Alto Shaam 1000-MR1 Service Manual

#8410/11 • 3/2001

PRINTED IN U.S .A .

OPERATION and CARE MANUAL

COOK/HOLD/SERVE SYSTEMS

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558.8744

U.S.A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

Mobile Refrigerated Cart

Models: 1000-MR1

1000-MR2

®

1.0 INTRODUCTION

This technical manual provides information

on the installation, operation, maintenance,

and inspection of this unit. A complete parts

breakdown is provided.

1.1 EQUIPMENT DESCRIPTION

The unit consists of the following:

Storage Compartment: The insulated food

storage compartment is clear storage area.

Included in this area are the adjustable

shelves and cooling coil.

Doors: Access to the storage compartment is

through a hinged-mounted insulated door.

Condensing Unit Compartment: This area

contains the condensing unit along with the

necessary controls.

Evaporator Coil: The evaporator coil is

located in the storage compartment and is

responsible for distributing the cold air

associated with the refrigeration system.

Cabinet: The cabinet is the enclosure in

which all of the above items are housed.

1.2 EQUIPMENT SUPPLIED

The unit is shipped from the factory fully

assembled except the adjustable shelving that

will require positioning on the side racks.

The complete assembly is palletized and

crated to reduce the possibility of damage in

shipping and storage.

1.3 LEADING PARTICULARS

Refrigerant: 134a

Electrical:

1000-MR1 1000-MR2

115VAC 115VAC

60 Hz, 1ø 60 Hz, 1ø

8.7 Amps 10.8 Amps

220-240VAC 220-240VA

50 Hz, 1ø 50 Hz, 1ø

4.4 Amps 6.3 Amps

Weight:

Net 410 lb (186 kg) 800 lb (363kg)

Shipping 671 lb (304kg) 1210 lb (549kg)

2.0 FUNCTIONAL DESCRIPTION

This unit is a self-contained, automatically

controlled, continuous duty perishable food

storage system. It is designed with the intent

and purpose of storing cold food items. The

operating temperature is automatically

monitored by controls that are factory-set to

maintain a predetermined, adequate

condition.

The unit consists of two basic compartment

assemblies:

a.

Condensing Unit Compartment which

includes the condensing unit, the electrical

control panel with power switch and

terminal box, and a heated condensation

evaporator.

b. Storage Compartment which consists of the

insulated clear storage area for perishable

food items requiring a temperature range

of 37° to 40°F (3° to 4°C). The clear

storage area includes adjustable shelving.

2.1 SYSTEM OPERATION

The primary focus for the design of the

refrigerated cabinet is for the safe storage of

food products which require refrigeration.

Considerable engineering attention was

placed on the qualities of function and

serviceability.

The refrigeration system is a closed loop

system. Unless the system develops a leak,

adding additional refrigerant is not necessary.

3.0 START-UP PROCEDURE

The refrigeration system is completely factoryassembled, precharged and ready for operation.

The control has been set to display temperature

in degrees Fahrenheit or degrees Celsius as

specified on the original order.

To energize the system, it is only necessary to

locate the power supply cord and connect it to a

proper electrical supply source. Once the

supply cord has been connected to a power

source, the unit can be started by switching the

power control switch to the “

ON” position.

3.1 SHUT-DOWN PROCEDURE

To shut-down, place the power control in the

"OFF" position and open the door to allow the

cabinet interior temperature to equalize with

the room temperature.

Use a mild detergent diluted in warm water to

wash the interior and exterior surfaces of the

cabinet.

Operation and Care Manual #8410/11 • 1

Alto-Shaam Mobile Refrigerated Carts

NEMA 5-15P

15A, 125V Plug

NEMA 5-15P

15A, 125V Plug

NEMA 6-15P

15A, 250V Plug

NEMA 6-15P

15A, 250V Plug

PROCEDURES

NAME

Thermostat

Suction Valve

Discharge Valve

Power Control Switch

(

ON/OFF)

LCD Display

TYPE

Contact Points

Service Valve

Service Valve

Contact Points

FUNCTION

Cycles the refrigeration

system (automatic)

Isolate suction at the

compressor.

Isolate discharge at

the receiver.

Terminates power to

the unit.

Indicates continuous

cabinet temperature.

CONTROLS AND INDICATORS

OPERATION

Activate system by inserting

electrical service cord into electrical

supply source. Turn power switch to

the “ON” position.

With the door closed and the

storage area empty of product, wait

for a period of 1 hour.

Verify correct operating

temperature.

Begin stocking the containment

area when the proper operating

temperature has been reached.

RESULTS

The compressor should immediately

come on-line and the condenser fan

and evaporator fan activate.

The temperature in the storage area

will begin to decrease.

Cabinet will have reached the

proper operating temperature of

36°F ±3°F (2°C, ±1°C).

START-UP PROCEDURE

3.3 EXTENDED PERIOD OF INACTIVITY

This unit is designed for continued use at

automatically cycled intervals. In case of an

extended shut-down, the food storage

compartment must be cleaned and wiped dry to

minimize the potential of odor build-up during

shutdown.

Operation and Care Manual #8410/11 • 2

Ensure the

available

power

source

matches the

voltage

stamped on

unit

nameplate

.

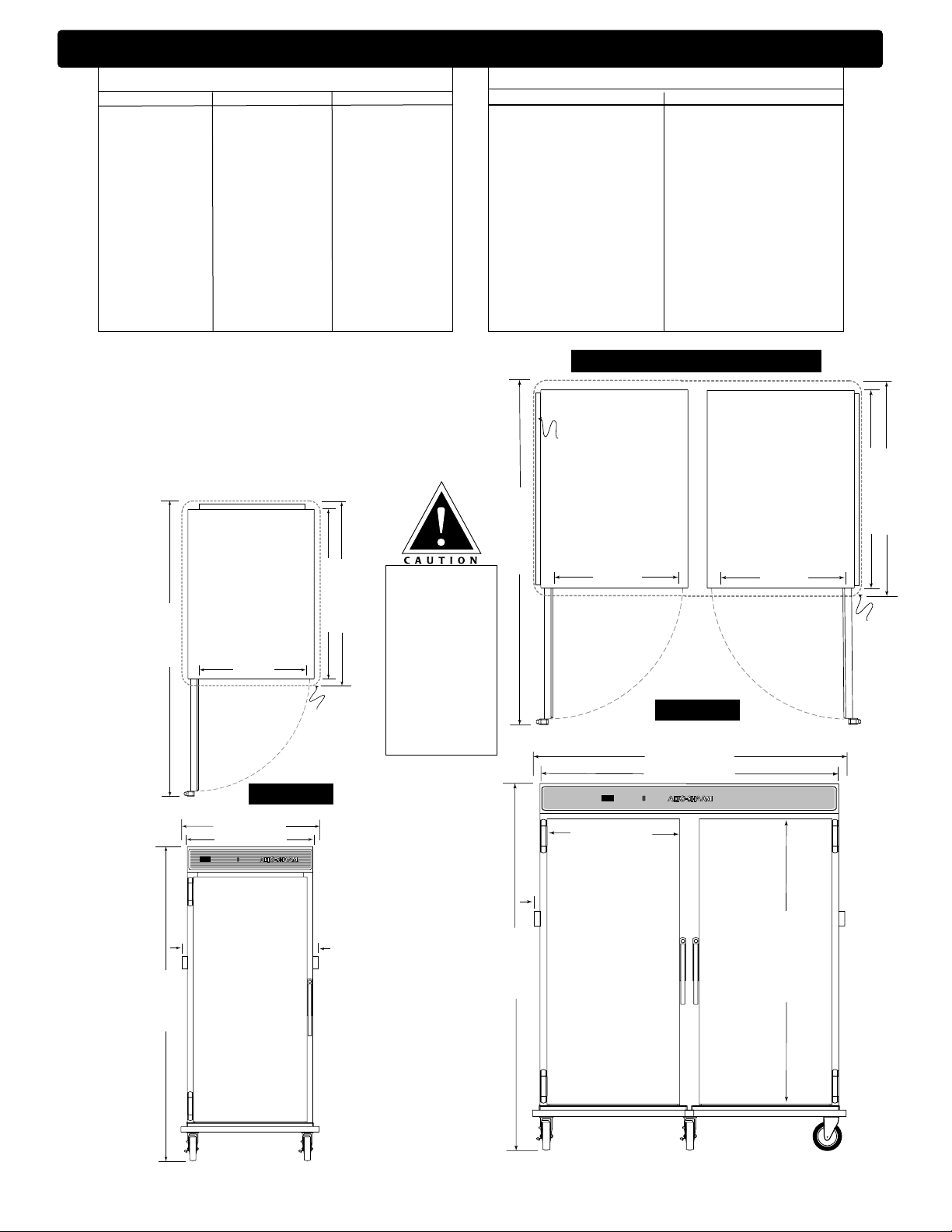

OUTSIDE DIMENSIONS

1000-MR2

1000-MR1

PUSH

HANDLE

24-1/4" (617mm)

length

29-3/4" (749mm)

24-1/2" (622mm)

53" (1346mm)

C

2°

1-3/8" (35mm)

21-1/4"

(540mm)

29-1/2" (749mm)

WITH BUMPER

26-1/2" (673mm)

on l

POWER

off o

36-1/2" (927mm)

FULL

PERIMETER

BUMPER

1-3/8" (35mm)

39-1/4" (997mm)

56-5/8" (1438mm)

29-1/2" (749mm)

1-1/2" (35mm)

68" (1727mm)

27-1/2"

(699mm)

C

2°

WITH BUMPER

67-1/2" (1714mm)

64-1/2" (1638mm)

on l

POWER

off o

27-1/2"

(699mm)

54-1/4" (1378mm)

FULL

PERIMETER

BUMPER

68" (1727mm)

Operation and Care Manual #8410/11 • 3

4.0 OPERATING PROCEDURES

The purpose of this mobile refrigerator is to

maintain cold foods at proper serving

temperatures. The unit should be used for

the intended purpose only.

a. Adjust the position of the shelves to

accommodate required storage needs.

b. Switch the power to the “ON” position.

c. Prechill the cabinet to the full, factory

preset temperature of 36°F ±3°F (2°C).

d. Load the refrigerator with chilled foods

only. Before loading, use a food

thermometer to make certain all products

are at a temperature of 41°F (5°C)

maximum or less. Cover foods to reduce

moisture build-up on the inside wall of

the cabinet. To maintain the proper

refrigerated food temperature, open the

door only when necessary. The mobile

refrigerator door may be locked if

required.

5.0 CLEANING and MAINTENANCE

A thorough, periodic maintenance schedule is

required to ensure the longest and most

trouble free operation. Maintenance

schedules should be aimed at maximizing the

efficient use of maintenance personnel,

reducing down-time, and providing the

orderly acquisition of spare parts support.

5.1 CLEANING

Follow appropriate state

and local health (hygiene)

regulations regarding all

applicable cleaning and

sanitation requirements

for food service equipment.

DAILY:

Wipe all spills at once.

WEEKLY:

a. Remove the wire shelves and side-rack

shelf supports. Clean these items

separately using a mild, non-abrasive

detergent and soft cloth.

b. With a mild, non-abrasive detergent and

water, use a soft cloth to wipe the interior

liner of the storage compartment. Begin

at the top and work down. Wipe the

gasket surrounding the storage

compartment opening.

c. Using a mild detergent and water, wipe

the vinyl door gasket. Make certain to

wipe under the gasket to remove any

mildew or residue.

d. Wipe interior surfaces with a clean cloth

and sanitizing solution for use on metal

and vinyl food contact surfaces. This is

an important step to control the build-up

of unwanted mildew and mold on the

evaporator coil and fan.

e. Vacuum right, left and back panel grill

vents to maintain maximum air flow.

e. Wipe the exterior of the unit with a mild

detergent and water. Always wipe with

the grain of the stainless steel to prevent

scratching the finish.

OPERATION/CLEANING

SWITCH UNIT POWER “OFF” AND

DISCONNECT THE POWER SUPPLY

CORD BEFORE CLEANING,

SERVICING, OR PERFORMING

SCHEDULED MAINTENANCE.

SCHEDULED MAINTENANCE

6.0 MAINTENANCE

Remember to de-energize the unit by

switching the toggle switch located on the

control panel to the “OFF” position.

Disconnect the unit from the power source.

6.1 MONTHLY INSPECTION & SERVICE

CHECK THE INLET AND OUTLET ENDS OF

THE DRAIN LINE to make certain there are

no obstructions. If an obstruction is found:

Use compressed air to unblock an obstructed

drain line in a forced air evaporator model.

Remove the drain line at the evaporator coil

and attach an air line using 60 pounds of

pressure. The use of chemicals to clear a

clogged drain is not recommended.

6.2 YEARLY INSPECTION & SERVICE

1. INSPECT THE DOOR GASKET for cracks,

splits, and dryness.

2. INSPECT THE MOVING PARTS OF THE

DOOR LATCH assembly for signs of wear.

Check the screw tightness on both latch

and strike.

3. CHECK THE HINGES by opening the

door to a 90-degree angle to the cabinet.

With minimum pressure, lift up on the

outer edge of the door. Replace the hinges

if there is an upward movement of 1/2-inch

(12,7mm) or more.

6.3 THERMOSTAT ADJUSTMENT

Before making any adjustment to the

thermostat, check the door gasket for proper

seal. Proper adjustment can be tested by

pulling a dollar bill through the gasket seal

and feeling a slight resistance. If it is

determined a proper seal is maintained

around the full perimeter of the gasket, a

thermostat adjustment may be necessary.

1. Remove all shelves and remove the left-hand

side rack.

2. Remove the interior back wall of the unit by

lifting up and out.

3. The thermostat is located behind the back

wall in the upper left corner of the unit and

is clearly marked for adjustment purposes.

To adjust the temperature, turn the

thermostat counter-clockwise one or two

increments for colder operation. Turn the

thermostat clockwise one or two increments

for warmer operation. To avoid an unsafe

temperature or freezing, make small

adjustments only.

4. Replace back wall, side rack and wire

shelves. Close the cabinet door and allow

the unit to operate without interruption for

a period of one hour.

5. At the end of one hour, check the

temperature in the display. Repeat

adjustment as necessary.

6.4 CONDENSER FAN & MOTOR REPLACEMENT

1. Disconnect all electrical power to the unit.

2. Remove the ventilation grill. Lift the grill

vertically 1-inch (25mm) while pulling out on

the bottom and lowering the grill from the

retainer angles.

3. Remove the mounting bolts on the

condensing unit base and slide the

refrigeration assembly out.

4. Remove the protective shroud from around

the motor.

5. Remove the mounting screws at the motor

base.

6. Using an allen wrench, loosen the set screw

on the blade hub and slide blade from the

shaft.

7. Install the new condenser fan by reversing

the process.

8. Install the motor by reversing the process.

Operation and Care Manual #8410/11 • 4

Loading...

Loading...