Page 1

Installation & Operation M anual

Te43 Outdoor Auxiliary Enclosure

Page 2

This page is intentionally left blank.

Alpha Technologies Ltd. 057-104-B0 Rev D WC

Printed in Canada. © 2010 Alpha Technologies Ltd. ALPHA and CORDEX are trademarks of Alpha Technologies Ltd. All Rights Reserved.

Page 3

Te43 Outdoor Auxiliary Enclos ure

057-104-20-101

The following documents and drawings are included in this manual to provide the necessary information required for

routine operation and fault diagnosis o the system:

Specifications: 029-030-B2

CSA/NRTL Equivalence 048-554-10

Safety and Installation Instructions 057-104-C0

Schematic 747-612-05

Outline drawings 057-104-06

Cust Connect, Intfc Kit, Te41 to Te40 w Cabl 747-602-08

Cust Connect, Intfc Kit, Te40 to Te40 w Cabl 747-603-08

Cust Connect, Intfc Kit, Te41 to Te40 w/o Cabl 747-607-08

Cust Connect, Interface Kit, Nokia Bridge 747-595-08

Cust Assy, Kit, 9” Top Extension 747-531-F0

Cust Assy, Kit, Plinth w/ Mounting Hard ware 747-592-F0

Cust Assy, Kit, 4x Cable Boot for Top Ext 747-627-F0

Alpha Technologies Ltd. 057-104-B0 Rev D WC

Printed in Canada. © 2010 Alpha Technologies Ltd. ALPHA and CORDEX are trademarks of Alpha Technologies Ltd. All Rights Reserved.

Page 4

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233.

Alpha Technologies Ltd.

Important Safety Instructions

Save These Instructions

This section contains important instructions that must be followed during the installation and maintenance of the

equipment and batteries. Read all of the instructions before installing or operating the equipment, and save this

manual for future reference.

All electrical connections must be performed by licensed electricians only. Installation of the power supply and

batteries must be performed by, or under the direct supervision of, service personnel knowledgeable of the

required electrical and battery safety procedures.

If instructions in this manual conflict with the local electrical codes, follow the local codes.

The following safety symbols are found throughout this manual. Carefully read all information and abide by the

instructions:

DANGEROUS VOLTAGE

This symbol indicates a dangerous voltage

exists in this area of the product.

GAS HAZARD

This symbol indicates a gas hazard

exists in the area of vented batteries.

The following warning levels are used in conjunction with the symbols:

DANGER: You WILL be KILLED or SERIOUSLY INJURED if instructions are not followed closely.

WARNING: You CAN be KILLED or SERIOUSLY INJURED if instructions are not followed closely.

CAUTION: You CAN be INJURED or equipment can be DAMAGED if instructions are not followed closely.

Mechanical safety

Keep hands and tools clear of fans. Fans are thermostatically controlled and switch on automatically.

Power supplies can reach extreme temperatures under load.

Use caution around sheet metal components and sharp edges.

NO MATCHES OR OPEN FLAMES

This symbol indicates a fire or explosive hazard

exists in the area of the product.

Page 5

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233.

Alpha Technologies Ltd.

Electrical safety

WARNING: Hazardous voltages are present at the input of power systems. The DC output from rectifiers

and batteries, though not dangerous in voltage, has a high short-circuit current capacity that may cause

severe burns and electrical arcing.

Before working with any live battery or power system, follow these precautions:

Remove all metallic jewelry, such as watches, rings, metal rimmed glasses, or necklaces.

Wear safety glasses with side shields at all times during the installation.

Use OSHA approved insulated hand tools.

DANGER: Lethal voltages are present within the power system. Always assume that an electrical

connection or conductor is energized. Check the circuit with a voltmeter with respect to the grounded

portion of the enclosure (both AC and DC) before performing any installation or removal procedure.

Do not work alone under hazardous conditions.

A licensed electrician is required to install permanently wired equipment. Input voltages can range up to

240 Vac. Ensure that the utility power is disconnected and locked out before performing any installation

or removal procedure.

Ensure that no liquids or wet clothes come into contact with internal components.

Hazardous electrically live parts inside this unit are energized from the batteries even when the AC input power is

disconnected.

Battery safety

Servicing and connection of batteries must be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove all

metallic objects from your hands and neck.

Use OSHA approved insulated hand tools. Do not rest tools on top of batteries.

Batteries contain or emit chemicals known to cause cancer and birth defects or other reproductive harm. Battery

post terminals and related accessories contain lead and lead compounds. Wash your hands after handling

batteries.

WARNING: Follow battery manufacturer’s safety recommendations when working around battery

systems.

WARNING: Do not smoke or introduce an open flame when batteries (especially vented batteries) are

charging. When charging, batteries vent hydrogen gas, which can explode.

Batteries are hazardous to the environment and should be disposed at a recycling facility. Consult the battery

manufacturer for recommended local authorized recyclers.

Post installation weather proofing

After installing the conduits and removing any knockouts to accommodate conduit locations, ensure that any gaps

between the conduit fittings and the shroud are sealed. Apply a weatherproof caulking to gaps to prevent wind

driven rain from reaching the electrical equipment.

Page 6

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 1 of 27

Table of contents

1 Introduction ............................................................................................................................ 4

1.1 Scope of manual ................................................................................................ ........................ 4

1.2 Product overview ........................................................................................................................ 4

1.3 Recommended pre-installation training ...................................................................................... 4

1.3.1 Cordex controller operation ............................................................................................... 4

1.3.2 Enclosure installation ........................................................................................................ 4

2 Features ................................................................................................................................. 5

2.1 Equipment compartment ................................................................ ............................................ 5

2.2 Equipment mounting rails ........................................................................................................... 5

2.3 Heating, ventilating, and air conditioning (HVAC) ....................................................................... 7

2.4 Security ...................................................................................................................................... 8

2.5 Rear access panel ..................................................................................................................... 9

2.6 Removable solar shield and hatch plate ..................................................................................... 10

3 Transportation and storage .................................................................................................... 11

3.1 Packaging .................................................................................................................................. 11

3.2 Storage ...................................................................................................................................... 11

3.3 Site Considerations .................................................................................................................... 11

3.4 Inspection................................................................................................................................... 11

4 Installation .............................................................................................................................. 12

4.1 Pre-installation considerations .................................................................................................... 12

4.1.1 Site selection ..................................................................................................................... 12

4.1.2 Enclosure support ............................................................................................................. 12

4.1.3 Base layout dimensions .................................................................................................... 13

4.1.4 Concrete slab .................................................................................................................... 14

4.1.5 Steel platform .................................................................................................................... 15

4.2 Installation component requirements .......................................................................................... 16

4.3 Installation tools and equipment ................................................................................................. 17

4.3.1 Tools Required .................................................................................................................. 17

4.3.2 Lifting equipment requirements ......................................................................................... 17

Page 7

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 2 of 27

4.4 Enclosure installation ................................................................................................................. 18

4.4.1 Enclosure preparation ....................................................................................................... 18

4.4.2 Lifting preparation ............................................................................................................. 18

4.4.3 Mounting the enclosure ..................................................................................................... 19

4.4.4 Installing multiple enclosures side-by-side......................................................................... 19

4.4.5 Enclosure-to-enclosure interface ....................................................................................... 20

4.4.6 Top hat installation ............................................................................................................ 21

4.4.7 Enclosure compartment integrity ....................................................................................... 21

4.5 Grounding .................................................................................................................................. 22

4.5.1 Site ground wire entry ................................................................................................ ....... 22

4.5.2 Master ground bus (MGB) ................................................................................................. 22

4.5.3 Enclosure chassis ground ................................................................................................. 22

4.6 Air conditioner connections ........................................................................................................ 23

5 Test and commissioning ........................................................................................................ 24

5.1.1 Environmental/intrusion ..................................................................................................... 24

5.2 Final cleanup .............................................................................................................................. 24

6 Maintenance .......................................................................................................................... 25

6.1 General maintenance schedule .................................................................................................. 25

6.2 Air conditioner ............................................................................................................................ 25

6.2.1 Air conditioner settings ...................................................................................................... 25

6.2.2 Air conditioner filter ........................................................................................................... 25

6.2.3 High temperature alarms and air conditioner failures ........................................................ 25

7 HVAC default settings ............................................................................................................ 26

7.1 Air Conditioner/heater ................................................................................................................ 26

7.2 Temperature alarms ................................................................................................................... 26

8 Alpha conventions ................................................................................................................. 27

8.1 Numbering system ..................................................................................................................... 27

8.2 Acronyms ................................................................................................................................... 27

Page 8

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 3 of 27

List of figures

Figure 1 – Tempest Te43 Outdoor Battery Enclosure............................................................................... 4

Figure 2 – Miscellaneous compartment features ................................................................ ...................... 5

Figure 3 – Alarm block ............................................................................................................................. 6

Figure 4 – Miscellaneous enclosure features ........................................................................................... 7

Figure 5 – Front door handle security ....................................................................................................... 8

Figure 6 – Top cover and rear panel intrusion alarm switch ..................................................................... 8

Figure 7 – 24” top panel ........................................................................................................................... 9

Figure 8 – Other panels ............................................................................................................................ 9

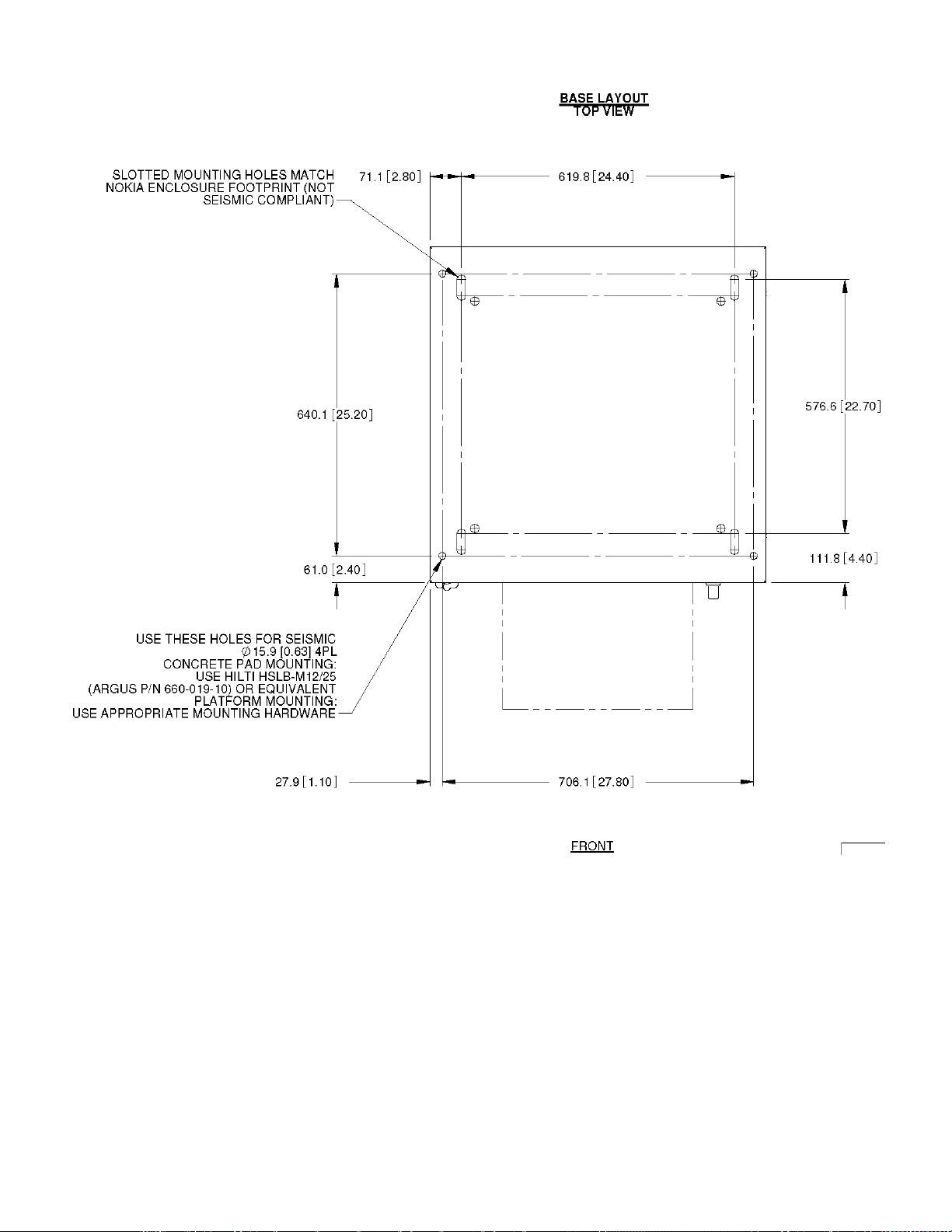

Figure 9 – Base layout drawing and mounting hole location for Te43 ....................................................... 13

Figure 10 – Concrete anchor bolt fastening detail .................................................................................... 14

Figure 11 – Installation on steel platform .................................................................................................. 15

Figure 12 – Example of an insulated tool kit ............................................................................................. 17

Figure 13 – Secure hooks in eyebolts ...................................................................................................... 18

Figure 15 – Gasket on lower side panel ................................................................................................... 20

Figure 14 – Typical enclosure-to-enclosure mounting .............................................................................. 20

Figure 16 – Enclosure ground connections .............................................................................................. 22

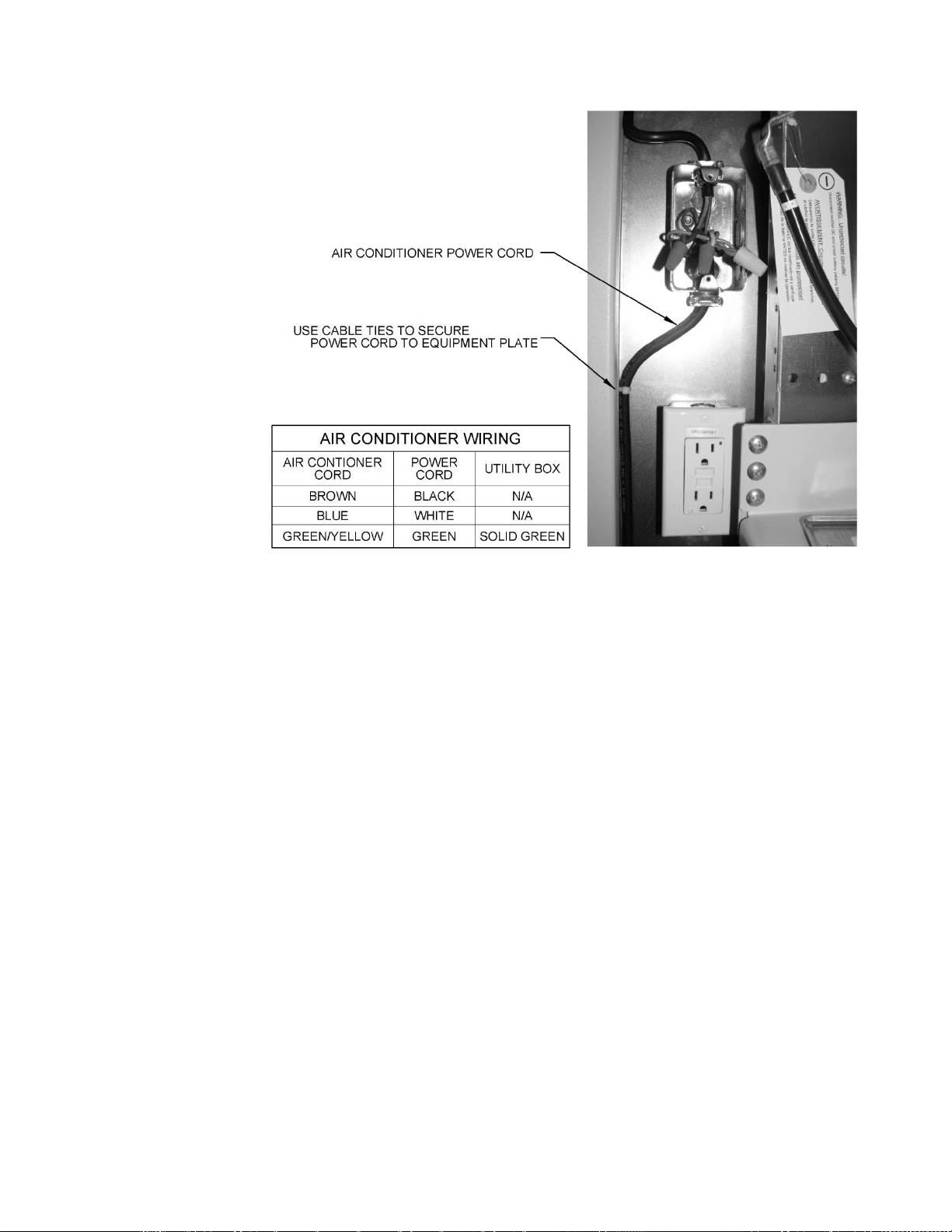

Figure 17 – Battery enclosure air conditioner connections ....................................................................... 23

Page 9

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 4 of 27

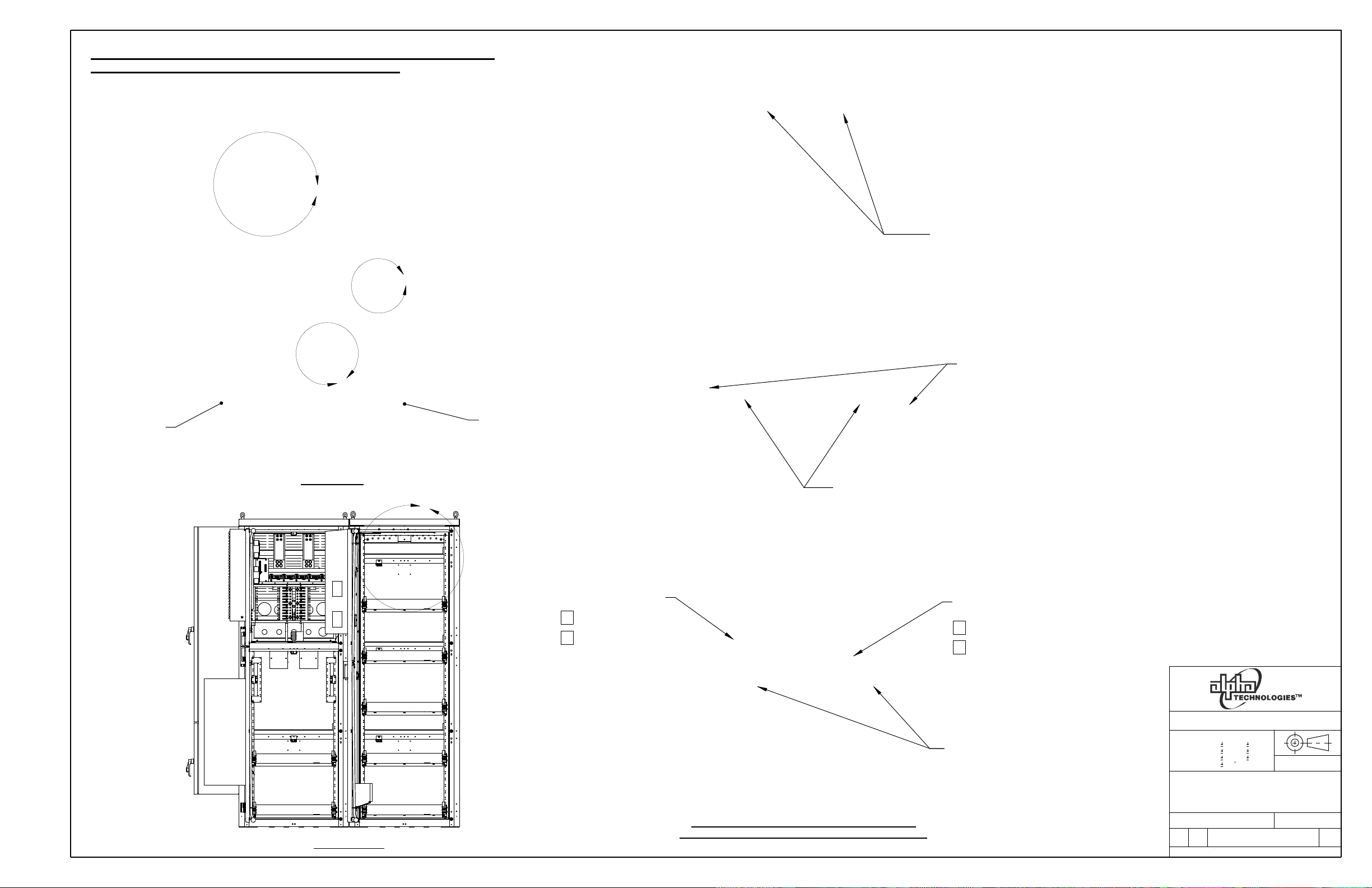

Figure 1 – Tempest Te43 Outdoor Auxiliary Enclosure

1 Introduction

1.1 Scope of manual

This instruction manual covers features, installation, startup, and maintenance of the Alpha Technologies’

Tempest Te43 Outdoor Auxiliary Enclosure.

Enclosure specifications are found in Alpha document #029-030-B2.

Operation instructions for the system controller and related modules are provided in separate component

manuals.

Separate manuals are provided for batteries and other accessory equipment, such as HVAC.

Images contained in this document are for illustrative purposes only and may not exactly match your unit.

1.2 Product overview

The Te43 Outdoor Auxiliary Enclosure is designed to be

used in conjunction with Alpha power enclosures (Te4x) or

other stand-alone equipment.

A Te43 system typically includes:

Zone 4 seismic enclosure design

AC junction box for HVAC equipment

Mates with Alpha outdoor power enclosure Te41

Front access, side-to-side inter-bay mating

Alarm interface

1.3 Recommended pre-installation training

1.3.1 Cordex controller operation

Go to http://www.argus.ca/web2/training-center.html and then find “Alpha Courses and Training” under Technical

Support Documents.

1.3.2 Enclosure installation

Courses are available on an “as needed” basis. Contact the factory for details.

Free emergency technical support:

North America 1-888-462-7487; Outside North America +604-436-5547

Page 10

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 5 of 27

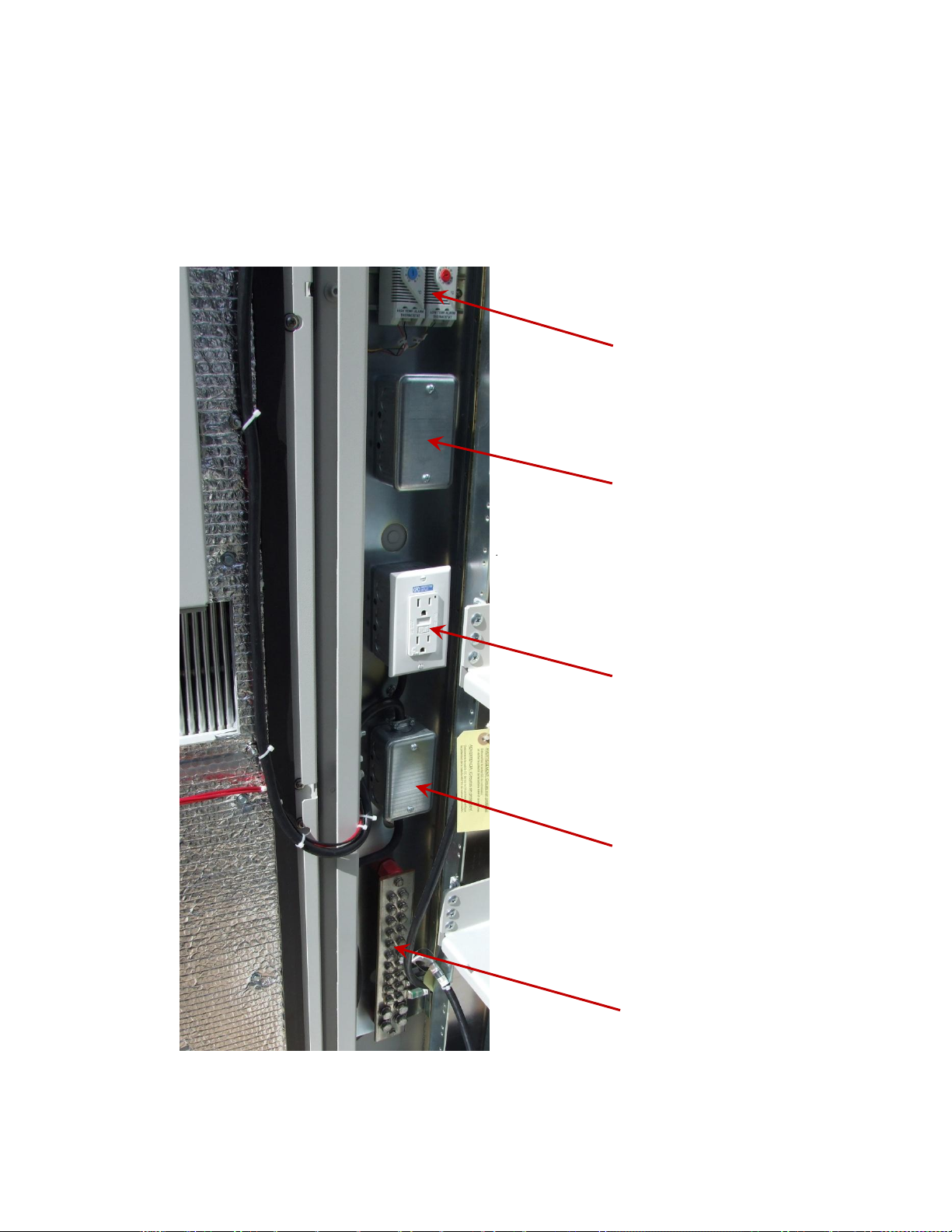

Air conditioner utility box

High/low temperature

alarm thermostats

GFCI outlet

Master ground bar

Spare utility box

Figure 2 – Miscellaneous compartment features

2 Features

2.1 Equipment compartment

The air-conditioned auxiliary enclosure is equipped with alarm wiring, an AC load termination for the air

conditioner, a GFCI outlet, and a master ground bar.

2.2 Equipment mounting rails

Four rails are installed in the enclosure. The rails are adjustable to a width of 19" or 23" (standard) and are also

adjustable front-to-back.

Page 11

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 6 of 27

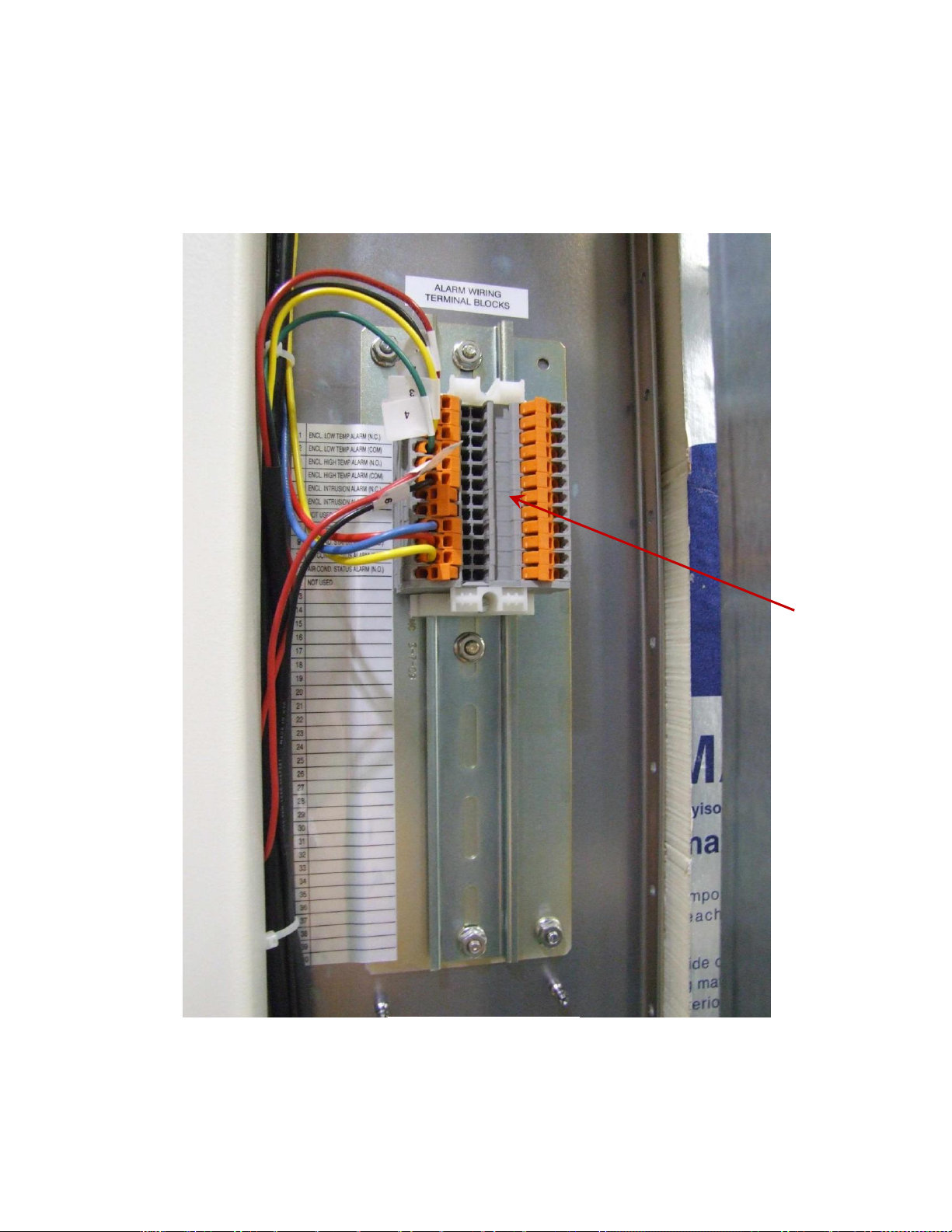

Figure 3 – Alarm block

Alarm block

Page 12

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 7 of 27

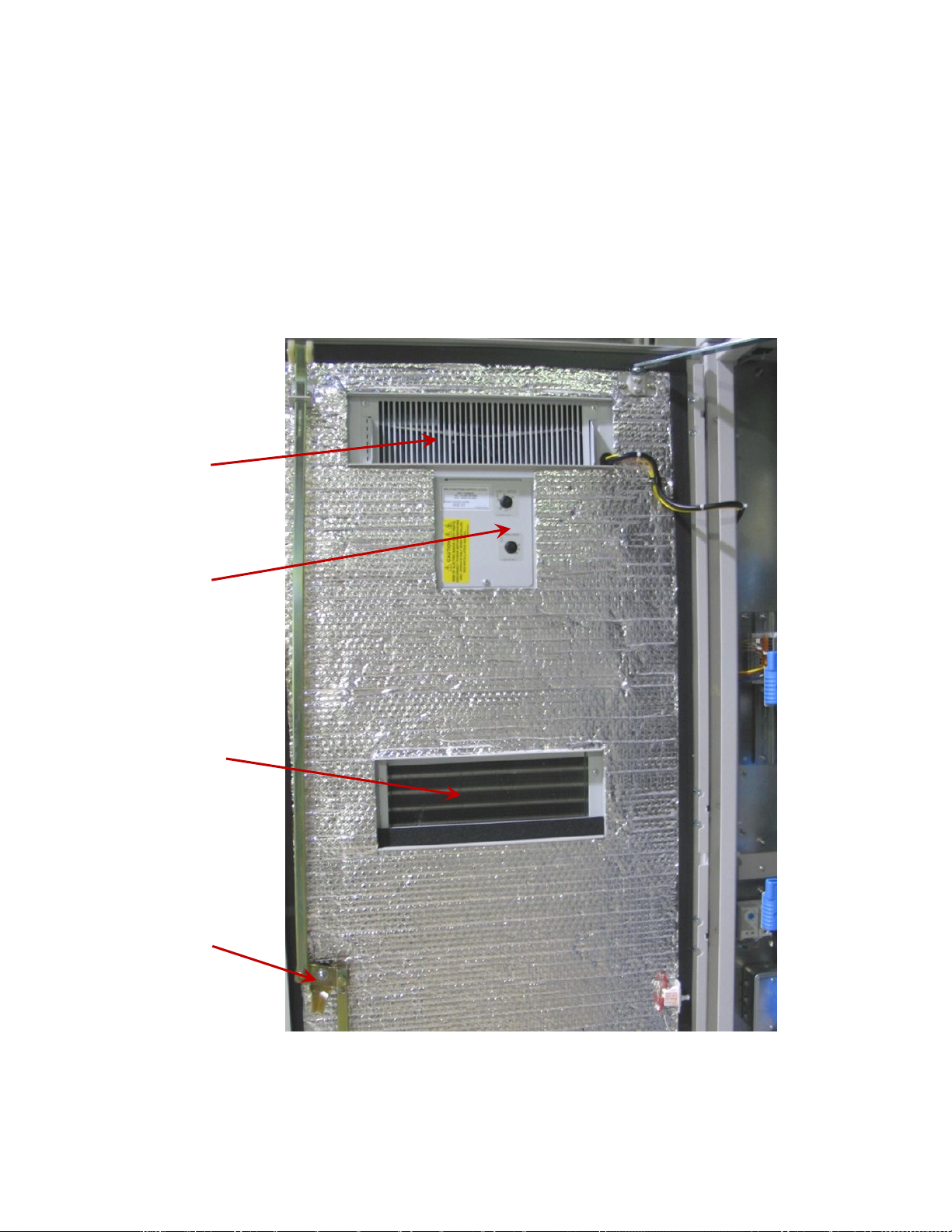

Three-point door latch

Figure 4 – Miscellaneous enclosure features

HVAC exhaust

HVAC controls

HVAC intake

2.3 Heating, ventilating, and air conditioning (HVAC)

An air conditioner/heater package is mounted on the front door of the enclosure. It provides cooling/heating for

the batteries and customer equipment. Refer to the HVAC manual supplied with the unit for operation and

maintenance details.

Page 13

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 8 of 27

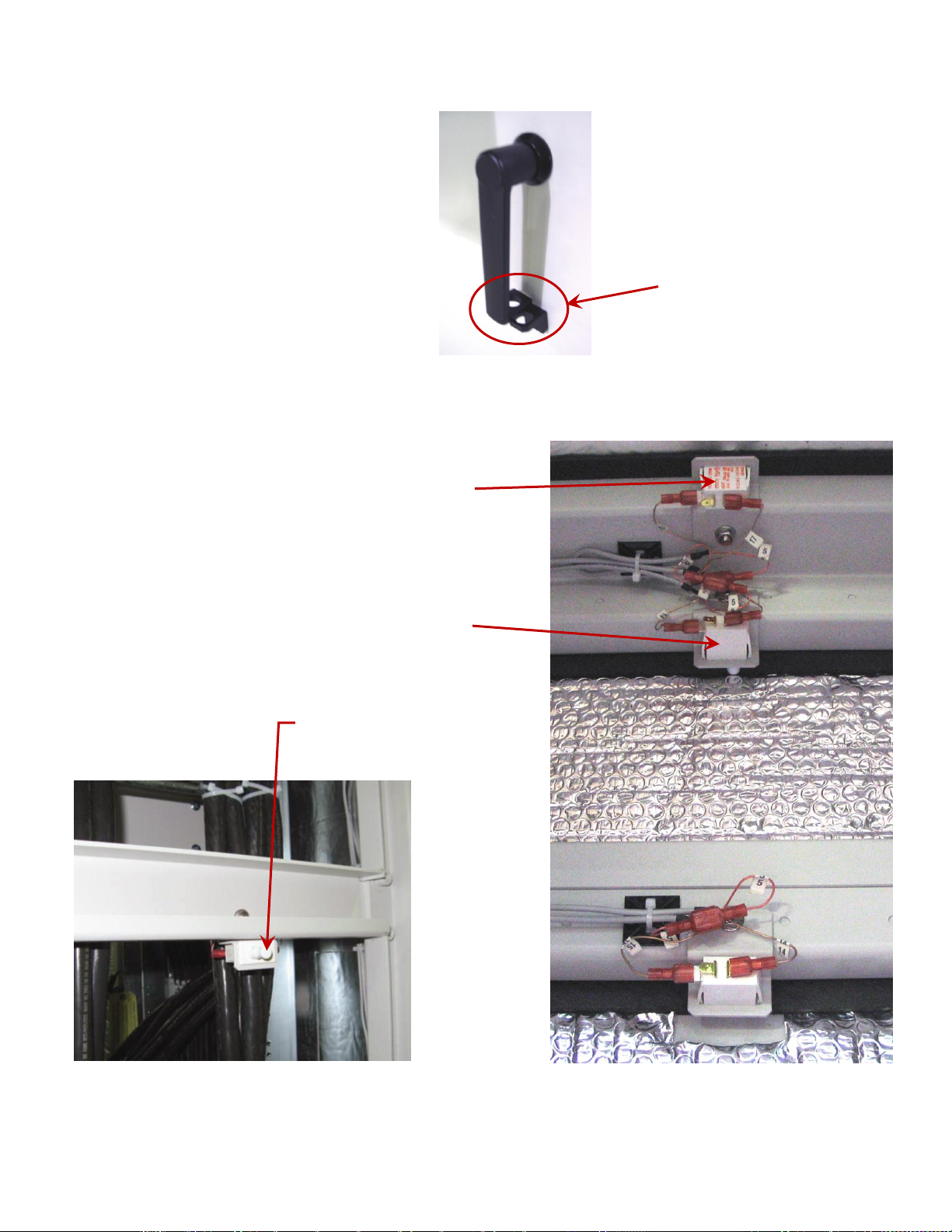

Once closed, the front door handle

can be secured with a padlock

Top cover intrusion alarm switch

Rear panel intrusion alarm switch

One per panel

Switches can be offset-mounted

Figure 5 – Front door handle security

Figure 6 – Top cover and rear panel intrusion alarm switch

2.4 Security

The front door can be padlocked:

Page 14

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 9 of 27

Pull on strap to release

top 24”rear panel, then

lift the panel up and out

of the enclosure.

Remove each set of wing

nuts, one on each side, to

release the other panels.

Figure 7 – 24” top panel

Figure 8 – Other panels

2.5 Rear access panel

There are four removable rear access panels, one top 8” panel and three 24” panels below. The 24” panel directly

below the 8” top panel is a slam latch panel. The top 8” panel and the lower two 24” panels use internal wing-

studs that must be removed to lift off the panels.

When installing the rear panels, first install the lower panel, then the next one up, then the top 8” panel, and finally

the top 24” slam latch rear panel.

Page 15

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 10 of 27

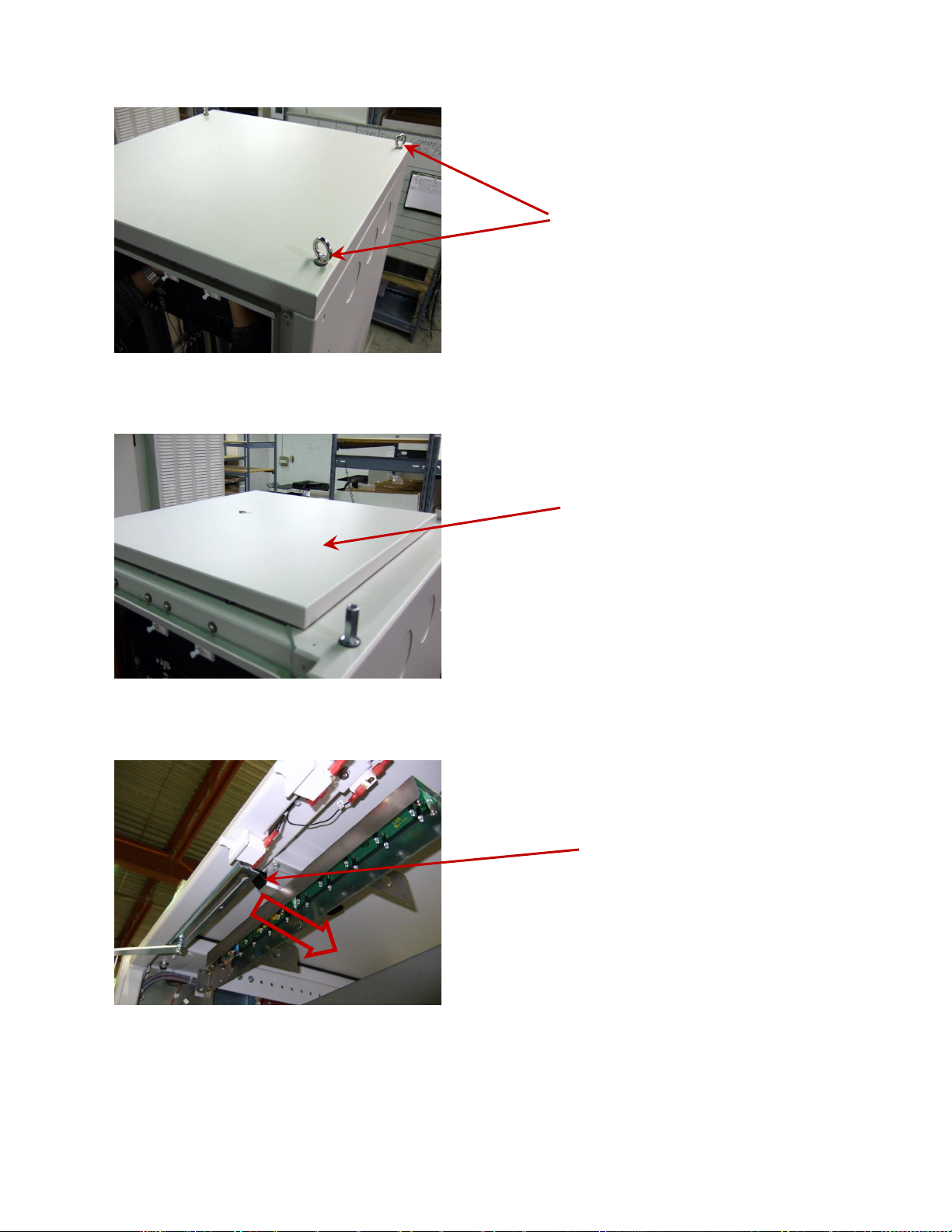

Remove eyebolts

Remove solar shield exposing hatch plate

To release hatch plate, pull the latch

ring toward the rear of the enclosure

in the direction shown by the large

arrow

2.6 Removable solar shield and hatch plate

To re-install, ensure the slam latch on the hatch plate is fully engaged.

Re-install the solar shield by re-installing the eyebolts.

Page 16

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 11 of 27

3 Transportation and storage

3.1 Packaging

The enclosure and components are shrink wrapped and shipped on individual pallets. The enclosures and

components must not be stacked on top of each other.

The pallet is approximately 0.15 m H x 1.22 m W x 1.22 m D (6" H x 48" W x 48" D). The overall height including

the pallet and enclosure is approximately 2.3 m (91").

Batteries are shipped on a separate pallet and packaged according to the manufacturer’s guidelines. Packaging

assemblies and methods have been tested to International Safe Transit Association standards.

3.2 Storage

The weight of the enclosure is written in the specifications. The equipment pallet can be moved using a forklift.

3.3 Site Considerations

The site should be ready for the enclosure installation before the enclosure arrives. A lift truck or crane is required

to lift and position the enclosure and its components. Make sure that there are no potential obstructions in the

transport path. Use safe lifting practices.

3.4 Inspection

Before unpacking the equipment, perform a visual inspection and note any damage. Unpack the equipment and

inspect the exterior for damage. Continue the inspection for potential internal damage. Contact the carrier

immediately if internal damage is detected. Then contact Alpha Technologies for advice on the consequence of

any damage.

Verify that you have all the required parts before proceeding with the installation.

Call Alpha Technologies if you have any questions: 1-888-462-7487

Page 17

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 12 of 27

4 Installation

4.1 Pre-installation considerations

The information in this section is intended to be used as a guideline only. There may be site-specific requirements

and other factors that may require different procedures. For example, your jurisdictional codes and construction

covenants may require different procedures than those in this manual.

4.1.1 Site selection

The Te43 has been designed as an outdoor power system enclosure. The most common mounting structures are:

An at-grade concrete slab.

A steel platform.

An existing structure, such as a rooftop.

The mounting structure must be strong enough to support a fully equipped enclosure. Existing structures may

need to be reinforced. The mounting site must be built in accordance with local building practices and codes.

Consider the following before selecting a mounting site:

The Alpha Te43 enclosure is designed for front, rear, and if necessary top access. Only front access is

required for maintenance.

Avoid areas that may be subjected to hot air exhaust from nearby equipment or buildings.

Find out if your intended area is subjected to architectural controls or environmental restrictions.

Avoid areas that are prone to flooding.

4.1.2 Enclosure support

The empty enclosure weighs approximately 450 lb and has a base area of 6.25 ft². The supporting structure must

have a loading capacity capable of supporting this weight (72 lb/ ft²) plus the additional weight of all the equipment

installed inside the enclosure.

Page 18

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 13 of 27

Figure 9 – Base layout drawing and mounting hole location for Te43

4.1.3 Base layout dimensions

Page 19

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 14 of 27

Figure 10 – Concrete anchor bolt fastening detail

4.1.4 Concrete slab

Cast-in-place or pre-cast concrete slabs can be used.

Place the enclosure on the concrete slab. Use the enclosed Hilti HSL heavy-duty expansion anchor bolts or

approved equivalents to secure the enclosure. Follow the specific recommendations from the fastener

manufacturer to ensure that the securing device achieves its full structural capacity. Take into account the

embedment depth and clear edge distances. Refer to the following figure.

Alternate mounting systems that are not provided directly with the enclosure must be reviewed by a registered

professional engineer that is qualified to practice within the jurisdiction where the enclosure is being installed.

An alternate mounting system could for example use a chemical anchoring system such as Hilti’s HY150 for

concrete or HY20 for masonry along with suitable threaded rods and inserts from the manufacturer. Follow the

manufacturer’s recommendations to determine the spacing and placement of the threaded rods.

The supporting structure must be designed to support a fully equipped enclosure. The concrete slab and any

existing structures must be properly reinforced to support the floor loading. The mounting site must be designed

and installed in accordance with local building practices and codes.

Page 20

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 15 of 27

Figure 11 – Installation on steel platform

4.1.5 Steel platform

Use 1.27 cm (½”) diameter A325 structural bolts in conjunction with a backing plate/clasp to grip the underside of

the grating. Once the enclosure is in place, secure the bolts on the inside using appropriate washers and bolts.

See the following figure:

CAUTION: Installation on a wood base is not recommended. The compressive strength of the base

material would not be able to maintain the load during a Type 4 seismic event.

Page 21

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 16 of 27

Roxtec seal port 9 way assembly

including boot, mounting collar and

hardware

Alpha part number: 037-193-20-000

Can be used for cable entry into the Te43 enclosure wherever there are 3” knockouts.

See

www.roxtec.com for additional

information

4.2 Installation component requirements

Concrete and metal grating mounting hardware is not supplied with the enclosure.

AC electrical conduit, cable and fittings are not supplied with the enclosure.

External DC conduit, cable and fittings are not supplied with the enclosure.

A cable entry port fitting is available as an option:

For multiple enclosure installations an interface kit is required.

Power to battery: 747-602-20

Battery to battery: 747-603-20

Power to battery without cables: 747-607-20.

Page 22

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 17 of 27

Figure 12 – Example of an insulated tool kit

4.3 Installation tools and equipment

4.3.1 Tools Required

Insulated tools are essential for DC power system installation. Use this list as a guide:

Electric drill with hammer action

Digital voltmeter equipped with test leads

Lap top computer with Cordex communication software (not required for initial installation and test)

Various crimping tools and dies, to match lugs used in installation

Torque wrench: ¼" drive, 0-150 in-lb for battery post connections

Torque wrench: 3/8" drive, 0-100 ft-lb for system connections

Insulating canvases as required (2' x 2', 1' x 1', 3' x 3', etc.)

Insulated hand tools:

-Combination wrenches -Ratchet and socket set

-Various screwdrivers -Electricians knife

-Fine tipped slot screwdrivers (“tweaker”) -Cable cutters

Cutters and wire strippers (#14 to #22 AWG) [2.5 – 34 mm2].

4.3.2 Lifting equipment requirements

Hoist or crane capable of lifting 1814 kg (4000 lb)

The forklift should have a rated lifting capacity of 1814 kg (4000 lb) with a minimum fork length of 36”

Four wire-rope slings at least 1.22 m (4') long with a capacity of 907 kg (2000 lb) each.

Four clevises.

Minimum 1.59 cm (5/8”) diameter rope to use as a tagline to guide the enclosure while lifting.

Page 23

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 18 of 27

Figure 13 – Secure hooks in eyebolts

4.4 Enclosure installation

4.4.1 Enclosure preparation

Remove the protective covering from the system. The doors are designed to be locked with a pad-lock and are

secured with tie-wraps for shipping. Cut the tie-wraps and open the doors. The inside of the enclosure contains

the installation hardware.

Inspect the packing slip to verify that you have received all the equipment that you ordered.

All documentation is packed inside the equipment compartment.

Inspect all moving parts, hardware, connectors, and other equipment.

Report any damage to the shipper and Alpha Technologies.

Remove and properly dispose of all packaging.

Remove the rear panels to access the rear mounting bolts.

Remove the four bolts that secure the enclosure to the pallet. These bolts are accessible from the inside of

the enclosure and are located in the corners of the enclosure. The enclosure is now ready for lifting.

4.4.2 Lifting preparation

WARNING: Follow all local safety practices and guidelines while lifting the enclosure. All personnel

involved with lifting and placing the enclosure must wear head, eye protection, gloves when required.

Only properly trained and certified personnel should operate the crane. Only properly trained and

certified personnel should operate the forklift.

Make sure that the lifting eyes are securely fastened before lifting. Ensure that the clevises are correctly installed

and that the enclosure is approximately level when it is lifted. This will simplify the enclosure placement.

Close and latch the enclosure front door. The rear panels do not need to be installed.

Place the enclosed rubber mat onto the slab or platform. Orient the mat so that the mounting holes line up.

Page 24

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 19 of 27

4.4.3 Mounting the enclosure

Concrete slab

Use the tagline to guide the enclosure as it is lifted. As the enclosure is lowered, align the mounting bolts and

drop the enclosure into place.

CAUTION: Follow all local safety practices and guidelines while lifting the enclosure. As the enclosure is

lowered, ensure that it remains as level as possible and lines up with the anchoring bolt locations. Ensure

the rubber mat is in the proper position. If the rubber mat is “ribbed”, the ribs should be against the

concrete. Open the door and proceed with leveling the enclosure and securing it into place.

Steel platform

If the steel platform is located at ground level, the procedures are the same as those for the concrete slab.

Roof mounting

CAUTION: The mounting platform must be installed before the enclosure can be installed. All grounding must be

in place before the installation.

Place the enclosure onto the roof using either a freight elevator with access to the roof, or a crane or hoist on the

roof.

Do not remove the enclosure from its pallet until it is on the roof and is ready to be placed.

4.4.4 Installing multiple enclosures side-by-side

If two or more enclosures are to be installed adjacent to one another, install the environmental components of the

interface kit before bolting the enclosures into place.

Page 25

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 20 of 27

Knock out enclosure-toenclosure holes. Bolt

enclosures together in the

top corners. Tighten the

bolts to the appropriate

torque.

Install “Nokia interface”

type gasket around conduit

openings

Figure 14 – Gasket on lower side panel

Figure 15 – Typical enclosure-to-enclosure mounting

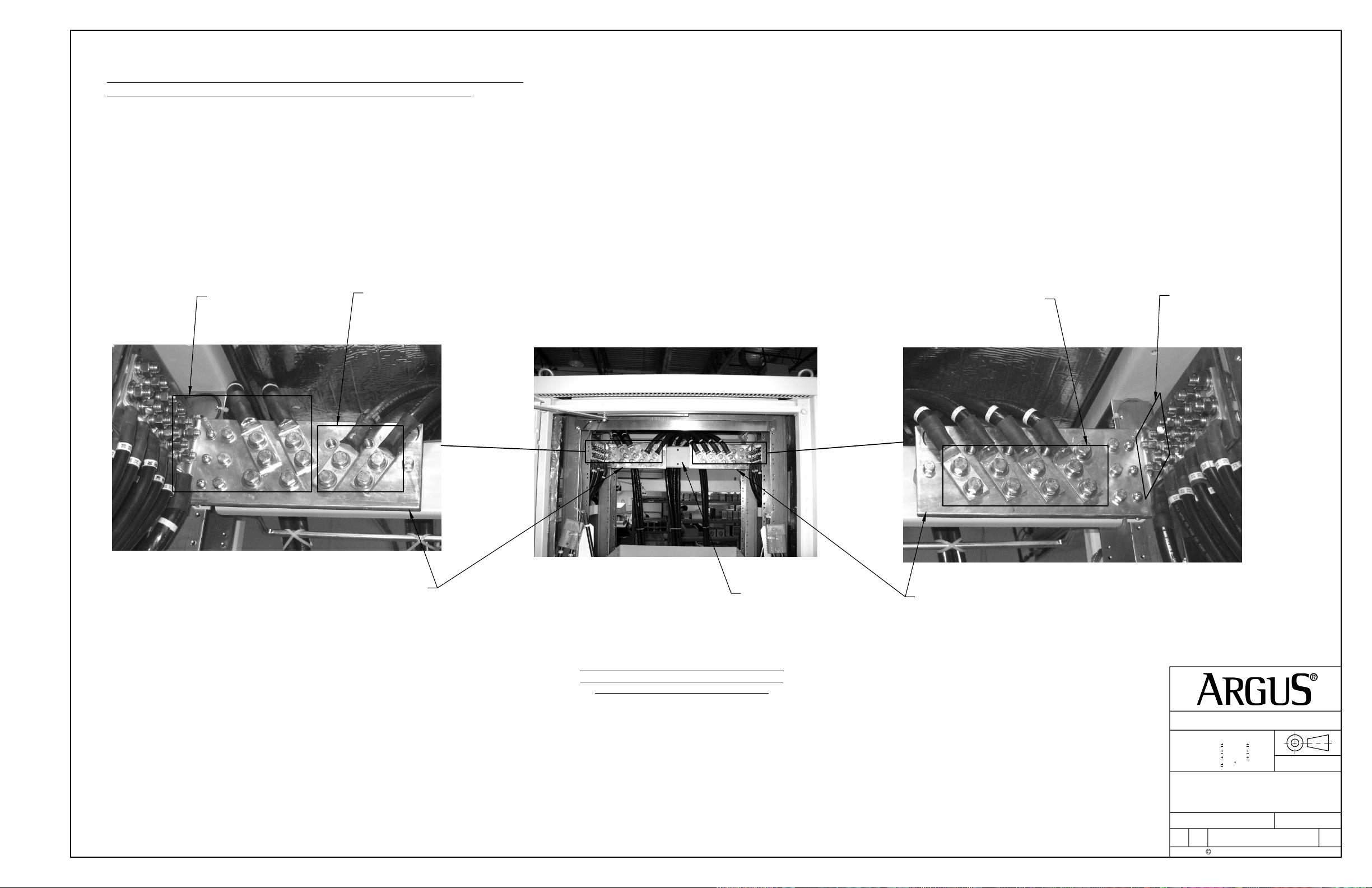

4.4.5 Enclosure-to-enclosure interface

The cable bridge kit between the enclosures can be mounted either on the left or right side of the enclosures.

This kit must be installed before installing adjacent enclosure.

See the enclosed drawings for the interface kit assembly.

Remove the knockouts on the lower rear side panels.

Apply a gasket around the opening used for cable routing.

Page 26

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 21 of 27

Remove solar shield and mounting

hardware including standoffs

Install top hat and fasten with eyebolts

Install standoffs on top edge of top hat

Prepare and install the hatch panel

Add Roxtec cable entry boots or conduits

If aligned with other top hats,

install feed through fittings

Bolt the solar shield onto the enclosure

4.4.6 Top hat installation

A top hat is an optional structure. See enclosed drawings for the top hat kit assembly. Install the top hat kit before

installing adjacent enclosures.

4.4.7 Enclosure compartment integrity

The Te43 enclosure compartment is air conditioned.

Use gaskets, boots, and other sealing materials to minimize air exchange between compartments and

enclosures. This will reduce the air conditioner loading.

Similarly use gaskets, boots, and other sealing materials to prevent water from entering the enclosures. See the

enclosed drawings for more details.

Page 27

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 22 of 27

External chassis ground

connected to site ground.

There are two connection

points, one at the front of the

enclosure, and one at the

rear. Only one connection is

required with an exothermic

connection.

Ground wire that connects

the site ground to the

master ground bar

Figure 16 – Enclosure

ground connections

Ground studs

MGB

4.5 Grounding

DANGER: An enclosure that is not properly grounded presents an electrical hazard.

A proper grounding system that meets or exceeds the specifications of the equipment must be designed and

installed prior to or in conjunction with the construction of the mounting pad. The ground system must be bonded

to the enclosure to ensure a “common” or “single-point” ground.

Examples of grounds:

New builds – a buried ground ring with a bare, solid conductor going to ground rods.

Rooftop – a connection to the building’s steel structure, water pipes, etc.

Refer to local codes and practices for proper acceptable grounding arrangements. Only a licensed electrician

should install the grounding system. Use a dedicated ground rod for the AC panel.

CAUTION: Do not route AC and DC wiring in the same conduit.

4.5.1 Site ground wire entry

External ground studs are located at the bottom front and rear

of the enclosure. Use these to make the site ground wire

connections. Terminate either the front or rear connection to

the external ground ring with an exothermic connection. A

minimum of #2 AWG solid wire is required.

4.5.2 Master ground bus (MGB)

The master (main) ground bus is located at the lower left front corner of the enclosure. Terminate the MGB to the

external ground ring with an exothermic connection. A minimum of #2 AWG solid wire is required.

4.5.3 Enclosure chassis ground

The enclosure chassis ground is pre-installed at the factory. It is connected to the enclosure frame and equipment

racks and is terminated to the MGB inside the enclosure.

Page 28

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 23 of 27

Only a licensed

electrician should

connect the AC

input power to the

enclosure

Figure 17 – Battery enclosure air conditioner connections

4.6 Air conditioner connections

Page 29

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 24 of 27

5 Test and commissioning

5.1.1 Environmental/intrusion

Check the operation of all enclosure features, such as the air conditioning unit settings, the high/low temperature

alarms and the intrusion alarm.

5.2 Final cleanup

Vacuum clean all metal filings and other debris from inside and around the enclosure.

Ensure that:

All cables and conduit are neatly secured.

Access panels are installed correctly.

All connections are tight.

All breakers are on and the system is running without any alarms.

Enclosure is locked and secure.

Page 30

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 25 of 27

Description

Interval

Clean ventilation openings

1-6 months

Inspect all cable connections, re-torque if necessary

1 year

Verify alarm/control settings

1 year

Verify alarm relay operation

1 year

Clean HVAC filter

2-6 months

6 Maintenance

The equipment requires regular maintenance. The maintenance should be done by qualified service personnel

only.

WARNING: HIGH VOLTAGE AND SHOCK HAZARD.

Use extreme care when working inside the enclosure/shelf while the system is energized. Do not make

contact with live components or parts. Static electricity may damage circuit boards, including RAM chips.

Always wear a grounded wrist strap when handling or installing circuit boards.

6.1 General maintenance schedule

6.2 Air conditioner

6.2.1 Air conditioner settings

The air conditioner is pre-programmed with default settings at the factory. Refer to the air conditioner manual if

you need to adjust these settings.

6.2.2 Air conditioner filter

Air conditioners often fail due to lack of maintenance, specifically dirty filters. Implement a structured filter

inspection/maintenance schedule to avoid unnecessary air conditioner failures.

6.2.3 High temperature alarms and air conditioner failures

The air conditioner is not always thoroughly tested at the factory. If the air conditioner fails to switch on when it

should, refer to the air conditioner manual and check the temperature settings.

If the air conditioner appears to be working properly but the “Hi-Temp” alarm is on, check that the enclosure's Hi-

Temp alarm thermostat is correctly set.

Page 31

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 26 of 27

Description

Setting

Cooling system ON temperature

80F (26.6C)

Heating system ON temperature

60F (15.5C)

HVAC fail alarm (dirty filter, broken condenser, etc.)

300 psi, reset at 225 psi

Compartment thermostat

Setting

High temperature alarm (blue)

45C (113F)

Low temperature alarm (red)

-15C (5F)

7 HVAC default settings

Refer to the air conditioner manual for operation and maintenance details.

7.1 Air Conditioner/heater

7.2 Temperature alarms

Page 32

Alpha Technologies Ltd. 057-104-C0 Rev B WC

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233. Page 27 of 27

Acronym

Definition

AC

Alternating current

AWG

American wire gauge

BTU

British thermal unit

CSA

Canadian Standards Association

CX

Cordex™ series; e.g., CXC for Cordex System Controller

DC

Direct current

GFCI

Ground fault circuit interrupter

HVAC

Heating, ventilating, and air conditioning

MGB

Master ground bus

NEMA

National Electrical Manufacturers Association

RAM

Random access memory

RU

Rack unit (1.75”)

UL

Underwriters Laboratories

VRLA

Valve regulated lead acid

8 Alpha conventions

8.1 Numbering system

Alpha Technologies uses an eight-digit drawing number system, which is broken into three blocks. The first three

digits describe the category of the product; e.g., rectifier or fuse panel. The next three digits indicate the sequence

in which the product number was allocated in a particular category. The last two digits indicate the type of

drawing, for example:

“-06” Outline Drawing

“-08” Customer Connections

“-20” Main Assembly

Alpha Technologies uses an eight-digit part numbering system for all components and sub assemblies. Each part

is covered by its own unique number. Due to the quantity, categories will not be listed within this manual.

8.2 Acronyms

The following acronyms are used in this manual:

Page 33

Specifications for Alpha Te43 Auxiliary Enclosure

Electrical

Input Voltage: 120Vac, 60Hz single phase (for air conditioner and CFGI receptacle)

Feeder Breaker: 15A recommended

Mechanical

Dimensions: 2134mm H x 762mm W x 762mm D

(84" H x 30" W x 30" D)

Weight: 205 kg (450 lb.)

Mounting: Pad or platform

HVAC: Air conditioner with 500-W built-in heater

Enclosure: Aluminum, 5052-H32

Environmental

Operating Temperature: -40 to +46°C

(-40 to 115°F)

Storage Temperature: -40 to +85°C

(-40 to +185°F)

Humidity: 0 to 95% non-condensing

Elevation: -50 to 4000 meters operating

(-164 to 13,123 feet)

Weather Tightness: NEMA Type 3R

Regulatory Approvals

Enclosure Ratings: CSA/UL Type 3R

IEC enclosure designation IP56

See also Environmental (above)

Telcordia: Compliance to GR-487, consult factory for detailed compliance information

Product Safety: CSA/UL 60950

The above information is valid at the time of publication. Consult factory for up-to-date ordering information.

Specifications are subject to change without notice.

Alpha Technologies Ltd. 029-030-B2 Rev B WC

Printed in Canada. © 2010 Alpha Technologies Ltd. ALPHA is a registered trademark of Argus Technologies Ltd. All Rights Reserved.

Page 34

1

2

3

4

5

6

REVISION

LTR

DESCRIPTION

DATE APPD

AIR CONDITIONER AND GFCI WIRING:

A A

BLK

WHT

GRN

8

9

10

TO TB9

N.C.

TO TB10

COM

TO TB11

N.O.

WIRE NUTS

TO ALARM WIRING TERMINAL BLOCKS

(REFER TO SHEET 2)

LINE

NEU

GND

120V SINGLE PHASE AC INPUT POWER FEED

(CUSTOMER SUPPLIED CONNECTION)

BLU - #18 AWG

4000 BTU/Hr AIR CONDITIONER

RETURN AIR

EXT. OUTPUT LEAD

(STATUS ALARM)

NOTE

DEFAULT SETPOINTS:

A/C: 27C (80F)

HEATER: 18C (65F)

AC POWER INPUT

120VAC, 60 Hz

B B

SUPPLY AIR

N.C.

COM

N.O.

LINE

NEU

GND

BLU - #18 AWG

RED - #18 AWG

YEL - #18 AWG

BRN - #16 AWG

BLU - #16 AWG

GRN - #16 AWG

BLK - #14 AWG

WHT - #14 AWG

GRN - #14 AWG

ORG

YEL

GRN - #14 AWG

LINE

NEU

GND

120V SINGLE PHASE AC INPUT POWER FEED

(CUSTOMER SUPPLIED CONNECTION)

RED - #18 AWG

YEL - #18 AWG

ORG

BONDING

SCREW

'UTILITY BOX'

BLK

J3

WHT

'WHT'

NEU

C C

GRN

YEL

BONDING

SCREW

GRN

GFCI AC RECEPTACLE

LINE

TERMINALS

HOT

TEST

RESET

J4

GND

15A/125V

'UTILITY BOX'

3:11:54 PM

Time:

2009/05/12

Date:

74761205PA_SHEET1.SCHDOC

File:

THESE DESIGNS AND SPECIFICATIONS ARE THE PROPERTY OF

ARGUS TECHNOLOGIES AND SHALL NOT BE COPIED OR USED

FOR MANUFACTURING WITHOUT ITS WRITTEN CONSENT.

DESIGN

DRAWN

J.K

J.K

09/05

09/05

MATERIAL

CHECKED

D D

NOTES:

1.) USE 14/3 SJ FLEXIBLE CORD FOR WIRING UNLESS OTHERWISE INDICATED.

APPROVED

TOLERANCES

Title

SCHEMATIC, ENCLOSURE, 84",

4K BTU A/C, V3 AUX

FINISH

SCALE

ISSUE

DATE

SIZE DWG NO.

TYPE

C

S5

1

2

3

4

5

747-612-05

Sheet of

6

1

2

Rev

P/A

Page 35

1

2

3

4

5

LTR DESCRIPTION DATE APPD

6

REVISION

ENCLOSURE TEMPERATURE & INTRUSION ALARM WIRING:

ALARM WIRING TERMINAL BLOCK

LOW TEMPERATUREHIGH TEMPERATURE

A A

DEFAULT SETTINGS:

HIGH TEMP = 45C (113F)

LOW TEMP = -15C (5F)

B B

ALARM THERMOSTAT ALARM THERMOSTAT

50 C

30 C 70 C

3 4

15 C

- 5 C 35 C

REDBLU

1 21 2

1 2

RED - #22 AWG

BLK - #22 AWG

YEL - #22 AWG

GRN - #22 AWG

P/N 877-673-20

FROM A/C ALARM

OUTPUT

(REFER TO SHEET 1)

N.C.

COM

N.O.

RED - #22 AWG

BLK - #22 AWG

YEL - #22 AWG

GRN - #22 AWG

RED - #22 AWG

BLK - #22 AWG

8

9

10

* REFER TO TABLE 1 FOR ALARMS

1

TB1 'ENCLOSURE LOW TEMP' ALARM (N.C.)

2

TB2

3

TB3

4

TB4

5

TB5

6

TB6

NOT USED

NOT USED

BLU - #18 AWG

RED - #18 AWG

YEL - #18 AWG

NOT USED

TB7

TB8

TB9

TB10

TB11

TB12

TABLE 1 - ENCLOSURE OUTPUT ALARMS

SIGNAL DESCRIPTIONTB POS

TB1

TB2

TB3

TB4

TB5

TB6

TB7

TB8

TB9

TB10

TB11

TB12

'ENCLOSURE LOW TEMP' ALARM (COM)

'ENCLOSURE HIGH TEMP' ALARM (N.O.)

'ENCLOSURE HIGH TEMP' ALARM (COM)

'ENCL. INTRUSION' ALARM (N.C.)

'ENCL. INTRUSION' ALARM (COM)

NOT USED

NOT USED

'AIR CONDITIONER STATUS' ALARM (N.C.)

'AIR CONDITIONER STATUS' ALARM (COM)

'AIR CONDITIONER STATUS' ALARM (N.O.)

NOT USED

ENCLOSURE GROUND BAR TERMINATIONS:

12 12

P/N 877-674-20

C C

24" X 30" (BOTTOM) REAR

PANEL INTRUSION

ALARM SWITCH

P/N 538-043-10

(12 PL)

6

D D

5

1

SW3

(OPEN)(COM)

QUICK CONNECTS

MALE: P/N 538-167-10

FEMALE: P/N 538-166-10

(6 PL)

MF

RED - #22 AWG

BLK - #22 AWG

24" X 30" (MID) REAR

24" X 30" (UPPER) REAR

PANEL INTRUSION PANEL INTRUSION

ALARM SWITCH

BLK - #22 AWG BLK - #22 AWG

16 15 14 13 17

RED - #22 AWG RED - #22 AWG RED - #22 AWG RED - #22 AWG RED - #22 AWG

SW2 SW1

2

ALARM SWITCH

BLK - #22 AWG BLK - #22 AWG

(OPEN)(COM)(OPEN)(COM)

3

8" X 30" (UPPER) REAR

PANEL INTRUSION

ALARM SWITCH

SW4

(OPEN)(COM)

4

SOLAR SHIELD

INTRUSION

ALARM SWITCH

SW5

(OPEN)(COM)

BLK - #22 AWG

GRN - #6 AWG FLEX

FRONT DOOR

INTRUSION

ALARM SWITCH

SW6

(OPEN)(COM)

5

RED - #22 AWG

5

TO EQUIPMENT RACK

GND

TO EXTERNAL SITE GROUND

GND

(CUSTOMER CONNECTION)

Time:

Date:

File:

THESE DESIGNS AND SPECIFICATIONS ARE THE PROPERTY OF

ARGUS TECHNOLOGIES AND SHALL NOT BE COPIED OR USED

FOR MANUFACTURING WITHOUT ITS WRITTEN CONSENT.

Title

ISSUE

DATE

SIZE

B

3:11:54 PM

2009/05/12

74761205PA_SHEET2.SCHDOC

SCHEMATIC, ENCLOSURE,

4K BTU A/C, V3 AUX

Sheet

TYPE

DWG NO.

S5

747-612-05

6

2 2

of

Rev

P/A

Page 36

DESCRIPTION

LTR

ADDED TE43P OUTLINE

P/B

REVISIONS

DWN

RP

DATE

10/04

CHKD

DX

APPD

JK

TYP

28.40

721.4

TYP

1.60

40.6

TYP

TYP

TYP

TYP

TYP

TYP

TYP

24.00

21.00

18.00

15.00

12.00

9.00

6.00

0

762.0 30.00

609.6

533.4

457.2

A

381.0

304.8

228.6

152.4

AAA

287.0 11.30

2365.4 93.13

2224.8

87.59

TYP

2188.8 86.17

6.50

9.00

0

165.0

228.6

381.0 15.00

533.4 21.00

596.8 23.50

762.0 30.00

AA A

2221.6 87.47

2136.8 84.13

2067.1 81.38

1249.2 49.18

A

A

A

1884.3

1782.7

1985.9

78.19

74.19

70.19

TYP

TYP

TYP

2020.4 79.54

1283.8 50.54

639.6 25.18

33.0 1.30

0

91.3KO3.59

FOR TRADESIZE

3" CONDUIT (A)

A

A

A

802.6

665.5

31.60

26.20

TYP

TYP

A

A

139.5

0

101.6

5.49

4.00

TYP

0

ITEM

QTY

0 0

TYP

26.25

666.8

TYP

3.75

95.3

DESIGN

DRAWN

CHECKED

APPROVED

NAME

RP

KL

RP

JK

DATE

2009/09

2009/09

2009/09

2009/09

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

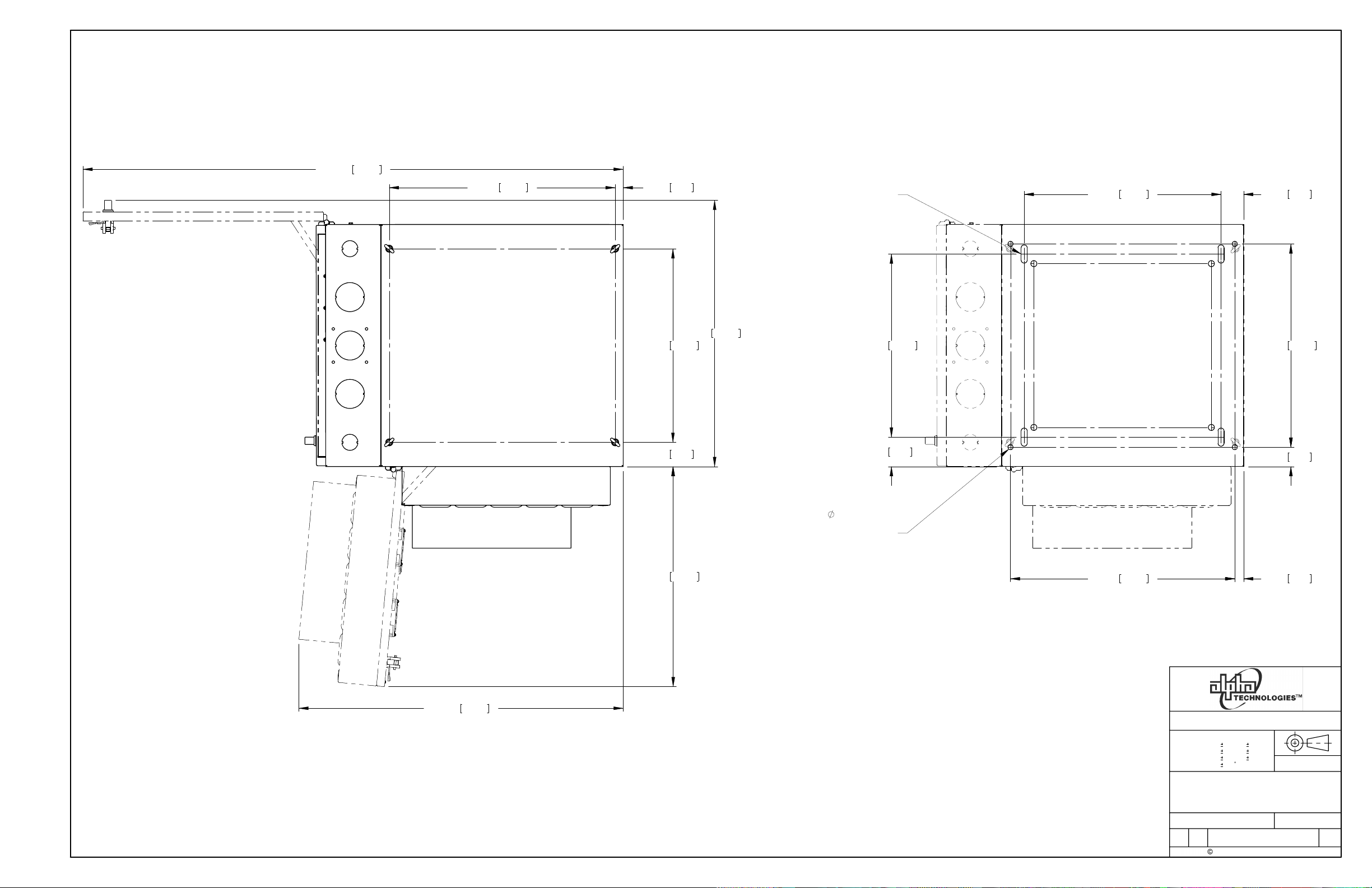

OUTLINE DRAWING, Te43

84" POWER SYSTEM AUX

ENCLOUSURE

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

6/24/2009 ALPHA TECHNOLOGIES

SHEET

057-104-06

NTS

1 4

OF

REV

P/B

Page 37

711.2 28.00

25.4 1.00

SLOTTED MOUNTING HOLES MATCH

NOKIA ENCLOSURE FOOTPRINT

(NOT SEISMIC COMPLIANT)

619.8 24.40

71.1 2.80

609.6 24.00

76.2 3.00

693.2 27.29

USE THESE HOLES FOR SEISMIC

15.9 [0.63] 4PL

CONCRETE PAD MOUNTING:

USE HILTI HSLB-M12/25

(ALPHA P/N 6600004) OR EQUIVALENT

PLATFORM MOUNTING:

USE APPROPRIATE MOUNTING HARDWARE

640.1 25.20

61.0 2.40

FRONT

706.1 27.80

BASE LAYOUT

TOP VIEW

576.6 22.70

92.7 3.65

27.9 1.10

1048.3 41.27

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

OUTLINE DRAWING, Te43

84" POWER SYSTEM AUX

ENCLOUSURE

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

6/24/2009 ALPHA TECHNOLOGIES

SHEET

057-104-06

NTS

2 4

OF

REV

P/B

Page 38

TE43P

1905.5 75.02

TYP

27.40

696.0

TYP

1.60

0

40.7

2062.1 81.18

1757.3 69.18

1711.5 67.38

474.7 18.69

390.7 15.38

352.6 13.88

47.8 1.88

0

0

TYP

0

TYP

9.46

240.2

30.57

776.5

5.05

128.3

256.8 10.11

663.8 26.13

0

6.47

164.4

0

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

NTS

OUTLINE DRAWING, Te43

84" POWER SYSTEM AUX

ENCLOUSURE

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

6/24/2009 ALPHA TECHNOLOGIES

057-104-06

SHEET

3 4

OF

REV

P/B

Page 39

1701.2 66.98

711.2 28.00

25.4 1.00

838.5 33.01

609.6 24.00

SLOTTED MOUNTING HOLES MATCH

NOKIA ENCLOSURE FOOTPRINT (NOT

SEISMIC COMPLIANT)

576.6 22.70

619.8 24.40

71.1 2.80

640.1 25.20

1021.2 40.20

76.2 3.00

693.1 27.29

92.7 3.65

USE THESE HOLES FOR SEISMIC

15.9 [0.63] 4PL

CONCRETE PAD MOUNTING:

USE HILTI HSLB-M12/25

(ALPHA P/N 6600004) OR EQUIVALENT

PLATFORM MOUNTING:

USE APPROPRIATE MOUNTING HARDWARE

FRONT

706.1 27.80

BASE LAYOUT

TOP VIEW

61.0 2.40

27.9 1.10

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

OUTLINE DRAWING, Te43

84" POWER SYSTEM AUX

ENCLOUSURE

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

6/24/2009 ALPHA TECHNOLOGIES

SHEET

057-104-06

NTS

4 4

OF

REV

P/B

Page 40

©

DESCRIPTIONLTR APPDDATEDWN CHKD

©

REVISIONS

ADD NOTEP/B

ME10/01KL JK

SIDE KNOCKOUT REMOVAL, PANEL CHANGE &

GASKET INSTALLATION:

NOTE: ONLY REMOVE KNOCK OUTS ON

P/B

REMOVE TOP CORNER KNOCKOUTS ON FACING

SIDES OF BOTH ENCLOSURES (2 PER SIDE)

FACING SIDES OF BOTH ENCLOSURES

TO

ACCEPT BOLTING HARDWARE

REMOVE EXISTING TOP ACCESS BLANK PANEL ON

POWER ENCLOSURE. INSTALL REPLACEMENT PANEL

(ITEM 5) WITH 4 MOUNTING SCREWS (ITEM 17). MOUNT

PANEL ON INSIDE POSITIONED TOWARDS THE FRONT

WITH OPENING FOR CABLES AT REAR. INSTALL SEALING

GASKET (ITEM 6) AROUND TOP ACCESS OPENING ON

POWER ENCLOSURE SIDE ONLY. REMOVE TOP ACCESS

PANEL FROM FACING SIDE OF BATTERY ENCLOSURE.

POWER AND BATTERY ENCLOSURE

SETUP & PREPARATION:

CUT AWAY A SMALL SECTION FROM

INNER WALL INSULATION IN THE UPPER

CORNERS OF BOTH ENCLOSURES AS SHOWN

FOR 3/8" HARDWARE INSTALLATION.

A

76 3.0

64 [2.5]

DETAIL A - INSIDE VIEW

INSULATION CUT DETAIL

REMOVE SIDE ACCESS CABLE KNOCKOUTS ON

FACING SIDES OF BOTH ENCLOSURES.

INSTALL SEALING GASKET (ITEM 6) AROUND

K.O. OPENINGS ON POWER ENCLOSURE SIDE ONLY.

RIGHT SIDE VIEW

POWER ENCLOSURE SHOWN

KNOCK OUTS REQUIRED TO BE

REMOVED MAY BE LOCATED ON THE

LEFT SIDE PANEL DEPENDING ON THE

ENCLOSURE CONFIGURATION

P/B

MOVE BATTERY ENCLOSURE INTO

POSITION LINING UP NEXT TO

POWER ENCLOSURE

B

BATTERY ENCLOSURE

(MAY BE LOCATED ON THE OTHER

SIDE OF POWER ENCLOSURE

DEPENDING ON CONFIGURATION)

REAR VIEW

POWER ENCLOSURE

P/B

127 5.0

279 11.0

382 15.1

EXISTING

CUT LINES

INSULATION CUT DETAIL

NAME DATE

DESIGN 2009/04

DRAWN

CHECKED

APPROVED

ME

SDW

JK

ME

DETAIL B - INSIDE VIEW

CUT AWAY A SMALL SECTION OF INNER

WALL INSULATION IN AREA OF SIDE

ACCESS CABLE KNOCKOUTS ON

BOTH ENCLOSURES AS SHOWN FOR

CHASE NIPPLE INSTALLATION.

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05 0.002]

0.5

[

SCALE:

CUSTOMER CONNECTION,

KIT, INTERFACE, w/ CBL

SET, PWR TO BATT, Te4x

2009/05

2009/06

2009/06

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

4/30/2009 ALPHA TECHNOLOGIES

SHEET

747-602-08

ITEM

QTY

NTS

OF

1 5

REV

P/B

Page 41

©

JOINING OF POWER & BATTERY ENCLOSURES:

©

3/8" BOLT INSTALLATION

SEALING

NUT WASHER

2021

2

SEALING

WASHER

20

2

BOLT

19

22

DETAIL A

LOCK NUT CHASE NIPPLE

14

2

13

2

CABLE TIE-OFF BAR

INSTALLATION

MOUNT IN HOLE #5

(FROM TOP)

C

A

18

4

2

1

DETAIL C

CHASE NIPPLE FITTING

INSTALLATION

DETAIL B

B

REAR VIEW - PANELS REMOVED

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05 0.002]

0.5

[

SCALE:

CUSTOMER CONNECTION,

KIT, INTERFACE, w/ CBL

SET, PWR TO BATT, Te4x

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

4/30/2009 ALPHA TECHNOLOGIES

SHEET

747-602-08

NTS

OF

2 5

REV

P/B

Page 42

©

POWER ENCLOSURE (Te41) TO BATTERY ENCLOSURE (Te40)

©

INTERFACE CABLE ROUTING & CONNECTIONS:

ROUTE INTERFACE CABLES FROM POWER ENCLOSURE THROUGH

CHASE NIPPLE FITTINGS INTO BATTERY ENCLOSURE AND UP TO

THE BATTERY CHARGE TERMINATION PANEL.

B

A

D

REAR SYSTEM OUTPUT BUS BAR

INSULATING COVERS

(+24V SYSTEM SHOWN)

TEMPORARILY REMOVE INSULATING COVERS

ON SYSTEM BUS BARS TO MAKE INTERFACE

CABLE CONNECTIONS. RE-INSTALL COVERS

ONCE CABLE CONNECTIONS ARE COMPLETED.

KEEP ALL INTERFACE CABLES AWAY FROM

REAR SECTION OF EQUIPMENT SLIDES.

USE CABLE TIES PROVIDED TO ATTACH

INTERFACE CABLES TO SIDES OF EQUIPMENT

RACK CHANNELS AS NECESSARY.

Te40 BATTERY

ENCLOSURE

REAR VIEW

FRONT VIEW

C

Te41 POWER ENCLOSURE

OBSERVE PROPER BUS POLARITY

-

FOR +24V SYSTEMS

FOR -48V SYSTEMS

+

ON THIS SIDE:

CUSTOMER EQUIPMENT SLIDES

REAR SYSTEM OUTPUT BUS

BAR CABLE ROUTING PATH

REAR SYSTEM OUTPUT BUS BAR

LUG CONNECTIONS

DETAIL A - POWER ENCLOSURE SYSTEM

OUTPUT BUS BAR CABLING & CONNECTIONS

OBSERVE PROPER BUS POLARITY ON THIS SIDE:

+

FOR +24V SYSTEMS

FOR -48V SYSTEMS

-

CONNECT INTERFACE CABLE LUGS BACK

TO BACK ONTO SYSTEM OUTPUT BUS BARS

USING 3/8" HARDWARE SUPPLIED IN KIT.

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05 0.002]

0.5

[

SCALE:

CUSTOMER CONNECTION,

KIT, INTERFACE, w/ CBL

SET, PWR TO BATT, Te4x

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

4/30/2009 ALPHA TECHNOLOGIES

SHEET

747-602-08

NTS

OF

3 5

REV

P/B

Page 43

©

POWER ENCLOSURE (Te41) TO BATTERY ENCLOSURE (Te40)

©

INTERFACE CABLE ROUTING & CONNECTIONS CONT'D:

NEATLY STRAP INTERFACE CABLES

TO TIE-OFF BAR USING CABLE TIES

(ITEM 36 & 37) PROVIDED IN KIT.CABLE TIE-OFF BAR

INTO BATTERY ENCLOSURE

DRAPE INTERFACE CABLES DOWN

USE CABLE TIES PROVIDED TO NEATLY

DRESS/BUNDLE CABLES TOGETHER.

FROM CABLE TIE-OFF BAR.

FROM POWER ENCLOSURE

NEATLY ROUTE CABLES THROUGH

BO

TH CHASE NIPPLE FITTINGS.

PUT NEGATIVE CABLES THROUGH

TOP NIPPLE AND POSITIVE CABLES

THROUGH BOTTOM NIPPLE TO

KEEP CABLES ORGANIZED.

CONNECT X2 #4/0 AWG

(-) CABLES (LUGS BACK

TO BACK) FROM Te41

OBSERVE PROPER BUS POLARITY ON THIS SIDE!

DETAIL B - REAR BATTERY CHARGE TERMINATION

PANEL CABLE ROUTING

CONNECT X2 #4/0 AWG

(-

) CABLES FROM Te41

CONNECT INTERFACE CABLES TO THEIR RESPECTIVE (+) AND (-) BUS BARS ON

CHARGE TERMINATION PANEL USING 3/8" HARDWARE SUPPLIED AS SHOWN.

ENSURE CORRECT POLARITY IS OBSERVED WHEN MAKING CONNECTIONS.

USE A MULTIMETER TO CHECK ALL TERMINATIONS BEFORE

CONNECTING BATTERIES AND APPLYING POWER TO THE SYSTEM.

DETAIL C - FRONT BATTERY CHARGE

TERMINATION PANEL CONNECTIONS

(+24V SYSTEM SHOWN)

BATTERY CHARGE

TERMINATION PANEL

DETAIL D - REAR CABLE ROUTING BETWEEN ENCLOSURES

OBSERVE PROPER BUS POLARITY ON THIS SIDE!

CONNECT X4 #4/0 AWG

(+) CABLES FROM Te41

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

CUSTOMER CONNECTION,

KIT, INTERFACE, w/ CBL

SET, PWR TO BATT, Te4x

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

12/27/2009 ALPHA TECHNOLOGIES

1

[ 0.040]

0.5

[ 0.020]

0.05 0.002]

[

0.5

747-602-08

SCALE:

SHEET

NTS

OF

4 5

REV

P/B

Page 44

©

AIR CONDITIONER & AC LOADCENTER AC POWER CONNECTIONS:

©

UTLIITY BOX

Te40 AIR CONDITIONER UTILITY BOX WIRING

CONNECT A SEPARATE POWER CABLE TO THE EXISTING AIR CONDITIONER

AC WIRING INSIDE UTILITY BOX AND ROUTE IT THROUGH BOTH

ENCLOSURES INTO THE Te41 UPPER COMPARTMENT TO THE

INTERNAL AC LOADCENTER.

Te41 UPPER COMPARTMENT INTERNAL AC LOADCENTER WIRING

(ONLY INCLUDED FOR ENCLOSURES NOT EQUIPPED WITH AN EXTERNAL LOADCENTER)

CONNECT THE POWER CABLE COMING FROM Te40 AIR CONDITIONER AC POWER

CONNECTION UTILITY BOX TO A 15A 120VAC RATED 1 POLE FEEDER BREAKER

INSTALLED IN LOADCENTER.

FOR ENCLOSURES WITH AN EXTERNAL LOADCENTER, CONNECT THE POWER CABLE

DIRECTLY TO A 15A 120VAC RATED 1 POLE FEEDER BREAKER INSTALLED IN LOADCENTER.

INTERNAL AC LOADCENTER

Te40 AIR CONDITIONER AC POWER CONNECTION TO Te41

Te41 AC LOADCENTER AIR CONDITIONER

AC POWER CONNECTION FROM Te40

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ALPHA TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05 0.002]

0.5

[

SCALE:

NTS

CUSTOMER CONNECTION,

KIT, INTERFACE, w/ CBL

SET, PWR TO BATT, Te4x

ISSUE

DATE

TYPE

SIZE

DWG NO.

D2

B

12/27/2009 ALPHA TECHNOLOGIES

SHEET

747-602-08

OF

5 5

REV

P/B

Page 45

LTR

DESCRIPTION

REVISIONS

DWN

DATE

CHKD

APPD

SIDE KNOCKOUT REMOVAL, PANEL CHANGE

& GASKET INSTALLATION

REMOVE TOP CORNER KNOCKOUTS ON FACING

SIDES OF BOTH ENCLOSURES (2 PER SIDE)

TO ACCEPT BOLTING HARDWARE

REMOVE THE TOP ACCESS BLANK PANEL ON EXISTING

BATTERY ENCLOSURE. INSTALL REPLACEMENT PANEL

(ITEM 5) WITH 4 MOUNTING SCREWS (ITEM 17). MOUNT

PANEL ON INSIDE POSITIONED TOWARDS THE FRONT

WITH OPENING FOR CABLES AT REAR. INSTALL SEALING

GASKET (ITEM 6) AROUND TOP ACCESS OPENING ON

SIDE OF EXISTING BATTERY ENCLOSURE. REMOVE TOP

ACCESS PANEL FROM LEFT SIDE OF 2nd BATTERY

ENCLOSURE.

:

ENCLOSURE SETUP & PREPARATION

CUT AWAY A SMALL SECTION FROM

INNER WALL INSULATION IN THE UPPER

CORNERS OF BOTH ENCLOSURE AS SHOWN

FOR 3/8" HARDWARE INSTALLATION.

A

:

75 [3.0]

64 [2.5]

INSULATION CUT DETAIL

127 5.0

279 11.0

DETAIL A - INSIDE VIEW

DETAIL B - INSIDE VIEW

REMOVE SIDE ACCESS CABLE KNOCKOUTS ON

FACING SIDES OF BOTH ENCLOSURES. INSTALL

SEALING GASKET (ITEM 6) AROUND K.O. OPENINGS

ON SIDE OF EXISTING BATTERY ENCLOSURE.

RIGHT SIDE VIEW

EXISTING BATTERY ENCLOSURE

SHOWN

ALIGN 2nd Te40 BATTERY ENCLOSURE WITH

INSTALLED Te40 BATTERY ENCLOSURE

B

EXISTING Te40 ENCLOSURE

2nd Te40 ENCLOSURE

REAR VIEW

INSULATION CUT DETAIL

DESIGN

DRAWN

CHECKED

APPROVED

413 16.3

EXISTING

CUT LINES

NAME

JK

SDW

JK

ME

CUT AWAY A SMALL SECTION OF INNER

WALL INSULATION IN AREA OF SIDE

ACCESS CABLE KNOCKOUTS ON

BOTH ENCLOSURES AS SHOWN FOR

CHASE NIPPLE INSTALLATION.

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ARGUS TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

DATE

2009/05

2009/05

2009/06

2009/06

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

ISSUE

DATE

TYPE

SIZE

B

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

CUSTOMER CONNECTION,

KIT, INTRFC, w/ CBL SET,

BATT TO BATT, Te4x

SHEET

DWG NO.

D2

2009 ARGUS TECHNOLOGIES

747-603-08

ITEM

QTY

NTS

1 7

OF

REV

P/A

Page 46

JOINING OF BATTERY & BATTERY ENCLOSURES

:

3/8" BOLT INSTALLATION

LOCK NUT

14

CABLE TIE-OFF

BAR INSTALLATION

MOUNT IN HOLE #5

(FROM TOP)

4

1

18

2

DETAIL D

NUT

21

2

SEALING

WASHER

20

2

SEALING

WASHER

20219

BOLT

2

18

4

MOUNT IN HOLE #5

(FROM TOP)

2

1

DETAIL C

A

DETAIL A

13

CHASE NIPPLE

2

2

C D

CHASE NIPPLE FITTING

INSTALLATION

DETAIL B

B

REAR VIEW - PANELS REMOVED

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ARGUS TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

CUSTOMER CONNECTION,

KIT, INTRFC, w/ CBL SET,

BATT TO BATT, Te4x

ISSUE

DATE

SIZE

B

TYPE

DWG NO.

D2

2009 ARGUS TECHNOLOGIES

SHEET

747-603-08

NTS

2 7

OF

REV

P/A

Page 47

BATTERY ENCLOSURE (Te40) TO BATTERY ENCLOSURE (Te40)

INTERFACE CABLE ROUTING & CONNECTIONS

:

* SEE NEXT SHEETS FOR FURTHER DETAILS.

A

B

C

D

FRONT VIEW

REAR VIEW

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ARGUS TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

CUSTOMER CONNECTION,

KIT, INTRFC, w/ CBL SET,

BATT TO BATT, Te4x

ISSUE

DATE

SIZE

B

TYPE

DWG NO.

D2

2009 ARGUS TECHNOLOGIES

SHEET

747-603-08

NTS

3 7

OF

REV

P/A

Page 48

BATTERY ENCLOSURE (Te40) TO BATTERY ENCLOSURE (Te40)

INTERFACE CABLE ROUTING & CONNECTIONS CONT'D

EXISITNG Te41 TO Te40

CABLE CONNECTIONS

CONNECT X2 #4/0 AWG

(-) CABLES TO 2ND Te40

:

CONNECT INTERFACE CABLES TO THEIR RESPECTIVE (+) AND (-) BUS BARS ON

CHARGE TERMINATION PANEL USING 3/8" HARDWARE SUPPLIED AS SHOWN.

ENSURE CORRECT POLARITY IS OBSERVED WHEN MAKING CONNECTIONS.

USE A MULTIMETER TO CHECK ALL TERMINATIONS BEFORE CONNECTING

BATTERIES AND APPLYING POWER TO THE SYSTEM.

EXISTING Te41 TO Te40

CABLE CONNECTIONS

CONNECT X2 #4/0 AWG (+) CABLES

(LUGS BACK TO BACK) TO 2nd Te40

OBSERVE PROPER BUS POLARITY ON THIS SIDE!

BATTERY CHARGE

TERMINATION PANEL

DETAIL B - FRONT BATTERY CHARGE

TERMINATION PANEL CONNECTIONS

ON EXISTING Te40 ENCLOSURE

(+24V SYSTEM SHOWN)

OBSERVE PROPER BUS POLARITY ON THIS SIDE!

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ARGUS TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

CUSTOMER CONNECTION,

KIT, INTRFC, w/ CBL SET,

BATT TO BATT, Te4x

ISSUE

DATE

SIZE

B

TYPE

DWG NO.

D2

2009 ARGUS TECHNOLOGIES

SHEET

747-603-08

NTS

4 7

OF

REV

P/A

Page 49

BATTERY ENCLOSURE (Te40) TO BATTERY ENCLOSURE (Te40)

INTERFACE CABLE ROUTING & CONNECTIONS CONT'D

CONNECT X2 #4/0 AWG

(-) CABLES

:

CONNECT INTERFACE CABLES TO THEIR RESPECTIVE (+) AND (-) BUS BARS ON

CHARGE TERMINATION PANEL USING 3/8" HARDWARE SUPPLIED AS SHOWN.

ENSURE CORRECT POLARITY IS OBSERVED WHEN MAKING CONNECTIONS.

USE A MULTIMETER TO CHECK ALL TERMINATIONS BEFORE CONNECTING

BATTERIES AND APPLYING POWER TO THE SYSTEM.

CONNECT X2 #4/0 AWG

(+) CABLES

OBSERVE PROPER BUS POLARITY ON THIS SIDE!

BATTERY CHARGE

TERMINATION PANEL

DETAIL A - FRONT BATTERY CHARGE

TERMINATION PANEL CONNECTIONS

ON 2nd Te40 ENCLOSURE

(+24V SYSTEM SHOWN)

OBSERVE PROPER BUS POLARITY ON THIS SIDE!

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ARGUS TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

CUSTOMER CONNECTION,

KIT, INTRFC, w/ CBL SET,

BATT TO BATT, Te4x

ISSUE

DATE

SIZE

B

TYPE

DWG NO.

D2

2009 ARGUS TECHNOLOGIES

SHEET

747-603-08

NTS

5 7

OF

REV

P/A

Page 50

BATTERY ENCLOSURE (Te40) TO BATTERY ENCLOSURE (Te40)

INTERFACE CABLE ROUTING & CONNECTIONS CONT'D

:

CABLE TIE-OFF

BAR

NEATLY STRAP INTERFACE CABLES

TO TIE-OFF BAR USING CABLE TIES

(ITEM 36 & 37) PROVIDED IN KIT.

ROUTE INTERFACE CABLES FROM EXISTING

Te40 ENCLOSURE CHARGE TERMINATION PANEL

THROUGH CHASE NIPPLE FITTINGS TO 2nd Te40

ENCLOSURE CHARGE TERMINATION PANEL

AS SHOWN.

2nd Te40 ENCLOSURE

EXISTING Te40 ENCLOSURE

DETAIL C - REAR BATTERY CHARGE TERMINATION PANEL

CABLE ROUTING (TYP.)

DETAIL D - REAR BATTERY INTERFACE

CABLE ROUTING

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ARGUS TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

CUSTOMER CONNECTION,

KIT, INTRFC, w/ CBL SET,

BATT TO BATT, Te4x

ISSUE

DATE

SIZE

B

TYPE

DWG NO.

D2

2009 ARGUS TECHNOLOGIES

SHEET

747-603-08

NTS

6 7

OF

REV

P/A

Page 51

AIR CONDITIONER AC POWER CONNECTION

UTLIITY BOX

:

Te40 AIR CONDITIONER UTILITY BOX WIRING

CONNECT A SEPARATE POWER CABLE TO THE EXISTING AIR CONDITIONER

AC WIRING INSIDE THE UTILITY BOX AND ROUTE IT OUT THROUGH

THE ENCLOSURE(S) TO A SEPARATE AC POWER SUPPLY FEED.

NOTE

:

THE AIR CONDITIONER UNIT MUST BE SUPPLIED FROM A SEPARATE

AC SOURCE PROTECTED BY A 15A 120VAC RATED 1 POLE CIRCUIT BREAKER

AHEAD OF IT.

THIS CONNECTION CAN ALSO BE MADE TO THE OPTIONAL EXTERNAL

AC LOADCENTER ON THE Te41 POWER ENCLOSURE IF INSTALLED.

Te40 AIR CONDITIONER AC POWER WIRING

THESE DESIGNS AND SPECIFICATIONS ARE CONFIDENTIAL, REMAIN

THE PROPERTY OF ARGUS TECHNOLOGIES LTD., AND SHALL NOT

BE COPIED OR USED WITHOUT ITS WRITTEN CONSENT.

UNITS: mm [in]

X [X.X]

X.X [X.XX]

X.XX [X.XXX]

ANGULAR:

TITLE:

1

[ 0.040]

0.5

[ 0.020]

0.05

0.5

[ 0.002]

SCALE:

CUSTOMER CONNECTION,

KIT, INTRFC, w/ CBL SET,

BATT TO BATT, Te4x

ISSUE

DATE

SIZE

B

TYPE

DWG NO.

D2

2009 ARGUS TECHNOLOGIES

SHEET

747-603-08

NTS

7 7

OF

REV

P/A

Page 52

©

76 3.0

©

4 18

1

MOUNT IN HOLE #5

FROM TOP

2

POWER AND BATTERY ENCLOSURE

SETUP & PREPARATION

PREPARATION OF BATTERY ENCLOSURE Te40:

SIDE KNOCKOUT REMOVAL, PANEL CHANGE, INSULATION

CUTOUT & TIE-OFF BAR INSTALLATION

CUT AWAY A SMALL SECTION FROM

INNER WALL INSULATION IN THE UPPER

CORNERS OF BOTH ENCLOSURES AS SHOWN

FOR 3/8" HARDWARE INSTALLATION.

REMOVE TOP CORNER KNOCKOUTS ON FACING

SIDES OF BOTH ENCLOSURES (2 PER SIDE)

REMOVE EXISTING TOP ACCESS BLANK PANEL ON