Page 1

i

SERVICE

MANUAL

Alpha-3R

Direct Thermal Portable Printer

Page 2

ii

Contents

1. FUNDAMENTAL OF THE SYSTEM ................................ 2

1.1 Overview ........................................................................................................... 2

2. ELECTRONICS ............................................... 3

2.1 Summary of Board Connectors ....................................................................... 3

3. MECHANISM ................................................ 7

3.1 Replacing the Platen Roller (Including media cover) ..................................... 7

3.2 Replacing the Keys Control Board .................................................................. 9

3.3 Replacing the Bluetooth Module (Option) ..................................................... 10

3.4 Replacing the Media Holder Assembly ......................................................... 11

3.5 Replacing the Main Board Assembly ............................................................ 13

3.6 Replacing the Print Head Assembly .............................................................. 14

3.7 Replacing the Stepping Motor ....................................................................... 15

3.8 Replacing the black mark sensor assembly ................................................. 16

3.9 Replacing the WiFi Module (Option) .............................................................. 17

4. TROUBLESHOOTING ......................................... 18

4.1 Common Problems ......................................................................................... 18

5. Maintenance ............................................... 20

Revise History ................................................ 21

Page 3

2

1. FUNDAMENTAL OF THE SYSTEM

1

2 3 4

5

6

1.1 Overview

Front View

1. LED indicator

2. Feed button

3. Power on/off button

4. Media cover release button

5. Media holder adjustment knob

6. Media cover

Page 4

3

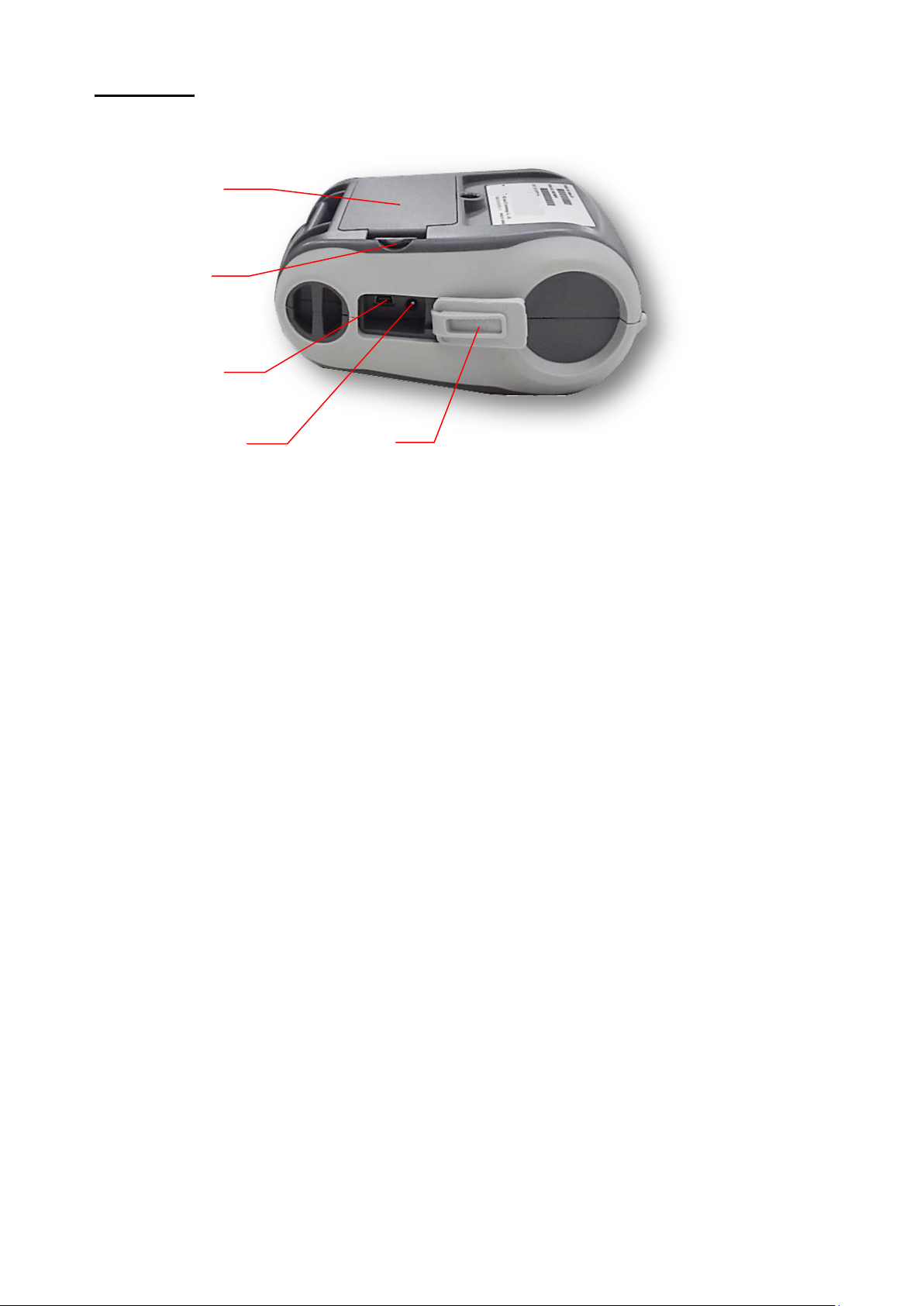

Interior View

2

1

4

3

5

1. Tear edge

2. Print head

3. Media holder

4. Platen

5. Black mark sensor

Page 5

2

Rear View

3

2

4

1

5

1. Li-ion battery

2. Battery open clasp

3. USB interface

4. Power jack

5. Interface cover

Page 6

3

2. ELECTRONICS

Connector

Description

1

LED & KEY board

2

WiFi or Bluetooth module connector

1

3

2

4

5 6 7 8 9

2.1 Summary of Board Connectors

Main board top

Page 7

4

Pin

Description

1

3.3V

2

BT/WiFi Reset

3

BT RXD

4

BT RTS

5

BT TXD

6

BT CTS

7

WiFi wake up

8

WiFi TCP

9

BT/WiFi Switch

10

GND

3

Stepping motor

Pin

Description

1

OUT1

2

OUT2

3

OUT1

4

OUT2

4

Download F/W connector

Pin

Description

1

3.3V

2

GND

3

RESET

4

BMS

5

NPCS0

6

MOSI

7

MISO

8

SPCK

5

Head open sensor

Pin

Description

1

HEAD

2

GND

6

USB & RS 232 connector

7

12V DC IN

8

TPH connector

Page 8

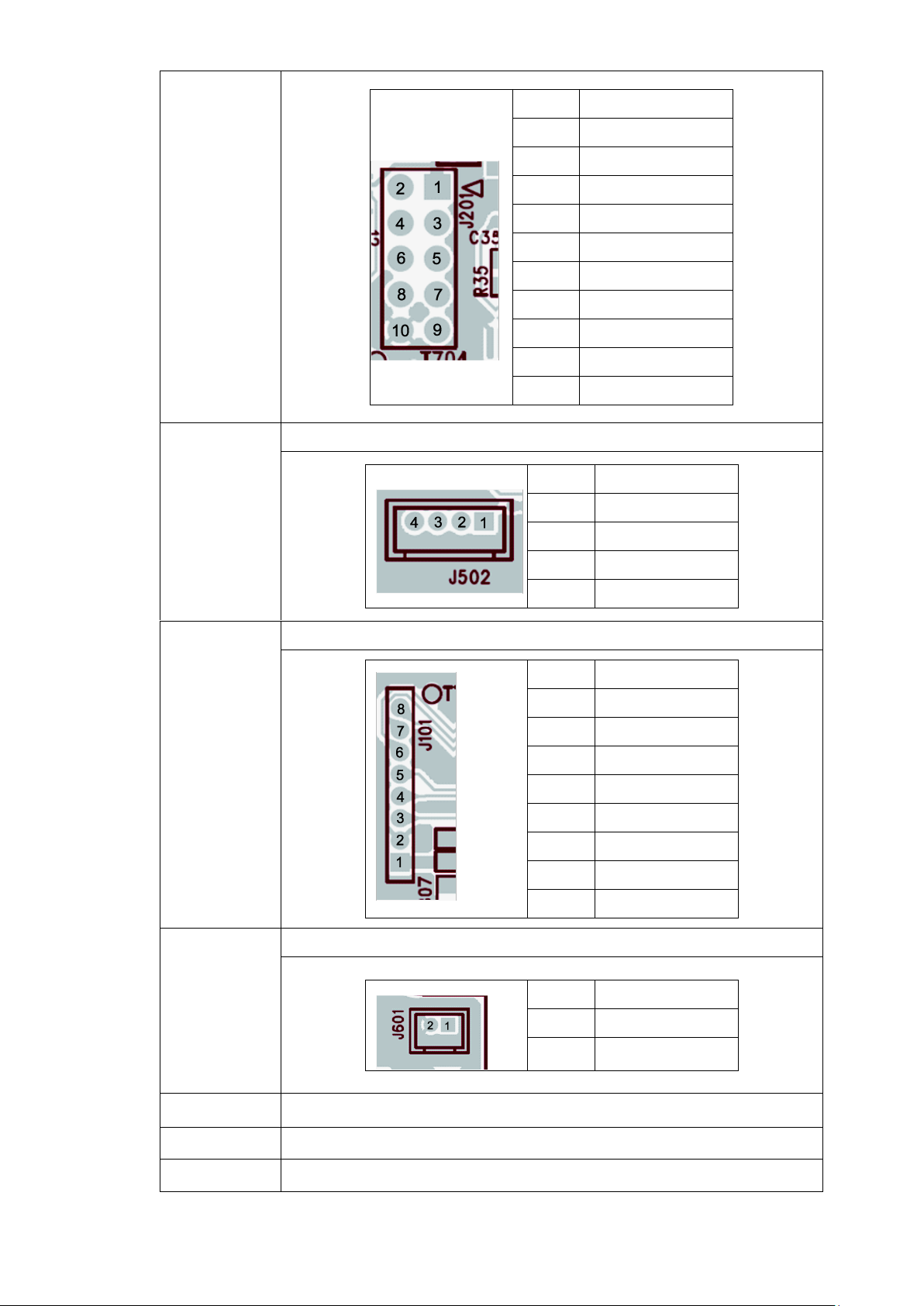

5

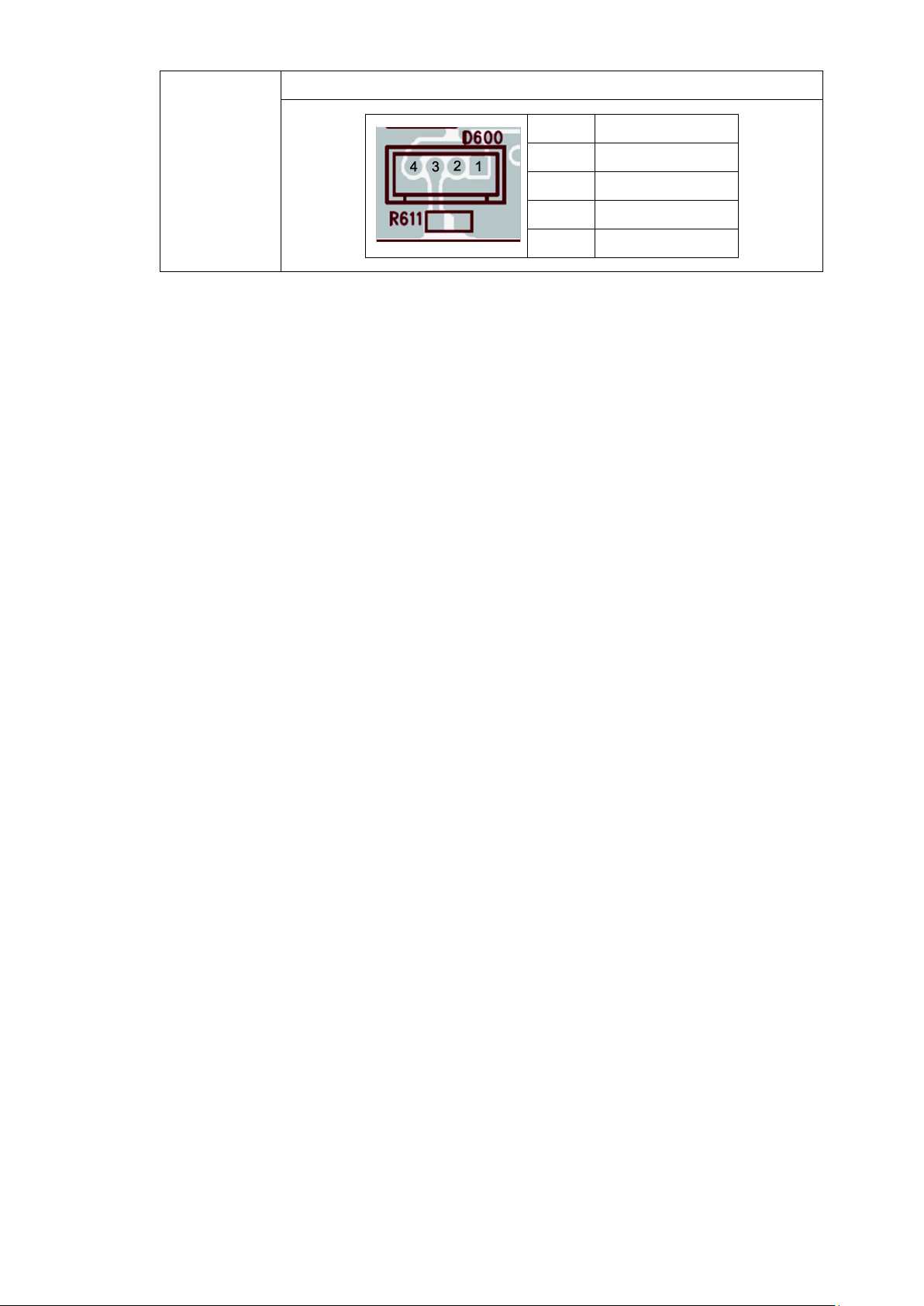

9

Paper sensor

Pin

Description

1

3.3V

2

BM_E

3

BM_R

4

3.3V

Page 9

6

Connector

Description

1

Battery connector

1

Main board bottom

Page 10

7

3. MECHANISM

3.1 Replacing the Platen Roller (Including media cover)

1. Remove two screws from the back of the printer and two screws from the front of

the printer.

2. Take the printer top cover off.

Page 11

8

3. Use a tool to remove the shaft. Remove/Replace the media cover. (including the

platen roller ass’y)

4. Reassemble the parts in the reverse procedures.

Page 12

9

3.2 Replacing the Keys Control Board

1. Refer to section 3.1 to remove the printer top cover.

2. Remove two screws on the keys control board.

3. Loosen the connector lock then disconnect the flat cable from the keys control board.

Remove/Replace the keys control board.

4. Reassemble the parts in the reverse procedures.

Page 13

10

3.3 Replacing the Bluetooth Module (Option)

1. Refer to section 3.2 to remove the keys control board.

2. Remove two screws on the Bluetooth control board.

3. Disconnect the connector on the board.

4. Reassemble the parts in the reverse procedures.

Page 14

11

3.4 Replacing the Media Holder Assembly

1. Remove two screws and media holder adjustment knob.

2. Take the interior mechanism from the printer bottom cover.

3. Plug the media holder adjustment knob to rotate the media holder to the closest position

and remove a screw on the other side.

.

Page 15

12

4. Take the media holder assembly from the mechanism.

5. Reassemble the parts in the reverse procedures.

Page 16

13

3.5 Replacing the Main Board Assembly

1. Refer to section 3.2 to section 3.4 to remove key control board, Bluetooth control board

(option), and the media holder assembly.

2. Remove two screws from the back of interior mechanism and disconnect all the

connectors on the main board assembly.

3. Reassemble the parts in the reverse procedures.

Page 17

14

3.6 Replacing the Print Head Assembly

Gear holder

Gear

1. Refer to section 3.2 to section 3.5 to remove key control board, Bluetooth control board

(option), the media holder assembly, and main board assembly.

2. Use the long-nose pliers to remove two spring torsions on each side.

3. Take the gear holder and the gear, and push the print head holder on the each side to

remove the print head assembly.

4. Reassemble the parts in the reverse procedures.

Page 18

15

3.7 Replacing the Stepping Motor

Gear holder

Gears

1. Refer to section 3.4 and section 3.5 to remove media holder assembly and main board

assembly.

2. Remove the gear holder and two gears.

3. Remove two screws.

4. Reassemble the parts in the reverse procedures.

Page 19

16

3.8 Replacing the black mark sensor assembly

Black mark sensor

assembly

1. Refer to section 3.2 to section 3.5 to remove key control board, Bluetooth control board

(option), the media holder assembly, and main board assembly.

2. Remove a screw and replace the black mark sensor.

3. Reassemble the parts in the reverse procedures.

Page 20

17

3.9 Replacing the WiFi Module (Option)

1. Refer to section 3.2 to remove the keys control board.

2. Remove two screws on the board.

3. Refer to section 3.5 to remove the main board assembly.

4. Replace the WiFi control board.

5. Reassemble the parts in the reverse procedures.

Page 21

18

4. TROUBLESHOOTING

Problem

Possible Cause

Recovery Procedure

Power indicator does not

illuminate

* The battery is not properly

installed.

* The battery is dead.

* Reinstall the battery.

* Switch the printer on.

* Charge the battery.

- The printer status from

DiagTool shows “Head

Open”.

* The printer carriage is open.

* Please close the print carriage.

- The printer status from

DiagTool shows “Out of

Paper”..

* Running out of media roll.

* The media is installed

incorrectly.

* Black mark sensor is not

calibrated.

* Supply a new media roll.

* Please refer to the steps on section 3.4 to

reinstall the media roll.

* Calibrate the black mark sensor.

- The printer status from

DiagTool shows “Paper Jam”.

* Black mark sensor is not set

properly.

* Make sure media size is set

properly.

* Media may be stuck inside

the printer mechanism.

* Calibrate the black mark sensor.

* Set media size correctly.

Memory full

( FLASH / DRAM )

* The space of FLASH/DRAM

is full.

* Delete unused files in the FLASH/DRAM.

* The max. numbers of DRAM is 256 files.

* The max. user addressable memory space

of DRAM is 256KB.

* The max. numbers of file of FLASH is 256

files.

* The max. user addressable memory space

of FLASH is 2560KB.

Poor Print Quality

* Media is loaded incorrectly

* Dust or adhesive

accumulation on the print

head.

* Print density is not set

properly.

* Printhead element is

damaged.

* Reload the supply.

* Clean the print head.

* Clean the platen roller.

* Adjust the print density and print speed.

* Run printer self-test and check the print

head test pattern if there is dot missing in

the pattern.

* Change proper media roll.

Missing printing on the left or

right side of label

* Wrong label size setup.

* Set the correct label size.

Gray line on the blank label

* The print head is dirty.

* The platen roller is dirty.

* Clean the print head.

* Clean the platen roller.

4.1 Common Problems

The following guide lists the most common problems that may be encountered when

operating this bar code printer. If the printer still does not function after all suggested

solutions have been invoked, please contact the Customer Service Department of your

purchased reseller or distributor for assistance.

Page 22

19

Irregular printing

* The printer is in Hex Dump

mode.

* The RS-232 setting is

incorrect.

* Turn off and on the printer to skip the

dump mode.

* Re-set the Rs-232 setting.

Page 23

20

5. Maintenance

Printer Part

Method

Interval

Print Head

1. Always turn off the printer before

cleaning the print head.

2. Allow the print head to cool for a

minimum of one minute.

3. Use a cotton swab and 100%

ethanol to clean the print head

surface.

Clean the print head when changing a new

label roll

Platen Roller

1. Turn the power off.

2. Rotate the platen roller and wipe it

thoroughly with 100% ethanol and

a cotton swab, or lint-free cloth.

Clean the platen roller when changing a

new label roll

Tear Bar/Peel Bar

Use the lint-free cloth with 100%

ethanol to wipe it.

As needed

Sensor

Compressed air or vacuum

Monthly

Exterior

Wipe it with water-dampened cloth

As needed

Interior

Brush or vacuum

As needed

This session presents the clean tools and methods to maintain your printer.

1. Please use one of following material to clean the printer.

Cotton swab

Lint-free cloth

Vacuum / Blower brush

100% ethanol

2. The cleaning process is described as following,

Note:

Do not touch printer head by hand. If you touch it careless, please use ethanol to clean it.

Please use 100% Ethenol. DO NOT use medical alcohol, which may damage the printer head.

Regularly clean the print head and supply sensors once change a new ribbon to keep printer

performance and extend printer life.

Page 24

21

Date

Content

Editor

2013/11/4

Modify some pictures for label model

Camille

Revise History

Page 25

22

Corporate Headquarters Li Ze Plant

9F., No.95, Minquan Rd., Xindian Dist., No.35, Sec. 2, Ligong 1st Rd., Wujie Township,

New Taipei City 23141, Taiwan (R.O.C.) Yilan County 26841, Taiwan (R.O.C.)

TEL: +886-2-2218-6789 TEL: +886-3-990-6677

FAX: +886-2-2218-5678 FAX: +886-3-990-5577

Web site: www.tscprinters.com

E-mail: printer_sales@tscprinters.com

tech_support@tscprinters.com

TSC Auto ID Technology Co., Ltd.

Loading...

Loading...