Alto Shaam 1000-HCM Installation Manual

#843 • 9/2001

PRINTED IN U.S .A .

OPERATION and CARE MANUAL

®

COOK/HOLD/SERVE SYSTEMS

W164 N9221 Water Street ●P.O. Box 450 ●Menomonee Falls, Wisconsin 53052-0450 U.S.A.

PHONE: 262.251.3800 FAX: 262.251.7067 • 800.329.8744 U.S.A. ONLY WEBSITE:

800.558.8744 U.S.A./CANADA 262.251.1907 INTERNATIONAL www.alto-shaam.com

HOT & COLD MERCHANDISER

1000-HCM

Operation & Care Manual #843 • 1.

UNPACKING and SET-UP

The Alto-Shaam Hot &

Cold Merchandiser has been

thoroughly tested, checked

for calibration, and inspected

to insure only the highest

quality cabinet is provided. When you receive your

cabinet, check for any possible shipping damage and

report it at once to the delivering carrier.

See

Transportation Damage and Claims section located in this manual.

The cabinet, complete with unattached items and

accessories, may be delivered in one or more packages. Make certain the number of packages received

matches the packing list and the accompanying bill

of lading.

Save all the information and instructions packed

inside the cabinet. Complete and return the warranty card to the factory as soon as possible to insure

prompt service in the event of a warranty parts and

labor claim.

The unit should NOT be used in any area where it

may be affected by steam, grease, dripping water,

high temperatures, drafts from ventilator openings,

radiant heat from light fixtures that are too close or

any other severely adverse conditions. The case is

designed to be used in areas that maintain a temperature at or below 75°F (24°C) dry bulb and a 55%

relative humidity. The case must be installed level in

order for the drain in the refrigerated section to work

properly.

The unit must be bolted to its base. In order to

maintain standards established by the National

Sanitation Foundation, stationary models mounted

directly on top of an base must be sealed to both the

base and the floor with a R.T.V. or silastic meeting

N.S.F. requirements. Counter and table units must

be mounted on legs of a sufficient 4" height to provide minimum unobstructed space beneath the unit.

Any countertop mounted installations must have

adequate ventilation at the bottom of the unit for

proper air circulation.

(Refer to counter layout in this

manual).

NOTE: Any claims for warranty must include

the full model number and serial number

of the cabinet.

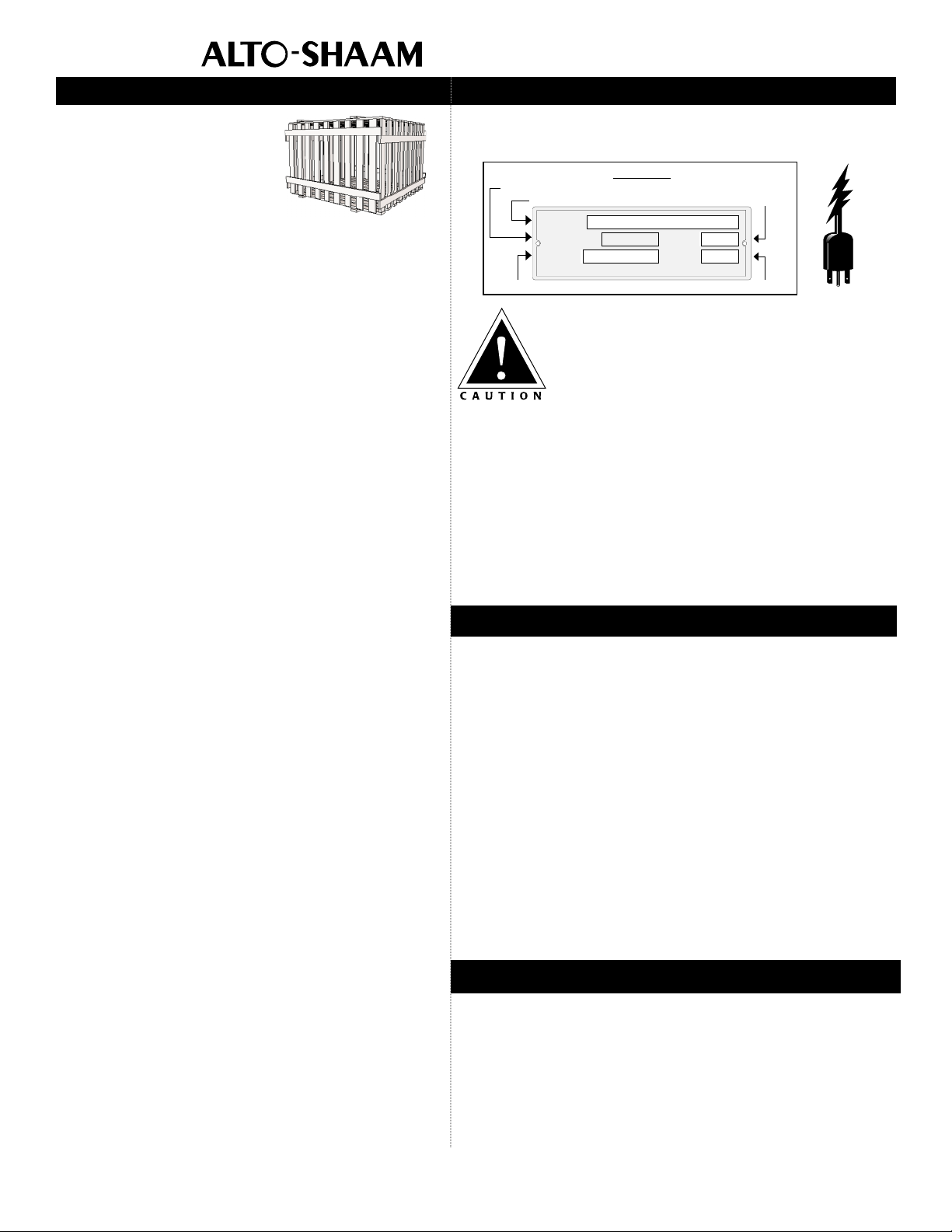

HARACT

ENSURE

POWER SOURCE

MATCHES VOLTAGE STAMPED

ON NAMEPLATE OF UNIT

WARMING CHARACTERISTICS

The cabinet is equipped with a special, low-heat-density,

heating cable. Through the Halo Heat concept, the heating

cable is mounted against the walls of the warming

compartment to provide an evenly applied heat source,

controlled by an electronic thermostat. The design and

operational characteristics of the unit eliminates the need for

a moisture pan or a heat circulating fan. Through even heat

application, the quality of a food product is maintained for

short periods or for longer time periods, up to several hours.

The heated compartment is equipped with an electronic ther-

mostat, pilot light, and digital display to monitor inside air

temperature.

REFRIGERATION CHARACTERISTICS

The cabinet is equipped with a 1/3 horsepower

compressor, R-404A refrigerant, low pressure safety switch

in the event a refrigerant leak should occur, and a

timer/defrost mechanism. Each cabinet is equipped with

an electronic thermostat and digital display to monitor inside

air temperature.

ELECTRICAL INSTALLATION

An identification tag is permanently mounted on

the cabinet.

A proper receptacle or outlet configuration, as required

for this unit must be installed by a licensed electrician

in accordance with applicable, local electrical codes.

Permanent wiring for this unit must be installed by a

licensed elecrician in accordance with applicable local

electrical codes. Position the merchandiser so that the

power supply cord is easily accessible in case of an

emergency.

– MERCHANDISERS

®

SERIAL NUMBER AND WARRANTY CODE

IDENTIFICATION MODEL NUMBER

MODEL

SERIAL NO. WATTS

VOLTS

MAXIMUM RATED VOLTAGE MAXIMUM RATED FREQUENCY

EXAMPLE

xxx-xx

xxxx-xx xxxx

AC

ALTO-SHAAM INC. MILW. WI. PAT. NO. 3521030

1 PH

MAXIMUM RATED

WATTAGE

xx

HZxxx

START-UP

1. Before operating the merchandiser, clean the interior and exterior of the unit with a damp cloth and mild soap solution. Rinse carefully.

2. Clean and install the cabinet wire shelves inside the hot and cold cavities, the bottom baffle pan in the hot cavity, and

the external condensate drip pan underneath the cold cavity.

3. Clean glass with a window cleaner.

4. After final hook-up, locate the circuit breaker box under the unit and flip breaker switches to the ON position for full

power to the merchandiser.

5. Let the case run through at least one defrost before loading with product, checking the duration of defrost (preferably

two or more) and frequency, to make sure the case is defrosting properly. Check the operating temperature to make

sure the case is functioning within the guidelines recommended for this case.

OPERATIONAL PROCEDURES

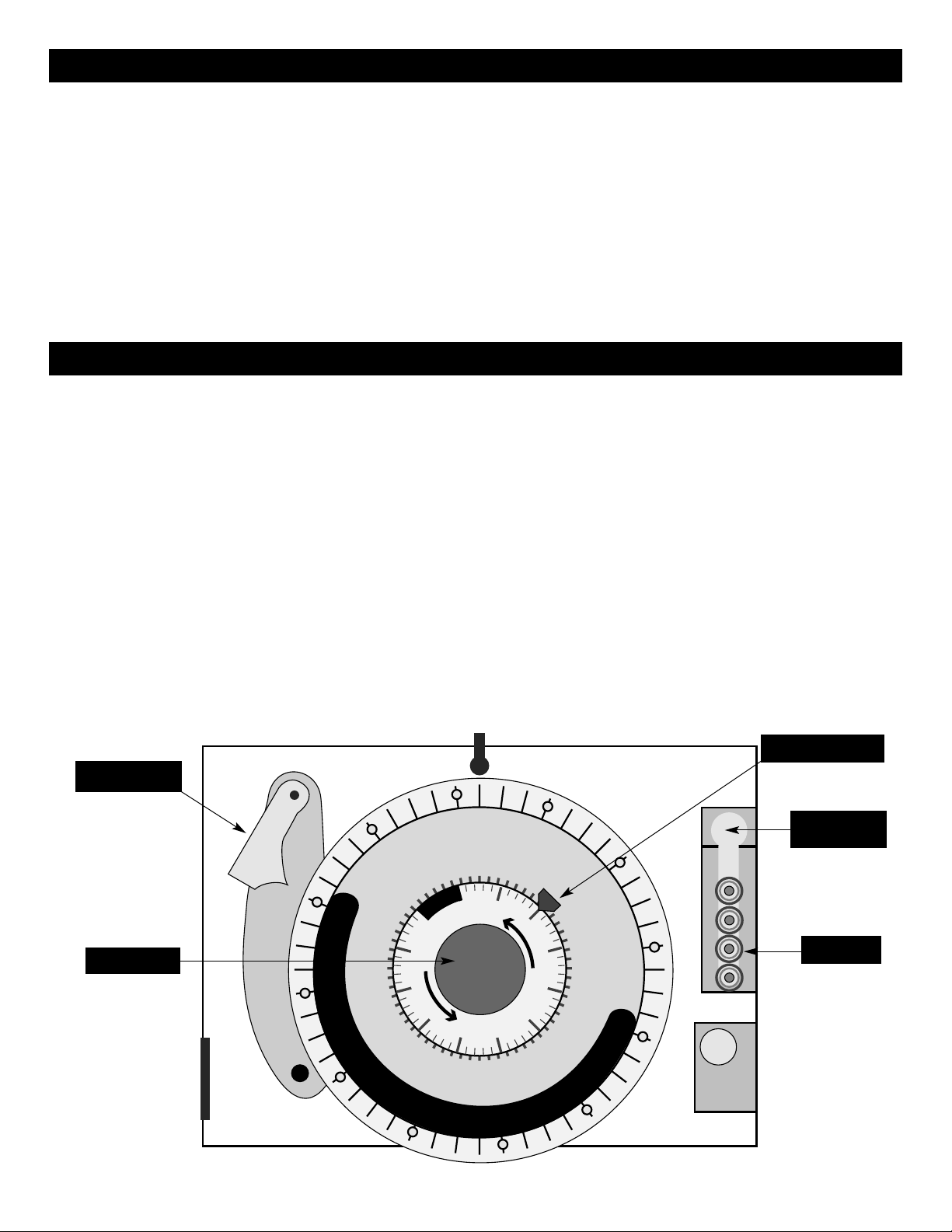

1. SETTING TIMER / DEFROST MECHANISM.

The timer/defrost mechanism is located behind the end panel on the refrigerated side of the merchandiser. The panel

can be removed by unscrewing two screws located at the top of the panel. Lift up and slide bottom of panel out to

remove. Press spring clip at right center of timer defrost box and open the metal case door.

A. To set the time of day, grasp knob in the center of the inner 2-hour dial and rotate it in a counter-clockwise direc-

tion. This will revolve the outer dial. Line up the correct time of day on the outer dial with the time pointer. Do

not try to set the time control by grasping the outer dial. Rotate the inner dial only.

B. To set the mechanical defrost termination, push down and rotate the copper pointer on the inside 2-hour dial until

it is opposite the desired time. Twenty (20) minutes is recommended in order to avoid frost build-up on the coils

and avoids warming of products kept in the cold compartment.

C. Slide the screw start pins out of the holder on the right side and place the start pins in the outer 24-hour dial at the

time of day that the defrosting should occur, and screw into place. Caution: Leave at least 1 hole between each

adjacent pin. It is recommended that the start pins be placed every 6 hours to coincide with off-peak times such as

before the store opens, after the store closes and lull periods during the business day to prevent the excess loss of

chilled air when the doors are continuously being opened.

Operation & Care Manual #843 • 2.

Copper Pointerr

Time Pointer

Inner Dial

Start Pin

Holder

Start Pin

TIME

1

1

0

1

9

8

7

6

5

4

3

2

O

0

N

K

1

1

N

R

U

T

0

0

1

0

9

0

8

0

7

N

O

O

N

1

2

1

0

B

2

0

3

0

4

T

0

U

R

N

K

5

N

0

O

B

6

0

3

4

5

6

2

1

T

H

D

I

G

I

M

N

D

I

1

1

M

7

8

9

1

0

Operation & Care Manual #824 • 3.

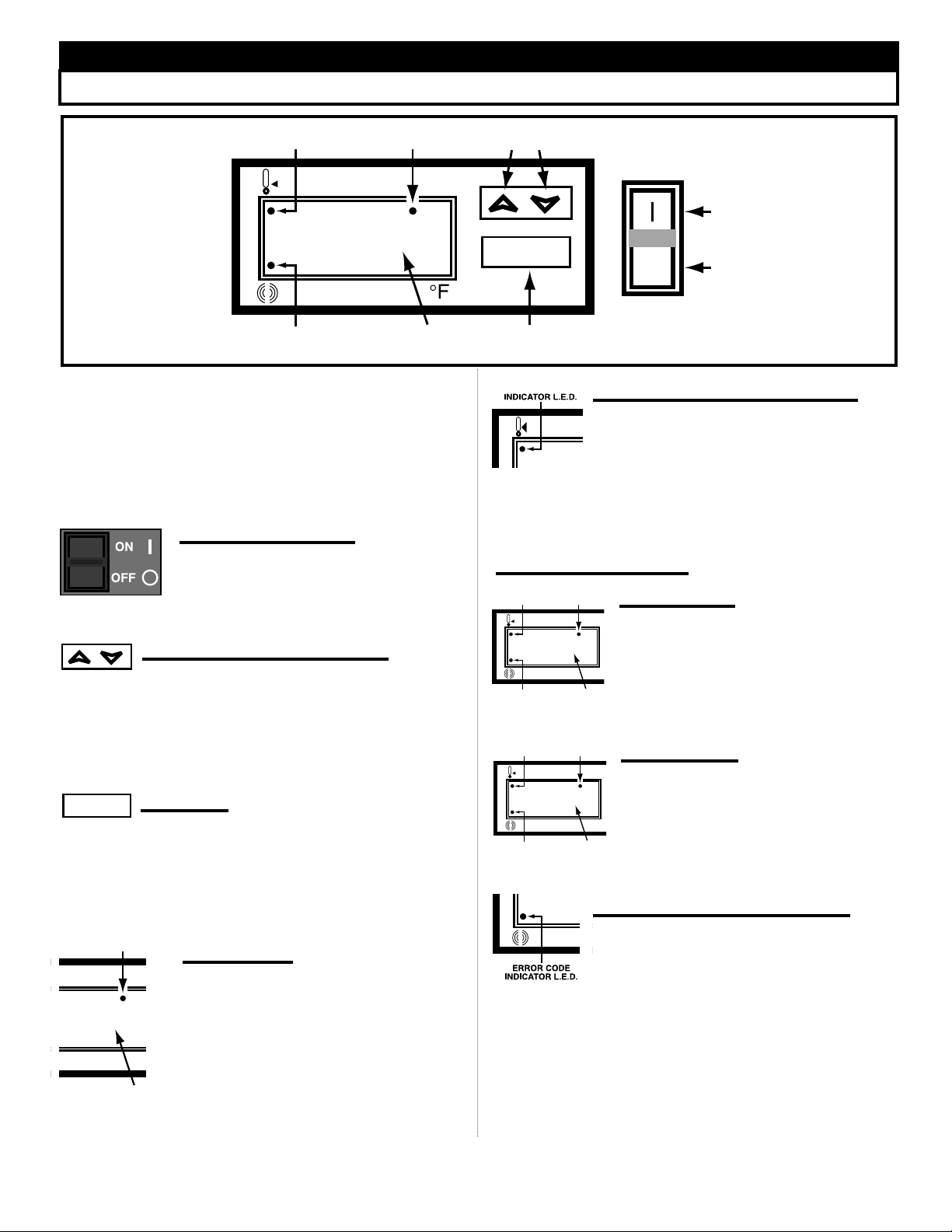

OPERATIONAL PROCEDURES

●

Thermostat Control Description and Function

The L.E.D., Light Emitting Diode, referred to is an electronic

device providing illumination.

The control has a three-digit L.E.D. display. When the warm or

cold cabinet is in operation, the L.E.D. will show the chamber's

internal temperature. The display will also show programming

and diagnostic information.

ON/OFF Rocker Switch

The Power On/Off Rocker Switch positions

may be marked with the international "

I" for

On and "O" for Off.

UP/DOWN Arrow Rocker Button

The UP/DOWN arrow rocker button is used to

increase or decrease the set-point temperature. The minimum setpoint temperature for the hot side is 90°F (32°C) while the maximum set-point temperature is 200°F (93°C). The temperature

range for the cold side is 27°F to 40°F (3°C to 5°C).

SET Button

The SET button is used to display the current

set-point temperature or program a new set-point temperature.

Pushing the SET button once will display the set-point temperature value for five seconds. Holding the SET button allows the

programming mode to become active.

L.E.D. Display

The L.E.D. display will show the set-point

temperature value when programming, or the

warm or cold chamber's temperature when

calling for heat or cold. When programming a

new set-point temperature, the L.E.D.1 indicator will blink. When a new set-point temperature is chosen, the Chamber Temperature

L.E.D. will flash three times to confirm.

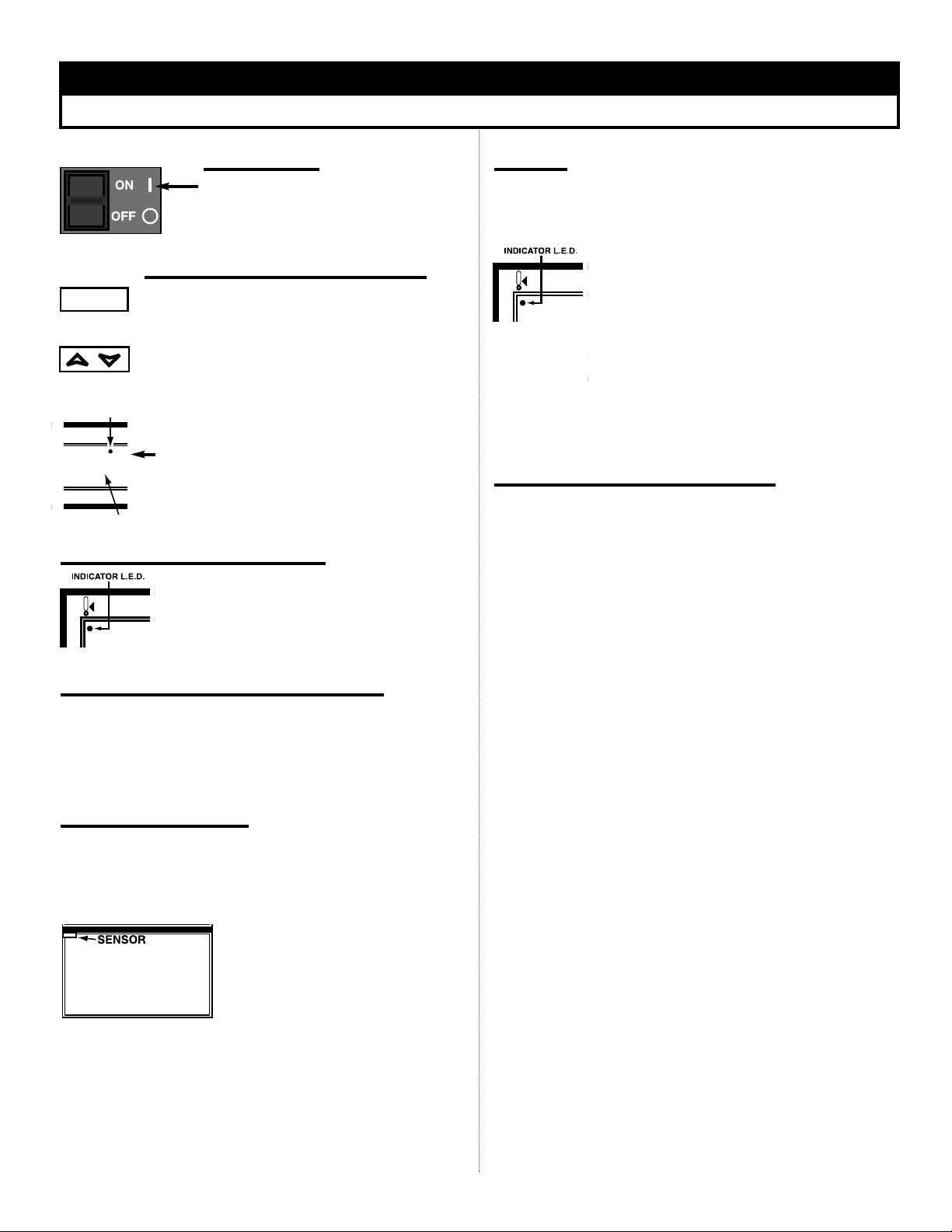

HEAT or COLD INDICATOR L.E.D.

The Heat or Cold Indicator L.E.D. will illuminate

and remain lit while the unit is calling for heat or

cold. It will go out when the air temperature

inside the chamber reaches the set-point

temperature on the control.

ERROR CODE DISPLAYS

Open-Circuited

If "ooo" is displayed in the Error Code L.E.D.,

the sensor is open-circuited. Follow Trouble

Shooting Guide instructions in this Operation

and Care Manual.

Short-Circuited

If "CCC" is displayed in the Error Code L.E.D.,

the sensor is short-circuited. Follow Trouble

Shooting Guide instructions in this Operation

and Care Manual.

ERROR CODE INDICATOR L.E.D.

If either of the above mentioned errors codes

should occur, the Error Code Indicator L.E.D. will

be illuminated and remain so until error is cleared.

L.E.D.1

L.E.D.1

HEAT/COLD

INDICATOR L.E.D.

L.E.D.1

200

THERMOSTAT

!

ERROR CODE

INDICATOR L.E.D.

POWER

ON/OFF

ROCKER SWITCH

SET

L.E.D.1

200

°F

CHAMBER

TEMPERATURE

L.E.D.

CHAMBER

TEMPERATURE

L.E.D.

INCREASE / DECREASE

BUTTON

prg

SET

TEMPERATURE

SET

BUTTON

INDICATOR L.E.D.

ooo

ERROR

CODE

DISPLAY

°F

!

ERROR CODE

INDICATOR L.E.D.

INDICATOR L.E.D.

CCC

!

ERROR CODE

INDICATOR L.E.D.

!

°F

ERROR

CODE

DISPLAY

"I" = "ON"

"●" = "OFF"

POWER

ON/OFF

ROCKER SWITCH

Operation & Care Manual #824 • 4.

Programming and Operating Thermostat Control

Turn Power On

Press the "ON" or "I" position of the

rocker switch to turn on control.

CHANGE SET-POINT TEMPERATURE

Press and hold

the SET button for at least

3 seconds. After L.E.D.1 indicator blinks, release

the Set Button. The control is now in the program-

ming mode.

Press and hold the UP or DOWN

arrow rocker button to change the value shown in the

display. Store the value by pressing the SET button.

The new set-point value will flash three times to

confirm.

HEAT or COLD INDICATOR L.E.D.

The Indicator L.E.D. will illuminate as the warming

or cooling chamber calls for heat or cold. It will

extinguish when the chamber's interior temperature reaches the set-point.

PREHEATING or PRECHILLING THE UNIT

Always preheat the warming chamber at 200°F (93°C) for 30 minutes before loading the merchandiser with hot food. Always prechill

the cooling chamber at 36°F (2°C) for 60 minutes before loading

with cold food.

LOADING THE CABINET

Load the merchandiser with hot or cold food only. The

purpose of this unit is to maintain hot food or cold food at proper

serving temperature. Use a food thermometer to make certain

all hot food has reached an internal temperature range of 140° to

160°F (60° to 71°C). Do not fill cabinet

closer than 2" from the sensor. Make

certain door is securely closed after loading. Reset the control to 160°F (71°C)

for hot food or 37° to 40°F (3° to 4°C)

for cold food.

This will not neces-

sarily be the final setting.

Proper temperature range for

the food being held will depend on the type and quantity of

product. It is advisable to periodically check the internal temperature of each item to assure maintenance of proper food serving

temperature.

+

CAUTION

The unit should be unplugged and a qualified

service technician should be consulted if any of the following situations occur:

• The Indicator L.E.D. does not illuminate after

normal start-up.

• The warm or cool cabinet does not hold the

temperature as set.

• The cabinet fails to heat or cool with the L.E.D.

illuminated.

• The cabinet heats or cools continuously with the

control “OFF”.

• Refer to Trouble Shooting Guide in this

manual.

ELECTRONIC CONTROL ACCURACY

The electronic control is a precise instrument and is designed to

offer trouble-free service. If you suspect the temperature inside

the cabinet does not match the temperature indicated on the

digital display, after stabilizing, follow the instructions

listed below.

1. Make certain the power meets the requirements of the

appliance, voltage and current rating as indicated on

identification tag.

2. Verify the temperature inside the cabinet with a quality

thermal indicator.

A. With the exception of the metal shelves, completely

empty the cabinet.

B. Make certain the sensor, located inside the cabinet at

the ceiling, is completely clean.

C. Suspend the thermal indicator in the center of the

cabinet.

D. Allow the temperature, set on the electronic thermostat,

to stabilize for a minimum of one hour before comparing the digital display with the reading on the thermal

indicator.

DO NOT OPEN THE CABINET DOOR(S) DURING THE

TEMPERATURE STABILIZATION PERIOD.

If the reading on the thermal indicator does not match the digital

display within 10°F (6°C), contact a qualified service technician

for appropriate action.

OPERATIONAL PROCEDURES

SET

L.E.D.1

200

°F

CHAMBER

TEMPERATURE

L.E.D.

Loading...

Loading...