Page 1

PWE-6FT

Pole-mount Enclosure

Installation and Operation Manual

PWE-6FT

Effective: August, 2005

Alpha T echnologies

Page 2

Alpha Technologies

Power

®

Page 3

Installation and Operation

PWE-6FT

Pole-mount Enclosure

031-259-B0-001, Rev A

Effective Date: August, 2005

Copyright© 2005

Alpha Technologies, Inc.

member of the Group

Photographs contained in this manual are for illustrative purposes only . These photographs may not match your

installation.

TM

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this powering system, please contact Alpha T echnologies or

your nearest Alpha represent ative.

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with its

intended purpose, or is installed or operated in an unapproved manner, or improperly maint ained.

Contacting Alpha Technologies: www.alpha.com

OR

For general product information and customer service (7 AM to 5 PM, Pacific Time), call

1-800-863-3930,

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacific Time or 24/7 emergency support

3031-259-B0-001, Rev A

Page 4

T able of Contents

Important Safety Instructions!................................................................................................. 6

1.0 Introduction to the PWE-6FT Enclosure .................................................................... 11

1.1 Specifications................................................................................................ 11

1.2 Optional Features .......................................................................................... 13

2.0 Installation ................................................................................................................ 15

2.1 Wooden Pole Installation ............................................................................... 15

2.2 Steel/Concrete Pole Inst allation...................................................................... 17

2.3 Pedestal and Enclosure Installation................................................................ 19

2.3.1 Pedestal-mount Considerations .......................................................... 19

2.3.2 Pedestal Installation ............................................................................ 20

2.3.3 Installing Enclosure on the Pedestal .................................................... 21

2.4 En closu re Grou nding ..................................................................................... 22

2.4.1 Enclosure Grounding for Pole-mount Configurations ........................... 22

2.4.2 Enclosure Grounding for Pedestal-mount Configurations..................... 23

2.5 Connecting the Utility Power .......................................................................... 24

2.5.1 Wiring the Utility Service ..................................................................... 24

2.5.2 Wiring From Duplex Receptacle to Service Disconnect....................... 25

2.5.3 Connecting Coaxial Cable .................................................................. 30

2.6 Battery Installation.......................................................................................... 32

2.6.1 Battery T erminal Assembly Procedure................................................. 32

2.6.2 Battery Installation Procedure.............................................................. 33

2.7 Power Supply Installation ............................................................................... 34

2.8 Cooling Fan Installation.................................................................................. 35

3.0 Pole-mount Enclosure Maintenance.......................................................................... 36

4 031-259-B0-001, Rev A

Page 5

Figures and T ables

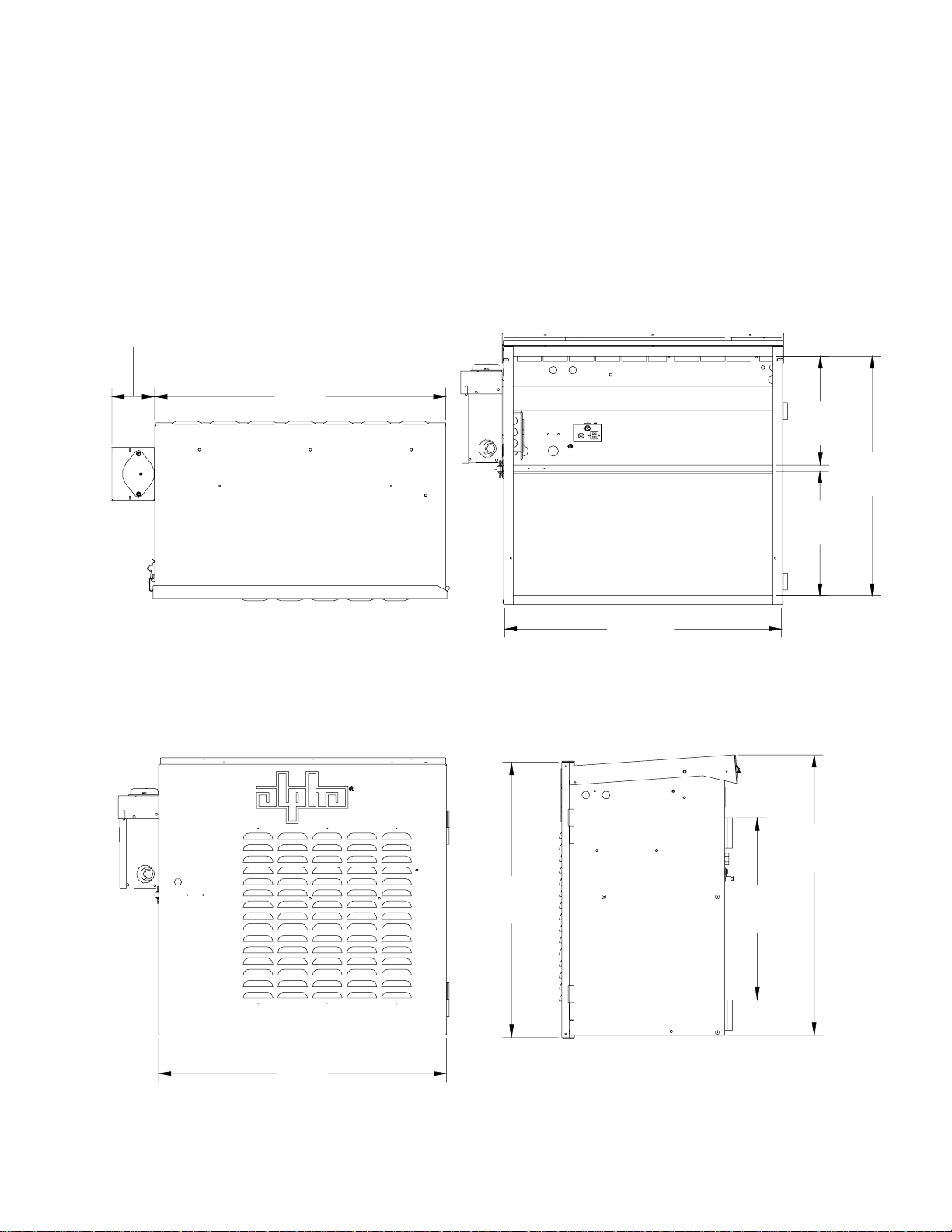

Fig. 1-1, PWE-6FT Views and Dimensions .......................................................11

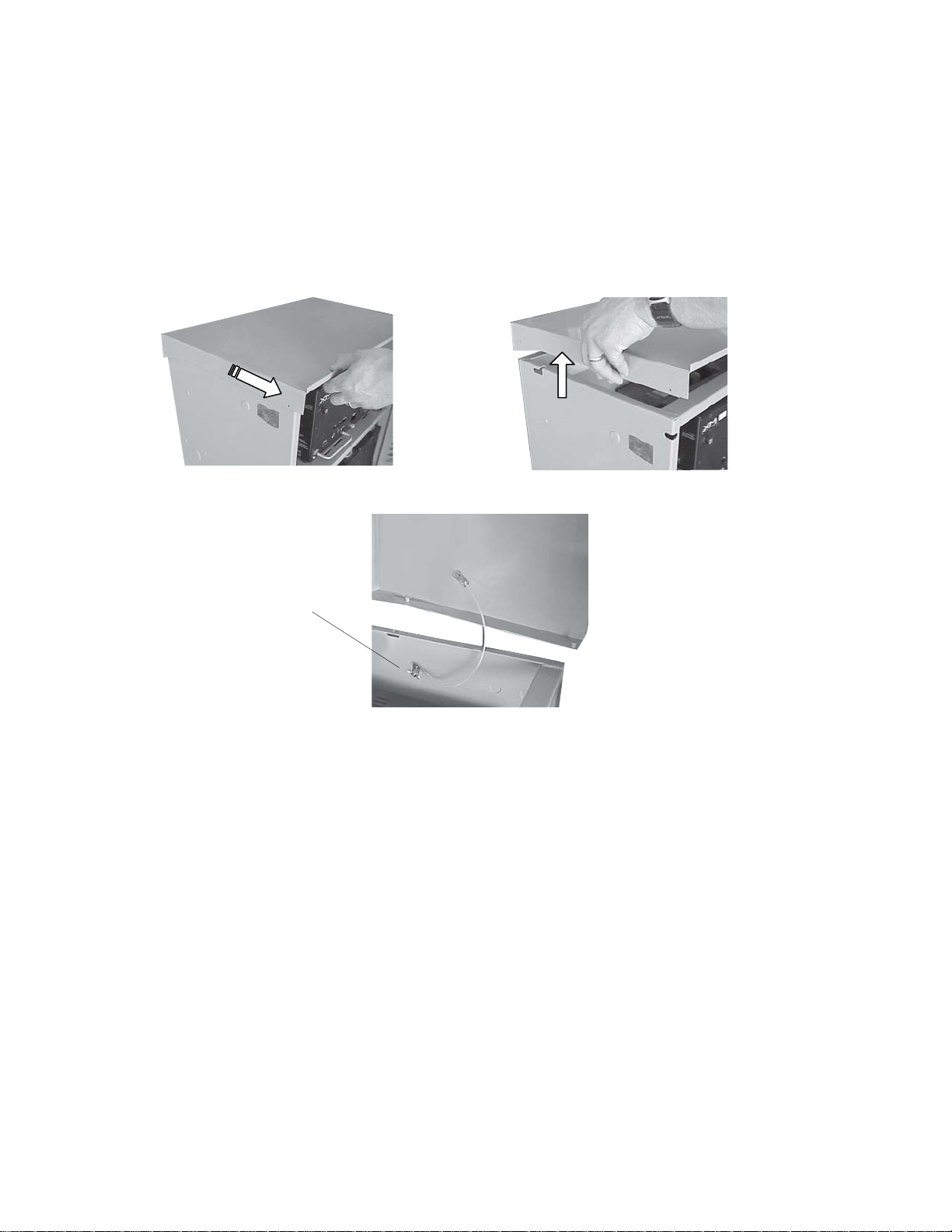

Fig. 1-2, PWE Enclosure Lid Removal .............................................................. 12

Fig. 2-1, PWE Series Pole-mount Enclosures (Wooden Poles).........................16

Fig. 2-2, PWE Series Pole-mount Enclosures

(Concrete and Steel Poles) ................................................................. 18

Fig. 2-3, Bollard Post Placement.......................................................................19

Fig. 2-4, Pedestal Installation ............................................................................ 20

Fig. 2-5, PWE-6FT Enclosure Mounted to Pedestal .......................................... 21

Fig. 2-6, Enclosure Grounding for Pole-mount Configuration..............................22

Fig. 2-7, Enclosure Grounding for Pedestal-mount Configurations ..................... 23

T able 2-1, Service Entrance Circuit Breaker Requirements.................................. 24

Fig. 2-8, T ypical Service Entrance Wiring .......................................................... 25

Fig. 2-9, Typical Receptacle Wiring...................................................................26

Fig. 2-10, T ypical BQO (Breaker Quad Option) Receptacle Wiring......................27

Fig. 2-1 1, PWE Pole Mount, 240V AC UL Wiring (030-051-C7-A)........................ 28

Fig. 2-12, PWE Pole Mount, 240V AC CSA Wiring (030-051-C8-A) .................... 29

Fig. 2-13, T ypical Ring Lug Assembly for Front Terminal Batteries, Single Lug ..... 32

Fig. 2-14, In-line Fuse Installation........................................................................33

Fig. 2-15, Battery Wiring Diagram.......................................................................33

Fig. 2-16, Cooling Fan Kit Installed......................................................................35

5031-259-B0-001, Rev A

Page 6

Important Safety Instructions!

Review the drawings and illustrations contained in this manual before proceeding. If there are any

questions regarding the safe installation or operation of the system, contact Alpha Technologies or the

nearest Alpha representative. Save this document for future reference.

T o reduce the risk of injury or death caused by electrical shock, explosion of fuel or moving parts; and

to ensure the continued safe operation of this product, the following symbols have been placed

throughout this manual. Where these symbols appear, use extra care and attention.

Symbols in this Manual

The use of ATTENTION is only for specific regulatory/code requirements that may affect the placement of

equipment and installation procedures.

A NOTE gives readers addtional information to help them complete a specific task or procedure.

A CAUTION presents safety information to PREVENT DAMAGE TO ALPHA or CUSTOMER’S EQUIPMENT. A

CAUTION tells you how to correctly perform a procedure or action and what could happen if you fail to follow

the the instructions.

A WARNING presents safety information to PREVENT INJURY OR DEATH to the technician/user. A W ARNING

tells you how to take specific safety precautions and then explains what may happen if those precautions are

not followed.

6 031-259-B0-001, Rev A

Page 7

Alpha T echnologies’ products are subject to change through continual improvement processes. Therefore,

specifications and/or design layouts may vary slightly from descriptions included in this manual. Updates

to the manual will be issued when changes affect form, fit or function.

General Safety Precautions

This enclosure and its associated hardware (power supply , batteries, cabling) may contain equipment,

batteries or parts which have accessible hazardous voltage or currents.

T o avoid injury:

• This enclosure and its associated hardware must be serviced only by authorized personnel.

• Enclosure must remain locked at all times, except when authorized service personnel are

present.

• Remove all conductive jewelry or personal equipment prior to servicing equipment, parts,

connectors, wiring, or batteries.

• Read and follow all installation, equipment grounding, usage, and service instructions included

in this manual.

• Use proper lifting techniques whenever handling enclosure, equipment, parts, or batteries.

• Batteries contain dangerous voltages, currents and corrosive material. Battery installation,

maintenance, service and replacement must be performed by authorized personnel only.

• Never use uninsulated tools or other conductive materials when installing, maintaining,

servicing or replacing batteries.

• Use special caution when connecting or adjusting battery cabling. An improperly connected

battery cable or an unconnected battery cable can result in arcing, a fire, or possible

explosion.

• A battery that shows signs of cracking, leaking or swelling must be replaced immediately by

authorized personnel using a battery of identical type and rating.

• Avoid any contact with gelled or liquid emissions from a valve-regulated lead-acid (VRLA)

battery . Emissions contain dilute sulfuric acid which is harmful to the skin and eyes.

Emissions are electrolytic, which are electrically conductive and are corrosive. Follow the

Chemical Hazards notes if contact occurs.

• Do not smoke or introduce sparks in the vicinity of a battery.

• Under certain overcharging conditions, lead-acid batteries can vent a mixture of hydrogen gas

which is explosive. Proper venting of the enclosure is required.

• Follow the battery manufacturer’s approved transportation and storage instructions.

7031-259-B0-001, Rev A

Page 8

Enclosure, equipment or parts may be damaged or cause damage if used or installed improperly .

T o avoid damage:

• Prior to installation, verify that the AC input voltage to the enclosure and it s equipment match

withrespect to voltage and frequency .

• Prior to installation, verify that the output voltage from the enclosure or its equipment match

the voltage requirements of the connected equipment (load).

• Prior to installation, verify that the enclosure’s utility service panel is equipped with a properly

rated circuit breaker for use with the equipment inside. Refer to manufacturer’s

recommendations.

• Review and upgrade utility service panel circuit breaker requirements whenever the equipment

within the enclosure is changed.

• Prior to installation, contact local utilities, local building maintenance departments, and cable/

piping locator services to ensure that installation does not interfere with existing utility or

building cables/piping.

• Do not exceed the output rating of equipment. Verify load requirement s prior and during

connection process.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge

thatmay have developed in your body .

Battery Safety Notes

Lead-acid batteries contain dangerous voltages, currents and corrosive material. Battery installation,

maintenance, service and replacement must be performed only by authorized personnel.

Chemical Hazards

Any gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery contain dilute

sulfuric acid, which is harmful to the skin and eyes. Emissions are electrolytic, which are

electrically conductive and corrosive.

T o avoid injury:

• Servicing and connection of batteries shall be performed by , or under the direct supervision of,

personnel knowledgeable of batteries and the required safety precautions.

• Always wear eye protection, rubber gloves, and a protective vest when working near batteries.

Remove all metallic objects from hands and neck.

• Batteries produce explosive gases. Keep all open flames and sparks away from batteries.

• Use tools with insulated handles, do not rest any tools on top of batteries.

• Batteries contain or emit chemicals known to the S tate of California to cause cancer and birth

defects or other reproductive harm. Battery post terminals and related accessories contain

lead and lead compounds. Wash hands after handling (California Proposition 65).

• If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow

your company’s approved chemical exposure procedures.

8 031-259-B0-001, Rev A

Page 9

Battery Safety Notes, cont.

• If any battery emission contacts the skin, wash immediately and thoroughly with water . Follow

your company’s approved chemical exposure procedures.

• Neutralize any spilled battery emission with the special solution contained in an approved spill

kit or with a solution of 1 lb. Bicarbonate of soda to 1 gal of water . Report chemical spill using

your company’s spill reporting structure and seek medical attention if necessary .

• Always replace batteries with those of an identical type and rating. Never install old or

untested batteries.

• Do not charge batteries in a sealed container . Each individual battery should have at least 0.5

inches of space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of

potentially dangerous gas.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge

that may have developed on your body .

• Never use uninsulated tools or other conductive materials when installing, maintaining,

servicing or replacing batteries.

• Use special caution when connecting or adjusting battery cabling. An improperly connected

battery cable or an unconnected battery cable can make contact with an unintended surface

that can result in arcing, fire, or possible explosion.

• A battery showing signs of cracking, leaking, or swelling should be replaced immediately by

Authorized Personnel using a battery of identical type and rating.

• Under extreme overcharging conditions, Lead-acid batteries can vent a mixture of Hydrogen

gas which is explosive.

Battery Maintenance Guidelines

The battery maintenance instructions listed below are for reference only . Battery manufacturer’s

instructions for transportation, installation, storage or maintenance take precedence over these

instructions.

• T o prevent damage, inspect batteries every 3 months for:

Signs of battery cracking, leaking or swelling. The battery should be replaced

immediately by authorized personnel using a battery of the identical type and rating.

Signs of battery cable damage. Battery cable should be replaced immediately by

Authorized Personnel using replacement parts specified by vendor .

Loose battery connection hardware. Refer to battery manufacturer’s documentation

for the correct torque and connection hardware for the application.

• Apply battery manufacturer’s specified antioxidant compound on all exposed connections.

• V erify battery terminals and/or exposed connection hardware is not within 2 inches of a

conductive surface. Reposition batteries as necessary to maintain adequate clearance.

• Clean up any electrolyte (battery emission) in accordance with all federal, state, and local

regulations or codes.

• Proper venting of the enclosure is recommended. Follow the Battery Manufacturer’s approved

transportation and storage instructions.

• Always replace batteries with those of an identical type and rating. Never install old or

untested batteries.

9031-259-B0-001, Rev A

Page 10

Mechanical Safety

• Keep hands and tools clear of fans. Fans are thermostatically controlled and will turn on

automatically.

• Power supplies can reach extreme temperatures under load.

• Use caution around sheet metal components and sharp edges.

Electrical Safety

• Lethal voltages are present within the power supply and electrical boxes. Never assume that

an electrical connection or conductor is not energized. Check the circuit with a volt meter with

respect to the grounded portion of the enclosure (both AC and DC) prior to any installation or

removal procedure.

• Do not work alone under hazardous conditions.

• A licensed electrician is required to install permanently wired equipment.

• Input voltages can range up to 240 V AC. Ensure that utility power is disabled before beginning

installation or removal.

• Ensure no liquids or wet clothes contact internal components.

• Hazardous electrically live parts inside this unit are energized from batteries even when the AC

input power is disconnected from the Mini-Bay .

Recycling and Disposal Instructions

Spent or damaged batteries are considered environment ally unsafe. Always recycle used batteries

or dispose of the batteries in accordance with all federal, state and local regulations.

• Do not charge batteries in a sealed container. Each individual battery should have at least 0.5

inches of space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of

potentially dangerous gas.

10 031-259-B0-001, Rev A

Page 11

1.0 Introduction to the PWE-6FT Enclosure

1.1 Specifications

The PWE-6FT enclosure accommodates six front-terminal batteries for broadband powering equipment

in pole-, wall-, or pedestal-mount configurations. The weight of the enclosure (empty) is 57 lbs (26kg).

4.26"

(10.9cm)

29.12"

(74cm)

11.14"

(28.3cm)

24.54"

(62.3cm)

12.78"

(32.5cm)

29.12"

(74cm)

27.46"

(69cm)

28.58"

(72.6cm)

27.76

(70.5cm)

18.0"

(45.7cm)

Fig. 1-1, PWE-6FT Views and Dimensions

11031-259-B0-001, Rev A

Page 12

1.0 Introduction to the PWE-6FT Enclosure, continued

1.1 Specifications, continued

The PWE series of enclosures have removable lids to facilitate installation of internal

components within the enclosure. The following photos are only for illustrative purposes.

PWE Lid Removal

1. Pull Out

Note: Lid can be completely

removed by releasing the provided

wing nut .

2. Pull Up

Lid Retention Strap helps prevent

enclosure lid from damage while

servicing the system.

Fig. 1-2, PWE Enclosure Lid Removal

12 031-259-B0-001, Rev A

Page 13

1.0 Introduction to the PWE-6FT Enclosure, continued

1.2 Optional Features

Options can be factory installed. Many of these options can be easily installed in the field by

the operator.

ACI (AC Indicator)

The AC Indicator (green lamp) is located next to the LRI lamp on the outside of the PWE/PME

Series enclosures. As long as there is volt age present at the output, the ACI lamp remains ON.

The ACI is a simple form of status monitoring which allows the operational status of the power

supply to be verified from the ground. The ACI-LL, long life LED is recommended, since it

provides much longer life than the original incandescent light bulb design. Models for 60V and

90V are available.

BHM (Battery Heater Mat)

The Battery Heater Mat is an AC line operated 150W heater mat which turns on at 40°F to

increase battery capacity in cold environments. BHM are available in 120V AC and 240V AC

versions.

ECF (Enclosure Cooling Fan)

The Enclosure Cooling Fan is a standby powered, thermostat controlled cooling fan system for

maintaining a cooler environment within the PWE Series enclosures. Alpha recommends the

enclosure cooling fan option for installations in extremely high temperature environments. The

fan is thermostatically controlled to turn on at 140°F/60°C, and off at 1 10°F/43°C. Replace the

fan fuse with a 1/4” X 1-1/4”, 5 Amp, 250 Volt fuse only (Alpha P/N 460-025-10).

LA-P+ (Lightning Arrester)

The LA-P+ Lightning Arrester consists of three Metal Oxide V aristors (MOV) and is plugged

directly into the enclosure’s convenience outlet, to provide additional protection from voltage

spikes caused by lightning and other power disturbances. The LA-P+ eliminates the need for

hard-wired MOVs, and no additional wiring is necessary . The LA-P+ 120 is used in 120V AC

applications, and the LA-PE+ 240 is used in 240V AC applications.

LRI (Local Remote Indicator)

The LRI lamp (red) is located on the outside of the PWE/PME Series enclosure. During normal

AC line operation, the lamp remains OFF. The lamp comes ON only when the power supply is

running in S tandby Mode. In the event that a major alarm is detected, the lamp flashes to

indicate service is required. The LRI is a simple form of status monitoring which allows the

operational status of the power supply to be verified from the ground.

MRC (Module Retaining Cable)

The Module Retaining Cable provides added security for the XM Series 2 power supply . It

attaches the unit to the PWE Series enclosure wall to prevent it from being inadvertently

knocked off of its shelf.

SPI (15A Service Power Inserter) and SPI-25 (25A Service Power Inserter)

The Service Power Inserter is required in all enclosures. The primary function of the SPI is to

provide a connection point between the Alpha power supply and the cable load. Additionally the

SPI can be used to bypass the power supply with a Service Power Supply . The SPI is rated for

15 amps output and is standard on the PWE/PME Series enclosures. The SPI-25 is the same

as the SPI but rated for 25 amps for use with higher output current power supplies.

13031-259-B0-001, Rev A

Page 14

1.0 Introduction to the PWE-6FT Enclosure, continued

1.2 Optional Features, continued

STH (Storm Hood Kit)

Enclosures equipped with the optional Storm Hood Kit of fer additional protection from possible

dirt and snow ingress. If the enclosure is equipped with Storm Hoods, Alpha recommends the

use of the ECF (Enclosure Cooling Fan).

TMPR SW (Tamper Switch)

The T amper Switch provides a magnetic door switch which plugs into the USM option for XM

power supplies and the USM2 for XM Series 2 power supplies. Most status monitoring systems

provide an alarm if the enclosure door is opened. Tamper Switches are available either as

normally open (NO) or normally closed (NC).

14 031-259-B0-001, Rev A

Page 15

2.0 Installation

The PWE-6FT can be mounted on wooden, concrete or steel utility poles. Most codes require the base

of the enclosure to be located a minimum height from the ground. Always verify height restrictions before

proceeding.

2.1 Wooden Pole Installation

Never transport the unit with batteries installed. Batteries must ONL Y be installed after the unit

is installed. Transporting the unit with installed batteries may cause injury to installer and/or

damage to enclosure and installed equipment.

Alpha recommends positioning enclosure on the opposite side of the pole from oncoming traffic. This can reduce

the danger caused by falling equipment in the event that a pole is struck by an automobile.

Mounting bolts must go completely through the wooden pole and be secured from the back with a large washer

and nut.

The majority of poles are the property of the local utility company . Before installing an enclosure, the location

and method of mounting must be approved by the utility company .

Materials required: (customer supplied)

• Two 5/8" diameter machine bolts (UNC thread); SAE (Grade 5 or better), length to suit pole

• Two 5/8" diameter zinc-plated flat washers

• Two 5/8" diameter hex nut s (UNC thread)

T ools required: (customer supplied)

• Auger or drill for boring 3/4" diameter holes in the wooden pole

• Mallet or hammer

• Assorted sockets or wrenches

Procedure:

1. Unpack the enclosure and galvanized brackets; turn the enclosure facedown on a soft

surface.

2. Slide one bracket up through the lower mounting straps on the rear of the enclosure. The

bracket’s flanges face away from the enclosure. Secure the lower mounting brackets using

the 3/8" x 3/4" hex bolt.

3. Mark the position for the upper mounting bracket on the utility pole. Drill a 3/4" hole

completely through the pole. Secure the bracket with a 5/8" machine bolt, washer and nut.

Do not fully tighten the bolt at this time.

4. Position the enclosure on the upper mounting bracket. It may be necessary to slightly rock

the enclosure and pull downward to properly seat it on the bracket. Center the enclosure on

the pole.

15031-259-B0-001, Rev A

Page 16

2.0 Installation, continued

2.1 Wooden Pole Installation, continued

5. Mark the hole for the lower mounting brackets. Lift the enclosure off the top bracket and drill

the lower hole. Sp acing between holes for enclosures is as follows:

PWE-6FT 18.0” on center

6. Slide the enclosure back into place over the top bracket. Align the lower bracket with the

hole and secure it with a 5/8" machine bolt, washer and nut. Tighten both brackets until the

flanges seat into the wood.

The enclosure is now ready for the utility connection, power module and batteries.

Upper Mounting Bracket

Nut & Washer

5/8" Bolts

Cable Power Out

ACI, LRI Options

Generator Access Port

Chassis Ground

Utility Power In

18"

3/8" X 3/4" Hex Bolt

Lower Mounting Bracket

Fig. 2-1, PWE Series Pole-mount Enclosures (Wooden Poles)

16 031-259-B0-001, Rev A

Page 17

2.0 Installation, continued

2.2 Steel/Concrete Pole Installation

Never transport the unit with batteries installed. Batteries must ONL Y be installed after the unit

is installed. Transporting the unit with batteries inst alled may cause injury to installer and/or

damage to enclosure and installed equipment.

Alpha recommends positioning enclosure on the opposite side of the pole from oncoming traffic. This can reduce

the danger caused by falling equipment in the event that a pole is struck by an automobile.

The majority of poles are the property of the local Utility . Before installing an enclosure, the location and method

of mounting must be approved by the Utility .

Materials required: (customer supplied)

Two (2) pole strap s to fit pole (straps must be stainless, galvanized or equivalent).

T ools required: (customer supplied)

Assorted sockets or wrenches

Procedure:

1. Unpack the enclosure and galvanized brackets; turn the enclosure facedown on a soft

surface.

2. Slide a bracket up through the enclosure’s lower mounting strap(s). The bracket’s flanges

must face away from the enclosure. Secure the lower mounting bracket(s)

using the 3/8" x 3/4" hex bolt included.

3. Position the upper mounting bracket on the pole and secure using a pole strap.

4. Lift the enclosure onto the upper mounting bracket and pull downward to properly seat it.

Center the enclosure on the pole.

5. Secure the lower mounting brackets on the pole using a pole strap. S pacing between

mounting straps for enclosure is as follows:

PWE-6FT 18.0” on center

The enclosure is now ready for the utility connection, power module and batteries (see following

page).

17031-259-B0-001, Rev A

Page 18

2.0 Installation, continued

2.2 Steel/Concrete Pole Installation, continued

Pole Straps

(Customer Supplied)

18"

Upper Mounting Bracket

Cable Power Out

ACI, LRI Options

Generator Access Port

Chassis Ground

Utility Power In

3/8" X 3/4" Hex Bolt

Lower Mounting Bracket

Fig. 2-2, PWE Series Pole-mount Enclosures (Concrete and Steel Poles)

(Configurations may vary .)

18 031-259-B0-001, Rev A

Page 19

2.0 Installation, continued

2.3 Pedestal and Enclosure Installation

A concrete pad must be in place prior to installing the pedestal. The installer must supply the

following materials to install the pedestal (P/N 745-677-20):

• Four (4) 1/2” anchor bolts (Hilti style-P/N 745-592-21)

• Four (4) 1/2” stainless steel washers

Required tools:

• Hammer drill • Metal punch

• 1/2” drill bit • Mallet or hammer

• 1/2” wrench • Torque wrench

• T ape measure

The following are general considerations to make prior to installing a ground-mounted enclosure:

• Do not install enclosure within 10 feet of a water sprinkler

to prevent water from entering enclosure.

• Ensure the enclosure is outside flood plain boundaries.

• Position the enclosure to prevent wind-driven snow and

drifts from blocking the vents.

• In hot climates, position the enclosure to maximize

afternoon shade.

2.3.1 Pedestal-mount Considerations

Alpha Technologies, Inc. cannot anticipate all of the ways a vehicle may potentially

threaten an installed system or the specific type of protection that is appropriate for a

particular location. Determining the threat to the equipment and the means of protection are the responsibility of the end user of the equipment and the authority having

jurisdiction. The following installation drawing for Alpha’s S tandby Power systems are

general recommendations and not intended to be a specific guideline for protecting the

equipment. The numbers of Bollard posts (or other protection devices) depend upon

equipment locations, site surveys, traffic patterns and local codes.

PAD

POSTS

10' Min.

Sprinkler

Head

SIDEWALK

Fig. 2-3, Bollard Post Placement

19031-259-B0-001, Rev A

Page 20

2.0 Installation, continued

2.3.2 Pedestal Installation

1. Place vapor barrier material on pad. The vapor barrier material (such as 30lb felt,

neoprene pond liner, or a heavy grade t ar paper) should initially extend six (6)

inches beyond the perimeter of the pedestal. It can be trimmed closer to the

pedestal after installation.

2. Using the pedestal as template, mark the location for installing the 1/2” anchor

bolts.

3. Position pedestal over mounting holes and insert anchor bolts.

4. T orque anchor bolt s to bolt manufacturer’s specifications. If using Hilti bolts, torque

until heads pop.

5. Trim vapor barrier material.

Optional AC Service

Mounting Location

28"

(71.12cm)

Optional SPI

Mounting Location

7.85"

(19.94cm)

Cover removed

for clarity

21 .725"

(55.18cm)

O .6" (1.5cm)

Pedestal Mounting Holes

18"

(45.72cm)

23.5"

(59.7cm)

Pedestal

(36.3cm)

6" Pad Overlap

14.3"

Fig. 2-4, Pedestal Installation

20 031-259-B0-001, Rev A

Page 21

2.0 Installation, continued

2.3.3 Installing Enclosure on the Pedestal

Never transport or move the pedstal or enclosure with batteries installed. Batteries must ONL Y

be installed after pedestal/enclosure installation. T ransporting with batteries installed may

cause injury to installer and/or damage to enclosure and installed equipment.

Before bolting the PWE-6FT enclosure to the top of the pedestal:

1. Locate and remove the four knockouts located at the bottom of the PWE-6FT

enclosure.

2. Place the empty enclosure on top of the pedestal and align the knockouts with the

bolt holes on the top of the pedestal.

3. Insert the four (included) 1/4” stainless steel bolts and washers and tighten.

Enclosure footprint

Fig. 2-5, PWE-6FT Enclosure Mounted to Pedestal

21031-259-B0-001, Rev A

Page 22

2.0 Installation, continued

2.4 Enclosure Grounding

2.4.1 Enclosure Grounding for Pole-mount Configurations

Alpha T echnologies recommends using the grounding method illustrated below . The grounding method for a

particular site will be dependent upon available space, local codes, NEC (National Electric Code), and other sitespecific characteristics.

Alpha Technologies assumes no responsibility or liability for failure of the installer to comply with the

requirements of all applicable local and national codes.

Power Meter

QUARTZ

0015

HOURS

HOUR METER

VOLTS AMPS

FAULT RESET 48V

RESET

36V

36/48 VDC Output

8” Ground Rod

#8 A WG (Minimum) Copper Wire Ground

Fig. 2-6, Enclosure Grounding for Pole-mount Configuration

22 031-259-B0-001, Rev A

Page 23

2.0 Installation, continued

2.4 Enclosure Grounding, continued

2.4.2 Enclosure Grounding for Pedestal-mount Configurations

Alpha T echnologies recommends using the grounding method illustrated below . The grounding method for a

particular site will be dependent upon soil type, available space, local codes, NEC (National Electric Code), and

other site-specific characteristics.

Alpha Technologies recommends 5 ohms maximum ground resistance between enclosure and ground rods, in

accordance with IEEE 1 100-1999 Powering and Grounding Electronic Equipment.

Alpha T echnologies assumes no responsibility or liability for failure of the inst aller to comply with the requirements

of all applicable local and national codes. Where allowed, exothermic welding may be used as an alternative to

Burndy clamps and connectors.

Connection made with Burndy c onnect or

(P/N YGHR58C2W-3 or equivalent)

Terminate at enclosure ground

Terminate at service

entrance ground

4

Enclosure Foo tprint

#6 AWG

t

e

e

f

)

2

n

i

m

(

1

#2 AWG

Two (2) 8' ground rods 6' apart minimum.

Note: May require additional ground rods to meet

NEC minimum grounding standard (25 Ohms or

less).

2

Fig. 2-7, Enclosure Grounding for Pedestal-mount Configurations

Service Grounding (required)

1 #6 bare copper wire from Service Neutral/Ground Bar with 2 ground rods located 6' apart.

Lightning Protection (optional)

2 1/2" x 8' copper ground rod, four places, driven about 2 feet (typical) from the corners of the pad.

3 #6 bare copper wire loop terminated to each ground rod and buried below grade 30 inches min.

Corrosion-proof connections (25+ year life-span) and hardware suitable for direct burial MUST be

used.

4 #6 bare copper wire from loop to the enclosure.

Connection made with Burndy connector

(P/N YGHP58C2W-2TN or equivalent)

3

23031-259-B0-001, Rev A

Page 24

2.0 Installation, continued

2.5 Connecting the Utility Power

The following procedure must only be performed by qualified service personnel and in compliance with local

electrical codes and common safety practices. Connection to utility power must be approved by the local utility

before installing the power supply .

UL and NEC require that a service disconnect switch (UL listed) be provided by the installer and be connected

between the power source and the ALPHA power supply . Connection to the power supply must include an

appropriate service entrance weather head.

2.5.1 Wiring the Utility Service

Utility power enters the enclosure through a 1-1/8" opening at the bottom or rear of the

PWE series, or through an optional breaker box. The enclosures accept a standard

electrical fitting.

A “high-magnetic” trip circuit breaker must be used in order to accommodate the high-inrush currents normally

associated with the start-up of ferroresonant transformers (400 Amp, no-trip, first-half cycle). Do not replace this

circuit breaker with a conventional service entrance circuit breaker. Alpha recommends Square D circuit

breakers for 120V installations, and HACR breakers for 240V installations .

Alpha T echnologies of fers a high-magnetic Square D circuit breaker and a BBX option (a UL Listed service

entrance). Contact your local sales representative for more information.

Description

240V Installation — HACR (15A)

120V Installation — High-magnetic (20A)

120V Installation — High-Magnetic (15A)

BBX — External Service Disco nnect

Alpha Part Number Square D Part Number

470-224-10

470-017-10

470-017-10

470-013-10

020-085-10

QO215

QO120HM

QO115HM

QO2-4L70RB

QO8-16L100RBBBX — External Service Disconnect 020-141-10

T able 2-1, Service Entrance Circuit Breaker Requirements

24 031-259-B0-001, Rev A

Page 25

2.0 Installation, continued

2.5 Connecting the Utility Power, continued

2.5.2 Wiring From Duplex Receptacle to Service Disconnect

In most cases, the following configurations (see next page) qualify for service entrance

use, however, other codes may apply. Always contact your local utility to verify that

the wiring conforms to applicable codes.

240V AC Service (XM Series 2 915-240 Power Supply) Enclosures used with the XM

Series 2 915-240 are equipped with a 240V AC duplex receptacle to provide power to

the power supply and peripheral equipment. The receptacle, NEMA 6-15R, is protected

by a single, 2-pole, common trip 15 Amp circuit breaker located inside the service

entrance. Wiring is typically 14AWG per NEC code, a grounding clamp, located on the

enclosure, facilitates dedicated grounding.

120V AC 20A Service (XM Series 2 915-120 Power Supply):

Enclosures used with the XM Series 2 915-120 are equipped with a 120V AC duplex

receptacle to provide power to the power supply and peripheral equipment. The receptacle, NEMA 5-20R, is protected by a single, 1-pole, 20 Amp circuit breaker located

inside the service entrance. Wiring is typically 12AWG per NEC code, a grounding

clamp, located on the enclosure, facilitates dedicated grounding.

120V AC 15A Service (XM Series 2 615 Power Supply):

Enclosures used with the XM Series 2 615 are equipped with a 120V AC duplex

receptacle to provide power to the power supply and peripheral equipment. The receptacle, NEMA 5-15R, is protected by a single-pole, 15 Amp High Magnetic circuit

breaker located inside the service entrance. Wiring is typically 14AWG per NEC code,

a grounding clamp, located on the enclosure, facilitates dedicated grounding.

Alpha recommends wiring with 12AWG, in the event that the enclosure will be upgraded to use 90V power

supplies.

When required to bond the box to the neutral plate, use the long green bonding screw provided with the box:

Alpha P/N 523-01 1-10 or Square D P/N 40283-371-50.

L1 (blac k)

Copper ground wire

#8 AWG (minimum)

grounding point made

to enclosure wall

L1 (black)

120VAC Servi ce En tr a nc e W iring

breaker

to utility

neutra l (white)

neutra l bus

to enclosure

receptacle

L1 (black)

Copper ground wire

#8AWG (minimum)

made to enclosure

L2 (red)

breaker

Grounding point

wall

L1

L2

Typical 240VAC Service Entrance Wiring

to utility

neutral (white)

neutral bus

to enclosure

receptacle

Fig. 2-8, Typical Service Entrance W iring

25031-259-B0-001, Rev A

Page 26

2.0 Installation, continued

(

)

(

)

2.5.2 Wiring From Duplex Receptacle to Service Disconnect, continued

L1

(black)

neutral

(white)

120VAC/15 Amp Receptacle -- 5-15R

P/N 531-003-10

ground

(green)

L1

(black)

neutral

(white)

120VAC/20 Amp Receptacle -- 5-20R

P/N 531-006-10

ground

(green)

L1

(black)

L2

(red)

ground

(green)

240VAC/15 A Recepta cle – 615R

(p/n 53 1- 004-10)

Fig. 2-9, T ypical Receptacle Wiring

26 031-259-B0-001, Rev A

Page 27

2.0 Installation, continued

2.5.2 Wiring From Duplex Receptacle to Service Disconnect, continued

Ground

Line 2

Line 1

ON

OFF

BQO 240V, 15A

Neutral

Ground

Line

ON

OFF

BQO 120V, 20A

Neutral

Ground

Line 2

Line 1

ON

OFF

BQO 240V, 120V

Fig. 2-10, T ypical BQO (Breaker Quad Option) Receptacle Wiring

Neutral

Ground

Line

OFF

ON

ON

OFF

BQO 120V, 20A

Dual Receptacle,

Dual Breaker

27031-259-B0-001, Rev A

Page 28

2.0 Installation, continued

2.5.2 Wiring From Duplex Receptacle to Service Disconnect, continued

15' MIN

(4.6m)

5'6"

(1.7m)

SERVICE DROP

CABLE

OUTPUT

UTILITY

GROUNDING

CLAMP

UTILITY POWER

METER

SERVICE ENTRANCE

INPUT

METER

NEUTRAL

LINE 1

SERVICE ENTRANCE

LINE 1

CIRCUIT BREAKER

(SQUARE D Q0220)

GROUND

NEUTRAL

GROUND

LINE 1

NOTE:

PLEASE CONSULT LOCAL

UTILITY COMPANY FOR

INSTALLATION REQUIREMENTS

AND CODES.

METER SOCKET

CLAMPS

GROUND

LINE 2

LINE 2

NEUTRAL

ON

20

OFF

NEUTRAL BUS

LINE 2

GROUND CLAMP

#8 AWG (MINIMUM) COPPER GROUND WIRE

8' GROUND ROD

Fig. 2-1 1, PWE Pole-mount, 240V AC UL Wiring

28 031-259-B0-001, Rev A

Page 29

2.0 Installation, continued

2.5.2 Wiring From Duplex Receptacle to Service Disconnect, continued

15' MIN

(4.6m)

5'6"

(1.7m)

SERVICE DROP

CABLE

OUTPUT

UTILITY

GROUNDING

CLAMP

UTILITY POWER

INPUT

METER

SERVICE ENTRANCE

LINE 1

SERVICE ENTRANCE

LINE 1

GROUND BUS

CIRCUIT BREAKER

(SQUARE D Q0220)

GROUND

NEUTRAL

LINE 1

METER

NEUTRAL

NOTE:

PLEASE CONSULT LOCAL

UTILITY COMPANY FOR

INSTALLATION REQUIREMENTS

AND CODES.

METER SOCKET

CLAMPS

GROUND

LINE 2

LINE 2

NEUTRAL

ON

20

OFF

NEUTRAL BUS

LINE 2

GROUND CLAMP

#8 AWG (MINIMUM) COPPER GROUND WIRE

Drawing No. 030-051-C8 (A)

8' GROUND ROD

Fig. 2-12, PWE Pole-mount, 240V AC CSA Wiring

Alpha offers a Meter Convenience Assembly (MCA) as a cost-effective alternative to building an

assembly on-site. The MCA is a factory configured pole mount meter and service disconnect

with integral bracket. It also provides consistent installations for metered pole mount power

systems.

T o order the MCA with an alternate meter (e.g., universal meter base) please contact your

Alpha representative.

Product Description: Part Number:

Meter assembly with mounting plate, Euserc meter base

• FBX (20 Amp fuse kit included) 745-126-20

• 100 Amp BBX 745-126-21

• 70 Amp BBX 745-126-22

29031-259-B0-001, Rev A

Page 30

2.0 Installation, continued

2.5 Connecting the Utility Power, continued

2.5.3 Connecting Coaxial Cable

T o prevent injury , DO NOT remove SPI cover until all sources of power have been removed.

1. V erify SPI IS NOT connected to power supply .

2. Remove the two screws holding cover onto SPI chassis.

3. Remove SPI cover , exposing circuit board and seizure screw assembly.

1

Seizure

Screw

Assembly

2

3

4. Insert Coaxial T ermination into Output Port on bottom of SPI.

Circuit

Board

Seizure Screw

Assembly

Stinger

4

Side View

SPI Case

Output Port

of

Coaxial Termination

30 031-259-B0-001, Rev A

Page 31

2.0 Installation, continued

2.5 Connecting the Utility Power, continued

2.5.3 Connecting Coaxial Cable, continued

5. Insert coaxial termination fully inside Seizure Screw assembly and tighten Seizure

Screws to 35 Inch-Pounds to prevent arcing and failure of unit.

5

6. Replace SPI cover and reinstall the screws.

7. Verify switch on top of SPI is in the ON

position.

7

6

ALT ON

6

31031-259-B0-001, Rev A

Page 32

2.0 Installation, continued

2.6 Battery Installation

2.6.1 Battery Terminal Assembly Procedure

This illustration shows the typical battery terminal assembly for front terminal battery

posts. Torque rating for all terminals is 60 in-lbs (6.5nM).

Bolt

Lock Washer

Flat Washer

Ring T erminal

Threaded Battery Post

Fig. 2-13, T ypical Ring Lug Assembly for Front T erminal Batteries, Single Lug

2.6.2 Battery Installation Procedure

1. Place the batteries, with the terminals oriented toward the front of the enclosure on

the battery shelf (see Fig. 2-15). Use the battery manufacturers’ recommended

spacing between batteries for maximum ventilation space.

2. For ease of identification and future record keeping, number batteries using labels

or masking tape. Record each battery's number and date code in the power supply

maintenance log

3. Connect the batteries in series to achieve 36VDC. You must install the batterymounted fuse in either single or dual 36VDC series (see Fig. 2-15).

V erify battery polarity and install battery jumper bars after attaching all terminals to respective terminal post s

4. Use a voltmeter to verify polarity and DC voltage at the module’ s battery connector.

5. The power supply battery charger utilizes a Remote Temperature Sensor (RTS) to

provide precise battery temperature compensation information. Using high strength

tape, attach the sensor to the center of the middle battery about 2/3 of the way up

from the base of the battery . Route the RTS connector into the power supply

compartment. DO NOT connect the RTS to the power supply at this time.

6. Route the battery cable connecter into the power supply compartment.

The cables are marked with a RED sleeve to indicate the (+) positive battery terminal.

The In-line Fuse is required for single or dual battery string installation. See Fig. 2-14.

32 031-259-B0-001, Rev A

Page 33

2.0 Installation, continued

2.6 Battery Installation, continued

2.6.2 Battery Installation Procedure, continued

Never allow live battery cables to contact the chassis whenever making or breaking battery

connections. Ifnecessary, wrap the lugs with electrical tape to prevent arcing and temporarily

disconnect one of the leads from the center battery . Ensure the battery string volt age and polarity are

correct before proceeding.

Recheck the battery string voltages and polarity at the connectors leading into the power supply.

DO NOT connect the batteries to the power supply at this time!

Connects to XM2

Power Supply

1A 2A 3A 1B 2B 3B

RTS Connection

Dual String

Neg. Connection (36VDC)

Single String (36VDC)

Fig. 2-14, In-line Fuse Installation

Single String

Pos. Terminal

Dual String

Pos. Terminal

top of battery

Dual String (36VDC)

Buss

Dual String

Pos. Connection (36VDC)

Bolt

Lock Washer

Flat Washer

Isolation Washer

Fuse

Nickel-plated Brass Washer (required)

Threaded Battery Post

Fig. 2-15, Battery Wiring Diagrams (viewed from the top)

Battery Cable Kit P/N 745-759-21 (shown)

33031-259-B0-001, Rev A

Page 34

2.0 Installation, continued

2.7 Power Supply Installation

These instructions are included only as reference.

1. Before installation; Inspect the power supply for damage, loose connectors, or other

potential failures. Correct discrepancies before proceeding.

2. Place the XM Series 2 Power Supply on the appropriate enclosure mounting shelf. For the

PWE-6FT , it is the upper-right comp artment of the enclosure.

3. Switch the BA TTERY BREAKER to OFF . This will prevent the inverter from starting when

the batteries are first connected to the XM Series 2 power supply .

4 Batteries are an important part of the XM Series 2 Power Supply. It is mandatory to properly

install and test all batteries, battery connections, and battery cables before connecting to

the power supply . For complete battery inst allation procedures, see Section 2.6.2 “Battery

Installation Procedure,” of this manual.

5. After the batteries, battery connections, and battery cables have been verified to be in good

working order, plug the quick connect s from the battery cable into the power supply’s

BA TTERY INPUT connector . The connector is keyed and color-coded to fit in one direction

only .

6. Plug the Remote Temperature Sensor into the TEMP PROBE connector located on the

Inverter Module assembly . Route the sensor end of the cable into the battery compartment.

7. If the optional LRI lamp (Local / Remote Indicator) is included, plug the LRI cable into the

LRI connector.

8. If status monitoring is used, plug the tamper switch into the 2-pin TMPR connector , and

plug the transponder cable into the connection on the transponder.

9. Plug the connector from the SPI(s) into the module's “OUTPUT 1” and (optional) “OUTPUT

2” connector(s). Make sure that the SPI’s “ALT/ON” switch is in the ON position.

If the installation includes an ACI lamp option, plug the lamp’s connector into the module's “AC OUTPUT”; then

plug the SPI into the second connector on the ACI.

If the installation includes a Module Retaining Cable option, attach end of cable at hole provided in top rear

center of enclosure; then thread strap through XM Series 2 handle and clip strap back on itself.

10. Installation is complete. DO NOT switch ON the Inverter Module’s BA TTERY BREAKER, or

apply AC power to the power supply. Refer to the power supply Operator’s Manual for Startup and T est procedures.

34 031-259-B0-001, Rev A

Page 35

2.0 Installation, continued

2.8 Cooling Fan Installation

T o prevent the possibility of injury to service or emergency personnel, always follow the next

procedure to safely shutdown the power supply .

T o shut down the power supply:

1. Turn the battery breaker to OFF.

2. Unplug the AC Input Line Cord from the service entrance.

3. Unplug both the Output 1 and Output 2 connections. If applicable,

unplug the N+1 connections at this time.

This procedure will require a service power supply (for example, an APP 9015S or APP 9022S) to maintain

power to the cable plant. Connect via the SPI and output switch.

Tools Required: Phillip s Screwdriver

Installation Procedure:

1. Identify enclosure fan installation location at upper rear of enclosure.

Locate two holes designated for fan assembly .

2. Attach fan assembly to enclosure using the two #6-32 x 3/8" Phillips screws provided.

3. Plug one end of Y cable into SPI wire.

4. Plug other end of Y cable into power supply output connection.

5. Position thermostat away from power supply , as shown.

1.

2.

3.

5.

4.

Fig. 2-16, Cooling Fan Kit Installed

This kit does not fit PWE models manufactured before April 2002.

35031-259-B0-001, Rev A

Page 36

3.0 Pole-mount Enclosure Maintenance

Preventive Maintenance must be performed every three to six months. By establishing a routine

maintenance program and following the guidelines contained in this manual, the Pole-mount Enclosure

will continue to provide years of trouble free operation.

Inspect the Pole Mount Enclosure

Perform a complete inspection of the Pole-mount Enclosure. Look for signs of rust and corrosion,

paying particular attention to the battery trays. Clean any rust or corrosion immediately .

Inspect the Mounting Brackets and Hardware

Carefully inspect the Pole-mount Enclosure’s Mounting Bracket and mounting hardware. Look for signs

of unusual wear and loose hardware. Correct all mounting hardware failures immediately.

Check Battery T erminals and Connecting W ires

Care of the batteries is a critical step in any maintenance program. In addition to voltage checks,

visually inspect the batteries for signs of cracking, leaking, or swelling. To aid in quick identification and

tracking of voltages in the maintenance log, number the batteries inside the enclosure using labels or

masking tape, etc. Batteries are temperature sensitive and susceptible to overcharging and undercharging. Since batteries behave differently in the winter than in the summer , Alpha’s battery chargers

automatically compensate for changes in temperature by adjusting float and accept charge voltages.

See the power supply Operator’s and T echnical Manual for complete Power Supply Preventive

Maintenance instructions.

Check each battery terminal and connection. V erify the posts are clean and the crimped connectors are

tight. Terminal connectors must be torqued to 60 in-lbs (±3%) / 6.77Nm (±3%) at installation. If there is

an “in-line” or battery-mounted fuse in the battery cable, check the fuse holder and fuse. Verify the

terminals are properly greased with an approved battery terminal corrosion inhibitor such as NCP-2.

Record date of maintenance in the maintenance log.

Check Battery Open Circuit Voltage

Switch the power supply’s BA TTER Y BREAKER to the OFF position. Disconnect the battery connector

from the Inverter Module and measure the individual voltage across each battery . The difference between

any battery in the string must not be greater than 0.3 VDC. Defective or marginal batteries must be

replaced with an identical type of battery . Record the unloaded battery voltages in the maintenance log.

Whenever the power supply’s BA TTER Y BREAKER is turned OFF or the batteries are not connected, the power

supply will not operate in Inverter Mode in the event of a utility power failure.

36 031-259-B0-001, Rev A

Page 37

Page 38

Alpha Technologies

Power

®

Alpha T echnologies

3767 Alpha Way

Bellingham, WA 98226

USA

T el: +1(360) 647-2360

Fax: +1(360) 671-4936

Web: www.alpha.com

Alpha T echnologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

T el: +1(604) 430-1476

Fax: +1(604) 430-8908

Alpha T echnologies

Europe Ltd.

Cartel Business Estate

Edinburgh Way

Harlow, Essex CM20 2TT

UNITED KINGDOM

Tel: +44-1279-422110

Fax: +44-1279-423355

Alpha T echnologies GmbH

Hansastrasse 8

D-91126 Schwabach

GERMANY

T el: +49-9122-79889-0

Fax: +49-9122-79889-21

Alphatec, Ltd

P .O. Box 56468

Limassol, Cyprus

CYPRUS

T el: +357-25-375675

Fax: +357-25-359595

Alpha T echnologies

5 Avenue Victor Hugo

F-92140 Calmart France

FRANCE

T el: +33-3-41-90-07-07

Fax: +33-1-41-90-93-12

38 031-259-B0-001, Rev A

Copyright © 2005 Alpha T echnologies, Inc. All right s reserved. Alpha is a registered trademark of Alpha Technologies. 031-259-B0-001, Rev. A 08/2005

Due to continuing product improvements, Alpha reserves the right to change specifications without notice.

Loading...

Loading...