Alpha PN-6x-T 7.5kW 48VDC Operation Manual

™

AlphaGen

7.5kW Generator Set

Installation and Operation Manual

PN-6x-T 7.5kW 48VDC Telecom Generator

Effective: January, 2006

Alpha Technologies

Alpha Technologies

Power

®

AlphaGen PN-6x-T 7.5kW 48VDC Telecom Generator

Installation and Operation Manual

745-020-B0-003, Rev. C

Effective Date: January, 2006

Copyright © 2006

Alpha Technologies, Inc.

member of The Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this power system, please contact Alpha Technologies or

your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, installed or operated in an unapproved manner, or improperly maintained.

TM

Contacting Alpha Technologies: www.alpha.com

or

For general product information and customer service (7 AM to 5 PM, Pacifi c Time), call

1-800-863-3930,

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacifi c Time or 24/7 emergency support

3

Table of Contents

Safety Notes ......................................................................................................................... 8

1.0 System Overview .................................................................................................... 13

1.1 System Diagram ............................................................................................14

1.2 Natural Gas System Block Diagram .............................................................. 15

1.3 Liquid Propane System Block Diagram ......................................................... 16

1.4 Specifi cations ................................................................................................. 17

2.0 Site Preparation ...................................................................................................... 19

2.1 Site Considerations ........................................................................................19

2.2 Acoustics ........................................................................................................ 19

2.3 Enclosure Impact Protection .......................................................................... 21

2.3.1 Generator Protection, Vehicular Areas ................................................ 21

2.4 Natural Gas Meter Confi gurations ................................................................. 23

2.5 Liquid Propane Systems ................................................................................ 24

2.6 Grounding Requirements ............................................................................... 25

3.0 Installation ...............................................................................................................26

3.1 Transportation ............................................................................................... 27

3.2 Lifting Procedure ............................................................................................ 28

3.3 Enclosure Installation Procedure ...................................................................29

3.4 Natural Gas Utility Fuel Hookup..................................................................... 30

3.5 Liquid Propane Utility Fuel Hookup................................................................ 31

3.6 Enclosure Grounding .....................................................................................32

3.7 Connecting the Ignition Battery ...................................................................... 33

3.8 Connecting the DC Output Connection..........................................................34

3.9 Terminal Block 2 (AC Line) Connection ......................................................... 35

3.10 Final Inspection Checklist ..............................................................................36

4.0 The Engine Control Module .................................................................................. 37

4.1 Theory of Operation ....................................................................................... 39

4.1.1 Standby Operating Condition Less Than Three Minutes .................... 39

4.1.2 Standby Operating Condition More Than Three Minutes .................... 39

4.1.3 Normal APU Shutdown ....................................................................... 40

4.1.4 Abnormal APU Shutdown.................................................................... 40

4.2 ECM Operating Mode Summary .................................................................... 40

4.3 LED Indicators ............................................................................................... 41

4.4 Control Functions ........................................................................................... 42

4.5 Alarm Classifi cations ...................................................................................... 43

4.6 ECM Alarm Overview ..................................................................................... 45

4.7 Connecting the Alarm and Control Connections ............................................46

4

745-020-B0-003, Rev. C

Table of Contents, continued

4.8 ECM DIP Switch and Fuse Confi guration ......................................................47

4.9 ECM Interface Block Diagram and Connectors .............................................49

4.10 ECM Input Voltage and Line Sense Confi gurations ....................................... 50

4.11 ECM Self-test ................................................................................................. 51

4.12 Maintenance Functions ................................................................................. 52

5.0 Turn-up and Test ..................................................................................................... 53

5.1 Appearance and Condition of Components ................................................... 55

5.2 System Preparation ....................................................................................... 55

5.3 Performing a Local APU Test ......................................................................... 56

5.4 Generator System Sensor Verifi cation ........................................................... 56

5.4.1 Enclosure Alarm Verifi cation ............................................................... 58

5.4.2 AC and DC Line Sense Verifi cation ....................................................57

6.0 Operation .................................................................................................................58

6.1 Normal Operating Condition .......................................................................... 58

6.1.1 AC Line Fail ......................................................................................... 58

6.1.2 Low DC Bus Level............................................................................... 58

6.2 Ignition Battery Charger Overview ................................................................. 59

7.0 Maintenance ............................................................................................................ 60

7.1 Servicing the APU .......................................................................................... 61

7.2 Filter Cleaning ................................................................................................ 62

7.3 Pad Shear Magnetic Switch Replacement..................................................... 63

7.4 Replacing Gas Hazard Sensor ...................................................................... 64

7.5 Replacing Ignition Battery Charger Module Assembly ................................... 65

7.6 Replacing Engine Control Module ................................................................ 66

7.7 Fuel Conversion – Natural Gas to LP ............................................................67

7.7.1 Pre-regulator Removal with Low Pressure Switch Installation ............ 67

7.7.2 Switching the LP Port to the NG Port .................................................. 68

7.8 Gas Solenoid Replacement Procedure..........................................................69

7.9 Maxitrol Pre-regulator Calibration ..................................................................70

8.0 Interconnection .......................................................................................................74

8.1 Gas Hazard Alarm Interface Connector ......................................................... 74

8.2 Low Fuel Pressure Interface Connector ........................................................ 74

8.3 Gas Solenoid Interface Connector ................................................................ 75

8.4 48V Charger Module Control Interface Connector.........................................75

8.5 ECM Enclosure Alarm Interface Connector ................................................... 76

8.6 Inverter Battery DC Sense Interface Connector ............................................ 76

8.7 48VDC Charger Control Interface Connector ................................................77

8.8 ECM AC Line Sense 120/240V Interface ....................................................... 77

8.9 ECM APU Control Interface ........................................................................... 78

8.10 ECM Alarm Interface & Communications ......................................................78

745-020-B0-003, Rev. C

5

List of Figures and Tables

Fig. 1-1, PN-6x-T Generator and Enclosure (operator’s side) ............................................. 13

Fig. 1-2, System Diagram .................................................................................................... 14

Fig. 1-3, Arrangement of Metered, Nominal Pressure (1-2psi) Natural Gas System........... 15

Fig. 1-4, Excess Flow Valve ...............................................................................................15

Fig. 1-5, LP Propane Vapor Withdrawal Block Diagram ...................................................... 16

Fig. 2-1, Generator Sound Levels at 100% Load ................................................................ 19

Fig. 2-2, Acoustical Measurements in Relation to Placement Near Residences ................. 20

Fig. 2-3, Vehicular Area Impact Protection for Collocated Natural Gas Meter ...................21

Fig. 2-4, Vehicular Area Impact Protection for Remote Natural Gas Meter ........................ 22

Fig. 2-5, Collocated Natural Gas Meter Setup.....................................................................23

Fig. 2-6, Remote Natural Gas Meter Setup ......................................................................... 23

Fig. 2-7, Liquid Propane Setup ........................................................................................... 24

Fig. 2-8, Grounding Requirements ......................................................................................25

Fig. 3-1, Sweep Dimensions................................................................................................ 26

Fig. 3-2, Pallet Bolt Locations .............................................................................................. 27

Fig. 3-3, Lifting Plates Attached to Cabinet ......................................................................... 28

Fig. 3-4, Pad Shear Sensor/Magnet Assembly.................................................................... 29

Fig. 3-5, Enclosure Grounding............................................................................................. 30

Fig. 3-6, Utility Gas Service Input ....................................................................................... 31

Fig. 3-7, Propane Fuel Hookup .......................................................................................... 32

Fig. 3-8, DC Output Safety Shroud ..................................................................................... 33

Fig. 3-9, DC Output Block ................................................................................................... 33

Fig. 3-10, Ignition Battery Installation .................................................................................. 34

Fig. 3-11, Terminal Block 2 Location .................................................................................... 35

Fig. 4-1, Location of Engine Control Module (ECM) ...........................................................37

Fig. 4-2 (a), ECM LED Indicators, Switches, and Interface Connections ............................ 38

Fig. 4-2 (b), ECM Printed Circuit Boards ............................................................................ 38

Fig. 4-3, LED Indicators and Control Functions...................................................................42

Fig. 4-4, RS-488 Communications Input Connector ............................................................46

Fig. 4-5, Terminal Block 1 ....................................................................................................46

Fig. 4-6, SW5 and Fuse Locations ......................................................................................47

Fig. 4-7, SW5 Settings.........................................................................................................48

Fig. 4-8, ECM/APU Interconnection ................................................................................... 49

Fig. 4-9, Input Voltage and Line Confi guration Schematic ..................................................50

6

745-020-B0-003, Rev. C

List of Figures and Tables, continued

Fig. 5-1, Generator Set Master Switch and Run/Auto/Stop (RAS) Switch .......................... 54

Fig. 6-1, Ignition Battery Charger LED ................................................................................ 59

Fig. 6-2, Wiring for ECM, Ignition Battery Charger, and Ignition Battery ............................. 59

Fig. 7-1, Air Filter Removal ..................................................................................................62

Fig. 7-2, Pad Shear Sensor ................................................................................................. 63

Fig. 7-3, Gas Hazard Sensor Location ............................................................................... 64

Fig. 7-4, Ignition Battery Charger ........................................................................................ 65

Fig. 7-5, ECM with Connectors Attached.............................................................................66

Fig. 7-6, Pre-regulator Removal ..........................................................................................67

Fig. 7-7, Switch Assembly Installed ..................................................................................... 67

Fig. 7-8, Load Block.............................................................................................................68

Fig. 7-9, Changing Load Block Confi guration ...................................................................... 68

Fig. 7-10, Fuel Solenoid Valve ............................................................................................. 69

Fig. 7-11, Primary Fuel Regulator ........................................................................................ 70

Fig. 7-12, Pre-regulator Calibration .....................................................................................71

Fig. 7-13, Secondary Demand Regulator ............................................................................ 71

Fig. 7-14, Manometer Connection ....................................................................................... 72

Fig. 8-1, Gas Hazard Detector Interface Connector ............................................................ 74

Fig. 8-2, Low Fuel Pressure Interface Connector ................................................................ 74

Fig. 8-3, Gas Solenoid Interface Connector ........................................................................ 75

Fig. 8-4, Charger Control Interface Connector .................................................................... 75

Fig. 8-5, ECM Enclosure Alarm Interface Connector...........................................................76

Fig. 8-6, Inverter Battery DC Sense Interface Connector ....................................................76

Fig. 8-7, 48VDC Charger Control Interface Connector........................................................77

Fig. 8-8, ECM AC Line Sense, 120/240V Interface ............................................................. 77

Fig. 8-9, APU Control Interface............................................................................................78

Fig. 8-10, ECM, SCM Connector Arrangement ................................................................... 78

Table 3-1, Terminal Block 2 Connections ............................................................................35

Table 4-1, Engine Crank Cycle ............................................................................................ 39

Table 4-2, Major/Minor Alarm Indications and Notifi cations ................................................. 45

Table 4-3, Telecom Defaults ................................................................................................47

Table 4-4, DIP Switch Settings ............................................................................................ 48

745-020-B0-003, Rev. C

7

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

ATTENTION:

The use of ATTENTION indicates specifi c regulatory/code requirements that may affect the placement of

equipment and installation procedures.

NOTE:

A NOTE provides additional information to help complete a specifi c task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING!

A WARNING presents safety information to PREVENT INJURY OR DEATH to the

technician or user.

8

745-020-B0-003, Rev. C

General Safety Precautions

To avoid injury:

• This enclosure and its associated hardware must be serviced only by authorized personnel.

• Enclosure must remain locked at all times, except when authorized service personnel are present.

• Remove all conductive jewelry or personal equipment prior to servicing equipment, parts, connectors,

wiring, or batteries.

• Read and follow all installation, equipment grounding, usage, and service instructions included in this

manual.

• Use proper lifting techniques whenever handling enclosure, equipment, parts, or batteries.

• Batteries contain dangerous voltages, currents and corrosive material. Battery installation, maintenance,

service and replacement must be performed by authorized personnel only.

• Never use uninsulated tools or other conductive materials when installing, maintaining, servicing or

replacing batteries.

• Use special caution when connecting or adjusting battery cabling. An improperly connected battery cable,

or unconnected battery cable, can result in arcing, fi re, or possible explosion.

• A battery that shows signs of cracking, leaking or swelling must be replaced by authorized personnel

immediately using a battery of identical type and rating.

• Avoid any contact with gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery.

Emissions contain dilute sulfuric acid that is harmful to the skin and eyes. Emissions are electrolytic, and

are electrically conductive and are corrosive. Follow the Chemical Hazards notes if contact occurs.

• Do not smoke or introduce sparks in the vicinity of the batteries or natural gas/propane connections.

• Under certain overcharging conditions, lead-acid batteries can vent a mixture of hydrogen gas that is

explosive. Proper venting of the enclosure is required.

• Follow the battery manufacturer’s approved transportation and storage instructions.

To avoid damage:

• Prior to installation, verify that the AC input voltage to the enclosure and its equipment match with respect

to voltage and frequency.

• Prior to installation, verify that the output voltage from the enclosure or its equipment match the voltage

requirements of the connected equipment (load).

• Prior to installation, verify that the enclosure’s utility service panel is equipped with a properly rated circuit

breaker for use with the equipment inside. Refer to manufacturer’s recommendations.

• Review and upgrade utility service panel circuit breaker requirements whenever the equipment within the

enclosure is changed.

• Prior to installation, contact local utilities, local building maintenance departments, and cable/piping

locator services to ensure that installation does not interfere with existing utility or building cables/piping.

• Do not exceed the output rating of equipment. Verify load requirements prior and during connection

process.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may

have developed in your body.

745-020-B0-003, Rev. C

9

Battery Safety Notes

WARNING!

Lead-acid batteries contain dangerous voltages, currents and corrosive material. Battery

installation, maintenance, service, and replacement must only be performed by authorized

personnel.

Chemical Hazards

Any gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery contain dilute sulfuric

acid, which is harmful to the skin and eyes. Emissions are electrolytic, and are electrically conductive and

corrosive.

To avoid injury:

• Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

• Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove

all metallic objects from hands and neck.

• Batteries produce explosive gases. Keep all open fl ames and sparks away from batteries.

• Use tools with insulated handles. Do not rest any tools on top of batteries.

• Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects,

or other reproductive harm. Battery post terminals and related accessories contain lead and lead

compounds. Wash hands after handling (California Proposition 65).

• Wear protective clothing (insulated gloves, eye protection, etc.) when installing, maintaining,

servicing, or replacing batteries.

• If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your

company’s approved chemical exposure procedures.

• Neutralize any spilled battery emission with the special solution contained in an approved spill kit or with

a solution of one pound Bicarbonate of soda to one gallon of water. Report chemical spill using your

company’s spill reporting structure and seek medical attention if necessary.

• Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

• Do not charge batteries in a sealed container. Each individual battery should have at least 0.5

inches of space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of potentially

dangerous gas.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have

developed on your body.

• Never use uninsulated tools or other conductive materials when installing, maintaining, servicing, or

replacing batteries.

• Use special caution when connecting or adjusting battery cabling. An improperly connected battery cable

or an unconnected battery cable can make contact with an unintended surface and can result in arcing,

fi re, or possible explosion.

• A battery showing signs of cracking, leaking, or swelling should be replaced immediately by Authorized

Personnel using a battery of identical type and rating.

10

745-020-B0-003, Rev. C

Battery Maintenance Guidelines

The battery maintenance instructions listed below are for reference only. Battery manufacturer’s instructions

for transportation, installation, storage, or maintenance take precedence over these instructions.

• To prevent damage, inspect batteries every 3 months for:

Signs of battery cracking, leaking or swelling. The battery should be replaced immediately by

authorized personnel using a battery of the identical type and rating.

Signs of battery cable damage. Battery cables should be replaced immediately by authorized personnel

using replacement parts specifi ed by vendor.

Loose battery connection hardware. Refer to battery manufacturer’s documentation for the correct

torque and connection hardware for the application.

• Apply battery manufacturer’s specifi ed antioxidant compound on all exposed connections.

• Verify battery terminals and/or exposed connection hardware is not within 2 inches of a conductive

surface. Reposition batteries as necessary to maintain adequate clearance.

• Clean up any electrolyte (battery emission) in accordance with all federal, state, and local regulations or

codes.

• Proper venting of the enclosure is recommended. Follow the Battery Manufacturer’s approved

transportation and storage instructions.

• Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

• Do not charge batteries in a sealed container. Each individual battery should have at least 0.5

inches of space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of potentially

dangerous gas.

Recycling and Disposal Instructions

Spent or damaged batteries are considered environmentally unsafe. Always recycle used batteries or dispose

of the batteries in accordance with all federal, state and local regulations.

Electrical Safety

• Lethal voltages are present within the power supply and electrical boxes. Never assume that an electrical

connection or conductor is not energized. Check the circuit with a volt meter with respect to the grounded

portion of the enclosure (both AC and DC) prior to any installation or removal procedure.

• Always use the buddy system when working under hazardous conditions.

• A licensed electrician is required to install permanently wired equipment.

• Input voltages can range up to 240VAC. Ensure that utility power is disabled before beginning installation

or removal.

• Ensure no liquids or wet clothes contact internal components.

• Hazardous electrically live parts inside this unit are energized from batteries even when the AC input

power is disconnected.

Gas Safety

• Do not smoke or use any source of fl ame around gas lines. Propane and natural gas are extremely

fl ammable, and explosive at high concentrations. Large releases can create a fl ammable vapor cloud.

• In high concentrations gas is an asphyxiant that displaces oxygen from the breathing atmosphere.

• Contact with liquid may cause skin and eye burns.

745-020-B0-003, Rev. C

11

Auxiliary Power Unit (APU) Notes

• When the engine is stopping, a small amount of unburned fuel may be present. Fans are used to expel

these fumes from the enclosure, but fumes may be detected outside the enclosure for a short period of

time after engine shutdown. This is a normal condition and does not present a hazard.

• Most utilities add a chemical agent to the gas which produces a strong odor so leaks can be detected

before they reach a dangerous or explosive level. It may be possible to detect this gas additive odor even

though the gas hazard sensor does not issue an alarm. The gas sensor will issue an alarm when the

detected levels of gas reaches 10% to 20% of the Lower Explosive Limit (LEL). The gas hazard sensor

has a 10 minute delay for periods of purging and power up. During the purge phase, the Green alarm light

will fl ash. When the purge phase is completed, the light will glow steadily. In the event the detector has

been disconnected from power for more than 24 hours, it may require a period of more than 10 minutes

to complete its purge phase. In that event, push the reset button to disable the alarm for repeated purge

cycles. The reset button may be used to disable the alarm for 10 minutes at any time.

• If gas fumes are detected before the engine is run, or more than 10 minutes after engine shutdown, you

must check the system for leaks and correct as necessary.

12

745-020-B0-003, Rev. C

1.0 System Overview

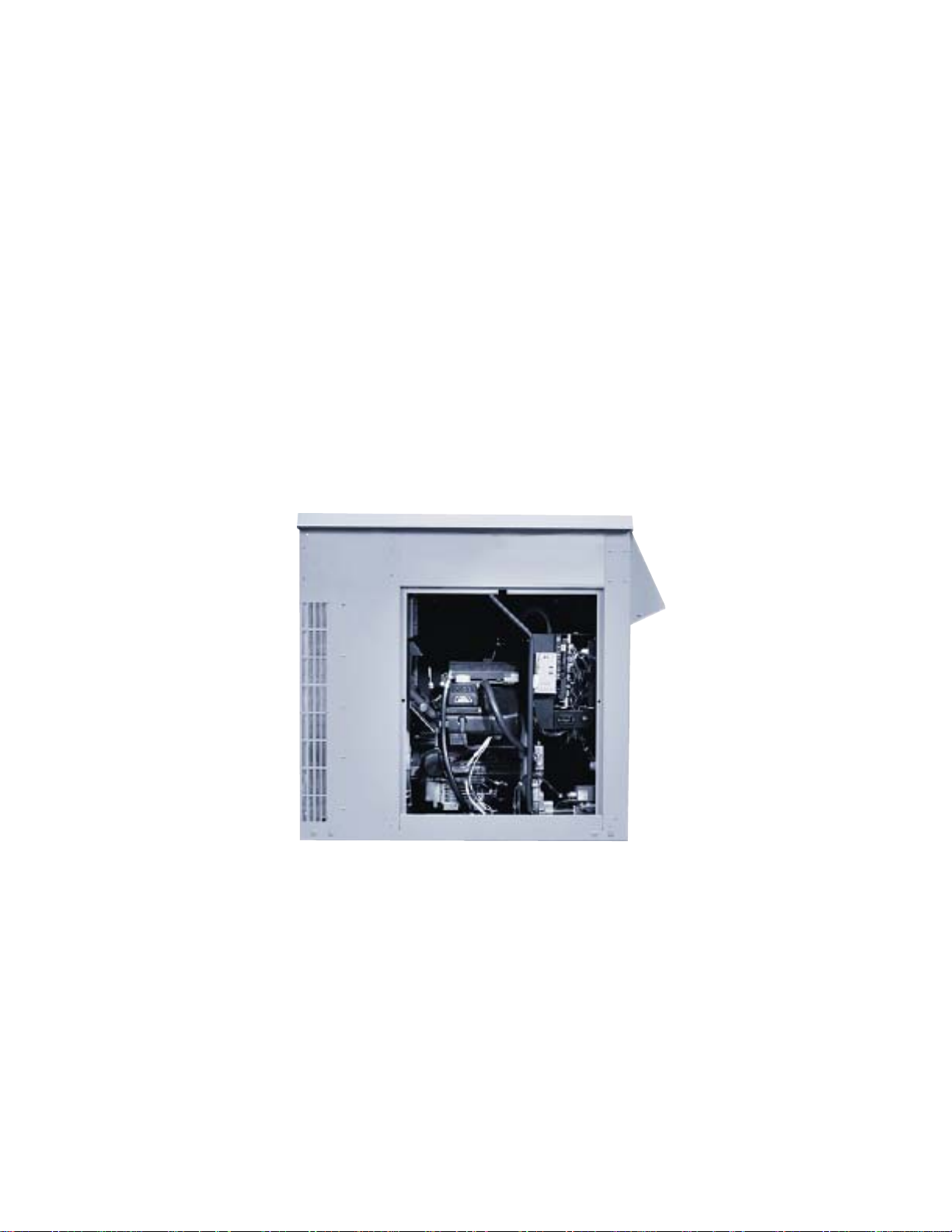

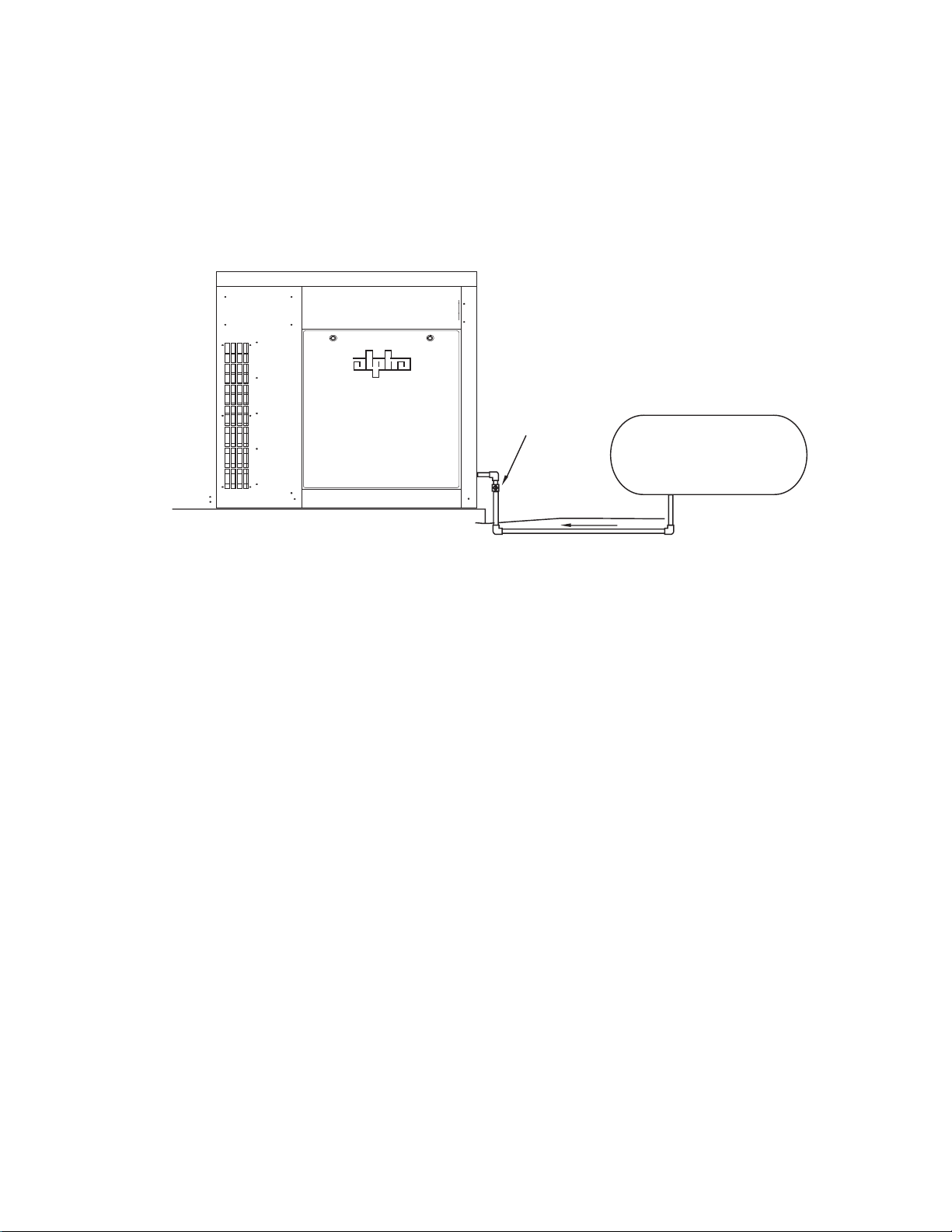

The AlphaGen PN-6x-T curb side generator system is designed to power outside plant

communication networks. Every AlphaGen system incorporates industry leading power technology,

including natural gas or propane fueling, exclusive audible noise baffl ing, remote status monitoring

features, and a durable, weather resistant enclosure.

The procedures in this document describe the installation, operation and maintenance of the PN-6x-T

generator and enclosure.

Features:

• Cost effective extended runtime solution for outdoor powering applications

• Quiet operation, small size, and low profi le allow for easier installation in populated areas

• Eliminates large quantities of batteries otherwise required for extended runtime

• Telecom grade 48VDC output

• Built-in safeguards to protect the system, operators and the public

• Safe unattended operation designed to UL2200, NFPA 37, 54, 58 & 70 standards

745-020-B0-003, Rev. C

Fig. 1-1, PN-6x-T Generator and Enclosure (operator’s side)

13

1.0 System Overview, continued

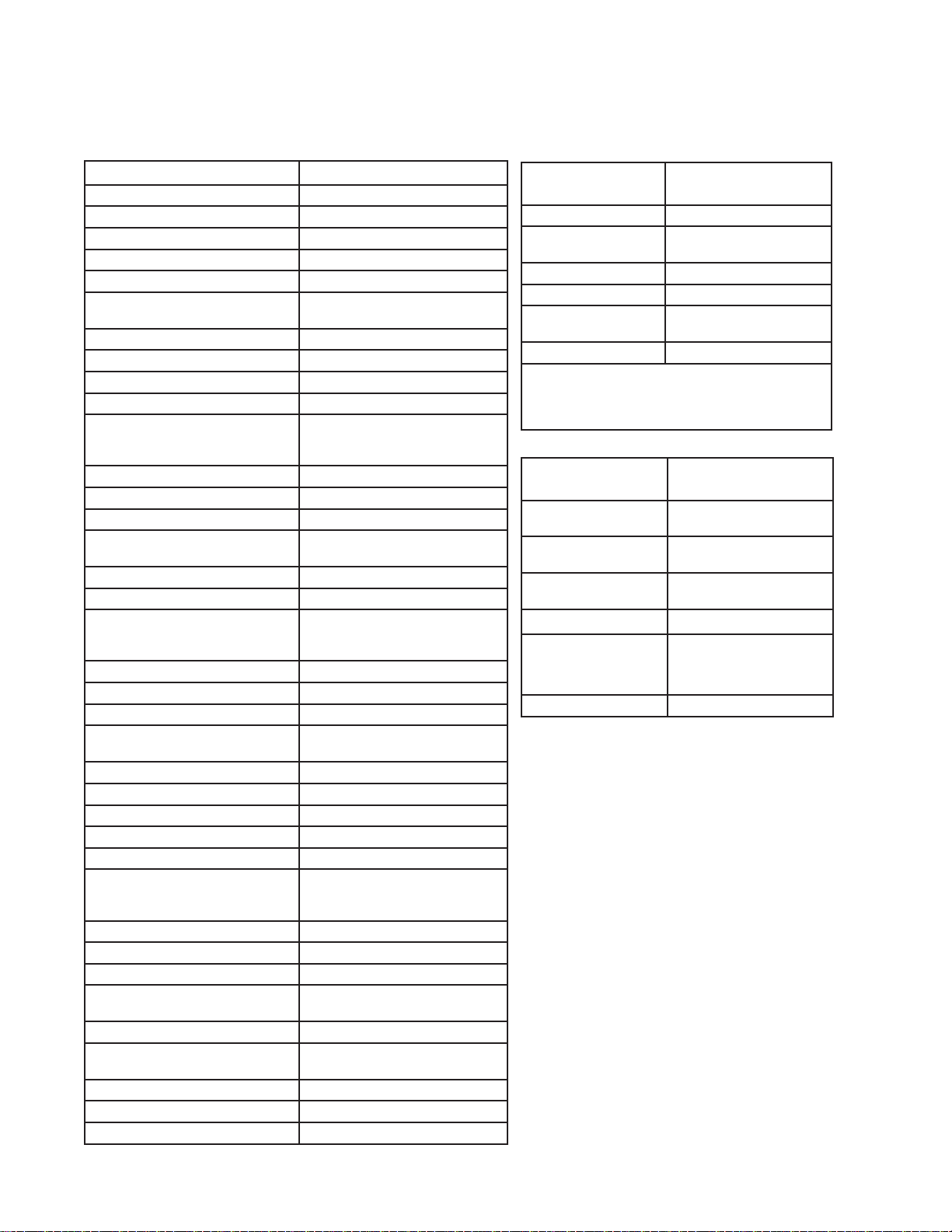

1.1 System Diagram

HR

BCA

SM

SS

SS

SR

P

P

Battery Charging

Regulator

+

SR

STARTER RELAY

0

1

7

N

7

0

-1

2

LP

UE

ROUND P2-2

F

G

CRANK P2-1

.

MP

PRESS.

E

L

T

RY +

TTE

3-5 BA

P

P

I

R

OW O

OVE

L

1

1

7

P1-

P1-10 E NGINE RUNNING

P1-

P1- 6 START

P1-2 GROUND

P1- 4 OVER CRANK

P1- 3 BATTERY+

P1-9 S TOP

P1-1 GROUND

TT

N

VC

N

P

S

STP

LOP

OVT

O

RUN

IGNITION MODULE

QCON1

IGN

3

NP2-1

O

NITI

IG

D

EE

P

1-12 O VERS

P

OVS

IGNITION MODULE

HR

70

GAUGES P2-6

CONTROL

PCB

SPEED SENSING

P3- 4

P3- 3

AC1

AC2

STM

YEL

RED

P7- 2

M4

P2-16

7

-1

2

P

37

P7-4

M2

0

-2

2

P

L

NTRO

O

C

THROT TLE

SECONDS AFTER

START, THEN 5

INHIBIT FOR

30

SECOND SHUTDOWN

WHT

P7-1

M1

P2-19

NT

E

TM

R

2-18

P

13

ENGINE

COMP A

SW

P

HIGH OILTEM

R

D

ATO

EA

ST

3L

EATER

H

BLOCK

T

HO

LOP

LOW OIL PRESSURE SWITCH

C

A

+

D

B

-

E

RECT

OR

T

E

R

ARBU

C

R

E

HEAT

AC

V

120

P7-3

M3

N

-12

-3

2

2

P

-) P

(

BAT

T

TPU

SING

N

SE

DCOU

P3-2

P3-1

DCP

DCN

IGNITION

BATTERY

-

C

NC

163

2

9

J4

M

EC

3

2

4

1

J9

K

C

RED

BLA

2

1

J1

34

J2

Y

2

1

ER

RGER

A

TT

BA

CH

BLACK

RED

J9

N

ER

SIO

T

A

TRU

W

N

I

N

487

5

YELLOW

1

R

EA

12

11

10

PADSHEAR

0

1

J

2

3

1 WATERINTRUSION

ORANGE

E

T

WHI

WHITE

RED

PADSH

L

SURE SW

S

LOW F U E

PRE

1

2

5

678

3

4

3

1

B1

T

R

WE

O

ESS.

P

R

LP

E

AZARD

H

S

A

GASHAZARD

LOW F U

G

0

5

462

9

8

7

1

TE

WHI

BLACK

BLACK

K

GE

N

GREEN

RA

BLAC

O

1

2

Y

L

PG M OD EL

ON

L

9

12

1011

N

E

P

O

OUND

R

NC

DOOR

12 V

G

4

11

1

13

12

-7

2

2-8

B

TB

T

R

O

S

123

S

A

G

HAZARD

SEN

AC SENSE

2

1

-2

2

B2-1

T

TB

TB2-11

-13

2

B

T

TB2- 20

00 AM P CB

2

1

2

345

6

7

8

9

0

1

11

12

13

4

1

15

6

1

17

18

19

20

21

2223

TB 2

C

L

A

C

N

A

G

AC

IL

AC/

FA

COM

O

AIL

AC/

F

N

/

IL

A

NC

AC

F

LPG

(12V)

(See Fig. 3-12 for details)

G

P

(-)

L

r

OM

Doo

C

O

oor

N

D

M

R

NO

COM

MINOR

ALA

M

R

NC

MINOR

ALA

NO

MINOR

ALARM

NC

ENG

RUN

N

NO

ENG

RU

ENG

RUN

COM

BY

NC

ALM

M

BY

NO

AL

M

O

BY

ALM

C

NC

COM

MINOR

ALARM

R

M

O

C

ALARM

RM

NO

ALA

M

R

A

NC

L

MAJORMAJORMAJO

A

POS

NEG

L

Y

A

COM

NC

NO

EL

N

AC FAIL

R

B

COM

C

W

UT

P

NC

NO

OUT

AUX S W

DOOR S

DOOR SW

S

S

Y

A

RM

A

AL

BYPA

6

2

8

REL

4

7

3

1

0

9

TB1

ECM

4

1-

CM

B

T

E

5

M

1-

C

B

T

E

-6

ECM

TB1

14

Fig. 1-2, System Diagram

745-020-B0-003, Rev. C

1.0 System Overview, continued

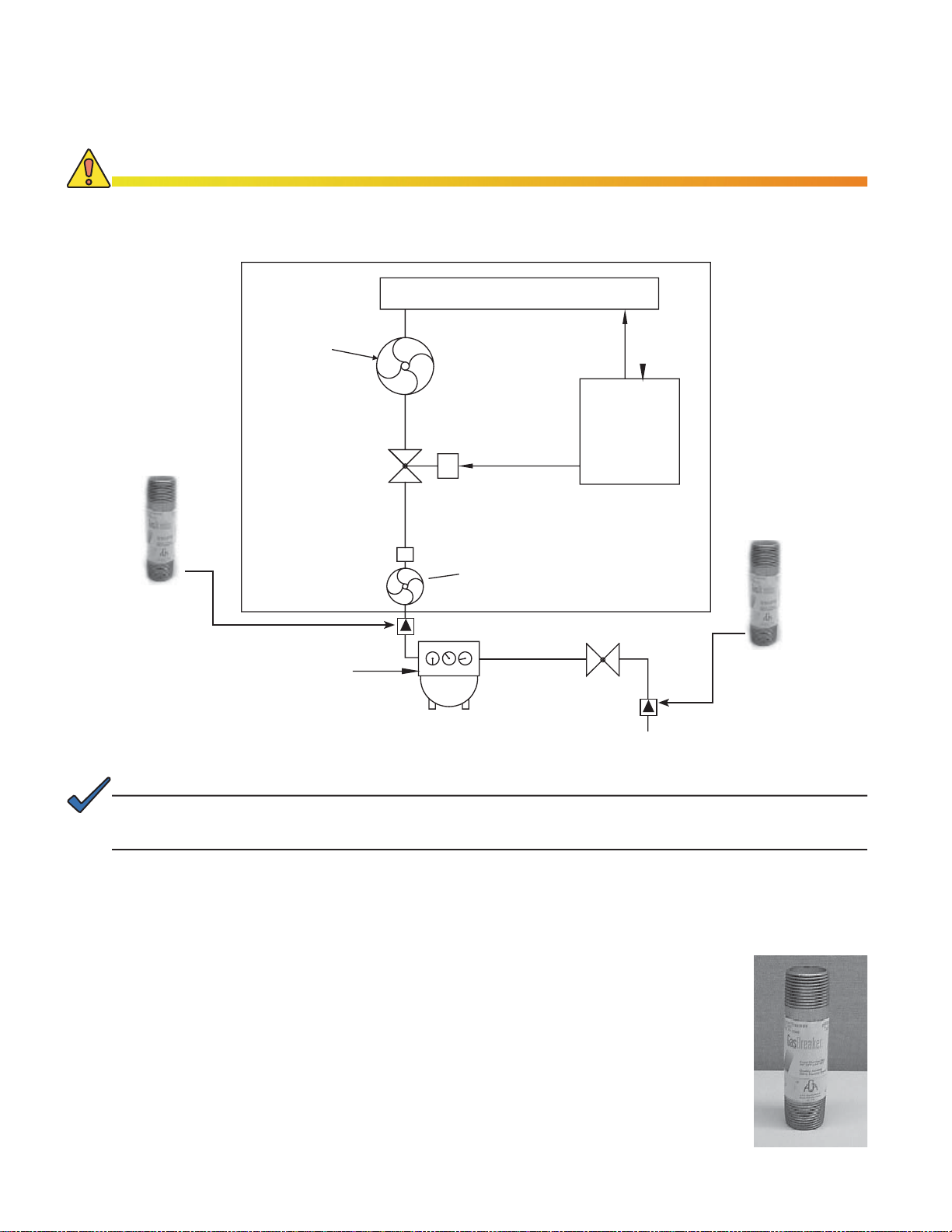

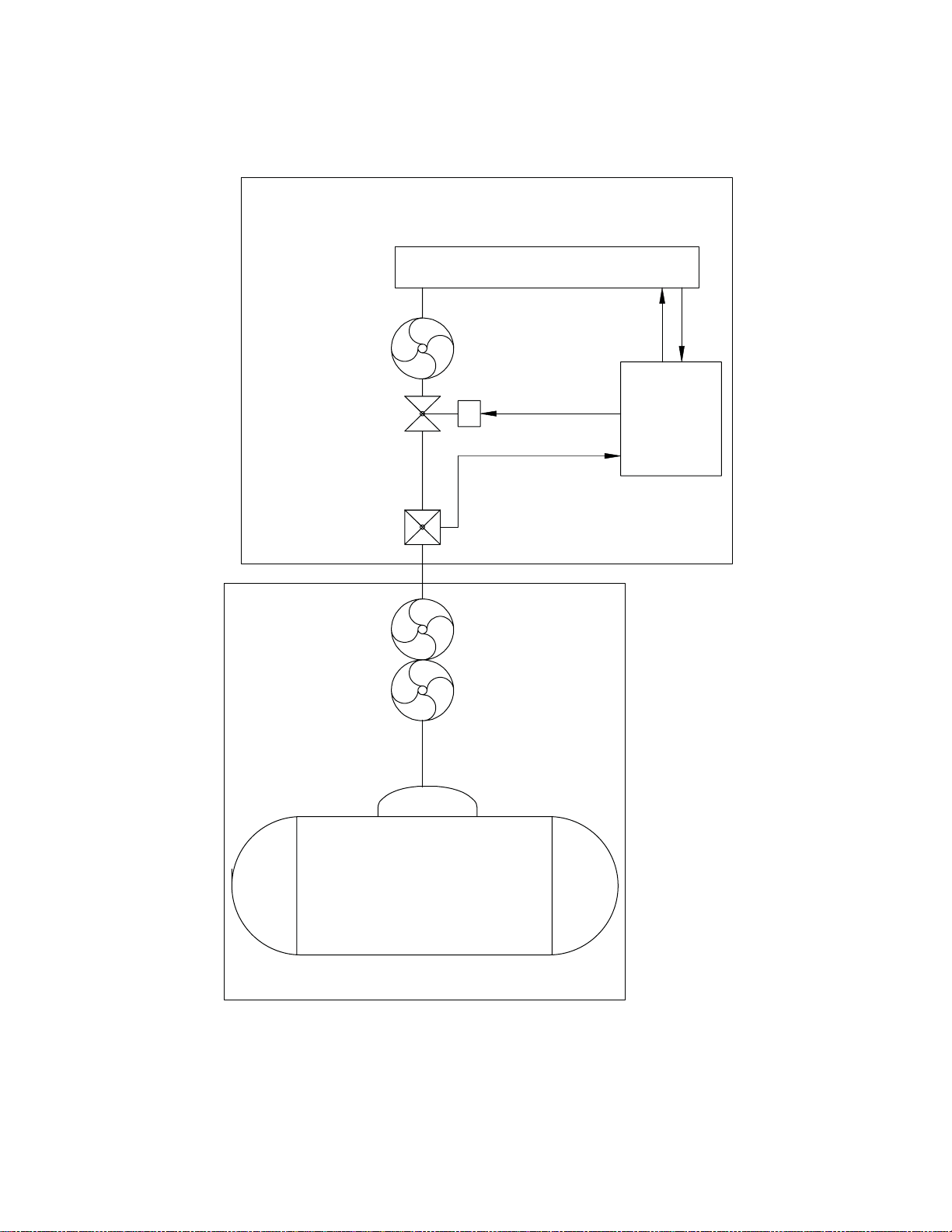

1.2 Natural Gas System Block Diagram

CAUTION!

Do not include the generator system as part of a local gas piping system test. Damage to the

generator pre-regulator may result. The generator system is pressure tested in accordance with

NFPA standards prior to shipment.

ENGINE

Demand

Low-pressure

Regulator

CONTROLS

APU

Enclosure

Flare Coupling

(Quick-Disconnect)

Low pressure excess

flow valve (optional)

NOTE: 1 psi = 28" WC

0.5 psi (min.)

1 psi (nominal)

10 psi (max)

14" WC

(max.)

Solenoid

S

Engine must have

7" to 11" WC and 156 cubic

feet/Hr. to operate

Pre-Regulator

Maxitrol 325-3

10 psi max input

Meter

WC = Water Column H

CONTROL

Manual

Shutoff

O

2

High pressure

(optional)

excess flow valve

Fig. 1-3, Arrangement of Metered, Nominal Pressure (1-2psi) Natural Gas System

NOTE:

For added safety, a low pressure and/or high pressure excess fl ow valve may be installed.

ATTENTION:

Federal DOT Regulation 49 CFR Part 192.383, Excess Flow Valve Customer Notifi cation, requires gas

utilities to either voluntarily install Excess Flow Valves (EFVs) on all new home service lines or to notify

builders about EFVs’ benefi ts and availability. EFVs are installed on gas service lines during pre-construction

site work, and automatically activate when a gas line is ruptured. Excess fl ow valves should never be used as

in-line regulators. They cannot perform this function and may damage equipment.

745-020-B0-003, Rev. C

Fig. 1-4, Excess Flow Valve

(above ground ¾" x 4" NPT nipple)

Alpha P/N 042-146-10

15

1.0 System Overview, continued

1.3 Liquid Propane System Block Diagram

LP PROPANE - VAPOR WITHDRAWAL

DEMAND

LOW PRESSURE

REGULATOR

MAX

APU

ENCLOSURE

SENSOR

8oz

11"WC

BLOCK DIAGRAM

ENGINE

SOLENOI

S

LOW FUEL ALM

LOW FUEL

PRESSURE

SWITCH

CONTROLS

D

CONTROL

11"W

OUTLE

C

T

PROPANE

POST-REG

PROPANE

ENCLOSURE

LPG TANK

Fig. 1-5, LP Propane Vapor Withdrawal Block Diagram

16

745-020-B0-003, Rev. C

1.0 System Overview, continued

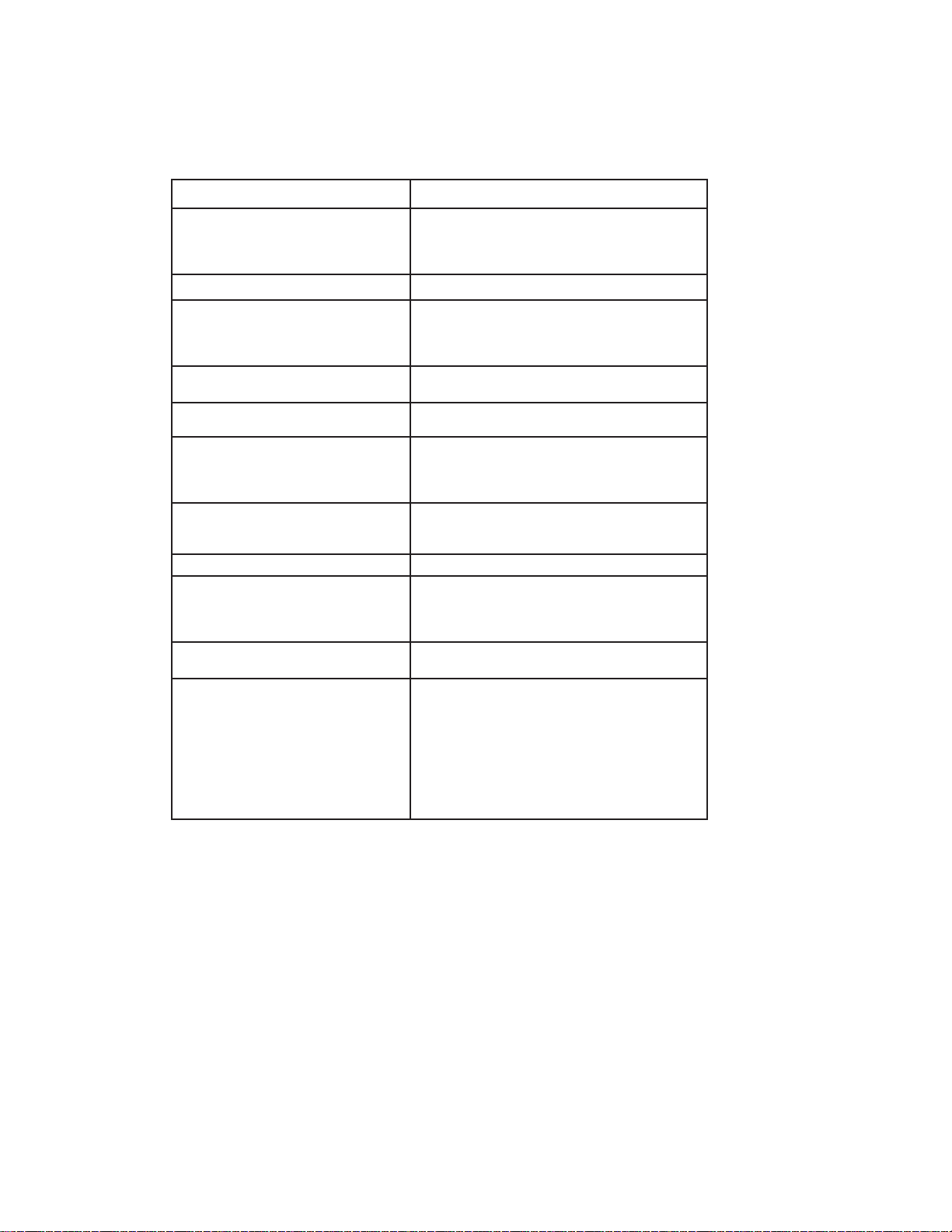

1.4 Specifi cations

System Specifi cations Specifi cation

System Size Height: 39.0" (57" with optional pedestal)

Acoustic 70.3 dBa @ 10 feet, (100% load)

DC Electrical Noise (PN-6x-T) RF: <100mV RMS in any 3kHz Band, 3kHz to

Gas Inlet Pressure 0.5-2 psi NOTE: Contact Alpha Technologies for

Integral Ignition Battery Charger Voltage 13.5 to 14.3VDC regulated, 15A max,

Width: 39.25"

Depth: 24"

Weight: 338 lbs (370 lbs with optional pedestal)

20MHz

Broadband: <250mV Pk to Pk

Voice Freq. Noise: Less than 56dBnrc

low pressure operation below 0.5 psi.

Remote Interface Length 12’ max. (sweep to sweep)

Agency Compliance UL 1778, UL2200, CSA 22.2 No. 107.1, and appli-

Exterior Surface Temperature 70°C max. (meets requirements of UL/CSA)

Fuel System Controls & Monitoring The controls and fuel system meet appropriate

Sensors Gas Hazard, Pad Shear, Water Intrusion, Tamper,

Safety Shutdowns Low oil shutdown

NOTE: Distance depends upon proper installation,

derating, and wire gauge. Contact Alpha Technologies for installations requiring greater distances.

cable sections of NFPA 37/54/58 and 70, EMC/FFC

Part 15 Class A

sections of NFPA 37,54, and 58 for automatic,

unattended remote operation of enclosed

generators.

Low Fuel Pressure

Oil over-temp

Engine over-speed

Over-crank (Crank limit)

Gas hazard (LPG or natural gas)

Low fuel pressure shutdown (LPG)

Water intrusion

Pad shear

Alternator over-voltage

745-020-B0-003, Rev. C

17

1.0 System Overview, continued

1.4 Specifi cations, continued

Engine Specifi cations Specifi cation

Manufacturer Kohler

Make/model CH20

Cycle 4

Compression Ratio 8:5:1

Displacement, cu. in. (cc) 38 (624)

Rated Horsepower

(using natural gas fuel)

Engine Speed (rpm): 2100-3450

Bore, in. (mm) 3.08 (77)

Stroke, in. (mm) 2.64 (67)

Valve Train Overhead valve

Valve Material:

Intake

Exhaust

Number of Cylinders 2

Cylinder Block Material Aluminum with cast iron liners

Cylinder Head Material Aluminum

Cylinder Head Tightening Torque, ft.

lb (Nm)

Piston Rings 2 compression, 1 oil

Crankshaft Material Heat treated, ductile iron casting

Bearings:

Number

Type

Governor Electronic

Starter Motor Electric, 12VDC, solenoid shift

Lubrication System Full pressure

Oil Capacity

(with fi lter and cooler), qt. (L) 2 (1.9 )

Oil Filter Tightening Torque 1/2 turn

Oil Pressure, psi (kPa) 25-35 (172-241)

Low Oil Pressure, psi (kPa) 3.5±1.5 (24.1±13.8)

Fuel Type Natural gas or propane

Fuel Pressure, kPA (in. water) 7-11 (1.7-2.7)

Fuel Consumption at 7.5kW:

Natural Gas, 1000 BTU/ft.

Propane, 2516 BTU/ft.

Battery Voltage 12VDC

Battery Ground Negative

Battery Recommendation (min.) 585 CCA @ 0ºF ( -18ºC)

Spark Plug Type

(Kohler P/N 24 132 02-S):

Spark Plug Gap, in. (mm) 0.030 (0.75)

Spark Plug Tightening Torque, ft. lb

(Nm)

Ignition System Capacitive discharge

Cooling System Air cooled

High Engine Temperature, ºF (ºC) 305 (152)

3

3

13.1

Steel

®

Stellite

face

30 (41)

2

Replaceable sleeve

150 cfh

50 cfh

(Champion RC12YC)

18-22 (24.4-29.8)

Generator Set

48VDC

Specifi cation

Manufacturer: Kohler

Dimensions (in/mm): 21.5"L x 20"W x 21.8"H/

Weight (lb/kg): 190/86

Rated* kW: 7.5

Rated Voltage

(after rectifi er):

Rated Amps: 144 @ 52VDC

* Derate approximately 4% per 1000 ft (300m) over

500 ft (153m) above sea level. Derate 1% for each

10ºF (5.5ºC) increase in temperature above 77ºF

(25ºC).

Generator

546 x 508 x 554

52 ± 0.5VDC @ no load

48VDC

Specifi cations

Stator Resistance

(ohms):

Stator Type: 3-phase, 3-lead,

Excitation Method: Permanent magnet,

Coupling Type: Direct-to-Engine

Insulation (stator): Class 180,

Winding Material: Copper

0.024

ungrounded

brushless

epoxy varnish,

vacuum-impregnated

18

745-020-B0-003, Rev. C

2.0 Site Preparation

2.1 Site Considerations

• Where possible, select a site that is above the 100 year fl ood plain, and away from

houses.

• Place in a shaded location to minimize the effects of solar loading.

• Avoid locating the enclosure where it is an obstruction and would inhibit visibility.

• Locate the enclosure away from sprinkler systems or other sources of forced water.

• Locate the enclosure out of the prevailing wind to minimize the buildup of snow or the

accumulation of wind-borne dust.

• Determine if soil conditions are suitable for the installation of the applicable required

grounding system.

• Verify utility power cabling has been run and terminated at the site.

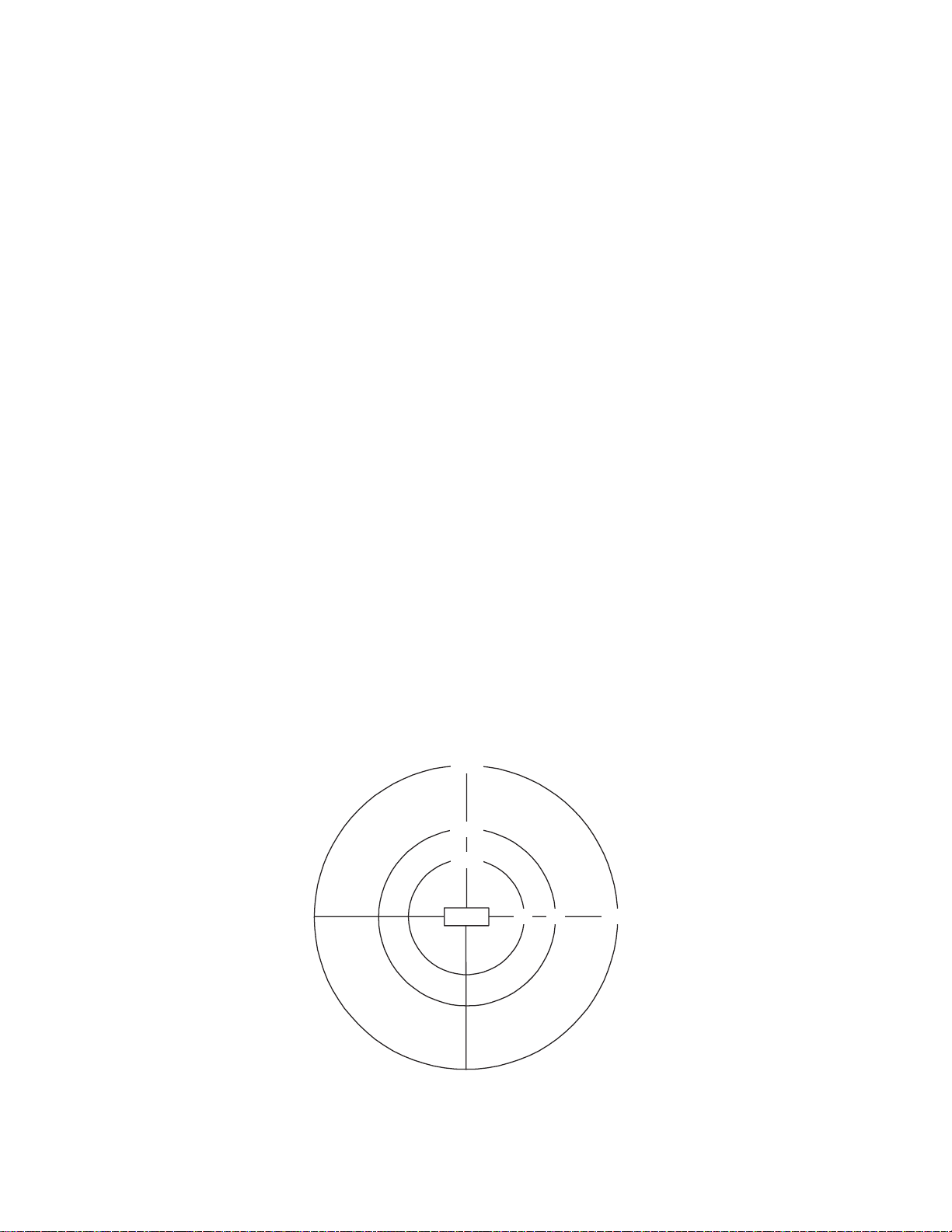

2.2 Acoustics

Nuisance noise is of concern to nearby residents. Nuisance noise is a directional noise

which can cause discomfort during engine-generator operation to nearby residential

occupants (audible levels may vary due to absorption and refl ection caused by the immediate

surroundings).

Audible impact on neighborhoods is mitigated by recent advances in muffl ers, fl ame resistant

sound materials, intake air sound attenuators, along with improved cabinet airfl ow dynamics.

The fi gures below show the measured audible levels from PN-6x-T 7.5kW generator at full

load. Note the symmetry of these emissions. Deployment decisions must include noise

consideration. The elimination of nuisance noise, and the reduction of directional impact

within a residential community, is critical.

dBa

56.3

745-020-B0-003, Rev. C

64.3

70.3

20'

10'

50'

Feet

Fig. 2-1, Generator Sound Levels at 100% Load

19

2.0 Site Preparation, continued

2.2 Acoustics, continued

The design of the engine-generator system should direct a majority of the operational noise

toward the street and away from residences that may be located behind the curb side system.

This strategic cabinet design and placement within the community can minimize nuisance

noise and city ordinance issues.

House

20 Feet, (64 dBa)

Engine-Generator

Street

50 Feet (56 dBa)

House

Fig. 2-2, Acoustical Measurements in Relation to Placement Near Residences

(generator sound levels at full load)

20

745-020-B0-003, Rev. C

2.0 Site Preparation, continued

2.3 Enclosure Impact Protection

The National Fire Protection Agency (NFPA) requires that equipment utilizing natural gas

or liquid propane be protected, based on good engineering practices, in areas where

vehicle traffi c is normally expected at that location. The required protection is based on the

anticipated speed of the vehicles operated in that area. The NFPA does not provide specifi c

guidelines for when protection is needed or the nature of the protection. However, the intent is

to provide suffi cient protection for the equipment should contact occur by a vehicle operating

in the area at a reasonably expected speed.

Alpha Technologies, Inc. cannot anticipate all the ways a vehicle may potentially threaten an

installed generator system, or the specifi c type of protection that is appropriate for a particular

location. The determination of the threat to the equipment and the means of protection are

the responsibility of the end user of the equipment and the authority having jurisdiction.

The following installation drawings are general recommendations and are not intended to

be specifi c guidelines for protecting the equipment. The numbers of bollard posts (or other

protection devices) depend upon equipment locations, site surveys, and traffi c patterns as

shown below in a typical installation.

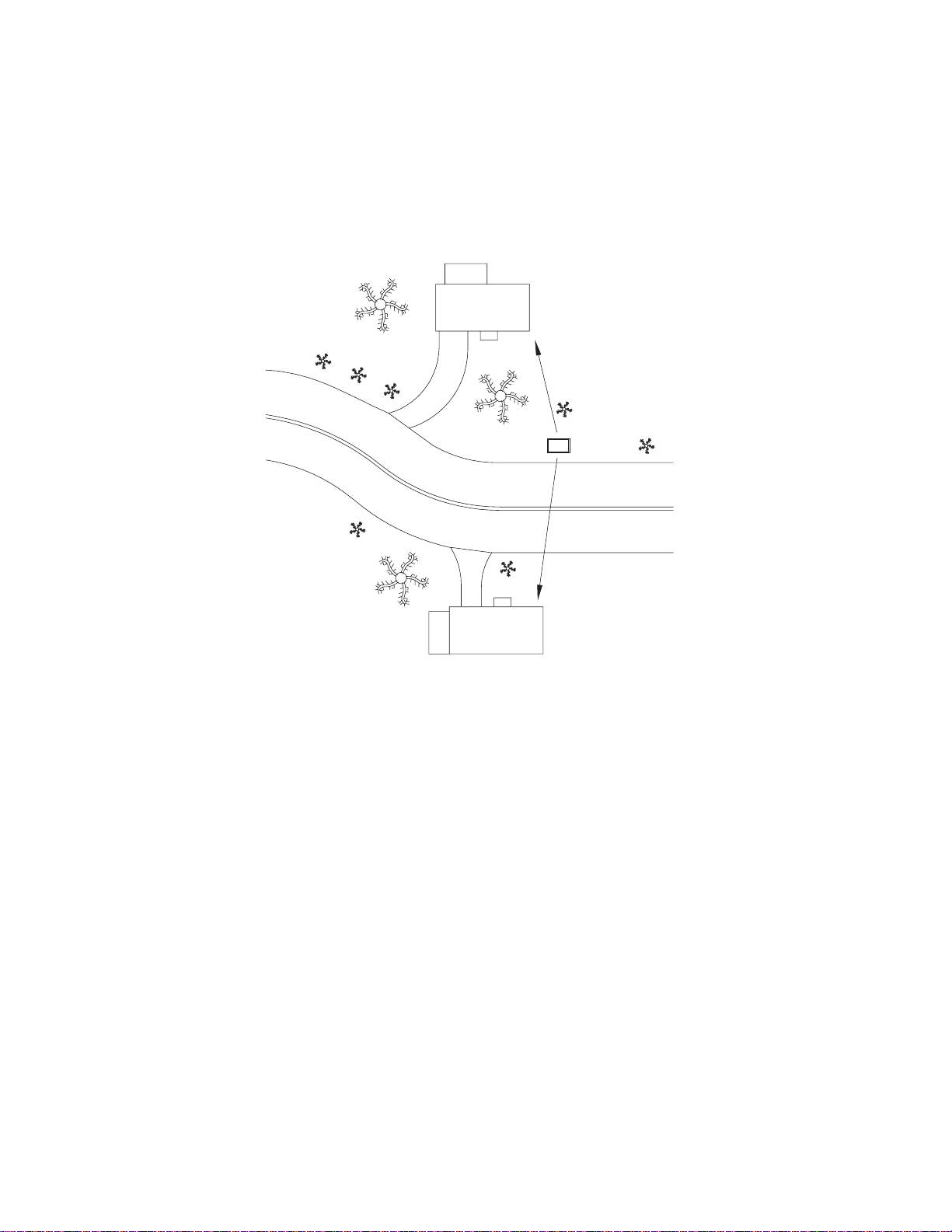

2.3.1 Generator Protection, Vehicular Areas

Several variations of installation are possible. The diagrams provide information on

the different confi gurations and site installations. The collocated natural gas meter

shown below may require two to four bollard posts depending on location, site

surveys, and traffi c patterns. Typical bollard post construction may change based on

local codes regarding pipe material, concrete, or stanchion design.

METER

POSTS

CURB

NATURAL

SIDEWALK

STREET

SIDEWALK

Generator

FRONT

TRAFFIC

TRAFFIC

COLLOCATED

GAS

Fig. 2-3, Vehicular Area Impact Protection for Collocated Natural Gas Meter

745-020-B0-003, Rev. C

21

2.0 Site Preparation, continued

2.3 Enclosure Impact Protection, continued

2.3.1 Generator Protection, Vehicular Areas, continued

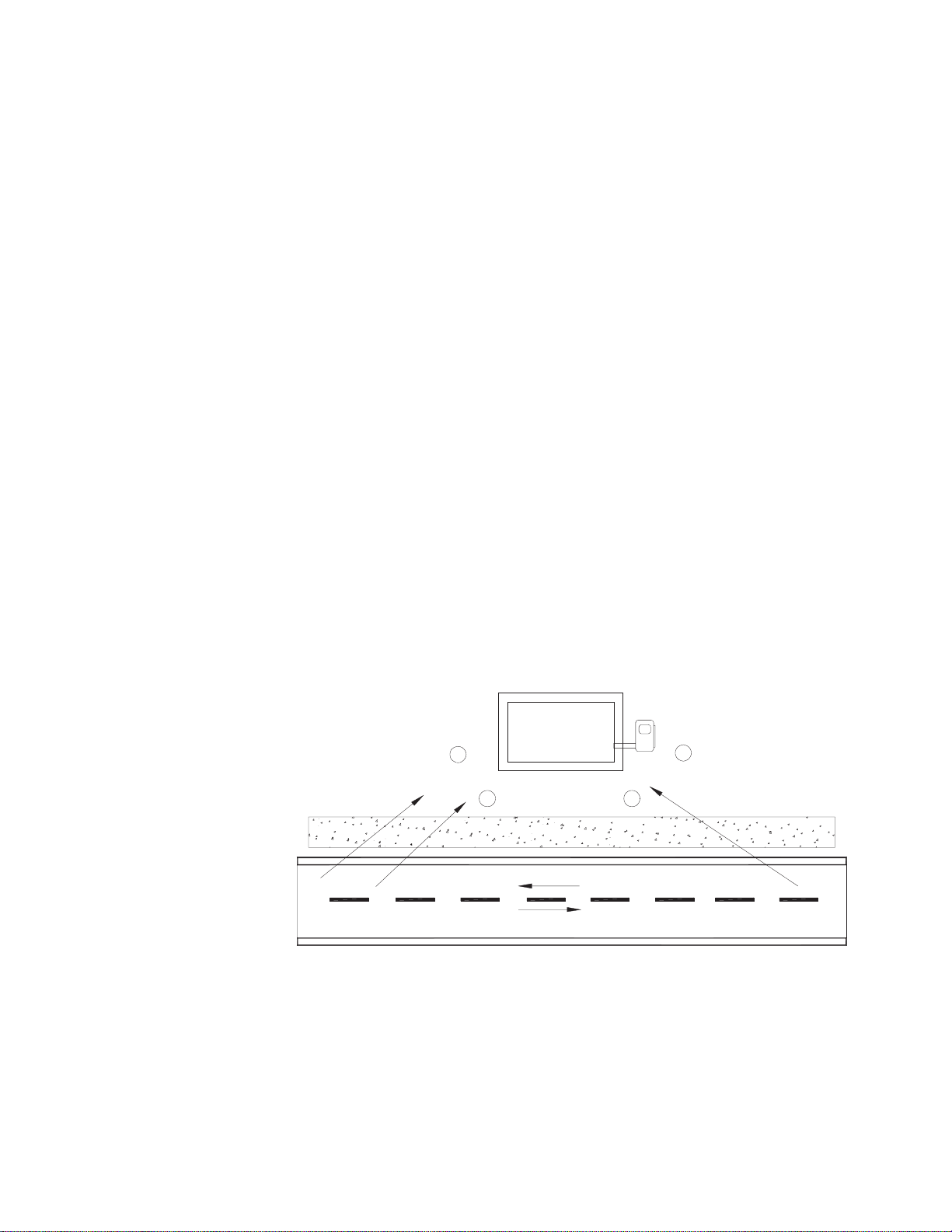

The remote located natural gas meter shown below may require two to four bollard

posts depending on location, site survey, and traffi c pattern. This is a typical

installation design, with gas meters supported by dual risers and located near the

cabinet (within 25 feet).

CHECK CODES FOR PIPE TYPE

UNDERGROUND USE

FOR

25'

Generator

FRONT

SIDEWALK SIDEWALK

TRAFFIC

TRAFFIC

MAX LENGTH

POSTS

POSTS

CURB

STREET

Fig. 2-4, Vehicular Area Impact Protection for Remote Natural Gas Meter

REMOTE

NATURAL

METER

GAS

22

745-020-B0-003, Rev. C

2.0 Site Preparation, continued

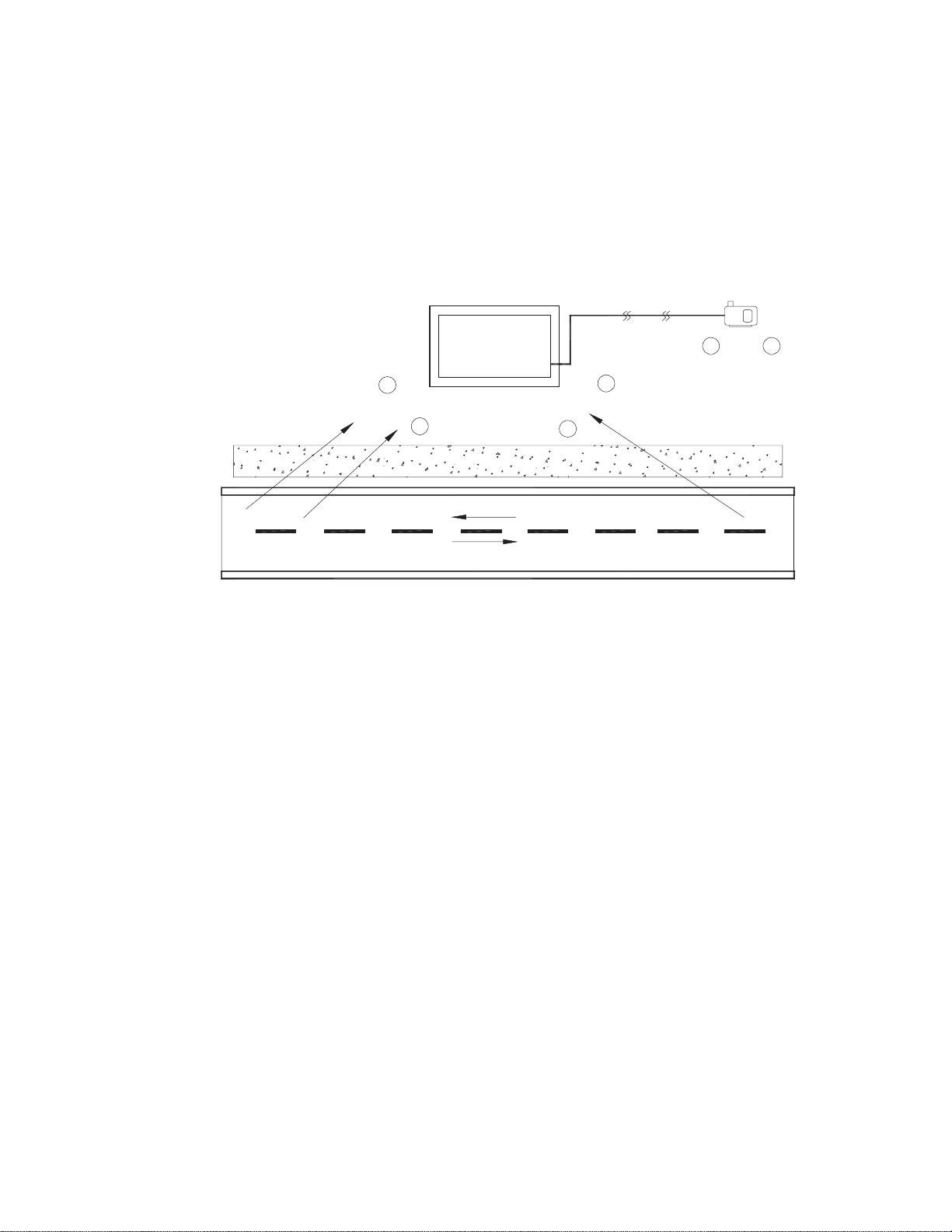

2.4 Natural Gas Meter Confi gurations

The gas utility should have the meter installed prior to generator arrival. Meter confi gurations

must comply with local codes. The illustrations provided are for illustrative purposes only.

NATURAL

S

GA

METER

STREET REGULATOR

MANUAL SHUTOFF

OPTIONAL HIGH PRESSURE

EXCESS FLOW VALVE

Fig. 2-5, Collocated Natural Gas Meter Setup

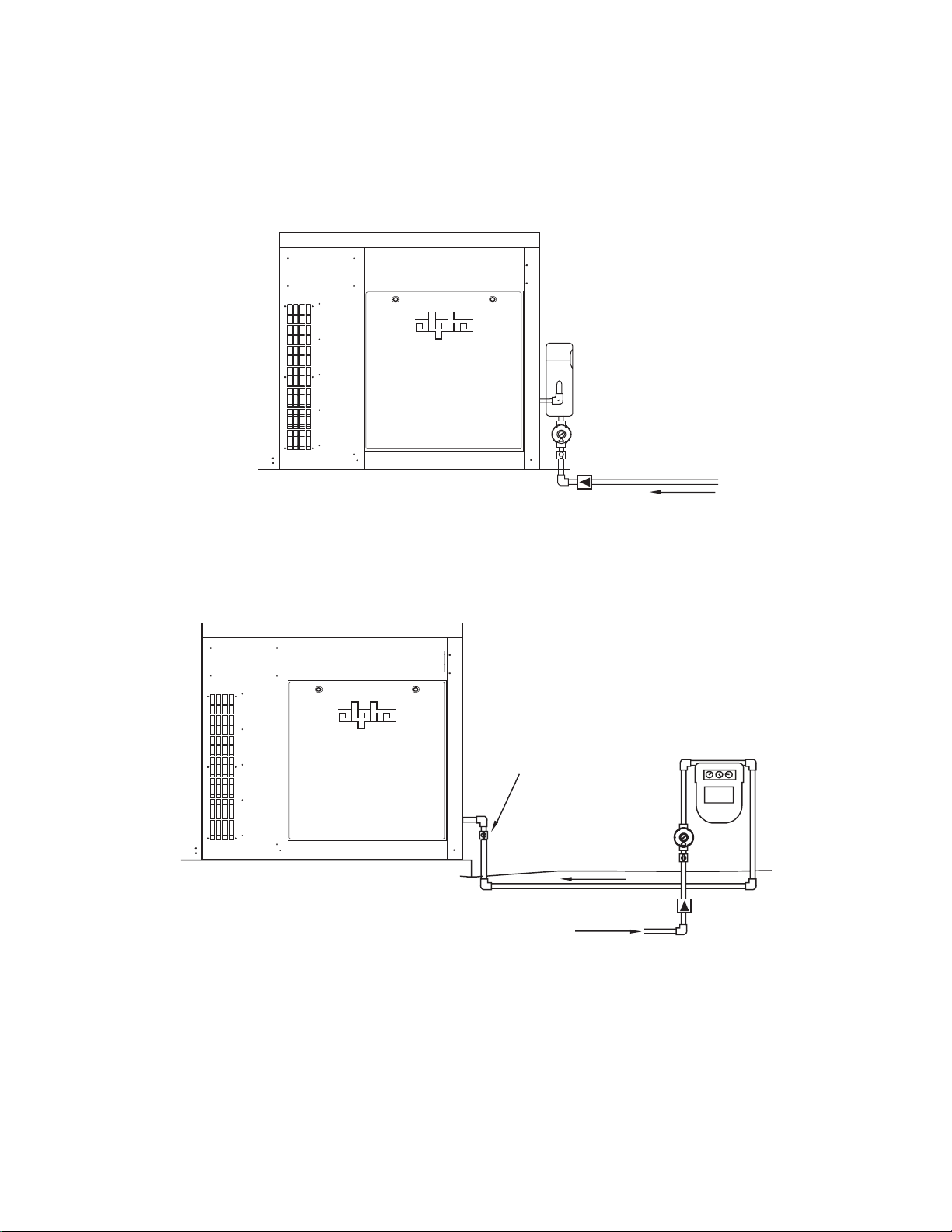

MANUAL SHUTOFF

REQUIRED IF METER

CANNOT BE SEEN

STREET REGULATOR

MANUAL SHUTOFF

METERED SUPPLY

STREET PRESSURE

STREET PRESSURE

NATURAL

GA

METER

Optional high pressure

S

excess flow valve

745-020-B0-003, Rev. C

Fig. 2-6, Remote Natural Gas Meter Setup

23

2.0 Site Preparation, continued

2.5 Liquid Propane Systems

For systems using liquid propane, the end user must provide a suitable LP tank.

Manual

Shutoff

User-provided LP Tank

Fig. 2-7, Liquid Propane Setup

24

745-020-B0-003, Rev. C

Loading...

Loading...