Page 1

SERIES

Status Monitoring

Installation and Technical Manual

DOCSIS® HMS Embedded Transponder

Effective: December , 2004

Alpha Technologies

®

Page 2

Alpha Technologies

Power

®

2

745-420-C0-002 Rev. B

Page 3

DOCSIS® HMS Embedded T ransponder

Installation and Technical Manual

745-420-C0-002, Rev . B

Effective Date: December, 2004

Copyright© 2004

Alpha Technologies, Inc.

A Member of the Alpha Group

Alpha denies responsibility for any damage or injury involving its enclosures, power supplies, generators,

batteries or other hardware, manufactured by Alpha or members of the Alpha Group, when used for an

unintended purpose, installed or operated in an unapproved manner , or improperly maintained.

Photographs and drawings contained in this manual are only for illustrative purposes. These photographs and

drawings my not exactly match your installation.

Review the written and illustrative information contained in this manual before proceeding. If there are questions

regarding the safe installation or operation of this product, please contact Alpha Technologies or your nearest

Alpha representative.

Contacting Alpha Technologies: www.alpha.com

OR

For general product information and customer service (7 AM to 5 PM, Pacific Time), call

1-800-863-3930

For complete technical support, call

1-800-863-3364

745-420-C0-002 Rev . B

7 AM to 5 PM, Pacific Time or 24/7 emergency support

DOCSIS® is a Registered Trademark of CableLabs.

3

Page 4

T able of Contents

Safety Notes ......................................................................................................................... 6

1.0 Introduction to the DOCSIS Transponder .................................................................... 7

1.1 System Overview............................................................................................. 8

1.2 LED Indicators............................................................................................... 10

2.0 Transponder Installation............................................................................................ 11

2.1 Provisioning the T ransponder ........................................................................ 11

2.1.1 Network Connectivity .......................................................................... 11

2.1.2 Transponder Configuration File ........................................................... 1 2

2.2 V erifying Software V ersion and Device Address ............................................ 13

2.3 Installing the T ransponder Hardware .............................................................. 13

2.4 RF Connection .............................................................................................. 15

2.5 V erifying Transponder Operation.................................................................... 15

3.0 Network/Element Management Software .................................................................. 16

3.1 Provisioning the SNMP Manager................................................................... 16

3.2 Transponder Acquisition by the SNMP Manager ............................................ 16

4.0 Local Port................................................................................................................. 17

5.0 Specifications........................................................................................................... 19

6.0 Acronym Definitions ................................................................................................. 20

4

745-420-C0-002 Rev. B

Page 5

List of Figures

Fig. 1-1, DOCSIS Embedded Transponder with EDSM......................................................... 7

Fig. 1-2, System Interconnection Diagram 1 .......................................................................... 8

Fig. 1-3, System Interconnection Diagram 2 .......................................................................... 9

Fig. 2-1, Attaching the10-pin Connector............................................................................... 14

Fig. 2-2, Att aching the PCB Standoff ................................................................................... 14

Fig. 2-3, Transponder Components..................................................................................... 14

Fig. 2-4, RF Connection with Ground Block ......................................................................... 15

Fig. 4-1, Local Port to PC Connection ................................................................................. 17

745-420-C0-002 Rev . B

5

Page 6

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

T o reduce the risk of injury or death and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

The use of A TTENTION indicates specific regulatory/code requirement s that may affect the placement of

equipment and /or installation procedures.

A NOTE provide additional information to help complete a specific task or procedure.

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING presents safety information to PREVENT INJURY OR DEA TH to the technician or

user.

6

745-420-C0-002 Rev. B

Page 7

1.0 Introduction to the DOCSIS Transponder

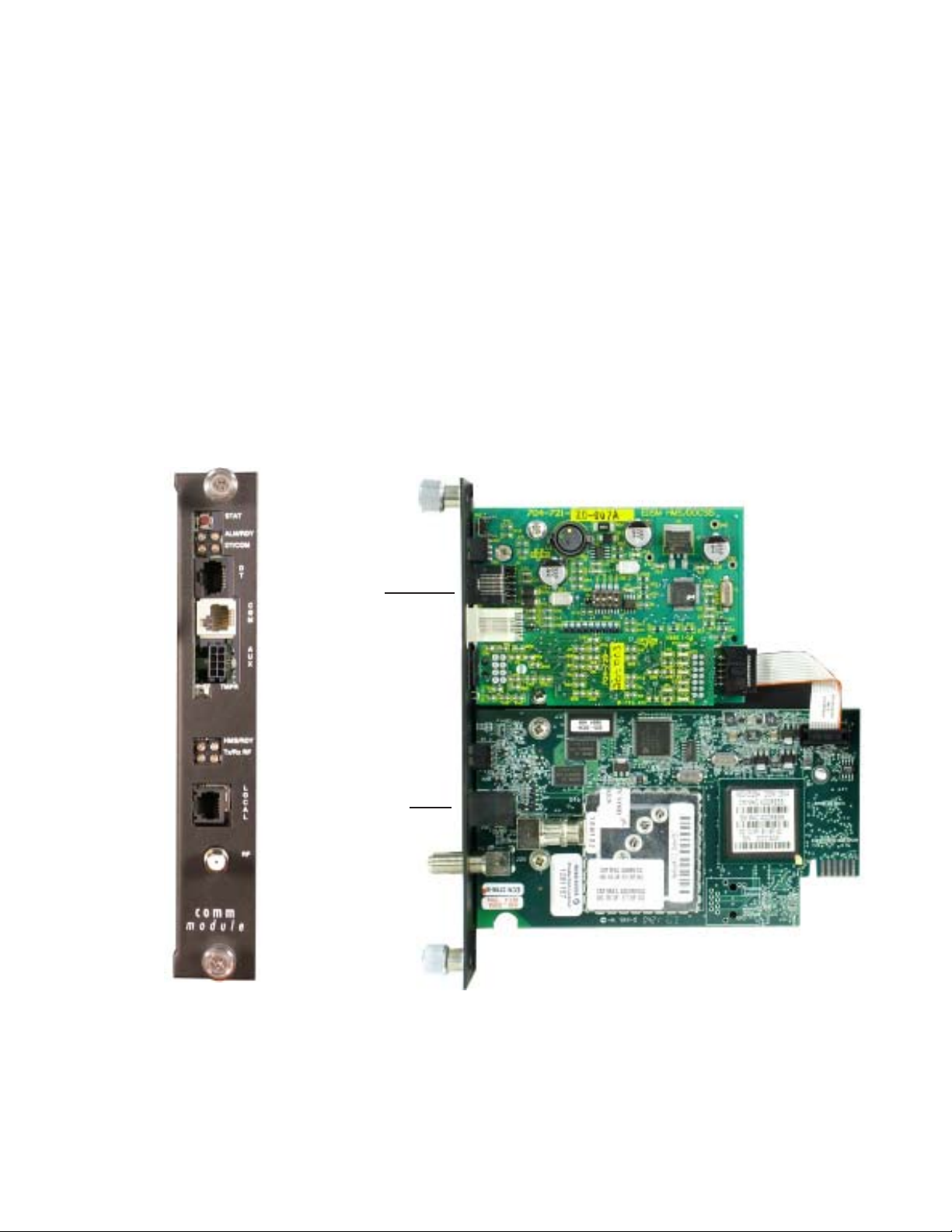

The DOCSIS Digital Embedded Transponder for the XM2 power supply manages network powering

through existing cable modem or high speed data infrastructure. A single transponder can monitor and

manage multiple power supplies, multiple strings of batteries, and one generator . The transponder

transmits data to a management system via the existing DOCSIS network. SNMP (Simple Network

Management Protocol) keeps bandwidth use to a minimum. S tatus monitoring dat a is compatible with

ANSI/SCTE HMS (Hybrid Management Sublayer) standards.

With optional V oIP test functionality , the power supply transponder becomes a powerful network

diagnostics tool. Contact Alpha Technologies for more information.

Outstanding Features:

• Uses existing headend DOCSIS CMTS equipment.

• Uses ANSI/SCTE HMS st andards.

• Single transponder supports up to six power supplies, two battery strings, and one generator .

• Additional battery strings (up to a total of six) can be monitored with Alpha’s extended MIBs.

EDSM

DOCSIS HMS Embedded

Transponder

Fig. 1-1, DOCSIS Embedded Transponder with EDSM

745-420-C0-002 Rev . B

7

Page 8

1.0 Introduction to the DOCSIS Transponder, continued

1.1 System Overview

The DOCSIS Digital T ransponder obtains data from the EDSM (Enhanced Digital S tatus

Monitoring) interface card through an XM2 Power Supply . The EDSM collects data directly from

the battery strings or from the AlphaBus Communications Network, depending on system

configuration.

Equipment monitored (direct battery monitoring):

• An XM2 Power Supply

• One or two 36VDC or 48VDC battery strings

• One AlphaGen st ationary generator system (if installed)

Generator (ECM)

Tamper

Switch

XM2

Dashed lines indicate

wiring for 48V strings

4A

H

M

S

C

O

M

Battery

Sense

24V 12V

48V

4B

36V

2B

3B

1B

Battery Wire Sense

Harness

Battery

RF

RF Cable

Sense

48V

24V 12V

36V

36/48V

Battery Pack

36/48V

Battery Pack

2A 1A

3A

Network

Fig. 1-2, System Interconnection Diagram 1

8

745-420-C0-002 Rev. B

Page 9

1.0 Introduction to the DOCSIS Transponder, continued

1.1 System Overview, continued

Equipment monitored (via AlphaGuard):

• A primary XM2 Power Supply (via an internal network connection).

• Up to five additional XM2 Power Supplies equipped with Serial Interface (SI) cards.

• One or two 36VDC or 48VDC battery strings with AlphaGuard CMM Battery Monitors

• Up to four additional AlphaGuards with extended CMM modules

• One AlphaGen st ationary generator system (if installed)

Generator (ECM) XM2 XM2 XM2

S

Y

S

C

O

M

AlphaGuard

CMM

1234

AlphaGuard

CMM

1234

S

Y

S

C

O

M

Battery

Sense

Battery

Sense

"Master"

XM2

S

Y

S

C

O

M

H

M

S

C

O

M

Tamper

Switch

RF

RF Cable

Network

2A

3A

1A

36/48V

Bat tery Pa ck

24V 12V

36V

2B

3B

1B

36/48V

Bat tery Pa ck

24V 12V

36V

745-420-C0-002 Rev . B

AlphaGuard

CMM

3C

1234

Battery

Sense

36V

Fig. 1-3, System Interconnection Diagram 2

2C

24V 12V

1C

36/48V

Bat tery Pa ck

9

Page 10

1.0 Introduction to the DOCSIS Transponder, continued

1.2 LED Indicators

HMS: Indicates status of serial communications between

transponder and EDSM

OFF: No communications

OFF flickering ON: Communicating with EDSM

RDY: Indicates status of transponder

OFF: No power to transponder from EDSM, or

malfunctioning transponder.

ON: Transponder reset in progress

Flashing ON & OFF: Normal operation

RX: Indicates status of link with CMTS

OFF: No communication with CMTS

ON flickering OFF: Receiving data, CMTS link established

OFF flickering ON: Receiving data, CMTS link failed

Flashing ON & OFF: Failed communications

TX: For future use

10

745-420-C0-002 Rev. B

Page 11

2.0 Transponder Installation

Steps to a Successful Installation:

• Operator’s IT Department must allow the transponders’ Cable Modem (CM) to obtain an IP address

from the DHCP Server.

• Operator’s IT Department must load the HMSINIT.ini file on the TFTP Server .

• Operator’s network security policies must allow SNMP traffic to pass between transponder and

SNMP manager .

• Install the transponder and any related equipment in the power supply .

• Connect an RF drop.

• Verify proper operation.

2.1 Provisioning the Transponder

Complete Sections 2.1.1 and 2.1.2 before connecting the transponder to the RF network.

Otherwise, you must reset each transponder.

2.1.1 Network Connectivity

The transponder’s CM must be recognized by the CMTS as a valid device. The CM

must obtain an IP address from the DHCP server, locate the TFTP and T OD servers,

and communicate with the SNMP management server (trap receiver). CMTS and

system vendors use different security methods to insure network integrity , but some

common issues are:

• A “subscriber account” (where the subscriber is the transponder) may be required

for each transponder.

• The transponder’s MAC address may have to be pre-loaded into the CMTS.

• MAC filtering may have to be modified to allow MAC addresses starting with

00:10:3f:xx:xx:xx to be registered.

• For SNMP access, UDP ports 161 & 162 must not be blocked.

• Firewalls must allow communication between the CM and the TFTP, DHCP, SNMP,

and TOD servers.

• If the address of the TFTP and/or TOD server is different than the DHCP server , the

response from the DHCP server must contain the TFTP and TOD addresses.

745-420-C0-002 Rev . B

11

Page 12

2.0 Transponder Installation, continued

2.1 Provisioning the Transponder, continued

2.1.2 Transponder Configuration File

The transponder’s CM, at first power-up or reset command, requests a configuration file

from the TFTP server . The file must contain the IP address of the SNMP manager. It

may also contain up to five additional SNMP trap recipients. The SNMP manager will

be the only device that can perform SNMP set/get/get-next commands. The trap

recipients and SNMP manager receive the same traps generated by the transponder .

• File type: ASCII text file

• File name: HMSINIT.ini

• File location: Root directory of the TFTP server

• Maximum file size: 4096 bytes (4Kb)

• File format:

// IP address of the SNMP manager

[SERVER IP]

10.1.1.5

// IP address of up to 5 additional trap receivers

[TRAP SERVER IP]

10.1.1.6

10.1.1.7

• The “//” characters indicate an optional comment line.

• The identifiers must be in all caps, and enclosed by brackets “[ ]”.

• The IP addresses must appear on the next line after the identifier , one address per

line. Replace the IP addresses in this example with the actual addresses used in

the network.

• The trap server IP identifier is optional. Addresses for up to five trap recipients can

be listed.

12

745-420-C0-002 Rev. B

Page 13

2.0 Transponder Installation, continued

2.2 Verifying Software Version and Device Address

Before removing the Inverter Module (IM), verify the power supply software version and device

address are correct.

• IM firmware v3.00.0 is the minimum version compatible with the DOCSIS Embedded

Transponder .

• The power supply device address must not be set to zero, and no two power supplies

monitored by a single transponder may have the same address.

1. Press the Enter key on the inverter module twice to access the SETUP Menu.

2. Press the Down key until CODE VER is displayed.

3. V erify that the software code is 3.00.0 or higher .

4. Press the Down key twice until DEVICE ADDRESS is displayed.

5. If the address is correct (and not zero), skip to S tep 10.

6. To change the address, press the Enter key to enter the Edit mode.

7. Press the Up or Down key until the desired address (between 1 and 7) is displayed.

Remember that each power supply on a single transponder must have a unique address.

8. Press the Enter key to load the new address.

9. Press the Enter key again to accept the new data.

10. Press ESC three times to return to the OPERATION NORMAL screen.

2.3 Installing the Transponder Hardware

The following installation procedure assumes the EDSM card, AlphaGuard CMM data collection

module and AlphaBus network have already been inst alled. If not, see the EDSM Installation

and T echnical manual (P/N 704-721-C0) for further instructions.

The Embedded Transponder is static sensitive. An ESD wrist strap should be worn when installing

the transponder .

T ools Required: #1 Phillips Screwdriver

1. Move the XM2 Battery Breaker to the OFF position.

2. Unplug all connections to the front of the Inverter Module (battery cable, RTS, etc).

3. Loosen the thumbscrews holding the Inverter Module into the power supply . Slide the

Inverter Module out just enough to disconnect the ribbon cable. Now slide the Inverter

Module out of the power supply .

T o reduce the risk of electric shock, completely remove the Inverter Module from the Power

Supply prior to installation.

745-420-C0-002 Rev . B

13

Page 14

2.0 Transponder Installation, continued

2.3 Installing the Transponder Hardware, continued

4. Attach the new transponder ribbon cable supplied to the 10-pin connector on the

transponder as shown in Fig. 2-1. The connectors are keyed to prevent incorrect

orientation.

5. Attach the plastic standoff to the transponder PC board as shown in Fig 2-2.

6. V erify that the MAC address label is installed on the transponder. If the label is missing,

locate the label in the packaging and apply to the transponder as shown in Fig 2-3.

7. Place the transponder as shown in Fig 2-3 below . The RF connector must be inserted

through the front of the Comm Module bracket.

8. Press the standoff into the Inverter Module chassis.

9. Secure the transponder to the Comm Module Bracket with the two screws provided.

10. Connect the transponder ribbon cable to the EDSM. Note the 90o twist in the cable.

1 1. Reconnect the Inverter Module ribbon cable, and reinstall the Inverter Module into the power

supply.

12. Reconnect all the cables unplugged in Step 2 .

13. Move the Battery Breaker to the ON position.

10-pin Connector

Fig. 2-1, Attaching the10-pin Connector

PCB Standof f

Fig. 2-2, Attaching the PCB St andoff

Ribbon Cable

EDSM

PCB Standof f

DOCSIS

Securing Screws

RF Connector

Comm Module Bracket

14

MAC Address Label

Fig. 2-3, Transponder Components

745-420-C0-002 Rev. B

Page 15

2.0 Transponder Installation, continued

2.4 RF Connection

Connect the RF drop to the face of the transponder . The drop must have a properly installed

ground block in or on the power supply enclosure. Recommended forward RF level is 0 dBmV .

Battery

Breaker

Batter y

Input

Temp

Probe

LOCAL

RF

RF Connection

Ground Surge

RF Cable

to Headend

Protector

See Caution Below

User Provided

Fig. 2-4, RF Connection with Ground Block

Alpha requires installing a grounded surge suppressor (Alpha P/N 162-028-10 or equivalent).

2.5 Verifying Transponder Operation

745-420-C0-002 Rev . B

During initial transponder power-up, the RDY LED will be on solid.

• Once the reset is complete, the RDY LED will flash at a ½ sec ON, ½ sec OFF rate.

• The RX LED will now be ON, flickering OFF occasionally , indicating a link with the CMTS

has been established.

• The HMS LED will occasionally flicker ON, indicating communication with the EDSM.

15

Page 16

3.0 Network/Element Management Software

3.1 Provisioning the SNMP Manager

The following MIB (Management Information Base) files are required for the SNMP Manager to

collect data from the transponders. These files can be found on the Society of Cable

T elecommunications (SCTE) web site

so they should be compiled in the following order listed below:

ANSI/SCTE 36 2002 (formerly HMS 028), SCTE-ROOT Management Information Base (MIB)

Definitions

ANSI/SCTE 37 2003 (formerly HMS 072), Hybrid Fiber/Coax Outside Plant S tatus Monitoring

SCTE-HMS-ROOTS Management Information Base (MIB) Definition

ANSI/SCTE 38-1 2002 (formerly HMS 026), Hybrid Fiber/Coax Outside Plant S tatus Monitoring

SCTE-HMS-PROPERTY -MIB Management Information Base (MIB) Definition

ANSI/SCTE 38-2 2002 (formerly HMS 023), Hybrid Fiber/Coax Outside Plant S tatus Monitoring

SCTE-HMS-ALARMS-MIB Management Information Base (MIB) Definition

ANSI/SCTE 38-3 2002 (formerly HMS 024), Hybrid Fiber/Coax Outside Plant S tatus Monitoring

SCTE-HMS-COMMON-MIB Management Information Base (MIB) Definition

ANSI/SCTE 38-4 2002 (formerly HMS 027), Hybrid Fiber/Coax Outside Plant S tatus Monitoring

SCTE-HMS-PS-MIB Management Information Base (MIB) Definition

ANSI/SCTE 38-6 2003 (formerly HMS 033) Hybrid Fiber/Coax Outside Plant St atus Monitoring SCTE-HMS-GEN-MIB Management Information Base (MIB) Definition

ANSI/SCTE 38-7 2002 (formerly HMS 050), Hybrid Fiber/Coax Outside Plant S tatus Monitoring

SCTE-HMS-Transponder-Interface-Bus(TIB)-MIB Management Information Base (MIB) Definition

www .scte.org. These are dependencies between MIB files

3.2 Transponder Acquisition by the SNMP Manager

The transponder must first complete its initialization/registration and retrieve the .ini file from

the TFTP server . The transponder will then send a warm-start trap to the SNMP Manager

(specified as the Server IP in the .ini file). This trap provides the SNMP Manager with the

MAC and IP addresses of the transponder and should, depending on the configuration of the

manager software, initiate monitoring of the power supply system.

16

745-420-C0-002 Rev. B

Page 17

4.0 Local Port

The local port allows the technician to communicate with the transponder and power supply through a

PC’s RS-232C serial port.

1. Connect the optional Local Port to RS-232C Adaptor Cable (Alpha P/N 875-349-10) between the

transponder’s Local Port and the computer’s serial port. Launch the computer’s Terminal Emulation

Software (HyperT erminal is recommended).

Fig. 4-1, Local Port to PC Connection

2. Communication settings are:

• 19,200 baud

• 8 data bits

• No parity bit

• 1 stop bit

• No flow control

3. Press ENTER to initiate communications.

4. Press “?” and ENTER to display the menu:

Battery

Breaker

Battery

LOCAL

Local port

Input

Temp

Probe

RF

Logic Level

Alpha P/N 875- 349-10

RS-232

Converter

Laptop Computer

port

With

HyperTerminal

(19,200,8,N, 1)

745-420-C0-002 Rev . B

HELP - This help

? - This help

RESET - Reset transponder

ST ATUS - Transponder config and status

ALARMS - Display active alarms

I D - Enter logical ID

PSDA TA - Display power supply data

DEVICE - Display device status

PSTEST - Initiate power supply test

GENDATA - Display generator data

GENTEST - Initiate generator test

GENRESET - Reset generator alarms

17

Page 18

4.0 Local Port, continued

Enter a command, and press ENTER. If there is more than one power supply connected to the

transponder , then PSDATA and PSTEST must be followed by the device address number .

Verify communications between the power supply , EDSM and transponder with the PSDA TA command.

The data returned should match the data of the power supply display .

MAC Address: 00-10-3F-00-00-0D

Serial No: 123450000

Version: 1.0.2.L 1600 950-0315 A 05.00

IP Address: 192.168.1.102

Check code: 0x0000

CommonNEStatus: 0x19

(actual data will be different)

18

745-420-C0-002 Rev. B

Page 19

5.0 Specifications

DOCSIS® Network Power Monitoring

General Specifications

General

Power Supplies Supported: XM2, XM2VP

DOCSIS Compatibility: DOCSIS 1.1

Monitoring Protocol: SNMPv1

Devices Monitored: Power Supply, Batteries and Generator

Hardware

RF Cable Interface: F-connector, female, 75ohm

Local Interface: RJ-12, RS-232, 19.2kb,N,8,1

LED Indicators: Transponder Ready; HMS CommuniEnvironmental: -40ºC to +65ºC

Emissions: EN50022 Class A and FCC Part 15 Class

Warranty: 2 years

RF Transmit / Receive

Tx Frequency Range: 5 to 42 MHz

Output Power: +8 to +58 dBmV

Channel Bandwidth: 6 MHz

Receive Center Freq Range: 91 to 857 MHz (Standard, HRC, IRC

Input Level: -15 to +15 dBmV

Monitored Parameters

Number of Power Supplies: Up to six, each reporting individual data

Power Supply Data: Major Alarm (includes: test fail, battery fail,

Power Supply Control: Remote test start/stop

Number of Battery String: One or Two Strings of 36V or 48V

Battery Data: Individual Battery Voltages

Generator Data: Status (off, running, alarm)

Generator Control: Remote test (start/stop)

compatible with ANSI/SCTE 25-3 2002,

(formerly HMS 022)

Requires serial port adapter and with

terminal emulation software (Hyper-

T erminal recommended)

cations; RF Transmit; RF Receive

10 to 90% non-condensing humidity

A (Installed in power supply enclosure system)

channels)

line isolation, output over load/fault, over

temp, N+1 active, fuse fail)

Minor Alarm (includes: temp probe error, AC

line loss, N+1 error)

Input AC Line Voltage

Output Voltage

Output Current 1

Output Current 2,3,4 (if installed)

Output Power

Power Supply Status (line, standby, test in

progress, test alarm)

Enclosure Door (open/closed)

Additional battery string monitoring available.

Call Alpha for more information.

Battery Compartment Temperature

(Alarm includes: low oil pressure, engine overtemp, engine over-speed, crank limit, overvoltage, low fuel, water intrusion, pad shear,

gas hazard, test fail)

Gas hazard

Water Intrusion

Pad Shear

Enclosure Door (open/closed)

Ignition Battery Voltage

Enclosure Temperature

Low Fuel

Ordering Information

EDSM-IDH2 DOCSIS Monitoring

DCS-XM2V-2 (XM2VP) Includes: transponder with VoIP test

IDH2 DOCSIS Embedded XM2 Transponder

875-349-10 Local port adaptor

875-155-20 10-pin Connector

Battery Sense Wire Kits

874-842-21 1x36V, 6 ft

874-842-20 2x36V, 6 ft

874-842-27 1x36V, 9 ft

874-842-28 2x36V, 9 ft

874-841-21 1x48V, 6 ft

874-841-20 2x48V, 6 ft

874-841-25 1x48V, 9 ft

874-841-24 2x48V, 9 ft

Extended wire lengths available. Contact Alpha for ordering information.

SI-XM2-KIT (XM2) Additional XM2 Interface Kit

SI-XM2V-KIT (XM2VP) Includes SI adaptor and integration kit

function, EDSM and bracket. Order

AlphaGuard Battery Management or wire

sense kit separately.

with VoIP Test Function( For installation

with existing EDSM. Order AlphaGuard

Battery Management or wire sense kit

separately.

for connecting an additional power

supply for monitoring. One kit required

for each additional power supply (up to

six total).

Management

NMS/EMS: Cheetah™ DOCSIS

HMS MIBs: Power Supply (ANSI/SCTE 38-4)

745-420-C0-002 Rev . B

®

Management Software

Standard SNMP Management T ools

Generator (ANSI/SCTE 38-6)

Transponder (ANSI/SCTE 38-3)

Alarm/Trap (ANSI/SCTE 38-1 and 38-2)

Power Supply

19

Page 20

6.0 Acronym Definitions

ANSI: American National Standards Institute

CM: Cable Modem

CMTS: Cable Modem T ermination System

DHCP: Dynamic Host Configuration Protocol

DOCSIS: Data Over Cable Service Interface S pecification

EDSM: Enhanced Digital Status Module

EMS: Element Management System

IT : Information Technology

MAC: Media Access Control

MIB: Management Information Base

NMS: Network Management System

QoS: Quality of Service

SCTE-HMS: Society of Cable Telecommunications Engineers-Hybrid Management Sublayer

SI: Serial Interface

SNMP: Simple Network Management Protocol

TFTP: Trivial File Transfer Protocol

TOD: Time of Day

UDP: User Datagram Protocol

VoIP: Voice over Internet Protocol

20

745-420-C0-002 Rev. B

Page 21

Alpha Technologies

Power

®

Alpha T echnologies

3767 Alpha Way

Bellingham, WA 98226

USA

T el: +1(360) 647-2360

Fax: +1(360) 671-4936

Web: www.alpha.com

Alpha T echnologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

T el: +1(604) 430-1476

Fax: +1(604) 430-8908

Alpha T echnologies

Europe Ltd.

Cartel Business Estate

Edinburgh Way

Harlow, Essex CM20 2TT

UNITED KINGDOM

Tel: +44-1279-4221 10

Fax: +44-1279-423355

Alpha T echnologies

Hansastrasse 8

D-91126 Schwabach

GERMANY

T el: +49-9122-79889-0

Fax: +49-9122-79889-21

Alphatec, Ltd

P .O. Box 56468

Limassol, Cyprus

CYPRUS

T el: +357-25-375675

Fax: +357-25-359595

Alpha T echnologies

5 Avenue Victor Hugo

F-92140 Calmart France

FRANCE

T el: +33-3-41-90-07-07

Fax: +33-1-41-90-93-12

Copyright © 2004 Alpha T echnologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 745-420-C0-002 Rev. B.

Due to continuing product improvements, Alpha reserves the right to change specifications without notice.

Loading...

Loading...