Page 1

Alpha Modular Power System 24 HP

Installation & Operation Manual

Part # 0260011-J0

Effective: 03/2012

member of The Group

™

Your Power Solutions Partner

Page 2

Page 3

Alpha Modular Power System 24 HP

Installation & Operation Manual

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs

may not match your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual

before proceeding. If there are questions regarding the safe operation of this powering system, contact Alpha Technologies or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators, batteries, or other hardware if used or operated in any manner or subject

to any condition not consistent with its intended purpose, or is installed or operated in an

unapproved manner, or improperly maintained.

For technical support, contact Alpha Technologies:

Copyright

Copyright © 2012 Alpha Technologies Ltd. All rights reserved. Alpha is a registered trademark of

Alpha Technologies.

No part of this documentation shall be reproduced, stored in a retrieval system, translated,

transcribed, or transmitted in any form or by any means manual, electric, electronic,

electromechanical, chemical, optical, or otherwise without prior explicit written permission from

Alpha Technologies.

This documentation, the software it describes, and the information and know-how they contain

constitute the proprietary, confidential and valuable trade secret information of Alpha Technologies,

and may not be used for any unauthorized purpose, or disclosed to others without the prior written

permission of Alpha Technologies.

The material contained in this document is for information only and is subject to change without

notice. While reasonable efforts have been made in the preparation of this document to assure

its accuracy, Alpha Technologies assumes no liability resulting from errors or omissions in this

document, or from the use of the information contained herein. Alpha Technologies reserves the right

to make changes in the product design without reservation and without notification to its users.

Canada and USA: 1-888-462-7487

International: +1-604-436-5547

Email: support@alpha.ca

Page 4

Table of Contents

1. Safety .............................................................................................................................. 6

1.1 Safety Symbols ............................................................................................................................. 6

1.2 General Safety .............................................................................................................................. 7

1.3 External Battery Safety ................................................................................................................. 8

1.4 Utility Power Connection ............................................................................................................... 8

1.5 Equipment Grounding ................................................................................................................... 9

2. Product Description....................................................................................................... 10

2.1 Theory of Operation .................................................................................................................... 10

2.2 System Components ................................................................................................................... 12

2.3 Rear Components ....................................................................................................................... 13

2.4 Low Voltage Battery Disconnect (Optional) ................................................................................ 15

2.5 Battery Temperature Probes ....................................................................................................... 16

2.6 Network Requirements ............................................................................................................... 17

3. Power Congurations.................................................................................................... 19

3.1 Power System Conguration Terminology .................................................................................. 19

3.2 4i Shelf Systems (No Battery Charger) ....................................................................................... 20

3.3 3i+1R Shelf Systems (Integrated Battery Charger) .................................................................... 20

3.4 System Spares ............................................................................................................................ 20

3.5 120V Single Phase Systems ....................................................................................................... 21

3.6 120V/240V Split Phase or 120/208V 2-Pole Systems ................................................................ 24

3.7 120V/208V 3-Phase Systems ..................................................................................................... 27

3.8 AMPS24 HP - Recommended DC Breaker and Wire Sizes ....................................................... 29

3.9 How to Congure Inverters in AC Input Groups, AC Output Groups and DC Input Groups ....... 30

4. System Pre-Installation ................................................................................................. 32

4.1 Site Selection .............................................................................................................................. 32

4.2 Recommended Installation Layout .............................................................................................. 32

4.3 Transporting the Cabinet ............................................................................................................. 33

4.4 Unpacking Instructions ................................................................................................................ 34

5. Installation ..................................................................................................................... 35

5.1 Input/Output Cabling ................................................................................................................... 35

5.2 AC Wiring .................................................................................................................................... 37

2

Doc. #: 0260011-J0 Rev B

Page 5

5.3 DC Battery and Ground Cabling ................................................................................................. 38

5.4 DC Ground .................................................................................................................................. 41

5.5 AMPS24 HP with External Maintenance Bypass Switch ............................................................ 42

5.6 Generator Automatic Transfer Switch ......................................................................................... 42

5.7 Commissioning the System for the First Time ............................................................................ 43

6. System Operation ......................................................................................................... 52

6.1 CXCU Controller Operation ........................................................................................................ 52

6.2 Inverter monitoring and control ................................................................................................... 55

6.3 Inverter Module Indicators .......................................................................................................... 62

6.4 Rectier Module .......................................................................................................................... 63

7. Preventive Maintenance ............................................................................................... 67

7.1 Recommended maintenance schedule ....................................................................................... 67

7.2 Tools and Equipment .................................................................................................................. 67

7.3 Spare Parts ................................................................................................................................. 68

7.4 Replacing a Rectier ................................................................................................................... 69

7.5 Replacing a Defective Fan—Inverter or Rectier ........................................................................ 69

7.6 Removing the CXCU Controller .................................................................................................. 69

7.7 Replacing the Surge Suppression Module .................................................................................. 70

7.8 Fuse Replacement ...................................................................................................................... 71

7.9 Synchronization with a Maintenance Bypass Switch (MBS) ....................................................... 73

8. Troubleshooting ............................................................................................................ 74

8.1 Non Recoverable Error ............................................................................................................... 74

8.2 Recoverable Error ....................................................................................................................... 74

9. System Specications ................................................................................................... 84

9.1 Power De-rating Due To Altitude ................................................................................................. 84

9.2 Power De-rating Due To Temperature ........................................................................................ 84

9.3 System Specications ................................................................................................................. 85

9.4 Specications for AIM 1500 Module ............................................................................................ 86

9.5 Specications for 48-1.8 kW Rectier (P/N 010-621-20-040) ..................................................... 87

10. Conguration Parameters ........................................................................................... 88

10.1 Transferring Inverter Settings to Another System ..................................................................... 88

10.2 Examples of Modications to Conguration Parameters .......................................................... 88

10.3 Global Settings (ID 1 – 50) ........................................................................................................ 90

Doc. #: 0260011-J0 Rev B

3

Page 6

10.4 Inverter Parameters (ID 51 – 550) ............................................................................................ 91

10.5 Alarm Settings (ID 551-950) ...................................................................................................... 97

11. Warranty ...................................................................................................................... 99

11.1 Battery Warranty ....................................................................................................................... 99

12. Certication ............................................................................................................... 100

List of Figures

Figure 1 — AMPS24 HP System Components .................................................................................. 13

Figure 2 — Surge Suppression Modules ........................................................................................... 14

Figure 3 — AMPS24 HP rear view (with protective covers removed) ................................................ 14

Figure 4 — Eight-pin terminal strip and 40-pin connector pin locations ............................................. 15

Figure 5 — LVD wiring ....................................................................................................................... 16

Figure 7 — Batteries > Congure Batteries ....................................................................................... 17

Figure 6 — Battery temperature probes ............................................................................................ 17

Figure 8 — Cable connection to CXCU for graphic display ............................................................... 18

Figure 9 — Single network connection to CXCU ............................................................................... 18

Figure 10 — Multiple network connections to the CXCU ................................................................... 19

Figure 11 — Split Phase from a Single phase supply ........................................................................ 20

Figure 12 — 2-Pole from a 3-phase supply ...................................................................................... 20

Figure 13 — Monitoring AC Input Groups, AC Output Groups and DC Input Groups ....................... 31

Figure 14 — DC input breakers ......................................................................................................... 32

Figure 15 — Shipping dimensions (in inches) ................................................................................... 34

Figure 16 — AMPS24 Power and Battery Connections ..................................................................... 37

Figure 17 — AC Wiring connections diagram .................................................................................... 38

Figure 18 — AC Wiring (shown for 3-phase) ..................................................................................... 38

Figure 19 — Single feed, parallel battery strings ............................................................................... 39

Figure 20 — Dual feed, two battery strings in parallel ....................................................................... 40

Figure 21 — DC battery wiring with independent dual A/B feed ........................................................ 41

Figure 22 — DC ground, inverter only systems ................................................................................. 42

Figure 23 — Representative system wiring for AMPS24 HP system with MBS ................................ 43

Figure 24 — Controller ....................................................................................................................... 45

4

Doc. #: 0260011-J0 Rev B

Page 7

Figure 25 — Controller default home screen ..................................................................................... 45

Figure 26 — Placement of initial inverters (shown for split phase system) ........................................ 46

Figure 27 — Inverter module showing AC input LED ........................................................................ 46

Figure 28 — Unlocking and locking an inverter module for removal or insertion ............................... 47

Figure 29 — Inserting and removing an inverter module ................................................................... 47

Figure 30 — Inverters > View Live Status.......................................................................................... 48

Figure 31 — Matching AC Input Groups to AC Output Groups ......................................................... 49

Figure 32 — Set Output (Split Phase System) .................................................................................. 50

Figure 33 — Inserting blanks in open slots ........................................................................................ 51

Figure 34 — CXCU system controller home screen .......................................................................... 53

Figure 35 — CXCU controller ............................................................................................................ 54

Figure 36 — Editing the user interface text. ....................................................................................... 55

Figure 37 — Inverters > View Live Status interface ........................................................................... 56

Figure 38 — Set Output window ........................................................................................................ 57

Figure 39 — Group Mapping window (shown for a two phase system) ............................................. 58

Figure 40 — Group Status window .................................................................................................... 58

Figure 41 — Set Input window .......................................................................................................... 59

Figure 42 — General Settings window .............................................................................................. 59

Figure 43 — Congure alarms window ............................................................................................. 60

Figure 44 — T2S alarms in event logs ............................................................................................... 61

Figure 45 — Retrieve alarm history le .............................................................................................. 61

Figure 46 — Signals (inverters) window ........................................................................................... 62

Figure 47 — Auto DC Priority ............................................................................................................. 62

Figure 48 — Inverter module status, power LEDs ............................................................................. 63

Figure 49 — Output power indicator LEDs ........................................................................................ 63

Figure 50 — Cordex 48-1.8kW .......................................................................................................... 64

Figure 51 — Surge Suppression Modules ......................................................................................... 71

Figure 52 — Rectier fuses (behind back top panel) ......................................................................... 72

Figure 53 — Fuse location for LCD touch screen .............................................................................. 73

Figure 54 — Maintenance Bypass Switch ......................................................................................... 74

Figure 55 — Manage Cong File window .......................................................................................... 89

Doc. #: 0260011-J0 Rev B

5

Page 8

List of Tables

Table A — Eight-pin Terminal Strip from AMPS 24 ............................................................................ 15

Table B — Pinouts for 40 Pin Connector Interface to CXCR ............................................................. 16

Table C — 10.5kVA, 9kVA and 4.5kVA, 120V Single Phase 3i+1R Shelf Systems ........................... 23

Table D — 12kVA and 6kVA, 120V Single Phase, 4i Shelf Systems ................................................. 24

Table E — 21kVA, 18kVA, & 9.0kVA 120/240V Split Phase or 120/208 2-Pole 3i+1R Shelf ............. 26

Table F — 24kVA & 12KVA 120/240V Split Phase or 120/208 2-Pole 4i shelf Systems .................... 27

Table G — 18kVA and 13.5kVA, 120V/208V 3-Phase Systems ........................................................ 29

Table H — DC Input Groups .............................................................................................................. 32

Table I — Tools .................................................................................................................................. 68

Table J — Spare Parts ....................................................................................................................... 69

Table K — Inverter Alarm Codes ........................................................................................................ 78

6

Doc. #: 0260011-J0 Rev B

Page 9

1. Safety

SAVE THESE INSTRUCTIONS: This manual contains important safety

instructions that must be followed during the installation, servicing, and maintenance of the product.

Keep it in a safe place. Review the drawings and illustrations contained in this manual before proceeding.

If there are any questions regarding the safe installation or operation of this product, contact Alpha

Technologies or the nearest Alpha representative. Save this document for future reference.

1.1 Safety Symbols

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the

following symbols have been placed throughout this manual. Where these symbols appear, use extra

care and attention.

The use of ATTENTION indicates specic regulatory/code requirements that may affect the

placement of equipment and /or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specic task or procedure. Notes

are designated with a checkmark, the word NOTE, and a rule beneath which the information

appears.

CAUTION!

CAUTION indicates safety information intended to PREVENT DAMAGE to material or equipment. Cautions are designated with a yellow warning triangle, the word CAUTION, and a rule

beneath which the information appears.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to personnel. Warnings are indicated by a shock hazard icon, the word WARNING, and a rule beneath which the

information appears.

HOT!

The use of HOT presents safety information to PREVENT BURNS to the technician or user.

Doc. #: 0260011-J0 Rev B

7

Page 10

1.2 General Safety

• Only qualified personnel shall install, operate, and service the power system and components.

• Observe all applicable national and local electrical and building codes during installation.

• Mount the AMPS24 HP system in a rack that is securely bolted to the floor.

• Always assume electrical connections and/or conductors are live.

• Turn off all circuit breakers and double-check potentially charged components with a voltmeter

before performing installation or maintenance.

• Before installation, verify that the input voltage and current requirements of the load are within

the specifications of the power system. Refer to the product nameplate label.

• Keep tools away from walk areas to prevent personnel from tripping over the tools.

• Wear safety glasses when working under any conditions that may be hazardous to your eyes.

• Do not work on the power system, or connect or disconnect cables, during atmospheric lightning

activity.

• Do not let water enter the enclosure as this can cause electrical shorts, shocks, or electrocutions.

• Do not remove the covers of electrical components as this can cause electrical shorts, shocks or

electrocutions. There are no user serviceable parts inside.

• The power system is certified for use in restricted access locations only.

• All operators must be trained to perform the emergency shutdown procedure.

• For 3i+1R shelf models containing rectifiers, see section 7.8 to replace internal fuses.

• The power system must be connected only to a dedicated branch circuit.

• Equip the utility service panel with a circuit breaker of appropriate rating.

• Do not exceed the output rating of the system when connecting the load.

• External metal surface temperatures on the rear of the AMPS24 HP system can exceed 70°C.

Use caution when working around the equipment while it is in operation.

• Always use proper lifting techniques when handling units, modules, or batteries.

• The power system contains more than one live circuit. Voltage may still be present at the output

even when the input voltage is disconnected.

• Minimize the risk of sparks and wear on the connectors. Always switch off the inverter’s battery

circuit breaker before connecting or disconnecting the battery pack.

• In the event of a short-circuit, batteries present a risk of electrical shock and burns from high

currents. Observe proper safety precautions.

• Always wear protective clothing, such as insulated gloves, and safety glasses or a face shield

when working with batteries.

• Carry a supply of water, such as a water jug, to wash eyes or skin in case of exposure to battery

electrolyte.

• Do not allow live battery wires to contact the enclosure chassis. Shorting battery wires can result

in a fire or possible explosion.

• Replace batteries with those of an identical type and rating. Never install old or untested batteries.

• Only use insulated tools when handling batteries or working inside the enclosure.

• Remove all rings, watches and other jewelry before servicing batteries.

• Recycle used batteries. Spent or damaged batteries are environmentally unsafe. Refer to local

codes for the proper disposal of batteries.

8

Doc. #: 0260011-J0 Rev B

Page 11

• A disconnect switch shall be provided by others for the AC input and AC output circuits.

• Risk of Electric Shock and Fire Hazard: replace fuse with the same type and rating.

1.3 External Battery Safety

• The power system requires an over-current protection device for the external batteries. The

maximum allowable current is typically 450A but can be less depending on the model. Follow

the local electrical codes.

• Ensure that the external battery connection is equipped with a disconnect.

• If the batteries are stored for extended periods before the installation, charge the batteries at

least once every three months to ensure optimum performance and maximum battery service

life.

• Refer to the battery manufacturer’s recommendation to select the correct float and equalize

charge voltage settings. Failure to do so can damage the batteries. Verify that the battery charger’s float and equalize settings are correct.

• The batteries are temperature sensitive. During extremely cold conditions, a battery’s charge

acceptance is reduced and requires a higher charge voltage. During extremely hot conditions,

a battery’s charge acceptance is increased and requires a lower charge voltage. To allow for

changes in temperature, the battery charger must be equipped with a temperature compensating system. For 3i+1R shelf systems, refer to the rectifier manual for information about temperature compensation.

• If the batteries appear to be overcharged or undercharged, first check for defective batteries

and then verify that the charger voltage settings are correct.

• To ensure optimal performance, inspect the batteries according to the battery manufacturers

recommendations. Check for signs of cracking, leaking, or unusual swelling. Some swelling is

normal.

• Check the battery terminals and connecting wires. Periodically clean the battery terminal con-

nectors and retighten them to the battery manufacturer's torque specifications. Spray the terminals with an approved battery terminal coating such as NCP-2 or No-Ox.

• Verify that the polarity of the cables are correct before connecting the batteries to the power

module. The polarity is clearly marked on the batteries. The battery breaker will trip and the rectifiers may be damaged if the cables are connected with the wrong polarity.

1.4 Utility Power Connection

Connecting to the utility must be performed by qualified service personnel only and must comply

with local electrical codes. The utility power connection must be approved by the local utility before

the installation.

Doc. #: 0260011-J0 Rev B

9

Page 12

1.5 Equipment Grounding

To provide a ready, reliable source of backup power, the power system must be connected to an

effective grounding and earthing system. The grounding system must be designed to protect both

personnel and equipment.

WARNING!

Low impedance grounding is mandatory for personnel safety, critical for the proper operation of the system, and must be in place and connected to the system before the supply

cables are connected.

1.5.1 Safety Ground

The safety ground is a two-part system – the utility service ground and the power system ground.

Utility Service Ground

As a minimum requirement for the protection of equipment, the local utility service must provide a

low-impedance path for fault current return to Earth. This must meet or exceed the requirements of

the US National Electrical Code or the Canadian Electrical Code.

Power System Ground

The power system ground consists of a low-impedance connection between the enclosure and an

Earth Ground, which must be located at least six feet away from the utility earth connection.

1.5.2 Lightning Strike Ground

Lightning strikes, grid switching, or other power surges on the power line and/or communications

cable can cause high-energy transients that can damage the power or communications systems.

Without a low-impedance path to the ground, the current will travel through wires of varying

impedance, which can produce damaging high voltages. The best method to protect the system

from damage is to divert these unwanted high-energy transients along a low-impedance path to the

ground.

See section "2.2 System Components" on page 13 for a description of the surge suppression modules

installed in the AMPS24 HP.

10

Doc. #: 0260011-J0 Rev B

Page 13

2. Product Description

The Alpha Modular Power System 24 HP (AMPS24 HP) is a unique, high performance AC power

system that is designed to provide highly reliable back-up power to cable headend, telecom or

server room facilities.

The AMPS24 HP features hot swappable 1.5 kVA/1.2 kW AC power modules and optional 1.8

kW rectifier modules that are the building blocks of a highly reliable power system with 99.999%

availability, 93% efficiency, and high power density. A smart, unified controller with an integrated

Ethernet/SNMP monitors and manages both AC power modules and rectifier modules through

a remote web-based GUI. The AMPS24 HP is designed for installation in a climate-controlled

environment where ambient temperatures are between 0°C to 50°C (32 to 122°F).

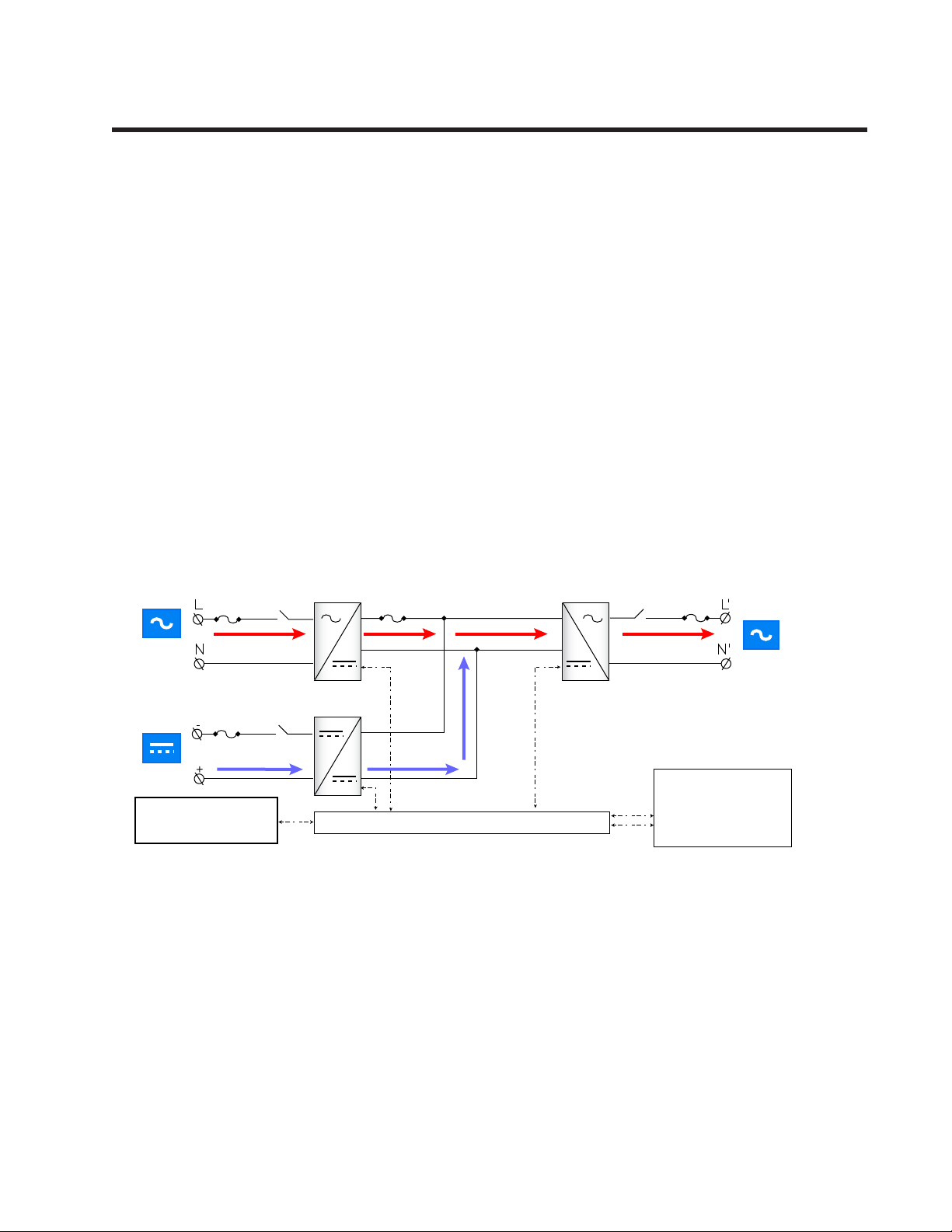

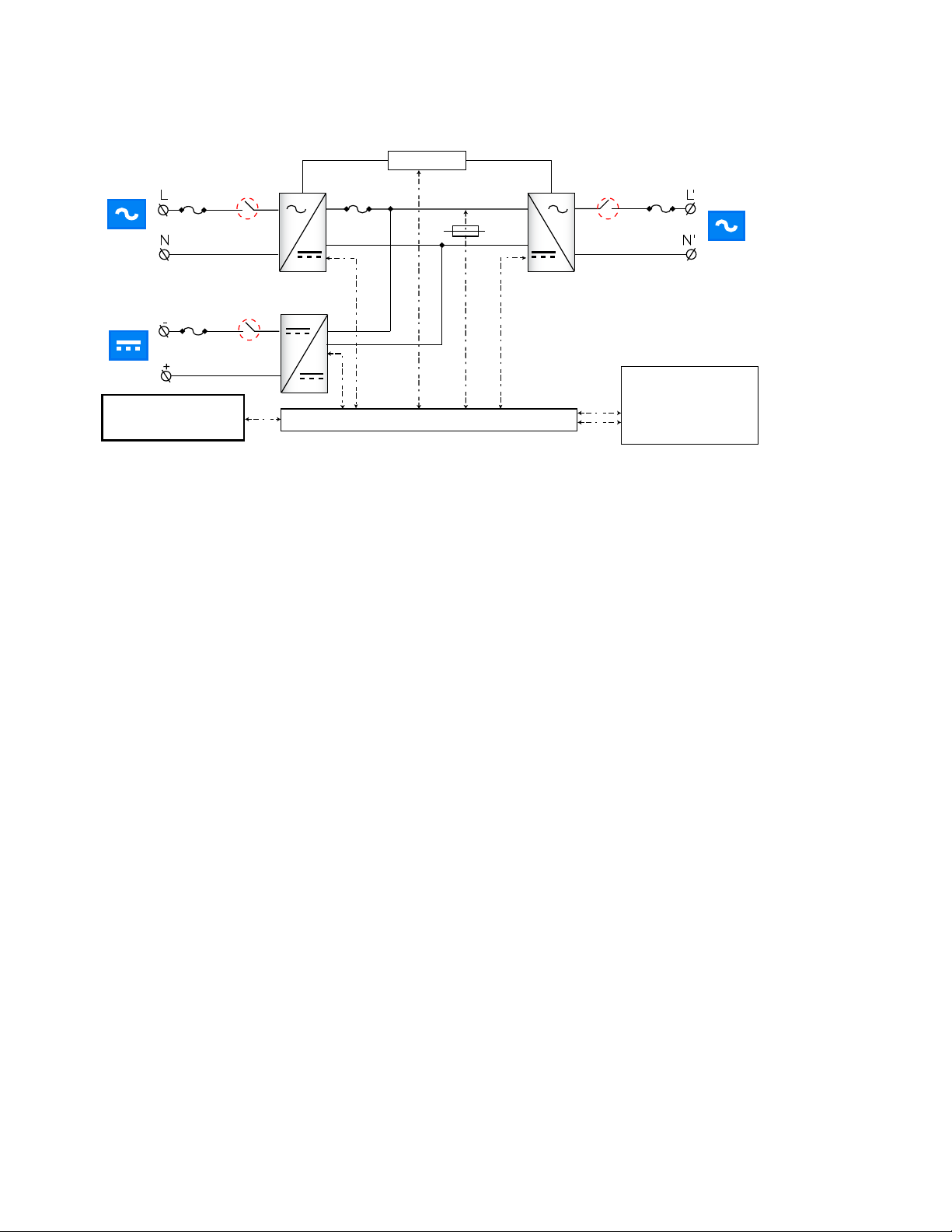

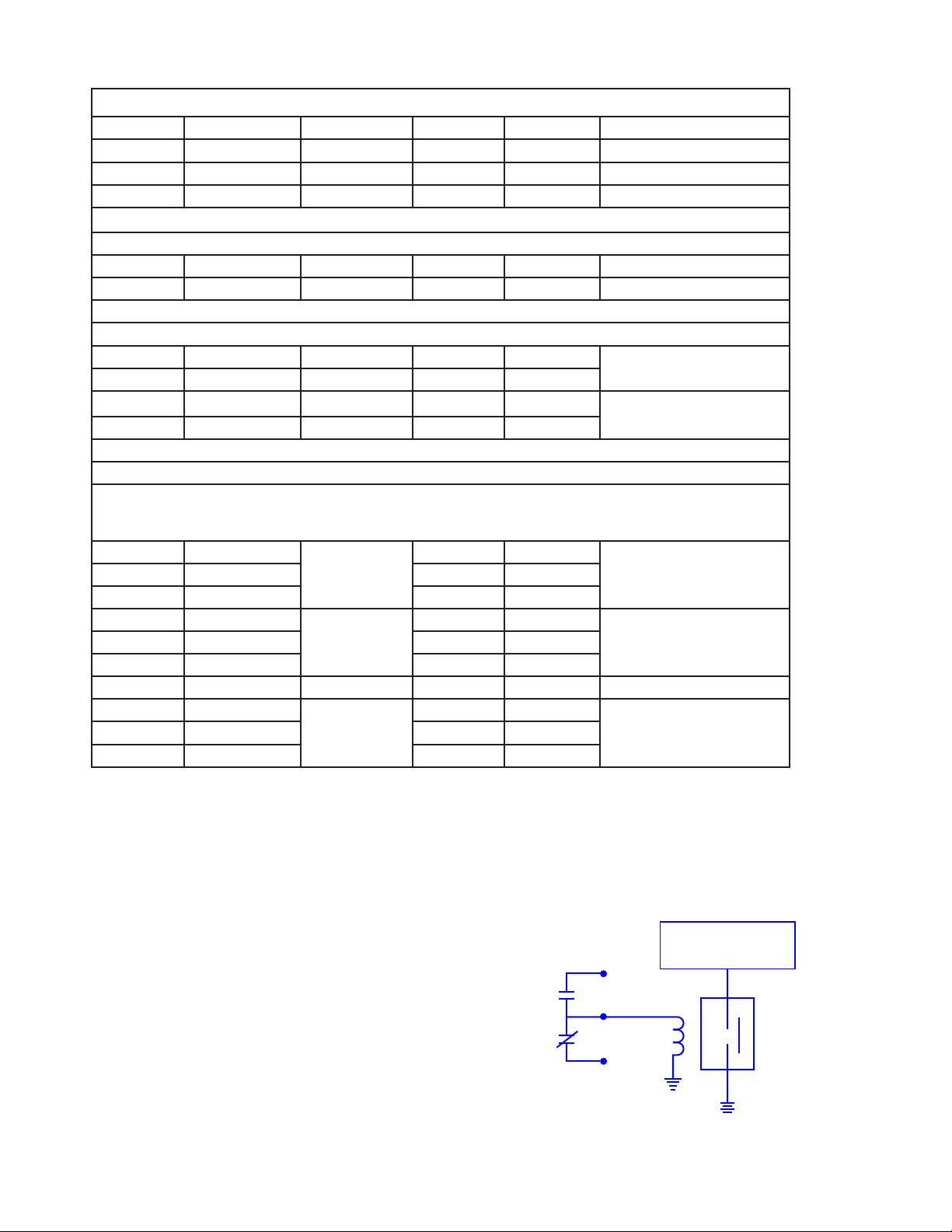

2.1 Theory of Operation

AMPS modules feature a revolutionary high performance technology that combines the high reliability

of a telecom-grade inverter system with the high efficiency of a UPS.

Each AMPS module includes a reliable 48VDC-to-120VAC inverter as well as an AC-to-DC rectifier.

When AC Mains is available, AC power is converted to a high voltage DC bus, which is then

converted back to AC. In this high performance (HP) mode, AMPS delivers fully conditioned, lineregulated telecom-grade AC power with 93% system efficiency.

AC

Mains

DC In

CAN bus external

communication

When AC Mains is unavailable, DC battery power is converted to AC with zero transfer time. An

intelligent high voltage DC bus decides when to draw power, and how much power to draw, from AC

or DC source. During AC input brownout condition, output power is supplemented by battery power.

In case of a fault, advanced DSP controls allow the AMPS module to isolate itself, while the rest of the

system continues to power the load (with reduced output).

DSP

Dual redundant

communication and

synchronization

between modules

Telecom Grade

AC Output

Doc. #: 0260011-J0 Rev B

11

Page 14

Boost

AC

Mains

DC In

CAN bus external

communication

AMPS modules also have a ‘Boost’ over-current feature with 10 times the rated current capacity

for 20ms, allowing it to trip breakers downstream, thus protecting the load.

2.1.1 AC or DC input priority

The user can choose either AC or DC input priority. If AC priority is chosen, the AMPS24 HP acts

more like an on-line, double conversion UPS. If AC commercial power is available, this power is

filtered twice and passed to the AC output. If the AC commercial power fails, the DC converter

simply takes over and supplies the power from the batteries.

DSP

400 Vdc

Telecom Grade

AC Output

Dual redundant

communication and

synchronization

between modules

12

If DC priority is chosen, AMPS24 HP acts more like an Inverter with AC bypass function.

Normally, power is drawn from the batteries. If DC power fails, the AC-DC converter takes over,

still providing regulated and filtered power to the load.

Doc. #: 0260011-J0 Rev B

Page 15

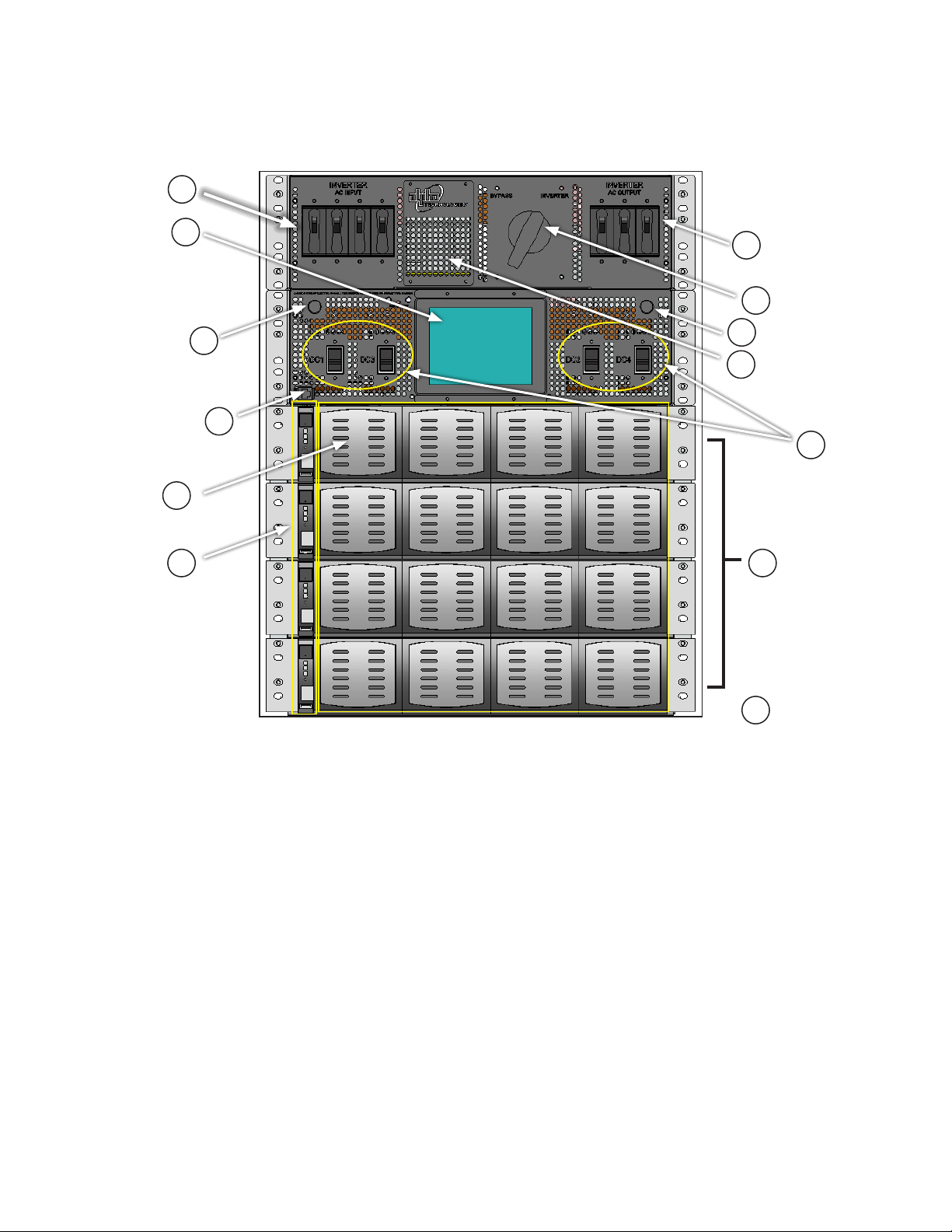

2.2 System Components

The AMPS24 HP is made up of a number of individual subsystems designed to work together to

provide highly reliable, filtered power in support of the load. A typical system contains the following:

1

10

4

11

5

6

3

2

12

13

7

8

9

Figure 1 — AMPS24 HP System Components

1. Inverter AC Input Breaker: Main disconnect for AC input

2. Internal Maintenance B ypass Switch (MBS) (optional): Can be used to route power directly

from the AC input to the AC output, bypassing the inverter modules.

3. Inverter AC Output Breaker: Serves as the main disconnect for the inverter AC outputs.

4. Graphic display touch screen: Connected to the CXCU controller by cable (see figure)

5. RJ45 cable connector: Front panel connection for cable from the CXCU to the Graphic display

6. CXCU Unified System Controller with integrated Ethernet / SNMP: Monitors and manages

both inverter and rectifier modules through a web-based GUI (only 1 per unit).

7. DC Input Breakers: Individual DC input breakers for each shelf.

8. 4i or 3i+1R shelves: Up to four shelves for installing up to four hot-swappable AIM 1500

modules OR three AIM 1500 modules plus one 1800W rectifier per shelf.

9. AIM 1500 Modules: Up to 4 AIM 1500 per 4i (4 x inverter modules) shelf or up to 3 AIM 1500

per 3i+1R (3 x inverter modules and 1 x rectifier module) shelf.

Doc. #: 0260011-J0 Rev B

13

Page 16

10. Rectifier Modules (opt ional): Up to one rectifier per

shelf. The rectifiers are used as the charging component

of a 3i+1R shelf system.

11. Fuse for the graphic display for the CXCU, and V+/ V- to

the controller

12. Fuse for customer use 2A load, pins #5 and #6 on 8-pin

terminal strip—see section 2.3.1 on page 15.

13. Surge Suppression Modules (behind removable

panel) built into the power distribution panel to protect

equipment from damage caused by surges and high

transient voltages. The surge suppression modules,

shown in Figure 2, short to ground any unwanted

voltages above a safe threshold.

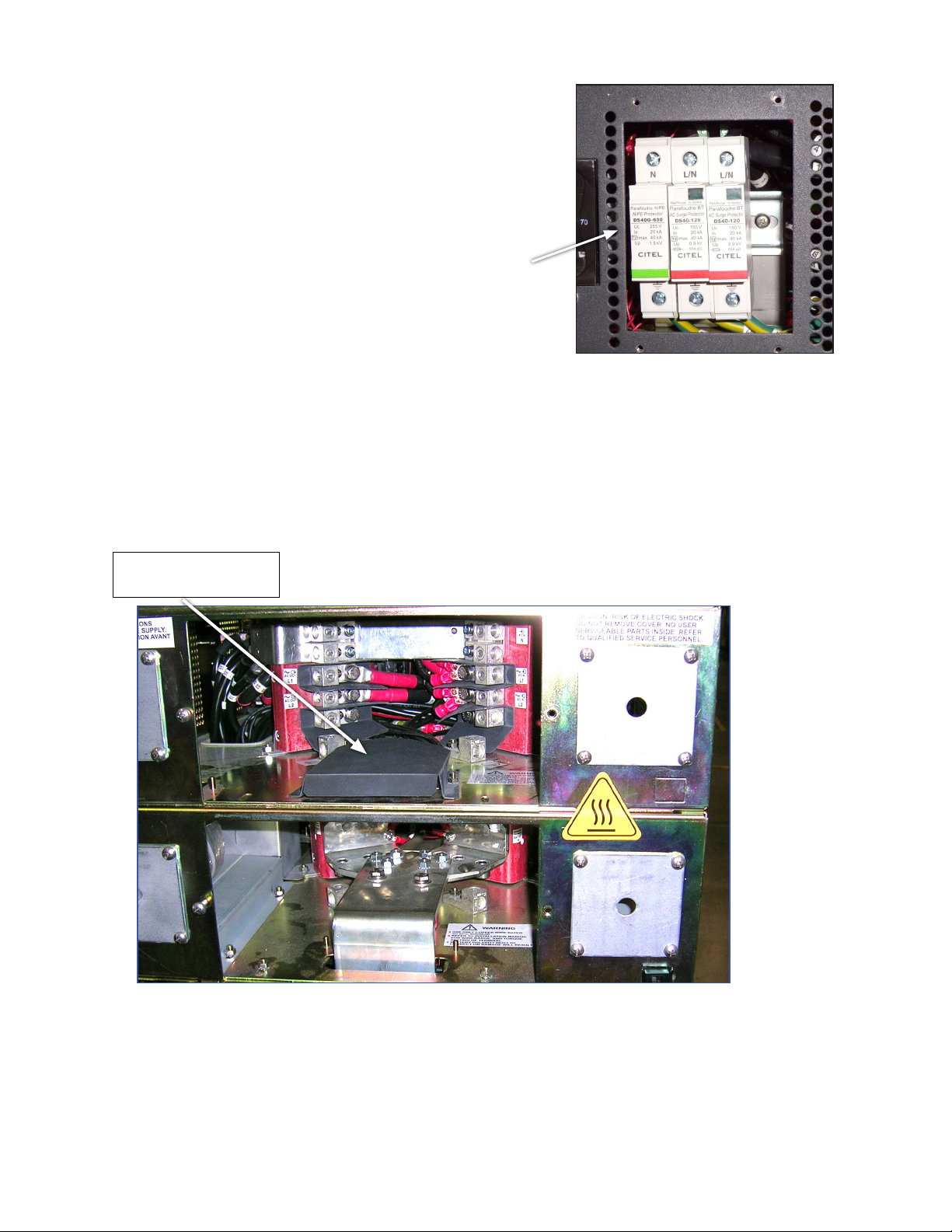

2.3 Rear Components

AC and DC wiring are accessed from the rear of the unit. See Chapter 5 for details.

A 3i+1R shelf system (one rectifier and three AIM1500 modules) has AC rectifier fuses that protect

the system from a wiring fault. Remove the back cover of the AC Wiring panel to access the fuses.

Figure 2 — Surge Suppression Modules

Remove grey cover to

change rectier fuses

Figure 3 — AMPS24 HP rear view (with protective covers removed)

AC distribution

panel

DC distribution

panel

14

Doc. #: 0260011-J0 Rev B

Page 17

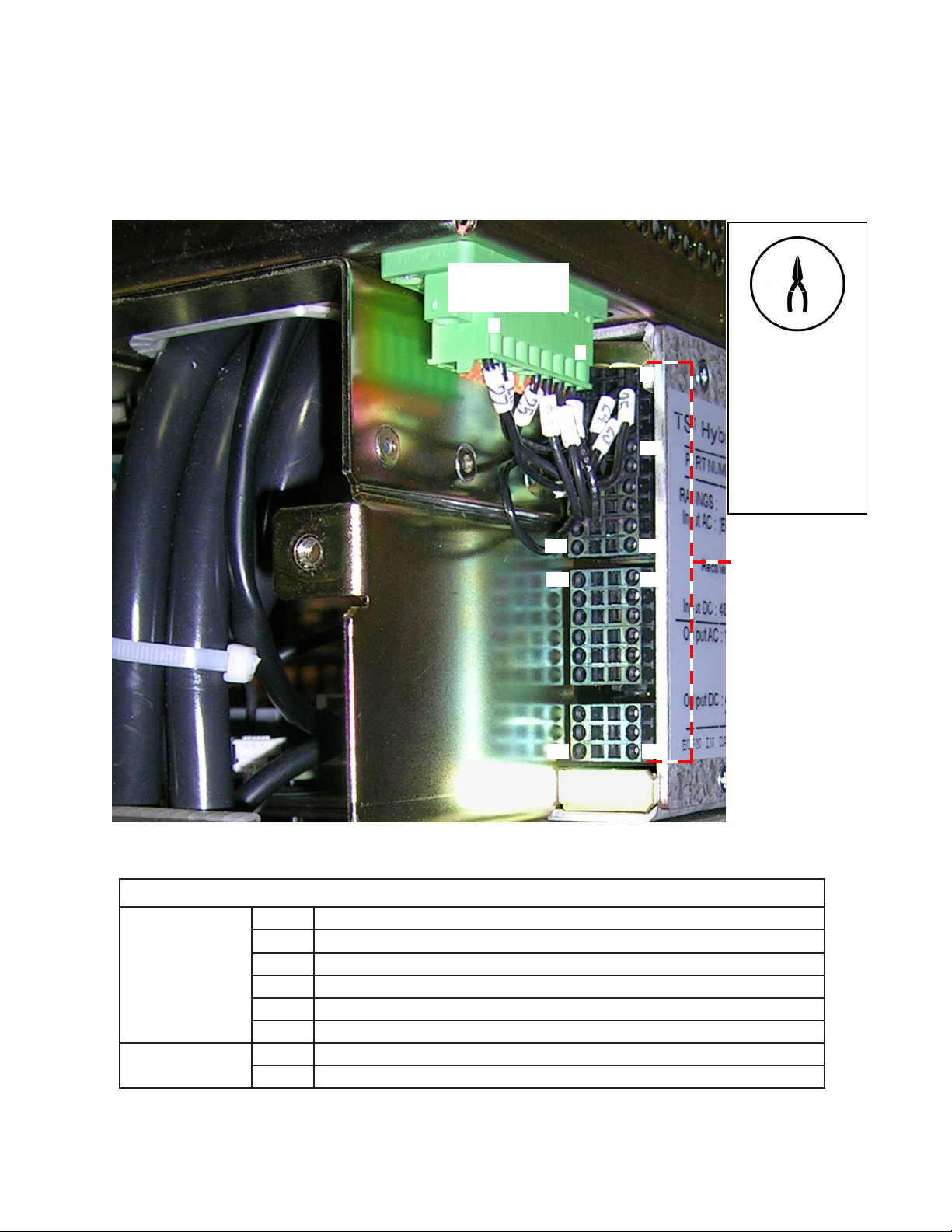

2.3.1 User Interface

On the side of the unit are two connectors. The eight-pin terminal strip is an interface to the AMPS24

with the pinouts listed in Table A. The 40-pin connector is an interface to the CXCR controller with the

pinouts listed in Table B. Some pins are available for customer use.

8-pin

terminal strip

8

19

21

39

1

2

10

20

22

To install wires

in the 40-pin

connector, use

needle-nose pliers

to remove the ter-

minal blocks in the

40-pin connector.

40 pin

connector

40

Figure 4 — Eight-pin terminal strip and 40-pin connector pin locations

Table A — Eight-pin Terminal Strip from AMPS 24

1 TVSS2 alarm

2 Input circuit breaker (CB6) alarm

Factory installed

wiring

Customer

Doc. #: 0260011-J0 Rev B

3 Maintenance bypass switch alarm

4 Output circuit breaker (CB5) alarm

7 Fused DC-: 3A, CXCU LCD, V- to controller (fuse location shown in Figure 1)

8 DC+: CXCU LCD, V+ to controller

5 Fused DC-: up to 2A load, (fuse location shown in Figure 1)

6 DC+

15

Page 18

Table B — Pinouts for 40 Pin Connector Interface to CXCR

1 DIN1 2 DIN2 Output circuit breaker CB5

3 D_COM Fused DC- 4 DIN3 MBS

5 DIN4 6 DIN5 Input circuit breaker CB6

7 D_COM Fused DC- 8 DIN6 TVSS

Not Used

9 N/A 10 N/A

11 N/A 12 N/A

Analog Inputs

13 V1+ 14 T1+

15 V1- 16 T1-

17 I1+ 18 T2+

19 I1- 20 T2-

Relay Contacts (rated at 60VDC or 42V AC, 0.5A)

From the factory, the Cordex controller is congured with the relay assignments shown below. The relays can

be unassigned from their factory conguration and remapped. For example Relay 2, K2, can be unassigned

from LVD #2 then remapped as an alarm relay. Refer to the Cordex controller manual for details.

21 K1_NO

LVD #1

25 K1_COM 26 K2_COM

27 K3_NO

LVD #3

31 K3_COM 32 K4_COM

33 Not installed 34 Not installed

35 K5_NO

Power System

Major alarm

39 K5_COM 40 K6_COM

22 K2_NO

28 K4_NO

36 K6_NO

Battery temperature probe

(Figure 6)

Battery temperature probe

(Figure 6)

LVD #223 K1_NC 24 K2_NC

Power System Minor alarm29 K3_NC 30 K4_NC

AC Mains High/Low alarm37 K5_NC 38 K6_NC

2.4 Low Voltage Battery Disconnect (Optional)

A built-in AMPS24 shutdown cuts off the load

during a lengthy power outage.

Installing an LVD (Alpha part number 020615-20), between the AMPS24 HP and the

batteries, disconnects the AMPS24 HP from

the batteries to prevent further drain of the

batteries during a lengthy power outage.

The controller is configured with a relay

assigned to LVD #1. Figure 5 shows how to

wire the normally closed contacts of the LVD

#1 relay to activate the LVD. The activation

value is set in the Controls >LVD Control

menu—see the controller software manual.

16

Pinouts available at the AMPS24 40 pin connector

– see Figure 4 and (Table B.

LVD#1

K1 Relay

-48V@Pin 3

AMPS24 HP

Pin 21

Pin 25

LVD

Pin 23

Batteries

Figure 5 — LVD wiring

Doc. #: 0260011-J0 Rev B

Page 19

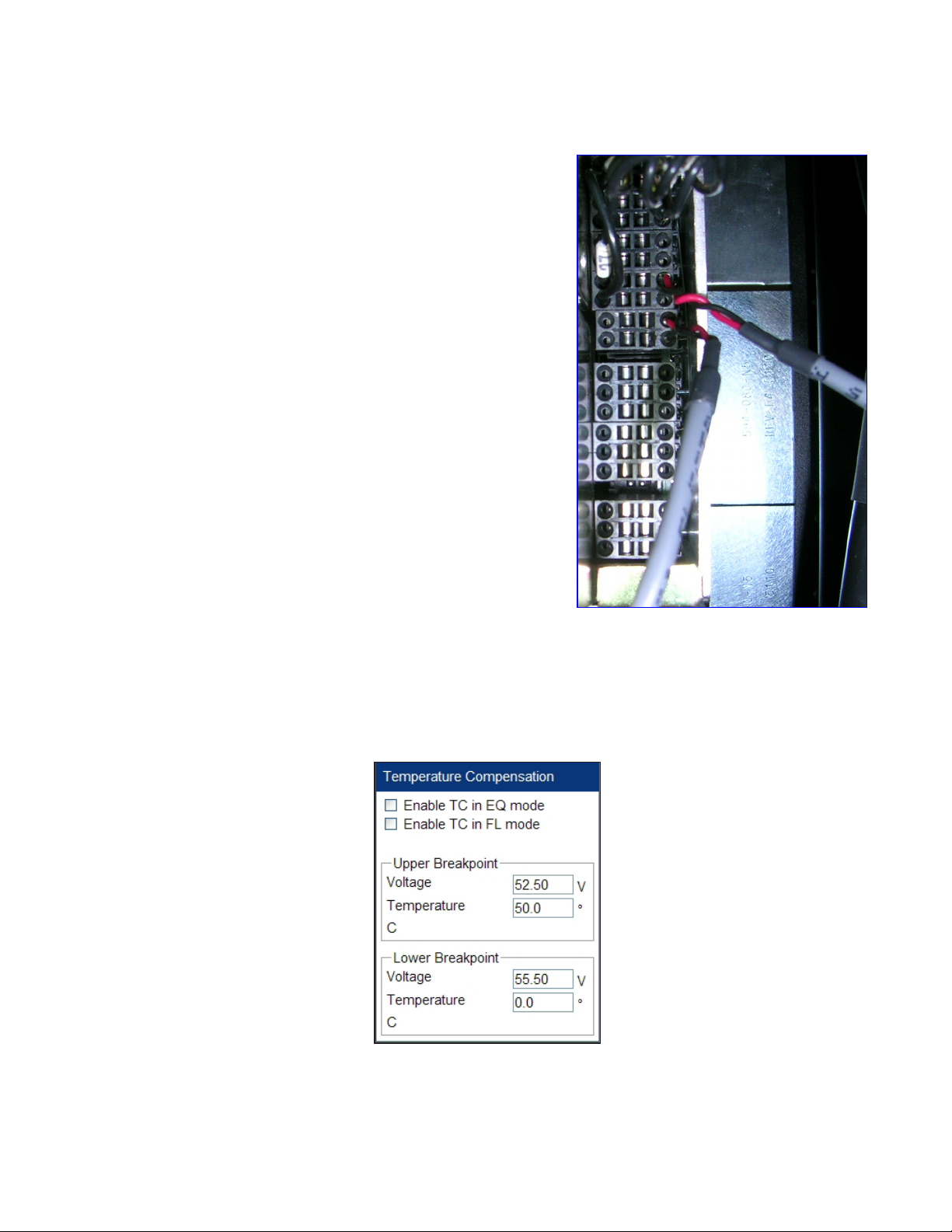

2.5 Battery Temperature Probes

Adjusting the battery’s float or equalize voltage to

correspond with temperature fluctuations ensures

maximum battery performance and life expectancy.

The CXC’s built-in automatic temperature

compensation function adjusts the system every ten

minutes as the temperature changes and changes the

voltage by a maximum of 0.1 V during this interval.

A battery probe from a single string can be connected

to pins #18 and #20 of the AMPS24 HP 40-pin

connector. Figure 6 shows the connection of two

battery probes where pins #14 and #16 are used for

the second probe.

Connection Procedure

1. Use needle nose pliers to remove the terminal

block.

2. Connect the battery temperature probes,

3. To calibrate the temperature probes, refer to

Analog Signal Calibration in the CXCU manual or

to the alpha website (www.alpha.ca): Technical

Documentation > Method of Procedures

> Cordex > Controller > Calibration –

Temperature (web interface).

4. Complete the Batteries > Battery Properties

parameters to enable the Temperature

Compensation feature. The Battery Properties window contains information provided by the

battery manufacturer.

Figure 6 — Battery temperature probes

5. Set up temperature compensation in Batteries > Configure Batteries—see Figure 7.

Doc. #: 0260011-J0 Rev B

Figure 7 — Batteries > Configure Batteries

17

Page 20

2.6 Network Requirements

The CXCU has a single Ethernet port on its front panel for communication with either the graphic

display or a laptop.

Cable that connects

the CXCU to the

graphic display

Figure 8 — Cable connection to CXCU for graphic display

CXCU RJ45

connection

2.6.1 Single Connection

The graphic display, which

uses a browser to launch CXC

web pages, is installed in

the DC distribution shelf (see

Figure 1). This display connects

to the Ethernet port on the front

of the CXCU.

To use a laptop to configure the

system, disconnect the graphic

display cable from the RJ45

jack on the CXCU (Figure 8).

Connect the laptop to the RJ45

jack with an Ethernet crossover

cable.

CXCU installed

in AMPS24 HP shelf

Ethernet

connector

Ethernet

connector

Figure 9 — Single network connection to CXCU

OR

Graphic Display

http://10.10.10.201/

Obtain an IP Address Using DHCP

Use the following IP Address

IP Address:

10. 10. 10. 202

Subnet Mask:

255. 255. 255. 0

Default Gateway:

PC running IE8.0

or Firefox

Application SettingsCXC Connection SettingsIP Protocol SettingsConnection Status

Cancel Apply

18

Doc. #: 0260011-J0 Rev B

Page 21

2.6.2 Multiple Connections

Since the CXCU controller only has one port, a switch must be used for the following requirements:

• Simultaneous display at the graphic display and a local laptop

• Local display at the graphic display and remote Simple Network Management Protocol (SNMP) /

Ethernet functionality

Alpha Technologies has tested the Netgear JFS516 network switch, but network switches with the following

functionality will work:

• Network Interface: RJ-45 connector for 10BASE-T or 100BASE-TX Ethernet interface

• Meets IEEE 802.3i 10BASE-T Ethernet, IEEE 802.3u,100BASE-TX Fast Ethernet

• Meets IEEE 802.3x Flow Control; compatible with Windows®

Graphic Display

http://10.10.10.201/

Obtain an IP Address Using DHCP

Use the following IP Address

IP Address:

10. 10. 10. 202

Subnet Mask:

255. 255. 255. 0

Default Gateway:

Application SettingsCXC Connection SettingsIP Protocol SettingsConnection Status

Cancel Apply

CXCU

Ethernet

connector

Remote Network

Access

PC running

IE7.0 or greater

or Firefox

Router or switch

Ethernet

Ethernet

PC running IE8.0

or Firefox

Figure 10 — Multiple network connections to the CXCU

Doc. #: 0260011-J0 Rev B

19

Page 22

3. Power Configurations

This section lists the power configurations available with the AMPS24 system and defines the

terminology used throughout this manual.

3.1 Power System Configuration Terminology

3.1.1 120Vac Single Phase

A single phase system is 120Vac from L1 to N (neutral).

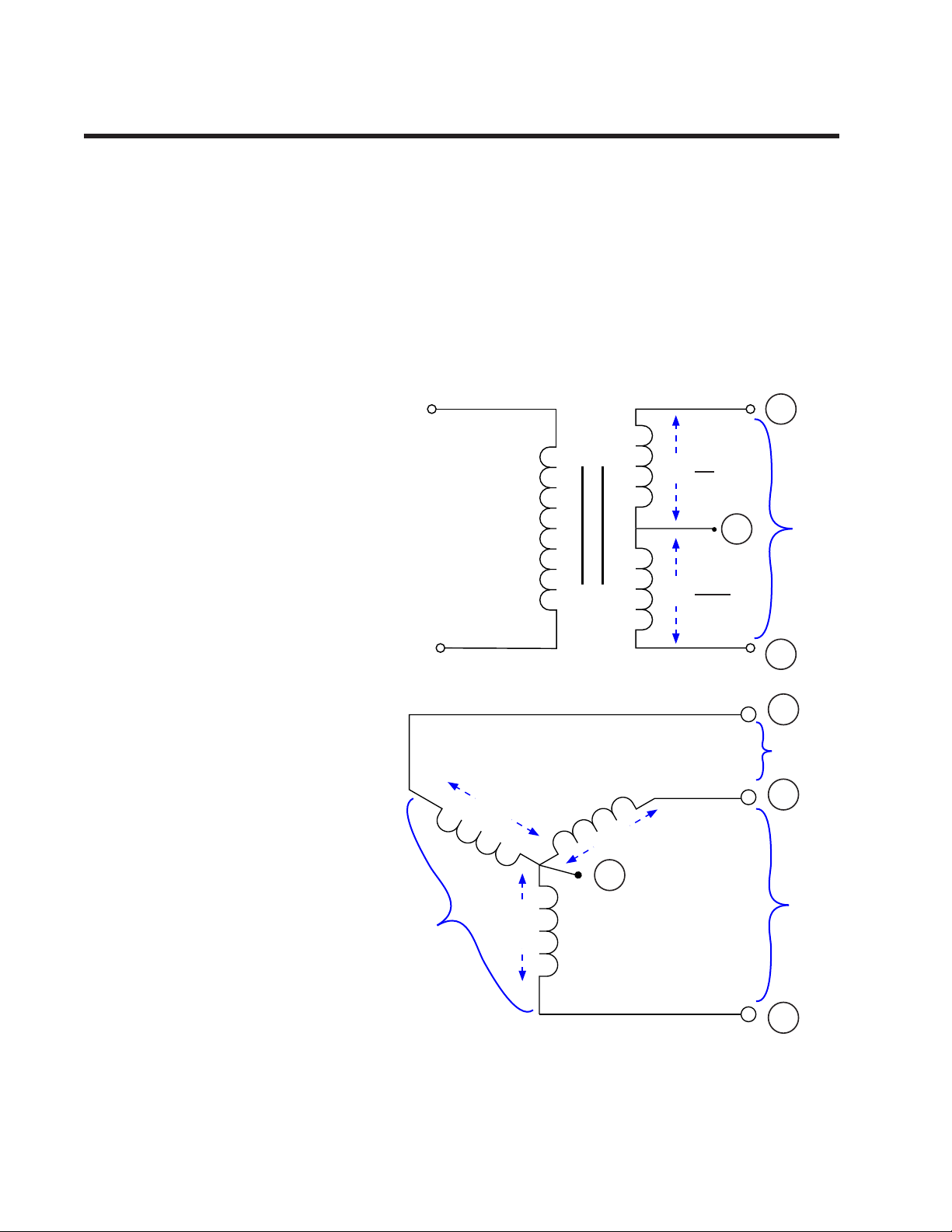

3.1.3 120/240Vac Split Phase

The term 120/240Vac SPLIT PHASE

is used throughout this manual to

identify the “3-wire/ 2 legs from a

single phase supply” configuration

shown in Figure 11.

3.1.2 120/208Vac 2-Pole

The term 120/208 2-POLE is used

throughout this manual to identify

the “2-pole from a 3-phase supply”

configuration such as L2 to L3 shown

in Figure 12.

120V /0°

N

120V /180°

Figure 11 — Split Phase from a Single phase supply

120V

120V

L1

240V

L2

L1

208V

L2

3.1.4 120/208Vac 3-Phase

Each phase conductor is 120 degrees out of phase with the other, as shown in Figure 12. All three

phases (3-pole) plus the neutral are used.

20

N

208V

Figure 12 — 2-Pole from a 3-phase supply

120V

208V

L3

Doc. #: 0260011-J0 Rev B

Page 23

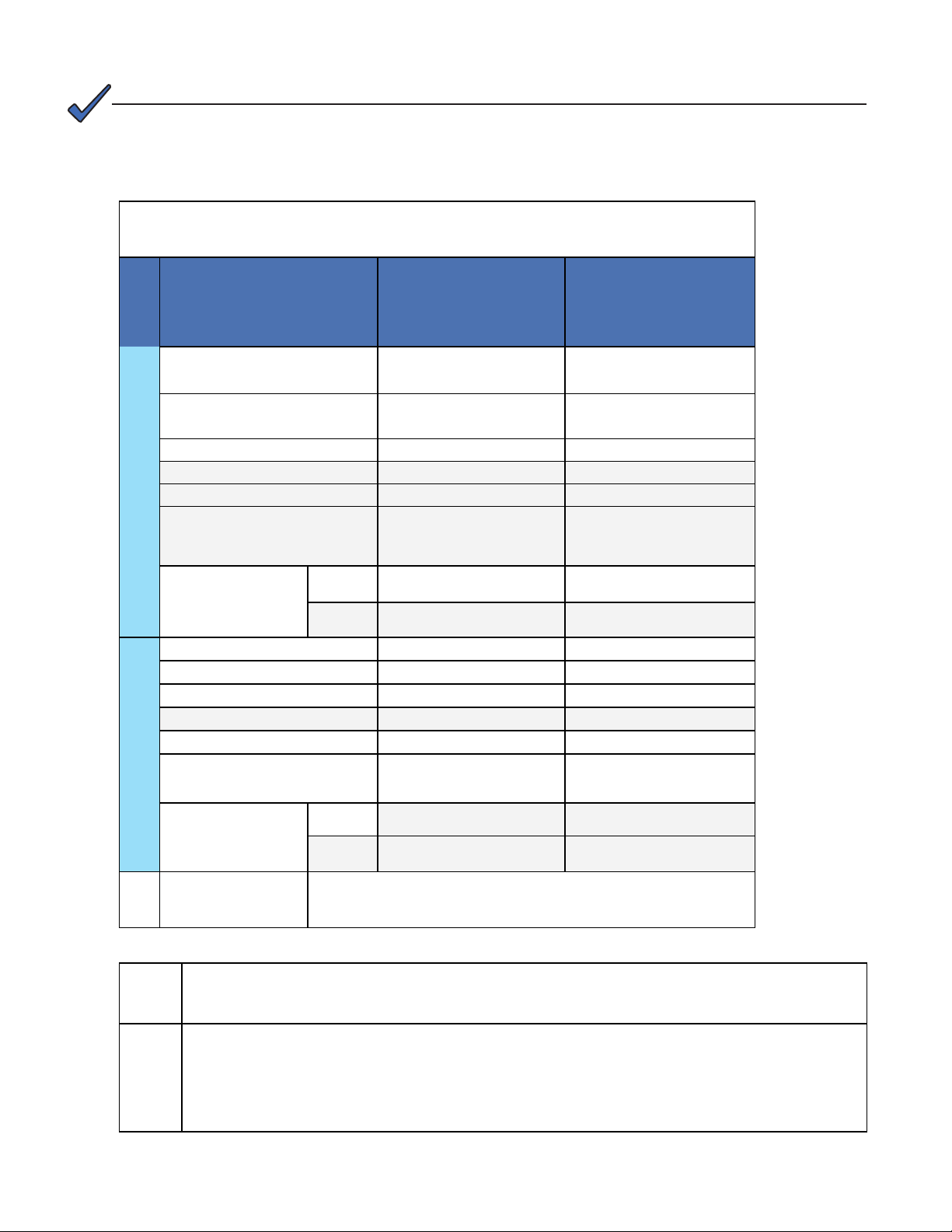

3.2 4i Shelf Systems (No Battery Charger)

The 4i systems, with up to 4 AIM1500 modules per shelf, do not have an integrated 48V charger. The

following table shows available configurations: refer to the section in the last column for more details.

System Part

Number

0260012-201 6kVA 4.8 kW

0260012-203 12kVA 9.6 kW 2 8

0260012-202

(no LCD)

0260012-204 12kVA 9.6 kW 120/208 V 2-phase

0260012-206 24kVA 19.2 kW 4 16

0260012-205 18kVA 14.4 kW 120/208 V 3-phase 3 12 Section 3.7

Max AC

output VA

" " " " " "

Max AC

output power

AC Input and

Output voltage

120 V single phase

or

120/240 V split phase

# of 4

Inverter

shelves

1 4

2 8

Max # of

AIM1500

modules

3.3 3i+1R Shelf Systems (Integrated Battery Charger)

3i+1R Shelf Systems have 1 rectifier per shelf and up to 3 inverters per shelf.

System Part

Number

0260011-101 4.5kVA 3.6 kW

0260011-102 9kVA 7.2 kW 2 x 3i+1R shelves 6

0260011-104

0260011-103

0260011-106 18kVA 14.4 kW 4 x 3i+1R shelves 12

0260011-107

0260011-105 13.5kVA 10.8 kW 120/208 V 3-phase 3 x 3i+1R shelves 9 Section 3.7

Max AC

output VA

10.5kVA 8.4 kW 1 x 3i+1R shelf

9kVA 7.2 kW

21kVA 16.8 kW 2 x 3i+1R shelf

Max AC

output power

AC Input and

Output voltage

120 V single phase

120/208 V 2-pole

or

120/240 V split

phase

# of 3i+1R

shelves

1 x 3i+1R shelf 3

plus 1 x 4i shelf

2 x 3i+1R shelves 6

plus 2 x 4i shelf

Max # of

AIM1500

modules

14

Reference

Section 3.5

Section 3.6

Reference

Section 3.5

7

Section 3.6

3.4 System Spares

See "Table J — Spare Parts" on page 69.

Doc. #: 0260011-J0 Rev B

21

Page 24

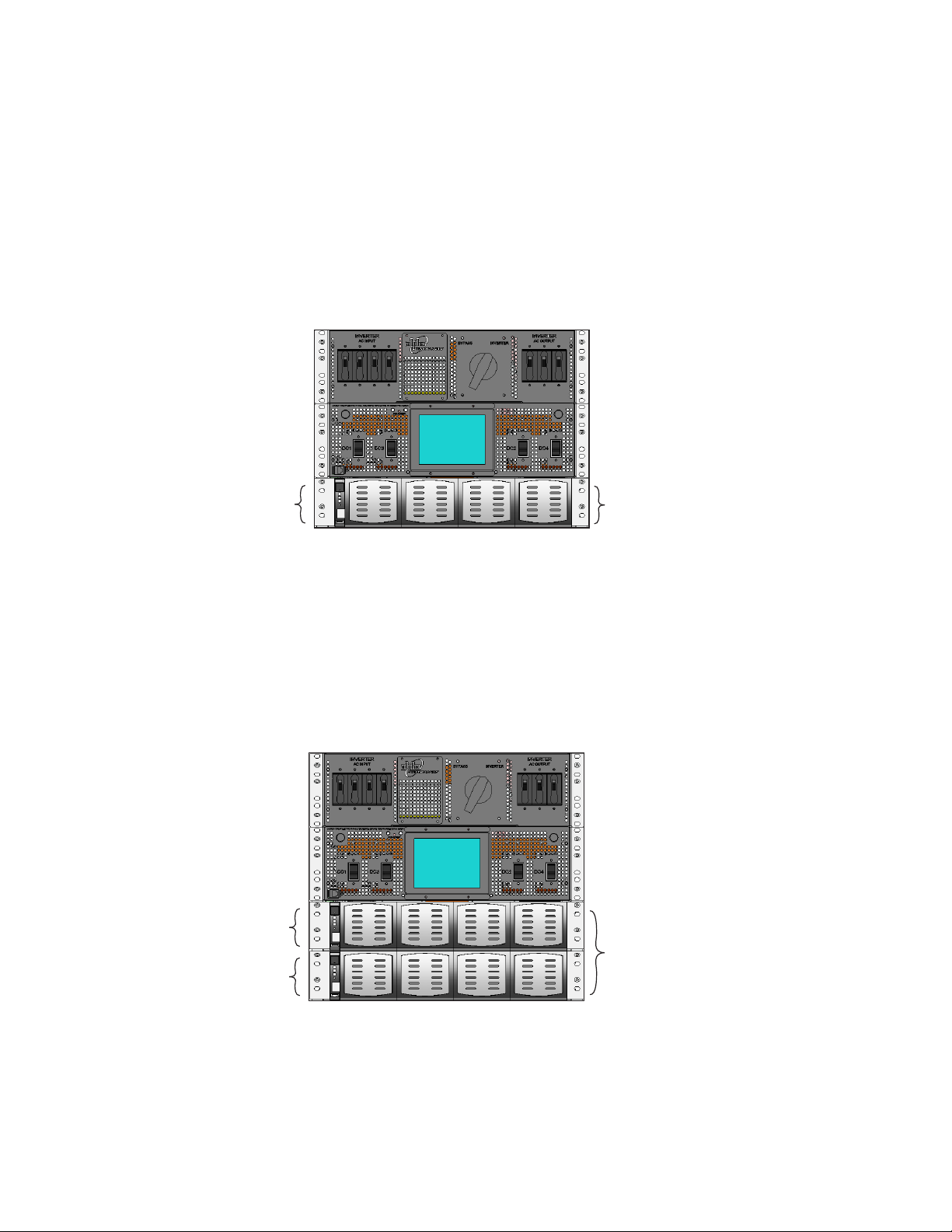

3.5 120V Single Phase Systems

See the facility planning data sheets for the two configurations shown below:

• "Table C — 10.5kVA, 9kVA and 4.5kVA, 120V Single Phase 3i+1R Shelf Systems" on page 23

• "Table D — 12kVA and 6kVA, 120V Single Phase, 4i Shelf Systems" on page 24

Configurations for a Single Shelf

• 4i shelf

• 3i+1R shelf

DC 1

Configurations for Two Shelves

• two 4i shelves

• two 3i+1R shelves

• one 3i+1R shelf and one 4i shelf

DC 1

DC 2

Phase 1

Phase 1

22

Doc. #: 0260011-J0 Rev B

Page 25

NOTE:

The recommendations in Table C are for reference only. A registered professional engineer

must review and approve or modify these recommendations in compliance with applicable

national and local electrical and building codes.

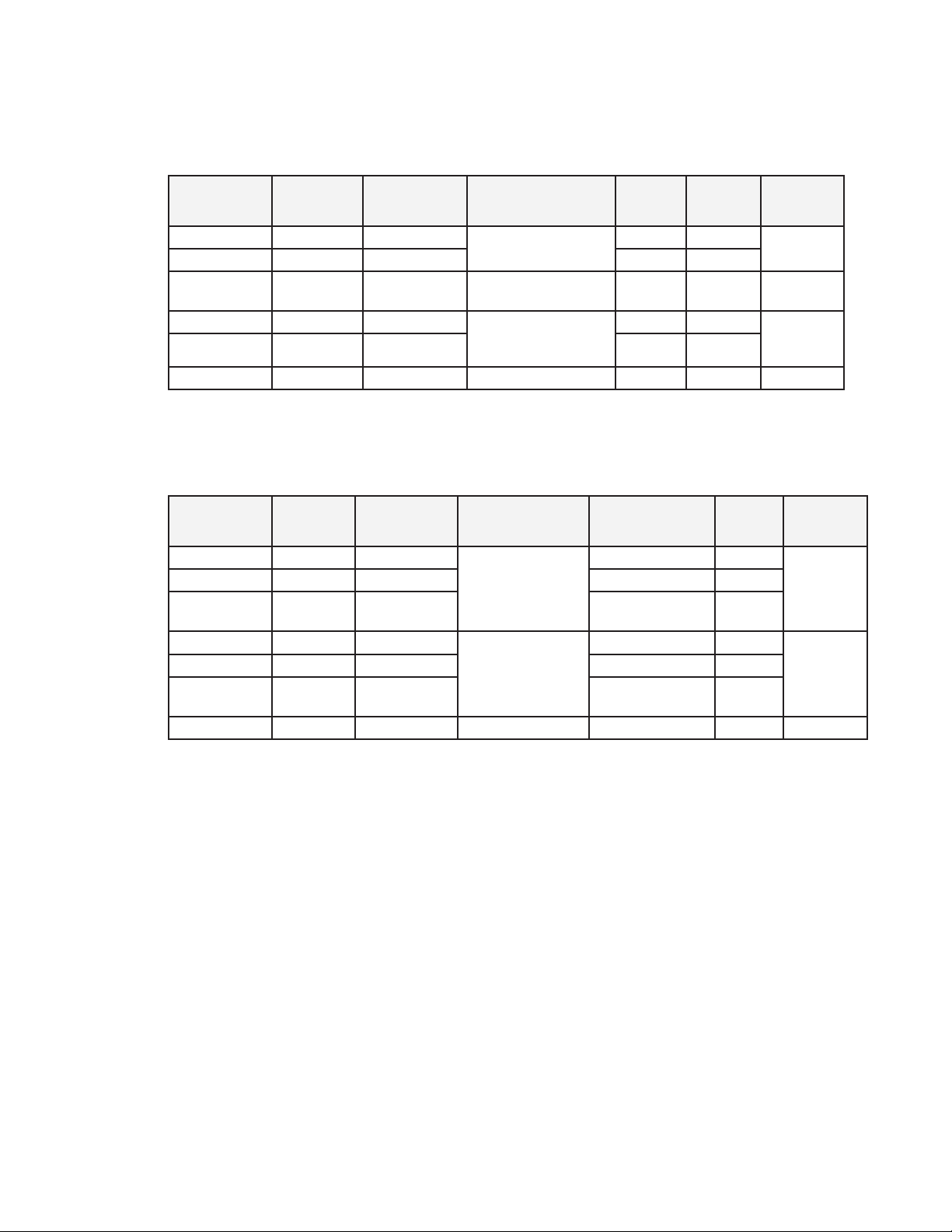

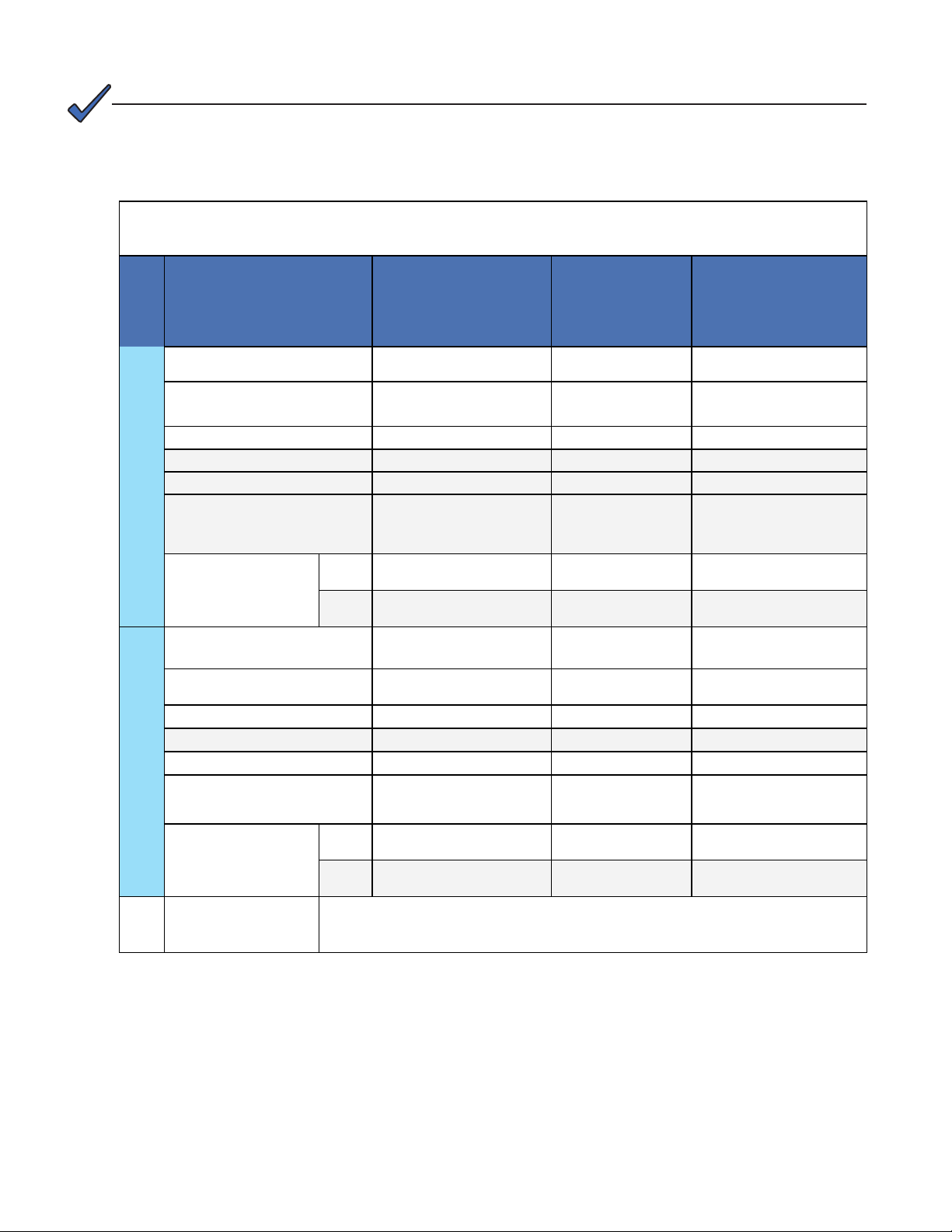

Table C — 10.5kVA, 9kVA and 4.5kVA, 120V Single Phase 3i+1R Shelf

Systems

Models

AC Input Voltage 120V 120V 120V

Full Load AC Input Current

(per phase)

AC Input poles & wiring 2w +G 2w + G 2w + G

Wiring 1 pole 1 pole 1 pole

SCCR 2100A 2100A 1600A

Recommended

AC Input

AC input Breaker/fuse

(Note: 2)

Recommended

AC Input Wire size,

90ºC copper (Note 1)

Total AC Output (Max)

AC Output Voltage 120V 120V 120V

AC Output poles & wiring 2w +G 2w +G 2w +G

Wiring 1 pole 1 pole 1 pole

AC Output Current (per Phase) 87.5A 75A 37.5A

NEC

50ºC

CEC

50ºC

AMPS24-1-10.5-H1-i1

#0260011-104

108A 108A 54A

125A 120A 70A

1 1/0 6

1/0 1/0 4

10.5kVA/

8.4kW

AMPS24-1-9-H2

#0260011-102

9kVA/7.2kW 4.5kVA/3.6kW

AMPS24-1-4.5-H1

#0260011-101

Installed Inverter Output

Circuit Breaker 100% rated

AC Output

Recommended

AC Input Wire size,

90ºC copper (Note 1)

AC Input & Output

connection terminals

Doc. #: 0260011-J0 Rev B

100A 100A 70A

NEC

50ºC

CEC

50ºC

Box lugs are rated for both Aluminum and Copper wire, #2/0 to #6 AWG. Fasten

clamping screw to 120 in-lbs (14 N-m)

1 1 6

1/0 1/0 4

23

Page 26

NOTE:

The recommendations in Table D are for reference only. A registered professional engineer

must review and approve or modify these recommendations in compliance with applicable

national and local electrical and building codes.

Table D — 12kVA and 6kVA, 120V Single Phase, 4i Shelf

Systems

Models

AMPS24-2-12-i2

#0260012-203/202

AC Input Voltage 120V 120V

Full Load AC Input Current

(per phase)

AC Input poles & wiring 2w +G 2w +G

Wiring 1 pole 1 pole

SCCR 2100A 1600A

Recommended

AC Input

AC input Breaker/fuse

(Note: 2)

Recommended

AC Input Wire size,

90ºC copper (Note 1)

Total AC Output (Max)

AC Output Voltage 120V 120V

AC Output poles & wiring 2w +G 2w +G

Wiring 1 pole 1 pole

AC Output Current (per Phase) 100A 50A

NEC 50ºC

CEC 50ºC

106A 53A

150A 70A

1 6

1/0 4

12kVA/

9.6kW

AMPS24-1-6-i1

#0260012-201

6kVA/

4.8kW

24

Installed Inverter Output

Circuit Breaker 100% rated

AC Output

Recommended

AC Input Wire size,

90ºC copper (Note 1)

AC Input & Output

connection terminals

Note 1:

Note 2:

Inverter AC Input & AC Output connections: Calculations based on full load and charging current, 0.8

derating with 5 current carrying conductors, (L1,L2,L3,2xN) due to possible high harmonic content load.

Temperature correction factor for 50C applied.

Maximum AC Utility Service protection feeding the AMPS24 is 150A. Actual supply circuit breaker must

be sized appropriately for the supply wire used. Consult your local and national electrical codes. Double

neutral is strongly recommended for AC output wiring (and AC input wiring to the MBS) for 3Ф systems with

signicant non-linear (ie rectied capacitive) loads. Since the AC input to systems without MBS is power

factor corrected, AC wiring to systems without MBS does not require double neutral wiring.

100A 70A

NEC 50ºC

CEC 50ºC

Box lugs are rated for both Aluminum and Copper wire, #2/0 to #6

AWG. Fasten clamping screw to 120 in-lbs (14 N-m)

1 6

1/0 4

Doc. #: 0260011-J0 Rev B

Page 27

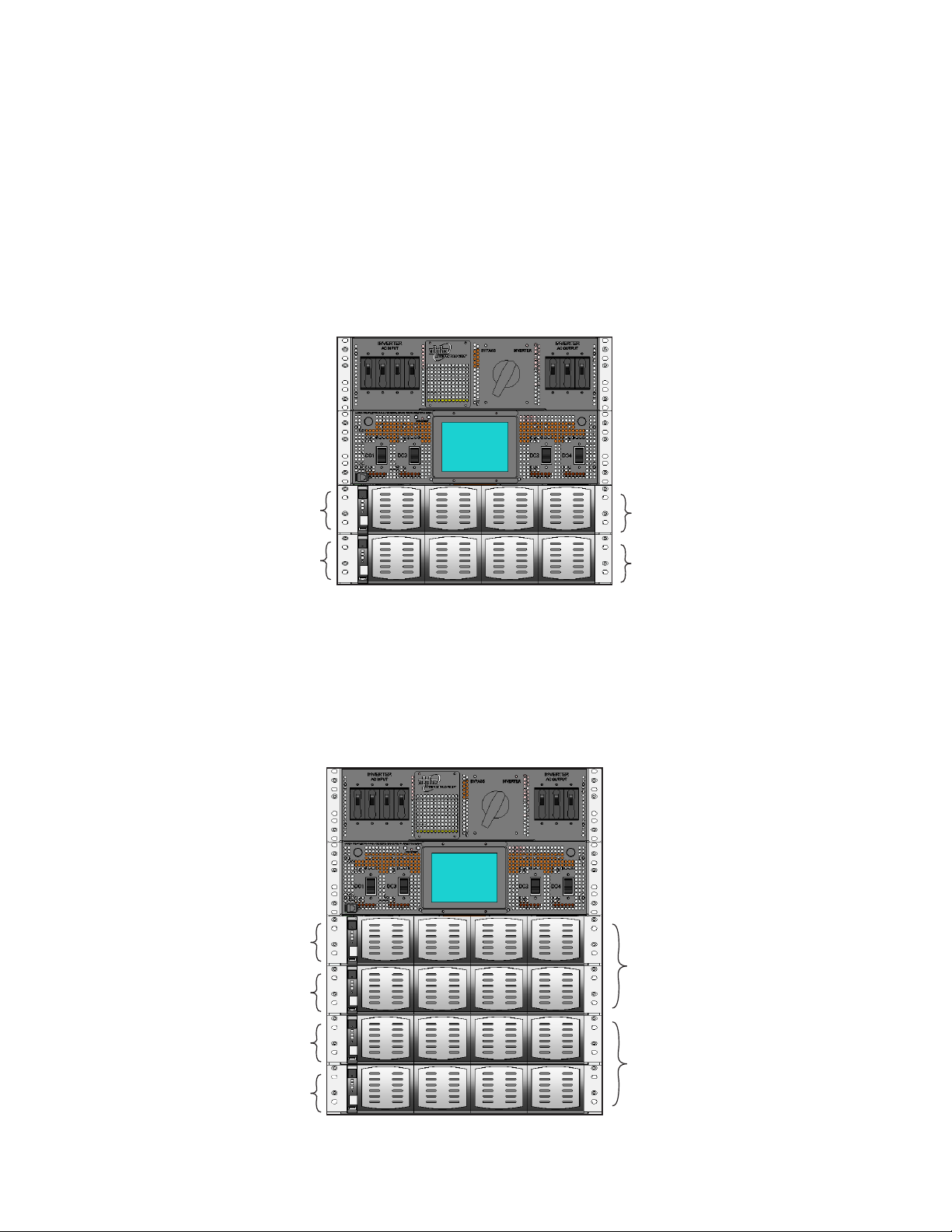

3.6 120V/240V Split Phase or 120/208V 2-Pole Systems

For facility planning data sheets, see

• "Table E — 21kVA, 18kVA, & 9.0kVA 120/240V Split Phase or 120/208 2-Pole 3i+1R Shelf Systems" on page

26 and

• "Table F — 24kVA & 12KVA 120/240V Split Phase or 120/208 2-Pole 4i shelf Systems" on page 27

Configurations for Two Shelves

• two 4i shelves (AMPS24-2-12-i2)

• two 3i+1R shelves (AMPS24-2-9-H2)

DC 1

DC 2

Configurations for Four Shelves

• four 4i shelves (AMPS24-2-24-i4)

• four 3i+1R shelves (AMPS24-2-18-H4)

• two 3i+1R shelves and two 4i shelves (AMPS24-2-21-H2-i2)

DC 1

Phase 1

Phase 2

Phase 1

DC2

DC 3

DC 4

Doc. #: 0260011-J0 Rev B

Phase 2

25

Page 28

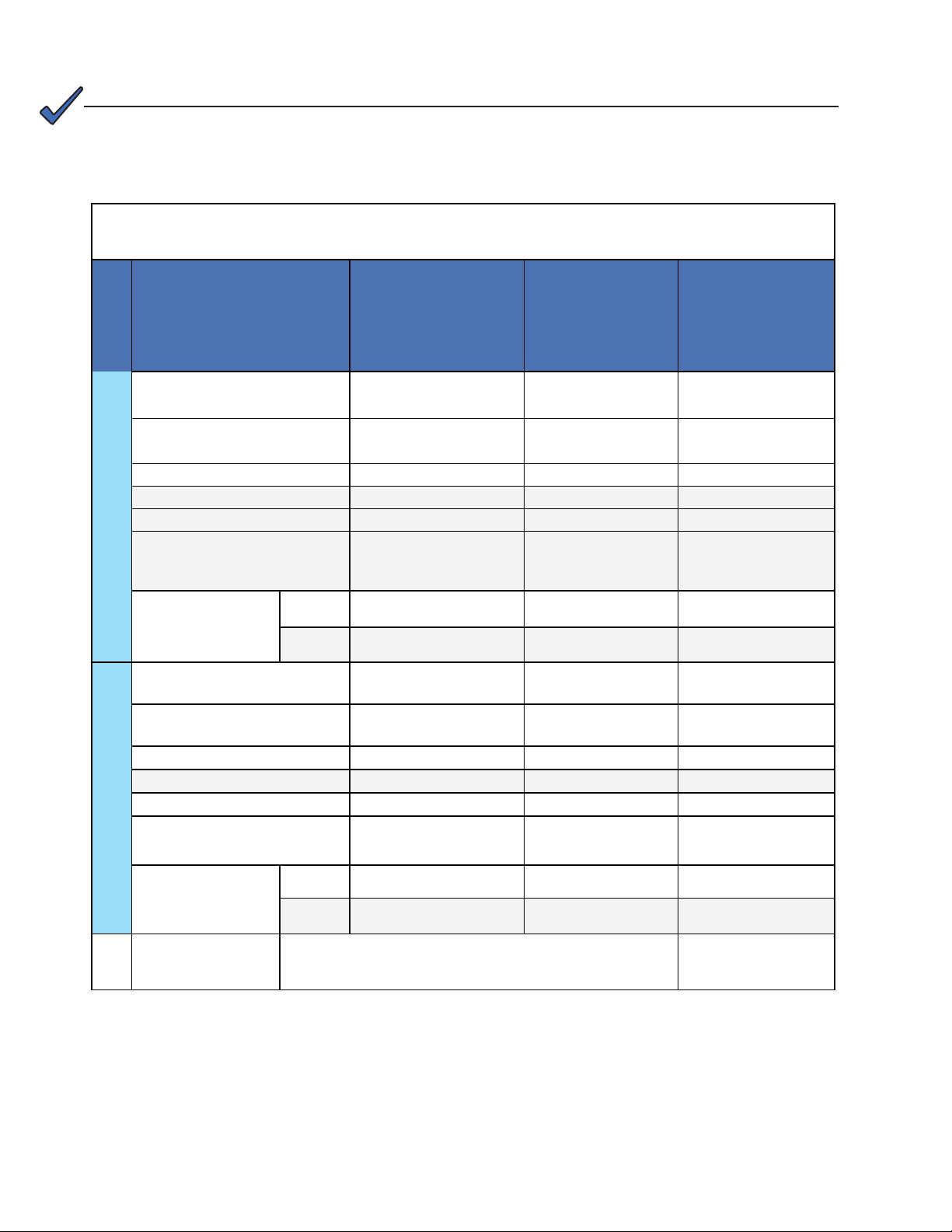

NOTE:

The recommendations in Table E are for reference only. A registered professional engineer

must review and approve or modify these recommendations in compliance with applicable

national and local electrical and building codes.

Table E — 21kVA, 18kVA, & 9.0kVA 120/240V Split Phase or 120/208

2-Pole 3i+1R Shelf Systems

Models

AC Input Voltage 120/208V or 120/240V 120/208V or 120/240V 120/208V or 120/240V

Full Load AC Input Current

(per phase)

AC Input poles & wiring 3w + G 3w + G 3w + G

Wiring 2 pole 2 pole 1 pole

SCCR 2100A 2100A 1600A

Recommended

AC Input

AC input Breaker/fuse

(Note: 2)

Recommended

AC Input Wire size,

90ºC copper (Note 1)

Total AC Output (Max)

AC Output Voltage 120/208V or 120/240V 120/208V or 120/240V 120/208V or 120/240V

NEC 50ºC

CEC 50ºC

AMPS24-2-21-H2-i2

0260011-107

118A 121A 61A

150A 150A 80A

2/0 2/0 3

2/0 2/0 3

21kVA/

16.8kW

AMPS24-2-18-H4

0260011-106

18kVA/

14.4kW

AMPS24-2-9-H2

0260011-103

9kVA/

7.2kW

26

AC Output poles & wiring 3w + G 3w + G 3w + G

Wiring 2 pole 2 pole 1 pole

AC Output Current (per Phase) 87.5A 75A 37.5A

Installed Inverter Output

Circuit Breaker 100% rated

AC Output

Recommended

AC Input Wire size,

90ºC copper (Note 1)

AC Input & Output

connection terminals

NEC 50ºC

CEC 50ºC

Box lugs are rated for both Aluminum or Copper wire, #2/0 to

#6 AWG. Fasten clamping screw to 120 in-lbs (14 N-m)

100A 100A 70A

2/0 2/0 3

2/0 2/0 3

Doc. #: 0260011-J0 Rev B

Page 29

NOTE:

The recommendations in Table F are for reference only. A registered professional engineer

must review and approve or modify these recommendations in compliance with applicable

national and local electrical and building codes.

Table F — 24kVA & 12KVA 120/240V Split Phase or 120/208

2-Pole 4i shelf Systems

Models

AC Input Voltage 120/208V or 120/240V 120/208V or 120/240V

Full Load AC Input Current

(per phase)

AC Input poles & wiring 3w + G 3w + G

Wiring 2 pole 2 pole

SCCR 2100A 1600A

Recommended

AC Input

AC input Breaker/fuse

(Note: 2)

Recommended

AC Input Wire size,

90ºC copper (Note 1)

Total AC Output (Max) 24kVA/19.2kW 12kVA/9.6kW

AC Output Voltage 120/208V or 120/240V 120/208V or 120/240V

AC Output poles & wiring 3w + G 3w + G

Wiring 2 pole 2 pole

AC Output Current (per Phase) 100A 50A

NEC 50ºC

CEC 50ºC

AMPS24-2-24-i4

0260012-206

106A 53A

150A 70A

2/0 4

2/0 4

AMPS24-2-12-i2

0260012-204

Installed Inverter Output

Circuit Breaker 100% rated

AC Output

Recommended

AC Input Wire size,

90ºC copper (Note 1)

AC Input & Output

connection terminals

Note 1:

Note 2:

Doc. #: 0260011-J0 Rev B

Inverter AC Input & AC Output connections: Calculations based on full load and charging current, 0.8

derating with 5 current carrying conductors, (L1,L2,L3,2XN) due to possible high harmonic content load.

Temperature correction factor for 50C applied.

Maximum AC Utility Service protection feeding the AMPS24 is 150A. Actual supply circuit breaker must

be sized appropriately for the supply wire used. Consult your local and national electrical codes. Double

neutral is strongly recommended for AC output wiring (and AC input wiring to the MBS) for 3Ф systems with

signicant non-linear (ie rectied capacitive) loads. Since the AC input to systems without MBS is power

factor corrected, AC wiring to systems without MBS does not require double neutral wiring.

100A 70A

NEC 50ºC

CEC 50ºC

Box lugs are rated for both Aluminum and Copper wire, #2/0 to #6

AWG. Fasten clamping screw to 120 in-lbs (14 N-m)

2/0 4

2/0 4

27

Page 30

3.7 120V/208V 3-Phase Systems

For facility planning data sheet, see "Table G — 18kVA and 13.5kVA, 120V/208V 3-Phase Systems"

on page 29.

Configurations for 3-Phase Three Shelf

• three 4i shelves (AMPS24-3-18-i3)

• three 3i+1R shelves (AMPS24-3-13.5-H3)

DC 1

DC 2

DC 3

Phase 1

Phase 2

Phase 3

28

Doc. #: 0260011-J0 Rev B

Page 31

NOTE:

The recommendations in Table G are for reference only. A registered professional engineer

must review and approve or modify these recommendations in compliance with applicable

national and local electrical and building codes.

Table G — 18kVA and 13.5kVA, 120V/208V 3-Phase

Systems

Models

AMPS24-3-18-i3

(4i Shelf)

0260012-205

AC Input Voltage 120/208V 120/208V

Full Load AC Input Current

(per phase)

AC Input poles & wiring 4 w + G 4 w + G

Wiring 3Ф Wye 3Ф Wye

SCCR 1600A 1600A

Recommended

AC Input

AC input Breaker/fuse

(Note: 2)

Recommended

AC Input Wire size,

90ºC copper (Note 1)

Total AC Output (Max) 18 kVA/ 14.4kW 13.5 kVA/ 10.8kW

AC Output Voltage 120/208V 120/208V

AC Output poles & wiring 4 w + G 4 w + G

Wiring

AC Output Current (per Phase) 50A 37.5A

NEC 50ºC

CEC 50ºC

56A 59A

80A 80A

4 4

3 3

3Ф Wye 3Ф Wye

AMPS24-3-13.5-H3

(3i+1R Shelf)

0260011-105

Installed Inverter Output

Circuit Breaker 100% rated

AC Output

Recommended

AC Input Wire size,

90ºC copper (Note 1)

AC Input & Output

connection terminals

Note 1:

Note 2:

Doc. #: 0260011-J0 Rev B

Inverter AC Input & AC Output connections: Calculations based on full load and charging current, 0.8

derating with 5 current carrying conductors, (L1,L2,L3,2XN) due to possible high harmonic content

load. Temperature correction factor for 50C applied.

Maximum AC Utility Service protection feeding the AMPS24 is 150A. Actual supply circuit breaker

must be sized appropriately for the supply wire used. Consult your local and national electrical

codes. Double neutral is strongly recommended for AC output wiring (and AC input wiring to the

MBS) for 3Ф systems with signicant non-linear (ie rectied capacitive) loads. Since the AC input to

systems without MBS is power factor corrected, AC wiring to systems without MBS does not require

double neutral wiring.

70A 70A

NEC 50ºC

CEC 50ºC

Box lugs are rated for both aluminum or copper wire, #2/0 to #6

AWG. Fasten clamping screw to 120 in-lbs (14 N-m)

4 4

3 3

29

Page 32

3.8 AMPS24 HP - Recommended DC Breaker and Wire Sizes

NOTE:

The recommendations in this table are for reference only. A registered professional engineer must review and approve or modify these recommendations in compliance with applicable national and local electrical and building codes.

Maximum wire gauge size is 350 kcmil; 4/ 0 or smaller is recommended, 90°C or better copper only.

Model Recommended minimum DC Breaker

rating (100% rated per feed),

Single DC feed Dual DC feed

AMPS24-2-24 x 300 21.4 kW 480 A

AMPS24-2-21 x 250 18.7 kW 406 A

AMPS24-2-18 x 225 16 kW 333 A

AMPS24-2-9 250 125 8 kW 166 A

AMPS24-2-12 300 150 10.7 kW 240 A

AMPS24-3-18 x 225 16 kW 350 A

AMPS24-3-13.5 350 175 15 kW 250 A

AMPS24-1-10.5 250 125 9.4 kW 203 A

AMPS24-1-12 300 150 10.7 kW 240 A

AMPS24-1-9 250 125 8 kW 166 A

AMPS24-1-6 150 75 5.4 kW 120 A

AMPS24-1-4.5 120 60 4 kW 83 A

Maximum DC Input

Wattage

Maximum DC

Input Current @

48Vdc, full load

Torque specifications for DC wiring (3/8" bolts that attach the DC lugs at the back of the DC

distribution box) are as follows:

• Imperial: 190 – 240 inch/lbs

• Metric: 21.5 – 27.1 N-m

30

Doc. #: 0260011-J0 Rev B

Page 33

3.9 How to Configure Inverters in AC Input Groups, AC Output

Groups and DC Input Groups

The following sections show how to distribute the inverters among the phases and also suggests how

to distribute the DC input to the inverters.

NOTE:

The groups in the software settings generally correspond to the AC phases or DC inputs.

3.9.1 AC Input Groups/ AC Output Groups

The CXCU System Controller

provides an interface to

assign inverters to phases

(Inverters > Group Mapp ing).

The logical approach is to

match the configuration of

inverters in the AC Input

Group to the configuration

of inverters in the AC Output

Group as shown.

green

black

red

orange

These groups of inverters can then be monitored as a unit in the View Group Status screen.

Figure 13 — Monitoring AC Input Groups, AC Output Groups and DC Input Groups

Doc. #: 0260011-J0 Rev B

31

Page 34

3.9.2 DC Input Groups

DC feed from the batteries to the inverters is protected by input breakers. The numbering of each DC

input breaker corresponds to the shelf it protects: DC3 input breaker, for example, protects shelf 3.

shows a four shelf, split phase system with the breakers and corresponding shelves labeled.

DC3 breaker

DC1 breaker

DC2 breaker

DC4 breaker

DC 1

Phase 1

DC2

DC 3

Phase 2

DC 4

Figure 14 — DC input breakers

Configuration of the DC input

The configuration of the DC input to the inverters provides several different ways to monitor DC input

power and input current. Table H provides possible configurations.

Table H — DC Input Groups

Monitoring DC Source

32

Bulk Assign all inverters to DC Input Group 1.

Shelf Assign Shelf 1 inverters to DC Input Group 1

Assign Shelf 2 inverters to DC Input Group 2

Assign Shelf 3 inverters to DC Input Group 3

Assign Shelf 4 inverters to DC Input Group 4

Dual Input If the system has two battery strings and makes use of the dual input feature (see 5.3.3):

• Battery 1 string is fed to the inverters through breakers DC1 (shelf 1) & DC3 (shelf 3)

• Battery 2 string is fed to the inverters through breakers DC2 (shelf 2) & DC4. (shelf 4)

To monitor Battery String 1, assign all the inverters in shelves 1 & 3 to DC Input Group 1.

To monitor Battery String 2, assign all the inverters in shelves 2 & 4 to DC Input Group 2.

The number of DC Input

Groups (maximum eight) is

set in the Inverters > Group

Mapping screen and monitored

as a unit in the View Group

Status screen.

Doc. #: 0260011-J0 Rev B

Page 35

4. System Pre-Installation

4.1 Site Selection

The power system must be mounted in a clean and dry environment.

Consider both the floor loading and the physical space required for the AMPS24 HP power system

and the batteries.

4.1.1 Floor Plan Layout

Sufficient free space must be provided at the front and rear of the power system to meet the cooling

requirements of the power system and to allow easy access to the power system components.

Consider the following before selecting a location for the AMPS24 HP power system

• Structure of building able to support the additional weight

• Enough space to meet requirements for access

• Enough space to meet cooling requirements

• Adequate space to do the install

• Route that equipment will take through the building to reach the site

• Check and record distances to load

• Check and record distances to AC power source

• Check and record distances to batteries/DC power source

• Understand the full load on the DC system

• Window for working hours and other similar restrictions

• How much and what kind of prep work can be done in advance

x Reinforce floors

x Install distribution panels

x Install cable racks

x Run wiring

x Minimize cable lengths (cost)

x Minimize cable flow and congestion

4.2 Recommended Installation Layout

• Minimum clearance front and back for installation and maintenance is 3ft (1m

• Minimum clearance front and back for for air flow is 1 foot

• Sides, top, bottom: no clearance required

Mount the AMPS24 HP system in 19" or 23" rack that is securely bolted to the floor.

Doc. #: 0260011-J0 Rev B

33

Page 36

4.3 Transporting the Cabinet

The cabinet is shipped upright on a 99 cm x 99 cm (39" x 39") pallet.

The height of the rack, including pallet and shipping material is 31" (78.7 cm).

The maximum weight of the AMPS24 rack is 123 kg/ 270 lb (4-shelf fully loaded AMPS24 modules

included).

34

Figure 15 — Shipping dimensions (in inches)

Doc. #: 0260011-J0 Rev B

Page 37

4.4 Unpacking Instructions

1. Remove 4 front screws.

2. Remove the screws that are holding the

AMPS24 against the inner frame of the

packaging (the # of screws varies depending

on the size of the AMPS24 unit, i.e. 1 shelf vs.

4 shelves).

3. Remove the 6 nails that hold

the entire packaging down

on the skid (3 nails on each

side of the box).

4. Remove entire wooden box up and over the AMPS24.

Doc. #: 0260011-J0 Rev B

35

Page 38

5. Installation

The AMPS24 is designed for installation in a controlled environment, sheltered from rain, excessive

moisture, dust and other contaminants. Mount the AMPS24 HP system in 19" or 23" rack – front or

mid-mount – that is securely bolted to the floor.

The system arrives pre-wired, and the installer is responsible for connecting the following:

• Utility input to the system (120 V line to neutral)

• Chassis and battery return to the reference ground

• Battery strings

• System to the load

5.1 Input/Output Cabling

The illustrations in the following sections show the locations of the AC input and output, and DC

connection points:

• Connection points are accessed from the back of the system.

• AC wires enter the cabinet through the AC box at the back (section 5.2).

• DC wires enter the cabinet through the DC box at the back (5.3).

Reference Notes:

The AMPS24 HP system is pre-configured from the factory for a single AC feed per phase for

inverters, an internal maintenance bypass switch, and rectifiers if present.

• If the AC input neutral is connected, remove the neutral to ground bonding wire. The neutral to

ground wire is provided for systems without AC input connections in which case the inverter

output is considered a separately derived source and the AC output neutral must be connected

to earth ground.

• In a 3-phase system equipped with an internal maintenance bypass switch and a load with a

significant distortion power factor, it is strongly recommended to provide the AC input and AC

output connection with a double neutral feed. Non-power factor corrected IT power supplies with

rectified-capacitive loads can contain high levels of 3rd harmonics, created in such 3-phase systems. The current in the neutral line can easily be twice the current in the line currents.

The required gauge of the AC input, DC+/DC- input and AC output cabling is determined by the

current rating, circuit breaker rating, typical ambient temperatures and the applicable local electrical

codes. Typically the AC input and standard AC output is 6 wires (L1, L2, and L3, N, N, G) up to

2/0 THHW or RW90 type cable that connects to the AMPS24 HP system with trade size up to 2.5"

conduit.

Refer to the appropriate model in the following sections for specific AC input and output connection

terminal torque specifications.

• Section "3.5 120V Single Phase Systems" on page 22

• Section "3.6 120V/240V Split Phase or 120/208V 2-Pole Systems" on page 25

• Section "3.7 120V/208V 3-Phase Systems" on page 28

36

Doc. #: 0260011-J0 Rev B

Page 39

Carefully review the following schematic and notes 1 through 7 before beginning the AC input and

output, and DC wiring.

Notes

1. All wiring must be in accordance with applicable electrical codes.

2. A low voltage battery disconnect (LVBD) should be provided with the battery system.

3. Inverter main input must always include a neutral connection.

4. Power and control cables must be in separate conduits.

5. N-G shorting jumper is factory installed for inverter systems only. Remove if AC input neutral is

connected. (Refer to note in Figure 16.)

6. L3 is only used with 3-phase systems.

7. Two independent battery strings can be connected. Tie bars are provided for single or dual DC

feed. (Refer to note in Figure 16.)

Doc. #: 0260011-J0 Rev B

Figure 16 — AMPS24 Power and Battery Connections

37

Page 40

5.2 AC Wiring

The two figures below provide both a representation of the AC wiring connections (Figure 17) as well

as an actual unit wired for 3-phase AC power (Figure 18).

N out N in

L1 out

L2 out

L3 out

GND out

Figure 17 — AC Wiring connections diagram

Customer connections

GND in

L1 in

L2 in

L3 in

38

Figure 18 — AC Wiring (shown for 3-phase)

Doc. #: 0260011-J0 Rev B

Page 41

5.3 DC Battery and Ground Cabling

5.3.1 Hardware and Torque Specifications

The DC wiring is attached with 3/8” hardware (1” bolt, washer, spring washer) and 8 are provided

with each AMPS24 system (2 per each of the 4 bolting locations). However, the crimp or lug is not

provided.

The crimp/lug can either be on 1” centers with 3/8” or ½” holes, or 1.75” centers with ½” holes only.

Bus bar tie kits for DC- are included to give the installer the option to make a single battery

connection or two separate battery connections (A/B feeds).

Torque specifications for DC wiring (3/8" bolts that attach the DC lugs at the back of the DC

distribution box) are as follows:

• Imperial: 190 – 240 inch/lbs

• Metric: 21.5 – 27.1 N-m

5.3.2 DC Battery Wiring – Single Feed

The following figures show a unit wired for single feed with two battery strings in parallel.

DC minusTie Bar

NOTE: the

wire lugs

shown are

for illustration

only. They

are not supplied with the

equipment.

DC plus

GND

To MGB

+

+

–

–

GND

AC

Doc. #: 0260011-J0 Rev B

AMPS24 HP

Figure 19 — Single feed, parallel battery strings

39

Page 42

5.3.3 DC Wiring Dual Feed – with Tie Bar

The following figure shows a unit wired for dual feed with two battery strings in parallel.

NOTE: the

wire lugs

shown are

for illustration

only. They

are not supplied with the

equipment.

Tie Bar

DC minus

Feed 1

DC minus

Feed 2

DC plus

Feed 1

DC plus

Feed 2

Ground

40

+

+

To

MGB

–

–

AMPS24 HP

Figure 20 — Dual feed, two battery strings in parallel

AC

Doc. #: 0260011-J0 Rev B

Page 43

5.3.4 DC Battery Wiring with Independent Dual A/B Feed

CAUTION!

Dual feed provides capacity sharing, but NO REDUNDANCY. The loss of one battery string

will result in the loss of half the inverters.

DC minus

Feed 2

DC plus

Feed 2

DC minus

Feed 1

DC plus

Feed 1

GND GND

Doc. #: 0260011-J0 Rev B

+

+

To

MGB

–

–

AMPS24 HP

Figure 21 — DC battery wiring with independent dual A/B feed

AC

41

Page 44

5.4 DC Ground

5.4.1 Inverter Only Systems

Ground reference is at the DC source, as shown in Figure 22

– –

AC

DC Plant

+

MGB

Figure 22 — DC ground, inverter only systems

5.4.2 Inverter plus Rectifier System

Refer to Figure 19 and Figure 20.

+

AMPS24 HP

AC

42

Doc. #: 0260011-J0 Rev B

Page 45

5.5 AMPS24 HP with External Maintenance Bypass Switch

An external MBS switch allows the entire AMPS24HP system to be taken offline for maintenance.

Figure 23 shows the logical interconnections. It is not a detailed representation of the actual system

wiring.

AC

24

Figure 23 — Representative system wiring for AMPS24 HP system with MBS

5.5.1 External MBS Installation

Install and test the MBS before beginning installation of the AMPS24 HP system.

1. Install the MBS according to the instructions in the MBS installation manual.

2. Place the bypass switch in both BYPASS and UPS and test the continuity at the dedicated AC

distribution panel (see Figure 23).

5.6 Generator Automatic Transfer Switch

An on-site Automatic Transfer Switch (ATS) for a generator (see Figure 23) must meet either of the

following requirements:

• Uses an open-transition transfer switch that has a minimum open time of one second for a re-

transfer from generator to utility or from utility to generator testing, or

• If the transfer is less than one second, then ATS monitors phase angle and will only initiate a

transfer if the two sources are within +/-30 degrees of synchronization.

Doc. #: 0260011-J0 Rev B

43

Page 46

5.7 Commissioning the System for the First Time

Tools Required

The following tools are required to commission the AMPS24 HP system for the first time:

• Medium flat screwdriver with approximately 3/8" (5 mm) blade width

• True RMS digital multimeter

• Computer with Ethernet port and Internet Explorer 7 or later

• Crossover Ethernet cable if a computer is directly connected to the CXCU controller

• Straight through Ethernet cable if the network connections are made through a router or hub

• Torque wrench

• 3/8" hex driver

WARNING!

The AMPS24 HP must have no power (utility breaker OFF and locked out) and no modules

installed prior to start-up.

Before you begin:

1. Verify that the AMPS24 HP system is mechanically secured to the rack or other structure.

2. Verify that the clearances around the AMPS24 system meet the minimum requirements (see 4.1).

3. Ohm-test the AC and DC bus bars to check for any shorts caused by cut wires, loose bolts,

washers and other conductive material. If possible do Megger testing.

4. Verify that the AMPS24 HP system is correctly and securely grounded to the building grounding

system.

5. Verify that the AMPS24 HP system is correctly and securely connected to the utility and batteries:

a. For the battery connections, follow the manufacturer's recommendations and record the

torques.

b. For the AC connections, torque 2/0 to 14 AWG wire to 120 in-lbs (14 N-m).

c. Triple check the polarity of the battery connections.

6. If this is a 3i+1R shelf system that includes rectifiers for charging, verify that all rectifier modules

are removed.

7. Verify that all breakers at the external load distribution box are switched OFF.

8. Refer to "Figure 1 — AMPS24 HP System Components" and verify that the following breakers are

OFF

• AC Input circuit breaker

• Inverter AC Output circuit breaker

• DC breakers

44

9. Place the internal maintenance bypass switch (MBS) in INVERTER mode.

10. If a Generator is installed, verify that the transfer switch has a minimum 1 second switching delay

or that the transfer is always in phase (+/- 30 deg). (After the installation is complete, see 10.2.3

to set the configuration parameter for Walk-in mode.)

Doc. #: 0260011-J0 Rev B

Page 47

Starting-up the system

11. Switch on the AC mains/utility power.

12. Refer to illustration "AC Wiring" on page 38 and verify the AC input

voltages at the AC wiring terminals:

System Voltage Value

ALL Neutral to Earth Ground ~0V

3 phase L1 to L2, L2 to L3, L3 to L1 ~208V

Neutral to L1 / L2 / L3 ~120V

2-pole L1 to L2 ~208V

Neutral to L1 / L2 ~120V

Split Phase L1 to L2 ~240V

Neutral to L1 / L2 ~120V

13. Check that the battery polarity is correct.

14. Turn on the AMPS24 DC Input breakers for each installed shelf.

15. Switch on the external battery breakers or complete the fuse circuit.

16. Verify that the system starts up and that the controller switches on: