Alto Shaam 100-HSL, 100-BCB-2 Operation Manual

#802/1 • 3/06

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-0450 USA

PHONE: 262.251.3800 • 800.558.8744 USA/CANADA FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY

WEBSITE

: www.alto-shaam.com

PRINTED IN U.S .A .

®

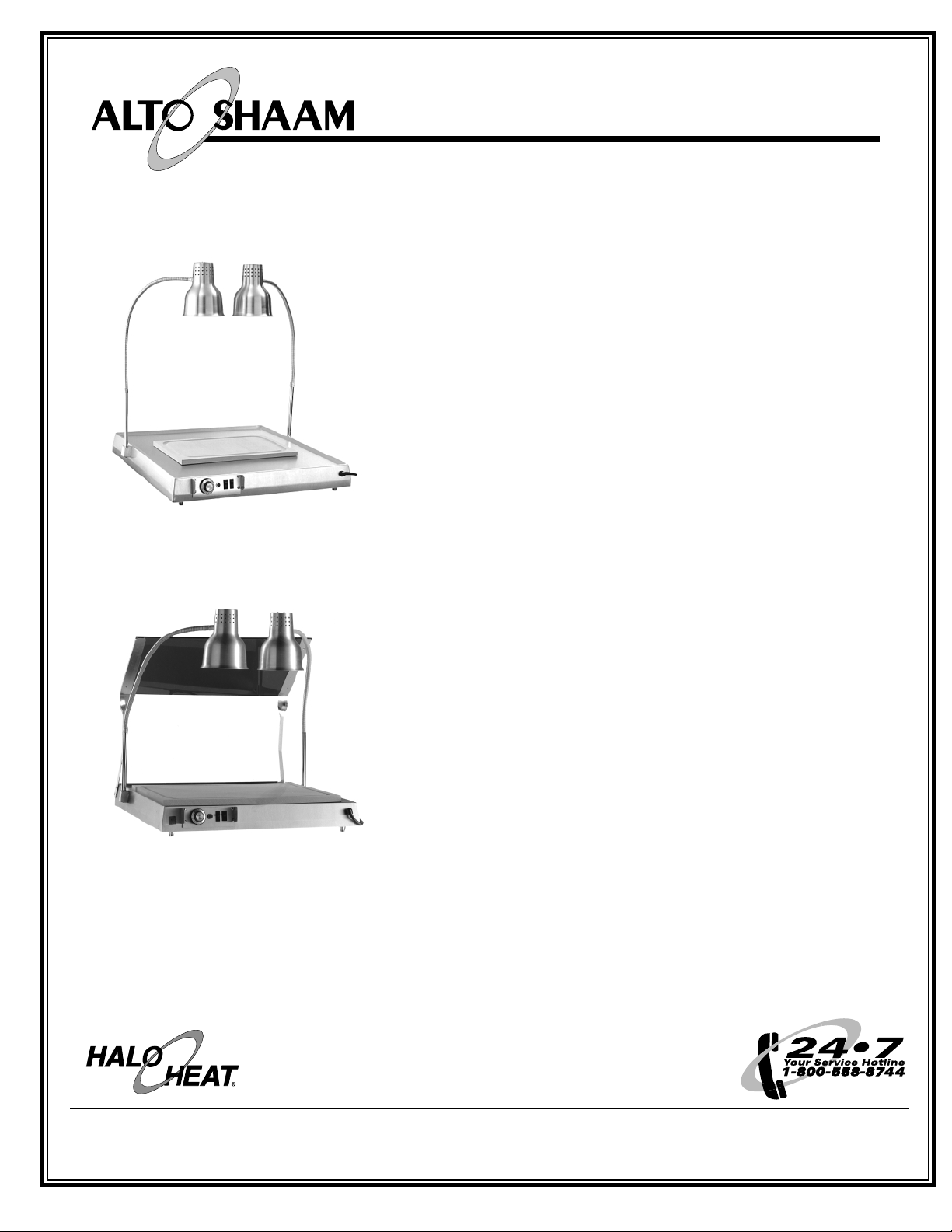

Hot Carving Shelf

Electric

Models:

100-HSL/BCB-2

100-HSL/BCS-2

100-HSL/BCS-2

• INSTALLATION

• OPERATION

• MAINTENANCE

#802/1 Operation & Care Manual • 1.

DELIVERY

This Alto-Shaam appliance has been

thoroughly tested and inspected to insure only

the highest quality unit is provided. Upon

receipt, check for any possible shipping

damage and report it at once to the delivering

carrier. See Transportation Damage and

Claims section located in this manual.

This appliance, complete with unattached

items and accessories, may have been

delivered in one or more packages. Check to

ensure that all standard items and options

have been received with each model as

ordered.

Save all the information and instructions

packed with the appliance. Complete and

return the warranty card to the factory as soon

as possible to assure prompt service in the

event of a warranty parts and labor claim.

This manual must be read and understood

by all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions

concerning installation, operation, or

maintenance.

NOTE: All claims for warranty must include

the full model number and serial

number of the unit.

UNPACKING

1. Carefully remove the

appliance from the

carton or crate.

NOTE: Do not discard the

carton and other

packaging

material until you

have inspected

the unit for

hidden damage

and tested it for proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this

appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the

owner or manager of the business or to the

person responsible for training operators.

Additional manuals are available from the

Alto-Shaam service department.

3. Remove all protective plastic film,

packaging materials, and accessories from

the appliance before connecting electrical

power. Store any accessories in a

convenient place for future use.

®

®

®

#802/1 Operation & Care Manual • 2.

SAFETY PROCEDURES

AND PRECAUTIONS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

Used to indicate the

presence of a hazard that

will cause severe personal

injury, death, or substantial

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can cause personal injury,

possible death, or major

property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor or

moderate personal injury

or property damage if the

warning included with this

symbol is ignored.

Used to indicate the

presence of a hazard that

can or will cause minor

personal injury, property

damage, or a potential

unsafe practice if the

warning included with this

symbol is ignored.

Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this

appliance is authorized or recommended.

2. This appliance is intended for use in

commercial establishments where all

operators are familiar with the purpose,

limitations, and associated hazards of this

appliance. Operating instructions and

warnings must be read and understood by

all operators and users.

3. Any troubleshooting guides, component

views, and parts lists included in this manual

are for general reference only and are intended

for use by qualified technical personnel.

4. This manual should be considered a

permanent part of this appliance. This

manual and all supplied instructions,

diagrams, schematics, parts lists, notices,

and labels must remain with the appliance

if the item is sold or moved to another

location.

NOTE:

#802/1 Operation & Care Manual • 3.

The carving shelf, complete with unattached

items and accessories should be checked to ensure

all the following items have been received as

standard with each unit.

4: 1" (25mm) Legs

4: Nylon Screws

1: Cutting Board

2: Lamps

4: Sneeze Guard Mounting Screws

(some models)

Alto-Shaam hot carving shelves are designed

for the purpose of maintaining hot food at a

temperature for safe consumption. The unit must

be installed on a level surface in a location that will

permit the equipment to function for its intended

purpose and allow adequate access for proper

cleaning and maintenance.

The carving shelf must not be installed in any

area where it will be affected by steam, grease,

dripping water, high temperatures, or any other

severely adverse conditions.

1. WHEN THE UNIT IS EQUIPPED WITH A

SNEEZE GUARD

:

Refer to the Service Views located in this

manual. Swing the sneeze guard up to the

proper position and secure each side with the

two (2) additional screws provided. Tighten

all four (4) screws to mount the sneeze guard

securely.

2. The hot carving shelf is designed to be

mounted directly on top of a Halo Heat

cook/hold oven or holding cabinet. The shelf

can also be used as a free-standing unit

without the Halo Heat cabinet.

A. CABINET MOUNTED SHELVES:

Install the four (4) nylon screws in the leg

mounting holes to protect the top surface of

the cabinet and to provide a more stable

placement between the shelf and the

cabinet. Do not install the 1" (25mm)

equipment legs.

B. FREE-STANDING SHELVES:

Install the 1" (25mm) legs before operating

the shelf. Failure to install the 1" legs prior

to heating the shelf could result in damage

to the surface on which the shelf is placed,

may pose a potential fire hazard, and

nullifies the validity of the UL listing mark.

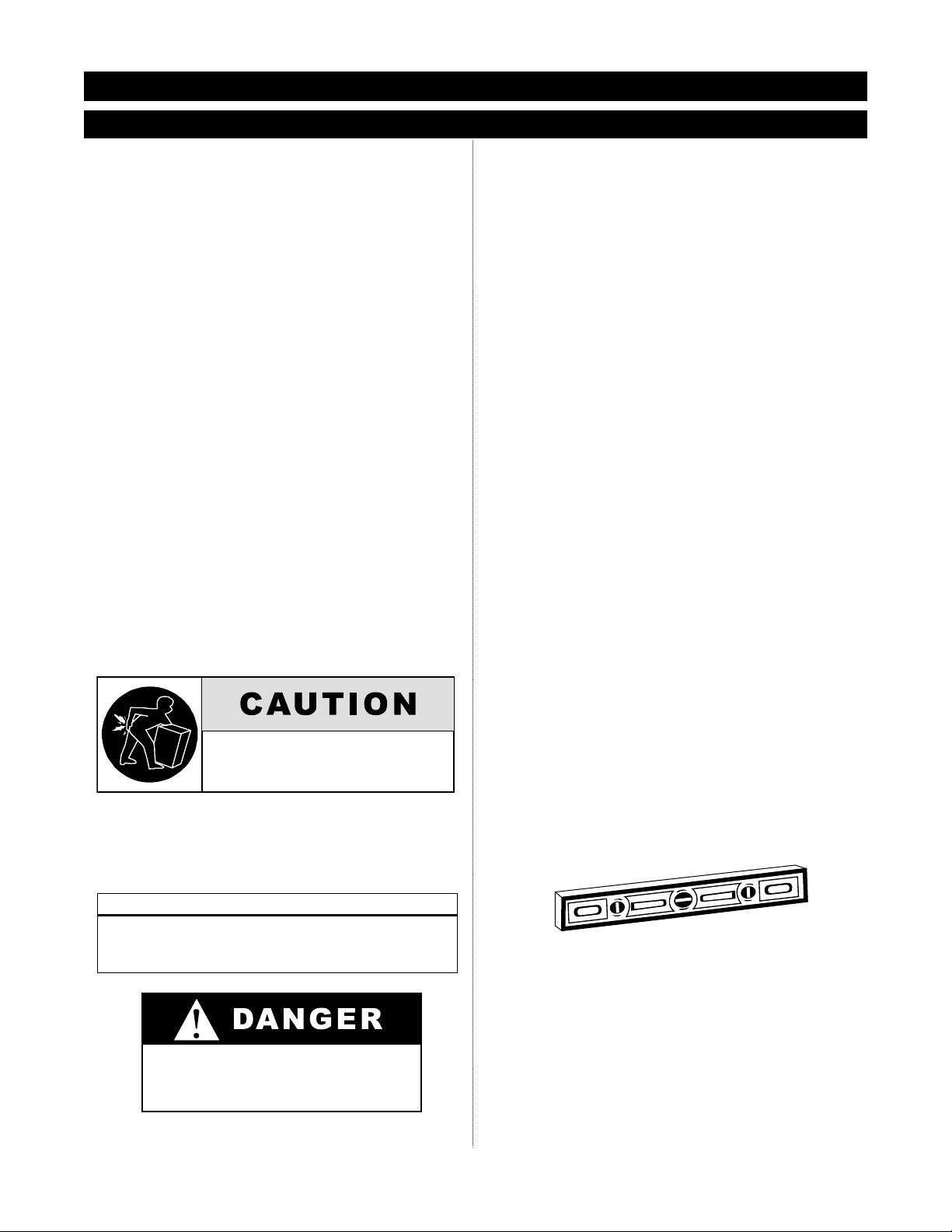

3. Level the appliance from side-to-side and

back-to-back with the use of a spirit level.

INSTALLATION

SITE INSTALLATION

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

NET WEIGHT

40 lbs with sneeze guard 45 lbs.

(18 kg) (20 kg)

IMPROPER INSTALLATION, ALTERATION,

ADJUSTMENT, SERVICE OR MAINTENANCE

COULD RESULT IN SEVERE INJURY, DEATH

OR CAUSE PROPERTY DAMAGE.

#802/1 Operation & Care Manual • 4.

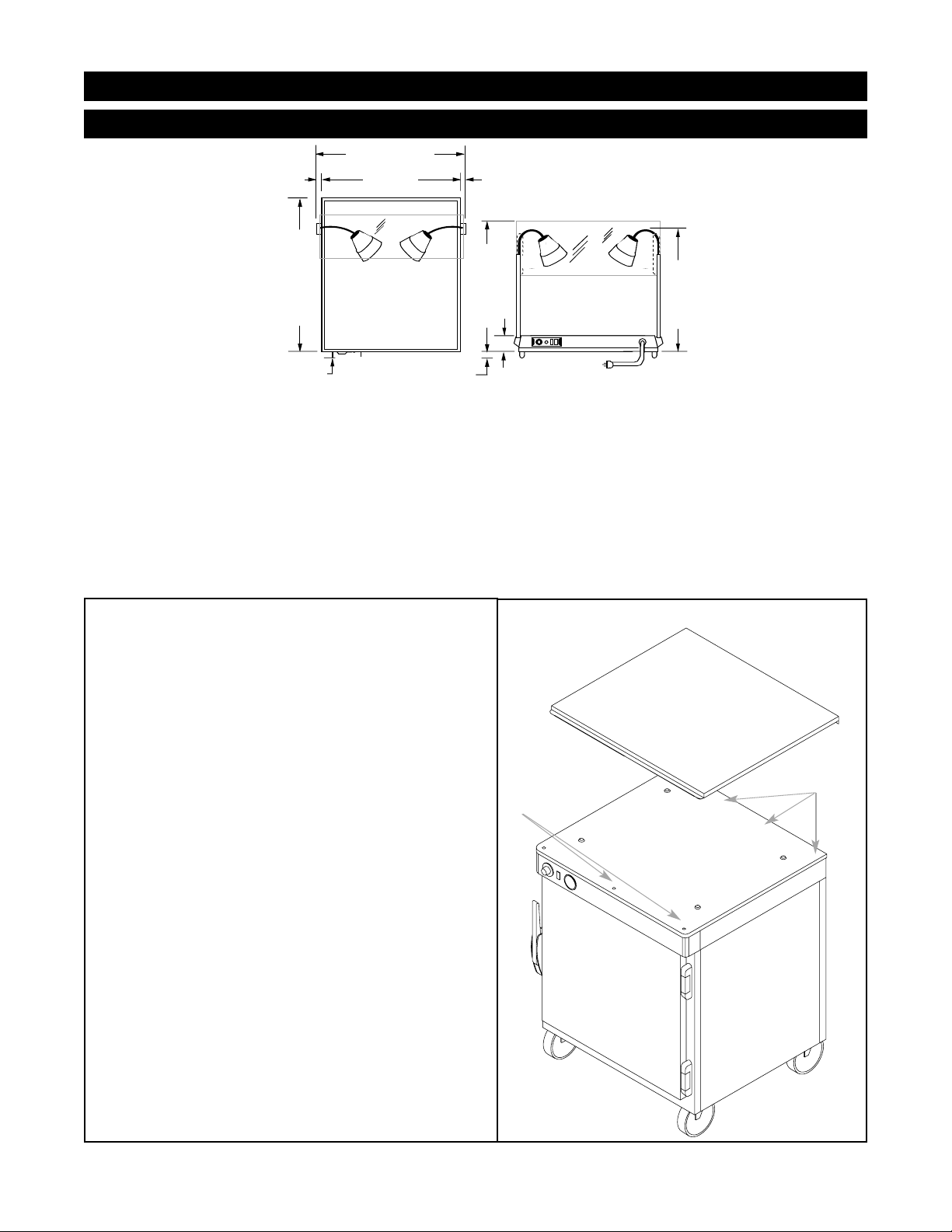

26-1/8"

(664mm)

28-1/8" (714mm)

1"

(25mm)

1"

(25mm)

1" (25mm)

FOR LEGS

100-HSL/BCB-2

100-HSL/BCS-2

100-HSL/BCS-2S

24-1/4" (616mm)

3" (76mm)

38" (965mm)

maximum

28-7/8" (733mm)

1-1/4" (32mm)

FOR CONTROLS

Using Stacking Platform from

kits 16222 or 16237

to provide carving shelf:

1. Remove the three screws in the top plate at the

front of the cabinet.

2. Remove the three screws in the back plate near the

top of the cabinet.

2. Position the stacking platform on top of the unit

with the flange in front, aligning the holes in the

platform over the holes in the cabinet.

3. Reinstall the cabinet screws removed in steps 1 and 2

through the platform holes to attach it to the cabinet,

front and back.

4. Place the carving shelf on the stacking platform.

No. 16222 or 16237 kit for

750-S

500-S or

stacking carving shelf

Step 1

Step 2

INSTALLATION

Options and Accessories

Carving Holder

Prime Rib . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HL-2635

Steamship or Cafeteria Round . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4459

Carving Shelf Mounting Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16237

Cutting Board, with gravy lane, 18" x 24" x 1/2" (457mm x 610mm x 13mm) . . . . . . . . . . . . . . . . . . . . .BA-2054

Cutting Board, with gravy lane, 18" x 12" x 1/2" (457mm x 305mm x 13mm) . . . . . . . . . . . . . . . . . . . . .BA-2358

Exterior Dimensions

SITE INSTALLATION

#802/1 Operation & Care Manual • 5.

1. An identification tag is permanently mounted

on the unit.

2. If necessary, a proper receptacle or permanent

wiring for this unit must be installed by a

licensed electrician in accordance with

applicable local electrical codes.

3. Plug the unit into a properly grounded

receptacle ONLY, positioning the unit so the

power supply cord is easily accessible in case

of an emergency. Arcing will occur when

connecting or disconnecting the unit unless

all controls are in the OFF position.

230V:

To prevent an electrical shock hazard between

the appliance and other appliances or metal

parts in close vicinity, an equalization-bonding

stud is provided. An equalization bonding lead

must be connected to this stud and the other

appliances / metal parts to provide sufficient

protection against potential difference. The

terminal is marked with the following symbol.

NOTE: The appliance must be connected to an

electrical circuit that is protected by an

external GFCI outlet.

INSTALLATION

ELECTRICAL CONNECTION

PATENT NOS.

3521030

4595247

®

PH

ELECTRICAL CONNECTIONS MUST

BE MADE BY A QUALIFIED SERVICE

TECHNICIAN IN ACCORDANCE WITH

APPLICABLE ELECTRICAL CODES.

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be made

in accordance with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

IMPROPER INSTALLATION, ALTERATION,

ADJUSTMENT, SERVICE OR MAINTENANCE

COULD RESULT IN SEVERE INJURY, DEATH

OR CAUSE PROPERTY DAMAGE.

ELECTRICAL

VOLTAGE PHASE CYCLE/HZ AMPS kW

125 1 50/60 8.0 1.0

230 1 50/60 4.5 1.0

NEMA 5-15P

15A 125V PLUG

CEE 7/7

220-233V PLUG

#802/1 Operation & Care Manual • 6.

This appliance is intended for use in commercial

establishments by qualified personnel who are

familiar with the purpose, limitations, and

associated hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

BEFORE INITIAL USE:

Clean the metal surface exterior of the appliance

with a clean, damp cloth and mild soap solution.

Rinse carefully.

NOTE:

Clean the acrylic sneeze guard with soap or

mild detergent and water. Dry with a clean,

damp chamois. Grease and oil may be removed

with naphtha or hexane. Do not use commercial

or household cleaners containing ammonia.

To avoid scratching, do not use dry cloths or

scouring compounds.

1. Turn power switch ON.

2. Turn lamp switch ON.

3. The base of the shelf is equipped with a

thermostat indicating a range of 1 through 10.

Set the dial at 8 to preheat the shelf. When the

indicator light goes out, the unit is preheated.

4. The product must be at the proper internal

temperature before transferring to the carving

shelf. Use a meat thermometer to check the

internal temperature of the product being held.

Adjust the thermostat on the shelf to give the

best overall setting based on the internal

product temperature.

5. The proper temperature range for the products

being held will depend on the type and

quantity of product. When holding food for

prolonged periods, it is advisable to

periodically check the internal temperature of

each item with a food thermometer to assure

maintenance of the proper temperature range

of 140° to 160°F (60° to 71°C). Read this

manual for additional information on safe

internal product temperatures, general holding

guidelines, and sanitation procedures.

➤ Use hand protection when

handling hot items.

➤ DO NOT use knives or utensils

on the hot shelf surface.

A cutting board is supplied.

OPERATING

USER SAFETY INFORMATION START-UP OPERATION

HEATING CHARACTERISTICS

The shelf is equipped with a special, low-heatdensity, heating cable. Through the Halo Heat

concept, the heating cable is mounted against the

top surface of the shelf to provide an evenly

applied heat source, controlled by a

thermostat.TThrough even heat application, the

quality of a food product is maintained up to as

much as several hours.

PRODUCT CAPACITY

70 lbs (31.7 kg) MAX.

(LARGE STEAMSHIP ROUND)

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

Loading...

Loading...