Allstar MVP Owner's Manual

|

As of date of manufacture, |

|

meets all ANSI/UL 325 Safety |

|

Requirements for Vehicular |

By |

Garage Door Openers |

Residential Vehicular Garage Door Operator

MODELS: MVP and MVP-SQ

I N S T A L L A T I O N A N D O W N E R ’ S M A N U A L

INSTALLER: Place this manual in the plastic envelope provided and permanently attach to the wall near the pushbutton.

107063

R EAD THIS MAN U AL CA REFUL LY BEFORE IN STALL ATION OR US E

TABLE OF CONTENTS

TABLE OF CONTENTS

Product Features.................................................... |

2 |

FCC and IC Radio Operation Statement ...... |

12 |

Tools Required/Component Identification..... |

2 & 3 |

Installation of Safe Finish Photosystem....... |

13 |

Assembly Instructions ........................................... |

3 |

Installation Checklist..................................... |

14 |

Identify Your Door Type......................................... |

4 |

Operation and Adjustment Instructions............ |

15 |

Important Installation Instructions........................ |

5 |

Important Safety Instructions ....................... |

15 |

Installing the Opener.............................................. |

6 |

Basic Operating Parameters......................... |

15 |

Mounting the Front Bracket ............................ |

6 |

Testing the Limit Settings ............................. |

16 |

Mounting the Power Head............................... |

7 |

Testing the Sensitivity................................... |

16 |

Using the Manual Release Mechanism........... |

7 |

Testing the Reversing System...................... |

16 |

Door Arm Installation ...................................... |

8 |

Testing the Safe Finish Photosystem........... |

17 |

Power Requirements/Permanent Wiring ........ |

9 |

Operating the Super Station Wall Station .... |

17 |

Control and Auxiliary Equipment ........................ |

10 |

Wiring Diagram..................................................... |

18 |

Standard Wall Push Button Installation ....... |

10 |

Auxiliary Equipment Wiring Diagram.................. |

19 |

Installation of the Super Station ................... |

10 |

Troubleshooting Guide ........................................ |

19 |

Remote Control Radio System ..................... |

11 |

Warranty Statement.............................................. |

20 |

READ THESE STATEMENTS CAREFULLY AND FOLLOW THE INSTRUCTIONS CLOSELY

The Warning and Caution boxes throughout this manual are there to protect you and your equipment. Pay close attention to these boxes as you follow the manual.

WARNING |

CAUTION |

WARNING |

CAUTION |

Indicates a |

Indicates a MECHANICAL |

Indicates an |

Indicates an ELECTRICAL |

MECHANICAL |

hazard of DAMAGE to the |

ELECTRICAL hazard |

hazard of DAMAGE to the |

hazard of INJURY |

door, door opener, or |

of INJURY OR |

door, door opener, or |

OR DEATH. Gives |

equipment. Gives |

DEATH. Gives |

equipment. Gives |

instructions to avoid |

instructions to avoid the |

instructions to avoid |

instructions to avoid the |

the hazard. |

hazard. |

the hazard. |

hazard. |

PRODUCT FEATURES |

|

|

2 |

|

|

|

|||

|

|

|||

The purpose of this booklet is to provide assembly, |

Manual Release: A pull cord allows separation of |

|||

installation and operation information concerning the |

the drive mechanism and manual operation of the |

|||

herein described Residential Garage Door Opener and |

door when desired, as in the event of a power failure. |

|||

related Accessory Products. |

(Page 7) |

|||

NOTICE |

Automatic Reconnection: Once power is restored, |

|||

IT IS IMPORTANT THAT THIS INSTRUCTION |

or automatic operation of the door is again desired, |

|||

initiating operation in the normal manner (Push |

||||

MANUAL BE READ AND UNDERSTOOD |

||||

Button, Radio Control, etc.) will effect automatic |

||||

COMPLETELY BEFORE INSTALLATION OR |

||||

reconnection of the Manual Release Mechanism. |

||||

OPERATION IS ATTEMPTED. |

||||

(Page 7) |

||||

NOTICE |

||||

Alternating Action Operation: The mechanical |

||||

THE IMPORTANT SAFEGUARDS AND |

||||

wall pushbutton functions in an Open/Stop/Close/ |

||||

INSTRUCTIONS IN THIS MANUAL CANNOT |

Stop & Reverse mode in normal operation. (Page 15) |

|||

COVER ALL POSSIBLE CONDITIONS AND |

Sensing System: A built-in sensing system detects |

|||

SITUATIONS WHICH MAY OCCUR DURING |

||||

obstructions during door operation. If in the |

||||

ITS USE. IT MUST BE UNDERSTOOD THAT |

||||

downward (close) travel mode, the opener will sense |

||||

COMMON SENSE AND CAUTION MUST BE |

||||

an obstruction and reverse the direction of the door. |

||||

EXERCISED BY THE PERSON(S) INSTALLING, |

||||

In the open mode, the opener will stop. Since all |

||||

MAINTAINING AND OPERATING THE |

||||

doors are different, the Sensing System has |

||||

EQUIPMENT DESCRIBED HEREIN. DO NOT |

||||

independent adjustments for customizing the level of |

||||

USE THIS EQUIPMENT FOR ANY OTHER |

||||

force required for the normal opening and closing of |

||||

THAN ITS INTENDED PURPOSE - OPERATING |

||||

specified doors. ( Page 16) |

||||

OVERHEAD GARAGE DOORS. |

||||

Close Limit Switch: In winter months it's common |

||||

STANDARD FEATURES: |

||||

for small pieces of ice or packed snow to be trapped |

||||

Digital Radio Controls: This opener is equipped with |

||||

under the door. Ground swelling can also effect the |

||||

a transmitter pre-programmed to one of over nineteen |

close limit setting of the opener. The opener’s Close |

|||

thousand private codes. The transmitter can be re- |

Limit Switch overrides the Sensing System during |

|||

programmed without difficulty using the external |

the last one inch of closing travel and prevents the |

|||

operation buttons. The power head is easily |

door from reversing if it encounters an obstruction at |

|||

programmed to accept the transmitter signal. |

this point. |

|||

(Page 11) |

Constant Contact To Close Operation: For utmost |

|||

Safe Finish™ Photosystem: An invisible infrared |

||||

safety and security, the operation mode allows |

||||

beam of light guards the door opening and reverses a |

constant contact on the mechanical Push Button to |

|||

downward moving door if the beam is broken by a |

close the door if the Safe Finish™ Photosystem |

|||

stationary or moving object. The opener’s motor |

beam becomes misaligned or if there is an |

|||

control circuitry constantly monitors the Safe Finish |

irregularity in the wiring to the device. In this mode |

|||

Photosystem for proper operation. |

of operation, a Radio Transmitter cannot be used to |

|||

Super Station (Deluxe Wall Push Button): A |

close the door. |

|||

feature-packed accessory unit, the Super Station allows |

OPTIONAL FEATURES: |

|||

access to all of the opener's functions. Independent |

Wireless Keyless Entry System: A tamper resistant |

|||

Open, Close, and Stop buttons permits full control of |

||||

outdoor keypad, the optional Wireless Keyless Entry |

||||

the door’s operation. The opener's built-in light can be |

||||

System permits entry to the garage without use of |

||||

turned on or off independent of door operation. A |

||||

key or radio transmitter. Easily programmable, it |

||||

Learn Enable button allows programming of the radio |

||||

accommodates a 4 digit PIN code (10,000 possible |

||||

controls at floor level. A Security Switch allows the |

||||

combinations). Lighted Buttons enhance nighttime |

||||

opener to be deactivated for extended periods of time. |

||||

use. The opener has the ability to learn the PIN |

||||

A Security Disable switch is provided if the garage |

||||

codes from two separate Wireless Keyless Entry |

||||

door is the only entryway into the garage. Lighted |

||||

Systems. |

||||

Push Buttons enhance nighttime use. (Page 17) |

||||

|

|

|||

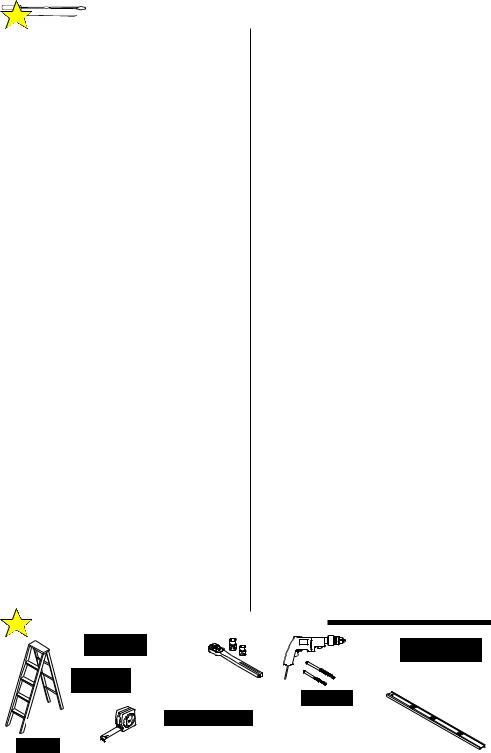

TOOLS REQUIRED FOR INSTALLATION |

|

|

|

|

|

DRILL |

|

HACKSAW |

SOCKETWRENCH |

DRILL BITS |

1/2” OPEN END |

|

|||

|

3/8” SOCKET |

|

WRENCH |

|

|

|

|

HAMMER |

7/16” SOCKET |

|

|

STEPLADDER |

|

SMALL SCREW |

SCREW DRIVER |

DRIVER (1/8” HEAD) |

|

|

LEVEL |

|

TAPE |

|

|

|

|

|

WOOD BLOCK MEASURE |

|

|

3 |

|

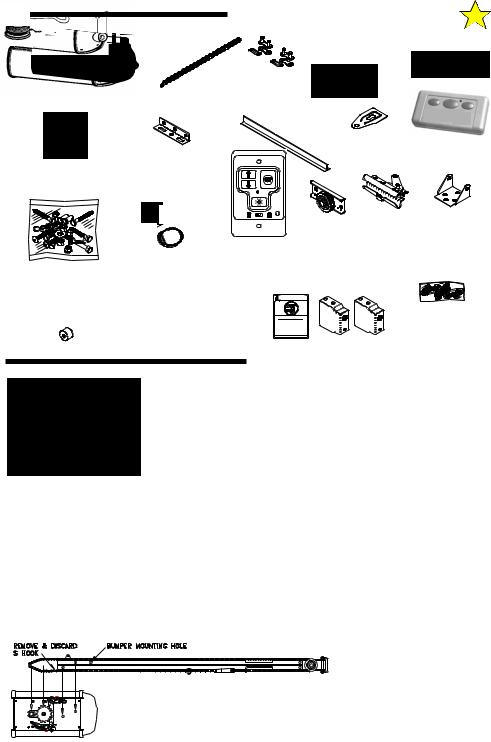

COMPONENT IDENTIFICATION |

|

|

DRIVE |

DOOR ARM |

DOOR ARM ROD |

|

CHAIN |

||

|

TUBE ASSEMBLY |

|

|

|

|

|

|

|

|

MASTER |

|

OPENER HEAD UNIT |

LINKS |

|

|

|

|

TEE RAIL |

|

|

|

CHAIN |

RADIO |

|

|

GUARD |

|

|

DOOR MOUNTING |

TRANSMITTER |

|

CONTROL WIRE |

|

||

BRACKET |

|

|

|

SPOOL |

|

|

|

|

|

SUPER STATION |

|

|

RELEASE |

DELUXE WALL |

|

OPENER |

PUSH BUTTON |

||

ROPE |

|||

|

|||

HARDWARE |

AND KNOB |

|

|

BAG |

|

! WARNI NG |

|

|

|

|

PUSHBUTTON |

Child can be pinned under automatic garage |

|

“WARNING” |

• Test door opener monthly: |

|

|

door. Death or serious injury can result. |

|

|

• Never let child walk or run under moving door. |

RUBBER BUMPER |

|

• Never let child use door opener controls. |

|

• Always keep moving door in sight. |

|

|

|

• If person is pinned, push control button or use |

|

|

emergency release. |

|

LABEL |

|

WALL FRONT TROLLEY MOUNTING IDLER OUTER BRACKET

HALF

SAFE FINISH

PHOTOSYSTEM

PHOTOSYSTEM

HARDWARE

104363 |

NOTE: The Tee |

|

Rail/Chain Assembly is |

|

|

|

packaged separately |

from the Power Unit. The Inner Trolley half, Front Idler Sprocket, Chain, and Limit Cams are assembled on the Tee Rail at the factory.

Follow the steps outlined below to complete assembly prior to installation. Refer to the component identification illustrations on the previous page.

STEP 1: Protect the Power Unit cover from scratching during assembly by placing it on cardboard. Remove the two 5/16"-18 washered nuts and save them for later use.

STEP 2: Position the Tee Rail/Chain Assembly box near the Power Unit. Open the box and locate the Installation Hardware Packet.

STEP 3: Locate the Outer Trolley half (packaged

ASSEMBLY INSTRUCTIONS

with the Power Unit) and slide it onto the Tee Rail/ Chain Assembly with the arrow on the Trolley pointing toward the door (Front Idler).

STEP 4: Using a 1/2" wrench, loosen the outer nut on the Chain Tension Bracket until it is at the end of the threaded rod. Remove and discard the small

"S" hook used to keep the chain tight during shipping.

STEP 5: Loop the chain around the Idler and Drive Sprocket on top of the Power Unit and then position the Tee Rail on the studs. Secure with the two nuts removed in Step 1.

Slightly tension the Chain by tightening the outer nut on the Chain Tension Bracket. Remove and discard the tape at each end of the Tee Rail Assembly. After double-checking the Chain's alignment with the Drive Sprocket and Front Idler Wheel, use the inner and outer adjusting nuts on the Chain Tension Bracket to adjust the chain to the proper tension, making sure the chain does not twist. When correctly adjusted, the

Chain should show no droop and be approximately 1/2" above the base of the Tee Rail.

104365

NOTE: If the chain is too loose or too tight, improper operation and/or excessive sprocket noise may result.

ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

STEP 6: Position the open and close Limit Switch Actuators to accept the Limit Cams on the chain, as shown. Install the Chain Guard by sliding the key-shaped hole onto the groove on the Idler Sprocket Shaft and fully seating the rear hole over the Drive Sprocket Shaft. The Limit Cams are installed at the factory. Their settings should be considered temporary and may be changed as required during installation.

STEP 7: Install the Rubber Bumper into its mounting hole on the Tee Rail (see illustration above for location). Secure the Bumper to the bottom of the Tee Rail using one 5/16"-18 X 1" hex head bolt and

|

|

|

|

|

|

|

|

4 |

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CLOSE LIMIT |

DOWN LIMIT |

|||

|

|

|

|

|

|

SWITCH |

|

CAM |

||

|

|

|

|

|

|

ACTUATOR |

|

|

|

|

|

|

CHAIN |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

GUARD |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

DRIVE |

|

|

|

|

|||||

|

SPROCKET |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

IDLER |

|

|

|

|

|

104366 |

|

|

|

|

SPROCKET |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

one 5/16"-18 washered nut (supplied) Tighten the bolt a MAXIMUM of 1.5 turns after the bolt and nut are snug.

|

MASTER |

|

|

104364 |

|

|

|

|

|

|

|

STEP 8: Recheck the nuts used to secure the Tee |

|||||

|

|

|

CHAIN |

|

|

|

|

||||||||||

|

|

LINK |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rail to the Power Unit, making sure they are tight. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Recheck the Chain tension, Chain twist, Chain Guard |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and the position of both the Close Limit Switch and |

|

|

|

|

|

OUTER |

|

|

|

|

|

|

|

|

|

|

Open Limit Switch Actuators. |

|

|

|

|

|

|

|

|

INNER |

|

|

|

|

|

|

|

|||

|

|

CHAIN |

|

|

|

|

|

|

MASTER |

|

|||||||

|

|

|

|

NUT |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

NUT |

|

|

|

LINK |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Assembly is now complete and you are ready to begin installation of the opener.

DOOR TYPE IDENTIFICATION

IMPORTANT!

IDENTIFY YOUR DOOR TYPE FROM THOSE ILLUSTRATED BELOW AND

FOLLOW INSTRUCTIONS FOR THAT TYPE OF DOOR

SECTIONAL DOOR |

|

ONE PIECE DOOR |

|||

CURVED TRACK |

|

HORIZONTAL TRACK |

|||

|

|

|

|

JAMB HARDWARE |

|

|

|

|

|||

|

HIGH ARC OF |

|

|

|

|

|

|

|

|||

|

|

|

|

HIGH ARC OF |

|

|

DOOR TRAVEL |

|

|

|

|

|

|

|

|

DOOR TRAVEL |

|

|

|

|

|

|

|

|

DOOR |

|

TRACK |

TRACK |

DOOR |

|

104367 |

ONE PIECE DOOR NO TRACK

JAMB HARDWARE

HIGH ARC OF

DOOR TRAVEL

DOOR |

JAMB |

HARD- |

WARE |

ONE PIECE DOOR NO TRACK

PIVOT HARDWARE

HIGH ARC OF

DOOR TRAVEL

DOOR |

|

PIVOT |

104368 |

FOR THESE TYPES OF DOORS USE MODEL MVP OR MODEL MVP-SB.

USE 7 FT, 8 FT OR 10 FT RAIL

(MATCH DOOR HEIGHT)

THE MODEL MVP SERIES IN NOT DESIGNED TO OPERATE THESE TYPES OF DOORS

SPRINGS, PULLEYS, CABLES AND MOUNTING

HARDWARE USED TO BALANCE YOUR GARAGE DOOR ARE UNDER EXTREME TENSION AT ALL TIMES AND CAN

WARNING CAUSE SEVERE INJURY OR DEATH IF DISTURBED. DO NOT ATTEMPT ADJUSTMENT.

5 |

IMPORTANT INSTALLATION |

|

INSTRUCTIONS |

WARNING! TO REDUCE THE

WARNING! TO REDUCE THE

RISK OF SEVERE INJURY OR DEATH

READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS!

AN UNBALANCED DOOR OR ONE THAT STICKS OR BINDS MAY PREVENT THE SENSING SYSTEM FROM WORKING PROPERLY, CAUSING INJURY OR DEATH. ENSURE DOOR IS PROPERLY BALANCED AND ELIMINATE ANY STICKING OR BINDING PRIOR TO INSTALLATION OF OPENER. A properly balanced door will open slowly from a 3/4 open position, close slowly from a 3/4 closed position, and remain still at a 1/2 open position. If the door is not properly balanced, HAVE A QUALIFIED SERVICE PERSON MAKE REPAIRS TO CABLES, SPRING ASSEMBLIES AND OTHER DOOR HARDWARE BEFORE INSTALLING THE OPENER

YOUR GARAGE DOOR IS THE LARGEST MOVING OBJECT IN YOUR HOUSE, THE SPRINGS, PULLEYS, CABLES AND MOUNTING HARDWARE UTILIZED TO BALANCE ITS OPERATION ARE UNDER EXTREME TENSION AT ALL TIMES AND CAN CAUSE SERIOUS PERSONAL INJURY, EVEN DEATH, IF DISTURBED. DO NOT ATTEMPT ADJUSTMENT. CALL A QUALIFIED SERVICE PERSON TO MOVE, LOOSEN OR ADJUST DOOR SPRINGS OR HARDWARE.

REMOVE ALL ROPES AND REMOVE OR MAKE INOPERATIVE ALL LOCKS CONNECTED TO THE GARAGE DOOR BEFORE INSTALLING THE OPENER.

DO NOT WEAR RINGS, WATCHES OR LOOSE CLOTHING WHILE INSTALLING OR SERVICING GARAGE DOOR OPENERS. WEAR SAFETY GOGGLES OR OTHER PROTECTIVE EYEWEAR.

IF POSSIBLE, INSTALL THE DOOR OPENER 7zFT OR MORE ABOVE THE FLOOR. MOUNT THE EMERGENCY RELEASE 6 FT ABOVE THE FLOOR.

REINFORCE LIGHTWEIGHT FIBERGLASS, ALUMINUM AND STEEL DOOR TOP SECTIONS TO AVOID DAMAGE AND TO INSURE PROPER OPERATION OF THE SAFETY REVERSE SYSTEM. CONTACT YOUR DOOR MANUFACTURER FOR A REINFORCEMENT KIT.

DO NOT CONNECT THE OPENER TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO.

CHECK LOCAL BUILDING AND ELECTRICAL CODES FOR MANDATORY INSTALLATION AND WIRING REQUIREMENTS.

CONNECT POWER CORD ONLY TO A PROPERLY GROUNDED OUTLET. IF PERMANENT WIRING IS REQUIRED BY CODES, DISCONNECT POWER AT FUSE BOX OR CIRCUIT BREAKER BEFORE ATTEMPTING ANY WIRING CONNECTIONS.

LOCATE THE CONTROL PUSH BUTTON:

•WITHIN SIGHT OF THE DOOR, AND,

•AT A MINIMUM HEIGHT OF 5 FT SO SMALL CHILDREN CAN'T REACH IT, AND,

•AWAY FROM MOVING PARTS OF THE DOOR.

INSTALL THE ENTRAPMENT WARNING LABEL NEXT TO THE CONTROL PUSH BUTTON IN A PROMINENT LOCATION. INSTALL THE EMERGENCY RELEASE INSTRUCTION CARD, ATTACHING IT ON OR NEXT TO THE EMERGENCY RELEASE.

ADJUST THE SENSITIVITY ADJUSTMENTS ENOUGH TO ALLOW THE DOOR TO OPERATE, BUT NOT SO FIRMLY AS TO EXERT EXCESSIVE PRESSURE ON AN OBSTRUCTION BEFORE REVERSING.

AFTER INSTALLING THE OPENER, THE DOOR SHOULD REVERSE WHEN IT CONTACTS A 1-1/2" HIGH OBJECT (A PIECE OF STANDARD 2 X 4 BOARD LAID FLAT) ON THE FLOOR.

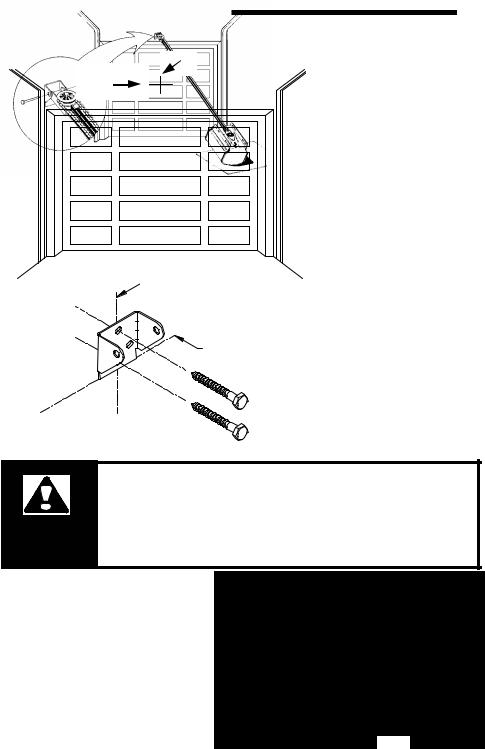

INSTALLING THE OPENER

INSTALLING THE OPENER

104369 |

VERTICAL |

|

CENTERLINE |

HORIZONTAL

LINE

VERTICAL

CENTERLINE

104371

HIGH ARC (RISE)

HORIZONTAL LINE

LAG SCREWS 5/16” X 1-7/8”

6

STEP 1: Mounting the Front Bracket — Mark a vertical centerline on the header above the door. By manually raising the door, determine the high arc of the door’s travel (see illustrations on page 4) and using a level, transfer this measurement to the header (see illustration at left). Draw a horizontal line, crossing the previously drawn centerline, at this point. Install the Front Mounting Bracket securely with the lag screws as illustrated below. If necessary, reinforce the header with steel angle iron or wood to ensure a secure mount.

|

FRONT MOUNTING BRACKET MUST BE INSTALLED TO A |

|

STRUCTURAL SUPPORT (STUD) ON THE HEADER WALL. |

|

FAILURE TO DO SO COULD CAUSE SENSING SYSTEM TO |

|

MALFUNCTION, RESULTING IN ENTRAPMENT, INJURY |

WARNING |

OR DEATH. REINFORCE HEADER IF NECESSARY USING |

|

A 2 x 6 AND LAG SCREWS (NOT PROVIDED). |

STEP 2: Raise the Tee Rail so that the Front Idler Bracket and Front Mounting Bracket align. Insert bolt and tighten nut loosely for now. Later in the installation, this nut must be tightened securely.

STEP 3: Raise the Opener and rest the |

|

Power Unit on a ladder or other sturdy support. |

|

Open the door to the full open position. Allow |

|

2" of space between the Tee Rail and the top |

|

section of the door (as shown in the illustration |

|

on the top of page 7, left). |

104372 |

Loading...

Loading...