Supplementary LPG Boiler

Instructions

Alpha CD25C/28C/35C

Wall Mounted, Fan Assisted, Room Sealed, Gas Fired

High Efficiency Condensing Boilers

For Technical help or for Service call ...

ALPHA HELPLINE Tel: 0870 3001964

website:www.alpha-innovation.co.uk

Nepicar House, London Road,

Wrotham Heath, Sevenoaks,

Kent TN15 7RS

British Gas

Service Listed

Alpha CD25C British Gas G.C. No. 47 532 32

0051

Alpha CD28C British Gas G.C. No. 47 532 34

Alpha CD35C British Gas G.C. No. 47 532 36

For use with LPG (Propane) only

Leave these instructions with the User

1 INTRODUCTION

This supplement is for the LPG model of the boiler; it must be read in conjunction with the 'Installation and Servicing

Instructions' supplied with the boiler and provides the extra information which is particular to LPG.

The Alpha CD25C, CD28C and CD35C are combination boilers providing both central heating and domestic hot water at

mains pressure.

The boilers are designed for use with a fully pumped, sealed and pressurised heating system using only PROPANE gas.

2 TECHNICAL DA T A

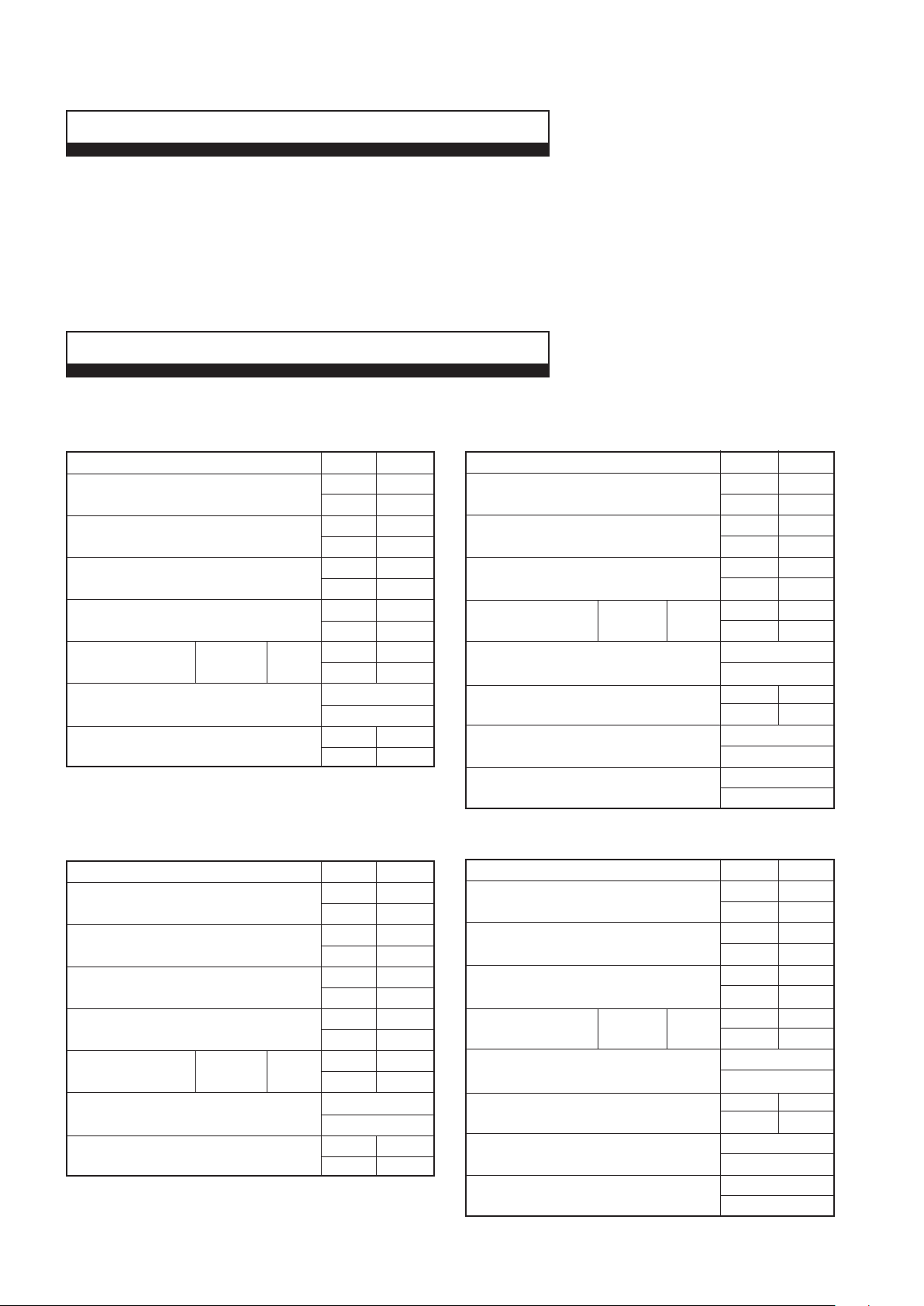

PERFORMANCE - PROPANE GAS (CAT I3P 3P - G31 - 37 mbar)

Alpah CD25C

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) kW

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Differential Burner mbar

Pressure in wg

Room sealed

chamber panel

fitted

Gas Supply Pressure (LPG) mbar

in wg

Gas Rate (LPG) m³/h

ft³/h

MAX.

20.4

69 600

18.4

62 780

19.5

66 550

18.0

61 420

3.15

1.26

0.78

27.6

21 800

19 780

20 820

18 780

37.0

14.8

MIN.

6.4

5.8

6.1

5.5

0.4

0.16

0.24

8.5

Alpha CD25C

Domestic Hot Water

Heat Input (H

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Output to Water (Hs)kW

(modulating) Btu/h

Differential Burner mbar

Pressure in wg

Gas Supply Pressure (LPG) mbar

Gas Rate (LPG) m³/h

Flow Rate at 35°C Rise L/min

Specific Flow Rate (D) at 30°C Rise L/min

(Flow rate @ 30K to EN625) gal/min

Alpha CD28C Alpha CD28C

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) kW

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Differential Burner mbar

Pressure in wg

Room sealed

chamber panel

fitted

Gas Supply Pressure (LPG) mbar

in wg

Gas Rate (LPG) m³/h

ft³/h

MAX.

27.1

92 400

24.4

83 250

25.9

88 400

24.0

81 900

7.27

2.9

1.04

36.7

MIN.

24 900

22 500

23 500

21 500

0.64

0.26

37.0

14.8

0.28

7.3

6.6

6.9

6.3

9.8

Domestic Hot Water

Heat Input (H

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Output to Water (Hs)kW

(modulating) Btu/h

Differential Burner mbar

Pressure in wg

Gas Supply Pressure (LPG) mbar

Gas Rate (LPG) m³/h

Flow Rate at 35°C Rise L/min

Specific Flow Rate (D) at 30°C Rise L/min

(Flow rate @ 30K to EN625) gal/min

MAX.

)kW

s

26.7

91 100

21 960

24.1

82 200

19 780

24.3

Room sealed

chamber panel

fitted

84 800

6.10

2.44

18 780

37.0

in wg

14.8

1.02

ft³/h

36

9.6

gal/min

2.2

11.2

2.5

MAX.

)kW

s

31.6

107 900

24 900

28.5

97 200

22 500

28.7

Room sealed

chamber panel

fitted

97 900

9.06

3.62

21 500

37.0

in wg

14.8

1.21

ft³/h

42.7

11.4

gal/min

2.5

13.3

2.9

MIN.

6.4

5.8

5.5

0.40

0.16

0.24

8.5

MIN.

7.3

6.6

6.3

0.64

0.26

0.28

9.8

CD25C/28C/35C LPG Supplement

2

Alpha CD35C

Central Heating

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Heat Output (Hs condensing) kW

(50°C/30°C) Btu/h

Heat Output (Hi non-condensing) kW

(80°C/60°C) Btu/h

Differential Burner mbar

Pressure in wg

Room sealed

chamber panel

fitted

Gas Supply Pressure (LPG) mbar

in wg

Gas Rate (LPG) m³/h

ft³/h

MAX.

31.6

107 800

28.5

97 200

30.3

103 400

28.0

95 550

2.49

1.0

1.21

42.7

30 600

27 600

29 000

26 600

37.0

14.8

%CO2 content (± 0.2%) Sedbuk rating

Boiler model

CD25C

CD28C

CD35C

LPG (propane) Efficiency

Min

10.0

10.1

9.1

CH Max

10.7

10.6

10.7

DHW max

10.6

10.6

10.8

MIN.

8.9

8.1

8.5

7.8

0.23

0.09

0.34

12.0

Alpha CD35C

Domestic Hot Water

Heat Input (H

)kW

s

(Gross) Btu/h

Heat Input (Hi)kW

(Net) Btu/h

Output to Water (Hs)kW

(modulating) Btu/h

Differential Burner mbar

Pressure in wg

Room sealed

chamber

panel fitted

Gas Supply Pressure (LPG) mbar

in wg

Gas Rate (LPG) m³/h

ft³/h

Flow Rate at 35°C Rise L/min

gal/min

Specific Flow Rate (D) at 30°C Rise L/min

(Flow rate @ 30K to EN625) gal/min

band

A

A

A

SAP efficiency

(%)

91.9

91.6

92.4

NOx class

5

5

5

MAX.

38.0

129 600

34.3

117 000

34.6

118 100

3.43

1.37

1.46

51.5

MIN.

8.9

30 600

8.1

27 600

8.0

27 300

0.23

0.09

37.0

14.8

0.34

12.0

14.2

3.13

15.6

3.44

2.3 GAS SUPPLY

The Alpha CD25C boiler requires a gas rate of 1.87 kg/h (4.0 lb/h) or 3.6 litres/h of liquid gas.

The Alpha CD28C boiler requires a gas rate of 2.22 kg/h (4.8 lb/h) or 4.2 litres/h of liquid gas.

The Alpha CD35C boiler requires a gas rate of 2.67 kg/h (5.7 lb/h) or 5.0 litres/h of liquid gas.

The supply pipes must be capable of delivering this quantity of gas in addition to the demand from any other appliances in the

house. The boilers require at least a 22 mm gas supply pipe.

The complete installation must be tested for gas soundness against leakage.

The local Propane gas supplier should be consulted, at the installation planning stage, in order to establish the availability of an

adequate supply of gas.

3 BOILER LOCATION

Installation pipes, cylinders and pressure regulators should be fitted in accordance with BS 5482:1. Bulk tank installation must

comply with the requirements of the Home Office code of practice for the storage of liquefied petroleum gas at fixed installations.

The boiler must not be installed in a room or internal space below ground level, e.g. in a basement or cellar, except where at

least one side is open to ground level.

4 INST ALLATION

In addition to the regulations and requirements stated in the Installation and Servicing instructions, the boiler must be installed

in accordance with BS 5482:1 - The Installation of Propane Burning Appliances in Permanent Dwellings.

CD25C/28C/35C LPG Supplement

3

5 COMMISSIONING

The boiler has been tested and factory set for use with Propane gas and it should only be necessary to ensure the correct gas

supply pressure of 37 mbar is available.

6 P ARTS LIST

Only the main burner injectors are special to Propane boilers. For other 'Short List Spare Parts', refer to the Installation and

Servicing instructions supplied with the boiler.

Propane components

Main burner injector - CD25C and 28C

Main burner injector - CD35C

Qty.

1

1

Type

4.0 mm

5.4 mm

Alpha Part No.

1.022509

1.024388

7 SERVICING

When servicing or replacing boiler components follow the procedures as described in the main Installation and Servicing

instructions supplied with the boiler.

Remembering the parts special for Propane boilers and the burner pressures special to Propane boilers given in this leaflet.

DETAILS OF BOILER INSTALLATION

Date of Installation: ......................................................................

Name of Installer: ........................................................................

Address: ......................................................................................

....................................................................................................

....................................................................................................

....................................................................................................

Postcode: ....................................................................................

Telephone No: .............................................................................

Boiler Serial Number: (LPG) ........................................................

(see inside controls panel hinged cover)

Alpha Therm Limited.

Nepicar House, London Road, Wrotham Heath,

Sevenoaks, Kent TN15 7RS

Tel: 0870 3001964

email: info@alphatherm.co.uk

website: www.alpha-innovation.co.uk

Leaflet compiled and designed by Publications 2000 - Tel: (01670) 356211 11/08/D232

These instructions have been carefully prepared but we reserve the right to

alter the specification at any time in the interest of product improvement.

© Alpha Therm Limited 2008.

Part No. 1.024987

Loading...

Loading...