Alpha CD24C, CD32C Installation and Servicing Instructions

Installation and Servicing

Instructions

Alpha CD24C/32C

Range of Wall Mounted, Fan Assisted, Room Sealed,

Gas Fired, High Efficiency Condensing Combination Boilers

For Technical help or for Service call ...

ALPHA HELPLINE

Tel: 0870 3001964

Nepicar House, London Road,

Wrotham Heath, Sevenoaks,

Kent TN15 7RS

*HEJEID/=I

Service Listed

Alpha CD24C G.C. No. 47 532 19

Alpha CD32C G.C. No. 47 532 21

For use with Natural Gas only

Leave these instructions with the User

CONTENTS

1 Introduction ....................................... 2

2 Technical data ................................... 3

3 General boiler information .................. 6

4 Installation ......................................... 12

5 Commissioning ................................. 18

6 Boiler operation ................................. 21

8 Component replacement ................... 24

9 Wiring diagrams ................................ 31

10 Fault finding ...................................... 33

11 Short parts list ................................... 37

12 Benchmark Checklist ......................... 38

13 Service record ................................... 39

7 Routine servicing ............................... 22

1 INTRODUCTION

The Alpha CD range of high efficiency condensing boilers are wall mounted, fan assisted room-sealed combination boilers.

The burner is lit electronically and the heat output is controlled by a modulating fan and gas valve.

The CD24C and CD32C are combination boilers providing both central heating and domestic hot water at mains pressure.

The boilers are supplied with a pump, pressure relief valve, expansion vessel and pressure gauge fully assembled and tested.

They are designed for use with a fully pumped, sealed and pressurised central heating system using only Natural gas.

The CD24C is suitable for central heating loads of between 4.7 and 25.4 kW (16 018 and 86 700 Btu/h).

The CD32C boiler is suitable for central heating loads of between 6.5 and 29.8 kw (22 200 and 101 700 Btu/h).

The maximum output available for domestic hot water is 24.2 kW (82 600 Btu/h), capable of providing 9.6 litres/min with a

temperature rise of 35°C for the Alpha CD24C boiler and for the Alpha CD32C boiler - 32 kW (109 200 Btu/h), providing 13.2

litres/min with a temperature rise of 35°C.

IMPORTANT

It is the law that all gas appliances are installed by a competent person, ie CORGI registered personnel, in accordance with

the following recommendations:-

Current Gas Safety (Installation and Use) Regulations

All current Building Regulations issued by the Department of the Environment, i.e. Approved Document L1.

Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development Department

UK Water Regulations/Byelaws (Scotland)

Health & Safety Document No. 635 (The Electricity At Work Regulations 1989)

The installation should also be in accordance with the following British Standard Codes of Practice:-

BS 5440:1:2000 Flues

BS 5449:1990 Forced circulation hot water systems

BS 5546:2000 Installation of hot water supplies for domestic purposes

BS 6700:1997 Design, installation, testing and maintenance of services supplying water

BS 6798:2000 Installation of gas fired hot water boilers

BS 6891:1998 Gas installation

BS 7593:1992 Code of Practice for treatment of water in heating systems

BS 7671:2001 Requirements for electrical installations, IEE Wiring Regulations

Reference should be made to DEFRA document 'Guide to condensing boiler installation assessment procedures for dwellings'.

If installation is in a timber framed building, refer to the Institute of Gas Engineers document IGE/UP/7.

This appliance meets the requirements of IPX4D, ie degree of protection against moisture.

Failure to install this appliance correctly could lead to prosecution. It is in your own interest and that of safety to ensure that the

law is complied with.

Manufacturer's instructions must NOT be taken in anyway as over-riding statutory obligations.

Notes: 1. Ensure that the Benchmark Log Book has been completed after the boiler has been installed and commissioned.

2. The boiler must only be used with Alpha CD condensing flue components.

Alpha CD24C/32C - Contents/Introduction

2

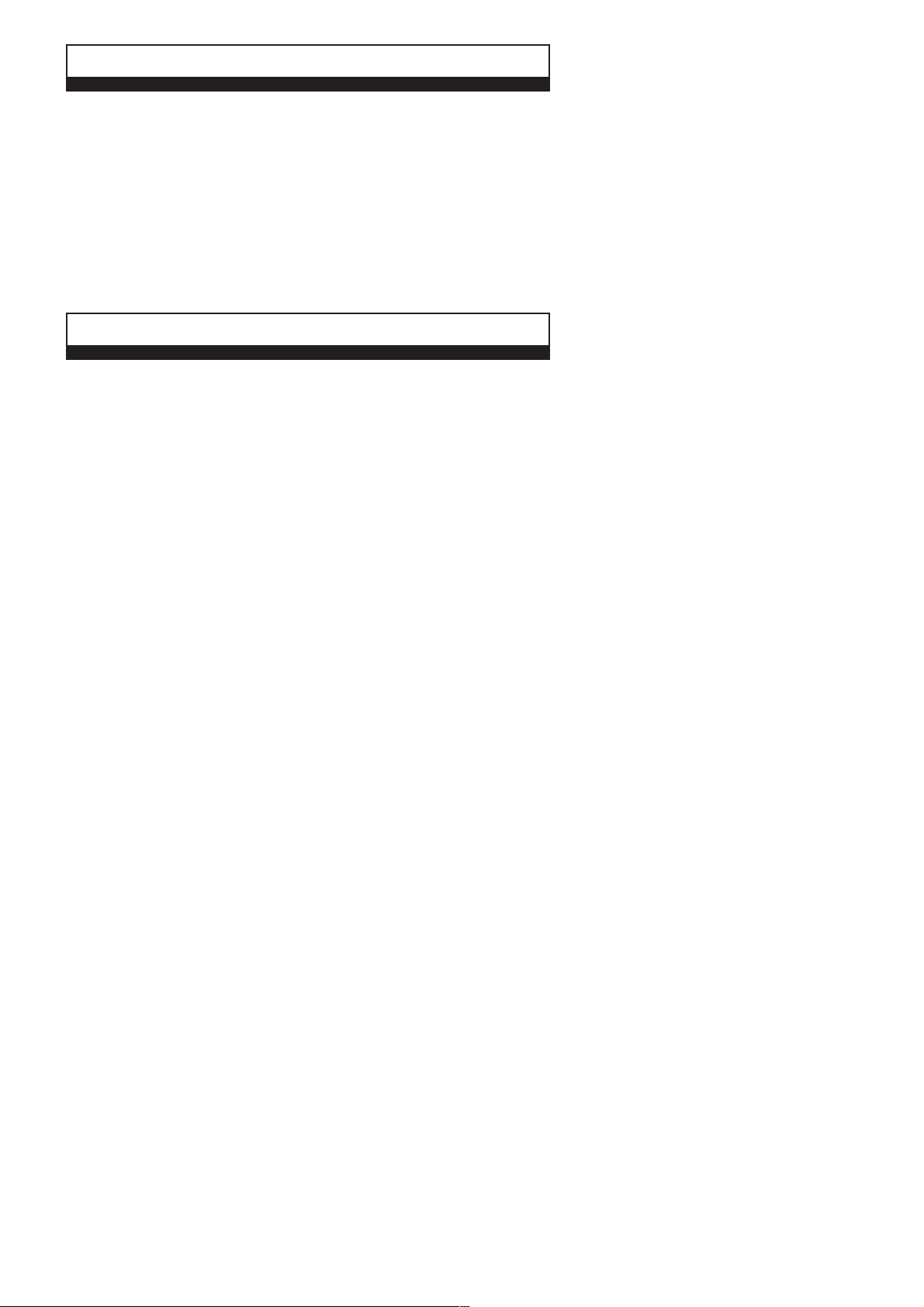

2 TECHNICAL DATA

2.1 PERFORMANCE - NATURAL GAS

(CAT: I2H 2H - G20 - 20 mbar)

Alpha CD24C

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) kW

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Differential Burner mbar

Pressure in wg

Room sealed

chamber panel

fitted

Gas Rate m³/h

ft³/h

MAX.

26.4

90 100

24.0

82 000

25.4

86 700

23.5

81 135

5.78

2.30

2.54

89.7

Alpha CD32C

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) kW

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Differential Burner mbar

Pressure in wg

Room sealed

chamber panel

fitted

Gas Rate m³/h

ft³/h

MAX.

31.1

106 100

28.0

95 550

29.8

101 700

28.0

95 500

3.33

1.33

2.98

105.2

2.2 SYSTEM

Alpha CD24C

Central Heating (Sealed System)

Max. Working System Pressure

Min. System Pressure

Max. System temperature

Pressure Relief Valve Setting

Expansion Vessel Size (pre-charge press.)

Flow Connection

Return Connection

Relief Valve Connection

Recommended System Pressure (cold)

CH Water Temp. (Approx. max.)

2.5 bar

0.5 bar

82°C

3 bar (44 PSI)

8 L at 0.8 bar

22 mm

22 mm

15 mm

1.0 bar

82°C (180°F)

MIN.

5.5

18 800

5.0

17 100

5.3

18 100

4.7

16 018

0.35

0.14

0.53

18.7

MIN.

7.3

24 900

6.6

22 500

7.0

23 900

6.5

22 200

0.39

0.16

0.69

24.4

Alpha CD24C

Domestic Hot Water

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Output to Water (Hs)kW

(modulating) Btu/h

Differential Burner mbar

Pressure in wg

Room sealed

chamber panel

fitted

Gas Rate m³/h

ft³/h

Flow Rate at 35°C Rise L/min

gal/min

Specific Flow Rate (D) at 30°C Rise L/min

(Flow rate @ 30K to EN625) gal/min

MAX.

26.4

90 100

24.0

82 000

24.20

82 600

5.78

2.3

2.54

89.7

9.6

2.2

11.2

2.5

Alpha CD32C

Domestic Hot Water

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Output to Water (Hs)kW

(modulating) Btu/h

Differential Burner mbar

Pressure in wg

Room sealed

chamber panel

fitted

Gas Rate m³/h

ft³/h

Flow Rate at 35°C Rise L/min

gal/min

Specific Flow Rate (D) at 30°C Rise L/min

(Flow rate @ 30K to EN625) gal/min

MAX.

36.2

123 500

32.6

111 300

32.0

109 200

4.27

1.71

3.45

121.8

13.2

2.9

15.4

3.9

Alpha CD24C and CD32C

Domestic Hot Water

Max. Mains Inlet Water Pressure

Min. Mains Water Pressure

Min. DHW Flow Rate

Mains Inlet Connection

DHW Outlet Connection

DHW Water Content CD24C

CD32C

Outlet Water Temp. (Approx. max.)

8 bar

0.2 bar

2.5 l/min

15 mm

15 mm

0.2 L

0.3 L

62°C (144°F)

MIN.

5.5

18 800

5.0

17 100

4.97

17 000

0.35

0.14

0.53

18.7

MIN.

7.3

24 900

6.6

22 500

6.6

22 500

0.39

0.16

0.69

24.4

2.3 COMPONENTS 2.4 ELECTRICAL

Burner

Main Heat exchanger

DHW Heat Exchanger

Main Burner Injector CD24

CD32

Flue - Outer Duct

Flue - Inner Duct

Stainless steel

Stainless steel

Stainless Steel

5.0 mm

6.6 mm

White

Plastic

Supply

External Fuse

Power Consumption CD24

Internal Fuse

Electrode Spark Gap

Alpha CD24C/32C - Technical Data

CD32

230/240 V ~ 50 Hz

3 A

130 W

140 W

F2 A

3 - 4 mm

3

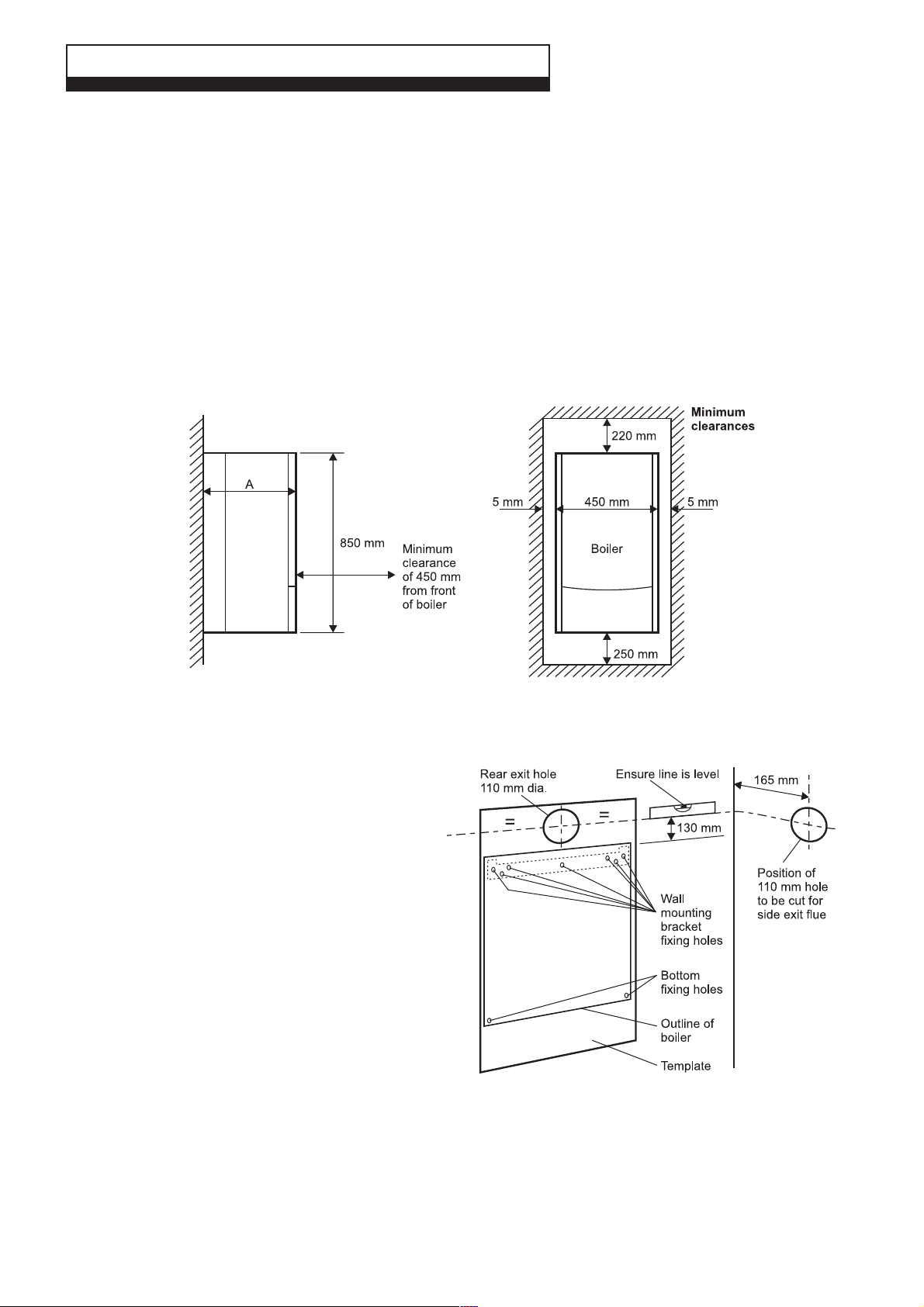

2.5 INSTALLATION

2.6 GENERAL

Min. Clearances for Servicing Top

(from casing) Bottom

Sides

Front

Flue Terminal Size

Flue Terminal Protruding

Hole Size Required For Flue Assy.

Lift Weight CD24C

CD32C

220 mm

250 mm

5 mm

450 mm

100 mm Dia.

100 mm

110 mm Dia.

49 kg

51 kg

Case Dimensions Height

Width

Depth (CD24)

Depth (CD32)

Gas Connection

Primary Water Content CD24

CD32

Air Duct Diameter

Flue Duct Diameter

850 mm

450 mm

345 mm

380 mm

22 mm

2.5 L

3.0 L

100 mm

60 mm

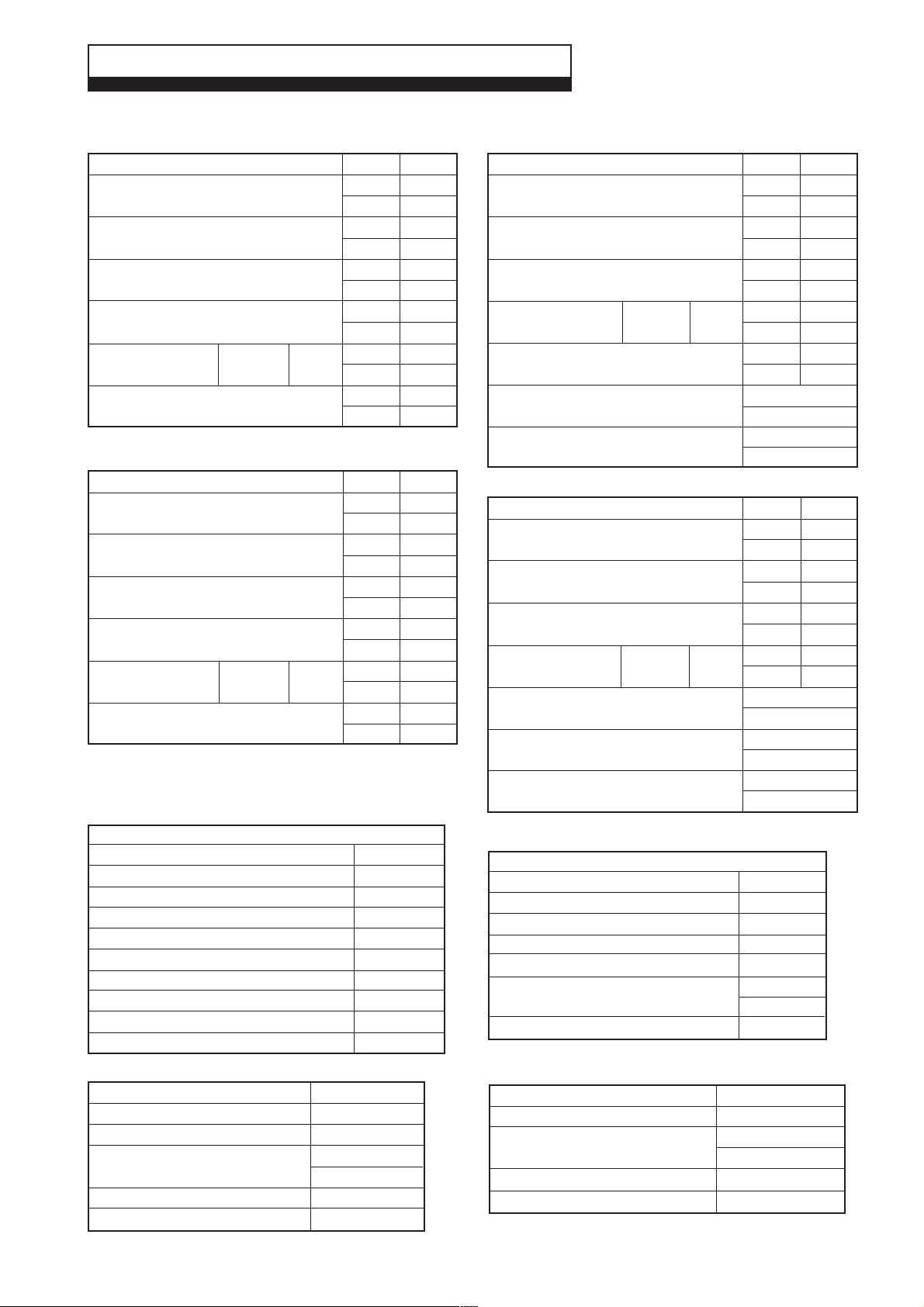

2.7 FLUE LENGTHS

CD Easy-Flue 500 mm with terminal and 90° bend. A CD Easy-Flue 1000 mm with terminal and 90° bend is also available.

CD 750 mm and 1000 mm flue extensions are available.

Length of Flue Required:-

Rear Flue = wall thickness + 170 mm (includes terminal)

Side Flue = wall thickness + distance between wall and side of boiler + 230 mm (includes terminal)

Vertical Flue = distance from top of boiler side panel to required roof position minus 1 m for vertical terminal assembly

Maximum horizontal flue length = 12 m.

Maximum vertical flue length including terminal is 15 m.

Each additional CD 90° Bend is equivalent to 1.3 m of flue length.

Each CD 45° Bend is equivalent to 0.9 m of flue length.

The CD Vertical Flue terminal assembly is equivalent to 1 m of flue length.

2.8 AVAILABLE PUMP HEAD FOR CENTRAL HEATING

Output (50/30°C) Available pump head

kW

25.40

18.70

15.60

12.35

5.30

Btu/h

86 700

64 000

53 000

42 200

18 100

20°C 20°C

metres

2.3

3.5

3.8

4.0

4.6

feet

7.6

11.6

12.6

13.2

15.2

This information is based on 20°C system design temperature difference.

Note: For outputs upto 28 kW refer to Section 3.7.

Flow rate

litre/min

16.6

12.6

10.5

8.3

3.2

gal/min

3.7

2.8

2.3

1.8

0.7

2.9 ELECTRICAL CONNECTIONS

Note: This Appliance Must Be Earthed

An optional integral single channel Clock kit is available if required.

Note: Only use the Alpha single channel clock. Do not fit any two channel clocks.

Blue

Red

Wire

Brown

Wire

Wire

12345

Red

Not

Wire

Used

Internal Clock Terminals

WARNING

1. Ensure wires are connected

correctly

2. Only fit the Alpha recommended

clock. Other clocks could cause

damage.

Clock connections

Alpha CD24C/32C - Technical Data

4

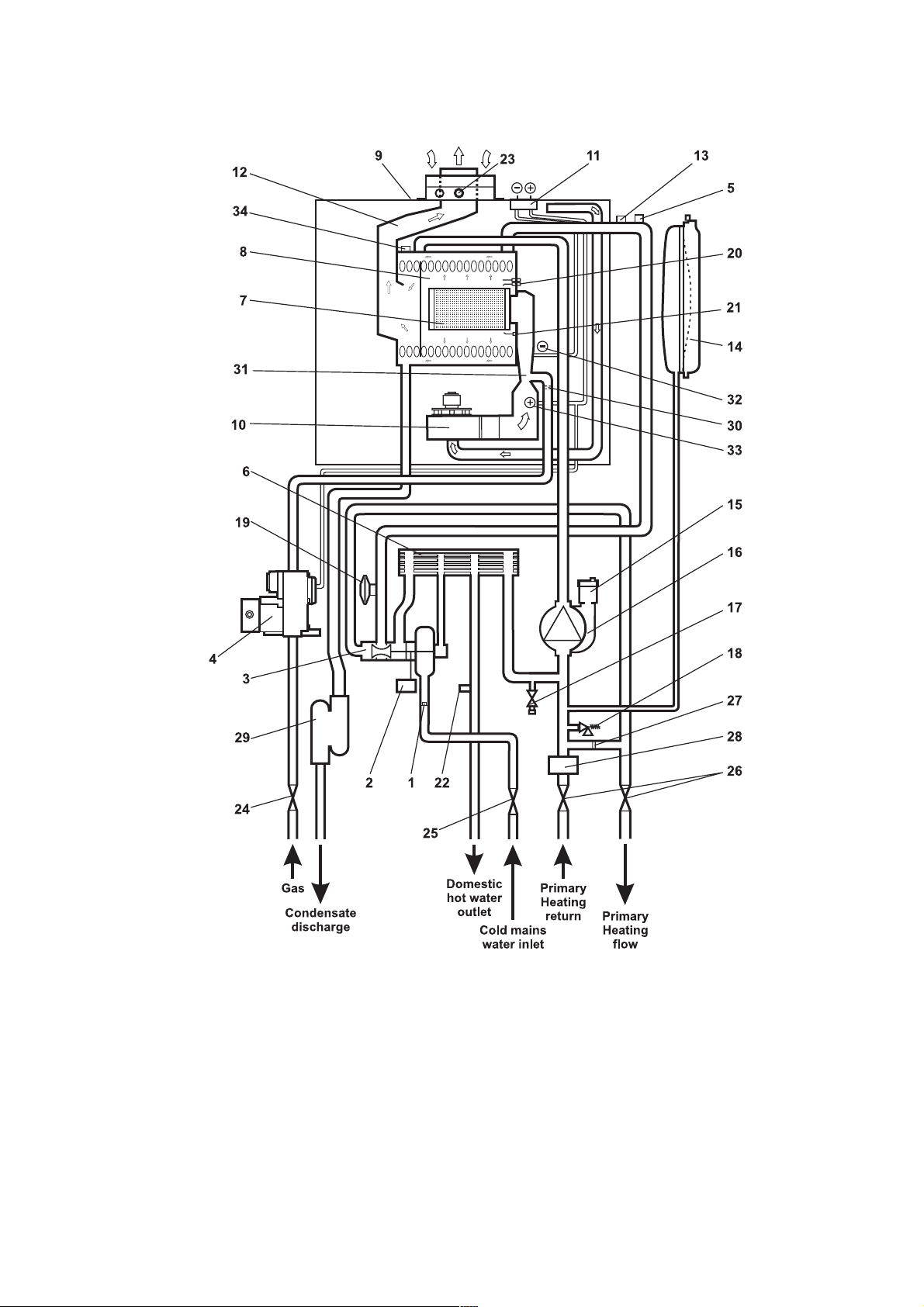

Fig. 1

Boiler terminal block

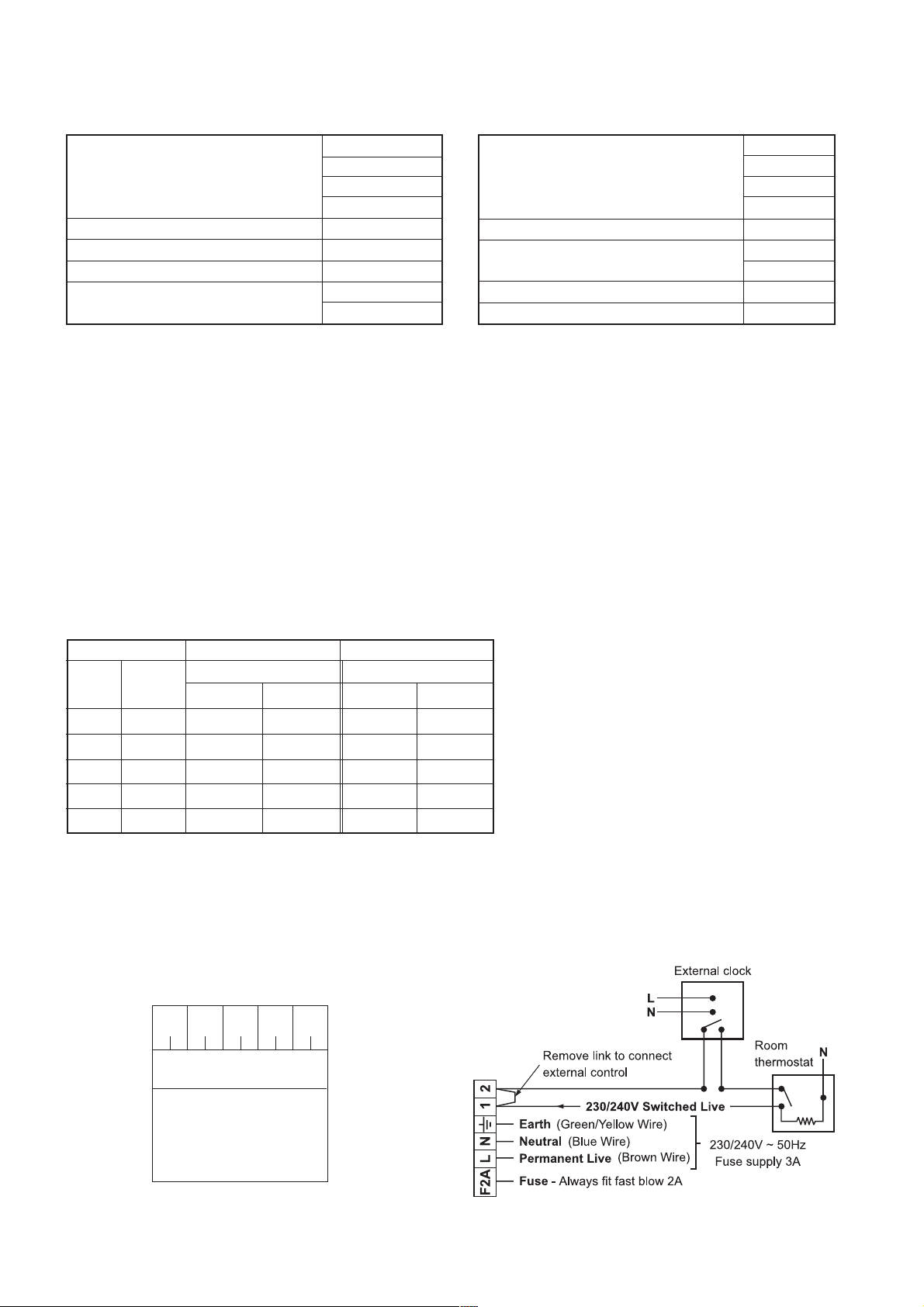

2.10 BOILER SCHEMATIC

1 - Flow regulator

2 - DHW flow switch

3 - Diverter valve and DHW flow valve

4 - Gas valve

5 - Primary temperature sensor

6 - DHW heat exchanger

7 - Main burner

8 - Primary/condensing heat exchanger

9 - Room sealed chamber

10 - Fan

11 - Pressure differential test points

12 - Flue hood

13 - Overheat thermostat

14 - Expansion vessel

15 - Automatic air vent

16 - Pump

17 - Drain point

18 - Pressure relief valve

19 - Primary pressure switch

20 - Ignition electrodes

21 - Flame sensing electrode

22 - DHW temperature sensor

23 - Flue sampling point

Fig. 2B

24 - Gas service cock

25 - Mains inlet on/off valve

26 - On/off valve (2 off)

27 - Automatic by-pass

28 - Cyclone separator

29 - Condensate trap

30 - Injector

31 - Venturi

32 - Venturi negative point

33 - Venturi positive point

34 - Flue thermostat

Alpha CD24C/32C - Technical Data

5

3 GENERAL BOILER INFORMATION

3.1 GAS SUPPLY

The Alpha CD24C boiler requires a gas rate of 2.54 m³/h (89.7 ft³/h).

The Alpha CD32C boiler requires a gas rate of 3.45 m³/h (121.8 ft³/h).

The meter and supply pipes must be capable of delivering this quantity of gas in addition to the demand from any other

appliances in the house. The boiler requires at least a 22 mm gas supply pipe.

The complete installation, including the meter, must be tested for gas soundness and purged as described in BS 6891.

3.2 ELECTRICAL SUPPLY

The boiler requires a 230/240 V ~ 50 Hz mains supply, fused at 3 A

The boiler must be earthed.

There must only be one common isolator, providing complete electrical isolation, for the boiler and any external controls.

This boiler has been fitted with a supply cable, however, if it is necessary to fit a cable use PVC insulated cable not less than

0.75 mm² (24 x 0.2 mm) to BS 6500 Table 16. The boiler should be connected to a fused three pin plug and unswitched

shuttered socket outlet (both complying with BS 1363), or a fused double pole switch with a contact separation of at least 3 mm

in both poles.

Wiring external to the boiler must be in accordance with the current IEE Wiring Regulations (BS 7671).

Note: If a room thermostat is fitted, it must be suitable for 230/240 V switching.

3.3 AIR SUPPLY

The boiler does not require any air vents for cooling in the room in which it is installed or when installed in a cupboard or

compartment. The minimum clearances for servicing must always be maintained.

Note: A cupboard or compartment used to enclose the boiler must be designed and constructed specifically for the purpose,

i.e. comply with the Building Regulations.

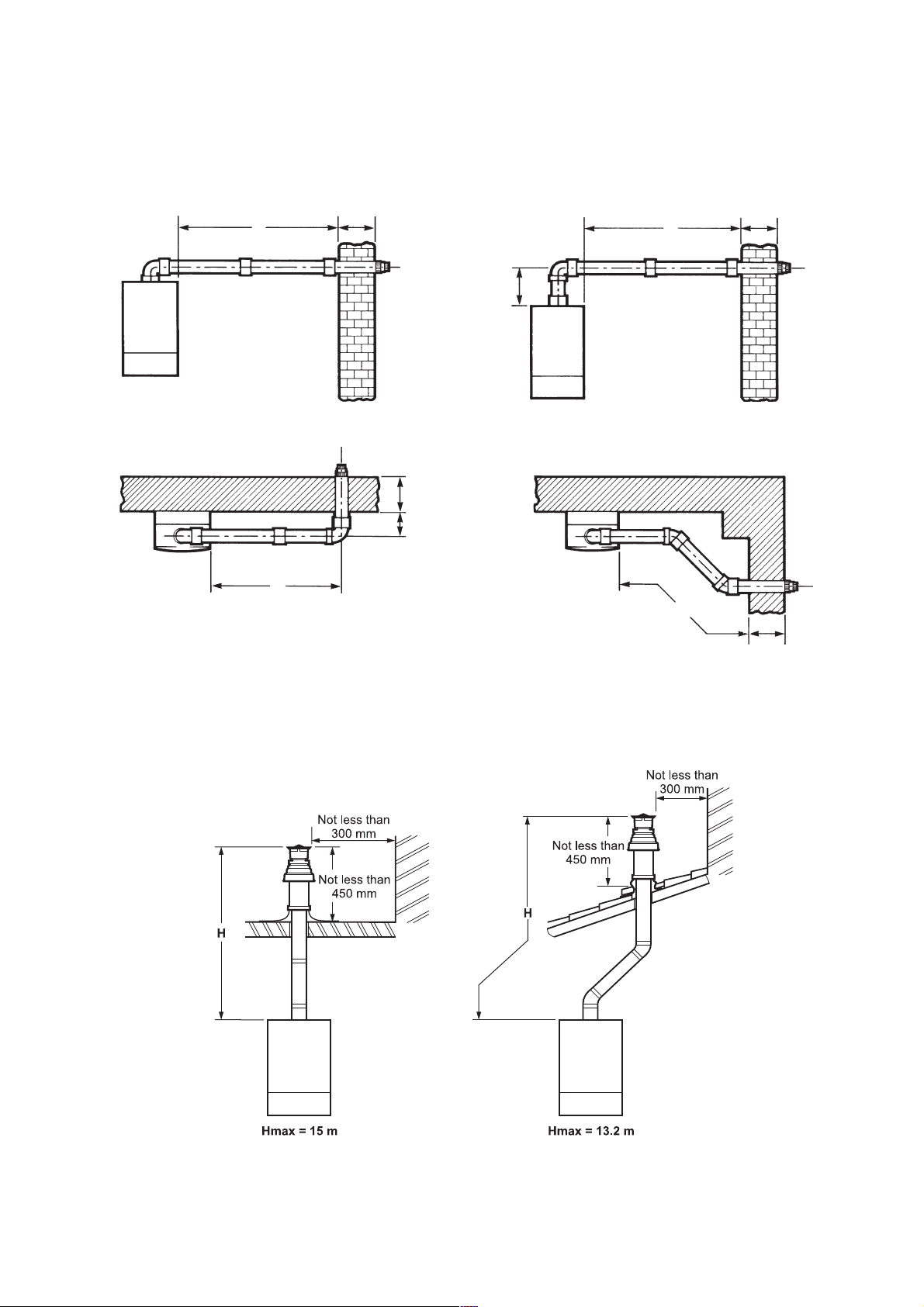

3.4 FLUE SYSTEM - Fig. 3

The flue system must be installed in accordance with BS 5440:1.

For horizontal flues ensure the flue assembly is horizontal and the inner duct is sloping downwards towards the boiler.

Flue components are available as follows:-

CD Easy-Flue 500 mm (includes 90° bend and terminal) - Part No. 6.2000500.

CD Easy-Flue 1000 mm (includes 90° bend and terminal) - Part No. 6.2001000.

CD 750 mm flue extension - Part No. 6.2000750.

CD 1000 mm flue extension - Part No. 6.2001050

CD 90° bend - Part No. 6.2000590.

CD 45° bend - Part No. 6.2000545.

CD Vertical flue terminal assembly. Refer to the separate installation instructions supplied with the assembly.

The following methods determine the correct length of flue required.

For rear exit flue (including terminal) L = B + 170 mm

For side exit flue (including terminal) L = B + C + 230 mm (min. side clearance required is 5 mm)

For vertical flue L = H minus 1000 mm for vertical terminal assembly

Where L = Required flue length

B = Finished wall thickness

C = Distance from the inside wall to the side of the boiler

H = Distance from top of boiler side panel to roof position

Note: 1. If an extra 90° bend is used, this reduces the maximum flue length by 1.3 m. Each 45° bend used reduces the maximum

flue length by 0.9 m.

2. Under no circumstances must the flue length (including allowances for extra bends) exceed 12 metres horizontally and

only 15 metres vertically.

3. Failure to use Alpha CD flue components with the boiler will invalidate the boilers CE approval, guarantee and may be

unsafe.

Alpha CD24C/32C - General Boiler Information

6

HORIZONTAL FLUE OPTIONS - Lmax = 12 metres

L = B + C + 230 mm

C

E

L = B + E + F + 230 mm + (90° bend = 1.3 metre)

B

B

F

L = B + C + E + 230 mm

C

E

C

B

B

VERTICAL FLUE OPTIONS

L = B + C + 230 mm + (2 x 45° bends = 1.8 metre)

Fig. 3

Alpha CD24C/32C - General Boiler Information

7

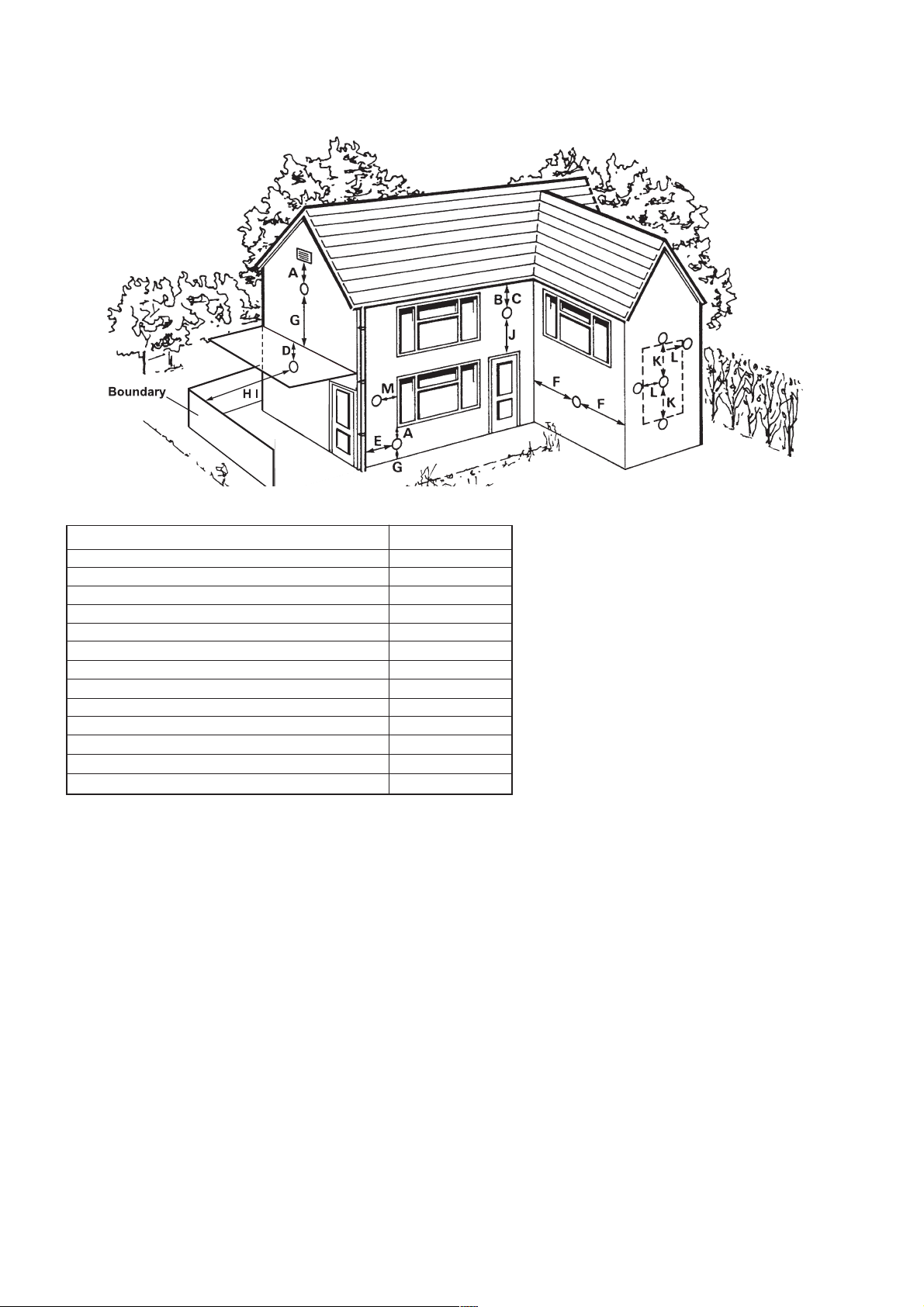

3.5 FLUE TERMINAL LOCATION - Fig. 4

Min. distance (mm)Terminal position

A Directly below an opening, air brick, windows, etc.

B Below gutters, soil pipes or drain pipes

C Below eaves

D Below balconies

E From a vertical drain pipe or soil pipe

F From an internal or external corner

G Above ground, roof or balcony level

H From a surface facing the terminal

I From a terminal facing the terminal

J Above an opening, air brick, window etc.

K Vertically from a terminal on the same wall

L Horizontally from a terminal on the same wall

M Horizontally from an opening, air brick, window etc.

300 mm (See Note 1)

Note: A terminal must not be sited under a car port roof

Fig. 4

300 (See Note 1)

75 (See Note 3)

200 (See Note 3)

200 (See Note 3)

150 (See Note 3)

300 (See Note 2)

300

600 (See Note 4)

1200 mm

300 (See Note 1)

1500 mm

300 mm

Notes: 1.In addition, the terminal should not be nearer

than 150 mm to the framework of an

opening into the buiding, i.e. a window

surround or door surround.

2. This clearance may be reduced to 25 mm

without effecting the performance of the

boiler. However, to ensure the condensate

plume does not affect adjacent surfaces a

clearance of 300 mm is preferable.

3. These clearances may be reduced to 25 mm

without effecting the performance of the

boiler. However, to ensure the condensate

plume does not affect adjacent surfaces the

terminal should be extended beyond gutters,

pipes, eaves, balconies etc.

4. To reduce the possibility of nuisance to

neighbouring buildings etc. it is

recommended the terminal shouild not be

less than 2500 mm from car parking spaces,

building boundary walls, fences etc.

Note: In certain weather conditions the terminal will emit a plume of steam. If possible avoid positioning the terminal where this may cause

a nuisance, i.e. positions A, D, G, H, J or M.

The flue terminal must be exposed to the external air and the position must allow the free passage of air across it at all times.

If the terminal is fitted within 850 mm of a plastic or painted gutter or 450 mm of painted eaves, an aluminium shield at least 1 m

long should be fitted to the underside of the gutter or painted surface. A terminal must not be sited below 2.1 m where people

have access to, such as public footpaths, access routes, patios etc. However, If the terminal is fitted less than 2.1 m above a

surface where there is no public access, the terminal must be protected by a terminal guard.

A suitable guard is available from Alpha Therm Ltd.

3.6 BOILER LOCATION

The boiler is not suitable for external installation unless it is installed within a purpose designed weatherproof building.

The boiler must be installed on a flat vertical wall which is capable of supporting the weight of the boiler. The boiler can be fitted

to or adjacent to a wall comprising of a combustible material without the need for a special thermal insulation barrier.

If the boiler is to be fitted in a timber framed building, it should be fitted in accordance with the Institute of Gas Engineers 'Guide

for Gas Installations in Timber Frame Housing', reference IGE/UP/7.

The boiler may be installed in any room or internal space, although particular attention is drawn to the requirements of the

current IEE Wiring (BS7671) Regulations, and in Scotland, the electrical provisions of the Building Regulations applicable in

Scotland, with respect to the installation of the boiler in a room or internal space containing a bath or shower. Where a roomsealed boiler is installed in a room containing a bath or shower, it must not be possible for a person using the bath or shower

to touch any electrical switch or boiler control utilising mains electricity.

The boiler may be installed in a cupboard or compartment, provided it is correctly designed for that purpose, i.e. complies with

the Building Regulations and the requirements of BS 6798.

Alpha CD24C/32C - General Boiler Information

8

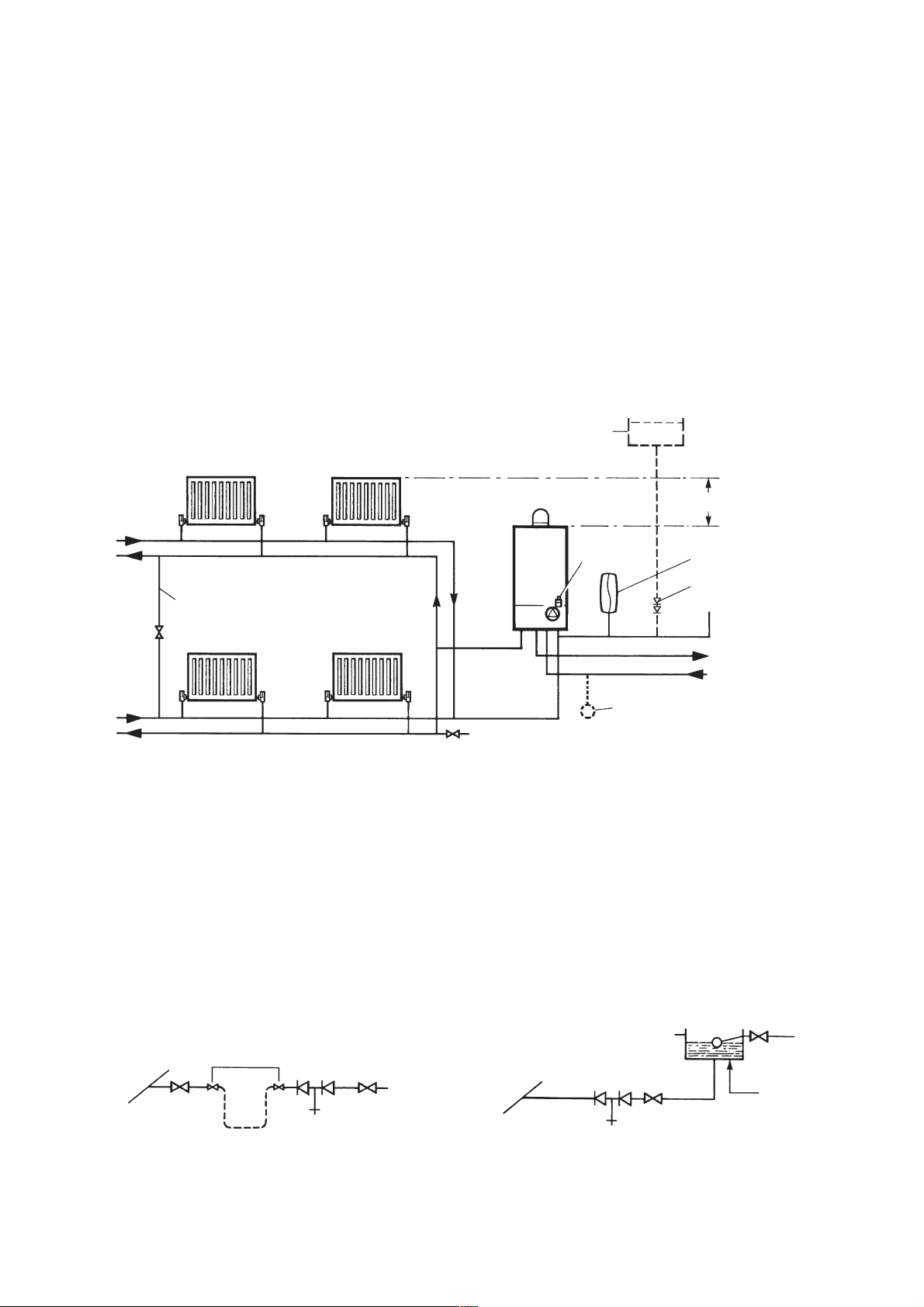

3.7 CENTRAL HEATING SYSTEM - Fig. 5

The boiler is designed for use in a sealed central heating system in accordance with the requirements of BS 5449 and BS 6798.

The system should be designed to operate with flow temperatures of up to 82°C. When designing the system, the pump head, expansion

vessel size, mean radiator temperature, etc. must all be taken into account. Refer to the pump performance table for guidelines.

System volume - The expansion vessel incorporated into the boiler is suitable for a sealed heating system with a maximum

water content of 80 litres (18 gal). Above 80 litres, consideration should be given to fitting an additional expansion vessel fitted

in the position shown in Fig. 5. To check correct operation of the expansion vessel(s) the system pressure should not be more

than 2.5 bar when the system is at maximum operating temperature (for further guidance refer to BS 7074:1).

The boiler is supplied with the following components built in:Pressure relief valve - complying with BS 6759 and set to operate at 3 bar. The discharge pipe must be routed clear of the

boiler and terminated in such a manner that it can be seen, but cannot cause injury to persons or property.

Pressure gauge - To indicate the system pressure to be maintained.

Expansion vessel - Conforming to BS 4814 with a capacity of 8 litres and pre-charged to a pressure of 0.8 bar.

By-pass - The boiler incorporates a by-pass, however where all radiators are fitted with thermostatic radiator valves it is

recommended a system by-pass, preferably automatic is fitted.

Cyclone - This is a device fitted in the heating return within the boiler to remove any foreign or solid matter etc. from the

system.

Make up vessel

Static head of system

Boiler

casing

Automatic

air vent

Additional expansion

vessel (if required)

Double check valve assy.

Heating

by-pass

(If required)

Note: if required, an automatic by-pass is

preferred.

Heating flow

Filling point

DHW outlet

Mains water inlet

Note: If the mains is fitted with water

meter, check valves or loose jumper stop

cock, then a DHW expansion device must

be fitted.

Note: A drain tap should be installed at the lowest

point of the heating circuit and beneath the appliance.

Heating return

System

drain tap

Fig. 5

3.8 FILLING THE CENTRAL HEATING SYSTEM - Figs. 6, 7

The system design pressure (cold) should be set to 1.0 bar. This pressure is equivalent to a static head (see Fig. 5) of 10.2 metres of water.

Provision should be made to replace water lost from the system. This can be by manual or automatic means, as shown in Figs.

6 and 7. The position for connecting an automatic make-up vessel is indicated in Fig. 5. A double check valve assembly must

be used, as shown in Fig. 7.

Filling of the system must be carried out in a manner approved by the local Water Undertaking. Where allowed, the system may

be filled via a temporary connection as shown in Fig. 6. After filling, always disconnect the flexible hose of the filling loop.

All fittings used in the system must be able to withstand pressures up to 3 bar.

Drain taps (to BS 2879) must be used to allow the system to be completely drained.

Mains

water

supply

Feed cistern to be

located above highest

point in the system

Heating circuit

return

Stop

valve

temporarily connected

Hose

unions

Filling loop

Double check

valve assembly

Test cock

Stop

valve

Mains

water

supply

Heating circuit

return

Double check

valve assembly

Test cock

Overflow

Stop

valve

Fig. 6 Fig. 7

Alpha CD24C/32C - General Boiler Information

9

3.9 FLUSHING THE HEATING SYSTEM

It is essential that the central heating system is thoroughly cleaned and flushed when fitting an Alpha CD boiler. Failure to do so

will invalidate the warranty.

The primary condensing heat exchanger is constructed in stainless steel and therefore is compatible with most materials used

in a heating system.

If a cleaning agent and inhibitor are used, they must be applied in accordance with their manufacturers instructions. Only

products from Fernox and Sentinel are acceptable for use with the Alpha CD boilers. Further information can be obtained from

Fernox (Tel: 0179 9521133) or Sentinel (Tel: 0151 4209563).

Although the Cyclone is fitted in the heating return on the boiler, the heating system should still be thoroughly flushed as

detailed below. The Cyclone collection point should be emptied via the drain point (see Fig. 11) after flushing has been

completed.

The system should be flushed in accordance with BS 7593 and BS 5449. The following procedures are recommended:

1. Installing onto a new system:a. Fill the system, vent at high points, at pump and radiators.

b. Check for leaks.

c. Rapidly drain the system.

d. If required, chemically clean the system as instructed by the recommended cleaner manufacturer.

Note: Ensure that the system is flushed to remove any remains of the cleaner.

e. If chemical cleaner is not used to clean the system:-

i) Refill the system.

ii) Switch on the boiler and allow the system to heat up to the normal operating temperature.

iii) Rapidly drain the system while the water is still hot.

iv) Refill the system.

f. As required, add the recommended inhibitor to the system as instructed by the inhibitor manufacturer.

g. Recheck for leaks.

2. Installing onto an existing system, clean the system before fitting the new boiler:a. If the old boiler is still working:-

i) Switch on the boiler and allow the system to heat up to the normal operating temperature.

ii) Rapidly drain the system while the water is still hot.

iii) Refill and chemically clean the system as instructed by the recommended cleaner manufacturer.

iv) Ensure the system is flushed to remove any remains of the cleaner.

v) Fit the new boiler.

b. If the old boiler is not working:-

i) Rapidly drain the system.

ii) Remove the old boiler.

iii) Flush the system through.

iv) Fit the new boiler.

v) Refill and chemically clean the system as instructed by the recommended cleaner manufacturer.

vi) Ensure the system is flushed to remove any remains of the cleaner.

c. As required, add the recommended inhibitor to the system as instructed by the inhibitor manufacturer.

d. Check for leaks.

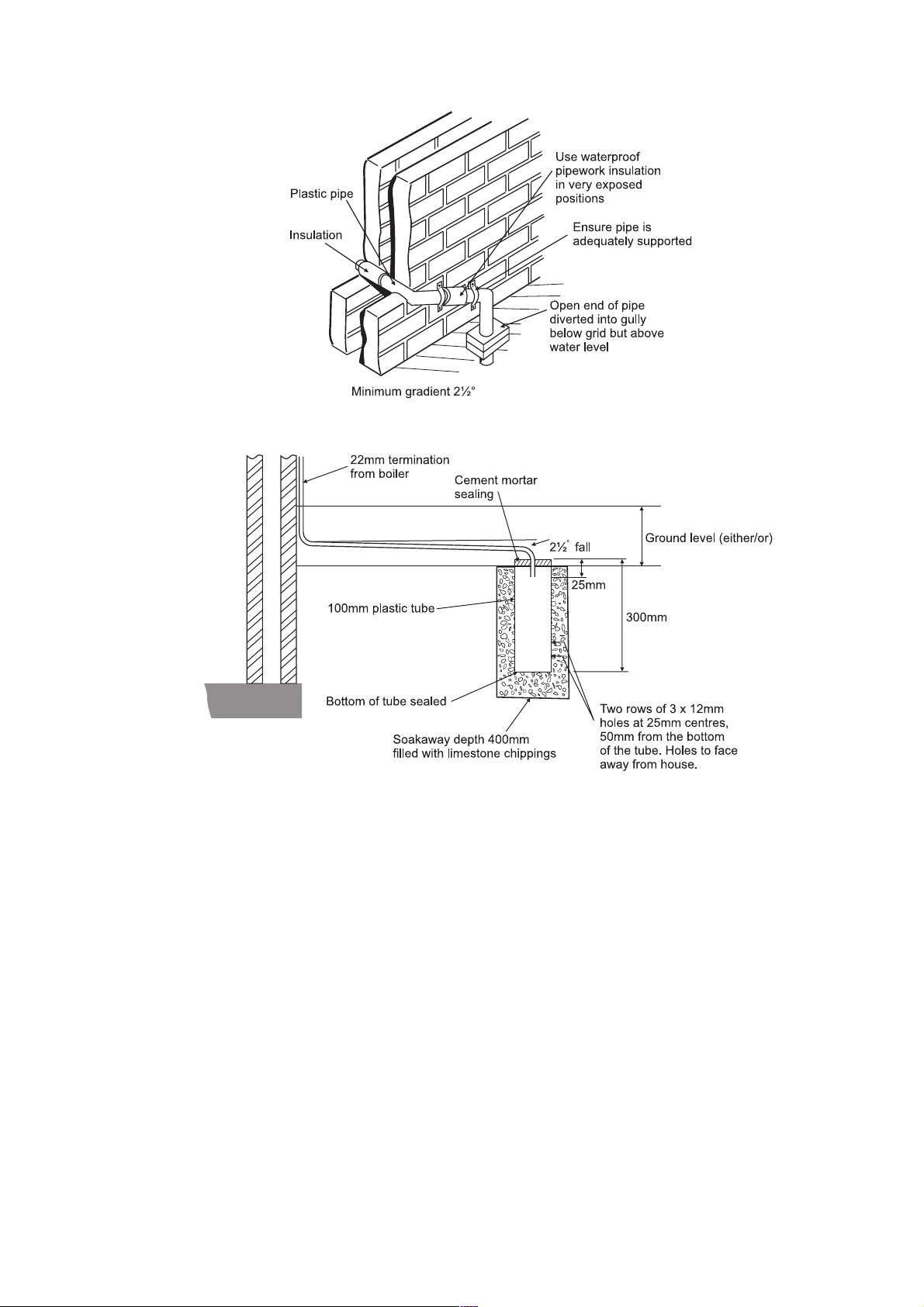

3.10 DISPOSAL OF CONDENSATE

Provision must be made for the safe disposal of condensate produced by the flue gases of the Alpha CD boilers and reference

should be made to BS 6798: 2000 for the requirements on the disposal of condensate.

The boilers incorporate a condensate trap which has a seal of 75 mm, therefore no additional trap is required.

The condensate should ideally be discharged internally into an internal waste pipe (washing machine/sink waste) or soil pipe to

avoid the possible risk of freezing. The pipework must be in 22 mm pipe.

External pipe runs should be avoided, but if it is necessary, the pipework should be at least 32 mm and protected from the risk

of freezing with a waterproof insulation and the length should be kept to a maximum of 3 m. Termination should be into an

external gulley or soakaway as shown in Figs. 8 and 9.

Note: All pipework must have a continuous fall (see Figs. 8 and 9) from the boiler and must be of an acid resistant material

such as plastic waste pipe. (copper or steel is not suitable).

It should be noted that the connection of a condensate pipe to a drain may be subject to local building control requirements.

Alpha CD24C/32C - General Boiler Information

10

Fig. 8 - External gully

Fig. 9 - External soakaway

3.11 DOMESTIC HOT WATER SYSTEM

The minimum flow rate needed for the flow switch and burner to operate is 2.0 litres/min.

The incoming mains water pressure should be between 0.2 and 8 bar to ensure efficient operation. If the pressure is above 7 bar

a pressure reducing valve must be fitted.

To ensure economic use, the pipe runs between the boiler and taps should be in 15 mm copper pipe and be as short as

possible. Where possible the pipework should be insulated to reduce heat loss.

All taps and mixing valves used with the hot water system must be suitable for operating at a mains pressure of up to 8 bar.

Showers - A shower may be used with the boiler if required.

If a loose or flexible head type shower is used it may require the fitting of a double check valve, to comply with Water Bye Law 17.

Bidets - No anti-syphonage arrangements are necessary, provided the outlets are shrouded and it is not possible to attach a

temporary hand held spray. A supply of direct mains fed hot and cold water is permitted provided the appliance is of the overrim flushing type.

Before the mains water supply pipe is connected to the boiler, it should be thoroughly flushed out to avoid the danger of dirt or

foreign matter entering the boiler.

Alpha CD24C/32C - General Boiler Information

11

4 INSTALLATION

4.1 UNPACKING

1. The boxes required when the boiler is installed with a horizontal flue are as follows:-

Box 1 Cased boiler fitted with water and gas valves, filling loop, union bends and washers

Mounting bracket plus screws and wall plugs

Literature pack and Wall template

Box 2 CD Easy-Flue 500 mm or CD Easy-Flue 1000 mm. Both include 90° bend and horizontal flue terminal

Note: NOT required for vertical flue

Notes: a. All flues must be suitable for CD condensing boilers.

b. CD 750 mm and 1000 mm flue extensions are available, if required.

2. Unpack boiler and remove the loose items packs and mounting bracket.

Note: The boiler can be stood in an upright position, (to allow this, the union bends have been turned upwards so that

they do not protrude beneath the bottom - check this before standing the boiler upright).

4.2 CLEARANCES REQUIRED - Fig. 10

A = 345 mm for CD24

A = 380 mm for CD32

Fig. 10

4.3 PREPARE THE WALL - Figs. 11, 12

1. Decide upon the position of the boiler taking into

account the clearances required for servicing and

the flue terminal position.

2. Tape the template to the wall (ensure it is level and

the right way up) and mark the position of the holes

for the boiler mounting bracket and bottom fixings. If

rear exit flue is used, mark the position of the hole

for the flue.

3. Side exit flue - Continue the horizontal centre line of

the flue across the wall to the side wall, then along the

side wall 165 mm (ensure the lines are horizontal). This

will give the position of the centre of the hole for the flue.

4. Cut the 110 mm diameter hole (or use a 107 mm

core drill) in the wall for the flue.

Notes: a. Ensure the hole is horizontal.

b. For internal fitting of the flue, using the

flue sealing collar supplied, cut a 130 mm

dia. flue hole using a 127 mm core drill.

5. Drill the fixing holes (10 mm dia.) to accept the No.10

plugs supplied. Using the screws supplied, fit the

mounting bracket.

6. Top pipe connections - Preform the pipework at the back of the boiler before hanging the boiler, see Fig. 12, and secure in

the clips provided.

Fig. 11

Alpha CD24C/32C - Installation

12

Loading...

Loading...