Page 1

110060

BY

CHALLENGER AC9000 SERIES

Residential Vehicular Garage Door Operator

MODEL NUMBERS AC9300, AC9500, and ACJ9500

INSTALLATION AND OWNER’S MANUAL

INSTALLER: Place this manual in the plastic envelope provided and permanently

attach to the wall near the pushbutton.

110044

As of date of manufacture,

meets all ANSI/UL 325

Safety Requirements for

Vehicular Garage Door

Operators

Serial #:

Date Installed:

Your Dealer:

READ THIS MANUAL

READ THIS MANUAL

READ THIS MANUAL READ THIS MANUAL

CAREFULLY BEFORE

CAREFULLY BEFORE

CAREFULLY BEFORE CAREFULLY BEFORE

INSTALLATION OR USE

INSTALLATION OR USE

INSTALLATION OR USEINSTALLATION OR USE

SAVE THESE INSTRUCTIONS

SAVE THESE INSTRUCTIONS

SAVE THESE INSTRUCTIONSSAVE THESE INSTRUCTIONS

1

Page 2

TABLE OF CONTENTS

Product Features ................................................... 3

Component Identification/Tools Required ........... 4

Section A: Assembly Instructions ....................... 5

Section B: Important Installation Instructions .... 6

Section C: Installing the Operator ....................... 7

Identify Your Door Type .................................... 7

Mounting the Front Bracket .............................. 8

Mounting the Power Head ................................. 9

Door Bracket Installation .................................. 9

Door Arm Installation ...................................... 10

Connecting Electrical Power .......................... 11

The Convenience Lamp .................................. 11

Section D: Control & Auxiliary Equipment ......... 12

Standard Wall Button Installation ................... 12

Safe Finish™ Photosystem Installation ......... 13

Radio Control Installation ............................... 13

Section E: Operation & Adjustments .................. 15

Important Safety Instructions ........................ 15

Turning on the Power ...................................... 15

Basic Operating Parameters ...........................15

How To Activate The Opener ...........................15

How the Door Moves When Activated ............16

How the Light Works ......................................16

How To Operate The Door Manually ...............16

Adjustments .....................................................17

Opening Travel Adjustments ...........................17

Open & Closing Force Adjustment .................17

Setting The Close Limit ...................................18

Obstruction Sensing Adjustment ....................18

Testing The Obstruction Sensing ...................18

Photoelectric Obstruction Test .......................19

Positive Mechanical Lock Adjustment ...........19

Resetting The Travel Timer Adjustment .........19

Safe Finish Wiring Diagram .................................20

Maintenance Schedule .........................................20

Installation Checklist ............................................21

Troubleshooting Guide ........................................22

Parts Breakdown and Listing ..............................23

Warranty Information ..........................................24

READ THESE STATEMENTS CAREFULLY AND FOLLOW THE

The Warning and Caution boxes throughout this manual are there to protect you and

your equipment. Pay close attention to these boxes as you follow the manual.

WARNING

WARNING

WARNINGWARNING

Indicates a MECHANICAL

hazard of INJURY OR

DEATH. Gives instructions

to avoid the hazard.

INSTRUCTIONS CLOSELY.

CAUTION

CAUTION

CAUTIONCAUTION

Indicates a MECHANICAL hazard

of DAMAGE to your door, door

operator, or equipment. Gives

instructions to avoid the hazard.

WARNING

WARNING

WARNINGWARNING

Indicates an ELECTRICAL

hazard of INJURY OR

DEATH. Gives instructions

to avoid the hazard.

2

CAUTION

CAUTION

CAUTIONCAUTION

Indicates an ELECTRICAL hazard

of DAMAGE to your door, door

operator, or equipment. Gives

instructions to avoid the hazard.

Page 3

PRODUCT FEATURES

The purpose of this booklet is to provide assembly,

installation and operation information concerning the

Challenger AC9000 Series (Models AC9300, AC9500, and

ACJ9500) Residential Garage Door Openers and related

Accessory Products.

NOTICE

IT IS IMPORTANT THAT THIS INSTRUCTION

MANUAL BE READ AND UNDERSTOOD

COMPLETELY BEFORE INSTALLATION OR

OPERATION IS ATTEMPTED.

NOTICE

THE IMPORTANT SAFEGUARDS AND

INSTRUCTIONS IN THIS MANUAL CANNOT

COVER ALL POSSIBLE CONDITIONS AND

SITUATIONS WHICH MAY OCCUR DURING ITS

USE. IT MUST BE UNDERSTOOD THAT

COMMON SENSE AND CAUTION MUST BE

EXERCISED BY THE PERSON(S) INSTALLING,

MAINTAINING AND OPERATING THE

EQUIPMENT DESCRIBED HEREIN. DO NOT

USE THIS EQUIPMENT FOR ANY OTHER THAN

ITS INTENDED PURPOSE - OPERATING

OVERHEAD GARAGE DOORS.

STANDARD FEATURES:

Safe Finish™ Photosystem: An invisible infrared beam of

light guards the door opening and reverses a downward moving

door if the beam is broken by a stationary or moving object.

The AC9000 Series motor control circuitry constantly monitors

the Safe Finish Photosystem for proper operation.

Manual Release: A pull cord allows separation of the drive

mechanism and manual operation of the door when desired, as

in the event of a power failure. (Page 16)

Automatic Reconnection: Once power is restored, or

automatic operation of the door is again desired, initiating

operation in the normal manner (Push Button, Radio Control,

etc.) will effect automatic reconnection of the Manual Release

Mechanism. (Page 16)

Alternating Action Operation: The mechanical wall

pushbutton functions in an Open/Stop/Close/Stop mode in

normal operation. (Page 16)

Sensing System: A built-in sensing system detects

obstructions during door operation. If in the downward

(close) travel mode, the Opener will sense an obstruction

and reverse the direction of the door. In the open mode,

the Opener will stop. Since all doors are different, the

Sensing System has independent adjustments for

customizing the level of force required for the normal

opening and closing of specified doors. ( Page 18)

Close Limit Switch: In winter months it's common

for small pieces of ice or packed snow to be trapped

under the door. Ground swelling can also effect the

close limit setting of the Opener. The AC9000 Series

Close Limit Switch overrides the Sensing System during

the last one inch of closing travel and prevents the door

from reversing if it encounters an obstruction at this

point.

Constant Contact To Close: For utmost safety and

security, the standard operation mode requires constant

contact on the mechanical Push Button to close the door

if the Safe Finish™ Photosystem becomes misaligned

or if there is an irregularity in the wiring to the device.

In this mode of operation, a Radio Transmitter cannot be

used to close the door. (Page 19)

OPTIONAL FEATURES:

Digital Radio Controls: The AC9000 Series

Openers covered in this Manual can be fitted with

Allstar’s optional Radio Controls. Up to 19,683 private

codes can be easily selected without use of tools.

(PageZ14)

Super Station Deluxe Wall Push Button: A

feature-packed accessory unit, the Deluxe Wall Station

allows access to all of the Opener's functions. Open/

Close button permits full control of the door’s operation.

The Opener's built-in light can be turned on or off

independent of door operation. A Security Switch

allows the Opener to be deactivated for extended periods

of time. (Page 12)

Keyless Entry System: A tamper resistant outdoor

keypad, the optional Keyless Entry System permits entry

to the garage without use of key or radio transmitter.

Easily programmable, it accommodates four separate

access codes of 4 digits. Lighted Buttons enhance

nighttime use.

110044

BY

3

Page 4

COMPONENT IDENTIFICATION

!

!

A

j

j

TRANSMITTER

OPTIONAL

POWER HEAD/DRIVE

RAIL ASSEMBLY

WALL

BRACKET

DOOR ARM ROD

DOOR ARM

TUBE SECTION

SENSOR ‘L’

BRACKET

MANUAL RELEASE

TAG

BELL WIRE

SPOOL

(when supplied)

110045

OPENER

HARDWARE

BAG

TOOLS REQUIRED

DOOR

BRACKET

PUSHBUTTON

“WARNING” LABEL

WALL PUSHBUTTON

WARNING

!

!

Child can be pinned under automatic ga rage

door. Death or serio us injury can re sult.

•

Never let child walk or run under movi ng door.

•

Never let child use door opener controls.

•

lways keep moving door in s ight.

•

If person is pinned, push c ontrol button or use

emergency release.

•

Test door opener monthly:

Refer to your owner’s manual

ect (or 2x4 laid flat) on floor.

Place one-inch ob

If door fails to reverse on contact, ad

If opener still fails to reverse door, repair or replace opener .

ust opener.

SENSOR ‘U’

BRACKET

RED

RELEASE

KNOB

SAFE FINISH

PHOTOSYSTEM

SENSORS

110046

SAFE FINISH HARDWARE

HAMMER

DRILL

1/2” OPEN END

HACKSAW

WRENCH

DRILL & BITS

STEPLADDER

SOCKET W RENCH

3/8” SOCKET

7/16” SOCKET

SMALL SCREW DRIVER

(1/8” HEAD)

LEVEL

WOOD

BLOCK

TAPE MEASURE

SCREW DRIVER

4

Page 5

A: ASSEMBLY INSTRUCTIONS

If Your Opener Is Supplied Fully Assembled, Please Disregard This Page.

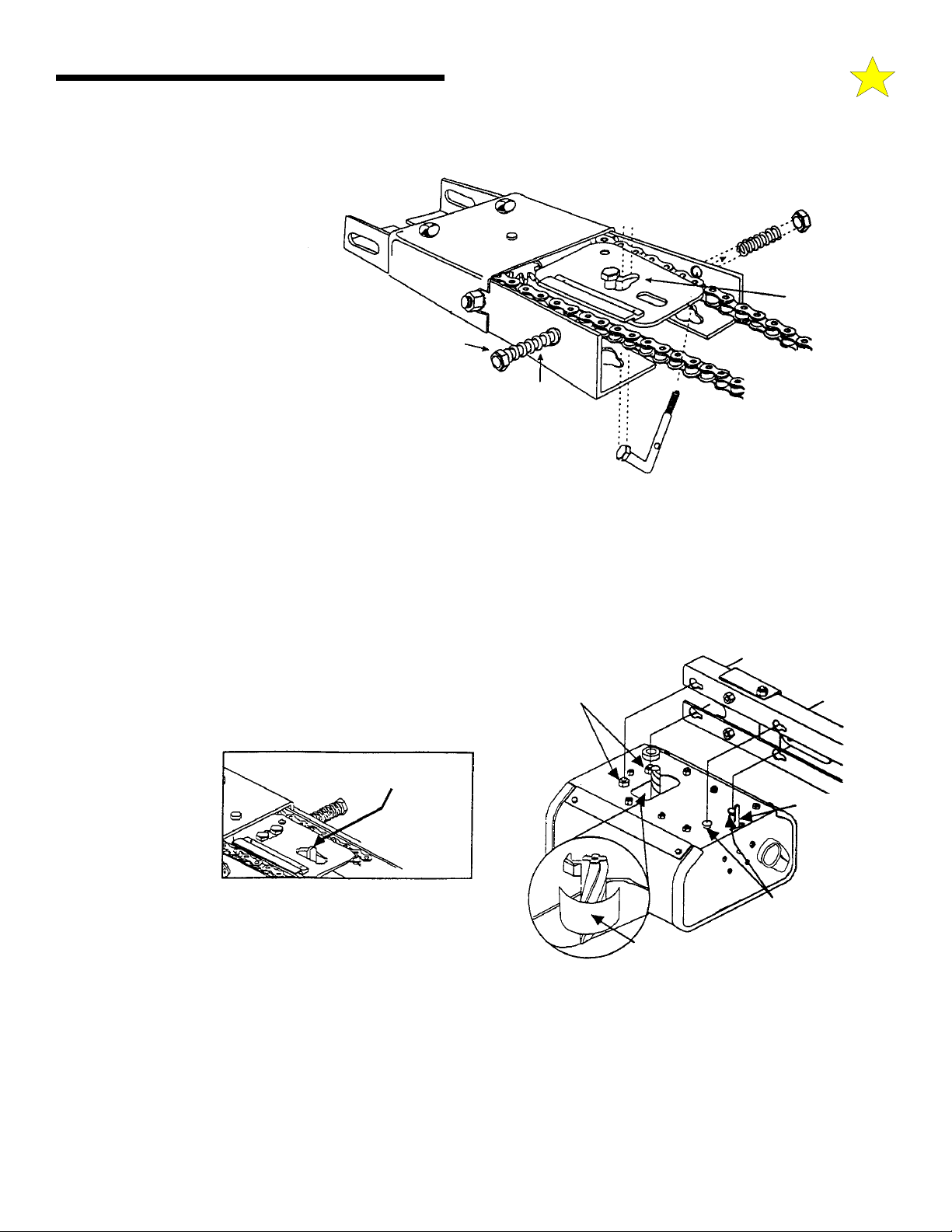

NOTE: The Rail/Chain Assembly is

packaged separately from the Power

Head Unit. The trolley, front idler/

Spring

tension adjustment assembly, chain,

drive gear and limit cams are assembled

to the Rail/Chain Assembly at the

factory. Follow the steps outlined

below to complete assembly prior to

installation. Refer to the component

identification illustrations on the

previous page.

Assembled and

In Position

STEP 1: Prior to attaching the motor

drive unit to the rail assembly, the Open

and Close adjustment bolts must be

installed. Place the threaded end of the

adjustment bolt through the hole in the

rail and then slip the head of the bolt

through the center of the double key

hole. Slide the spring over the bolt and attach load adjusting nut. Tighten until the tip of the bolt extends 3/16” outside the nut.

Repeat above for the other side.

Spring

L-Shaped Adjustment Bolt

Force Adjusting

Plastic-Insert

Locking Nut

Double Key Hole

110047-1

STEP 2: Protect the Power Unit cover from scratching during assembly by placing it on cardboard. Loosen the two 5/16" lock

washer nuts on top of the power head drive unit.

STEP 3: VERY IMPORTANT ! Position a paper shim around the power head unit drive gear (standard weight paper, see

illustration). Shim must remain in place while assembling the power head unit to the Rail/Chain assembly to ensure a proper gear

mesh and avoid excessive long term wear.

STEP 4: Align the four key holes in the Rail/Chain assembly with

the two front guide tabs and the two rear bolt studs on the power

head unit and place the rail/chain assembly in place over the power

head unit. The power head drive unit limit lever protrudes up

through the rail/chain assembly sensing plate. Take care not to bend

the lever when

assembling. Slide the

power head drive unit

110047-2

Limit Lever

forward until the gear

meshes with the rail/

chain assembly drive

gear. Check to make

sure the front guide tabs

on the power head unit

are securely locked on

the rail/chain assembly.

Take care not to

bend limit lever

5/16” Lock

Washer Nuts

Limit

Lever

Front Guide

Tabs (2)

Paper Shim

110047-3

STEP 5: The power head drive unit should be move forward until

all play between the gears has been eliminated, but no additional force should be used that could cause pressure on the motor (power

head unit) drive gear. Tighten the two 5/16" lock washer nuts on top of the power head drive unit that were loosened in Step 2 above.

When the opener is first activated the paper shim will be ejected. The paper shim should have the profile of the gears to indicate the

proper mesh between them.

STEP 6: Recheck the nuts used to secure the Rail/Chain assembly to the Power Head Unit, making sure they are tight.

Assembly is now complete and you are ready to begin installation of the opener.

5

Page 6

B: IMPORTANT INSTALLATION INSTRUCTIONS

IMPORTANT INSTALLATION INSTRUCTIONS

TO REDUCE THE RISK OF SEVERE

INJURY OR DEATH: READ AND FOLLOW

WARNING

WARNING: AN UNBALANCED DOOR OR

ONE THAT STICKS OR BINDS MAY

PREVENT THE SENSING SYSTEM FROM

WORKING PROPERLY, CAUSING INJURY OR

DEATH. ENSURE DOOR IS PROPERLY

BALANCED AND ELIMINATE ANY STICKING OR

BINDING PRIOR TO INSTALLATION OF

OPERATOR. A properly balanced door will open

slowly from a 3/4 open position, close slowly from a

3/4 closed position, and remain still at a 1/2 open

position. If the door is not properly balanced, HAVE

A QUALIFIED SERVICE PERSON MAKE

REPAIRS TO CABLES, SPRING ASSEMBLIES

AND OTHER DOOR HARDWARE BEFORE

INSTALLING THE OPENER

WARNING:

LARGEST MOVING OBJECT IN YOUR

HOUSE, THE SPRINGS, PULLEYS, CABLES

AND MOUNTING HARDWARE UTILIZED TO

BALANCE ITS OPERATION ARE UNDER

EXTREME TENSION AT ALL TIMES AND CAN

CAUSE SERIOUS PERSONAL INJURY, EVEN

DEATH, IF DISTURBED. DO NOT ATTEMPT

ADJUSTMENT. CALL A QUALIFIED SERVICE

PERSON TO MOVE, LOOSEN OR ADJUST

DOOR SPRINGS OR HARDWARE.

• REMOVE ALL ROPES AND REMOVE OR MAKE

INOPERATIVE ALL LOCKS CONNECTED TO

THE GARAGE DOOR BEFORE INSTALLING

THE OPENER.

• DO NOT WEAR RINGS, WATCHES OR LOOSE

CLOTHING WHILE INSTALLING OR

SERVICING GARAGE DOOR OPENERS.

WEAR SAFETY GOGGLES OR OTHER

PROTECTIVE EYEWEAR.

• IF POSSIBLE, INSTALL THE DOOR OPENER

7zFT OR MORE ABOVE THE FLOOR. MOUNT

THE EMERGENCY RELEASE 6 FT ABOVE THE

FLOOR.

• REINFORCE LIGHTWEIGHT FIBERGLASS,

YOUR GARAGE DOOR IS THE

ALL INSTALLATION INSTRUCTIONS!

ALUMINUM AND STEEL DOOR TOP SECTIONS

TO AVOID DAMAGE AND TO INSURE PROPER

OPERATION OF THE SAFETY REVERSE

SYSTEM. CONTACT YOUR DOOR

MANUFACTURER FOR A REINFORCEMENT

KIT.

• DO NOT CONNECT THE OPENER TO A

POWER SOURCE UNTIL INSTRUCTED TO DO

SO.

• CHECK LOCAL BUILDING AND ELECTRICAL

CODES FOR MANDATORY INSTALLATION

AND WIRING REQUIREMENTS.

• CONNECT POWER CORD ONLY TO A

PROPERLY GROUNDED OUTLET. IF

PERMANENT WIRING IS REQUIRED BY

CODES, DISCONNECT POWER AT FUSE BOX

OR CIRCUIT BREAKER BEFORE ATTEMPTING

ANY WIRING CONNECTIONS.

• LOCATE THE CONTROL PUSH BUTTON:

A. WITHIN SIGHT OF THE DOOR, AND,

B. AT A MINIMUM HEIGHT OF 5 FT SO SMALL

CHILDREN CAN'T REACH IT, AND,

C. AWAY FROM MOVING PARTS OF THE

DOOR.

• INSTALL THE ENTRAPMENT WARNING LABEL

NEXT TO THE CONTROL PUSH BUTTON IN A

PROMINENT LOCATION. INSTALL THE

EMERGENCY RELEASE INSTRUCTION CARD,

ATTACHING IT ON OR NEXT TO THE

EMERGENCY RELEASE.

• ADJUST THE SENSITIVITY ADJUSTMENTS

ENOUGH TO ALLOW THE DOOR TO

OPERATE, BUT NOT SO FIRMLY AS TO

EXERT EXCESSIVE PRESSURE ON AN

OBSTRUCTION BEFORE REVERSING.

• AFTER INSTALLING THE OPENER, THE DOOR

SHOULD REVERSE WHEN IT CONTACTS A

1-1/2" HIGH OBJECT (A PIECE OF STANDARD

2 X 4 BOARD LAID FLAT) ON THE FLOOR.

6

Page 7

C: INSTALLING THE OPERATOR

IMPORTANT!

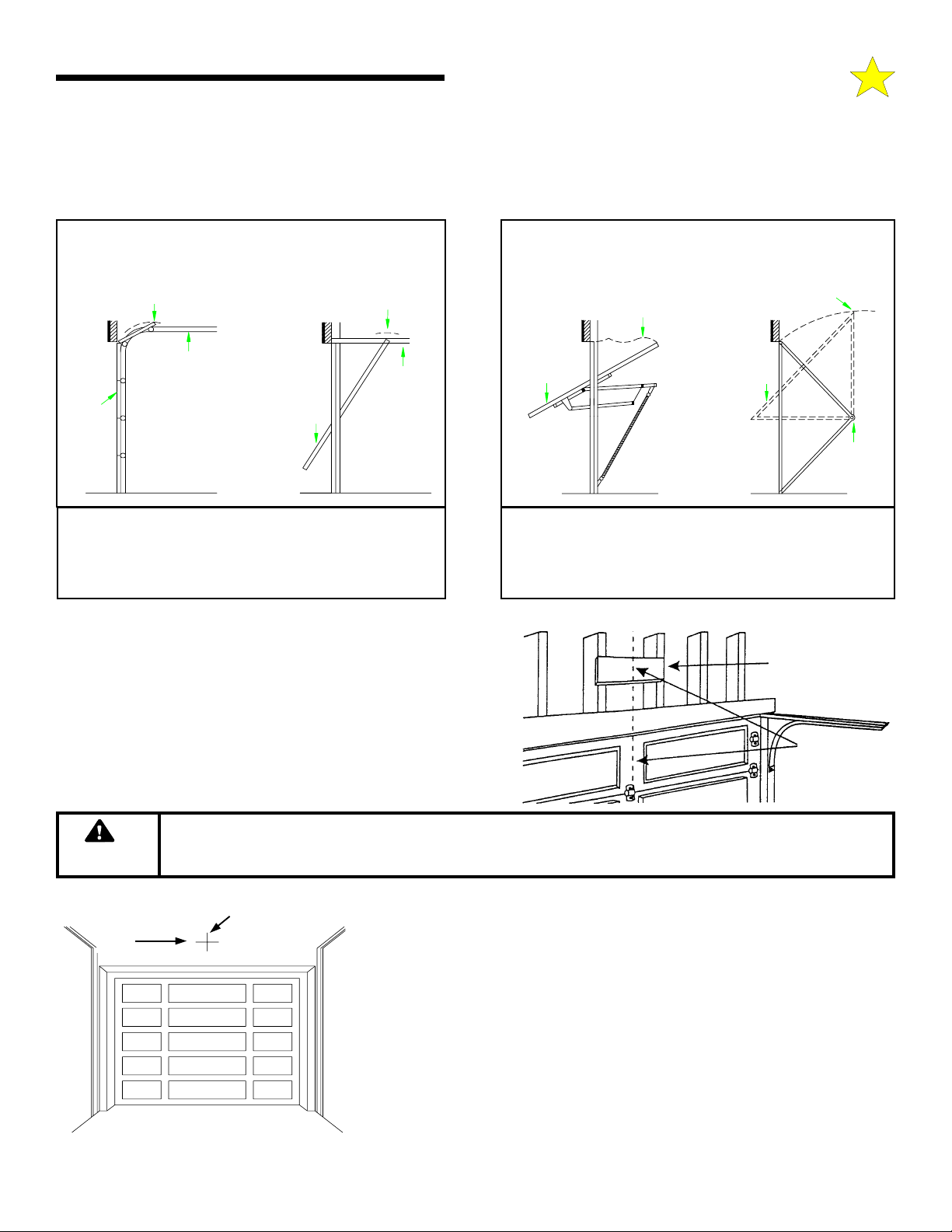

IDENTIFY YOUR DOOR TYPE FROM THOSE ILLUSTRATED BELOW AND FOLLOW

INSTRUCTIONS FOR THAT TYPE OF DOOR

104367

SECTIONAL DOOR

CURVED TRACK

ONE PIECE DOOR

HORIZONTAL TRACK

JAMB HARDWARE

HIGH ARC OF

DOOR TRAVEL

TRACK

DOOR DOOR

HIGH ARC OF

DOOR TRAVEL

TRACK

FOR THESE TYPES OF DOORS USE 1/3 HP

MODEL AC9300 OR 1/2 HP MODEL AC9500.

USE 7 FT, 8 FT OR 10 FT RAIL ASSEMBLY

(MATCH DOOR HEIGHT)

REINFORCE THE HEADER WALL

Reinforce the header wall (wall above the door opening as required,

to ensure rigid mounting of the front wall bracket.

Locate the vertical centerline of your garage door and mark it on the

header above the door and on the top rail of the door.

ONE PIECE DOOR

NO TRACK

JAMB HARDWARE

HIGH ARC OF

DOOR TRAVEL

DOOR

JAMB

HARD-

WARE

FOR THESE TYPES OF DOORS USE

1/2 HP MODEL ACJ9500.

(FOR DOOR HEIGHT UP TO 8 FT)

110048

104368

ONE PIECE DOOR

NO TRACK

PIVOT HARDWARE

HIGH ARC OF

DOOR TRAVEL

DOOR

PIVOT

USE 7J RAIL

Reinforce with 2” x 6”

as required to insure

rigid mounting.

Vertical Center

Line

WARNING

WARNING

WARNINGWARNING

HORIZONTAL

LINE

104369

SPRINGS, PULLEYS, CABLES AND MOUNTING HARDWARE USED TO BALANCE YOUR

GARAGE DOOR ARE UNDER EXTREME TENSION AT ALL TIMES AND CAN CAUSE SEVERE

INJURY OR DEATH IF DISTURBED. DO NOT ATTEMPT ADJUSTMENT.

VERTICAL

CENTERLINE

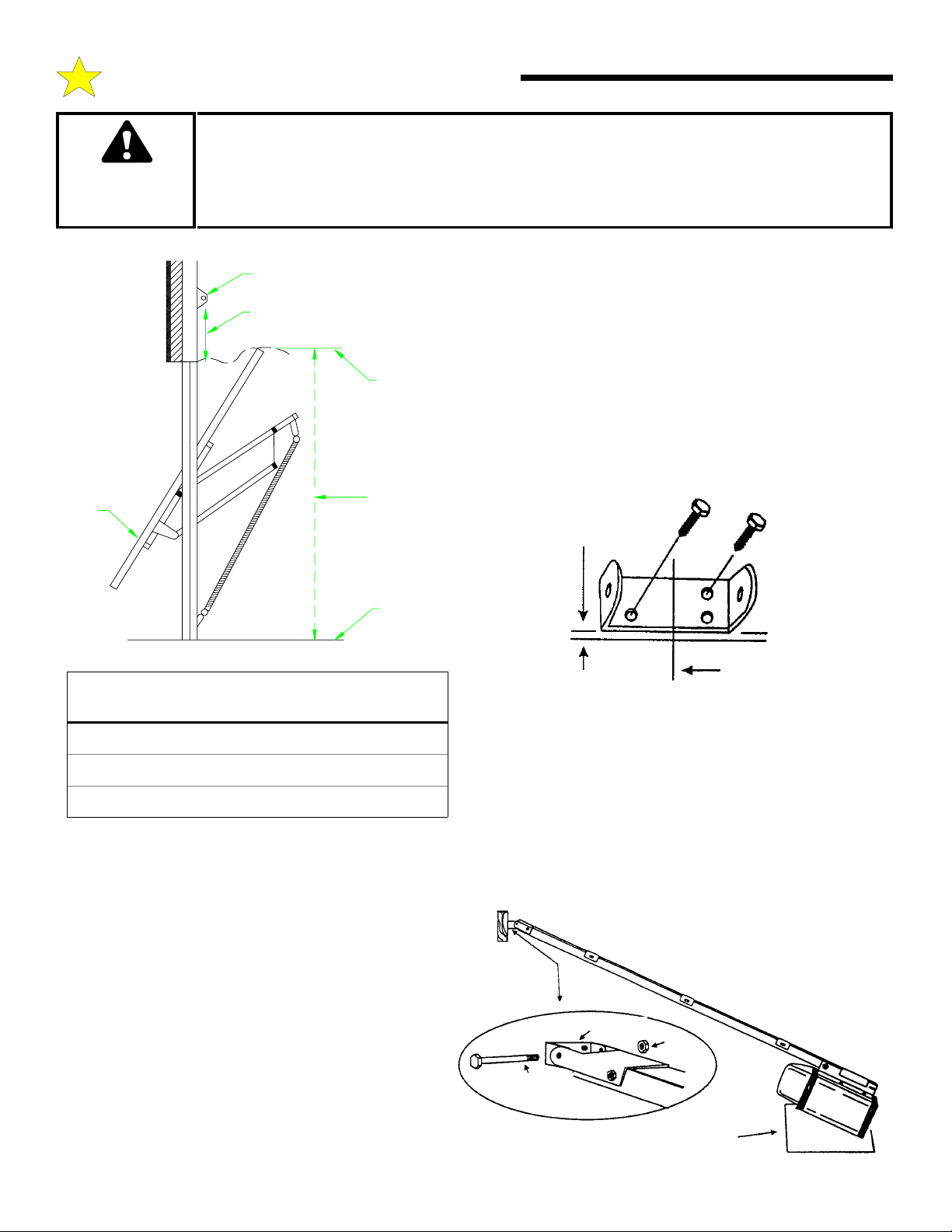

STEP 1: Mounting the Front Bracket — Sectional Doors and One-

Piece Doors with Track (For One-Piece Doors without track see Step 1A,

next): Mark a vertical centerline on the header above the door. By

manually raising the door, determine the high arc of the door’s travel (see

illustration, top of previous page) and using a level, transfer this

measurement to the header (see illustration at left). Draw a horizontal line,

crossing the previously drawn centerline, at this point. Install the Front

Mounting Bracket securely wit lag screws as shown below. If necessary,

reinforce the header with steel angle iron or wood to ensure a secure

mount.

7

Page 8

C: INSTALLING THE OPERATOR

WARNING

WARNING

WARNINGWARNING

10437

Door

FRONT MOUNTING BRACKET MUST BE INSTALLED TO A STRUCTURAL SUPPORT

(STUD) ON THE HEADER WALL. FAILURE TO DO SO COULD CAUSE SENSING

SYSTEM TO MALFUNCTION, RESULTING IN ENTRAPMENT, INJURY OR DEATH.

REINFORCE HEADER USING 2 x 6 WOOD STUDS AND LAG SCREW OR ANGLE

IRON AND LAG SCREWS AS NECESSARY (NOT PROVIDED).

STEP 1A: Mounting the Front Bracket — One

Header Bracket

Bracket Distance Above Floor

(See Chart)

Highest Point

of Travel

Measure

Distance

to Floor

Garage

Floor

Piece Doors Without Track: Mark a vertical

centerline on the header above the door. Manually raise

the door to its high arc position and temporarily clamp

in that position. With the door in this high arc position,

measure the distance from the top of the door to the

floor (see figure at left). Subtract the actual door height

from the high arc distance to the floor. This is the high

arc rise of the door. Unclamp and close the door.

Using the table below, draw a horizontal line at the

appropriate height above the door to intersect with the

vertical centerline.

110049

1/2” Above

High Arc Mark

Front Wall

Bracket

Center of

HIGH ARC RISE HIGH ARC RISE

High Arc Mark

Door

HORIZONTAL LINE

4 INCHES 8 INCHES

Mount the Front Mounting Bracket securely with lag

screws as shown in figure above. If necessary,

4 TO 8 INCHES 13 INCHES

8 TO 12 INCHES 18 INCHES

reinforce the header with steel angle iron or wood to

ensure a secure mount.

STEP 2: Raise the front of the Rail/Chain assembly so that the Front Rail Bracket and Wall Mounting Bracket align. Insert the

1/4” x 4” bolt and tighten nut loosely for now. Later in the installation, this nut must be tightened securely.

STEP 3 — Sectional Doors and One Piece Doors with Track: Raise the Opener and rest the Power Unit on a ladder or other

sturdy support. Open the door the full open position.

Allow 2" of space between the Tee Rail and the top

section of the door (as shown in the illustration on page

9).

STEP 3A — One Piece Doors without Track: Raise

the opener and rest the power unit on a ladder or other

sturdy support. Open the door to the high arc position.

Allow 2” of space between the tee rail and the door (at the

high arc position) as shown in the illustration on page 9.

The opener will be angled as shown. This is necessary for

proper operation.

NOTE: Since the Opener will be secured permanently

in this position, open and close the door a few times to be

sure the door does not rub on the Tee Rail and that you

have allowed the proper clearances before proceeding.

Wall

Mounting

Bracket

Wall Mounting Bracket

Nut

1/4” x 4”

Hex Head Bolt

Cardboard or Cloth to

protect the Housing

110050-1

8

Page 9

C: INSTALLING THE OPERATOR

STEP 4: Mount Power Head to Ceiling: Since there is such variety in ceiling structures, all the mounting possibilities for the Power

Unit cannot be illustrated here. The main concern is mounting the Power Unit securely to the ceiling joists for operational strength,

rigidity and safety. Although there are a series of mounting slots provided on the power unit, try to secure the mounting straps in

the slots closest to the front. Mounting

may usually be accomplished using

standard 1-1/4“ perforated steel angle

available at most hardware stores. If in

doubt about location of, and attachment to,

ceiling joists, a carpenter should be

contacted to provide assistance. A cross

brace will be necessary if power head is

mounted 8” or more from the ceiling.

STEP 5: Return to the Rail/Wall

Mounting Bracket and securely tighten

the bolt and nut that connect the Rail Front

Idler bracket and the Wall Mounting

Bracket. Take care not to over tighten the

nut; tighten only until the end of the bolt is

(See Step 2).

SECTIONAL DOORS AND ONE-

PIECE DOORS WITH TRACKS

ALLOW 2” BETWEEN

TOP OF DOOR AND RAIL

DOOR FULLY

OPEN

ONE PIECE DOORS

WITHOUT TRACKS

ALLOW 2” BETWEEN

TOP OF

DOOR IN

HIGH ARC

POSITION

HIGH ARC

104373

Mounting The Power Head End of

Opener

110050-2

STEP 6: Align the center of opener tracks

with the center line previously marked on the

top section of the garage door to ensure rail

will be parallel with the direction of door

travel.

Use supplied hangers from the ceiling beams

to hang the opener at the power head end (be

Structural

Beams

Cut and bend

Hangers to fit

sure to locate and mount to the solid structural

beams, as illustrated). Predrill with 3/16” drill

bit and use supplied 1/4” x 1-1/2” lag screws

to ensure a rigid mount.

Opener

Power Head

NOTE: Hanging brackets should be at an

angle to provide rigid support. If hangers have no angle or if you use longer hangers, cross brace the

hangers to eliminate the possibility of sway during operation of the opener.

Fiberglass, aluminum or lightweight steel garage

WARNING

STEP 7: Door Bracket Installation

the door mounting bracket Contact your door

manufacturer for a reinforcement kit or instructions.

doors will require

reinforcement before installation of

NOTE: If the door is of light construction it may be necessary to reinforce the

center stile with steel angle or wood to prevent damage to the door if it

encounters an obstruction on closing.

Mount the door bracket using two 1/4”-20 x 2” carriage bolts and 1/4” nuts

(supplied), on center line of door with the middle hole in line with the top

rollers.

For finished ceilings, or if

structural beams are out of

position for mounting use a

third mounting angle (not

included) making sure it is

securely mounted to beams.

Top Roller

Guideline

Reinforce Door

Vertically and

Horizontally

Door Center Line

Mounting

Bracket

If your door comes equipped with a strut

mounted opener bracket, proceed to Step 8.

110051-1

Top Roller

Guideline

110051-2

9

Page 10

C: INSTALLING THE OPERATOR

Step 8: Connecting Door Arm to Trolley

(THIS IS FOR SECTIONAL DOORS ONLY - FOR ONE

PIECE DOORS PROCEED TO STEP 10)

The door arm assembly consists of the door arm tube section and door arm

rod which are packaged separately. To assemble, screw the door arm rod into

the the door arm tube in a clockwise direction approximately ten turns.

Connect the door arm assembly into the trolley with the open end of the rod

hook facing the power head unit (away from the door). Extend the manual

release cord (connected to the trolley) and thread through the warning tag and

red pull knob handle. Adjust so the knob is 6 feet above the floor and secure

with a double overhand knot in the end of the release cord.

Release the trolley (leave door arm attached) with the manual release cord

and pull trolley toward the door.

Trolley

(Close Limit Pos ition)

Cushion

Arm

Assembly

110053-2

110054-2

Step 9: Connecting the Door Arm to the Door

Type 1: Door Mounted Bracket

Visually align the door arm connecting hole with the middle hole of

the door bracket by rotating the tube section in the appropriate

direction.

Release the trolley (leave door arm attached) with the manual release

cord and pull trolley toward the power head unit. Now rotate the door

arm tube section two turns counterclockwise (increasing the exposed

length of the door rod) to provide a cushion when the door is closed or

encounters an obstruction. Align connecting hole in the door arm to

middle hole in the door bracket; insert 3/8” diameter bolt and tighten

locking nut, allowing for free pivot of the arm. Note: Do not

overtighten locking nut as this will cause binding between the door

arm and door bracket.

Type 2: Strut Mounted Bracket

Visually align the door arm connecting hole with the connecting

pin of the strut by rotating the tube section in the appropriate

direction.

Release the trolley (leave door arm attached) with the manual

release cord and pull trolley toward the power head unit. Now

rotate the door arm tube section two turns counterclockwise

(increasing the exposed length of the door rod) to provide a cushion

when the door is closed or encounters an obstruction. Align

connecting hole in the door arm with the strut mounted connecting

bracket. Insert connecting pin through the hole in the door arm.

Secure the connecting pin to the strut bracket according to the

manufacturer’s instructions.

Note: Door Bracket Mount or Strut Mount - If rod

bottoms in cushion tube, cut rod to allow for proper

function of this assembly.

110054-2

Alternate Strut

Connecting Bracket

Cut to Fit

10

Page 11

C: INSTALLING THE OPERATOR

Step 10: Connecting the Door Arm to the Door - ONE PIECE

DOORS (USING OPTIONAL ONE PIECE DOOR ARM ASSEMBLY)

Attach door arm brackets to the top surface of the door on the center line.

Reposition Open and Close limit stops so trolley stops in locations as shown.

Assemble the door arm by screwing curved rod into straight tube section. Allow

approximately 6” of rod to project outside of the straight tube.

Release trolley with red knob handle and move to a convenient position between

Closed Limit

Stop Location

Door Arm

Closed Door

Open Limit

Stop Location

Fully Closed

Trolley

Fully Open

Door Arm

Connection

Door Arm Door Arm Bracket Open Door

110055-1

6”

Door

Brackets

Straight Tube

Bolt/Nut

110054-2

Open and Close limits. Connect curved rod

section to trolley.

Slide door arm and trolley toward door; connect

the tube assembly to the door bracket with the

3/8” diameter bolt and locking nut, tightening

enough to allow for door arm pivot. Do not

overtighten the locking nut.

Press door control button and run opener through

full open and close cycles, adjusting the limit

stops as required to fully open and close the

door. At full closed position, the door arm

assembly should compress approximately one

inch.

STEP 11: Connecting The Electrical Power Consult the label on the rear panel of the Opener to determine its proper

working voltage. Normally it will be marked for 115V, 60 cycle operation. (If it is an export model designed for 220V, 50 cycle

operation, the label will clearly indicate this.) The Opener must be plugged into a properly grounded receptacle within 3 FT of the

Power Unit. A GFI Type receptacle is recommended. Do not use 2-prong adapters and do not use extension cords for anything

more than temporary hook-up and testing purposes. Receptacle wiring should be No. 14 or heavier, and must be in compliance with

local building and electrical codes.

110053-1

Permanent Wiring Connection

Using the two wires (black & white) that were left when you

cut off the line cord, splice in the permanent connections.

WARNING

IMPROPER WIRING COULD CAUSE

ELECTROCUTION OR DAMAGE TO

WARNING

WARNINGWARNING

CIRCUITRY. FOLLOW LOCAL BUILDING

Normal

Connection

Ground Wire

If local codes require permanent wiring, a GFI type circuit

breaker is recommended to protect the line. Remove the Strain

Relief Bushing and withdraw the Line Cord from the rear of the

Power Unit to expose the three insulated connectors. Cut the

wire at the rubber jacket of the Line Cord and wire in

permanently, employing proper wiring practices. Discard Strain

Relief. It is not used with permanent wiring.

Step 12: Install a Rough Service lamp bulb (75 Watt maximum) firmly

in the light socket. Light bulbs in Door Openers are subject to vibration

during normal operation which may shorten their life spans. Rough

Service bulbs, available at most hardware stores, are recommended. Fit

Light Diffuser tabs into the panel tabs as shown.

AND ELECTRICAL CODES.

110051-3

Clips

11

Page 12

D: CONTROL AND AUXILIARY EQUIPMENT

A

j

j

p

INSTALLATION OF A STANDARD WALL PUSH BUTTON OR DELUXE WALL STATION CONTROL

A standard wall push button is included

in your hardware package, an optional

Deluxe Wall Station may be purchased

from your installing dealer. The operating parameters for the standard wall

push button and the Deluxe Wall Station

are outlined on pages that follow

(“Operating Instructions”) to see what

mode of operation is right for you. Allstar recommends the Deluxe Wall Station installation, as it will provide full

control over the garage door operator and its functions at all times. You may install one Deluxe Wall Station and one or more standard push buttons to a Challenger AC9000 Series operator following the cautions and instructions outlined below.

STEP 1: After determining a suitable location, usually near the access door and at least 5 feet above the floor to prevent use by

children, use the standard wall push button or Deluxe Wall Station as a guide to mark the mounting holes. Drill holes for drywall

anchors or screws. NOTE: Do not mount directly to masonry walls. Use backer board.

STEP 2: A length of 2-conductor, #22 gauge wire (or heavier) is required to connect the control button to the garage door operator.

Strip approximately 2” of the wire jacket from one end and 1/2” of insulation from each wire. Carefully connect one wire to each of

the two terminals. Carefully tuck the loose wires into the case and mount the unit using appropriate screws.

STEP 3: Run the wire from the control button to the operator, supporting it at 18” intervals with suitable staples. Leave a

sufficient length to make the necessary connections to the operator terminal strip.

WARNING: SOME LOCAL BUILDING CODES DO NOT ALLOW

SURFACE WIRING. BE SAFE AND CHECK WITH YOUR LOCAL

BUILDING INSPECTOR FIRST.

STEP 4: Ensure power is OFF to the operator or disconnect the power from the

operator. Strip approximately 4” of jacket from the end of the wire and 1/2”

insulation from each wire. Connect to terminals 0 and 1 as shown in the

illustration. Support the wire near the operator with wire ties.

109986

WARNING

WARNING

WARNINGWARNING

A CHILD OPERATING THE DOOR CONTROLS

RISKS INJURY — OR DEATH — TO HIMSELF AND

OTHERS. DO NOT ALLOW CHILDREN TO

OPERATE ANY DOOR CONTROLS.

MOUNT THE PUSHBUTTON AT LEAST 5 FT FROM

THE FLOOR, OUT OF REACH OF CHILDREN.

104350

!!!!

Step 5: Install the

Control Button

Warning Label

supplied with your

Challenger AC9000

Series operator near

the control button

(see illustration).

Repeat the Steps 1

thru 5 above to install additional standard wall push buttons if desired.

Every control must

have a separate Control Button Warning

Label mounted near it. Contact the factory for additional labels if

needed.

Child ca n be pinned under automatic garage

door.

•

Neve r let c hild walk or run under moving door.

•

Neve r let c hild use door ope ner controls.

•

lways keep moving door in sight.

•

If person is pinned, push control button or use

emergency release.

•

Test door opener monthly:

Refer to your owner’s manual

Place one-inch ob

If door fails to reverse on contact, ad

If o

CONTROL BUTTON WARNING LABEL

WARNING

Death or serious injury can result.

ect (or 2x4 laid flat) on floor.

ener still fails to r everse door, r epair or replace opener.

ust opener.

WARNING

WARNING

WARNINGWARNING

IMPROPER DOOR OPERATION COULD

CAUSE INJURY OR DEATH. WARNING

LABEL MUST BE MOUNTED ON WALL NEAR

THE PUSHBUTTON. ALL WARNINGS AND

INSTRUCTIONS ON THE LABEL SHOULD BE

STRICTLY ADHERED TO.

12

Page 13

D: CONTROL AND AUXILIARY EQUIIPMENT

SAFE FINISH™ PHOTOSYSTEM INSTALLATION

12 Inches From Door Opening

Identify which side of the garage door opening (if any) the sun is “likely” to shine

into. As sunlight may cause undesirable operation, mount the sending unit (black

button below the window) on the side of the door opening exposed most to the sun.

#8 Hex

Head

Screw

110052-1

STEP 1: Mounting the Photosystem Wall Brackets Select a

mounting position 5 inches above the floor to the center line wall bracket. The

sending and receiving units should be mounted inside the door opening to minimize

any interference by the sun. However, the sensors should be mounted as close to

the door track or inside edge of the door as possible to offer maximum entrapment

protection. The brackets may be temporarily

104382

mounted to the wall (or jamb) with the 1” flathead

5 Inches

Above the Floor

nail provided. Leave this nail in place after

installation of the lag screw below to prevent

accidental rotation of the bracket NOTE: It is very important that the wall brackets be mounted at

exactly the same height so they will be aligned.

Using the 1/4” x 1-1/2” lag screw provided, attach the wall bracket securely to the wall. In some

installations it may be necessary to attach wooden spacers to the wall to achieve the required

clearance. Expansion bolts (not supplied) may be required to attach brackets to walls constructed of

materials other than wood or gypsum. Repeat for the wall bracket on the other side of the door

STEP 2: Wire Connect the Photosystem

opening.

Refer to page 20 for wiring diagrams of the Safe Finish™ Photosystem and garage door opener. The following outlines the

“PHOTOCELL SERIES CONNECTION (RECEIVER FIRST)” wiring diagram.

A. Run a wire pair (not supplied) around the garage door jamb between the transmitter and receiver "L" mounting brackets.

NOTE: Leave about 12” of extra wire at each end. Use a minimum 22 gauge solid "trace" wire (one wire in set should be

marked to identify it at each end) for interconnect.

B. Run a wire pair (20 or 22 gage solid wire) from the receiver position (unit with "LED" light in the front, may be either side of

the door) back to the rear bulkhead of the garage door opener. NOTE: Leave about 12” of extra wire at the receiver end and

about 24” of extra wire at the opener end. Use a minimum 22 gauge solid "trace" wire (one wire in set should be marked to

identify it at each end) for interconnect.

C. Strip approximately 5/16” from each wire end at the photosystem units and at the opener.

D. Using two (2) wire nuts (supplied), connect the wire ends at the Safe Finish™ Photosystem transmitter to the pigtail wire ends

coming out of the transmitter unit.

unmarked wire ends together. See wiring diagrams on page 20 .

Observe polarity, connect the trace wire ends (with black stripe) together and the

Using two (2) wire nuts (supplied), connect the wire ends at the SAFE FINISH™ Photosystem receiver to the pigtail wire ends

coming out of the receiver unit.

Observe polarity, connect the trace wire ends (with black stripe) together and the

unmarked wire ends together.

STEP 3: Final Installation of Photosystem Units

A. Attach the"U" brackets to the "L" brackets with a 1/4-20 carriage bolt,

washer and hex nut (provided). Insert the bolt from the inside of the

"U" bracket and hand tighten only at this time.

B. Place the transmitter and receiver units into their respective "U"

brackets. NOTE: It is easier to slip the photosystem units in from the

side of the bracket than forcing them in from the front of the bracket.

See Illustration, at right.

C. Connect the interconnect wire pair to the garage door opener terminals.

Connect the trace wire (with black stripe) to the operator

terminal marked “4” and the solid color wire to the operator

terminal marked “5”. See Wiring Diagrams on page 20 .

1/4” x 1-1/2”

Lag Screw

104383

13

Page 14

D: CONTROL AND AUXILIARY EQUIPMENT

INSTALLATION OF RADIO CONTROLS:

The following instructions detail installation of Model 9931 Radio Controls. For other Radio models, see instructions

packaged with product.

TRANSMITTER:

To gain access to

the Transmitter

Coding Switches,

remove the Battery

Cover from the

front of the

Transmitter by

sliding it toward the

bottom of the

Transmitter as

illustrated.

Setting The Coding Switches: When setting the Coding Switches THE FACTORY

PRE-SET CODES MUST BE CHANGED TO PREVENT UNAUTHORIZED

OPERATION. Transmitter and Receiver codes must be set IDENTICALLY. If just

one Code Switch is mismatched, the Radio Controls will not function.

NOTE: For security reasons, it is advisable NOT to set all the switches in the

same position.

Mounting The Receiver: After setting the Coding Switches, mount the Receiver on

the rear panel of the Opener by connecting it to Terminals 1, 2 and 3. For proper

operation, the Antenna Wire should be POINTED STRAIGHT DOWN toward the

floor.

POINT ANTE NNA

STRAIGHT DOWN

Transmitter in the car. If the distance is still inadequate, try bending the Antenna Wire

to a different angle. If the distance is still

inadequate, replace the Battery with a standard 9Volt “transistor radio” Battery (NEED 1604). The

Battery is located in the front compartment next to

the Coding Switches.

The Transmitter may be hand held if desired by

removing the Visor Clip from the rear of the Case

as illustrated. Place your finger in the loop at the

top of the visor, and your thumb on the top edge

of the Transmitter. Push down with your thumb

and pull up with your finger. The clip will release

and pull out easily.

108386

104384

After installing the Radio

Controls, check their operation

by moving approximately 35

FT away from the garage door

and pressing the Transmitter

Button. Operation at this

distance should be reliable.

If the Transmitter doesn't

activate door operation, check

that all Coding Switches are set

identically. If the operational

distance is inadequate, try

moving the position of the

RECEIVER: The

Receiver Coding

Switches can be

accessed by

removing the small

door from the back

of the

Receiver using a

small screwdriver or

knife.

104388

104385

104386

CODING BLOCK: Transmitter and

Receiver Coding Switches are contained

in identical Coding Blocks, consisting of

nine small switches, labeled 1 - 9, each

of which can be set in any of three

positions, labeled +, 0, -

WARNING

WARNING

WARNINGWARNING

TO PREVENT THE RISK

OF PERSONAL INJURY,

DAMAGE TO DOOR OR

PROPERTY, ONLY

OPERATE DOOR

CONTROLS WHEN DOOR

IS IN CLEAR VIEW. KEEP

REMOTE CONTROL

AWAY FROM CHILDREN

IN SECURE AREA.

14

Page 15

E: OPERATION AND ADJUSTMENT INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

TO REDUCE THE RISK OF SEVERE

INJURY OR DEATH: READ AND FOLLOW

WARNING

ALL USER / SAFETY INSTRUCTIONS!

• NEVER let children operate or play with door controls. Keep the Remote Control away from

children.

• ALWAYS keep a moving door in sight and keep people and objects away from the door area

until the door is completely closed. NO ONE SHOULD CROSS THE PATH OF A MOVING

DOOR.

• NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR.

• TEST THE DOOR OPENER MONTHLY. The door MUST reverse upon contact with a 1-1/2”

high object (or a 2 X 4 board laid flat) on the floor. After adjusting the sensitivity or the limit

of travel, ALWAYS RETEST the Opener. Failure to ADJUST THE OPENER PROPERLY may

result in SERIOUS INJURY OR DEATH.

• If possible, USE THE EMERGENCY RELEASE only when the door is closed. Use caution

when using the Release with the door open. WEAK OR BROKEN SPRINGS MAY ALLOW

THE DOOR TO CLOSE RAPIDLY, CAUSING SEVERE INJURY OR DEATH.

• KEEP THE GARAGE DOOR PROPERLY BALANCED. See the door owner's manual. An

improperly balanced door MAY CAUSE SEVERE INJURY OR DEATH. Have a QUALIFIED

SERVICE PERSON MAKE REPAIRS TO CABLES, SPRING ASSEMBLIES AND OTHER

HARDWARE.

• SAVE THIS INSTRUCTION MANUAL.

TURNING ON POWER TO THE OPERATOR

NOTE: It is now necessary to turn on the power in order to run the Opener to test the operation and check the

limit settings. Before doing so, ensure that all mounting hardware is installed and has been properly tightened,

that all electrical connections are per local code requirements, and that proper wiring practices have been

followed. Also, double-check that all ropes have been removed from the door and that the doorway is clear.

BASIC OPERATING PARAMETERS

Please note the following Operating Parameters which apply to Openers with Auxiliary Entrapment Protection System (Safe Finish™ Photosystem, Installation Instructions on Page 13) and a standard wall push button connected. Please see page 17 for instructions concerning the Deluxe Wall Push Button operating parameters.

HOW TO ACTIVATE THE OPENER

Never let children operate or play with the door controls. Keep Remote Control Away for Children.

Use any of the following devices:

1. The Remote Control Transmitter. Hold the push button down until the door starts to move, then release button.

2. The Door Control Button. Momentary push of the button until the door starts to move. Constant push of the button until the

door is closed is required if light flashes.

3. An Outside Keylock or Keyless Entry System (if you have installed either of these options, see Mfg’s instructions).

15

Page 16

E: OPERATION AND ADJUSTMENT INSTRUCTIONS

HOW THE DOOR MOVES WHEN THE OPENER IS ACTIVATED

Always keep moving door in sight and away from people and objects until it is completely closed

IF THE DOOR IS...

...FULLY OPEN, then pushing the standard wall Push Button or the radio control will cause the door to begin MOVING

DOWNWARD.

...FULLY CLOSED, then pushing the wall Push Button or the radio control will cause the door to begin MOVING UPWARD.

...MOVING UPWARD, then pushing the wall Push Button will cause the door to STOP. The next push of the wall button will

cause the door to begin MOVING DOWNWARD (Alternate Action Operation).

...MOVING DOWNWARD, then pushing the wall Push Button or the radio control will cause the door to STOP. The next

activation will cause the door to BEGIN MOVING UPWARD.

...MOVING DOWNWARD and an obstruction is encountered, the door will STOP, PAUSE AND REVERSE TO THE OPEN

DIRECTION.

...MOVING UPWARD and an obstruction is encountered, the door will STOP. The next activation will CLOSE the door.

The SAFE FINISH PHOTOELECTRIC uses an invisible beam which, when broken by an obstruction, causes a closing door to open

and prevents an open door from closing.

HOW THE LIGHT WORKS AND WHAT IT MEANS WHEN IT FLASHES

1. The convenience light automatically turns on when the opener is activated and remains on for 4-1/2 minutes for your convenience

and safety.

2. The light will flash after coming upon an obstruction in the down direction to alert you of a problem. It will continue to flash for

4-1/2 minutes, then shut off.

3. Optional Wall Station adds the convenience of allowing the light to be turned on and stay on until turned off by a second push of

the button or

If the light begins to flash and the door does not move in the close direction from a push button or radio, the

external safety device (Safe Finish Photoelectric) is activated or defective (misaligned or blocked etc.). To

temporarily override and close door, activate pushbutton or wall station for 2 seconds; opener will begin moving

in the down direction. The button must remain depressed until the cycle is completed. If the button is released

before cycle is completed, the door will reverse and come to a fully open position. Problems with the safety system

should be inspected by a professional garage door installer.

NO ONE SHOULD CROSS THE PATH OF A MOVING DOOR.

activation of door cycle.

HOW TO OPERATE THE DOOR MANUALLY - MANUAL RELEASE DISCONNECT

The door should be fully closed, if possible, before using the manual disconnect. Weak or broken springs

could allow an open door to fall rapidly. Property damage or serious personal injury could result. Do not

Your opener is equipped with a manual release recessed trolley-type disconnect

system, enabling manual operation of the garage door during a power failure.

The trolley is disconnected from the chain by pulling down on the red release

handle, allowing the garage door to be operated manually.

The trolley will automatically reconnect when power is restored and the door is

activated.

If the manual release is used, close the door before reactivating the opener.

NOTE: Outside keylock manual releases are an available accessory and are recommended for garages without a service

entrance.

use the manual release handle to pull the door open or closed.

Trolley

110058-1

Manual Release Knob

16

Page 17

E: OPERATION AND ADJUSTMENT INSTRUCTIONS

OPTIONAL THREE FUNCTION DELUXE WALL STATION

When the Wall Station is connected to the operator per instructions supplied with the wall station, it will provide the following

features:

1. “OFF-ON” will prevent inadvertent operation of the door from any other push button, radio or keyless entry device. It will also

as additional protection from unwanted operation during absence of the owner. This feature is to be activated only when the door is

at the full open or close position and never while the door is moving.

2. “LIGHT” button allows the convenience light to be turned on and stay on until turned off by a second push of the button or

activation of the door cycle.

3. “UP/DOWN” button provides normal opening and closing of the door by momentary activation of this push button. Function of

door cycle is described above - “How the Door Moves When the Opener is Activated”.

Adjustment #1: Opening Travel

Your opener is assembled at the factory with the trolley in the forward position with the

open limit stops snapped in place on the chain, set for a standard door.

DO NOT USE ADJUSTMENTS TO COMPENSATE FOR A POORLY WORKING DOOR. THIS WILL

INTERFERE WITH THE PROPER OPERATION OF THE REVERSING MECHANISM AND MAY

DAMAGE THE DOOR.

110056-1

Limit Stops

Load Adjusting Nut

If you door is non-standard, move BOTH open limit stops, located just behind the trolley.

As an example: For a 6 FT, 6 INCH door, move both open limit stops six inches or 12 links

toward the power head unit.

To confirm final opening travel adjustment, activate the opener to bring the foor to the

fully open position. When properly adjusted, center of the open limit stops should come to

rest opposite the load adjusting nut.

NOTE: If the door drifts forward, move the open limit stops toward the

power head unit. If the door does not drift forward it is still advised that you

perform one additional check. Operate manual release on the trolley and

Chain

Limit Stops

allow the door to seek its natural fully open position, then move the open limit

stops to align trolley to this position. If the door does not open fully at its

natural open position, it indicates a door spring or hardware problem that

should be referred to a door system professional.

(See instruction label on side of track for proper limit stop location.)

Adjustment #2: Opening and Closing Force

Hex nuts for adjusting force are located on either side of the rail at the motor end.

The left hex nut, labeled “CLOSE”, adjusts the closing force; the right hex nut,

labeled “OPEN”, adjusts the opening force.

Turning the hex nuts clockwise increases force; counterclockwise decreases force.

Your garage door opener is built with a safety system that allows the door to reverse

in the close direction and stop in the open direction. This must be adjusted so your

opener does not use excessive force in the down direction or react to the weight of the

door during upward travel.

To help determine that the force is not excessive, grasp the door handle or bottom

edge during downward travel. The opener should reverse to this force. Do not stand

under the door during this test.

If the handle is hard to hold and the door does not reverse, adjust the CLOSE hex nut to decrease force until the door reacts properly.

Repeat the adjustment procedure for upward travel. The door should stop without using excessive force.

110056-2

Leave One Link Open Between

the Two Open Limit Stops

Close Adjustment Nut

Open Adjustment Nut

17

Page 18

E: OPERATION AND ADJUSTMENT INSTRUCTIONS

Adjustment #3: Setting Door Close Limit

9”to10”

Confirm trolley close position 9” to 10” between the inside face of the door

and the point where the door arm connects to the trolley (see illustration).

If adjustment of the close trolley position is necessary, activate the opener and

move the trolley 12” to 18” to provide access to the “Limit Stop” devices

(mounted on the chain). Move the limit stop to establish the correct trolley

close position as above.

Trolley

(Close Limit Pos ition)

Chain

Relocation of “Limit Stop” toward the door increases down travel.

Limit Stop

Relocation of the limit stop away from the door reduces down travel. Note

that each chain link provides 1/2” adjustment of trolley travel.

Adjustment #4: Obstruction Sensing (Closing Direction)

Your opener is designed to automatically reverse the door during closing travel

Door

Bracket

Cushion Arm

Assembly

WARNING

WARNING

WARNINGWARNING

110054-1

whenever it comes into contact with an object up to the last 1-1/2 inch of travel

above the floor. An object on the floor with a height of less than 1-1/2 inch will

cause the door to stop. (Test according to the instructions below.)

If the opener reverses properly with a 2” x 4” laid flat on the garage floor (as the test

below) and stops in the fully closed position, proceed to Adjustment #5.

If the door reverses when it comes into contact with the floor, move the close limit

stop, located on the left side (inside looking out, see figure Adjustment #1), towards

the power head unit. It is advised that you move the close limit stop one link at a

IF LIMITS ARE NOT ADJUSTED

PROPERLY, THE EMERGENCY

RELEASE MECHANISM MAY

NOT WORK PROPERLY AND

DOOR OPERATION COULD

RESULT IN DOOR DAMAGE,

SERIOUS PERSONAL INJURY

OR DEATH!

time and run opener through another close cycle, until the door stops when it comes

into contact with the floor.

When the door comes into contact with a 2” x 4” laid flat on the garage floor and stops intends of reversing, move the close limit stop

away from the power head unit. It is advised that you move the close limit stop one link at a time and run opener through another

close cycle, until the door reverses when it comes into contact with the 2” x 4”.

Important Test: Opener Obstruction Sensing Feature for Doors (both Sectional and One Piece)

A. Activate door to the Open position.

B. Place 2” x 4” laid flat on garage floor under path

of the door. See Figure.

C Activate door to close position; upon contacting

solid object, the door should stop, then reverse

direction within 2 seconds and travel to the full

open position.

Note: If the fails to pass this test, see Adjustment

3 above and move the Close Limit Stop one

increment towards the door to increase down

travel. Also review Steps 8 and 9, Page 10 for

Sectional Doors or Step 10, Page 11 for One

Piece Doors.

REPEAT THIS TEST MONTHLY!

18

Solid Test Object

110055-3

Page 19

E: OPERATION AND ADJUSTMENT INSTRUCTIONS

Adjustment #5: Alignment and Initial Test of Safe Finish Photosystem

A. Keep a portable transmitter with you to control the garage door opener. The red light on the receiver unit should now be on. If

not, recheck that the mounting screws are tight then, if necessary, align the photosystem by slightly bending the wall bracket

until proper operation is obtained.

B. Place an object (packing insert box or a similar object approximately six inches high) one foot in front of the transmitter or

receiver. The red LED should go OFF and remain OFF until the object is removed. NOTE: There may be a slight delay in

returning to normal depending upon how long the photosystem was blocked. If the light fails to go off when the object is placed

in the path of the beam check the wire connections and the installation height of the units (see Page 13).

C. Move to the center of the door. Make sure the red LED light is on. Move a solid object slowly through the beam. The

LED should go OFF and then ON.

D. Using the pushbutton or transmitter, activate the opener and check that it will operate through the full open and close cycles. If

not, re-align the photosystem by slightly bending the wall bracket until proper operation is obtained.

E. Tighten all mounting screws and bolts, loop and secure any extra wire.

Important Test: Photoelectric Obstruction Test

Test Procedure

Place an object 6” x 12” on the floor (as illustrated)

progressively on foot from the left side of the door; center of

the door and one foot from the right side of the door. The

object must prevent an open door from closing in any other

mode other than constant pressure on the wall button. The

object should also cause a closing door stop and reverse to

the open position. If it doesn’t, the Safe Finish photoelectric

system must be adjusted lower and the test repeated until the

door responds properly to the 6” object.

If adjustments are needed, refer to preceding adjustment.

If the unit still will not respond and fails this obstruction

sensing beam test, the door may cause severe injury or death.

Have a qualified service person make repairs.

12”

Garage Door

Opening

12”

6”

110055-2

Sensor

12”

Adjustment #6: Positive Mechanical Lock Adjustment

The garage door opener is designed with an automatic mechanical

locking system. This lock secures the door in the fully closed

position.

To adjust, activate your opener and allow the door to go to its

fully closed position. Loosen the two screws on the rail stop

and move it behind behind the chain latch assembly with a gap

of 1/2” between “stop” and “latch”.

Adjustment #7 :Resetting the Travel Timer

Your opener is shipped with the jumper connected, allowing the operator to run continuously for

17 seconds, then stop in the Open cycle or reverse in the closing cycle, activating the flashing

light mode.

On all doors having over 9 feet of travel, it is necessary to cut the run timer jumper on the motor

control board to allow the opener to run for 29 seconds. Disconnect the power from the opener

before removing cover and cutting the jumper. MAKE SURE YOU DISCONNECT THE

POWER BEFORE CUTTING THE JUMPER. THE RUN TIMER WILL NOT CHANGE IF

THE JUMPER IS CUT WITH THE POWER CONNECTED.

This jumper is located under operator cover on the control board, as illustrated.

19

“Latch”

110057-2

Rail “Stop”

1/2”

Stop Limits

110057-1

Cut and

Separate

Page 20

SAFE FINISH WIRING DIAGRAM / MAINTENANCE SCHEDULE

SAFE FINISH PHOTOSYSTEM WIRING - SERIES AC9000

109985

MAINTENANCE OF YOUR OPENER

Once a Month:

1. Test for reversal on a 1-1/2 inch high object or a 2 x 4 board laid flat on the floor (see “Important Test: Opener

Obstruction Sensing Feature”, page 18). If adjusting either the force or the limit of travel, retest the opener.

Failure to adjust the opener may cause serious injury or death.

2. Test for reversal with a 6 inch high by 12 inch wide object breaking the Safe Finish™ Photosystem beam (see

“Important Test: Photoelectric Obstruction Test”, page 19).

3. Manually operate the door (ensure door is in the closed position before attempting to engage manual operation, see

Cautions on page 16). If it is unbalanced or binding, call a professional garage door service person.

4. Check to be sure the door opens and closes fully. Adjust limits or force of travel if necessary.

5. Repeat safety reverse test (No. 1 above). Make any necessary adjustments.

Twice a Year:

1. Check chain tension. Adjust if necessary.

Once a Year:

1. Oil door rollers, bearings and hinges (silicone lubricant

spray).

20

Page 21

INSTALLATION CHECKLIST

BEFORE PLACING DOOR OPERATOR IN REGULAR SERVICE, MAKE SURE THAT:

1. THE FRONT AND REAR MOUNTS FOR THE OPENER ARE SOUND AND SECURE AND

THE RAIL IS POSITIONED CORRECTLY ABOVE THE HIGH ARC OF THE DOOR, AND

THAT THE OPENER IS POSITIONED OVER THE DOOR ACTION CENTERLINE.

2. FOR SECTIONAL DOORS AND ONE-PIECE DOORS WITH TRACKS, THE POSITION OF

THE DOOR ARM, WITH THE DOOR CLOSED, IS SUCH THAT ITS CONNECTING POINT

ON THE TROLLEY IS 5" TO 8" BEHIND ITS CONNECTING POINT ON THE DOOR

BRACKET. THE DOOR ARM SHOULD NEVER BE PERFECTLY VERTICAL WHEN THE

DOOR IS IN THE CLOSED POSITION.

3. FOR ONE-PIECE DOORS WITHOUT TRACKS, THE POSITION OF THE DOOR ARM,

WITH THE DOOR CLOSED, IS SUCH THAT ITS CONNECTING POINT ON THE

TROLLEY IS 30" TO 32" BEHIND ITS CONNECTING POINT ON THE DOOR BRACKET.

4. THE EMERGENCY RELEASE HANDLE AND CORD ARE SECURE TO THE

EMERGENCY RELEASE LEVER. THE HANDLE IS LOCATED 6 FT ABOVE FLOOR

LEVEL AND REQUIRES NO MORE THAN 50 LBS. PULL TO ACTUATE. THE TROLLEY

AND RELEASE MECHANISM ARE PROPERLY LUBRICATED.

5. THE STANDARD WALL PUSH BUTTON OR THE DELUXE WALL PUSHBUTTON

STATION IS IN SUCH A POSITION AND OF SUCH A HEIGHT THAT IT CAN ONLY BE

ACTUATED BY AN ADULT OF AVERAGE HEIGHT. THE CAUTION LABEL IS

PROMINENTLY DISPLAYED NEXT TO THE PUSH BUTTON OR WALL STATION.

6. ALL WIRING IS CORRECT TO CODES OR BETTER. THERE IS GROUND CONTINUITY

IN THE SUPPLY. THE GROUND PRONG ON THE POWER CORD IS INTACT.

7. ALL ROPES HAVE BEEN REMOVED FROM THE DOOR. THE DOOR MOVES FREELY

WITHOUT BINDING WHEN RAISED OR LOWERED MANUALLY. THE DOOR IS

CORRECTLY BALANCED AND LUBRICATED. ALL DOOR HARDWARE IS SECURE

AND SOUND. THE SENSITIVITY HAS BEEN ADJUSTED TO MINIMUM FORCE FOR

THE APPLICATION.

8. THE DOOR REVERSES ON OBSTRUCTIONS TO WITHIN 1-1/2" OF THE FLOOR. THE

CONCRETE OR OTHER SURFACE BENEATH THE CLOSED DOOR PROVIDES

UNIFORM CONTACT.

9. THE PLASTIC ENVELOPE FOR THIS MANUAL IS ATTACHED TO THE WALL NEAR

THE PUSH BUTTON OR WALL STATION AND THIS MANUAL IS PLACED THERE FOR

OWNER USE AND REFERENCE.

10. ON DOORS WITH EXTENSION TYPE COUNTERBALANCE SPRINGS, RESTRAINT

CABLES HAVE BEEN INSTALLED THROUGH THE SPRINGS.

11. THERE IS GFI PROTECTION ON THE LINE TO POWER THE OPENER OR IN THE

RECEPTACLE. THIS IS PARTICULARLY IMPORTANT ON INSTALLATIONS

INVOLVING DOORS OF STEEL CONSTRUCTION.

12. ON DOORS WITH ADJUSTABLE BOTTOM EDGES, LOCK EDGES HAVE BEEN

LOCKED AFTER ADJUSTMENT

21

Page 22

TROUBLESHOOTING GUIDE

WARNING

USE EXTREME CAUTION AT ALL TIMES WHEN ATTEMPTING TO DIAGNOSE

AND RECTIFY PROBLEMS WITH YOUR GARAGE DOOR OPENER. BEFORE

ATTEMPTING ANY SERVICE ON UNIT, DISCONNECT OPENER FROM

POWER SUPPLY. YOUR GARAGE DOOR IS THE LARGEST MOVING

OBJECT IN YOUR HOUSE, AND THE SPRINGS, PULLEYS, CABLES AND MOUNTING HARDWARE

UTILIZED TO BALANCE ITS OPERATION ARE UNDER EXTREME TENSION AT ALL TIMES AND CAN

CAUSE SERIOUS PERSONAL INJURY, EVEN DEATH, IF DISTURBED. CALL AN EXPERIENCED

SERVICE PERSON TO MOVE, LOOSEN OR ADJUST DOOR SPRINGS OR HARDWARE.

SYMPTOM:

Opener does not activate ...............................................................

Operates with Push Button but not with radio control ...................

Stops before reaching full Open or Closed position .......................

Reverses before reaching Full Close position .............................

Reverses after door closes and contacts floor .............................

Door opens and closes by itself .....................................................

Light will not come on ...................................................................

Light will not turn off after Opener runs ....................................

Transmitter has short range .........................................................

PROBABLE CAUSE:

1. Mechanical door lock enabled

2. 120 Volt power not present at outlet

3. Broken or shorted Push Button, wiring or radio receiver

4. Grid lock on Motor Control Board

5. Motor Thermal Overload Protector opened

6. Door jammed due to broken or incorrectly adjusted

spring

7. Defective Motor Control Board

8. Weak Battery in Transmitter

9. Radio Coding Switches mismatched

10. Improper placement of Limit Stops on Chain

11. Door obstructed

12. Defective Transmitter or Receiver

13. Up sensitivity force improperly adjusted

14. Down sensitivity force improperly adjusted

15. Bottom of door frozen to ground

16. Ice and snow built up under door

17. Floor risen or sunk from weather change

18. Someone in area with identical code

19. Defective or burned out lamp bulb

20. Radio Receiver not receiving signal

21. Transmitter location in car

PROBABLE CAUSE/SOLUTION:

(1) (2) (3) (4) (5) (6) (7) (15)

(8) (9) (21) (12) (23)

(3) (5) (6) (10) (11) (13) (14) (23)

(6) (11) (14)

(16) (17)

(3) (18) (23)

(19) (7)

(20) (7)

(8) (21) (12) (23)

SOLUTION:

1. Disable or remove all door locks.

2. Check wall switch, fuse box, circuit breaker, etc.

3. Remove Push Button wiring and Radio Receiver from the

terminal strip on the back panel of the operator. Activate

Opener by momentarily connecting Terminals 1 & 2 with a

test wire. If Opener runs, reconnect items one at a time to find

defective circuit. Replace.

4. Unplug Opener, then reconnect.

5. Wait 30 minutes for Motor to cool, try again.

6. Ensure that door is in a closed position. Activate Emergency

Release Mechanism. If Opener will run without door

attached, contact your Allstar garage door professional to

repair door.

7. Contact your local Allstar garage door professional.

8. Replace Battery.

9. Reset Switches to identical codes (See instructions).

10. See instructions for proper placement of Limit Stops.

11. Remove all obstructions from door area.

12. Contact your Allstar garage door professional.

13. Adjust sensitivity. See instructions.

14. Adjust sensitivity. See instructions.

15. Activate Emergency Release, clear away ice.

16. Clear away ice and snow to allow door to close.

17. See instructions to reset Down Limit Cam.

18. Reset all radio controls to new code.

19. Replace with rough service bulb (60W max.)

20. Ensure that antenna wire from Opener is pointing straight

down toward the floor.

21. Ensure Transmitter is clipped to sun visor. If it is clipped to

dashboard or in ashtray, etc., range will be diminished.

22

Page 23

PARTS BREAKDOWN & LISTING

# Part # Description

1 109874 Frame

2 260587 Motor,1/3HP,AOS F42C55A29

260584 Motor,1/2HP,AOS F42C56A29

3 109938 Motor Control Board

4 005320 Power Supply Cord

5 260572 Capacitor,43-52 MFD,250V

260570 Capacitor,53-64 MFD,250V

6 109948 Wire Harness, Low Voltage

109947 Wire Harness,High Voltage

7 109845 Lamp Socket

8 220981 Light Diffuser

10 157149 MCB Spacer

11 229863 Limit Switch

12 221012 Nylon Washer

13 220992 Limit Lever

14 109843 Shoulder Screw

15 157501 12-24 Nylon Insert Nut

16 109932 Diffuser Clips

17 249257 Capacitor Clamp

22 102618 Sensor Wall Mounting Bracket

23 102641 Sensor Mounting Bracket

24 109369 Safe Finish Sending Unit

25 109370 Safe Finish Receiving Unit

# Part # Description

1a 282900 Rail Angle,Idler,R.H.

1b 282899 Rail Angle,Idler,L.H.

2 198077 Trolley Assembly

3 221020 Trolley Wing Foot

4 220961 Nylon Button

5 252109 Chain Latch Assembly

6 009224 3 pc. Chain Master Link

7 009011 Chain (specify length)

8 160366 Limit Stop

9 220960 Rail Spacer Bracket

10 229865 Rail Stop w/Set Screws

11 252110 Front Chain Guide ASSY

12 220959 Front Wall Bracket

13 006114 1/4-20 x 4 Hex Bolt

13a 157561 1/4-20 Lock Nut

14 220958 Front Rail Bracket

15 220956 Door Bracket

16 229858 Arm Rod

17 252107 Tube Arm

18 220953 5/16-18 Carriage Bolt

19 220986 Gear Cap

20 252105 Load Leverw/Retainer

21 220315 Combo Gear & SPRKT

22 221014 Spacer Tube

23 252098 Gear Base w/Shaft

24 006043 5/16-18 Keps Nut

25 221010 Load Adjusting Screw

26 221016 Load Spring

27 157561 1/4-20 Nylon Insert Nut

28a 006115 3/8-16 x 1-1/4 Hex Bolt

28b 006076 3/8-16 Nylock Nut

110059-2

29 220987 Molded Chain Guard

33 220977 Release Cord

34 157143 Release Knob Handle

110059-1

Optional Trackless One Piece

Door Arm & Hardware

35 157666 Chain Adjusting Nut

23

Page 24

Manufacturer’s Limited Warranty

Allstar warrants its AC9000 Series Challenger residential vehicular garage door operators as follows:

A. The drive train to be free from defects in materials and workmanship for:

Models AC9300/AC9500/ACJ9500: for 10 years from the date of purchase by the original purchaser.

The drive train includes the motor, rails, frame and chain.

B. The controller circuit board, capacitor, photobeams and all other parts in all models will be free from defects in

materials and workmanship for a period of two (2) years from the date of purchase by the original purchaser.

Contact your dealer to obtain service for your operator .

To obtain service under this warranty the buyer must obtain authorization instructions for the return of any goods

from Allstar before returning the goods. The goods must be returned with complete identification, with copy of

proof-of-purchase, freight prepaid and in accordance with Allstar's instructions or they will not be accepted. In no

event will Allstar be responsible for goods returned without proper authorization or identification.

Goods returned to Allstar for warranty repair within the warranty period, which upon receipt by Allstar are

confirmed to be defective and covered by this limited warranty, will be repaired or replaced at Allstar's sole option,

at no cost and returned pre-paid. Defective parts will be repaired or replaced with new or factory rebuilt parts at

Allstar’s sole option.

This limited warranty does not cover non-defect damage, damage caused by unreasonable use, damage caused by

improper installation or care, vandalism or lightning, fire or excessive heat, flood or other acts of God (including,

but not limited to misuse, abuse or alterations, failure to provide reasonable and necessary maintenance), labor

charges for dismantling or reinstalling a repaired or replaced unit, or replacement batteries.

These warranties are in lieu of all other warranties, either expressed or implied. All implied warranties of

merchantability and/or fitness for a particular purpose are hereby disclaimed and excluded. Under no

circumstances shall Allstar be liable for consequential, incidental or special damages arising in connection with the

use or inability to use this product. In no event shall Allstar’s liability for breach of warranty, breach of contract,

negligence or strict liability exceed the cost of the product covered hereby. No person is authorized to assume for

Allstar any other liability in connection with the sale of this product.

This warranty gives you specific legal rights. You may also have other rights which vary from state to state.

Warranty effective after March 1st, 2000.

This garage door operator is built in the USA

and complies with all requirements of

c.p. Allstar Corporation

Downingtown, PA 19335

Underwriters Laboratories Standard UL-325.

P/N 109987 Rev. C April 2003

24

Loading...

Loading...