Page 1

Powernode System Enclosures

Powernode System Enclosures

®

© 2002

Site Preparation and Installation

PN-3 Models

PN-4 Models

Effective: March, 2002

®

TM

Page 2

PN-3 & PN-4

www.alpha.com

Protecting The Power in Communications.

031-103-B0-003 Rev. C

2

© 2002

TM

Page 3

Powernode System Enclosures

PN-3, PN-4 Models

Site Preparation and Installation

031-103-B0-003 Rev. C — © 2002 Alpha Technologies

This manual covers the installation of the PN-3 and PN-4 Enclosure. Installation may involve connection to the electrical

utility lines and fuel vapor (Natural Gas or Propane). Always work with the local utilities when connecting the enclosure to

these utilities and observe all local and national laws which may be applicable for your area. Refer to Section 2, PreInstallation, for siteplanning and preparation.

Photographs contained in this manual are for illustrative purposes only. These photographs may not exactlymatch your

installation.

Review the drawings and illustrations contained in the manual before proceeding. If there are questions regarding the

safe installation and operation of this enclosure or the Powering System, please contact Alpha Technologies or your nearest

Alpha representative.

To contact Alpha Technologies:

For general product information and customer service

1-800-863-3930

(7:00 AM to 5:00 PM Pacific Time )

For complete technical support

1-800-863-3364

(7:00 AM to 5:00 PM Pacific Time, or 24/7 emergency support)

© 2002

TM

3

031-103-B0-003 Rev. C

Page 4

PN-3 & PN-4

Product Safety ....................................................................................................................................6

1. Introduction.................................................................................................................................... 9

1.1 Introduction ........................................................................................................................9

1.2 PN-3 and PN-4 Powernode Enclosure................................................................................10

2. Pre-Installation............................................................................................................................. 11

2.1 Site Preparation ................................................................................................................11

2.2 Concrete Pad Preparation..................................................................................................12

2.3 Enclosure Grounding.........................................................................................................13

3. Installation.................................................................................................................................... 15

3.1 T ransportation and Lifting.................................................................................................15

3.2 Enclosure Mounting Procedure..........................................................................................15

3.3 Utility Powering.................................................................................................................16

3.4 Coaxial Cable to Service Power Inserter (SPI) Installation.................................................22

3.5 Battery Installation ...........................................................................................................24

Table of Contents

Important Notes About Installation .................................................................................................... 7

Product Information, Customer Service or Technical Support ............................................................ 8

3.3.1 Connection Procedure for the BBX-100A-8POS Service Disconnect: ................................ 17

3.3.2 Connection Procedure for the BBX-70A Service Disconnect: ............................................ 18

3.3.3 Sample Input Power Panels..............................................................................................19

3.4.1 SPI to Ground Bar Connection Procedure ......................................................................... 22

3.4.2 Conduit Placement ........................................................................................................... 23

3.5.1 Battery Safety Notes.........................................................................................................24

3.5.2 Battery Identification ....................................................................................................... 25

3.5.3 Battery Terminal Connections........................................................................................... 25

3.5.4 Battery Terminal Assembly Procedure............................................................................... 26

3.5.5 Battery Installation Procedure .........................................................................................26

3.5.6 Battery Installation Layout ............................................................................................... 27

3.5.7 Battery Temperature Sensor .............................................................................................32

4. PN Series Options ........................................................................................................................ 33

4.1 Star Lock Security Bolt ......................................................................................................33

4.2 Battery Interface Unit (BIU)...............................................................................................34

4.3 Service Disconnects ..........................................................................................................34

4.4 Input Power Panel (IPP) ....................................................................................................35

4.5 Cooling Fan Kit.................................................................................................................36

4.6 Lightning Arrester (LA-P+)................................................................................................37

5. Alpha Part Numbers..................................................................................................................... 38

5.1 PN Series Options .............................................................................................................38

5.2 Pre-Cast Concrete Pads.....................................................................................................39

031-103-B0-003 Rev. C

4

© 2002

TM

Page 5

PN-3 & PN-4

List of Figures

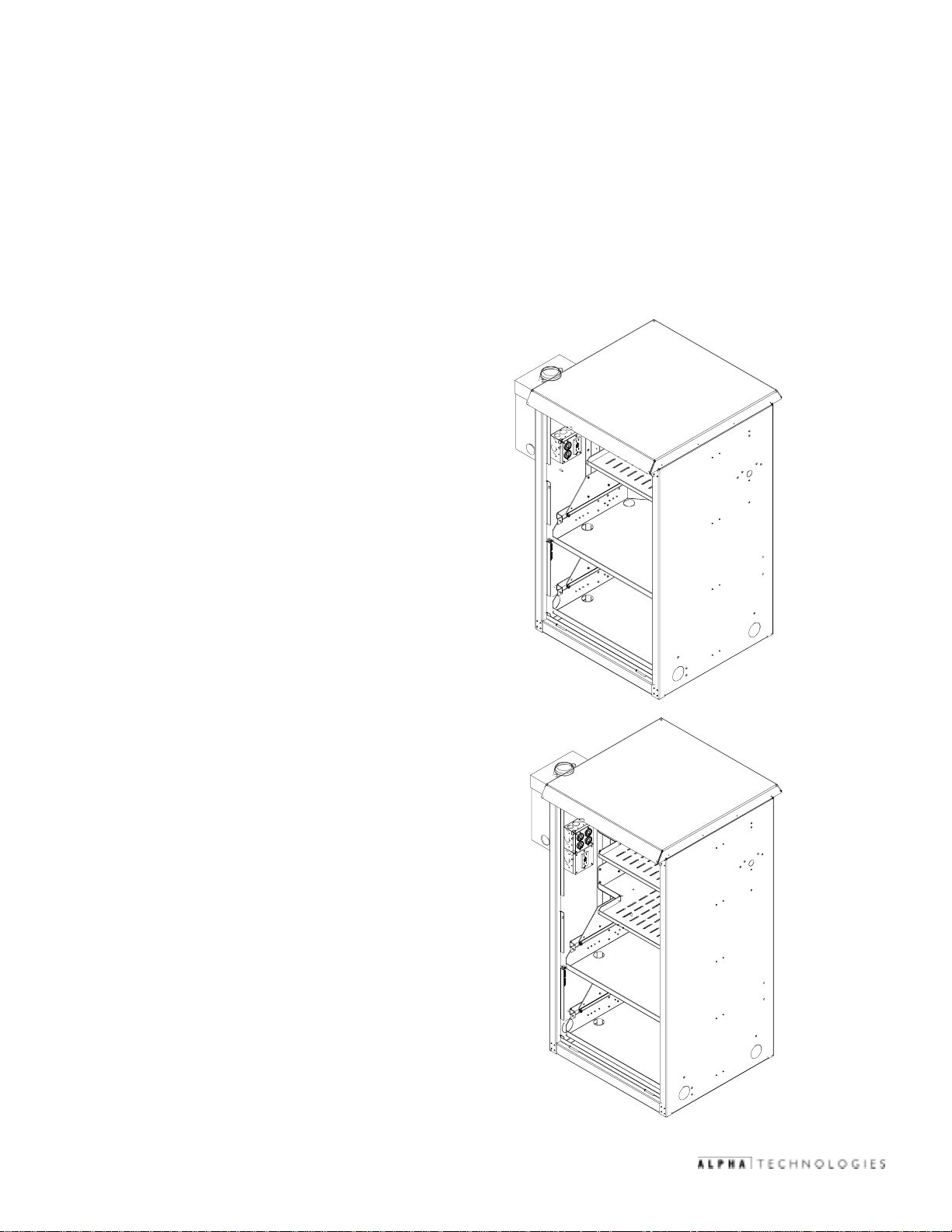

Figure 1-1; Enclosure as it Arrives from Alpha ...................................................................................................................... 9

Figure 1-2; Packing Label Location ........................................................................................................................................ 9

Figure 1-3; PN-3 Specifications ........................................................................................................................................... 10

Figure 1-4; PN-4 Specifications ........................................................................................................................................... 10

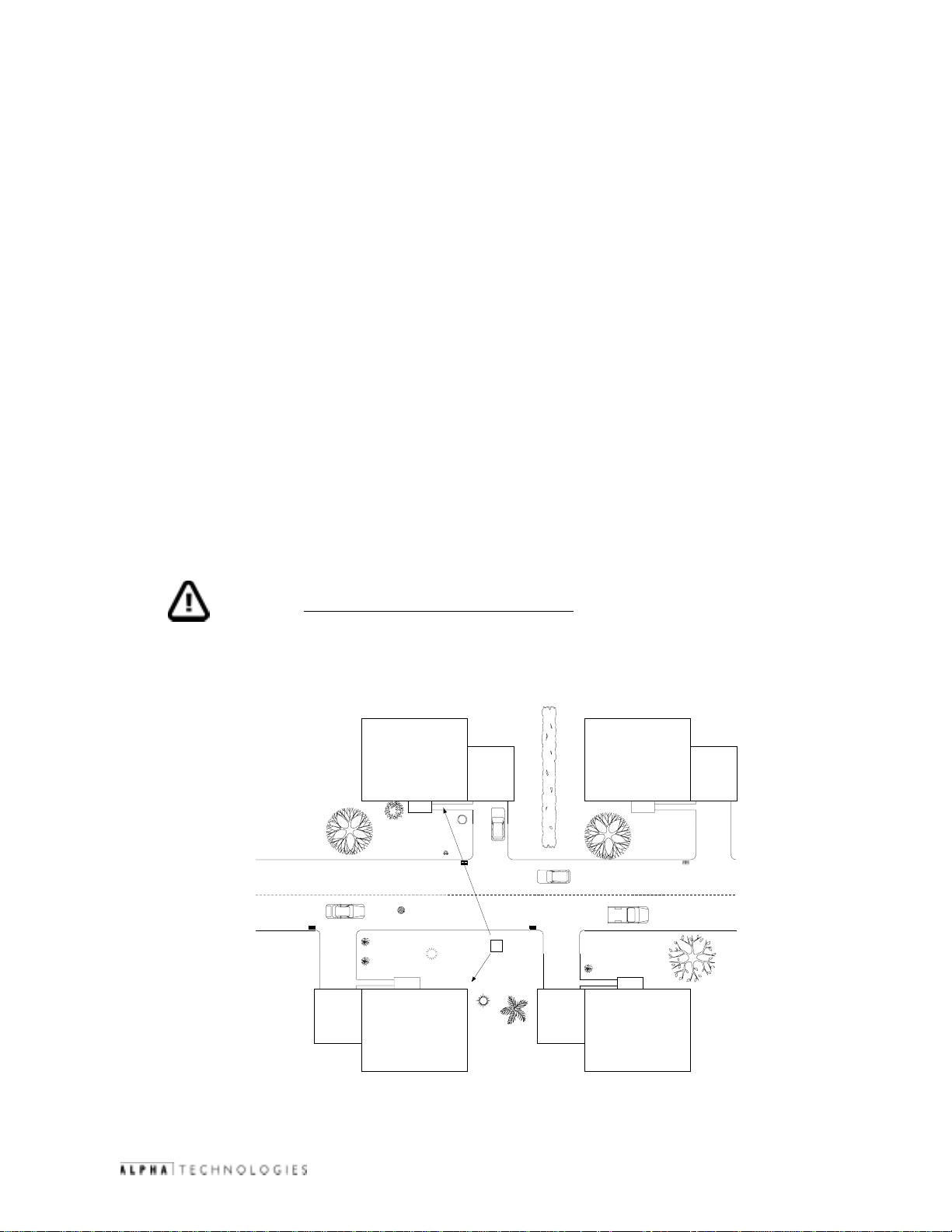

Figure 2-1; Suggested Site Selection, PN-3 and PN-4 ......................................................................................................... 11

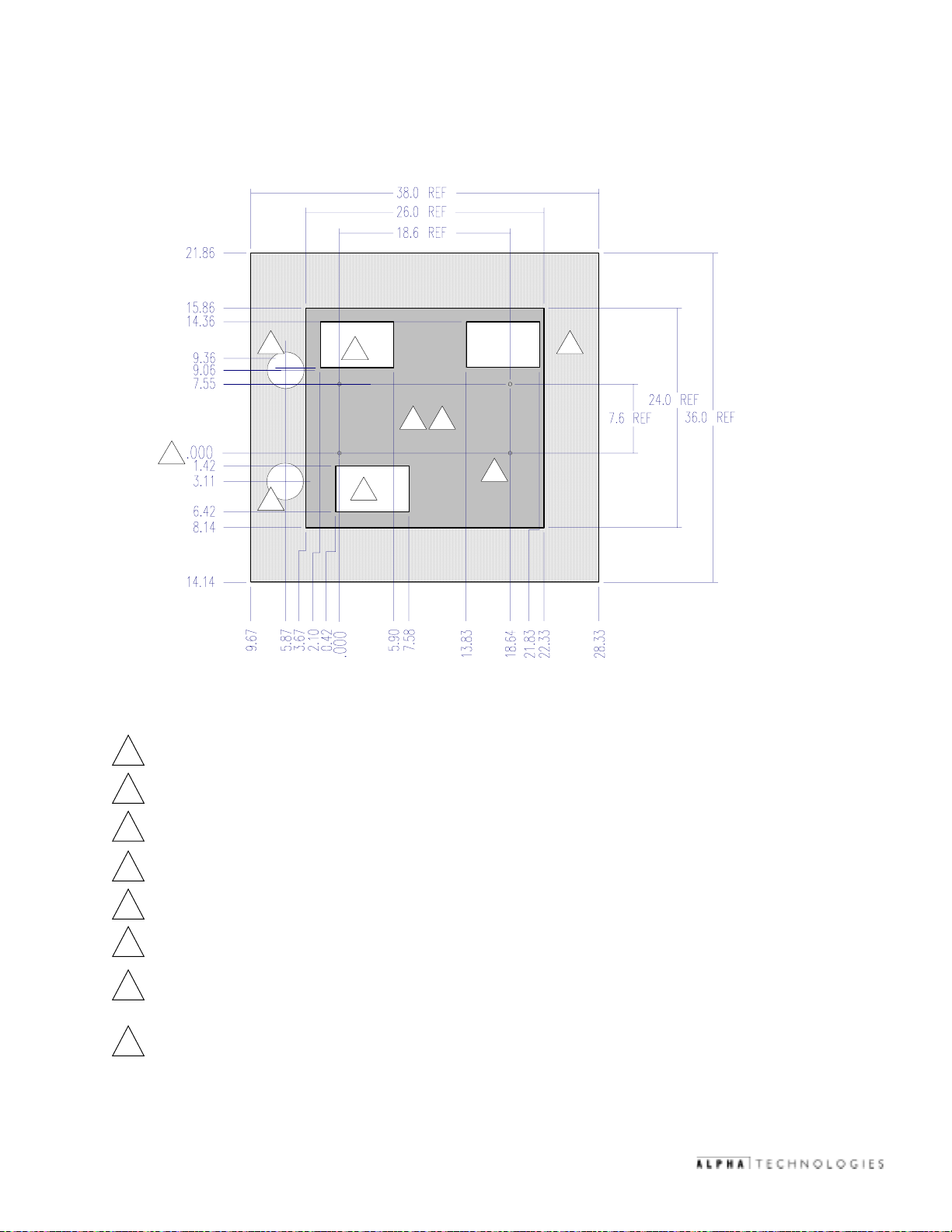

Figure 2-2; Single-Wide Concrete Pad for PN-3 and PN-4 ................................................................................................... 12

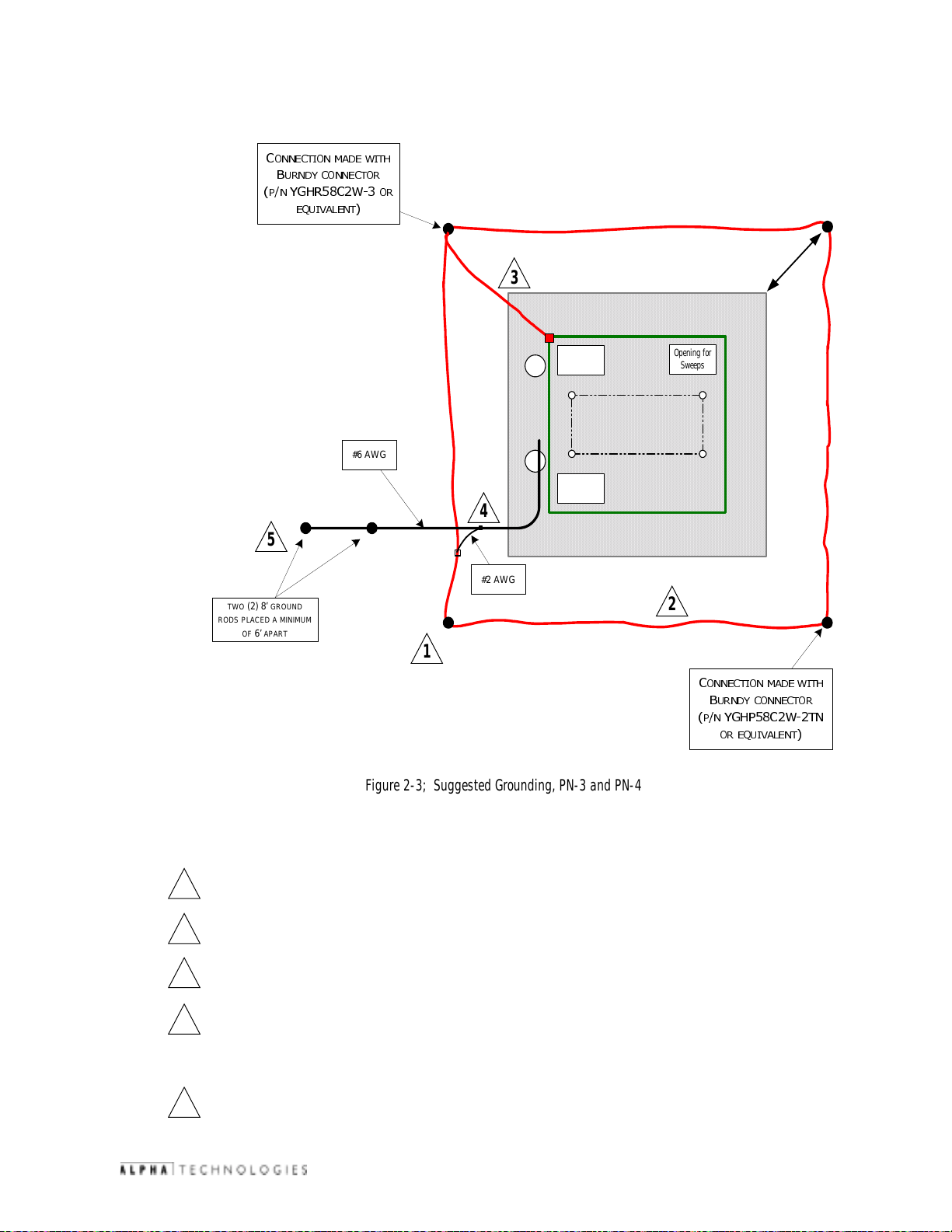

Figure 2-3; Suggested Grounding, PN-3 and PN-4 .............................................................................................................. 13

Figure 2-4; Alternate Grounding, PN-3 and PN-4 ................................................................................................................ 14

Figure 3-1; PN-3 Mounted to the Prepared Pad ................................................................................................................... 15

Figure 3-2; BBX-100A-8POS Service Disconnect.................................................................................................................. 17

Figure 3-3; BBX-70A Service Disconnect.............................................................................................................................. 18

Figure 3-4; Schematic: Primary Service BBX-100A-8POS with IPP-240-3 ........................................................................... 19

Figure 3-5; Schematic: Primary Service BBX-100A-8POS with IPP-120-3 ........................................................................... 19

Figure 3-6; Schematic: Secondary Service BBX-100A-8POS with IPP-120-2 ....................................................................... 20

Figure 3-7; Schematic: Secondary Service BBX-100A-8POS with IPP-240-2 ....................................................................... 20

Figure 3-8; Schematic: Secondary Service BBX-70A with IPP-120-1 ................................................................................... 21

Figure 3-9; Schematic: Primary Service BBX-70A with IPP-240-1 ....................................................................................... 21

Figure 3-10; Connector Fitting in Rear of Equipment Tray.................................................................................................... 22

Figure 3-11; Location of SPI in Equipment Tray .................................................................................................................... 22

Figure 3-12; SPI Ground Wire Connected to Enclosure Ground Bar ..................................................................................... 22

Figure 3-13; Conduit Location.............................................................................................................................................. 23

Figure 3-14; Coaxial Connectors .......................................................................................................................................... 23

Figure 3-15; Alpha Cell Battery Date Code .......................................................................................................................... 25

Figure 3-16; In-Line Fuse Link Mounting.............................................................................................................................. 25

Figure 3-17; Vertically Mounted Battery Post...................................................................................................................... 26

Figure 3-18; Battery Installation Arrangement.................................................................................................................... 27

Figure 3-19; Wiring Diagram for two 36V Battery Strings — PN3 Enclosure...................................................................... 28

Figure 3-20; Wiring Diagram for two 48V Battery Strings — PN3 Enclosure...................................................................... 29

Figure 3-21; Wiring Diagram for three 36V Battery Strings — PN4 Enclosure................................................................... 30

Figure 3-22; Wiring Diagram for three 48V Battery Strings — PN4 Enclosure................................................................... 31

Figure 3-23; Battery Temperature Sensor Mounting Location............................................................................................. 32

Figure 4-1; Security Bolt Location ........................................................................................................................................ 33

Figure 4-2; Black Clip in Place............................................................................................................................................. 33

Figure 4-3; Retaining Washer .............................................................................................................................................. 33

Figure 4-4; Security Key (Part Number 647-089-10)............................................................................................................ 33

Figure 4-5; Battery Interface Unit........................................................................................................................................ 34

Figure 4-6; BBX 70A (BBX-FI2)............................................................................................................................................ 34

Figure 4-7; BBX 100A (BBX-FI8).......................................................................................................................................... 34

Figure 4-8; MTS (Showing100A and 60A boxes) ................................................................................................................... 35

Figure 4-9; FBX-60A............................................................................................................................................................. 35

Figure 4-10; IPP for Three Power Supplies............................................................................................................................ 35

Figure 4-11; IPP for Two Power Supplies............................................................................................................................... 35

Figure 4-12; IPP for One Power Supply ................................................................................................................................. 35

Figure 4-13; Breaker Duplex Option (BDO) for One Power Supply......................................................................................... 35

Figure 4-14; Cooling Fan Panel............................................................................................................................................ 36

Figure 4-15; Panel is Installed in Top Rear of Enclosure...................................................................................................... 36

Figure 4-16; Cooling Fan Plugged into Power Supply and SPI.............................................................................................. 36

Figure 4-17; LA-P+ Installed in BDO ................................................................................................................................... 37

Figure 4-18; Location of LED on LA-P+. ............................................................................................................................... 37

Figure 5-1; Single-Wide Pad, for CE8/9 or PN 3/4 ............................................................................................................... 39

Figure 5-2; Double-Wide Pad, for CE8/9 or PN 3/4 .............................................................................................................. 40

Figure 5-3; Double-Wide Pad, for CE 3x2/9x2 and CE8/9 or PN 3/4 .................................................................................... 41

© 2002

TM

5

031-103-B0-003 Rev. C

Page 6

Product Safety

Important Safety Instructions Used Throughout this Manual

To reduce the risk of injury or death caused by electrical shock, explosion of fuel or moving parts; and to ensure the continued

safe operation of this product, the following symbols have been placed throughout this manual. Where these symbols

appear, use extra care and attention.

CAUTION

HAZARDOUS CONDITION

Dangerous Voltage

This symbol indicates a “dangerous voltage” may exist in this area of the product. Use caution whenever

working in the area to prevent electrical shock.

Inhalation Hazard - Don't Breathe Vapors

This symbol indicates an “inhalation hazard” may exist in this area of the product. Use caution

whenever working in the area to prevent possible inhalation of harmful (fuel or exhaust) vapors.

No Matches or Open Flames

This symbol indicates a “fire or explosive hazard” may exist in this area of the product. Use caution

whenever working in the area to prevent possible combustion of fuel vapors.

Mechanical or Moving Parts Hazard

This symbol indicates an “mechanical or moving parts hazard” may exist in this area of the product.

Use caution whenever working in the area to prevent possible injury to the operator or service personnel.

Leak Hazard

This symbol indicates a “leak hazard” may exist in this area of the product. Use caution whenever

working in this area to prevent and correct any leaks detected.

Attention

This symbol indicates important installation, operation or maintenance instructions. Always follow

these instructions closely.

031-103-B0-003 Rev. C

Save these instructions for future reference.

NOTE: Alpha Technologies’ products are subject to change through continual improvement

processes. Therefore, specifications and/or design layouts may vary slightly from

descriptions included in this manual. Updates to the manual will be issued when

changes affect form, fit or function.

6

© 2002

TM

Page 7

Product Safety

Important Notes About Installation

• The system must be installed only by qualified service personnel.

• Always consult local codes for mounting pad requirements.

• Consult local utility codes for additional cabinet grounding and utility requirements.

• Consult the local gas company for correct meter type and riser location.

• Whenever possible, it is best that the enclosure be installed above flood zones .

• Precast Mounting Pads may either be purchased from Alpha or poured in place. The pad must be

capable of holding 1,000 lbs (minimum). Rebar may be placed in a crosshatch pattern for pad

reinforcement, as needed.

• If the pad is to be located in an area with a deep frost line or unstable soil, concrete pylon footings (4"

diameter X 4' deep, or 1' deeper than the regional frost line) can be placed below the concrete pad, in

front of and below the (4) mounting features.

• The top of the pad must be above grade to reduce the buildup of debris around the base of the cabinet.

• Adequate space must be allowed for Cable TV input/output conduit; plant grounding electrode

conductor(s); RF cable entrance via (1) 4", (2) 3" or (3) 2 1/2" rigid conduit sweep(s) with 2' bend radius

(minimum); and fiber optic cable entrance (refer to fiber manufacturer's specification for minimum

bend radius requirements).

• Prior to pouring concrete, any wire running through the pad must have a thermal expansion jacket (i.e.,

PVC) to prevent cracking of the concrete during lightning strikes.

• Alpha Technologies is not responsible for broken welds or other damage to the cabinet caused by

improper installation.

• A 25+ year vapor barrier must be used between the concrete pad and the base of the enclosure to further

inhibit the ingress of moisture. Alpha Technologies is not responsible for water damage or moisture

damage resulting from improper installation.

• Concrete filled, 6" diameter steel posts (or equivalent) can be placed at the corners of the pad to reduce

exposure to accidental traffic damage.

• All dimensions are given in inches.

• For further information regarding this installation, contact Alpha Technologies or your nearest Alpha

representative.

© 2002

TM

7

031-103-B0-003 Rev. C

Page 8

Contacting Alpha Technologies

Product Information, Customer Service or Technical Support

For general product information and customer service 7:00 AM to 5:00 PM

Pacific Time, call:

1-800-863-3930

To obtain complete technical support 7:00 AM to 5:00 PM Pacific Time, or for

after-hours emergency support, call:

1-800-863-3364

(7 days per week, 24 hours a day)

Product Returns

Returns for Repair

In the event of a need for repair, Alpha products may be returned by either method listed below:

Download the necessary forms directly from Alpha's Web site, under "Support":

www.alpha.com/support/

OR

Call (800) 322-5742 for assistance.

Returns for Credit

Credit return requests must be initiated with a phone call. Call: (800) 322-5742.

031-103-B0-003 Rev. C

8

© 2002

TM

Page 9

1.1 Introduction

To ensure operator safety:

• Enclosures must be installed only by qualified personnel and in accordance with all applicable electrical

codes.

• Use eye protection whenever working with batteries.

• Use only sealed, lead-acid type batteries (gelled-electrolyte or equivalent, 65 Ah min.)

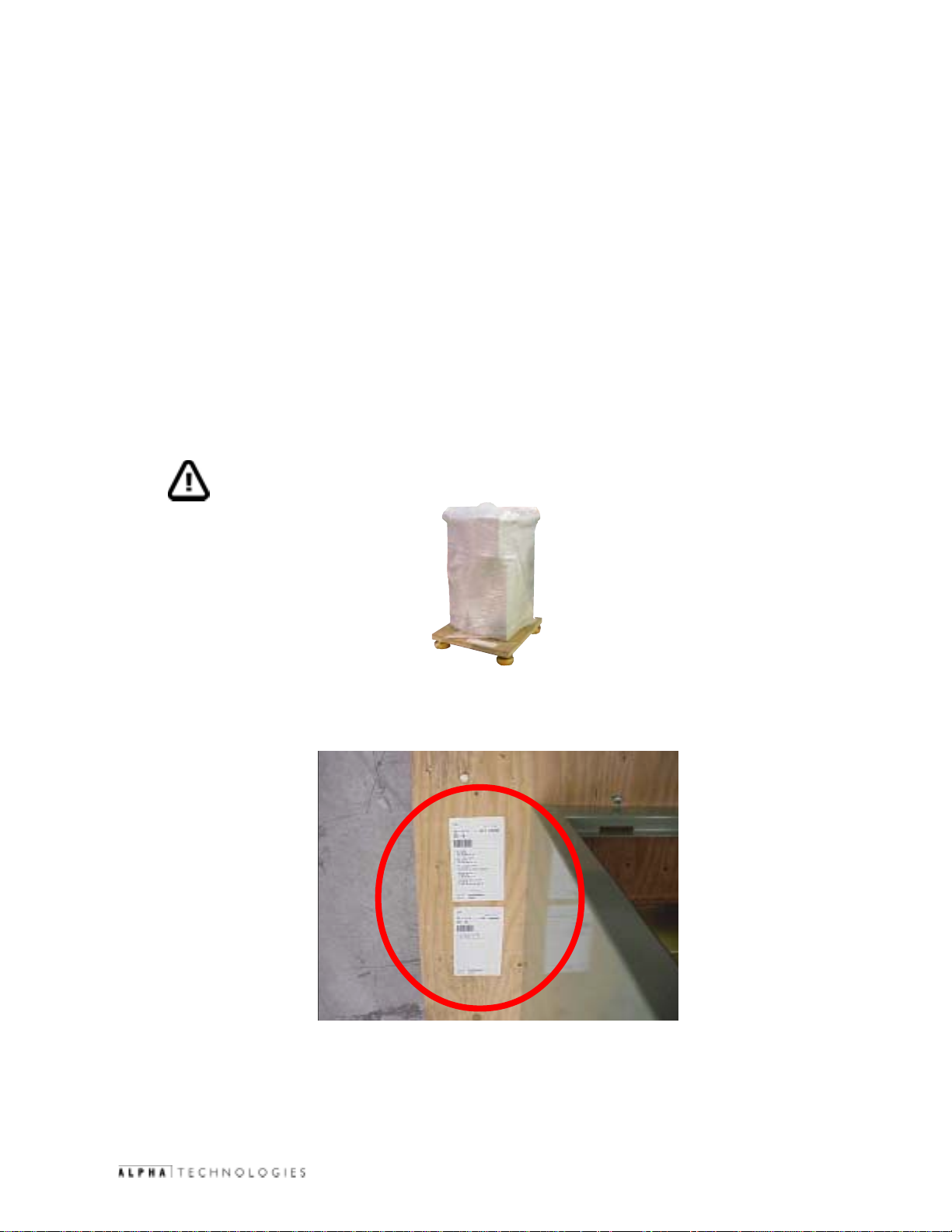

Unpacking and Inspection:

Carefully remove the enclosure from the shipping container. Verify that:

• The correct unit was shipped (either Alpha PN-3 or PN-4 enclosure).

• Ordered options have been included. (Refer to packing label details located on wooden pallet. See

figure 1-2)

NOTE: Batteries are shipped separately.

1. Introduction

Figure 1-1; Enclosure as it Arrives from Alpha

Figure 1-2; Packing Label Location

Inspect the contents. If items are damaged or missing, contact Alpha Technologies and the shipping company immediately .

Most shipping companies have only a short claim period.

© 2002

TM

9

031-103-B0-003 Rev. C

Page 10

1. Introduction

1.2 PN-3 and PN-4 Powernode Enclosure

Alpha's PN Series Power Module enclosures offer complete flexibility and modular expendability for Cable TV powering

applications. The Modular Tray system simplifies installation while allowing for future expansion or reconfiguration. The PN

Series is designed to accommodate current system power requirements while allowing the cost-effective addition of power

capacity, as well as enhanced reliability options, when new services are integrated. Excellent for either distributed or

centralized powering architectures, PN Series enclosures are available to accommodate multiple power supplies, battery

strings and/or natural gas or propane generators

Power Supply Capacity: Up to three power supplies (6kW)

Weight: 100-170 lbs ( depending on options)

Figure 1-3; PN-3 Specifications

Dimensions: 26" W x 44" H x 24" D

Material: Aluminum, .080-.125 inches

Power Supply Capacity: Up to three power supplies (6kW)

031-103-B0-003 Rev. C

Figure 1-4; PN-4 Specifications

Dimensions: 26" W x 52" H x 24" D

Weight: 110-180 lbs ( depending on options)

Material: Aluminum, .080-.125 inches

10

© 2002

TM

Page 11

2. Pre-Installation

2.1 Site Preparation

The site must be planned so that the enclosure will receive good air flow. If possible, in areas of extreme heat, it is best to

position the enclosure so that it will be shaded from the afternoon sun. In areas of prevailing winds, it is best that the

enclosure be located so that the sides of the cabinet face the winds instead of the doors. This will greatly reduce the buildup

of sand or snow against the enclosure’s air vents.

In areas of potential flooding, the geographical site and concrete pad must be located above the flood plain. Pedestals are

available to raise the Power Node enclosures above expected snow and water levels.

The enclosure must be placed where it will be free of obstructions, allowing easy access to the doors for service or equipment

access. For ventilation and maintenance, allow a minimum space of 36 inches in the front and 36 inches in the rear, between

the enclosure and other solid structures.

Place the enclosure well away from ground level sources of forced water, such as underground sprinkler systems and direct

roadway splash.

The concrete pad drawing is provided in the Pre-Installation Section of this manual contains all of the required mounting

details, including electrical service and cable plant entrances.

The vapor barrier material (such as 30 lb. felt, neoprene pond liner, or heavy grade tar paper) must initially extend at least

6" in all directions around the perimeter of the enclosure and be trimmed closer to the enclosure, using the appropriate utility

knife or cutting tool.

WARNING:

Never transport the unit with batteries installed. Batteries must ONL Y be installed after the

unit is transported to the site and secured to the pad. Transporting the unit with batteries

installed may cause a short circuit, fire, explosion, and/or damage to the battery pack,

enclosure and installed equipment. Damage caused by improper shipping or transporting a

unit with batteries installed is not covered under warranty.

House

50 feet

PN-3/4

House

© 2002

25 feet

House

Figure 2-1; Suggested Site Selection, PN-3 and PN-4

TM

11

House

031-103-B0-003 Rev. C

Page 12

2. Pre-Installation

2.2 Concrete Pad Preparation

Pads can either be poured on site, or precast by Alpha Technologies. A vailable concrete pad configurations and part numbers

can be found in section 5, "Alpha Part Numbers".

5

1

4

7

2

8

6

7

Figure 2-2; Single-Wide Concrete Pad for PN-3 and PN-4

All dimensions shown in inches. Mounting holes and sweeps indexed from this position.

1

Indicates PN-3 and PN-4 pedestal enclosure mating surface.

2

3

3

4

5

6

7

8

031-103-B0-003 Rev. C

Alpha standard; recommended distance (6" minimum) between edge of pad and cabinet.

Four inch diameter hole for AC power IN (non-metered installation).

Four inch diameter opening for DC Output cable and Status Monitoring harness.

All mounting hardware must be stainless, galvanized, or better to prevent corrosion.

5" x 8" rectangular cutout (2 places), open area for all internal connections including: generator power

and/or coax cable conduit sweeps.

A 25+ year continuous vapor barrier must be used between the enclosure and the pad to prevent

moisture ingress and possible corrosion caused by metal to concrete contact. The vapor barrier material

(such as 30 lb felt, neoprene pond liner, or heavy grade tar paper) must be initially extended at least 6"

in all directions around the perimeter of the enclosure. After the enclosure is secured to the pad, the

material can be cut closer to the enclosure, using the appropriate knife or cutting tool.

12

© 2002

TM

Page 13

2.3 Enclosure Grounding

&

211(&7,210$'(:,7+

%

851'<&211(&725

31<*+5&:

(48,9$/(17

#6 AWG

25

2. Pre-Installation

2 feet

min)

3

Enclosure Footprint

Opening for

Sweeps

Opening for

Sweeps

Opening for

Sweeps

4

(

5

#2 AWG

TWO (2) 8’ GROUND

PLACED A MINIMUM

RODS

6’ APART

OF

2

1

Figure 2-3; Suggested Grounding, PN-3 and PN-4

Lightning Protection (Optional)

1/2" x 8' copper ground rod, four places, driven about 2 feet (typical) from the corners of the pad.

1

#2 bare copper wire loop terminated to each ground rod and buried below grade 2 to 12 inches.

2

Corrosion-proof connections (25+ year life-span) and hardware suitable for direct burial MUST be used

#2 bare copper wire from loop to the enclosure

3

&

211(&7,210$'(:,7+

%

851'<&211( &7 25

31<*+3&:71

25(48,9$/(17

© 2002

When the electrical supply is a primary service (not a secondary or feeder service) a #2 bare copper wire

4

must be bond the lightning protection loop to the Grounding Electrode Conductor where they are closest.

Service Grounding (required)

#6 bare copper wire from Service Neutral / Ground Bar with 2 ground rods located 6' apart.

5

TM

13

031-103-B0-003 Rev. C

Page 14

2. Pre-Installation

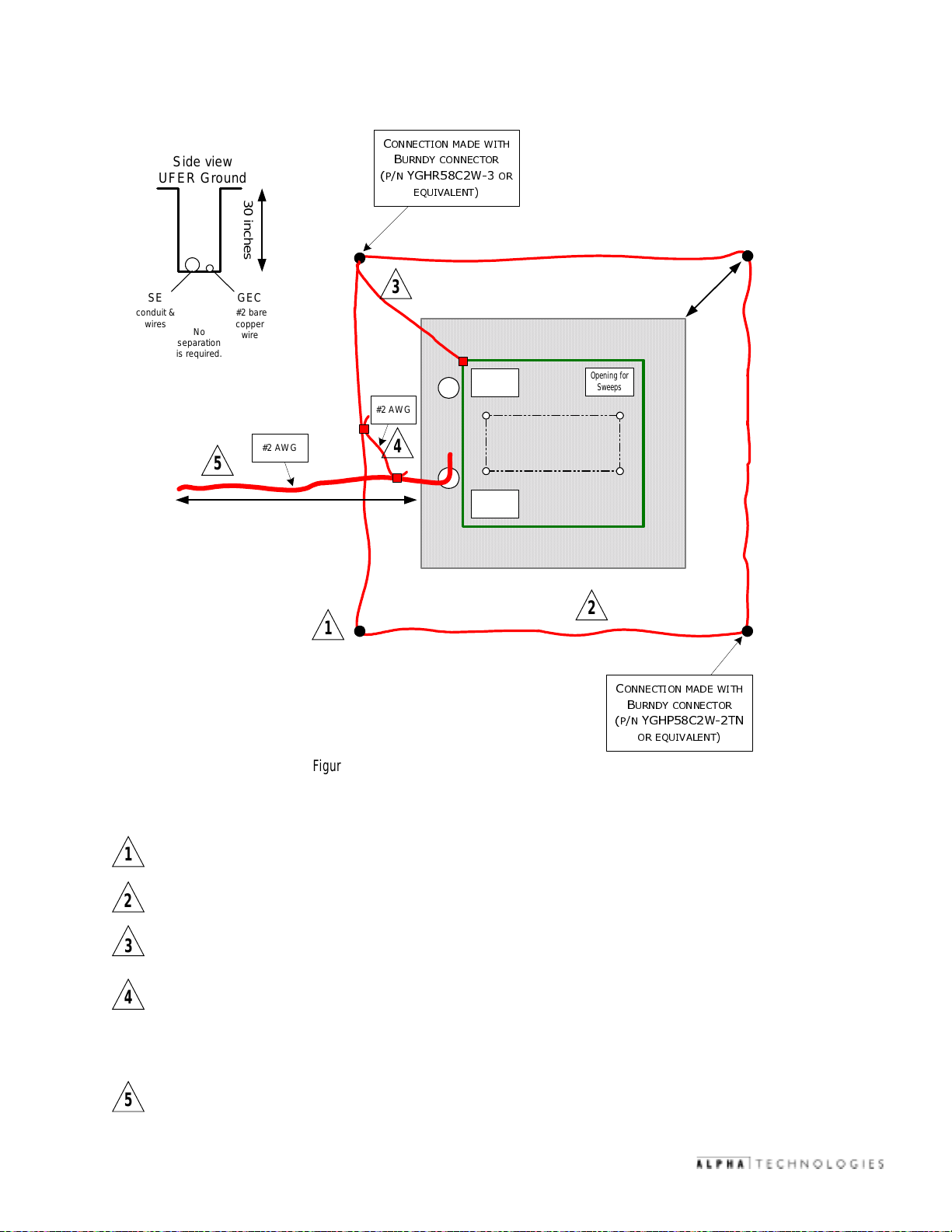

2.3 Enclosure Grounding,

Side view

UFER Ground

30 inches

SE

conduit &

wires

separation

is required.

GEC

#2 bare

copper

No

wire

5

20 feet (minimum)

#2 AWG

continued

&

211(&7,210$'(:,7+

%

31<*+5&:

3

#2 AWG

4

851'<&211(&725

(48,9$/(17

Opening for

Sweeps

Opening for

Sweeps

25

Enclosure Footprint

Opening for

Sweeps

t

e

e

f

n)

i

2

(m

2

1

&

211(&7,210$'(:,7+

%

31<*+3&:71

Figure 2-4; Alternate Grounding, PN-3 and PN-4

Lightning Protection (Optional)

1/2" x 8' copper ground rod, four places, driven about 2 feet (typical) from the corners of the pad.

1

#2 bare copper wire loop terminated to each ground rod and buried below grade 2 to 12 inches.

2

Corrosion-proof connections (25+ year life-span) and hardware suitable for direct burial MUST be used.

#2 bare copper wire from loop to the enclosure

3

When the electrical supply is a primary service (not a secondary or feeder service) a #2 bare copper wire

4

must be bonded to the lightning protection loop to the Grounding Electrode Conductor where they are

closest.

Service Grounding (required)

851'<&211(&725

25(48,9$/(17

5

031-103-B0-003 Rev. C

#2 bare copper wire from Service Neutral / Ground Bar down 30 inches and out 20 feet beyond the pad

edge. This is often called a UFER ground (Ground Ring in the NEC).

14

© 2002

TM

Page 15

3. Installation

3.1 T ransportation and Lifting

The PN-3 or PN-4 cabinet as shipped weighs approximately 100-150 lbs. A safe means of transportation to the site and a

safe procedure for unloading the enclosure is necessary. Do not transport or lift with a device that may not be able to bear

the unit's weight, and do not place the unit upon a surface that will not be able to fully support it.

NOTE: Enclosure must always remain in the upright position during the shipping, storage and installation

process. Damage may result from enclosure being shipped or stored on its side.

NOTE: Electronic modules, batteries or other components must not be installed until the enclosure is securely

set in place at its permanent location.

3.2 Enclosure Mounting Procedure

The enclosure bolts directly to the concrete pad. Mounting holes are provided in the base of the internal enclosure rack to

accommodate the pad’s 3/8" stainless or galvanized anchor bolts.

1. Place vapor barrier material on pad and make cutouts for anchoring hardware and other openings as

necessary. A 25+ year vapor barrier

moisture ingress and to prevent corrosion caused by concrete-to-metal contact.

MUST be used between the concrete and enclosure base to inhibit

2. With no less than two field personnel lifting the enclosure, position it above the concrete pad and slowly

lower it into position over the pad's 3/8" anchor bolts.

3. Secure the enclosure using stainless, galvanized (or better) flat washers, lock washers and 3/8" nuts at

each mounting bolt.

NOTE: Enclosures must be mounted flush with a smooth surface. If the concrete pad is uneven or has

bumps, cracks or other imperfections, the installer is responsible for correcting these defects prior

to installing the enclosure.

4. Install electronic modules and batteries at this time.

26"

44"

© 2002

6"

38"

3 " to 6"

Figure 3-1; PN-3 Mounted to the Prepared Pad

TM

15

031-103-B0-003 Rev. C

Page 16

3. Installation

3.3 Utility Powering

The XM2 Power Supplies are powered by either 120VAC or 240VAC (depending upon the model), attached to an external

service entrance. The size of the service conductors must be based upon the actual size of the utility service and be in

accordance with applicable electrical code requirements.

The utility conduit may be placed in one of two locations, depending upon the utility service entrance requirements. Note the

optional conduit location for use with meter base and the standard location for entry directly to the load center.

Proper grounding is critical. The enclosure MUST have a hard-wired ground to the service entrance. A qualified electrician

will need to verify that grounding is in compliance with applicable electrical codes. (Refer to section 2.3, "Enclosure

Grounding".

NOTE: All applicable codes must be adhered to when installing a system, pouring concrete, or placing a

preformed pad. These codes supersede any procedures outlined in this document.

NOTE: All mounting hardware must be

conditions. Use of improper hardware may cause corrosion, which is not covered under warranty.

NOTE: Soil conditions vary and may affect the integrity of the pad. Alpha Technologies r ecommends that

proper steps be taken to ensure that the soil supporting the pad is stable. Improper installation

of the pad may cause uneven settling or cracking, which is not covered under warranty.

Both standard and EUSERC style meter bases are available for some configurations as illustrated in the following

figures. Consult Alpha Technologies or your local representative regarding compatibility with your specific application.

CAUTION: The following utility powering procedures must be performed only by qualified service personnel

and in compliance with local electrical codes.

Verify electrical codes prior to installation. Codes may vary and contain specific conduit and wire sizes for

connection to the service entrance.

Connection to utility power must be approved by the local utility before installing the power supply.

The enclosure is equipped with a Square D, rainproof service entrance (SUSE rated). The service entrance is equipped with

a circuit breaker for a 120/240VAC, split phase, 3-wire w/GND source.

Materials Required:

stainless

or

galvanized

, depending on local environmental

031-103-B0-003 Rev. C

1" diameter conduit (or larger)- PVC or Galvanized Steel (threaded)

#6 AWG - Red /stranded insulated wire

#6 AWG - Black / stranded insulated wire

#6 AWG - White / stranded insulated wire

#2 AWG or larger - Stranded copper ground wire

16

© 2002

TM

Page 17

3. Installation

3.3 Utility Powering,

continued

3.3.1 Connection Procedure for the BBX-100A-8POS Service Disconnect:

1. Locate the service entrance panel on the enclosure (exterior). Remove the cover to access the circuit

breaker assembly. If this service panel is to be used as the primary service entrance, neutral must be

bonded to ground by installing the green ground screw (provided) in the hole in the neutral bus.

2. Remove the knockout located at the base of the service entrance to accept the conduit.

3. Install the conduit nipple into the service entrance via the knockout and secure with the appropriate

threaded conduit locknut.

4. Locate the two screw terminals (L1 and L2) on the bottom of the input circuit breaker.

5. Connect one of the incoming Black #6 AWG wires to L1 (left terminal). Connect the remaining Black (or

Red) #6 AWG wire to L2 (right terminal). NOTE: If the wire at L2 is Black, Mark it with red tape (or label).

6. Connect the #6 AWG White wire to the neutral (N) bus lug located to the top right of the circuit breaker

assembly.

7. Connect the #6 Bare solid or stranded for Grounding Electrode Conductor (Earth Ground) to the ground

and neutral bus located to the right side of the circuit breaker assembly.

8. Notify the electrical inspector to approve the service entrance wiring. Once approved, contact the local

power utility for electrical service.

1

Neutral

Grounding Electrode

Conductor

Line 1

Line 2

© 2002

Figure 3-2; BBX-100A-8POS Service Disconnect

Bond made by bonding screw only if no other service panel is used. (Must be installed on site only if this

1

is the primary service entrance.)

TM

17

031-103-B0-003 Rev. C

Page 18

3. Installation

3.3 Utility Powering,

continued

3.3.2 Connection Procedure for the BBX-70A Service Disconnect:

1. Locate the service entrance panel on the enclosure (exterior). Remove the cover to access the circuit

breaker assembly. If this service panel is to be used as the primary service entrance, neutral must be

bonded to ground by installing the green ground screw (provided) in the hole in the neutral bus.

2. Remove the knockout located at the base of the service entrance to accept the conduit.

3. Install the conduit nipple into the service entrance via the knockout and secure with the appropriate

threaded conduit locknut.

4. Locate the two screw terminals (L1 and L2) on the top of the input circuit breaker.

5. Connect one of the incoming Black #6 AWG wires to L1 (left terminal). Connect the remaining Black (or

Red) #6 AWG wire to L2 (right terminal). NOTE: If the wire at L2 is Black, mark it with red tape (or label).

6. Connect the #6 AWG White wire to the neutral (N) bus lug located to the top right of the circuit breaker

assembly.

7. Connect the #6 Bare solid or stranded for Grounding Electrode Conductor (Earth Ground) to the ground

and neutral bus located to the right side of the circuit breaker assembly.

8. Notify the electrical inspector to approve the service entrance wiring. Once approved, contact the local

power utility for electrical service.

Neutral

Line 1

1

Line 2

Grounding Electrode

Conductor

1

031-103-B0-003 Rev. C

Figure 3-3; BBX-70A Service Disconnect

Bond made by bonding screw only if no other service panel is used. (Must be installed on site only if this

is the primary service entrance.)

18

© 2002

TM

Page 19

3. Installation

3.3.3 Sample Input Power Panels

For more information on available models of the Input Power Panel, refer to "PN Series Options", section 4.4.

From

Service

Supply

Grounding

Electrode

Conductor

Lightning

Protection

Service and

Distribution

Service

Main

Line 1

Line 2

Neutral

50A

N

Main Bonding Jumper

G

Primary Service:

1) Main Bonding Jumper is Installed.

2) Grounding Electrode Conductor is Installed.

3) Lightning Protection is bonded outside of cabinet.

15A

15A

15A

BBX-100A-8POS

Load

IPP-240-3

120V/15A

GFCI

240V/15A

240V/15A240V/15A

From

Service

Supply

Grounding

Electrode

Conductor

Lightning

Protection

Figure 3-4; Schematic: Primary Service BBX-100A-8POS with IPP-240-3

Service and

Distribution

Service

Main

Line 1

Line 2

Neutral

50A

N

Main Bonding Jumper

G

Primary Service:

1) Main Bonding Jumper is Installed.

2) Grounding Electrode Conductor is Installed.

3) Lightning Protection is bonded outside of cabinet.

Figure 3-5; Schematic: Primary Service BBX-100A-8POS with IPP-120-3

15A

20A

20A

20A

BBX-100A-8POS

Load

120V/20A 120V/20A 120V/20A 120V/15A

GFCI

IPP-120-3

© 2002

TM

19

031-103-B0-003 Rev. C

Page 20

3. Installation

3.3.3 Sample Input Power Panels,

Service and

Distribution

From

Feeder

Supply

Main

Disconnect

Line 1

Line 2

Neutral

Equipment

Grounding

Conductor

N

NO Main Bonding Jumper

G

Secondary Service:

1) Main Bonding Jumper is NOT Installed.

2) Grounding Electrode Conductor is NOT Installed.

3) Lightning Protection is part of feeder supply.

20A

20A

15A50A

BBX-100A-8POS

continued

Load

IPP-120-2

120V/15A

GFCI

120V/20A 120V/20A

From

Feeder

Supply

Figure 3-6; Schematic: Secondary Service BBX-100A-8POS with IPP-120-2

Service and

Distribution

Main

Disconnect

Line 1

Line 2

Neutral

Equipment

Grounding

Conductor

50A

N

NO Main Bonding Jumper

G

Secondary Service:

1) Main Bonding Jumper is NOT Installed.

2) Grounding Electrode Conductor is NOT Installed.

3) Lightning Protection is part of feeder supply.

Load

15A

15A

15A

120V/15A 240V/15A240V/15A

BBX-100A-8POS

GFCI

031-103-B0-003 Rev. C

IPP-240-2

Figure 3-7; Schematic: Secondary Service BBX-100A-8POS with IPP-240-2

20

© 2002

TM

Page 21

3. Installation

3.3.3 Sample Input Power Panels,

Service and

Distribution

From

Feeder

Supply

Line 1

Line 2

Neutral

Equipment

Grounding

Conductor

15A

20A

N

NO Main Bonding Jumper

G

BBX-70A

Secondary Service:

1) Main Bonding Jumper is NOT Installed.

2) Grounding Electrode Conductor is NOT Installed.

3) Lightning Protection is part of feeder supply.

continued

Load

120V/20A 120V/15A

GFCI

IPP-120-1

From

Service

Supply

Grounding

Electrode

Conductor

Lightning

Protection

Figure 3-8; Schematic: Secondary Service BBX-70A with IPP-120-1

Service and

Distribution

Line 1

Line 2

Neutral

20A

N

Main Bonding Jumper

G

Primary Service:

1) Main Bonding Jumper is Installed.

2) Grounding Electrode Conductor is Installed.

3) Lightning Protection is bonded outside of cabinet.

BBX-70A

Load

IPP-240-1

120V/15A

GFCI

240V/15A

© 2002

Figure 3-9; Schematic: Primary Service BBX-70A with IPP-240-1

TM

21

031-103-B0-003 Rev. C

Page 22

3. Installation

3.4 Coaxial Cable to Service Power Inserter (SPI) Installation

3.4.1 SPI to Ground Bar Connection Procedure

Tools List:

1" Socket (3/8" drive)

3/8" Rachet

#2 Phillips Screwdriver

Zip Tie Gun

1). Install SPI by tightening the attached

coaxial connector to the equipment tray.

Figure 3-10; Connector Fitting in Rear of Equipment Tray

2). Secure SPI ground wire to the SPI with

attached screw, and connect to enclosure

ground bar.

3). Terminate stripped end of wire at enclosure

ground bar.

Figure 3-12; SPI Ground Wire Connected to Enclosure Ground Bar

Figure 3-11; Location of SPI in Equipment Tray

031-103-B0-003 Rev. C

22

© 2002

TM

Page 23

3. Installation

3.4.2 Conduit Placement

Conduit location is in the back of the enclosure, on the right side. (Location is specified on concrete pad.)

Figure 3-13; Conduit Location

Figure 3-14; Coaxial Connectors

© 2002

TM

23

031-103-B0-003 Rev. C

Page 24

3. Installation

3.5 Battery Installation

3.5.1 Battery Safety Notes

Electrical Hazards

Battery systems represent a risk of electrical shock and high short circuit currents. The following precautions

must be observed when maintaining batteries:

• Remove all personal metal objects (watches, rings, etc.)

• Use insulated tools.

• Wear eye protection and rubber gloves.

• Observe circuit polarities.

• Do not make or break live circuits.

• Do not lay metal tools and hardware on top of the batteries.

The battery is enclosed in cabinets with limited access. Again, extreme caution must be exercised when maintaining

and collecting data on the battery system.

Disposal

• Lead acid batteries are to be recycled. Batteries contain lead and dilute sulfuric acid. Dispose of in accordance

with Federal, State, and local regulations. Do not dispose of in a landfill, lake or other unauthorized location.

Chemical Hazards

• Any gelled or liquid emissions from a battery is electrolyte, and contains dilute sulfuric acid which is harmful to

the skin and eyes; is electrically conductive; and is corrosive.

• If electrolyte contacts the skin, wash immediately and thoroughly with water. If electrolyte enters the eyes, wash

thoroughly for 10 minutes with clean water or a special neutralizing eye wash solution and seek immediate medical

attention.

• Neutralize any spilled electrolyte with the special solutions contained in a “spill kit” or with a solution of 1 lb.

bicarbonate of soda to 1 gallon of water.

Fire, Explosion, and Heat Hazards

• Lead acid batteries can contain an explosive mixture of hydrogen gas which can vent under overcharging conditions.

• Do not smoke or introduce sparks in the vicinity of the battery.

• Do not charge batteries in a sealed container. The individual batteries must have 0.5 inches of space between

them to allow for convection cooling. If contained, assure the container or cabinet and room have adequate

ventilation to prevent an accumulation of potentially vented gas.

031-103-B0-003 Rev. C

24

© 2002

TM

Page 25

3. Installation

3.5.2 Battery Identification

Each battery contains a DATE CODE usually located near the positive (+) terminal of the battery. This date code

must be recorded in the maintenance log (

used, consult the battery manufacturers’ documentation for date code type and placement.

MAINTENANCE

manual). If batteries other than those installed by Alpha are

0702

MONTH: (JUL) 07

YEAR: 2002

Figure 3-15; Alpha Cell Battery Date Code

3.5.3 Battery Terminal Connections

The accompanying drawings are for

styles and hardware may be shipped with the system. ALWAYS refer to the battery manufacturer's specifications for

correct mounting hardware and torque requirements. During maintenance procedures, refer to the manufacturer's

specifications for the maintenance torque requirements.

Mounting hardware requirements may vary with battery manufacturers. Use only the hardware recommended by

your particular battery manufacturer.

NOTE: Use a corrosion inhibitor (such as NCP-2) on battery terminals.

illustrative

purposes only. Various types of batteries with different mounting

Battery Terminal

Battery Cable, and

Spacer

Crimp Connector to

next Battery

In-line Fuse Link

© 2002

Washers & Bolt

TM

Figure 3-16; In-Line Fuse Link Mounting

25

031-103-B0-003 Rev. C

Page 26

3. Installation

3.5.4 Battery Terminal Assembly Procedure

These illustrations show the Battery Terminal assembly for vertically mounted battery posts. Refer to the battery

manufacturers’ specifications for tightening torque.

Battery Cable

Flat Washer

Split Washer

Nut

Figure 3-17; Vertically Mounted Battery Post

Battery Terminal

Flat Washer

Bolt

3.5.5 Battery Installation Procedure

1. Place the batteries on their respective shelves as shown in Figure 3-18; "Battery Installation Arrangement"

on the next page.

2. Connect the three (or four) batteries in series (negative to positive) to achieve 36VDC (or 48VDC). Route

the battery cables inside the vertical rail for connection to the power supply. Terminal connectors must

be torqued to approximately 75 inch/pounds at installation and then re-torqued to 50 inch/pounds

during routine maintenance.

3. Use a voltmeter to verify polarity and DC voltage at the module's battery connector.

4. Mate the battery connectors to their respective sockets on the power supply module.

5. Number the batteries 1, 2, 3, (4) using labels, masking tape, or china marker. Record each battery's

6. For installations with multiple battery strings in parallel, each string must be fused. Verify that the

031-103-B0-003 Rev. C

NOTE: The cables are marked with a RED sleeve to indicate the (+) positive battery terminal.

CAUTION: Whenever making or breaking battery connections, never allow live battery cables to

contact the chassis. If necessary, wrap the lugs with electrical tape to prevent arcing

and temporarily disconnect one of the leads from the center battery. Check the battery

voltages at the connectors leading into the XM power supply.

NOTE: Ensure that voltage and polarity are correct before proceeding.

number and date code in the power supply's maintenance log.

enclosure was ordered with a fused Battery Cable Kit (BCK). For replacement fuses, or to add fuses to

a BCK without fuses, order the Battery Terminal Fuse Kit, Alpha part number SPB98-645-1.

26

© 2002

TM

Page 27

3.5.6 Battery Installation Layout

_

To "Battery Input"

+

3. Installation

Upper Battery Tray

1

2

36VDC configuration

_

To "Battery Input"

+

Fuse

Location

3

© 2002

Upper

Battery

Tray

12

4

Fuse

Location

3

48VDC configuration

Figure 3-18; Battery Installation Arrangement

TM

27

031-103-B0-003 Rev. C

Page 28

3. Installation

3.5.6 Battery Arrangement, Power Supply Connection,

Module Tray

_

+

XM Series Quick

Disconnect Battery

Connector

Upper Battery tray

continued

4

5

Lower Battery tray

1

6

Fuse

Location

2

3

Fuse

Location

031-103-B0-003 Rev. C

Figure 3-19; Wiring Diagram for two 36V Battery Strings — PN3 Enclosure

28

© 2002

TM

Page 29

3. Installation

3.5.6 Battery Arrangement, Power Supply Connection,

Module Tray

_

+

XM Series Quick

Disconnect Battery

Connector

Upper

Battery

8

tray

continued

5

Lower

Battery

tray

1

6

7

Fuse

Location

4

2

3

Fuse

Location

© 2002

Figure 3-20; Wiring Diagram for two 48V Battery Strings — PN3 Enclosure

TM

29

031-103-B0-003 Rev. C

Page 30

3. Installation

3.5.6 Battery Arrangement, Power Supply Connection,

Module Tray

_

+

XM Series Quick

Disconnect

Battery

Connector

Upper Battery tray

8

7

9

continued

Middle Battery tray

5

4

Lower Battery tray

2

1

Fuse

Location

6

Fuse

Location

3

Fuse

Location

031-103-B0-003 Rev. C

Figure 3-21; Wiring Diagram for three 36V Battery Strings — PN4 Enclosure

30

© 2002

TM

Page 31

3. Installation

3.5.6 PN4 Battery Arrangement, Power Supply Connection,

Module Tray

_

+

XM Series Quick

Disconnect

Battery

Connector

Upper

Battery

12

tray

10

9

11

continued

Fuse

Location

Middle

Battery

tray

5

Lower

Battery

tray

1

8

6

7

Fuse

Location

4

2

3

Fuse

Location

© 2002

Figure 3-22; Wiring Diagram for three 48V Battery Strings — PN4 Enclosure

TM

31

031-103-B0-003 Rev. C

Page 32

3. Installation

3.5.7 Battery Temperature Sensor

Sensor wiring connects to

Temperature Sensor Input connector of

XM2 Power Supply.

Use adhesive tape to attach the

sensor so that the flat side of the sensor

is flush to the side of the battery.

TM

®

Figure 3-23; Battery Temperature Sensor Mounting Location

To prevent incorrect temperature readings, attach the Battery Temperatur e Sensor associated with each XM2

Power Supply on different batteries.

031-103-B0-003 Rev. C

32

© 2002

TM

Page 33

4. PN Series Options

4.1 Star Lock Security Bolt

See section five, "Alpha Part Numbers" for PN Series options shown in this section.

The Star Lock Security Bolt kit comes factory installed when ordered with a new enclosure. The kit can also be added to

existing enclosures using the procedure below.

NOTE: The Security Key is a special tool that must be ordered separately. Alpha recommends ordering security

keys for each maintenance crew.

1). Drill dimple located approximately half way down enclosure doors.

®

Figure 4-1; Security Bolt Location

2). Place black clip over flange and align with factory-drilled hole in flange.

Figure 4-2; Black Clip in Place

3). Place bolt into hole, apply retaining washer, and tighten with Security Key.

© 2002

Figure 4-3; Retaining Washer Figure 4-4; Security Key (Part Number 647-089-10)

TM

33

031-103-B0-003 Rev. C

Page 34

4. PN Series Options

4.2 Battery Interface Unit (BIU)

The BIU is used in Powernode systems with multiple power supplies and/or multiple battery strings, and an AlphaGen DC

generator. The BIU provides a parallel DC bus with convenient connectors for each power supply and battery string.

(For installation and operation instructions, refer to the BIU Installation Manual, part number 018-311-C1.)

Upper battery shelf

Lower battery shelf (PN-3 enclosure)

Middle battery shelf (PN-4 enclosure)

Power Supply shelf

(optional mounting location for BIU)

BIU installed beneath

upper battery shelf

Figure 4-5; Battery Interface Unit in Place

4.3 Service Disconnects

There are four Service Disconnects available (installed at the factory):

For single power supply applications

031-103-B0-003 Rev. C

Square-D, 2-position

34

Figure 4-7; BBX 100A (BBX-FI8)Figure 4-6; BBX 70A (BBX-FI2)

Square-D, 8-position

For multiple power supply applications.

© 2002

TM

Page 35

4. PN Series Options

4.3 Service Disconnects,

Figure 4-8; MTS (Showing100A and 60A boxes)

For applications requiring

a protected AC generator.

continued

Figure 4-9; FBX-60A

Fused safety switch. For applications

with high AIC rating requirements.

4.4 Input Power Panel (IPP)

There are four basic configurations of the IPP. Each is available in 120V and 240V. Units in figures 4-10, 4-11, and 4-12

are factory pre-wired, include Square-D high-magnetic breakers for each power supply, and provide a GFCI convenience

outlet.

Figure 4-10; IPP for Three Power Supplies Figure 4-11; IPP for Two Power Supplies

© 2002

Figure 4-12; IPP for One Power Supply

TM

35

Figure 4-13; Breaker Duplex Option (BDO)

for One Power Supply

(NOT factory pre-wired.)

031-103-B0-003 Rev. C

Page 36

4. PN Series Options

4.5 Cooling Fan Kit

When using more than one power supply in the PN Series Enclosures, a cooling fan is required. The Cooling Fan kit includes

an intake filter, located inside the front door of the enclosure by the ventilation louvers. The filter must be cleaned

periodically as part of the power supply preventative maintenance program.

Replacement fuses and filters are available. Refer to section five for part numbers.

Connected to SPI

Figure 4-14; Cooling Fan Panel

Location of Fuse Holder

Figure 4-15; Panel is Installed in Top Rear of Enclosure

Connected to XM2

"Output 1"

031-103-B0-003 Rev. C

Figure 4-16; Cooling Fan Plugged into Power Supply and SPI

36

© 2002

TM

Page 37

4. PN Series Options

4.6 Lightning Arrester (LA-P+)

The Lightning Arrester is available in 120VAC and 240VAC, and is installed by plugging into an IPP or BDO.

Figure 4-17; LA-P+ Installed in BDO

The unit is operating properly when the green LED is lit.

Figure 4-18; Location of LED on LA-P+.

© 2002

TM

37

031-103-B0-003 Rev. C

Page 38

5. Alpha Part Numbers

5.1 PN Series Options

Item: Part Number:

Star Lock Security Bolt 744-897-20

Security Key 647-089-10

Battery Interface Unit (BIU) 018-311-24

Service Disconnects

BBX-70A 744-656-20

BBX-100A-8POS 744-657-20

MTS 240-40 SPB99-512-12

FBX-60A 744-534-20

Input Power Panels (IPP) (Pre-Wired)

IPP-CE, 1x240 1xGFCI 744-735-20

IPP-CE, 2x240 1xGFCI 744-701-20

IPP-CE, 3x240 1xGFCI 744-868-20

IPP-CE3x/9x 120V for BATT HTR 744-702-20

IPP-CE, 1x120 1xGFCI 744-735-21

IPP-CE, 2x120 1xGFCI 744-701-22

IPP-CE, 3x120 1xGFCI 744-868-21

IPP-CE, 3x120 1xGFCI 120Vin 744-868-22

BDO (NOT installed)

BDO-515 120V 15A Not SUSE Rated 744-148-20

BDO-520 120V 20A Not SUSE Rated 744-148-21

BDO-615 240V 15A Not SUSE Rated 744-147-21

Cooling Fan Kit 744-839-20

Replacement Fuse 460-025-10

Replacement Filter

Lightning Arrester

LA-P+ 120V (L-N, L-G, N-G) 020-098-24

LA-PC+ 120V (L-N, L-G, N-G) 020-098-26

LA-PE+ 240V (L1-L2, L1-G, L2-G) 020-098-25

Extra SPI (15 Amp) 744-279-22

Extra SPI (25 Amp) 744-789-21

NOTE: Alpha part numbers are correct at the time of printing. As part numbers are subject to

change, please contact your Alpha Representative prior to ordering to ensure that numbers

are correct.

031-103-B0-003 Rev. C

38

© 2002

TM

Page 39

5. Alpha Part Numbers

5.2 Pre-Cast Concrete Pads

Alpha offers a line or precast, polymer concrete and reinforced concrete pads for the PN Series Enclosures. Polymer

concrete is significantly lighter and more stable when compared to reinforced concrete. Both materials represent a significant

savings in labor costs and quality improvement over "pour-in-place" pads. Other precast pad configurations are available.

Contact your nearest Alpha representative for additional information.

+3.0

REF. 3.00

-0.0

0.000

0.25

+.25

-.125

REF.

© 2002

Figure 5-1; Single-Wide Pad, for CE8/9 or PN 3/4

Part Number:

PCD-3: 641-070-10 (Reinforced concrete)

PCC-3: 641-067-10 (Polymer concrete)

TM

39

031-103-B0-003 Rev. C

Page 40

5. Alpha Part Numbers

5.2 Pre-Cast Concrete Pads,

3.00 REF.

+3.0

0.000

-0.0

2

continued

0.25

+.25

-.125

REF.

1

1

4" diameter opening (2 plcs.)

Figure 5-2; Double-Wide Pad, for CE8/9 or PN 3/4

Part Number:

PCD 3-3: 641-072-10 (Reinforced concrete)

PCC 3-3: 641-069-10 (Polymer concrete)

2

031-103-B0-003 Rev. C

5" x 8" opening (6 plcs.)

40

© 2002

TM

Page 41

5. Alpha Part Numbers

5.2 Pre-Cast Concrete Pads,

1

1.42

3.60

0.000

+3.0

-0.0

2

3.00 REF.

21.86

15.86

14.36

11.11

9.11

7.55

.000

3.11

continued

26 REF

18.6 REF

26 REF

19.5 REF

0.25

+.25

-.125

REF.

14.71 REF

7.6 REF

0.6

8.14

14.14

1

4

9

9

9

6

.

9

4

9

.

5

0

6

1

4

.

.

.

0

3

2

0

0

.

1

8

.

5

Figure 5-3; Double-Wide Pad, for CE 3x2/9x2 and CE8/9 or PN 3/4

4" diameter opening (2 plcs.)

6

5

.

7

1

8

.

3

1

Part Number:

0

6

.

8

1

5

8

2

.

1

2

1

8

.

1

PCD 3-3x: 641-071-10-003

PCD 3-3x: 641-068-10-003

2

3

.

5

4

6

5

.

8

4

6

6

5

0

.

.

4

0

5

5

© 2002

5" x 8" opening (3 plcs.)

2

TM

41

031-103-B0-003 Rev. C

Page 42

Page 43

Page 44

www.alpha.com

Protecting The Power in Communications.

UNITED STATES

ASIA PACIFIC

LATIN AMERICA

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

Tel: (360) 647-2360

Fax: (360) 671-4936

Web: www.alpha.com

CANADA

Alpha Technologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

Tel: (604) 430-1476

Fax: (604) 430-8908

UNITED KINGDOM

Alpha Technologies Europe, Ltd.

Cartel Business Estate

Edinburgh Way

Harlow, Essex CM20 2TT

Tel: +44-1279-422110

Fax: +44-1279-423355

GERMANY

Alpha Technologies

Hansastrasse 8

Schwabach D-91126

Tel: +49-9122-79889-0

Fax: +49-9122-79889-21

MIDDLE EAST

Alphatec, Ltd.

339 St. Andrews St., Suite 101

Andrea Chambers

Limassol, Cyprus

Tel: +357-25-375675

Fax: +357-25-359595

AUSTRALIA

Alpha Technologies

8 Anella Ave., Unit 6

Castle Hill, NSW 2154

Tel: +61-2-9894-7866

Fax: +61-2-9894-0234

TM

Copyright © 2002 Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 031-103-B0-003 Rev. C.

Due to continuing product improvements, Alpha reserves the right to change specifications without notice.

Loading...

Loading...