Instructions for adjusting the PCB and

Honeywell gas valve

Alpha CD24C, 32C and CD18S, 24S, 30S

and CD50 Boiler Range

1. GENERAL

When the printed circuit board (PCB) or Honeywell gas valve have been replaced or require adjustment, the following

must be carried out:-

a. Check and adjust (if necessary) the CO2 content of the exhaust flue gases.

Note: A flue gas combustion analyser is required for these measurements. Also a 'star drive' screwdriver will be

required to adjust the gas valve.

b. Check and adjust (if necessary) the burner pressures.

Note: A differential pressure gauge will be required to enable the pressure to be correctly set.

c. Set the maximum DHW output.

d. Set the maximum CH output.

e. Ensure that all electrical plugs and connectors are pushed fully home and soundly connected.

Note: Before fitting a new PCB ensure the polarity of the electrical supply is correct by testing the supply, using a

suitable multimeter, as follows:

Live to Neutral 240 Volts AC

Live to Earth 240 Volts AC

Neutral to Earth zero Volts AC

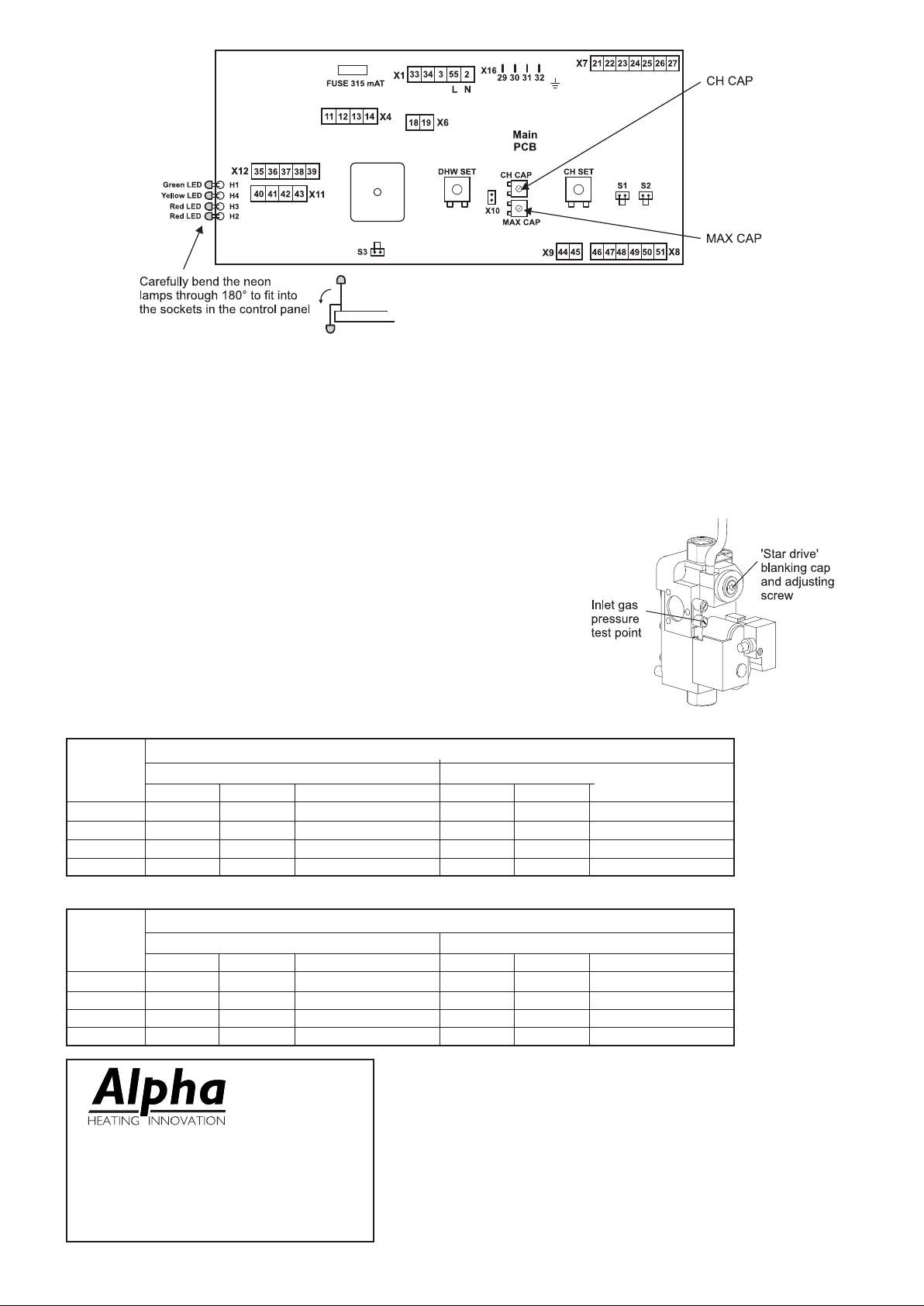

Note: Before fitting the PCB, carefully bend the four neons through 180° so that they locate into the control

panel, see Fig. 3.

2. FIT THE REPLACEMENT PCB AND/OR GAS VALVE

Refer to the Installation and Servicing instructions to gain access to and replacement of the PCB and/or gas valve.

3. ADJUST THE PCB AND GAS V AL VE TO THE CORRECT SETTINGS

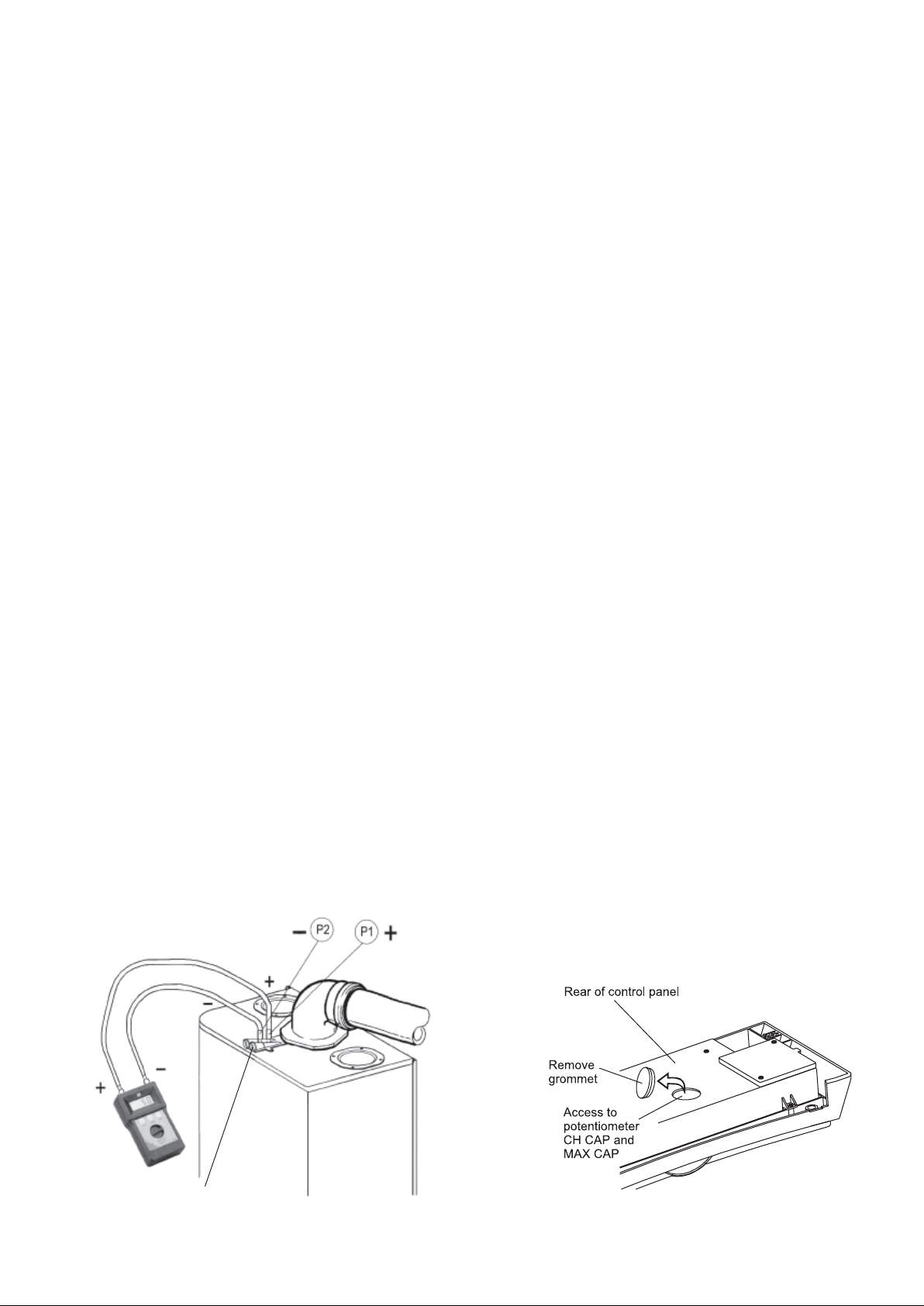

a. Remove the screws from the pressure test points P1 and P2 and connect a differential pressure gauge to the test

points as shown in Fig. 1. Remove the screw plug and place the flue gas analyser probe into the flue sampling

point (marked 'F' on the boiler).

b. Remove the grommet in the rear of the control panel (see Fig. 2) to gain access to the PCB. Using a small

screwdriver turn the 'CH CAP' potentiometer fully clockwise to maximum output, see Fig. 3.

Flue sample point

(marked 'F')

Fig. 1

Fig. 2

Fig. 3

c. Turn the selector switch to the reset position until the neon 'A' (red) is illuminated. This will operate the boiler at

maximum output for 10 minutes.

d. Allow the boiler to operate for 5 minutes to stabilise, then using a small screwdriver turn the 'MAX CAP'

potentiometer (clockwise to increase) until the maximum DHW pressure is obtained on the differential pressure

gauge (refer to table 1 for the correct pressure).

e. Adjust the 'CH CAP' potentiometer by turning screw fully anticlockwise to the minimum output position.

f. Measure the CO

the CO2% given in table 2 at the minimum output, then the gas valve must be adjusted.

content of the exhaust flue gas at the minimum output with the analyser. If the reading is not within

2

g. Using a 'star drive' screwdriver, remove the gas valve blanking cap, see

Fig. 4. Turn the inner screw clockwise to increase CO2 and anticlockwise to

reduce CO2 until the correct value is obtained. Replace the blanking cap.

h. Adjust the 'CH CAP' potentiometer (clockwise to increase) to give the maximum

CH output, i.e. set the burner pressure to the CH Max stated in table 1.

i. At the maximum outputs check that the CO

is approximately that given in table 2. If not, repeat the procedure.

content of the exhaust flue gas

2

j. Remove the analyser and pressure gauge and re-assemble in the reverse

order, ensuring that all the pressure test points and flue sampling points have

been refitted with the screws/cap removed and been tested for soundness.

Fig. 4

Table 1

Boiler

model

CD24C/S

CD32C/30S

CD50

CD18S

Min

0.35

0.39

0.27

0.3

Natural gas LPG (propane)

CH Max

5.78

3.33

2.91

3.5

Differential burner pressure (mbar)

DHW Max (if applicable)

5.78

4.27

3.7

-

Min

0.4

0.24

0.24

0.35

CH Max

6.7

4.16

4.16

3.9

DHW Max (if applicable)

6.7

5.9

5.7

-

Table 2

Boiler

model

CD24C/S

CD32C/30S

CD50

CD18S

Min

9.0

9.0

9.0

9.0

Natural gas LPG (propane)

CH Max

9.2

9.4

9.4

9.1

DHW Max (if applicable)

Alpha Therm Limited.

Nepicar House, London Road, Wrotham Heath,

Sevenoaks, Kent TN15 7RS

Tel: 0870 3001964

email: info@alphatherm.co.uk

website: www.alpha-innovation.co.uk

Manual compiled and designed by Publications 2000 - Tel: (01670) 356211 03/08/D217

%CO2 content (± 0.2%)

9.2

9.5

9.5

-

These instructions have been carefully prepared but we reserve the right to

alter the specification at any time in the interest of product improvement.

© Alpha Therm Limited 2008.

Min

9.7

10.0

10.0

9.7

CH Max

10.6

10.1

10.1

10.6

DHW Max (if applicable)

10.6

10.2

10.2

-

Loading...

Loading...