Page 1

CE-G Series

Propane Enclosures

CE-3G / CE-9G

Installation Manual

031-093-C0-001 © 3/99

Page 2

031-093-C0-001 © 3/99

Page 3

CE-G Series Enclosure

Installation Manual

Preface

Topic page

Overview i

About this Manual i

Table of Contents ii

List of Figures iii

Safety Information iv

Installation Notes v

Battery Safety Notes vi

Preface

Overview: The purpose of the CE-G Enclosure Installation Manual is to

provide an overview of the system and to detail the

enclosure installation procedure.

Audience: This manual intended for the installers and operators of the

system.

Contents: Section 1, System Overview. This section describes the

CE-G Series Enclosure.

Section 2, Pre-Installation. This section describes

site selection and pad layout.

Section 3, Installation. This section describes the

procedures for installing the cabinet.

Section 4, Operation. This section describes the preparation of

the cabinet for initial turn-up and the conversion of the APU fuel

source from Natural Gas to Propane.

i

031-093-C0-001 © 3/99

Page 4

Preface

CE-G Series Enclosure

Installation Manual

Table of Contents

Section 1, System Overview

1.1 Overview .................................................................................. 1-1

1.2 Block Diagram............................................................................... 1-2

Section 2, Pre-Installation

2.1 Site Preparation............................................................................ 2-1

2.1.1 Site considerations.............................................................. 2-1

2.1.2 Concrete pad layout ............................................................ 2-2

2.1.3 Enclosure impact protection ................................................. 2-3

Section 3, Installation

3.1 Tools and materials ....................................................................... 3-1

ii

3.2 Transportation.............................................................................. 3-2

3.3 Installation procedure .................................................................... 3-3

3.4 Enclosure impact protection ........................................................... 3-6

Section 4, Operation

4.1 Installation of tanks ...................................................................... 4-1

4.2 Installation of Regulator assembly ................................................... 4-2

4.3 Installation of HP/LP hoses ............................................................. 4-4

4.4 Converting the APU From Natural Gas To Propane Gas ........................ 4-5

4.4.1 Accessing the APU .............................................................. 4-5

4.4.2 Dual Fuel Load block conversion procedure ............................. 4-9

4.4.3 Conversion completion ....................................................... 4-10

4.5 Natural Gas To LP Gas conversion .................................................. 4-11

4.5.1 Pre-Regulator / Low Fuel-pressure switch conversion ............. 4-11

4.6 Remotely located CE-G enclosures................................................ 4-14

4.7 Converting Collocated enclosure for remote application ..................... 4-15

031-093-C0-001 © 3/99

Page 5

List of Figures

Section 1, Introduction

Figure 1.1 Colocated CE-X, CE-G enclosures .................................... 1-1

Figure 1.2 System Block Diagram .................................................... 1-2

Section 2, Pre-Installation

Figure 2.1 Concrete Pad Layout ..................................................... 2-2

Figure 2.2 Impact post arrangement .............................................. 2-3

Section 3, Installation

Figure 3.1 Gas Utility Box cutout .................................................... 3-3

Figure 3.2 Impact post arrangement ............................................... 3-6

Preface

Section 4, Operation

Figure 4.1 Tank base locator tabs ................................................... 4-1

Figure 4.2 Vapor outlet orientation .................................................. 4-1

Figure 4.3 Stop nut ............................................................ 4-2

Figure 4.4 Regulator assembly ........................................................ 4-2

Figure 4.5 Tank securing bracket .................................................... 4-3

Figure 4.6 High Pressure Hose arrangement ...................................... 4-4

Figure 4.7 Low Pressure Hose connection ........................................ 4-4

Figure 4.8 Exhaust pipe access panel .............................................. 4-5

Figure 4.9 Exhaust pipe flange bolts ................................................ 4-6

Figure 4.10 Fuel hose fitting ............................................................ 4-6

Figure 4.11 APU housing connectors ................................................. 4-7

Figure 4.12 APU tray locking bolts .................................................... 4-7

Figure 4.13 APU tray ............................................................ 4-8

Figure 4.14 Dual fuel load block ........................................................ 4-9

Figure 4.15 Exhaust pipe flange gasket ............................................. 4-10

Figure 4.16 Fuel hose placement, APU............................................... 4-10

Figure 4.17 Nat Gas pre-regulator removal ......................................... 4-11

Figure 4.18 Low fuel pressure switch wire placement........................... 4-12

Figure 4.19 Low fuel pressure switch placement ................................. 4-12

Figure 4.20 Low fuel pressure switch connector ................................. 4-13

Figure 4.21 Remote CE-G arrangemant .............................................. 4-14

Figure 4.22 Bolt hole locations ......................................................... 4-15

Figure 4.23 Remote gas utility box mounting location........................... 4-15

Figure 4.24 Hose connection ........................................................... 4-16

iii

031-093-C0-001 © 3/99

Page 6

Preface

IMPORTANT SAFETY INSTRUCTIONS

CONTAINED IN THIS MANUAL

CAUTION

HAZARDOUS CONDITION

To reduce the risk of electrical shock, injury or death caused by explosion of

fuel or moving parts, and to ensure the safe operation of this unit, the following symbols have been placed throughout the manual. Where these symbols

appear, servicing should be performed only by qualified personnel.

DANGEROUS VOLTAGE

This symbol indicates a dangerous voltage exists in this area of the

product. Use caution whenever working in the area to prevent

electrical shock.

iv

INHALATION HAZARD - DONT BREATHE VAPORS

This symbol indicates an inhalation hazard exists in this area of the

product. Use caution whenever working in the area to prevent possible

inhalation of harmful (fuel or exhaust) vapors.

NO MATCHES OR OPEN FLAMES

This symbol indicates a fire or explosive hazard exists in this area of

the product. Use caution whenever working in the area to prevent

possible combustion fuel vapors.

MECHANICAL OR MOVING PARTS HAZARD

These symbols indicate the presence of a mechanical or moving parts

hazard in this area of the product. Use caution whenever working in

the area to prevent possible injury to the operator or servicepersonnel.

LEAK HAZARD

This symbol indicates a leak hazard exists in this area of the product.

Use caution whenever working in the area to prevent and correct any

leaks detected.

ATTENTION

This symbol indicates important installation, operation or maintenance

instructions. Always follow these instructions closely.

SAVE THESE INSTRUCTIONS

NOTE:

continual improvement processes. Therefore, specifications and/or

design layouts may vary slightly from descriptions included in this

manual. Updates to the manual will be issued when changes affect

form, fit or function.

031-093-C0-001 © 3/99

Alpha Technologies products are subject to change through

Page 7

IMPORTANT INSTALLATION NOTES

It is important that the installation procedures be followed as outlined in this

manual. The procedures have been developed to facilitate the installation of

the equipment and for the safety of the installation and service personnel.

Read the documentation thoroughly before proceeding with the installation.

The system should be installed ONLY by qualified service personnel.

Consult local utility codes for additional cabinet grounding and utility

requirements.

ALPHA TECHNOLOGIES is not responsible for broken welds of other damage to

the cabinet caused by improper installation.

All dimensions are given in inches.

For further information regarding this installation, contact ALPHA

TECHNOLOGIES or your nearest ALPHA representative.

Preface

v

031-093-C0-001 © 3/99

Page 8

Preface

Propane Safety Notes

1. Never overfill your LP-gas container. LPgas containers not

containing a fixed liquid level gauge must be filled by

weight to 80% of their total capacity. Propane expands

1.5% for each 10 °F increase in temperature. 20% of the

container must remain available for expansion. Some tanks

supplied by Alpha Technologies come equipped with automatic stop fill valves. Tanks must be filled in accordance

with manufactures, D.O.T, NFPA Code 58, state and local

regulations.

2. Do not use pliers to close the POL valve on your tank.

These valves are designed to be closed leak tight by hand or

screwdriver as appropriate. If pliers are needed to stop a

vi

leak , the valve needs replacement.

3. When tightening the POL Nut (left-hand thread) on the

service valve, draw it up snug with a proper wrench do not

jam it. No thread sealant is necessary. Check for leaks

after connecting, by using a leak detection solution or soapy

water.

4. If you take your LP-gas tank to a LP-gas dealer for filling,

transport it in the proper position in which it is used (vertical for all Alpha Technologies supplied tanks), with the

valves closed and the POL plug inserted. Secure the tank

against falling or rolling.

5. The outside of the tank should be kept corrosion free by

periodic checks and a coat of paint should be used if needed

(light reflective color).

031-093-C0-001 © 3/99

Page 9

Propane Safety Notes

6. Do not store LP-gas tanks indoors or in enclosed areas. Do

not expose the tanks to heat, relief valve may open. Always store with the service valve closed tight and plugged.

7. Do not attempt to repair LP-gas containers or valves or

regulators.

8. When using make sure that the tank is level, securely fastened down, and vertical.

9. Check all tank and line connections periodically to be sure

they are tight. When testing for leaks use soapy water or a

leak detect solution. Do not use any open flame for leak

testing.

Preface

vii

031-093-C0-001 © 3/99

Page 10

Preface

viii

031-093-C0-001 © 3/99

Page 11

1. System Overview

1.1 Overview

The CE-X series of enclosures from Alpha Technologies has been

designed to meet the needs of todays outside plant powering requirements.

When an alternate fuel source is not available, the CEG propane natural gas

option can provide up to 16 hours of continuous operation.

The procedures described in this document describe the installation of a

CE-G Series Propane Enclosure. The installation procedures are identical for

the CE-3G and the CE-9G. The cabinet footprint (and mounting hole location)

is identical for each enclosure. The only physical difference between the

enclosures is that the CE-3G is 44 tall and the CE-9G is 52 tall.

Fig.1.1, Collocated CE-X/CE-G enclosures

1-1

031-093-C0-001 © 3/99

Page 12

1. System Overview

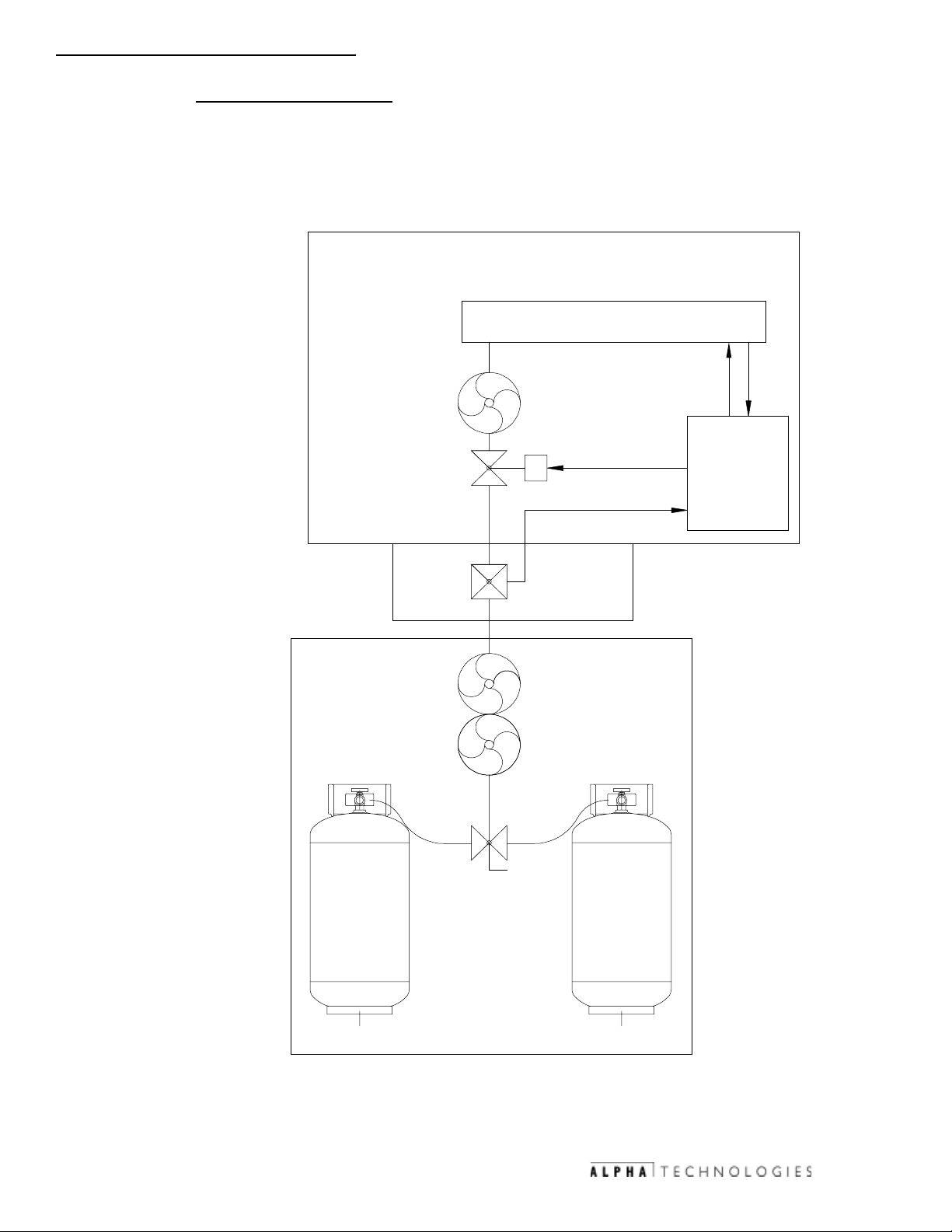

1.2 Block Diagram

The block diagram shown illustrates the overall system interconnection

between the CE-X enclosure with Auxiliary Power Unit, and the CE-G enclosure

with supplemental propane supply.

LOW PRESSURE

ENCLOSURE

LP PROPANE - VAPOR WITHDRAWAL

BLOCK DIAGRAM

ENGINE

DEMAND

CONTROLS

REGULATOR

8oz

APU

MAX

S

11"WC

SOLENOID

CONTROL

LOW FUEL ALM

1-2

SENSOR

11"WC

OUTLET

PROPANE 150 PSI

HIGH PRESSURE

PRE-REGULATOR

AUTO/MANUAL

PROPANE

PROPANE

10 PSI TO 11"WC

DUAL TANK

VALVE

LOW FUEL

PRESSURE

SWITCH

POST-REG

PROPANE

ENCLOSURE

PROPANE

GAS

UTILITY

BOX

031-093-C0-001 © 3/99

Fig. 1.2, System block diagram

Page 13

1. System Overview

this page intentionally Blank

1-3

031-093-C0-001 © 3/99

Page 14

1. System Overview

1-4

this page intentionally Blank

031-093-C0-001 © 3/99

Page 15

2. Pre-Installation

2.1 Site Preparation

2.1.1 Site considerations

The site for the collocated CE-G will be predetermined by

the location of the CE-X enclosure.

The site for the remotely located CE-G should be planned so

that the enclosure will receive good air flow. If possible, in areas

of extreme heat, the enclosure should be positioned so that it

will be shaded from the afternoon sun. In areas of prevailing

winds, the enclosure should be located so that the side of the

cabinet face into the direction of the prevailing wind. This will

greatly reduce the amount of wind borne matter (dirt, snow, and

debris) which may enter the enclosure through the louvers or

vents.

In areas of flooding, the geographical site and concrete pad

should be located above the flood plane.

Place the front of the enclosure facing the street, where

component access will be curbside. In most instances,

landscaping such trees, shrubs, or wooden fences serve to

provide a more acceptable appearance in keeping with

surrounding neighborhood designs.

The enclosure should be placed where it will be free of

obstructions.

2-1

031-093-C0-001 © 3/99

Page 16

2. Pre-Installation

2.1 Site Preparation, continued

The illustration below shows the general dimensions for a poured

in place concrete pad. When placing the pad, allow at least 36

inches of clearance to allow the front and rear doors to fully

open.

2.1.2 Concrete Pad Layout

2-2

1

2

1

Fig.2-1, Concrete pad layout (all dimensions shown in inches)

1

1

031-093-C0-001 © 3/99

1

3/8" diameter (4 places) bolts (which should extend

1"-1 1/2" above the surface of the pad). All mounting hardware

must be stainless steel to prevent corrosion.

A 25+ year continuous vapor barrier must be used between the

2

enclosure and pad to prevent moisture ingress and corrosion

caused by metal-to-concrete contact. The vapor barrier material

(such as 30 lb. felt, neoprene pond liner, or heavy grade tar

paper) should initially extend at least 6" in all directions around

the perimeter of the enclosure. After the enclosure is in place, the

material should be cut closer to the enclosure, using the

appropriate knife or cutting tool.

Page 17

2. Pre-Installation

2.1 Site Preparation, continued

2.1.3 Enclosure Impact Protection

As described in the NFPA Technical Compliance Statement,

the cabinet must be protected by impact posts, placed in

strategic locations according to traffic patterns. The illustration

below shows the general arrangement of the 6 diameter,

concrete-filled posts. The actual positioning of the posts may

vary by location.

FRONT

TRAFFIC

TRAFFIC

PROPANEAPU

POSTS

CURB

CE-X CE-G

PAD

Fig.2-2, Impact post arrangement (typical)

SIDEWALKSIDEWALK

2-3

STREET

031-093-C0-001 © 3/99

Page 18

2. Pre-Installation

2-4

this page intentionally Blank

031-093-C0-001 © 3/99

Page 19

3. Installation

3.1 Tools and Materials

The following procedure will allow for installation of the Collocated CE-G with

the CE-X/ CE-X2. The CE-G enclosure re is bolted to the concrete pad using

7/16 bolts and to the CE-X APU enclosure by carriage bolts. Also this

procedure will explain step by step how to install the two 40 LB propane tanks

and the regulator /control valve.

Tools:

(2) Pipe wrench 10

7/8 combination box and open ended wrench

Straight slot screw driver

Multimeter

Adjustable crescent wrench 10

1/2 open ended wrench

Materials

QTY

(1) Regulator hold down bracket assembly

(2) 40 pound DOT approved propane tanks

(1) CE-G Enclosure

3-1

031-093-C0-001 © 3/99

Page 20

3. Installation

3.2 Transportation

transported, loaded, and unloaded while bolted to the shipping pallet. A safe

means of transportation to the site and unloading the enclosure must be

considered. Do not transport, lift, or place the unit on any surface unable to

fully support its weight.

The enclosure is shipped bolted to a shipping pallet. It should be

3-2

NOTE:

The enclosure should only be transported, lifted, and

installed as shipped from the factory. Do not install the

propane tanks until the enclosure is installed on the pad.

031-093-C0-001 © 3/99

Page 21

3. Installation

3.3 Installation Procedure

1. Install the CE-G enclosure so that the gas utility box of the CE-X

enclosure fits into the gas utility box cutout on the CE-G (dashed line) as

pictured below. Ensure the two cabinets are placed flush against each

other.

2. With the two cabinets sitting flush against each other, mark the anchor

bolt pattern onto the concrete pad using the four slotted anchor bolt

holes found in the corners of the base plate of the CE-G enclosure as an

template.

3. Also, mark the hole which will be used to bolt the cabinets together

(located at the lower left corner of the gas utility box cutout).

1

3

Fig. 3.1, Gas utility box cutout, connection bolt location

3-3

031-093-C0-001 © 3/99

Page 22

3. Installation

3.3 Installation Procedure, continued

3. Slide the CE-G enclosure away from the CE-X enclosure.

4. Drill with a 1/4 hole through the wall of the CE-X enclosure where

previously marked.

3-4

NOTE:

5. With the anchor bolt pattern marked, drill holes for the installation of

anchor studs.

Tools required:

Stainless steel wedge-type stud anchor , 3/8" dia., 3-3/4" in length (4).

4 each, 3/8 flat washer, 3/8 lock washer, and hex nut.

Hand Drill or Rotary Hammer

3/8 Concrete or Masonry bit(s)

Hammer

Mounting bolt installation procedure:

1. At the points located in step 3 above, drill holes for the anchor studs.

Each hole should be at least 1-3/4 deep to properly secure the

enclosure to the pad.

2. With the hammer, tap the anchor studs into their respective holes.

3. Brush away any debris from the drilling prior to proceeding.

Before drilling through the CE-X cabinet wall,

ensure that the area behind the wall is clear

of any wires, gas hoses, or pipes.

031-093-C0-001 © 3/99

Page 23

3. Installation

3.3 Installation Procedure, continued

5. Lay down the vapor barrier material. With a utility knife, make small

cutouts in the material through which the anchor studs protrude.

6. Place the CE-G enclosure back into place over the mounting studs.

7. With CE-G enclosure in place and flush against the CE-X enclosure,

install the mounting hardware (flat washers, lock washers, and 3/8

nuts) on each mounting bolt. Do not tighten at this time.

8. Install the 1 x 1/4 x 20 bolt through the lower left side bolt hole of the

gas utility box cutout (drilled in Step 4). Secure the bolt using a lock

washer, flat washer and nut.

9. Once the two cabinets have been secured together, evenly tighten the

anchor stud mounting hardware.

NOTE:

ALPHA TECHNOLOGIES is not responsible for

broken welds of other damage to the cabinet

caused by improper installation.

3-5

031-093-C0-001 © 3/99

Page 24

3. Installation

3.4 Enclosure Impact Protection

As described in the NFPA Technical Compliance Statement, the cabinet must

be protected by impact posts, placed in strategic location according to traffic

patterns.

3-6

FRONT

TRAFFIC

TRAFFIC

PROPANEAPU

POSTS

SIDEWALKSIDEWALK

CURB

STREET

CE-X CE-G

PAD

Fig.3.2, Impact post arrangement (typical)

Once the impact posts (Concrete-filled, 6 diameter, steel) have been

placed, proceed to the next section for the Propane Tank Installation procedure.

031-093-C0-001 © 3/99

Page 25

3. Installation

this page intentionally Blank

3-7

031-093-C0-001 © 3/99

Page 26

4. Operation

4.1 Installation of the propane tanks and regulator assembly

4.1.1 Installation of tanks

1. Place the rear tank into the enclosure through the rear access and the

front tank through the front access. Ensure that the base of each tank

fits into the tabs of the base plate, as shown below.

Figure 4.1, Tank base locator tabs

2. The tanks' vapor outlets should be facing towards the gas utility box (the

front left of the enclosure).

4-1

Figure 4.2, Vapor outlet orientation

031-093-C0-001 © 3/99

Page 27

4. Operation

4.2 Installation of Regulator Assembly

1. On tank hold down rod adjust stop nut so that the tank hold down

bracket aligns with the bottom edge of the tank valve guard / handle, as

shown below.

4-2

Figure 4.3, Stopnut

2. Slide regulator / hold down bracket assembly onto the hold down rod.

Ensure regulator assembly is facing same direction of tank valve vapor

ports, and that the hold down brackets outermost grooves fits onto the

bottom edge of the valve guard.

031-093-C0-001 © 3/99

Figure 4.4, Regulator assembly

Page 28

4.2 Installation of Regulator Assembly, continued

3. Install the hold down bracket wing nut onto the hold down rod and

tighten down.

4. Operation

Figure 4.5, Tank securing bracket

4-3

031-093-C0-001 © 3/99

Page 29

4. Operation

4.3 Installation of High Pressure and Low Pressure Hoses

4.3.1 Installation of high pressure Hoses

1. Install high pressure hoses into the tanks vapor outlet port with a

service loop pointing upward, as shown below.

4-4

Figure 4.6, High-pressure hose arrangement

4.3.2Installation of high pressure Hoses

1. Install the Low pressure hose onto the Low fuel pressure switch,

located in the gas utility box, as shown below.

031-093-C0-001 © 3/99

Figure 4.7, Low-pressure hose connection

Page 30

4. Operation

4.4 Converting APU From Natural Gas To Propane Gas

4.4.1 Accessing the APU

1. Remove rear cabinet door.

2. Remove the exhaust pipe access panel, by removing the 6 panel screws.

Remove panel screws

Figure 4.8, Exhaust pipe access panel

4-5

031-093-C0-001 © 3/99

Page 31

4. Operation

4.4 Converting APU From Natural Gas To Propane Gas, cont.

4.4.1 Accessing the APU, continued

3. Use a 10mm socket and ratchet remove the two flange bolts

that connect the flex exhaust pipe to the upper exhaust pipe.

4-6

Figure 4.9, Exhaust pipe flange bolts

4. Disconnect fuel hose at the APU 45° fitting. Cut cable ties from hose.

031-093-C0-001 © 3/99

Figure 4.10, Fuel hose fitting

Page 32

4. Operation

4.4 Converting APU From Natural Gas To Propane Gas, cont.

4.4.1 Accessing the APU, continued

5. Disconnect the APU connector, Battery Connector, Fuel Solenoid and ACU

12 pin connector from the top panel of thegenerator enclosure.

Figure 4.11,APU housing connetors

6. Use a 9/16" socket remove the two slide retaining bolts. (picture)

4-7

Figure 4.12, APU tray locking bolts

031-093-C0-001 © 3/99

Page 33

4. Operation

4.4 Converting APU From Natural Gas To Propane Gas, cont.

4.4.1 Accessing the APU, continued

7. Slide the APU out.

4-8

Figure 4.13, APU in tray

031-093-C0-001 © 3/99

Page 34

4. Operation

4.4 Converting APU From Natural Gas To Propane Gas, cont.

8. Dual Fuel Load Block conversion from Natural Gas to Liquid Propane Gas.

Procedure:

1. Remove the blanking plug from the lower outlet port on the load

block.

2. Loosen the hose clamp on the fuel supply hose at the load block.

3. Loosen the brass fitting and remove from the upper outlet port (NG

port) and install in the lower outlet port (LP port).

4. Retighten the hose clamp.

5. Install the blanking plug into the upper outlet port.

NOTE

1

: Apply a high-quality gas pipe thread sealant to the

blanking plug and brass fitting threads.

4-9

3

2,4

5

Figure 4.14,Dual fuel load block

031-093-C0-001 © 3/99

Page 35

4. Operation

4.4 Converting APU From Natural Gas To Propane Gas, cont.

9. Reconnect the APU exhaust and Fuel Hose

Procedure:

1. Install new gasket at the exhaust Flex pipe flange.

2. Apply antiseize compound to the flange bolts and install into flange

3. Torque the exhaust pipe flange bolts, bolt to bolt, to 7-ft/pounds.

4-10

Figure 4.15, Exhaust pipe flange gasket

4. Reconnect the fuel hose with cable ties to the proper anchor points (see

below). Verify the chafe guard is properly seated in the cut out before the

APU drawer is closed.

5. Once the fuel hose is securely fastened, slide the APU drawer back in the

enclosure and re-fasten the retaining bolts.

NOTE:

Verify fuel hose

is completely

wrapped in

chafe guard

material and

fully seated in

cutout.

031-093-C0-001 © 3/99

Figure 4.16, Fuel hose placement, APU

Page 36

4. Operation

4.5 Pre-Regulator/Low-Fuel Pressure Package Conversion

4.5.1 Converting from Natural Gas Pre-regulator Gas Package to LP Gas

Low fuel Pressure switch

Removal Procedure:

1. Have authorized personnel disconnect the Natural Gas at the manual

shutoff valve.

2. De-couple the input piping at a point outside of the gas utility box.

3. In the Gas Utility Box locate the Pre-regulator, disconnect at the coupler

fitting. (see picture)

4. Lift pre-regulator up and out of the gas utility box.

Figure 4.17,Natural Gas pre-regulator removal

4-11

031-093-C0-001 © 3/99

Page 37

4. Operation

4.5 Pre-Regulator/Low-Fuel Pressure Package Conversion, cont.

LP Gas low fuel pressure switch Installation procedure

1. Route the low fuel pressure switch wires (connector not installed)

located on the back wall of the gas utility box.

4-12

Figure 4.18, Low fuel pressure switch wire placement

2. Install the Low fuel pressure Switch package on to the gas inlet elbow

fitting.

NOTE:

The switch package is joined to the input pipe with a

compression fitting. DO NOT overtighten this fitting,

as that will cause it not to be leak tight.

031-093-C0-001 © 3/99

Figure 4.19, Low fuel pressure switch placement

Page 38

4. Operation

4.5 Pre-Regulator/Low-Fuel Pressure Package Conversion, cont.

LP Gas low fuel pressure switch Installation procedure

3. Install the two position connector onto the low fuel pressure switch wire

harness, Black wire to Pin 1, White to Pin 2.

4. Connect the switch side wire harness connector to the cabinet side low

fuel pressure switch connector.

Figure 4.20,Low fuel pressure switch connector

4-13

031-093-C0-001 © 3/99

Page 39

4. Operation

7. CEG Enclosures Used In Remote Applications

The collocated CEG enclosure can be converted to be a remotely located

enclosure at distances of no more than 25 feet from the APU. This remote

operation requires the use of interconnecting buried gas pipe, between the

APU cabinet and the CEG cabinet. All pipe and pipe fittings running from the

CEX to the CEG will be installed in accordance with local code. All materials

used must meet approval of all local codes.

4-14

CAUTION

3" SWEEP

: Due to the Low Pressure Output of the CEG,

(1"), all interconnecting gas pipe must be 1"

to 3/4" inch diameter to ensure proper flow.

GAS

DWYER LOW

FUEL SENSOR

MANUAL SHUTOFF

REQUIRED IF CE-G

CANNOT BE SEEN

PROPANE VAPOR

031-093-C0-001 © 3/99

Figure 4.21, Remote CE-G arrangement

Page 40

4. Operation

7.1 Converting Collocated CEG Enclosure For Remote Application

1. Locate the gas utility box cut out on the left wall of CEG.

2. Align the Remote Gas Utility Box Assembly with the pre drilled bolt holes

surrounding the cut out.

2

Figure 4.22, Bolt hole locations

3. Use the six carriage bolts and supplied hardware, to mount the remote gas

utility box to the outside of the CE-G enclosure wall.

4-15

Figure 4.23,Remote gas utility box mounting location

031-093-C0-001 © 3/99

Page 41

4. Operation

7.1 Converting Collocated CEG Enclosure For Remote Application

3. Install the gas hoses to the brass fitting located on the inside of remote

gas utility box. (see picture)

4. Hook up interconnecting gas pipe to the remote utility gas box pipe

fixture.

4-16

Figure 4.24,Hose connection

End of conversion Procedure

1. Securely fasten all hoses.

2. Open previously-filled gas bottles.

3. Perform leak check with approved leak-detection solution

031-093-C0-001 © 3/99

Page 42

4. Operation

this page intentionally blank

4-17

031-093-C0-001 © 3/99

Page 43

031-093-C0-001 © 3/99

Page 44

Investigate the

of Alpha @www.alpha.com

UNITED STATES

ASIA PACIFIC

LATIN AMERICA

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

Tel: (360) 647-2360

Fax: (360) 671-4936

Web: www.alpha.com

CANADA

Alpha Technologies

7033 Antrim Ave.

Burnaby, B.C. V5J 4M5

Tel: (604) 430-1476

Fax: (604) 430-8908

UNITED KINGDOM

Alpha Technologies

Cartel Business Estate

Edinburgh Way

Harlow, Essex CM20 2DU

Tel: +44-1279-422110

Fax: +44-1279-423355

Due to continuing product

improvements, Alpha reserves

the right to change

specifications without notice.

©1999

Alpha Technologies Inc.

All rights reserved.

031-093-C0-001 © 3/99

GERMANY

Alpha Technologies

Hansastrasse 8

D-91126 Schwabach

Tel: +49-9122-997303

Fax: +49-9122-997321

MIDDLE EAST

Alphatec

P.O. Box 6468

3307 Limassol, Cyprus

Tel: +357-5-375675

Fax: +357-5-359595

AUSTRALIA

Alpha Technologies

8 Anella Ave., Unit 6

Castle Hill, NSW 2154

Tel: +61 (0)2 9894-7866

Fax: +61 (0)2 9894-0234

Loading...

Loading...