Page 1

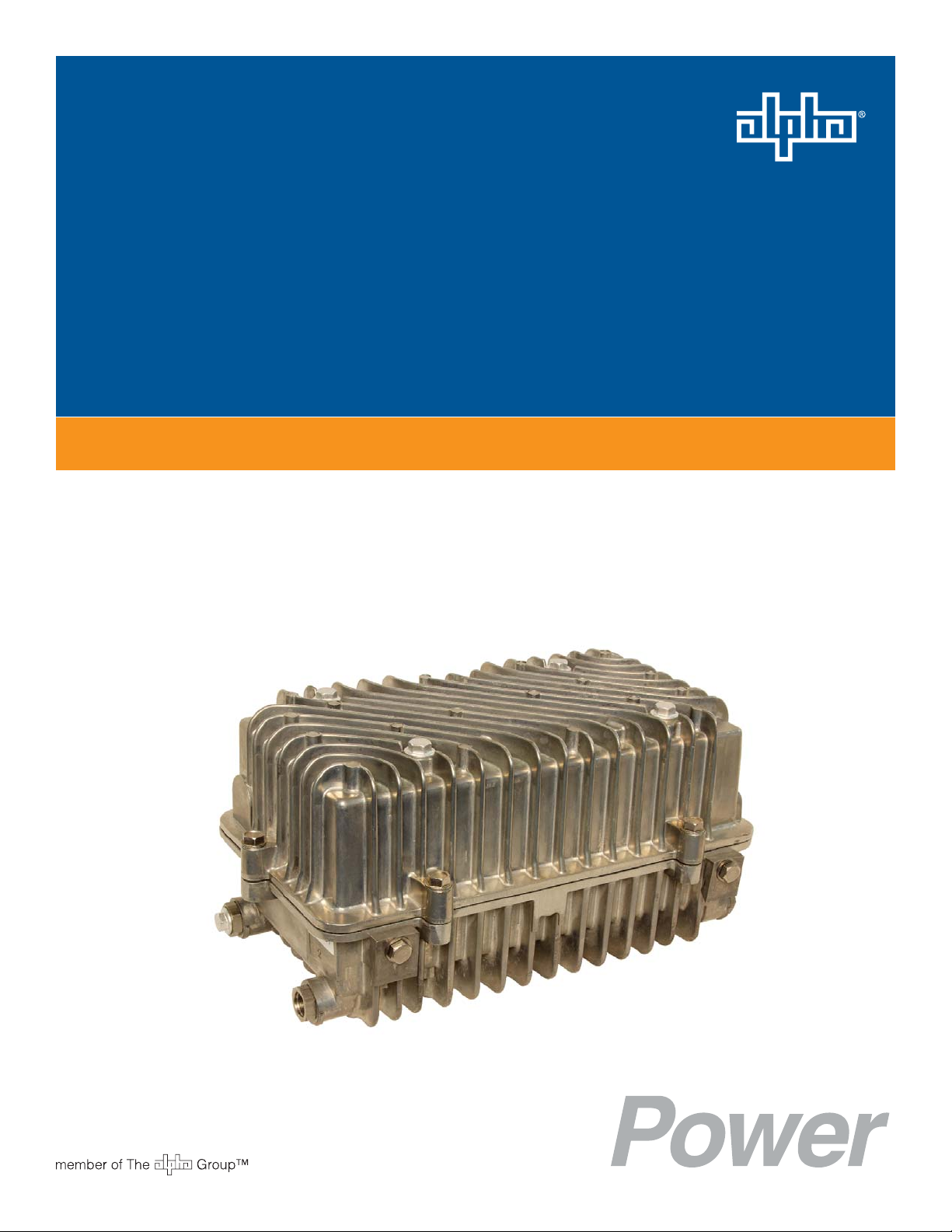

Alpha Power Booster

Technical Manual

APB HFC Voltage Booster

Effective: December 2011

Page 2

Alpha Technologies

Power

®

Page 3

Alpha Power Booster

APB HFC Voltage Booster

016-559-B0-001, Rev. A

Effective Date: December, 2011

Copyright

© 2011

Alpha Technologies, Inc.

member of The Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this powering system, please contact Alpha Technologies

or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

TM

For general product information and customer service (7 AM to 5 PM, Pacifi c Time), call

016-559-B0-001 Rev. A

Contacting Alpha Technologies: www.alpha.com

or

1-800-863-3930

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacifi c Time or 24/7 emergency support

3

Page 4

Contents

Safety Notes ..........................................................................................................................6

Safety Precautions ................................................................................................................ 6

1.0 System Overview ........................................................................................................ 7

1.1 Introduction ...................................................................................................... 7

1.2 Internal Components........................................................................................ 8

2.0 Installation...................................................................................................................9

2.1 Enclosure Installation .......................................................................................9

2.1.1 Strand Mounting .................................................................................... 9

2.1.2 Surface Mounting ................................................................................ 10

2.2 Output Voltage Confi guration ..........................................................................11

2.3 Cable Preparation .......................................................................................... 12

2.4 RF Module Removal ...................................................................................... 14

2.5 Coaxial Cable Attachment..............................................................................15

2.6 RF Module Reinstallation ............................................................................... 16

2.7 Power Up and Test ......................................................................................... 17

2.7.1 Initial Power Up ................................................................................... 17

2.8 Final Assembly ............................................................................................... 18

2.9 Specifi cations ................................................................................................. 19

2.10 Troubleshooting ............................................................................................. 20

2.11 Voltage Booster Service.................................................................................21

2.11.1 PCB Replacement Procedure ............................................................. 21

2.11.2 Transformer Replacement Procedure ................................................. 22

4

016-559-B0-001 Rev. A

Page 5

Figures

Fig. 1-1, APB Voltage Booster .................................................................................... 7

Fig. 1-2, APB Internal Components ............................................................................ 8

Fig. 2-1, Label with Factory Confi g Field ...................................................................11

Fig. 2-2, Confi guration Connect .................................................................................1 1

Fig. 2-3, Coaxial Cable Connector............................................................................ 12

Fig. 2-4, RF Module Removal ................................................................................... 14

Fig. 2-5, RF Module Removed.................................................................................. 14

Fig. 2-6, Seizure Connector ...................................................................................... 15

Fig. 2-7, Visible Center Conductor of Installed Connector ........................................ 15

Fig. 2-8, RF Module Installation ................................................................................ 16

Fig. 2-9, Cover Bolts ................................................................................................. 18

Tables

Table 2-1, Troubleshooting Guide ............................................................................ 20

016-559-B0-001 Rev. A

5

Page 6

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of this product, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

ATTENTION:

The use of ATTENTION indicates specifi c regulatory/code requirements that may affect the placement of

equipment and/or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specifi c task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to the technician

or user.

Safety Precautions

• Only qualifi ed personnel may service the APB Voltage Booster.

• Verify the voltage requirements of the equipment to be protected (load), the AC input voltage to the voltage

booster (line), and the output voltage of the system prior to installation.

• When connecting the load, DO NOT exceed the output rating of the voltage booster.

• Always use proper lifting techniques whenever handling units.

• Avoid using uninsulated tools or other conductive materials when working inside the enclosure.

• Remove all rings, watches and other jewelry before servicing voltage booster.

6

016-559-B0-001 Rev. A

Page 7

1.0 System Overview

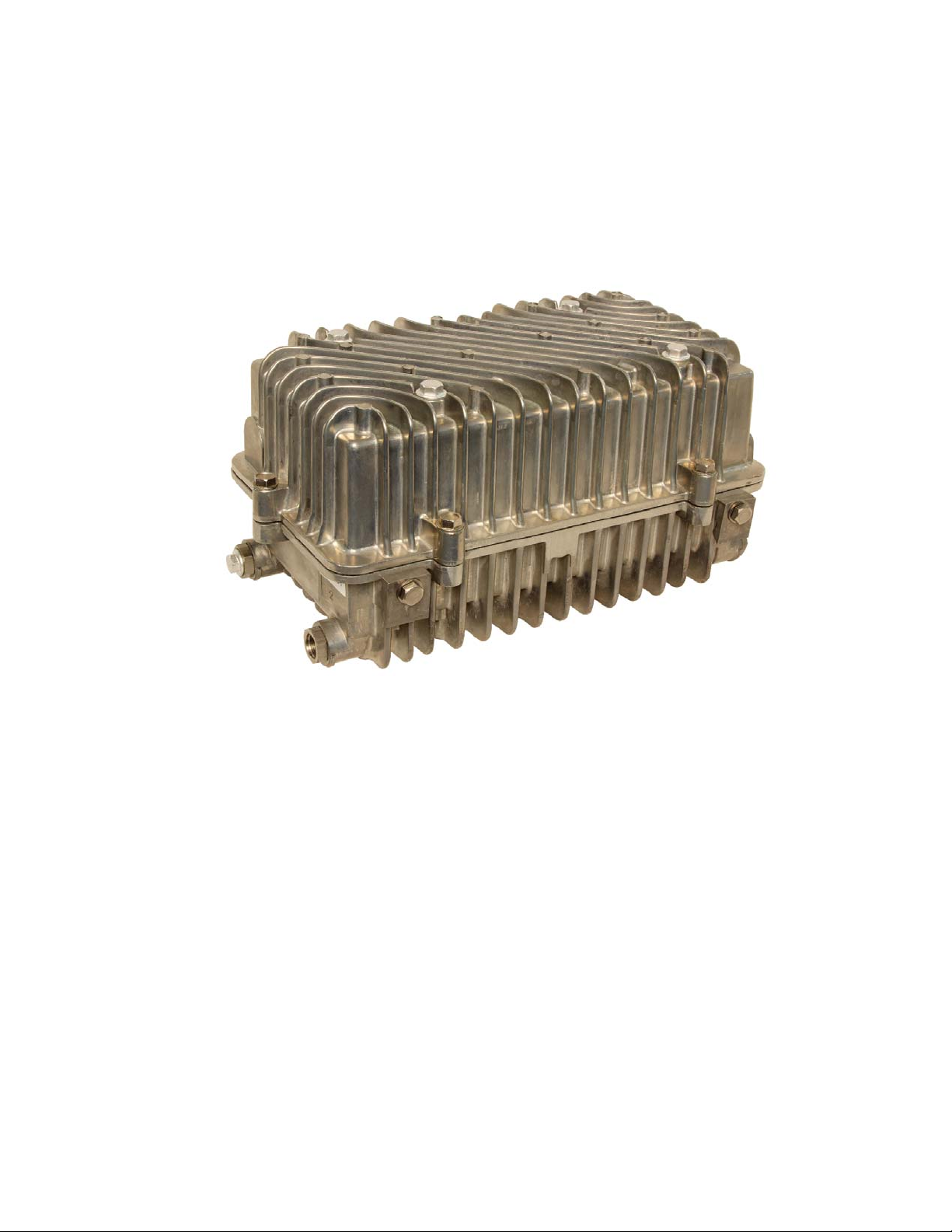

1.1 Introduction

The Alpha Power Booster (APB) was created to improve network effi ciency and reduce life

cycle cost by eliminating lightly loaded power supplies at the end of long amplifi er cascades.

The voltage booster accomplishes this by boosting end-of-line voltages. The voltage boost

allows deeper penetration of the HFC network and eliminates the need for power supplies

and batteries near the end of the HFC network.

016-559-B0-001 Rev. A

Fig. 1-1, APB Voltage Booster

7

Page 8

1.0 System Overview, continued

1.2 Internal Components

Input

Tap-switch PCBA

RF Module with

Input and Output Connectors

Output

Step-up Autotransformer

Fig. 1-2, APB Internal Components

8

016-559-B0-001 Rev. A

Page 9

2.0 Installation

2.1 Enclosure Installation

2.1.1 Strand Mounting

Tools Required:

• 1/2” Socket

• 0-100 in-lb torque wrench

Procedure:

1. Loosen the two strand clamps on the enclosure. Ensure that the side labeled "INPUT" is facing the

correct direction.

2. Place the strand wire under the clamp plates and torque the bolts to 75 in-lbs.

3. Ensure that the output voltage is confi gured properly. Refer to section 2.2 if the output voltage requires

changing.

4. Prepare the coaxial connector(s) as outlined in Section 2.3, "Cable Preparation". Install the

connector(s) and tighten to proper torque supplied by the manufacturer.

Strand Wire

Side View

Strand Clamps Strand Clamps

Top View

016-559-B0-001 Rev. A

9

Page 10

2.0 Installation, continued

2.1 Enclosure Installation, continued

2.1.2 Surface Mounting

Tools Required:

• 1/2” Socket

• 0-100 in-lb torque wrench

• Drill

• 3/8” drill bit

Procedure:

1. Loosen the two strand clamps on the enclosure. Ensure that the side labeled "INPUT" is

facing the correct direction.

2. Verify that the mounting surface is fl at between the mounting locations prior to drilling.

3. Drill two 3/8” holes that are 10” apart.

4. The threaded holes in the enclosure are 1/2” deep. Verify the bolts extend no more than 3/8”

through the mounting surface. Use 5/16-18 threaded bolts.

5. Tighten the mounting bolts to 90 in-lbs.

6. Tighten the coaxial connector(s) to proper torque provided by the manufacturer.

Mounting Surface

Mounting

Holes

5/16"-18

Mounting

Bolts

10

016-559-B0-001 Rev. A

Page 11

2.0 Installation, continued

2.2 Output Voltage Confi guration

Tools Required:

• True RMS Volt Meter

• Clamp-On Amp Meter

1. Note the factory confi gured output voltage by reading the label on the side of the housing. The

label has a fi eld named FACTORY CONFIG that will be fi lled with either 63Vac or 87Vac.

Fig. 2-1, Label with Factory Confi g Field

2. If the factory confi guration must be changed, unplug the quick connects and attach the connector

labelled LOG87 (for 90V plant) or LOG63 (for 60V plant) to the “Confi guration” male quick

connect. The unused wire should be attached to P4 to prevent arcing to the power supply

housing.

016-559-B0-001 Rev. A

Fig. 2-2, Confi guration Connect

11

Page 12

2.0 Installation, continued

2.3 Cable Preparation

Tools Required:

• Wire Cutters

• Open-End wrenches (refer to manufacturer’s assembly instructions)

WARNING!

Coaxial cables may carry AC power. To avoid possible shock or damage to the

equipment, always handle coaxial cables with extreme caution. Always install coaxial

connectors with the RF module removed from the enclosure.

NOTE:

This section is for reference only; follow instructions provided by the connector’s manufacturer.

Procedure:

1. Assemble coaxial connectors with no more than 13 inches between ends.

2. Cut the pin length as shown on the following page.

1-7/16"

to

1-5/8"

Fig. 2-3, Coaxial Cable Connector

12

016-559-B0-001 Rev. A

Page 13

2.0 Installation, continued

2.3 Cable Preparation, continued

Installation is complete. Go to Power Up and Test (Section 2.7, Power Up and Test).

3. Locate the measuring gauge near port number 1 or 2.

4. Place the connector’s collar against the edge of the

measuring gauge molded into the enclosure.

5. Using heavy duty wire cutters, clip the pin as close to the

016-559-B0-001 Rev. A

line as possible.

13

Page 14

2.0 Installation, continued

2.4 RF Module Removal

Tools Required:

• No. 2 Flat head screwdriver

Procedure:

1. Disconnect the two Molex connectors (Output, J4, Input, J5).

2. Loosen the two captive screws near the center of the module.

3. Grasp the pull rings with your index fi ngers and pull fi rmly away from the enclosure.

Pull Ring

Disconnect per step 1

Captive Screws

Pull Ring

14

Disconnect per step 1

Fig. 2-4, RF Module Removal

Fig. 2-5, RF Module Removed

016-559-B0-001 Rev. A

Page 15

2.0 Installation, continued

2.5 Coaxial Cable Attachment

Tools Required:

• 5/8” socket wrench with 6” extension

• 20-200 in-lb torque wrench

Procedure:

1. Remove the two seizure connectors from

the enclosure.

NOTE:

Verify center conductor is centered in the groove in

the plastic base.

2. Insert the prepared coaxial connector into

the desired port (1-input; 2-output) and

torque to 180 in-lbs.

3. Replace the seizure connectors and

torque to 90 in-lbs.

Fig. 2-6, Seizure Connector

Fig. 2-7, Visible Center Conductor of Installed

Connector

016-559-B0-001 Rev. A

15

Page 16

2.0 Installation, continued

2.6 RF Module Reinstallation

Tools Required:

• No. 2. Flat head screwdriver

• Torque screwdriver

Procedure:

1. Firmly seat the module over the seizure connectors, with the open side facing AWAY from

the circuit board.

2. Tighten the captive screws to 18 in-lbs.

WARNING!

The enclosure may become electrifi ed if mis-wired or in the event of an internal short.

Measure the voltage between the enclosure and earth ground before touching with bare

hands.

3. Connect the Molex connectors (Output, J4, Input, J5). Ensure that the output connector is

plugged into J4 and the input connector is plugged into J5.

Reconnect per step 3

Fig. 2-8, RF Module Installation

Captive Screws

Reconnect per step 3

16

016-559-B0-001 Rev. A

Page 17

2.0 Installation, continued

2.7 Power Up and Test

2.7.1 Initial Power Up

Tools Required:

• True RMS Volt Meter

• Clamp-On Amp Meter

WARNING!

There will be up to 90Vac present on the PCB when a live connector is plugged into the

input or output connectors.

Procedure:

1. Plug the Output Connector from the RF Module

into the J4 Output Connector (item 1) of the PCB.

2. Plug the Input Connector from the RF Module into

the J5 Input Connector (item 2) of the PCB. Verify

the GREEN LED (item 3) on PCB is lit.

3. Using the volt meter, measure the output voltage

between TP13 and the enclosure chassis. The

voltage should be approximately 87Vac for the

87Vac confi guration or 63Vac for the 63Vac

confi guration.

3

TP13

2

1

016-559-B0-001 Rev. A

4. Place a Clamp-on amp meter over the output wire

coming from the Output connector J4 on the PCB

and the RF Module. The current must be less than

8A RMS. If the current exceeds 8A RMS, resolve

the cause of the short-circuit or overload condition.

17

Page 18

2.0 Installation, continued

2.8 Final Assembly

Tools Required:

• 1/2” Socket

• 0-100 in-lb torque wrench

Procedure:

1. Close the cover of the enclosure, making sure no wires are being pinched. Tighten all bolts

fi nger tight.

2. Tighten the enclosure cover bolts to 30 in-lbs, in the sequence shown. Repeat the procedure,

tightening the bolts to 70 in-lbs.

6

4

2

1

3

18

5

Fig. 2-9, Cover Bolts

016-559-B0-001 Rev. A

Page 19

2.0 Installation, continued

2.9 Specifi cations

Specifi cations

Electrical

Input Voltage 45-65Vac 60Hz / 65-90Vac 60 Hz

Input Current 10 Amps RMS (max)

Output Voltage 63Vac 60Hz / 87Vac 60Hz

Output Current <8 Amps RMS (max)

Output Rating 650 VA (max)

Overload Protections 115% for 27 minutes

Short Circuit Bypass mode, automatic recovery

Overload Recovery Automatic

Surge Resistance 6kV/3000A (IEEE C61.45 part 15)

Effi ciency >96% at 25 to 100 percent load

RF Freq Range 5MHz to 1000MHz

RF Insertion Loss

Maximum

Flatness ±0.25 dB (5MHz to 50MHz)

RF Slope Maximum 0.80dB (5MHz to 50MHz)

Hum Modulation

Return Loss Minimum 17 dB (5MHz to 1000MHz)

Electrical Egress <-120dBm (45MHz to 870MHz)

Isolation Neutral carries through

Environmental

Operating Temperature -40°F to 149°F (-40°C to 65°C)

Storage Temperature -58°F to 158°F (-50°C to 70°C)

Outdoor Rating Type 4 Enclosure

Standard Compliance

Safety CSA (C/US)

Standard Features

High-effi ciency autotransformer

Intelligent overload protection

Water-tight enclosure; wall or strand mounted

1.2 dB (5MHz to 50MHz)

1.2 dB (50MHz to 870MHz)

1.6 dB (870MHz to 1000MHz)

±0.35 dB (50MHz to 870MHz)

±0.50 dB (870MHz to 1000MHz)

-1.0dB (50MHz to 870MHz), -1.25dB (870MHz to 1000MHz)

< -68 dB (5MHz to 1000MHz)(< -82 dB freq. domain)

CAN/CSA C22.2 No. 60950-1-07

UL 60950-1, 2nd Edition

016-559-B0-001 Rev. A

19

Page 20

2.0 Installation, continued

2.10 Troubleshooting

Troubleshooting Guide

Symptom Probable Cause and Solution

No Output No Input Voltage

63Vac Confi g: Verify that no less than 45Vac is present on

the input connector.

87Vac Confi g: Verify that no less than 65Vac is present on

the input connector.

RF Module Not Fully Seated

Ensure the RF Module is fully seated and the captive screws

are tight. Module should be fl ush with the rim of the lower

half of the enclosure. Check connections from RF Module to

power supply.

PCBA Connectors Not Fully Seated

Ensure the RF Module connectors are fully seated to the

PCBA at J4 & J5, and that the transformer connector is fully

seated at J1.

Overload Relay Open

If the unit is overloaded it will open a relay to protect vital

components and cease output. A solid green LED will light up

on the PCBA if the unit is functional, but overloaded. In this

situation the unit must be repositioned in the network where

the input current is less than 10A.

Output Voltage Low Input Voltage Below 45/65Vac

Inspect input connections and upstream power supplies,

verify no less than 45Vac (63Vac Confi g) or 65Vac (87Vac

Confi g) is present at the input port (measure voltage from

TP14 to the enclosure).

Input and Output Coax Connectors Reversed

Verify the Coax Input Connector is connected to Port 1.

Output Voltage High Input Voltage Above 63/90Vac

Inspect input connections and upstream power supplies,

verify no greater than 63Vac (63Vac Confi g) or 90Vac (87Vac

Confi g) is present at the input port (measure voltage from

TP14 to the enclosure).

20

Table 2-1, Troubleshooting Guide

016-559-B0-001 Rev. A

Page 21

2.0 Installation, continued

2.11 Voltage Booster Service

Tools Required:

• No. 2 Phillips head screwdriver

WARNING!

There will be up to 90Vac present on the PCB when a live connector is plugged into the

input or output connectors.

2.11.1 PCB Replacement Procedure

1. Unplug Input Connector from J5 of the PCB.

2. Unplug Output Connector from J4 of the PCB.

3. Unplug XFMR Connector from J1 of the PCB.

4. Loosen captive bracket screws at "4" (2 places).

5. Remove assembly.

6. Install new assembly and tighten the captive bracket screws at "4" (2 places).

7. Plug XFMR Connector into J1 of the PCB.

8. Plug Output Connector into J4 of the PCB.

9. Plug Input Connector into J5 of the PCB.

10. Perform power up test (section 2.7.1), and fi nal assembly (section 2.8).

2

1

4

2

3

4

016-559-B0-001 Rev. A

21

Page 22

2.0 Installation, continued

2.11 Voltage Booster Service, continued

Tools Required:

• 11/32 Nutdriver

WARNING!

There will be up to 90Vac present on the PCB when a live connector is plugged into the

input or output connectors.

2.11.2 Transformer Replacement Procedure

1. Unplug transformer connector from J1 of the PCB.

2. Unplug transformer quick connects from Confi guration (P1) and P4 of the PCB. Note which

connector is attached to the Confi guration male connector (LOG63 or LOG87).

3. Remove nuts at "3" (4 places).

4. Remove transformer.

5. Install new transformer with nuts at "3" (4 places).

6. Plug the connector from step 2 into the Confi guration male connector (P1). Plug the other

unused connector into P4.

7. Plug the transformer connector into J1 of the PCB.

3

1

2

3 3

3

22

016-559-B0-001 Rev. A

Page 23

this page intentionally blank

Page 24

Alpha Technologies Inc.

3767 Alpha Way

Bellingham, WA 98226

United States

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Alpha Technologies Ltd.

7700 Riverfront Gate

Burnaby, BC V5J 5M4

Canada

Tel: +1 604 436 5900

Fax: +1 604 436 1233

Toll Free: +1 800 667 8743

Alpha Industrial Power Inc.

1075 Satellite Blvd NW,

Suite 400

Suwanee, GA 30024

United States

Tel: +1 678 475 3995

Fax: +1 678 584 9259

Alpha Energy

1628 W Williams Drive

Phoenix, AZ 85027

United States

Tel: +1 623 251 3000

Fax: +1 623 249 7833

Alpha Technologies Europe Ltd.

Twyford House Thorley

Bishop’s Stortford

Hertfordshire, CM22 7PA

United Kingdom

Tel: +44 1279 501110

Fax: +44 1279 659870

Alpha Technologies

Unit 504, 5/F,

Fourseas Building

No 208-212 Nathan Road

Kowloon, Hong Kong

Tel: +852 2736 8663

Fax: +852 2199 7988

Alpha Technologies GmbH

Hansastrasse 8

D-91126

Schwabach, Germany

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec Ltd.

339 St. Andrews St.

Suite 101 Andrea Chambers

P.O. Box 56468

3307 Limassol, Cyprus

Tel: +357 25 375 675

Fax: +357 25 359 595

Alpha Innovations Brasil

Avenida Ibirapuera,

2120 – Cj 76

Moema - 04028-001

Santos SP, Brazil

Tel: +55 11 2476 0150

Fax: +55 11 2476 0150

T echnologies Argus

First de Mexico

Anatole France Num. 17

Colonia Polanco

11560, México D.F.

Tel: +52 55 5280 6990

Alpha TEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1, Offi ce 403

Moscow, 109028

Russia

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltic

S. Konarskio Street 49-201

Vilnius, LT-03123

Lithuania

Tel: +370 5 210 5291

Fax: +370 5 210 5292

Visit us at www.alpha.com

Due to continuing product development, Alpha Technologies reserves the right to change specifi cations without notice.

Copyright © 2011 Alpha Technologies. All Rights Reserved. Alpha

®

is a registered trademark of Alpha Technologies. 016-559-B0-001 Rev. A

Loading...

Loading...