Page 1

Power

Choke

Knob

CLOSED

OP EN

Fuel Valve

Lever

ON

O

OFF

OPEN

DC Voltage

Selector

Switch

Maintenance

Cover

Choke

Knob

CLOSED

OP EN

Fuel Valve

Lever

ON

O

OFF

O

OFF FF

O

ONN

Starter Grip

Direction

to pull

OPEN

DCX3000 3.0kW, 36/48VDC Portable Generator Quick Guide

The following instructions are intended to supplement the DCX3000 Operator’s Manual. Read and adhere to all safety

instructions listed in the Operator’s Manual (Alpha P/N 041-028-B0) and this document. If you have any questions

regarding safe operation of the generator, consult the Operator’s Manual or contact Alpha Technical Support.

WARNING!

Do not make or break any connections between the power supply battery pack and generator while the

generator is running. Turn the generator off before disconnecting any cables or equipment.

CAUTION!

Always check the engine oil level prior to operating the generator. Failure to do so could lead to

irreparable damage to the engine.

CAUTION!

Only use 86 octane fuel or higher and no more than 10% Ethanol or 5% Methanol by volume.

1.0 Connecting Generator

1. Open the maintenance cover (see Figure 1-1).

2. Using the DC voltage selector switch, select either 36V or 48V (see Figure 1-1).

3. Close the maintenance cover.

4. Connect the power cord of the UPS to the DC output coupler, ensuring there is no gap (see Figure 1-2).

DC Voltage

Selector

Switch

Voltmeter

Maintenance

Cover

Figure 1-1, DC Voltage Selector Switch location.

Note: When the UPS battery string is connected to the generator, the backlight in the Voltmeter is turned on

and indicates the battery string voltage.

Figure 1-2, Connecting the UPS to the DC Output Coupler.

2.0 Operating Generator

1. Turn the Fuel Valve Lever to the ON position (see

Figure 2-1).

2. Adjust Choke Knob (see Figure 2-1).

– Pull the Choke Knob to the CLOSED position to

start a cold engine.

– Leave the Choke Knob in the OPEN position to

restart a warm engine.

041-028-B1-001 Rev. B (09/2012) 1

Fuel Valve

Lever

Figure 2-1, Fuel Valve Lever and Choke Knob operation.

DC Output Coupler

Power

Coupler

ON

OFF

O

Choke

Knob

CLOSED

No gap

OPEN

OP EN

Page 2

Total Power Solutions

Choke

Knob

CLOSED

OP EN

ON

O

OFF

OPEN

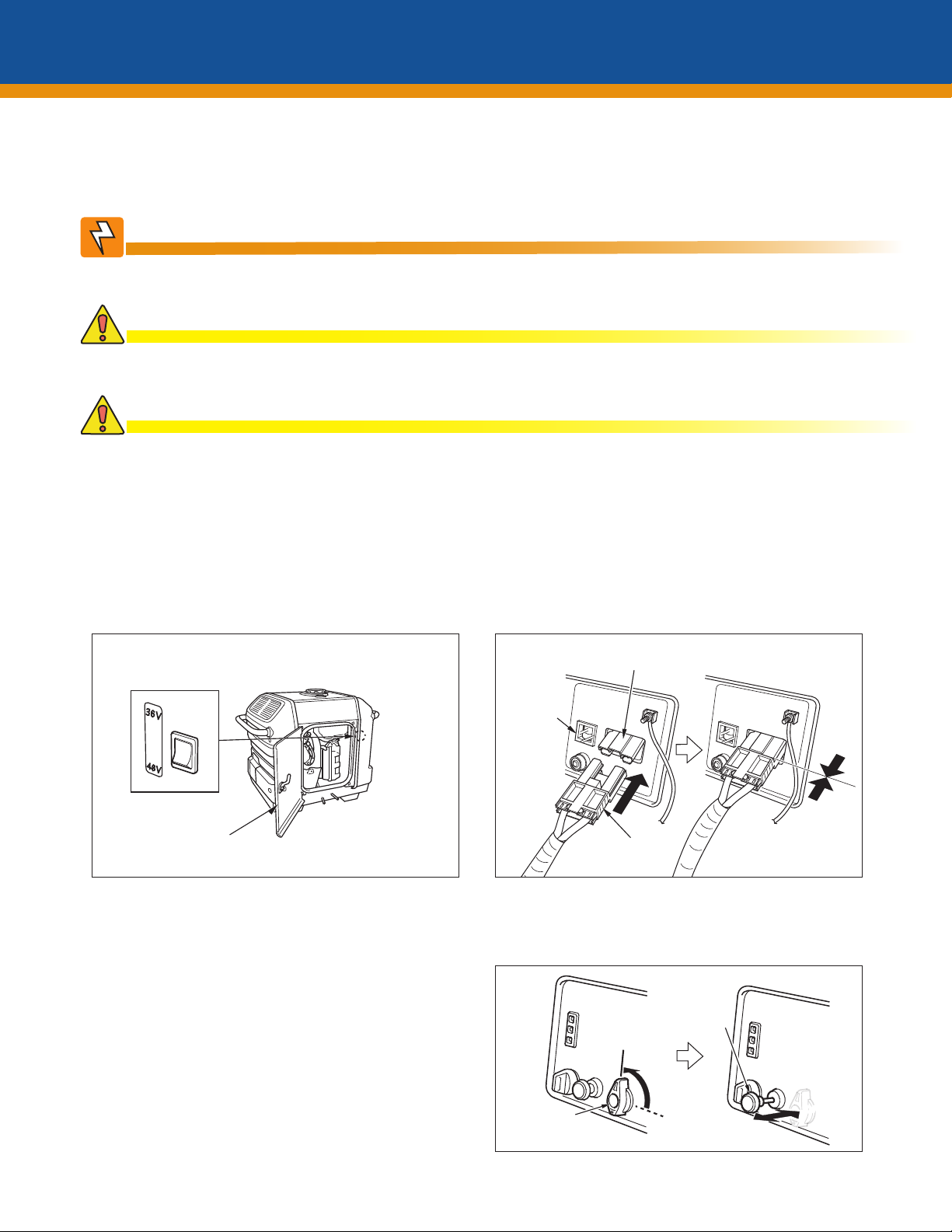

3. Turn the Engine Switch to the ON position (see Figure 2-2).

4. Pull the Starter Grip until you feel resistance, then pull

strongly in a straight line (see Figure 2-2).

Note: Pulling the Starter Grip at sharp angle to the

O

engine will prematurely wear out the cord. Do NOT let

OFF FF

the starter grip snap back against the engine.

5. If the choke was CLOSED to start the engine, gradually

push the choke in to the OPEN position as the engine

warms up.

Note: When the engine starts, DC output will begin

Engine

Switch

charging the UPS battery string automatically and the

output indicator (green) will go ON. If the UPS battery

Figure 2-2, Engine Switch and Starter Grip operation.

string voltage is too low, the DC output will turn off. At

this time, the output indicator (green) will go OFF and

the overload indicator (red) will go ON (see Table 2-1).

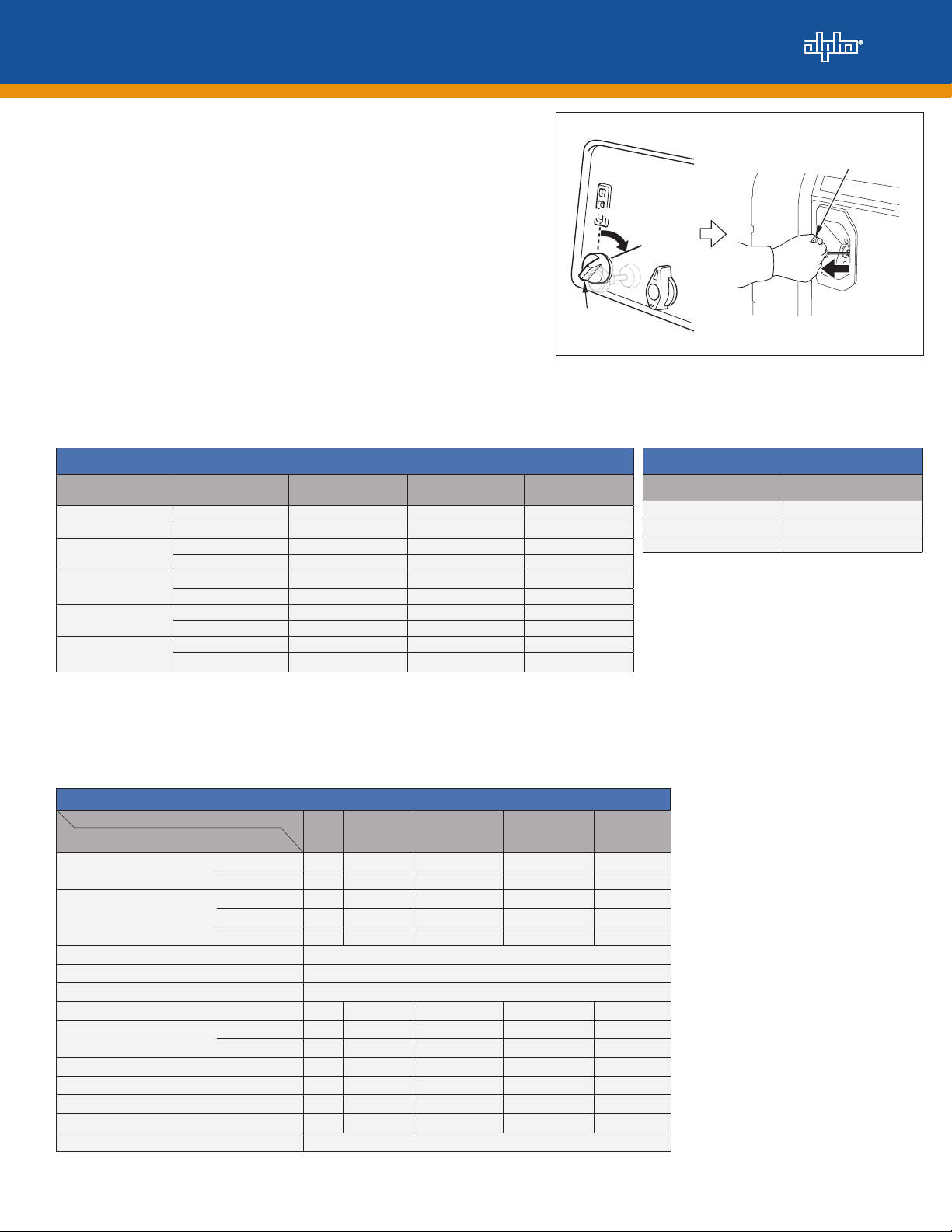

Battery Voltage Alarm Indicators

Voltage Select

Battery Voltage

0V to 2V

2V to 27V

27V to 42V

42V to 55V

>56V

(1)–All battery voltage measurements are ± 1V.

(2)–To enable forced output when the Overload Alarm LED is ashing, press the output button for at least 5 seconds. The Overload Alarm

LED stops ashing. Release the output button, and then press it again for at least ve seconds. The Output Indicator LED turns on steady,

and power output begins. The operator may then release the output button.

(3)–Engine shuts down after 1 second.

1

Switch Position

36V OFF OFF Not Available

48V OFF OFF Not Available

36V OFF FLASHING ENABLED

48V OFF FLASHING ENABLED

36V ON OFF Not Available

48V OFF FLASHING ENABLED

36V OFF FLASHING Not Available

48V ON OFF Not Available

36V OFF FLASHING Not Available

48V OFF FLASHING Not Available

3.0 Maintenance Schedule

REGULAR SERVICE PERIOD

Note: Perform at every indicated month or oper-

ating hour interval, whichever comes rst.

Engine Oil Check Level O

Air Cleaner Check O

Canister Check Every 2 years (Replace if necessary)

Purge tube Check Every 2 years (Replace if necessary)

Charge tube Check Every 2 years (Replace if necessary)

Sediment Cup Check O

Spark Plug Check-adjust O

Spark Arrester Clean O

Valve Clearance Check-adjust O

Combustion chamber Clean

Fuel tank and lter Clean O

Fuel tube Check Every 2 years (Replace if necessary)

Change O O

Clean O

Replace O

Replace O

Output Indicator

(Green LED)

Overload Alarm

(Red LED)

Table 2-1, Battery Voltage alarm indicators.

MAINTENANCE SCHEDULE

Each

use

First month

or 20 hrs.

Every 3 months

or 50 hrs.

2

Every 6 months

or 100 hrs.

Table 2-3, Battery Voltage alarm indicators.

Forced Output

Every year or

300 hrs.

3

3

3

2

3

3

Starter Grip

O

ONN

Run Time Table

2

1

3

3

Load Run Time (Hours)

25% 20

80% 10

100% 7.2

Table 2-2, Load to approximate run time.

(1)–Replace the paper air lter element only.

(2)–Service more frequently when used in dusty areas.

(3)–These items should be serviced by an authorized

AlphaGen dealer.

For commercial use, log hours of operation to

determine proper maintenance intervals. Failure to

follow this maintenance schedule could result in nonwarrantable damage.

Direction

to pull

041-028-B1-001 Rev. B (09/2012)2

Page 3

Total Power Solutions

Oil Filler Cap

Oil Drain Plug

Oil Maintenance

Cover

Dipstick

Oil Filler Cap

Upper Limit

Oil Drain Plug

Oil Maintenance

Cover

Dipstick

4.0 Engine Oil Recommendations

Oil affects performance and service life for the engine. Always use 4-stroke automotive detergent oil. The engine

can hold .58 U.S. qt (.55 L) of oil.

SAE 10W-30 is recommended for general use. Other viscosities shown in the chart may be used when the average

temperature in your area is with the recommended range (see Figure 4-1).

AMBIENT TEMPERATURE

Figure 4-1, Oil recommendations for ambient temperature.

The SAE oil viscosity and service category are in the API label on the oil container. We recommend that you use

API SERVICE category SJ or later (or equivalent) oil.

5.0 Changing Engine Oil

CAUTION!

Hot engine oil can BURN. The engine should be warm to the touch but not hot when changing the oil.

Draining warm oil assists rapid and complete draining.

1. Open and remove the oil maintenance cover (see Figure 5-1).

2. Place a suitable container below the engine to catch the used oil, then remove the oil ller cap/dipstick. Using

a 10mm wrench remove the drain plug and sealing washer (see Figure 5-1).

3. Allow the used oil to drain completely, then reinstall the drain plug and sealing washer. Tighten the plug

securely.

Note: Improper disposal of engine oil can be harmful to the environment and may violate local and federal

laws. Dispose of the used oil in accordance with all local, state and federal laws.

4. With the generator in a level position, ll to the outer edge of the oil lter hole with the recommended oil (see

Figure 5-2).

5. Screw in the oil ller cap/dipstick securely.

6. Reinstall, close, and latch the oil maintenance cover.

Note: Always wash your hands after handling motor oil.

Oil Drain Plug

Oil Maintenance

Cover

Oil Filler Cap

Figure 5-1, Draining oil.

041-028-B1-001 Rev. B (09/2012) 3

Dipstick

Upper Limit

Figure 5-2, Filling oil limit.

Page 4

Sediment Cup

Sediment Cup

O-Ring

(replace)

Filter

Total Power Solutions

6.0 Draining Fuel Tank and Carburetor

WARNING!

Gasoline is highly ammable and explosive. You can be burned or otherwise seriously

injured improperly handling fuel. STOP the engine and let it fully cool before adding or

draining fuel. Remove all sources of ignition, heat, and spark from the immediate area.

Wipe up spills immediately.

1. Open the maintenance cover.

2. Place a suitable gasoline conatiner below the carburetor

drain hose.

3. Loosen the carburetor drain screw and drain the gasoline

from the carburetor (see Figure 6-1).

4. After all the fuel has drained into the container, tighten the

drain screw securely.

5. Place an approved gasoline container below the sediment

cup, and use a funnel to avoid spilling fuel (see Figure 6-2).

Note: The engine fuel tank can hold 3.5 U.S. gallons

(13.3L) of fuel.

6. Remove the sediment cup, then move the Fuel Valve Lever

to the ON position.

Drain Screw

Figure 6-1, Draining carburetor.

7. Allow the fuel to drain completely, then reinstall the

Sediment Cup

Filter

sediment cup.

O-Ring

8. Close the maintenance cover.

(replace)

Sediment Cup

Figure 6-2, Draining/cleaning sediment cup.

7.0 Storing Generator

Proper storage preparation will help prevent corrosion damage and help extend the life of the fuel system. Prior to

storage clean the generator entirely with a damp rag. Once dry, touch up damaged paint and lightly coat exposed

metal surfaces with a quality rust inhibitor. To prevent fuel oxidizing, entirely drain the fuel system. If this is not

possible, ll the fuel tank entirely to reduce the air in the tank (air hastens fuel oxidation) and ensure a quality

gasoline stabilizer is used per the manufacturer's recommendations. It is also good practice to change the oil before

long term storage.

Alpha Technologies

Inc.

3767 Alpha Way

Bellingham WA 98226

USA

Tel: +1 360 647 236 0

Fax: +1 360 671 4936

Alpha Techn ologies Alpha re serves the right to ch ange spec icati ons witho ut notice.

© 2012 Alpha Technologies Inc. All Rights Reserved.

Alpha is a register ed tradem ark of Alpha Technologi es. 041-02 8-B1- 001 Rev B. (09 /2012) For more information visit www.alpha.com

Alpha Technologies

Ltd.

7700 Riverfront Gate

Burnaby BC V5J 5M4

Canada

Tel: +1 604 436 5900

Fax: +1 604 4 36 1233

Alpha Technologies Europe Ltd.

Twyford House, Thorley

Bishop’s Stortford, Hertfordshire

CM22 7PA

United Kingdom

Tel: +44 1279 501110

Fax: +44 1279 659870

Alpha Technologies

GmbH

Hansastrasse 8

D 91126 Schwabach

Germany

Tel: +49 9122 79889 0

Fax: +49 9122 7 9889 21

Al phaTe c L td .

339 Sai nt Andrews S treet

Suite 101 An drea Cham bers

3307 Limassol

Cyprus

Tel: +357 25 375675

Fax: +357 25 359595

AlphaTEK ooo

Khokhlovskiy Pereulok

16

Stroenie 1 Ofce 403

109028 Moscow

Russia

Tel: +7 495 916 1854

Fax: +7 495 916 1349

member of The Group

Alpha Technologies

Suite 190 3, 19/F., Tower 1

33 Canto n Road, Tsim Sha

Tsui

China Hong Kong City,

Kowloon

Hong Kong

Tel: +852 2736 8 663

Fax: +852 2199 7988

TM

Loading...

Loading...