Page 1

APX Series

Non-standby Power Supply

®

APX Series

Installation and Operation Manual

Effective: April 2006

Alpha Technologies

Page 2

Alpha Technologies

Power

®

Page 3

APX Series

Non-standby Power Supply

016-030-B0-005, Rev C

Effective Date: April 2006

Copyright© 2006

Alpha Technologies, Inc.

A Member of the Alpha Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. iIf

there are questions regarding the safe operation of this powering system, please contact Alpha Technologies

or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

Contacting Alpha Technologies: www.alpha.com

or

For general product information and customer service (7 AM to 5 PM, Pacifi c Time), call

1-800-863-3930,

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacifi c Time or 24/7 emergency support

3016-030-B0-005, Rev. C

Page 4

Table of Contents

Safety Notes ..........................................................................................................................7

1.0 Introduction .................................................................................................................8

1.1 Operating Principle .......................................................................................... 8

1.2 Standard Confi gurations ................................................................................10

1.3 Optional Features .......................................................................................... 12

2.0 Installation.................................................................................................................14

2.1 Pole Mount Installations ................................................................................. 14

2.1.1 Wooden Poles ..................................................................................... 14

2.1.2 Concrete and Steel Poles ................................................................... 15

2.2 Wall Mount Installations .................................................................................16

2.3 Pedestal Mount Installations .......................................................................... 17

2.4 Rack Mount Installations ................................................................................ 20

2.5 Shelf Mount Installations ................................................................................ 23

2.6 Connecting Utility Power ................................................................................ 24

2.6.1 Wiring the Enclosure Utility Service .................................................... 24

2.7 External Service Disconnect ..........................................................................27

2.8 Modular Transformer Assembly (MTA) .......................................................... 29

2.9 AC Output Connection ...................................................................................31

2.10 Options........................................................................................................... 32

2.11 APX Output Voltage Reconfi guration ............................................................. 39

3.0 Operation ..................................................................................................................40

3.1 Start-up and Test ............................................................................................ 40

3.2 Shutdown and MTA Removal ......................................................................... 41

4.0 Troubleshooting and Repair ..................................................................................... 42

4.1 Return Procedure........................................................................................... 42

4.2 Replacement Parts ........................................................................................ 43

5.0 Specifi cations............................................................................................................ 44

5.1 APX Schematics ............................................................................................44

5.2 Specifi cations for APX.................................................................................... 46

4

016-030-B0-005, Rev. C

Page 5

List of Figures

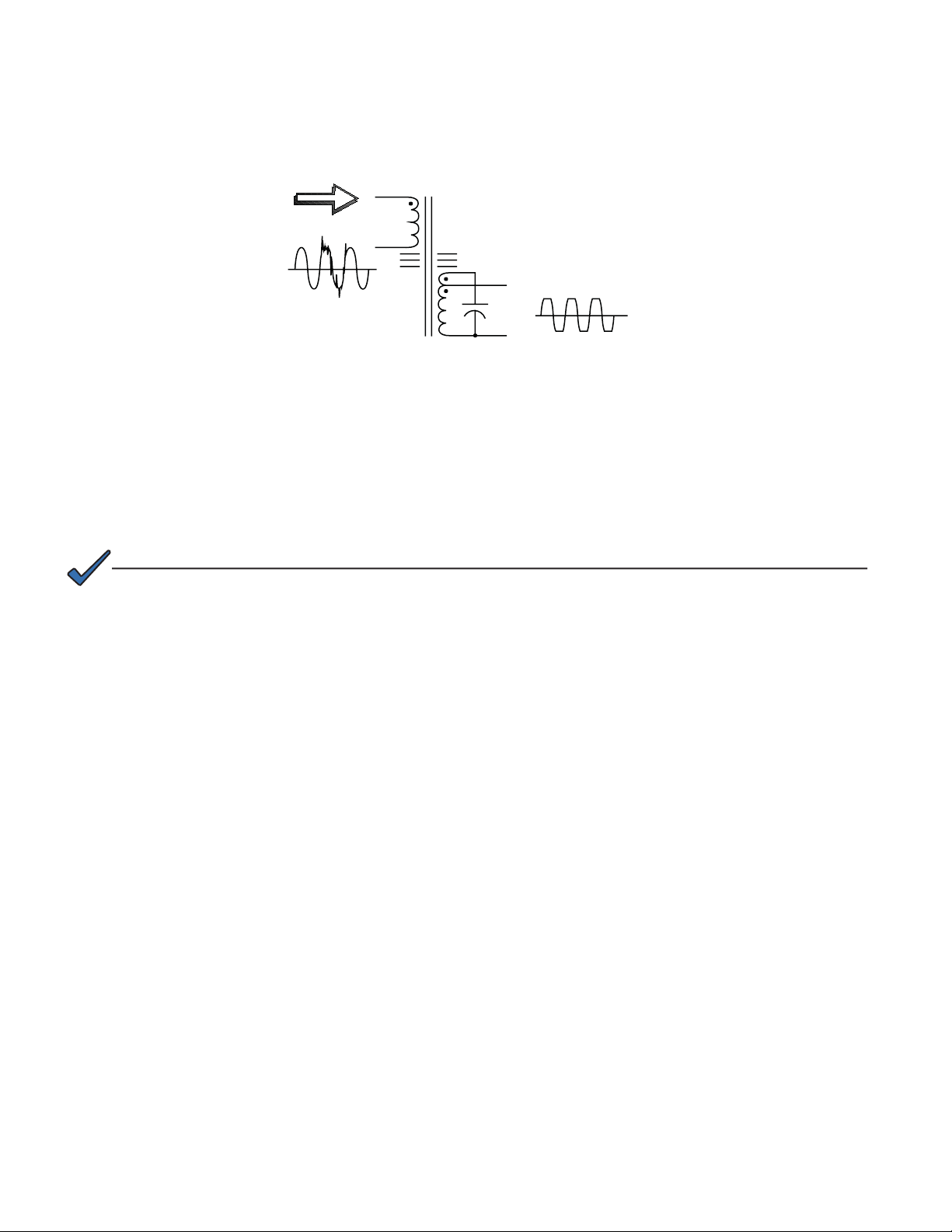

Fig. 1-1, Ferroresonant “Tank” Circuit and Resulting Output Waveform ..............................................9

Fig. 1-2, Pole Mount Enclosure ...........................................................................................................11

Fig. 1-3, APX Main Transformer Assembly ..........................................................................................11

Fig. 1-4, The Alpha APX (PM) and Installable Options1 ..................................................................... 13

Fig. 2-1, APX Enclosure Pole Mounting ............................................................................................. 15

Fig. 2-2, Wall Mount Installation ......................................................................................................... 16

Fig. 2-3, Stake Mounting Installed in PED .......................................................................................... 17

Fig. 2-4, PED Enclosure ..................................................................................................................... 18

Fig. 2-5, Soil-mount PED Enclosure Installed in Poured Concrete ....................................................18

Fig. 2-6, Concrete Pad Mounting ........................................................................................................ 19

Fig. 2-7, APX Rack Mount (120VAC Version) ..................................................................................... 20

Fig. 2-8, Option Placement and Power Connections .......................................................................... 21

Fig. 2-9, APX-E Rack Mount (230VAC Version) ................................................................................. 21

Fig. 2-10, Shelf Mount (SM) ...............................................................................................................22

Fig. 2-11, PED-M, PWE or UPE Enclosure Mounting ....................................................................... 23

Fig. 2-12, PED-M, PWE or UPE Enclosure Mounting ....................................................................... 23

Fig. 2-13, APX Bottom View ...............................................................................................................24

Fig. 2-14, 120VAC/60Hz Wiring .......................................................................................................... 25

Fig. 2-15, APX 230VAC/50Hz Wiring .................................................................................................. 26

Fig. 2-16, Service Entrance/Meter Connections, 120VAC .................................................................. 28

Fig. 2-17, Service Entrance/Meter Connections, 240VAC .................................................................. 28

Fig. 2-18, MTA Mounted on Baseplate Assembly of PM Enclosure ................................................... 30

Fig. 2-19, Universal Bracket for PED-mount ......................................................................................30

Fig. 2-20, Cable Connector/Output Port Assembly ............................................................................. 31

Fig. 2-21, SIL-C Installed in Baseplate ............................................................................................... 32

Fig. 2-22, LA-M Inserted into Receptacle Box ................................................................................... 33

Fig. 2-23, LA-P Inserted into Receptacle ............................................................................................ 33

Fig. 2-24, LA-E Option (230VAC models) Mount Under Receptacle Box ........................................... 34

Fig. 2-25, LA-E Installation ................................................................................................................. 35

5016-030-B0-005, Rev. C

Page 6

List of Figures, continued

Fig. 2-26, AMM-C Ammeter Kit .......................................................................................................... 36

Fig. 2-27, AMM-C Install Steps ........................................................................................................... 36

Fig. 2-28, AMM-C Installation ............................................................................................................. 37

Fig. 2-29, TDR-M Potentiometer ........................................................................................................37

Fig. 2-30, TDR-M and ACAT-3P Options Installed in the APX ............................................................ 38

Fig. 2-31, ACAT-3P and TDR-M Installed in the APX Rack Mount ..................................................... 38

Fig. 3-1, APX Circuit Breaker and Fuse Location ...............................................................................40

Fig. 3-2, Shutdown and MTA Removal ............................................................................................... 41

Fig. 4-1, APX Schematic ..................................................................................................................... 44

Fig. 4-2, APX 90V Schematic ............................................................................................................. 45

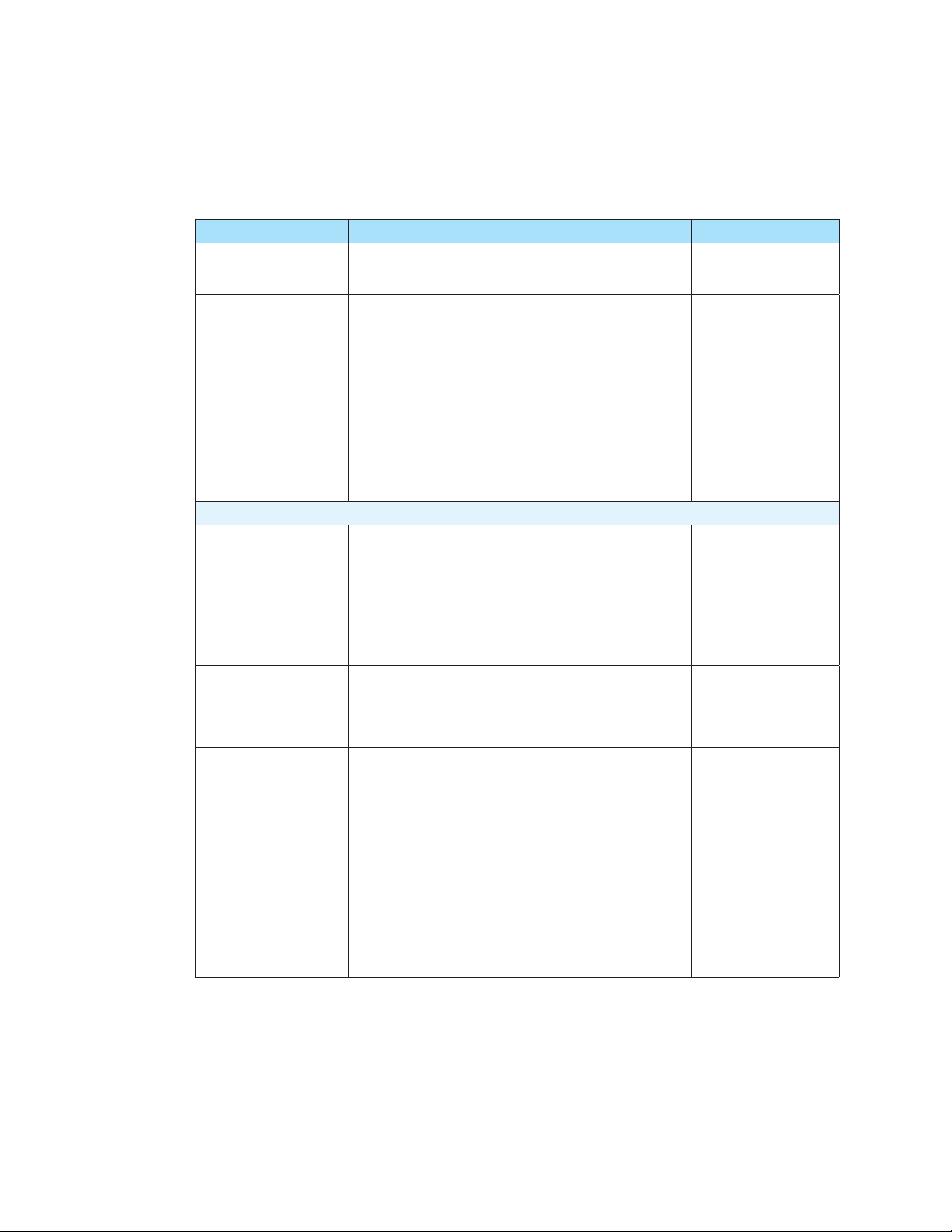

List of Tables

Table 1-1, Standard Features ............................................................................................................. 10

Table 1-2, Optional Features .............................................................................................................. 12

Table 2-1, High-Magnetic Breakers for Square D Service Entrances ................................................. 27

Table 2-2, APX Output Voltage Reconfi guration ................................................................................. 39

Table 4-1, Troubleshooting Guide ....................................................................................................... 42

Table 4-2, Replacement Parts ............................................................................................................ 43

Table 5-1, APX Series Specifi cations ................................................................................................. 46

6

016-030-B0-005, Rev. C

Page 7

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any

questions regarding the safe installation or operation of the system, contact Alpha Technologies or the

nearest Alpha representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the

following symbols have been placed throughout this manual. Where these symbols appear, use extra

care and attention.

ATTENTION:

The use of ATTENTION indicates specifi c regulatory/code requirements that may affect the placement

of equipment and installation procedures.

NOTE:

A NOTE provides additional information to help complete a specifi c task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material

or equipment.

WARNING!

A WARNING presents safety information to PREVENT INJURY OR DEATH to the

technician or user.

7016-030-B0-005, Rev. C

Page 8

1.0 Introduction

The Alpha APX Series Non-standby Power Supply provides conditioned power to signal amplifi ers in

cable television and broadband distribution systems. The modular design, consisting of a baseplate,

transformer assembly and enclosure cover, supplies the load with current-limited, regulated AC

power, that is free from spikes, surges and other forms of power line transients. The design supports

easy upgrades simply by replacing the transformer assembly, saving time and money.

Alpha’s non-standby power supplies are extremely effi cient, with a typical effi ciency rating of 90% or

better.

The versatile APX Series includes an AC input circuit breaker, output fuse, *output receptacle,

VSF fi tting, and external grounding clamp and can be mounted on poles, walls, racks, shelves, or

pedestals. Operator controls are inside the enclosure on the main transformer assembly.

You can equip the APX with various options, including a *Time Delay Relay (TDR-M), Plug-in

Lightning Arrestor (LA-M), Status Indicator LED (SIL-C), plug-in *Amp-Clamp (ACAT-3P), *Ammeter

(AMM-C), and Enclosure Security Lock (GLK). See Section 1.3 for a complete description of all

available options

1.1 Operating Principle

The Alpha Modular Transformer Assembly (MTA) contains the ferroresonant transformer,

resonant circuit capacitor, and control panel with line input circuit breaker and output fuse

assembly.

The Ferroresonant Transformer

Alpha APX Series uses ferroresonant transformer technology to provide line conditioning and

voltage regulation. The primary and secondary windings of the transformer are physically

isolated from each other by a large steel core which signifi cantly reduces the capacitive

coupling of spikes and noise to the secondary winding. This provides a regulated, currentlimited output with excellent isolation and noise attenuation, (120dB common mode and 60dB

transverse mode).

Another unique feature of the ferroresonant transformer is its ability to provide current limiting

in the event of a short circuit. This effect is called foldback. The transformer’s output current

can typically reach 150% of the nameplate output current rating for a short period of time

without damage to the transformer. When the transformer reaches the saturation point, the

output current will decrease (foldback on itself) to a minimum value, and thereby provide

current limiting. Designs based on ferroresonant transformer are extremely rugged and

reliable offering many years of trouble-free operation.

The Resonant Circuit Capacitor

An oil-fi lled resonant AC capacitor is connected to the resonant (secondary) winding of

the transformer forming a tank circuit. This provides the resonant circuit function which

contributes to the voltage regulation of the supply. The advantage of this type of transformer/

capacitor design is the ability of the ferroresonant transformer to regulate its output voltage

over a wide range of input voltages and output loading. Typical output voltages may vary

+/- 3% to 5%, with input voltages variations of +/- 15% of nominal line voltage, and output

loading of 20% to 100%. This tight regulation is advantageous in cable television applications

as the active devices are protected from dangerous voltages fl uctuations.

8

016-030-B0-005, Rev. C

Page 9

1.0 Introduction, continued

1.1 Operating Principle, continued

T1

Ferroresonant Transformer and AC Capacitor

Noisy Input Waveform

Fig. 1-1, Ferroresonant ‘Tank’ circuit and resulting output waveform

AC power enters the module where it is converted to a “quasi” square wave and regulated (at

the required output voltage). It is then passed on to the load via the VSF fi tting located on the

baseplate assembly.

NOTE:

A true RMS voltmeter must be used to correctly measure the output voltages.

C1

Clean Output Waveform

9016-030-B0-005, Rev. C

Page 10

1.0 Introduction, continued

1.2 Standard Confi gurations

The APX Series non-standby power supplies are available in the following confi gurations:

Available Confi gurations Description

APX 6008 120VAC, 60Hz Input; 8A, 480VA, 60V Output; available in

APX 6014 120VAC, 60Hz Input; 14A, 840VA, 60V Output; available in

APX 6008 E 230VAC, 50Hz Input; 8A, 480VA, 60 or 48V Output;

APX 6014 E 230VAC, 50Hz Input; 14A, 840VA, 60 or 48V Output;

APX 4808 E 230VAC, 50Hz Input; 8A, 384 VA, 48V Output; available in

APX 6008 P 220VAC, 60Hz Input; 8A, 480VA, 60V Output; available in

APX 6014 P 220VAC, 60Hz Input; 14A, 840VA, 60V Output; available in

APX 9015 120VAC, 60Hz Input; 15A, 60, 75 or 90V Output;

APX 9015 240VAC, 60Hz Input; 15A, 60, 75 or 90V Output; available

Pole, Rack, Wall, Shelf, or Pedestal Mount confi gurations.

Includes: 8A thermal input circuit breaker, 120VAC output

receptacle and 10A output fuse.

Pole, Rack, Wall, Shelf, or Pedestal Mount confi gurations.

Includes: 12A thermal input circuit breaker, 120VAC output

receptacle and 15A output fuse.

available in Pole, Rack, Wall, Shelf, or Pedestal Mount

confi gurations. Includes: 8A thermal input circuit breaker,

230VAC output receptacle and 10A output fuse

available in Pole, Rack, Wall, Shelf, or Pedestal Mount

confi gurations. Includes: 12A thermal input circuit breaker,

230VAC output receptacle and 15A output fuse.

Pole, Rack, Wall, Shelf, or Pedestal Mount confi gurations.

Includes: 8A thermal input circuit breaker, 230VAC output

receptacle and 10A output fuse.

Pole, Rack, Wall, Shelf, or Pedestal Mount confi gurations.

Includes: 8A thermal input circuit breaker, 120VAC output

receptacle and 10A output fuse.

Pole, Rack, Wall, Shelf, or Pedestal Mount confi gurations.

Includes: 12A thermal input circuit breaker, 120VAC output

receptacle and 15A output fuse

available in Pole, Rack, Wall, Shelf, or Pedestal Mount

confi gurations. Includes: 20A thermal input circuit breaker,

120VAC output receptacle and 20A output fuse

in available in Pole, Rack, Wall, Shelf, or Pedestal Mount

confi gurations. Includes: 10A thermal input circuit breaker,

240VAC output receptacle and 20A output fuse.

10

Table 1-1, Standard Confi gurations

016-030-B0-005, Rev. C

Page 11

1.0 Introduction, continued

1.2 Standard Confi gurations, continued

Main Transformer Assembly

(MTA)

Baseplate

Assembly

Enclosure

Cover

Holes for

Padlock

Fig. 1-2, Pole Mount Enclosure

Fig. 1-3, APX Main Transformer Assembly

11016-030-B0-005, Rev. C

Page 12

1.0 Introduction, continued

1.3 Optional Features

You can equip the APX Series with the following options.See Section 2.10, for installation

instructions.

Option Description Part Number

GLK

Enclosure Locks

LA-M

Plug-in Lightning Arrestor

LA-E (230VAC)

SIL-C

Status Indicator LED

The following options are available for the APX Series power supplies only

AMM-C

Ammeter

Security lock for pole mount enclosures. PM models are

equipped with a security hole to accomodate a standard

padlock.

The LA-M is a 350 joule, Metal Oxide Varistor (MOV) for

primary site protection. It provides protection from voltage

spikes caused by lightning and other disturbances. The

LA-M is enclosed in plastic housing and plugs directly into

a dedicated receptacle, eliminating the need for additional

wiring.

LA-E housed in an aluminum enclosure and must be hard

wired into the APX.

Indicates that the APX is supplying AC output to the load

and can be viewed from outside the enclosure. The light

(red) remains ON as long as power is present at the

modules output.

Displays the output current to the load. It is also useful as a

status indicator: a zero reading indicates no output current

is being drawn by the load, a pegged meter indicates a

short circuit condition in the plant.

GLK-PED: 740-263-22;

GLK-PM: 744-229-21

LA-L120V: 744-173-20;

LA-E240V: 744-174-20

LA-P+120V:020-098-24

LA-M120V: 020-116-21

(x2 for 240V)

740-239-21

10A :

740-238-21

15A :

740-238-22

TDR-M

Plug-in Time Delay Relay

ACAT-3P

Plug-in Amp Clamp

In the event of a AC utility line outage and subsequent

voltage return, the TDR-M delays power to the output for 10

to 60 seconds, thereby providing time for the line voltage

to stablize and reducing possible noise spikes and other

transients.

Protects active and passive equipment from voltage surges

and transients. Provides “Crowbar” clamping protection

from voltage spikes in excess of 104V.

Consists of two rugged SCR’s (silicon controlled rectifi ers)

connected in an inverse parallel confi guration with a steady

state current of 35A and a one cycle (8 ms) pulse rating of

500A. The SCR’s are triggered into conduction whenever

the Amp Clamp’s bidirectional trigger diodes senses the

presence of voltage transients exceeding 104-115V peak

threshold. The fast response trigger circuit gates the

appropriate SCR ON (in nanoseconds) to shunt the surge

current to ground, effectively protecting sensitive equipment

from transient overvoltage conditions.

Table 1-2, Optional Features

15A:

(9015 only)

744-594-20

60V:

020-114-21

90V:

020-114-23

60V:

020-115-21

90V:

020-115-23

12

016-030-B0-005, Rev. C

Page 13

1.0 Introduction, continued

1.3 Optional Features, continued

See Table 1-1 for a complete description of these features.

Modular

Transformer

Assembly (MTA)

GLK

Enclosure

Locks

®

Enclosure

Cover

ACAT-3P

TDR-M

LA-M

SIL-C

AMM-C

Fig. 1-4, The Alpha APX (PM) and Installable Options

13016-030-B0-005, Rev. C

Page 14

2.0 Installation

2.1 Pole Mount Installations

The APX-PM can be mounted on wooden, steel, or concrete poles. Most local codes require

that the base of the enclosure be at a minimum height from the ground. Always verify height

restrictions before proceeding.

NOTE:

Poles are typically the property of the local utility. The utility must approve both the location and the

method used to mount the APX before installation.

NOTE:

Before installing the MTA, verify that all options have been installed and properly connected.

2.1.1 Wooden Poles

For wooden poles, use mounting bolts that completely penetrate the pole.

Materials Required:

Two (2) 5/8" diameter machine bolts (UNC thread) SAE Grade 5 or better, length

•

to suit pole

Four (4) 5/8" diameter zinc-plated fl at washers

•

Two (2) 5/8" diameter hex nuts (UNC thread)

•

Tools Required:

Auger or drill for boring 3/4" diameter holes through the wooden pole

•

•

Associated sockets or wrenches

Procedure:

1.

Remove the APX from the shipping container and set the unit on its back (mounting bracket down).

Loosen the enclosure front panel hold-down screw and tilt the cover forward.

2.

Remove the cover by sliding it (at the hinges) to the right.

Loosen the captive screw at the bottom of the baseplate. Lift the Modular

3.

Transformer assembly up and off of the baseplate. Set the MTA aside.

Mark the position for the upper mounting bolt on the utility pole. Drill a 3/4" hole

4.

completely through the pole.

Using the baseplate as a template, align the upper hole in the baseplate with the

5.

upper hole in the utility pole. Verify that the spacing between the marks is 4 1/2"

center to center. Drill the lower mounting hole.

Place a fl at washer on each bolt and insert the mounting bolts through the base-

6.

plate assembly and pole.

14

Secure both bolts using a 5/8" washer and nut. Tighten nuts until the fl anges on

7.

the baseplate mounting bracket dig into the wood approximately 1/4".

Install the Modular Transformer Assembly (MTA) onto the baseplate (see Section

8.

2.8).

016-030-B0-005, Rev. C

Page 15

2.0 Installation, continued

2.1 Pole Mount Installations, continued

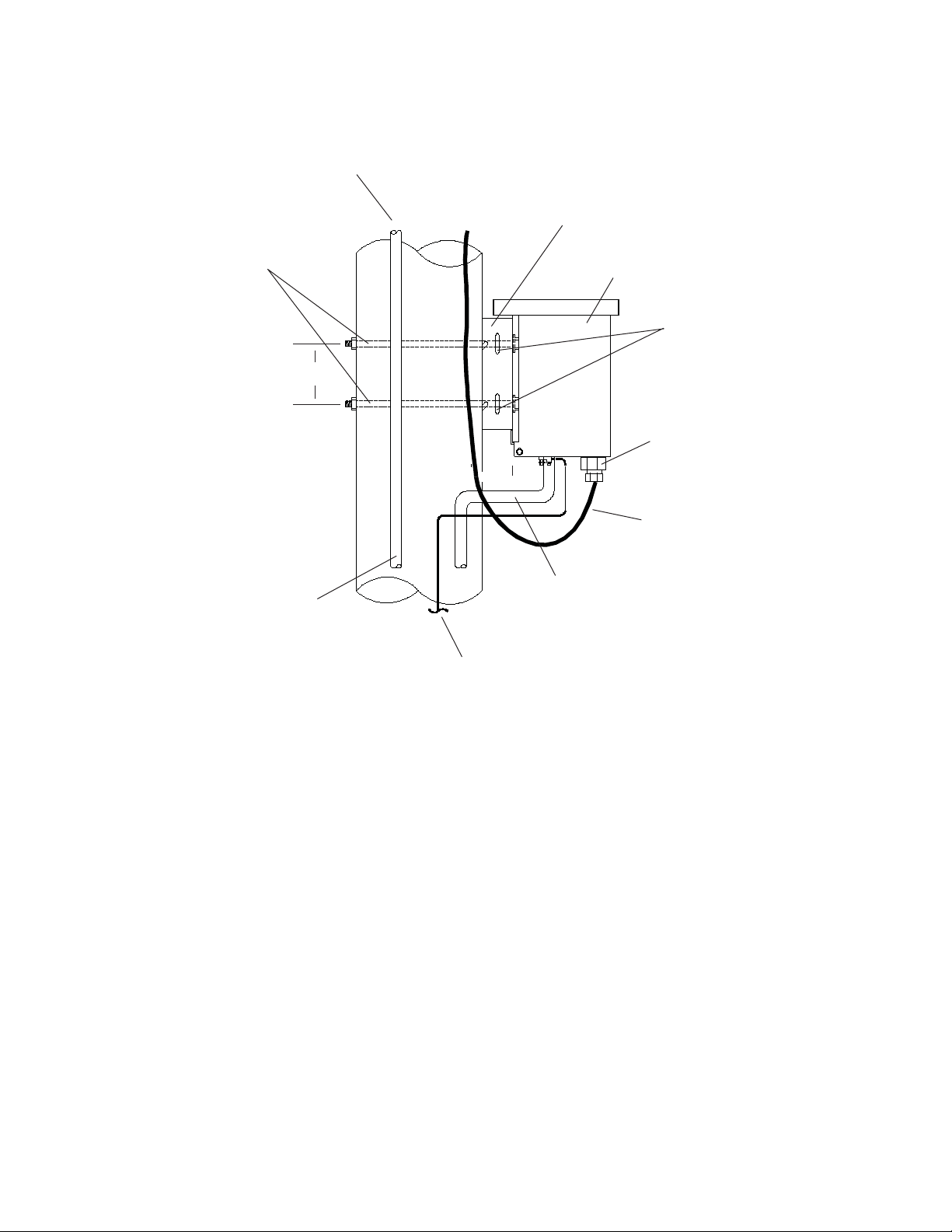

Service Drop

5/8" Diameter Bolts and

Associated Hardware

4 1/2”

center-center

Enclosure Mounting Bracket

APX Enclosure

NOTE: If mounting to a

steel or concrete pole, use

these two strap slots

VSF Output Connector

Cable Output

To Service

Entrance

#8 AWG (Minimum)

Copper Ground Wire

Fig. 2-1, APX Enclosure Pole Mounting

2.1.2 Concrete and Steel Poles

Materials Required:

Two (2) 1-1/2" approved mounting straps, length to suit pole.

Tools Required:

Assorted sockets or wrenches

Procedure:

Mark the position for the upper mounting strap on the utility pole.

1.

Run two approved 1-1/2" mounting straps through the mounting bracket located

2.

on the back of the baseplate assembly.

Utility Power Input

(from Service Entrance)

Center the baseplate assembly on the pole and tighten the mounting straps.

3.

Install the Modular Transformer Assembly (MTA) onto the baseplate (see Section

4.

2.8 for details).

15016-030-B0-005, Rev. C

Page 16

2.0 Installation, continued

2.2 Wall Mount Installations

The wall mount version is equipped with an adaptor bracket to ensure that the APX pole

mount enclosure can be mounted on a fl at, vertical surface. If the wall mount bracket cannot

be installed on a fl at, vertical surface and positioned over a wall stud (2x4; 2x6; etc), use

appropriate anchors and lag bolts.

NOTE:

Install and connect all optional features before you install the MTA.

Procedure:

Mark the location of the wall mounting holes, using

1.

the bracket as a template. The distance between the

holes is 4 1/2 inches center-to-center.

Drill the holes using a 1/4" drill bit. Mount the bracket

2.

to the wall using two 3/8" x 1 1/2" long steel lag bolts

and washers. The 1/4-20 (Phillips) screw must be

located in the upper right-hand side of the bracket

before you secure it to the wall.

1/4-20 Screw

(upper-right hand

side)

To mount the enclosure to the wall bracket, fi t the

3.

slots (in the APX enclosure bracket) over the rivets in

the wall bracket. The enclosure bracket fi ts over the

outside of the wall bracket.

Tighten the screw located on the upper-right corner of

4.

the wall bracket using a #2 Phillips head screwdriver.

Install the Modular Transformer Assembly (MTA) onto

5.

the baseplate. See Section 2.8 for details.

Align slots with rivets and screw

Wall Mounting

Holes

Step 1, Wall Bracket

Tighten screw

16

Step 2, Aligning slots

Fig. 2-2, Wall Mount Installation

Step 3, Tighten screw

016-030-B0-005, Rev. C

Page 17

2.0 Installation, continued

2.3 Pedestal Mount Installations

The pedestal mount (PED) is constructed of weather-resistant steel and is ideal for ground

mount applications. The PED model is supplied with a stake for soil-mounting applications.

An optional concrete mounting kit may be ordered for mounting to a concrete pad.

NOTE:

Before you install the MTA, fi rst install and connect optional features.

NOTE:

Install the pedestal enclosure above the fl ood plane and locate it in an area safe from damage caused

by traffi c accidents, lawn equipment, or other hazards.

CAUTION!

When you sink the stake into the soil be extremely careful not to damage any underground cabling,

utility wires, water or gas pipes. Your local utility company can tell you the location of these items.

Procedure: (Soil Mount)

Before proceeding, loosen the hex screw located on the right side of the enclosure. Lift off

the hood and remove the MTA (if installed), and Universal Bracket (UB1) from the PED. The

UB1 is secured by a wing-nut located near the top of the PED.

Locate the area to install the PED. Create a slight depression in the soil, 6" deep x 14"

1.

wide. This provides room to work while you are installing the PED, and additional security

and stability.

Drive the mounting stake into the soil at the chosen location, leaving about 6" of the stake

2.

above the soil depression. The stake must be completely vertical.

Place the PED over the utility and cable feeds. Align two of the holes in the back of the

3.

enclosure with two holes in the stake. Secure the enclosure to the stake using the two

bolts, washers and nuts provided.

Move soil around the outside of the enclosure to level the area. For additional stability,

4.

soil can be added inside of the enclosure to bring it level with the outside soil line.

Reinstall the UB1 Bracket and place the MTA on the bracket. Tighten the captive screw

5.

on the bottom of the UB1 to secure the MTA, (See Section 2.6 Connecting Utility Power,

and 2.8 Modular Transformer Assembly).

Fig. 2-3, Stake Mount

Installed in PED

17016-030-B0-005, Rev. C

Page 18

2.0 Installation, continued

2.3 Pedestal Mount Installations, continued

Wing nut

PED-Universal

Bracket (UB1)

PED Enclosure Hood

PED Enclosure

Base Unit

Mounting Stake

and Hardware

Fig. 2-4, PED Enclosure

NOTE:

If a more secure confi guration is required, mount the enclosure level with the surrounding soil (with no

depression), place a wooden form around the outside of the enclosure, and pour concrete to a depth of

3 or 4 inches.

®

18

Poured Concrete

3" to 4"

Mounting Stake

Cable

Utility

Fig. 2-5, Soil Mount PED Enclosure Installed in Poured Concrete

016-030-B0-005, Rev. C

Page 19

2.0 Installation, continued

2.3 Pedestal Mount Installations, continued

You can mount the PED enclosure to a concrete pad using the optional mounting bracket.

The bracket mounts inside the rear of the enclosure using two hex bolts and washers. There

are two 0.5" oblong mounting holes in the bracket to mount the enclosure to the concrete

pad.

Place two (2) 3/8" J-bolts in the pad as specifi ed and center two conduits (utility and cable

output) in front of these bolts. If required, place an 8' dedicated ground rod near the utility

conduit. To mount the enclosure to the pad, use a 3/8" lock washer and nut on each mounting

bolt.

NOTE:

To prevent damage, you must mount the enclosure on a fl ush smooth surface. Do not over-torque.

Alpha Technologies is not responsible for damages incurred to the enclosure by improper mounting on

uneven surfaces.

Procedure: (Concrete Mount)

Before proceeding, remove both the MTA (if installed) and universal bracket (UB1) from the

PED.

Install the concrete mounting bracket on the enclosure using the included bolts,

1.

washers and nuts. Insert the bolts from the outside of the enclosure.

Center the enclosure over the utility and cable conduits. Align the oblong holes in the

2.

mounting bracket with the 3/8” J-bolts. Secure the enclosure with a lock washer and

nut.

Reinstall the UB1 bracket and place the MTA on the bracket. Tighten the captive screw

3.

on the bottom of the UB1 to secure the MTA (see Section 2.6 Connecting Utility Power,

and 2.8 Modular Transformer Assembly).

Pad Mounting

Slots

Concrete Mounting

Bracket and Hardware

PED Mounting Holes

Concrete Mounting Bracket

Installed in Unit

Fig. 2-6, Concrete Pad Mounting

19016-030-B0-005, Rev. C

Page 20

2.0 Installation, continued

2.4 Rack Mount Installations

The APX is also available in a rack mount version that can be installed into a standard 19"

rack.

NOTE:

Install and connect all optional features, before installing the MTA.

Procedure:

To mount the APX into a standard 19" rack, secure the APX to the rack rails, using 10-32

1.

screws and cup washers (not supplied). To provide clearance when other equipment is

installed in the rack, leave an inch above and below the 7” panel height.

The APX is supplied with an additional 3 three-foot (1.0m) power cord to connect the

2.

short cord on the rack mount APX to the standard receptacle box.

The APX is now ready for operation (see Section 3.1, Start-up and Test).

3.

You can stack other APX power supplies in the same rack without additional clearance

between the power supplies, as long as you leave suffi cient clearance between the top and

bottom supplies in the stack, adjacent equipment, and walls.

If you are using an enclosed rack or cabinet, leave at least 2" clearance between the

transformer and surrounding wall panels, and provide ventilation through the use of louvered

rear panels (or leave open if possible).

TDR-M Adjustment Access Hole

LA-P Receptacle

20

Rack Mounting Slots

Ammeter

Push-Push Circuit Breaker

Fuse

SIL-C

Fig. 2-7, APX Rack Mount (120VAC Version)

016-030-B0-005, Rev. C

Page 21

2.0 Installation, continued

2.4 Rack Mount Installations, continued

LA-P Receptacle

Output Connector

Power Input Cord

Fig. 2-8, Option Placement and Power Connections

TDR-M

ACAT-3P

3-Pin Connector

2-Pin Connector

Shorting Connector

Fig. 2-9, APX-E Rack Mount (230VAC Version)

21016-030-B0-005, Rev. C

Page 22

2.0 Installation, continued

2.5 Shelf Mount Installations

The shelf mount version of the APX consists of the standard MTA (Modular Transformer

Assembly) which rests on a mounting plate (SM). You can install the mounting plate and

MTA into a number of Alpha enclosures, including the PED-M, PWE or UPE. The shelf mount

option also includes an input AC power extension cable (APX model only) and an APX-SPI

adaptor.

NOTE:

Before you install the MTA, fi rst install and connect all optional features..

Procedure:

To place the modular transformer assembly (MTA) on the shelf mount (SM), fi t the slot on

1.

the top of the MTA over the tab on the SM bracket.

Locate the captive screw on the opposite side of the shelf mount adaptor (next to the

2.

terminal block). Fit the captive screw into the threaded portion of the MTA and tighten.

Place the assembled shelf mount bracket and modular transformer assembly into the

3.

shelf of the enclosure (PED-M, PWE or UPE). Place one of the key-slot holes over the

threaded screw hole in the enclosure shelf. Install a 8-32 x 1/2" long screw and tighten.

Connect the AC input power extension cable to the AC power cable on the unit. Connect

4.

the plug of the extension cable into the AC receptacle.

Output connection to the plant is accomplished via the terminal block or by using the

5.

APX- SPI adaptor cable.

The APX is now ready to connect to utility power via the terminal block on the MTA (see

6.

Section 3.1 Start-up and Test).

NOTE:

Only one screw hole is used to mount the SM to the enclosure shelf. To install additional APX-SM units

in the enclosure, drill and tap another mounting hole.

SPI Adaptor Cable

Power Extension Cable

Captive Screw

APX Output Connection Block

22

Shelf Mount

Fig. 2-10, Shelf Mount (SM)

016-030-B0-005, Rev. C

Page 23

2.0 Installation, continued

2.5 Shelf Mount Installations, continued

APX Output to

Terminal Block

Hold-Down Screw

Fig. 2-11, PED-M, PWE or UPE Enclosure Mounting

(using terminal block output)

APX Output to SPI

(via SPI adaptor cable)

Hold-Down Screw

Fig. 2-12, PED-M, PWE or UPE Enclosure Mounting

(using SPI output)

23016-030-B0-005, Rev. C

Page 24

2.0 Installation, continued

2.6 Connecting Utility Power

CAUTION!

Contact your local utility for approval before you install the power supply and connect to utility

power. All work should be performed by qualifi ed service personnel in compliance with local

electrical codes.

NOTE:

UL and NEC require the installer to connect a service disconnect switch (UL listed) between the power

source and the Alpha power supply.

2.6.1 Wiring the Enclosure Utility Service

The following procedure does not apply to either the rack mount (RM) or shelf mount

models (SM) which plug into a receptacle in the rack or enclosure.

Utility power enters the enclosure through a 7/8" diameter opening at the bottom of

the APX enclosure. The enclosure accepts a standard conduit fi tting. When used in

conjunction with the PED-M metered, ground-mount enclosure, utility power enters

through a dedicated raceway.

24

Output

VSF Connector

SIL-C Option

Utility Input

Ground Lug for

Grounding Rod

Fig. 2-13, APX Bottom View

016-030-B0-005, Rev. C

Page 25

2.0 Installation, continued

2.6 Connecting Utility Power, continued

2.6.1 Wiring the Enclosure Utility Service, continued

CAUTION!

Before you begin, turn off all utility power. Do not plug APX into AC receptacle at this time.

Procedure (120VAC, 60HZ):

If the Modular Transformer Assembly (MTA) is installed it must be completely

1.

removed during utility wiring. To remove the transformer assembly, loosen the

captive screw on the bottom of the baseplate and lift.

Loosen the two captive screws securing the receptacle box. Turn the receptacle

2.

box over to expose the internal wiring.

Route the utility conduit through the 7/8" diameter opening located at the bottom

3.

of the APX. Secure the fi tting with a locknut.

Connect the utility black (hot) wire (120VAC; 60Hz) to the black wire inside the

4.

receptacle box using the existing wire nut.

Connect the white (neutral) wire to the white wire inside the receptacle box us-

5.

ing the existing wire nut.

Connect the utility green with yellow tracer ground wire to the grounding-wire-

6.

clamp on the baseplate and tighten the clamping screw. An external grounding

clamp is also provided on the outside of the enclosure for connection to a

ground-rod.

Reposition the rear tab on the receptacle box into the slot in the baseplate.

7.

Tighten the two captive screws.

Reinstall the MTA and tighten the screw.

8.

LA-M Receptacle

MTA Power Receptacle

Grounding Lug

(Internal)

Hot Wire

(Black 120VAC/60Hz)

Neutral Wire

(White 120VAC/60Hz)

120VAC Utility Input

Grounding Wire

(Green)

Fig. 2-14, 120VAC/60Hz Wiring

25016-030-B0-005, Rev. C

Page 26

2.0 Installation, continued

2.6 Connecting Utility Power, continued

2.6.1 Wiring the Enclosure Utility Service, continued

Procedure (230VAC, 50 HZ):

If the MTA is installed, completely remove it prior to utility wiring. To remove the

1.

transformer assembly, loosen the captive screw on the bottom of the baseplate

and lift.

Loosen the two captive screws securing the receptacle box. Turn receptacle box

2.

over to expose the internal wiring.

Route utility conduit through the 7/8" diameter opening at the bottom of the APX

3.

PM Enclosure. Secure the fi tting with a lock nut.

Connect the utility brown-hot wire (230VAC; 50Hz) to the brown wire inside re-

4.

ceptacle box using existing wire nut.

Connect blue-neutral wire to the blue wire inside the receptacle box using the

5.

existing wire nut.

Connect utility green/yellow tracer -ground wire to the grounding wire clamp on

6.

the baseplate. Tighten clamping screw. An external grounding clamp is also provided on the outside of the enclosure for connection to a ground-rod.

Reposition the rear tab on the receptacle box into the slot in the baseplate.

7.

Tighten the two captive screws.

Reinstall the MTA and tighten screw.

8.

MTA Power Receptacle

LA-E

Hot Wire

(Brown 230VAC/50Hz)

Neutral Wire

(Blue 230VAC/50Hz)

Grounding Wire

(Green/Yellow Tracer)

Fig. 2-15, APX 230VAC/50Hz Wiring

26

016-030-B0-005, Rev. C

Page 27

2.0 Installation, continued

2.7 External Service Disconnect

Position the external service disconnect between the utility power connection and the APX.

For pole mount enclosures, attach it directly to the utility pole using 1/4" x 2-1/4" steel wood

screws. If a utility power meter is being used, secure its mounting base in the same manner.

Use a suitable conduit to interconnect the meter base, service disconnect, and power supply

enclosure.

NOTE:

Use a high-magnetic 15A circuit breaker to accomodate the high inrush currents normally associated

with the start-up of ferroresonant transformers (400A, no-trip, half cycle). Conventional service

entrance breakers are not recommended.

High-magnetic breakers for Square D service entrances enclosures are available from

Alpha Technologies:

Description Alpha Part Number Square D Part Number

Circuit Breaker 470-013-10 Q0115HM

Alpha BBX Option 020-085-10 Q02-4L70RB

Table 2-1, High-Magnetic Breaker for Square D Service Entrances

APX

Connect the load side of the circuit breaker to the black wire from the APX receptacle box

•

for 120VAC/60Hz operation (or brown wire for 230VAC/50Hz operation).

Connect the neutral bus to the white wire from the APX receptacle box for 120VAC/60Hz

•

operation (or blue wire for 230VAC/50Hz operation).

Connect the utility ground to the enclosure ground terminal. See Figures 2-15 and 2-16.

•

27016-030-B0-005, Rev. C

Page 28

2.0 Installation, continued

2.7 External Service Disconnect, continued

NOTE:

Service electric ground must be unbroken to service disconnect. All local utility and building codes

apply.

Fig. 2-16, Service Entrance / Meter Connections, 120VAC

To Utility

1

Neutral (WHITE)

2

Neutral Bus

3

4

To Enclosure Receptacle

10

1

6

2

7

8

3

9

4

5

Ground Clamp

5

L2 (RED)

6

L1 (BLACK)

7

Breaker

8

Ground (GREEN)

9

#8AWG (minimum)

10

Copper Ground Wire

28

Fig. 2-17, Service Entrance / Meter Connections, 240VAC

016-030-B0-005, Rev. C

Page 29

2.0 Installation, continued

2.8 Modular Transformer Assembly (MTA)

The modular transformer assembly in the APX is designed for quick installation and removal.

A captive screw in the baseplate secures the MTA into the enclosure.

NOTE:

Prior to installing the MTA, the enclosure must be mounted and utility and cable lines must be wired as

previously described in this manual.

Pole and Wall Mount Procedure:

Place the MTA on the baseplate. Fit the tab on the top of the baseplate through the slot in

1.

the the MTA.

Secure the MTA by tightening the captive screw on the lower portion of the baseplate.

2.

On the left side of the MTA, locate the white connectors attached to a black and white

3.

harness. The APX has two 2-pin and one 3-pin connectors.

Connect a free 2-pin connector to the output connector attached to the baseplate. The 3-

4.

pin connector contains a shorting plug for the TDR/M option. Do not remove the shorting

plug.

Pedestal Mount (PED) Procedure:

The pedestal mount enclosure uses the same MTA as the pole mount units. The PED model

uses the Universal Bracket 1 (UB1) instead of the baseplate. The UB1 has an additional

mounting bracket.

Position the slot on the extended portion of the universal bracket over the stud located

1.

on the lower inside rear portion of the pedestal unit. Secure the top of the UB1 using the

wing nut placed on the carriage bolt installed on the PED near the top of the enclosure.

Carefully slide the MTA downward on the Universal Bracket. The slot in the top of the

2.

MTA fi ts over the tab on the UB1.

Tighten the captive screw to secure the MTA to the lower portion of the universal bracket

3.

assembly.

Follow steps 3 and 4 in the pole mount and wall mount procedure (above).

4.

29016-030-B0-005, Rev. C

Page 30

2.0 Installation, continued

2.8 Modular Transformer Assembly (MTA), continued

Main Transformer Assembly

Fit tab on baseplate

through slot in MTA.

Output Connector

Baseplate Assembly

Fig. 2-18, MTA Mounted on Baseplate Assembly of PM Enclosure

MTA Mounting Tab

Wing Nut

APX Output Connector

PED Enclosure

Universal Bracket (UB1)

Receptacle Box

Extended Mounting Bracket

30

Fig. 2-19, Universal Bracket for PED Mount

016-030-B0-005, Rev. C

Page 31

2.0 Installation, continued

2.9 AC Output Connection

Procedure:

Prepare the incoming coaxial cable used for the distribution of power (including external

1.

fi ttings not supplied by Alpha).

Loosen the APX brass seizure screw output fi tting to accommodate the center pin of the

2.

cable connector.

Screw the cable connector into the output port (large hex nut fi tting) located on the

3.

baseplate of the APX. Place the center pin far enough into the fi tting to secure the seizure

assembly.

Tighten the brass seizure screw on the center pin. Loose connections can cause arcing

4.

and possible damage to the center conductor. During routine maintenance, always check

the seizure screw assembly to ensure that it is tight.

NOTE:

For a fl ush fi t, trim the center conductor. The length of the center conductor must be 1 1/4" from the

end to the center of the O-Ring.

Brass Seizure Screw

Fig. 2-20, Cable Connector/Output Port Assembly

1 1/4"

Hex Nut Fitting

(VSF Connector)

31016-030-B0-005, Rev. C

Page 32

2.0 Installation, continued

2.10 Options

Options for the APX can be installed easily in the fi eld in a minimum amount of time.

See Section 1.3, Optional Features, for a complete list of available options.

CAUTION!

Always disconnect the power supply from the unit by unplugging the power cord before

you install options.

NOTE:

All options ordered with the unit are installed by the factory. Use qualifi ed service personnel to install

additional options.

Status Indicator LED (SIL-C)

The Status Indicator LED (SIL-C) indicates AC output from the power supply during LINE

operation.

Procedure:

SIL-C

Before installing the SIL-C, remove the knockout plug from the base of the enclosure,

1.

using a large fl at-blade screwdriver.

Route the connector end of the SIL-C option up through the knockout hole and into the

2.

base of the enclosure.

Route the large star washer and nut over the SIL-C connector and wires. Screw the nut

3.

onto the threaded portion of the lamp base and tighten.

Connect the small 2-pin connector to its mating connector located in the enclosure base.

4.

Apply power and test the lamp for proper operation.

5.

Connections from Baseplate to

SIL-C (2-pin Connector)

32

Fig. 2-21, SIL-C Installed in Baseplate

016-030-B0-005, Rev. C

Page 33

2.0 Installation, continued

2.10 Options, continued

Lightning Arrestors

Lightning arrestors provide additional protection to sensitive electronic equipment from line

disturbances caused by lightning strikes, surges, and spikes.

LA-M (Lightning Arrestor for the APX Series)

The LA-M requires no hard-wiring and plugs directly into the 2-pin receptacle to the right to

the APX’s power receptacle. Install the LA-M with the imprinted label up.

Fig. 2-22, LA-M Inserted into Receptacle

.

(PM and PED Models)

LA-P (Lightning Arrestor for 120VAC Rack Mount Models)

The LA-P version is electrically identical to the LA-M, but contains contact pins mounted in

an “L” confi guration. The LA-P is used in the APX Rack Mount model and simply plugs into

the front panel of the APX Rack Mount. The LA-P can also be used in PED-M, and PWE

enclosures using an available receptacle outlet.

Fig. 2-23, LA-P Inserted into Receptacle

(Rack Mount Model)

33016-030-B0-005, Rev. C

Page 34

2.0 Installation, continued

2.10 Options, continued

LA-E (Lightning Arrestor for APX-E Version)

The LA-E lightning arrestor is hard-wired into the receptacle housing of the APX base unit.

Install the device when initially wiring the APX to the 230VAC mains.

NOTE:

The APX-E receptacle box does not contain a separate receptacle for the LA-E.

Procedure, Wiring the LA-E lightning arrestor:

If the MTA is installed, remove it from the baseplate.

1.

Remove the two screws from the front fl ange of the receptacle housing and lift it up to

2.

expose the wires underneath.

Remove the center screw from metal base of the LA-E option (if installed) and fi t the LA-

3.

E into the left side of the receptacle housing. Replace the screw (removed in Step 2) from

the outside of the receptacle housing and tighten.

Connect the brown wire from the LA-E to the brown (hot) wire in the receptacle box. This

4.

wire also connects to the brown (hot) wire from the utility. Use the existing wire nut to

connect and secure the wires.

.

Connect the BLUE wire from the LA-E to the blue (neutral) wire in the receptacle box.

5.

This wire also connects to the blue (neutral) wire from the utility. Use the existing wire nut

to connect and secure the wires.

If wiring to the utility at this time, follow steps 4 and 5 above. Reposition the receptacle

6.

box back onto the baseplate and replace the two screws.

Fig. 2-24, LA-E Option (230VAC models)

Mounted Under Receptacle Box

34

016-030-B0-005, Rev. C

Page 35

2.0 Installation, continued

2.10 Options, continued

LA-E (Lightning Arrestor for 230VAC Rack Mount Models)

The LA-E lightning arrestor mounts to the back of the front panel and is secured by the

existing screw. This option must be hard-wired into the Rack Mount unit using quick-connect

connectors.

Remove the wing nut from the screw on the LA-E mounting bracket. Position the LA-E

1.

and secure using the same screw.

Trim the wires supplied with the LA-E fl ush, leaving no copper wire exposed. Insert

2.

the trimmed end into the quick-splice connector until the end is fl ush with the internal

wire stop. Fold this end of the connector shut and crimp tight using pliers. Repeat for

additional wire.

Locate the blue wire from the AC power cord. Place into the open end of the quick-splice

3.

connector (connected to the blue wire on the LA-E), fold, and crimp.

Locate the brown wire from the AC power cord. Place it into the open end of the quick-

4.

splice connector (connected to the brown wire on the LA-E), fold, and crimp.

.

Blue or Brown

Wire (from LA-E)

Brown Wire

(from AC Power Cord)

Blue or Brown Wire

(from AC Power Cord)

Quick-splice

Connectors

Fig. 2-25, LA-E installation

Wires Installed

Blue Wire

(from AC Power Cord)

35016-030-B0-005, Rev. C

Page 36

2.0 Installation, continued

2.10 Options, continued

AMM-C (Ammeter)

The AMM-C Ammeter displays output current to the load and provides a visual indication of

the load applied to the APX. You can also use the AMM-C to determine if an open or short

circuit condition exists.

The AMM-C options consists of an ammeter, pressure mounting bracket, and an 8"

connecting cable with spade-lug connectors.

Ammeter

8" Wire

Fig. 2-26, AMM-C Ammeter Kit

Installation Procedure:

The AMM-C Ammeter is placed in series with the transformer (Tab #4) and output fuse.

Before installing the ammeter, disconnect the black wire connected to the rear-most section

of the fuse holder (the other end of this wire is connected to Tab #4 on the transformer).

Meter Pressure Clip

.

Remove this wire

from fuse-holder.

Mounting Slot for

Shelf Mount Installations

Mounting Slot for

Ammeter

Insert the AMM-C partially into the slot on the fuse / meter bracket, making sure that the

1.

0-Amp reading is at the bottom. For shelf mount installations, use slot shown.

Partially place the meter pressure clip so it just catches the meter. Keep the AMM-C free

2.

to easily reach the wire connections. The teeth on the pressure clip should face the rear

of the ammeter.

Connect the wire removed in step 1 to the upper terminal of the AMM-C.

3.

Connect the 8" wire to the rear-most terminal on the fuse holder. Connect the other end

4.

to the lower terminal on the AMM-C.

Fully insert the AMM-C into the slot and slide the pressure clip completely forward until it

5.

contacts the underside of the fuse/meter bracket.

Reconnect the APX to line power and test the AMM-C for proper operation.

6.

Install on upper terminal

36

Fig. 2-27, AMM-C Install Steps

016-030-B0-005, Rev. C

Page 37

2.0 Installation, continued

2.10 Options, continued

Install 8" wire here

TDR-M (Plug-in Time Delay Relay)

The TDR-M briefl y delays power to the output during utility start-ups (after an outage has

occurred). With the easily accessible potentiometer, you can vary the delay time between 10

and 60 seconds.

.

Fig. 2-28, AMM-C Installation

TDR-M Installation Procedure:

Remove the single SEMS screw from the text side of the TDR-M (if installed).

1.

Place the tab on the TDR-M into the upper slot (adjacent to the capacitor).

2.

Slide the TDR-M toward the left side until fl ush with the left fl ange on the APX. Align the

3.

slot in the fl ange with the screw hole in the TDR-M.

Replace and tighten the screw.

4.

Disconnect the shorting plug from the 3-pin connector. Save the shorting plug; if the TDR-

5.

M is removed, it must be reinstalled. Plug the 3-pin connector into its mating connector

on the TDR-M.

Connect a true reading RMS digital multimeter to the output of the APX. Apply power to

6.

the APX and adjust the potentiometer for the desired output delay time using the digital

multimeter.

Increases Delay

Decreases Delay

Fig. 2-29, TDR-M Potentiometer

37016-030-B0-005, Rev. C

Page 38

2.0 Installation, continued

2.10 Options, continued

TDR-M Mounted in

Upper Slot

SEMS Mounting

Screw

ACAT-3P Mounted in

Lower Slot

Fig. 2-30, TDR-M and ACAT-3P Options Installed in the APX

ACAT-3P (AMP Clamp)

The ACAT-3P clamps dangerous spikes and surges to ground protecting sensitive electronic

equipment.

ACAT-3P Installation Procedure:

The procedure for mounting the ACAT-3P is the same as that for the TDR-M. However, the

ACAT-3P mounts in the lower slot and connects to the 2-pin connector. See Fig. 2-30.

.

3-Pin Connector with

Shorting Wire

3-Pin Connector

2-Pin Connector

ACAT-3P and TDR-M Options for Rack Mount Models

Both of these options are available for the APX.

Installation Procedure:

Mount these options on the rear of the unit and secure with one SEMS screw. The screw

1.

is inserted from the front panel of the APX.

Connect the proper connector into the option. If you are installing a TDR-M, fi rst remove

2.

the 3-pin shorting connector.

Fig. 2-31, ACAT-3P and TDR-M Installed in the APX Rack Mount

38

016-030-B0-005, Rev. C

Page 39

2.0 Installation, continued

2.11 APX Output Voltage Reconfi guration

The APX 90V series has a user-selectable output voltage between 60VAC, 75VAC, and

90VAC. Verify appropriate output voltage selection for each application. The default setting is

90VAC.

To reconfi gure the output voltage, move the 12-gauge black wire to the appropriate output

tap on the transformer. See Table 2-2.

NOTE:

If the SIL-C option is installed, the 20-gauge black wire connected to the SIL-C must remain connected

to the 60VAC (tap 6A) output tap.

Black Wire White Wire

90VAC / 6C 5

75VAC / 6B 5

60VAC / 6A 5

Table 2-2, APX Output Voltage Reconfi guration

39016-030-B0-005, Rev. C

Page 40

3.0 Operation

3.1 Start-up and Test

After all utility and cable connections are complete, test the APX before placing it into service.

Test Procedure:

Before you apply power, verify that the AC LINE circuit breaker is in the OUT (off)

1.

position. The white portion of the stem will be visible. If it is not, press the breaker button.

Plug the APX power plug into the receptacle provided in the internal AC receptacle box.

2.

If the APX is equipped with a LA-M (or LA-P) Plug-in MOV, plug it into the designated

3.

receptacle.

Switch the external service entrance breaker (located outside of the enclosure) to ON.

4.

To reset the APX internal AC LINE circuit breaker, press the button (the white portion on

5.

the stem will not be visible).

Measure the output voltage at the APX output connector, using a true reading RMS digital

6.

multimeter. An acceptable voltage range is between 57 and 63 VAC for 60VAC output

models (45.6 to 50.4 for 48V models).

If the AMM-C Ammeter option is installed (APX models only), ensure that the current

7.

draw is in the correct range, (for example, below 8A for 8A units, and below 14A for 14A

units).

Place the cover on the APX, aligning the tabs on the cover with the base plate assembly.

8.

Secure the hold-down screw and lock the enclosure.

NOTE:

In Step 6, if a non-RMS type voltmeter is used, the reading may be off by as much as 10% due to the

“quasi” square wave output of the ferroresonant transformer.

Input AC Line

Breaker

AC Output

Fuse

40

Fig. 3-1, APX Circuit Breaker and Fuse Location

016-030-B0-005, Rev. C

Page 41

3.0 Operation, continued

3.2 Shutdown and MTA Removal

WARNING!

Use heavy gloves when handling a power module that has just been taken out of

service. The ferroresonant transformer generates heat and may cause burns if

handled with bare hands.

Shutdown Procedure:

Switch the external service disconnect circuit breaker to OFF.

1.

Unplug the power cord.

2.

Disconnect the APX output connector.

3.

Loosen the captive screw located on the bottom of the APX enclosure that secures the

4.

MTA to the baseplate assembly and remove the MTA from the baseplate.

If reinstalling a transformer assembly or upgrading, reverse the above procedure.

5.

1

3

2

Fig. 3-2, Shutdown and MTA removal

4

41016-030-B0-005, Rev. C

Page 42

4.0 Troubleshooting and Repair

Symptom Probable cause Remedy

No output to cable

(no AC line power)

No output to cable (AC line

power is available).

Incorrect output voltage. Incorrect type of voltme-

Utility power outage

•

AC power cord un-

•

plugged

AC input circuit breaker

•

tripped.

AC output fuse open

•

Local seizure screw

•

Poor connection at

•

cable output connector

Loose connection at

•

transformer lug

•

ter used.

Under-loaded output

•

(<1A)

Over-loaded output

•

Faulty tank circuit

•

capacitor (may appear

swollen or distorted;

may leak oil).

Table 4.1, Troubleshooting Guide

Use voltmeter to verify

•

120VAC (or 230VAC at

receptacle)

Plug in AC power cord

•

Reset AC circuit breaker.

•

Replace fuse

•

Tighten seizure screw

•

Check connector

•

Check connection

•

Use a TRUE RMS meter

•

Correct or increase load

•

Reduce load

•

Replace capacitor, C1

•

4.1 Return Procedure

When returning a unit for service please include the power supply maintenance log. The log

helps the technician troubleshoot the problem.

Please use the original shipping container. If the original container is not available, use at

least three inches of shock absorbing material to prevent damage during shipping.

NOTE:

Do not use popcorn-type material. Alpha Technologies is not responsible for damage caused by

improper packing on returned units.

Alpha products may be returned by either method listed below:

On the Internet follow these steps:

•

1. Go to www.alpha.com.

2. Select your region from the drop-down menu.

3. Select the link for “Support.”

4. From the drop-down menu, choose “RMA Request Form (PDF).”

Or call (800) 322-5742 for assistance.

•

42

016-030-B0-005, Rev. C

Page 43

4.0 Troubleshooting and Repair, continued

4.2 Replacement Parts

The following parts, available from Alpha Technologies, can be replaced in the fi eld. When

you order parts, please specify both the model number from the nameplate and the part

number listed below

Type Description Part Number Used in Models

Capacitor, oil-fi lled 60µF; 370VAC 210-017-10 (APX) 6014, 6014E, 6014P

Capacitor, oil-fi lled 100µF; 240VAC 210-018-10 (APX) 6008, 6014E, 6008E, 6008P

Circuit Breakers Thermal 12A; 250VAC, 28VDC 470-007-10 (APX) 6014

Circuit Breakers Thermal 5 Amp; 250VAC; 28VDC 470-001-10 (APX) 6008E, 4808E, 6008P

Circuit Breakers Thermal 8A; 250VAC; 28VDC 470-004-10 (APX) 6008, 6014E, 6014P

Fuses, Slow Blow 1/4" x 1-1/4"; 15A 460-043-10 (APX) 6014, 6014E, 6014P

Fuses, Slow Blow 1/4" x 1-1/4", 10A 460-102-10 (APX) 60008, 6008E, 4808E, 6008P

Table 4-2, Replacement Parts

43016-030-B0-005, Rev. C

Page 44

5.0 Specifi cations

5.1 APX Schematics

The schematic diagram displays the main components of the APX Series, as well as where

the options are electrically installed in the circuit. See Section 2.10 for details on installing

available options..

44

Fig. 4-1, APX Schematic

016-030-B0-005, Rev. C

Page 45

5.0 Specifi cations, continued

5.1 APX Schematics, continued

.

MODULARCHASSIS

TRANSFORMER

ASSEMBLY

240VAC

INPUT

1

HOT

.

.

SHORT

PLUG

321

xJ3

120VAC

INPUT

P/O T1

CB1

10A

152

CB1

HOT

2

4

3

HOT

20A

4

3

NEU

TDR-M

(OPTION)

321

xJ3

(SHORTING PLUG REMOVED

IF THE TDR-M IS INSTALLED)

J3

F1

20A

AMM-C

(OPTION)

C1

7

321

(BLK)

6A6B6C

1

xJ1

2

TIME DELAY

(WHT)

8

(GRN)

3

LINE

xJ4

J4

CONNECTOR

(BLK)

T1

(BLK)

J5

POWER

CONNECTOR

ACAT-3P

(OPTION)

2

1

AMP CLAMP

CONNECTOR

2

1

(WHT)

(WHT)

2

1

OUTPUT

CONNECTOR

J6

(BLK)

2

(WHT)

1

STATUS

INDICATOR

CONNECTOR

BASE

PLATE

HOT (BLK)

NEU (WHT)

AC INPUT

120VAC

ASSEMBLY

(WHT)

(BLK)

2

1

J2

GND (GRN)

2

1

xJ2

LA-M

120V OPT.

60Hz

J2

CONNECTOR

LIGHTNING

ARRESTOR

xJ2

1

J1

(WHT)

(BLK)

2

1

2

1

EXTRA PLUG

120VAC

(COVERED)

2

LIGHTNING

ARRESTOR

3

HOT (BLK)

HOT (RED)

.

AC INPUT

240VAC

GND (GRN)

60Hz

CONNECTOR

120VAC INPUT

VSF

(WHT)

J2

xJ2

1

2

xJ5

OUTPUT

90VAC

(BLK)

2

1

LA-M

120V OPT.

2

1

NEU (WHT)

HOT (BLK)

CONNECTOR

LIGHTNING

ARRESTOR

(WHT)

J2

xJ2

xJ6

(BLK)

J1

(BLK)

2

1

2

1

LA-M

120V OPT.

2

1

(WHT)

SIL-C

(OPTION)

213

(GRN)

LIGHTNING

ARRESTOR

Fig. 4-2, APX 90V Schematic

CONNECTOR

240VAC INPUT

45016-030-B0-005, Rev. C

Page 46

5.0 Specifi cations, continued

5.2 APX Specifi cations

Model

Input Voltage

(Nom)

Input Freq (Hz) 60

Input Current

(A) (Max)

Output Voltage

(VAC) (Nom)

Output Current

(A) (Max)

Output Power (VA) 480

Output Current Limit 150% of Max Output Rating

Regulation +/- 5%

Input Protection

(Circuit Breaker)

Output Protection

(Fuse)

Effi ciency 90% or better with nominal input voltage, frequency, full load 25c ambient

Finish Gray, ASA Polyester Powder Coat

Operating Temp

Range

Dimensions HxWxD

Pole mount

Shelf mount

w/MTA

Pedestal mount (PM)

Universal Bracket

Rack mount

Wall mount Bracket

w/PM unit installed

Weight

(lbs/kg)

APX 6008 E APX 6014 E APX 6008 P APX 6014 P APX 4808 E APX 9015

120

230

50

3.5

1.9

60

60

8

8

480

8 Amp 12 Amp 8 Amp 12 Amp 8 Amp 20 Amp

10 Amp 15 Amp 10 Amp 15 Amp 10 Amp 20 Amp

21/14.5 30/13.6 24/10.9 34/15.4 22/10 48/21.7

120

230

60

50

6.2

3.2

60

60

14

14

840

840

11.75" x 7.5" x 10.5"

2.3" x 6.7" x 11.6" (60mm x 170mm x 295mm)

7.9" x 6.7" x 11.6" (200mm x 170mm x 295mm)

27.3" x 8.5" x 8.5" (693mm x 216mm x 216mm)

14.0" x 7.1" x 7.35" (356mm x 180mm x 187mm)

7.0" x 19" x 6.5" (178mm x 483mm x 165mm)

7.1" x 2.7" x 2.0" (180mm x 69mm x 51mm)

11.5" x 7.85" x 10.75" (298mm x 200mm x 267mm)

220 220 230 240

60 60 50 60

2.3 3.4 2 11.2

60 60 40 90/75/60

8148 15

480 840 384 1350

-40° F to +130° F (-40° C to +55° C)

(298mm x 190mm x 267mm)

15" x 10.5" x 7.5"

(381mm x 267mm x

190mm)

46

Table 5-1, APX Series Specifi cations

016-030-B0-005, Rev. C

Page 47

Alpha Technologies

Power

®

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

USA

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Web: www.alpha.com

Alpha Technologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

Tel: +1 604 430 1476

Fax: +1 604 430 8908

Alpha Technologies

Europe Ltd.

Twyford House

Thorley

Bishop's Stortford

Hertfordshire

CM22 7PA

UNITED KINGDOM

Tel: +44 0 1279 501110

Fax: +44 0 1279 659870

Alpha Technologies GmbH

Hansastrasse 8

D-91126 Schwabach

GERMANY

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec, Ltd

P.O. Box 56468

Limassol, Cyprus

CYPRUS

Tel: +357 25 375675

Fax: +357 25 359595

AlphaTEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1

109028 Moscow

RUSSIA

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltics

S. Konarskio G. 49

Vilnius 2009

LITHUANIA

Tel: +350 5 210 5291

Fax: +350 5 210 5292

Alpha Technologies

5 Avenue Victor Hugo

F-92140 Calmart France

FRANCE

Tel: +33 3 41 90 07 07

Fax: +33 1 41 90 93 12

Copyright © 2006 Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 016-030-B0-005 Rev. C.

Due to continuing product improvements, Alpha reserves the right to change specifi cations without notice.

Loading...

Loading...