Installation and Servicing

Instructions

Alpha CombiMax 350 and 600

Unvented Hot Water Store

for use with the

Alpha 240/280 Range of Gas Fired Combination Boilers

For Technical help or for Service call ...

ALPHA HELPLINE

Tel: 0870 3001 964

Nepicar House, London Road,

Wrotham Heath, Sevenoaks,

Kent TN15 7RS

These instructions must be used in conjunction with the Installation instructions provided

with the selected combination boiler.

Building Regulations

Certificate No. ETC 03198

Leave these instructions with the User

CONTENTS

1 Introduction ....................................... 2

2 Technical data...................................3

3 Installation information ....................... 5

4 Installation......................................... 7

5 Commissioning ................................. 11

6 Operation .......................................... 13

7 Routine servicing...............................13

8 Component replacement ................... 14

9 Wiring diagrams ................................ 16

10 Short parts list ................................... 17

11 Fault finding ...................................... 17

12 Appendix 1 (remote location) ............. 18

1 INTRODUCTION

The CombiMax is a wall mounted unvented secondary hot water storage cylinder for use with the Alpha 240/280 range of gas

fired combination boilers.

Two models are available - the CombiMax 350 with a 35 litre capacity and the CombiMax 600 with a 60 litre capacity.

The store is supplied with a pump, thermostats, pressure reducing valve, check valve, expansion vessel, expansion relief

valve, temperature/pressure relief valve and tundish. It is also supplied with all the required fittings and pipework to enable

connection to the selected Alpha combination boiler.

The CombiMax provides hot water at temperatures of up to 56°C at flow rates of up to 18 l/min (4 gal/min).

Note: To enable this flow rate to be achieved:-

1.The cold water mains supply must be able to deliver 22 l/min to the appliance.

2.Pipework to the hot water outlets should be as short as is practical and have minimal pressure loss.

The CombiMax can be converted to enable a secondary circulation loop to be connected to it, thus supplying domestic hot

water immediately a hot water tap is opened. The CombiMax pump is used to circulate the hot water within the loop. For full

details contact Alpha Therm Ltd.

The CombiMax storage cylinder has the facility for fitting an electric immersion heater (which must be obtained from Alpha

Therm Ltd.) and an external clock for timing the domestic hot water operation.

IMPORTANT

This appliance has been approved to the Building Regulations for unvented hot water storage systems and the Local Authority

must be notified of the intention to install. Therefore the installation must be carried out by a person competent to install

unvented hot water systems in accordance with the following recommendations:-

All relevant Building Regulations issued by the Department of the Environment

Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development Department

Local Water Bye Laws

Health & Safety Document No. 635 (The Electricity At Work Regulations 1989)

The installation should also be in accordance with the following British Standard Codes of Practice:-

BS 5546:1990 Installation of hot water supplies for domestic purposes

BS 6700:1987 Design, installation, testing and maintenance of services supplying water

BS 7671:1992 Requirements for electrical installations, IEE Wiring Regulations

Failure to install this appliance correctly could lead to prosecution. It is in your own interest and that of safety to ensure that the

law is complied with.

Manufacturer's instructions must NOT be taken in anyway as over-riding statutory obligations.

NOTE: Failure to use an Alpha boiler with the CombiMax will invalidate its approval, warranty and may be unsafe.

Alpha CombiMax 350 and 600

2

2 TECHNICAL DATA

2.1 DOMESTIC HOT WATER

Domestic Hot Water

Max. Mains Inlet Pressure

Min. Mains Water Pressure

Mains Inlet Connection

DHW Outlet Connection

DHW Storage (350 model)

Expansion Vessel Size (pre-charge press.)

Pressure Reducing Valve Setting

Temperature and Pressure Relief Valve

Expansion Relief Valve Setting

Flow Rate L/min

Outlet Water Temp. (Approx.) °C

Time to raise water storage 50°C(350 model)

Reheat time for 70% of storage (350 model)

(inlet of pressure reducing valve)

(600 model)

(350 model)

(600 model)

G.P.M.

°F

(600 model)

(600 model)

8 bar

0.1 bar

15 mm

15 mm

35 L

60 L

4 L at 2.5 bar

5 L at 2.5 bar

2.5 bar

90°C/7 bar

4 bar

18.0

4.0

56

133

7.25 mins

12 mins

4.0 mins

7 mins

2.2 INSTALLATION

Min. Clearances required for Servicing

Top

Bottom

Sides

Front

Dimensions CombiMax Height

(350 model) Width

(600 model) Width

Depth

Overall width when fitted with boiler

(350 model)

(600 model)

Lift Weight of Store (350 model)

(600 model)

Weight Full and Operational (350 model)

(CombiMax and Boiler) (600 model)

220 mm

250 mm

5 mm

450 mm

950 mm

270 mm

365 mm

360 mm

720 mm

815 mm

12 kg

25 kg

92 kg

130 kg

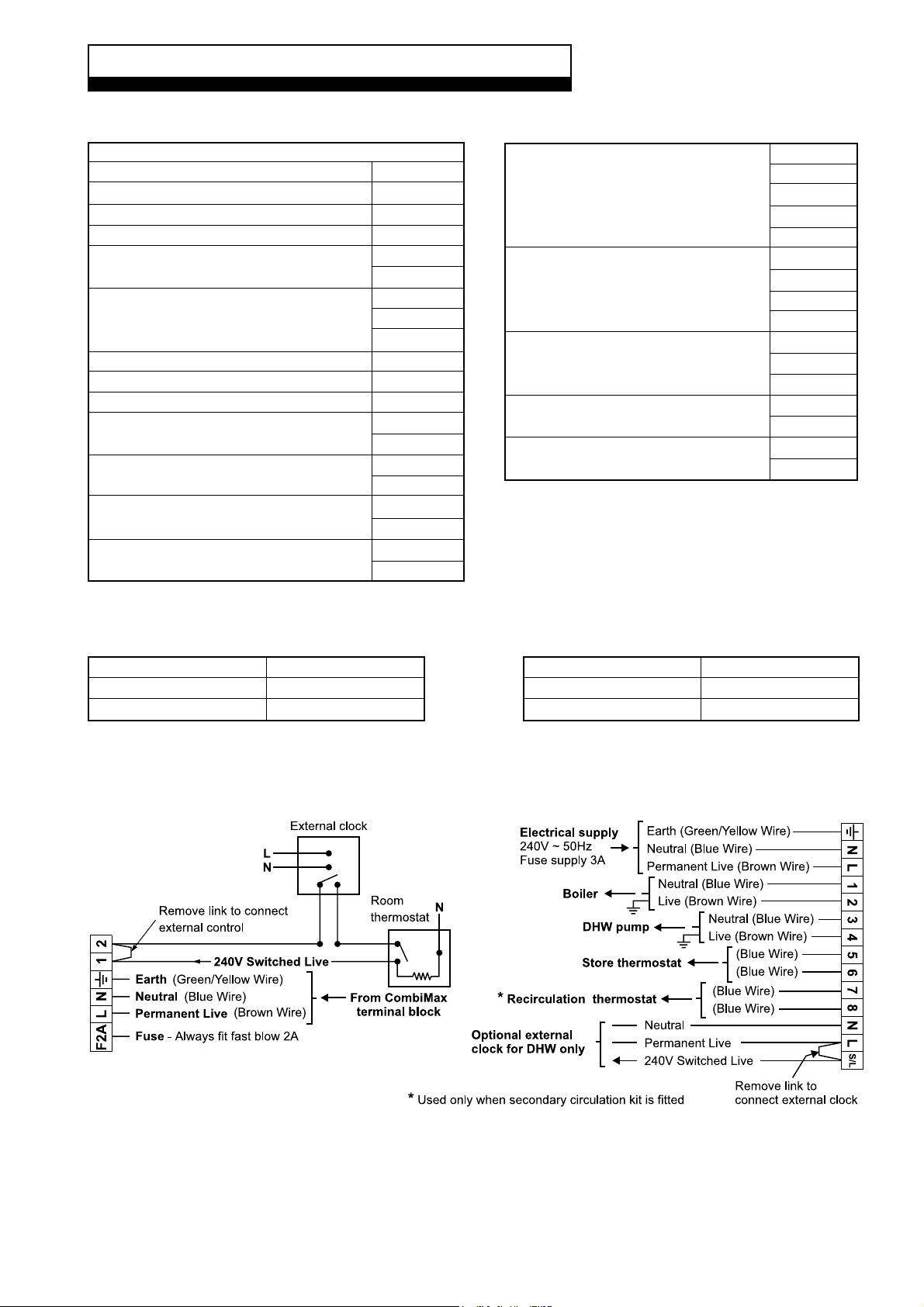

2.3 ELECTRICAL

Supply

External Fuse

Power Consumption

230/240 V ~ 50 Hz

3 A

90 W

2.4 ELECTRICAL CONNECTIONS

Note: This Appliance Must Be Earthed

Alpha Immersion Heater (optional)

Supply

External Fuse

Power Consumption

230/240 V ~ 50 Hz

10 A

2 kW

Boiler terminal block CombiMax terminal block

Alpha CombiMax 350 and 600

3

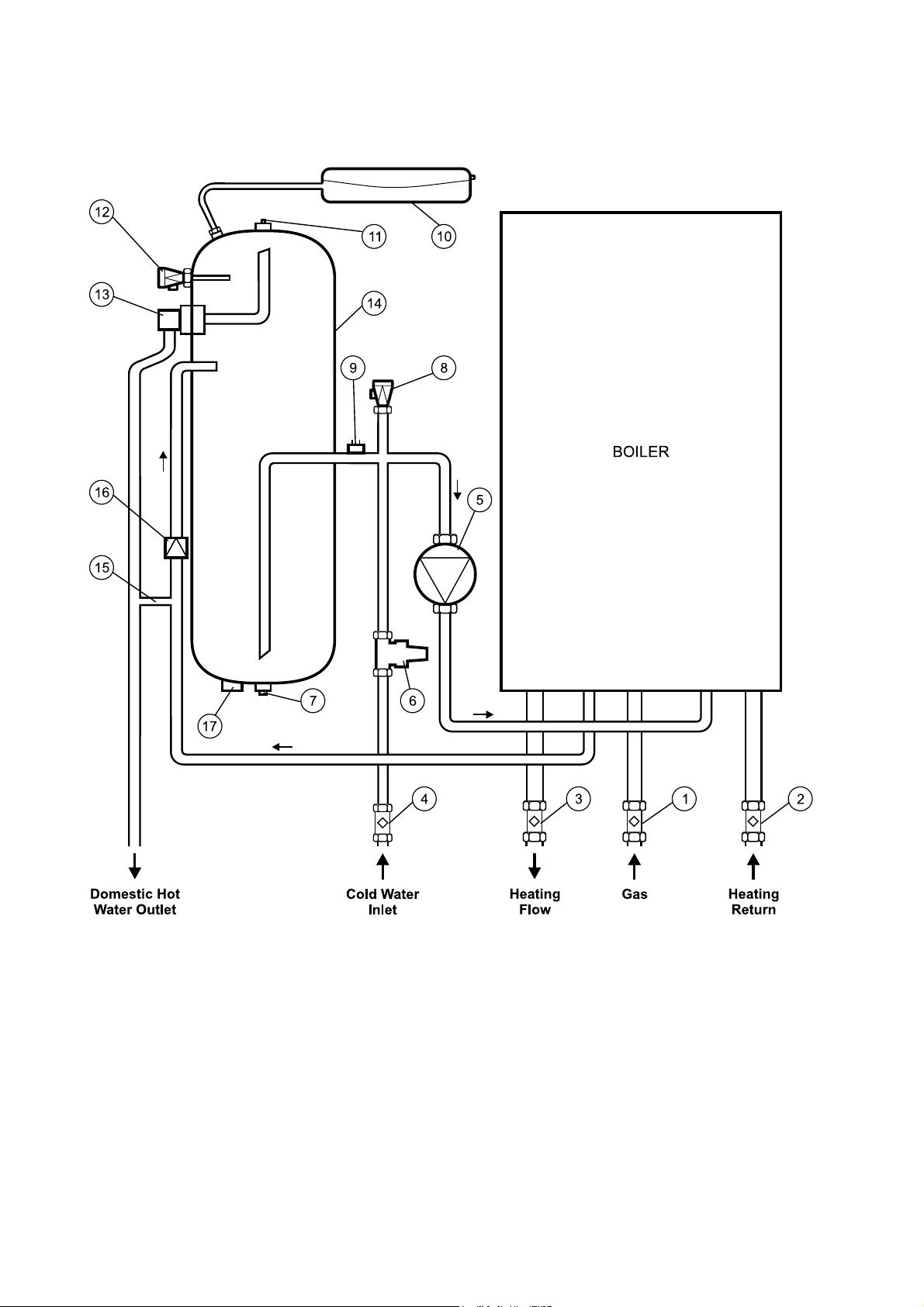

2.5 COMBIMAX SCHEMATIC

1. Gas service cock

2. On/Off valve and filter

3. On/Off valve

4. On/Off valve and filter

5. DHW pump

6. Pressure reducing valve with filter and check valve

7. Drain point

8. DHW expansion relief valve

Alpha CombiMax 350 and 600

4

9. Store thermostat

10. DHW expansion vessel

11. Manual air vent

12. DHW temperature/pressure relief valve

13. DHW outlet thermostat

14. Storage cylinder

15 Boiler flow control regulator

16 Non return valve

17 Immersion heater boss

3 INSTALLATION INFORMATION

3.1 ELECTRICAL SUPPLY

The CombiMax requires a 230/240 V ~ 50 Hz electrical mains supply.

This appliance must be earthed.

The mains supply to the CombiMax and boiler must be directly connected to the CombiMax terminal block, i.e. not the boiler. A

supply cable from the CombiMax terminal block has been provided for connection to the boiler terminal block.

Notes: 1. If an external control is to be fitted, it must be suitable for 240 V and it must be connected to the boiler terminal block.

2. If an external DHW clock is to be fitted, it must be suitable for 240 V and it must be connected to the CombiMax

terminal block.

There must only be one common isolator, providing complete electrical isolation, for the CombiMax, boiler and any external controls.

However, if an immersion heater is to be fitted, an independant electrical supply must be provided. Refer to the instructions supplied

with the Alpha immersion heater kit.

The appliance should be connected to a fused three pin plug and unswitched shuttered socket outlet (both complying with BS 1363),

or a fused double pole switch with a contact separation of at least 3 mm in both poles using heat resisting cable (i.e. 85°C) not less

than 0.75 mm² (24 x 0.2 mm) to BS 6500 Table 9.

Wiring external to the boiler must be in accordance with the current IEE Wiring Regulations (BS 7671).

Note: If an immersion heater is to be fitted, this

with the kit. A standard 3 kW immersion heater must not be fitted.

DHW CLOCK - Sometimes it may be required to switch off the CombiMax and, if fitted, the secondary circulation overnight to

avoid unnecessary heat loss and operation of the appliance. This can be achieved by connecting an external clock to the 'Ext

Prog' terminals on the CombiMax terminal block, as shown in section 2.4.

Note: When the clock is in an OFF position the CombiMax will not operate, i.e. hot water will only be supplied from the water

left within the storage cyliner. Therefore the OFF periods should be set at times when hot water will not be required.

If a secondary circulation kit is to be fitted, refer to the instructions supplied with the kit.

must be supplied by Alpha Therm Ltd. and be installed as per the instructions supplied

3.2 LOCATION

The appliance is not suitable for external installation.

The CombiMax and boiler must be installed on a flat vertical wall which is capable of supporting a weight of approximately 92 kg

(350 model) or 130 kg (600 model)..

The CombiMax may be installed in any room or internal space, although particular attention is drawn to the requirements of the current IEE

Wiring Regulations, and in Scotland, the electrical provisions of the Building Regulations applicable in Scotland, with respect to the installation

in a room or internal space containing a bath or shower. Where it is installed in a room containing a bath or shower, it must not be possible

for a person using the bath or shower to touch any electrical switch or boiler control utilising mains electricity.

The appliance may be installed in a cupboard or compartment, provided it is correctly designed for that purpose and that the

requirements of BS 6798 are complied with.

The appliance does not require any air vents for cooling in the room in which it is installed or when installed in a cupboard or

compartment.

If required, the CombiMax (produced after February 1999, i.e. from serial No. A906) may be located remotely (up to 1 metre)

from the boiler. Refer to Appendix 1, starting on page 18.

3.3 DOMESTIC HOT WATER SYSTEM

To ensure a hot water flow rate of 18 l/min the mains water supply must be capable of delivering 22 l/min to the appliance at 2 bar.

The incoming mains water pressure is regulated to 2.5 bar within the Combimax by a pressure reducing valve. However, all taps

and mixing valves used with the hot water system must be suitable for operating at a pressure of up to 8 bar.

To ensure economic use, the pipe runs between the appliance and taps should be in 15 mm copper pipe and be as short as

possible. Where possible the pipework should be insulated to reduce heat loss.

Showers - A shower may be used with the CombiMax if required.

If a loose or flexible head type shower is used it may require the fitting of a double check valve, to comply with Water Bye Law 17.

Bidets - No anti-syphonage arrangements are necessary, provided the outlets are shrouded and it is not possible to attach a temporary

hand held spray. A supply of direct mains fed hot and cold water is permitted provided the appliance is of the over-rim flushing type.

Before the mains water supply pipe is connected, it should be thoroughly flushed out to avoid the danger of dirt or foreign

matter entering the CombiMax or boiler and the filter incorporated within the pressure reducing valve cleaned.

The stored water temperature is approximately 56°C. In hard water areas this should avoid possible scale build-up. However, if

descaling is necessary contact Alpha Therm Ltd. for guidance.

Alpha CombiMax 350 and 600

5

3.4 UNVENTED HOT WATER STORAGE SYSTEM

The installation is subject to Building Regulations approval and the Local Authority must be notified of the intent to install.

The CombiMax store is supplied with the components required for an unvented hot water system, i.e. temperature/pressure and

expansion relief valves, expansion vessel, check valve and tundish. All these components are factory fitted, except for the expansion

vessel, which is to be connected to the top of the storage cylinder after installation, and the tundish which must be installed as follows:-

Discharge pipe - The discharge pipes from both the temperature/pressure and expansion relief valves have been joined together

within the appliance. The combined discharge pipe from the appliance must be routed to the tundish supplied in 15 mm pipe.

Tundish - The tundish must be positioned within 500 mm of the appliance, so that it is visible to the User and away from electrical

devices. The minimum size of the discharge pipe downstream of the tundish is given in the following table.

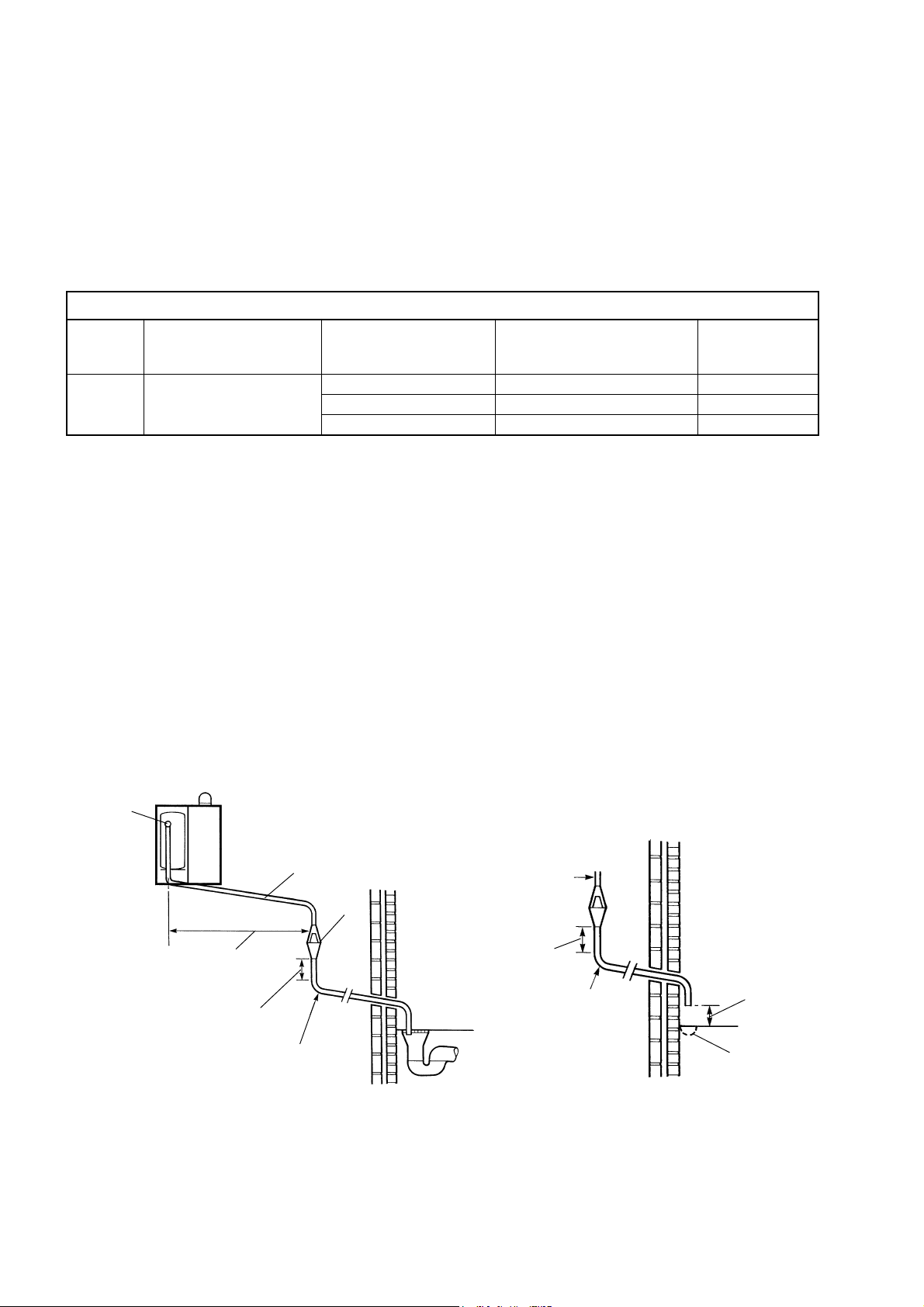

Sizing of copper discharge pipe 'D2' - refer also to Figs. 1a and 1b

Valve

outlet size

Minimum size of discharge

pipe 'D1' to tundish

Minimum size of discharge

pipe 'D2' from tundish

Maximum resistance allowed,

expressed as a length of straight

pipe (i.e. no elbows or bends)

up to 9 m

up to 18 m

up to 27 m

G½

15 mm

22 mm

28 mm

35 mm

The discharge pipework from the tundish:-

a. Shall fall continuously through its length.

b. Shall be of a heat resistant material, e.g. metal.

c. Shall not be fitted with any valves or taps.

d. Shall discharge to a safe visible position, e.g. onto the surface of an external wall or into a gulley.

e. Shall have a minimum of 300 mm straight pipework directly from the tundish.

Note: Where children may play or otherwise come into contact with discharges, a wire cage or similar guard must be

positioned to prevent contact whilst maintaining visibility.

Refer to Figs. 1a and 1b for suggested methods of terminating the discharge pipe safely.

Where a single pipe serves a number of discharges, such as in blocks of flats, the number served should be limited to not more

than 6 systems so that any installation can be traced reasonably easily. The single common discharge pipe should be at least

one pipe size larger than the largest individual discharge pipe to be connected.

If the system is installed where discharges from safety devices may not be apparent, i.e. in dwellings occupied by blind, infirm or disabled

people, consideration should be given to the installation of an electronically operated device to warn when discharge takes place.

Resistance created

by each elbow

or bend

0.8 m

1.0 m

1.4 m

Temperature/pressure

relief valve

Metal discharge pipe (D1)

from relief valves to tundish

500 mm max.

from appliance

300 mm

minimum

Metal discharge pipe (D2) from

tundish with continuous fall

LOW LEVEL TERMINATION

Tundish

Fig. 1a

300 mm

minimum

D1

D2

Pipe close to wall to

allow water to fan out

safely

100 mm max.

70 mm min.

Ground level

Gulley if

available

Alpha CombiMax 350 and 600

6

Loading...

Loading...