Alto Shaam 10.10iN Service Manual

EELLEECCTTRRIICC

MODELS:

6•05

ML

6•10iNML

10•10iN

7•14i

EELLEECCTTRRIICC

SSMMOOKKEERR

MODELS:

6•10iN/SK

10•10iN/SK

7•14i/SK

INSTALLATION

MAINTENANCE

AND

SERVICE MANUAL

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 ●U.S.A.

PHONE: (262)251-3800 (800)558-8744

U.S.A./CANADA FAX: (262)251-7067 (800)329-8744 U.S.A.

www.alto-shaam.com

PRINTED IN USA #6002•09/06

COMBINATION OVEN/STEAMERS

COMBITHERM ELECTRIC BOILER-FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 1

COMBITHERM®INSTALLATION

DELIVERY

This Alto-Shaam appliance has been

thoroughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and

report it at once to the delivering carrier. See

Transportation Damage and Claims section

located in this manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

NOTE: All claims for warranty must include the

full model number and serial number of

the unit.

UNPACKING

1. Carefully remove the appliance from the

carton or crate.

NOTE: Do not discard the carton and other

packaging material until you have

inspected the unit for hidden damage

and tested it for proper operation.

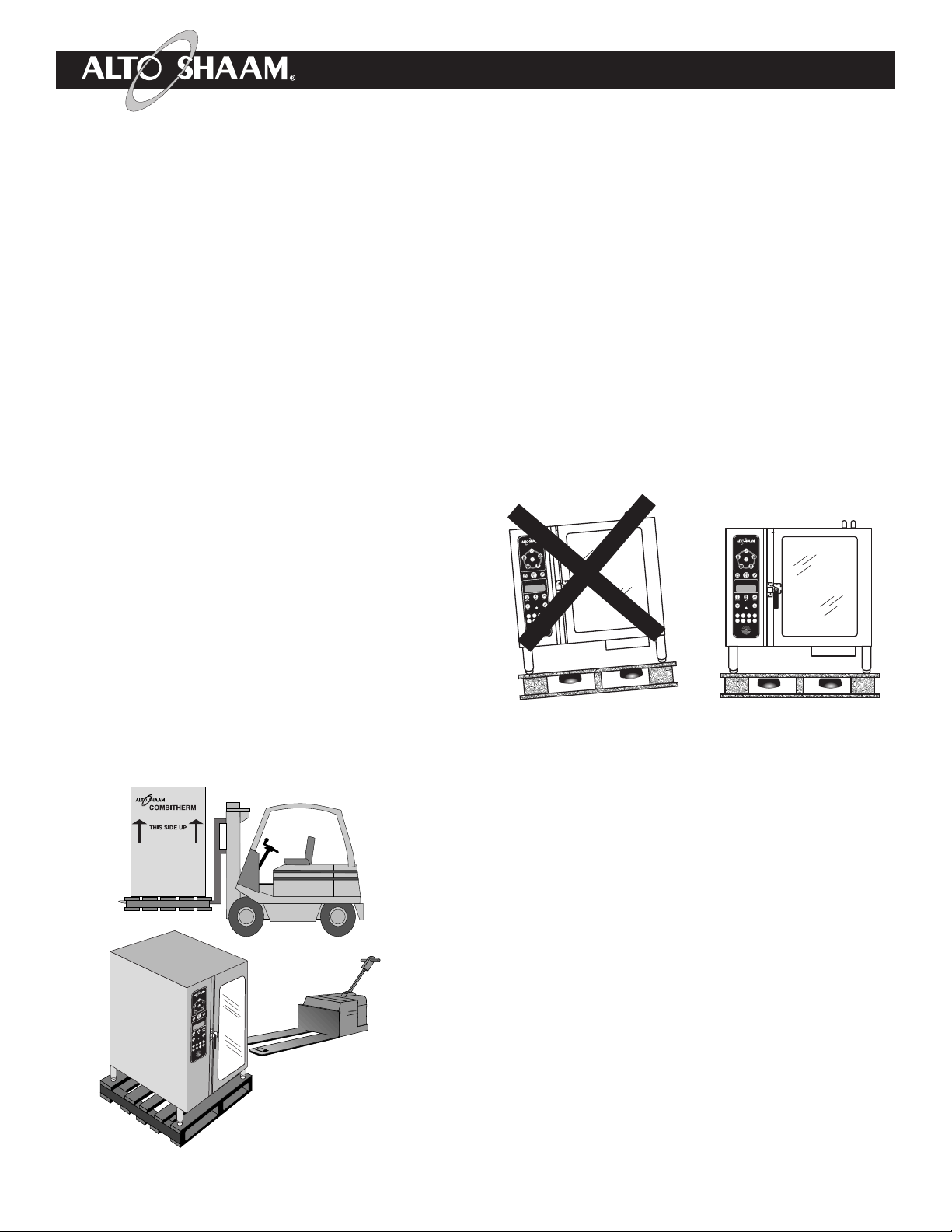

2. The oven must remain on the pallet

while being moved to the installation

site by fork lift or pallet lift truck.

Note dimensions required for doorways and aisles

for access of the oven and pallet to the

installation site. Transport the oven in an upright

and level position only. Do not tilt the oven.

With the oven on the original pallet, remove the

carton and all packaging materials. Open the

oven door and remove all documents and other

materials from the oven interior. Remove the

roll-in cart if so equipped.

3. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto-Shaam

service department.

4. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

#6002 COMBITHERM ELECTRIC BOILER- FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 2

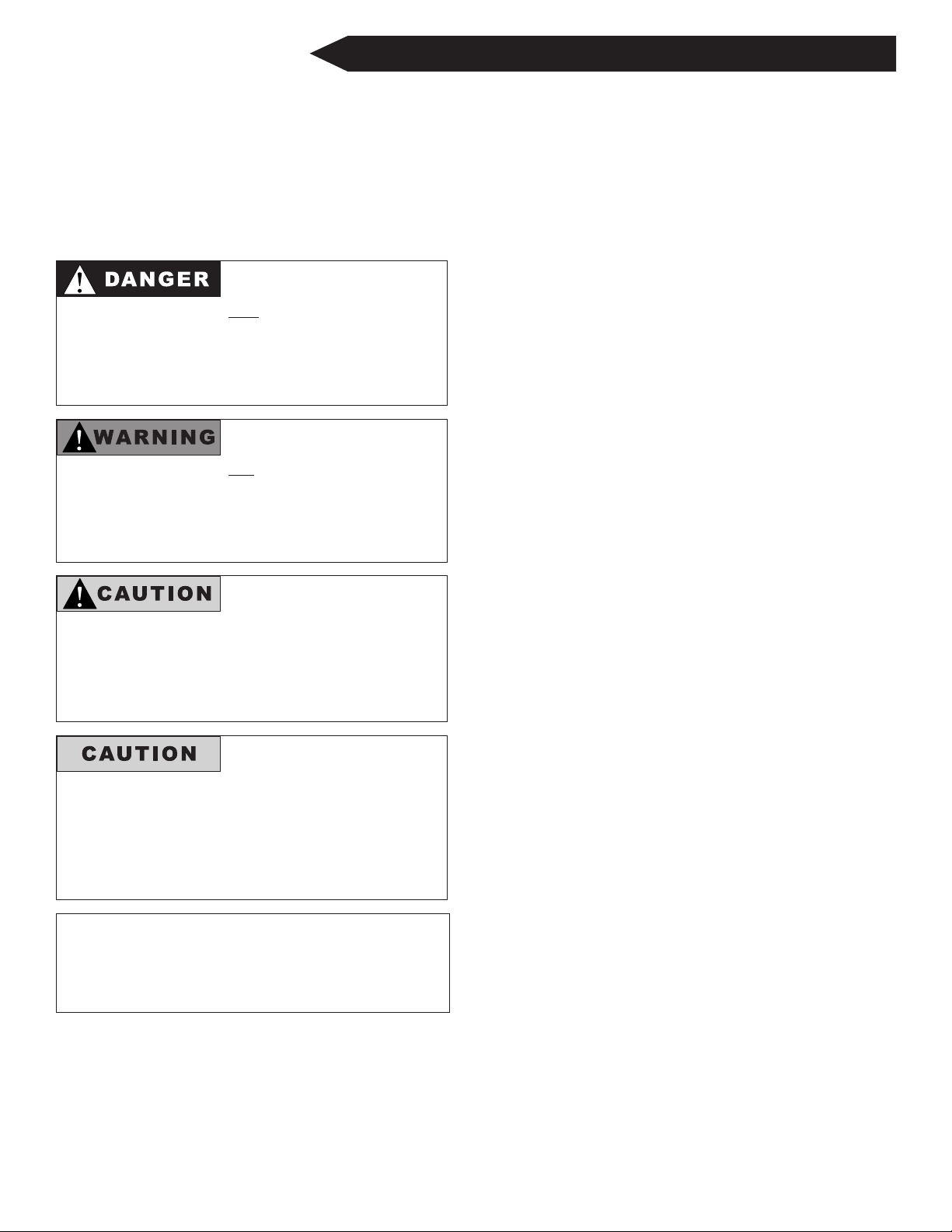

SAFETY PROCEDURES

AND PRECAUTIONS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

Used to indicate the

presence of a hazard that

will cause severe personal

injury, death, or substantial

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can cause personal injury,

possible death, or major

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor or

moderate personal injury

or property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor

personal injury, property

damage, or a potential

unsafe practice if the

warning included with this

symbol is ignored.

Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this

appliance is authorized or recommended.

2. This appliance is intended for use in

commercial establishments where all

operators are familiar with the purpose,

limitations, and associated hazards of this

appliance. Operating instructions and

warnings must be read and understood by

all operators and users.

3. Any troubleshooting guides, component

views, and parts lists included in this manual

are for general reference only and are intended

for use by qualified technical personnel.

4. This manual should be considered a

permanent part of this appliance. This

manual and all supplied instructions,

diagrams, schematics, parts lists, notices, and

labels must remain with the appliance if the

item is sold or moved to another location.

NOTE:

COMBITHERM ELECTRIC BOILER-FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 3

COMBITHERM®INSTALLATION

N

O

T

E

Where automatically operated appliances are vented through a ventilating hood or exhaust

system equipped with a damper or with a power means of exhaust, provisions shall be made

to allow the equipment to operate only when the damper is open to a position to properly

vent the appliance and when the power means of exhaust is in operation.

IN ACCORDANCE WITH NFPA 54 COMMONWEALTH OF MASSACHUSETTS ONLY.

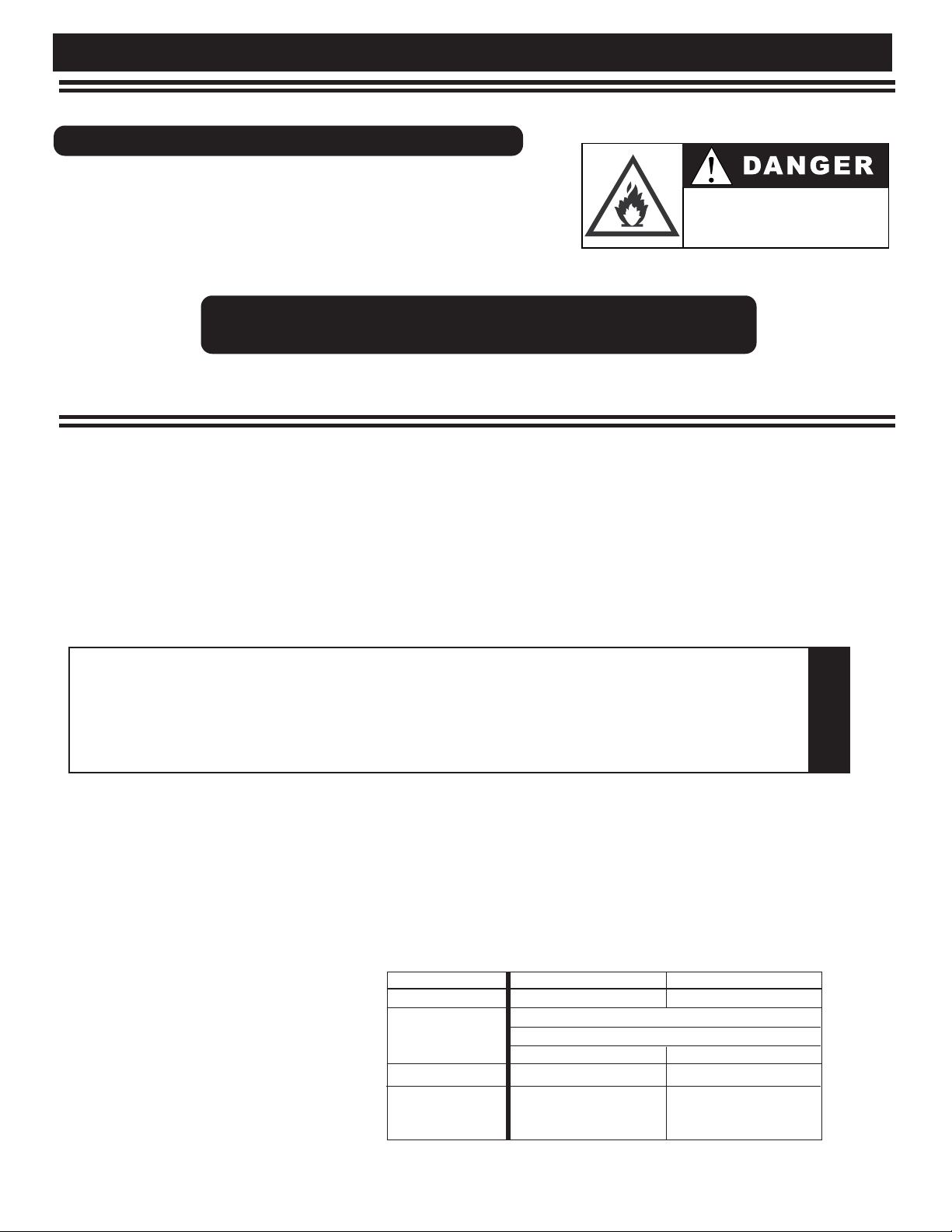

BASIC INSTALLATION SITE REQUIREMENTS

HOOD INSTALLATION IS REQUIRED

• Installation surface must be level.

• Do not install adjacent to flammable surfaces.

• Deep fat fryers or similar heat producing

equipment must not be installed in the

immediate vicinity of the hand shower.

The oven must remain on the pallet while being moved

to the installation site with fork lift or pallet lift truck.

Do not tilt the oven.

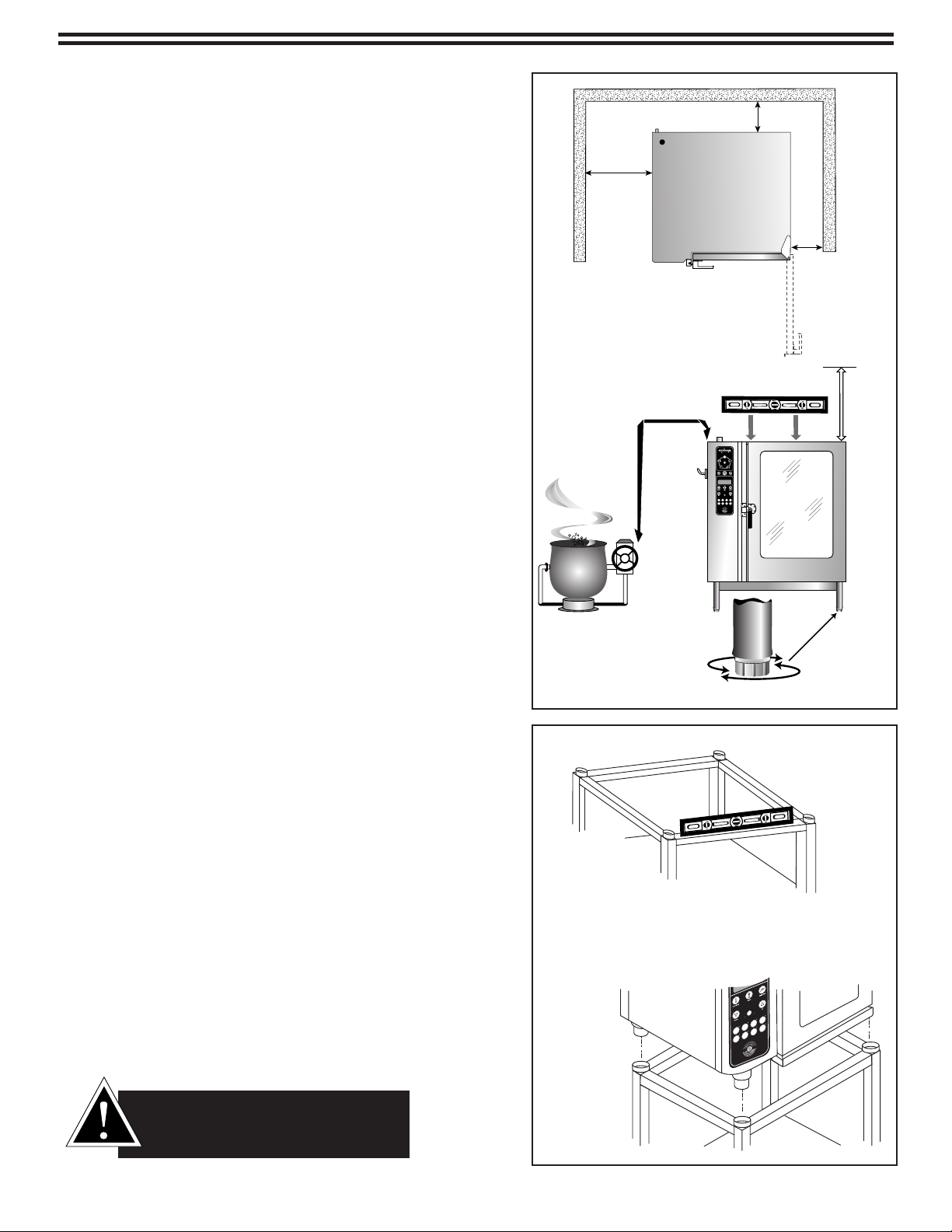

VENTILATION REQUIREMENTS

A steam ventilation hood is mandatory for the operation of the oven. The ventilation hood must be installed

in accordance with local building codes for steam exhaust and must protrude 12-inches to 20-inches

(300mm to 500mm) over the front side of the oven. A grease filter must be located in the protruding area of

the hood. Grease filters should be thoroughly cleaned on a regular basis following manufacturer's

instructions. Ventilation hoods must ensure an adequate amount of incoming air during operation and must

be operated whenever the combination oven/steamer is used in order to avoid the accumulation of

condensation in the hood area.

If a ventless hood is to be installed, we recommend the

Combitherm Ventless Hood for the appropriate model oven.

VHML5

Combitherm model 6•05, 6•10iNML, and 10•10iN

VHML-10

Combitherm model 7•14i

MODEL

Air Movement

Drain Connection

Electrical

Ship Weight

Replacement

Filters GREASE

CHARCOAL

VHML-5

530 CFM

100 watts, .50 amps

100 lb (45 kg)

FI-24113

FI-24114

VHML-10

1200 CFM

240 watts, 1.0 Amps

126 lb (57 kg)

FI-23062

FI-24102

3/4" (19,1mm) NPT

208-240 V.A.C. — 50/60 Hz, 1 ph

DO NOT store or use any flammable

liquids or allow flammable vapors

in the vicinity of any appliance.

#6002 COMBITHERM ELECTRIC BOILER- FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 4

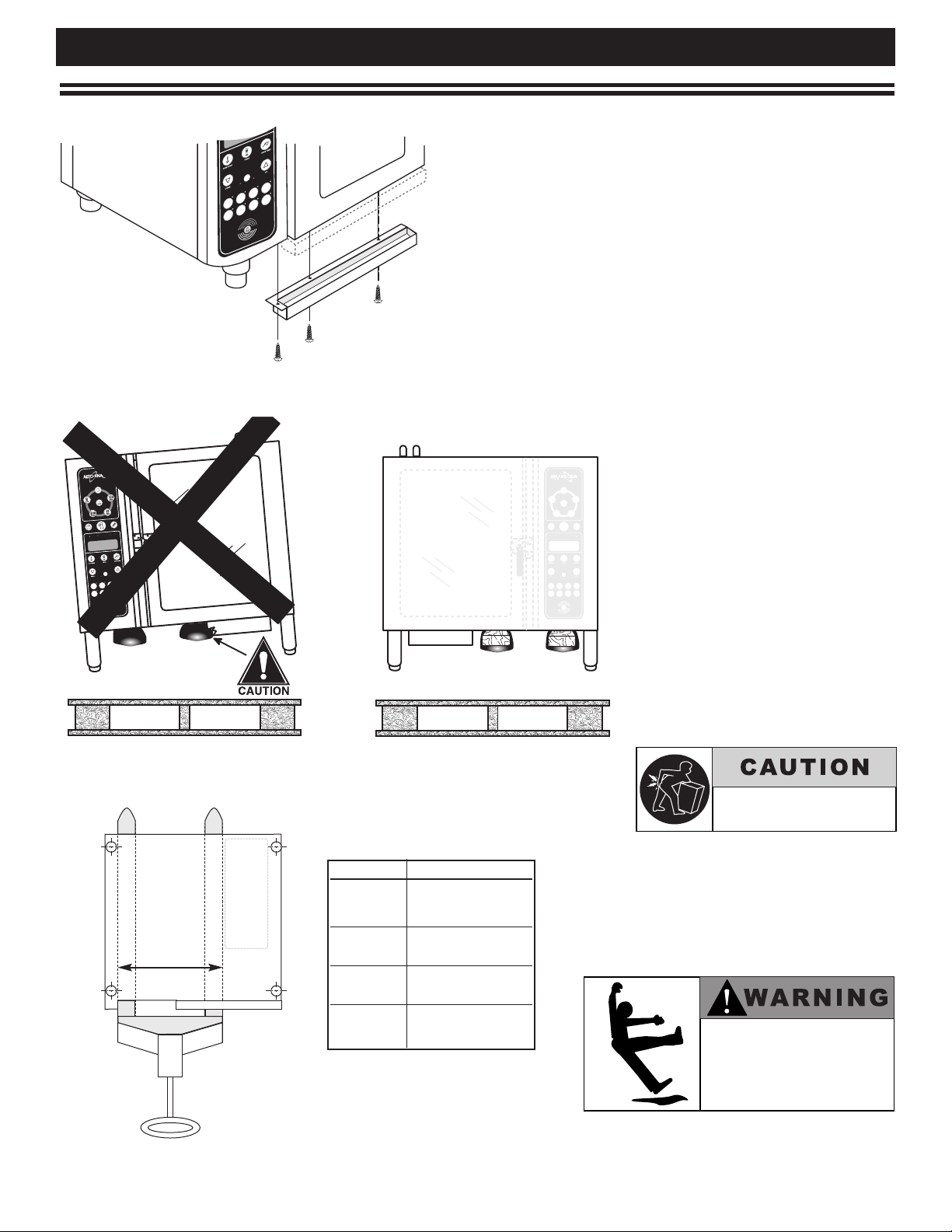

POSITIONING ON SITE

Before removing the oven from the pallet for

positioning on site, it is important to remove the drip

tray to prevent damage to the tray caused by the

lifting forks. The drip tray is fastened to the bottom of

the oven with three sheet metal screws as illustrated.

This requirement pertains to the following models.

Lift the oven from the pallet

with a fork lift or pallet lift

truck positioned at the front

of the oven. To avoid

damage, position the lift forks

to the left of the condenser as

indicated in one of the two

diagrams shown below. For

additional damage protection,

the use of two wooden boards,

placed between the bottom of

the oven and the lifting forks,

is strongly recommended.

After the oven is correctly

positioned on site, reattach the

drip tray.

MODEL

6•05

6•10iN

10•10iN

7•14i

NET WEIGHT

180 lb (82 kg)

285 lb (129 kg)

385 lb (175 kg)

405 lb (184 kg)

8"

(203mm)

CONDENSER

MODELS 6• 05

6•10iN

ML 6•10iN/SK

10•10iN 10•10iN/SK

7•14i 7•14i/SK

COMBITHERM®INSTALLATION

➤

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

FAILURE TO PROPERLY INSTALL

THE DRIP TRAY CAN OR WILL

CAUSE MAJOR EQUIPMENT

DAMAGE AND WILL RESULT IN A

LEAKAGE HAZARD THAT CAN

CAUSE PERSONAL INJURY.

COMBITHERM ELECTRIC BOILER-FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 5

INSTALLATION REQUIREMENTS

■■

■■

Do not install oven adjacent to flammable

surfaces. Strictly observe all local fire

safety regulations.

■■

■■

In order to ensure proper ventilation, a minimum

distance of at least 6-inches (152mm) must be kept

from the control panel side [LEFT] of the oven and

any adjoining surfaces.

NOTE: In addition to ventilation requirements,

additional clearance is needed for service access.

A minimum distance of 18-inches (457mm) is

strongly recommended. If adequate service

clearance is not provided, it will be necessary to

disconnect the gas, water, and drain to move the oven

with a fork lift for service access. Charges in

connection with inadequate service access is not

covered under warranty.

■■

■■

Allow a minimum of 4-inches (102mm) from the

right side of the oven to allow the door to open to

at least a 90° angle. Fully opened, the door will

extend up to a 225° angle. If the oven is furnished

with the retractable door option, allow a minimum

clearance of 6-1/2-inches (16cm).

■■

■■

Allow a minimum clearance of

4-inches (102mm) from the back of the oven

for plumbing connections.

■■

■■

Allow a 20-inch (50cm) clearance at the top of the

oven for free air movement and for the steam vent(s)

located at the top [RIGHT-REAR].

■■

■■

Do not install the oven adjacent to heat producing

equipment such as fryers, broilers, etc. Minimum

clearance recommended: 20-inches (50cm).

Place the Combitherm oven on a stable, non-combustible

LEVEL horizontal surface. For counter-top models, the

oven stand must be level. In addition, the overall height

of the oven should be positioned so the operating

controls and shelves may be conveniently reached

from the front.

ALL INSTALLATION INSTRUCTIONS

AND REQUIREMENTS MUST BE

STRICTLY OBSERVED.

IMPROPER CONNECTION

OF THIS APPLIANCE

NULLIFIES ALL WARRANTIES.

18"

(46cm)

MINIMUM

20"

(50cm)

(102mm)

4"

4" (102mm)

RETRACTABLE

DOOR OPTION:

6-1/2" (165mm)

20"

(50cm)

#6002 COMBITHERM ELECTRIC BOILER- FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 6

COMBITHERM®INSTALLATION

ASSEMBLY REQUIREMENTS

HAND SHOWER HOLDER

Fasten the hand shower holder in the holes

provided on the oven using the three (3)

screws packaged

with the holder.

DRIP TRAY INSTALLATION

Hang the drip tray at the front of the oven

as indicated on the drawing.

FAILURE TO PROPERLY INSTALL

THE DRIP TRAY CAN OR WILL

CAUSE MAJOR EQUIPMENT

DAMAGE AND WILL RESULT IN A

LEAKAGE HAZARD THAT CAN

CAUSE PERSONAL INJURY.

IMPROPER INSTALLATION, ALTERATION,

ADJUSTMENT, SERVICE OR MAINTENANCE

COULD RESULT IN SEVERE INJURY, DEATH

OR CAUSE PROPERTY DAMAGE.

COMBITHERM ELECTRIC BOILER-FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 7

COMBITHERM®INSTALLATION

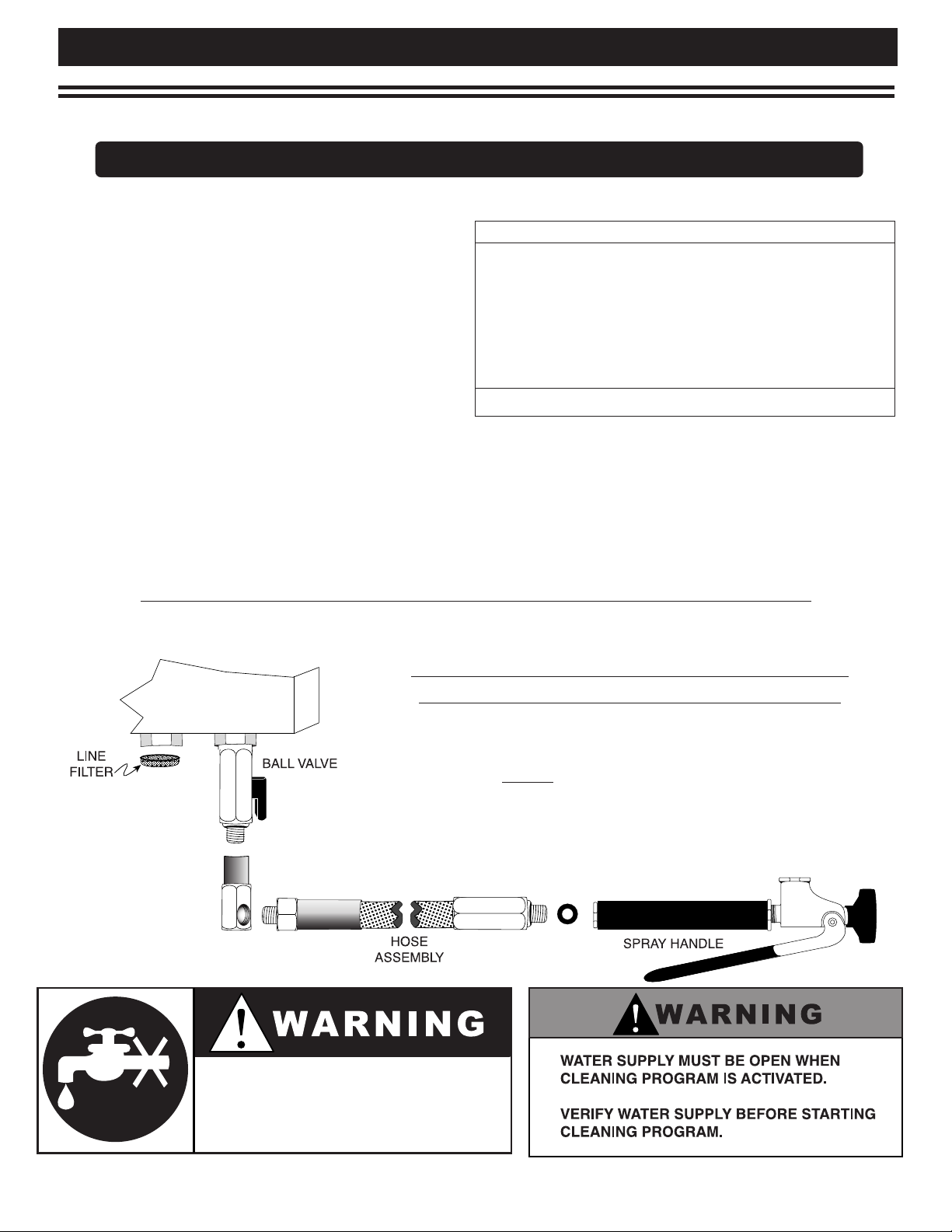

WATER SUPPLY

CONNECT TO POTABLE (DRINKABLE) COLD WATER ONLY

A water conditioning system is recommended if the

water supply is between 5 and 9 grains of hardness.

If water tests over 9 grains of hardness, the

installation of a water softener is strongly

recommended. Without treated water and

the use of Alto-Shaam's CombiGuard™, the

operation life of the unit will be diminished

and affect the warranty.

Flush the water line at the installation site before connecting the oven to the water supply. A shut-off valve

and approved back-flow preventer must be installed when connecting the oven to the cold water intake.

The water supply line must be a minimum of 3/4-inch NPT (19mm). Install the line filter at the cold water

intake connection point.

PIPE SEALING TAPE (TEFLON®) MUST BE USED AT ALL CONNECTION POINTS.

The use of a pipe sealing compound is not recommended.

THE MAIN WATER SHUT-OFF VALVE MUST BE IN THE

OPEN POSITION WHEN THE OVEN IS BEING USED.

The hand shower spray hose is installed adjacent to the cold water

intake connection. A ball valve is installed on the oven for hose

connection to the COLD water source. Assemble the washer and

the flexible hose on the ball valve and hang the spray handle on the

holder previously installed on the oven.

ELBOW

WATER

COLD WATER INLET — DRINKING QUALITY

INDIRECT WASTE PIPE WITH AIR GAP: 1-1/4" NPT

INLET: 3/4" NPT LINE PRESSURE: 30 to 90 psi

2.8 to 6.2 bar

CHLORINE: less than 0.8 ppm CHLORIDE: less than 70 ppm

HARDNESS: 5 to 9 gpg PH RANGE: 7.0 to 9.0

85 to 154 ppm

WATER SOFTENER SHOULD BE UTILIZED IN HARD WATER AREAS.

WATER OUTLET: 1-1/4” (33mm) DRAIN WITH AIR GAP

TO PREVENT WATER PIPES OR HOSES

FROM BURSTING, INCOMING WATER

SUPPLY SHOULD BE TURNED OFF WHEN

THE APPLIANCE IS NOT IN USE.

COMBITHERM®INSTALLATION

#6002 COMBITHERM ELECTRIC BOILER- FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 8

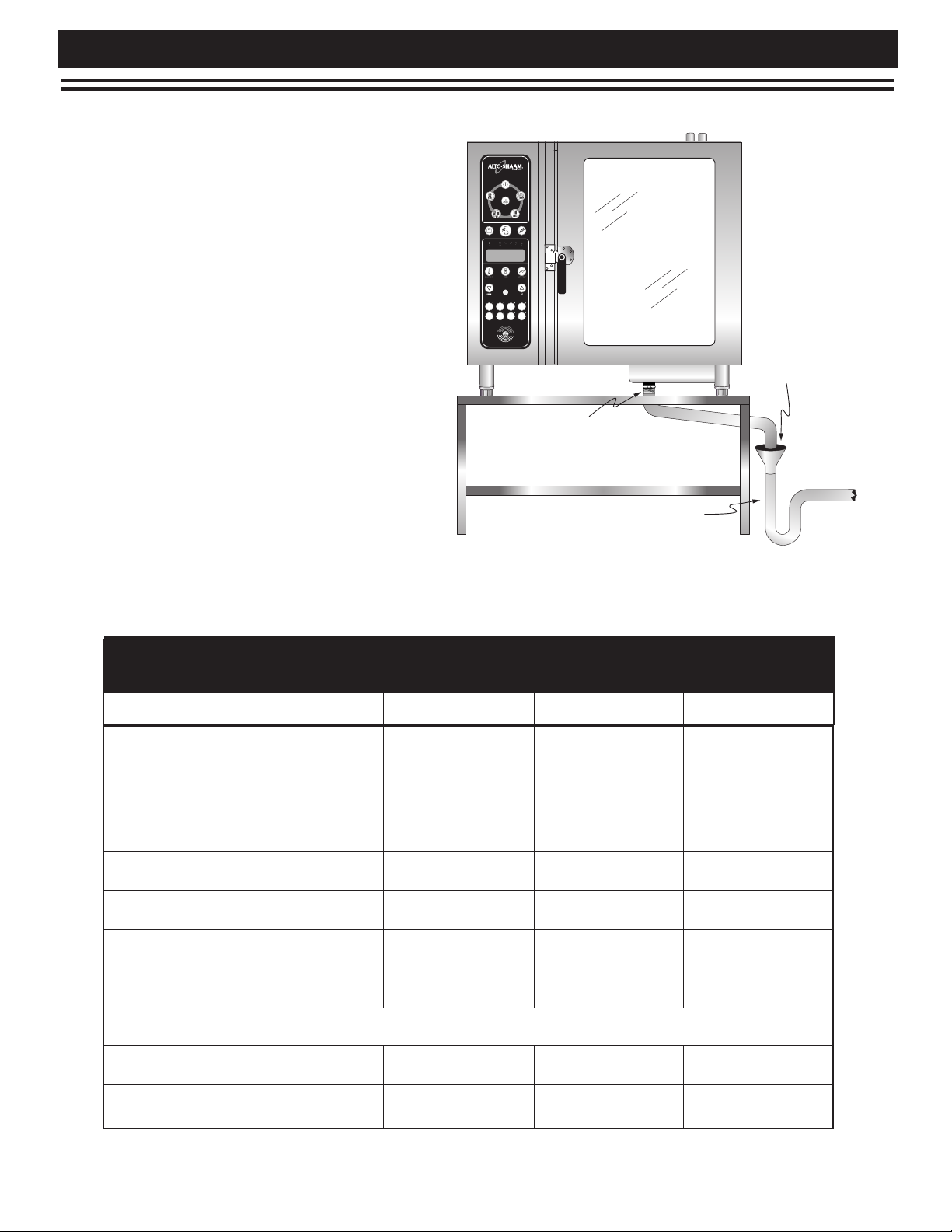

WATER DRAINAGE

The oven must discharge through an indirect

waste pipe by means of an air gap. The drain

thread is 1-1/4-inch (32mm) NPT.

A union is required. Install a 1-1/4-inch

(32mm) diameter drain line. The drain line

must always be a positive gradient away

from the Combitherm oven and not more than

12-inches (305mm) before an air gap.

NOTE: In the U.S.A., this equipment is to be

installed to comply with the Basic

Plumbing Code of the Building

Officials and Code Administrators

International, Inc. [BOCA], and the

Food Service Sanitation Manual of the

Food & Drug Administration [FDA].

If several units are to be connected to one

drain pipe, the dimensions of the pipe must be

sufficient to allow an unobstructed water drain system.

Type of Oven counter counter counter counter

oven stand oven stand oven stand oven stand

Pan INCHES 6: 12" x 10" 6: 12" x 20" 10: 12" x 20" 14: 12" x 20"

Capacity 12: 12" x 6" 6: 18" x 13" 10: 18" x 13" 7: 18" x 26"

12: 12" x 10"

GASTRONORM 6: GN 1/2 6: GN 1/1 10: GN 1/1 14: GN 1/1

12: GN 1/3 18: GN 1/3

Side Rack INCHES 2-5/8 2-5/8 2-5/8 2-5/8

Spacing (MILLIMETERS) (65mm) (65mm) (65mm) (65mm)

Interior INCHES 15-1/4 13-1/4 13-1/4 23-1/2

Width (MILLIMETERS) (596) (387) (387) (596)

Interior INCHES 17-7/8 26-1/4 26-1/4 28-7/16

Depth (MILLIMETERS) (455) (665) (665) (722)

Interior INCHES 17-3/4 17-3/4 27 20-5/16

Height (MILLIMETERS) (450) (450) (685) (515)

Noise

Level

Spray Hose 81-inches 81-inches 81-inches 81-inches

Length (2050mm) (2050mm) (2050mm) (2050mm)

Water Consumption 3 - 5 gal/hr 4 - 6 gal/hr

(

APPROX.) (12 - 20 l/hr) (15 - 25 l/hr)

ADDITIONAL TECHNICAL DATA

6•05ML 6• 10-iNML 10• 10iN 7• 14i

MODEL ➜➜

The noise emission level related to the workplace is lower than: 70 dBA

AVERAGE

DRAIN WATER

TEMPERATURE

149°F (65°C)

2" (51mm)

Air Gap

1-1/4" (32mm) diameter NPT

WASTE PIPE

1-1/2" to 2" minimum diameter

(c. 38mm to 51mm)

COMBITHERM ELECTRIC BOILER-FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 9

ELECTRICAL INSTALLATION

An electrical wiring diagram is located behind the

control panel on the left side of the oven. The oven

must be installed by a qualified electrician. This

appliance must be branch circuit protected with

proper ampacities, in accordance with the wiring

diagram located in the electrical compartment of the

oven. The oven must be properly grounded in

accordance with the National Electrical Code and

applicable local codes.

Wire size for the main incoming power to the unit

must match the minimum size listed in the

specifications applicable to the specific oven

model. For supply connections, locate the wire

size posted on the label located on the electrical

control box cover, behind the service panel or

elsewhere listed in this manual.

When connecting to a Delta-B (wild leg) on a 3phase system, the wild leg must be connected to

line 3.

Before operating the oven, check all cable

connections in the electrical connection area

for tightness since connections can loosen

during transport.

NOTE: After both water and electrical

connections have been completed,

operate the oven in any cooking

mode for a period of 15 minutes and

recheck the main power connections

at the terminal block to make

certain they remain tight.

COMBITHERM®INSTALLATION

ELECTRICAL CONNECTIONS MUST

BE MADE BY A QUALIFIED SERVICE

TECHNICIAN IN ACCORDANCE WITH

APPLICABLE ELECTRICAL CODES.

MOTOR

with

Rotation Direction

Terminal

Block

Ground

Electrical

Connection

FOLLOWING ELECTRICAL CONNECTION,

THE FAN

DIRECTION AS THE ARROW LOCATED

ON THE OVEN FAN MOTOR.

THIS APPLIANCE

PROPERLY AND DAMAGE CAN OCCUR IF

THE MOTOR ROTATION IS NOT CORRECT.

Electrical

Panel

MUST

ROTATE IN THE SAME

WILL NOT

FUNCTION

TO CHANGE MOTOR DIRECTION,

EXCHANGE TWO OF THE INCOMING PHASES

.

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be made

in accordance with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

RESTRAINT REQUIREMENTS — MOBILE EQUIPMENT

Any appliance that is not furnished with a power supply

cord but that includes a set of casters must be provided

with a tether. Adequate means must be provided to limit

the movement of this appliance without depending on or

transmitting stress to the electrical conduit. The

following requirements apply:

1. Casters must be a maximum height of 6" (152mm).

2. Two of the casters must of be the locking type.

3. Such mobile appliances or appliances on mobile stands must be

installed with the use of a flexible connector secured to the

building structure.

A mounting connector for a restraining device is located on the

lower back flange of the appliance chassis or on an oven stand,

approximately 18" (457mm) from the floor. A flexible connector is

not supplied by nor available from the factory.

#6002 COMBITHERM ELECTRIC BOILER- FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 10

COMBITHERM®INSTALLATION

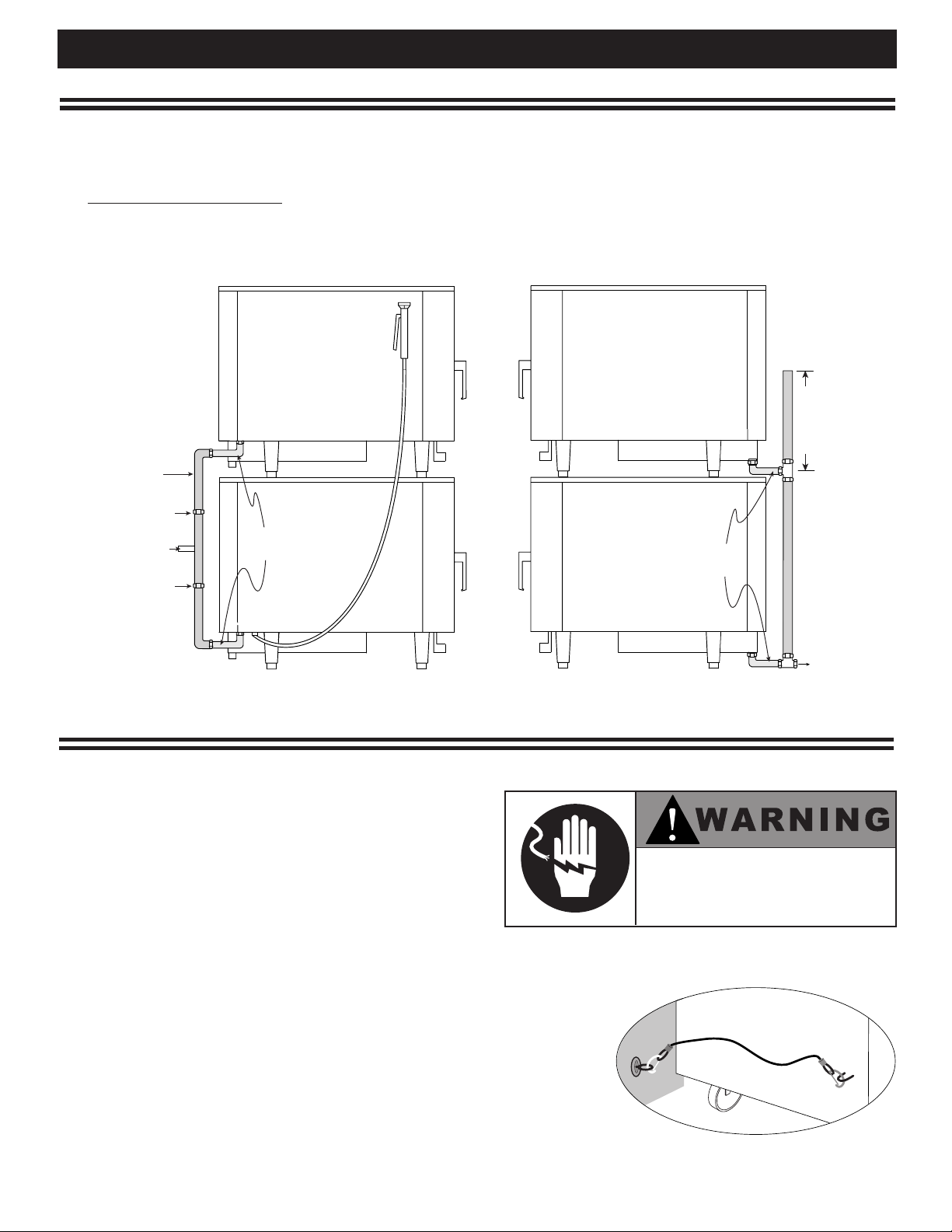

STACKING INSTALLATION

Stacking Combitherm ovens require two (2) water connections, two (2) drain connections, and two (2)

electrical connections.

If local code allo

If local code allowsws,,

the water and drain may be manifolded as long as the size of the water inlet is increased to

1-inch (25,4mm) and the drains include an external vent. The drawing illustrates one

suggested method of a manifold installation.

RISK OF ELECTRIC SHOCK.

Appliance must be secured

to building structure.

WATER INTAKE DRAIN

1"

(25,4mm)

VENT

15" (381mm)

UNION

Intake

1" (25,4mm)

UNION

3/4"

(19mm)

1-1/4"

(32mm)

1-1/2" (38mm)

COMBITHERM ELECTRIC BOILER-FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 11

CLEARANCES:

All clearances must conform with the standards set by Alto-Shaam as indicated in

the installation manual. Standards include a minimum 20” (50cm) clearance from

any heat-producing device such as an open burner range, flat top grille, fryer,

steamer, etc. Also make sure sufficient service access is provided on the left side

of the oven. There must be an allowance of free air access to all vents.

RIGHT SIDE CLEARANCE: ______________

LEFT SIDE CLEARANCE: ______________

REAR CLEARANCE: ______________

UPPER CLEARANCE: ______________

WATER SUPPLY AND DRAINS:

Verify hook-up to cold water supply with a 3/4” (19mm) single water connection

supply line. Verify inlet water pressure is at a minimum of 30 PSI (2 bar) for electric

ovens. Maximum pressure is not to exceed 90 PSI (6 bar). Verify the installation of a

water filter and the installation of a water conditioner if water supply is over 10 grains

of hardness. Verify drain diameter of 1-

1

/4” (32mm) with a positive descending slope,

and with a 2” (51mm) air gap which is free of obstructions before connection to the site

drain. Verify

1

/8 ” (3,2mm) pitch to 10’ (305cm) of drain line. After pressure is

adjusted, seal screw with enamel such as nail polish.

WATER SUPPLY LINE DIA: ______________

COLD WATER:

■■ YES ■■ NO

WATER INLET PRESSURE: ______________

DRAIN LINE DIA: ______________

2” (51mm) AIR GAP:

■■ YES ■■ NO

ELECTRICAL CONNECTIONS:

Verify electrical power requirements

for oven. Verify voltage at terminal

block. Verify correct power cable

size. Verify equipment disconnect per NEC or applicable local

codes. Motor direction should correspond with the direction of

the arrow on the motor. Verify clockwise motor rotation from

the rear of the motor. Check all terminals for tightness.

LINE VOLTAGE AT TERMINAL BLOCK (TO GROUND):

➥ LINE 1: _________ LINE 2:_________ LINE 3: _________

LINE VOLTAGE (

PHASE TO PHASE): LINE 1 to 2: __________

LINE 2 to 3: __________

LINE 3 to 1: __________

ELECTRICAL SUPPLY LINE SIZE: ______________

CORRECT MOTOR ROTATION:

■■ YES ■■ NO

ALL ELECTRICAL TERMINALS TIGHT:

■■ YES ■■ NO

VOLTA G E : ______________

PHASE: ______________

CONTROL BOARD CONNECTIONS & OPERATION:

Verify all control board connections are tight including tightness

and proper connection of ribbon/computer cables. Verify all

buttons and lights illuminate. With the Power Key

OFF, press and

hold the Chef Function Key to access software version, and record.

Verify all functions operate.

ALL BOARD CONNECTIONS TIGHT: ■■ YES ■■ NO

ALL FUNCTIONS LIGHT UP: ■■ YES ■■ NO

ALL FUNCTIONS OPERATE:

■■ YES ■■ NO

SOFTWARE VERSION:

BM_____________ SM_____________ KM_____________

PHYSICAL CONDITION: ✔

Bottom of oven has been checked for damage due to improper positioning on site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .■■

Verify all gaskets, hoses, and carts are in place and function properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .■■

If oven includes a cart, verify proper installation of the rack guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .■■

Verify the installation of drip pans, racks, shelves, drain screen, spray hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .■■

Verify the oven is level and installed on a solid, water resistant floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

■■

SERVICE AGENCY:_____________________________________ START-UP DATE: _____________________________________

INSTALLATION NAME:_________________________________

SIGNATURE:___________________________________________ SIGNATURE:_________________________________________

CUSTOMER

TECH

ELECTRIC COMBITHERM INSTALLATION CHECKLIST

Use this list as a final check of oven installation conformance. Damage directly attributed to

improper set up, installation, or cleaning can invalidate warranty claims.

®

#6002 COMBITHERM ELECTRIC BOILER- FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 12

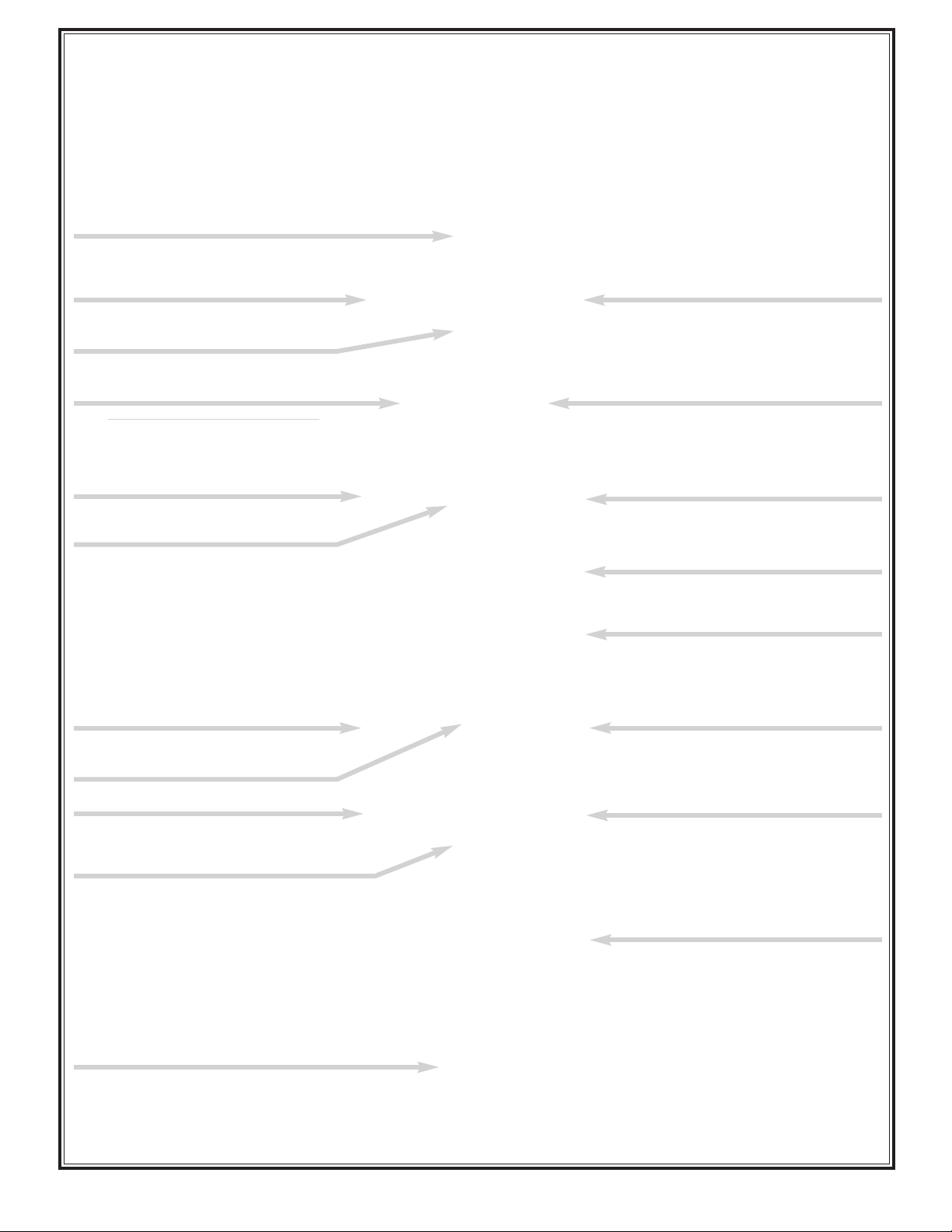

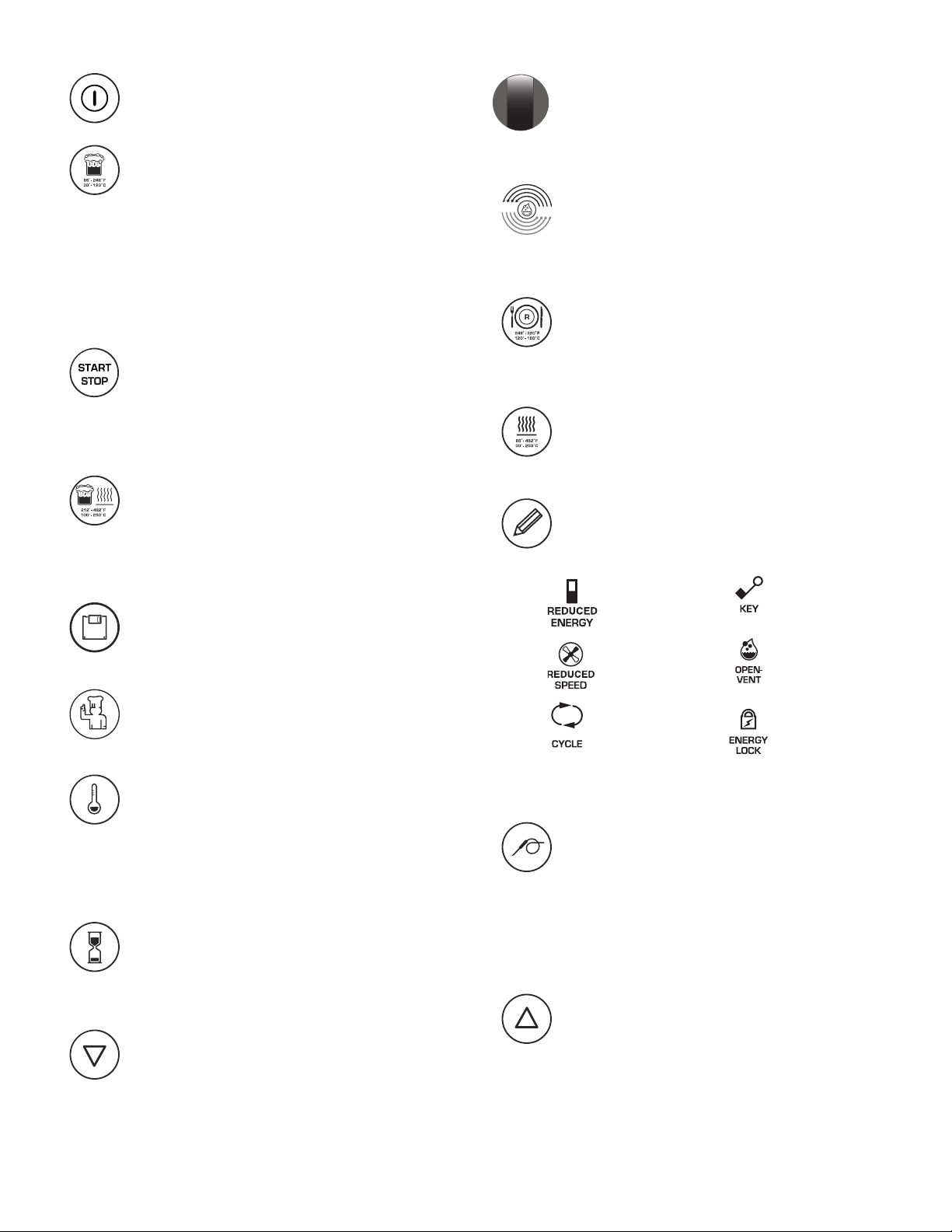

POWER ON/OFF KEY

STEAM MODE KEY

PROGRAMMED MENU KEY

COOKING TEMPERATURE KEY

DOWN ARROW KEY

MOISTURE VENT KEY

START/ STOP KEY

CHEF FUNCTION KEY

TIME KEY

SUPERHEATED STEAM AND

RETHERM MODE KEY

CONVECTION MODE KEY

PROGRAM INSTALL/EDIT KEY

FUNCTION & OPERATING

CONTROL PANEL DISPLAY

CORE TEMPERATURE KEY

UP ARROW KEY

QUICK PROGRAM KEYS

CONVECTION MODE KEY

INDICATORS

DELUXE MODELS ONLY

DELUXE MODELS ONLY

DELUXE MODELS ONLY

ELECTRIC MODELS ONLY

CONTROL PANEL IDENTIFICATION

ADJUSTMENT KNOB

COMBITHERM ELECTRIC BOILER-FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 13

POWER ON/OFF KEY

Activates power to the oven.

STEAM MODE KEY

The oven will operate in the steam mode at

a temperature range of 86°F to 248°F

(30°C to 120°C).

• Automatic steaming at 212°F (100°C)

FACTORY-SET DEFAULT

.

• Quick steaming between 213°F and 248°F

(101°C and 120°C).

• Low Temperature Steaming between

86°F and 211°F (30°C and 99°C).

START/STOP KEY

Initiates all cooking mode functions and

programmed procedures stored in memory.

Stops an activated cooking mode or

programmed procedure currently in

progress, and exits Chef function key.

SUPERHEATED STEAM AND

CONVECTION MODE KEY

Selection key for the combination steam

and convection cooking mode which can be

set within a temperature range of

212°F to 482°F (100°C and 250°C).

PROGRAMMED MENU KEY

Shows a list menu in display of all stored

cooking programs and is also used to exit

the list menu display. DELUXE MODELS ONLY.

CHEF FUNCTION KEY

Used to select programmed menu

functions, various auxiliary functions, and

several chef help instructions.

COOKING TEMPERATURE KEY

Used to set the required cooking

temperature, to recall the set cooking

temperature, or to check the actual oven

temperature in conjunction with the down

arrow key , the up arrow key or the

adjustment knob

.

TIME KEY

Used to set the required cooking time or

recall the set cooking time in conjunction

with the down arrow key , the up arrow

key or the adjustment knob .

DOWN ARROW KEY

Used to decrease displayed cook temperature

, time , or core temperature and as a

scrolling key for programming functions.

ADJUSTMENT KNOB

Serves the same function as the up and

down arrow keys to increase or decrease

the displayed cook temperature , time ,

or core temperature .

MOISTURE VENT KEY

Immediately vents steam and condensate

from the oven compartment while cooking in

the Convection mode or in the

Superheated Steam and Convection mode .

RETHERM MODE KEY

Food rethermalization or reheating mode

will operate with automatic steam injection

at a temperature range of 248°F and 320°F

(120°C and 160°C).

CONVECTION MODE KEY

Selection key for convection cooking

without steam at a temperature range of

86°F to 482°F (30°C and 250°C).

PROGRAM INSTALL AND EDIT KEY

Used to create, change, duplicate, and delete

programmed menus. DELUXE MODELS ONLY.

FUNCTION & OPERATING INDICATORS

CONTROL PANEL DISPLAY

CORE TEMPERATURE KEY

Used to set the required internal product

temperature, to recall the internal product

temperature set by the operator, or to display

the current internal temperature of the

product in conjunction with the down arrow

key , the up arrow key or the adjustment

knob .

UP ARROW KEY

Used to increase displayed cook temperature ,

time , or core temperature and as a

scrolling key for programming functions.

QUICK PROGRAM KEYS

Immediate access to frequently used

operator set programs including cooking

modes, cleaning, and other oven functions.

DELUXE MODELS ONLY.

CONTROL PANEL IDENTIFICATION

Reduced Power

Reduced Fan Speed

Confirmation of

Oven Operation

Key Lock

Moisture Vent

Peak Power Use

Energy Protection

ELECTRIC MODELS ONLY

#6002 COMBITHERM ELECTRIC BOILER- FREE INSTALLATION AND MAINTENANCE MANUAL

PG. 14

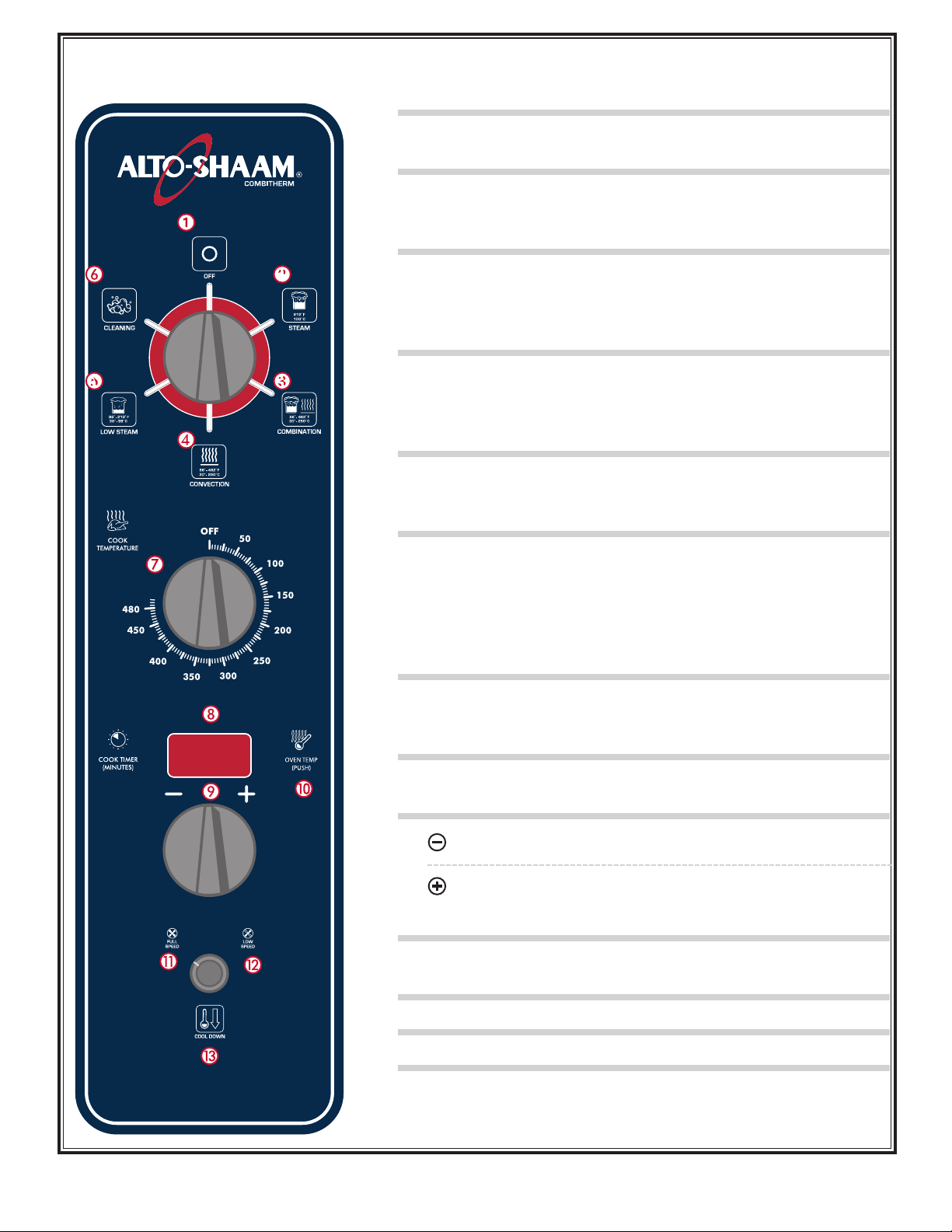

S-CONTROL PANEL IDENTIFICATION

OFF POSITION

Maintains oven in a stand-by mode.

STEAM

The oven will operate at a fixed steam temperature of

212° F (100°C).

COMBINATION

A combination of steam and convection heat to cook at a

temperature between 86°F and 482°F (30°C to 250°C) to be

set by the operator.

CONVECTION

Convection heat to cook without steam at a temperature

between 86°F and 482°F (30°C and 250°C) to be set by

the operator.

LOW STEAM

Low temperature steaming within an operator set temperature

range of 86°F to 210°F (30°C and 99°C).

CLEANING FUNCTION

An automatic cleaning cycle to heat the oven to the correct

temperature, followed by a manual application of Combitherm

Liquid Oven Cleaner and a 10 minute steam cleaning cycle.

An automatic boiler flush is initiated on boiler equipped models

and a vinegar decalcification can also be conducted.

COOKING TEMPERATURE DIAL

To be manually set by the operator to the cooking

temperature required.

OVEN DISPLAY

Indicates time remaining or interior oven temperature.

COOKING TIMER

Turned to the left for continuous cooking time or to

decrease time in increments of one minute.

Turn to the right to set and increase time in increments

of one minute.

OVEN TEMPERATURE

To be pressed to display interior oven temperature.

FULL SPEED FAN POSITION

HALF SPEED FAN POSITION

OVEN COOL-DOWN POSITION

Assists in cooling the oven at an accelerated pace when

changing from high to lower temperature cooking.

The oven

door should be open when using this feature.

Loading...

Loading...