Alto Shaam AR-6G Service Manual

#853 • 3/2003

PRINTED IN U.S .A .

OPERATION & SERVICE MANUAL

®

COOK/HOLD/SERVE SYSTEMS

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 ●U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A . ONLY WEBSITE:

800.558.8744 U.S.A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

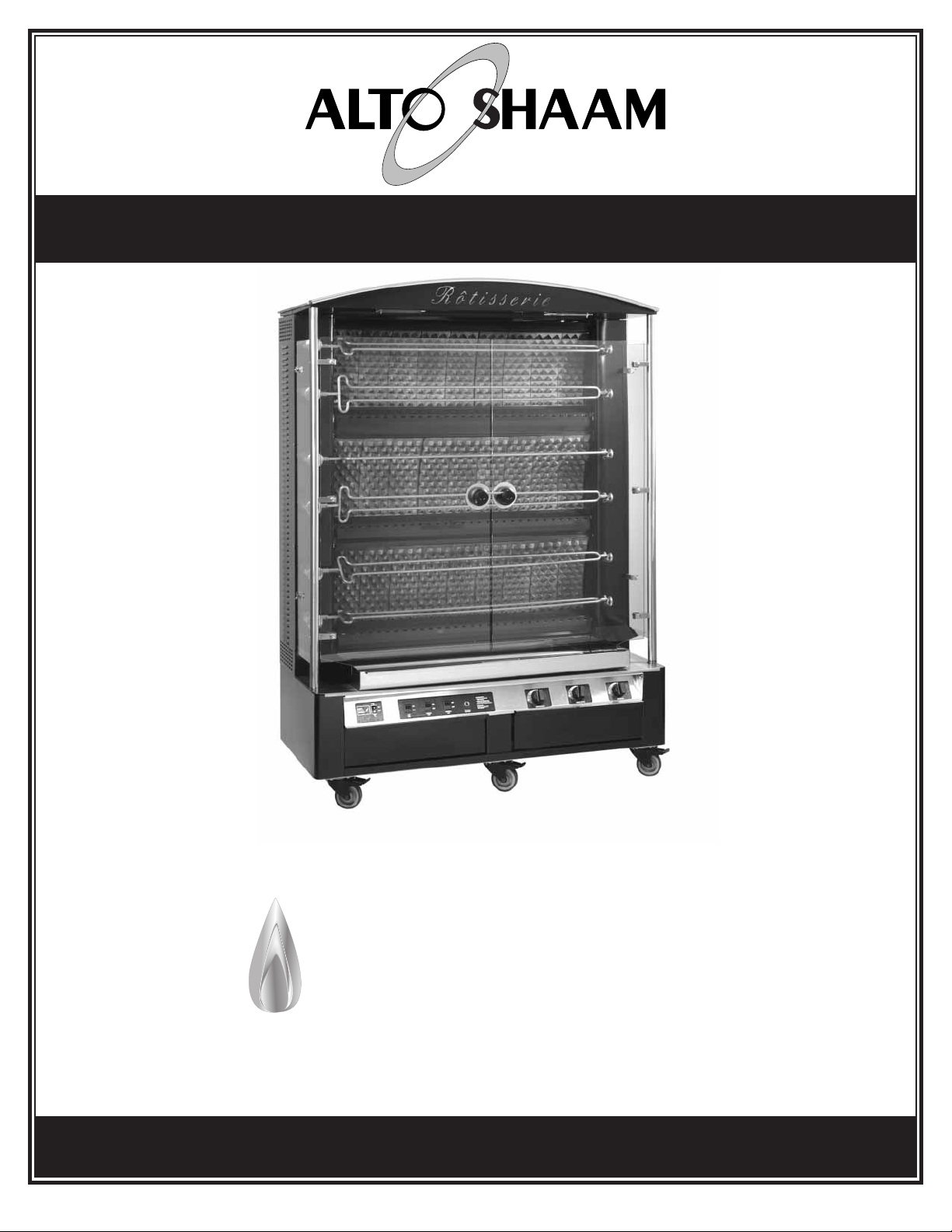

GAS ROTISSERIE

SPIT MODEL WITH ACTIVE FLAME

Model: AR-6G

®

GAS ROTISSERIE

Model: AR-6G

Installation, Operation & Maintenance Manual

Note:

Note:

In some prominent location, instructions obtained from the

local gas supplier must be posted indicating

procedures to be followed in the event that

the user smells gas.

GAS FOOD SERVICE EQUIPMENT

ANS Z83,11.CGA 11 b - (2000) Food Service Equip.

The information contained in this manual is important for the proper installation,

use and maintenance of this oven. Please read carefully and retain for future

reference. Improper connection of this appliance will nullify all warranties.

9M14

CLASSIFIED TO

NSF 4 - 1992

For Y

For Y

our Safety:

our Safety:

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

WWarning:

arning:

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

NOTE

NOTE

Les instructions provenant du fournisseur local de

gas doivent être affichées de manière à indiquer les

procedures à suivre au cas où l'utilisateur sentirait le gaz.

GAS FOOD SERVICE EQUIPMENT

ANS Z83,11.CGA 11 b - (2000) Food Service Equipment

MISE EN GARDE

Les informations contenues dans ce manuel sont importantes pour l'installation,

l'utilisation et l'entretien de ce four. S'il vous plait lisez-le très attentivement et

conservez-le. La non-application de ces instructions annule toutes garanties.

NOTICE D’INSTALLATION ET D’ENTRETIEN A L ‘ATTENTION DE

L’UTILISATEUR ET DE L’INSTALLATEUR

®

ROTISSOIRE AR-6G

9M14

CLASSIFIED TO

NSF 4 - 1992

AAVER

VER

TISSEMENT

TISSEMENT

Ne pas entreposer ni utiliser de l'essence

ni d'autres vapeurs ou liquides inflammables

dans le voisinage de cet appareil,

ni de tout autre appareil.

AAVER

VER

TISSEMENT

TISSEMENT

Une installation, un ajustement, une altération, un service

ou un entretien non conforme aux normes peut causer des

dommages àla propriété, des blessures ou la mort. Lisez

attentivement les directives d'installation, d'opération et

d'entretien avant de faire l'installation ou l'entretien

de cet équipement.

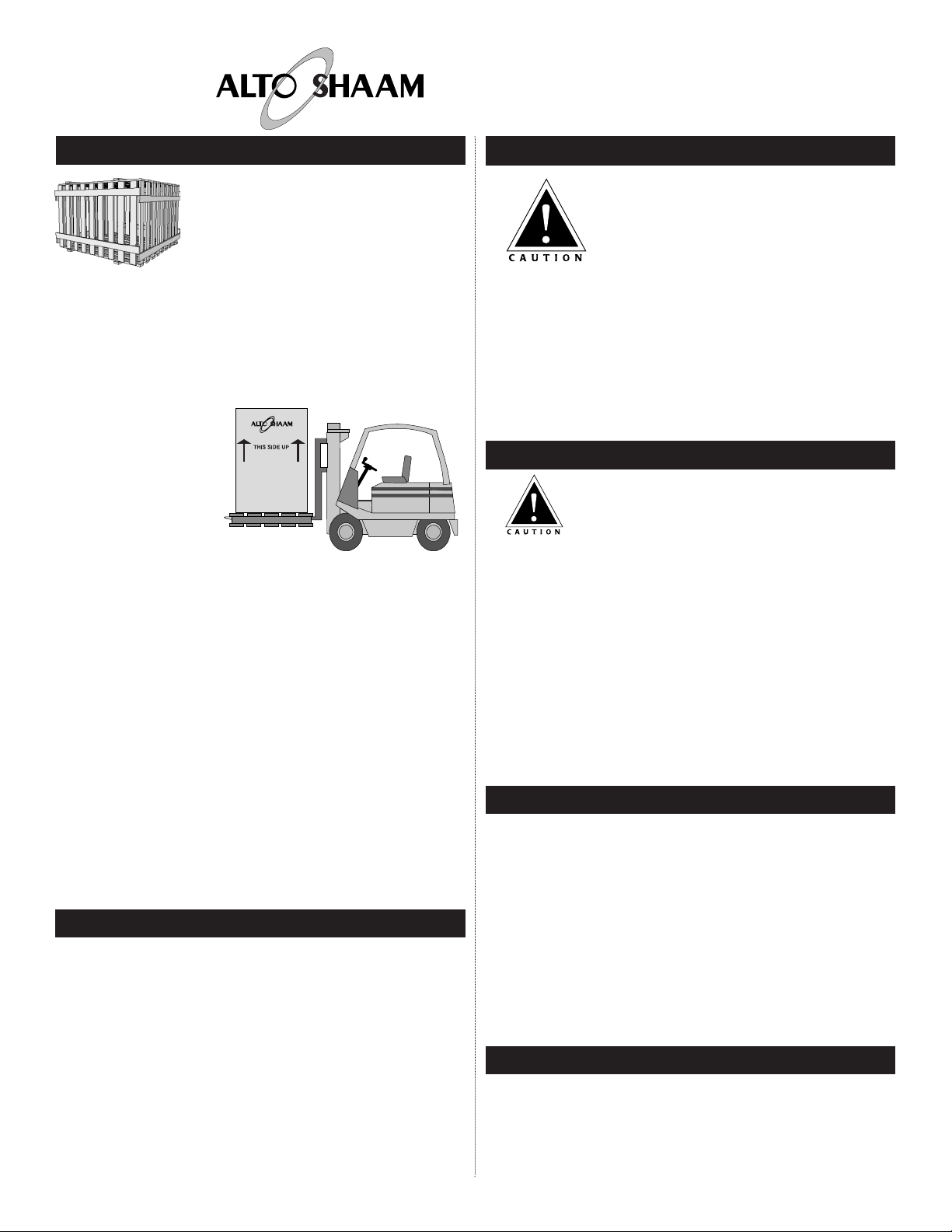

Upon receipt of the Alto-Shaam

gas rotisserie, check the exterior

of the shipping crate for any

physical damage that could result

in damage to the contents. If the

rotisserie was not received from the carrier in an

upright position, there is a strong possibility of

concealed damage. Immediately report any

possible shipping damage to the delivering carrier.

See Transportation Damage and Claims section

located in this manual.

The rotisserie

must remain on

the pallet while

being moved to

the installation

site by fork-lift or

pallet-lift truck.

Check to ensure that all items have been received

with each unit. Save all the information and

instructions packed inside the cabinet. The time

and care given to reading this manual will be well

compensated by the information in it. Understanding the information in this manual will

prevent incorrect use of the rotisserie and risk of

damage, which may at times be irreparable.

Complete and return the warranty card to the

factory as soon as possible to assure prompt service

in the event of a warranty parts and labor claim.

NOTE: All claims for warranty must include the

full model number and serial number of

the rotisserie.

In order to eliminate any operation problems and

to insure proper operation, the installation of this

rotisserie must be done in accordance with the

instructions given in this manual by a qualified

gas service installer. Failure to do so may cause

damage to the rotisserie and building, or cause

personal injury to personnel. The following

requirements are required for installation of this

rotisserie: Air Supply, Electrical Connections, Gas

Connections, and Gas Exhaust.

The gas appliance installation must be

completed in accordance with local

codes. In the absence of local codes

installation must comply with National

Fuel Gas Code, ANSI Z223.1 (latest

edition). In Canada, the appropriate code is the

Natural Gas Installation Code, CAN/CGA-B149.1.

Installation and adherence to these codes must be

completed by a qualified installer with regard to:

Gas Plumbing, Gas Appliance installation,

Commercial Cooking Ventilation, Water and

Plumbing, and OSHA Regulations.

The wall construction type

must be non-combustible.

The rotisserie must be installed on a strong, level,

non-combustible surface in the upright position.

It is highly recommended that this rotisserie or

any mobile gas appliance be tethered by an

approved method that complies with Federal,

State and local codes. Failure to tether a mobile

gas appliance could result in premature failure of

the flexible gas lines and other gas components.

A gas shut-off valve, installed in an accessible

location near any gas appliance, is highly

recommended for emergency purposes.

To maintain adequate ventilation as well as the

protection of surrounding wall surfaces and

nearby equipment, allow a minimum of 4-inches

(100mm) of air space at the back of the rotisserie.

Maintain 18-inches (457mm) of air space on both

sides of the unit.

In order to provide sufficient clearance for service

access, additional space can be provided, otherwise

it may be necessary to disconnect the electric and

gas line before moving the unit for service.

After unpacking the rotisserie, wash and disinfect

all components including the spits and drip pan.

Ensure that the drain plug is securely inserted in

the bottom of the drip pan.

ROTISSERIE OPERATION AND CARE — PG. 1.

GAS ROTISSERIE

®

CLEARANCES

ASSEMBLY

INSTALLATION REQUIREMENTS

CODES & STANDARDS

UNIT PLACEMENT

DELIVERY

®

Installation of this rotisserie must include a

provision for an adequate flow of fresh air for gas

combustion. This requirement must be observed by

the installer as well as the operator. The bottom of

the rotisserie provides air supply access for gas

combustion and must be kept clear at all times.

OPERATOR

CAUTION

Make certain the area around

the bottom of the rotisserie is

kept clear of obstructions to

allow a continuous supply of

fresh air for gas combustion.

Make certain the rotisserie installation maintains

adequate air ventilation to provide cooling for

electrical and gas components. The area around the

rotisserie should be clear of any obstructions which

might retard the flow of cooling air. Failure to

observe this caution may result in damage to the

control components and will void the warranty.

OPERATOR

CAUTION

Do not use circulating fans on

the floor. Floor fans will cause

the loss of pilot flame and will

affect burner operation.

Local and the National Fuel Gas Code provide rules

for determining the amount of fresh air necessary

for combustion and ventilation of commercial

cooking appliances. The codes will help determine

if additional outside air may be necessary to meet

health and safety regulations.

Ensure that the electrical supply matches the

specification on the rotisserie data plate. Gas models

available for USA and Canada are typically rated for

110-120V, 60Hz, 1Ph. An electric cord is supplied

and is ready to use. The oven must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 (latest edition) or in Canada

with the Canadian Electrical Code, CSA C22.1. The

installation of any wiring or electrical connections

must be done by a licensed electrical contractor.

ACCESSING CONTROL AREA

To access the electrical/control system, make sure to

disconnect power and ensure the gas supply is shut

OFF before removing any access panels. The

electrical diagram is affixed to the rear of the unit.

A copy of the electrical diagram is shown at the back

of this manual. Service or changes must be done by a

licensed electrical contractor in accordance with local

codes and regulations.

ROTISSERIE OPERATION AND CARE — PG. 2.

AIR SUPPLY

WARNING

ELECTRICAL GROUNDING INSTRUCTIONS

This appliance is equipped with a threeprong (grounding) plug for your protection

against shock hazard and should be plugged

directly into a properly grounded threeprong receptacle. Do not cut or remove the

grounding prong from this plug

ELECTRICAL CONNECTIONS

The installation of this rotisserie must be

completed by a qualified installer familiar with the

local codes and regulations governing the installation

of commercial gas appliances. The installation must

be made in accordance with local codes or, in the

absence of local codes, with the National Fuel Gas

Code ANSI Z223.1 (latest edition). In Canada, the

appropriate code is the Natural Gas Installation

Code, CAN/CGA-B149.1 or the Propane Installation

Code, CAN/CGA-B149.2.

Both the appliance and the individual appliance

shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that

system at test pressures in excess of 1/2 psi (3.45 kPa).

The appliance must be isolated from the gas

supply piping system by closing the individual

appliance manual shutoff valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.45 kPa).

GAS TYPE & PRESSURE

Check the nameplate information to determine

the type of gas for which the rotisserie was

manufactured (natural or propane) and make certain

the gas supply matches the nameplate information.

Check the nameplate to determine the gas

manifold pressure for the rotisserie. The minimum

supply pressure to the appliance must exceed this

value by at least 1" w.c. It is recommended that the

supply pressure be between 6" w.c. and 14" w.c. for

natural gas, and 11" w.c. and 14" w.c. for propane.

GAS CONNECTION

The minimum size of the gas piping or flexible

connector is 3/4" (19mm). For long runs of gas

piping, the pipe diameter must conform to the tables

in the National Fuel Gas Code, ANSI/NFPA Z223.1

A listed gas shut off valve must be installed

upstream of the appliance for shutting off the gas

supply while servicing. This valve should be

installed so that it is accessible with the appliance in

the normally installed position.

The rotisserie is supplied with casters, therefore,

installation must be made with a flexible connector

that complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69; or in Canada,

Connectors for Movable Gas Appliances, CAN/CGA-

6.16-M87. When using a flexible connector, a quick

disconnect device must also be used that complies

with the Standard for Quick-Disconnect Devices for

Gas Fuels, ANSI Z21.41; or in Canada, Quick

Disconnect Devices for Use with Gas Fuels, CAN1-6.9.

When a quick disconnect device and flexible

connector are used, a restraining device must be

installed to limit the movement of the appliance in

order to prevent damage to the connector or quick

disconnect. An example of such a system uses 2000

pound test stainless steel cable attached to a

structural member of the kitchen wall behind the

unit. The attachment means must include a quick

connect snap that can be disconnected when the

appliance must be moved away from the wall. The

other end of the cable should be permanently

attached to the rear frame of the rotisserie. The cable

should be of sufficient length so that no strain is ever

placed upon the flexible gas connector if the

appliance is accidentally moved without initially

disconnecting the gas connector.

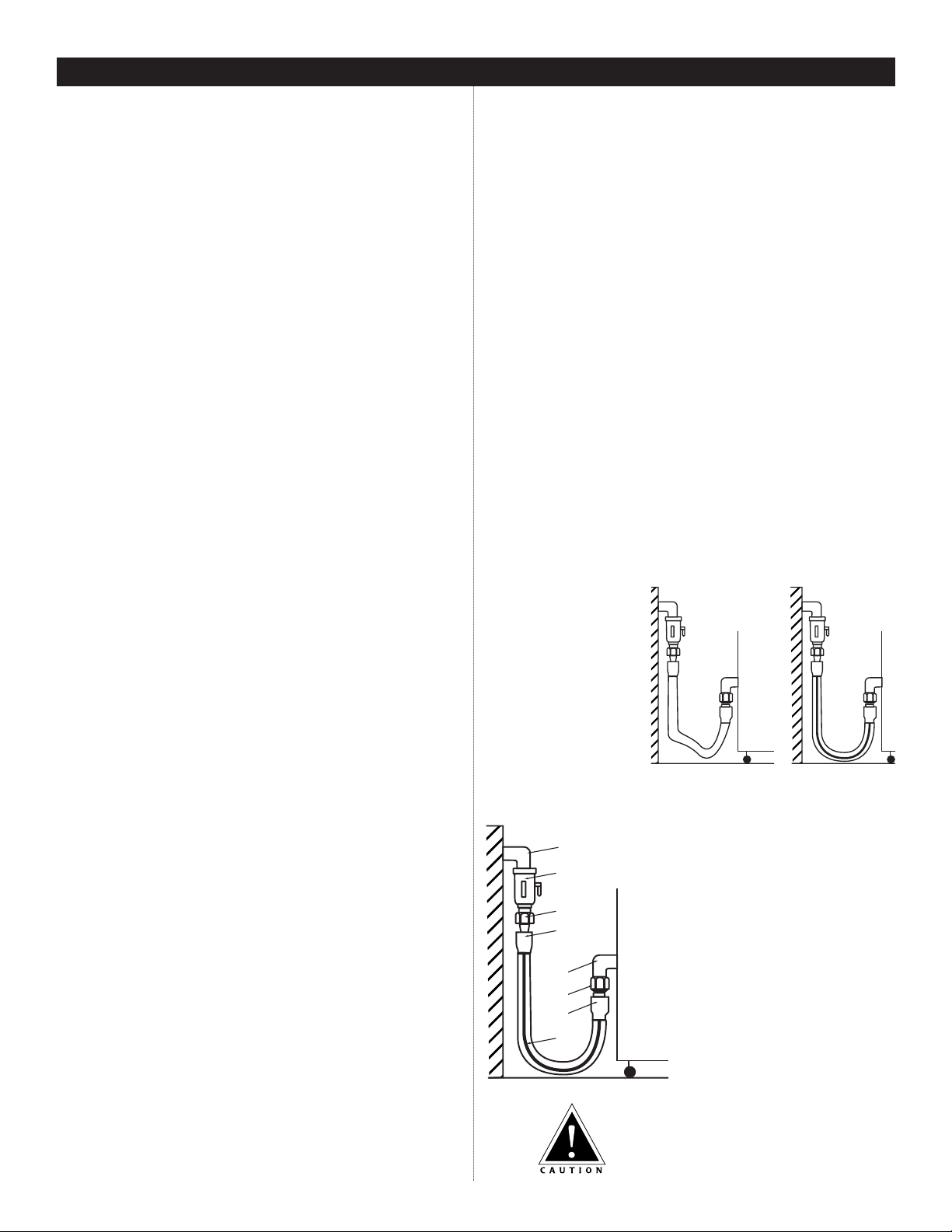

Routing of the flexible connector must not be

installed under the

rotisserie. The

temperature in this

location is much

too hot for safe

operation. The

flexible connector

must be routed so that

it forms a downward

"U" loop between the

building gas supply

and the attachment at the rear of the rotisserie.

OVERHEATING DANGER!

THE GAS PIPING MUST NEVER

RUN UNDER THE BURNER

#853 ROTISSERIE OPERATION AND CARE — PG. 3.

GAS CONNECTIONS

INCORRECT CORRECT

A

B

C

D

E

F

G

H

GAS INTAKE

A-G Installation elbow

B Wall Valve

C-D Three-piece union fitting

(minimum 1 per installation)

E-F End connector for the flexible tube

H Marking line

LEAK TESTING

If a pressure leak test above 1/2 psi is to be

conducted on the building supply gas piping, the

shutoff gas valve and rotisserie inlet gas supply line

must be disconnected from the building supply

piping before conducting the pressure test. Failure

to do so may result in damage to the manual gas

valve and/or gas components in the rotisserie.

If any gas leak tests are to be conducted at

pressures equal to or below 1/2 psi, the manual gas

shut off valve upstream of the rotisserie must be

turned off before conducting the tests.

Leak testing of the internal oven piping system

was conducted before shipping the rotisserie from

the factory. If additional testing is needed, it should

only be conducted at normal gas supply pressures. If

the testing is performed using combustible gas in the

piping, leak testing should be conducted with a soap

solution (bubble checking) or other approved liquid.

NEVER CHECK FOR LEAKS

USING AN OPEN FLAME

The use of electronic combustible gas leak

detectors may be helpful. Such detectors can be

oversensitive, however, they may help find leaks that

are not visible when checking with a liquid solution,

and, therefore, present no hazard.

When starting the rotisserie after initial

installation, the gas lines must be free of air which

may take up to 30 minutes. If the burners do not light

after this period of time, call factory for assistance.

The rotisserie is not to be directly connected to a

chimney vent system nor directly connected to a

horizontal exhaust system. The unit must be

installed under a ventilation hood listed as ANSI/UL

705 (latest edition), and the installation must be

conducted in accordance with the ANSI/NFPA 961987, Standard for Ventilation Control and Fire

Protection of Commercial Cooking Operations.

Operators of the rotisserie should be

instructed not to place any material on top of

the rotisserie that would obstruct the flow

of flue products from the opening.

Operators should also be instructed that

flue gases are hot and any material or items placed

on top or in front of the flue defector could be

damaged or cause a fire hazard.

This unit is equipped with a manual "direct spark

ignition" for ease of lighting the burners. The

intermittent push button switch is located on the

control panel to the left of the control knobs. This

switch sends a signal to a spark module that

energizes all of the igniters and lights the burner.

The electrodes are located just above the burner

under the burner cover on the right hand side of the

rotisserie. These electrodes are very fragile and care

must be taken if adjustment is required. Special care

must be used to prevent breakage of the porcelain

insulator. If the porcelain is damaged or broken, the

igniter assembly must be replaced. The end of the

electrode must have a gap of 1/8” to 3/16” (3mm to

5mm) from the top surface of the burner. The spark

must be maintained between the electrode and the

burner for proper ignition.

The gas train and orifice for the main burner has

been fitted according to the gas type specified on the

data plate. Technical specifications for the gas

system are as follows:

AR-6G

NATURAL GAS

Min. Connected Pressure . . . . . . . .5 in W.C.

Max. Connected Pressure . . . . . . . .10 in W.C.

Air Gap . . . . . . . ..158 (4mm)

Manifold Pressure . . . . . . . .5.0 in W.C.

Gas Consumption . . . . . . . .78.4 cu.ft./hr.

Gross Thermal Output . . . . . . . .195,000 Btu/hr.

Orifice HL Dia. . . . . . . . ..137 (3,5mm)

PROPANE GAS

Min. Connected Pressure . . . . . . . .12 in W.C.

Max. Connected Pressure . . . . . . . .14 in W.C.

Air Gap . . . . . . . ..079 (2mm)

Manifold Pressure . . . . . . . .10 in W.C.

Gas Consumption . . . . . . . .57.6 cu.ft./hr.

Gross Thermal Output . . . . . . . .195,000 Btu/hr.

Orifice HL Dia. . . . . . . . ..090 (3,5mm)

#853 ROTISSERIE OPERATION AND CARE — PG. 4.

GAS CONNECTIONS

GAS EXHAUST

IGNITION SYSTEM

PRESSURE CHARGE

Loading...

Loading...