Alto Shaam AR-7E Parts Diagram

S E R V I C E

LOCK-OUT OR POST BREAKER

PANEL UNTIL SERVICE WORK

HAS BEEN COMPLETED.

T R O U B L E S H O O T I N G G U I D E

RROR P O S S I B L E C A U S E

E

O D E D E S C R I P T I O N/RE S U LT S S E RV I C E R E Q U I R E D

C

E-10 Air Sensor Fault (shorted) Air sensor defective?

E-11 Air Sensor Fault (open) A

Inoperative Oven Test air sensor by placing sensor in ice water bath. Use an ohm

E-30 Under Temperature Door gasket need replacement?

Oven will shut down Preheating procedure skipped?

E-31 Over Temperature Defective air sensor?

Oven will shut down A

IRSEN SO RTES T

meter set on the ohm scale. The reading should be 100 ohms

resistance. The sensor must be replaced if the reading is more

than 2 ohms higher or lower.

Oven overloaded or frozen product used?

Defective air sensor or probe?

IRSEN SO RTES T

Test air sensor by placing sensor in ice water bath. Use an ohm

meter set on the ohm scale. The reading should be 100 ohms

resistance. The sensor must be replaced if the reading is more

than 2 ohms higher or lower.

E-60 Real Time Clock Error Control must be replaced.

Inoperative Oven

E-70 Configuration Connector Error Check control connections for loose wires.

Inoperative Oven If none, control must be replaced.

E-78 Voltage Low If 208-240 VAC voltage is below 190 VAC. Correct.

E-79 Voltage High If 208-240 VAC, voltage is over 250 VAC. Correct.

Inoperative Oven

E-80 EEPROM - Function Data Error

E-82 EEPROM - Calibration Data Error

E-84 EEPROM - Unit ID Error

E-86 EEPROM - Preset Data Error

Inoperative Oven Replace control.

#852 • AR - 7 E Ro t i s s e r i e Operation & Care Manual • 24

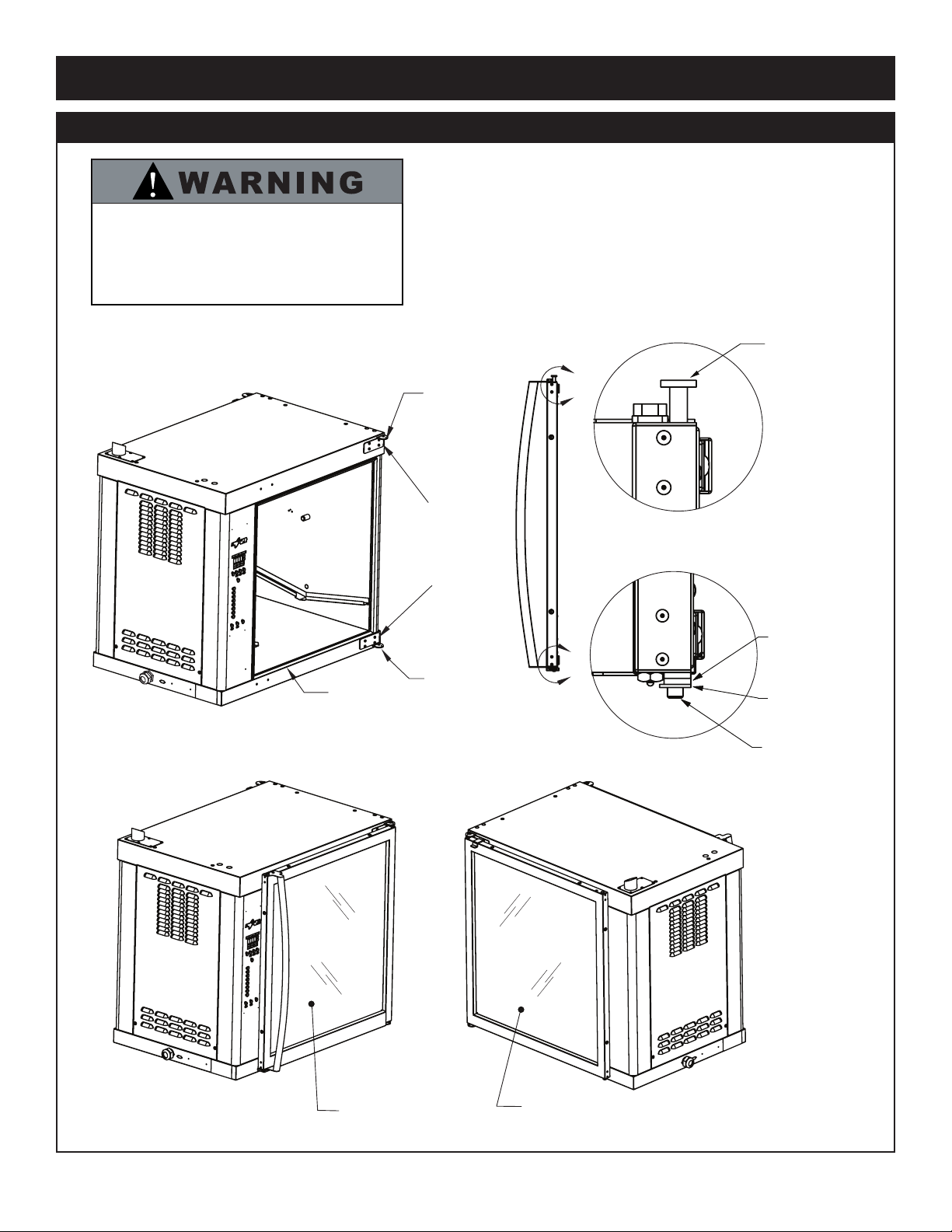

F U L L A S S E M B LY S E R V I C E V I E W

S E R V I C E

Panel,

ontrol-Side Access

C

1001585

Gasket, Door

S-25753

G

oor Assembly,

D

Non-Control Side

5006426

Door Assembly,

Control Side

5005773

Panel,

Control Overlay

PE-25869

Pan,

Grease Drip

1001976

Tray, Grease

Deflection

1001555

Hinges

Control Side

1007672 TOP

1007673 BOT TO M

Pin, Door

PI-26350 TO P

PI-26352 BOTT OM

Door Magnet

MA-27568

#852 • A R - 7 E Ro t i s serie Operation & Care Manual • 25

S E R V I C E

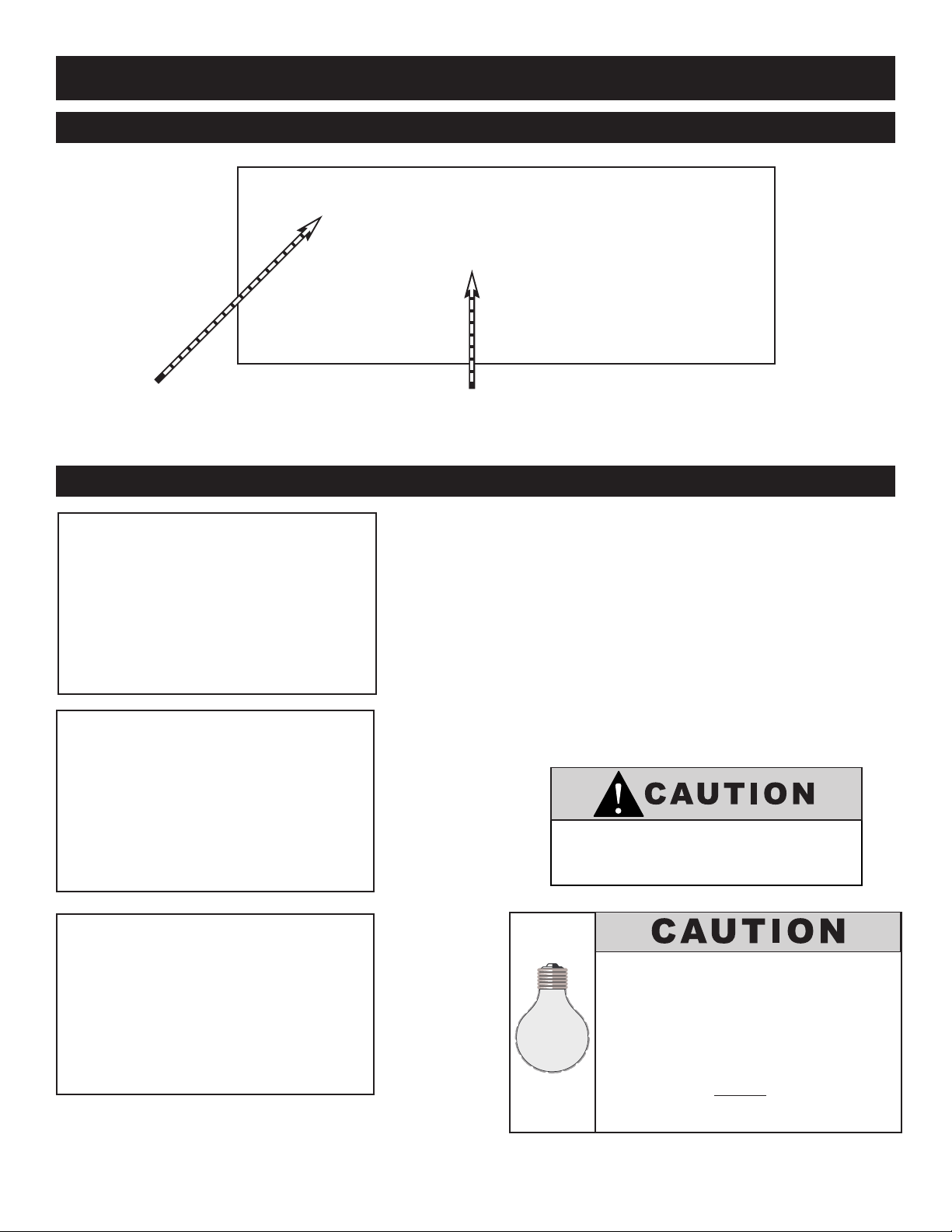

The performance of this unit has been

optimized using the factory provided bulbs.

These bulbs should be replaced with an

exact replacement or with a factory

recommended replacement. These bulbs

have been treated to resist breakage and

must be replaced with similarly treated

bulbs in order to maintain compliance with

NSF standards. DO NOT over-tighten bulbs

in their receptacles as this can cause

damage to the bulb filament.

DO NOT HANDLE NEW BULB WITH BARE

HANDS. WHITE COTTON GLOVES SHOULD

BE WORN WHEN REPLACING BULBS.

I N T E R I O R S E R V I C E V I E W

Lamp Assembly

LP-34185

Radiant Heater

208V - EL-33974

240V - EL-33973

B U L B R E P L A C E M E N T IN S T R U C T I O N S

A

To Replace Bulbs:

A Remove four screws holding glass light

B Pull bulb out

C Push replacement bulb (LP-34213)

D Re-install glass cover and gasket,

B & C

cover and gasket in place,taking care to

not let the glass cover fall into the oven.

in place

securing with four screws removed in

step one.

#852 • A R - 7 E Ro t i s serie Operation & Care Manual • 26

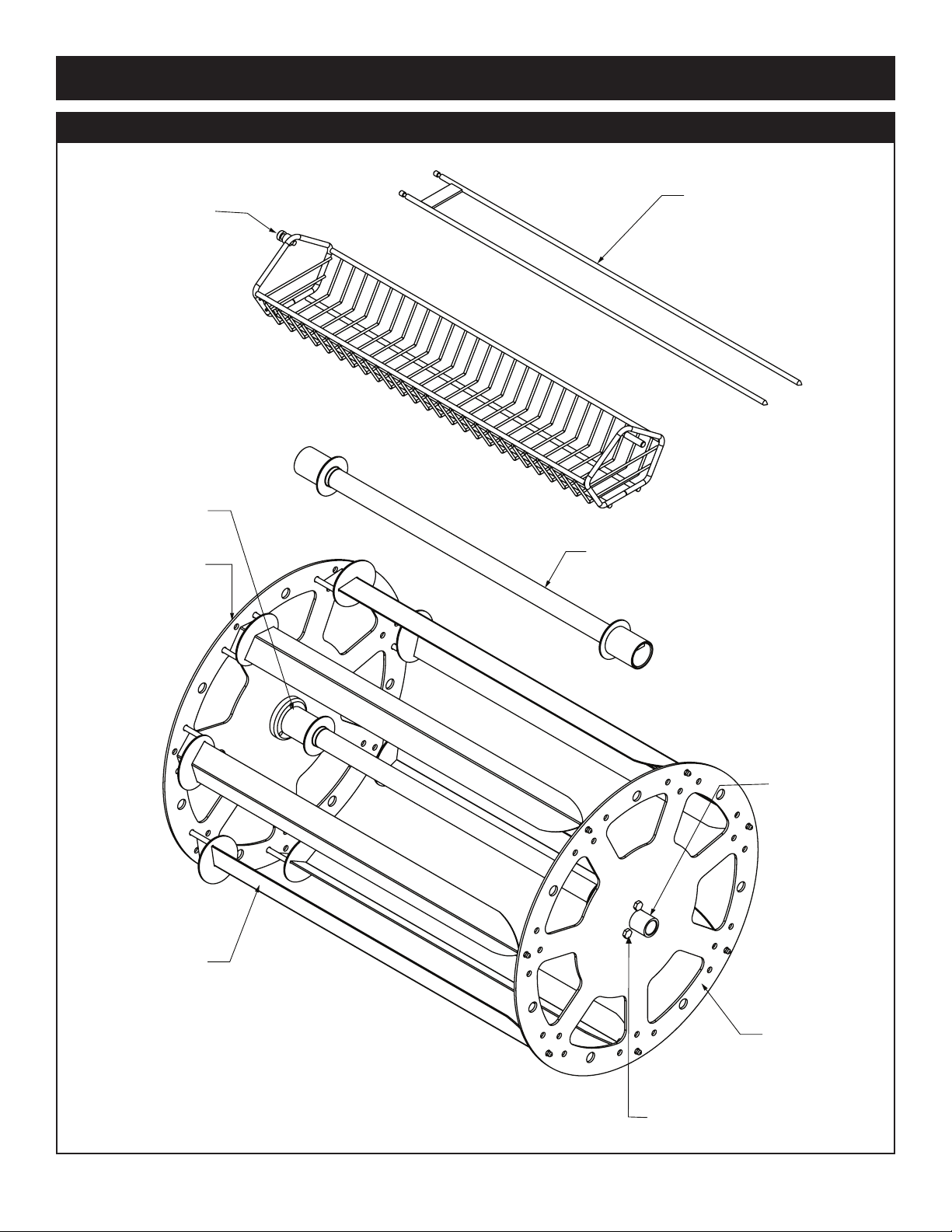

D

SI-25729

Spit, Piercing Rod, S/S

(

option)

BS-26019

Basket, Wire Form,S/S

(option)

DV-26863

Drive, Tube Assembly

DV-26648

Drive, Disk Hub, S/S

1001636

Drive, Disk

SI-25934

Spit, Angled Assembly

DV-26108

Slave, Disk Hub

1001636

Disk, Slave

SC-22729 - 1/4-20 x 1/2 Slot Hex-Head Screws

WS-2294 - Washer, 1/4 Lockwasher

AD-22591 - Adhesive, Thread, Sealing Compound

REV 01/07

S E R V I C E VI E W 1

S E R V I C E

#852 • A R - 7 E Ro t i s serie Operation & Care Manual • 27

S E R V I C E

GS-25753

GASKET, DOOR

A

“A”

DETAIL A

DETAIL B

B

5006996

DOOR ASSEMBLY

— NON CONTROL SIDE

5006806

DOOR ASSEMBLY

— CONTROL SIDE

(1) PI-26352

PIN, DOOR

(1) WS-22298

WASHER

(1) 1002143

SPACER

(1) PI-26350

PIN, DOOR

“B”

1002596 top

HINGES

— CONTROL SIDE

1002597 bottom

DO NOT ATTEMPT TO REMOVE THE

DOOR WITHOUT ASSISTANCE. THE

DOOR IS EXTREMELY HEAVY, WILL BE

DAMAGED IF DROPPED, AND MAY

CAUSE SERIOUS INJURY.

S E R V I C E VI E W 2: S I N G L E PA N E F L A T G L A S S DO O R

DOOR REPLACEMENT:

STEP 1: REMOVE TOP PIN (PI-26350) FROM BRACKET

"A" USING A SMALL SCREWDRIVER.

STEP 2: ASSEMBLE DOOR ON UNIT WITH SPACERS

AS SHOWN.

STEP 3: MAKE CERTAIN DOOR IS ALIGNED AND

REINSERT TOP PIN.

#852 • A R - 7 E Ro t i s serie Operation & Care Manual • 28

Loading...

Loading...