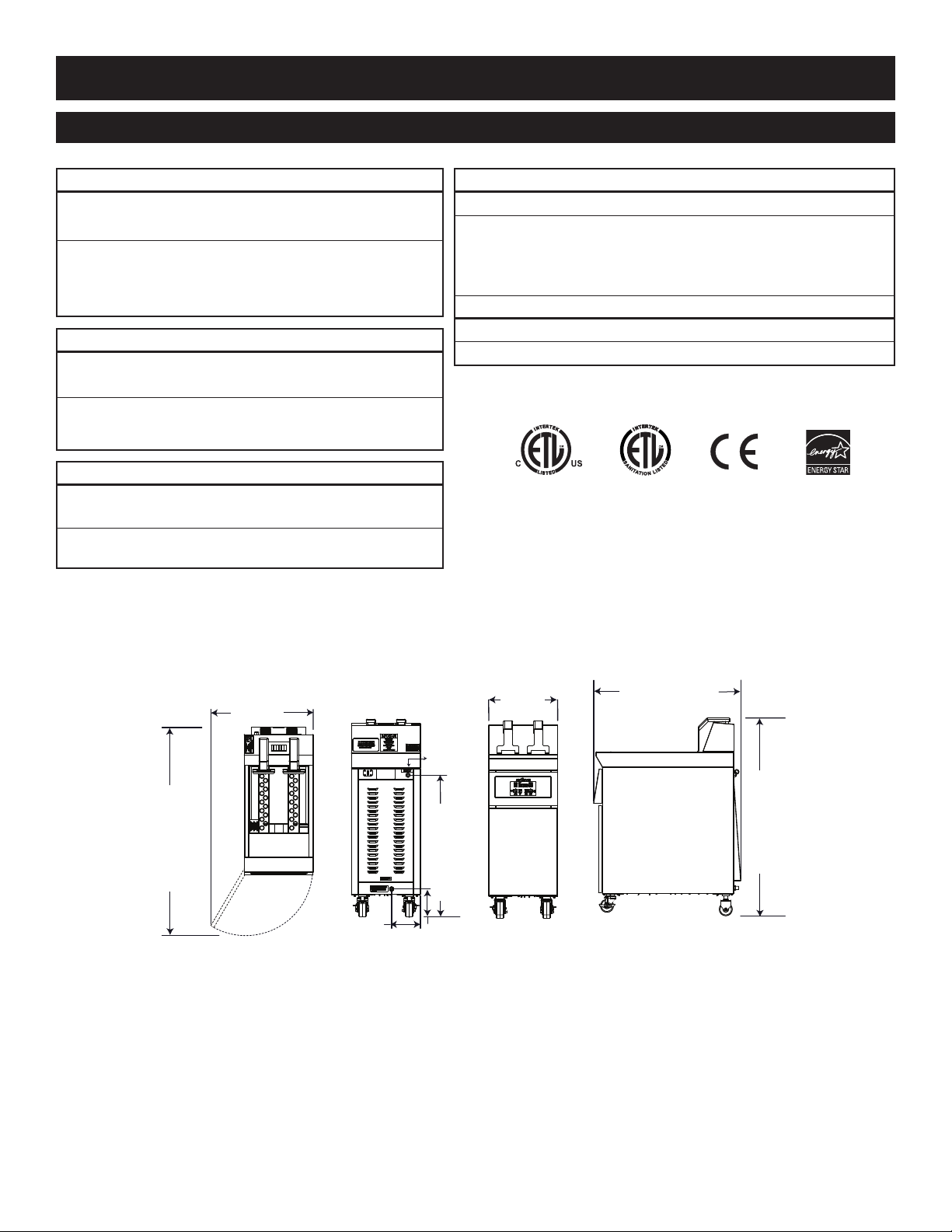

A S F - 6 0 G S P E C I F I C A T I O N S

DI MENSI ONS EXTERIO R H x W x D:

45-1/8" x 15-3/4" x 33-5/8"

(1146mm x 400mm x 854mm)

BA SKET D IMENSI ONS (H X W X D)

5-7/8" x 5-3/16" x 13-13/16"

(149mm x 131mm x 351mm)

C A PA C I T Y

SHORTENING/OIL:

62 lb (28 kg) MA XIMUM

LOAD CAPACITY:

8 lb (4 kg)

MAXIMUM

WE IGHT

NE T WEIG HT: 248 lb (113 kg)

SH IP WEI GHT: 330 lb (150 kg) EST

CA RTON DI ME NSIONS

: 39" x 22" x 55" EST

(991mm x 559mm x 1397mm) EST

STA NDARD AC CES SO RIE S

■■

Basket, Half-Size (2 INCLU DED AS STAND ARD) BS-27963

Brush Set (ONE 3-BRU SH SET INC LUDE D AS S TANDA RD)

■■

AN GLE BR USH BH-28692

■■

CR UB BRU SH

S

■■

ST RAIGHT B RUSH BH-28691

BH-28693

O P T I ON S

Fry Pot Cover 5007596

■■

■■

Strainer/Skimmer CE-27400

Gas F r y e r O p e r a t i o n & Care M a n u a l • 4

D A N G E R

IMPROPER INSTALLATION,

A

LTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

D A N G E R

AVERTISSEMENT : UNE INSTALLATION,

UN AJUSTEMENT, UNE ALTÉRATION,

UN SERVICE OU UN ENTRETIEN NON

CONFORME AUX NORMES PEUT CAUSER

DES DOMMAGES À LA PROPRIÉTÉ, DES

BLESSURES OU LA MORT.

LIRE ATTENTIVEMENT LES DIRECTIVES

D’OPÉRATION ET D’ENTRETIEN AVANT

DE FAIRE L’INSTALLATION, OU

L’ENTRETIEN DE CET ÉQUIPEMENT.

C A U T I O N

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

I N S T A L L A T I O N

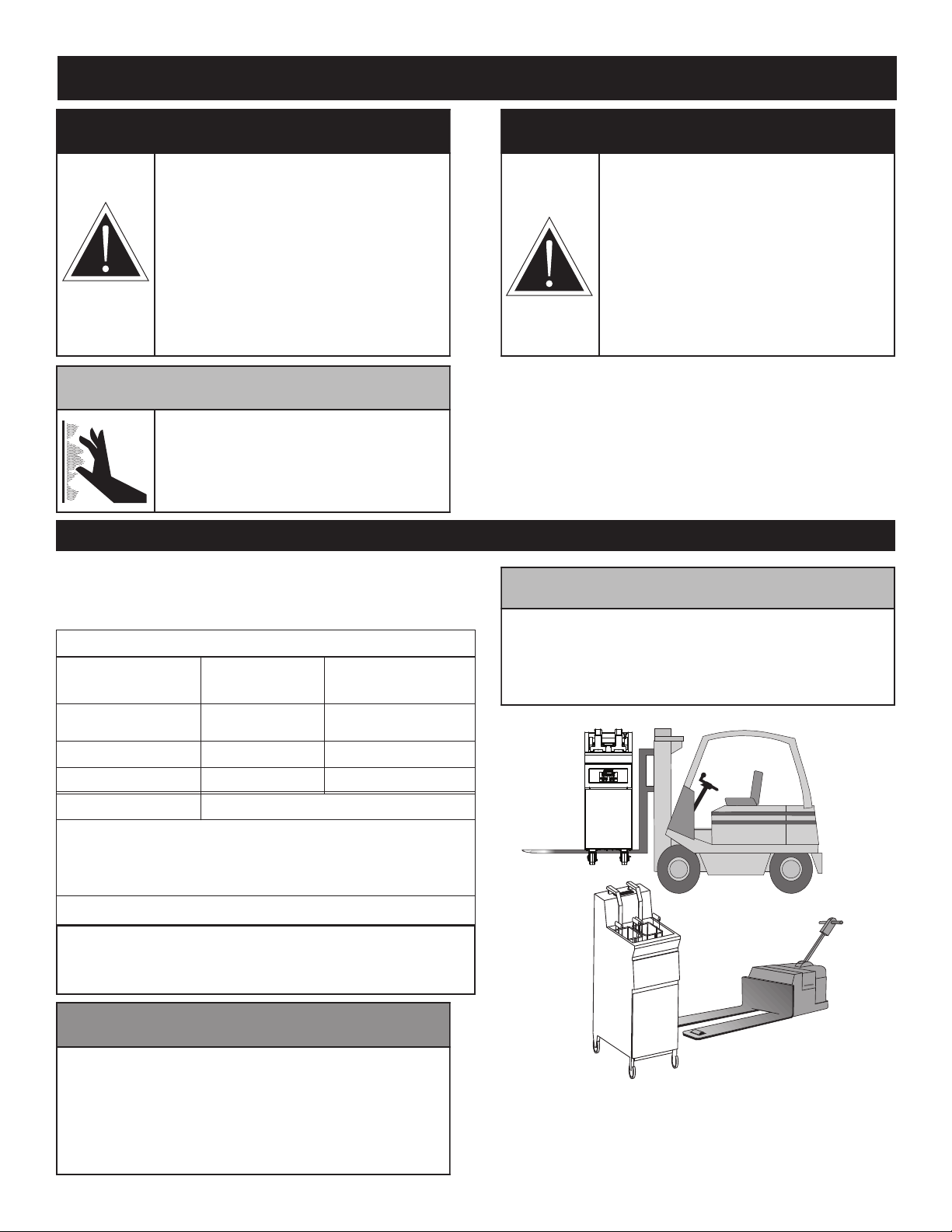

C A U T I O N

DO NOT USE FORKLIFT FROM

FRONT OR REAR OF UNIT.

USE FORKLIFT FROM SIDE ONLY.

W A R N I N G

MINIMUM CLEARANCES MUST

REMAIN UNOBSTRUCTED.

DDOO NNOOTT ppllaaccee iinnssuullaattiioonn oorr

aannyy ootthheerr ttyyppee ooff mmaatteerriiaallss

iinn cclleeaarraannccee aarreeaass..

S I T E I N S T A L L A T I O N

NOT E: To avoid equipment damage, remove the

Mobile Oil Trolley before moving this

appliance with a forklift or pallet lift.

MINIMUM CLEARANCE REQUIREMENTS

CO M BUS TIB LE NON -CO MBU STI BLE

SUR FA CE S SUR FA CE S

RIG HT SI DE 0" (152mm) 0" (0mm)

LEF T SID E 0" (0mm) 0" (0mm)

BAC K 6" (152mm) 6" (152mm)

FRO NT 25" (635mm)

PL US: 6" (152mm) minimum between the element swing in the

extended position and the lower edge of the exhaust hood

and filter media.

ENT RY C LEA RAN CE: 30" (762mm)

Ne pas installer à une distance inférirure à celle

indiqu ée ce-d esso us d'un e parol en matié re

combustible: Côtés 6 pouches, Arriére 6 pouches.

UNCRATED

Gas F r y e r O p e r a t i o n & Care M a n u a l • 5

C A U T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

D A N G E R

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be

made in according with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

I N S T A L L A T I O N

W A R N I N G

BURN WARNING: Make certain the fryer

is stabilized before operation to prevent

any movement or tipping and the

possibility of severe burns caused by

hot, splashing shortening or oil.

W A R N I N G

IMPROPER INSTALLATION

MAY RESULT IN FIRE.

Carefully read and follow all installation

instructions located in this manual.

S I T E I N S T A L L A T I O N

. It is the responsibility of the installer to verify that this

1

fryer installation is in compliance with the

specifications listed in this manual and with local code

requirements.

2. Hood installation is required.

3. Both cooking and cleaning functions require

unobstructed access. The frypot, control panel, and

front access door must be maintained free from

obstruction. The access door must be accessible for

service and maintenance.

4. Locate the fryer on a firm, level surface ONLY. The

area surrounding the fryer must be kept clear of all

combustible materials.

5. FOR Y OUR SAF ETY DO N OT store or use any

flammable liquids or allow flammable vapors in the

vicinity of this fryer or any other appliance.

6. FOR Y OUR SAF ETY DO N OT place insulation

or any other type of materials in clearance areas.

7. When properly installed, the electric fryer is designed

for operation adjacent to non-combustible floors and

walls with a 6" clearance at the back. Clearances from

all combustible construction is a minimum of 6"

(152mm) at the back and both sides. Concrete, tile,

terrazzo, or metal surfaces are recommended. Metal

over a combustible material may not meet code for

non-combustible surfaces. Verify site selection with

local codes for specific requirements.

Doit être utilisé seulement sur des planchers non

inflammables.

. DO NOT install this fryer in any area where it may be

9

affected by any adverse conditions such as steam or

dripping water, etc. DO NOT install the fryer over a

drain.

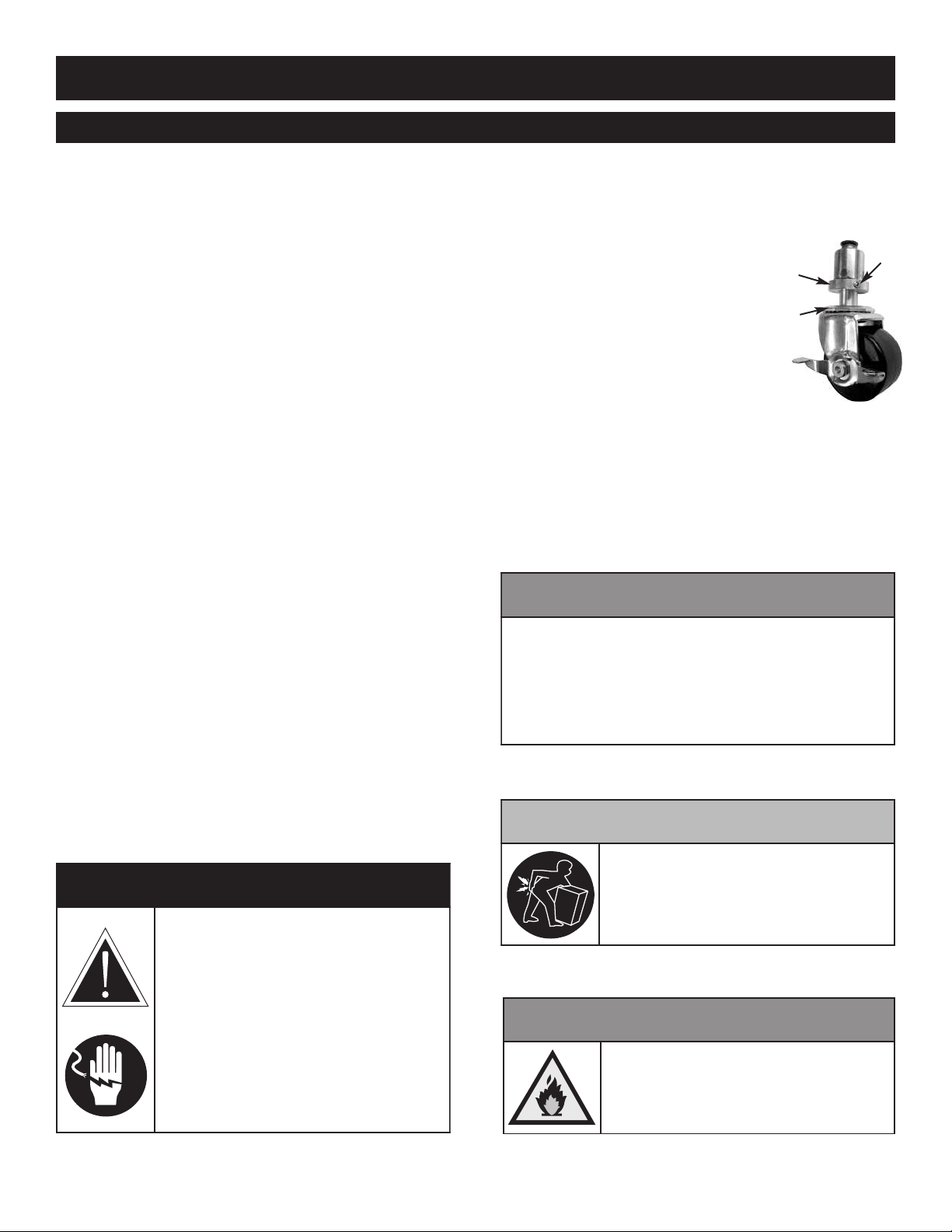

10. LEVELING: Make certain the fryer

is positioned firmly on all four

supporting casters. Level fryer

front-to-back and side-to-side by

holding lower collar (#2) while

twisting upper collar (#1).

Restraining ties can be used for

stabilization if necessary. Use an allen

wrench (#3) to lock caster in position.

1

2

3

8. Adequate means must be provided to limit the

movement of this appliance. A restraining device is

required for field installation.

Gas F r y e r O p e r a t i o n & Care M a n u a l • 6

D A N G E R

Installation, air adjustment and/or

service work must be in accordance

with all local codes and must be

performed by a certified service

technician qualified to work on

gas appliances.

C A U T I O N

To prevent malfunction or cause

negative back draft, DO NOT obstruct

exhaust flues or attach any flue

extension that will impede proper

burner operation.

I N S T A L L A T I O N

D A N G E R

FAILURE TO VENT THIS FRYER PROPERLY

MAY BE HAZARDOUS TO THE

HEALTH OF THE OPERATOR.

Equipment damage and operational problems

may also be the consequence of improper venting.

Any damages sustained by a failure to properly

vent this fryer are not covered under warranty.

Ventilating hoods and exhaust systems shall be permitted to be

used to vent appliances installed in commercial applications.

Where automatically operated appliances are vented through a

ventilating hood or exhaust system equipped with a damper or

with a power means of exhaust, provisions shall be made to allow

the flow of gas to the main burners only when the damper is open

to a position to properly vent the appliance and when the power

means of exhaust is in operation. IN ACCORDANCE WITH NFPA 54

COMMONWEALTH OF MASSACHUSETTS ONLY.

V E N T I L A T I O N

An adequate ventilation system is required for commercial cooking equipment. Information may be obtained by writing

to the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. When writing refer to NFPA No. 96.

1. A single ASF-75G or ASF-60G auto-lift gas fryer

requires a minimum of 120 CFM make-up air for

natural gas and 48 CFM for propane gas. Kitchen

ventilation must be of sufficient capacity to prevent a

negative-pressure condition. DO

restrict ventilation nor the air flow required to support

combustion.

2. DO

NO T obstruct the flow of the exhaust flue at the

top rear of the fryer. It is especially critical that gas

supply piping and electrical support cord and/or

receptacle be routed away from the path of the hot

combustion fumes.

NO T obstruct or

3. This fryer cannot be direct vented.

4. Install the fryer under a ventilation hood meeting all

applicable code requirements. Combustion fumes

must be vented in accordance with local, state, or

national codes.

Gas F r y e r O p e r a t i o n & Care M a n u a l • 7

D A N G E R

CONNECTING TO THE WRONG GAS

SUPPLY COULD RESULT IN FIRE OR

AN EXPLOSION CAUSING SEVERE

INJURY AND PROPERTY DAMAGE.

W A R N I N G

TO AVOID SERIOUS PERSONAL

INJURY, installation of this appliance

must conform to local, state, and

national codes; the current edition of

the American National Standard

Z223.1, National Fuel Gas Code, and

all local municipal building codes. In

Canada, installation must be in

accordance with Standard CAN/CSA

B 149.1 and Installation Codes - Gas

Burning Appliances, and local codes.

I N S T A L L A T I O N

G A S S P E C I F I C A T I O N S

The Alto-Shaam open gas fryer has been set to operate

with either natural gas or propane as indicated on the

fryer identification name plate.

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2

psi. The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psi.

NOTE: Customer/installer must provide manual gas shut-

off valve in accordance with local code

requirements.

GA S P R ES SU RE CH AR T

The fryer has been factory adjusted according to

the gas type specified on the fryer identification

name plate.

GAS FRYER TECHNICAL SPECIFICATIONS

G A S S P E CI F I C AT I O N S

■■

NATURA L GA S

120,000 BTU/hr. IN PUT 120,000 BTU/hr. IN PUT

I N S T A L L AT I ON R EQ U I R EM E N T S

GA S CONN ECTION : 1/2" NPT

CH ECK PL UMBING CODES FO R PROPER SUPPLY LINE S IZING TO

ATTAIN M INIMUM BURNER M AN IFOLD PR ESSURE S HOWN

NATURAL GAS: 5.0" W.C.

PR OPAN E GAS : 10.0" W.C.

MA XIMUM IN LET PR ESSURE : 14" W.C.

■■

PR OPAN E GAS

:

NO TE: If a flexible gas line is used, it must be AGA

approved, commercial type and at least 3/4" I.D.

HO OD IN STALL ATION I S R EQUI RED

Gas F r y e r O p e r a t i o n & Care M a n u a l • 8

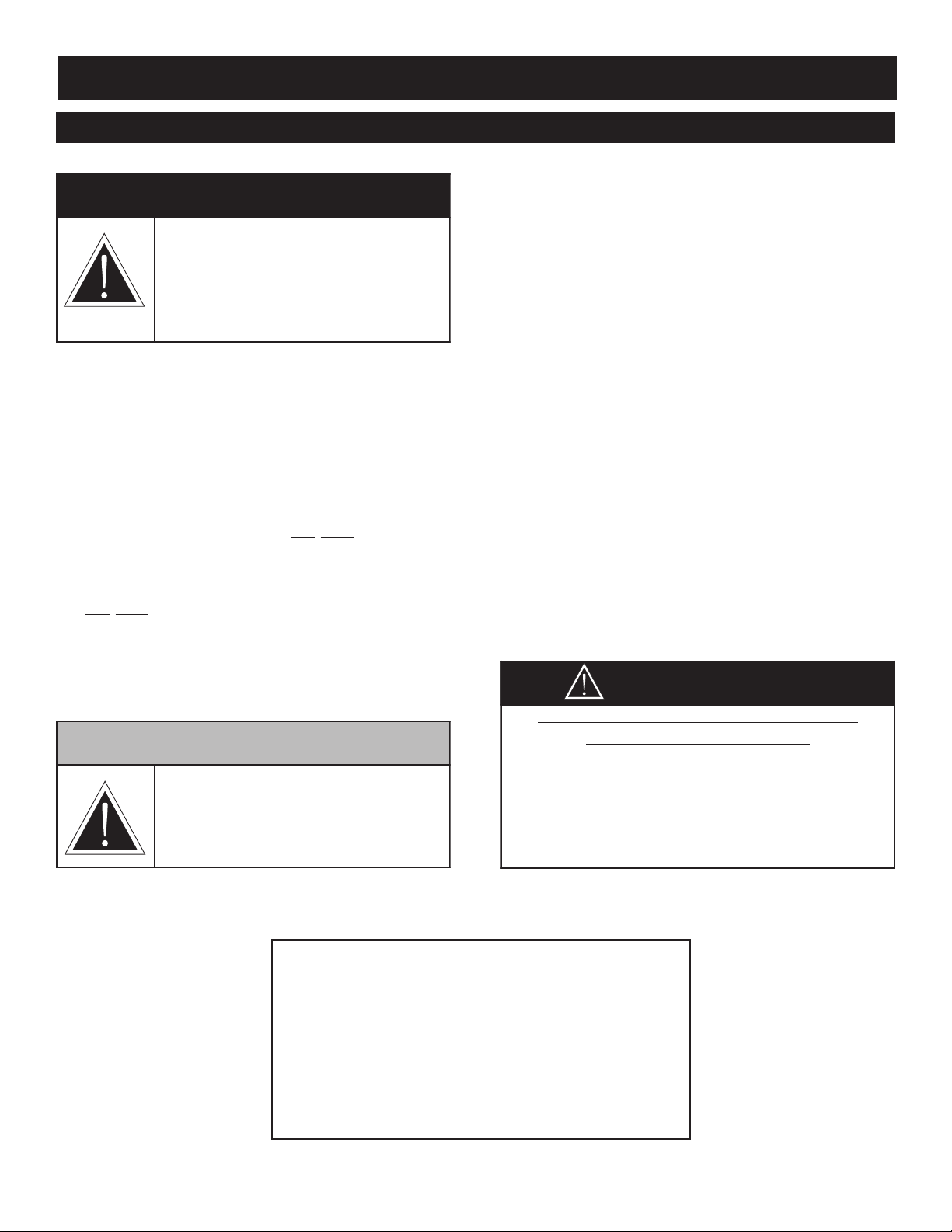

N a t u r a l G as

Min. Connected Pressure 5.0" W.C. 1.2 kPa

Max. Connected Pressure 14.0" W.C. 3.5 kPa

Gas Consumption 120 CFM

Gross Thermal Output 120,000 Btu/hr

Propa n e Ga s

Min. Connected Pressure 10.0" W.C. 2.5 kPa

Max. Connected Pressure 14.0" W.C. 3.5 kPa

Gas Consumption 48 CFM

Gross Thermal Output 120,000 Btu/hr

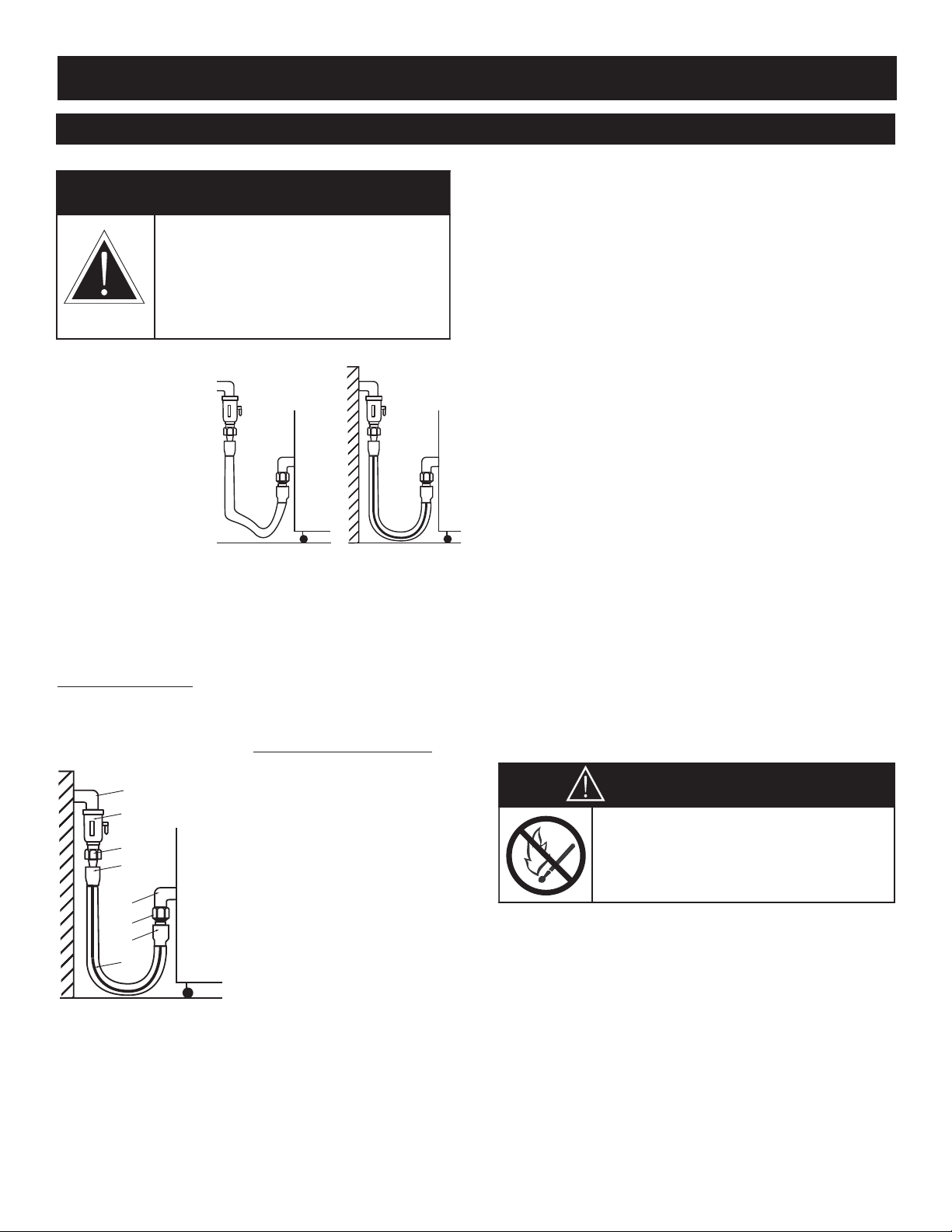

Use an approved gas

I

NCORRECT CORRECT

A

B

C

D

E

F

G

H

D A N G E R

Installation, air adjustment and/or

service work must be in accordance

with all local codes and must be

performed by a certified service

technician qualified to work on

gas appliances.

D A N G E R

NEVE R USE AN OPEN

FL AME TO LEAK TEST.

pipe sealant at all

external threaded

connections, gas

piping used on gas

connections must

avoid sharp bends

that may restrict the

flow of gas to the

appliance. If the

connected pressure exceeds 14.0" W.C. (3.5 kPa), a

step-down regulator is required to be supplied by the

owner/operator.

Close the i n d i v i d u a l manual shut-off valve to

isolate the f r y e r from the gas supply piping system

during any pressure testing at test pressures equal to

or less than

individual shut-off valve m u s t be disconnected

1

/

psig. (3.4 kPa). The fryer and

2

from the gas supply piping system during

any pressure testing at pressures in

excess of 1/2 psig. (3,4 kPa).

I N S T A L L A T I O N

G A S C O N N E C T I O N

In the U.S.A., ins tallation must conform to local

codes or, in the absenc e of local codes, with t he

current e dition of the Na tional Fuel Gas Cod e,

NFPA-54 and ANSI Z83.11a C SA 1.8a 2004 ( or

latest editio n). In Canada, installation must be in

accordance with local co des, CAN/CGA-B149.1,

Installat ion for Natural Gas Burning Applia nces

and Equipment (latest edition) or CAN/CGA-

B149.2 Instal lation for Prop ane Burning

Appliance s an d Equipment (latest e dition).

The inlet s u p p l y line must be p roperly s i z e d to

accommodate all i n d i v i d u a l appliances

simultaneously used o n the same line b u t mu s t

never be s m a l l e r than 3/4" I.D.

LEA K TESTI NG

Installation requires gas leak testing on all gas

piping and fittings. Use an approved electronic leak

device or a soap and water solution at all gas

connections. If bubbling appears when using a soap

and water solution, the connection must be refitted.

Never use an open flame to leak test.

GAS INTAKE

A-G Installation elbow

B Wall Valve

C-D Three-piece union fitting

(minimum 1 per installation)

E-F End connector for the flexible tube

H Marking line

Gas F r y e r O p e r a t i o n & Care M a n u a l • 9

W A R N I N G

RISK OF ELECT RIC SHOCK .

Appliance must be secured

to building structure.

I N S T A L L A T I O N

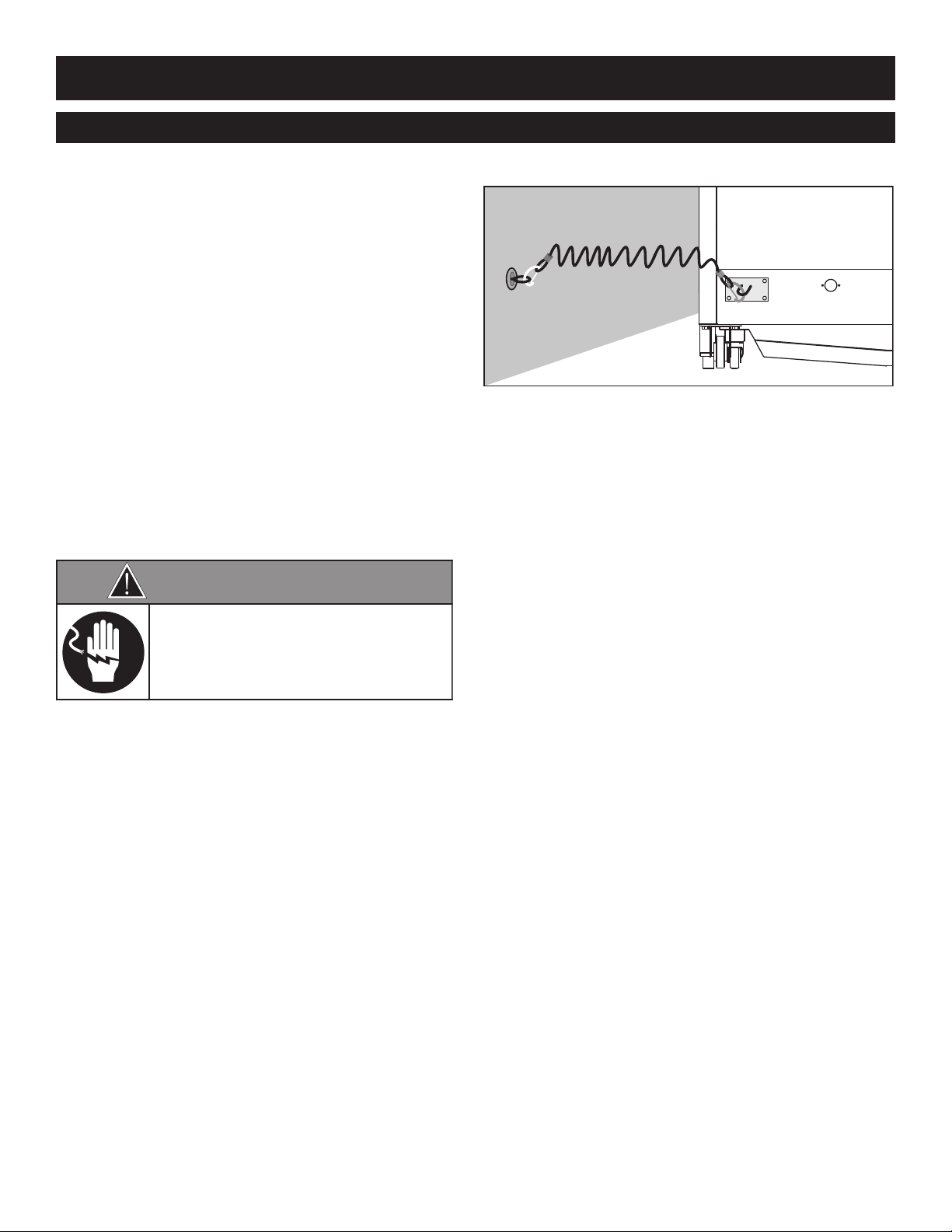

R E S T R A I N T R E Q U I R E M E N T S - M O B I L E E Q U I P M E N T

The fryer must be supplied with a connector that

complies with all state and local installation codes.

Any appliance that is not furnished with a power

supply cord but that includes a set of casters must be

tethered. Adequate means must be provided to limit

the movement of this appliance without depending

on or transmitting stress to the electrical conduit.

The following requirements apply:

1. Casters must be a maximum height of 4-inches (102mm).

Such mobile appliances must be installed with

2.

the use of a flexible connector secured to the

building structure.

A mounting connector for a restraining device is

located on the lower back flange of the appliance

chassis, approximately 7-inches (178mm) from the

floor. A flexible connector is not supplied by nor is it

available from the factory.

Gas F r y e r O p e r a t i o n & Care M a n u a l • 10

An electrical wiring diagram is located in the front access

D A N G E R

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be

made in according with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

D A N G E R

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED

ON APPLIANCE NAMEPLATE.

door of the fryer. The fryer must be installed by a

qualified electrician. This appliance must be branch circuit

protected with proper ampacities, in accordance with the

wiring diagram located in the fryer. The fryer must be

properly grounded in accordance with the National

Electrical Code and applicable local codes. A means to

disconnect the unit must be incorporated into the fixed

wiring in accordance with wiring codes.

I N S T A L L A T I O N

E L E C T R I C A L R E Q U I R E M E N T S

locate the wire size posted on the label located on the

electrical control box cover, behind the service panel or

elsewhere listed in this manual.

Before operating the fryer, check all cable connections in

the electrical connection area for tightness since

connections can loosen during transport.

230V:

To prevent an electrical shock hazard between the

appliance and other appliances or metal parts in close

vicinity, an equalization-bonding stud is provided. An

equalization bonding lead must be connected to this

stud and the other appliances / metal parts to provide

sufficient protection against potential difference. The

terminal is marked with the following symbol.

Wire size for the main incoming power to the unit must

match the minimum size listed in the specifications

applicable to the specific fryer. For supply connections,

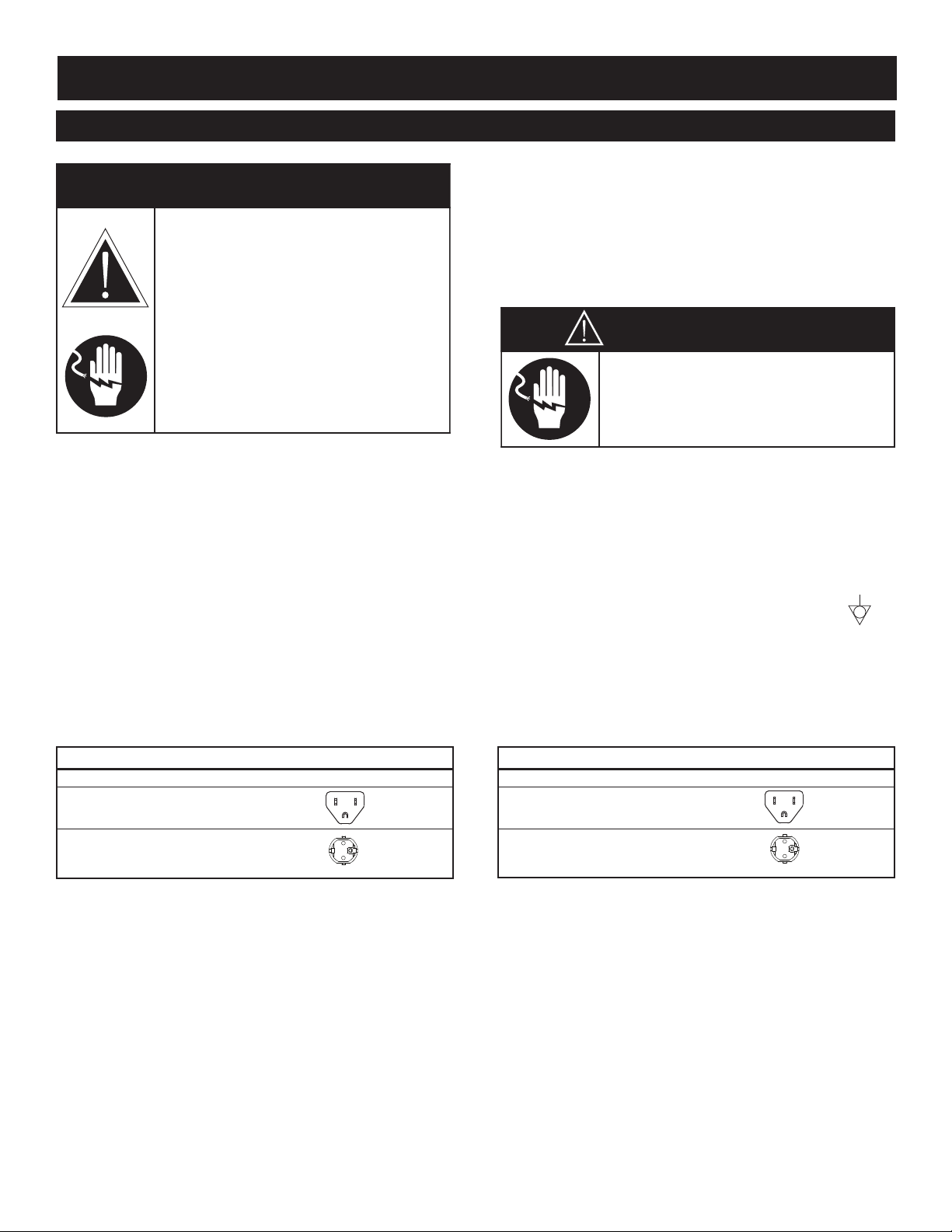

EL ECTRI CAL • ASF -60G W ITH DE LUX E C ON T RO L

VOLTAGE PHASE CYCLE/HZ AMPS KW

120 (A GCY)1 60 1.2 1.5

230 1 50/60 1.0 2.3

N EM A 5-15P

15A-125V PLUG

C EE 7 / 7

220-230V PLUG

Gas F r y e r O p e r a t i o n & Care M a n u a l • 11

EL ECTRI CAL • ASF -75G W ITH DE LUX E C ON T RO L

VOLTAGE PHASE CYCLE/ HZ AMPS KW

120 (A GCY)1 60 7.2 0.864

230 (AGC Y)1 50/60 4.0 0.92

NN EE MM AA

15A-125V Plug

C EE 7 / 7

220-230V

5-15P

PLUG

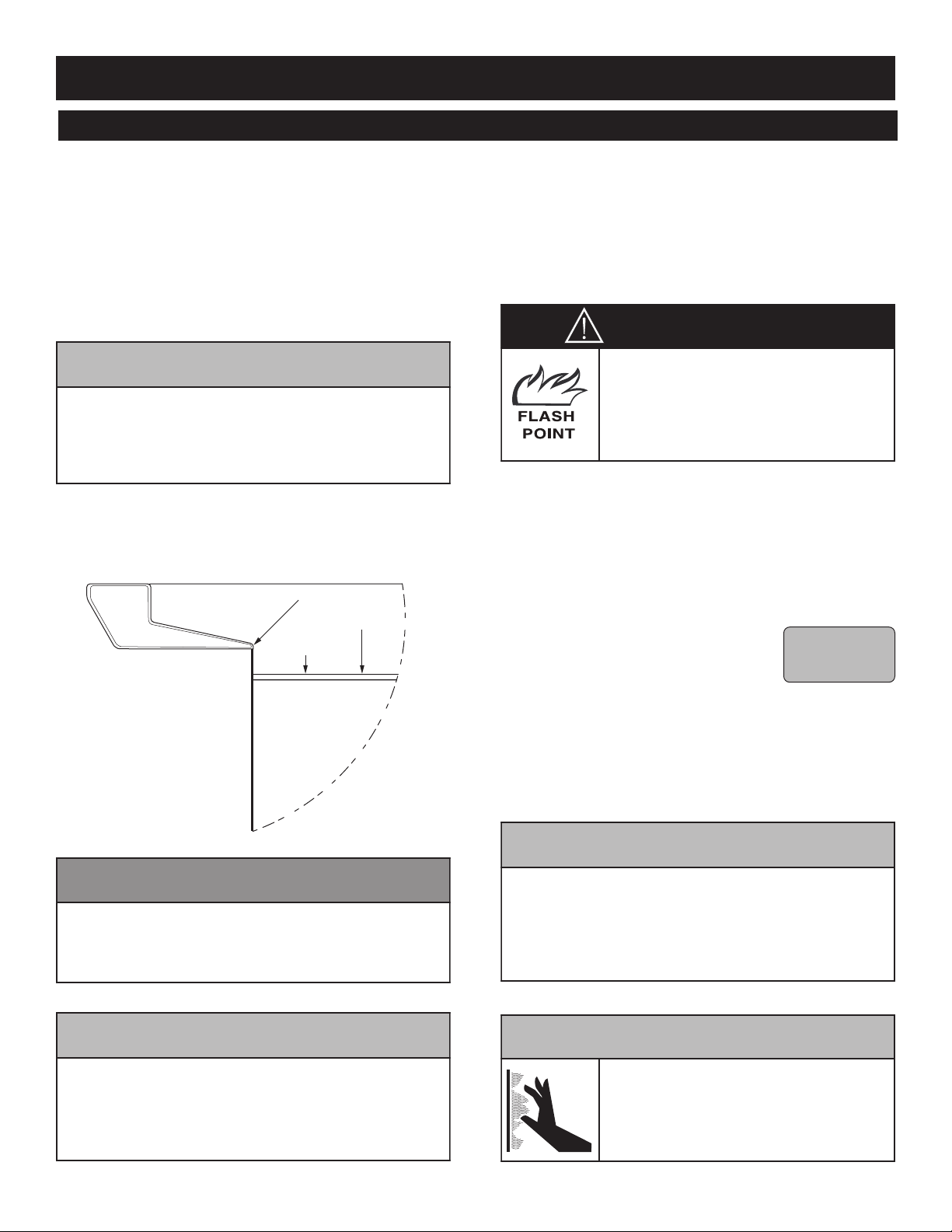

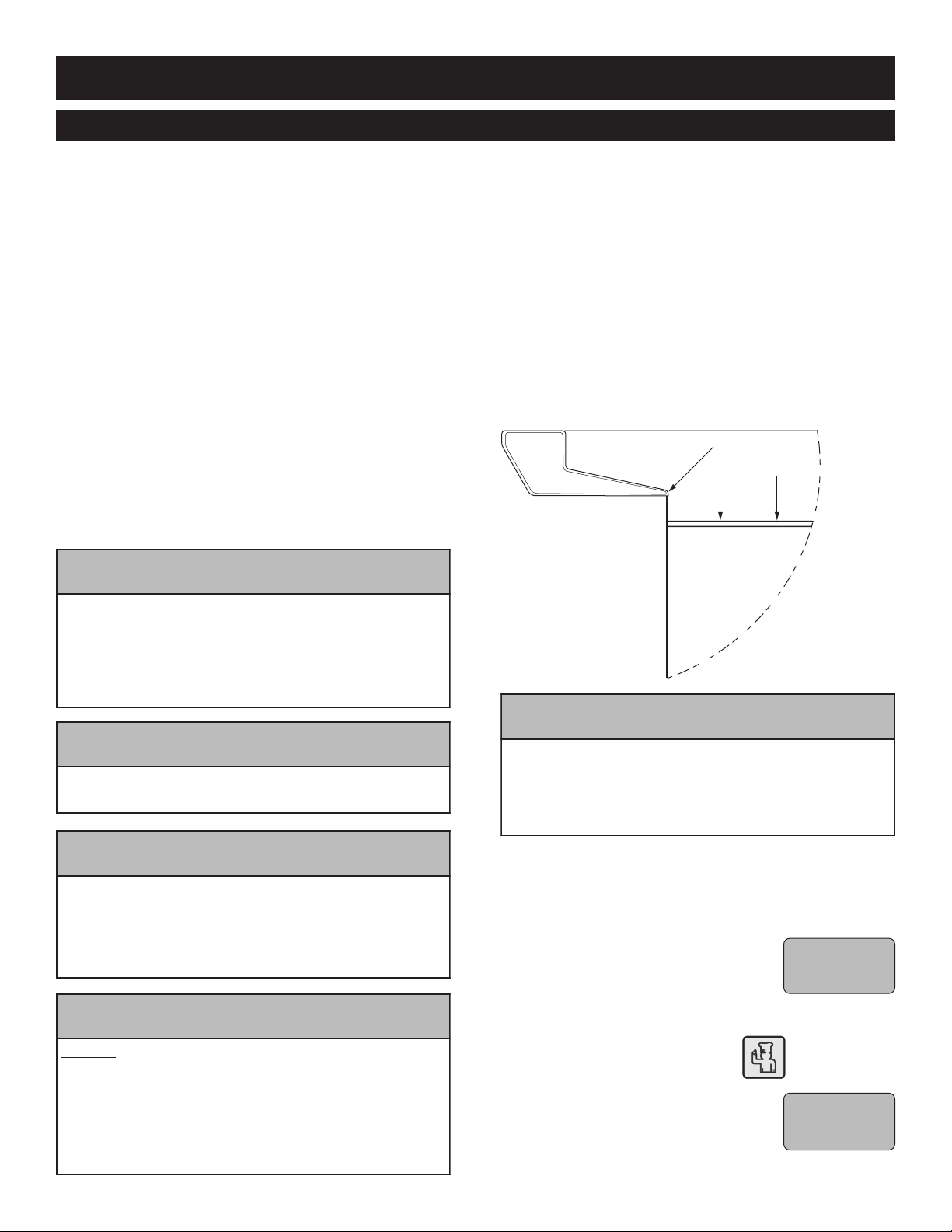

O P E R A T I O N

MAXIMUM HOT OIL FILL LINE

MINIMUM

HOT OIL FILL LINE

TOP BEND INSIDE

OIL KETTLE

FR

O

NT

OF KETTL

E

C A U T I O N

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

C A U T I O N

KEEP A CONTAINER OF COLD WATER ON HAND

DURING BOIL-OUT IN CASE OF BOIL-OVER. IF BOILOVER IS IMMINENT, IMMEDIATELY TURN OFF MASTER

POWER SWITCH AND POUR COLD WATER INTO FRYPOT

TO QUICKLY REDUCE SOLUTION TEMPERATURE.

W A R N I N G

FAILURE TO PLACE SOLID SHORTENING

DIRECTLY ON THE BOTTOM OF THE

FRYPOT CAN CAUSE SERIOUS

E QU I P M E N T DAMAG E .

C A U T I O N

ENSURE THERE IS NO WATER IN THE FRYPOT BEFORE

FILLING WITH OIL/SHORTENING. WHEN COOKING

COMPOUNDS ARE HEATED TO COOKING

TEMPERATURE, WATER IN THE FRYPOT WILL CAUSE

OIL TO SPLATTER AND MAY BE A BURN HAZARD.

C A U T I O N

FIRE OR EQUIPMENT DAMAGE CAN RESULT FROM

IMPROPER SHORTENING LEVELS. THE LEVEL OF

SHORTENING MUST ALWAYS BE ABOVE THE HEATING

ELEMENTS WHEN THE FRYER IS OPERATING.

THE REQUIRED SHORTENING LEVEL MUST ALWAYS

BE ABOVE THE MINIMUM HOT OIL FILL LINE.

D A N G E R

The fl ash point of sh ortening

occurs at a lower tem perature

the lo nger the shortening is

used. Discard any shortening

showing signs of deterioration

to avo id serious burns, fire,

and property damage.

O I L / S H O R T E N I N G R E Q U I R E M E N T S

IL/SHORTENING REQUIREMENTS

O

The ASF-75G requires 73-pounds (33 kg) of oil or

shortening in the frypot and the ASF-60G requires

62-pounds (28 kg) of oil or shortening. Use only

quality, high-grade oil/shortening in the fryer. The high

moisture content of many lower grade shortening will

result in excessive foaming and boil over. The cold

oil/shortening level requirement for the fryer is indicated

below.

NOTE: Always maintain the proper level of

shortening by adding fresh oil/shortening

to the frypot whenever needed.

Check the quality of the oil/shortening in the frypot on a

daily basis for signs of deterioration. Use an approved test

kit. Signs of shortening deterioration include excessive

boiling, smoking, foaming, bad taste, and rancid odor.

Discard any shortening before it degrades to the point of

affecting product quality. Always filter the oil on a regular

basis and keep the frypot clean.

Remove ice crystals and ensure that food is dry before

frying. Excessive water and ice can cause oil to splatter or

overflow. Do not over fill the basket. Food needs to be

surrounded by oil for best frying results.

Maximum shortening life is achieved by lowering the

temperature of the fryer to 250°F (121°C) whenever the

fryer is not being used. This is an

automatic program function through the

control program designation of

OIL /S H ORT EN I NG

LEV ELS

“IdleMode.” The factory default is set at

a period of 30 minutes of non use before triggering a

temperature decrease, however; this time period can be

adjusted between “0” and “60” minutes. (

PROGRAMMING THE CONTROL

)

3 0 : 0 0

Id leM od e

SEE

Gas F r y e r O p e r a t i o n & Care M a n u a l • 12

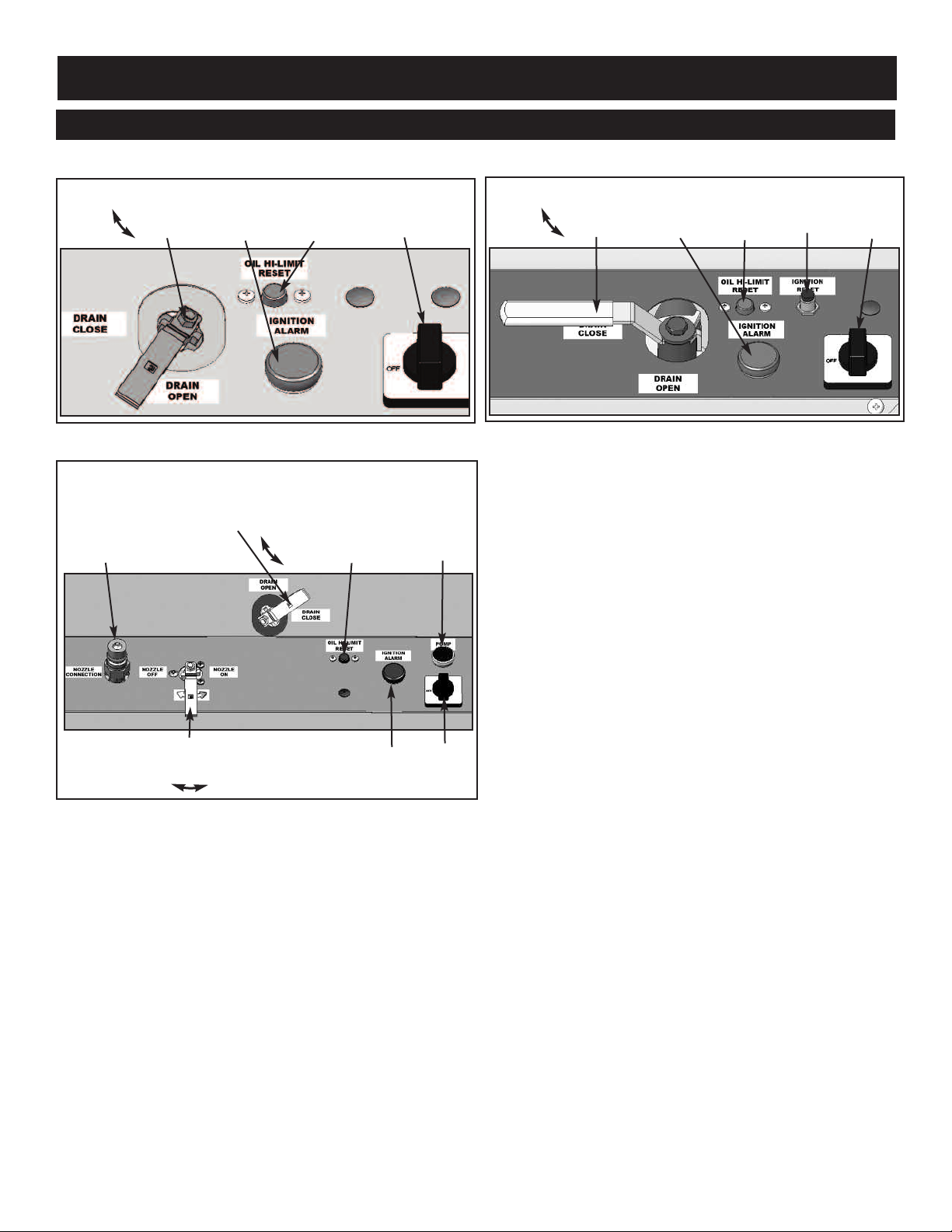

O P E R A T I O N

C O N T R O L S B E H I N D L O W E R A C C E S S PA N E L

ASF-60G, 120V

CLOSED

PEN

O

KETTLE DRAIN

SELECTOR

IGNITION

ALARM

OIL

HI-LIMIT

RESET

ASF-75G, 120V WITH FILTRATION

ETTLE DRAIN

K

ELECTOR

NOZZLE

CONNECTION

S

O

PEN

CLOSED

OIL

HI-LIMIT

RESET

MASTER

POWER

SWITCH

PUMP

ASF-60G, 230V

CLOSED

OPEN

ETTLE DRAIN

K

ELECTOR

S

IGNITION

ALARM

H

A

O

I

-L

LARM

IL

IMIT

IGNITION

RESET

ASTER

M

OWER

P

WITCH

S

NOZZLE

OFF

NOZZLE

KETTLE

SELECTOR

NOZZLE

ON

IGNITION

ALARM

MASTER

POWER

SWITCH

Gas F r y e r O p e r a t i o n & Care M a n u a l • 13

O P E R A T I O N

MAXIMUM HOT OIL FILL LINE

M

INIMUM

H

OT OIL FILL LINE

TOP BEND INSIDE

OIL KETTLE

FR

ON

T

O

F

KE

TTLE

C A U T I O N

BOIL-OUT SOLUTION AND SURROUNDING METAL

SURFACES BECOME EXTREMELY HOT. TO AVOID

BURNS, ALWAYS USE HAND PROTECTION WHEN

PERFORMING THE BOIL-OUT FUNCTION AND FOLLOW

THE MANUFACTURER'S SAFETY INSTRUCTIONS FOR

THE BOIL-OUT PRODUCT BEING USED.

C A U T I O N

BEFORE ENTERING THIS PROGRAM, MAKE CERTAIN

THE FRYPOT IS EMPTY OF ALL OIL OR SHORTENING.

C A U T I O N

TO AVOID DAMAGING THE PUMP AND CONTAMINATING

CLEAN OIL WITH BOIL-OUT CHEMICAL ON UNITS

EQUIPPED WITH A FILTRATION SYSTEM, NEVER ALLOW

BOIL-OUT SOLUTION OR RINSE WATER TO CIRCULATE

THROUGH THE FRYER PUMP SYSTEM OR FAT DRAWER.

C A U T I O N

DO NOT LEAVE THE FRYER UNATTENDED DURING THE

BOIL-OUT PROCESS. THE FRYER MUST BE

CONTINUOUSLY MONITORED FOR BOIL-OVER

CONDITIONS, PARTICULARLY IN HIGH-ALTITUDE

LOCATIONS. IF BOIL-OVER IS IMMINENT, IMMEDIATELY

TURN THE MASTER POWER SWITCH OFF AND ALLOW

THE SOLUTION TO COOL. WHEN THE SOLUTION HAS

COOLED, RE-ENTER THE BOIL-OUT MODE.

C A U T I O N

KEEP A CONTAINER OF COLD WATER ON HAND

DURING BOIL-OUT IN CASE OF BOIL-OVER. IF BOILOVER IS IMMINENT, IMMEDIATELY TURN OFF MASTER

POWER SWITCH AND POUR COLD WATER INTO FRYPOT

TO QUICKLY REDUCE SOLUTION TEMPERATURE.

B O I L - O U T P R O C E D U R E

NOTE: Perform an initial Boil-Out to clean and

sanitize the fryer before operating.

Carbonized deposits along with an accumulation of oil

will eventually build-up on the interior of the frypot as

well as fryer accessories. It is important to periodically

remove these deposits, not only to maintain fryer

efficiency but also to provide the highest product quality.

NOTE: Always wear eye protection or a face

shield and protective rubber gloves

when cleaning the frypot as boil-out

chemical is an alkaline solution and can

cause severe burns.

1. After emptying the fryer of oil or shortening, remove

filter cartridge from unit if equipped with a filtration

system. (See filtration instructions on page 16-17.)

NOTE: Initial access to the programming mode

must start with the control in the “OFF”

position.

2. Open the front access door. With the Kettle/Nozzle

selector in the “KETTLE” position, rotate the drain

valve clockwise until rotation stops and the drain

valve is “CLOSED.”

3. Fill the fryer to the maximum hot oil fill line with a

mixture of cold water and fryer boil-out solution.

Carefully follow the boil-out manufacturer's

directions for mixing the boil-out solution.

Gas F r y e r O p e r a t i o n & Care M a n u a l • 14

4. Turn the Master Power Switch (located within the

front access door) to the “ON” position if not already

on.

5. Within a few seconds, both LED's on

the operational control panel will

display “OFF” when the Master

Of f

Power Switch is initially engaged.

6. Press and hold the Program Key for 10 seconds.

“Boil” will appear as the first item

on the display whenever the

“PROGRAM” key is initially

Bo il

pressed.

O P E R A T I O N

C A U T I O N

ENSURE THERE IS NO WATER IN THE FRYPOT BEFORE

FILLING WITH OIL/SHORTENING. WHEN COOKING

COMPOUNDS ARE HEATED TO COOKING

TEMPERATURE, WATER IN THE FRYPOT WILL CAUSE

OIL TO SPLATTER AND MAY BE A BURN HAZARD.

B O I L - O U T P R O C E D U R E

7. Press the Right arrow key to enter the “Boil”

program.

8. The display will indicate “READY ?”. Press the

Right arrow key to start the boil-out function. The

boil-out solution will begin to heat to a temperature of

195°F (91°C). When the temperature has been

reached, the appliance

will begin a 10 minute countdown.

NOTE:

9. At the end of the boil-out period, an alarm will sound

10. Rotate the drain to the “OPEN” position. Allow the

11. Rotate the drain valve clockwise to the

TThhee ccoouunnttddoowwnn ppeerriioodd wwiillll

nnoott sshhooww iinn tthhee ddiissppllaayy..

and the control will revert to the “OFF” state.

boil-out solution to completely drain into trolley or a

heat safe container. Discard boil-out solution and

return the trolley to the fully inserted position beneath

the fryer if equipped with filtration system.

“CLOSED” position and follow the boil-out solution

manufacturer’s additional boil-out instructions to

rinse the frypot in order to neutralize boil-out cleaner

residue. Discard rinse solution.

NOTE: Make sure the inside of the frypot, the

rain opening and all parts that come

d

into contact with new oil/shortening are

as dry as possible.

14. Wipe the exterior of the fryer cabinet with a

degreaser/sanitizer suitable for use on food contact

surfaces. Always follow the manufacturer's

instructions and/or mixing directions for proper

solution strengths.

Wipe exterior stainless steel surfaces with the grain of

the metal and avoid the use of abrasive pads, steel

wool, or metal implements.

15. Replace the oil filter if equipped with filtration system.

(See instructions on pages 15-17.)

16. Fill tank with new oil or shortening.

12. There may be residual boil-out solution in the oil fill

hole and tube. This must be flushed out and discarded

separately before filling the tank with new oil to avoid

contamination of new oil.

13. Following the boil-out and rinse procedure, wipe dry

all accessible interior metal surfaces and interior

accessories with a clean, dry cloth to remove any

remaining rinse solution. Clean and dry the fry

baskets separately.

Gas F r y e r O p e r a t i o n & Care M a n u a l • 15

O P E R A T I O N

D A N G E R

BEFORE STARTING THE

APPLIANCE, MAKE CERTAIN

YOU DO NOT DETECT THE

ODOR OF GAS.

IF THE ODOR OF GAS IS DETECTED:

• DO NOT attempt to light any appliance.

• DO NOT touch any electrical switches.

• Extinguish any open flame.

• Use a telephone OUTSIDE THE

PROPERTY & IMMEDIATELY

contact your gas supplier.

• If unable to contact your gas supplier,

contact the fire department.

W A R N I N G

BYPASSING THE "MELT-CYCLE" WHEN USING SOLID

SHORTENING CAN RESULT IN MAJOR EQUIPMENT

DAMAGE AND WILL VOID ALL WARRANTIES.

S T A R T U P & G E N E R A L O P E R A T I O N

NOTE: Perform an initial Boil-Out to clean and

sanitize the fryer before operating. (See

page 13.)

1. Service is to be performed by an authorized

Alto-Shaam service agent.

2. Assure all local electrical codes, fire codes, and all

other requirements such as hood installation have

been met in the process of installation.

3. Open front access door and insure drain valve is in the

“CLOSED” position. The handle should be rotated

clockwise until it stops.

4. Fill frypot with frying compound as indicated.

(SEE ILLUSTRATION ON THE OIL/SHORTENING REQUIREMENTS PAGE)

5. The Master Power Switch is located behind the front

access door. Turn Master Power Switch “ON.”

alpha/numeric display will indicate “MELT-CYCLE.”

It is recommended to allow the fryer to complete the

"Melt Cycle" when using solid shortening; however, if

liquid shortening is used the "Melt Cycle" may be

bypassed by pressing Temperature Key

for 3 seconds.

8. After fryer has reached the factory-set oil temperature

of 350°F (177°C) or the temperature set by the

operator, product can be fried.

9. More detailed operating guidelines along with

information on presets and other options are located

within this manual.

10. For fryer “Shutdown” press the Power Key on the

main control panel to the “OFF” position. Then turn

the Master Power Switch located behind the front

access door to the “OFF” position.

NOTE: FOR YOUR PROTECTION the fryer is

furnished with a hi-limit safety shutoff that

will disengage the control if the oil

temperature in the frypot would ever exceed

432°F (222°C). In this event, the oil

temperature must be allowed to decrease to

375°F (191°C) before restarting the appliance.

After allowing the oil temperature to

decrease, open the front access door and

press the RESET BUTTON for a period of 3seconds to restart the control.

6. Both “LED” displays on the control panel will indicate

“OFF” when the Master Power Switch is initially

turned to the “ON” position.

7. Press and hold the Power “ON” Key on the main

control panel for 3 seconds. Both “LED” displays on

the control panel will indicate actual oil temperature

or ambient room temperature. The bottom of

Gas F r y e r O p e r a t i o n & Care M a n u a l • 16

O P E R A T I O N

C A U T I O N

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

C A U T I O N

OOPPEERRAATTOORRSS MMUUSSTT BBEE MMAADDEE AAWWAARREE OOFF TTHHEE HHAAZZAARRDDSS

IINNVVOOLLVVEEDD IINN TTHHEE OOPPEERRAATTIIOONN OOFF AA HHOOTT OOIILL FFIILLTTEERRIINNGG

SSYYSSTTEEMM.. OONN--SSIITTEE SSUUPPEERRVVIISSIIOONN DDUURRIINNGG TTHHEE

FFIILLTTRRAATTIIOONN PPRROOCCEESSSS AANNDD TTHHEE CCLLEEAANNIINNGG PPRROOCCEESSSS IISS

SSTTRROONNGGLLYY RREECCOOMMMMEENNDDEEDD..

W A R N I N G

TO AVOID PERSONAL INJURY, USE

CAUTION WHEN SURFACES BECOME

SLIPPERY DUE TO SPILLED OR

DRIPPING OIL.

A S F - 7 5 G O I L / S H O R T E N I N G F I LT R A T I O N

Careful observation of the finished food product will

help determine optimal filtering frequency. Filtering

he cooking oil at regular intervals will help ensure

t

food quality.

F O R B E S T R E S U LT S

temperature of the oil to decrease below the “Idle

Mo de” temperature of 250°F (121°C) when filtering.

If filtering at the end of the day, pump oil back into the

kettle while still hot. Do not allow oil to cool before

returning to kettle.

: Do not allow the

1. Open the front access door. With the

Kettle/Nozzle selector in the “N OZZ LE O FF”

osition, rotate the drain valve counterclock-

p

wise until rotation stops and the drain valve is

in the “O PEN ” position. Power to the main

control panel will automatically switch “OFF.”

2. Allow contents of the fryer to completely drain.

3. Press the P UMP “ON” to allow the oil to

circulate through the drain system to flush

crumbs. Using the brushes provided, brush the

sides and bottom of the fryer while the oil is

circulating through the system. Use the angle

brush under the heat exchangers.

4. Press the P UMP “OFF” and allow contents of

the fryer to completely drain.

5. Rotate the drain valve clockwise to the

“CLOSED” position.

6. Press the P UMP “ON” and allow the fryer to

refill to the recommended level adding

additional oil/shortening as required to

maintain proper fill level.

Gas F r y e r O p e r a t i o n & Care M a n u a l • 17

7. Press the P U M P “ O F F ” button.

8. After the frypot has completely refilled, pull

out the mobile oil trolley and discard the filter

into a proper receptacle. Clean the filter

assembly and oil trolley, if needed.

9. Replace the oil filter and return the trolley to

the proper position beneath the fryer.

10 . Press and hold the “O N/O FF” key on

the main control panel for 1-1/2 to 2 seconds to

energize the fryer. Continue normal fryer

operation after the preheat function has been

completed.

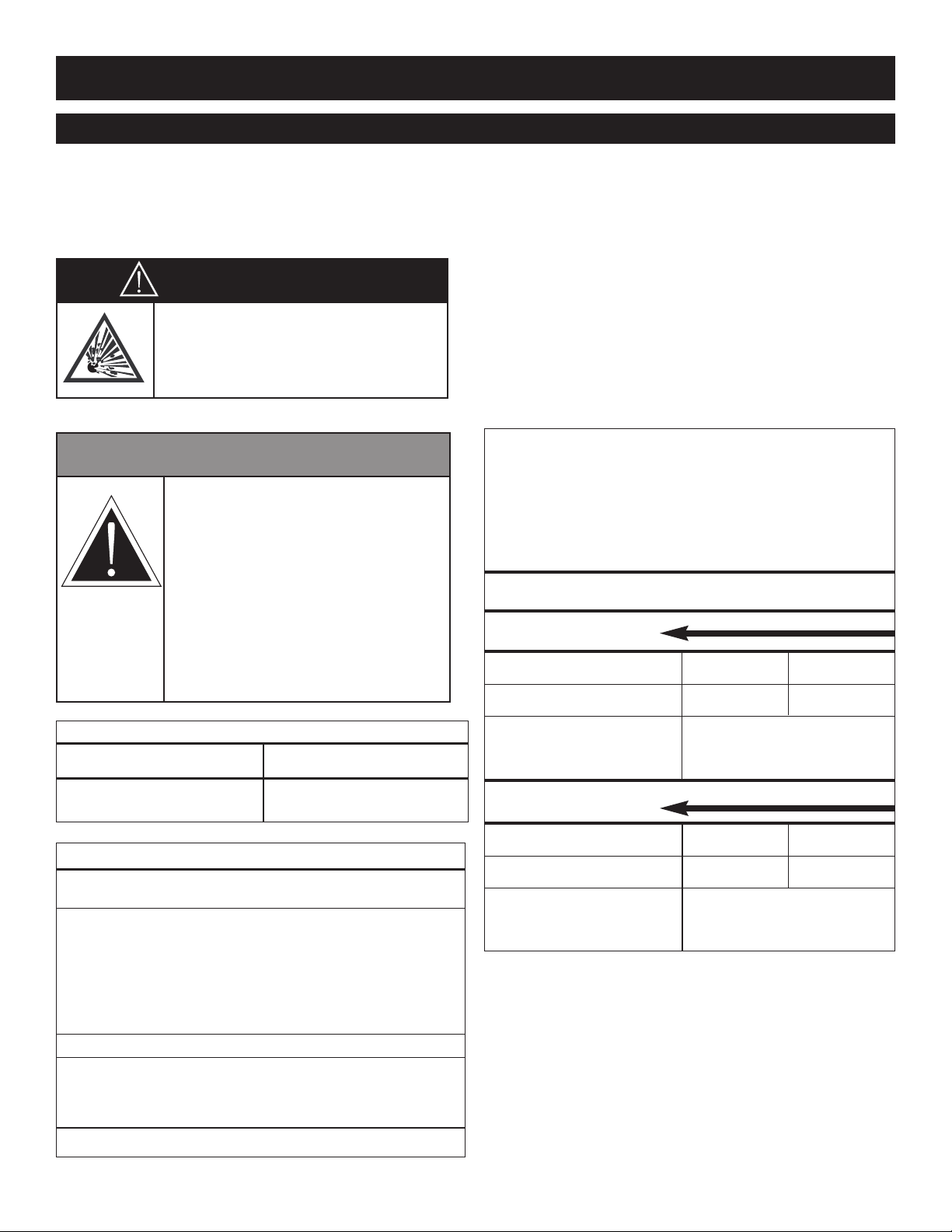

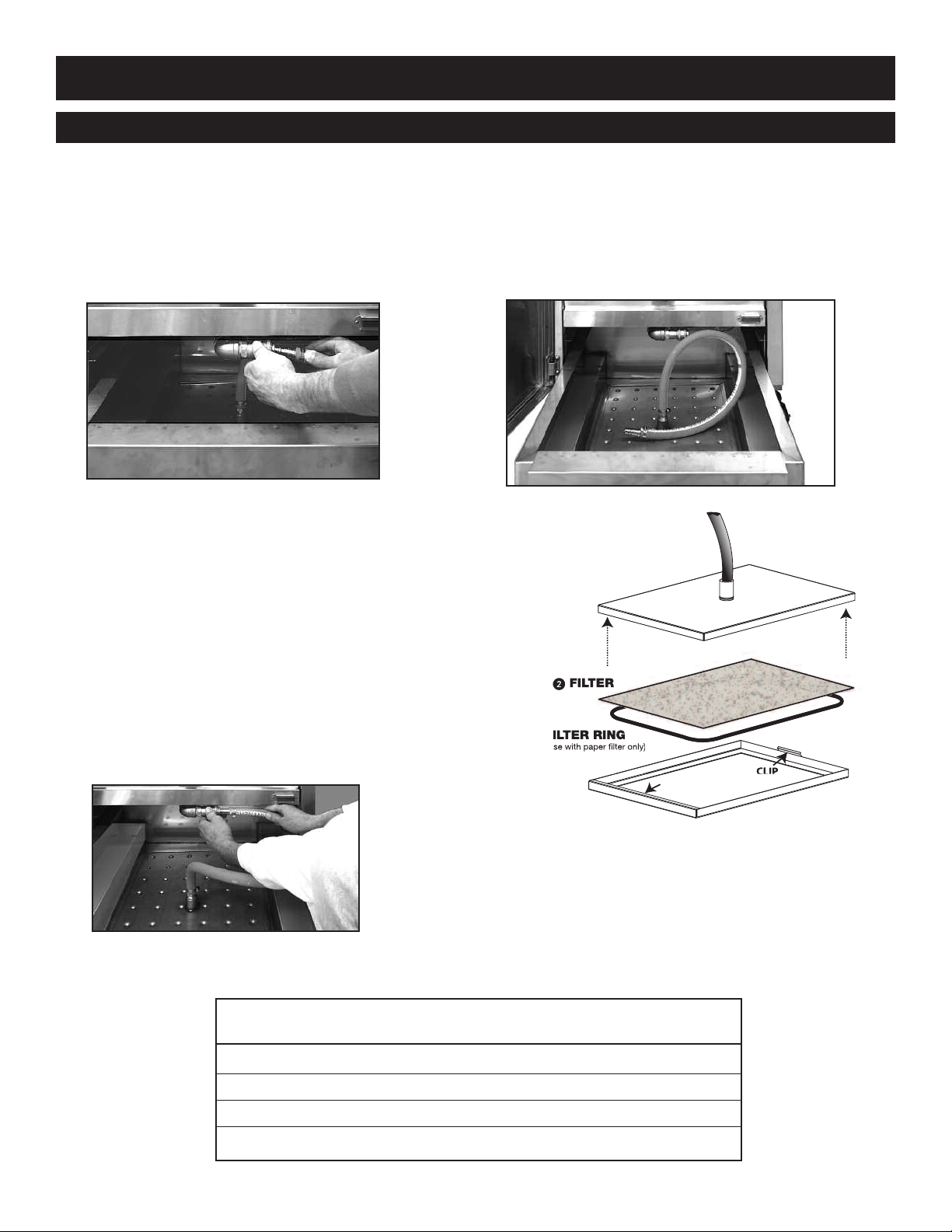

2 FILTER

4 FILTER

FRAME

A FILTER

CARTRIDGE

CL

IP

FRA

M

E

L

IP

3 FILTER RING

(Use with paper filter only)

O P E R A T I O N

A S F - 7 5 G O I L / S H O R T E N I N G F I LT R A T I O N

FILTER REPLACEMENT

1. With the DRAIN in the “CLOSED” position, pull the trolley from the fryer and disconnect the hose from the fryer.

Use optional trolley handle if available, or take care when pulling trolley from fryer as it has sharp edges. (Contact

factory for optional trolley handle information.)

2. Pushing down on filter frame clip, pull side of filter

cartridge closest to clip upwards. Slide opposite edge of

filter cartridge out from beneath the filter frame lip.

3. Remove used filter and filter ring . Discard filter .

Retain filter ring .

4. Place new filter and filter ring next to screen on

underside of filter cartridge . Reverse step 2 above.

5. Reconnect hose to fryer and return trolley to

the full position under the fryer.

STANDARD AND OPTIONAL FILTERS

PART NO. DESCRIPTION

FI-27791 PAPER (STANDARD WITH FRYER) 7-count package

FI-27794 PAPER (STANDARD WITH FRYER) 100-count package

FI-27648 CHARCOAL/CARBON FILTER 30-count pkg.

FI-27014 REUSABLE MESH FILTER, single

Gas F r y e r O p e r a t i o n & Care M a n u a l • 18

Loading...

Loading...