Page 1

MODEL: MS1

Page 2

CONTENT

1. INTRODUCTION.................................................................... ..........1

2. TECHNICAL SPECIFICATION ........................................................1

3. BLOCK DIAGRAM..........................................................................2

4. SCHEMATIC DIAGRAM..................................................................3

5. PCB LAYOUT..................................................................................4

6. TEST PROCEDURE........................................................................5

7. EXPLODED VIEW & MECHANICAL PARTS LIST.........................15

8. BOM ..............................................................................................17

Page 3

z 16 effects preset

1. INTRODUCTION

2. TECHNIACAL SPECIFICATION

- 1 -

z 2-channel input and output connectors are compatible with balanced JACK

z Front panel LED indicator for clip and power on

z Accurate level control

Connectors 1/4”jack

Type RF filtered, servo balanced input

AUDIO INPUT

Impedance 30 Kohm balanced, 22 Kohm unbalanced

Max. input level +26 dBu balanced and Unbalanced

CMRR Typ. 40dB,>55dB@1 kHz

Connectors 1/4” jack

Type Balanced

AUDIO OUTPUT

Min. output impedance 100 Ohm

Max. output level +26 dBu balanced

Frequency response 10Hz to 30kHz, +/-1dB(FLAT)

SYSTEM

S/N >110dB, unweighted, 22Hz to 22kHz

SPECIFICATIONS

THD 0.005% typ.@ 0 dBu, 1khz, (unity gain), FLAT

INDICATORS Input level CLIP LED display: +7dBu

AC adaptor USA/Canada 120V~, 60Hz

U.K./Australia 240v~, 50Hz

POWER SUPPLY

Europe 230V~, 50Hz

Power consumption 5W

Dimension 130(W)×117(D)×45(H)mm(5.1”×4.6” ×1.7”)

PHYSICAL

Net weight 0.8kg

Page 4

D

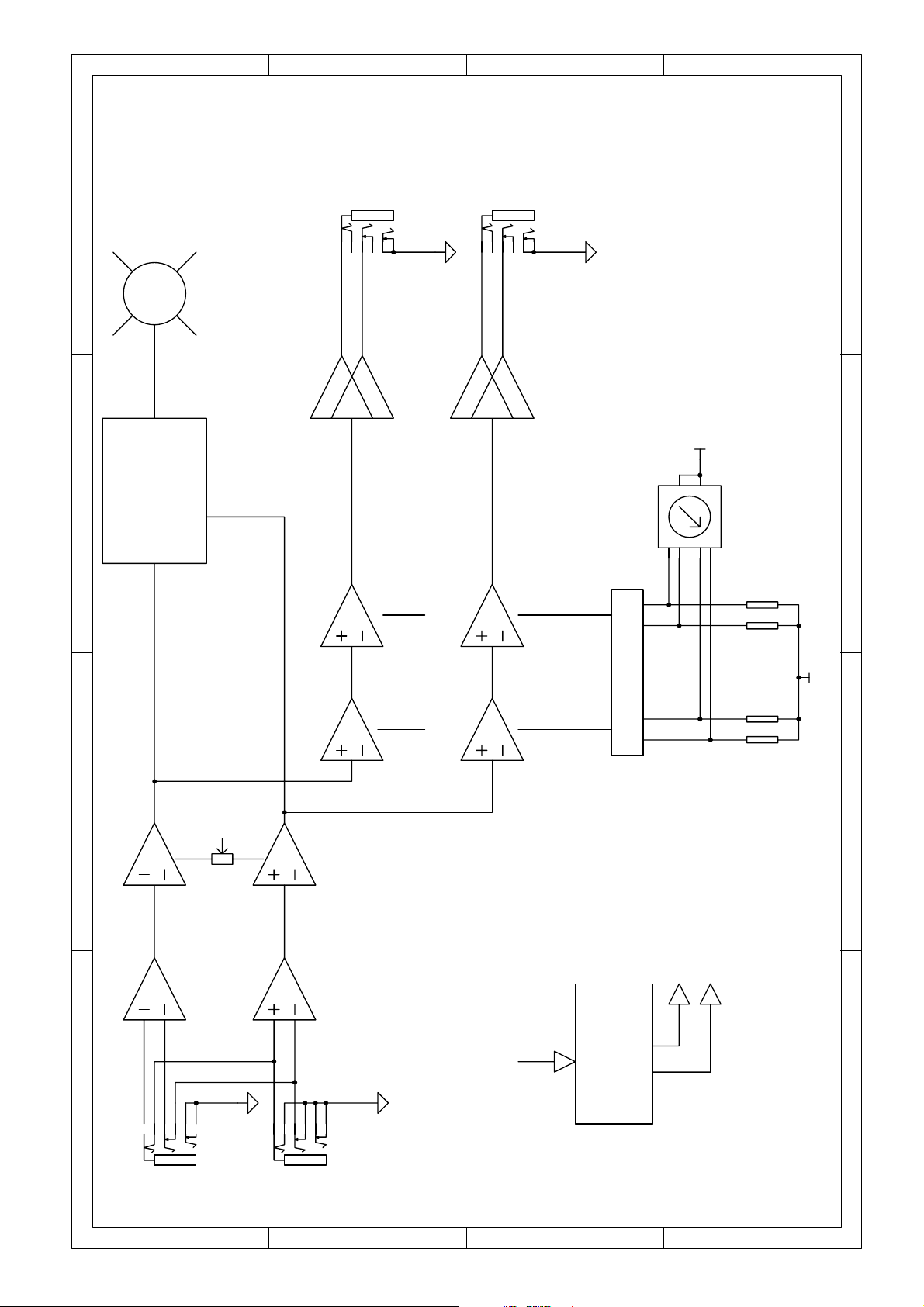

3. BLOCK DIAGRAM

- 2 -

4

C

B

A

CLIP

J2

12345

OUTPUT LCH

6

J4

12345

OUTPUT RCH

6

G

-12V

5

6

321

SIGNAL SENSE

SW1

3

4

4BIT ENCODER

1

2

+12V

12345

J1

ENCODER 4BIT CONTROL

A0 A1 A2 A3

INPUT GAIN

6

INPUTLCH

12345

J3

6

INPUT RCH

AC ADAPTOR

AC 15V 200mA INPUT

A0 A1 A2 A3

+12VDC

-12VDC

1 2 34

POWER SUPPLY

D

C

B

A

Page 5

B

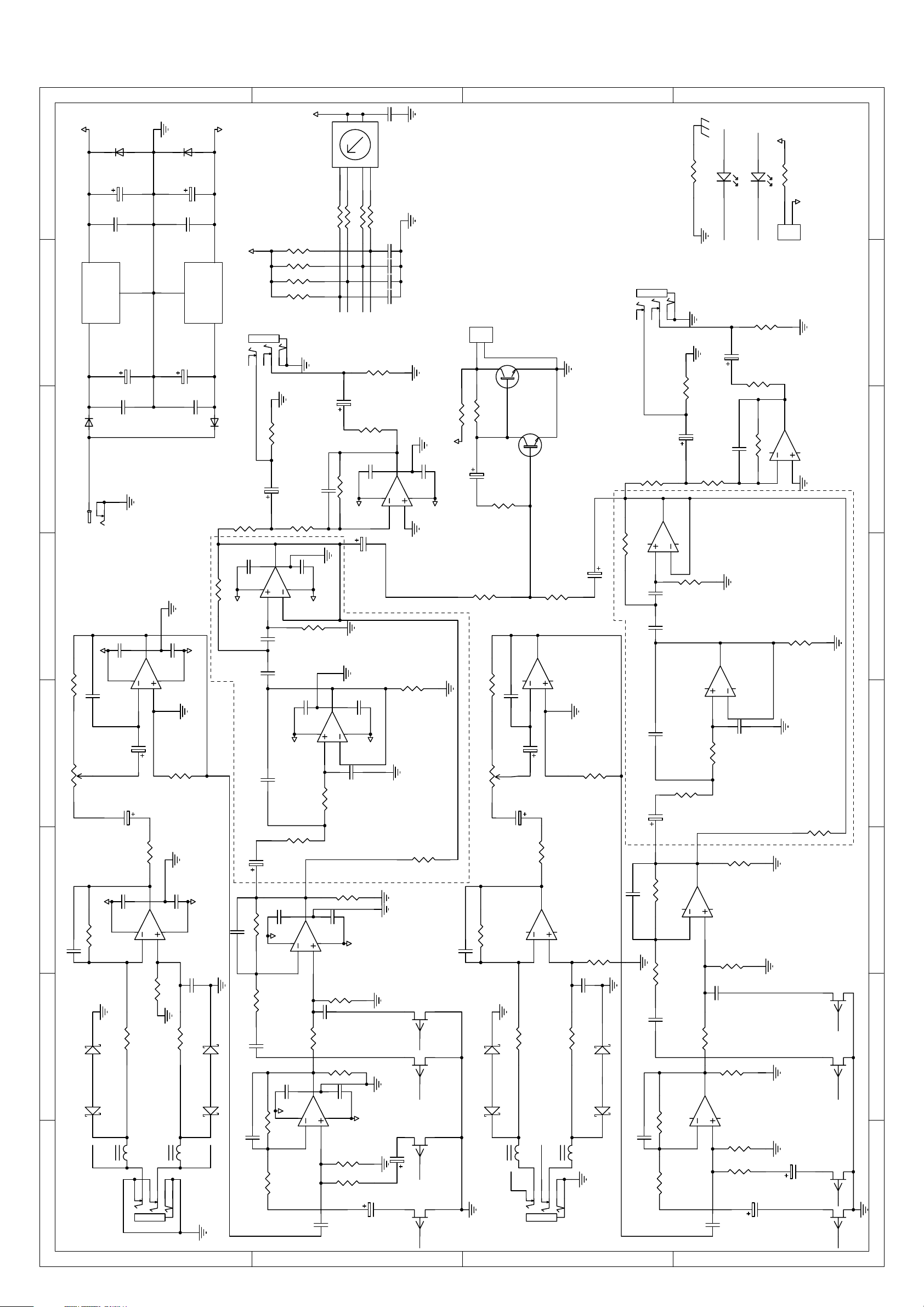

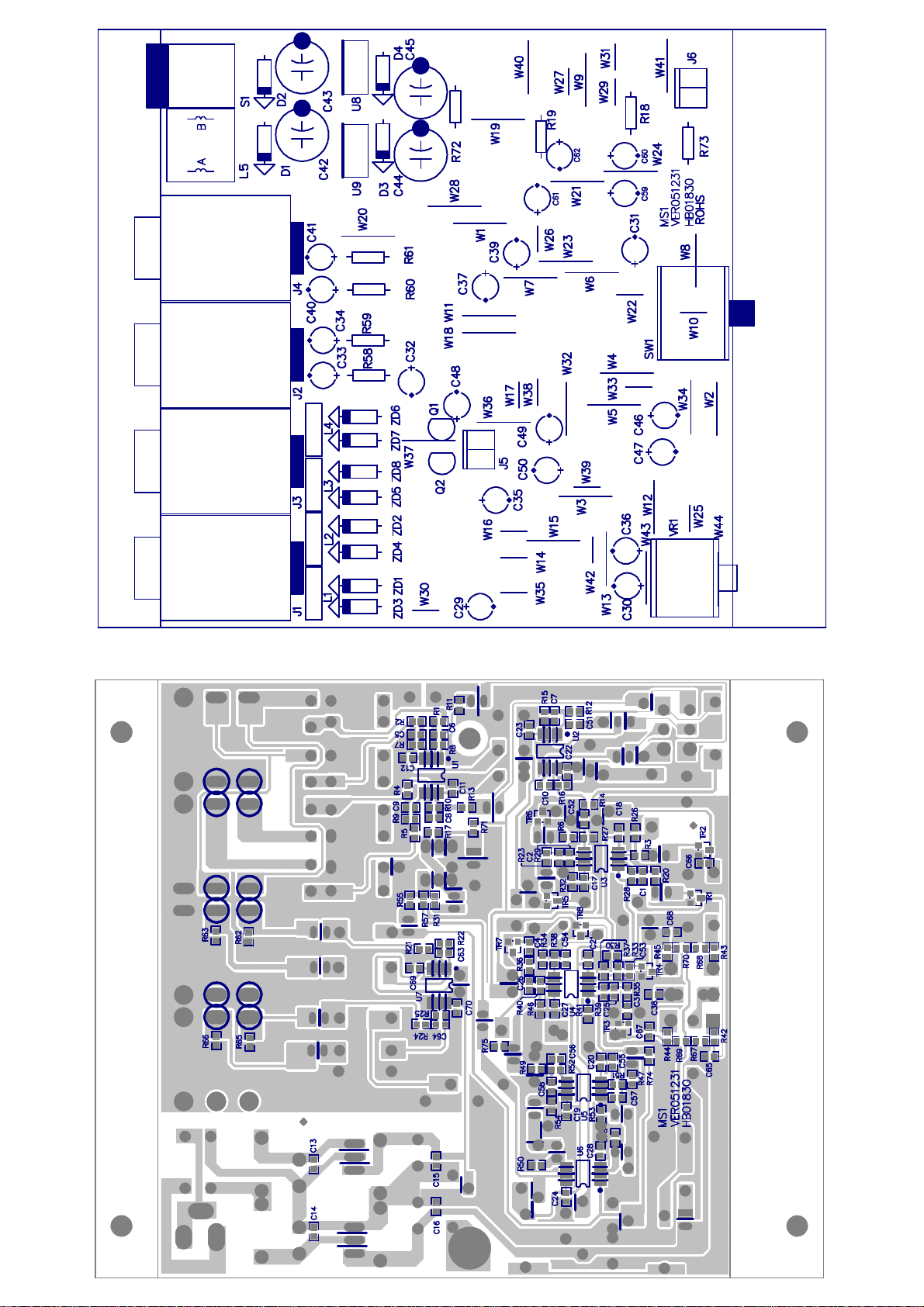

4. SCHEMATIC DIAGRAM

- 3 -

connect to J5 -1

CLIP

LED2

RED

R72

0R 1/4W

LED1

SW1

123

100K

R42

5

100K

R43

C

6

100K

R44

C38

22P

288S0366

4

100K

R45

D

-VCC

+VCC

8

D3

1N5817

C44

220UF/25V

D4

1N5817

-VCC

C45

220UF/25V

connect to J5 -2

R70

3

C15

0.1u c er

+12V

GND

2

7654321

Vin

1

U9

LM7812CT

D1

1N4002

C13

0.1u

123

S1

DJ-005A

1

U8

C42

1000UF/35V

3

C16

0.1u c er

GND

2

LM7912CT

C43

1000UF/35V

D2

C14

0.1u

-12V

Vin

1N4002

+VCC

6

J2

LJB0661-6

R58

100 1/4W

1M

R69

1M

R68

1M

R67

1M

A0A1A2

A3

R63

12345

C34

R62

51K

C63

22P

C33 47U/25V

R21

10.0K

51K

47U/25V

R59

100 1/4W

C69

0.1u c er

R22

10.0K

-VCC

C68

1.0U

C67

1.0U

C66

1.0U

C65

1.0U

6

1

2

J5

CON2

J4

A0~A3:ON=+VCC,OFF=-VCC,DELAY=0.1-1S

1.5K

R17

R71

+VCC

1

3

2

C70

0.1u c er

C48

8 4

+VCC

C2E

3

B

Q2

2SC1815

1

6.8K

2.2U/25V

Q1

2SC1815

C2E

3

B

1

R31

4.7K

LJB0661-6

12345

C41

47U/25V

R65

51K

C64

22P

C40 47U/25V

R60

100 1/4W

7

R24

10.0K

A

+VCC

connect to J6 -1connect to J6 -2

POWER

R73

4.7K 1/4W

RED

R66

51K

R61

100 1/4W

R25

10.0K

-VCC

1

2

J6

CON2

7

U7B

MC33078

5

6

12V 1W

U6B

R19

3.74K

C62

C61

C39

C26

10P

C4

1

C24

0.1u c er

C28

84

3.74K

U6A

+VCC

C60

C59

C31

C2510P

R35

C3

R18

C23

0.1u cer

1

-VCC

3

R12

1.10K

C7

13

VR1A

2

10KB

-VCC

R8

C6 22P

ZD3

22P

12V 1W

7.50K

2

C30

47U/25V

C29

47U/25V

R11

1.10K

C12

0.1u c er

1

3

2

R7

R1

15.0K

7.50K

C22

U2A

MC33078

R15

C11

MC33078

+VCC

0.1u cer

8 4

6.8K

0.1u c er

+VCC

8 4

U1A

C5

22P

R2

15.0K

ZD4

12V 1W

R39

3

1.0U

1.20K

47U/25V

27nF

C57

1.50K

C21

2

1.0U

C19

1000P

-VCC

C18

MC33078

0.1u c er

+VCC

R47

0.1u c er

2

0.1u c er

0.1u cer

-VCC

R48

7.50K

1

U5A

84

3

2

R51

30.0K

7.50K

1

C27

8 4

3

U4A

MC33078

R37

220.0K

C53

10nF

R33

1.0K

R30

4.7K

1

Fc=30hz

MC33078

C55

R41

100K

0.1u c er

+VCC

C32

-12db/OCT

C20

0.1u c er

-VCC

330P

47U/25V

MC33078

Fc=18K

U7A

C37

CLIP LED LIGHT SET=+6dbU

R57

R55

9.1K

R14

1.10K

R53

20K

-12db/OCT

HIGH Fc=18K,LOW Fc=30HZ IS NOT USED,R74=0R

R74

0R*

C8 22P

TR4

J176

TR3

J176

C10

22P

46

C36

VR1B

5

10KB

C35

47U/25V

R10

7.50K

ZD8

12V 1W

9.1K

7

5

6

6

15.0K

U2B

MC33078

47U/25V

R13

1.10K

7

5

U1B

MC33078

R4

R5

47U/25V

R16

6.8K

R9

7.50K

C9

22P

15.0K

ZD7

MC33078

Fc=30hz

5

6

1.0U

R50

1.0U

C58

1000P

R49

7.5K

47U/25V

R40

1.50K

6

R36

1.20K

27nF

-12db/OCT

7.5K

7

R54

20K

U5B

MC33078

Fc=18K

-12db/OCT

5

6

C56

330P

R52

30.0K

HIGH Fc=18K,LOW Fc=30HZ IS NOT USED,R75=0R

R75

0R*

R46

100K

7

5

U4B

MC33078

R38

220.0K

TR8

J176

C54

10nF

R34

1.0K

R32

4.7K

7

TR7

J176

ZD1

12V 1W

L1

IN-CH2+

6

J1

LJB0661-6

balanced input

L2

FL5R

D

ZD2

FL5R

12345

C17

MC33078

R3

220nF

0.1u c er

8 4

+VCC

U3A

R26

15.0K

C

C47

TR2

J176

2.2U/25V

150.0K

TR1

J176

C46

2.2U/25V

A0 A1 A2 A3

ZD5

12V 1W

L3

6

IN-CH2+

J3

LJB0661-6

balanced input

L4

FL5R

IN-CH2-

ZD6

12V 1W

5

6

R29

30.0K

FL5R

12345

B

C2 100nF

R23

10.0K

U3B

MC33078

R27

150.0K

C50

R6

15.0K

C52

220nF

C49

2.2U/25V

2.2U/25V

A

J176

TR6

J176

1 2 3 4 5 6 78

TR5

A0 A1 A2 A3

12V 1W

IN-CH2-

C1 100nF

-VCC

3

2

R28

30.0K

R20

10.0K

C51

Page 6

PCB:MS1 Bottom Layer Bttom Overlay Bottom Solder

PCB:MS1 Top Overlay

5. PCB LAYOUT

- 4 -

Page 7

First: Use VP-7724 to test

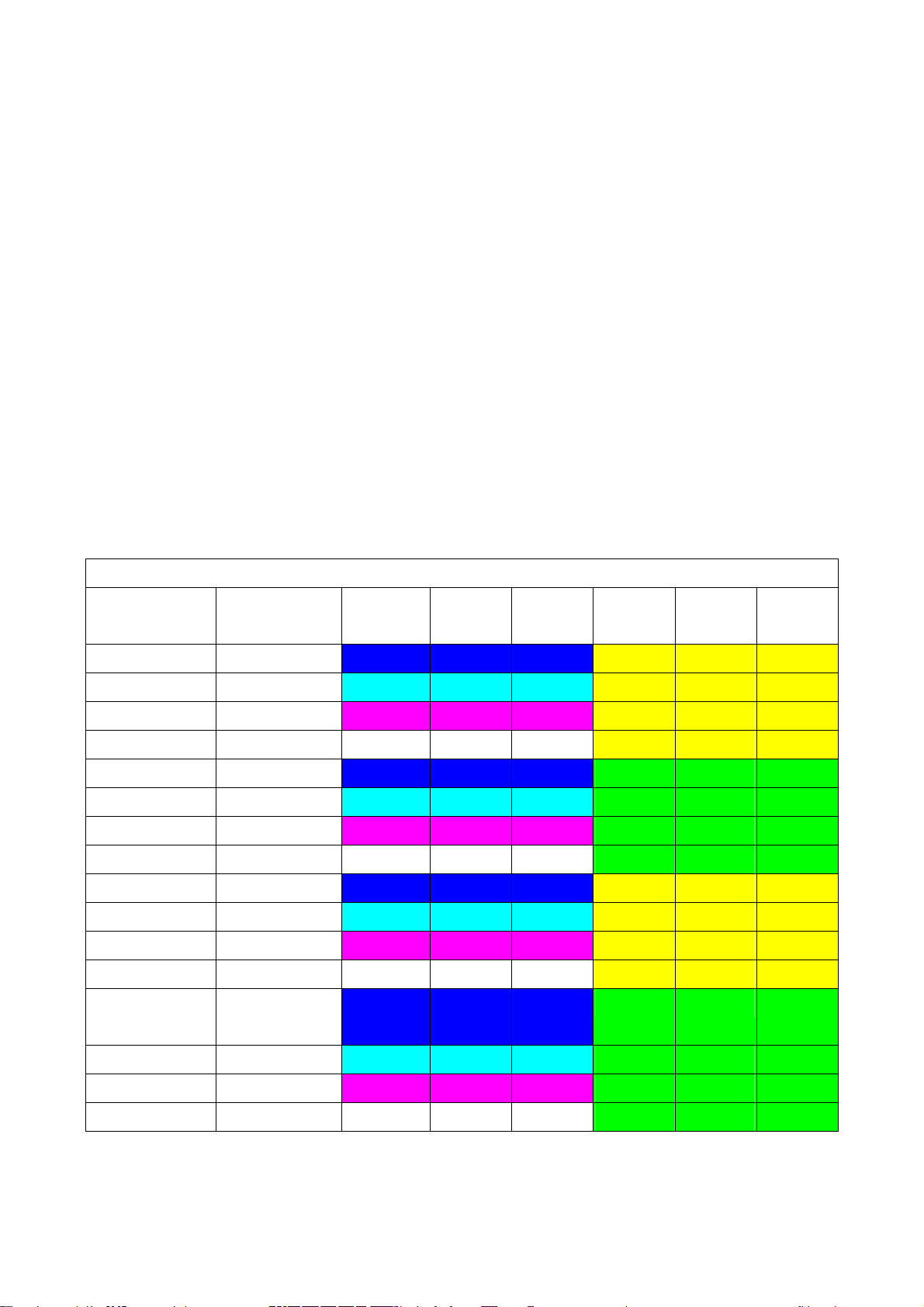

6. TEST PROCEDURE

The Finished Products Test

- 5 -

1. Set the encoder to FLAT (encoder setting: 0000), INPUT/OUTPUT use 1/4 TRS BAL jack to co nnect

LCH IN, LCH/RCH OUT, plug in POWER&CLIP LED wires(semi product), the red POWER LED

lights up.

2. Input 1KHZ–6dBu(VP-7724 BAL) signal, then adjust INPUT GAIN VR, when INPUT GAIN VR is

minimum, the output is -20+/-2dbu, distortion<0.03%.

3. Adjust INPUT GAIN V R to maximum, the output i s +20+/-2dbu, distortio n<0.01 %( Please select the

corresponding filter when testing distortion).

4. Adjust INPUT GAIN VR, and set the output to +6.5~+8.5dbu, make sure the CLIP LED lights up

slightly.

5. Adjust INPUT GAIN VR, set the output to 0+/-0.2dbu, and also make sure the scale of GAIN VR at

0dB position.

6. According to the following table to test the frequency response, specifications are the following

(altogether 4*4=16 modes), under FLAT mode, make sure the distortion<0.005%.

7. Adjust the input signal to 1 kHz +10dbu, turn GAIN VR from minimum to maximum, make sure the

distortion will become bigger gradually till clipping (FLAT position).

LCH/RCH OUTPUT SPECIFICATION(Test Frequency dBu)

Corresponding

Function

FLAT 0000 -1.0~+1.0 -0.5~+0.5 -0.5~+0.5 -0.5~+0.5 -1.2~+0.8 -5.0~-3.0

DRUM KICK 0001 +9.5~+11.5 +7.5~+9.5 +6.0~8.0 -0.5~+1.0 -1.2~+0.8 -5.0~-3.0

ANTIRUMBLE 0010 -11.5~-9.5 -3.5~-1.5 -2.5~-0.5 -0.5~+0.5 -1.2~+0.8 -5.0~-3.0

CONCERT HALL 0011 -0.5~+1.5 +5.0~+7.0 +4.5~+6.5 -0.5~+1.0 -1.2~+0.8 -5.0~-3.0

ARENA+SUB 0100 -1.0~+1.0 -1.0~+1.0 -0.5~+0.5 +0.2~+1.5 +4.5~+6.5 +1.5~+3.5

LOUDNESS 0101 +9.5~+11.5 +7.5~+9.5 +6.0~8.0 +0.5~+1.5 +4.5~+6.5 +1.5~+3.5

ROCK&ROLL+SUB 0110 -11.5~-9.5 -3.5~-1.5 -2.5~-0.5 +0.5~+1.5 +4.5~+6.5 +1.5~+3.5

ACOUSTIC 0111 -0.5~+1.5 +5.0~+7.0 +4.5~+6.5 +0.5~+1.5 +4.5~+6.5 +1.5~+3.5

JAZZ CLUB+SUB 1000 -1.0~+1.0 -1.0~+1.0 -0.5~+0.5 -0.5~+0.5 -2.0~-0.5 -9.0~-7.0

VIRTUAL SUB 1001 +9.5~+11.5 +7.5~+9.5 +6.0~8.0 -0.0~+0.8 -2.0~-0.5 -9.0~-7.0

STAGE MONITOR 1010 -11.5~-9.5 -3.5~-1.5 -2.5~-0.5 -0.5~+0.5 -2.0~-0.5 -9.0~-7.0

JAZZ CLUB 1011 -0.5~+1.5 +5.0~+7.0 +4.5~+6.5 -0.0~+0.8 -2.0~-0.5 -9.0~-7.0

CONCERT

HALL+SUB

Encoder Setting

20HZ 70HZ 100HZ 1KHZ 8KHZ 20KHZ

(Binary System)

1100 -1.0~+1.0 -1.0~+1.0 -0.5~+0.5 +0.2~+1.5 +3.5~+5.5 -2.0~-0.5

DISCO 1101 +9.5~+11.5 +7.5~+9.5 +6.0~8.0 +0.2~+1.5 +3.5~+5.5 -2.0~-0.5

VOCAL 1110 -11.5~-9.5 -3.5~-1.5 -2.5~-0.5 +0.2~+1.5 +3.5~+5.5 -2.0~-0.5

ROCK&ROLL 1111 -0.5~+1.5 +5.0~+7.0 +4.5~+6.5 +0.2~+1.5 +3.5~+5.5 -2.0~-0.5

Page 8

8. Cut off input signal, when output noise and GAIN VR are minimum, the output noise is less

- 6 -

than-95dBu(Please select the corresponding filter), when the GAIN VR is maximum, the output

noise is less than -78dBu, at the same time, make sure the variations of the waveform are normal

when turning the GAIN VR.

9. Connect OUTPUT to RCH OUT, make su re the R CH output specification is the sam e as above, and

connect the INPUT to RCH IN; also the RCH output specification is the same as above.

10. Listening Test: Input music signal, set the encoder and adjust the GAIN VR, make sure the volume

can change, and also the treble and bass have corresponding variations; cut off the input signal,

make sure the noise sound is normal, set the encoder, make sure the CLICK NOISE is normal.

Second: Use AP to test

1. Set the encoder to FLAT (encoder setting: 0000), INPUT/OUTPUT, use 1/4 TRS Balanced jack to

connect LCH IN, LCH/RCH OUT, plug in POWER&CLIP LED wires(semi product), the red POWER

LED lights up.

2. Input signal is 1KHZ 0dBu (VP-7724 BAL), make sure INPUT GAIN VR is minimum, the output is

-20+/-2dbu, and distortion<0.03%.

3. Adjust INPUT GAIN VR to maximum, the output is +20+/-2dbu, the distortion<0.01 %( It must select

the corresponding filter when test the distortion).

4. Adjust INPUT GAIN VR, set the output to +6.5~+8.5dbu, make sure the CLIP LED lights up slightly at

the moment.

5. Adjust INPUT GAIN V R, set the output to 0+/-0.2dbu, at the same time, make sure the scale of GAIN

VR at 0dB position.

6. According to the following table to test the frequency response, specifications are the following

curves (altogether 4*4=16 modes). In the meantime, make sure the distortion<0.005% under the

FLAT mode.

7. Adjust the input signal to 1 kHz +10dbu, turn GAIN VR from minimum to maximum, and make sure

the distortion will become bigger gradually till clipping (FLAT position).

8. Cut off the input signal, make sure the output noise and GAIN VR are minimum, the output noise is

less than-95dBu (select the corresponding filters), when GAIN VR is maximum, the output noise is

less than -78dBu, at the same time, make sure the variations of the waveform are normal when

turning the GAIN VR.

9. Listening Test: Input music signal, set encoder and adjust the GAIN VR, make sure the volume can

change, and also the treble and bass have the corresponding variation, cut off input signal, make sure

the noise sound is normal, set the encoder, and also make sure the CLICK NOISE is normal.

Page 9

- 7 -

Page 10

- 8 -

Page 11

- 9 -

Page 12

- 10 -

Page 13

- 11 -

Page 14

- 12 -

Page 15

- 13 -

Page 16

- 14 -

Page 17

7. EXPLODED VIEW & MECHANICAL PARTS LIST

- 15 -

Page 18

No. Part No. Description Specification Pcs

MECHANICAL PARTS LIST

- 18 -

1

MA05666

2

SA00053 LED φ3

HK05843 K-PCB P-MS1-DIP

3

4

MB04491

5

NI00502 self-adhere foot cushion φ10.5*5mm(RF-011)

6

NI00002 T-plastic nut-HC00108 accessories φ7/16"*G20/15*4.8

7

ME00081 T-nut-HI00107 φ7

8

MF00014 shakeproof washer φ3*φ6.5*0.5t

9

MG00036 screw M3*4

10

NC00131 T-wooden washer 1*φ11.3*φ15.3 red

11

MC00769 ZC-top cover ALTO MS1

12

NI02386 plastic knob φ14*13mm\

13

NI00363 plastic knob φ21*16mm

14

MG00386 screw M3*4

15

MG00058 screw M2*4

ZC-panel

MS1 ALTO_V1.3

ZC-rear board MS1 ALTO_V1.1

1

2

1

1

4

2

1

3

7

2

1

1

1

2

1

Page 19

No. Part No. Description Specification Remark

8. BOM

- 17 -

1 HK05843 PC board P-MS1-DIP

2 HK06476 PC board P-MS1-SMD

3 RD00125 SMD fixed resistor 1/10W 1.0MΩ ±5% 0603 R67,R68,R69,R70

4 RD00085 SMD fixed resistor 1/10W 1.5KΩ ±5% 0603 R71

5 RD00116 SMD fixed resistor 1/10W 100KΩ ±5% 0603 R41,R42,R43,R44,R45,R46

6 RD00306 SMD fixed resistor 1/10W 20KΩ ±5% 0603 R53,R54

7 RD00093 SMD fixed resistor 1/10W 4.7KΩ ±5% 0603 R30,R31,R32

8 RD00354 SMD fixed resistor 1/10W 51KΩ ±5% 0603 R62,R63,R65,R66

9 RD00097 SMD fixed resistor 1/10W 6.8KΩ ±5% 0603 R15,R16,R17

10 RD00100 SMD fixed resistor 1/10W 9.1KΩ ±5% 0603 R55,R57

11 CI00228

12 CI00071

13 CI00123

14 CI00185

15 CI00075

16 CI00179

17 CI00175

18 CI00047

19 CI00062

20 SF00049 transistor PMBFJ176(SOT23)/(PHI) TR1,TR2,TR3,TR4,TR5,TR6,TR7,TR8

21 RD00282

22 RD00396

23 RD00321

24 RD00201

25 RD00214

26 RD00218

27 RD00457

28 RD00461

29 RD00329

30 RD00213

31 HB01830 PCB MS1_VER051231

32 CI00266

33 SG00558 integrated circuit-RS UTC4580M(4580M )(SOP8)/(YW) U1,U2,U3,U4,U5,U6,U7

SMD ceramic capacitor

0603

SMD ceramic capacitor

0603

SMD ceramic capacitor

0603

SMD ceramic capacitor

0603

SMD ceramic capacitor

0603

SMD ceramic capacitor

0603

SMD ceramic capacitor

0603

SMD ceramic capacitor

0603

SMD ceramic capacitor

0603

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD precise resistor

1/10W

SMD ceramic capacitorRS 0603

0.001uF/50V C0G±5%(C1608C0G1H102JT)/TDK C57,C58

0.01uF/50V X7R ±10% C53,C54

0.027uF/50V X7R ±10% C3,C4

0.1uF/50V X7R±10%(C1608X7R1H104KT)/TDK C1,C2

0.1uF/50V Y5V +80,-20%

0.22uF/25V X7R±10%(C1608X7R1E224KT)/TDK C51,C52

1.0uF/16V X7R±10%(C1608X7R1C105KT)/TDK C65,C66,C67,C68

10PF/50V C0G±0.25PF(C1608C0G1H100CT)TDK C25,C26

330PF/50V NPO ±5﹪ C55,C56

1.00KΩ ±1% 0603 R33,R34

1.15KΩ ±1% 0603 R11,R12,R13,R14

1.20KΩ ±1% 0603 R35,R36

1.50KΩ ±1% 0603 R39,R40

10.0KΩ ±1% 0603 R20,R21,R22,R23,R24,R25

15.0KΩ ±1% 0603 R1,R2,R3,R4,R5,R6

150KΩ ±1% 0603 R26,R27

220KΩ ±1% 0603 R37,R38

30.0KΩ ±1% 0603 R51,R52,R28,R29

7.50KΩ ±1% 0603 R7,R8,R9,R10,R47,R49

22PF/50V NPO ±5﹪ C5,C6,C7,C8,C9,C10,C63,C64

C11,C12,C13,C14,C15,C16,C17,C18,C19,C20,C21,C22,C23

,C24,C27,C28,C38,C69,C70

Page 20

No. Part No. Description Specification Remark

- 18 -

34 HC00183 DC jack-RS KJ-36-S φ3.5 S1

35 HC00108 stereo MIC jack φ6.3 stereo LJB0661-6 J1,J2,J3,J4

36 RA00158 fixed resistor 1/4W 0.0Ω M type R72

37 RA00184 fixed resistor 1/4W 100Ω M type R58,R59,R60,R61

38 RA00231 fixed resistor 1/4W 4.7KΩ M type R73

39 HI00192 rotary switch 288S0366 SW1

40 HC00076 connector(male) 2P 2.5mm 180° J5,J6

41 RC00578 potentiometer-RS B10KΩ R1220GOJH1B103FE0016 VR1

42 SB00034 transistor 2SC1815GR(SC43)/(TOSHIBA) Q1,Q2

43 SD00124 integrated circuit-RS-ACT L7912CV(TO220)/(ST) U8

44 SD00066 integrated circuit L7812CV(TO220)/(ST) U9

45 SA00105 zener diode 1W 12V 1N4742 ZD1,ZD2,ZD3,ZD4,ZD5,ZD6,ZD7,ZD8

46 SA00094 rectifier diode 1N4002/100V D1,D2

47 CB00194 electrolytic capacitor 47uF/25V φ5*11mm

48 CB00057 electrolytic capacitor 220uF/25V φ8*11mm C44,C45

49 CB00239 electrolytic capacitor 2.2uF/50V φ5*11mm C46,C47,C48,C49,C50

50 CB00256 electrolytic capacitor 1000uF/25V φ10*20mm 5mm C42,C43

51 AC00179 tin without lead-RS M705E Sn 3Ag-0.5Cu

52 HA01919 jump 5mm

53 HA02249 wire φ0.6_tin-plating

C29,C30,C31,C32,C33,C34,C35,C36,C37,C39,C40,C41,C59

,C61

W10,W14,W16,W17,W22,W25,W26,W27,W29,W30,W31,

W33, W35,W38,W39,W42,L5A,L5B

W1,W2,W3,W4,W5,W6,W7,W8,W9,W11,W12,W13,

54 HA01925 jump 10mm

55 HA02249 wire φ0.6_tin-plating

56 CG00018 filter-EMI FILTER LF-22UH(WAH TAYI) L1,L2,L3,L4

57 SA00088 Schottky barrier diode 1N5817 D3,D4

58 HA01933 jump 2.5mm C60,C62

59 MA05666 panel MS1 ALTO_V1.3

60 MA05641 panel MS1

61 AE00343 solvent No.330

62 AE00177 paint-RS 4866

63 MA05563 panel-RS-ACT MS1 130.5*44*14.5_V1.4

64 MI01297 panel 2.1*44*14.5*130.5_V1.1

65 MB04491 chassis MS1 ALTO_V1.1

66 MB04484 chassis MS1

67 AE00055 solvent solvent

68 AE00056 paint-RS 2745

69 MB04390 chassis MS1 1.0t*128*113x38.8_V1.1

70 MJ00058 single light board 1*2135*1220 20.45kg

71 ME00037 iron pillar hexagon6.35*M3*4.5

72 MC00769 top cover MS1_V1.0

73 AE00055 solvent solvent

W15,W18,W19,W20,W21,W23,W24,W28,W32,W34,

W36,W37, W40,W41, W43,W44

Page 21

No. Part No. Description Specification Remark

- 19 -

74 AE00056 paint-RS 2745

75 MC00768 top cover MS1 1t*130*114.3*40_V1.0

76 MJ00058 single light board 1*2135*1220 20.45kg

77 NI00363 knob-RS-C φ21*16mm COOL GRAY 8C/072C_V1.1

78 NI02386 konb-RS φ14*13mm

79 SA00053 L.E.D φ3 round(red)long foot 26mm

80 MG00386 screw-RS M3*4

81 MG00036 screw M3*4

82 MG00058 screw M2*4

83 NI00002 plastic nut φ7/16"*G20/15*4.8(hexagon)

84 NC00131 washer 1*φ11.3*φ15.3 red

85 NI00240 sleeve φ2.5*10mm

86 NI00239 sleeve φ2.5*1000mm

87 NI00502 self-adhere foot cushion φ10.5*5.0

88 HJ00002 dessicant 10g

89 NB04289 inner case MS1 ALTO_V1.1

90 NB04291 barrier MS1 164*84mm _V1.0

91 NB04290 barrier MS1 215*183mm _V1.1

92 HA05010 wire-RS φ6.3 STCO*φ4*2C*1250mm

93 TG00195 adaptor-RS 230V/50Hz_AC15V/200mA_EI-41_UL CSA

94 NA00120 PE bag 0.04t*220*200mm

95 NE05004 label ALTO

96 NH00334 cone paper 0.040*1m

97 AD00012 twin adhesive-RS 90*120mm_V1.0

98 NE15702 lable MS1_V1.0

99 NI00014 membrane 0.035*1M

100 NH00012 bond paper 0.04*1M

101 NE15701 lable MS1 ALTO_V1.0

102 NI00027 membrane 0.105*1M

103 NH00021 bond paper 0.11*1M

104 NI04213 barrier-RS-ACT MS1 0.5t*115*110_V1.2

105 NI04630 film-RS-CT 450*605*0.5mm 0.184kg_V1.0

106 NF02530 instnction-RS-ACT MS1 ALTO_V1.1

107 NH00149 paper 889*640mm

108 NF00061 assurance card ALTO

109 NB04747 carton-RS MS1 ALTO_V1.1

110 HA01551 wire-RS 2P 80mm UL1007 26AWG

Loading...

Loading...