Alpha CXPS 48-1.8-i, 48V Pos Gnd User Manual

Power System Manual

CXPS 48-1.8-i, 48V Pos Gnd

053-990-B0

This page intentionally left blank.

Argus Technologies Ltd. Visit www.argus.ca

Burnaby, British Columbia. Telephone: 604 436 5900 Fax: 604 436 1233

Argus Technologies reserves the right to make changes to the products and information contained in this document without notice.

Copyright 2008 Argus Technologies Ltd. Argus

Printed in Canada.

®

is a registered trademark of Argus Technologies Ltd. All Rights Reserved.

Power System Manual

CXPS 48-1.8-i, 48V Pos Gnd Power System

053-990-B0

Drawing List:

The following drawings are included in this manual to provide the necessary

information required for routine operation and fault diagnosis of the system.

System Specifications 053-990-B1

CXCI Specifications 707-492-B1

Safety and Installation Instructions 053-990-C0

Outline Drawing 053-990-06

Schematic, Power System 053-990-05

Customer Connections 053-990-08

Warranty and Service 048-700-10

Service Centers 048-693-10

Manuals to be included with this package are as follows:

Cordex Controller Software (Current Version) CXC SOFT

Copyright 2008-06-26 Argus Technologies Ltd 053-990-B0 Rev B

Printed in Canada. Argus is a registered Trademark. All rights reserved.

Specifications for Argus’ CXPS 48-1.8-i 48Vdc Power System

Output

Voltage: 42 to 58Vdc within rated limits

Current: System: 150A maximum @ nominal input

~96A @ 115Vac input

Rectifier Module: 37.5A maximum @ 48Vdc (nominal input)

~24A @ 48Vdc (115Vac input)

Power: System: 7200W maximum @ nominal input

~4600W @ 115Vac input

Rectifier Module: 1800W maximum @ nominal input

~1150W @ 115Vac input (de-rated linearly to 900W @ 90Vac)

Heat Dissipation (per rectifier): <607 BTU per hour per rectifier module

Static Load Regulation: Better than ±0.5% for any load change within rated limits

Dynamic Load Regulation: Better than ±2% for 10% - 90% load step

(output shall recover to static limits within 10ms)

Static Line Regulation: Better than ±0.1% for any change in input voltage within rated limits

Dynamic Line Regulation: Better than ±1% for any change in input voltage within rated limits

(output voltage shall recover to static limits within 2ms)

Electrical Noise: <32dBrnC (voice band)

<30mVrms 10kHz to 10MHz (wideband)

<150mVp-p 10kHz to 100MHz

<1.0mV (psophometric)

Acoustic Noise: <60dBa @ 1m (3ft.) @ 30°C (86°F)

Input

Voltage: Nominal: 208/240Vac

Operating: 176 to 312Vac

Extended (High): 312 to 320Vac (de-rated power factor)

Extended (Low): 90 to 176Vac (de-rated output power)

Frequency: 45 to 66Hz

Current: 8.5A @ 240Vac (11.5A maximum @ 176Vac)

Power Factor: >0.99 at nominal conditions and 50-100% load

Efficiency: >90% at nominal conditions and 50-100% load

Recommended Feeder Breaker

Single Phase: 15A, 120 or 240Vac, 2.5mm

2

(#14 AWG) per rectifier module

Argus Technologies Ltd. 053-990-B1 Rev A WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved.

Page 1 of 3

Specifications for Argus Technologies’ CXPS 48-1.8-i 48Vdc Power System Continued

Connections

Load Connections: AM breakers (1-pole): 1/4” holes on 5/8” centers

AM breakers (multiple pole): 3/8” holes on 1” centers (with adapter)

Battery Terminations: AM breakers (1-pole): 1/4” holes on 5/8” centers

AM breakers (multiple pole): 3/8” holes on 1” centers (with adapter)

Alarm/Signal Connections: 0.081mm

AC Input: Terminal blocks 2.5mm

2

to 0.55mm2 (#28 to #20 AWG)

2

to 6mm2 (#14 to #10 AWG),

individual feeds for four modules

Cable Access: Front and top

Environmental

Operating Temperature: -40 to +65°C, power derated to 75°C (167°F)

(-40 to 149°F)

Storage Temperature: -40 to +85°C

(-40 to 185°F)

Humidity: 0 to 95% non-condensing

Elevation: -500m to 2800m; to 4000m with temperature derated to 40°C

(-1640 feet to 9186 feet; to 13124 feet with temperature derated to 104°F)

Miscellaneous

Number of Rectifiers: Up to four (4) Cordex 48-1.8kW modules;

Argus #010-602-20 (pre-RoHS #010-580-20)

Distribution Capacity:

Load: 14x 1-pole positions, plug-in type (bullet terminals), AM-style, 5 to 250A

Battery: 4x 1-pole positions, plug-in type (bullet terminals), AM-style, 5 to 250A

Dimensions: 438mm W x 222mm H x 310mm D

(17.24” W x 8.75” H x 12.2” D)

[-000 configuration – excludes mounting brackets, rear cover, and module

handles. For additional options see outline drawings at the rear of this manual.]

MTBF (rectifier module): >400,000 hours ground benign @ 30°C (86°F)

Argus Technologies Ltd. 053-990-B1 Rev A WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved. Page 2 of 3

Specifications for Argus Technologies’ CXPS 48-1.8-i 48Vdc Power System Continued

Safety

NOTE: Safety certifications performed at rectifier level only.

EN 60950: Rectifier output shall be rated SELV suitable for connection to TNV-1 circuits

UL: 60950

CSA: C22.2 No. 60950

CE: EN 60950, CB Scheme

73/23/EEC Low Voltage Directive with amendment 93/68/EEC

Telcordia (Bellcore): GR-1089-CORE (requirements applicable to rectifier)

Other Referenced Standards

EN 300 386-2: EMC and ERM; Telecommunication Network Equipment

EN 55022 (CISPR 22): Information Technology Equipment – Radio Disturbance Characteristics – Limits

and Methods of Measurement

EN 61000-3-2: Harmonic Current Emissions

EN 61000-3-3: Voltage Fluctuations and Flicker

EN 61000-4-2: ESD Immunity

EN 61000-4-3: Radiated Electromagnetic Immunity

EN 61000-4-4: Electrical Fast Transient/Burst Immunity

EN 61000-4-5: Power Line Surge Immunity

EN 61000-4-6: Conducted Electromagnetic Immunity

EN 61000-4-11: Voltage Dips, Short Interruptions and Variations

ETS 300 019-1-1: Environmental Conditions; Storage

ETS 300 019-1-2: Environmental Conditions; Transportation

ETS 300 132-2: Power Supply Interface at the Input to Telecommunications Equipment;

Operated by Direct Current (DC)

ETS 300 753: Acoustic Noise Emissions

IEC 60950: Safety of Information Technology Equipment, Including Electrical Business

Equipment (UL/CSA 60950)

The above information is valid at the time of publication. Consult factory for up-to-date ordering information.

Specifications are subject to change without notice.

Argus Technologies Ltd. 053-990-B1 Rev A WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved. Page 3 of 3

Specifications for Argus’ CXCI Cordex Controller Integrated Model

Basic Unit, CXCI

Input Voltage: 17 to 65Vdc within rated limits

[9 to 65Vdc for shelf systems with 12V rectifiers (List 3)]

Current: <100mA @ 48Vdc

<200mA @ 24Vdc

MTBF: 472,000 hours @ 25°C (77°F)

EMC: The unit meets requirements of:

ICES-003 Class B

EN 55022 Class B (CISPR 22)

EN 61000-4-2 ESD

EN 61000-4-3 Radiated Immunity

EN 61000-4-4 EFT /Burst

EN 61000-4-6 Conducted Immunity

FCC Part 15 Class B, FCC Part 68

In accordance with FCC requirements, we provide the following statement as specified in the FCC guidelines for

conformance to Part 15, Class B:

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordan ce with

the instructions, may cause harmful interference to radio communication s. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications to this equipment not expressly described in this manual could void the FCC

compliance.

Environmental

Temperature: -40 to 65°C standard @ 3000m derate to 55°C @ 4000m

(-40 to 149°F derate to 131°F @ 13124ft)

Humidity: 0 to 95% non-condensing

Elevation: -500 to +4000m

(-1640 to 13124 ft)

Argus Technologies Ltd. 707-492-B1 Rev B WC

Printed in Canada. © 2007 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved. Page 1 of 2

Specifications for Argus’ CXCI Cordex Controller Integrated Model Continued

Hardware Specifications, CXCI

CPU: Coldfire

RAM: 8MB

Flash: 4MB standard

Display: 4 digit LCD

Front Panel Controls: Display pushbutton toggle switch for voltage (V) or current (A)

CXCI reset switch (soft reset button; hold for 3 seconds to reset IP)

LED’s: System OK (Green)

Power System Minor Alarm (Yellow)

Power System Major Alarm / Controller Fail (Red)

Audio: Built-in speaker for alarm and popup message tones

Dimensions: 88mm H x 26mm W x 280mm D

(3.5” H x 1” W x 11“ D)

Weight: 0.34 kg (0.75 lb.)

Mounting: Integrated on Cordex 2RU series 19” and 23” shelves

Relay Outputs: Four (4) Form C, 60Vdc 1A maximum

Digital Inputs: Two (2), 0 to 60Vdc

Analog Inputs: One (1) DC voltage, 0 to 60Vdc

One (1) DC current, ±50mV

Two (2) temperature, 0 to 20Vdc with power source

Communication Ports: Ethernet RJ-45, Argus Mo dem DB-9, CAN [see shelf specifications]

Recommended Signal Wire Sizes (as per UL/CSA)

Wire Size Range: 0.14 to 1.50mm2

(#26 to #16 AWG)

Temperature Range: 0 to 50°C

(32 to 122°F)

CAUTION – TO REDUCE RISK OF FIRE, USE ONLY 0.14mm

2

(#26 AWG) OR LARGER WIRE.

The above information is valid at the time of publication. Consult factory for up-to-date ordering information.

Specifications are subject to change without notice.

Argus Technologies Ltd. 707-492-B1 Rev B WC

Printed in Canada. © 2007 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved. Page 2 of 2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This section contains important instructions that should be followed during the installation and maintenance of

equipment and batteries. Please read all of the instructions before operating the equipment, and save this

manual for future reference.

A licensed electrician MUST perform connections to the branch circuit of service feed. Installation of the power

supply and batteries must be performed by, or under the direct supervision of service personnel knowledgeable of

the required electrical and battery safety precautions.

If instructions in this manual conflict with local electrical codes, those instructions shall be superseded by the local

code.

The following safety symbols will be found throughout this manual, carefully read all information and a bide by the

instructions:

DANGEROUS VOLTAGE

This symbol indicates a dangerous voltage

exists in this area of the product.

GAS HAZARD

This symbol indicates a gas hazard

exists in the area of vented batteries.

NO MATCHES OR OPEN FLAMES

This symbol indicates a fire or explosive hazard

exists in the area of the product.

The following levels of warning will be used with the above symbols:

DANGER: You WILL be KILLED or SERIOUSLY INJURED if instructions are not followed closely.

WARNING: You CAN be KILLED or SERIOUSLY INJURED if instructions are not followed closely.

CAUTION: You CAN be INJURED or equipment can be DAMAGED if instructions are not followed closely.

Mechanical Safety

Keep hands and tools clear of fans. Fans are thermostatically controlled and will turn on automatically.

Power supplies can reach extreme temperatures under load.

Use caution around sheet metal components and sharp edges.

Electrical Safety

WARNING

Hazardous voltages are present at the input of a power system. The DC output from rectifiers and

batteries, though not dangerous in voltage, has a high short-circuit current capacity that may

cause severe burns and electrical arcing.

Before working with any live battery or power system, follow these precautions:

• Remove all metallic jewelry; e.g., watches, rings, metal rimmed glasses, necklaces.

• Wear safety glasses with side shields (and prescription lenses if necessary) at all times during installation.

• Use OSHA approved insulated hand tools.

Lethal voltages are present within a power system. Never assume that an electrical connection or conductor is not

energized. Check the circuit with a voltmeter with respect to the grounded portion of the enclosure (both AC and

DC) prior to any installation or removal procedure.

Do not work alone under hazardous conditions.

A licensed electrician is required to install permanently wired equipment. Input voltages can range

up to 240Vac. Ensure that utility power is disabled before beginning installation or removal.

Ensure no liquids or wet clothes contact internal components.

Hazardous electrically live parts inside this unit are energized from batteries even when the AC input powe r is

disconnected.

Battery Safety

Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove all

metallic objects from hands and neck.

Use OSHA approved insulated hand tools. Do not rest tools on top of batteries.

Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. Battery post terminals and related accessories contain lead a nd lead compounds; wash hands

after handling (California Proposition 65).

WARNING

Follow battery manufacturer’s safety recommendations when working around battery systems.

WARNING

Do not smoke or present an open flame when batteries (especially vented batteries) are on

charge. Batteries vent hydrogen gas when on charge, which creates an explosion hazard.

Batteries are hazardous to the environment and should be disposed of safely at a recycling facility. Consult the

battery manufacturer for recommended local authorized recycle r s.

TABLE OF CONTENTS

1 INTRODUCTION .............................................................................................................................................................1

1.1 Scope of the Manual.....................................................................................................................................1

1.2 Product Overview..........................................................................................................................................1

1.3 System Configurations..................................................................................................................................2

1.4 Part Numbers and List Options.....................................................................................................................2

2 FEATURES ................................................................................................................................................................... 3

2.1 System Overview.......................................................................................................................................... 3

2.2 Distribution Center ........................................................................................................................................3

2.3 Cordex Integrated System Controller (CXCI) ............................................................................................... 6

2.4 Cordex 48-1.8kW Rectifier............................................................................................................................8

3 INSPECTION................................................................................................................................................................12

3.1 Packing Materials........................................................................................................................................ 12

3.2 Check for Damage......................................................................................................................................12

3.3 General Receipt of Shipment......................................................................................................................12

4 INSTALLATION............................................................................................................................................................13

4.1 Safety Precautions......................................................................................................................................13

4.2 Tools Required............................................................................................................................................13

4.3 Power System Assembly and Mounting.....................................................................................................14

4.4 Rectifier Module Insertion/Removal............................................................................................................14

4.5 Breaker Installation.....................................................................................................................................14

4.6 Breaker Removal ........................................................................................................................................14

4.7 Battery Installation.......................................................................................................................................15

5 WIRING......................................................................................................................................................................17

5.1 Grounding ...................................................................................................................................................17

5.2 AC Feeder Protection/Sizing.......................................................................................................................17

5.3 AC Input Connections.................................................................................................................................17

5.4 Calculating Output Wire Size Requirements...............................................................................................18

5.5 DC Output Connections..............................................................................................................................18

5.6 System and Battery Connections................................................................................................................18

5.7 Alarm Connections......................................................................................................................................20

5.8 CAN Serial Ports.........................................................................................................................................20

5.9 Network Connection and Remote Communications via CXCI....................................................................21

5.10 Signal Wiring Connections for CXCI...........................................................................................................21

6 SYSTEM STARTUP......................................................................................................................................................24

6.1 Check System Connections........................................................................................................................24

6.2 Verify AC and Power the Rectifier Shelf.....................................................................................................24

6.3 Check Battery Polarity and Connect...........................................................................................................24

6.4 CXCI Reset................................................................................................................................................. 25

6.5 LVD Control.................................................................................................................................................25

7 OPERATION................................................................................................................................................................26

7.1 Main Rectifier States...................................................................................................................................26

7.2 Main Rectifier Modes ..................................................................................................................................26

7.3 Factory Ranges and Defaults .....................................................................................................................27

8 MAINTENANCE ...........................................................................................................................................................28

i

8.1 Fan Replacement........................................................................................................................................28

8.2 MOV Replacement...................................................................................................................................... 28

8.3 CXCI Replacement (as used with 1.8kW shelf).......................................................................................... 29

9 ARGUS CONVENTIONS................................................................................................................................................30

9.1 Numbering System......................................................................................................................................30

9.2 Acronyms and Definitions...........................................................................................................................30

FIGURES

Figure 1–Front view of the 053-990-20-000 rail mount CXPS 48-1.8-i configuration...................................................... 1

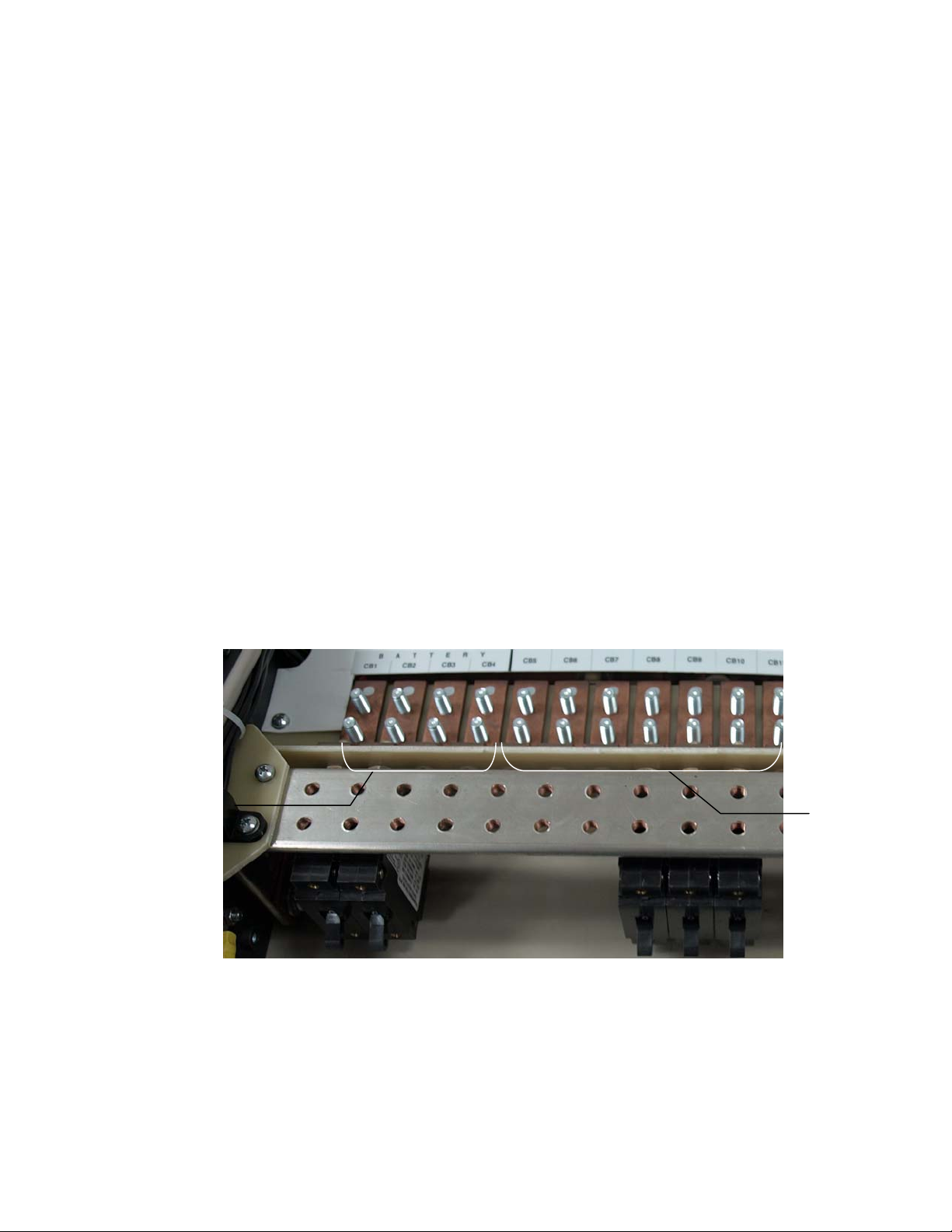

Figure 2–DCP03 configured for 4 battery and 14 load breakers......................................................................................3

Figure 3–Internal alarm card ............................................................................................................................................ 4

Figure 4–Internal alarm card and CXCI I/O terminal block...............................................................................................4

Figure 5–4R/8D ADIO option............................................................................................................................................5

Figure 6–Cordex CXCI model system controller front panel............................................................................................6

Figure 7–Cordex 48-1.8kW modular switched mode rectifier.......................................................................................... 8

Figure 8–CXRF 48-1.8kW module performance............................................................................................................10

Figure 9–Example of an insulated tool kit.......................................................................................................................13

Figure 10–Rear view of DCP03 distribution panel .........................................................................................................19

Figure 11–Battery, load, and return connection locations..............................................................................................19

Figure 12–DCP03 wire routing example.........................................................................................................................20

Figure 13–Showing relay connections............................................................................................................................21

Figure 14–Showing digital input connection method...................................................................................................... 22

Figure 15–Showing CXCI replacement..........................................................................................................................29

ii

1 Introduction

1.1 Scope of the Manual

This instruction manual covers the features and installation of Argus Technologies’ CXPS 48-1.8-i 48V 150A

Power System.

NOTE: To aid the user with installation, frequent reference is made to drawings located at the rear of this manual.

1.2 Product Overview

The CXPS 48-1.8-i is a complete integrated 48Vdc power system with 150A capacity. The system utilizes the

advanced Cordex CXCI controller and 48V 1.8kW rectifier modules. The DCP03 300A distribution center provides

front access for DC distribution, site controller, and battery connections.

Cordex rectifier modules use a high frequency, switched mode conversion techn ique to provide a fully regulated

and isolated DC output from the AC mains. The rectifier input is wide range to allow use on

120/208/220/230/240/277Vac 50/60Hz electrical service. NOTE: System has de-rated ou tput below 176VAC

input, see specifications at the front of this manual.

Rectifier power modules are “hot swappable” meaning they can be inserted or removed from the shelf with out

cutting power to or from the system or the load.

NOTE: Rectifier modules are not included with the base system, but may be purchased along with the system at the tim e

of ordering or added after the shelf has been installed.

The shelf rectifier system is designed to operate with the Argus Cordex System Controller (CXC).

This system uses the CXCI integrated version of the controller, which is factory installed on the Cordex rectifier

system shelf.

The CXC allows the user to configure, monitor and control the entire DC power system locally or remotely via a

web browser such as Internet Explorer. Features of the unit include temperature compensation, auto equalization,

remote access, e-mail alarm notification, battery diagnostics, as well as web server and SNMP support for

configuration and monitoring.

Details of controller operation are provided in the current version software manual.

Figure 1–Front view of the 053-990-20-000 rail mount CXPS 48-1.8-i configuration

Argus Technologies Ltd. 053-990-C0 Rev A WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved. Page 1 of 30

1.3 System Configurations

The system is available to order in the following configurations:

Description Part Number

CXPS 48-1.8-i, Cordex base 48V 150A power system, 19/23” rail mount........................................ 053-990-20-000

CXPS 48-1.8-i system installed in 7foot Z4 23” rack with 2x battery trays........................................ 053-990-20-040

CXPS 48-1.8-i system installed in 7foot Z4 19” rack with 3x battery trays........................................ 053-990-20-031

1.4 Part Numbers and List Options

This product is available to order with the following options and accessories:

Description Part Number

Cordex 48-1.8kW rectifier power module (pre-RoHS 010-580-20).................................................... 010-602-20-040

Breaker, AM-type mid-trip plug-in, 1A........................................................................................................470-300-10

Breaker, AM-type mid-trip plug-in, 3A........................................................................................................470-301-10

Breaker, AM-type mid-trip plug-in, 5A........................................................................................................470-302-10

Breaker, AM-type mid-trip plug-in, 10A......................................................................................................470-303-10

Breaker, AM-type mid-trip plug-in, 15A......................................................................................................470-304-10

Breaker, AM-type mid-trip plug-in, 20A......................................................................................................470-305-10

Breaker, AM-type mid-trip plug-in, 25A......................................................................................................470-306-10

Breaker, AM-type mid-trip plug-in, 30A......................................................................................................470-307-10

Breaker, AM-type mid-trip plug-in, 35A......................................................................................................470-308-10

Breaker, AM-type mid-trip plug-in, 40A......................................................................................................470-309-10

Breaker, AM-type mid-trip plug-in, 45A......................................................................................................470-310-10

Breaker, AM-type mid-trip plug-in, 50A......................................................................................................470-311-10

Breaker, AM-type mid-trip plug-in, 60A......................................................................................................470-312-10

Breaker, AM-type mid-trip plug-in, 70A......................................................................................................470-313-10

Breaker, AM-type mid-trip plug-in, 80A......................................................................................................470-314-10

Breaker, AM-type mid-trip plug-in, 90A......................................................................................................470-315-10

Breaker, AM-type mid-trip plug-in, 100A....................................................................................................470-316-10

Load breaker kit, AM-type mid-trip plug-in, 125A (2-pole).........................................................................747-523-20

Load breaker kit, AM-type mid-trip plug-in, 150A (2-pole).........................................................................747-524-20

Load breaker kit, AM-type mid-trip plug-in, 175A (3-pole).........................................................................747-525-20

Load breaker kit, AM-type mid-trip plug-in, 200A (3-pole).........................................................................747-526-20

Load breaker kit, AM-type mid-trip plug-in, 250A (3-pole).........................................................................747-527-20

Battery breaker, AM-type series-trip plug-in, 100A....................................................................................470-347-10

Battery breaker kit, AM-type series-trip plug-in, 150A (2-pole)..................................................................747-503-20

Battery breaker kit, AM-type series-trip plug-in, 250A (3-pole)..................................................................747-504-20

Fan assembly, (spare for Cordex 48-1.8kW).............................................................................................747-272-20

MOV assembly, (spare for Cordex 48-1.8kW)...........................................................................................707-436-20

Replacement CXCI controller.....................................................................................................................747-427-20

23” battery tray expansion kit (for use with –040 configuration)................................................................058-156-20

19” battery tray expansion kit (for use with –031 configuration)................................................................058-157-20

Cordex DC Modem ....................................................................................................................................018-585-20

(complete with Argus cable)

Cordex Smart Peripheral Kit, 4 O/P Relays, 8 Digital I/P ..........................................................................747-521-20

The above information is valid at the time of publication. Consult factory for up-to-date ordering information.

Argus Technologies Ltd. 053-990-C0 Rev A WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved. Page 2 of 30

2 Features

2.1 System Overview

The basic system configuration is called out by Argus part number 053-990-20-000; which includes:

• 300A DCP03 distribution center

• Cordex Integrated System Controller (CXCI)

• One (1) Cordex 48-1.8kW 4-module rectifier shelf

• Kydex rear cover

• 19” rack mount rails (center and flush mount)

• 19” to 23” rack mount adaptors

• System integration cabling and bus work

• Two (2) battery temperature compensation probes (12’ each).

Optional system configurations are available as:

053-990-20-031: basic configuration factory installed into a 7 foot 19” zone 4 relay rack and three (3) battery

trays with cabling and 100A battery disconnects for up to three (3) 48V VRLA strings.

053-990-20-040: basic configuration factory installed into a 7 foot 23” zone 4 relay rack and two (2) battery trays

with cabling and 100A battery disconnects for up to two (2) 48V VRLA strings.

2.2 Distribution Center

2.2.1 Distribution Configurations

The DCP03 contains 18 total AM-type plug-in breaker positions with two-hole connection points for both breaker

output and the ground return bus. The breaker distribution, for the CXPS 48-1.8-i, is configured for 4 battery

breaker and 14 load breaker positions as shown below:

Battery breaker

connections

Figure 2–DCP03 configured for 4 battery and 14 load breakers

Load breaker

connections

NOTE: Load breakers require mid-trip AM plug-in breakers, and battery breakers require series-trip AM plug-in breakers.

NOTE: When there is no power on the rectifiers and there is only one battery circuit breaker, there will be no alarm if the

circuit breaker trips.

2.2.2 Low Voltage Battery Disconnect (LVBD)

A 400A LVD is included for the CXPS 48-1.8-i system configuration. The LVD is installed in series with the

batteries (LVBD).

Argus Technologies Ltd. 053-990-C0 Rev A WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved. Page 3 of 30

2.2.3 Shunt

A 400A shunt is included, in the CXPS 48-1.8-i system, for system current measurement. The shunt is installed in

series with the batteries and the system controller automatically calculates load current.

2.2.4 Internal Alarm Card

The DCP03 includes a standard alarm card providing a common interface point to internal system I/O

connections, an LVD override switch, and LED indication of breaker trip.

The alarm card provides terminal block access to internal signals such as binary alarm s for breaker trip & LVD

open, alarm relay for driving LVD, and analog inputs for current (shunt) and voltage measurements. The terminal

blocks provide a single point of access to these signals for connecting to an external system controller. Refer to

the customer connections (“–08”) drawing at the rear of this manual for details on terminal blo ck assignments.

The LVD override switch provides the user with the ability to inhibit or override LVD contactor operation as a

safeguard during controller maintenance. A green LED signals when the LVD is in normal operation mode and a

yellow LED signals when the switch has been placed into the override position.

I/O customer connection points

LVD override switch

2.2.5 CXCI I/O Terminal Block

A CXCI I/O terminal block kit is installed in the UDC front door for front access to controller signals and interfaces

to the CXCI controller, on the rectifier shelf, via a 25-pin D-sub wire harness.

The internal signals from the distribution center are wired to the CXCI I/O board direct from the internal alarm

board. The remaining relay outputs, digital inputs, and analog inputs are available on the board via terminal

blocks for customer connection of external signals. Refer to the customer connections (“–08”) drawing at the rear

of this manual for details on terminal block assignments.

Figure 3–Internal alarm card

D-sub wire harnesses

to 1.8kW shelf

CXCI I/O terminal

block assembly

Figure 4–Internal alarm card and CXCI I/O terminal block

Argus Technologies Ltd. 053-990-C0 Rev A WC

Printed in Canada. © 2008 Argus Technologies Ltd. ARGUS and CORDEX are trademarks of Argus Technologies Ltd. All Rights Reserved. Page 4 of 30

Loading...

Loading...