Alto Shaam 767-SK, 1767-SK Operation Manual

C oo k , H ol d , S mo k e O ve n

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3 800 • 800. 558.8744

US A/C ANA D A FAX: 262.251. 7067 • 80 0.329.8744 U.S. A . O N LY

www.alt o-shaam.com

M a n u a l C o n t r o l

Models:

767-S K

1767-SK

1767-SK

767-SK

• IN STALLATION

• OPERATION

• MAI NTENANCE

P R I N T E D I N U . S . A .

MN-28601 • 03/10

Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Procedures and Precautions . . . . . . . . . . . . 2

Sanitation

Sanitation/Food Safety . . . . . . . . . . . . . . . . . . . 15

Internal Food Product Temperatures . . . . . . . . . 15

Installation

Installation Requirements . . . . . . . . . . . . . . . . . . 3

Clearance Requirements . . . . . . . . . . . . . . . . . . 3

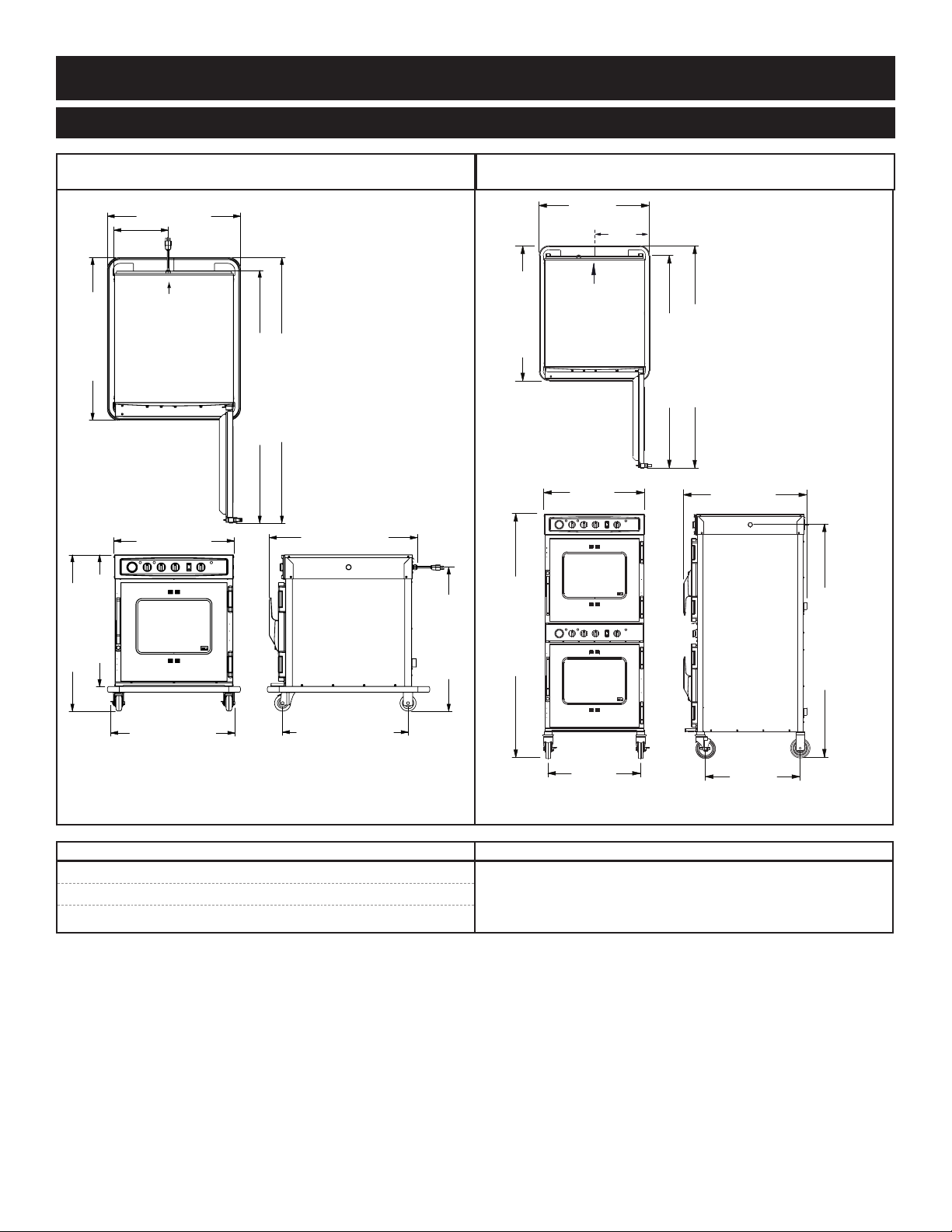

Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . 4

Net/Ship Weight . . . . . . . . . . . . . . . . . . . . . . . . . 4

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Options and Accessories . . . . . . . . . . . . . . . . . . 5

Stacking Instructions . . . . . . . . . . . . . . . . . . . . . 6

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Restraint Requirements - Mobile Equipment . . . . 7

Drip Tray Installation . . . . . . . . . . . . . . . . . . . . . 8

Electrical Specifications . . . . . . . . . . . . . . . . . . . 9

Operating Instructions

User Safety Information . . . . . . . . . . . . . . . . . . 10

Start-Up Operation . . . . . . . . . . . . . . . . . . . . . . 10

Manual Control Operation . . . . . . . . . . . . . . . . . 11

Cooking Oven Characteristics. . . . . . . . . . . . . . 11

General Holding Guidelines . . . . . . . . . . . . . . . 12

Care and Cle aning

Cleaning and Preventative Maintenance . . . . . . 13

Protecting Stainless Steel Surfaces . . . . . . . . . 13

Cleaning Agents . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning Materials . . . . . . . . . . . . . . . . . . . . . . 13

Equipment Care . . . . . . . . . . . . . . . . . . . . . . . . 14

Clean Daily. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clean the Door Vents . . . . . . . . . . . . . . . . . . . . 14

Check Overall Condition of Oven . . . . . . . . . . . 14

Service

Thermostat/Pilot Light Sequence . . . . . . . . . . . 16

Thermostat Calibration . . . . . . . . . . . . . . . . . . . 16

Trouble Shooting Checklist . . . . . . . . . . . . . . . . 17

Exterior Service View

- 767-SK . . . . . . . . . . . . . . 18

Exterior Service Parts List - 767-SK . . . . . . . . . . 19

Electronic Components Service View - 767-SK . . 20

Electronic Components Parts List - 767-SK . . . . . 21

Cable Heating Kits - 767-SK, 1767-SK . . . . . . . . . . 21

Exterior Service View - 1767-SK . . . . . . . . . . . . . 22

Exterior Service Parts List - 1767-SK. . . . . . . . . . 23

Electronic Components - 1767-SK . . . . . . . . . . . . 24

Electronic Components Parts List - 1767-SK . . . . 25

Wire Diagrams

767-SK, 1PH, 120V . . . . . . . . . . . . . . . . . . . . . 26

767-SK, 1PH, 208-240V . . . . . . . . . . . . . . . . . . 27

767-SK, 1PH, 230V . . . . . . . . . . . . . . . . . . . . . 28

1767-SK, 1PH, 208-240V . . . . . . . . . . . . . . . . . 29

1767-SK, 1PH, 230V . . . . . . . . . . . . . . . . . . . . 30

Warranty

Transportation Damage and Claims . . BAC K COVER

Limited Warranty . . . . . . . . . . . . . . . . . BACK COVER

D E L I V E R Y

This Alto-Shaam appliance has been

thoroughly tested and inspected to ensure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and report

it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to ensure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

N O T E : All claims for warranty must include the

full model number and serial number of

the unit.

U N P A C K I N G

1. Carefully remove the

appliance from the

carton or crate.

N O T E : Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner or

manager of the business or to the person

responsible for training operators. Add itional

manuals are available from the Alto-Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

767-SK, 176 7-SK IN STAL L ATI O N/ O PER ATIO N /S E RV I CE MA NU A L Pg. 1.

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated

hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

N O T E : Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

C A U T I O N

Used to indicate the presence of a hazard that can

or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

C A U T I O N

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

D A N G E R

Used to indicate the presence of a

hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

W A R N I N G

Used to indicate the presence of a

hazard that CAN cause personal injury,

possible death, or major property

damage if the warning included with

this symbol is ignored.

SAFETY P ROCEDU R E S

AND P R E C AUTION S

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

N O T E

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

Pg. 2. 767-SK, 176 7-S K IN STAL L ATI O N/ O PER ATIO N /S E RV I CE MA NU A L

®

I N S T A L L A T I O N

D A N G E R

IMPROPER INSTALLATION,

A

LTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH,

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C A U T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

C A U T I O N

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

O

PERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

D A N G E R

DO NOT store or use gasoline or other

flammable vapors or liquids in the

vicinity of this or any other appliance.

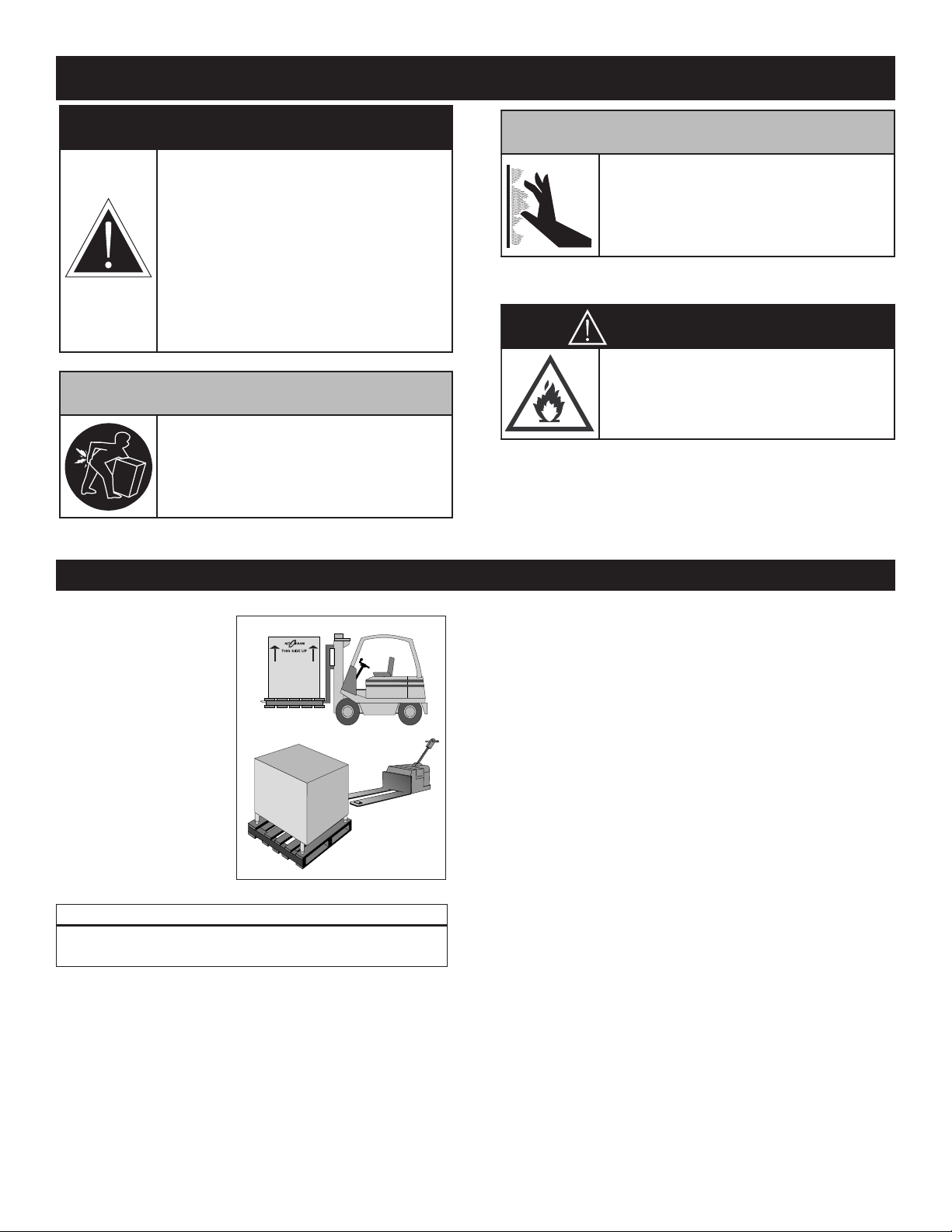

The Alto-Shaam cook

and hold oven must

be installed in a

location that will

permit the oven to

function for its

intended purpose

and to allow

adequate clearance

for ventilation,

proper cleaning, and

maintenance access.

C L E A R A N C E R E Q U I R E M E N T S

3-inches (76mm) at the back, 2-inches (51mm) at the

top, and 1-inch (25mm) at both sides

S I T E I N S T A L L A T I O N

1. The oven must be installed on a stable and

level surface.

2. DO NOT install this appliance in any area

where it may be affected by any adverse

conditions such as steam, grease, dripping

water, high temperatures, or any other severely

adverse conditions.

3. DO NOT store or use any flammable liquids or

allow flammable vapors in the vicinity of this

oven or any other appliance.

4. This appliance must be kept free and clear of

any combustible materials.

5. This appliance must be kept free and clear of

any obstructions blocking access for

maintenance or service.

767-SK, 176 7-SK IN STAL L ATI O N/ O PER ATIO N /S E RV I CE MA NU A L Pg. 3.

S I T E I N S T A L L A T I O N

28-5/8" (726mm)

Shown with

optional bumper

34-7/8" (886mm)

56-15/16" (1445mm)

Electrical

Connection

54-13/16" (1376mm)

11-5/8"

(

295mm)

26-5/8" (676mm)

25-3/4" (654mm)

28-1/4" (717mm)

33-1/2" (851mm)

with 3-1/2" casters*

*31-13/16" (807mm) - with optional 2-1/2" casters

*35-1/4" (894mm) - with optional 5" casters

*34-7/16" (874mm) - with optional 6" legs

31-3/4" (805mm)

30-7/8" (784mm)

(electrical connection)

26-15/16" (683mm)

62-3/8" (1583mm)

with 5

" Casters

25-3/4"

(

653mm)

23-5/8"

(600mm)

*60-15/16" (1548mm) - with optional 3-1/2" (89mm) casters

*62-1/2" (1589mm) - with optional 6" (152mm) legs

3

1-9/16"

(801mm)

59-1-2" (1511mm)

24-1/8"

(613mm)

28-3/16"

(

716mm)

54-3/4" (1390mm)

34-1/2" (876mm)

56-3/4" (1441mm)

with optional bumper

12-7/8"

(326mm)

Electrical

Connection

S

hown with

O

ptional

Bumper

767-SK 1767-SK

I N S T A L L A T I O N

WE I GHT

MODEL NET WEIGHT SHIP WEIGHT

767-SK 196 lb (89 kg) 225 lb (102 kg)

1767-SK 359 lb (163 kg)

EST. 450 lb (204 kg)

CA PACITY PER C O MPART MENT

100 lb (45 kg)

VO LU ME MAX IMU M

MAXIMUM

: 53 QUA RTS (67 LIT ERS )

Pg. 4. 767-SK, 176 7-S K IN STAL L ATI O N/ O PER ATIO N /S E RV I CE MA NU A L

S I T E I N S T A L L A T I O N

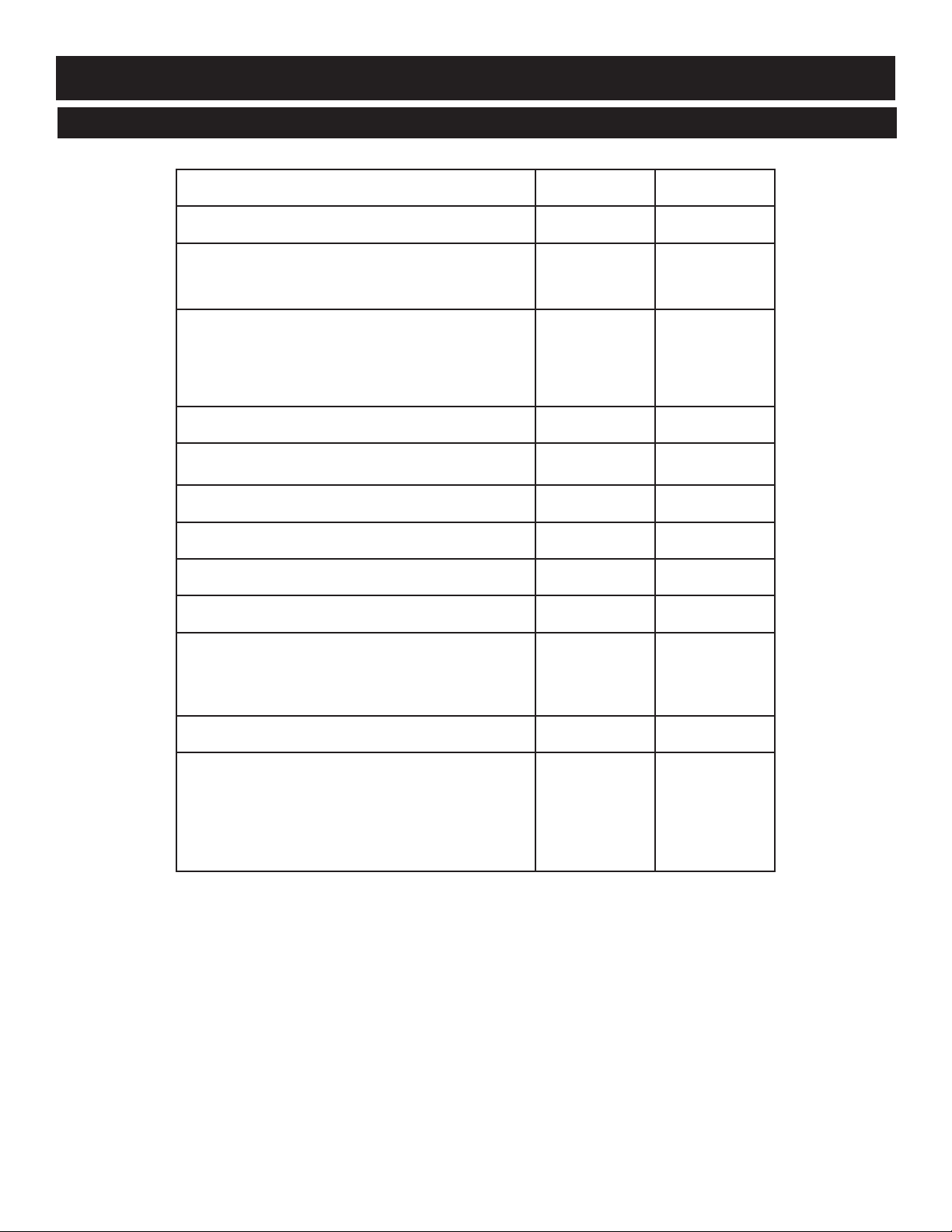

OPTIONS AND ACCESSO R IES 767-SK 1767-SK

Bumper, Full Perimeter 5010371 5010371

Carving Holder

S

Casters - 2 RIGID, 2 SWIVEL W/BRAKE

Door Lock with Key LK-2763 LK-2763

Drip Pan with Drain 14831 14831

Legs, 6" (152mm), Stemmed (SE T OF FOUR ) 5011149 5011149

I N S T A L L A T I O N

RI ME RIB

P

TE AMS HIP

AF ETE RIA

(C

5" (127mm)

3-1/2" (89mm)

2-1/2" (64mm)

) R

OU ND

HL-2635

4459

5004862

TANDAR D

S

5008022

HL-2635

4459

TANDAR D

S

5008017

––

Pan Grid, Wire - 18" X 26" PAN INSERT PN-2115 PN-2115

Pan Slides (230V ONLY) 1010813 1010813

Security Panel 5004750 5004750

Shelf, Stainless Steel

FL AT WIRE , REAC H-I N

RI B RACK

SH-2324

SH-2743

SH-2324

SH-2743

Stacking Hardware 5004864 ––

Wood Chips, bulk pack

Apple 20 lb (9 kg)

Cherry 20 lb (9 kg)

Hickory 20 lb (9 kg)

Maple 20 lb (9 kg)

WC-22543

WC-22541

WC-2829

WC-22545

WC-22543

WC-22541

WC-2829

WC-22545

767-SK, 176 7-SK IN STAL L ATI O N/ O PER ATIO N /S E RV I CE MA NU A L Pg. 5.

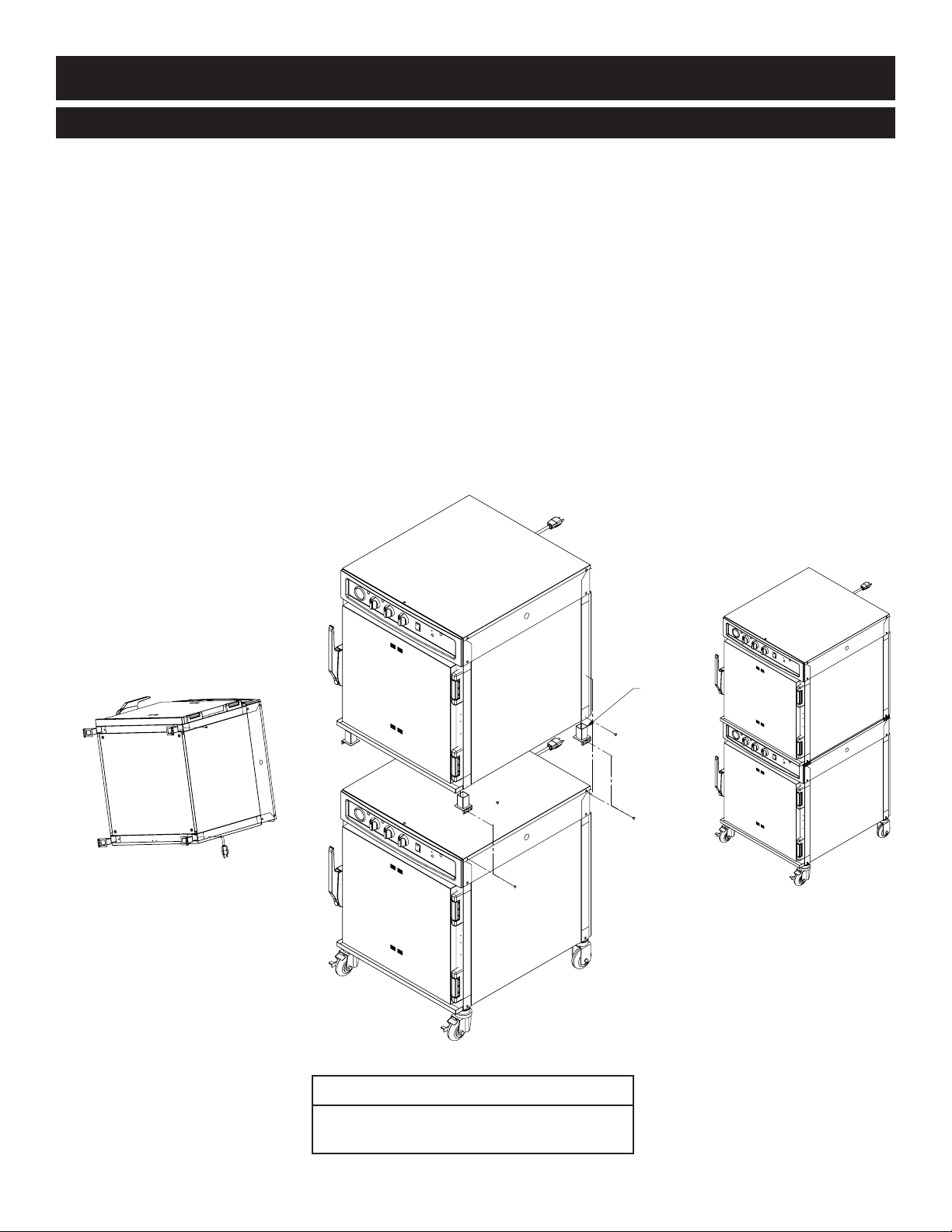

I N S T A L L A T I O N

CASTER SET

SCREW

TOP

MOUNTING

SCREWS

STACKING

POSTS

TOP

MOUNTING

SCREWS

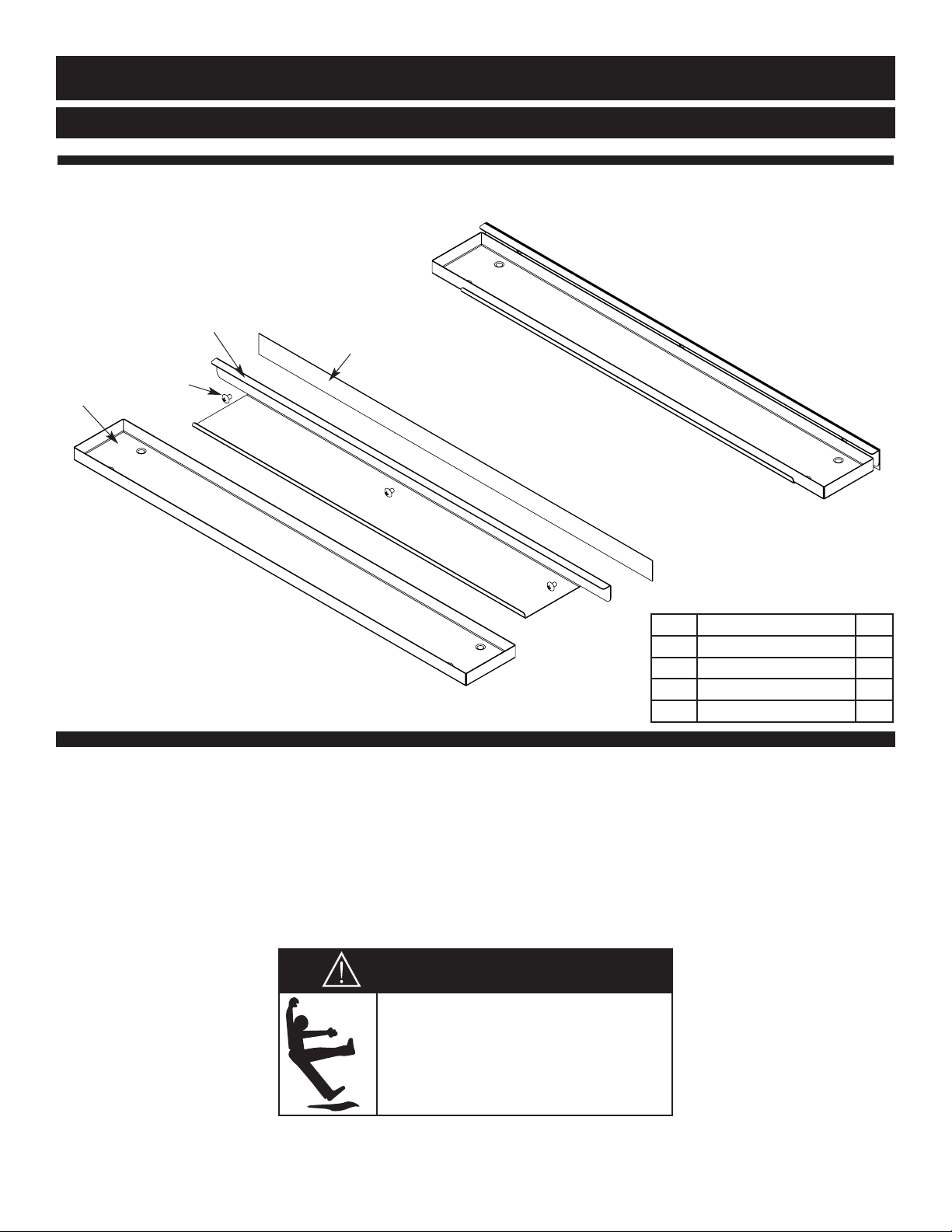

STACKING INSTRUCTIONS

1

) I f the two a p p liances w ere s h i pped togethe r from the f a ctory, t he top unit w ill have t h e

ca s t e rs alread y removed. A st acking k i t will be i n c l uded w i t h the shipment.

If casters need to be removed: lay the unit on its back, and remove the set screw on each caster. Pull the

casters out of the unit.

2) W hile applian c e is laid on its b a c k, insert o ne stacking post in e a c h of the four c o r n e rs

of the upper unit. Secure th e stacking p osts using one screw and two f l at washers t hat

co m e wi th the stackin g ki t .

Not e : The flange on the stacking posts must face the outside of the unit.

3) R emove t h e four top mountin g sc rews f rom t h e lower unit. Place th e up per applianc e ,

wh i c h has the stackin g po s ts installed, on to p of the bottom unit. Center the top

un i t from f ront t o ba c k. Re-install th e fo ur screws th rough t h e flange o f th e four

sta c king posts.

S I T E I N S T A L L A T I O N

Stacking Configurations

767-SK with 767-SK, 750-TH/III, 750-TH-II,

767-SK/III, or 750-S

Pg. 6. 767-SK, 176 7-S K IN STAL L ATI O N/ O PER ATIO N /S E RV I CE MA NU A L

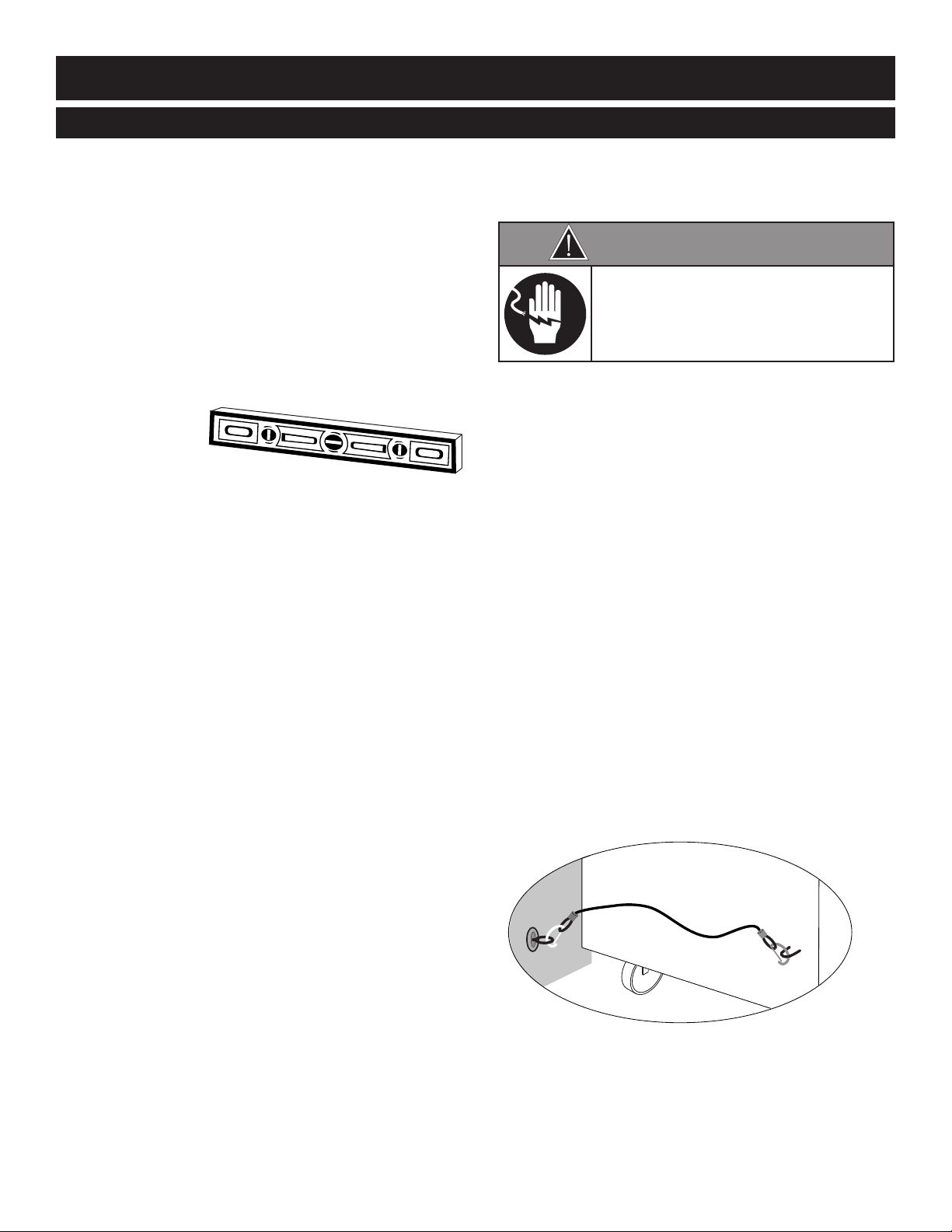

S I T E I N S T A L L A T I O N

W A R N I N G

RISK OF ELE CTRIC SHOCK.

Appliance must be secured

to building structure.

I N S T A L L A T I O N

A number of adjustments are associated with

initial installation and start-up. It is important

hat these adjustments be conducted by a qualified

t

service technician. Installation and start-up

adjustments are the responsibility of the dealer or

user. These adjustments include but are not

limited to thermostat calibration, door adjustment,

leveling, electrical hook-up and installation of

optional casters or legs.

LEVELING

Level the oven from sideto-side and front-to-back with the use of a spirit

level. For ovens installed with casters, it is

important that the installation surface be level due

to the probability of frequent oven repositioning.

We recommend checking the level of the oven

periodically to make certain the floor has not

shifted nor the oven moved.

NOT E : Failure to properly level this oven can

cause improper function and will result

in the uneven baking with products

consisting of semi-liquid batter.

RESTRAINT REQU IREMENTS

—MOBILE EQUIPM ENT

Any appliance that is not furnished with a power

supply cord but that includes a set of casters must

be installed with a tether. Adequate means must

be provided to limit the movement of this

appliance without depending on or transmitting

stress to the electrical conduit. The following

requirements apply:

1. Casters must be a maximum height of 6" (152mm).

2. Two of the casters must be the locking type.

Such mobile appliances or appliances on mobile

3.

stands must be installed with the use of a flexible

connector secured to the building structure.

A mounting connector for a restraining device is

located on the lower back flange of the appliance

chassis or on an oven stand, approximately 18"

(457mm) from the floor. A flexible connector is not

supplied by nor is it available from the factory.

767-SK, 176 7-SK IN STAL L ATI O N/ O PER ATIO N /S E RV I CE MA NU A L Pg. 7.

I N S T A L L A T I O N

W A R N I N G

FAIL UR E TO P RO PE RLY I NS TALL THE

DRIP TRAY CAN OR WILL CAUS E

MAJOR E QU IP ME NT DAMAGE AND

WILL RESULT IN A LEAKAGE

HAZARD THAT CAN CAU SE

PERSONAL INJURY.

S I T E I N S T A L L A T I O N

DRIP TRAY INSTALLATION INSTRUCTIONS

Item Description Qty

1 Double-Sided Tape 1

2 Drip Tray Holder 1

3 8-32 x 1/4" Phil Screw 3

4 Drip Tray 1

1. Poke holes through double-sided tape which is attached to the back of drip tray holder .

2. Remove backing on double-sided tape .

3. Put screws through holes and attach drip tray holder to unit.

4. Optional - apply a line of food-grade silicone caulk along top edge of drip tray holder to seal.

5. Place drip tray in drip tray holder .

Pg. 8. 767-SK, 176 7-S K IN STAL L ATI O N/ O PER ATIO N /S E RV I CE MA NU A L

Loading...

Loading...