Alto Shaam 10.18 Installation Manual

COMBITHERM®

COMBINATION OVEN/STEAMER

MANUAL CONTROL

INSTALLATION

AND

MAINTENANCE

MODELS: 6•10

10•10

10•18

12•20

20•20

PRINTED IN U. S .A .

#M6002-6 • 6/98

W164 N9221 Water Street ●P.O. Box 450

Menomonee Falls, Wisconsin 53052-0450

●

U.S.A.

PHONE:

(262) 251-3800

(800) 558-8744

U. S .A ./CANADA

FAX:

(262) 251-7067

(800) 329-8744

U. S .A ./CANADA

SYSTEMS

®

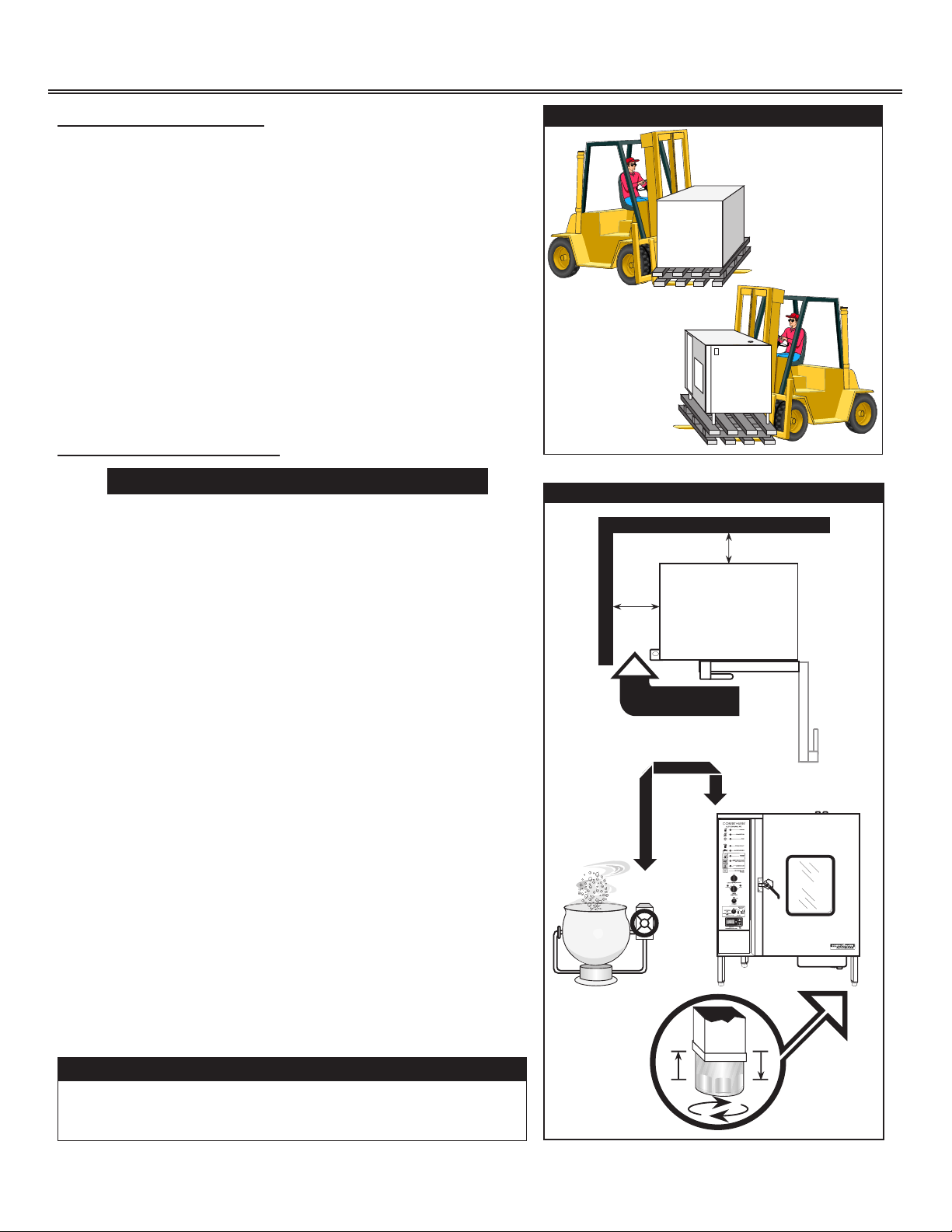

TRANSPORTATION

Upon receipt of the Combitherm Combination Oven-Steamer, check

the exterior of the shipping crate for any physical damage that could

result in damage to the contents. If the oven was not received from

the carrier in an upright position, there is a stronger possibility of

concealed damage. Uncrate the unit carefully and inspect for any

transit damage. Immediately report any damage to the delivering

freight carrier.

The oven must remain on the pallet while being moved to the

installation site by fork-lift or pallet lift truck.

CAUTION: When removing the oven from the pallet to the

installation site, DO NOT LIFT at the condenser

housing. Care should also be used to prevent

damage to the drip-tray hanger permanently mounted

at the bottom of the oven door.

INSTALLATION SITE

HOOD INSTALLATION IS REQUIRED

In order to ensure proper ventilation, a minimum distance of at least

6” (152mm) must be kept from the control panel side [left] of the

oven and any adjoining surfaces. Determine any additional

clearance needed for access to the fuses or to gain access for

servicing.

Allow a minimum of 3-1/2” to 5” (89mm to 127mm) from the right side

of the oven to allow the door to open to at least a 90° angle. Fully

opened, the door will extend up to a 225° angle.

Allow a minimum clearance of 4” (102mm) from the back of the oven

for plumbing connections.

Allow adequate clearance for the steam vent(s) located at the top

[right-rear] of the oven.

Do not install the oven adjacent to heat producing equipment such

as fryers, broilers, etc. Minimum clearance recommended: 20”

(50cm).

Adjust the Combitherm Oven to LEVEL on a stable, horizontal

surface by means of the height-adjustable legs. For counter-top

models, the overall height of the oven should be positioned so the

operating controls and shelves may be conveniently reached from

the front.

The electrical wiring diagram is located behind the control panel on

the left side of the oven.

ALL INSTALLATION INSTRUCTIONS AND

REQUIREMENTS MUST BE STRICTLY OBSERVED.

CAUTION

IMPROPER CONNECTION OF THIS APPLIANCE

NULLIFIES ALL WARRANTIES.

Pg. 1

INSTALLATION AND TECHNICAL INFORMATION

TRANSPORTATION

THIS S IDE UP

COMBITHERM

➞

➞

INSTALLATION SITE

(102mm)

6"

(152mm)

MINIMUM

4"

o

o

ALLOW ADDITIONAL

ACCESS FOR SERVICE

20"

(50cm)

MINIMUM

COMBITHERM®

OFF

POWER

ON

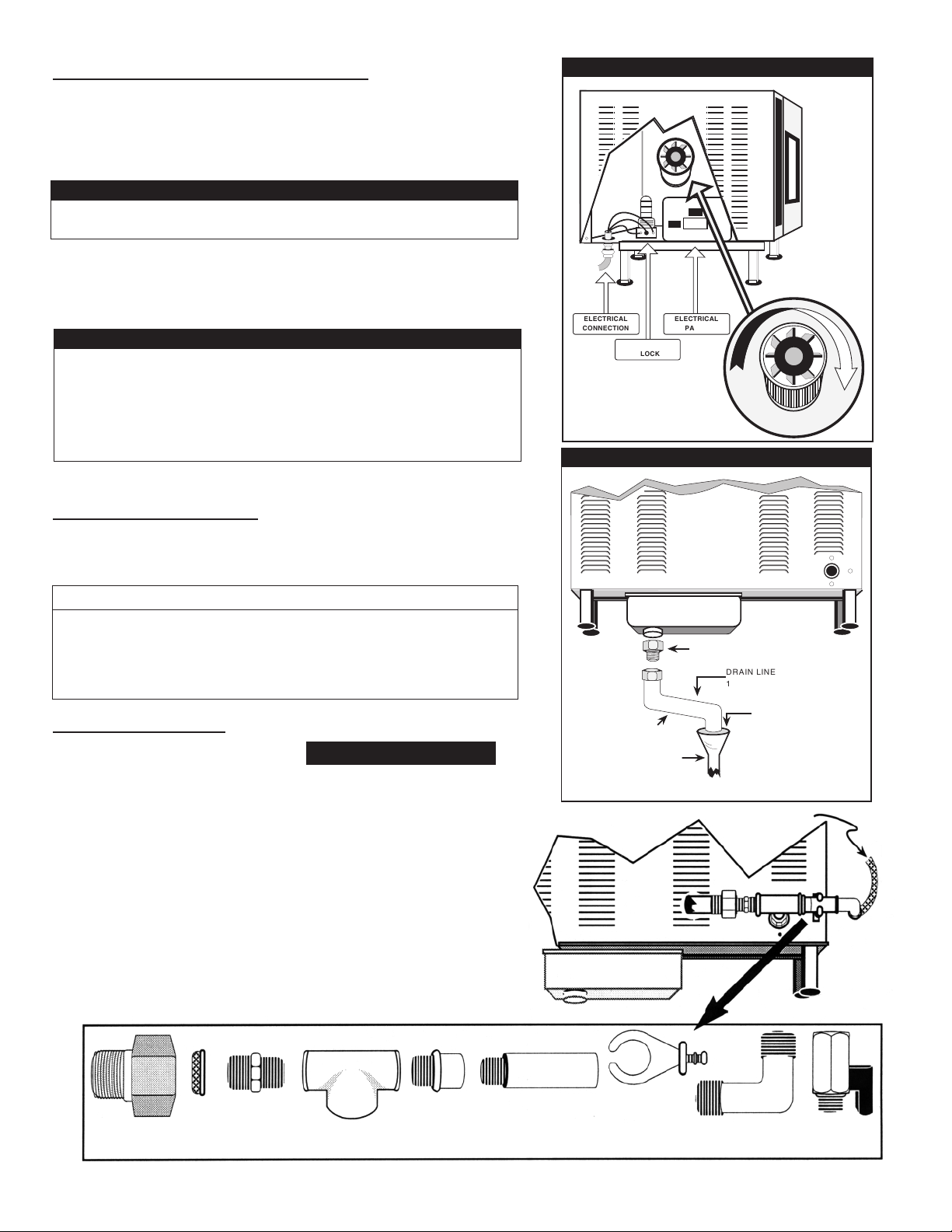

ELECTRICAL INSTALLATION

The oven must be installed by a qualified electrician. This appliance

must be branch circuit protected with proper ampacities, in accordance

with the wiring diagram located in the electrical compartment of the

oven. The oven must be properly grounded in accordance with the

National Electrical Code and applicable local codes.

CAUTION

ENSURE THE AVAILABLE POWER SOURCE MATCHES THE

VOLTAGE STAMPED ON THE NAMEPLATE OF THE OVEN.

For supply connections, use the wire size posted on the label located

on the electrical control box cover, behind the service panel.

Each oven motor displays an arrow showing the direction of the motor

rotation.

CAUTION

AFTER THE ELECTRICAL CONNECTION IS COMPLETED,

IT IS IMPERATIVE THE DIRECTION OF THE FAN ROTATION

CORRESPONDS WITH THIS ARROW. THIS APPLIANCE WILL

NOT FUNCTION PROPERLY AND DAMAGE CAN OCCUR IF THE

MOTOR ROTATION IS NOT CORRECT.

To change motor direction, exchange two of the phases.

WATER DRAINAGE

The oven must discharge through an indirect waste pipe by means

of an air gap. The drain thread is 1-1/4-inch NPT. A union is

required. Install drain line with a gradient.

ATTENTION

The equipment is to be installed to comply with the Basic Plumbing Code

of the Building Officials and Code Administrators International, Inc.

[BOCA], and the Food Service Sanitation Manual of the Food & Drug

Administration [FDA].

WATER SUPPLY

CONNECT TO POTABLE COLD WATER ONLY

WATER PRESSURE REQUIREMENTS: Minimum 45 psi

Maximum 75 psi

A shut-off valve and back-flow preventer must be installed when

connecting the oven to the cold water intake. The connecting pipe

thread in 3/4-inch NPT. A conversion adapter (British Standard to

NPT) is provided for this connection. Pipe sealing tape is

recommended at all connections. The shut-off valve must be in

the OPEN position when the oven is being used.

To prevent the twisting or crimping of the hand-held hose, the

connecting elbow must be installed in a horizontal or slightly

downward position.

Pg. 2

SPRAY HOSE

FILTER

SCREEN

FI

-2946

DOUBLE

NIPPLE

NP

-22115

TEE

TE

-22117

REDUCER

RR

-22118

EXTENSION PIPE

PP

-22120

PIPE CLIP

CL

-22119

ELBOW

EB

-22121

BALL VALVE

VA

-22684

CONVERSION

ADAPTER

CT

-2917

ELECTRICAL INSTALLATION

ELECTRICAL

PANEL

ELECTRICAL

CONNECTION

TERMINAL

BLOCK

ELECTRICAL

PANEL

WATER DRAINAGE

MOTOR

3% TO 5%

GRADIENT

1-1/2" to 2" minimum diameter

WASTE PIPE

(c. 38-m m to 51-m m)

CONVERSION ADAPTER (some models)

PB-2918

DRAIN LINE

1-1/4" (32-mm) diameter

12" (305mm) maximum length

AIR GAP

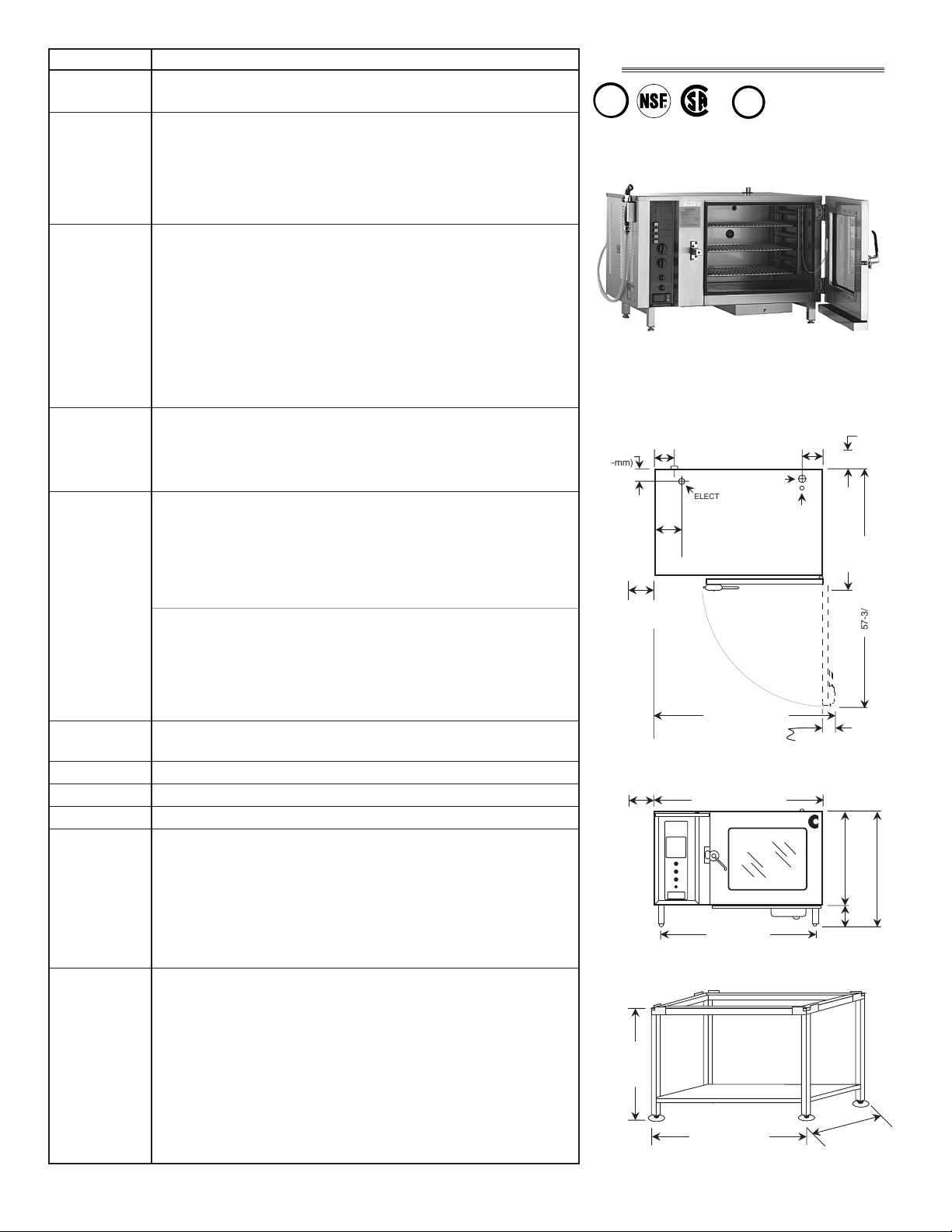

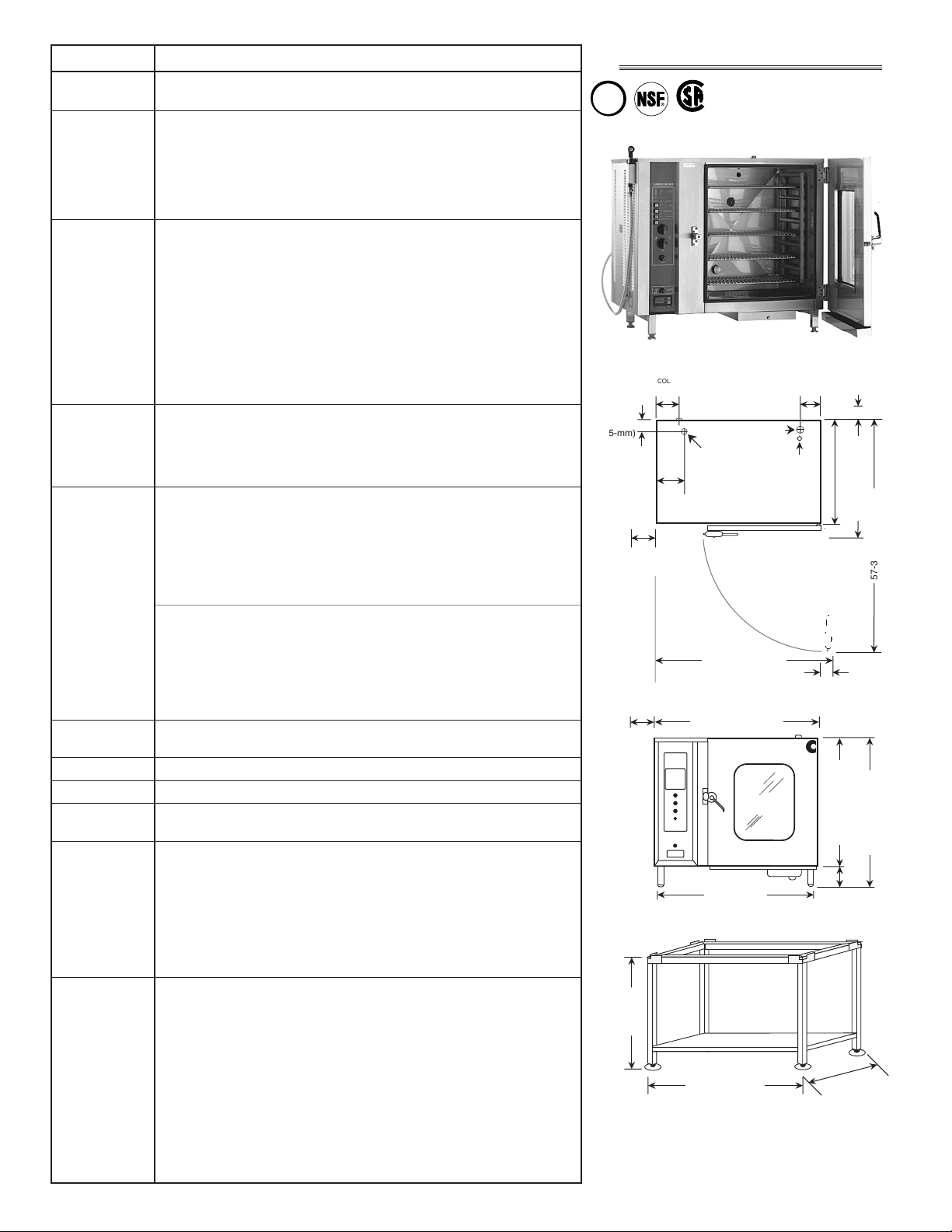

6 • 10

Up to approximately 40 lb (c. 18 kg)

TOTAL PAN CAPACITY [maximum]: 45 quarts (c. 57 liters)

FULL-SIZE PANS:

— Six (6) 20" x 12" x 2-1/2" (530mm x 325mm x 65mm GN 1/1)

HALF-SIZE SHEET PANS*

— Six (6) 18" x 13" x 1" On wire shelves only

*Extra optional wire shelves required for maximum capacity

INSIDE DIMENSIONS (W x D x H): 23-7/16" x 20-7/8" x 17-3/4"

(595mm x 530mm x 450mm)

— One (1) 15 watt appliance bulb

— One (1) steam generator drain valve with removable cap

— One (1) oven drain screen

— Two (2) stainless steel side racks with six (6) pan support rails:

SIDE RACK SPACING:

21-3/8" (535mm) horizontal width between rails

2-5/8" (65mm) vertical spacing between rails

— Three (3) stainless steel wire shelves

WIRE SHELF DIMENSIONS: 21-3/16" x 12-3/4"

(530mm x 325mm)

20 gauge stainless steel

OUTSIDE DIMENSIONS (W x D x H ): 40-9/16" x 29-1/16" x 27-1/2"

(c. 1030mm x 738mm x 699mm)

WINDOW DOOR DIMENSIONS (W x H): 19-3/16" x 15-3/16"

(480mm x 380mm)

208-240 V.A.C. — 60 Hz, 1 ph

At 208 V: 39.9 Amps/Phase At 240 V: 45.8 Amps/Phase

8.0 kW — Steamer 10.7 kW — Steamer

8.0 kW — Convection 10.7 kW — Convection

.3 kW — Motor .3 kW — Motor

TOTAL: 8.3 kW TOTAL: 11.0 kW

TERMINAL BLOCK CONNECTION: 2 Wire Plus Ground (AWG 6 or larger)

208-240 V.A.C. — 60 Hz, 3 ph

At 208 V: 23.1 Amps/Phase At 240 V: 26.5 Amps/Phase

8.0 kW — Steamer 10.7 kW: — Steamer

8.0 kW — Convection 10.7 kW: — Convection

.3 kW — Motor .3 kW — Motor

TOTAL: 8.3 kW TOTAL: 11.0 kW

TERMINAL BLOCK CONNECTION: 3 Wire Plus Ground (AWG 8 or larger)

COLD WATER INTAKE: 3/4" NPT

WATER PRESSURE REQUIREMENTS: 45 psi—minimum 75 psi—maximum

Indirect waste pipe with air gap — 1-1/4" NPT

278 lb (126 kg)

345 lb (156 kg)

●

Oven must be installed level — hood installation required

●

Minimum Clearance Required: Left: 6" (152mm)

Right: 3-3/16" (80mm) for door

Back: 4" (102mm)

Bottom: 5-3/16" (130mm) Legs

Top: Vent Clearance [right, rear]

●

Install water supply shut-off valve

●

Install back-flow preventer

●

Rotation of motor must be in direction of arrow

CHICKEN ROASTING SHELF (Holds 6 chickens)...............SH-23000

CHICKEN ROASTING SHELF (Holds 10 chickens) .............SH-22634

COUNTER-TOP LEG ASSEMBLY .................................4504

GREASE TRAY PACKAGE

— (Use with chicken roasting shelf #SH-22634) .......................4757

HIGH OVEN STAND (39-1/4" x 22-1/4" x 38-3/4")

— Accomodates placement of various equipment models ..........4931

LOW OVEN STANDS — Stainless Steel w/pan slides ............4554

— Stainless Steel ..........................4557

STACKING HARDWARE...........................................5982

VENTLESS HOOD (

SEE SEPARATE SPEC SHEET)...................15555

WIRE SHELVES: Stainless Steel.............................SH-2903

COMBI OVEN CLEANER FOUR (4) 1 GAL. CONTAINERS/CASE ........CE-2906

A

A

A

A

●●

SIZES & SPECIFICATIONS

®

U

L

®

COUNTER-TOP INSTALLATIONS MUST

MAINTAIN 4" (102MM) MINIMUM

CLEARANCE FROM SURFACE.

®

U

L

C

MODEL

PRODUCT

CAPACITY

PAN CAPACITY

INTERIOR

EXTERIOR

ELECTRICAL

WATER

DRAIN

NET WEIGHT

SHIP WEIGHT

IMPORTANT

INSTALLATION

REQUIREMENTS

OPTIONS and

ACCESSORIES

Pg. 3

3"

(75-mm)

(149-mm)

6"—(152-mm)

CLEARANCE

CLEARANCE

6" (152-mm)

COLD WATER INTAKE

4-3/4"

(120-mm)

5-7/8"

■

■

■

27-3/16"

(690-mm)

(130-mm)

WATER DRAIN

ELECTRICAL

CONNECTION

(bottom)

43-5/8"—(1107-mm)

40-9/16"—(1030-mm)

•

•

•

•

•

•

•

39"—(990-mm)

39-1/4"—(998-mm)

LOW OVEN STAND (OPTION)

MODEL 6•10

5-1/8"

STEAM

VENT

(top)

3-3/16" (80-mm)

CLEARANCE

(565-mm)

4"

(102-mm)

CLEARANCE

29-1/16"—(738-mm)

57-3/16"—(1453-mm)

22-11/16"

(575-mm)

5-1/8"

(130-mm)

22-1/4"

27-1/2"

(698-mm)

●●

SIZES & SPECIFICATIONS

®

U

L

®

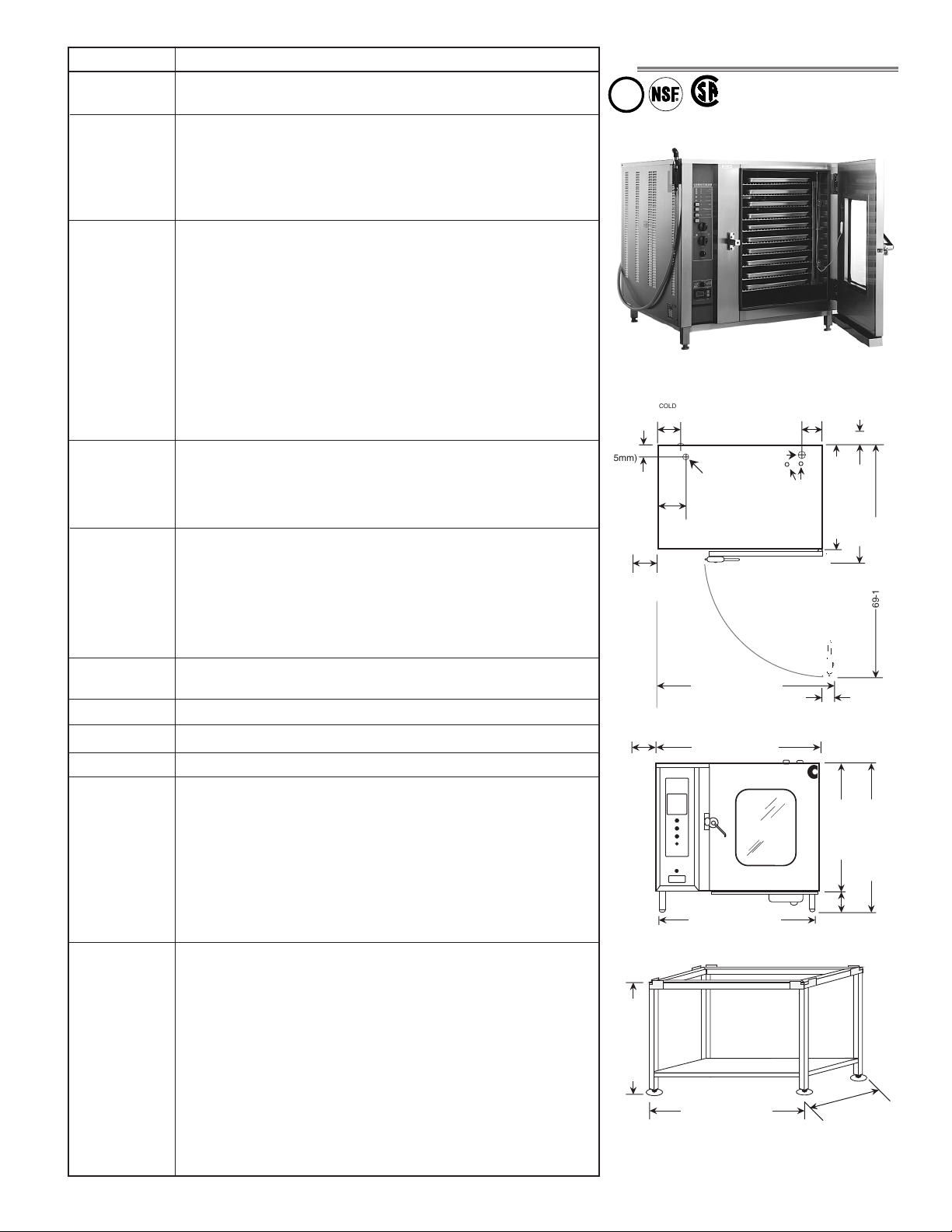

10• 10

Up to approximately 100 lb (c. 45 kg)

TOTAL PAN CAPACITY [maximum]: 75 quarts (c. 95 liters)

FULL-SIZE PANS:

— Ten (10) 20" x 12" x 2-1/2" (530mm x 325mm x 65mm GN 1/1)

HALF-SIZE SHEET PANS*

— Ten (10) 18" x 13" x 1" On wire shelves only

*Extra optional wire shelves required for maximum capacity

INSIDE DIMENSIONS (W x D x H): 23-1/2" x 21-1/8" x 27-1/8"

(597mm x 537mm x 689mm)

— One (1) 15 watt appliance bulb

— One (1) steam generator drain valve with removable cap

— One (1) oven drain screen

— Two (2) stainless steel side racks with ten (10) pan support rails:

SIDE RACK SPACING:

20-7/8" (530mm) horizontal width between rails

2-9/16" (65mm) vertical spacing between rails

— Five (5) stainless steel wire shelves

WIRE SHELF DIMENSIONS: 20-13/16" x 12-3/4"

(530mm x 325mm)

20 gauge stainless steel

OUTSIDE DIMENSIONS (W x D x H ): 40-9/16" x 29-1/16" x 37-3/16"

(c. 1030mm x 738mm x 945mm)

WINDOW DOOR DIMENSIONS (W x H): 14-3/4" x 18-3/4"

(375mm x 476mm)

208-240 V.A.C. — 60 Hz, 1 ph

At 208 V: 66.2 Amps/Phase At 240 V: 76.4 Amps/Phase

13.5 kW — Steamer 18.0 kW — Steamer

13.5 kW — Convection 18.0 kW — Convection

.3 kW — Motor .3 kW — Motor

TOTAL: 13.8 kW TOTAL: 18.3 kW

TERMINAL BLOCK CONNECTION: 2 Wire Plus Ground (AWG 3 or larger)

208-240 V.A.C. — 60 Hz, 3 ph

At 208 V: 38.2 Amps/Phase At 240 V: 44.1 Amps/Phase

13.5 kW — Steamer 18.0 kW: — Steamer

13.5 kW — Convection 18.0 kW: — Convection

.3 kW — Motor .3 kW — Motor

TOTAL: 13.8 kW TOTAL: 18.3W

TERMINAL BLOCK CONNECTION: 3 Wire Plus Ground (AWG 6 or larger)

COLD WATER INTAKE: 3/4" NPT

WATER PRESSURE REQUIREMENTS: 45 psi—minimum 75 psi—maximum

Indirect waste pipe with air gap — 1-1/4" NPT

327 lb (148 kg)

416 lb (189 kg) CRATED W x D x H: 46" x 35" x 45"

(1168mm x 889mm x 1143mm)

●

Oven must be installed level — hood installation required

●

Minimum Clearance Required: Left: 6" (152mm)

Right: 3-3/16" (80mm) for door

Back: 4" (102mm)

Bottom: 5-1/8" (130mm) Legs

Top: Vent Clearance [right, rear]

●

Install water supply shut-off valve

●

Install back-flow preventer

●

Rotation of motor must be in direction of arrow

BIO-STEAMING & PROBE OPTION (

NOT SOLD SEPARATELY)

— Core Temperature Control (CTC) with Digital Display......CC-3760

— Core Temperature Sensor Probe............................PR-3680

CHICKEN ROASTING SHELF (Holds 10 chickens) ...........SH-22634

COUNTER-TOP LEG ASSEMBLY ..................................4504

GREASE TRAY PACKAGE (Use with chicken roasting shelf) .....4757

HIGH OVEN STAND (39-1/4" x 22-1/4" x 38-3/4")

— Accomodates placement of various equipment models .........4931

LOW OVEN STANDS — Stainless Steel w/pan slides .............4554

— Stainless Steel ...........................4557

RETHERMALIZE OPTION (

NOT SOLD SEPARATELY) ............CT-22034

STACKING HARDWARE ............................................5982

VENTLESS HOOD (

SEE SEPARATE SPEC SHEET) ....................15555

WIRE SHELVES: Stainless Steel..............................SH-2903

COMBI OVEN CLEANER

FOUR (4) 1 GAL. CONTAINERS/CASE .........CE-2906

MODEL

PRODUCT

CAPACITY

PAN CAPACITY

INTERIOR

EXTERIOR

ELECTRICAL

WATER

DRAIN

NET WEIGHT

SHIP WEIGHT

IMPORTANT

INSTALLATION

REQUIREMENTS

OPTIONS and

ACCESSORIES

COUNTER-TOP INSTALLATIONS MUST

MAINTAIN

4" (102mm) MINIMUM

CLEARANCE FROM SURFACE.

Pg. 4

(75-mm)

(150-mm)

3"

5-7/8"

COLD WATER INTAKE

4-3/4" (120-mm)

ELECTRICAL

CONNECTION

(130-mm)

WATER DRAIN

(bottom)

5-1/8"

STEAM

VENT

(top)

CLEARANCE

4" (102-mm)

(703-mm)

27-11/16"

29-1/16"—(738-mm)

6"(152-mm)

CLEARANCE

57-3/16"—(1453-mm)

CLEARANCE

6" (152-mm)

27-3/16"

(690-mm)

43-5/8"—(1107-mm)

40-9/16"—(1030-mm)

•

•

•

•

•

n

•

n

•

n

o

39"—(990-mm)

3-3/16" (80-mm)

CLEARANCE

32-1/16"—(815-mm)

5-1/8"

(130-mm)

37-3/16"—(945-mm)

39-1/4"—(998-mm)

LOW OVEN STAND (OPTION)

MODEL 10•10

22-1/4"

(565-mm)

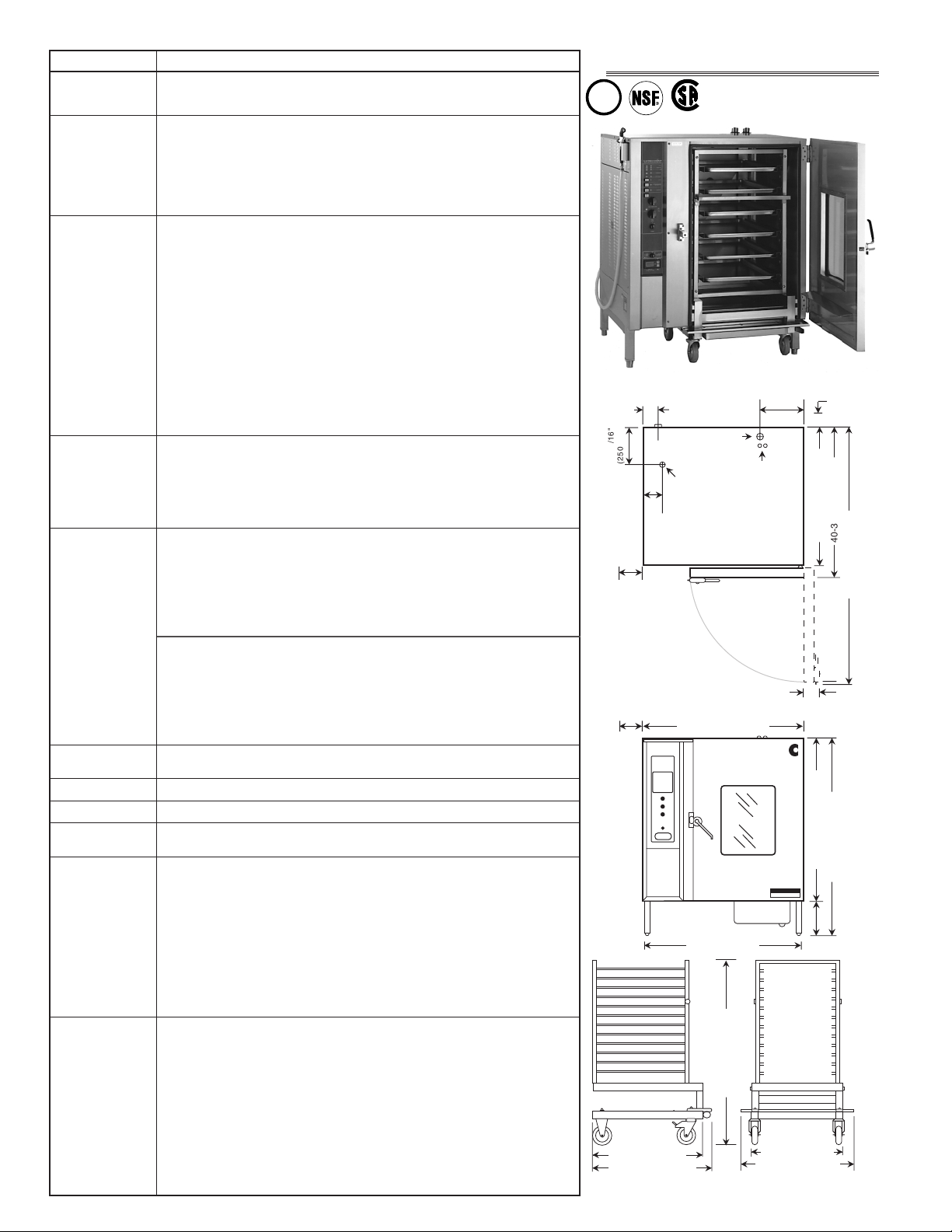

10• 18

Up to approximately 200 lb (c. 90 kg)

TOTAL PAN CAPACITY [maximum]: 150 quarts (c. 190 liters)

FULL-SIZE PANS:

— Twenty (20) 20" x 12" x 2-1/2" (530mm x 325mm x 65mm GN 1/1)

FULL-SIZE SHEET PANS*

— Ten (10) 18" x 26" x 1" On wire shelves only

*Extra optional wire shelves required for maximum capacity

20 gauge non-magnetic (non-corrosive) stainless steel

INSIDE DIMENSIONS (W x D x H): 23-7/16" x 34-1/8" x 31"

(595mm x 866mm x 787mm)

— Two (2) 15 watt appliance bulbs

— One (1) steam generator drain valve with removable cap

— One (1) oven drain screen

— Two (2) stainless steel side racks with ten (10) pan support rails:

SIDE RACK SPACING:

21-1/16" (535mm) horizontal width between rails

2-7/8" (73mm) vertical spacing between rails

— Five (5) stainless steel wire shelves

WIRE SHELF DIMENSIONS: 20-13/16" x 12-3/4"

(530mm x 325mm)

20 gauge stainless steel

OUTSIDE DIMENSIONS (W x D x H): 41-5/16" x 45-1/2" x 41-1/8"

(1049mm x 1155mm x 1045mm)

WINDOW DOOR DIMENSIONS (W x H): 14-3/4" x 18-3/4"

(375mm x 476mm)

208-240 V.A.C. — 60 Hz, 3 ph

At 208 V: 60.3 Amps/Phase At 240 V: 69.6 Amps/Phase

20.1 kW — Steamer 26.7 kW: — Steamer

21.4 kW — Convection 28.6 kW: — Convection

.3 kW — Motor .3 kW — Motor

TOTAL: 21.7 kW TOTAL: 28.9 kW

TERMINAL BLOCK CONNECTION: 3 Wire Plus Ground (AWG 2 or larger)

COLD WATER INTAKE: 3/4" NPT

WATER PRESSURE REQUIREMENTS: 45 psi—minimum 75 psi—maximum

Indirect waste pipe with air gap — 1-1/4" NPT

661 lb (300 kg)

705 lb (320 kg)

●

Oven must be installed level — hood installation required

●

Minimum Clearance Required: Left: 6" (152mm)

Right: 3-3/16" (80mm) For door

Back: 4" (102mm)

Bottom: 5-1/8" (130mm) Legs

Top: Vent Clearance [right, rear]

●

Install water supply shut-off valve

●

Install back-flow preventer

●

Rotation of motor must be in direction of arrow

CHICKEN ROASTING SHELF..................................SH-23000

CHICKEN ROASTING SHELVES - TWO

(1 holds 10 and 1 holds 5) ....4566

COUNTER-TOP LEG ASSEMBLY ...................................4774

GREASE TRAY PACKAGE (use with #4566 Roasting Shelves) ......4758

OVEN STANDS — Stainless Steel with Pan Slides ..................4563

— Stainless Steel ..................................4564

RACK-TRACK .....................................................14151

RACK-TROLLEY...................................................15084

SLIDE-IN PAN-RACK ..............................................15111

STACKING HARDWARE KIT (Stacks 6•10 over 10• 18)..............5196

VENTLESS HOOD (

SEE SEPARATE SPEC SHEET)......................15555

WIRE SHELVES: Stainless Steel ..............................SH-22584

COMBITHERM OVEN CLEANER

FOUR (4) 1 GAL. CONTAINERS/CASE . . . CE-2906

●●

SIZES & SPECIFICATIONS

®

U

L

®

COUNTER-TOP INSTALLATIONS MUST

MAINTAIN

4" (102-mm) MINIMUM

CLEARANCE FROM SURFACE.

MODEL

PRODUCT

CAPACITY

PAN CAPACITY

INTERIOR

EXTERIOR

ELECTRICAL

WATER

DRAIN

NET WEIGHT

SHIP WEIGHT

IMPORTANT

INSTALLATION

REQUIREMENTS

OPTIONS and

ACCESSORIES

Pg. 5

COLD WATER INTAKE

(75mm)

(150mm)

6"(152mm)

6" (152mm)

3"

5-7/8"

CLEARANCE

CLEARANCE

4-3/4" (120mm)

43-15/16"—(1115mm)

41-5/16"—(1049mm)

•

•

•

•

•

n

•

n

•

n

o

39-11/16"—(1008mm)

27-3/16" (690mm)

39-11/16"—(1008mm)

OVEN STAND (OPTION)

WATER DRAIN

ELECTRICAL

CONNECTION

(bottom)

6-5/16"

(160mm)

STEAM

VENT

(top)

3-3/16" (80mm)

CLEARANCE

MODEL 10•18

CLEARANCE

4" (102mm)

41-1/8" (1044mm)

45-1/2"—(1155mm)

36"—(915mm)

41-1/8"—(1045mm)

5-1/8"

(130mm)

35-7/16"

(900mm)

69-11/16"—(1770mm)

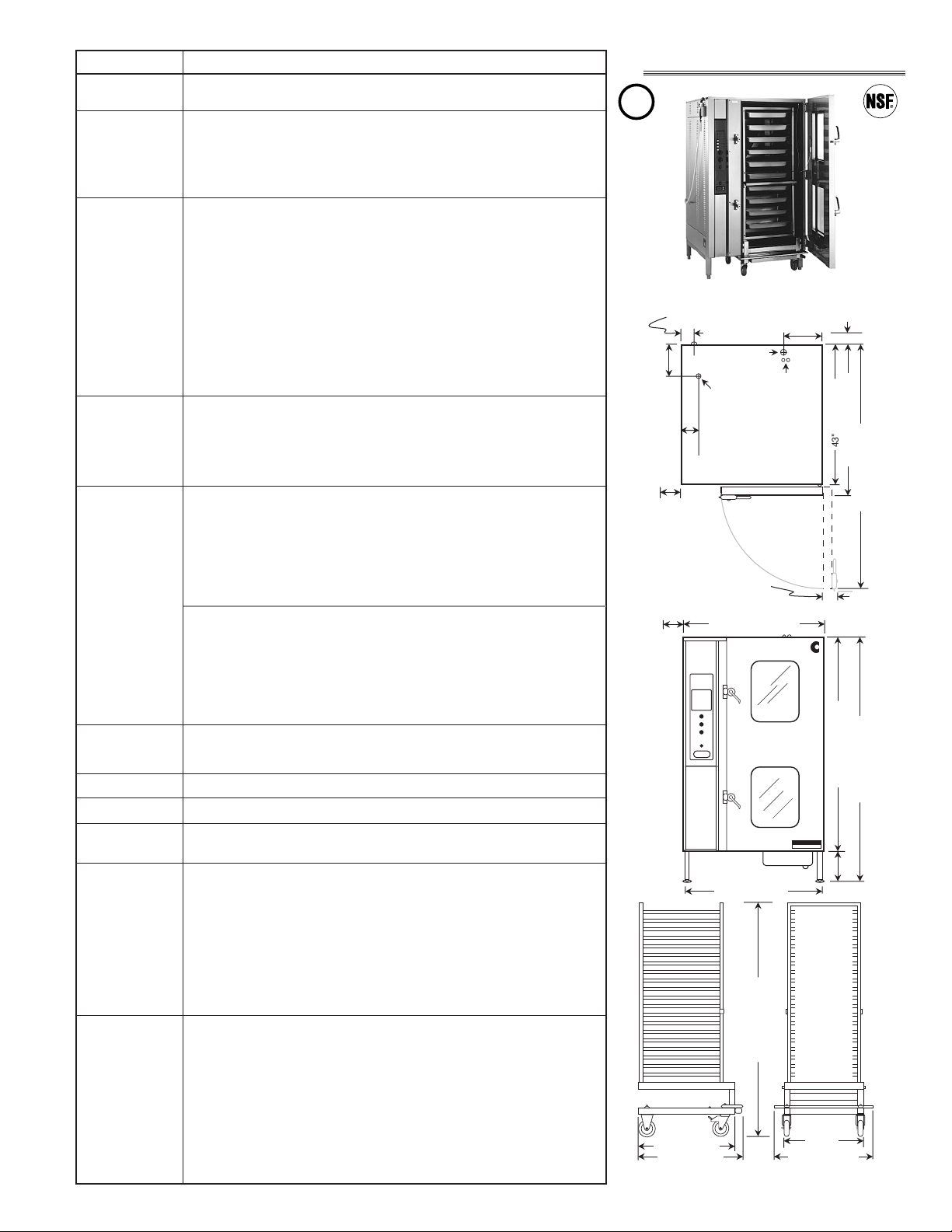

12• 20

Up to approximately 240 lb (c. 108 kg)

TOTAL PAN CAPACITY [maximum]: 180 quarts (

c. 170 liters)

FULL-SIZE PANS: Twenty-four (24) maximum

20" x 12" x 2-1/2"

(530mm x 325mm x 65mm — GN 1/1)

FULL-SIZE SHEET PANS 18" x 26" x 1"

— Six (6) with wire shelves furnished as standard

— Twelve (12) maximum with additional wire shelves

20 gauge non-magnetic (non-corrosive) stainless steel

INSIDE DIMENSIONS (W x D x H): 26-1/4" x 30-1/8" x 38-3/8"

(667mm x 765mm x 975mm)

— One (1) 15 watt appliance bulb

— One (1) steam generator drain valve with removable cap

— One (1) oven drain screen

ROLL-IN CART [5814]:

All stainless steel construction

— Four (4) casters [2 rigid and 2 swivel with brake]

— One (1) removable push-handle

— Twelve (12) pan support rail positions

2-5/8" (67mm) vertical spacing between rails

21-1/8" (537mm) horizontal width between rails

— Six (6) stainless steel wire shelves

20 gauge stainless steel

OUTSIDE DIMENSIONS (W x D x H): 43-7/16" x 40-3/8" x 53-3/4"

(1103mm x 1026mm x 1365mm)

WINDOW DOOR DIMENSIONS (W x H): 14-3/4" x 18-3/4"

(375mm x 476mm)

208-240 V.A.C. — 60 Hz, 3 ph

At 208 V: 75.6 Amps/Phase At 240 V: 87.2 Amps/Phase

24.1 kW — Steamer 32.2 kW: — Steamer

26.9 kW — Convection 35.9 kW: — Convection

.3 kW — Motor .3 kW — Motor

TOTAL: 27.2 kW TOTAL: 36.2 kW

TERMINAL BLOCK CONNECTION: 3 Wire Plus Ground (AWG 2 or larger)

440-480 V.A.C. — 60 Hz, 3 ph

At 440 V: 39.8 Amps/Phase At 480 V: 43.4 Amps/Phase

24 kW — Steamer 28.5 kW — Steamer

30 kW — Convection 35.7 kW — Convection

0.3 kW — Motor 0.3 kW — Motor

TOTAL: 30.3 kW TOTAL: 36.0 kW

TERMINAL BLOCK CONNECTION: 3 Wire Plus Ground (AWG 6 or larger)

COLD WATER INTAKE: 3/4" NPT

WATER PRESSURE REQUIREMENTS: 45 psi—minimum 75 psi—maximum

Indirect waste pipe with air gap — 1-1/4" NPT

510 lb (231 kg)

819 lb (371 kg) CRATED W x D x H: 49" x 47" x 61"

(1245mm x 1194mm x 1549mm)

●

Oven must be installed level

●

Minimum Clearance Required: Left: 6" (152mm)

Right: 4-3/8" (111mm) For door

Back: 4" (102mm)

Bottom: 9-1/8" (232mm) Legs

Top: Vent Clearance [right, rear]

●

Install water supply shut-off valve

●

Install back-flow preventer

●

Rotation of motor must be in direction of arrow

●

Hood installation required

BIO-STEAMING & PROBE OPTION (

NOT SOLD SEPARATELY)

— Core Temperature Control (CTC) with Digital Display.........CC-3760

— Core Temperature Sensor Probe .............................PR-3680

CHICKEN ROASTING SHELF - Holds 6 ..........................SH-23000

CHICKEN ROASTING SHELVES - TWO (1 holds 10 & 1 holds 5)...... 4566

GREASE TRAY PACKAGE (use with chicken roasting shelf) .......... 4758

RETHERMALIZE OPTION......................................CT-22034

ROLL-IN CART .....................................................5814

STAINLESS STEEL WIRE SHELVES

— To accommodate full-size sheet pans .......................SH-22473

Combitherm Oven Cleaner

FOUR (4) 1 GAL. CONTAINERS/CASE........CE-2906

●●

SIZES & SPECIFICATIONS

®

U

L

®

MODEL

PRODUCT

CAPACITY

PAN CAPACITY

INTERIOR

EXTERIOR

ELECTRICAL

WATER

DRAIN

NET WEIGHT

SHIP WEIGHT

IMPORTANT

INSTALLATION

REQUIREMENTS

OPTIONS and

ACCESSORIES

Pg. 6

COLD WATER INTAKE

3-15/16" (100-mm)

9-13/16"

(250-mm)

5-3/16"

(132-mm)

6" (152-mm)

CLEARANCE

CLEARANCE

6" (152-mm)

COMBITHERM

•

•

•

•

•

■

•

■

•

■

29-1/2"—(749-mm)

31-15/16"—(811-mm)

11-13/16"

(300-mm)

WATER DRAIN

ELECTRICAL

CONNECTION

(bottom)

43-7/16"—(1103-mm)

43"—(1092-mm )

50-1/2"—(1282-mm)

TOP VENTS

4-3/8" (111-mm)

CLEARANCE

convotherm

Alto-Shaam

24-1/8"-(617-mm)

30-5/16"—(770-mm)

MODEL 12•20

CLEARANCE

4" (102-mm)

37-13/16"—(960-mm)

40-3/8"—(1026-mm)

68-7/8"—(1749-mm)

43-15/16"—(1116-mm)

53-3/4"—(1365-mm)

20• 20

Up to approximately 400 lb (c. 181 kg)

TOTAL PAN VOLUME [maximum]: 300 quarts (

c. 285 liters)

FULL-SIZE PANS: Forty (40) maximum

20" x 12" x 2-1/2"

(530mm x 325mm x 65mm — GN 1/1)

FULL-SIZE SHEET PANS: 18" x 26" x 1"

— Ten (10) with wire shelves furnished as standard

— Twenty (20) maximum with additional wire shelves

20 gauge non-magnetic (non-corrosive) stainless steel

INSIDE DIMENSIONS (W x D x H): 26-1/2" x 34-7/8" x 60-15/16"

(673mm x 885mm x 1548mm)

— Two (2) 15 watt appliance bulbs

— One (1) steam generator drain valve with removable cap

— One (1) oven drain screen

ROLL-IN CART [5815]:

All stainless steel construction

— Four (4) casters [2 rigid and 2 swivel with brake]

— One (1) removable push-handle

— Twenty (20) pan support rail positions

2-9/16" (65mm) vertical spacing between rails

21" (533mm) horizontal width between rails

— Ten (10) stainless steel wire shelves

20 gauge stainless steel

OUTSIDE DIMENSIONS (W x D x H): 43-5/16" x 45-7/16" x 74-7/8"

(1100mm x 1153mm x 1900mm)

WINDOW DOOR DIMENSIONS (W x H): 14-3/4" x 18-3/4"

[each of two (2) windows] (375mm x 476mm)

208-240 V.A.C. — 60 Hz, 3 ph

At 208 V: 150.9 Amps/Phase At 240 V 174.4 Amps/Phase

33.9 kW — Steamer 39.3 kW — Steamer

53.6 kW — Convection 71.6 kW — Convection

.7 kW — Motors (2) .8 kW — Motors (2)

TOTAL: 54.3 kW TOTAL: 72.4 kW

TERMINAL BLOCK CONNECTION: 3 Wire Plus Ground (AWG 4/0 or larger)

440-480 V.A.C. — 60 Hz, 3 ph

At 440 V: 80.0 Amps/Phase At 480 V: 87.2 Amps/Phase

32.0 kW — Steamer 42.8 kW: — Steamer

60.2 kW — Convection 71.8 kW: — Convection

.6 kW — Motors (2) .6 kW — Motors (2)

TOTAL: 60.8 kW TOTAL: 72.4 kW

TERMINAL BLOCK CONNECTION: 3 Wire Plus Ground (AWG 2 or larger)

COLD WATER INTAKE: 3/4" NPT

WATER PRESSURE REQUIREMENTS:

45 psi—minimum 75 psi—maximum

Indirect waste pipe with air gap — 1-1/4" NPT

786 lb (356 kg)

1079 lb (488 kg) CRATED W x D x H: 49" x 52" x 83"

(1245mm x 1321mm x 2108mm)

●

Oven must be installed level

●

Minimum Clearance Required: Left: 6" (152mm)

Right: 4-3/8" (111mm) For door

Back: 4" (102mm)

Bottom: 9-1/8" (232mm) Legs

Top: Vent Clearance [right, rear]

●

Install water supply shut-off valve

●

Install back-flow preventer

●

Rotation of motor must be in direction of arrow

●

Hood installation required

BIO-STEAMING & PROBE OPTION (

NOT SOLD SEPARATELY)

— Core Temperature Control (CTC) with Digital Display.....CC-3760

— Core Temperature Sensor Probe...........................PR-3680

CHICKEN ROASTING SHELF — HOLDS 6 .......................SH-23000

CHICKEN ROASTING SHELVES - TWO (1 holds 10 & 1 holds 5).......4566

GREASE TRAY PACKAGE (use with chicken roasting shelf) ...........4758

RETHERMALIZE OPTION ....................................CT-22034

ROLL-IN CART ....................................................5815

STAINLESS STEEL WIRE SHELVES

— To accommodate full-size sheet pans ....................SH-22473

Combitherm Oven Cleaner

FOUR (4) 1 GAL. CONTAINERS/CASE ......CE-2906

●●

SIZES & SPECIFICATIONS

®

U

L

MODEL

PRODUCT

CAPACITY

PAN CAPACITY

INTERIOR

EXTERIOR

ELECTRICAL

WATER

DRAIN

NET WEIGHT

SHIP WEIGHT

IMPORTANT

INSTALLATION

REQUIREMENTS

OPTIONS and

ACCESSORIES

Pg. 7

COLD WATER INTAKE

3-15/16" (100-mm)

9-13/16"

4-15/16"

(125-mm)

6"(152-mm)

CLEARANCE

(250-mm)

WATER DRAIN

ELECTRICAL

CONNECTION

(bottom)

TOP VENTS

11-13/16"

(300-mm)

CLEARANCE

4" (102-mm)

43"—(1092-mm)

45-7/16"—(1153-mm)

74-3/4"—(1898-mm)

4-3/8"(111-mm)

CLEARANCE

43-7/16"—(1103-mm)

COMBITHERM

CLEARANCE

6" (152-mm)

■

■

■

•

•

•

•

•

•

•

43"—(1092-mm)

convotherm

Alto-Shaam

65-3/4"—(1670-mm)

74-7/8"—(1900-mm)

71-1/2"—(1816-mm)

29-1/2"—(749-mm)

31-7/8"—(810-mm)

MODEL 20•20

24-5/16"

(617-mm)

30-5/16"—(770-mm)

Loading...

Loading...