Alto Shaam 1000-S Service Manual

F o o d H o l d i n g C a b i n e t

W164 N9221 Water Street • P.O. Box 450 • Menomonee Falls, Wisconsin 53052-045 0 USA

PHONE: 262.251.3800 • 800.558. 8744

US A/CANAD A FAX: 262.251.7067 • 800.329.8744 U.S .A . ONLY

www.alto-shaam.com

®

E l e c t r i c

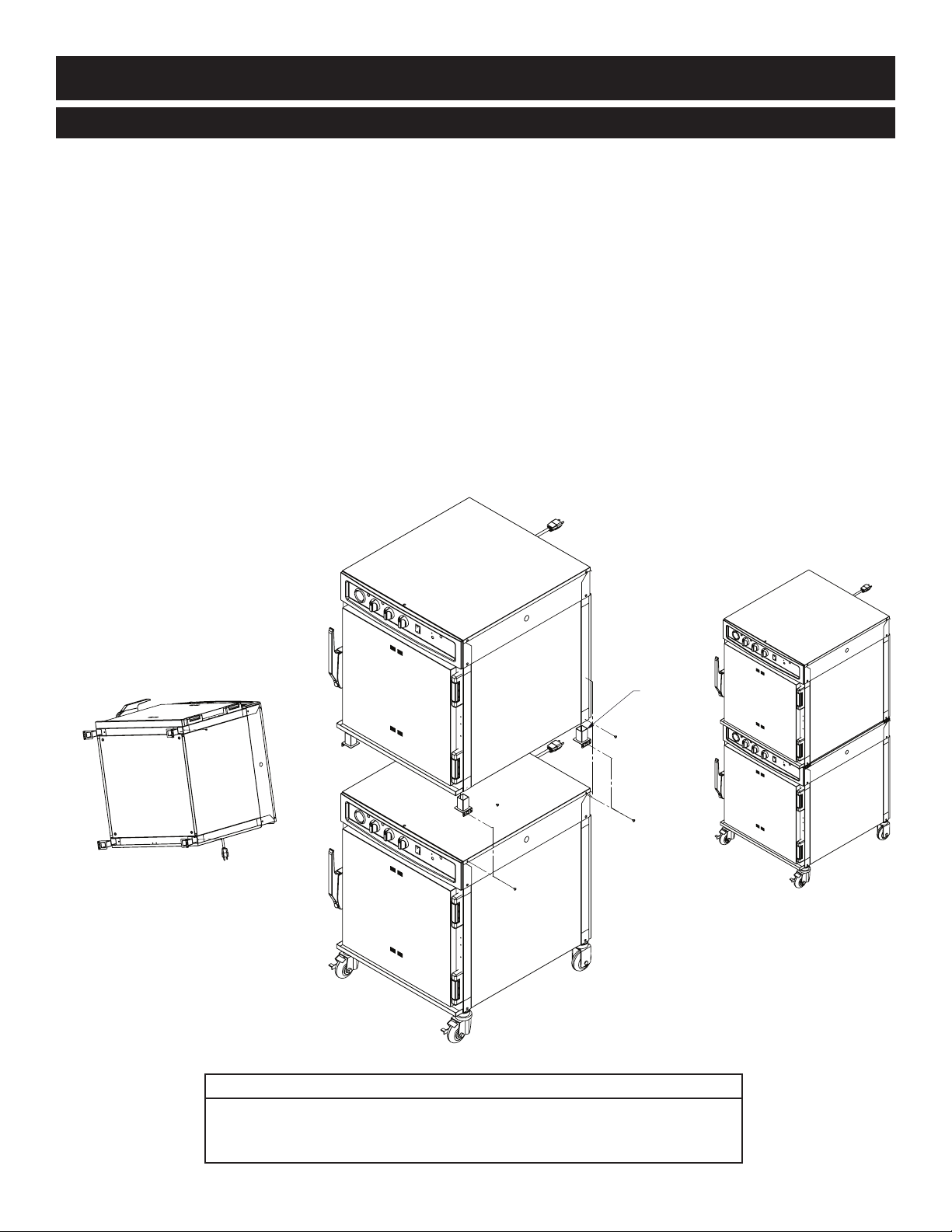

Model:

500-S

750-S

1000-S

1000-UP

1000-UP

1000-S

750-S

500-S

P R I NT E D I N U .S .A .

• INSTALLATION

• OPERATION

• MAI NTENANCE

M N - 2 8 5 9 6 • 0 5 / 0 8

D E L I V E R Y

This Alto-Shaam appliance has been

thoroughly tested and inspected to insure only the

highest quality unit is provided. Upon receipt,

check for any possible shipping damage and report

it at once to the delivering carrier. See

Transportation Damage and Claims section

located in thi s manual.

This appliance, complete with unattached

items and accessories, may have been delivered in

one or more packages. Check to ensure that all

standard items and options have been received

with each model as ordered.

Save all the information and instructions

packed with the appliance. Complete and return

the warranty card to the factory as soon as

possible to assure prompt service in the event of a

warranty parts and labor claim.

This manual must be read and understood by

all people using or installing the equipment

model. Contact the Alto-Shaam service

department if you have any questions concerning

installation, operation, or maintenance.

N O T E: All claims for warranty must include the

full model number and serial number of

the unit.

U N P A C K I N G

1. Carefully remove the

appliance from the

carton or crate.

N O T E: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully

before initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner or

manager of the business or to the person

responsible for training operators. Additional

manuals are available from the Alto -Shaam

service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power. Store any

accessories in a convenient place for future use.

®

®

®

500-S, 750-S, 100 0- S, 10 00 -UP • INSTALLATIO N/ OP ER ATION/SERV IC E MAN UA L • 1.

1. This appliance is intended to cook, hold or

process foods for the purpose of human

consumption. No other use for this appliance is

authorized or recommended.

2. This appliance is intended for use in commercial

establishments where all operators are familiar

with the purpose, limitations, and associated

hazards of this appliance. Operating

instructions and warnings must be read and

understood by all operators and users.

3. Any troubleshooting guides, component views,

and parts lists included in this manual are for

general reference only and are intended for use

by qualified technical personnel.

4. This manual should be considered a permanent

part of this appliance. This manual and all

supplied instructions, diagrams, schematics,

parts lists, notices, and labels must remain with

the appliance if the item is sold or moved to

another location.

N O T E : Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

C A U T I O N

Used to indicate the presence of a hazard that can

or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

C A U T I O N

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

D A N G E R

Used to indicate the presence of a

hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

W A R N I N G

Used to indicate the presence of a

hazard that CAN cause personal injury,

possible death, or major property

damage if the warning included with

this symbol is ignored.

SAFE T Y PRO C E D URES

AND PRECAU T I O NS

Knowledge of proper procedures is essential to the

safe operation of electrically and/or gas energized

equipment. In accordance with generally accepted

product safety labeling guidelines for potential

hazards, the following signal words and symbols

may be used throughout this manual.

N O T E

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 2.

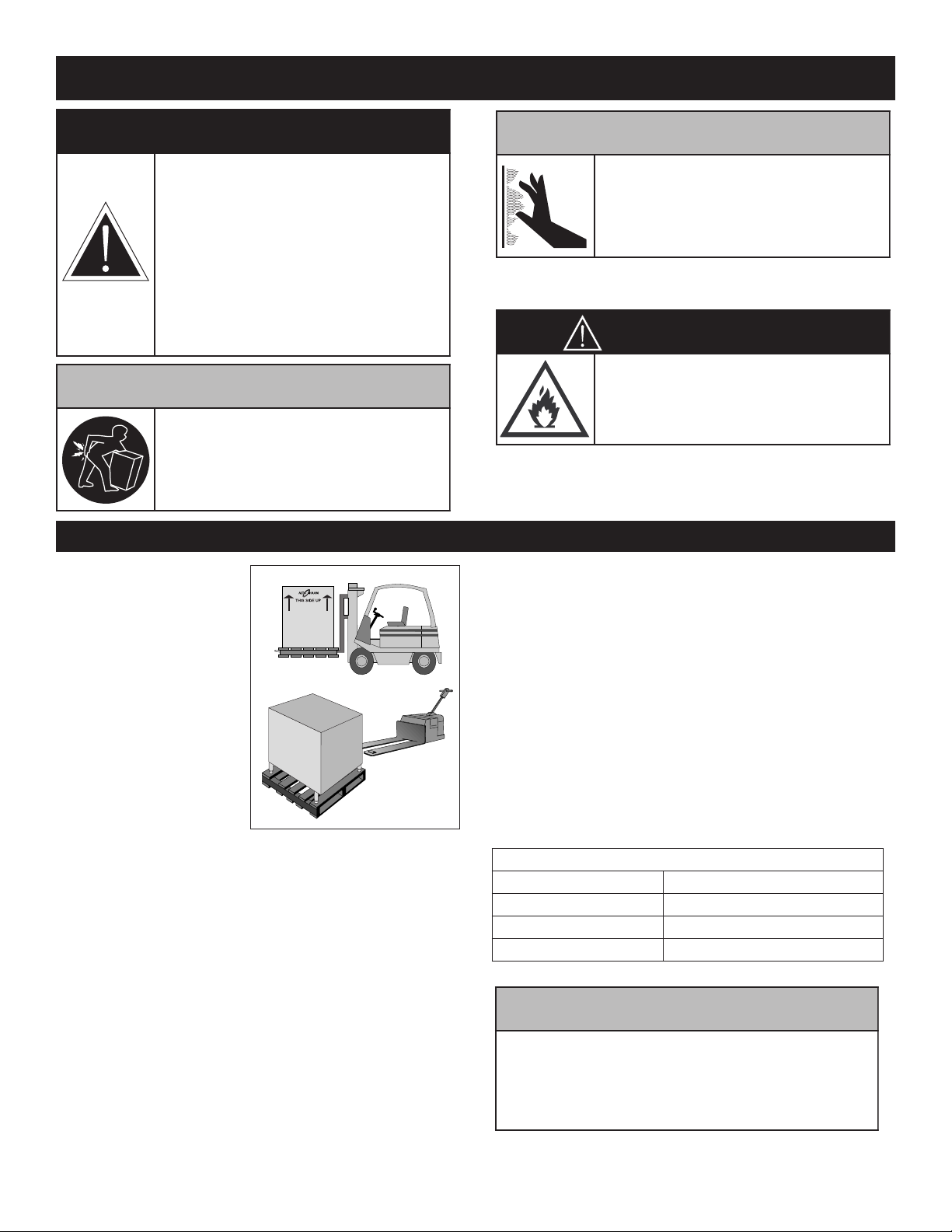

I N S TA L L A T I O N

®

D A N G E R

IMPROPER INSTALLATION,

ALTERATION, ADJUSTMENT,

SERVICE, OR MAINTENANCE COULD

RESULT IN SEVERE INJURY, DEATH

OR CAUSE PROPERTY DAMAGE.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C A U T I O N

TO PREVENT PERSONAL INJURY,

USE CAUTION WHEN MOVING OR

LEVELING THIS APPLIANCE.

D A N G E R

DO NOT store or use gasoline or other

flammable vapors or liquids in the

vicinity of this or any other appliance.

C A U T I O N

METAL PARTS OF THIS EQUIPMENT

BECOME EXTREMELY HOT WHEN IN

OPERATION. TO AVOID BURNS,

ALWAYS USE HAND PROTECTION

WHEN OPERATING THIS APPLIANCE.

N O T E

If the appliance has been unplugged for an

extended period of time, the Real Time

Clock may require recharging. Plug the unit

into the proper receptacle for a minimum of

24 hours.

The Alto-Shaam cook

and hold oven must be

installed in a location

that will permit the

oven to function for its

intended purpose and

to allow adequate

clearance for

ventilation, proper

cleaning, and

maintenance access.

1. The oven must be installed on a stable and

level surface.

2. DO NOT install this appliance in any area

where it may be affected by any adverse

conditions such as steam, grease, dripping

water, high temperatures, or any other severely

adverse conditions.

3. DO NOT store or use any flammable liquids or

allow flammable vapors in the vicinity of this

oven or any other appliance.

4. This appliance must be kept free and clear of

any combustible materials.

5. This appliance must be kept free and clear of

any obstructions blocking access for

maintenance or service.

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 3.

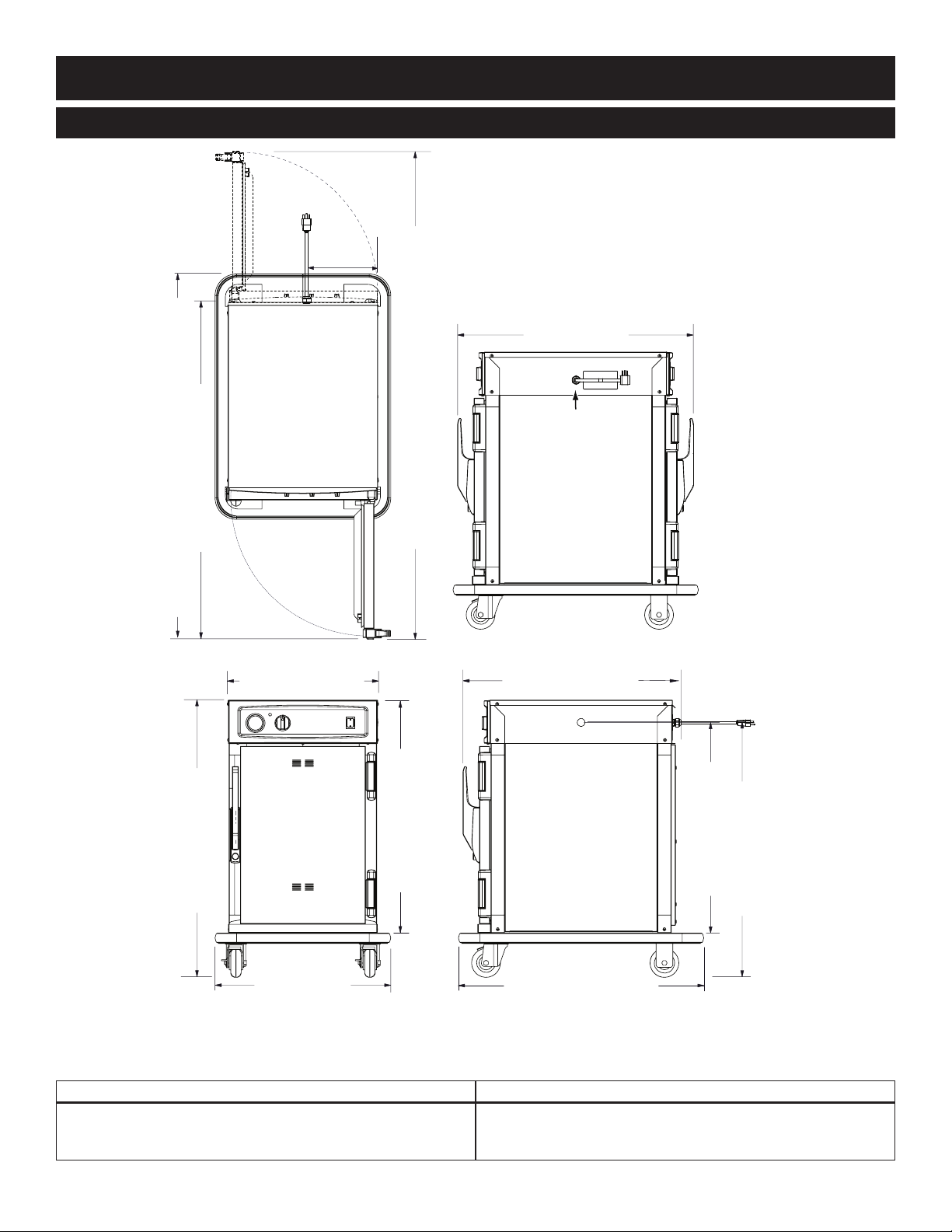

S I T E I N S T A L L A T I O N

Emissions testing conducted by Underwriters

Laboratories, Inc.® was found to be in

compliance with the applicable requirements of

NFPA96: 2004 Edition, Par. 4.1.1.2. U.L

emissions sampling of grease laden vapor

resulted in a total of 0.55 milligrams per cubic

meter with no visible smoke and is considered

representative of all oven models in the line.

Based on these results, hood installation and/or

outside venting should not be a requirement in

most areas. Verify local codes for locations

where more restrictive codes are applicable.

MINIMUM CLEARANCE REQUIREMENTS

BAC K

LE FT S IDE

RI GH T SIDE

TOP

3" (76mm)

1" (25mm)

1" (25mm)

2" (51mm)

I N S TA L L A T I O N

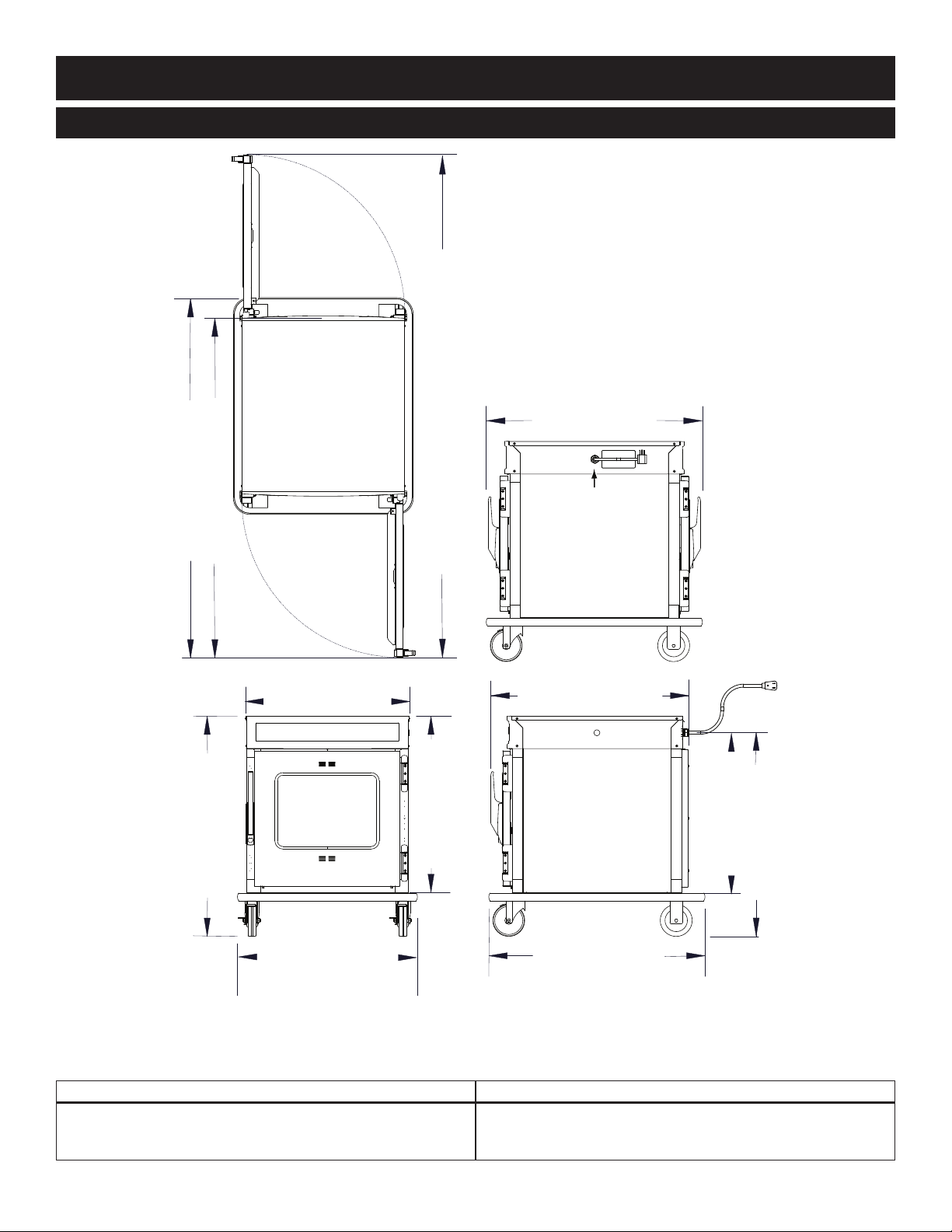

17-7/8" (454mm)

25-1/2" (648mm)

25-1/8" (637mm)

30-3/8" (772mm)

21" (532mm)

with optional bumper

42-15/16" (1091mm) with optional bumper

39-13/16" (1011mm)

*34-5/16" (874mm) - with optional 5" casters

*32-1/16" (814mm) - with optional 2-1/2" casters

*34-11/16" (880mm) - with optional 6" legs

33-1/16" (839mm)

with 3-1/2" Casters

27-3/4" (705mm)

29-1/4" (743mm)

with optional bumper

56-5/8" (1438mm) - Pass-Through Option

28" (711mm)

Electrical

Connection

8-15/16"

(227mm)

Pass-Through

Option

Electrical

Reach-in

E X T E R I O R D I M E N S I O N S - 5 0 0 - S

WEIGHT

NE T: 94 lb (43 kg)

SHIP : 120 lb (54 kg)

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 4.

PRODU C T CAPA CITY

60 lbs (27 kg)

VO LU ME MAXIMUM

MAXI MUM

: 50 QU ARTS (47.5 L IT ER S)

I N S TA L L A T I O N

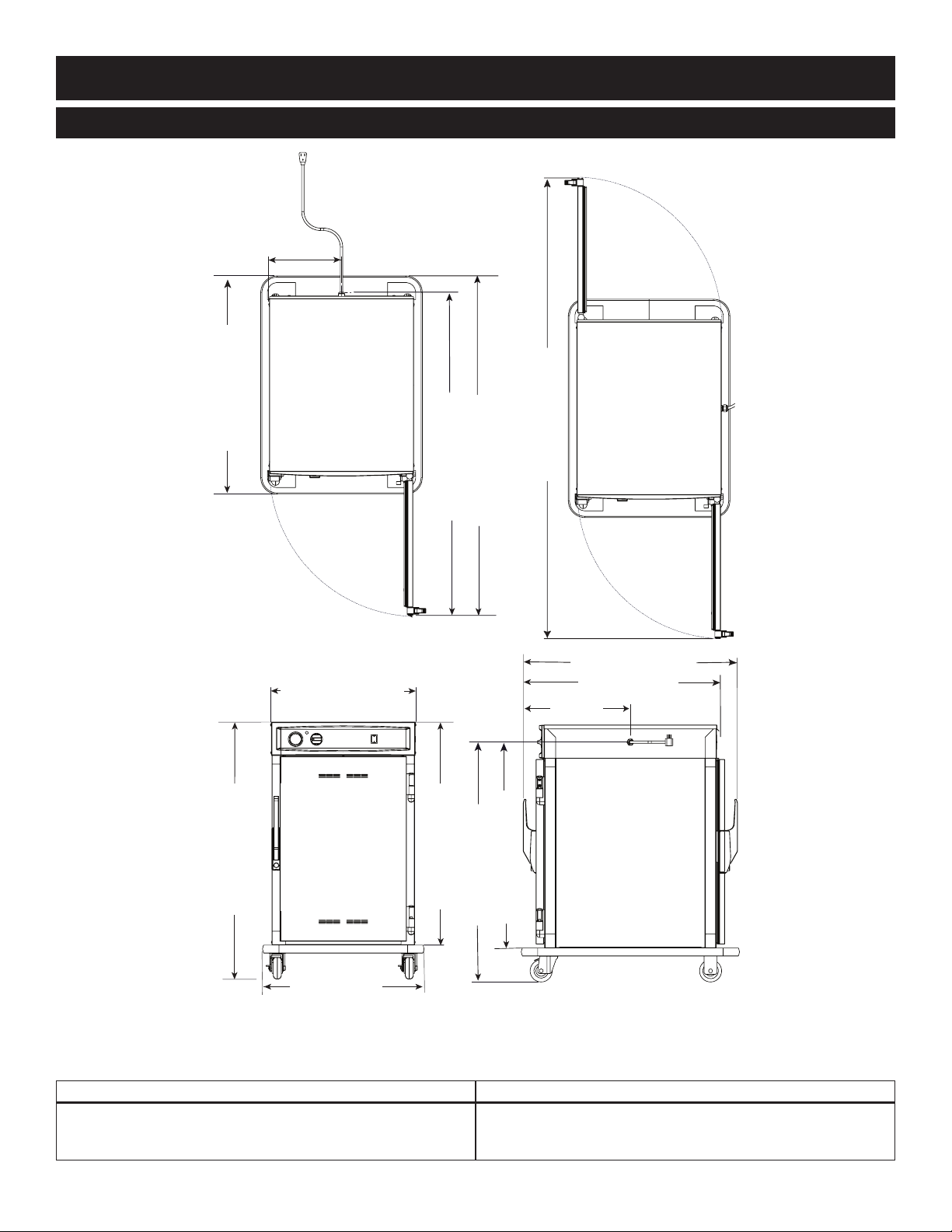

28-1/4" (716mm)

with optional bumper

33-3/16" (843mm)

with 3-1/2" casters*

25-3/4" (653mm)

33-7/8" (860mm)

with optional bumper

30-15/16" (785mm)

25-1/8" (638mm)

30-7/16" (772mm)

53-9/16" (1360mm)

55-1/2" (1408mm)

77-1/2" (1967mm) - Pass-Through Option

33-7/8" (860mm)

Electrical

Connection

Pass-Through

Option

27-7/8" (708mm)

*32-3/16" (817mm) - with optional 2-1/2" casters

*34-5/8" (878mm) - with optional 5" casters

*34-13/16" (884mm) - with optional 6" legs

E X T E R I O R D I M E N S I O N S - 7 5 0 - S

WEIGHT

NE T: 152 lb (69 kg)

SHIP : 193 lb (88 kg)

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 5.

PRODU C T CAPA CITY

120 lbs (54 kg)

VO LU ME MAXIMUM

MAXI MUM

: 100 QUA RTS (95 LI TE RS )

I N S TA L L A T I O N

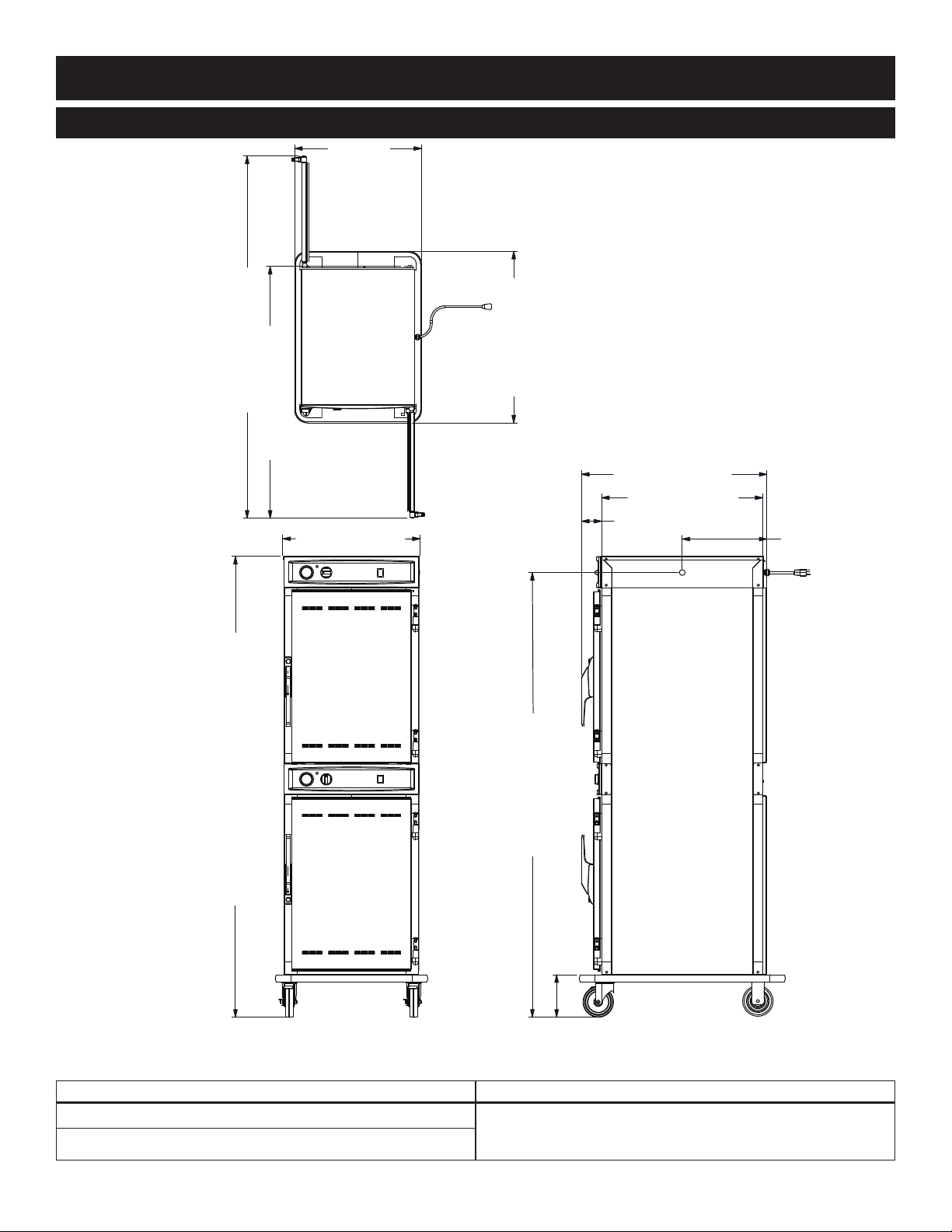

11-5/16"

(287mm)

33-7/8" (860mm)

with optional bumper

25" (636mm)

with optional bumper

50-1/8" (1273mm)

52-5/8" (1337mm)

71-7/16" (1814mm)

22-9/16" (573mm)

39-7/8" (1012mm)

with 3-1/2" casters

33-1/4" (844mm)

16-5/8"

(422mm)

37-3/16" (945mm)

31-15/16" (810mm)

31" (788mm)

Electrical

Reach-in

Electrical, Pass-thru

Pass-thru

option

*38-7/8" (987mm) - with optional 2-1/2" casters

*41-1/4" (1047mm) - with optional 5" casters

*41-1/2" (1053mm) - with optional 6" legs

34-1/2" (878mm)

E X T E R I O R D I M E N S I O N S - 1 0 0 0 - S

WEIGHT

NE T: 138 lb (63 kg) (EST. )

SHIP : 163 lb (74 kg) (ES T.)

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 6.

PRODU C T CAPA CITY

120 lbs (54 kg)

VO LU ME MAXIMUM

MAXI MUM

: 60 QU ARTS (76 LIT ER S)

I N S TA L L A T I O N

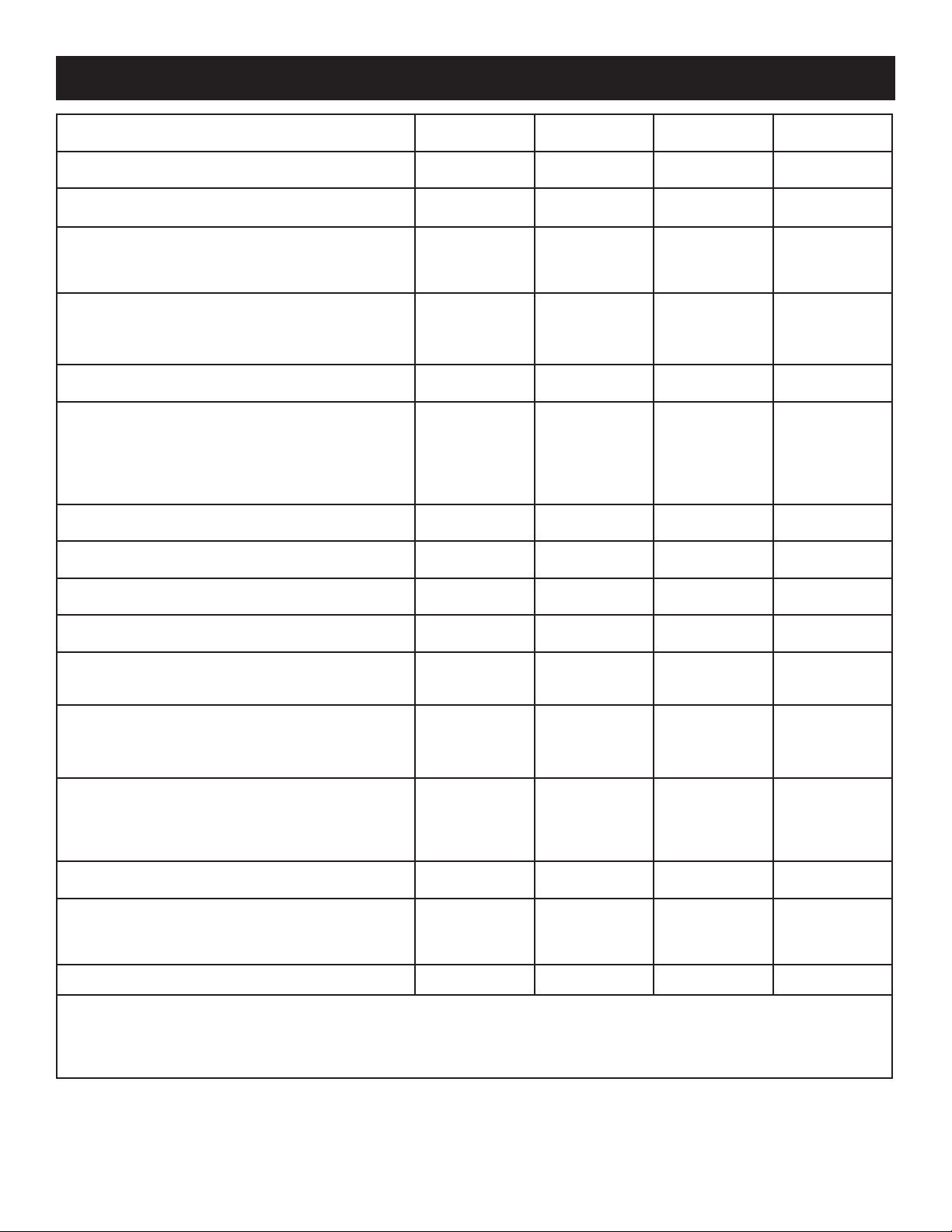

75-11/16" (1922mm) with 5" casters*

73-1/16" (1855mm)

7" (177mm)

30-1/2" (774mm)

26-1/2" (673mm)

3-5/16"

(84mm)

13-15/16"

(353mm)

71-7/16" (1813mm)

49-5/8" (1260mm)

33-7/8" (860mm)

with bumper

22-5/8" (573mm)

25-1/16"

(636mm)

with bumper

electrical

pass-thru

*74-5/16" (1887mm) - with optional 3-1/2" casters

E X T E R I O R D I M E N S I O N S - 1 0 0 0 - U P

W E I G H T 1000-UP/STD 1000-UP/HD

NET 241 lb (109 kg) 270 lb (122kg)

SHIP 275 lb (125kg) 303 lb (137kg)

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 7.

PRODU C T CAPA CITY

120 lbs (54 kg)

VO LUME MAXIMUM

MAXI MUM

: 60 QU ARTS (76 LIT ER S)

I N S TA L L A T I O N

OPTI ONS AND ACCES SORIES 500-S 750-S 1000-S 1000-UP

Bumper, Full Perimeter 5006782 5004861 5005103 5005103

Carrying Handle Kit 55662 55662 55662 ––

Carving Holder

PR IM E RI B

ST EA MSHIP (C AFETERI A) R OU ND

Casters - 2 RIGID, 2 SWIVEL W/BRAKE

5" (127mm)

2-1/2" (64mm)

Door Lock with Key LK-22567 LK-22567 LK-22567 LK-22567

Drip Pan

1" (25mm)

WI TH DRA IN, 1-11/16" (43mm)

1-7/8" (48mm)

EX TR A DEEP, 2-7/16" (62mm)

Drip Tray, External 1007267 5004975 –– ––

HL-2635

4459

5004862

5008022

PN-2122

––

––

––

HL-2635

4459

5004862

5008022

––

14831

––

––

––

––

5004862

5008022

––

––

11906

1115

––

––

5008017

––

––

––

––

––

Legs, 6" (152mm), Flanged (SE T OF FOUR) 5004863 5004863 5004863 5004863

Pan Grid, Wire - 18" X 26" PAN INSERT –– PN-2115 PN-2115 PN-2115

Pass-Through Design AVAILABLE AVAILA BL E AVAIL ABLE AVAILABLE

Probe, Internal Temperature

ELECTR ON IC CONTROL ONLY

AVAILABLE AVAILA BL E AVAILABLE AVAILABLE

Shelf, Chrome Plated

RE AC H-IN

PASS-TH RO UGH

SH-2107

––

SH-2105

SH-2327

––

––

––

––

Shelf, Stainless Steel

RE AC H-IN

PASS-TH RO UGH

RI B RACK

SH-2326

––

––

SH-2324

––

SH-2743

SH-2325

SH-2346

––

SH-2325

SH-2346

––

Stacking Hardware 5004864 5004864 5004864 ––

Water Reservoir (REMO VABLE FOR PROOFIN G)

PAN

CO VE R

––

––

––

––

1775

1774

1775

1774

Window Door –– 55609R 15148R 15148R

HACCP Network Options (ELECTR ON IC CONTROL ONLY)

➥ HACCP Documentation

➥ HACCP with Kitchen Management

* REFER TO HACCP SPECIFICATION #9015 FOR A PPLICA BLE PART NUMBERS.

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 8.

I N S TA L L A T I O N

CASTER SET

SCREW

TOP

MOUNTING

SCREWS

STACKING

POSTS

TOP

MOUNTING

SCREWS

STACKING INSTRUCTIONS

1) If th e two ap plia nces w ere s hipp ed togeth er from the fac tory, the t op uni t will h ave t he

ca ster s already remo ved. A sta ckin g kit w ill be i nclu ded w ith th e ship ment.

If casters nee d to be removed: lay the unit on its back, and remove the set screw on each caster. Pull th e

casters out of the unit.

2) Whi le app lian ce is l aid on i ts bac k, ins ert o ne sta ckin g post i n each o f the f our co r ners

of t he upp er uni t. Secu re the stac king p osts u sing o ne screw a nd two f lat wa sher s that

co me wit h the st acki ng kit .

Note: The flange on the stacking posts must f ace the outside of the unit.

3) Rem ove th e four t op mou nting screws f rom t he low er uni t. Place t he upper ap plia nce,

wh ich ha s the st acki ng pos ts instal led, o n top of t he bot tom u nit. Cen ter t he top u nit

from front t o back . Re -ins tal l the fo ur screws t hro ugh th e flan ge of th e four s tack ing

po sts.

S I T E I N S T A L L A T I O N

Stacking Configurations

––1000-S with 1000-S, 1000-TH/III, or 1000-TH-II /Split

––75 0-S with 750-S, 750-TH-II, 750 -TH/III, 767-SK, 767-SK/III

––500-S with 500-S, 500-TH-II, 500-TH/III

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 9.

S I T E I N S T A L L A T I O N

W A R N I N G

RISK OF ELECTRIC SHOCK.

Appliance must be secured

to building structure.

I N S TA L L A T I O N

A number of adjustments are associated with

initial installation and start-up. It is important

that these adjustments be conducted by a qualified

service technician. Installation and start-up

adjustments are the responsibility of the dealer or

user. These adjustments include but are not

limited to thermostat calibration, door adjustment,

leveling, electrical hook-up and installation of

optional casters or legs.

LEVE LING

Level the oven

from side-to-side and front-toback with the use of a spirit level. For ovens

installed with casters, it is important that the

installation surface be level due to the probability

of frequent oven repositioning.

We recommend checking the level of the oven

periodically to make certain the floor has not

shifted nor the oven moved.

NOTE: Failure to properly level this oven can

cause improper function and will result

in the uneven baking with products

consisting of semi-liquid batter.

REST RAINT REQUI REMENTS

—MOB ILE EQUIPME NT

Any appliance that is not furnished with a power

supply cord but that includes a set of casters must

be installed with a tether. Adequate means must

be provided to limit the movement of this

appliance without depending on or transmitting

stress to the electrical conduit. The following

requirements apply:

1. Maximum height of casters is 6" (152mm).

2. Two of the casters must of be the locking type.

3.

Such mobile appliances or appliances on mobile

stands must be installed with the use of a flexible

connector secured to the building structure.

A mounting connector for a restraining device is

located on the lower back flange of the appliance

chassis or on an oven stand, approximately 18"

(457mm) from the floor. A flexible connector is not

supplied by nor is it available from the factory.

500-S , 750- S, 1000-S , 10 00 -UP • IN STAL LATION/O PERATI ON/SERV ICE MANUA L • 10 .

I N S TA L L A T I O N

W A R N I N G

FAIL URE TO PRO PERLY I NSTALL THE

DRIP TRAY CAN OR WILL CAUS E

MAJOR EQUIPMENT DAMAGE AN D

WILL RESULT IN A LEAKAGE

HAZARD THAT CAN CAUSE

PERSONAL INJURY.

S I T E I N S T A L L A T I O N

DRIP TRAY INSTALLATION INSTRUCTIONS

STA NDARD DRIP PAN *

[B OTTOM OF OVEN INT ER IO R

• BEL OW SI DE -RACKS]

HA NG DRIP TRAY ON SC REWS

500-S , 750- S, 1 00 0-S, 1 000-U P • INSTA LLATIO N/OPE RATION /S ERVIC E MA NU AL • 1 1.

DR IP

TR AY*

*S EE ALTO-SHAAM PART S LIST FO R ALTO-SHA AM PART NUMB ER S.

I N S TA L L A T I O N

D A N G E R

ENSURE POWER SOURCE

MATCHES VOLTAGE STAMPED

ON APPLIANCE NAMEPLATE.

D A N G E R

To avoid electrical shock, this

appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence of

local codes, with the current edition

of the National Electrical Code

ANSI/NFPA No. 70. In Canada, all

electrical connections are to be

made in according with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

C A U T I O N

THIS SECTION IS PROVIDED FOR THE ASSISTANCE

OF QUALIFIED SERVICE TECHNICIANS ONLY AND

IS NOT INTENDED FOR USE BY UNTRAINED OR

UNAUTHORIZED SERVICE PERSONNEL.

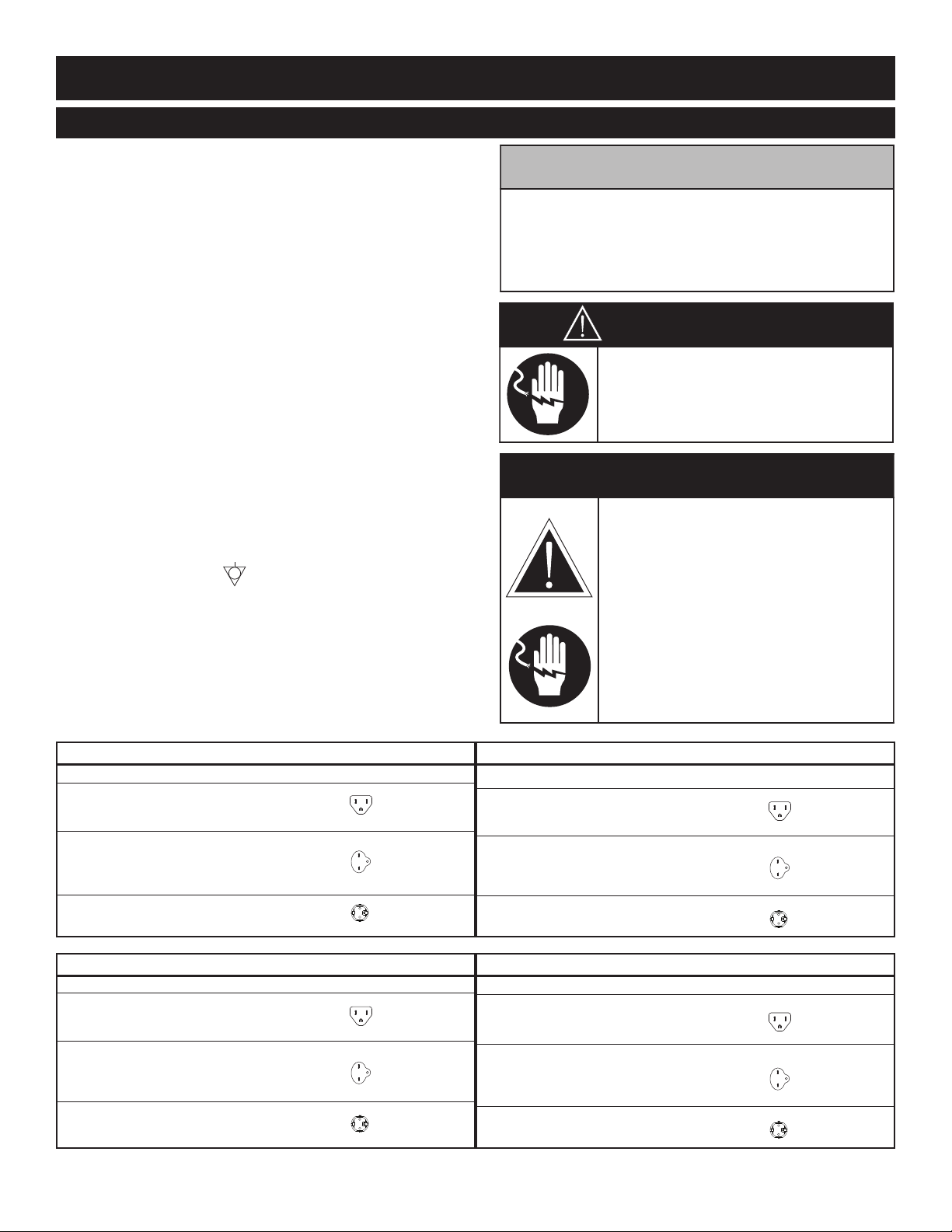

E L E C T R I C A L

1. An identification tag is permanently mounted on

the cabinet.

2. Plug cabinet into a properly grounded receptacle

ONLY, positioning the unit so the power supply cord

is easily accessible in case of an emergency.

Arcing will occur when connecting or disconnecting

the unit unless all controls are in the “OFF” position.

3. If necessary, a proper receptacle or outlet

configuration as required for this unit, must be

installed by a licensed electrician in accordance with

applicable, local electrical codes.

For 230V:

To prevent an electrical shock hazard between the

appliance and other appliances or metal parts in

close vicinity, an equalization-bonding stud is

provided. An equalization bonding lead must be

connected to this stud and the other appliances /

metal parts to provide sufficient protection against

potential difference. The terminal is marked with the

following symbol.

NOTE:

The appliance must be connected to an electrical

circuit that is protected by an external GFCI outlet.

E L E C T R I C A L - 50 0 - S

VOLTAGE PH ASE CY CL E/HZ A MPS

120 1 60 8.3 1.0 NE MA

208-240 (UL )1 60 4.2 1.0 NE MA

at 208 1 60 3.7 .76

at 240 1 60 4.2 1.0 (US A ONLY)

230 1 50 4.1 .95 C EE 7/7,

E L E C T R I C A L - 75 0 - S

VOLTAGE PH ASE C YCL E/HZ AMP S

120 1 60 9.0 1.08 NE MA

kW

kW

208-240 (UL )1 60 4.5 1.08 N EMA

at 208 1 60 3.9 .80

at 240 1 60 4.5 1.08 (USA ONLY)

230 1 50 4.3 1.0 CEE 7/7,

500-S , 750- S, 1000-S , 10 00 -UP • IN STAL LATION/O PERATI ON/SERV ICE MANUA L • 12 .

CORD&PL UG

5-15P,

15A-125

15A-250

220-230

15A-125

15A-250

220-230

V PL UG

6-15P,

V PL UG

V PLUG

CORD&PL UG

5-15P,

V PL UG

6-15P,

V PL UG

V PLUG

EL ECT RIC AL - 1 000 -S

VOLTAGE PH ASE C YCL E/HZ AM PS K

120 1 60 8.0 .96 NEMA

208-240 (UL )1 60 4.0 .96 NE MA

at 208 1 60 3.5 .72

at 240 1 60 4.0 .96 PLUG ( USA ONLY)

230 1 50 3.85 .88 C EE 7/7,

EL ECT RIC AL - 1 000 -UP

VOLTAGE PHASE CYCLE/HZ AMPS

120 1 60 16.0 1.92 N EM A

208-240 (UL )1 60 8.0 1.92 NE MA

at 208 1 60 6.9 1.44

at 240 1 60 8.0 1.92

230 1 50 7.7 1.76 CE E 7/7,

kW

W

CORD&PL UG

15A-125

15A-250

220-230

CORD&PL UG

20A-125

15A-250

USA ONLY)

(

220-230

5-15P,

V PL UG

6-15P,

V

V PLUG

5-20P,

V PL UG

6-15P,

V PL UG

V PLUG

Loading...

Loading...