Alpha CD50S, CD70S Installation and Servicing Instructions

Installation and Servicing

Instructions

Alpha CD50S and 70S

W all Mounted, Fan Assisted, Gas Fired, High Efficiency

Condensing System Boilers

For Technical help or for Service call ...

ALPHA HELPLINE

Tel: 0870 3001964

Nepicar House, London Road,

Wrotham Heath, Sevenoaks,

Kent TN15 7RS

0051

For use with Natural Gas or Propane Gas (LPG)

Leave these instructions with the User

CONTENTS

1 Introduction ....................................... 2

2 Technical data................................... 3

3 General boiler information..................8

4 Installation......................................... 15

5 Commissioning ................................. 19

7 Wiring diagram.................................. 29

8 Fault finding ...................................... 30

9 Short parts list ................................... 31

10 Benchmark Checklist ........................ 32

11 Service record ................................... 33

6 Routine servicing............................... 24

1 INTRODUCTION

The Alpha CD50S and 70S are wall mounted high efficiency condensing, fan assisted system boilers. The burner is lit

electronically and the heat output is controlled by a modulating fan and gas valve.

These are system boilers providing heating only for sealed central heating systems. However, they may be used with an

open central heating system if required - refer to Section 3.8.

The boilers are supplied with type B23 flue configuration (open chamber and forced draught) but can be changed to type C

(room sealed) by using a kit.

The boilers are fitted with a pump, 4 bar pressure relief valve and pressure gauge fully assembled and tested. They are

designed for use with a fully pumped, sealed and pressurised central heating system. If used with an open system refer

to Section 3.8.

The CD50S boiler is suitable for central heating loads of between 10 and 53.8 kW (34 121 and 183 700 Btu/h).

The CD70S boiler is suitable for central heating loads of between 18.1 and 72.8 kw (61 800 and 248 600 Btu/h).

The boilers can be supplied for use with Natural gas or Propane Gas (LPG).

Note: There are a number of additional controls and accessories available for use with the boilers to enable cascade and

zone installations to be used. Further information is available from Alpha Therm Ltd.

IMPORTANT

It is the law that all gas appliances are installed by a competent person, ie CORGI registered personnel, in accordance

with the following recommendations:-

Current Gas Safety (Installation and Use) Regulations

All current Building Regulations issued by the Department of the Environment, i.e. Approved Document L1.

Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development Department

UK Water Regulations/Byelaws (Scotland)

Health & Safety Document No. 635 (The Electricity At Work Regulations 1989)

The installation should also be in accordance with the following British Standard Codes of Practice:-

BS 5440:1:2000 Flues

BS 5449:1990 Forced circulation hot water systems

BS 5546:2000 Installation of hot water supplies for domestic purposes

BS 6700:1997 Design, installation, testing and maintenance of services supplying water

BS 6798:2000 Installation of gas fired hot water boilers

BS 6891:1998 Gas installation

BS 7593:1992 Code of Practice for treatment of water in heating systems

BS 7671:2001 Requirements for electrical installations, IEE Wiring Regulations

Reference should be made to DEFRA document 'Guide to condensing boiler installation assessment procedures for dwellings'.

If installation is in a timber framed building, refer to the Institute of Gas Engineers document IGE/UP/7.

This appliance meets the requirements of IPX5D, ie degree of protection against moisture.

This appliance contains no asbestos and no substances have been used in the construction process that contravene the

COSHH Regulations (Control of Substances Hazardous to Health).

Failure to install this appliance correctly could lead to prosecution. It is in your own interest and that of safety to ensure

that the law is complied with.

Manufacturer's instructions must NOT be taken in anyway as over-riding statutory obligations.

Notes: 1. Ensure that the Benchmark Checklist has been completed after the boiler has been installed and

commissioned.

2. It is the law that all boiler installations are registered by the installer through the CORGI Gas Work Notification

Scheme.

3. The boiler must only be used with the flue components supplied with the boiler.

Propane Gas (LPG) - In addition to the regulations and requirements stated, the boiler must be installed in accordance

with BS 5482:1 - The Installation of Propane Burning Appliances in Permanent Dwellings.

Alpha CD50S/70S - Contents/Introduction

2

2 TECHNICAL DA T A

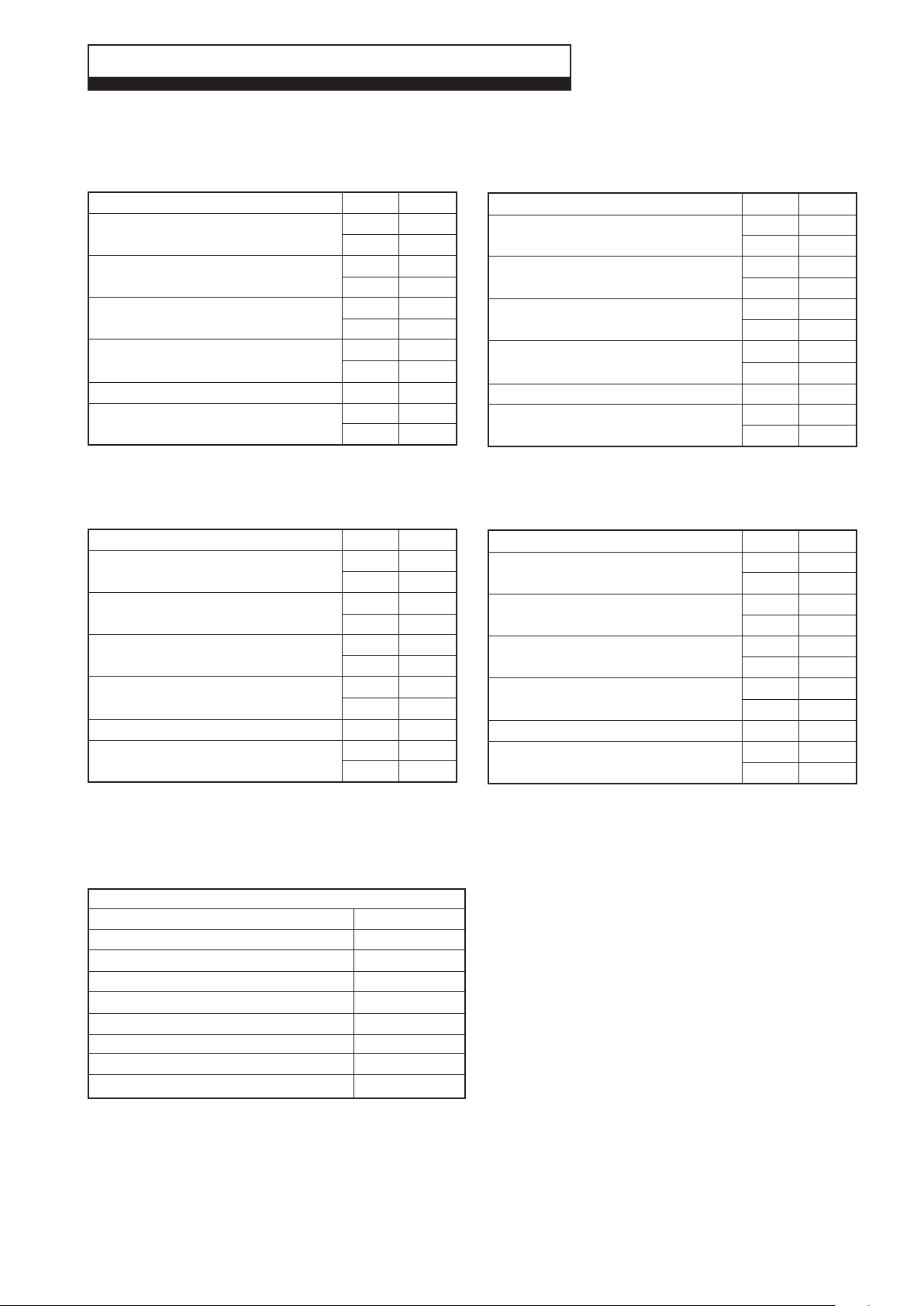

2.1 PERFORMANCE

NATURAL GAS (CAT: I2H 2H - G20 - 20 mbar)

Alpha CD50S

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) kW

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Fan Speed rpm

Gas Rate m³/h

ft³/h

MAX.

56.4

192 400

50.8

173 300

53.8

183 700

50.0

170 600

5 180

5.37

189.6

MIN.

11.5

39 250

10.4

35 500

11.1

37 800

10.0

34 120

1 280

1.10

38.8

PROPANE GAS (CAT I3P 3P - G31 - 37 mbar)

Alpha CD50S

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) kW

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Fan Speed rpm

Gas Rate m³/h

ft³/h

MAX.

56.4

192 400

50.8

173 300

53.8

183 700

50.0

170 600

5 200

2.15

75.9

MIN.

11.5

39 250

10.4

35 500

11.1

37 800

10.0

34 120

1 250

0.44

15.5

Alpha CD70S

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) k W

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Fan Speed rpm

Gas Rate m³/h

ft³/h

MAX.

77.5

264 300

69.8

238 200

72.8

248 600

67.9

231 700

5 240

7.4

261.2

70 060

63 120

67 100

61 800

Alpha CD70S

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) k W

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Fan Speed rpm

Gas Rate m³/h

ft³/h

MAX.

77.5

264 300

69.8

238 200

72.8

248 600

67.9

231 700

5 240

2.96

104.5

70 060

63 120

67 100

61 800

MIN.

20.5

18.5

19.7

18.1

1 400

1.96

69.2

MIN.

20.5

18.5

19.7

18.1

1 450

0.78

27.7

Note: The above appliances are fully modulating and are not range rated.

2.2 SYSTEM

Central Heating (Sealed System)

Max. Working System Pressure

Min. System Pressure

Max. System temperature

Pressure Relief Valve Setting

Flow Connection

Return Connection

Relief Valve Connection

Recommended System Pressure (cold)

CH Water Temp. (Approx. max.)

3.5 bar

0.5 bar

82°C

4 bar (58.8 PSI)

1½" BSP

1½" BSP

¾" BSP

1.0 bar

82°C (180°F)

Alpha CD50S/70S - Technical Data

3

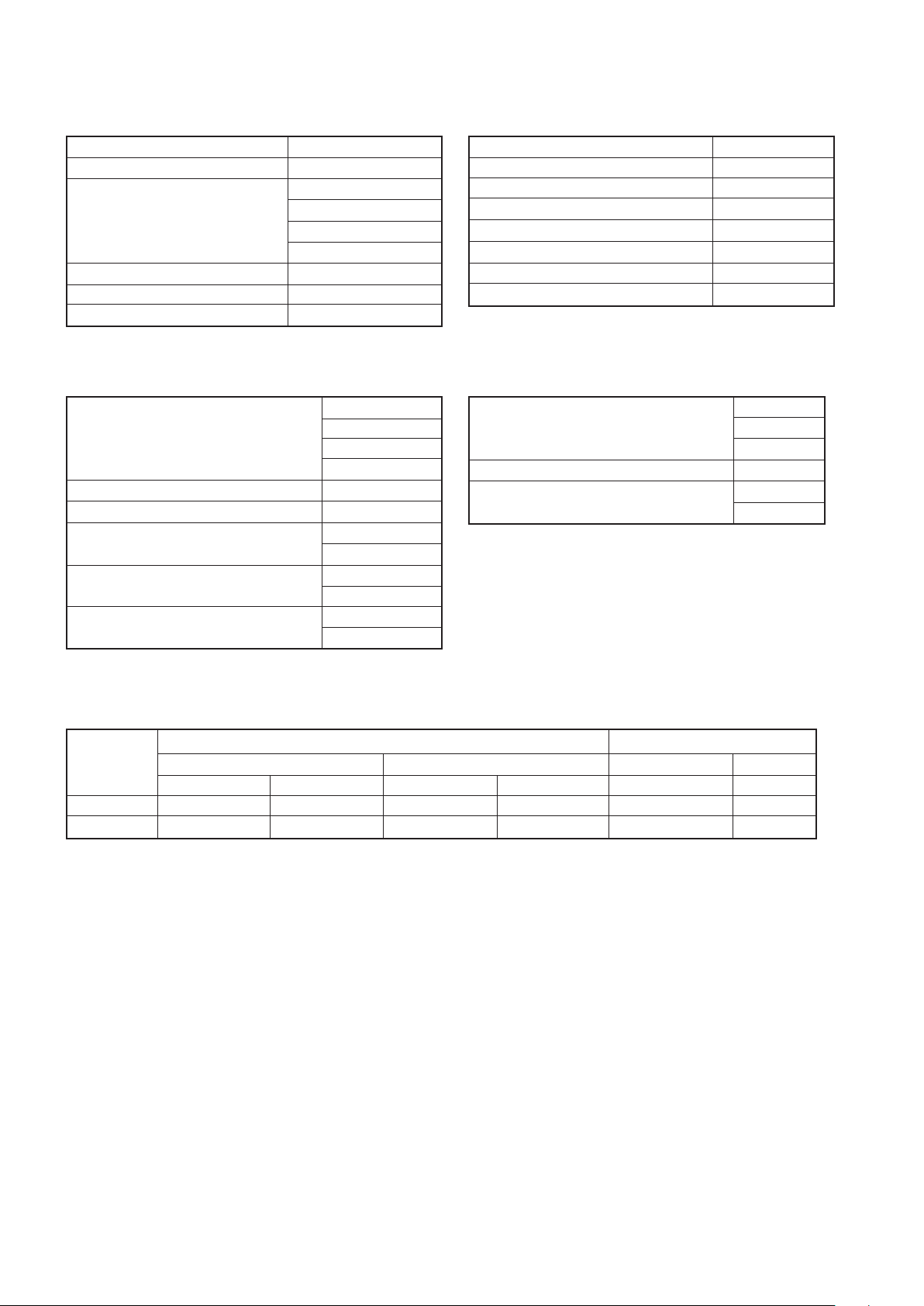

2.3 COMPONENTS 2.4 ELECTRICAL

Burner

Main Heat Exchanger

Main Burner Injector CD50S NG

CD70S NG

CD50S LPG

CD70S LPG

Concentric Flue Outer Duct

Concentric Flue Inner Duct

Open Flue Single Flue Pipe

2.5 INSTALLATION

Min. Clearances for Servicing Top

(from casing) Bottom

Sides

Front

Flue Diameter Open Flue

Concentric Flue

Flue Protruding Outside Open Flue

Concentric Flue

Hole For Flue Assy. Open Flue

Concentric Flue

Lift Weight CD50S

CD70S

Stainless steel

Stainless steel

7.85 mm

13.0 mm

5.7 mm

7.8 mm

125 mm dia.

80 mm dia.

80 mm dia.

350 mm

250 mm

10 mm

450 mm

80 mm

125 mm

80 mm

180 mm

100 mm dia.

127 mm dia.

63 kg

68 kg

Supply

External Fuse

Power Consumption

Internal Fuse - Main Terminal

PCB Fuse F1

PCB Fuse F3

Electrode Spark Gap

Electrical Enclosure Degree of Moisture Protection

2.6 GENERAL

Case Dimensions Height

Width

Depth

Gas Connection

Water Content CD50S

CD70S

230/240 V ~ 50 Hz

3 A

180 W

F2A

T2A

T4A

3 to 4 mm

IPX5D

950 mm

600 mm

525 mm

28 mm

3.7 L

4.0 L

2.7 PERFORMANCE DATA

Boiler model

CD50S

CD70S

Natural Gas Efficiency

Min

9.25

9.00

%CO2 content (± 0.2%) Sedbuk rating

(LPG) Propane Gas

CH Max

9.30

9.25

Min

10.1

9.7

CH Max

10.6

10.5

band

A

A

NOx class

5

5

Alpha CD50S/70S - Technical Data

4

2.8 FLUE LENGTHS - See also Section 3.4

Open flue - Maximum horizontal or vertical flue with single 80 mm dia. open flue is 30 metre

90° bend is equivalent to 2.1 m of flue length

45° bend is equivalent to 1.3 m of flue length

Vertical terminal is equivalent to 3 m of flue length

Concentric flue - Maximum horizontal flue is 14 metre, maximum vertical flue is 18 metre

90° bend is equivalent to 1.9 m of flue length

45° bend is equivalent to 1.4 m of flue length

Vertical terminal is equivalent to 3.4 m of flue length

Notes: 1. Ensure all flues slope downwards towards the boiler by a minimum of 25 to 30 mm per metre of flue.

2. It is recommended that horizontal and vertical flue assemblies should be supported approximately every 1.5 m

with access provided to the joints.

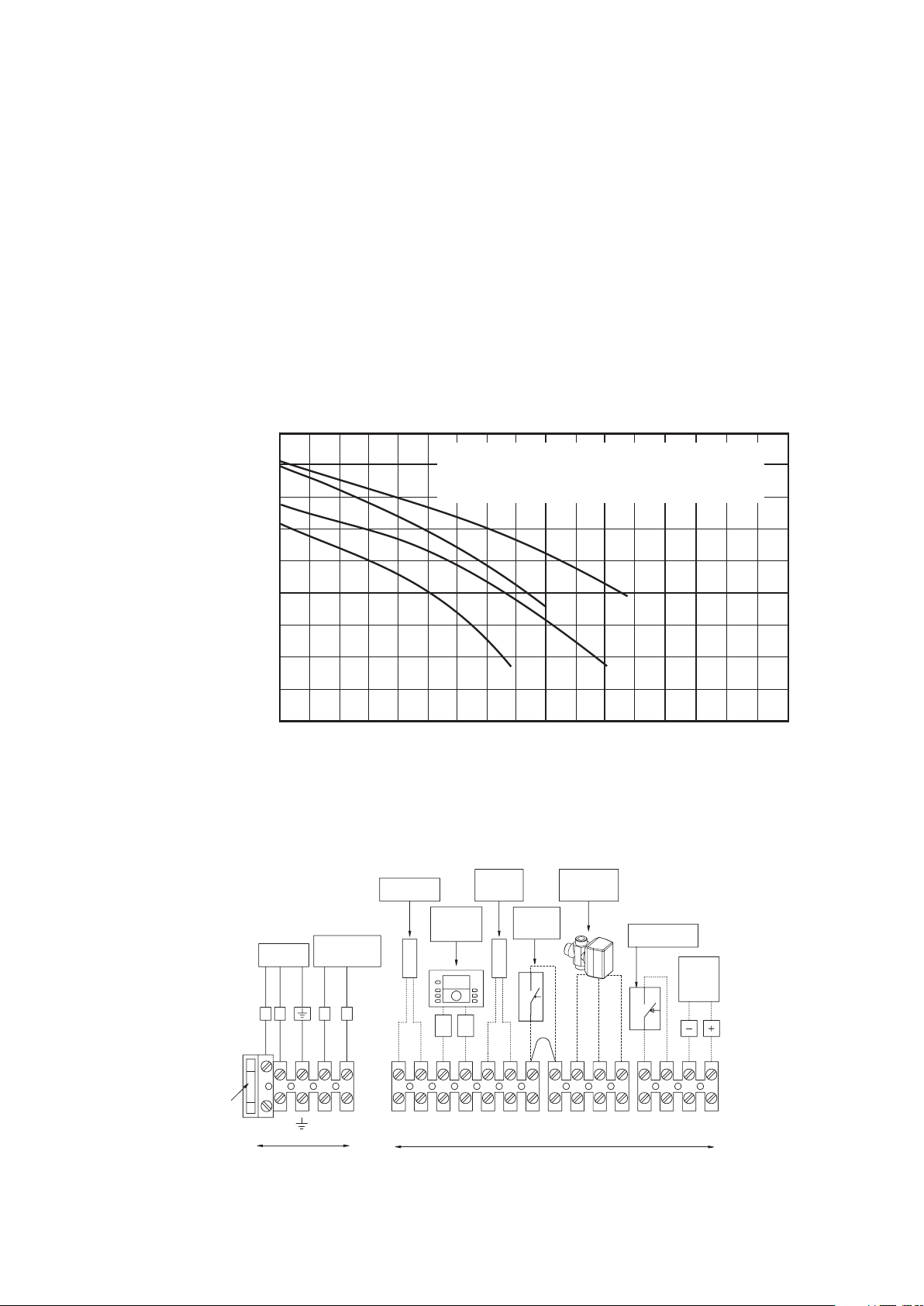

2.9 AVAILABLE PUMP HEAD FOR CENTRAL HEATING

9

A = CD50S - Available head with pump at maximum speed

B = CD50S - Available head with pump at speed two

C = CD70S - Available head with pump at maximum speed

D = CD70S - Available head with pump at speed two

D

C

TOTAL HEAD

(M water)

8

7

6

5

4

3

2

1

0

200 400 600 800 10001200 14001600 1800 20002200 2400 2600 2800 3000 32000

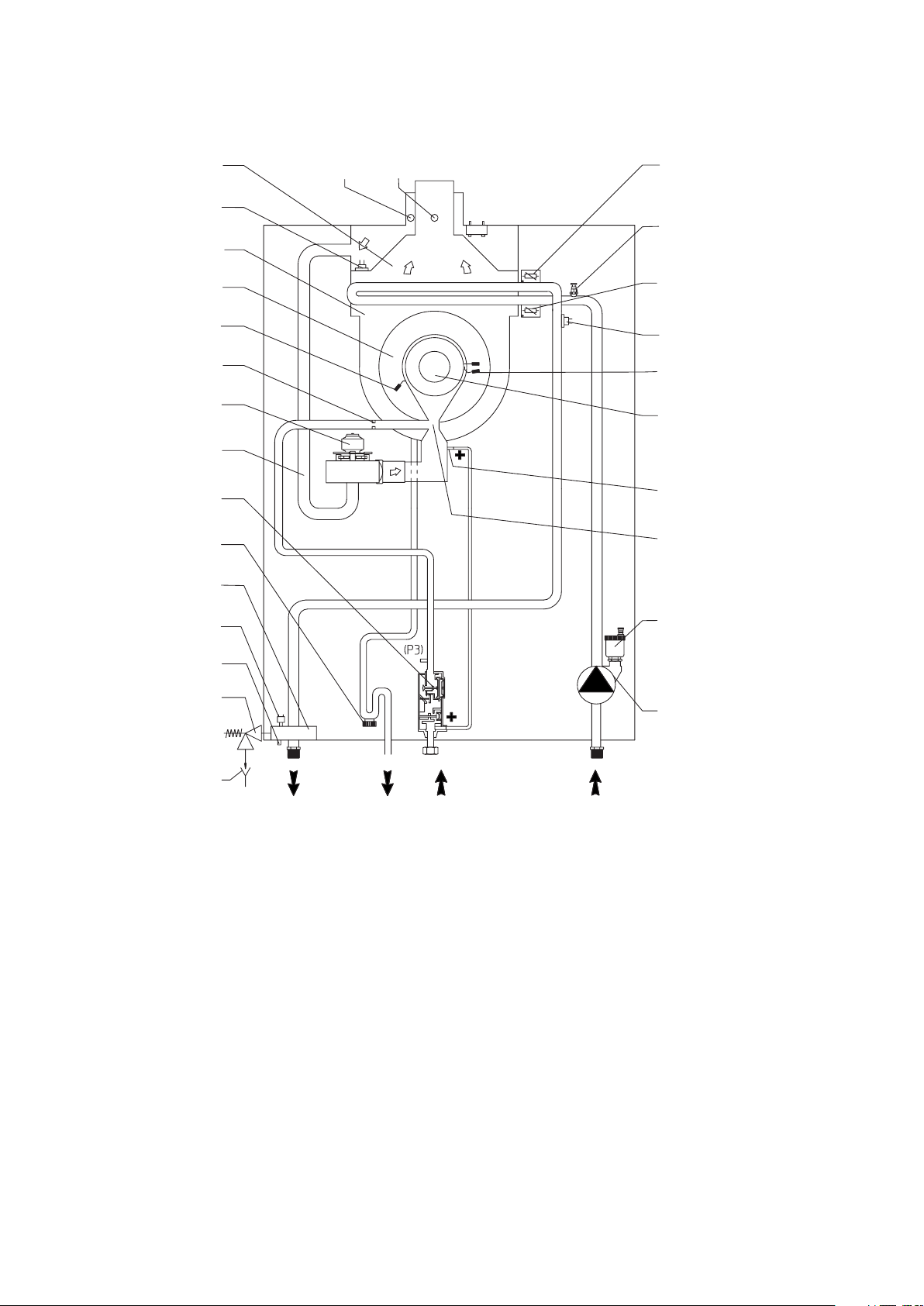

2.10 ELECTRICAL CONNECTIONS

Note: This Appliance Must Be Earthed

External Pump

Max 1A

(Optional)

N

N

Fuse F2A

230V ~ 50Hz

Fused at 3A

L

L

L

PQN

B

A

FLOW RATE (litre/h)

Fig. 1

External sensor

(Optional)

Zone

manager

(Optional)

37A38

temp sensor

(Optional)

B

DHW

thermostat

Room

(Optional)

LINK

Diverter valve

motor

(Optional)

3

6

Summer switch

2

(Optional)

X85

GJ MOR HF E TS KVUY Z

Analog

input

0 - 10 Volt

(Optional)

X86

230/240 V ~ 50 Hz only Maximum 24 V connection only

Note: Do not connect 230/240 V ~ 50 Hz

Fig. 2

Alpha CD50S/70S - Technical Data

5

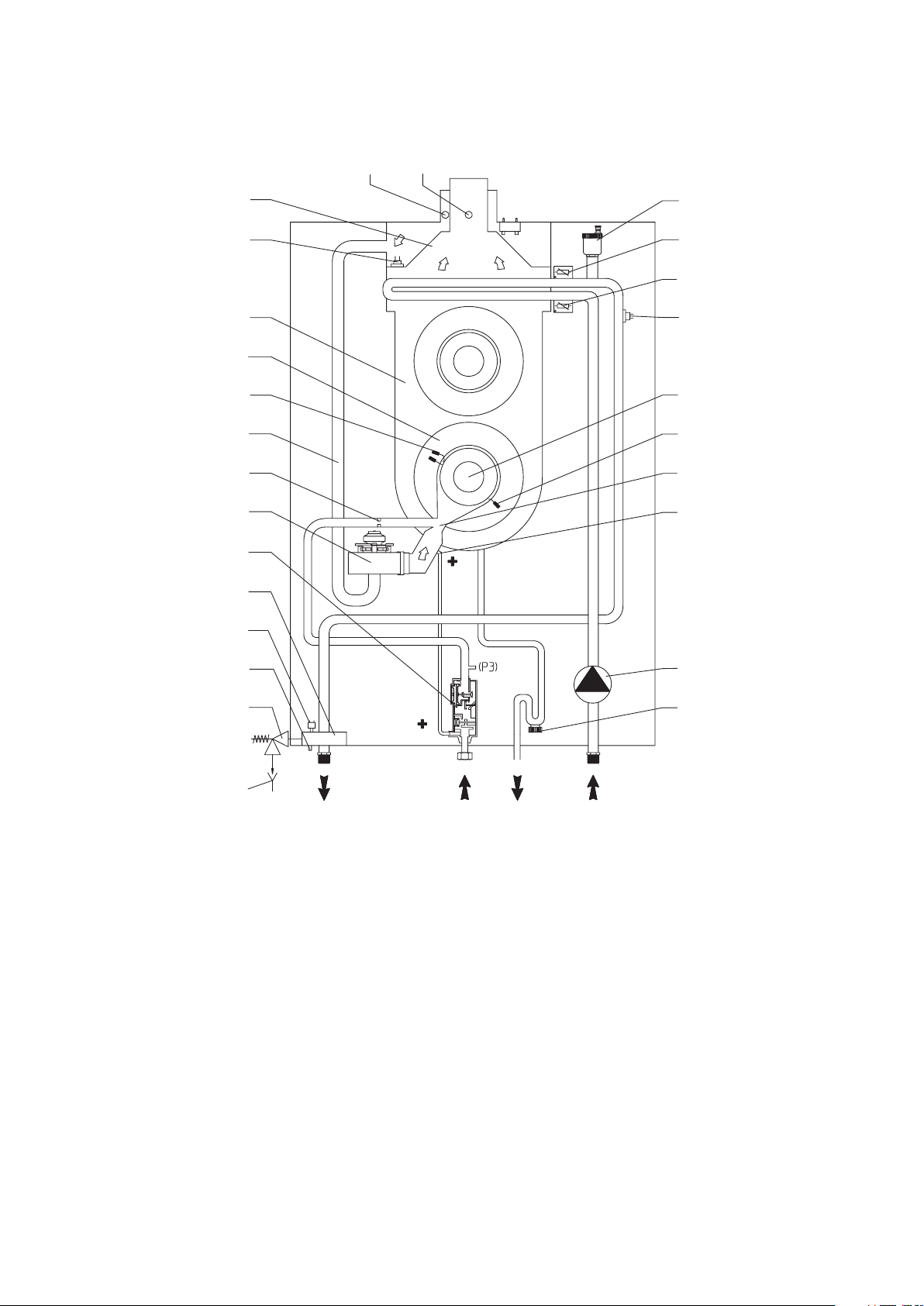

2.11 BOILER SCHEMATIC - CD50S

15

14

13

12

11

10

16 17

9

8

7

6

5

18

19

20

21

22

23

24

25

4

3

2

1

1 Tundish

2 Pressure relief valve (4 bar)

3 Drain point

4 Primary pressure switch

5 Flow manifold

6 Condensate trap

7 Gas valve

8 Air inlet pipe

9 Fan

10 Injector

11 Flame sensing electrode

12 Combustion chamber cover

13 Heat exchanger

14 Flue overheat thermostat

26

27

ReturnGasFlow Condensate

discharge

15 Flue hood

16 Air inlet sampling point

17 Flue sampling point

18 Primary flow temperature sensor

19 Air vent - manual

20 Primary return temperature sensor

21 Overheat thermostat

22 Ignition electrodes

23 Burner

24 Venturi positive point (P1)

25 Venturi

26 Automatic air vent

27 Pump

Alpha CD50S/70S - Technical Data

6

Fig. 3 - CD50S

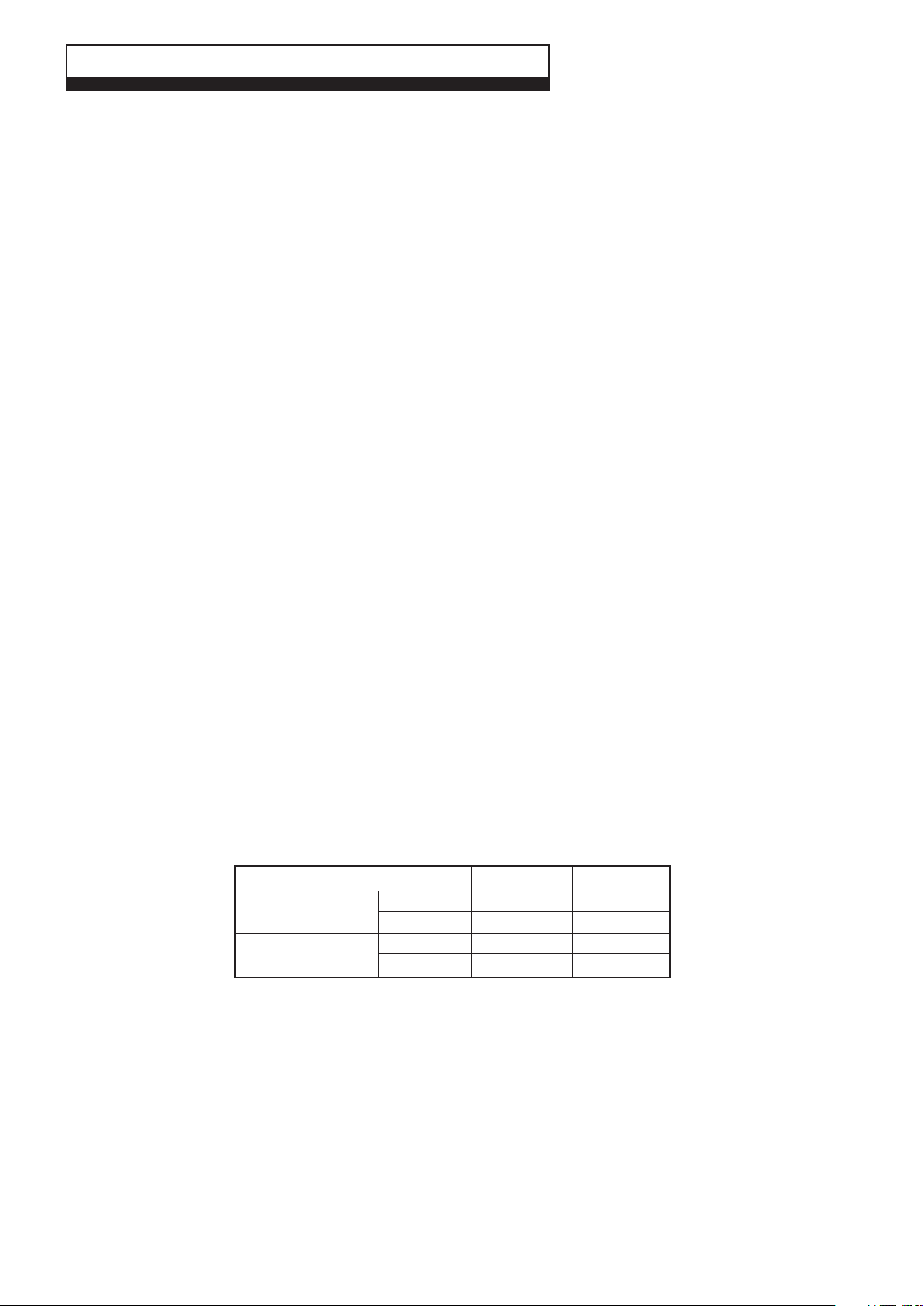

2.12 BOILER SCHEMATIC - CD70S

15 16

14

13

12

11

10

17

18

19

20

21

9

8

7

6

5

4

22

23

24

3

2

1

1 Tundish

2 Pressure relief valve (4 bar)

3 Drain point

4 Primary pressure switch

5 Flow manifold

6 Gas valve

7 Fan

8 Injector

9 Air inlet pipe

10 Ignition electrodes

11 Combustion chamber cover

12 Hear exchanger

13 Flue overheat thermostat

25

26

ReturnGasFlow Condensate

discharge

14 Flue hood

15 Air inlet sampling point

16 Flue sampling point

17 Automatic air vent

18 Primary flow temperature sensor

19 Primary return temperature sensor

20 Overheat thermostat

21 Burner

22 Flame sensing electrode

23 Venturi

24 Venturi positive point (P1)

25 Pump

26 Condensate trap

Fig. 4 - CD70S

Alpha CD50S/70S - Technical Data

7

3 GENERAL BOILER INFORMATION

3.1 GAS SUPPLY

Natural Gas:

The Alpha CD50S boiler requires a gas rate of 5.37 m³/h (189.6 ft³/h).

The Alpha CD70S boiler requires a gas rate of 7.4 m³/h (261.2 ft³/h).

Propane Gas (LPG):

The Alpha CD50S boiler requires a gas rate of 3.94 kg/h (8.4 lb/h) or 7.6 litres/h of liquid gas.

The Alpha CD70S boiler requires a gas rate of 5.42 kg/h (11.6 lb/h) or 10.4 litres/h of liquid gas.

The local Propane Gas supplier should be consulted, at the installation planning stage, in order to establish the

availability of an adequate supply of gas.

The meter and supply pipes must be capable of delivering this quantity of gas in addition to the demand from any other

appliances. The boiler requires at least a 28 mm gas supply pipe and ensure the inlet supply pressure is at least 20 mbar

for Natural Gas or 37 mbar for Propane Gas (LPG).

The complete installation, including the meter, must be tested for gas tightness and purged as described in BS 6891.

3.2 ELECTRICAL SUPPLY

The boiler requires a 230/240 V ~ 50 Hz mains supply, fused at 3 A

Note: The boiler must be earthed.

There must only be one common isolator, providing complete electrical isolation, for the boiler and any external controls.

This boiler has been fitted with a supply cable, however, if it is necessary to fit a cable use PVC insulated cable not less

than 0.75 mm² (24 x 0.2 mm) to BS 6500 Table 16. The boiler should be connected to a fused three pin plug and

unswitched shuttered socket outlet (both complying with BS 1363), or a fused double pole switch with a contact

separation of at least 3 mm in both poles.

Wiring external to the boiler must be in accordance with the current IEE Wiring Regulations (BS 7671).

3.3 AIR SUPPLY

Open flued (Type B23 flue)

Alpha CD50S and CD70S boilers leave the factory with 'B23' type configuration (open chamber and forced draught single flue pipe) and receive the air for combustion from openings in the rear of the boiler, therefore air supply for

combustion and ventilation must be provided in accordance with BS5440:2.

1. If the boiler is installed in a room - The room must have a permanent air vent either direct to the outside air or to an

adjacent room which itself has a permanent air vent to the outside air. The minimum effective air vent(s) required is:

Alpha CD50S: 220 cm² Alpha CD70S 315 cm²

2. If the boiler is installed in a cupboard or compartment - Permanent air vents are required in the cupboard or

compartment, one at high level and one at low level, either direct to the outside air or to a room. Both the high and

low level air vents must communicate with the same room or must be on the same wall to outside air. The minimum

effective areas required are given in Table 1.

Where the cupboard or compartment is ventilated to a room, the room itself must have an effective air vent direct to

outside air of minimum effective area as given above in paragraph 1.

Boiler model

Vents to outside air

Vents into a room

High level

Low level

High level

Low level

CD50S

255 cm²

510 cm²

510 cm²

1020 cm²

CD70S

350 cm²

700 cm²

700 cm²

1400 cm²

Table 1

Room sealed (Type C flue)

If the boilers are converted to a 'C' type configuration (sealed chamber and forced draught - concentric flue pipe) as

described in Section 3.4 only air for ventilation is required.

1. If the boiler is installed in a room - No air vents are required in the room in which the boiler is installed.

2. If the boiler is installed in a cupboard or compartment - Permanent air vents for ventilation are required in the

cupboard or compartment, one at high level and one at low level, either direct to the outside air or to a room. Both

the high and low level air vents must communicate with the same room or must be on the same wall to outside air.

Both the high and low level vent must each have a free area as follows. The free area of each vent may be halved if

the ventilation is provided directly from outside.

Alpha CD50S: 510 cm² Alpha CD70S 700 cm²

The minimum clearances for servicing must always be maintained.

Alpha CD50S/70S - General Boiler Information

8

3.4 FLUE SYSTEM

The flue system must be installed in accordance with BS 5440:1.

For horizontal flues ensure the flue assembly slopes downwards towards the boiler by a minimum of 25 - 30 mm per

metre of flue.

It is recommended that horizontal and vertical flue assemblies should be supported approximately every 1.5 m with access

provided to the joints.

Alpha CD50S and CD70S boilers leave the factory with 'B23' type flue configuration (open chamber and forced draught -

single flue pipe). To change the configuration to 'C' type (sealed chamber and forced draught - concentric flue pipe),

remove the 80 mm dia. adapter, the bracket and gasket from the top of the boiler and fit the concentric flue adaptor, see

Section 4.5.

Note: 1. Under no circumstances must the flue length (including allowances for extra bends) exceed the maximum flue

lengths stated for each type of flue.

2. Failure to use the correct Alpha flue components with the boiler will invalidate the boilers CE approval, guarantee

and may be unsafe.

Seals for flue elements - If lubrication of components (already performed by the manufacturer) is not sufficient, remove

the residual lubricant using a dry cloth, then to ease fitting apply a small amount of common or industrial talc to the seal.

Ensure that the seals are correctly located in the elbows and extensions as shown in Fig. 5.

Seal Seal

Fig. 5

Flue components are available as follows:-

Open flue - 80 mm dia. single pipe

Horizontal terminal kit 80 mm dia. (includes 1 m straight with terminal, one 90° bend and two collars)

Vertical terminal kit 80 mm dia.

Extension pipe 1 m x 80 mm dia.

90° bend 80 mm dia.

45° bend 80 mm dia.

Concentric flue - 80/125 mm dia.

Horizontal terminal kit 80/125 mm dia. (includes 1 m straight with terminal, one 90° bend, two collars and adaptor)

Vertical terminal kit 80/125 mm dia. (includes adaptor)

Extension kit 1 m x 80/125 mm dia.

90° bend 80/125 mm dia.

45° bend 80/125 mm dia.

Alpha CD50S/70S - General Boiler Information

9

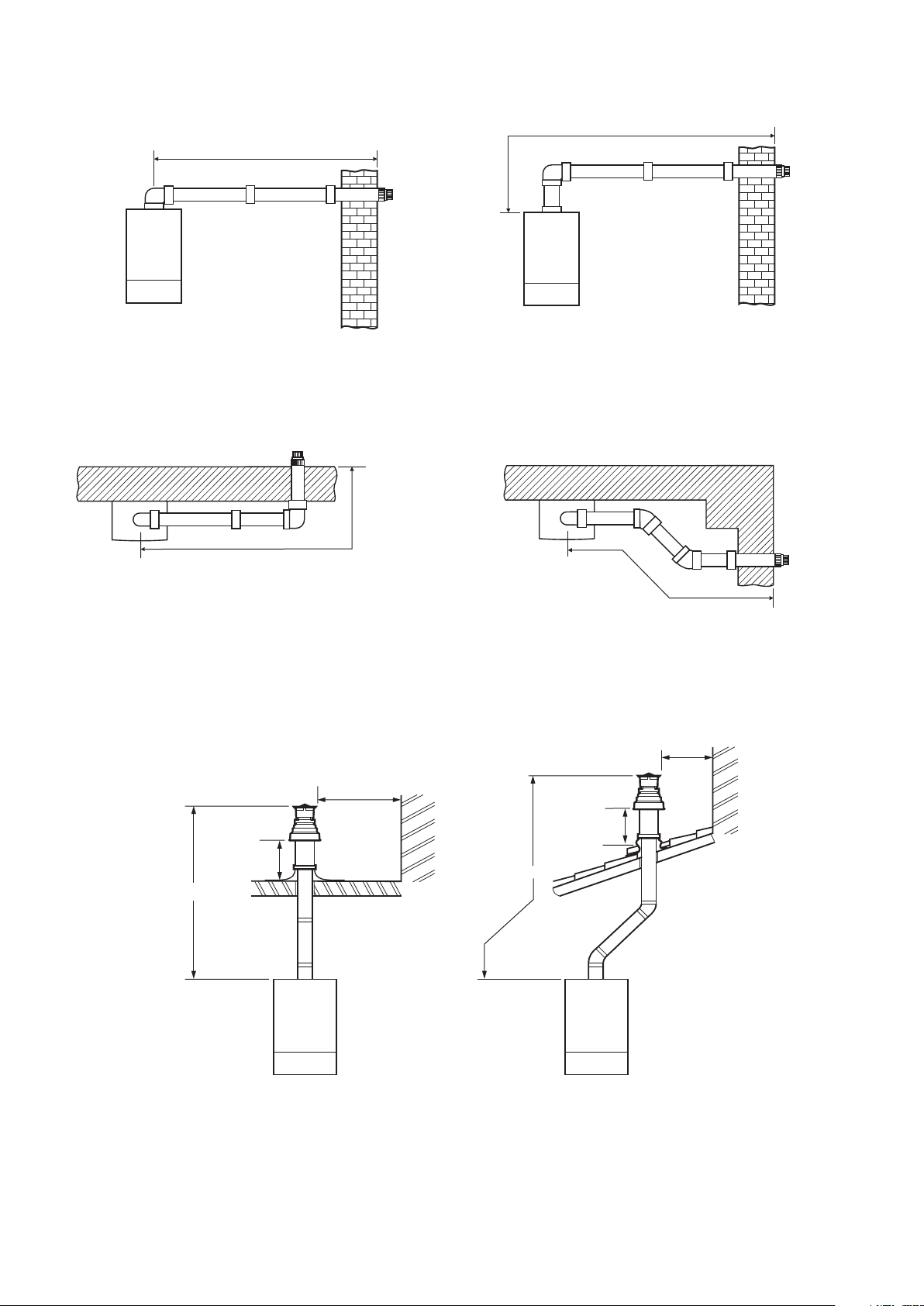

3.4.1 Horizontal Flue Options

L max

L max

L max

Open flue: 80 mm dia. single pipe Lmax = 30 m

90° bend is equivalent to 2.1 m of flue length

45° bend is equivalent to 1.3 m of flue length

Concentric flue: 80/125 mm dia. Lmax = 14 m

90° bend is equivalent to 1.9 m of flue length

45° bend is equivalent to 1.4 m of flue length

Open flue: 80 mm dia. single pipe Lmax = 27.9 m

Concentric flue: 80/125 mm dia. Lmax = 12.1 m

3.4.2 Vertical Flue Options

Not less than

300 mm

Not less than

300 mm

H

L max

Open flue: 80 mm dia. single pipe Lmax = 27.4 m

Concentric flue: 80/125 mm dia. Lmax = 11.2 m

Fig. 6 - Horizontal flues

Not less than

300 mm

Not less than

300 mm

H

Open flue: 80 mm dia. single pipe Hmax = 30 m

Concentric flue: 80/125 mm dia. Hmax = 18 m

Alpha CD50S/70S - General Boiler Information

10

Open flue: 80 mm dia. single pipe Hmax = 27.4 m

Concentric flue: 80/125 mm dia. Hmax = 15.2 m

Fig. 7 - Vertical flues

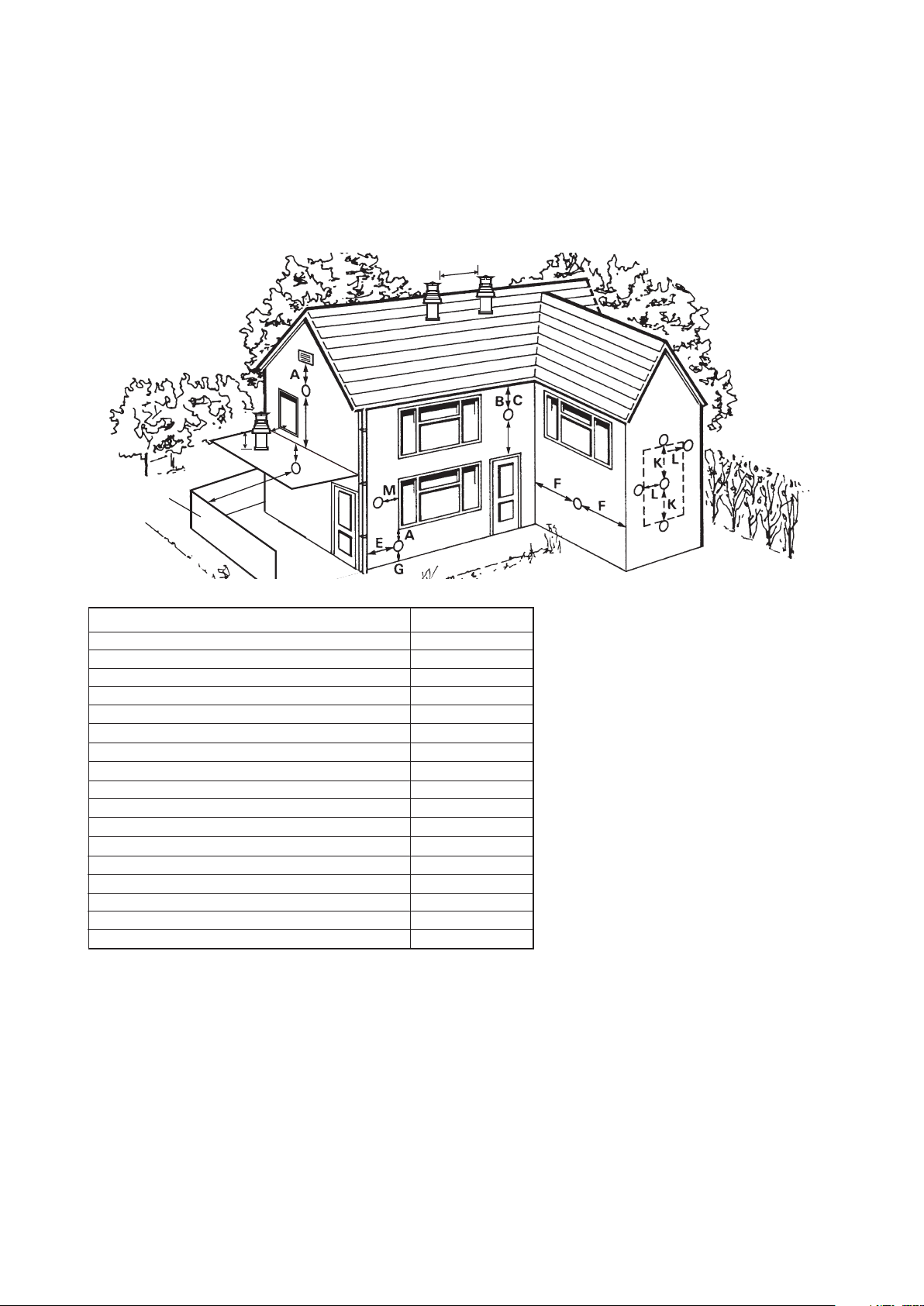

3.5 FLUE TERMINAL LOCATION - Fig. 8

Note: In certain weather conditions the terminal will emit a plume of steam. If possible avoid positioning the terminal where this may

cause a nuisance, i.e. positions A, D, G, H, J or M.

The flue terminal must be exposed to the external air and the position must allow the free passage of air across it at all times.

A terminal must not be sited below 2.1 m where people have access to, such as public footpaths, access routes, patios

etc. However, If the terminal is fitted less than 2.1 m above a surface where there is no public access, the terminal must

be protected by a terminal guard. A suitable guard is available from Alpha Therm Ltd.

Q

P

O

G

N

D

J

Boundary

A Directly below an opening, air brick, windows, etc.

B Below gutters, soil pipes or drain pipes

C Below eaves

D Below balconies

E From a vertical drain pipe or soil pipe

F From an internal or external corner

G Above ground, roof or balcony level

H From a surface or boundary facing the terminal

I From a terminal facing the terminal

J Above an opening, air brick, window etc.

K Vertically from a terminal on the same wall

L Horizontally from a terminal on the same wall

M Horizontally from an opening, air brick, window etc.

N Minimum protrusion through a roof

O From a vertical obstruction

P From an openable window

Q From an adjacent vertical terminal

HI

Min. distance (mm)Terminal position

300 mm (See Note 1)

Note: A terminal must not be sited under a car port roof

300 (See Note 1)

75 (See Note 3)

200 (See Note 3)

200 (See Note 3)

150 (See Note 3)

300 (See Note 2)

300

600 (See Note 4)

1200 mm

300 (See Note 1)

1500 mm

300 mm

300 mm

300 mm

600 mm

600 mm

Fig. 8

Notes: 1.In addition, the terminal should not be nearer

than 150 mm to the framework of an

opening into the buiding, i.e. a window

surround or door surround.

2.This clearance may be reduced to 25 mm

without effecting the performance of the

boiler. However, to ensure the condensate

plume does not affect adjacent surfaces a

clearance of 300 mm is preferable.

3.These clearances may be reduced to 25 mm

without effecting the performance of the boiler.

However, to ensure the condensate plume

does not affect adjacent surfaces the terminal

can be extended beyond gutters, pipes, eaves,

balconies etc. by upto 500 mm. If the flue is

extended more than 500 mm outside, it should

be boxed and insulated.

4.To reduce the possibility of nuisance to

neighbouring buildings etc. it is

recommended the terminal shouild not be

less than 2500 mm from car parking spaces,

building boundary walls, fences etc.

3.6 BOILER LOCATION

The boiler is not suitable for external installation unless it is installed within a purpose designed weatherproof building.

The boiler must be installed on a flat vertical wall which is capable of supporting the weight of the boiler. The boiler can be

fitted to or adjacent to a wall comprising of a combustible material without the need for a special thermal insulation barrier.

If the boiler is to be fitted in a timber framed building, it should be fitted in accordance with the Institute of Gas Engineers

'Guide for Gas Installations in Timber Frame Housing', reference IGE/UP/7.

The boiler may be installed in any room or internal space, although particular attention is drawn to the requirements of the

current IEE Wiring (BS7671) Regulations, and in Scotland, the electrical provisions of the Building Regulations applicable in

Scotland, with respect to the installation of the boiler in a room or internal space containing a bath or shower. Where a roomsealed boiler is installed in a room containing a bath or shower, it must not be possible for a person using the bath or shower

to touch any electrical switch or boiler control utilising mains electricity.

The boiler may be installed in a cupboard or compartment, provided it is correctly designed for that purpose, i.e. complies

with the Building Regulations and the requirements of BS 6798.

Alpha CD50S/70S - General Boiler Information

11

Loading...

Loading...