Page 1

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

PowerAgent™ SC3 Site Controller

Installation and Operation

DRAFT

Phoenix Broadband Technologies, LLC 10/28/2010

Page 1 of 57

Page 2

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

Table of Contents

1 Important Information ................................................................................................ 4

1.1 Revision History.............................................................................................................. 4

1.2 Safety Notes ..................................................................................................................... 4

1.3 Important Symbols ......................................................................................................... 5

1.4 Definition of Terms......................................................................................................... 5

1.5 Contact Information ....................................................................................................... 6

2 System Overview .......................................................................................................... 7

2.1 Sensor Description .......................................................................................................... 8

2.1.1 “High Voltage” and “Low Voltage” Sensors.......................................................................... 8

2.1.2 Sensor Selector Guide............................................................................................................. 9

2.2 Site Controller Description .......................................................................................... 11

2.3 Accessories..................................................................................................................... 12

2.3.1 Cable Kits ............................................................................................................................. 12

2.3.2 Power Transformer ............................................................................................................... 13

2.3.3 Rack Mount Bracket ............................................................................................................. 13

3 Initial Bench Evaluation........................................................................................... 14

4 Sensor Installation .................................................................................................... 16

5 Site Controller Installation ....................................................................................... 16

5.1 Powering ........................................................................................................................ 16

5.2 Network Connections.................................................................................................... 17

5.3 Connecting Battery Sensors ......................................................................................... 17

5.4 Connecting RIMs and ROMs ...................................................................................... 17

5.5 Connecting Current Sensors........................................................................................ 17

5.6 Setting the IP Address .................................................................................................. 18

5.7 Configuring the Site Controller................................................................................... 18

5.7.1 Direct USB Connection ........................................................................................................ 19

5.7.2 USB Port Selection ............................................................................................................... 19

5.8 Accessing the Setup Menu............................................................................................ 20

5.8.1 Ethernet Crossover Cable Method........................................................................................ 20

5.8.2 Router Method ...................................................................................................................... 20

5.8.3 Running the Site Controller Telnet Setup............................................................................. 21

5.9 Site Controller Setup Menu ......................................................................................... 22

5.9.1 Setting the IP Address (0) ..................................................................................................... 23

5.9.2 Web Passwords (1) ............................................................................................................... 24

5.9.3 SNMP Agent Configuration (3)............................................................................................ 25

5.9.4 HMS Defaults (4) ................................................................................................................. 25

Phoenix Broadband Technologies, LLC 10/28/2010

Page 2 of 57

Page 3

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.9.5 Email Setup (5) ..................................................................................................................... 26

5.9.6 Time Server Configuration (6) ............................................................................................. 28

5.9.7 Restore Factory Defaults (7) ................................................................................................. 29

5.9.8 Exit (8).................................................................................................................................. 29

5.9.9 Save and Exit (9) .................................................................................................................. 29

5.9.10 Erase All String and Jar Data (13) ........................................................................................ 29

5.9.11 Reset All Sensors (14) .......................................................................................................... 29

5.9.12 Erase String (15) ................................................................................................................... 29

5.9.13 Erase RIM/ROM Flash (16) ................................................................................................. 29

5.10

Web Server................................................................................................................. 30

5.10.1 Accessing the Web Server .................................................................................................... 30

5.10.2 Ports...................................................................................................................................... 30

6 Navigating the Web Pages ........................................................................................ 31

6.1 Overview Display .......................................................................................................... 32

6.2 Single String Display..................................................................................................... 33

6.3 Single Jar Display ......................................................................................................... 35

6.4 RIM and ROM Main Display ...................................................................................... 37

6.5 Provisioning................................................................................................................... 38

6.5.1 Provisioning Site Settings ..................................................................................................... 39

6.5.2 Provisioning String Settings ................................................................................................. 41

6.5.3 Provisioning Jar Settings ...................................................................................................... 43

6.5.4 Provisioning the Sensor Calibration ..................................................................................... 45

6.5.4.1 Calibrating using an Instrument........................................................................................ 45

6.5.4.2 Setting the Calibration ...................................................................................................... 46

6.5.4.3 Provisioning the Baseline ................................................................................................. 47

6.5.4.4 Baselining using the Present Measurement ...................................................................... 47

6.5.4.5 Baselining using Manufacturer’s Specifications............................................................... 47

6.5.4.6 Setting a Baseline ............................................................................................................. 47

6.5.5 Provisioning Analog Alarms ................................................................................................ 49

6.5.6 Provisioning Discrete Alarms............................................................................................... 50

6.5.7 Provisioning The ROM......................................................................................................... 51

7 SNMP......................................................................................................................... 52

7.1.1 MIBs ..................................................................................................................................... 53

7.1.2 Community Strings ............................................................................................................... 54

7.1.3 Traps ..................................................................................................................................... 54

7.1.4 MIB Browsers....................................................................................................................... 54

8 Updating Firmware ................................................................................................... 55

9 Summary of Port Usage ............................................................................................ 56

10 Resolving Common Problems................................................................................ 57

Phoenix Broadband Technologies, LLC 10/28/2010

Page 3 of 57

Page 4

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

1 Important Information

1.1 Revision History

Release Date Revision Description

Rev 1 04/27/2010 Draft for review, Firmware version 4.04, Web version 1.1

Rev 2 05/12/2010 On going revisions, Firmware version 4.10, Web version 1.3

1.2 Safety Notes

High currents and voltages may be present on the equipment terminals and on the

interior of the equipment. Make sure you understand and observe all appropriate

safety codes and regulations. Follow prudent electrical safety practices when

installing or servicing the equipment. Installation, maintenance and servicing of

the equipment should only be performed by qualified, trained and authorized

personnel.

Before installation, take measurements with a Volt Meter to ensure that no jar post in the

system has lethal AC or DC voltages relative to earth ground.

Except as explained in this manual, there are no user-serviceable parts inside the

PowerAgent Battery Monitoring System components. Opening the equipment could

expose you to dangerous voltages and void the product warranty. All product servicing

should be referred to factory-authorized personnel.

Use only interconnection cables supplied or authorized by Phoenix Broadband

Technologies. Use of user-made interconnection cable assemblies could result in

damage to equipment and potential safety hazards and voiding of equipment warranties.

Do not exceed the voltage specifications of the product.

Make sure the equipment is grounded properly.

The equipment should be protected from liquids, moisture, explosive, and corrosive

vapors.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 4 of 57

Page 5

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

CAUTION!

NOTE:

Installation and Operation

1.3 Important Symbols

The following symbols are used in this document.

The use of CAUTION indicates safety information intended to prevent damage and/or injury

A NOTE to provide additional information to help complete a specific task or procedure

1.4 Definition of Terms

Admittance – The inverse of Impedance in units of Siemens. Admittance is a measure of how

easily a circuit or device will allow a current to flow. Resistance is a measure of the opposition of

a circuit to the flow of a DC current, while impedance takes in to account not only the resistance

but AC effects (known as reactance) as well. Likewise, admittance is not only a measure of the

ease with which a DC current can flow (conductance, the inverse of resistance), but also takes in

to account the AC effects of susceptance (the inverse of reactance).

Battery – A collection of jars connected in series. A battery is sometimes referred to as a Battery

String or String in this document.

Cell – A collection of plates connected to a single positive and single negative terminal immersed

in electrolyte in a single container. The cell may have multiple positive and negative connections

but they connect to a single set of plates. A lead acid cell produces approximately 2.1 volts.

Jar – A collection of one or more cells connected in series in a single housing. A 12 volt jar

contains 6 cells. A Jar is commonly and incorrectly referred to as a battery.

P-Bus – A Phoenix proprietary communications interface and protocol used to connect devices to

the Site Controller for the purpose of providing additional input, output, and measurement

capability.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 5 of 57

Page 6

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

1.5 Contact Information

If you have any questions about the installation or use of the equipment described in this manual,

contact Phoenix Broadband Technologies (PBT) at (215) 997-6007 or

customerservice@phoenixbroadband.com.

When contacting Phoenix Broadband please have the following information available:

1. Site Controller Model Number and firmware version (from the Site Controller Web Page).

2. Battery Sensor Model Number, hardware version and firmware version. The version

numbers are shown on the Site Controller single Jar Web Page.

3. The Battery and String Voltage.

4. The battery model number.

5. UPS or DC power plant.

6. If a UPS the manufacturer and model number.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 6 of 57

Page 7

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

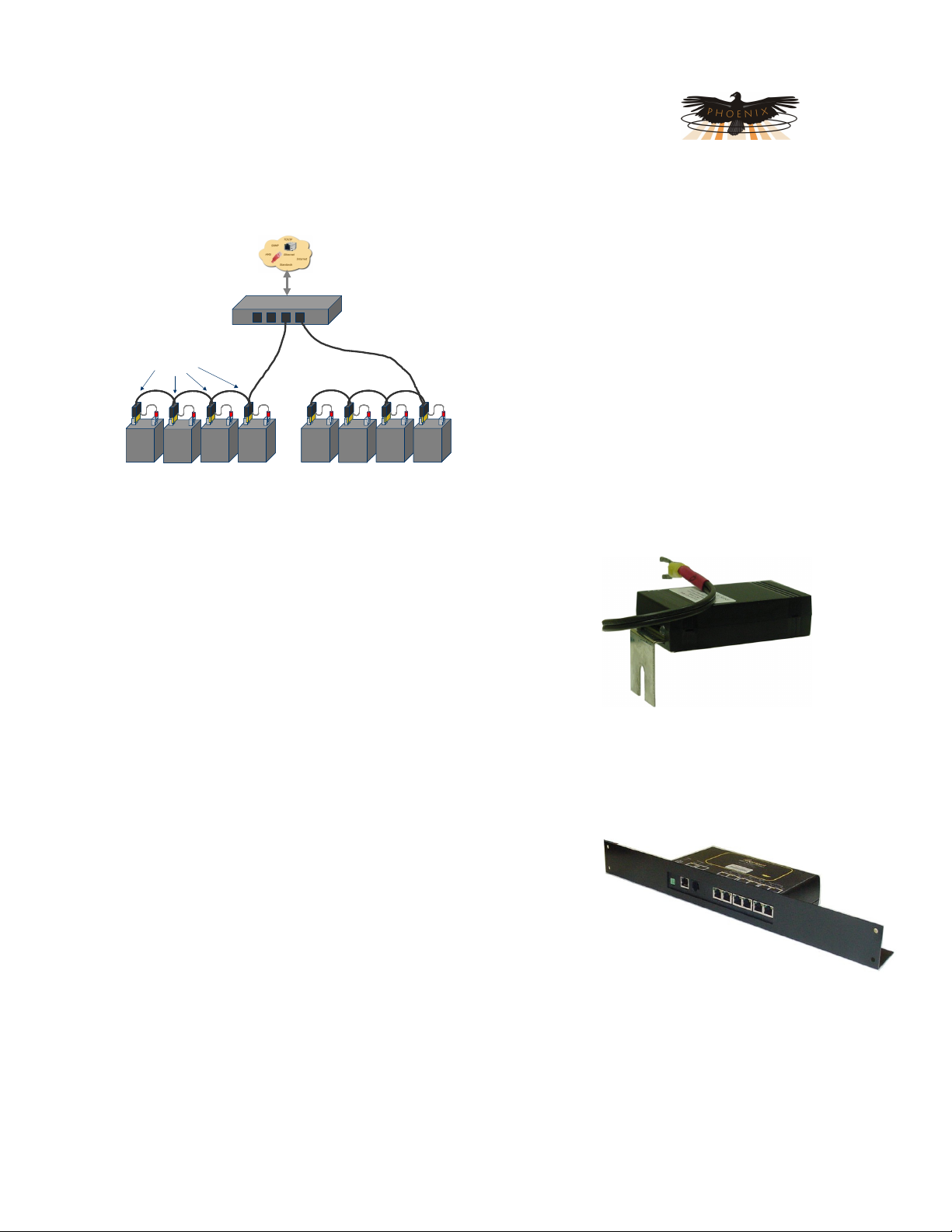

2 System Overview

Network

Conn ectivity

MasterA gent

Site

Contro ller

Up To 6

Batter y

Batte ryAgent

Sensor

Units

Batt ery String # 1 Batt ery String # 2

String s

RJ-11

“Dai sy Chain ”

area network. The Sensor modules are designed for use with 2 or 12 volt jars in DC power plants

and UPS power systems up to 600 volts DC and with several choices of mounting brackets for

different post configurations.

Each sensor in a PowerAgent

TM

Battery Management System

measures its associated cell or jar’s terminal voltage, post or

case temperature, and internal cell impedance (admittance).

Multiple sensors within a string of monitored jars are

interconnected in a “daisy-chain” utilizing CAT-5 cabling and RJ45 connectors. Each daisy-chain of sensors is connected via

another CAT-5 cable to one of the six string ports on the Site

Controller. Each site controller can manage up to six strings of

batteries with a maximum of 40 batteries in any string and a site

total of 240 batteries. The site controller has extensive user-definable set-up capabilities,

including labels for every monitored jar and alarm thresholds for voltage, temperature and

admittance on each individual jar.

The site controller has several user interface mechanisms built-in, including a configurable web

server that displays site, string, and individual jar

information, as well as an SNMP (Simple Network

Management Protocol) interface that allows any SNMP

compliant management software to collect data and

perform jar tests. Other features of the site controller

include a password protected Telnet port for remotely

configuring the unit, A DHCP (Dynamic Host

Configuration Protocol) client that automatically obtains

an IP (internet protocol) address from a DHCP server,

and TFTP (Trivial File Transfer Protocol) server for

uploading firmware changes remotely.

The Phoenix Broadband Technologies (PBT)

PowerAgent TM Battery Management System is

a comprehensive solution for remotely

monitoring the state of health for individual cells

or jars within the battery bank of a UPS or DC

power plant system.

The system consists of a series Sensor modules

which are electrically and mechanically affixed to

the terminal posts of the jars being monitored,

and a PowerAgent TM Site Controller unit which

collects readings from the individual sensors and

makes the information available for

management purposes via an Ethernet local

Phoenix Broadband Technologies, LLC 10/28/2010

Page 7 of 57

Page 8

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

2.1 Sensor Description

Sensor modules are small, inexpensive units designed to

mount in close mechanical, electrical, and thermal

proximity to the monitored jar’s terminal posts. The sensor

takes a very small amount of “idling” power from the

monitored jar (typically less than 10ma). Internally, a

programmable microcontroller chip provides an optically

isolated communications interface for the site control unit.

Sensors are connected to the Site Controller using a

CAT5 cable daisy chain.

The sensor continuously monitors the voltage and

temperature of the jar. At user-defined intervals, the

microcontroller generates a digitally synthesized AC test

signal of approximately 0.5 to 6.0 amps (depending on

sensor type) which drives the jar’s terminals for testing

purposes. This test current causes a small AC voltage,

proportional to jar impedance, to be superimposed on the

jar’s DC terminal voltage. This AC voltage is separated from the DC terminal voltage and

amplified inside the sensor module. It is then fed to an analog-to-digital converter inside the

microcontroller chip. The microcontroller digitally samples the AC waveform and performs a DSP

(digital signal processing) algorithm that filters out noise and measures the amplitude of the AC

signal. These measurements and subsequent calculations determine the jar’s internal AC

impedance, which is the basis for Admittance measurements.

Mechanically, the sensor consists of a nickel-plated copper mounting bracket which fits on the

jar’s negative terminal post, a short wire terminated in terminal lug that connects to the jar’s

positive terminal post, and an electronics assembly that contains the test signal generation and

measurement circuitry. Sensors with two wires are also available.

The sensors with brackets have the advantage of being able to more accurately measure the

temperature of the electrolyte in the cell. The two wire sensors have the advantage of working

with a wide variety cell and jar mechanical configurations that could requires several different

bracket types. Refer to the Sensor Selector Guide later in this section for more details.

Each sensor is shipped with a 1 foot CAT5 cable to connect the sensor to the daisy chain. This

cable is the proper length for most applications. Longer cables are available from PBT.

2.1.1 “High Voltage” and “Low Voltage” Sensors

Sensors are typically used in DC power plant and UPS applications. DC power plant applications

commonly utilize two volt cells and twelve volt jars wired in series with total nominal string

voltages typically ranging from 24 to 48 VDC nominal. In many UPS systems, voltages can be

significantly higher (480 volts or more). Because of the specific requirements of high voltage

systems, Phoenix Broadband has developed two types of sensors to accommodate each

environment.

When working in environments where string voltages are greater than 64 VDC, always use the

High Voltage sensors. “High voltage” (HV) sensors are completely optically isolated from the

Phoenix Broadband Technologies, LLC 10/28/2010

Page 8 of 57

Page 9

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

PBT

-

PA

-

BS1

-12-2

Installation and Operation

controller and each other, with no string-level voltages present in the interconnecting CAT5

cables. This architecture was designed to ensure safety and prevent damage. For environments

where string voltages are 64 VDC and lower Low Voltage sensors are appropriate, however

either sensor (High or Low voltage) can be used low voltage strings.

CAUTION: Installing Low Voltage sensors on a high voltage string will damage the

sensors and may present a shock hazard.

Both sensor types will be auto-discovered by the controller. The Low Voltage sensor has the

advantage that its position in the string is automatically discovered. This means the sensors can

be connected in any order and the controller will automatically discover upon which cell or jar the

sensor was installed. High Voltage sensors have an address. The address and cell or jar

number must be recorded when the sensor is installed. These addresses are then entered into

the Site Controller Web page so that the ordering of the cells or jars will be correct.

High Voltage and Low Voltage sensor should not be mixed in the same string.

Each sensor has a bi-color red/green LED that indicates the operational state of the sensor and

its communications status with the site controller. Each sensor is also is internally fused so that

improper connection to the jar will not damage the jar, the jar cabling, or the sensor. Again, the

sensors are fully optically isolated from the site controller.

2.1.2 Sensor Selector Guide

Selecting a sensor requires first determining if a Low or High voltage sensor is required. Then a

jar voltage is selected, either 2 or 12 volts. Finally the bracket style is selected. The sensor

model number is constructed as shown below.

String Voltage

-BS1- Low Voltage (< 64 Volts)

-BS2- High Voltage (> 64 Volts)

-BS1B- Series B Low Voltage

-BS2B- Series B High Voltage

-BS3B- Series B Low Voltage, High Current

Jar Voltage

-2- 2 Volt Jars

-12- 12 Volt Jars

Series B sensors should be used for all new installations, they offer improved noise immunity and

an enhanced feature set including battery balancing. These sensors require a B series

SiteController.

When selecting a bracket be sure to consider the clearance above the jar. This is particularly

important when the jars are installed in a cabinet as is typical with most UPSs. Be sure there is

enough space for the CAT-5 cables to exit the sensor without kinking.

Bracket Type

-1 L Bracket

-2 Z Bracket

-3 Front Mount Bracket

-4 2 Wire Sensor

-5 12 mm Z Bracket

Phoenix Broadband Technologies, LLC 10/28/2010

Page 9 of 57

Page 10

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

Type 1 Bracket

This bracket commonly referred to as

the “L” bracket, is typically used on Jar

terminals where the sensor must stand

up from the jar. An example is the

vertical blade type terminal where the

bolt is parallel to the top of the Jar.

The maximum bolt size for the terminal and bracket is 5/16 inch.

Type 2 Bracket

This bracket, commonly referred to as the “Z” bracket, is

typically used jars that are connected together with straps.

It is also used when the jar cables are secured by bolts

that extend into the jar. The maximum bolt size for the

terminal and bracket is 5/16 inch.

Type 3 Bracket

This bracket, commonly referred to as the “Front

Mount” bracket, is used front terminal Jars. While

specifically designed for the Marathon, the bracket

will fit most front terminal Jars. This bracket was

designed for a M6 (6 mm) bolt.

Type 4 Bracket

This bracket is not a bracket at all

but a sensor with two wire

connections. This is the universal

sensor that will work with most

jars. The maximum bolt size for

the terminals is 5/16 inch. The

one disadvantage of this sensor is

that it does not directly measure

the jar post (electrolyte)

temperature like the bracketed sensors. When the sensor is mounted to the top of the jar, and

not in the direct cooling air flow, the sensor will read the approximate jar case temperature. The

sensor is equipped with a self adhesive industrial velcro strip for fastening the sensor to the jar.

Type 5 Bracket

This bracket is similar to the Type 2 bracket but is designed for a larger bolt. The maximum bolt

size for the terminal and bracket is ½ inch or M12 (12mm). Because of the higher torque

required for the larger bolt this bracket has a round hole rather than a slot. This prevents

distorting the bracket when tightening the bolt.

Contact PBT if none of these brackets fit your requirements.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 10 of 57

Page 11

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

2.2 Site Controller Description

The Site Controller is a small, rack-mountable unit that monitors the sensor modules and makes

the data collected by them available via a local area network or the internet. The SC3 Site

Controller has 6 string ports for connection to strings of up to 40 jars each for a total capacity of

240 jars. Two P-Bus ports provide expansion capability for connection to current sensors, RIMs

and ROMs for additional input and output capability. A USB setup port allows direct connection

to a PC for configuration. A USB thumb drive provides storage of logged data and additional

USB ports provide expansion capability.

The SC3 Site Controller has most of the connections on the rear panel and indicators on the front

panel.

The SC3 Site Controller can be

powered directly from a battery

string voltage of 24-48VDC, or it

can be powered from an

optional small wall-mount

24VDC wall transformer. The

voltage range is 18 to 65 VDC

and power consumption is about

5 watts, with current draw

dependent on the input voltage.

Power is supplied to the unit via

a rear-panel screw-type terminal

block. The power supply input is

floating. The terminal block also

provides a chassis ground

connection.

A Front panel USB connection provides access to configure the Site Controller IP address and

other parameters during installation. Setup can also be performed over the network connection.

The site controller has six RJ-45 connectors on the rear panel for interfacing to up to six strings of

monitored jars. Each string has a front panel indicator. The LED lights when the string is being

polled. A green LED indicates everything is normal, a red LED indicates abnormal conditions

within that string.

An Rear Panel Ethernet connection provides a TCP/IP (internet protocol) interface to a local area

network or to the internet. A built-in web server is accessible via this interface, with no need for

any software other than a common PC web browser. More sophisticated monitoring and control

Phoenix Broadband Technologies, LLC 10/28/2010

Page 11 of 57

Page 12

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

of the site controller can be performed remotely using any SNMP-capable network management

software system. These systems are described in additional detail in the SNMP section of this

Manual.

Upon power-up, the site controller automatically begins a search sequence to determine which of

its string ports are attached to battery sensors and discovers each sensor module.

When a string of High Voltage sensors is discovered, the controller discovers the factoryprogrammed address of the sensor module as part of this discovery process. The HV sensor is

also assigned to one of the jars in the string, but the user can change these assignments after

installation is complete.

When a string of Low Voltage sensors is discovered the controller automatically discovers each

sensor and its correct position in the string (no factory programmed address is necessary with low

voltage sensors).

Once the “auto-discovery” process is finished, the site controller can individually address each

sensor, collect its readings, and display those reading in the hierarchical web page display.

Except for the final user assignment of High Voltage sensors to jars, this process is ‘plug & play’.

All sensor assignments and configuration information are saved in non-volatile memory, so the

system automatically reconfigures itself if power is lost or if the system is turned off for

maintenance.

The site controller can be mounted in any small, inconspicuous location that is available, or it can

be rack-mounted in a standard 19” (or 23” with adapter ears) equipment

rack by using the optional rack-mount bracket. One rack bracket can hold

one or two site control units. Rubber feet, screws for mounting the site

controller to the rack bracket, and extra sensor fuses are included with the

Site Controller.

2.3 Accessories

Various optional accessories are available to aid in the system installation.

2.3.1 Cable Kits

A Cable kits provides the cables necessary to connect a string of jars to the site controller. Each

string requires a Cable Kit. The Cable Kit contains the cables most commonly required to

connect the string of jars. Cable Kits are

Cable Kit Model Number Jars per string

PBT-PAC-BMS-04 4

PBT-PAC-BMS-12 12

PBT-PAC-BMS-20 20

PBT-PAC-BMS-24 24

PBT-PAC-BMS-30 30

PBT-PAC-BMS-40 40

NOTE: We strongly recommend that you order the appropriate Cable Kit for each string

and not make your own sensor cables. A single improperly made cable can destroy an

entire string of sensors.

Phoenix Broadband Technologies, LLC 10/28/2010

available for common string sizes. Contact PBT

for any special requirements. The Cable Kit

contains the cables most commonly required to

connect the string of jars.

Page 12 of 57

Page 13

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

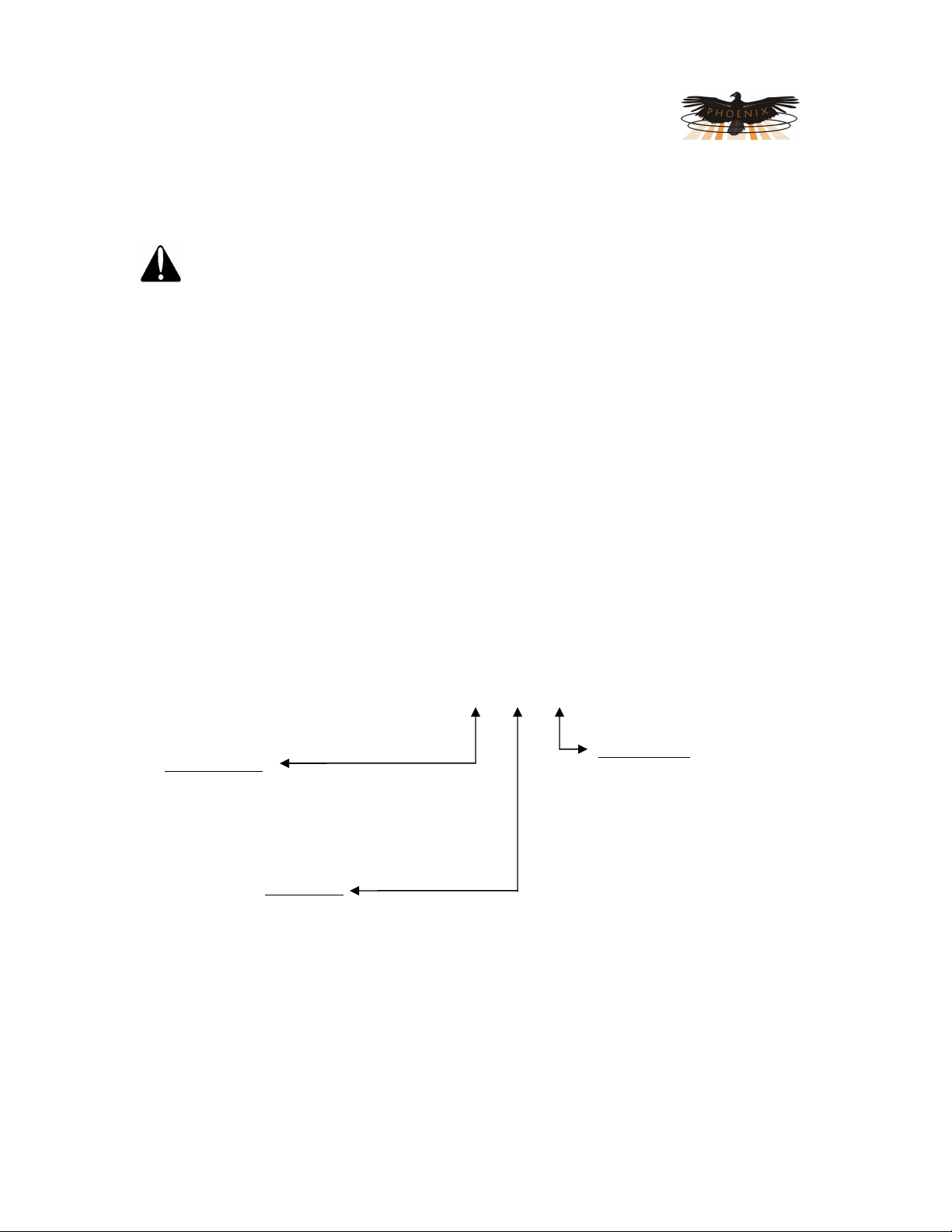

2.3.2 Power Transformer

The Site Controller is normally powered from the Rectifier or UPS battery

charger (24 to 60 VDC). In cases where this power is not available a 24 VDC

wall mount transformer is required to power the Site Controller. This

transformer can be ordered from PBT as model number WT-3.

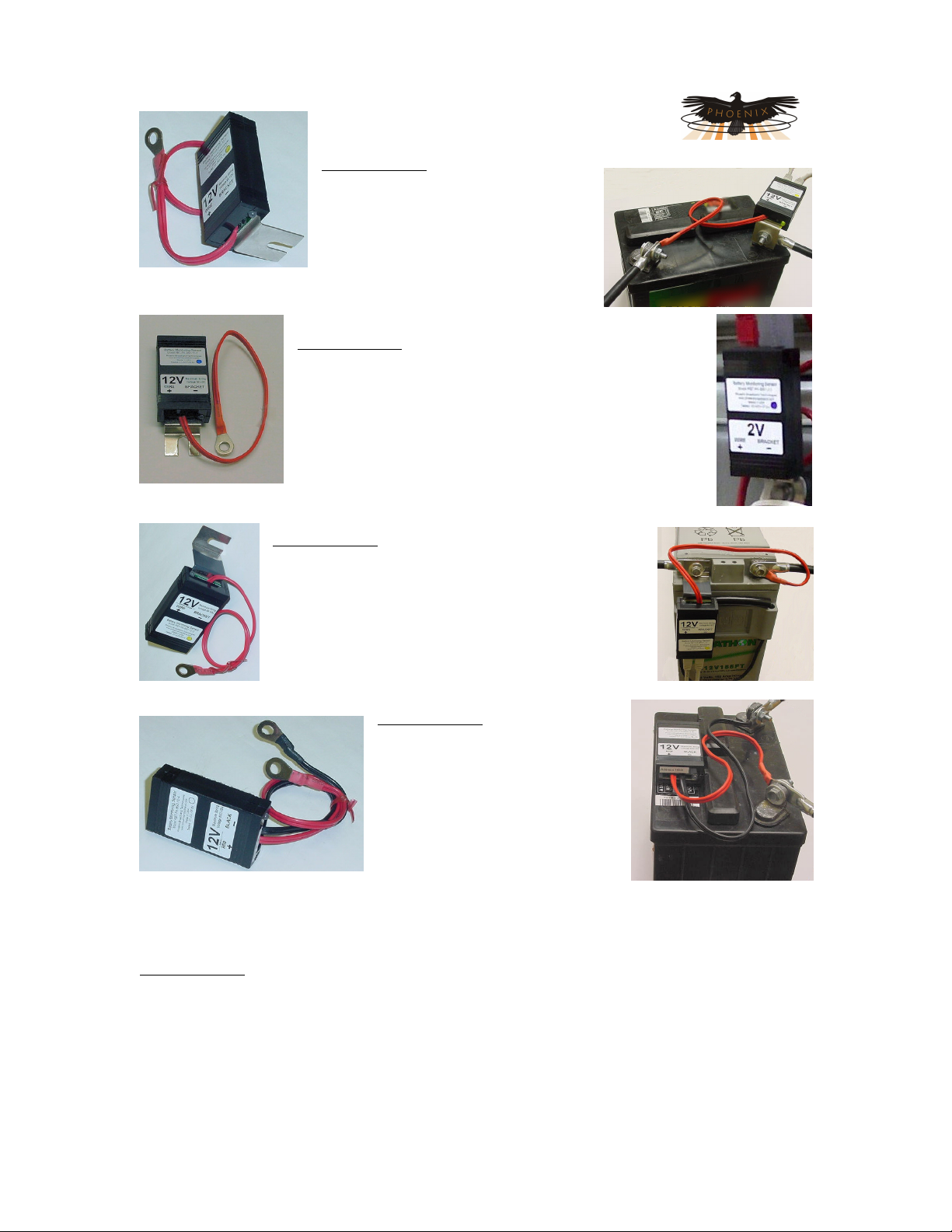

2.3.3 Rack Mount Bracket

A bracket that mounts up to

2 Site Controller in a 1U

space in a 19” rack is

available by ordering model

PBT-RK-1.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 13 of 57

Page 14

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

3 Initial Bench Evaluation

If the user has no previous experience with the PowerAgent TM Battery Management System, it is

recommended that a small local test and evaluation of the system components be set up prior to

field deployment of the equipment. This approach can save a significant amount of time before

connecting to a much larger network. It will allow you to verify proper operation of the site

controller’s web server; telnet configuration, and DHCP client without having to troubleshoot

larger network issues (firewalls, router, and connectivity etc.).

NNeettwwoorrkk RRoouutteerr

EEtthheerrnneett ccaabblleess

SSeennssoorr DDaaiissyy cchhaaiinn

CCAATT 55 ccaabblleess

BBMMSS ccoonnttrroolllleerr

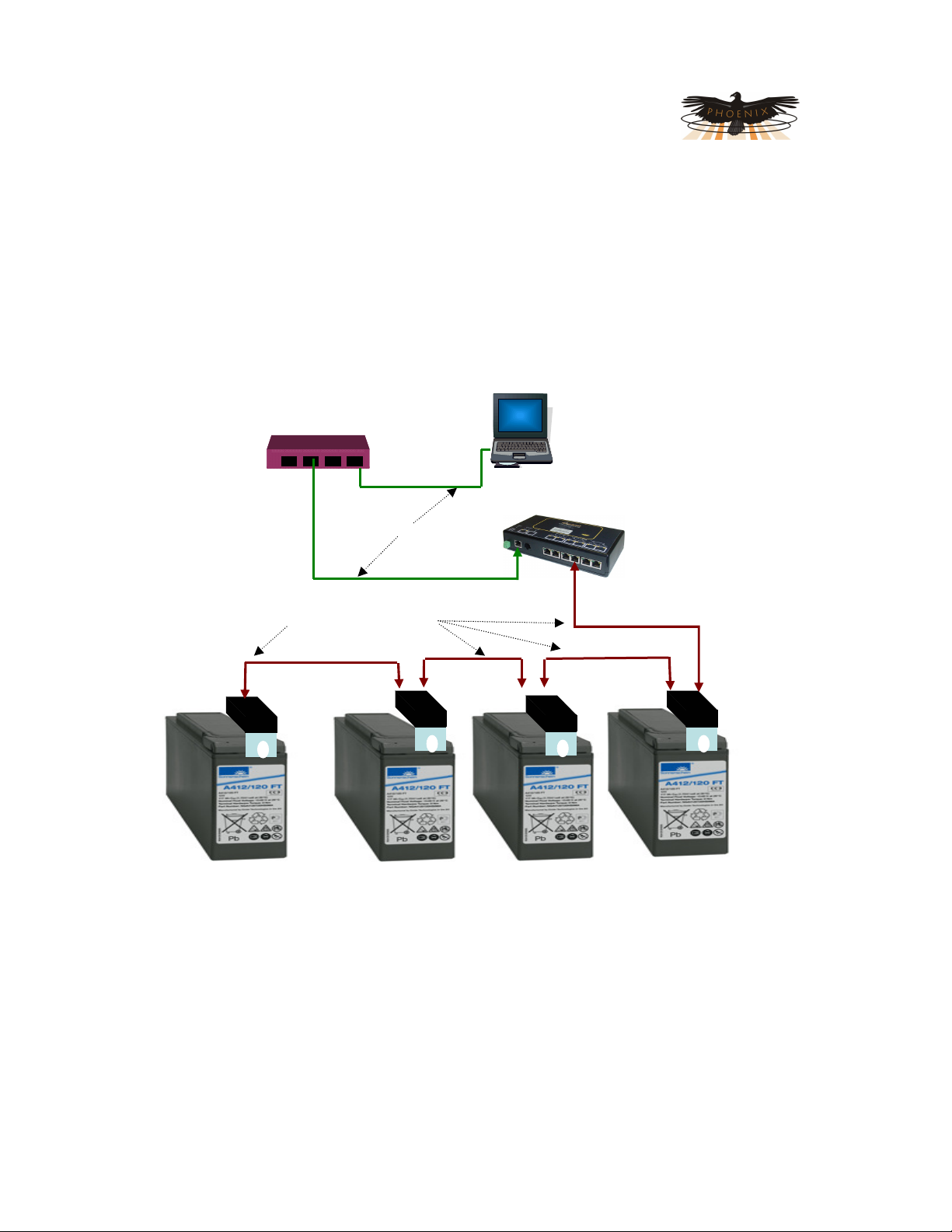

The above diagram shows a low cost networking router (D-Link™, NetGear™, or other)

connected to a laptop/Desktop and the Site Controller. In this scenario the installation steps are

as follows:

1. Power up router

2. Power up laptop and connect laptop to router

3. Verify that the laptop has acquired an IP address from the router (view the router’s

configuration web page and write the address down)

4. Connect controller to router (via Ethernet connection)

5. Power up controller (upon power up, the controller will seek an IP address from the

router)

6. Connect sensors to the each other (via CAT 5 cables daisy chained from sensor to

sensor)

Phoenix Broadband Technologies, LLC 10/28/2010

Page 14 of 57

Page 15

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

7. Connect last sensor in the daisy chain to one of the six controller’s sensor input ports

8. View the router’s web page to determine which IP address has been given to the

controller (write it down)

9. Type the IP address of the controller into your laptop’s web browser and verify that the

web page displays properly. Verify that all sensors have been auto-discovered. Verify

that the parameter information displayed in the web page appears reasonable

10. Verify telnet connectivity by connecting to the controller via telnet (remember Phoenix

Broadband uses port 9999 for our telnet connection)

11. If you are using an SNMP manager, verify proper SNMP operation (gets, sets & traps)

This bench evaluation can also be performed using the free Lookout software described in the

SNMP section of this manual.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 15 of 57

Page 16

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

4 Sensor Installation

Refer to the Battery Management System Manual (700-000006-02) for detailed information

before installing the battery sensors.

CAUTION! Lethal voltages may be present on the battery strings. If you are not sure of

what you are doing leave the installation to a certified technician. Read the sensor

installation instructions carefully.

CAUTION! Be sure to disconnect the Rectifier or Charger before installing the Sensors.

Failure to do so could result in sensor damage.

5 Site Controller Installation

NOTE: Before any sensor strings are connected to the Site Controller, it should be

mounted (either in a rack or shelf), connections should be made to the network (Ethernet

connection) and it should be powered up and checked out for network connectivity.

Select a location for the Site Controller. The location should be central to the strings being

monitored. It should be dry and free of corrosive or explosive vapors.

The maximum cable length between the SC3 Site Controller and the battery string varies with the

number of battery sensors on the string. With 40 sensors a maximum total cable length of 200

feet is recommended. This includes the sensor to sensor cables. With 24 sensors this increases

to 300 feet.

Mount the Site Controller in an equipment rack using the optional rack mount bracket, or place

the Site Controller on a shelf.

5.1 Powering

Connect a source of 18 to 65 volts DC to the rear panel power connector. This can be DC power

from a DC power plant or it can be 24 VDC from the optional WT-3 plug-in transformer. For UPS

installations the Site Controller should be powered from the WT-3 or other DC source. The WT-3

should be plugged into a outlet that is running on the UPS. Never power the Site Controller from

UPS batteries. The SC3 Site Controller can also be powered from low voltage AC. Consult PBT

for the voltage range limitations. There is a power input fuse inside the Site Controller. It is

extremely rare for this fuse to blow.

The power supply input is floating on the SC3 Site Controller. To ground the Site Controller

connect the center ground pin on the power connector to an earth ground.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 16 of 57

Page 17

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.2 Network Connections

Connect the rear panel Ethernet connector to the network through a hub or switch. On a

managed switch, make sure that the switch port has been enabled.

Set the IP Address of the Site Controller as described in the following section.

Verify network communications by accessing the Web page and telnet setup menu over the

network.

5.3 Connecting Battery Sensors

Connect the cable from the battery sensor daisy-chain to an available “BATTERY STRINGS”

connector on the Site Controller rear panel.

NOTE: We strongly recommend that you order the appropriate Cable Kit for each string

and not make your own sensor cables. A single improperly made cable can destroy an

entire string of sensors.

The site controller will begin to auto-discover the sensors connected in each of the daisy-chains.

You will notice the String LEDs on the front panel flashing in sequence left to right. This indicates

that the controller is polling each string and looking for sensors on that string. Once a string has

been discovered it will be visible in the Web page.

5.4 Connecting RIMs and ROMs

RIMs and ROMS are connected to one of the P-BUS connectors on the rear of the Site Controller

using CAT-5 cables. Up to 200 feet of cable can be connected each of the two P-BUS ports. Up

to 4 RIMs and 4 ROMs can be connected to each P-Bus port, for a total of 8 RIMs and 8 ROMs.

Refer to the RIM and ROM installation manual for information on mounting and configuring the

RIM and ROM.

5.5 Connecting Current Sensors

Up to 6 Current Measurement Interfaces (CMI) can be connected to P-BUS port A. These 6 units

correspond to the 6 strings. Each CMI must be set to a unique addresses, from 1 to 6. The

Addresses correspond to the 6 strings. For example; current measurements made on CMI

address 2 are displayed with string 2.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 17 of 57

Page 18

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.6 Setting the IP Address

In order to communicate over the network, the Site Controller must be assigned an IP address.

There are several ways the IP address can be assigned.

• You can pre-configure your DHCP server to assign a reserved IP address to the Site

Controller based on the Site Controller MAC Address. The MAC address is printed on

the Site Controller label. This method is commonly used for field installations.

• You can let your DHCP server assign an address and then interrogate the DHCP server

to determine what address was used. This technique works well in the lab environment

where the DHCP server may be in a router. This method is not very practical for field

installations since the IP address can change if the Site Controller resets or the DHCP

server decides there is a reason to change the address.

• You can program a static IP address in the Site Controller using a temporary connection

to a router with a built-in DHCP server and the Site Controller Telnet configuration port.

• You can program a static IP address in the Site Controller directly using the USB

interface and a PC as described in the next section.

• You can program a static IP address in the Site Controller using an Ethernet Crossover

cable and a PC as described in the next section.

Generally, static IP addresses are used so that the Network Manager can associate the IP

address with a physical location. Contact your network administrator or IT department to obtain a

static IP address, gateway address, and sub net mask that will work on your network.

The Site Controller is shipped from the factory configured to obtain an IP address automatically

from a DHCP server.

5.7 Configuring the Site Controller

The Site Controller can be configured over the network through a telnet connection or through a

USB connection directly from a PC. Support of telnet is a standard part of Windows so virtually

any PC can configure the Site Controller.

There are several ways of connecting your PC to the Site Controller to access the configuration

program.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 18 of 57

Page 19

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.7.1 Direct USB Connection

This method can always be used, and is required when the Site Controller has been programmed

with an unknown static IP Address.

The Site Controller is equipped with a USB interface that allows a PC to be connected to the Site

Controller through a USB cable to access the configuration program. A PC with a USB Port, a

serial communications program such as HyperTerminal or Tera Term is required. The USB

cable is provided with the Site Controller.

NOTE: HyperTerminal which has been part of Microsoft Windows since the beginning, is

no longer included with Microsoft Vista or Windows 7. HyperTerminal can be downloaded

from the internet and added to these systems. There are many other terminal programs available

on the internet that will work. We recommend Tera Term which can be downloaded for free at

http://www.ayera.com/teraterm/. Be sure to comply with all licensing requirements.

A USB driver may be required for your PC to connect to the Site Controller. The driver may be

downloaded from www.PhoenixBroadband.com/Downloads/mchpcdc.inf

Before connecting the Site Controller to your PC, download this driver to you desktop. Apply

power to the Site Controller and connect the USB3 port on the Site Controller front panel to your

PC using the cable provided. A flashing red LED next to USB3 indicated the USB connection has

not been established. The USB installation should begin shortly. When the wizard asks for the

location of the driver, point to your desktop. The LED next to USB3 will light green when the

USB interface has initialized.

5.7.2 USB Port Selection

To connect to the Site Controller with your serial communications program you will need to

identify which COM port is being used for the USB

serial communications.

1) Open the PC’s “Control Panel” and click on

the “System” icon.

2) Select the “Hardware” tab and click the

“Device Manager” button.

3) Navigate down the tree of Devices and

expand the “Ports (COM & LPT)” item.

4) Find the item labeled “Site Controller Com

Port (

COM#

installed on is shown in the parenthesis (

5) To change the Port, right-click the Device and select “Properties”. Select the “Port

Settings” tab and click on the “Advanced” button. A new Port # may now be selected

and applied from the “Advanced Settings” Window.

When configuring your Serial Communications program use the COM port number

identified above. If you program only supports low number COM ports, change the port

number as described in step 5.

)”. The Com Port that was

COM7 in the example

).

Phoenix Broadband Technologies, LLC 10/28/2010

Page 19 of 57

Page 20

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.8 Accessing the Setup Menu

To access the Site Controller setup menu connect the Serial Communications program

to the Site Controller using the USB interface as described above. Confirm that the USB

connection has been established by looking for the green LED next to USB3. Open the

Serial Communications program, select the COM Port identified above, and set the date

rate to 9600, 8 data bits, one stop bit, no parity, and no flow control. When the program

is configured properly the USB3 LED should flash off when you type on the keyboard.

Hold down the x (lower case) for about 5 seconds. A message “-- Device Reset, hold ‘x’

key down until prompted. --“, will appear. Continue to hold the x key until the setup

menu appears and then follow the setup instructions below.

5.8.1 Ethernet Crossover Cable Method

This method can be used when the Site Controller IP address is set to a known static address.

Connect an Ethernet Crossover cable between the PC and the Site Controller. Set your PC IP

address to the Site Controller Address + or – 1. Follow the telnet setup instructions below.

5.8.2 Router Method

This method can be used when the Site Controller is set for DHCP operation (Factory Default).

Connect the Site Controller to a router that supports DHCP. This is generally done with a router

designed for home use but this process can also be used with most commercial routers and

DHCP servers if the proper access is available. The DHCP server will automatically assign an IP

address to the Site Controller which will enable network access to the Site Controller for

configuration. Your router should have a built in Web Server or some other method of

determining what IP address was assigned to the Site Controller(refer to the router manual).

Once the IP Address is known the Site Controller can be configured through a telnet connection

as described below.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 20 of 57

Page 21

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.8.3 Running the Site Controller Telnet Setup

To open a telnet connection to the Site

Controller select “Run” from the Windows Start

menu. Enter “telnet” followed by a space,

then, the IP address of the Site Controller

followed by a space, and then the port number

“9999” followed by “Enter”. If the Site

Controller is on, line and the telnet password

is enabled the following screen will be

displayed. If the telnet password is not

enabled, skip to the next step. Note that the

screens in this document may be slightly

different than your Site Controller screens. The Site Controller will not ask for the password when

using the direct USB connection.

Enter the password. You only

have a few seconds before

the session times out. If the

password is accepted the

following screen will be

displayed, if the password is

not accepted the telnet session will be terminated.

Type “Enter”, to display the

setup menu shown in the

next section. For security

purposes, if “Enter” is not

typed in a few seconds the

telnet session will be

terminated by the Site

Controller.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 21 of 57

Page 22

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.9 Site Controller Setup Menu

No matter what method of access was used the Setup Menu will then be displayed as shown

below. These screen shots were made with a telnet client but they will look the same in a serial

program.

The top two thirds of the screen

displays the present

configuration. The menu at the

bottom of the screen displays

the setup menu.

Closing the telnet window

will terminate the telnet

session and reset the Site

Controller. To avoid resetting

the Site Controller exit by

pressing “8” followed by “Enter”.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 22 of 57

Page 23

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.9.1 Setting the IP Address (0)

Various options can be controlled by setting the IP address. For static IP address operation the

IP address should be set to the address assigned by the IT department or other authority. Other

IP address options are as follows.

If the IP address is set to 0.0.0.0 DHCP is enabled. (Factory Default)

If the IP address is set to 0.0.1.0 DHCP is enabled and AutoIP is disabled.

If the IP address is set to 0.0.9.0 DHCP is enabled, DHCP option 81 is disabled, and AutoIP is

disabled.

To change the IP Address select option 0 from the setup menu by typing a 0 followed by “Enter”.

The following screen will appear.

The current value of the first

octet of the IP address will be

shown in parenthesis. This

indicates that the first octet of

the IP address is 0. To

change the octet, type the

new number followed by

“Enter”. To move on without

making any changes, just type

”Enter”.

In this example the first octet

of the IP address was

changed to 192.

Continue entering each octet

of the IP address until all 4

octets have been entered. To

skip any entry without making

any changes type “Enter”

without typing any numbers.

Next the Site Controller will ask if you would like to set the Gateway IP Address. The Gateway

address is required for the Site Controller to initiate communications with other devices on the

network; such as the time or

email servers. This address

is obtained automatically

when running with DHCP,

however when a static IP

address is assigned to the

Site Controller the Gateway

Address must be set

manually. The Gateway Address is normally set to the IP Address of the first router encountered

by outbound network traffic. To change the address, type a “Y” and enter the IP address as

described above. To skip the address, type an “N”.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 23 of 57

Page 24

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

The Site Controller will now ask for the Network Mask. To change the mask, enter the number of

bits required for the local host.

Example; For 255.255.255.0

enter 8, for 255.255.252. 0

enter 10. Verify the Net

Mask was set correctly by

observing the displayed value

when the menu returns to the

screen. The table below shows the value to be entered for common Net Masks.

Next the Site Controller will ask if a telnet password is desired. A

four character password can be selected to secure telnet access to

the Agent. Use caution when selecting a password. If you forget the

password or enter it incorrectly the Site Controller must accessed

using the Programming Adapter to reset the password. To set the

password, enter a “Y” and then the password following the prompt.

To remove a password enter a “Y” and then an enter at the prompt.

Value

Net Mask

2 255.255.255.252

3 255.255.255.248

4 255.255.255.240

5 255.255.255.224

6 255.255.255.192

7 255.255.255.128

8 255.255.255.0

9 255.255.254.0

10 255.255.252.0

Finally the Site Controller will

ask if you would like to

change the DHCP device

name. We recommend that you do not change this setting. Type enter to return to the menu.

To save your changes, type ” 9” from the menu. The changes will be saved in nonvolatile

memory, the telnet session will be terminated, and the Site Controller will reset.

5.9.2 Web Passwords (1)

To change the Passwords used for Web Page access type “1” followed by “Enter”. The user

Password will be displayed. To change the user password type the new password followed by

“Enter”. To keep the present

password type “Enter”.

Passwords can be 20

characters long and are case

sensitive.

Change the administrator

password in a similar fashion.

The password changes will

immediately be saved to

nonvolatile memory and become effective. Type “8” followed by “Enter” to close the telnet

session without resetting the Site Controller.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 24 of 57

Page 25

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.9.3 SNMP Agent Configuration (3)

The SNMP Community Strings and Trap destinations are configured from the SNMP

Configuration.

The default community strings

are set to “public”. To change

the community string type “3”

followed by “Enter”. The

present read (Set) community

string will be displayed in

parenthesis as shown. To

change the community string,

type the new string followed

by “Enter”. To move to the

next item without changing

the community string just type

“Enter”. The write (Set)

community string is next and is handled the same way, followed by the Trap community string.

NOTE: Community strings are case sensitive.

Up to 3 Trap destinations can be configured. The IP addresses of the Trap destinations are set

similar to the IP address

described above. To disable

sending Traps to any of the

three IP address enter zeros

for the IP address.

The Site Controller includes a feature that will reset the device if a SNMP message is not

received for approximately 2

hours. This safety feature is

primarily used when the

device is located in a remote

unmanned location. If the

SNMP firmware hangs this

may recover the device

without a visit to the remote location. The default setting is disabled. To enable the reset type a

“Y”, to disable the feature type an “N” or “Enter”.

The menu will be redisplayed at the end of the SNMP Configuration. Select “9” to save the

changes and close the telnet session.

5.9.4 HMS Defaults (4)

To restore the factory default settings for all SNMP objects, type a “4” followed by “Enter”. The

SNMP, Email, NTP, Gateway, Net Mask, and IP Address will not be changed. The telnet session

will be closed and the Site Controller will be reset.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 25 of 57

Page 26

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.9.5 Email Setup (5)

The Email system will mail alarm messages to up to 3 email addresses.

To setup the Email system, select 5 from the setup main menu. Enter the outgoing Email server

name. If there is no server name the email system is disabled. If a server name was previously

entered it will be shown. To

change the server name just

type the new name followed

by “Enter”. To keep the

server name shown, type

“Enter”. To remove the

server name (or the contents of any other text field) type any character, then “Backspace”

followed by “Enter”. The IP address of the mail server can be entered in place of the server

name if the server is unnamed.

If your server requires a user name and password enter the user name followed by “Enter”. If the

user name is left blank the Site Controller will not

send the user name and password to the mail

server. To keep the present name type”Enter”.

Now enter the server password followed by “Enter”.

Up to 3 Email address may now be entered.

The address are changed the same as the

server name.

Next enter the From Address. This is the

address that will show up in the Email when it

is received.

NOTE: The From Address should generally be set to an address that is registered on the

SMTP server. Many servers use this to authenticate the outgoing Email.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 26 of 57

Page 27

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

Finally set the Domain Name

Server (DNS) IP address. The

DNS allows the Email

application to obtain the IP

address of the specified server

so it can send the mail. There

are fields for a primary and

secondary DNS. The IP

Address are set as described in the IP Address section of this document. The default is a

commonly used DNS (4.2.2.2). Change this to your local DNS if you prefer. As long as the Site

Controller can see the internet the default DNS will work. If the DNS IP addresses are set to

zeros, the Email will be disabled.

To save your changes, type ” 9” from the menu. The changes will be saved in nonvolatile

memory, the telnet session will be terminated, and the Site Controller will reset.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 27 of 57

Page 28

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.9.6 Time Server Configuration (6)

The Site Controller can set its internal clock from any internet time server that supports Network

Time Protocol (NTP). There are many such servers around the world. Many of these servers are

operated by government standards organizations. Most private networks also have time servers.

The Site Controller is shipped with the NTP configuration set to get the time from two different US

National Institute of Standards time servers. The IP addresses of these servers can be changed

in the NTP Configuration. If the time server addresses are not configured or the Site Controller is

unable to contact either time server the Site Controller will initialize the time to 00:00:00 1/1/2008.

If communications is not established with a time server the internal clock will run from this point.

The time provided by most time servers is Greenwich Mean Time (GMT). The Site Controller will

convert this to Local Time using a time offset that can be entered in the NTP Configuration.

To configure the NTP select

option 6 from the

Configuration Main Menu.

Enter the IP addresses as

described in the IP Address

section of this manual. There

are two Time Server addresses. The Site Controller will use the

Time Offset

from GMT

12 NZST 720

11 660

10 GST 600

9 JST 540

8 CCT 480

7 420

6 360

5.5 IST 330

5 300

4 240

3 BT 180

2 EET 120

1 CET 60

0 GMT 0

-1 WAT 65476

-2 AT 65416

-3 65356

-4 AST 65296

-5 EST 65236

-6 CST 65176

-7 MST 65116

-8 PST 65056

-9 YST 64996

-10 AHST 64936

-11 NT 64876

-12 IDLW 64816

Time

Zone

Time

Offset

primary server unless it fails to respond and then it will switch to

the secondary. It will not switch back unless the secondary

server fails to respond or the Site Controller is reset. To change a

default Time Server IP Address to undefined, enter zeros for the

IP address.

The Site Controller will reset itself if there is no communications

with either time server for approximately 2 hours. To disable the

reset function enter zero for all 4 octets of the primary time server

IP address. The Site Controller will use the secondary Time

Server to set the time if the second IP address valid.

The time read from the time server is GMT. There is an option in

the NTP Setup to enter a time offset to correct the time to read

local time. If the time offset is positive, east of the UK, simply

enter the offset in minutes. If the time offset is negative, west of

the UK, the offset must be entered in 2’s compliment form. To

compute the value subtract the time offset in minutes from 65536

and enter the result. For example the offset to Eastern Daylight

time is 4 hours. 65536 - 240 = 65296 Enter 65296 as the time

offset for Eastern Daylight time. The table to the left contains the

offset value for each major time zone.

To save the changes, type ”9” from the menu. The changes will

be saved in nonvolatile memory, the telnet session will be

terminated, and the Site Controller will reset.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 28 of 57

Page 29

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.9.7 Restore Factory Defaults (7)

To restore the factory default settings type a 7. All SNMP, Email, NTP, and HMS values will be

set to the factory defaults. The IP Address will not be changed, however the Gateway and Net

Mask settings will be set to the factory default values.

NOTE: Be careful. Changing the Gateway and Net Mask settings could prevent

communications with the Site Controller, requiring a site visit.

5.9.8 Exit (8)

Type a “8” followed by an “Enter”, to exit the setup program, close the telnet window without

saving the changes to nonvolatile memory, and without resetting the Site Controller. Some

changes will take affect (SNMP) others will not (Email).

5.9.9 Save and Exit (9)

Type a “9” followed by an “Enter”, to save all changes to nonvolatile memory, close the telnet

window, exit the setup program, and reset the Site Controller so all changes take affect.

5.9.10 Erase All String and Jar Data (13)

Typing “13” followed by “Enter” will erase all of the String and Jar data from the Site Controller

nonvolatile memory and then reset the Site Controller. All user entered data for the strings and

jars including names and alarm setups will be lost. The other settings will not be changed.

5.9.11 Reset All Sensors (14)

Typing “14” followed by “Enter” will reset all the Sensors. The telnet session will remain open and

no settings will be changed. The reset will force all of the sensors to be rediscovered.

5.9.12 Erase String (15)

Typing “15” followed by “Enter” will erase a specified string. You will be prompted for the string

number. The telnet session will remain open and no settings will be changed.

5.9.13 Erase RIM/ROM Flash (16)

Typing “16” followed by “Enter” will erase the RIM and ROM database. All settings will be lost

and the devices will no longer appear in the Web page or SNMP MIBs unless they are

rediscovered. The telnet session will close and the Site Controller will reset.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 29 of 57

Page 30

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

5.10 Web Server

The Site Controller contains a Web Server that provides a complete set of Web Pages to observe

and configure the Monitoring System from a Web Browser.

The Web Browser will load a Java applet from the Site Controller when the Web Page is opened.

The applet is used to support the communications between the Web Browser on your PC and the

Site Controller. For this to operate, the Java Runtime Environment (JRE) must be installed on

your PC. This is a common function of many Web Sites so it is likely that the Java Runtime

Environment is already loaded on your PC.

If you need to load the Java Runtime Environment go to the Sun Java Web Site at:

http://java.com/en/download/windows_automatic.jsp

and follow the directions to download and install the latest version of the JRE. This is a free

download.

The Site Controller web server has been tested to work with many versions of the Sun

Java Runtime Environment. Versions of the Java Runtime Environment older than 1.4.2

may not function properly. Most newer versions appear to work properly but occasionally a

version may have a bug that inhibits some feature. Contact PBT if you suspect an incompatibility.

To check which version you are using on your PC open a Microsoft Internet Explorer and select

Tools -> Internet Options -> Advanced. Scroll down to the line that displays Java (Sun). The

version number of the Java Runtime environment installed on your PC will be shown. If this line

is not present the Sun Java Runtime Environment is not installed on your PC.

5.10.1 Accessing the Web Server

To access the Site Controller Web page type: “http://192.168.0.5” from your web browser. This

IP Address is an example, substitute your Site Controller’s IP address in place of “192.168.0.5”.

5.10.2 Ports

The Site Controller Web server uses Ports 80 and 30704 to receive requests from the PC. The

ports on the PC are selected automatically. Port 80 is the normal HTTP port. Port 30704 is used

by the Java applet to get data from the Site Controller for the real time screen updates.

The transaction goes something like this; When the Web browser is opened the PC assigns an

outgoing port X and sends a request to port 80 on the Site Controller. The Site Controller replies

with a response to the PC sent to port X. The java applet opens a connection on PC port Y to

request the real time data and sends this request to Site Controller port 30704. The Site

Controller responds to PC port Y with the requested data.

Both ports X and Y are selected by the PC. These ports may be mapped to other ports by

routers in the communication path. This does not cause any problems since the Site Controller

always responds to the port specified in the request.

If the Web page draws but the applet is unable to connect to the Site Controller chances are good

that port 30704 is being blocked by a firewall or router. This could be on your PC or somewhere

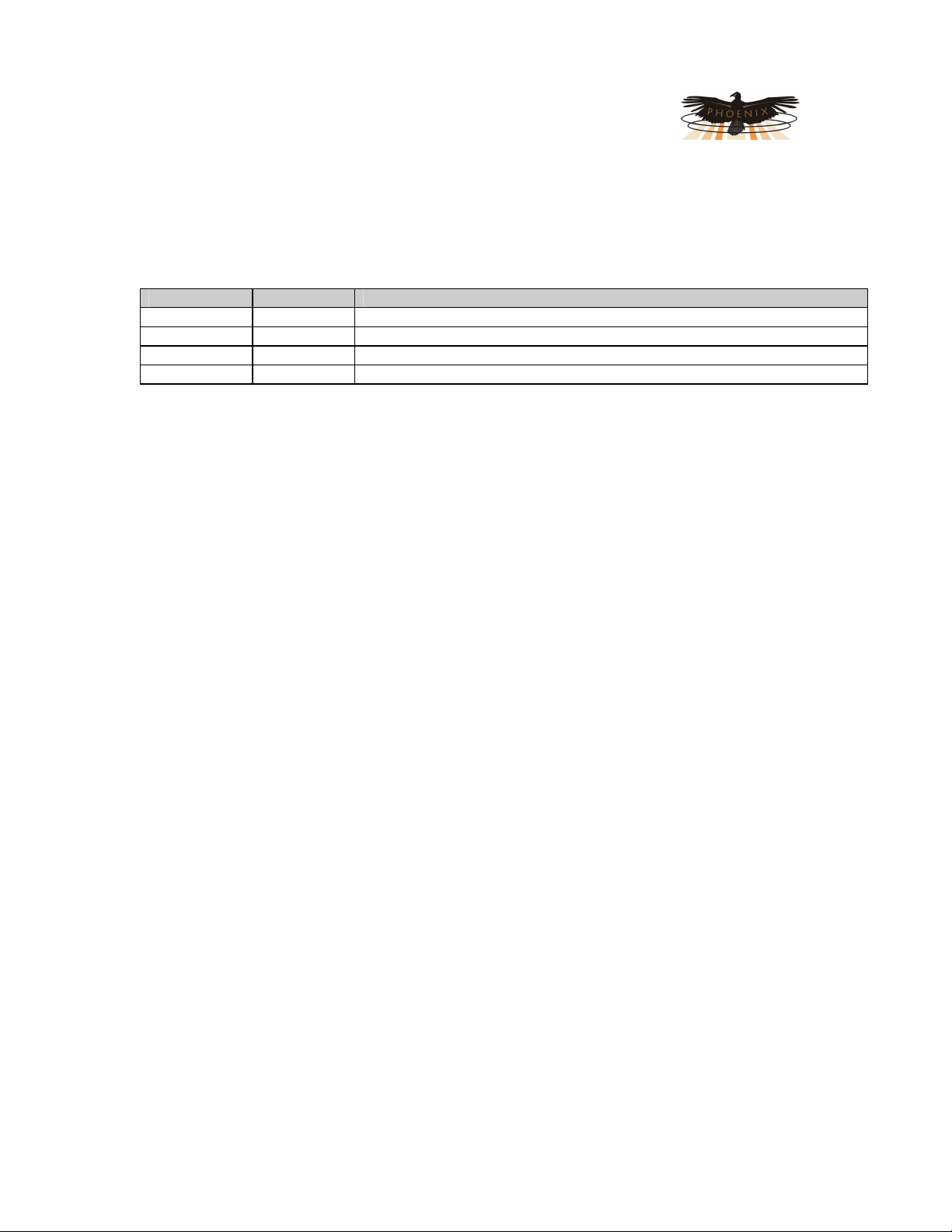

in the network. Consult with your IT people to find the problem.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 30 of 57

Page 31

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

6 Navigating the Web Pages

NOTE: The site controller web page uses a java applet, communicating on UDP port

30704, to deliver real time information. If you have trouble viewing the web page this port

may be blocked, contact your IT department.

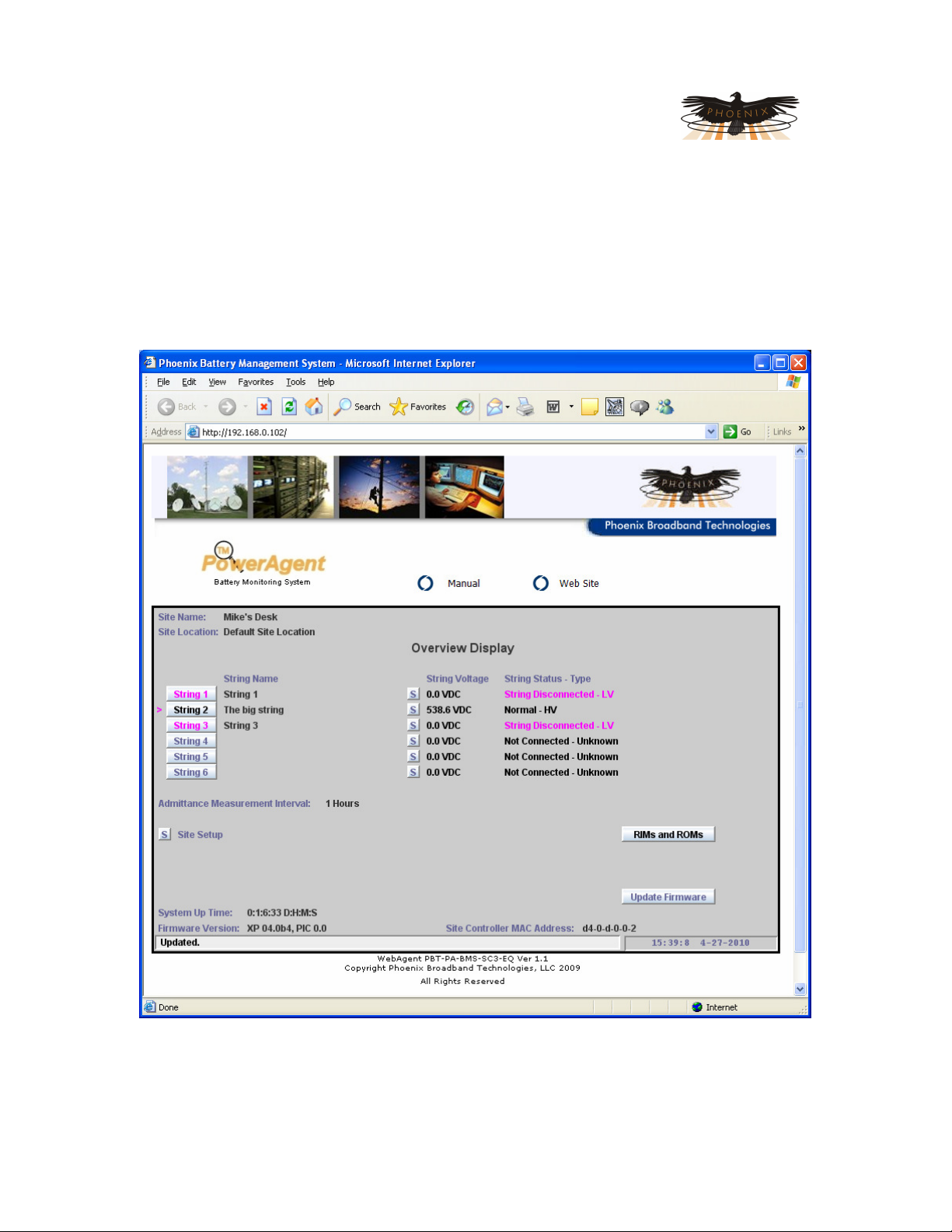

The status of the batteries that are being monitored by a Site Controller can be viewed using any

network-connected PC that has a web browser.

Type the IP address of the site controller in the browser’s URL address space, for example

“192.168.0.102”. The

controller will serve

the intial web page

which lists all battery

strings discovered,

their total string

voltage and their

status. On the bottom

left hand corner of the

web page you will see

text which toggles

between “Updated”

and “Connected”.

This indicates normal

operation, however, if

you see the message

“Trying to Connect” or

“Unable To Connect”

you may have

problems with a

firewall or router

blocking UDP port

30704. Contact your

IT department for

assistance.

The time displayed at

the lower right of each

web page is the PC

time, not the Site Controller time.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 31 of 57

Page 32

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

6.1 Overview Display

From the initial web page the user can select any available string and view details.

The button text on this page is color coded to indicate the String status. Normal status is

indicated by black, red indicates a major alarm, yellow indicates a minor alarm, green indicates

an admittance measurement is in process on the string, and magenta indicates a warning

condition.

When the Site Controller starts the previous string configuration is loaded from the database. This

configuration will be updated as new strings or jars are discovered. During the Site Controller

initialization a message “Site Controller Initializing” will appear. While this message is present the

Site Controller is checking for new sensors and collecting data (including admittance

measurements) for all sensors. Alarm checking and SNMP communications are disabled until

initialization is complete and the message disappears, to prevent alarming or reporting erroneous

readings.

Pressing the RIM/ROM button brings up RIM and ROM main page which is described later in this

document. This button is color coded with the RIM and ROM alarm status.

The Update Firmware button is used to load new firmware into various system components.

This capability is currently available for the float current sensor and is under development for

other system components. Consult PBT for the latest information on availability of this feature.

System Up Time is the time the Site Controller has been running since the last reset.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 32 of 57

Page 33

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

6.2 Single String Display

The Single String Display lists all jars associated with a string. Each string can be given its own

name which is displayed near the top of the page.

This page will display up to 40 jars. For each jar present in the string the jar voltage and

admittance change is displayed. The admittance change field will indicate “undefined” until the

initial cell admittance has been set in the Jar Setup Display.

The button text on this

page is color coded to

indicate the jar status.

Black Normal

Green Measuring

Admittance

Blue Equalizing

Red Major Alarm

Yellow Minor Alarm

Magenta Warning

Buttons will change

from Cell, for a 2 volt

cell, to Jar for a multicell jar. Press a Jar or

Cell button to view the

detailed information on

the jar.

The Discharge Status

indicator displays the

present state to this

string either “Normal”

or Discharging”. The

discharge event is

detected by the Float

Current Sensor. A

count of the Discharge

Events and the duration of the Present (or Previous) Event and the Total discharge Time are

also displayed. The event counter and total time are stored in nonvolatile memory and can be

reset from SNMP or by deleting the string. Alarms may be provisioned for the Discharge Status

by pressing the associated A button.

All Conductance measurements and Equalization are automatically disabled on all strings when a

discharge event is detected on any string.

The String Status field displays the present string monitoring status which is a summary of the

sensor status as described below.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 33 of 57

Page 34

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

String Status Description

Normal The status of all sensors on this string are Normal

Disabled The string is disable through SNMP

Shorted The Site Controller output is shorted somewhere in the sensor daisy chain

MissingSensors More sensors were expected

TooManySensors More sensors are present than the string can handle

SensorFault One or more sensors are not communicating

Alarms One or more sensors have alarms

Initializing The string is initializing

SensorDisabled One or more sensor is disable through SNMP

StringDisconnected Nothing is connected to the Site Controller string port

NoSensorCom Something is connected to the port, but no sensors are communicating

The String Voltage reading displays the total string voltage measured by the sensors. For a Low

Voltage string this voltage is measured directly by the sensor on the most negative jar. For a

High Voltage string this voltage is the sum of the individual jar voltages. Alarms may be

provisioned for this voltage by pressing the associated A button.

The Cell Voltage Delta reading displays the difference between the highest and lowest jar

voltage. Too much variation in jar voltages could be an indication that there are problems with

some jars. Alarms may be provisioned for this voltage by pressing the associated A button.

The Sensor Com indicator will display “Normal” when the Site Controller is communicating with

all the battery sensors in the string and will display “Failed” when the Site Controller has lost

communications with one or more battery sensors. Alarms may be provisioned for this indicator

by pressing the associated A button.

The Current Sensor box will appear when there is a Current Monitoring Interface, with its

address set to the string number, connected to the Site Controller P-Bus A port. If the Float

Current Sensor is connected to the Interface the Float Current reading will be displayed. If the

sensor is not connected the reading will display “No Sensor”. Alarms may be provisioned for this

current by pressing the associated A button.

If the Discharge Current

Sensor is connected to the

Interface the Discharge

Current reading will be

displayed. If the sensor is

not connected the reading

will display “No Sensor”.

Alarms may be provisioned

for this current by pressing the associated A button.

If the Float Current Sensor is connected to the Interface the Ripple Current reading will be

displayed. If the sensor is not connected the reading will display “No Sensor”. Ripple current

readings are made automatically once per hour or on demand by pressing the “Measure Ripple

Current” button. Alarms may be provisioned for this current by pressing the associated A button.

The Com Status indicator will display “Normal” when the Site Controller is communicating with all

the Current Monitoring Interface and will display “Failed” when the Site Controller has lost

communications with the Current Monitoring Interface. Alarms may be provisioned for this

indicator by pressing the associated A button.

Refer to the String Setup Display for other Current Sensor Interface setup options.

Phoenix Broadband Technologies, LLC 10/28/2010

Page 34 of 57

Page 35

PowerAgent TM SC3 Site Controller Document # 700-000014-01 Rev 2

Installation and Operation

The String Current field in the lower right hand corner displays the string charge or discharge

current in amperes. This field is for use with a current sensor that is in development.

Pressing the Previous String or Next String buttons will move to the previous or next string on

this Site Controller. Pressing the Return to Overview Display button brings up the Overview

Display.

6.3 Single Jar Display

This web page displays the measurements and control for a single Jar. Alarming parameters are

color coded with red for major alarms and yellow for minor alarms.

A user definable Jar (or Cell) Name is displayed for each jar. Some operators use this field to

identify the manufacturer and model number of the jar, or the installation date. The name may be

modified by pressing the associated S button.

The Jar (or Cell) Voltage measured by the battery sensor is displayed. Measurements are

made and report each time the sensor is polled. Alarms may be provisioned for this current by

pressing the associated A button.

The Jar (or Cell) Temperature measured by the battery sensor is displayed. Measurements are

made and report each time the sensor is polled. Alarms may be provisioned for this current by