Page 1

Radium MiniBay

Enclosure Installation Manual

Radium MiniBay

Effective: June 2006

Alpha Technologies

Page 2

Alpha Technologies

Power

®

Page 3

Radium MiniBay

Enclosure Installation Manual

044-001-C0-003, Rev. C

Effective Date: June 2006

Copyright© 2006

Alpha Technologies, Inc.

member of The Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this powering system, please contact Alpha Technologies

or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

TM

Contacting Alpha Technologies: www.alpha.com

or

For general product information and customer service (7 AM to 5 PM, Pacic Time) call,

1-800-863-3930

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacic Time or 24/7 emergency support

3

Page 4

Table of Contents

Important Safety Instructions ................................................................................................. 6

1.0 Overview and Specications..................................................................................... 10

1.1 Standard Cordex Congurations.................................................................... 15

1.2 Enclosure Specications ................................................................................ 18

1.3 MiniBay Accessories ...................................................................................... 18

1.4 Enclosure Cooling Options ............................................................................ 19

1.5 Enclosure Heating Options ............................................................................ 20

1.6 Storage Unit Cooling Options ........................................................................ 21

1.7 Battery Storage Unit Battery Options ............................................................. 22

2.0 DC Air Conditioner .................................................................................................... 23

2.1 Overview and Theory of Operation ................................................................ 23

2.2 DC Air Conditioner Specications .................................................................. 24

2.3 Temperature Control Board............................................................................ 25

2.4 Air Conditioner Installation and Removal ....................................................... 27

2.5 48/24VDC Power Connection ........................................................................ 28

2.6 Alarm Connector ............................................................................................ 29

2.7 Function Test .................................................................................................. 29

2.8 Jumpers ......................................................................................................... 30

2.9 DC Air Conditioner Preventative Maintenance .............................................. 31

2.10 DC Air Conditioner Trouble Shooting ............................................................ 32

2.11 DC Air Conditioner Parts List ......................................................................... 33

3.0 AC Air Conditioner .................................................................................................... 34

3.1 Verifying Default Settings for the IceQube Air Conditioner ............................ 35

3.2 AC Air Conditioner Specications .................................................................. 36

3.3 AC Air Conditioner Condensate Hose Mounting ........................................... 37

3.4 AC Air Conditioner Preventative Maintenance ............................................... 38

3.5 AC Air Conditioner Troubleshooting ............................................................... 38

3.6 Replacement or Spare 2400 AC Air Conditioner............................................ 38

4.0 Site Preparation ........................................................................................................ 39

4.1 Site Selection ................................................................................................. 39

4.2 Precast Pads.................................................................................................. 40

4.3 Pour-in-place Concrete Pads ......................................................................... 42

4.4 Site Conguration .......................................................................................... 45

4.5 Enclosure Grounding ..................................................................................... 47

5.0 Installation................................................................................................................. 48

5.1 Lifting ............................................................................................................ 49

5.2 Special Instructions for Double-wide Installation ........................................... 51

5.3 Battery Connection ........................................................................................ 52

5.4 Connecting to Utility Power ............................................................................ 53

Appendix A........................................................................................................................... 55

4

044-001-C0-003, Rev. C

Page 5

List of Figures

1.0 Overview ................................................................................................................... 10

Fig. 1-1, MiniBay Cabinet ................................................................................................................................. 10

Fig. 1-2, Typical MiniBay Cabinet Conguration, with Side Chamber ...............................................................11

Fig. 1-3, Interior View of the MiniBay Side Chamber ........................................................................................ 12

Fig. 1-4, Equipment Bay Detail ......................................................................................................................... 13

Fig. 1-5, Electronic Components (typical)......................................................................................................... 13

Fig. 1-6, Equipment Bay, Front View ................................................................................................................ 14

Fig. 1-7, Equipment Bay, Rear View ................................................................................................................. 14

Fig. 1-8, Radium MiniBay Standard Conguration #1 ...................................................................................... 15

Fig. 1-8, Radium MiniBay Standard Conguration #2 ...................................................................................... 16

Fig. 1-9, Radium MiniBay Equipment Rack View ............................................................................................. 17

2.0 DC Air Conditioner .................................................................................................... 23

Fig. 2-1, DC Air Conditioner Basic Block Diagram ........................................................................................... 23

Fig. 2-2, Temperature Control Board ................................................................................................................ 25

Fig. 2-3, Wiring Diagram................................................................................................................................... 26

Fig. 2-4, Shroud and Air Conditioner Bolts ....................................................................................................... 27

Fig. 2-5, Power Connections ............................................................................................................................ 28

Fig. 2-6, Alarm Connections ............................................................................................................................. 29

Fig. 2-7, Setpoint Jumper ................................................................................................................................. 29

3.0 AC Air Conditioner .................................................................................................... 34

Fig. 3-1, AC Air Conditioner ............................................................................................................................. 34

Fig. 3-2, AC Air Front Panel Display ................................................................................................................. 35

Fig. 3-3, Condensate Hose Mounting ............................................................................................................... 37

4.0 Site Preparation ........................................................................................................ 39

Fig. 4-1, Conduit Seal Location ........................................................................................................................ 39

Fig. 4-2, Precast Pad Dimensions for Single-wide Enclosure ......................................................................... 40

Fig. 4-3, Precast Pad Dimensions for Single-wide Enclosure with Side Chamber ........................................... 41

Fig. 4-4, Pad Frame Template for Single MiniBay Cabinet .............................................................................. 42

Fig. 4-5, Isometric View, Pad Frame Template, Single MiniBay ....................................................................... 42

Fig. 4-6, Isometric View, Pad Frame Template, Single MiniBay with Side Chamber ....................................... 43

Fig. 4-7, Isometric View, Pad Frame Template, Dual MiniBay with Side Chamber ......................................... 43

Fig. 4-8, Footprint of Dual Enclosure, Dual Side Chamber System ................................................................. 44

Fig. 4-9, Typical Site Arrangement, (cabinet with optional side chamber) ....................................................... 45

Fig. 4-10, Typical Site Arrangement, (stand-alone cabinet) .............................................................................. 46

Fig. 4-11, Suggested Grounding ....................................................................................................................... 47

5.0 Installation................................................................................................................. 48

Fig. 5-1, Enclosure Lifting Arrangement (without side chamber) ...................................................................... 49

Fig. 5-2, Enclosure Lifting Arrangement (with optional side chamber in place) ................................................ 49

Fig. 5-3, Rear View of Enclosure, (showing ladder bar) .................................................................................. 50

Fig. 5-4, Dual Enclosure Installation ................................................................................................................. 51

Fig. 5-5, Battery Terminal Connections ............................................................................................................ 52

Fig. 5-6, Service Entrance Wiring ..................................................................................................................... 54

5044-001-C0-003, Rev. C

Page 6

Important Safety Instructions

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

Symbols in this Manual

ATTENTION:

The use of ATTENTION indicates regulatory/code requirements that may affect the placement of equipment

or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specic task or procedure.

CAUTION!

A CAUTION presents safety information to PREVENT DAMAGED EQUIPMENT.

WARNING!

A WARNING presents safety information to PREVENT INJURY OR DEATH to the

technician/user.

ATTENTION:

Alpha Technologies’ products are subject to change through continual improvement processes. Therefore,

specications or design layouts may vary slightly from the descriptions included in this manual. Updates to the

manual are issued when changes affect form, t or function.

6

044-001-C0-003, Rev. C

Page 7

General Safety Precautions

CAUTION!

This enclosure and its associated hardware (power supply, batteries, cabling) may contain

equipment, batteries or parts that have hazardous voltage or currents.

To avoid injury:

• This enclosure and its associated hardware must be serviced only by authorized personnel.

• Enclosure must remain locked at all times, except when authorized service personnel are present.

• Remove all conductive jewelry or personal equipment prior to servicing equipment, parts, connectors,

wiring, or batteries.

• Read and follow all installation, equipment grounding, usage, and service instructions included in this

manual.

• Use proper lifting techniques whenever handling enclosure, equipment, parts, or batteries.

• Batteries contain dangerous voltages, currents and corrosive material. Battery installation, maintenance,

service and replacement must be performed by authorized personnel only.

• Never use uninsulated tools or other conductive materials when installing, maintaining, servicing or

replacing batteries.

• Use special caution when connecting or adjusting battery cabling. Battery cables that are either

improperly or unconnected can result in arcing, a re, or possible explosion.

• A battery that shows signs of cracking, leaking or swelling must be replaced immediately by authorized

personnel using a battery of identical type and rating.

• Avoid any contact with gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery.

Emissions contain dilute sulfuric acid which is harmful to the skin and eyes. Emissions are electrolytic,

which are electrically conductive and are corrosive. Follow the Chemical Hazards notes if contact occurs.

• Do not smoke or introduce sparks in the vicinity of a battery.

• Under certain overcharging conditions, lead-acid batteries can vent a mixture of hydrogen gas that is

explosive. Proper venting of the enclosure is required.

• Follow the battery manufacturer’s approved transportation and storage instructions.

CAUTION!

Enclosure, equipment or parts may be damaged or cause damage if used or installed improperly.

To avoid damage:

• Prior to installation, verify that the AC input voltage to the enclosure and its equipment match with respect

to voltage and frequency.

• Prior to installation, verify that the output voltage from the enclosure or its equipment match the voltage

requirements of the connected equipment (load).

• Prior to installation, verify that the enclosure’s utility service panel is equipped with a properly rated circuit

breaker for use with the equipment inside. Refer to manufacturer’s recommendations.

• Review and upgrade utility service panel circuit breaker requirements whenever the equipment within the

enclosure is changed.

• Prior to installation, contact local utilities, local building maintenance departments, and cable/piping

locator services to ensure that installation will not interfere with existing utility or building cables/piping.

• Do not exceed the output rating of equipment. Verify load requirements prior and during connection

process.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have

developed in your body.

7044-001-C0-003, Rev. C

Page 8

Battery Safety Notes

WARNING!

Lead-acid batteries contain dangerous voltages, currents and corrosive material. Battery

installation, maintenance, service and replacement must be performed only by authorized

personnel.

Chemical Hazards

To avoid injury:

• Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove

all metallic objects from hands and neck.

• Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

• All gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery contain dilute sulfuric acid,

which is harmful to the skin and eyes. Emissions are electrolytic, which are electrically conductive and

corrosive.

• Batteries produce explosive gases. Keep all open ames and sparks away from batteries.

• Use tools with insulated handles, do not place tools on top of batteries.

• Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm. Battery post terminals and related accessories contain lead and lead

compounds. Wash hands after handling. (California Proposition 65)

• Wear protective clothing (insulated gloves, eye protection, etc.) whenever installing, maintaining,

servicing, or replacing batteries.

• If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your

company’s approved chemical exposure procedures.

• Neutralize any spilled battery emission with the special solution contained in an approved spill kit or with

a solution of one pound Bicarbonate of soda to one gallon of water. Report chemical spill using your

company’s spill reporting structure and seek medical attention if necessary.

• Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

• Do not charge batteries in a sealed container. Each individual battery should have at least 0.5 inches of

space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of potentially

dangerous gas.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have

developed on your body.

• Never use uninsulated tools or other conductive materials when installing, maintaining, servicing or

replacing batteries.

• Use special caution when connecting or adjusting battery cabling. An improperly connected battery cable

or an unconnected battery cable can make contact with an unintended surface that can result in arcing,

re, or possible explosion.

• A battery showing signs of cracking, leaking, or swelling should be replaced immediately by Authorized

Personnel using a battery of identical type and rating.

• Under extreme overcharging conditions, lead-acid batteries can vent a mixture of hydrogen gas which is

explosive.

• All battery compartments must have adequate ventilation to prevent accumulation of potentially

dangerous gas. Ventilation should prevent trapped hydrogen gas pockets from exceeding a one percent

concentration as per regulation 70E of the National Fire Protection Agency (NFPA).

8

044-001-C0-003, Rev. C

Page 9

Battery Maintenance Guidelines

The battery maintenance instructions listed below are for reference only. Battery manufacturer’s instructions

for transportation, installation, storage or maintenance take precedence over these instructions.

• To prevent damage, inspect batteries every 3 months for signs of:

Battery cracking, leaking or swelling. The battery should be replaced immediately by authorized

personnel using a battery of the identical type and rating.

Battery cable damage. Battery cable should be replaced immediately by authorized personnel using

replacement parts specied by vendor.

Loose battery connection hardware. Refer to battery manufacturer’s documentation for the correct

torque and connection hardware for the application.

• Apply battery manufacturer’s specied antioxidant compound on all exposed connections.

• Verify battery terminals and/or exposed connection hardware is not within two inches of a conductive

surface. Reposition batteries as necessary to maintain adequate clearance.

• Clean up any electrolyte (battery emission) in accordance with all federal, state, and local regulations or

codes.

• Proper venting of the enclosure is recommended. Follow the Battery Manufacturer’s approved

transportation and storage instructions.

• Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

• Do not charge batteries in a sealed container. Each individual battery should have at least 0.5 inches of

space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of potentially

dangerous gas.

Recycling and Disposal Instructions

Spent or damaged batteries are considered environmentally unsafe. Always recycle used batteries or dispose

of the batteries in accordance with all federal, state and local regulations.

Electrical Safety

• Lethal voltages are present within the power supply and electrical boxes. Never assume that an electrical

connection or conductor is not energized. Check the circuit with a volt meter with respect to the grounded

portion of the enclosure (both AC and DC) prior to any installation or removal procedure.

• Always use the buddy system when working under hazardous conditions.

• A licensed electrician is required to install permanently wired equipment.

• Input voltages can range up to 240VAC. Ensure that utility power is disabled before beginning installation

or removal.

• Ensure no liquids or wet clothes contact internal components.

• Hazardous electrically live parts inside this unit are energized from batteries even when the AC input

power is disconnected from the MiniBay.

Mechanical Safety

• Keep hands and tools clear of fans. Fans are thermostatically controlled and will turn on automatically.

• Power supplies can reach extreme temperatures under load.

• Use caution around sheet metal components and sharp edges.

9044-001-C0-003, Rev. C

Page 10

1.0 OverviewandSpecications

The MiniBay’s modular design allows the exible conguration necessary to meet a wide range of

applications, including traditional and advanced hybrid ber coax (HFC), FTTx ber deep, Wi-Max

networks, wireless outdoor base stations, wireless IP access, and bulk power.

The MiniBay is comprised of a set of CSA listed assemblies that allow new agency approved

congurations to be rapidly constructed. The equipment section can be congured to 19" or 23"

wide rack units (RU), consisting of 23 RU in the front and 23 RU in the rear. An optional “swing rack”

provides 17 RU of additional equipment space.

Thermal management options include conformal-coated fans with electrostatic lters, heat

exchangers, and two high efciency air conditioning systems.

Each battery storage unit is isolated from the equipment section and can house a variety of battery

types, including a 48V string of GNB M12V155FT batteries that can support a 19.4A load for 8 hours.

A second battery storage module can be added to provide additional capacity or redundancy.

The MiniBay integrates Alpha’s comprehensive line of power solutions for today’s complex

communications powering requirements, including the Cordex series of high efciency hot swappable

switch mode 48VDC rectiers and the AlphaGen series of telephony grade DC generators.

NOTE:

For MiniBay wiring diagrams and alarm information, see Radium MiniBay System Schematics, Alpha P/N

044-001-C2.

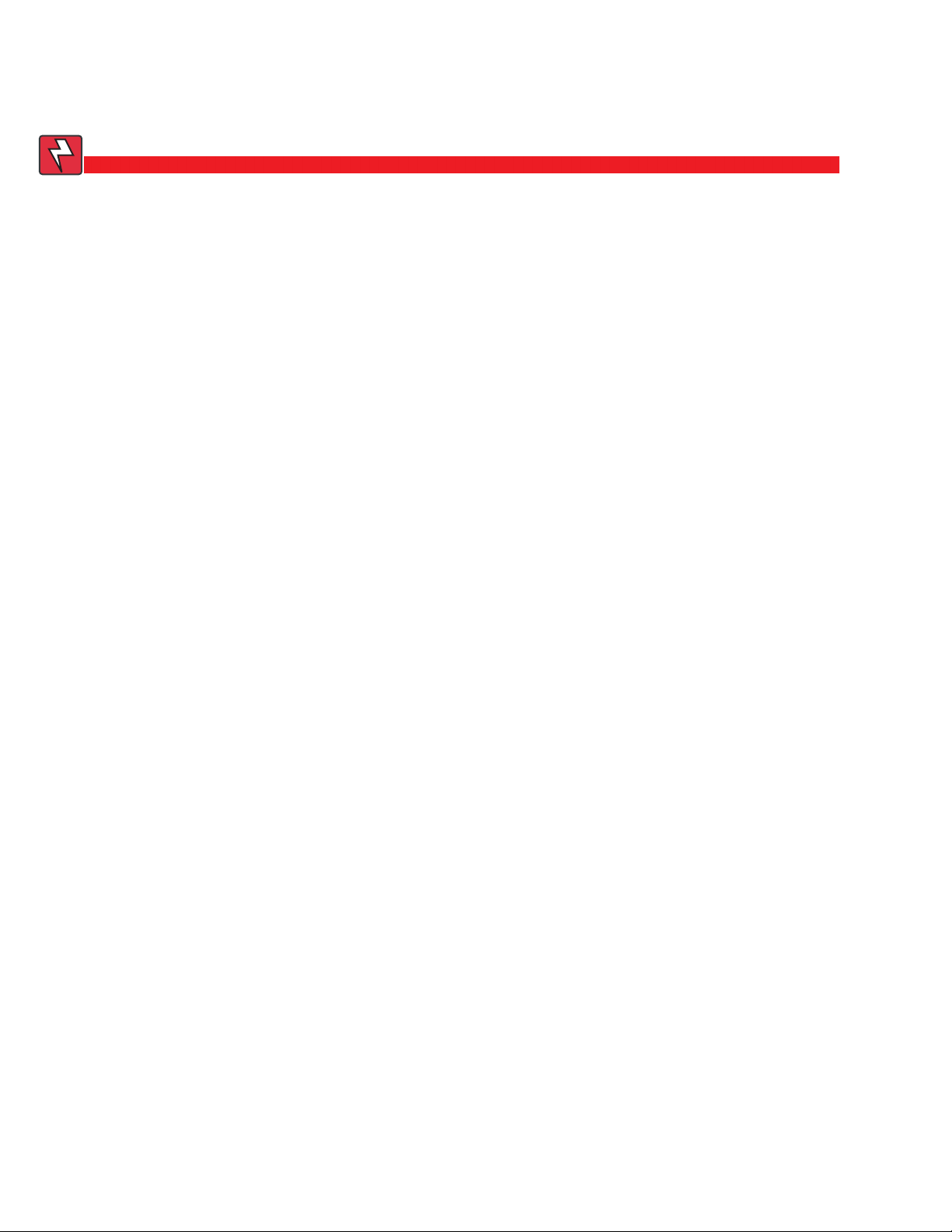

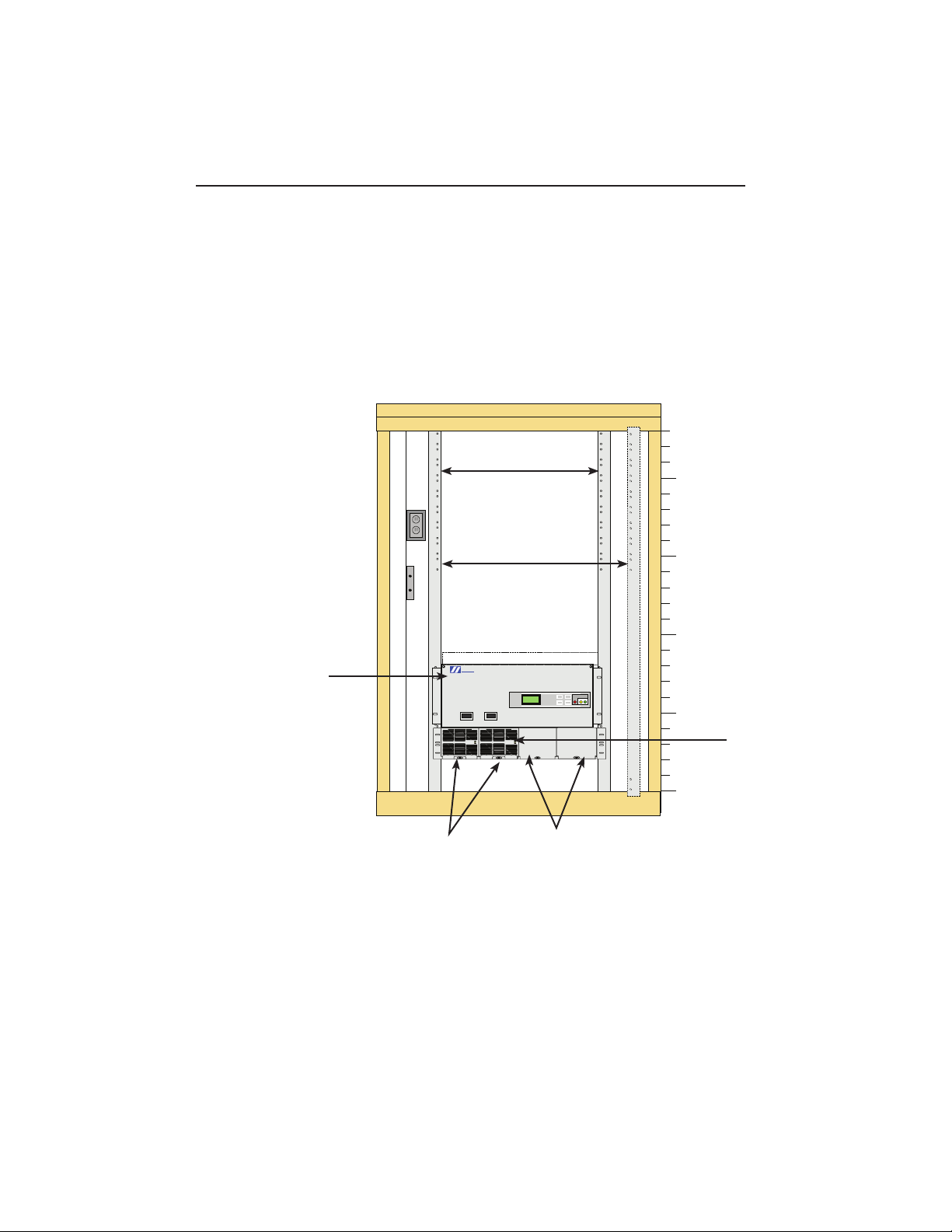

Air Conditioning Unit

(optional)

Lifting Ear

Pin Allen Telecom

Security Locks

Battery Storage Unit

(lockable)

Fig. 1-1, MiniBay Cabinet

10

044-001-C0-003, Rev. C

Page 11

1.0 OverviewandSpecications,continued

Viewing Window

Lifting Ear

Lockable Door

Air Conditioning

Unit

Battery Storage Unit

(lockable)

Fig. 1-2, Typical MiniBay Cabinet Conguration, with Side Chamber

11044-001-C0-003, Rev. C

Page 12

1.0 OverviewandSpecications,continued

MiniBayconguredwiththefollowingoptions:

Side Chamber (designed to NEMA 4X specications)

60A Internal AC Service (Square D QO Series)

EUSERC Meter Base (240VAC with Test Bypass Blocks)

Fusible Service Entrance Disconnect (100,000 AIC rating)

Side Chamber Door Viewing Window

TVSS (Transient Voltage Surge Suppression) Module

Cable Entry Seals

Master Ground Bar

Telcom 3-point Door Latch

Door Activated Light and Tamper Switch

Also shown on this unit:

3,000 BTU DC Air Conditioner

Battery Storage Unit

Pin Allen Telecom Locks

Viewing Window

Fused Disconnect

Door-activated

Tamper Switch

and Light.

Pin Allen 3-point

Door Latch

Ground Bar

Meter Base

EUSERC

Meter Base

AC Distribution

Breaker Panel

Cable Entry Port Seals

12

Fig. 1-3, Interior View of the MiniBay Side Chamber

044-001-C0-003, Rev. C

Page 13

1.0 OverviewandSpecications,continued

DC Air Conditioning Unit

Insulating Material

(used on front/rear

doors and interior of

cabinets equipped with

air conditioning)

Fig. 1-4, Equipment Bay Detail

Air Conditioner

Controller Board

GFCI

Convenience

Outlet

Door-activated Switches

(tamper alarm and service light)

Rectier Shelf

(Cordex 48-650W

shown)

Fig. 1-5, Electronic Components (typical)

13044-001-C0-003, Rev. C

Page 14

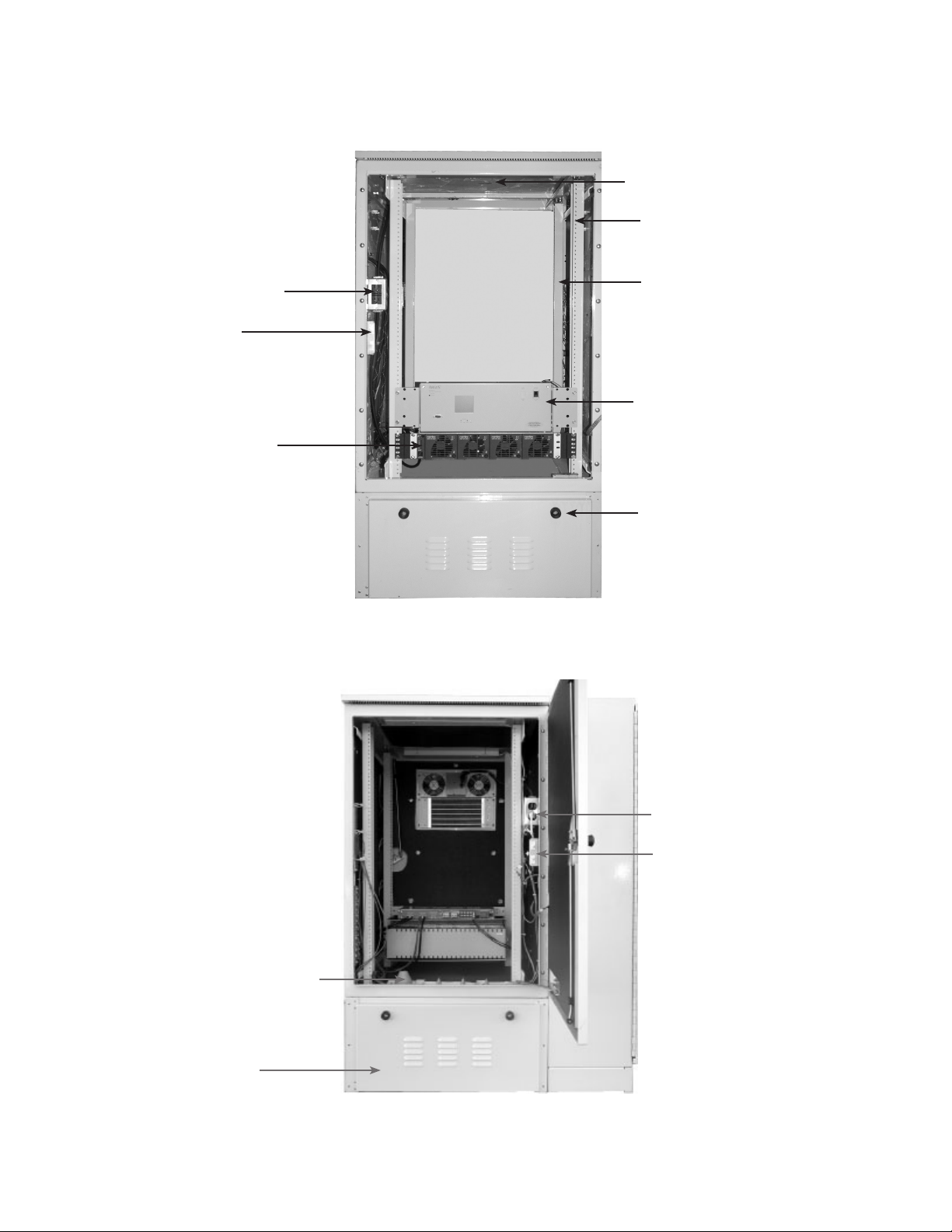

1.0 OverviewandSpecications,continued

Front Service Light

Equipment Rack

(23" shown)

GFCI Convenience Outlet

Door-activated

Switches

(tamper alarm and

service light)

48-1.8kW Rectier Shelf

(shown)

19" Rear Swing Rack

Front Access Circuit Breaker

Distribution Center with

Integrated Cordex Controller

(shown)

Lockable Battery

Module

Fig. 1-6, Equipment Bay, Front View

14

GFCI Convenience Outlet

Door-activated Switches

(tamper alarm and

service light)

Cable Entry Port Seals

Lockable Battery

Compartment

Fig. 1-7, Equipment Bay, Rear View

044-001-C0-003, Rev. C

Page 15

1.0 OverviewandSpecications,continued

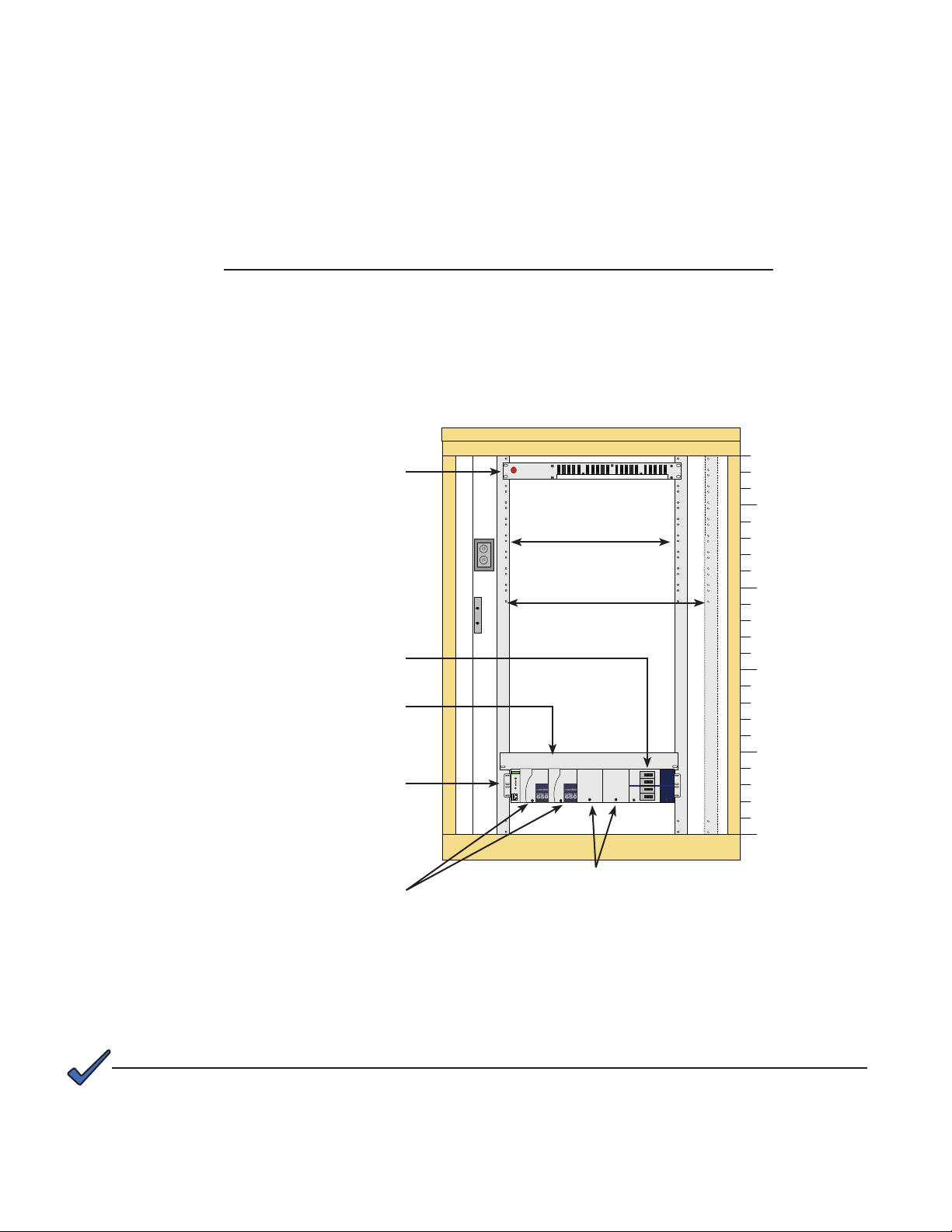

1.1 StandardCordexCongurations

The Radium MiniBay may be equipped with Cordex 48-650W, 48-1kW, or 48-1.8kW AC/DC

rectiers. Previous models were equipped with RSM 48/10 AC/DC rectiers. Due to customer

requirements, the following illustrations may not resemble your model exactly.

RMB DC Power & Distribution Standard Conguration #1

• Cordex 48-650W 19" shelf with two rectier modules with load LVD

• Provides 13.5A @ 48VDC, N+1

• Fully equipped shelf provides 2.6kW (54A @ 48VDC), N+0

• 2RU shelf needs 1RU above and below, convection cooled

• Heat dissipation <221 BTU/hr, per rectier module

• Comnet GMT fuse panel, 10A/10B position -48VDC

GMT Fuse Panel

2 RU

P/N C016-111-10

10A/10B -48VDC

(Rack Units)

23

20

Load Breakers (qty 4)

Available Sized 1-100A

19" or 23" Heat Deector

1 RU

CDX 19/23" 48-650W Shelf

2 RU

P/N 030-728-20-A010

208/240AC CXCI, Load LVD

(Battery LVD available)

CXRC 48-650W Rectier Modules (qty 2-4)

2 RU

P/N 010-570-20-A002

19" Rack

23" Rack

HEAT DEFLECTOR

Blank Plate

P/N 030-728-20-A005

15

10

5

0

Fig. 1-8, Radium MiniBay Standard Conguration #1

NOTE:

For units equipped with a Battery LVD, a manual reset of the battery contactor is required after the low voltage

disconnect has been tripped, if there is no resumption of AC power, and DC power is applied to the unit using

an alternate power source (DC generator).

15044-001-C0-003, Rev. C

Page 16

1.0 OverviewandSpecications,continued

1.1 StandardCordexCongurations,continued

RMB DC Power & Distribution Standard Conguration #2

• Cordex 1.8kW 19" Shelf, with two Cordex 48-1.8kW rectier modules

• Provides 37.5A @ 48VDC, N+1

• Fully equipped shelf provides 7.2kW (150A @ 48VDC), N+0

• 2 RU shelf, fan cooled

• Heat dissipation <350 BTU/hr, per rectier module

• 584 Distribution Center with Cordex Controller, load LVD, eight load breakers, and shunt

Front ACS Distribution Center

5 RU

P/N 020-584-20-A012

19/23" 48VDC 400A

8 position Circuit Breaker

Sized 1-100A with Load LVD

2 to 4 (qty) CXCM 48-1.8kW Rectier Modules

2 RU

P/N 010-580-20-A001

ARGUS

TECHNOLOGIES

P/N 020-584-20

23

19" Rack

23" Rack

Leave 1RU Space

SM03

Blank Plate

P/N 030-749-20-A002

(Rack Units)

20

15

10

5

CDX 19" Shelf

2 RU

0

48-1.8kW

P/N 030-749-20-A001

208/240VAC

16

Fig. 1-9, Radium MiniBay Standard Conguration #2

044-001-C0-003, Rev. C

Page 17

1.0 OverviewandSpecications,continued

1.1 StandardCordexCongurations,continued

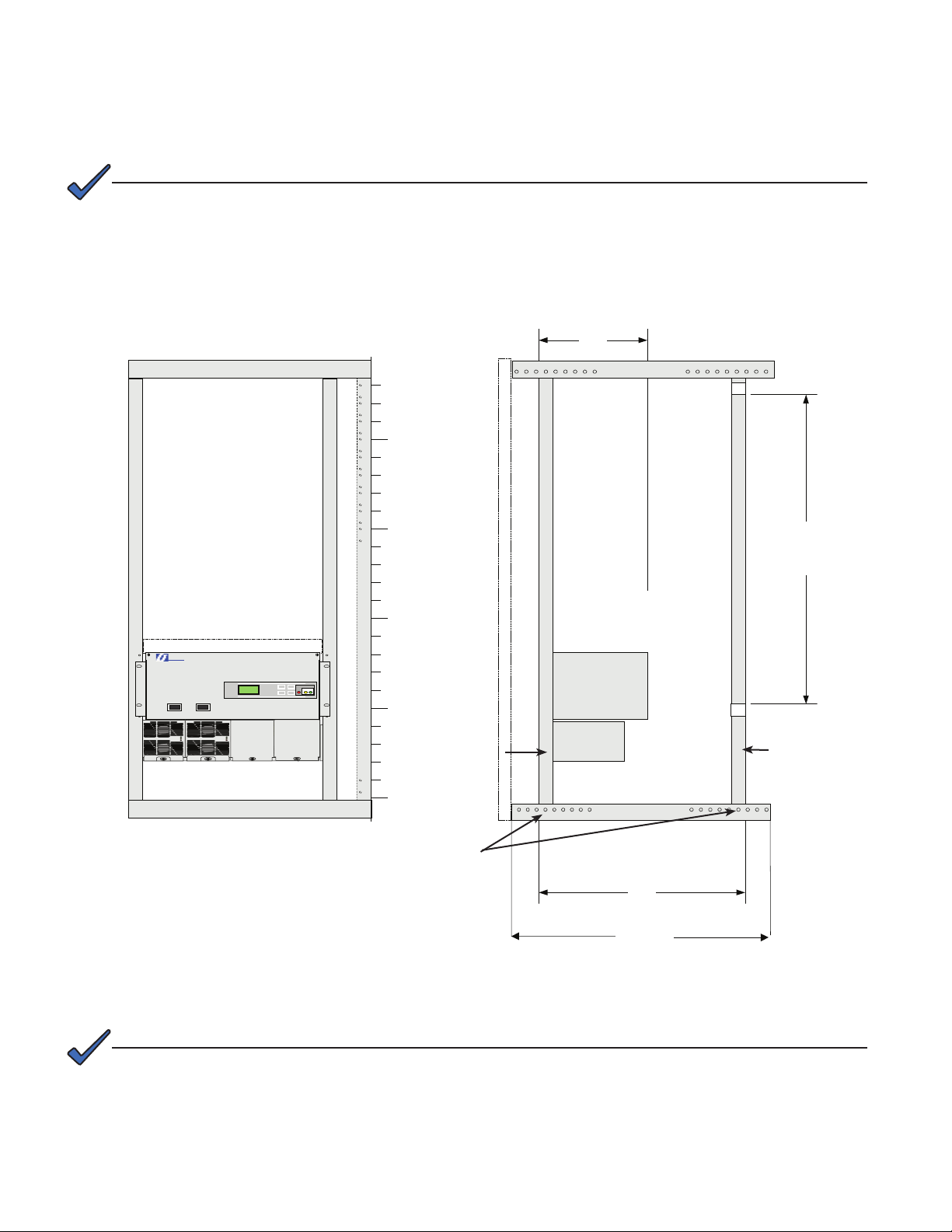

NOTE:

Rack height is shown in Rack Units (RU). One RU is equal to 1.75 inches.

Equipment Rack Side ViewEquipment Rack Front View

15.0"

20

P/N 020-584-20

ARGUS

TE

CHNOLOGIES

Leave 1RU Space

SM03

15

10

Front Door

5

19" Rear Equipment

Rack (xed)

0

Installed in fourth

hole position

23.5"

32.0

"

Fig. 1-10, Radium MiniBay Equipment Rack View

17 RU Available

for Equipment

19" Rear Equipment

Rack (swing)

NOTE:

For wiring diagrams and alarm information, see Radium MiniBay System Schematics, Alpha P/N 044-001-05.

Contact Alpha Application Engineering for information on Cordex congurations.

17044-001-C0-003, Rev. C

Page 18

1.0 OverviewandSpecications,continued

1.2 EnclosureSpecications

Equipment Enclosure Weight: 195 lbs (88.5kg)

19" or 23" wide Fixed Relay Rack

tapped or with Tinnerman nuts

19" Swing Rack (tapped only)

Battery Storage Unit Weight (without batteries): 130 lbs (59kg)

Slide Tray, Alpha P/N 033-083-20,

will hold four GNB M12V155FT batteries

Fixed Tray, Alpha P/N 033-083-23,

will hold three Avestor batteries.

Riser Module

14" Riser Alpha P/N 033-083-21

7" Skirt/Riser Alpha P/N 033-084-20

7" C-channel Riser Alpha P/N 745-650-20

Side Chamber SC1 Weight: 100 lbs (45.4kg)

Side Chamber SC2 Weight: 89 lbs (40.4kg)

Dimensions (in/mm):

44H x 30W x 32D (1067 x 762 x 813)

Material: High Strength Corrosion Resistant

Aluminum

Finish: Almond Color Powdercoat Finish

Dimensions (in/mm):

14.0H x 30W x 32D (356 x 762 x 813)

Weight: 102 lbs (46.3kg)

Dimensions (in/mm):

14H x 30W x 32D (356 x 762 x 813)

Dimensions (in/mm):

72H x 32W x12D (813 x 1829 x 305)

Dimensions (in/mm):

58H x 32W x 12D (813 x 1321 x 305)

1.3 MiniBay Accessories

Precast Polymer Concrete Padfor Single Radium MiniBay P/N 641-110-10

Precast Polymer Concrete Pad for Single Radium MiniBay + Side

Chamber

Pour-in-place Pad Template P/N 604-039-N1

Pour-in-place Pad Template Tie-bars (spacers for 2 template kits) P/N 745-332-20

Pour-in-place Side Chamber Template P/N 745-333-20

Vapor Barrier for MiniBay (die cut template matches MiniBay) P/N 564-990-10

SRG PROT, 5-pin, Gas Tube, 3B1E P/N 162-016-10

Touch-up Spray Paint, Almond P/N 972-056-10

Pad Mounting Hardware Kit (4 Hilti KBII sleeve anchors 1/2 x 3-3/4) P/N 745-592-21

Pad Mounting Hardware (4 Hilti HSLG M12/0 *60 heavy duty sleeve

anchors) requires 12mm metric drill Kit for Zone 4

P/N 641-114-10

P/N 745-592-20

18

044-001-C0-003, Rev. C

Page 19

1.0 OverviewandSpecications,continued

1.4 Enclosure Cooling Options

NOTE:

Consultation with Alpha Applications Engineering is required. Provisions must be made for adequate air

ow in the cabinet, equipment total heat dissipation load inside the cabinet, equipment min/max operating

temperatures, equipment over-temp fail safe shutdown capability, environmental outdoor design conditions,

and battery back up run times.

FanFilterCoolingDoor,48VDC,rightorlefthinged:AlphaP/N745-204-20(R)or745-204-21(L)

• Cooling capacity 1000W dissipated with 15ºC rise over ambient.

• Two 150 CFM fans with variable speed temperature control and low voltage disconnect, hysteresis xed

at 42VDC.

• Inline 5A fuse.

• Fans run continuously below 25ºC at 40% speed. Fans increase from 40% to 100% with increased

enclosure temperature from 25ºC to 55ºC.

• Form C dry contact alarm, fan fail, open on alarm.

• Maximum power draw 32W.

FanFilterCoolingDoor,120VAC,rightorlefthinged:Alpha745-204-25(R)or745-204-24(L)

• Cooling capacity 750W dissipated with 15ºC rise over ambient.

• Two 115 CFM fans are powered from the included line cord with designated inline 5A fuse and bimetal

thermostat control (Alpha P/N 875-075-20).

• Fixed thermostat set point, close at 29ºC and open at 19ºC.

• Included adjustable enclosure over-temp alarm (Alpha P/N 745-338-20).

• Form C dry contact, open on alarm. Factory setting is 40ºC.

• Maximum power draw 30W.

HeatExchangerDoor,48VDC,rightorlefthinged:AlphaP/N745-204-45(R)or745-204-46(L)

• Cooling capacity 690W dissipated with 15ºC rise over ambient.

• Variable speed fan temperature control and low voltage disconnect. Fans off below 23ºC. Fans turn on at

25ºC and run from 25% to 100% with increased enclosure temperature from 25ºC to 45ºC.

• Two Form C dry contact alarms (Minor: Fan fail, open on alarm and Major: Enclosure over-temp xed at

60ºC, open on alarm).

• Maximum power draw 120W.

HeatExchangerCoolingDoor,120VAC, rightorlefthinged:AlphaP/N745-204-40(R)or745-204-41(L)

• Cooling capacity 690W dissipated with 15ºC rise over ambient

• Heat exchanger fans are powered from included line cord with designated inline 5A fuse and bimetal

thermostat control (Alpha P/N 875-075-20)

• Fixed thermostat set point, close at 29ºC and open at 19ºC

• Included adjustable enclosure over-temp alarm (Alpha P/N 745-338-20). Form C dry contact, open on

alarm. Factory setting is 40ºC.

• Maximum power draw 115W.

19044-001-C0-003, Rev. C

Page 20

1.0 OverviewandSpecications,continued

1.4 EnclosureCoolingOptions,continued

AirConditionerDoor,48VDC,rightorlefthinged:AlphaP/N745-204-50(R)or745-204-51(L)

• Cooling capacity 878W dissipated at 43ºC outdoor ambient and maximum internal ambient temperature

of 40ºC.

• Variable speed compressor temperature control and low voltage disconnect.

• Adjustable enclosure temperature set point jumper, factory set to 25ºC.

• Two Form C dry contact alarms (Minor: High condensing temp and/or enclosure over-temp, open on

alarm and Major: cooling system failed, open on alarm). See DC air conditioner operation section for

details.

• Maximum power draw 500W.

AirConditionerDoor,24VDC,rightorlefthinged:AlphaP/N745-204-52(R)or745-204-53(L)

• Cooling Capacity 878W dissipated at 43ºC outdoor ambient and maximum internal ambient temperature

of 40ºC.

• Variable speed compressor temperature control and low voltage disconnect. Adjustable enclosure

temperature set point jumper factory set to 25ºC.

• Two Form C dry contact alarms (Minor: High condensing temp and/or enclosure over-temp, open on

alarm and Major: cooling system failed, open on alarm). See DC air conditioner operation section for

more details.

• Maximum power draw 500W.

AirConditionerDoor,240VAC,rightorlefthinged:AlphaP/N745-204-58(R)or745-204-59(L)

• Cooling capacity 1464W dissipated at 43ºC outdoor ambient and maximum internal ambient of 40ºC.

• Digital display with programmable set points.

• Included adjustable enclosure over-temp alarm (Alpha P/N 745-338-20).

• Form C dry contact, open on alarm. Factory setting is 40ºC. See AC air conditioner operation section for

more details.

• Maximum power draw 989W.

1.5 Enclosure Heating Options

Heater,450W,48VDC:AlphaP/N745-588-22or745-588-21

• PCBA thermistor temperature control and low voltage disconnect.

• Heater turns on when enclosure temperature drops below 6ºC.

• Functional test button.

• Model 745-588-22 includes 20A circuit breaker.

• Model 745-588-21 does not include circuit breaker, but has a piggyback connector that allows it to share

input power from the DC air conditioner 20A circuit breaker.

Heater,450W,120VAC:AlphaP/N745-589-21

Line cord with bimetal thermostat control. Thermostat set point is xed to close at 4ºC and open at 15ºC.

Plugs into GFCI outlet.

20

044-001-C0-003, Rev. C

Page 21

1.0 OverviewandSpecications,continued

1.6 Storage Unit Cooling Options

Fan,120VAC:AlphaP/N745-214-21

One 64CFM fan powered from 875-075-20 line cord with designated in-line 5A fuse and bimetal thermostat

control. Thermostat set point is xed to close at 29ºC and open at 19ºC.

Fan,48VDC:AlphaP/N745-214-20

• One 110CFM fan, turns off below 25ºC. Turns on at 25ºC and increases from 40% to 100% full speed with

increased enclosure temperature from 25ºC to 45ºC.

• Form C dry contact alarm, fan fail, open on alarm.

Fan,24VDC, AlphaP/N745-214-22

• One 110CFM fan, turns off below 25ºC. Turns on at 25ºC and increases from 40% to 100% full speed with

increased enclosure temp from 25ºC to 45ºC.

• Form C dry contact alarm, fan fail, open on alarm.

21044-001-C0-003, Rev. C

Page 22

1.0 OverviewandSpecications,continued

1.7 BatteryStorageUnitBatteryOptions

The Battery Storage Unit (slide tray), Alpha P/N 033-083-20, and Battery Storage Unit (xed

tray), Alpha P/N 033-031-21, accommodates four of the following battery types:

• C&D TEL 12-45

• C&D TEL 12-70

• AlphaCell 85GXL-HP

• AlphaCell 165GXL

• AlphaCell 185GXL

• AlphaCell 195GXL-3FTG

• AlphaCell 225AGM-3FTA

• C&D TEL 12-105F

• GNB Marathon M12V155FT

• AlphaCell SMU12V 155F

The Battery Storage Unit (xed tray) also accommodates three Avestor SE48S63 48VDC

batteries.

22

Fig. 1-11, Battery Storage Unit

The MiniBay equipment enclosure can house a maximum of four batteries on the oor of

enclosure when the fan ltered cooling door or roof vent option is used. The roof vent must

have a minimum of four .375" vent holes to provide adequate hydrogen venting (Alpha P/N

745-669-20 or equivalent). The following batteries may be used in the battery compartment or

equipment enclosure:

• C&D TEL 12-45

• C&D TEL 12-70

• AlphaCell 85GXL-HP

• AlphaCell 195GXL-3FTG

• AlphaCell 225AGM-3FTA

044-001-C0-003, Rev. C

Page 23

2.0 DC Air Conditioner

2.1 Overview and Theory of Operation

The MiniBay DC Air Conditioner comes in 24V and 48V models and uses a brushless

compressor and variable speed controller. A temperature control board varies capacity by

varying compressor speed depending on the enclosure internal setpoint temperature. The

compressor runs between 50% and 100% of full speed depending on the load and enclosure

set point temperature. When the temperature drops more than 4°C below the set point, the

compressor and condenser fans shut off. The evaporator fans run continuously regardless of

the set point to maintain an even temperature inside the enclosure.

Theory of Operation:

1. Low pressure gas is drawn into the compressor.

2. The high pressure gas is sent through a condenser where air is blown over it, cooling the

gas into a liquid.

3. The high pressure liquid passes through an expansion valve, where the liquid is allowed

to expand and boil off into a gas. As the gas expands, it cools.

4. The cool saturated low pressure gas is sent through the evaporator. Warm interior air is

blown over the evaporator and back into the interior, several degrees cooler.

5. The low pressure gas is then drawn into the compressor, where the cycle starts over.

Thermostatic

Expansion Valve

-48VDC Bus

Ground

Return Bar

Minor Alarm Connect

Major Alarm Connect

Evaporator

Liquid is allowed to expand at

low pressure back into gas,

cooling interior air.

20A

Temp

Control

Board

Speed Control

Board

Evaporator Fans

(always on)

Suction Line

Liquid Line

Sight Glass

Discharge Line

Variable Speed

Compressor

Condenser Fans

(thermostatically controlled)

Condenser

Hot gas is cooled by outside

ambient air and condensed

into a high pressure liquid.

Fig. 2-1, DC Air Conditioner Basic Block Diagram

23044-001-C0-003, Rev. C

Page 24

2.0 DCAirConditioner,continued

2.2 DCAirConditionerSpecications

Capacity: 3,000 BTU @ 110°F (43ºC) See chart below

External Amb. Operating Range: -40°C (-104°F) to +50°C (+122°F) RH 13%

Max Internal Amb. Temperature: +40°C (+104°F) RH 25%

Maximum Internal Hysteresis: 10°C (50°F)

Maximum Operational Power Draw: 500W ±10% (see chart)

DC Operation @ 48VDC: 42VDC to 60VDC range with LVD xed at 42V

DC Operation @ 24VDC: 21VDC to 30VDC range with LVD xed at 21V

Cooling System Control: Low current DC or dry contact on/off

Major Alarm: Compressor/controller system fail

Minor alarm: High condensing temperature, Low evaporator

Refrigerant Type: R134a

Fan Life: >50,000 Hours

Color: Almond semigloss (other colors available)

External Dimensions (in/mm): 19.50 W x 38.25 H x 7.50 D (495 x 972 x 191)

Agency: CSA

Enclosure Rating: IP55 - Weather tight hose directed spray

Noise Level: 60 dBA at one meter

Materials: Corrosion and salt-fog resistant (including fans)

circuit breaker, magnetic short delay 15A

circuit breaker, magnetic short delay 30A

temperature, Enclosure over-temp

1400

1200

1000

800

600

Capacity Wattage

400

200

0

10 20 30 40 50

Ambient Temp (C)

Capacity (watt/hr)

Total Unit Watts

NOTE:

The chart above table illustrates air conditioner capacity under controlled conditions. A safety factor should

be used depending on cabinet insulation and outside air ltration. To calculate capacity in BTUs at a given

outdoor ambient temperature multiply 3.413 x (capacity watt/hr).

24

044-001-C0-003, Rev. C

Page 25

2.0 DCAirConditioner,continued

2.3 Temperature Control Board

The temperature control board monitors the compressor, condenser fan, and alarm control.

Its remote temperature sensors monitor compressor discharge and evaporator suction line

temperature. A board-mounted temperature sensor monitors enclosure temperature. An

optional remote temperature sensor can monitor a specic area in the enclosure. The board

incorporates a low-voltage shutdown xed at 42V for the 48VDC air conditioner, and 21V for

the 24VDC air conditioner.

A temperature sensor on the discharge line of the compressor regulates the condenser fans.

At low outdoor ambient temperatures, the condenser fans cycle on or off to maintain pressure

across the expansion valve.

A temperature sensor on the suction line exiting the evaporator monitors low evaporator

temperature, which can result from blocked evaporator air ow or faulty evaporator fans. This

condition sends out a minor alarm and shuts down the compressor until the suction lines

warm up again.

704-713-

Temperature

Set Point Jumper

Local-Remote Temp

Sensor Jumper

DC Power

Input

+

-

DC Aux

Output

+ -

Major/Minor

Alarm Output

Under Temp

Shutdown Jumper

Enclosure Over

Temp Jumper

Minor Alarm LED and

N/C - N/O Jumper

Major Alarm LED and

N/C - N/O Jumper

Remote Enclosure

Temp Probe

Fig. 2-2, Temperature Control Board

25044-001-C0-003, Rev. C

Page 26

2.0 DCAirConditioner,continued

2.3 TemperatureControlBoard,continued

AIR COND TEMP CONTROL

SHDOWN

Evap temp

MINOR

J10

ALARM

SETPOINT

18C

23C

MAJO

N0NC

R

MAJOR4MAJOR3MINOR2MINOR

1

28C

33C

38C

N0NC

PWR (+)1PWR (-)

MM

L

(-)

J11

J12

(+)

2

Evap Temp Sensor

LOCAL

RMT

Remote T

em

p

J1

SPEED CONTROL BOARD

PWR (-)

PWR (+)

Cond Temp Sensor

(BREAKER IS INSTALLED ON THE UNGROUNDED LEAD)

BLACK

RED

RED

YELLOW

48 or 24VDC

MAJOR ALARM CONNECT

MINOR ALARM CONNECT

EVAP FANS

COMPRESSOR

A

B

C

COND FANS

26

Fig. 2-3, Wiring Diagram

044-001-C0-003, Rev. C

Page 27

2.0 DCAirConditioner,continued

2.4 Air Conditioner Installation and Removal

Allow 20 minutes for completion of procedure.

Tools required: 7/16" deep-well socket and ratchet handle

Removal:

1. Disconnect power to the air conditioner.

2. Disconnect input and alarm wires from the control board (see Fig. 2-2).

3. From the inside of the door, remove the 5 bolts (labeled S below) holding the shroud to

the door. Remove the shroud. Remove grounding lug.

4. While another installer supports the air conditioner on the outside of the door, remove the

10 remaining bolts (labeled A below). Remove the air conditioner.

5. Reverse order for installation. Replace PORON washers if they are damaged (Alpha P/N

684-020-10).

S

S S

–

S

A

A

A

A

–

S

A

A

A

A

A

A

Fig. 2-4, Shroud and Air Conditioner Bolts

27044-001-C0-003, Rev. C

Page 28

2.0 DCAirConditioner,continued

2.5 48/24VDCPowerConnection

Allow 20 minutes for completion of procedure.

Tools required: Assorted wrenches and screwdrivers

1. Install circuit breaker mounting plate in a convenient location near the 48/24VDC source

(see Fig. 2-5 below). Leave circuit breaker IN THE OFF POSITION.

2. Connect black wire leading from circuit breaker to the 48/24VDC Bus.

3. Connect the red wire to the ground/return bar.

The air conditioner can be positively or negatively grounded. The overcurrent protection

must be placed in the ‘Hot’ lead.

Circuit

Breaker

To Ground Return Bar

Fig. 2-5, Power Connections

To Circuit Breaker

28

044-001-C0-003, Rev. C

Page 29

2.0 DCAirConditioner,continued

2.6 Alarm Connector

1. Set major and minor alarm jumpers to the desired position.

2. Connect yellow wire (minor) and red wire (major) to status monitoring device.

Minor Alarm Jumper

Shown Normaly Closed

2.7 FunctionTest

1. Set the 48VDC Circuit Breaker to the ON position.

2. Remove SETPOINT jumper and verify fans are running. Compressor will start after 10

second delay.

3. Replace SETPOINT jumper and verify AC unit shuts down.

Major Alarm Jumper

Shown Normaly Closed

Fig. 2-6, Alarm Connections

SETPOINT Jumper

Fig. 2-7, Setpoint Jumper

29044-001-C0-003, Rev. C

Page 30

2.0 DCAirConditioner,continued

2.8 Jumpers

Enclosure Temperature Setpoint Jumper

Determines what temperature the system will maintain inside the enclosure. The diagram

below details the start and shutdown temperatures for each setting.

104°F/40°C

95°F/35°C

86°F/30°C

77°F/25°C

68°F/20°C

59°F/15°C

50°F/10°C

40° C Maximum Internal Temp.

38° C Startup

38° C Setpoint

34° C Shutdown

33° C Startup

33° C Setpoint

29° C Shutdown

28° C Startup

28° C Setpoint

24° C Shutdown

23° C Startup

23° C Setpoint

19° C Shutdown

18° C Startup

18° C Setpoint

14° C Shutdown

Remote Temperature Sensor Jumper

Determines where the control card gets its temperature information. In the LOCAL position

the card receives temperature information from its onboard temperature sensor. In the RMT

position, temperature information is received from an optional Remote Temperature Sensor

that can be placed anywhere in the enclosure.

Major and Minor Alarm Jumpers

Determines the state of the alarm relays in the non-alarm state. In the NO position, the nonalarm state is OPEN. In the NC position, the non-alarm state is CLOSED.

NOTE:

See Fig. 2-2 for jumper locations.

30

044-001-C0-003, Rev. C

Page 31

2.0 DCAirConditioner,continued

2.9 DC Air Conditioner Preventative Maintenance

A preventative maintenance check should be conducted on initial startup, and on a yearly

basis thereafter.

1. Check that the evaporator fans, located on the inside of the door, run continuously.

2. Remove temp setpoint jumper. Make sure the compressor comes on after 10 seconds.

3. Check for proper function of the outdoor condenser fans (located under the shroud on the

outside of the door). The outdoor condenser fans are controlled by the temperature of the

outdoor condenser coil. These fans should cycle on and off, or run continuously when the

setpoint jumper is removed. They may not turn on unless outdoor ambient is above 70ºF

(21ºC). As the outdoor condenser coil heats up, rst one fan and then the other cycles

on. If the unit is hot already, the fans turn on simultaneously, when the setpoint jumper is

removed. After ten seconds the compressor will turn on.

4. Using a DC clamp-on ampere probe, check the input current to the air conditioner while

the compressor is running. The 48VDC air conditioner should draw between 6A and

10.4A (10.4 FLA, Full Load Amps), for normal operation. The 24VDC air conditioner

should draw between 12A and 20.8A (20.8 FLA).

5. Replace setpoint jumper when functional check is complete.

6. Visually inspect the outdoor condenser coil with a ashlight. It should look clean and clear

of debris. If there is excess dirt build up, turn off circuit breaker, remove shroud and clean

it with soft brush or compressed air (be careful not to damage ns).

7. With a ashlight, visually inspect that the condensate drain is working and clear of debris.

There should be no excess water build up in the pan below the inside evaporator coil.

The evaporator coil should be offset far enough so water drips into the drain pan below,

and does not bead up on the edge of the door.

8. To complete the check, replace the setpoint jumper and all guards. Turn the circuit

breaker on.

31044-001-C0-003, Rev. C

Page 32

2.0 DCAirConditioner,continued

2.10 DC Air Conditioner Trouble Shooting

ATTENTION:

Contact Alpha Technical Service to determine proper diagnosis. See page 3 for contact information.

1. Check that wire connections and input voltage are correct.

2. Check the evaporator and condenser thermostat wires are not reversed. These are on

the inside of the evaporator box and look like telephone jacks. The evaporator sensor is

attached to the suction line inside the evaporator box. The condenser sensor goes to the

outside and attaches to the discharge line. Look on the front of the PCBA for silkscreen

connector label “EVAP” and “COND”. If these are reversed the condenser fans will not

turn on, and the circuit breaker will trip.

3. When the breaker is turned on, both evaporator fans should run continuously.

4. Verify the compressor comes on 10 seconds after pulling the setpoint jumper.

5. Watch the sight glass for bubbles. Bubbles should go to clear liquid after about a minute.

If there are no bubbles or liquid ow, or the moisture indicator shows wet and the bubbles

don't clear, there is low or no charge. This is not eld serviceable, and the unit should be

replaced.

6. Check the discharge line to see if it is warming up. Both condenser fans should come on

(rst one, then the other) when discharge line is above 104ºF (40ºC).

7. If unit control board indicates a yellow LED minor alarm, check for plugged outdoor

condenser or bad condenser fan.

8. If the unit control board indicates a red LED major alarm, the compressor may be over

heated or overloaded, or there is a bad three-phase connection to the compressor. Check

for a plugged outdoor condenser, or compressor overload.

9. Using a DC clamp-on ampere probe, check the input current to the air conditioner while

the compressor is running. The 48VDC air conditioner should draw between 6A and

10.4A (10.4 FLA, Full Load Amps), for normal operation. The 24VDC air conditioner

should draw between 12A and 20.8A (20.8 FLA).

10. Check the Delta-T across the evaporator coil. It should be between 9ºF and 18ºF (5ºC

and 10ºC).

11. The unit is overloaded if the FLA is too high and evaporator Delta-T is 9ºF (5ºC).

• Check heat dissipation load inside the cabinet.

• Check blocked condenser or bad condenser fans.

12 Check the suction line entering the compressor. It should be getting cooler. If it is not

getting colder, and the sight glass looks full or clear, there may be a refrigerant blockage

at the TX valve screen (this is not eld serviceable). Replace the unit and send it back

for evaluation and repair. To protect the unit from damage during shipping, use proper

packing to keep the unit in an upright vertical position.

32

044-001-C0-003, Rev. C

Page 33

2.0 DCAirConditioner,continued

2.11 DC Air Conditioner Parts List

Part Number Description

745-289-20 48VDC, 3000BTU replacement air conditioner assembly for Radium MiniBay

745-355-20 48VDC,150CFM outdoor condenser fan with sealed connectors

(qty 2 per unit)

500-074-10 48VDC,126CFM Inside Evaporator fan (qty 2 per unit)

704-713-20 48VDC, temperature control PCBA.

745-356-20 48VDC, controller inside fan assembly (contains 2 evaporator fans,

temperature control board, variable speed controller)

745-289-40 24VDC, 3000BTU replacement air conditioner assembly for Radium MiniBay

745-355-40 24VDC,150CFM outdoor condenser fan with sealed connectors

(qty 2 per unit)

500-087-10 24VDC,126CFM inside evaporator fan (qty 2 per unit)

704-713-21 24VDC, temperature control PCBA.

745-356-40 24VDC, controller inside fan assembly (contains 2 evaporator fans,

temperature control board, variable speed controller)

33044-001-C0-003, Rev. C

Page 34

3.0 AC Air Conditioner

IceQube AC Air Conditioner Overview, Basic Theory of Refrigeration:

1. The compressor pump draws in and compresses cool, low-pressure gas into a high pressure gas.

Compression raises the boiling point of the gas.

2. The hotter, high-pressure gas passes through a coil called a condenser. A fan blows air over the

coil which cools the gas into a liquid.

3. This high-pressure liquid passes through an expansion valve, where the liquid expands to boil off

as a gas. As the gas expands, it absorbs heat.

4. The cool low-pressure gas is sent through another set of coils called an evaporator or heat

exchanger. Warm interior air is blown over the coil and back into the interior, several degrees

cooler.

5. The low-pressure gas is then drawn into the compressor, where the cycle starts over. The

air conditioning system is actually three systems, which function simultaneously to maintain

environmentally friendly conditions for your equipment within the enclosure: The closed-loop cold

air system, warm air system, and vapor-compression refrigeration system.

The closed-loop cold air system circulates cold air from the cooling system to the electronics

enclosure. This air captures the heat and humidity within the enclosure and carries it through the heat

exchanger, the part of the vapor-compression system that removes the heat/humidity.

The vapor-compression refrigeration system is run by an efcient rotary compressor which circulates

NON-CFC refrigerant to transfer heat from the heat exchanger (evaporator) in the closed-loop air

stream to a condenser located in the warm air system. Heat from the enclosure transfers from the

warm air heat exchanger and dissipates to the ambient.

34

Air Filter Access

Fig. 3-1, AC Air Conditioner

044-001-C0-003, Rev. C

Page 35

3.0 ACAirConditioner,continued

3.1 VerifyingDefaultSettingsfortheIceQubeAirConditioner

Procedure:

1. Remove IceQube controller's access panel on the enclosure door shroud (2 screws).

2. Turn on the AC power.

3. Record the displayed temperature information.

4. Check the STATUS LEDs (On/Off/Blink):

• COOL - On if temperature is above 70ºF

• HEAT - On if temperature is below 32ºF

• ALM - Contact Alpha

• FILT - Turn off lter alarm (if on) and clean lter if needed

5. To enter programming mode, enter the default PIN code in sequence on the front panel

display. The code must be entered with less than 2 seconds between keystrokes.

• ADJUST up arrow (1)

• ADJUST down arrow (2)

• SELECT (3)

• EXIT (4)

6. The programming LEDs ashes, and a pattern of boxes appears in the digital display to

indicate program mode has been entered. If no selection is made within one minute, the

system returns to normal operating mode.

7. To verify or adjust the AC default parameters use the ADJUST up and down arrows.

Press SELECT to accept the current setting and cycle to the next.

8. Pressing the EXIT button saves setting changes and returns the unit to normal operating

mode.

Programming LED

Cooling Mode

Heating Mode

Digital Display

General Alarm

LED's Indicate Parameter Displayed

Filter Alarm

PIN

Fig. 3-2, AC Air Front Panel Display

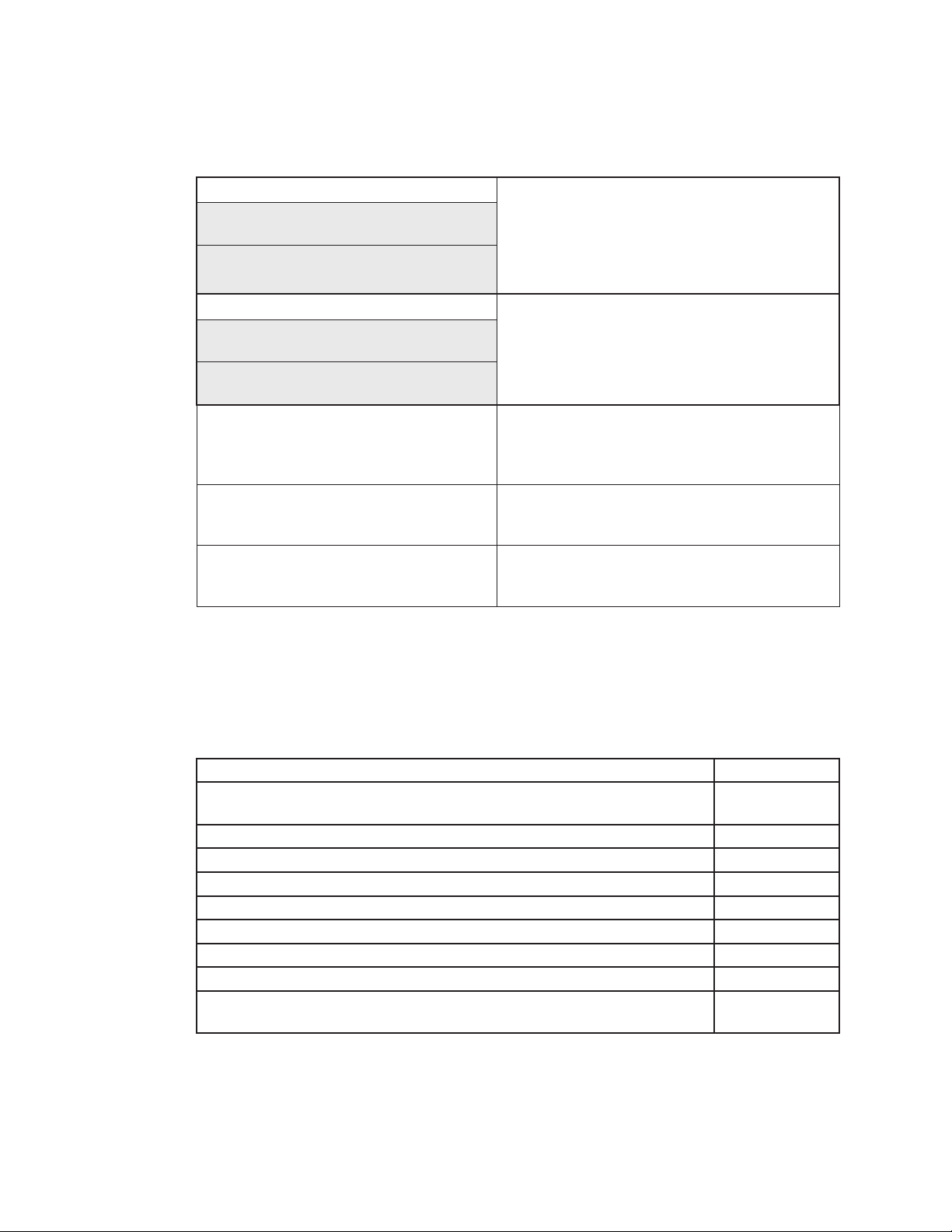

Default Settings

Parameter Default Setting

HI Temp set point: 72°F

LO Temp set point: Set to lowest limit (approx. 40°F)

HI Alarm set point: 100°F

LO Alarm set point: Set to lowest limit (approx. 33°F)

ALL: ON

AUD: OFF

-F-: Do not change

PIN: Do not change

FIL: 0.0 Days

Add: 0.0

35044-001-C0-003, Rev. C

Page 36

3.0, ACAirConditioner,continued

3.2 ACAirConditionerSpecications

Specications

Capacity 5000 BTUH (sensible) @ 43ºC ambient

Maximum Operating Temperature 125º F

Electrical 8.7A @ 120VAC/60HZ maximum

Microprocessor Controller Displays temperature in Fahrenheit and Celsius

Refrigeration System Efcient, long lasting rotary compressor

Evaporator Fan Lustran ABS 633 housing and squirrel cage

Condenser Fan Lustran ABS 633 housing and squirrel cage

4.3A @ 230VAC/60HZ maximum

4.8A @ 220VAC/50HZ maximum

UL/CUL recognized per UL50-File#SA12062 CE

Compliant

Programmable heating and cooling set points

Standard on/off differential 7º Fahrenheit

Programmable high/low temperature alarms

Condenser air lter maintenance indicator

Security programming access code

Integral EMI / RFI protection

24VAC input power

Operating status indicators for cooling, heating and

alarm conditions

Coil construction: Aluminum n with copper tube

Solid core 4 stage lter drier

Pressure balancing refrigerant ow control

HCFC refrigerant 22, Chlorodiuoromethane

Life lubricated ball bearing system

.05 HP shaded pole therm. protected motor

Maximum 247 CFM free air @120VAC/60HZ

Life lubricated ball bearing system

.05 HP shaded pole thermal protected motor

Maximum 247 CFM free air @120VAC/60HZ

36

044-001-C0-003, Rev. C

Page 37

3.0 ACAirConditioner,continued

3.3 AC Air Conditioner Condensate Hose Mounting

The MiniBay AC air conditioner comes with a condensate hose that must be secured to the

mounting pad. The hose may be run out the front or back of the pad, and should extend three

inches from the edge.

Tools Required:

• Rotary Hammer Drill with 1/4" bit

• Hammer

Procedure:

1. Locate the hose hardware kit (packaged with the battery cable kits).

2. Extend the hose out in the desired direction and position brackets.

3. Locate the anchor holes so the hose does not interfere with the door opening. Drill two

holes for the anchors into the pad.

4. Place anchors in anchor holes.

5. Run the pins through the brackets and hammer into the anchors.

6. Trim the hose to approximately three inches over the edge of the pad.

Pin

Washer

Bracket

Anchor

NOTE:

The condensate hose should have a minimum two-inch bend radius and should not kink when the door is

opened. Check the hose every six months for blockage or disconnection.

Fig. 3-3, Condensate Hose Mounting

37044-001-C0-003, Rev. C

Page 38

3.0 ACAirConditioner,continued

3.4 AC Air Conditioner Preventative Maintenance

Inspect the systems lters for replacement or cleaning every six months, depending on time

of year or environment. Clean the lters by back ushing with water in the direction indicated

and reinstall the lter. See page 3 for contact information.

NOTE:

Some environments may require more frequent inspections to maintain optimum airow.

3.5 AC Air Conditioner Troubleshooting

Contact Alpha Technologies Technical Support for troubleshooting procedures and warranty

issues. See page 3 for contact information.

3.6 Replacement or Spare 5000 AC Air Conditioner

Ice Cube 5000BTU AC Air Conditioner congured for Minibay:

KT,AIR COND,5K BTU/HR,230VAC,60HZ,RAD-MB, Alpha P/N 745-636-20

The IceQube Manual can be found on line at http://www.iceqube.com/pdf/manual.pdf

38

044-001-C0-003, Rev. C

Page 39

4.0 Site Preparation

4.1 Site Selection

Considerations:

• Where possible, select a site above the 100-year ood plain, and away from houses.

• Place in a shaded location to minimize the effects of solar loading.

• Locate in an area where airow can be maximized.

• Avoid locating the enclosure where it is an obstruction and would inhibit visibility.

• Locate the enclosure away from sprinkler systems or other sources of forced water.

• Locate the enclosure out of the prevailing wind to minimize the buildup of snow or the

accumulation of wind-borne dust.

• Evaluate the soil conditions for suitability for the installation of the required grounding

system applicable to your particular installation.

• Ensure cabling has been run and terminated at the site.

• Will the enclosure be placed on a precast concrete pad or on a pad poured on site?

• An enclosure with both front and rear doors is required for batteries with terminals located

on top. Allow for at least 36" of front and rear clearance so the door(s) may be opened

adequately for servicing.

• Contact a cable locating service, the local utility, and adjacent building supervisors

to ensure installation location and cable routing does not interfere with existing utility

connections.

NOTE:

Prior to paving the pad or placing cables and conduit, familiarize yourself with the location of the conduit

seals. The pad should include a rectangular sweep opening lled with drain rock to allow cables and conduit

to be maneuvered into position to enter the seals.

Fig. 4-1, Conduit Seal Location

39044-001-C0-003, Rev. C

Page 40

4.0 SitePreparation,continued

4.2 Precast Pads

The type of enclosure mounting pad is determined by the size of the enclosure (single bay,

single bay with side chamber, dual bay, dual bay with single side chamber, and dual bay

with dual side chambers). Typically, Alpha Technologies recommends using precast polymer

mounting pads. These pads are designed for proper cabinet support and ease of installation.

Drilling areas for openings are indicated for coax and service sweeps, and pre-installed

threaded inserts for enclosure attachment.

44" SYMM.

32" SYMM.

5-1/2"

27-3/4" SYMM.

4-5/8"

RAD-MB

.

MM.

" SYMM

SY

"

42" SYMM.

2-

1/

24" SYMM.

30

25-7/8

4"

Sweep Opening

8-1/2"

10-3/4"

Front of Pad

3-

5

/8

"

4-

1/

2"

Front of Pad

IN.

M

3"

40

Fig. 4-2, Precast Pad Dimensions for Single Enclosure

(P/N 641-110-10)

044-001-C0-003, Rev. C

Page 41

4.0 SitePreparation,continued

4.2 PrecastPads,continued

29.88"

28.62"

27.75"

26.48"

23.12"

FAR SIDE

FRONT OF

RAD-MB SC

Side Chamber

"

1.26

.000"

2.12"

4.38"

8.12

"

B

54.5"

42.5"

SYMM

.

ENCLOSURE OUTLINE

REFERENCE

A

A

RAD-MB

SYMM.

Sweep Openings

44.0"

32.0"

Front of Pad

AA

"

74"

2.

20.59"

8.69

14.59"

0.91"

24.91"

25.82"

"

000

.

Front of Pad

N.

MI

3.0"

Fig. 4-3, Precast Pad Dimensions for Single Enclosure with Side Chamber

(P/N 641-114-10)

41044-001-C0-003, Rev. C

Page 42

4.0 SitePreparation,continued

4.3 Pour-in-place Concrete Pads

Pad Frame Templates

NOTE:

The illustrations below show the overall size of the pad frame template for a single MiniBay enclosure. The

actual outer dimensions of the pad will be determined by the customer’s requirements. When placing the pad,

allow at least 36 inches of clearance for the front and rear doors to open fully.

29.25"

Front Rear

25.00" Ref.

Front Rear

25.82"

4.0"

(2 places)

4.0"

(2 places)

Fig. 4-4, Pad Frame Template for Single MiniBay Cabinet

Front

42

Rear

Fig. 4-5, Isometric View, Pad Frame Template, Single MiniBay

(P/N 604-039-N1)

044-001-C0-003, Rev. C

Page 43

4.0 SitePreparation,continued

4.3 Pour-in-placeConcretePads,continued

Pad Frame Templates

The illustration below shows the various components of the optional modular pourin-place pad template for a dual-cabinet application. Use template to easily and

accurately locate the open area for the AC service and TSC conduit as well as the

threaded inserts to which the cabinet is attached.

Base Pad Frame Template

(P/N 604

-039

-N1)

Side Chamber Conduit Locator

P/N 745-333-20

Fig. 4-6, Isometric View, Pad Frame Template, Single MiniBay with Side Chamber

Template for Second Enclosure.

Locator Bar for Second Pad FrameTemplate

Locator Bar for Second Pad Frame Template

Base Pad Frame Templ

(P/N 604-039-N1)

P/N 745-332-20

ate

Side Chamber Conduit Locator

P/N 745

-333-20

Fig. 4-7, Isometric View, Pad Frame Template, Dual MiniBay with Side Chamber

43044-001-C0-003, Rev. C

Page 44

4.0 SitePreparation,continued

4.3 Pour-in-PlaceConcretePads,continued

Pad Frame Templates

Figure 4-7 (below) provides the necessary dimensions to layout and pour a concrete

pad on site.

5-

2

3/4"

PL

1-

2

1/8"

PL

5-7/8" 2 PL

5-3/4" 2 PL

7/8" 2 PL

2

2

5

PL

"

SWEEP OPENING

see Section 4.0 Note

2

3-

PL

1

/

2

"

Front of MiniBay

E

TING

UN

2 PL

TH TEMPLAT

USED W I

ES

OL

UND H

L

RO

OBROUNDS USED FOR STUD MO

P

24-1/8" 2

7/8" 2 PL 7/8"

SWEEP OPENING

see Section 4.0 Note

4-1/8"

PAD

FRONT OF

30" 30" 12-1/2"

2-1/8" 2 PL 2-1/8" 2 PL

12-1/2"

44

2-

1/8"

1-

3/8"

1-

3

/

8

3

2

"

"

2-

1

/

8

"

Fig. 4-8, Footprint of Dual Enclosure, Dual Side Chamber System

(dimensions in inches)

044-001-C0-003, Rev. C

Page 45

4.0 SitePreparation,continued

4.4 SiteConguration

Figure 4-9 (below) shows the cable conduit route into the side chamber.

Front

of

Enclosure

C

D

E

A

B

C

D

E

A

B

PRE-CAST PAD

Precast Polymer Pad

Compacted Gravel (12" depth recommended

Level Grade

Area of Backlled Soil

Trench for Sweep (sweep enters back of cabinet)

Fig. 4-9, Typical Site Arrangement, (cabinet with optional side chamber)

NOTE:

Verify the conduit is trimmed 1" to 2" above the pad surface (for side chamber), or 1" to 4" for riser.

45044-001-C0-003, Rev. C

Page 46

4.0 SitePreparation,continued

4.4 SiteConguration,continued

Figure 4-10 (below) shows the cable conduit route into the back of the enclosure.

Back

C

D

E

A

B

C

A

B

PRE-CAST PAD

Precast Polymer Pad

Compacted Gravel (12" depth recommended

Level Grade

Front

Area of Backlled Soil

D

Trench for Sweep (sweep enters back of cabinet)

E

Fig. 4-10, Typical Site Arrangement, (stand-alone cabinet)

NOTE:

Verify the conduit is trimmed 1" to 2" above the pad surface (for side chamber), or 1" to 4" for riser.

46

044-001-C0-003, Rev. C

Page 47

4.0 SitePreparation,continued

4.5 Enclosure Grounding

NOTE:

Alpha Technologies recommends using the grounding method illustrated below. The grounding method for a

particular site is dependant upon soil type, available space, local codes, NEC (National Electric Code), and

other site-specic characteristics.

NOTE:

It is the responsibility of the installer to ensure the requirements of all applicable national and local codes are

met. Alpha Technologies assumes no responsibility or liability for failure of the installer to comply with the

requirements of all applicable local and national codes.

Lightning Protection (Optional)

• 1/2" x 8' copper ground rod, four places, driven about 2 feet (typical) from the corners of

the pad.

• #2 bare copper wire loop terminated to each ground rod and buried a minimum of 30

inches below grade. Corrosion-proof connections (25+ year life-span) and hardware

suitable for direct burial MUST be used.

• #2 bare copper wire from loop to the enclosure.

• When the electrical supply is a primary service (not a secondary or feeder service) a

#2 bare copper wire must bond the lightning protection loop to the Grounding Electrode

Conductor where they are closest.

• Service Grounding (required), #6 bare copper wire from Service Neutral/Ground Bar with

2 ground rods located 6' apart.

Connection made with Burndy connector

(P/N YGHR58C2W-3 or equivalent)

et

fe

)

2

in

(m

Enclosure Footprint

Terminate at enclosure ground

#2 AWG

Connection made with Burndy connector

(P/N YGHP58C2W-2TN or equivalent)

Fig. 4-11, Suggested Grounding

47044-001-C0-003, Rev. C

Page 48

5.0 Installation

This section describes the procedures for installing the enclosure and preparing it for turn-up and test.

The procedures are comprised of the following steps:

• Cabinet installation

• Battery installation and connection

• Utility power connection

Before installation verify the following:

• All necessary grounding rods and materials are in place.

• Utility power is onsite in accordance with NEC (National Electric Code).

• Review and comply with all local safety practices for working with high-voltage systems.

• All necessary permits and permissions are granted.

• The lifting/transport path is free of obstructions.

To perform the installation procedures, the installer(s) needs to have the following tools and materials

on hand:

• Crane to lift enclosure from shipping pallet and place on pedestal

• Key to enclosure doors (P/N 964-022-10 — Pin Allen type)

• Digital RMS voltmeter

• Torque wrench with insulated handle and 7/16" socket

• 7/16" box-end wrench

• NO-OX or other suitable corrosion inhibiting agent

• Battery Cabling Kit

• Silicone sealant (GE RTV123)

CAUTION!

The enclosure MUST be loosed from the pallet BEFORE lifting the enclosure from the truck and

placing it on the pad. Problems such as broken welds, corrosion, etc., resulting from improper

installation are not covered under warranty.

48

044-001-C0-003, Rev. C

Page 49

5.0 Installation,continued

5.1 Lifting

The enclosure is shipped from Alpha Technologies bolted to a wooden pallet. Follow the

procedure below for lifting and positioning the unit.

NOTE:

Remove the lifting ears after installation. The ears are made of steel and may rust over time.

Installation Procedure:

1. Unbolt the enclosure from the pallet. The bolts fastening the enclosure to the pallet are

located in the feet of the rack/rail assembly. They can be reached through the front and

rear doors of the enclosure or battery module (if applicable).

2. Remove the side chamber cable entry port seal plate (if equipped).

3. Position the 25-year vapor barrier material over the concrete pad, and make all

necessary cutouts.

WARNING!

Do not allow personnel to walk beneath the suspended unit during the lifting operation. Use

steel-toe work shoe protection. Use “hard hats” at all times during this procedure.

CAUTION!

Do not lift the enclosure with the batteries in place.

4. Attach the lifting chain to the lifting ears located in the top of the enclosure. Verify the

adjustable chain links are tightened securely. Also verify the length of the cable between

the liftng ears and the lifting hook (2d) is at least twice the distance (d) between the lifting

ears, and that the lifting angle of the chain is greater than or equal to 60 degrees.

2

DX

D

Fig. 5-1, Enclosure Lifting Arrangement

(without side chamber)

Fig. 5-2, Enclosure Lifting Arrangement

(with optional side chamber in place)

49044-001-C0-003, Rev. C

Page 50

5.0 Installation,continued

5.1 Lifting,continued

NOTE: