Page 1

Te45, 72" Auxiliary Outdoor Enclosure

Installation & Operation Manual

Equipment #: 057-106-20-203

Page 2

Alpha Technologies Ltd. 057-106-B0 RevF

Printed in Canada. © 2010 Alpha Technologies Ltd. ALPHA and CORDEX are trademarks of Alpha Technologies Ltd. All Rights Reserved.

Page 3

Te45, 72" Auxiliary Outdoor Enclosure w/4k BTU AC, w/ LC

Equipment #: 057-106-20-203

Document #: 057-106-B0

The following documents and drawings are included in this manual to provide the necessary information

required for routine operation and fault diagnosis of the system:

Safety and Installation Instructions: 057-106-C0

Specifications: 029-039-B1

Schematic: 747-666-05

Outline drawing 057-106-06

Schematic Interface Kit 747-670-05

Customer Connection Kit 747-670-08

CSA/NRTL Equivalence 048-554-10

Manuals included in this package:

DCP03 300A Distribution Center 020-702-B2

Cordex 48-1.8kW 23" Shelf 030-807-B2

Cordex Controller Software 034-136-B2

Quick Reference Card for Controller 954-472-10

Alpha Technologies Ltd. 057-106-B0 RevF

Printed in Canada. © 2010 Alpha Technologies Ltd. ALPHA and CORDEX are trademarks of Alpha Technologies Ltd. All Rights Reserved.

Page 4

Important Safety Instructions

Save These Instructions

This section contains important instructions that must be followed during the installation and maintenance of the

equipment and batteries. Read all of the instructions before operating the equipment, and save this manual for

future reference.

All electrical connections must be performed by licensed electricians only. Installation of the power supply and

batteries must be performed by, or under the direct supervision of, service personnel knowledgeable of the required

electrical and battery safety procedures.

If instructions in this manual conflict with the local electrical codes, follow the local codes.

The following safety symbols are found throughout this manual. Carefully read all information and abide by the

instructions:

DANGEROUS VOLTAGE

This symbol indicates a dangerous voltage

exists in this area of the product.

GAS HAZARD

This symbol indicates a gas hazard

exists in the area of vented batteries.

NO MATCHES OR OPEN FLAMES

This symbol indicates a fire or explosive hazard

exists in the area of the product.

The following warning levels are used in conjunction with the symbols:

DANGER: You WILL be KILLED or SERIOUSLY INJURED if instructions are not followed closely.

WARNING: You CAN be KILLED or SERIOUSLY INJURED if instructions are not followed closely.

CAUTION: You CAN be INJURED or equipment can be DAMAGED if instructions are not followed closely.

Mechanical safety

Keep hands and tools clear of fans. Fans are thermostatically controlled and switch on automatically.

Power supplies can reach extreme temperatures under load.

Use caution around sheet metal components and sharp edges.

Page 5

Electrical safety

WARNING: Hazardous voltages are present at the input of power systems. The DC output from

rectifiers and batteries, though not dangerous in voltage, has a high short-circuit current capacity

that may cause severe burns and electrical arcing.

Before working with any live battery or power system, follow these precautions:

Remove all metallic jewelry, such as watches, rings, metal rimmed glasses, or necklaces.

Wear safety glasses with side shields at all times during installation.

Use OSHA approved insulated hand tools.

DANGER: Lethal voltages are present within a power system. Always assume that an electrical

connection or conductor is energized. Check the circuit with a voltmeter with respect to the

grounded portion of the enclosure (both AC and DC) before performing any installation or removal

procedure.

Do not work alone under hazardous conditions.

A licensed electrician is required to install permanently wired equipment. Input voltages can range up to

240 Vac. Ensure that the utility power is disconnected and locked out performing any installation or

removal procedure.

Ensure that no liquids or wet clothes come into contact with internal components.

Hazardous electrically live parts inside this unit are energized from the batteries even when the AC input power is

disconnected.

Battery safety

Servicing and connection of batteries must be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove all metallic

objects from your hands and neck.

Use OSHA approved insulated hand tools. Do not rest tools on top of batteries.

Batteries contain or emit chemicals known to cause cancer and birth defects or other reproductive harm. Battery

post terminals and related accessories contain lead and lead compounds. Wash your hands after handling

batteries.

WARNING: Follow battery manufacturer’s safety recommendations when working around battery

systems.

WARNING: Do not smoke or introduce an open flame when batteries (especially vented batteries)

are charging. Batteries vent hydrogen gas when charging, which creates an explosion hazard.

Batteries are hazardous to the environment and should be disposed of safely at a recycling facility. Consult the

battery manufacturer for recommended local authorized recyclers.

Post installation weather proofing

After installing the conduits and removing any knockouts to accommodate conduit locations, ensure that any gaps

between the conduit fittings and the shroud are sealed. Apply a weatherproof caulking to gaps to prevent wind

driven rain from reaching the electrical equipment.

Page 6

Contents

1 Introduction ............................................................................................................. 7

1.1 Scope of manual......................................................................................................... 7

2 Product overview .................................................................................................... 2

2.1 Typical power configuration ........................................................................................ 3

2.2 Typical battery configuration ................................ ....................................................... 4

2.3 Air conditioning and heating ....................................................................................... 5

2.4 AC panel board and generator connector ................................................................... 6

2.5 Equipment mounting rails ........................................................................................... 6

2.6 Battery trays and battery retaining brackets ................................................................ 6

2.7 T1 surge suppression ................................................................................................. 6

2.8 Fiber cable slack box ................................ .................................................................. 7

2.9 Emergency ventilation system (EVS) .......................................................................... 8

2.10 Doors and access panels ........................................................................................... 8

2.11 Rear access panel ...................................................................................................... 9

2.12 Removable solar shield and hatch plate ..................................................................... 10

2.13 DC power equipment .................................................................................................. 11

2.13.1 Distribution panel ............................................................................................... 11

2.14 Rectifier and shelf ....................................................................................................... 11

2.15 Controller .................................................................................................................... 12

2.15.1 GMT fuse block ................................................................................................. 12

3 Transportation and storage .................................................................................... 13

3.1 Packaging................................................................................................................... 13

3.2 Storage ....................................................................................................................... 13

3.3 Inspection ................................................................................................................... 13

4 Installation .............................................................................................................. 14

4.1 Pre-installation considerations .................................................................................... 14

4.2 Power system ............................................................................................................. 14

4.3 HVAC system ............................................................................................................. 14

4.4 Site selection .............................................................................................................. 14

4.5 Enclosure support ....................................................................................................... 14

4.5.1 Base layout dimensions ..................................................................................... 15

4.5.2 Concrete slab .................................................................................................... 16

4.5.3 AC connections with concrete slab mounting ..................................................... 17

4.5.4 Steel platform .................................................................................................... 17

4.6 Multiple enclosure installations ................................................................................... 18

Page 7

4.7 Installation component requirements .......................................................................... 19

4.8 Installation tools and equipment ................................................................................. 20

4.8.1 Tools Required .................................................................................................. 20

4.8.2 Lifting equipment requirements.......................................................................... 20

4.9 Enclosure installation .................................................................................................. 21

4.9.1 Enclosure preparation ....................................................................................... 21

4.9.2 Lifting preparation .............................................................................................. 21

4.10 Mounting the enclosure .............................................................................................. 22

4.10.1 Concrete slab .................................................................................................... 22

4.10.2 Steel platform .................................................................................................... 22

4.10.3 Roof mounting ................................................................................................ ... 22

4.10.4 Installing multiple enclosures side-by-side ......................................................... 22

4.11 Grounding................................................................................................................... 23

4.11.1 Site ground wire entry ........................................................................................ 23

4.11.2 Master ground bus (MGB) ................................................................................. 23

4.11.3 Enclosure chassis ground .................................................................................. 23

4.12 Wiring, cable management, and connections ............................................................. 24

4.12.1 Alarm connections ............................................................................................. 24

4.13 Utility connections ....................................................................................................... 26

4.13.1 AC conduit installations ..................................................................................... 26

4.13.2 Procedure .......................................................................................................... 27

4.14 Other cable connections ............................................................................................. 27

4.15 Internal cable routing .................................................................................................. 28

4.16 Battery installation ...................................................................................................... 29

4.16.1 Preparation/mounting ........................................................................................ 29

4.16.2 Battery installation in Alpha Tempest power systems ........................................ 29

5 System startup ........................................................................................................ 31

5.1 Connecting the batteries ............................................................................................. 31

5.2 Test and commissioning overview .............................................................................. 32

5.2.1 System ................................................................................................ .............. 32

5.2.2 Environmental/intrusion ..................................................................................... 32

5.3 Battery ........................................................................................................................ 32

5.3.1 Documentation ................................ .................................................................. 32

5.4 Air Conditioner/heater factory settings ........................................................................ 33

5.5 EVS (Emergency Ventilation System) factory settings ................................................ 33

5.6 Enclosure temperature alarms .................................................................................... 33

Page 8

6 Final cleanup .......................................................................................................... 34

7 Maintenance ........................................................................................................... 35

7.1 General maintenance schedule .................................................................................. 35

7.2 Air conditioner ............................................................................................................ 35

7.2.1 Air conditioner settings ................................ ...................................................... 35

7.2.2 Air conditioner filter ............................................................................................ 35

8 Batteries ................................................................................................................. 36

8.1.1 Monthly maintenance ........................................................................................ 36

8.1.2 Semi-annual maintenance ................................................................ ................. 36

8.1.3 Performance/ integrity checks............................................................................ 36

8.1.4 String or cell replacement .................................................................................. 36

8.2 EVS intake and exhaust filter ...................................................................................... 37

9 Alpha conventions .................................................................................................. 38

9.1 Numbering system ...................................................................................................... 38

9.2 Acronyms ................................................................................................................... 38

Page 9

List of figures

Figure 1 – Tempest outdoor auxiliary enclosure. Rear view. ......................................................... 2

Figure 2 – Tempest outdoor auxiliary enclosure. Front view. ......................................................... 2

Figure 3 – Typical Te45 enclosure power configuration ................................................................ 3

Figure 4 – Typical Te45 Battery Configuration .............................................................................. 4

Figure 5 – Miscellaneous enclosure features ................................................................................ 5

Figure 6 – Surge suppression mounted on rear of fibre slack box bracket .................................... 6

Figure 7 – Fiber slack box mounted on rear rails ........................................................................... 7

Figure 8 – Fiber cable slack box ................................................................................................... 7

Figure 9 – Locking front door ........................................................................................................ 8

Figure 10 – Rear panel latch ......................................................................................................... 9

Figure 11 – Rear panel released ................................................................................................... 9

Figure 12 – Wing nuts retaining lower panels ................................................................................ 9

Figure 13 – Disconnect lanyard and ground strap ......................................................................... 9

Figure 14 – Base layout drawing and mounting hole locations ...................................................... 15

Figure 15 – Concrete anchor bolt fastening detail ......................................................................... 16

Figure 16 – AC conduit outside concrete slab ............................................................................... 17

Figure 17 – Installation on steel platform ....................................................................................... 17

Figure 18 – Multiple enclosure installation ..................................................................................... 18

Figure 19 – Example of an insulated tool kit .................................................................................. 20

Figure 20 – Secure hooks in eyebolts ........................................................................................... 21

Figure 21 – Enclosure ground connections ................................................................................... 23

Figure 22 – Alarm connections ...................................................................................................... 24

Figure 23 – Alarm block ................................................................................................................ 25

Figure 24 – Slab AC conduit installation ........................................................................................ 26

Figure 25 – Underground AC conduit installation. AC panel extends of edge of concrete slab ...... 26

Figure 27 – DC and fibre cable routing at top of enclosure ............................................................ 27

Figure 26 – DC and fibre cable routing at bottom of enclosure ...................................................... 27

Figure 28 – Fiber optic cables must be protected by a loom at the cable entry.............................. 28

Figure 29 – Gasket installation on batteries location Te40panels release ..................................... 29

Figure 30 – Battery fuse kits and battery cabling. See attached drawing for more details ............. 30

Figure 31 – Completed installation ................................................................................................ 34

Figure 32 – Plastic plug - 4 positions ............................................................................................. 37

Figure 33 – Loosen internal nuts ................................................................................................... 37

Figure 34 – Slide cover up and off................................................................................................. 37

Figure 35 – Filter is located inside cover ....................................................................................... 37

Page 10

1 Introduction

1.1 Scope of manual

This instruction manual covers the features, installation, startup, and maintenance of the Alpha Technologies’

Tempest Te45 Outdoor Auxiliary Enclosure.

Enclosure specifications are found in Alpha document #029-039-B2.

Operation instructions for the system controller and related modules are provided in separate component

manuals.

Separate manuals are provided for batteries and other accessory equipment, such as HVAC.

Images contained in this document are for illustrative purposes only and may not exactly match your unit.

Page 11

Figure 2 – Tempest outdoor

auxiliary enclosure. Front view.

AC Load center

Generator connector

Removable rear panels (3)

EVS intake

4000 btu air

conditioner w/ heater

EVS exhaust

Figure 1 – Tempest outdoor auxiliary

enclosure. Rear view.

2 Product overview

The Te45 Outdoor Auxiliary Enclosure is a 72" tall enclosure that can be configured for power, battery or auxiliary

applications. Each configuration is designated by a part number that may include separate available options.

A Te45 system typically includes:

Zone 4 seismic enclosure

Optional AC distribution or junction box

DC power components

Alarm interface

4000 BTU air conditioner and EVS

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 2 of 38

Page 12

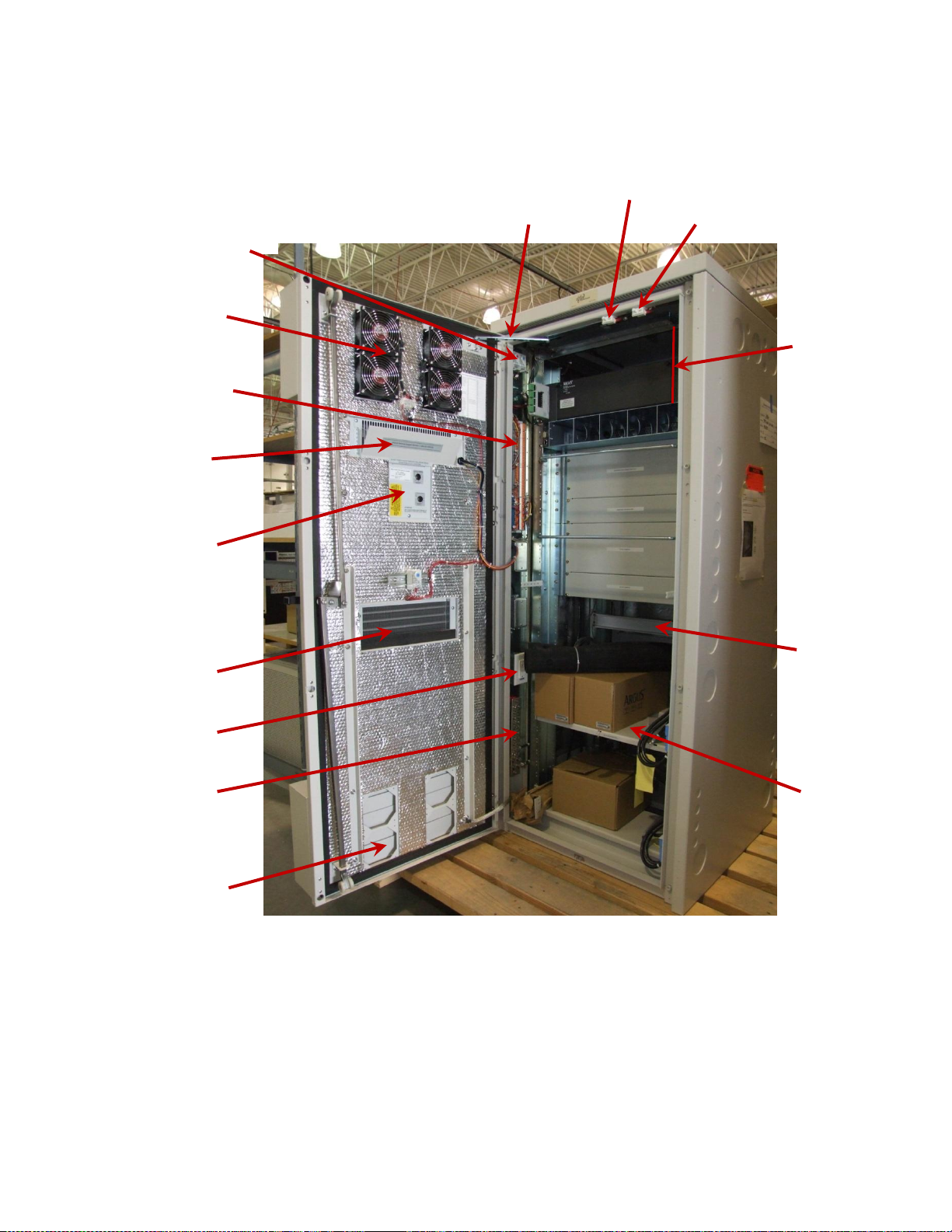

EVS intake fans

Air Conditioner

return air

Wind latch

DC light

Air conditione/

heater temp

set point

Air conditioner

supply air

Alarm connection

blocks

High/low temp alarms

GFCI plug in

Ground bar

Cordex

power and

distribution

system

(typical)

Battery

retaining

bracket

Battery

shelves

EVS exhaust

Figure 3 – Typical Te45 enclosure power configuration

Door intrusion alarm

2.1 Typical power configuration

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 3 of 38

Page 13

Ground bar

GFCI outlet

Alarm

termination

blocks

Hi/low temp

alarms

Battery termination bus bars

Battery retaining

bracket

Battery trays

Figure 4 – Typical Te45 Battery Configuration

2.2 Typical battery configuration

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 4 of 38

Page 14

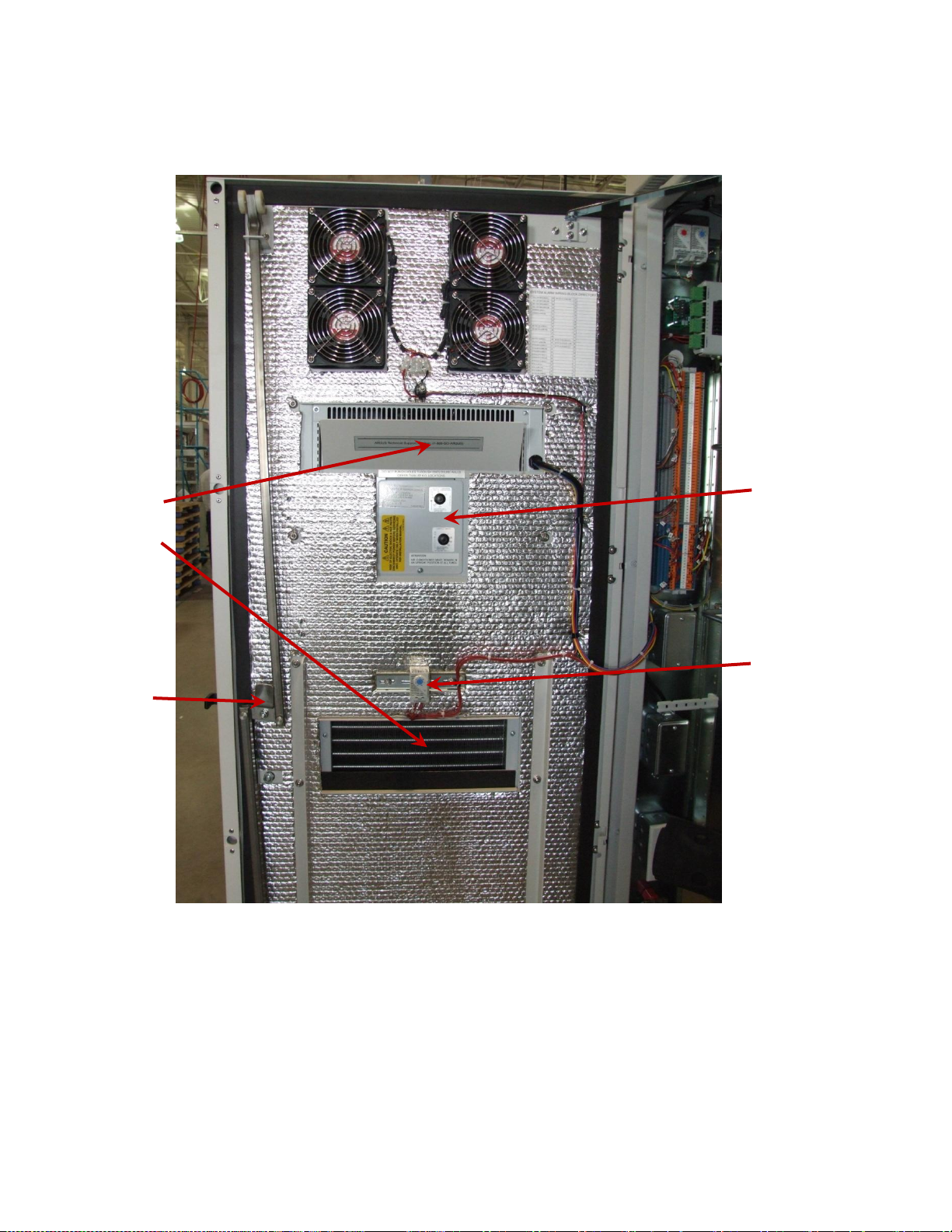

EVS thermostat

Threepoint door

latch

HVAC intake

and exhaust

HVAC controls

Figure 5 – Miscellaneous enclosure features

2.3 Air conditioning and heating

A 4000 BTU air conditioner/500 watt heater package provides cooling or heating to the batteries. It is mounted on

the front door of the enclosure. Refer to the HVAC manual that is supplied with the unit.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 5 of 38

Page 15

Figure 6 – Surge suppression mounted on rear of fibre slack box bracket

2.4 AC panel board and generator connector

The AC panel board and generator connector are supplied by Intersect Corporation. The panel includes an

automatic transfer switch, an additional emergency generator connection, and a manual transfer switch. Refer to

the Intersect manual that is supplied with the unit.

2.5 Equipment mounting rails

4 x 23" mounting rails are installed in the enclosure.

2.6 Battery trays and battery retaining brackets

Two battery trays are provided. Battery retaining brackets are supplied for mounting positions both in front and on

top of the batteries.

Battery trays and retaining brackets are designed specifically for GNB155 batteries. Any deviation from this battery

may affect Zone 4 seismic compliance. Call Alpha before changing battery models.

2.7 T1 surge suppression

The enclosure is provided with a rail mounted bracket that accommodates a fiber slack box and two AC data Model

MPM6-TTTTEE-DL “Multi-port Max 6" surge suppression devices.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 6 of 38

Page 16

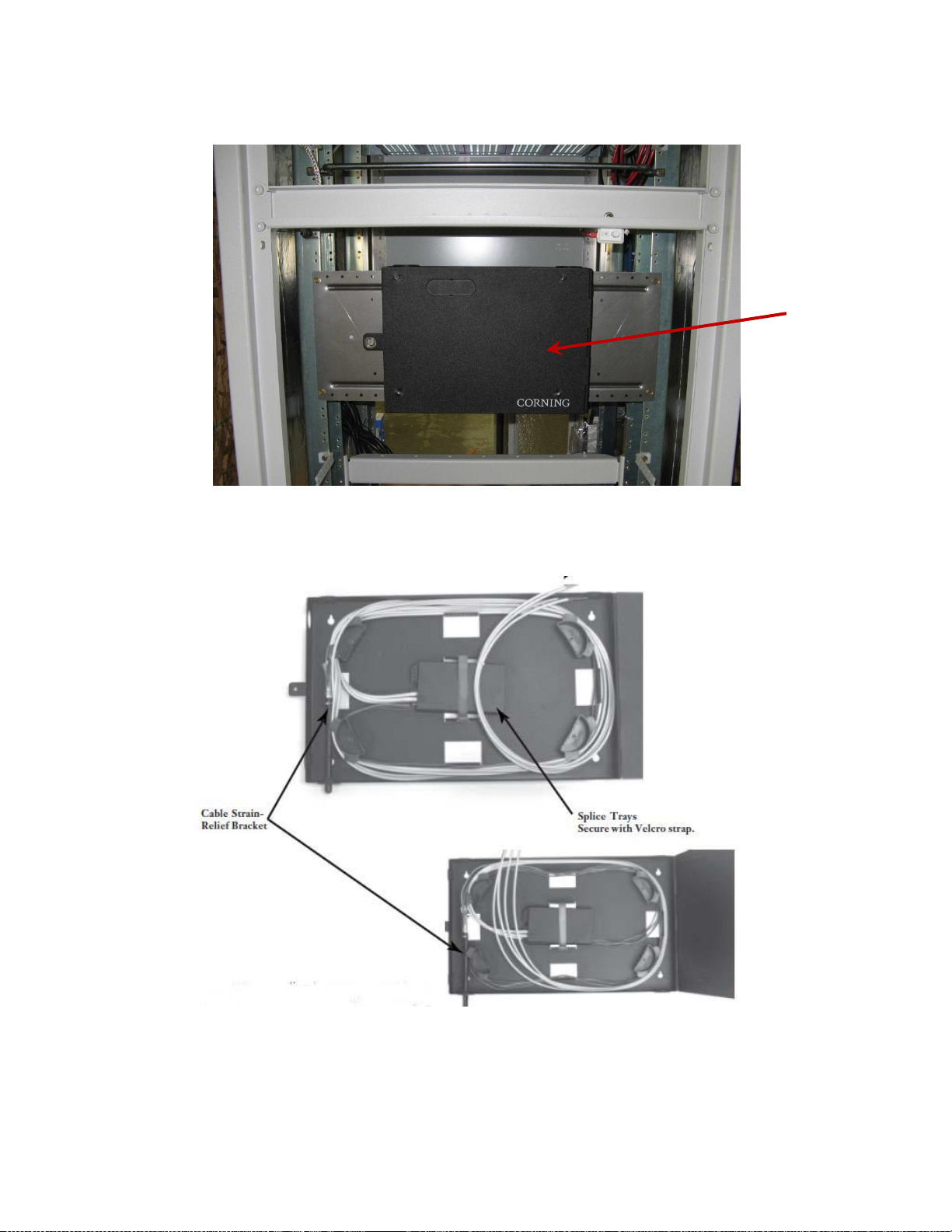

Figure 8 – Fiber cable slack box

Figure 7 – Fiber slack box mounted on rear rails

Fiber cable

slack box

2.8 Fiber cable slack box

A fiber cable slack box is provided on the enclosure.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 7 of 38

Page 17

The front door

can be secured

at the handle

via a padlock

Figure 9 – Locking front door

Door mounted

EVS thermostat

2.9 Emergency ventilation system (EVS)

The EVS unit provides ambient cooling when the inside temperature exceeds a predetermined temperature setting

on the EVS control thermostat.

The EVS is a DC system that operates when any one or more of the following conditions is present:

AC power failure. The air conditioner shuts down.

Air conditioner compressor failure.

Extreme ambient temperatures above 45°C.

2.10 Doors and access panels

The hinged front door is held closed by a 3 position latching system with a pad lockable handle.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 8 of 38

Page 18

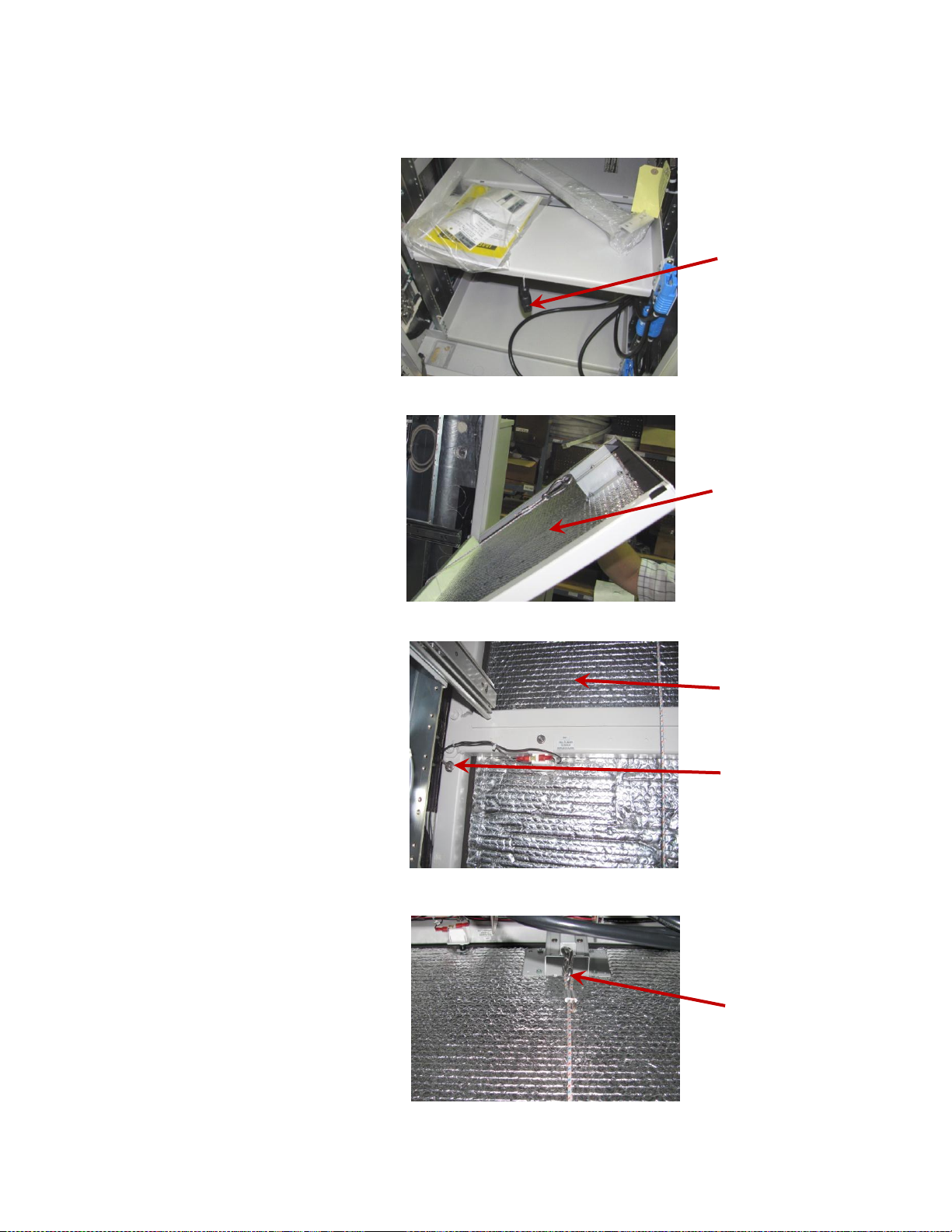

Remove rear top panel

CAUTION:

The rear panels are

connected by a

ground strap and

release cable, but can

fall upon release.

Pull on handle to

release top rear panel

Remove each set of wing

nuts, one on each side, to

release the lower panel.

To remove rear

panel, disconnect

lanyard and ground

strap once the panel

is released

Figure 10 – Rear panel latch

Figure 11 – Rear panel released

Figure 12 – Wing nuts retaining lower panels

Figure 13 – Disconnect lanyard and ground strap

When installing the rear panels,

first install the lower panel, and

then install the middle panel.

When installing either panel, first

connect the ground strap, then

move the panel into place, and

finally tighten the wing nuts

securely.

On the upper panel, re-install the

ground strap and re-attach the

lanyard as shown

2.11 Rear access panel

There are three rear access panels. The top panel is a slam latch panel. The lower two panels use internal wingstuds that must be removed to lift off the panels. The following procedure explains how to remove the rear panels:

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 9 of 38

Page 19

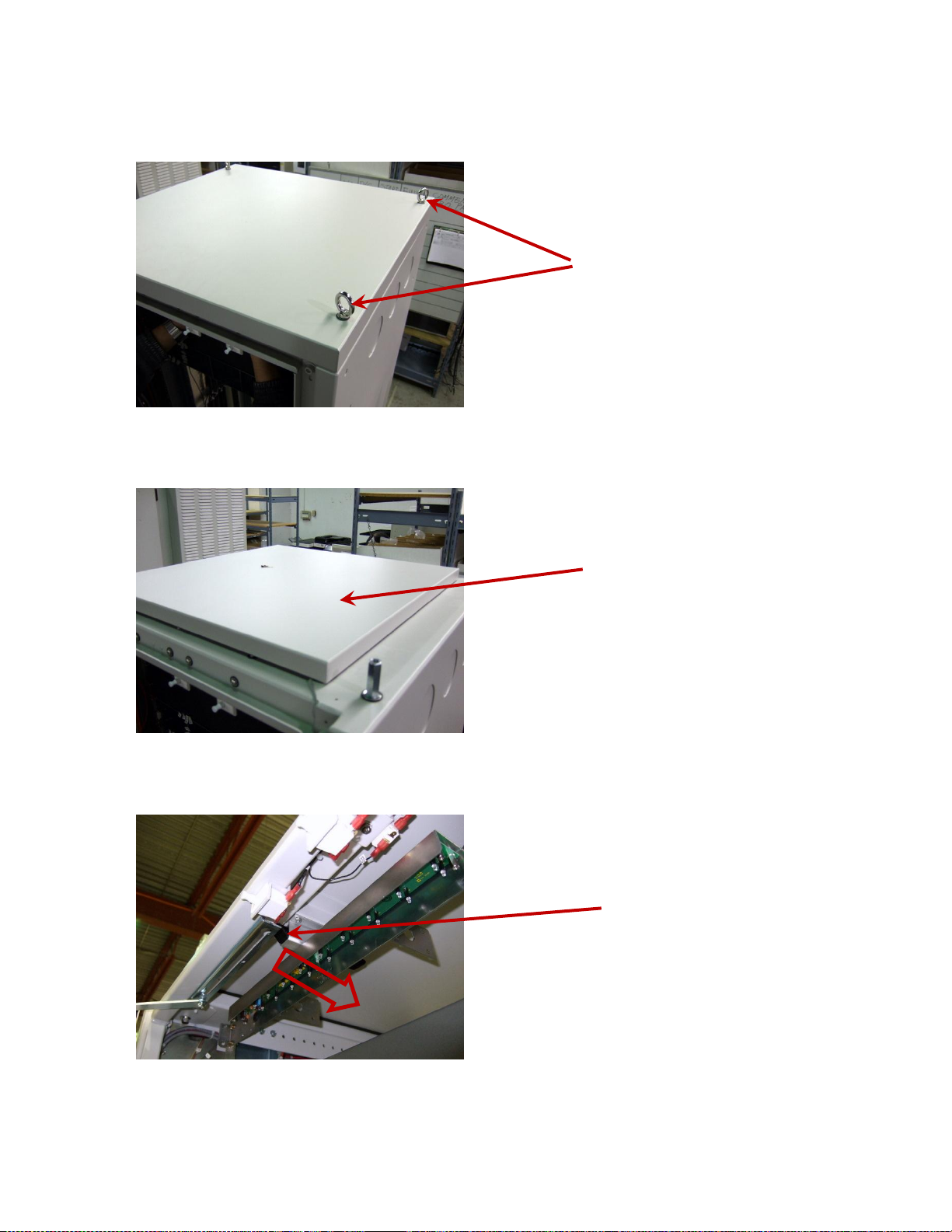

Remove eyebolts

Remove solar shield to

expose hatch plate

To release hatch plate, pull the

latch ring toward the rear of the

enclosure in the direction shown

by the large arrow

2.12 Removable solar shield and hatch plate

To re-install, ensure the slam latch on the hatch plate is fully engaged.

Re-install the solar shield by re-installing the eyebolts.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 10 of 38

Page 20

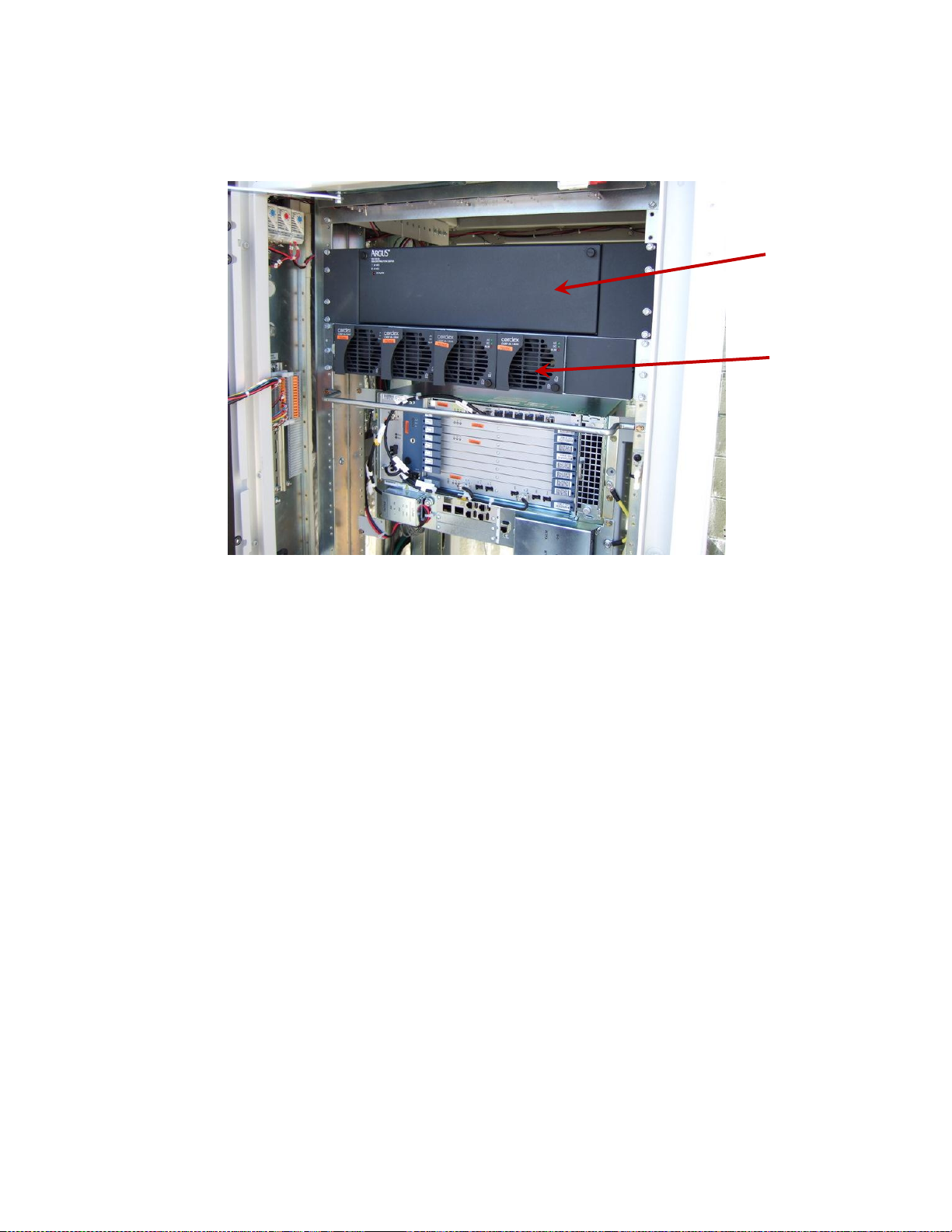

Distribution

center

Rectifier

2.13 DC power equipment

2.13.1 Distribution panel

The DCP03, 300 A distribution center in an integrated DC system distribution package designed for small to

mid size power applications.

The distribution panel takes up three rack units of space.

The DC system and signal connections are accessible from the front of the panel.

All distribution wires are connected via two-hole termination lugs.

Up to 18 plug-in breakers can be installed at up to 100 A per position. Optional multiple pole breaker adapter

kits are available.

The 4R/8D ADIO Cordex peripheral is installed in the front door, expanding the I/O capability of the controller.

2.14 Rectifier and shelf

37.5 A @ 48 Vdc is provided to each rectifier.

Rectifiers are hot swappable.

2RU ultra compact rectifier design.

The fan cooled 1.8 kW rectifier has extremely high density with a compact 2RU design that allows five rectifiers per

23" shelf and four rectifiers per 19" shelf together with an integrated CXCI controller. An optional CXCM2 controller

with a touch screen display is available.

Local and remote setup, adjustments, and control are a single step process via the controller. By using TCP/IP

technology, complete configuration and monitoring of power equipment can be done through a network web

browser.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 11 of 38

Page 21

CXCI Cordex

controller

GMT fuse block

mounted to side

of distribution

center

2.15 Controller

The compact CXCI Cordex controller is an integrated option that fits inside the rectifier shelves and takes up 2RU

of space. The controller includes a complete range of standard software features.

The controller includes a web server interface that provides easy set ups via local or remote IP access using a

standard Internet Explorer browser. The controller features LED indicator lights and an LCD screen that displays

voltage and current.

An integrated logging feature is typically available only with an advanced, standalone, data logging system. It

allows the capture of data from multiple AC/DC voltages, load/battery currents, and cell voltages/temperatures.

Common applications of the logging include power system details, thermal performance of outdoor enclosures,

battery cell specifics, and mains variations captured by an AC voltage watchdog.

The CXCI I/O features can be expanded by adding CXC smart peripherals, such as battery cell monitoring, shunt

multiplexing, or alarm relay expansion.

Cordex CXC controllers are designed to ensure effortless operation of Cordex rectifiers. Otherwise complicated and

time consuming set ups are greatly simplified.

2.15.1 GMT fuse block

An 8-position GMT fuse block is installed in the enclosure to provide additional distribution capability.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 12 of 38

Page 22

3 Transportation and storage

3.1 Packaging

The enclosure and components are shipped on individual pallets and shrink wrapped. The enclosures and

components must not be stacked. Packaging assemblies and methods are tested to International Safe Transit

Association standards.

The pallet is approximately 0.15 m H x 1.22 m W x 1.22 m D (6" H x 48" W x 48" D) and the overall height including

pallet and enclosure is approximately 1.98 m (78").

Batteries are shipped on a separate pallet and packaged according to the manufacturer’s guidelines. Packaging

assemblies and methods have been tested to International Safe Transit Association standards.

3.2 Storage

The weight of the enclosure is written in the specifications. The equipment pallet can be moved using a forklift.

Do not hoist/lift the enclosure with batteries installed.

The warehouse facility may need to be certified for handling the batteries, which are shipped on a separate pallet.

3.3 Inspection

Before unpacking the equipment, perform a visual inspection and note any damage. Unpack the equipment and

inspect the exterior for damage. Contact the carrier immediately if any damage is observed.

Continue the inspection for potential internal damage. Contact the carrier immediately if internal damage is

detected. Then contact Alpha Technologies for advice on the consequence of any damage.

Verify that you have all the required parts before proceeding with the installation.

Call Alpha Technologies if you have any questions: 1-888-462-7487

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 13 of 38

Page 23

4 Installation

4.1 Pre-installation considerations

The information in this section is intended to be used as a guideline only. There may be site-specific requirements

and other factors that may require different procedures. For example, your jurisdictional codes and construction

covenants may require different procedures than those in this manual.

4.2 Power system

An Alpha system provides sufficient power for a defined frame load plus the capacity to recharge the batteries

within 24 hours.

“N+1 recharge” time refers to the estimated hours to recharge the batteries to 95% while operating at full load with

all the rectifiers working and where a “redundant” rectifier is installed. Consult the factory if your equipment

configuration has changed from its original layout.

4.3 HVAC system

The 4000 BTU air conditioning/heater and the emergency ventilation system are optimized and tested for a

particular equipment configuration within the enclosure. Consult the factory if your equipment configuration has

changed from the original layout. Factory testing may be required for new equipment configurations.

4.4 Site selection

The Te45 has been designed as an outdoor power system enclosure. The most common mounting structures are:

An at-grade concrete slab.

A steel platform.

An existing structure, such as a rooftop.

The mounting structure must be strong enough to support a fully equipped enclosure. Existing structures may need

to be reinforced to support the enclosure. The mounting site must be built in accordance with local building

practices and codes. A fully equipped power enclosure with 5 rectifiers and 8 batteries weighs approximately 2000

lb. A fully configured power enclosure with 16 batteries weighs approximately 3000 lb.

Consider the following before selecting a mounting site:

The Alpha Te45 enclosure is designed for front, rear, and if necessary top access. Only front access is required

for maintenance.

Avoid areas that may be subjected to hot air exhaust from nearby equipment or buildings.

Find out if your intended area is subjected to architectural controls or environmental restrictions.

Avoid areas that are prone to flooding.

4.5 Enclosure support

A supporting structure with a minimum load capacity of 350 lb/ft² is required to support a fully equipped power

enclosure with rectifiers, batteries, air conditioner, etc.

A support structure with a minimum load capacity of 500 lb/ft² is required to support a fully equipped battery

enclosure.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 14 of 38

Page 24

Figure 14 – Base layout drawing and mounting hole locations

4.5.1 Base layout dimensions

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 15 of 38

Page 25

Figure 15 – Concrete anchor bolt fastening detail

4.5.2 Concrete slab

Cast-in-place or pre-cast concrete slabs can be used.

Place the enclosure on the concrete slab. Use the enclosed Hilti HSL heavy-duty expansion anchor bolts, or

approved equivalents, and the enclosed square seismic washers to secure the enclosure. Follow the specific

recommendations from the fastener manufacturer to ensure that the securing device achieves its full structural

capacity. Take into account the embedment depth and the clear edge distances. Refer to the following figure.

Alternate mounting systems that are not provided directly with the enclosure must be reviewed by a registered

professional engineer that is qualified to practice within the jurisdiction where the enclosure is being installed.

An alternate mounting system could for example use a chemical anchoring system such as Hilti’s HY150 for

concrete or HY20 for masonry along with suitable threaded rods and inserts from the manufacturer. Follow the

manufacturer’s recommendations to determine the spacing and placement of the threaded rods.

The structure must be designed to support a fully equipped enclosure. The concrete slab and any existing

structures must be properly reinforced to support the floor loading. The mounting site must be designed and

installed in accordance with local building practices and codes.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 16 of 38

Page 26

Figure 17 – Installation on steel platform

Figure 16 – AC conduit outside concrete slab

AC conduit

located outside

cement pad

4.5.3 AC connections with concrete slab mounting

4.5.4 Steel platform

Use 1.27 cm (½") diameter A325 structural bolts in conjunction with a backing plate/clasp to grip the underside of

the grating. Once the enclosure is in place, secure the bolts on the inside using appropriate washers and bolts. See

the following figure:

CAUTION: Installation on a wood base is not recommended. The compressive strength of the base

material would not be able to maintain the load during a Type 4 seismic event.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 17 of 38

Page 27

Figure 18 – Multiple enclosure installation

4.6 Multiple enclosure installations

For multiple enclosure installations, a kit is required that includes gaskets and cable components. See Drawing

747-670-08 for complete instructions.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 18 of 38

Page 28

Roxtec seal port 9 way assembly including

boot, mounting collar and hardware

Alpha part number: 037-193-20-000

Can be used for cable entry into the Te45 enclosure wherever there are 3" knockouts.

See www.roxtec.com for

additional information

4.7 Installation component requirements

Concrete and metal grating mounting hardware is not supplied with the enclosure.

AC electrical conduit, cable and fittings are not supplied with the enclosure.

Internal DC cables are supplied. External DC conduit, cable and fittings are not supplied with the enclosure.

A cable entry port fitting is available as an option:

For multiple enclosure installations, an interface kit is required.

Power to battery: 747-602-20

Battery to battery: Currently not available

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 19 of 38

Page 29

Figure 19 – Example of an insulated tool kit

4.8 Installation tools and equipment

4.8.1 Tools Required

Insulated tools are essential for DC power system installation. Use this list as a guide:

Electric drill with hammer action

Digital voltmeter equipped with test leads

Lap top computer with Cordex communication software (not required for initial installation and test)

Various crimping tools and dies, to match lugs used in installation

Torque wrench: ¼" drive, 0-150 in-lb for battery post connections

Torque wrench: 3/8" drive, 0-100 ft-lb for system connections

Insulating canvases as required (2' x 2', 1' x 1', 3' x 3', etc.)

Insulated hand tools:

-Combination wrenches -Ratchet and socket set

-Various screwdrivers -Electricians knife

-Fine tipped slot screwdrivers (“tweaker”) -Cable cutters

Cutters and wire strippers (#14 to #22 AWG) [2.5 – 34 mm2].

4.8.2 Lifting equipment requirements

Hoist or crane capable of lifting 1814 kg (4000 lb)

The forklift should have a rated lifting capacity of 1814 kg (4000 lb) with a minimum fork length of 36"

Four wire-rope slings at least 1.22 m (4') long with a capacity of 907 kg (2000 lb) each.

Four clevises.

One minimum 1.59 cm (5/8") diameter rope to use as a tagline to guide the enclosure while lifting.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 20 of 38

Page 30

Figure 20 – Secure hooks in eyebolts

4.9 Enclosure installation

4.9.1 Enclosure preparation

Remove the protective covering from the system. The doors are designed to be locked with a pad-lock and are

secured with tie-wraps for shipping. Cut the tie-wraps and open the doors. The inside of the enclosure contains the

rectifiers, and other hardware.

Inspect the packing slip to verify that you have received all the equipment that you ordered.

If the batteries are on a separate pallet, do not install them until after the enclosure has been secured and the

ground wires and other cable entries are connected. It is easier to route the cables when the batteries are not

installed.

All documentation is packed inside the equipment compartment.

Inspect all moving parts, hardware, connectors, and other equipment.

Report any damage to the shipper and Alpha Technologies.

Remove and properly dispose of all packaging.

Save the rectifier boxes for future transport.

Remove the rear panels to access the rear mounting bolts.

Remove the four bolts that secure the enclosure to the pallet. These bolts are accessible from the inside of the

enclosure and are located in the corners of the enclosure. The enclosure is now ready for lifting.

4.9.2 Lifting preparation

CAUTION: Follow all local safety practices and guidelines while lifting the enclosure. All personnel

involved with lifting and positioning the enclosure must wear head and eye protection and gloves.

Only properly trained and certified personnel should operate the crane. Only properly trained and

certified personnel should operate the forklift.

Make sure that the lifting eyes are securely fastened before lifting the enclosure. Ensure that the clevises are

correctly installed and that the enclosure is approximately level during the lift. This will simplify the enclosure

positioning.

Close and latch the enclosure front door. The rear panels do not have to be installed.

Place the enclosed rubber mat onto the slab or platform. Orient the mat so that the mounting holes line up. If

the rubber mat is “ribbed” the ribs should be against the concrete.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 21 of 38

Page 31

Place shims

close to corners

4.10 Mounting the enclosure

4.10.1 Concrete slab

Use the tagline to guide the enclosure as it is lifted. As the enclosure is lowered, align the mounting bolts and

slowly lower the enclosure into place.

CAUTION: Follow all local safety practices and guidelines while lifting the enclosure. As the

enclosure is lowered, ensure that it remains as level as possible and lines up with the anchoring

bolt locations. Ensure the rubber mat is in the proper position. Open the door and proceed with

leveling the enclosure and securing it into place.

Leveling the enclosure

Four 0.125" shims are provided with the enclosure. Before securing the enclosure, make sure that it is level.

Place the shims as close as possible to the bolts.

Check that the enclosure is level font-to-back and side-to-side.

A shim may need to be added under one or two of the corners of the enclosure. To place a shim, take just

enough weight off the enclosure to slide the shim into place.

Allow the full weight of the enclosure to rest on the shims, and then check the level again.

Once the enclosure is level, tighten all bolts to the appropriate torque. After securing the enclosure, remove the

slings and lifting eyes.

4.10.2 Steel platform

If the steel platform is located at ground level, the procedures are the same as those for a concrete slab.

4.10.3 Roof mounting

CAUTION: The mounting platform must be installed before the enclosure can be installed. All grounding

must be in place before the installation.

Place the enclosure onto the roof using either a freight elevator with access to the roof, or by using a crane or

Do not remove the enclosure from its pallet until it is on the roof and is ready to be positioned.

4.10.4 Installing multiple enclosures side-by-side

If two or more enclosures are to be installed adjacent to one another, install the environmental components of

For detailed procedure, refer to the next chapter and drawings 747-602-08, 747-603-08, or 747-607-08.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 22 of 38

hoist on the roof.

the interface kit before bolting the enclosures into place.

Page 32

External chassis ground

connected to site ground.

There are two connection

points, one at the front of

the enclosure, and one at

the rear. Only one

connection is required

with an exothermic

connection.

Ground wire that

connects the site ground

to the master ground bar

Figure 21 – Enclosure

ground connections

Ground studs

MG

4.11 Grounding

DANGER: An enclosure that is not properly grounded presents an electrical hazard.

A proper grounding system that meets or exceeds the specifications of the equipment must be designed and

installed prior to or in conjunction with the construction of the mounting pad. The ground system must be bonded to

the enclosure to ensure a “common” or “single-point” ground.

Examples of grounds:

New builds – a buried ground ring with a bare, solid conductor going to ground rods.

Rooftop – a connection to the building’s steel structure, water pipes, etc.

Refer to local codes and practices for proper acceptable grounding arrangements. Only a licensed electrician

should be used to install the grounding system. Use a dedicated ground rod for the AC panel.

CAUTION: Do not route AC and DC wiring in the same conduit.

4.11.1 Site ground wire entry

External ground studs are located at the bottom front and rear of the

enclosure. Use these for the site ground wire connections. Terminate

either the front or rear connection to the external ground ring with an

exothermic connection. A minimum of #2 AWG solid wire is required.

4.11.2 Master ground bus (MGB)

The master (main) ground bus is located at the lower left front corner

of the enclosure. Terminate the MGB to the external ground ring with an exothermic connection. A minimum of #2

AWG solid wire is required.

4.11.3 Enclosure chassis ground

The enclosure chassis ground is pre-installed at the factory. It is connected to the enclosure frame and equipment

racks and is terminated to the MGB inside the enclosure.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 23 of 38

Page 33

Figure 22 – Alarm connections

4.12 Wiring, cable management, and connections

This section explains how to install and interconnect the power components within the enclosure. For battery

installation, refer primarily to the manufacturer’s manuals.

Ensure the cables are not routed against any unprotected steel edges.

The cables must be neatly tie-wrapped or contained within a plastic loom.

Run the DC, ground, AC, and data cables in separate conduits.

4.12.1 Alarm connections

Route the alarm cable through the bridge interface to the adjacent enclosure. See the enclosed schematic for alarm

connection details. If necessary, configuration changes can be made at the alarm wiring terminal block.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 24 of 38

Page 34

Figure 23 – Alarm block

Alarm block

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 25 of 38

Page 35

Figure 24 – Slab AC conduit installation

Figure 25 – Underground AC conduit installation.

AC panel extends of edge of concrete slab

4.13 Utility connections

Different sites require different methods of conduit installations.

4.13.1 AC conduit installations

Verify local and national electrical codes prior to the installation. The codes may vary and contain specific

conduit and wire sizes for the panel board connection.

The connection to the utility power must be approved by the local utility before the power supply can be

connected.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 26 of 38

Page 36

Figure 26 – DC and fibre cable routing at top of enclosure

Figure 27 – DC and fibre cable routing at bottom of enclosure

4.13.2 Procedure

1. Ensure that all AC breakers are in the off position at the AC source and within the AC panel.

2. To access the interior assembly, open the AC panel door and remove the cover.

3. Use the knockouts supplied on the AC enclosure for the cable routing.

4. Install the conduit nipple into the service entrance opening. Secure the nipple into place using the appropriate

locking nut(s) and sealing washer(s).

5. Review the AC panel documentation and then connect the AC cables.

6. Measure and record all voltages before switching on the main breaker. Do not switch on individual breakers.

7. If required, notify the local electrical inspector to approve the AC input wiring.

4.14 Other cable connections

Holes must not be drilled into the enclosure other than at conduit knockouts.

All cable entry fittings must be water tight.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 27 of 38

Page 37

Figure 28 – Fiber optic cables must be protected by a loom at the cable entry

4.15 Internal cable routing

Keep internal cable routing neat and secured with tie wraps.

Ensure that fiber optic cables do not make sharp bends and are protected by a flexible conduit. A split loom

with a length of 28' and a diameter of 1" is supplied with the enclosure. It is used to for the top and bottom fiber

optics cable installations.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 28 of 38

Page 38

Install gaskets at

the front and rear

of each of 3 of 4

batteries.

Figure 29 – Gasket installation on batteries

4.16 Battery installation

WARNING: Follow the battery manufacturer’s safety recommendations when working around

battery systems and review the safety instructions provided in this manual.

4.16.1 Preparation/mounting

Make sure the enclosure is properly mounted and secured before starting the battery installation.

The batteries should be located in a temperature-controlled environment (Tempest). Regulate the temperature

to approximately 25°C (77°F). Significantly lower temperatures reduce the battery performance and higher

temperatures decrease the battery life.

Clean the batteries cells according to the battery manufacturer's recommendations. First neutralize any acid

with a baking soda and water solution, rinse the batteries with clean water, and then wipe them dry.

Install gaskets at the front and rear of each 3 of 4 batteries.

4.16.2 Battery installation in Alpha Tempest power systems

Verify that all battery breakers, DC circuit breakers, and fuses on the distribution panels are either

in the OFF position or removed. For each of the following steps, verify that the rubber terminal caps

or plastic covers are installed and completely cover the positive and negative terminal connections.

1. Apply a corrosion-inhibiting agent, such as NO-OX-ID “A”™, on all battery terminal connections.

2. Lift each battery onto the front edge of the shelf, and then slide the battery into the shelf.

3. Ensure that each battery output cable reaches the [+] and [–] terminals of the series battery string. Make sure

that the batteries are oriented for easy installation of the inter-unit “series” connectors.

4. Remove any NO-OX-ID “A”™ grease from the battery terminals.

5. Burnish the terminal posts with a non-metallic brush, polishing pad, or 3M Scotch Brite™ scouring pad.

6. Apply a light coating of NO-OX-ID “A”™ grease to the terminal posts.

7. If lead plated inter-unit connectors are used, they should also be burnished and NO-OX-ID “A”™ grease

applied as above.

8. Install the battery shelf retaining brackets.

9. Install the inter-unit connectors.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 29 of 38

Page 39

Figure 30 – Battery fuse kits and battery cabling. See attached drawing for more details

10. Locate battery string fuse kits and connect the batteries to the pre-installed cables coming from the system DC

output bus bars.

Install all the battery terminations with the correct torque settings. Refer to the above drawing and

the battery manufacturer's manual.

Repeat the above installation procedure for each shelf and battery string.

WARNING: Do not connect the Anderson connectors before reviewing the startup procedures.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 30 of 38

Page 40

5 System startup

After completing the enclosure installation and the power system wiring, perform the following startup and test

procedure:

5.1 Connecting the batteries

1. Check and verify the polarity of all the batteries.

2. Open all the DC breakers and temporarily remove all the DC fuses. The breakers must be closed and the fuses

reinstalled after the testing is complete.

3. Unplug all rectifiers except one.

4. Switch on the AC breakers to apply power to the rectifier shelf.

5. The controller will perform a short self-test as it boots up.

6. Alarm conditions will likely be present and will probably not clear because there is no DC load on the rectifiers

since all the loads are disconnected.

7. The system voltage will be visible on the controller display.

8. With the batteries disconnected, measure the voltage difference between the power system and the battery

string. The voltage difference should be less than 3 V. If the voltage difference is greater than 3 V, check the

cable connections and the conditions of the batteries. Correct the problems and then proceed. If you are

unable to correct the problem, switch off the AC input power and contact Alpha Technologies.

9. Measure the battery voltage at the battery connector and ensure that the polarity is correct. Connect the first

string of batteries by plugging in the Anderson connector. Repeat this step for the remaining string of batteries.

10. Plug in the remaining rectifiers one at a time.

11. All the alarms should clear and the audible alarm will switch off provided the batteries are slightly discharged.

12. Switch on the all the remaining breakers. The air conditioner fans should start.

13. Apply the DC loads by switching on the DC powered equipment.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 31 of 38

Page 41

5.2 Test and commissioning overview

5.2.1 System

All power system components undergo thorough factory testing. All levels and alarms are set to values according to

the information given in the component manuals, unless custom levels are specified. Check the operation of all

features and alarms and ensure that the power system levels are set in accordance with the specific requirements

of your system. See the component manuals for more details.

5.2.2 Environmental/intrusion

Check the operation of all enclosure features, such as the air conditioning unit settings, the high/low temperature

alarms and the intrusion alarm.

5.3 Battery

After the batteries have been installed, the batteries must be “initially charged” to eliminate plate sulfation. Follow

the guidelines in the battery manual. Record the initial charge readings, which are: specific gravity, cell voltage,

charge current, and temperature. Battery warranty may be void if the batteries are not initially charged following the

manufacturer's guidelines and proper records maintained.

Some VRLA batteries do not require initial charging if they are placed on charge within 3-6 months of manufacture.

Check the battery manufacturer’s manual.

After the equalization period, reduce the battery voltage to the recommended float level.

Once the batteries have been initially charged, perform a short duration high rate discharge test on the batteries to

verify that the cable connections are good and that there are no open or failed cells. Monitor the cell voltages during

this process:

Discharge for 15 minutes at the C/8 rate.

Record cell voltages every 5 minutes.

Check for overheating connections.

5.3.1 Documentation

Complete all the required commissioning documentation such as:

Battery reports.

DC wiring lists.

AC distribution tables.

Floor plans.

Fill out tag wire identification strips.

Identify circuit breakers.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 32 of 38

Page 42

Description

Setting

Cooling system ON temperature

80F (26.6C)

Heating system ON temperature

60F (15.5C)

HVAC fail alarm (dirty filter, broken condenser, etc.)

300 psi, reset at 225 psi

EVS thermostat

Setting

EVS ON temperature

45C (113F)

Battery compartment thermostat

Setting

High temperature alarm (blue)

45C (113F)

Low temperature alarm (red)

-15C (5F)

5.4 Air Conditioner/heater factory settings

The air conditioner is programmed with the following factory default settings.

5.5 EVS (Emergency Ventilation System) factory settings

The EVS thermostat is programmed with the following factory default setting.

5.6 Enclosure temperature alarms

The enclosure compartment thermostat is programmed with the following default factory settings.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 33 of 38

Page 43

Figure 31 – Completed installation

6 Final cleanup

Vacuum clean all metal filings and other debris from inside and around the enclosure.

Ensure that:

All cables and conduit are neatly secured.

Access panels are installed correctly.

All connections are tight.

All breakers are on and the system is running without any alarms.

Enclosure is locked and secure.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 34 of 38

Page 44

Description

Interval

Clean ventilation openings

1-6 months

Test and calibrate controller and other control circuits

1 year

Inspect all cable connections, re-torque if necessary

1 year

Verify alarm/control settings

1 year

Verify alarm relay operation

1 year

Check batteries

6 months

Clean HVAC filter

2-6 months

7 Maintenance

The equipment requires regular maintenance. The maintenance should be done by qualified service personnel

only.

WARNING: HIGH VOLTAGE AND SHOCK HAZARD.

Use extreme care when working inside the enclosure/shelf while the system is energized. Do not

make contact with live components or parts. Static electricity may damage circuit boards, including

RAM chips. Always wear a grounded wrist strap when handling or installing circuit boards.

7.1 General maintenance schedule

7.2 Air conditioner

7.2.1 Air conditioner settings

The air conditioner is pre-programmed with default settings at the factory. Refer to the air conditioner manual if

you need to adjust these settings.

The air conditioner is not always thoroughly tested at the factory. If the air conditioner fails to switch on when it

should, refer to the air conditioner manual and check the temperature settings.

If the air conditioner appears to be working properly but the “Hi-Temp” alarm is on, check that the enclosure's

Hi-Temp alarm thermostat is correctly set.

7.2.2 Air conditioner filter

Air conditioners usually fail because of lack of maintenance, specifically dirty filters. Initially this filter must be

checked frequently until a proper maintenance schedule has been developed.

IMPORTANT: Scheduled filter maintenance must be dutifully followed to reduce the chance of air

conditioner failure.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 35 of 38

Page 45

8 Batteries

The following generic maintenance instructions apply to valve regulated lead acid (VRLA) batteries. Each battery

type and manufacturer will have their own unique maintenance instructions, which must take priority over the

generic instructions listed here.

8.1.1 Monthly maintenance

Check and record each individual battery voltage.

Check and record the ambient temperature.

8.1.2 Semi-annual maintenance

Check the voltage of each cell.

Check the total voltage of all cells.

Check the temperature of each cell.

Visually inspect the general appearance and cleanliness of the batteries.

Check for cracks in cells or electrolyte leakage.

Check for corrosion.

Re-torque all intercell connector bolts.

Check the connections resistances cell-to-cell and cell-to-terminal.

Measure the conductance and impedance of each cell.

8.1.3 Performance/ integrity checks

The controller can perform real time monitoring of the performance of each battery. Parameters that can be

monitored include voltage, specific gravity, conductance, and impedance. See the controller manual.

8.1.4 String or cell replacement

1. Ensure that the system is not operating on backup power.

2. Unplug the battery string at the Anderson connector.

3. Remove the cables and fuses.

4. Remove the battery retaining brackets.

5. Replace batteries and reverse the procedure.

6. Check the battery polarities and the connectors before reinstalling the Anderson connector.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 36 of 38

Page 46

Figure 32 – Plastic plug - 4 positions

Figure 33 – Loosen internal nuts

Figure 35 – Filter is located inside cover

Filter is located inside

panel. Clean or replace

the filter. It is reusable

Reverse the sequence

to re-install the cover.

Slide cover up and

away from door.

Loosen but do not

remove the four

retaining nuts.

Head size is 7/16"

Remove four plastic plugs

to gain access to cover

retaining nuts

Early versions of EVS units use blue filter material and

later versions use grey filter material.

Part # for blue replacement filter: 649-199-10

Part # for grey replacement filter: 649-211-10

Figure 34 – Slide cover up and off

8.2 EVS intake and exhaust filter

An intake and exhaust filter is installed in the EVS intake and exhaust covers located on the front door. The

following filter replacement procedure applies to both the intake and exhaust filter.

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 37 of 38

Page 47

Acronym

Definition

AC

Alternating current

AWG

American wire gauge

BTU

British thermal unit

CSA

Canadian Standards Association

CX

Cordex™ series; e.g., CXC for Cordex system controller

DC

Ground fault circuit interrupter

EVS

Emergency ventilation system

HVAC

Heating, ventilating, and air conditioning

MGB

Master ground bus

NEMA

National Electrical Manufacturers Association

RAM

Random access memory

RU

Rack unit (1.75")

9 Alpha conventions

9.1 Numbering system

Alpha Technologies uses an eight-digit drawing number system, which is broken into three blocks. The first three

digits describe the category of the product; e.g., rectifier or fuse panel. The next three digits indicate the sequence

in which the product number was allocated in a particular category. The last two digits indicate the type of drawing,

for example:

“-06” Outline drawing

“-08” Customer connections

“-20” Main assembly

Alpha Technologies uses an eight-digit part numbering system for all components and sub assemblies. Each part is

covered by its own unique number. Due to the quantity, categories will not be listed within this manual.

9.2 Acronyms

Alpha Technologies Ltd. 057-106-C0 Rev D

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 38 of 38

Page 48

Specifications for Alpha Te45 Outdoor Power Enclosure

Electrical

Input Voltage: 120/240 Vac, 60 Hz single phase

120 Vac for auxiliary equipment

120/240 Vac for rectifiers

AC Distribution Panel Options: Main breaker 42 KAIC rated

Output Voltage: 24 Vdc system

48 Vdc system

Output Power: 9.0 kW (5x Cordex 48 V rectifiers; Alpha #010-580-20)

Recommended Feeder Breakers (no integration at ac distribution panel)

Per rectifier shelf : 2 AC feeds:

1 feed (3 rectifiers) 2-pole, 50 A (120/240 Vac single phase)

1 feed (2 rectifiers) 2-pole, 30 A (120/240 Vac single phase)

Supplied Feeder Breakers (integrated at ac distribution panel)

Per rectifier shelf: 2 AC feeds (Integrated at load center):

1 feed (3 rectifiers) 2-pole, 50 A (120/240 Vac single phase)

1 feed (2 rectifiers) 2-pole, 30 A (120/240 Vac single phase)

Mechanical

Dimensions: 1829 mm H x 762 mm W x 762 mm D

(72" H x 30" W x 30" D)

1829 mm H x 1016 mm W x 1067 mm D w/ 200 A AC panel

(72" H x 40" W x 42" D)

Weight: 355 kg (780 lb.), no batteries, no rectifiers; no AC panel

455 kg (1000 lb.), no batteries, no rectifiers, with AC panel

Mounting: Pad or platform

Cooling: 4000 btu air conditioner with built in 500 W heater

Enclosure: Aluminum, 5052-H32

Internal Rack: 19"/23", 39 RU

Alpha Technologies Ltd. 029-039-B1 Rev B

Printed in Canada. © 2010 Alpha Technologies Ltd. ALPHA and CORDEX are trademarks of Alpha Technologies Ltd. All Rights Reserved. Page 1 of 2

Page 49

Specifications for Alpa Te45 Outdoor Power Enclosure Continued

Environmental

Operating Temperature: -40 to +46°C

(-40 to 115°F)

Storage Temperature: -40 to +85°C

(-40 to +185°F)

Humidity: 0 to 95% non-condensing

Elevation: 3600 m, see Operating Temperature

(12,000 feet)

Weather Tightness: NEMA Type 3R

Regulatory Approvals

Enclosure Ratings: CSA/UL Type 3R

Product Safety: CSA/UL 60950

The above information is valid at the time of publication. Consult factory for up-to-date ordering information. Specifications are subject to change without notice.

Alpha Technologies Ltd. 029-039-B1 Rev B

Printed in Canada. © 2010 Alpha Technologies Ltd. ALPHA and CORDEX are trademarks of Alpha Technologies Ltd. All Rights Reserved. Page 2 of 2

Page 50

1

2

3

4

5

LTR

DESCRIPTION

REVISION

6

DATE APPD

AIR CONDITIONER, GFCI, LED LIGHT WIRING:

A A

7

BLU - #18 AWG

4000 BTU/Hr AIR CONDITIONER

RETURN AIR

BLU - #18 AWG

EXT. OUTPUT LEAD

NOTE

DEFAULT SETPOINTS:

A/C: 30C (86F)

HEATER: 16C (60F)

B B

(STATUS ALARM)

AC POWER INPUT

120VAC, 60 Hz

SUPPLY AIR

N.C.

RED - #18 AWG

COM

N.O.

BRN - #16 AWG

LINE

BLU - #16 AWG

NEU

GRN - #16 AWG

GND

ORG

GRN - #14 AWG

RED - #18 AWG

ORG

YEL

BONDING

SCREW

'UTILITY BOX'

N.C.

COM

WIRE NUTS

A/C FAIL ALARM

TO TB63-64

LINE

120V SINGLE PHASE AC INPUT POWER FEED

NEU

(CUSTOMER SUPPLIED CONNECTION)

GND

8

BLK

WHT

GRN

BLK - #14 AWG

WHT - #14 AWG

GRN - #14 AWG

BLK

J3

WHT

'WHT'

NEU

C C

GRN

YEL

BONDING

SCREW

GFCI AC RECEPTACLE

D D

1

LINE

TERMINALS

HOT

TEST

RESET

J4

GND

15A/125V

GRN

'UTILITY BOX'

2

LINE

120V SINGLE PHASE AC INPUT POWER FEED

NEU

(CUSTOMER SUPPLIED CONNECTION)

GND

TO 1200A TERMINATION

BARS

(REFER TO SHEET 3)

14

+V

15

-V

3

BLK - #18 AWG

RED - #18 AWG

FRONT DOOR LIGHT

CONTROL SWITCH

SW6

15 39

(CLOSED)(COM)

BLK - #18 AWG

4

LED LIGHT STRIP

14

+

TB1

39

-

LED LIGHT PCB P/N 707-670-20

9:07:28 AM

Time:

2009/12/03

Date:

74766605PA_SHEET1.SCHDOC

File:

THESE DESIGNS AND SPECIFICATIONS ARE THE PROPERTY OF

ARGUS TECHNOLOGIES AND SHALL NOT BE COPIED OR USED

FOR MANUFACTURING WITHOUT ITS WRITTEN CONSENT.

09/10

09/10

747-666-05

MATERIAL

FINISH

Sheet of

6

SCALE

1

6

Rev

P/A

J.K

DESIGN

J.K

DRAWN

CHECKED

APPROVED

TOLERANCES

Title

SCHEMATIC, ENCLOSURE, 72",

CX48-1.8kW, DISTRN, W/ EVS

ISSUE

DATE

SIZE DWG NO.

TYPE

C

5

S5

Page 51

1

ENCLOSURE ALARM WIRING:

P/N 538-043-10

(10 PL)

6

LOW TEMPERATUREHIGH TEMPERATURE

- 5 C 35 C

1 2

24" X 30" (BOTTOM) REAR

PANEL INTRUSION PANEL INTRUSION

ALARM SWITCH

A A

DEFAULT SETTINGS:

HIGH TEMP = 45C (113F)

LOW TEMP = -15C (5F)

ALARM THERMOSTAT ALARM THERMOSTAT

50 C

30 C 70 C

3 4

B B

C C

BLK - #22 AWG

RED - #22 AWG

20" X 30" (UPPER) REAR

PANEL INTRUSION

ALARM SWITCH

BLK - #22 AWG BLK - #22 AWG

D D

11 12 13

SW3

(OPEN)(COM)

RED - #22 AWG

1

2

15 C

1 21 2

RED - #22 AWG

BLK - #22 AWG

YEL - #22 AWG

GRN - #22 AWG

SW2 SW1

BLK - #22 AWG

10

SOLAR SHIELD

INTRUSION

ALARM SWITCH

SW4

BLK - #22 AWG

(OPEN)(COM)

2

FROM A/C ALARM

OUTPUT

(REFER TO SHEET 1)

FROM EVS ALARM

OUTPUT

(REFER TO SHEET 5)

24" X 30" (UPPER) REAR

ALARM SWITCH

(OPEN)(COM)(OPEN)(COM)

11

FRONT DOOR

INTRUSION

ALARM SWITCH

SW5

(OPEN)(COM)

5

RED - #22 AWG

3

RED - #22 AWG

BLK - #22 AWG

YEL - #22 AWG

GRN - #22 AWG

RED - #22 AWG

BLK - #22 AWG

N.C.

COM

N.C.

COM

3

1

2

3

4

5

6

7

BLU - #18 AWG

8

RED - #18 AWG

3637RED - #22 AWG

BLK - #22 AWG

INSTALL 657-545-19

JUMPERS (10 PL)

ALARM 'BUNCHING' BLOCKS

4

101 101

TB51

TB52

TB53

102

TB54

103

TB55

TB56

TB57

104

TB58

105

TB59

TB60

TB61

106

TB62

107

TB63

TB64

TB65

108

TB66

TB67

TB68

TB69

TB70

TB71

TB72

109

110

4

FROM CXCI ALARM

RELAY K2

(REFER TO SHEET 3)

FROM CXCI ALARM

RELAY K3

(REFER TO SHEET 3)

FROM CXCI ALARM

RELAY K4

(REFER TO SHEET 3)

FROM GMT PCB FUSE

FAIL RELAY

(REFER TO SHEET 6)

FROM ADIO ALARM

RELAY K1

(REFER TO SHEET 3)

FROM ADIO ALARM

RELAY K2

(REFER TO SHEET 3)

FROM ADIO ALARM

RELAY K3

(REFER TO SHEET 3)

FROM ADIO ALARM

RELAY K4

(REFER TO SHEET 3)

N.C.

COM

N.O.

N.C.

COM

N.O.

N.C.

COM

N.O.

N.C.

COM

N.C.

COM

N.O.

N.C.

COM

N.O.

N.C.

COM

N.O.

N.C.

COM

N.O.

5

RED - #22 AWG

102

102BLK - #22 AWG

103YEL - #22 AWG

104GRN - #22 AWG

105RED - #22 AWG

106BLK - #22 AWG

NOT USED

NOT USED

NOT USED NOT USED

107RED - #18 AWG

108YEL - #18 AWG

NOT USED

NOT USED

109BLK - #22 AWG

110RED - #22 AWG

42

BLK-#22 AWG

43

WHT-#22 AWG

44

RED-#22 AWG

45

GRN-#22 AWG

46

BRN-#22 AWG

47

BLU-#22 AWG

48

ORG-#22 AWG

49

YEL-#22 AWG

50

PUR-#22 AWG

51

RED - #22 AWG

52

BLK - #22 AWG

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

55

BLK-#22 AWG

56

WHT-#22 AWG

57

RED-#22 AWG

58

GRN-#22 AWG

59

BRN-#22 AWG

60

BLU-#22 AWG

61

ORG-#22 AWG

62

YEL-#22 AWG

63

PUR-#22 AWG

64

GRA-#22 AWG

65

PNK-#22 AWG

66

TAN-#22 AWG

ALARM BLOCKS

5

TB1

TB2

TB3

TB4

TB5

TB6

TB7

TB8

TB9

TB10

TB11

TB12

TB13

TB14

TB15

TB16

TB17

TB18

TB19

TB20

TB21

TB22

TB23

TB24

TB25

TB26

TB27

TB28

TB29

TB30

TB31

TB32

TB33

TB34

TB35

TB36

TB37

TB38

TB39

TB40

TB41

TB42

TB43

TB44

TB45

TB46

TB47

TB48

TB49

TB50

LOW TEMP

N.C.

ALARM

COM

(FROM LOW TEMP THERMOSTAT)

HIGH TEMP

N.C.

ALARM

COM

(FROM HIGH TEMP THERMOSTAT)

INTRUSION

N.C.

ALARM

COM

(FROM INTRUSION SWITCHES)

NOT USED

NOT USED

AIR CONDITIONER FAIL

N.C.

ALARM

COM

(FROM A/C ALARM RELAY)

NOT USED

NOT USED

EVS ACTIVE

N.C

ALARM

(FROM EVS ALARM PCB)

COM

N.C.