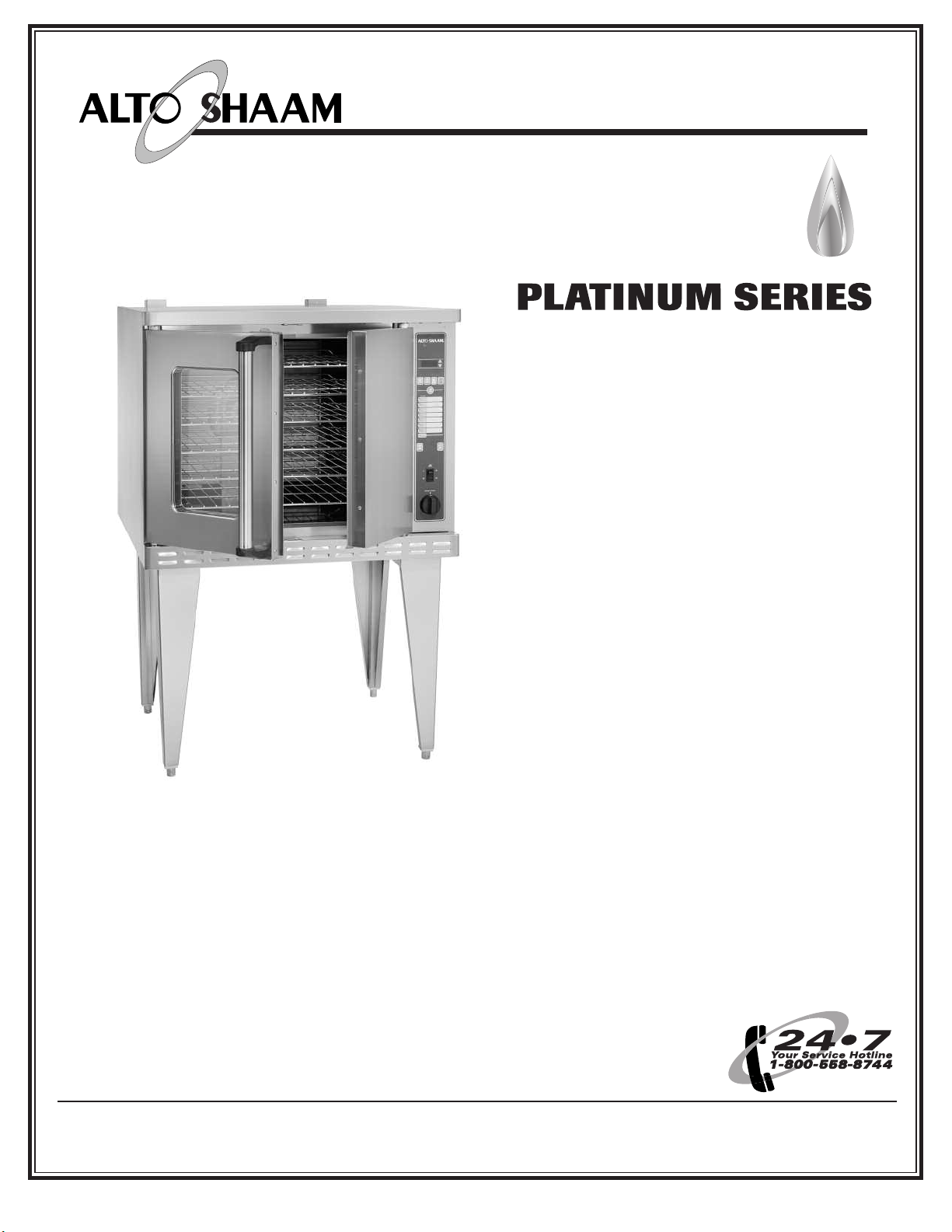

Alto-Shaam ASC-4G User Manual

C o n v e c t i o n O v e n

W164 N9 221 Water Street • P.O. Box 450 • Men omonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744 USA /CA NAD A FAX: 262.251.7067 • 800. 329.8744 U.S. A . ON LY

www.alto-shaam. com

®

G a s

Model:

ASC-4G

Electronic

Control

• I N STALLATIO N

• OP ERAT IO N

• MAI NT ENAN CE

P RI N TE D I N U .S .A .

MN -2 86 63 • 12/ 08

D E L I V E R Y

This Alto-Shaam appliance has been

thoroughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and report

it at once to the delivering carrier. See

Transportation Damage and Claims section

locate d in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

N O T E : All claims for warranty must include the

full model number and serial number of

the unit.

U N P A C K I N G

1. Carefully remove the

appliance from the

carton or crate.

N O T E : Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner or

manager of the business or to the person

responsible for training operators. Add itional

manual s are available from the Alto-Shaam

servic e department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

®

Gas Convection Oven - Electronic Control

Pg. 1.

1

. This appliance is intended to cook, hold or

p

rocess foods for the purpose of human

c

onsumption. No other use for this appliance is

a

uthorized or recommended.

2

. This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated

hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

N O T E : Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

C A U T I O N

Used to indicate the presence of a hazard that can

or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

C A U T I O N

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

D A N G E R

Used to indicate the presence of a

hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

W A R N I N G

Used to indicate the presence of a

hazard that CAN cause personal injury,

possible death, or major property

damage if the warning included with

this symbol is ignored.

SAFETY PROCEDURES

AND P R E CA U TI O NS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

N O T E

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

Pg. 2.

Gas Convection Oven - Electronic Control

I N S T A L L A T I O N S A F E T Y W A R N I N G S

®

C A U T I O N

DO N OT L I F T O R MOV E THE

O V E N BY U SING T HE D O ORS

O R T HE D O OR H A N DLES .

D A N G E R

IMPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C A U T I O N

M

ETAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

W

HEN OPERATING THIS APPLIANCE.

D A N G E R

DO NOT store or use gasoline or other

flammable vapors or liquids in the

vicinity of this or any other appliance.

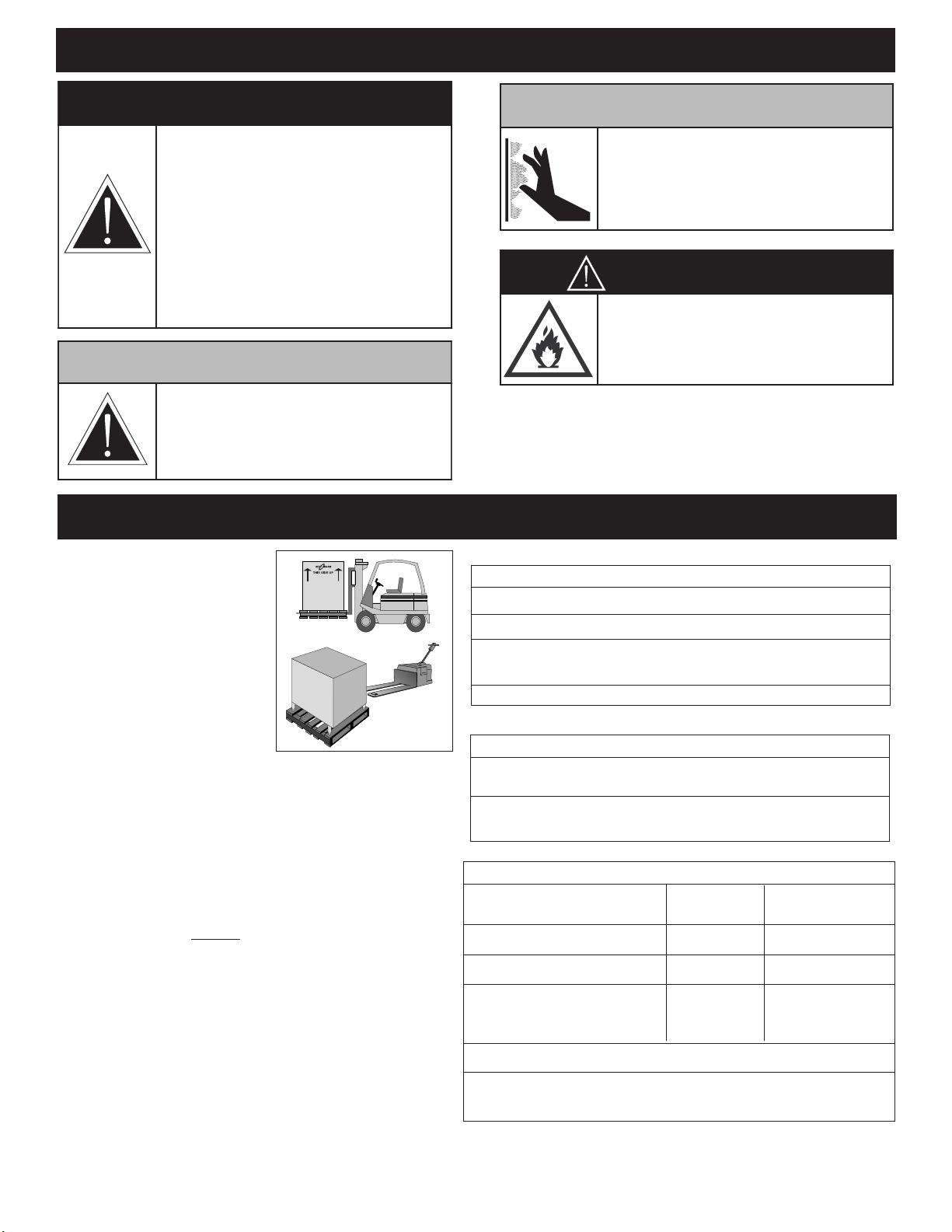

S I T E I N S T A L L A T I O N

The Alto-Shaam convection

oven must be installed in a

location that will permit the

oven to function for its

intended purpose and to

allow adequate clearance for

ventilation, proper cleaning,

and maintenance.

1. Hood installation is required.

(C HECK LOC AL CODES.)

2. The oven must be installed on a stable and

level surface. A non-combustible, heat

resistant, and fireproof surface is highly

recommended. If the oven is to be installed

on a combustible surface, factory supplied legs

or oven stand MUST be used.

3. DO NOT install this oven in any area where it

may be affected by any adverse conditions such

as steam, grease, dripping water, high

temperatures, etc.

4. This appliance must be kept free and clear of

any combustible materials.

5. This appliance must be kept free and clear of

any obstructions blocking access for

maintenance or service.

Gas Convection Oven - Electronic Control

W E I G H T

NET 393 lb (178 kg)

SHIPPING 438 lb (199 kg)

CR ATE

D I M E N S I ON S : (1016mm x 1118mm x 1346mm)

MI NI MUM EN TRY C LEARA NC E 31-1/2" (800mm) UNCRATED

40" H X 44" W X 53" D

D I M E N S I O N S H x W x D:

EX TE RIOR: 58-1/2" x 38" x 44-1/2"

(1486mm x 964mm x 1130mm)

IN TE RIOR: 24" x 29-1/8" x 25"

(610mm x 740mm x 635mm)

MINIMUM CLEARANCE REQUIREMENTS

CO MBU ST I BL E NON-CO M BU S TI BLE

SU RFAC ES SU RFAC ES

BA CK 0" (0mm) 0" ( 0mm)

LE FT SI D E 2" (51mm) 0" ( 0mm)

RI GHT S I DE 2" (51mm) 2" (51mm)

FROM GREASE PRODUCING EQUIPMENT 6" (152mm) 6" (152mm)

EN T RY CLE A R A NCE: 31-1/2" (800mm) U NCRATED

RE C O MM E N DED SE R V IC E AC C E SS : 20" (508mm) R IG H T

CO NTR OL SI D E

Pg. 3.

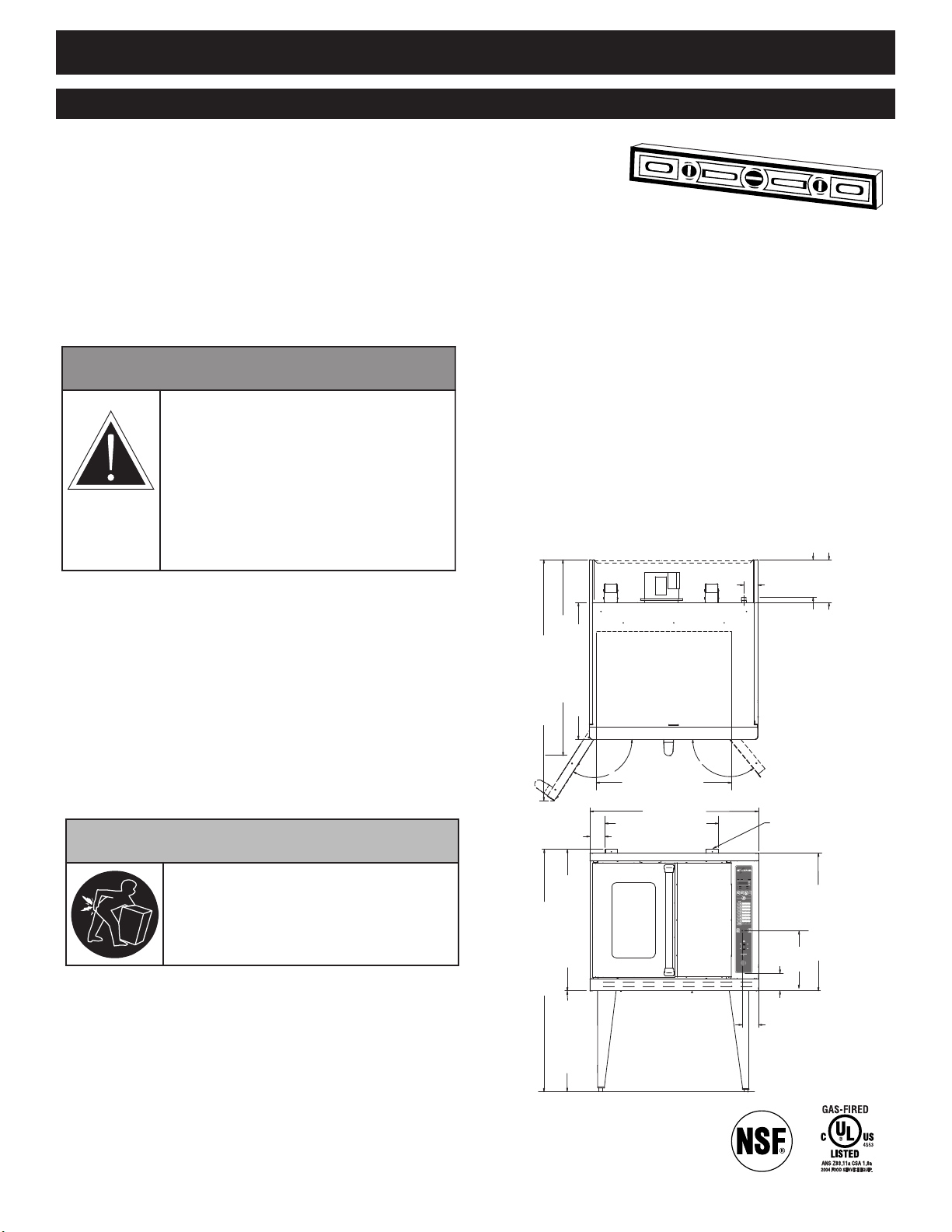

30-5/8" (778mm)

44-1/2" (1130mm)

58-1/2" (1486mm)

31-15/16" (810mm)

38" (965mm)

25-11/16" (652mm)

3-5/16" (84,4mm)

29-1/8" (740mm)

3/4"

GAS INLET

3

-5/32"

(80,1mm)

8-1/2" (215mm)

9-15/16" (252mm)

LINE CORD ENTRANCE

31-1/16" (789mm)

4" (102mm)

3/4" GAS INLET

EXHAUST

VENT

CAVITY WIDTH

123°

129°

26-1/2" (673mm)

54-5/8" (1387mm)

3-11/16" (93mm)

6' (1828mm)

LINE CORD ENTRANCE

12-15/16"

(329mm)

I N S T A L L A T I O N

W A R N I N G

Inadequate ventilation, or failure to

ensure an adequate supply of fresh

air will result in a high ambient

temperature at the rear of the

appliance. An excessive ambient

temperature can cause the thermaloverload protection device on the

blower motor to trip resulting in severe

damage to the blower motor.

C A U T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

I N S T A L L A T I O N R E Q U I R E M E N T S

The oven must be mounted on the factory equipped

oven legs or on an optional oven stand. Installation

on a solid or concrete base that in any way restricts

air flow may void the warranty.

All clearances for a proper ventilation air supply

must be maintained to minimize fire hazard. Do

not locate the oven immediately adjacent to any

other heat-generating appliance.

A number of adjustments are associated with initial

installation and start-up. Adjustments must be

conducted by a qualified service technician.

Installation and start-up adjustments are the

responsibility of the dealer or user. These

adjustments include but are not limited to

thermostat calibration, door adjustment, leveling,

and gas pressure verification. The Platinum series

oven burners are factory-adjusted with fixed air

openings and require no field adjustment.

LEVELING

he oven should

T

be leveled before the gas supply

is connected. Level the oven from side-to-side and

front-to-back with the use of a spirit level. For

ovens installed on a mobile stand, it is important

that the floor surface be level due to the probability

of frequent oven repositioning.

We recommend checking the level of the oven

periodically to make certain the floor has not

shifted nor the oven moved.

NOT E: Failure to properly level this oven can

cause improper function as a result of

erratic burner combustion and will result

in the uneven baking of products

consisting of semi-liquid batter.

Pg. 4.

MOD EL ASC-4 G

El e ctron ic Control

Gas Convection Oven - Electronic Control

GAS SPECIFICATIONS

D A N G E R

C

ONNECTING TO THE WRONG GAS

SUPPLY COULD RESULT IN FIRE OR

AN EXPLOSION CAUSING SEVERE

INJURY AND PROPERTY DAMAGE.

W A R N I N G

TO AVOID SERIOUS PERSONAL

INJURY, installation of this appliance

must conform to local, state, and

national codes; the current edition of

the American National Standard

Z223.1, National Fuel Gas Code, and

all local municipal building codes. In

Canada, installation must be in

accordance with Standard CAN/CSA

B 149.1 and Installation Codes - Gas

Burning Appliances, and local codes.

G A S S U P P LY & I N S T A L L A T I O N

IN STALL ATION REQ UIRE MENT S

GA S CONN EC TION: 3/4" NPT

CH EC K PL UM BING CODES FOR PROPER SUPPLY LI NE S IZING

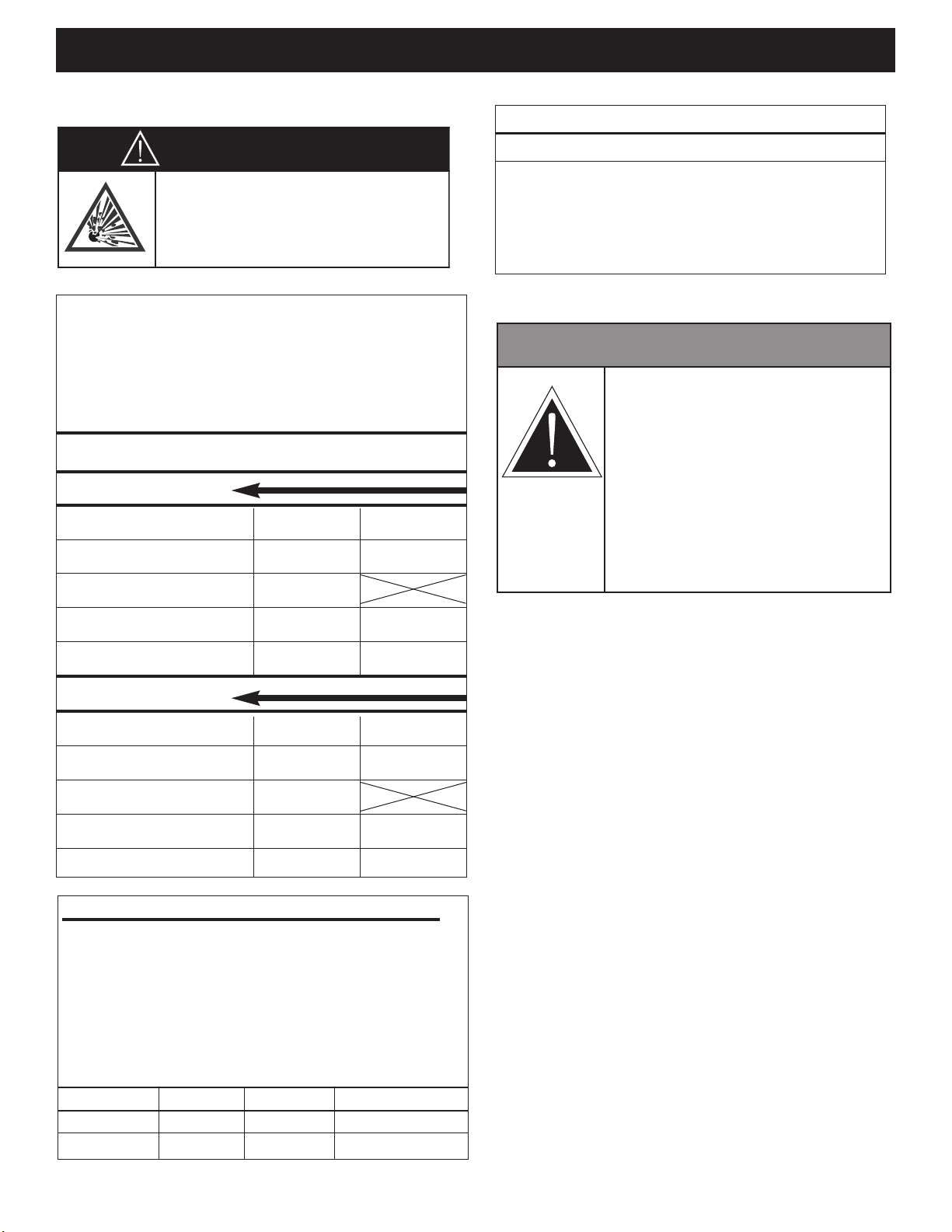

GAS P R E SSURE CHA R T

The g as va lve a nd bu rne r h ave b een f itt ed

acc ord i ng to t he ga s typ e spe cif ied o n t he

ide nti fic ati on na me pl ate .

TEC HNIC AL S P ECI FIC AT ION S

N a t u r a l G a s

Min. connected pressure 7.0" W.C. 1.74 kPa

Max. connected pressure 14.0" W.C. 3.48 kPa

Orifice Size #26

Manifold pressure 5.0" W.C. 1.25 kPa

TO ATTAIN BUR NE R MA NI FOLD

line is used, it must be AGA approved, commercial

type and at least 1" I.D.

OT E: If a flexible gas

N

Gross thermal output

50,000 Btu/hr

Pro pa n e Gas

Min. connected pressure 11.0" W.C. 2.74 kPa

Max. connected pressure 14.0" W.C. 3.48 kPa

Orifice Size #43

Manifold pressure 10.0" W.C. 2.49 kPa

Gross thermal output

50,000 Btu/hr

FIELD CONVERSION O F FUEL TYPE

To convert from either fuel type, replace the orifice

located at the burner inlet with the desired orifice.

Set the manifold pressure to the corresponding

values located in the following table. The pressure

tap is located at either the lower elbow of the gas

train, below the main

near the regulator.

F U E L T Y P E OR I F I C E S I Z E O R I FI C E P / N MA N I F O L D P R E S S U R E

Natu ra l # 2 6 OR-2643 1 5.0 IN/WC

Prop an e # 43 OR-2643 0 10.0 IN/WC

ON /OFF valve or in the pipe

Gas Convection Oven - Electronic Control

Pg. 5.

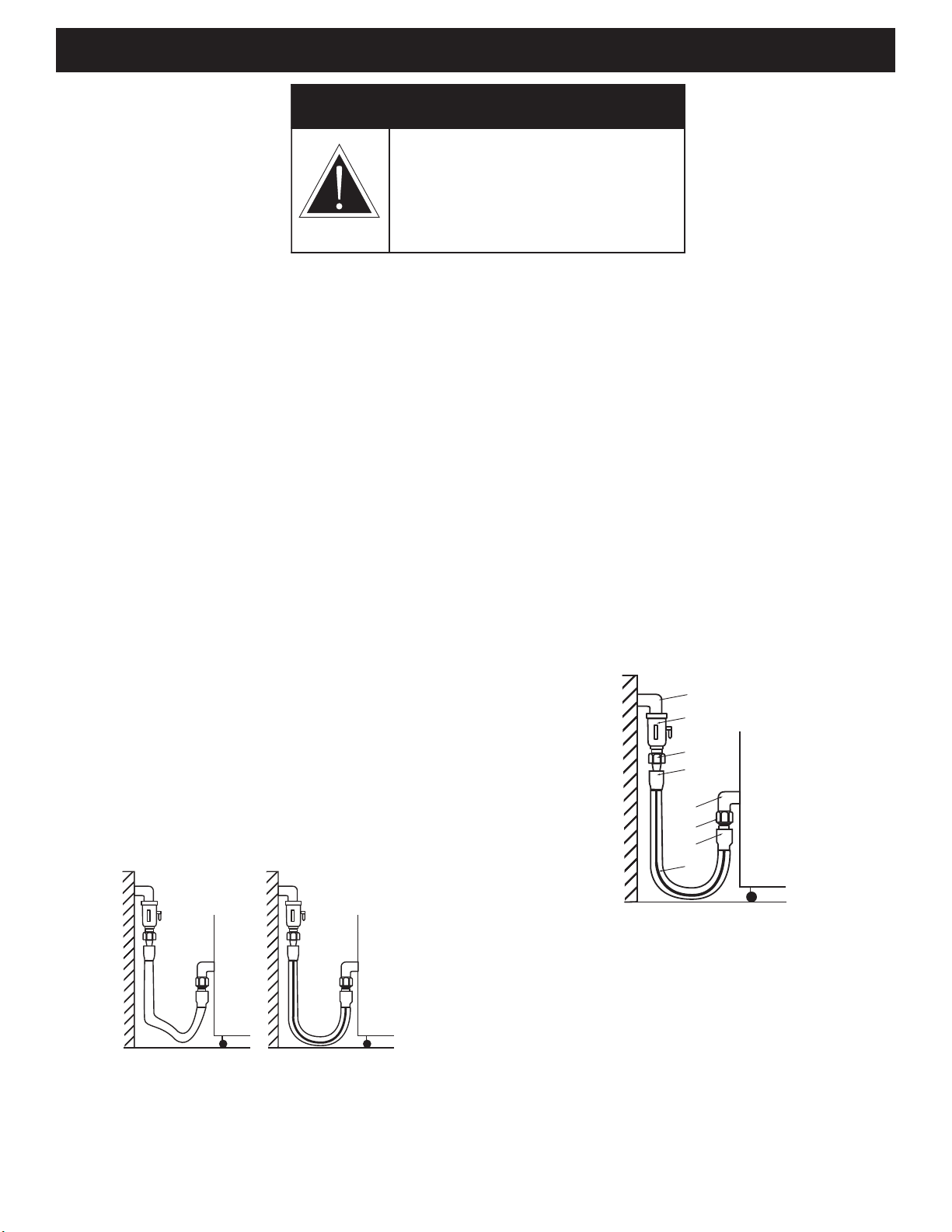

GAS SUPPLY & INSTALLATION

INCORRECT CORRECT

A

B

C

D

E

F

G

H

D A N G E R

Installation, air adjustment and/or

s

ervice work must be in accordance

with all local codes and must be

performed by a certified service

technician qualified to work on

gas appliances.

GAS REQUIREMENTS

The gas inlet is located at the back of the oven.

Code requires the installation of a manual gas

shutoff valve to be installed in the gas line ahead

of the oven. This oven is also equipped with fixed

burner orifices determined by the elevation

specified as the initial installation location.

The oven is furnished with a regulator integral to

the operation of the gas solenoid valve and may

not require an additional external regulator. To

ensure safe and proper operation, the gas

pressure regulator installed in the oven is

required for use with both natural gas and

propane. If the connected pressure exceeds 14.0"

W.C. (3.48 kPa), a step-down regulator is

required. A step-down regulator is not the

responsibility of the manufacturer.

Use an approved pipe sealant at all connections.

Do not use Teflon® tape. Gas supply connections

and pipe joint compound must be resistant to the

action of propane gases. Pipes must be clean, free

of obstructions and pipe joint compound.

GAS CONNECTION

In the U.S.A. , installation must c onform to

loc al codes o r, in the absence of local codes,

wit h the current edition of the Nat ional Fuel

Gas Code, NFPA-54 and ANSI Z223.1-1980

(la test edition). In Canada, installation must

be in accordance with local codes,

CAN /CGA-B149. 1, Installa tion for N a tural Gas

Bur n ing Applia nces and E q uipment (latest

edition) or C AN/CGA-B14 9.2 Install a tion for

Propane Bur n ing Applia n ces and Equ ipment

(la test edition).

The in l et sup ply lin e m u st be p rope rly si z ed

to acc o mmo date al l i n div i dua l a p pli a nce s

sim ulta neo u sly us e d o n t h e s ame lin e b u t

mus t n e ver be sm a lle r t h an 3/4 " N P T.

Pg. 6.

GAS INTAKE

A-G Installation elbow

B Wall Valve

C-D Three-piece union fitting

(minimum 1 per installation)

E-F End connector for the flexible tube

H Marking line

Gas Convection Oven - Electronic Control

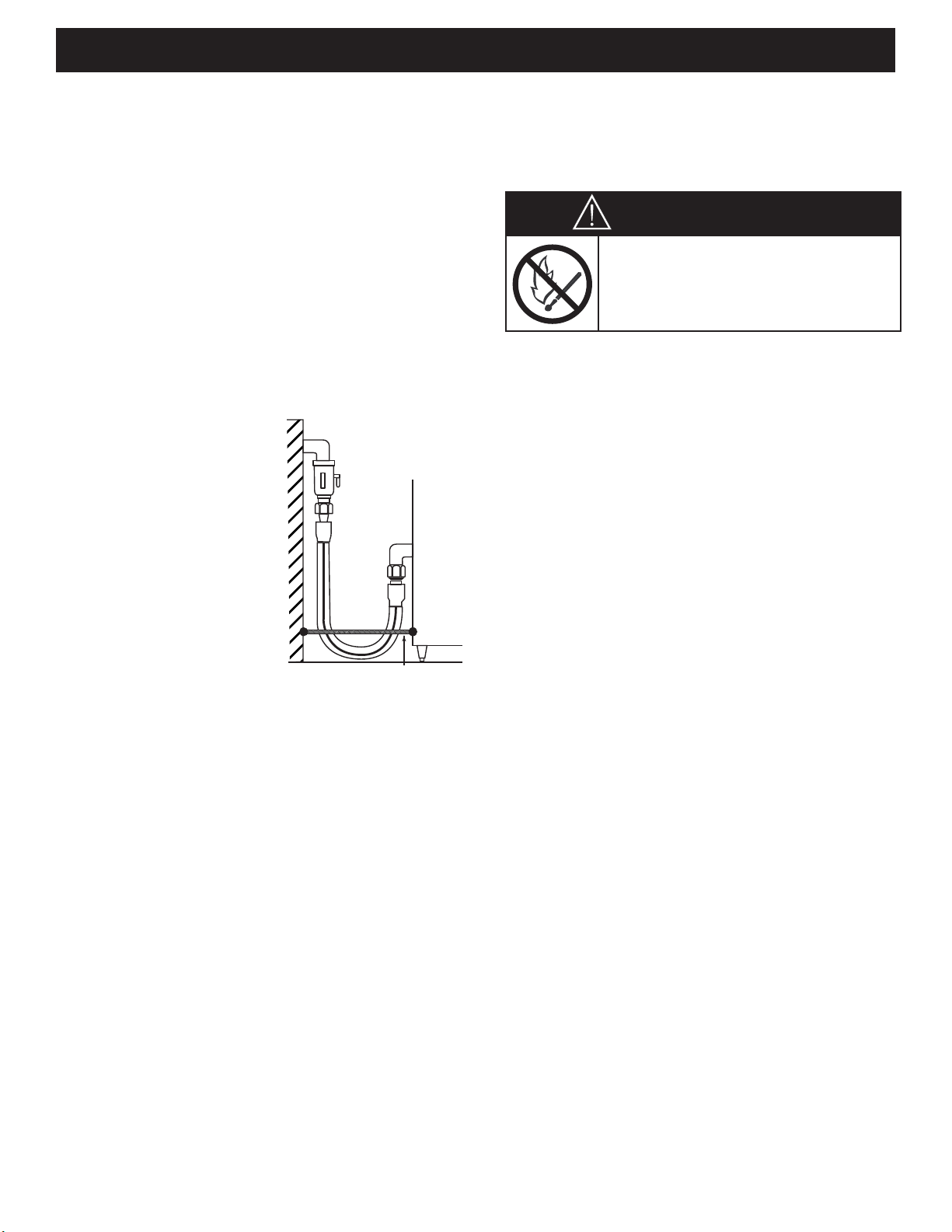

GAS SUPPLY & INSTALLATION

CORRECT

RESTRAINT

D A N G E R

NEVER USE AN OPEN

FL AME TO LEA K TEST.

GAS CONNECTION

➥ FOR OVENS O N CASTERS

The oven must be supplied with a flexible

connector that complies with The Standard for

Connectors for Movable Gas Appliances, ANSI

Z21.69, CGA 6.16 and addenda Z21.69a (latest

editions). A quick disconnect device must be

installed to comply with The Standard for Quick

Disconnect Devices for Use with Gas Fuel, ANSI

Z21.41 and CAN1-6.9 (latest editions). A flexible

connector is not supplied by the factory.

Adequate means must be

provided to limit the

movement of the

appliance. Limitation of

movement must be made

without depending on the

connector, the quick

disconnect device, nor the

associated piping designed

to limit oven movement.

Mounting holes for a

restraining device are

located on the lower back

flange of the oven chassis.

LEAK TESTING

Use a soap and water solution on all gas supply

line connections.

Sh u t t he ga s s u ppl y

ne c e ss a ry to di s co n n ec t t h e r e st r a in t .

Re c o nn e ct the re s tra i nt im m edi a tel y

fo l low i ng th e re t ur n o f t he ov e n t o i ts

or i gin a l p osi t io n . Turn the gas supply ON

after the restraint has been reconnected.

O F F i f i t b eco m es

Gas Convection Oven - Electronic Control

Pg. 7.

I N S T A L L A T I O N

D A N G E R

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED

ON APPLIANCE NAMEPLATE.

D A N G E R

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be

made in according with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

E L E C T R I C A L C O N N E C T I O N

This appliance is equipped with a three-prong

grounding plug. For your protection against shock

hazard this appliance should be plugged directly into

a properly grounded three-prong receptacle. Do not

cut or remove the grounding prong from this plug.

Plug the unit into a properly grounded receptacle

ONLY, positioning the unit so that the plug is easily

accessible in case of an emergency. Arcing will occur

when connecting or disconnecting the unit unless all

controls are in the “OFF” position.

Proper receptacle or outlet configuration or permanent

wiring for this unit must be installed by a licensed

electrician in accordance with applicable local

electrical codes.

E L E C T R I C A L

6' (1828mm) cord with plug included: NEMA 5-15P

Pg. 8.

VO LTAGE PH AS E CY CL E/HZ AMPS

120V 1 60 12.5

Gas Convection Oven - Electronic Control

V E N T I L A T I O N

D A N G E R

F

AILURE TO VENT THIS APPLIANCE

PROPERLY MAY BE HAZARDOUS TO

THE HEALTH OF THE OPERATOR.

Equipment damage, operational

problems and unsatisfactory baking

performance may also be the

consequence of improper venting.

Any damage sustained by a failure to

properly vent this oven are not

covered under warranty.

D A N G E R

Installation, air adjustment and/or

service work must be in accordance

with all local codes and must be

performed by a certified service

technician qualified to work on

gas appliances.

VENTILATION H O O D S

Proper venting along with a sufficient quantity of

make-up air is essential for proper oven operation.

A mechanically driven, canopy exhaust hood is the

preferred method of ventilation and must conform

to local codes along with the current version of

NFPA-96 Vapor Removal from Cooking Equipment

(latest edition). The oven hood must extend 6"

(152mm) beyond all sides of the oven. The distance

from the floor to the bottom edge of the hood

should be between 6'6" (1981mm) and 7' (2134mm).

I N S TA L L A T I O N

DIRECT VENTING

Whe n n ecessary, direct ve nting can be used in

situations where space is limited or to help offset

the high cost of ventilat ion hoods.

Direct venting should be installed in compliance

with local codes by a certified professional.

In the absence of local codes, refer to National

Fuel Code NFPA 54, ANSI Z223.1 (latest revision).

A ventilation hood that supplies make-up air down

the back vertical wall should be avoided since air

currents can interfere with the oven flue exits. If

such installation is unavoidable, an additional draft

hood, specifically designed to deflect downdrafts,

must be installed.

Ventilating hoods and exhaust systems shall

be permitted to be used to vent appliances

installed in commercial applications.

Where automatically operated appliances are

vented through a ventilating hood or exhaust

system equipped with a damper or with a

power means of exhaust, provisions shall be

made to allow the flow of gas to the main

burners only when the damper is open to a

position to properly vent the appliance and

whe n the power mean s of exhaust is in

ope ration. IN A CCORDA NCE WI T H NFPA 54

CO MMONWEALT H OF MAS SAC HUSETTS ONLY.

Gas Convection Oven - Electronic Control

Pg. 9.

Loading...

Loading...