Page 1

AT-DC2552XS/L3

ENTERPRISE CORE SWITCH

Installation Guide

613-002097 Rev. B

Page 2

Copyright 2015 Allied Telesis, Inc.

All rights reserved. No part of this publication may be reproduced without prior written permission from Allied Telesis, Inc.

Allied Telesis and the Allied Telesis logo are trademarks of Allied Telesis, Incorporated. All other product names, company names,

logos or other designations mentioned herein are trademarks or registered trademarks of their respective owners.

Allied Telesis, Inc. reserves the right to make changes in specifications and other information contained in this document without prior

written notice. The information provided herein is subject to change without notice. In no event shall Allied Telesis, Inc. be liable for

any incidental, special, indirect, or consequential damages whatsoever, including but not limited to lost profits, arising out of or related

to this manual or the information contained herein, even if Allied Telesis, Inc. has been advised of, known, or should have known, the

possibility of such damages.

Page 3

Electrical Safety and Emissions

Note

Note

Standards

This section contains the following:

“US Federal Communications Commission”

“Industry Canada”

“Emissions, Immunity and Electrical Safety Standards” on page 4

“Translated Safety Statements” on page 4

US Federal Communications Commission

Radiated Energy

This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with this instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own

expense.

Modifications or changes not expressly approved of by the manufacturer or the FCC, can void

your right to operate this equipment.

Industry Canada

Radiated Energy

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

3

Page 4

Emissions, Immunity and Electrical Safety Standards

Warning

Warning

RFI Emissions FCC Class A, EN55022 Class A, CISPR 22 Class A, VCCI Class A, C-TICK

In a domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures. E84

EMC (Immunity) EN55024, EN61000-3-2, EN61000-3-3

Electrical Safety EN60950-1 (TUV), UL 60950-1 (

Laser Safety: EN60825-1 L7

CULUS

)

Translated Safety Statements

Important: The indicates that a translation of the safety statement is available in a PDF

document titled Translated Safety Statements on the Allied Telesis website at

www.alliedtelesis.com/support.

4

Page 5

Contents

Document Conventions ................................................................................................................................................12

Contacting Allied Telesis ..............................................................................................................................................13

Chapter 1: Overview ........................................................................................................................................................ 15

AT-DC2552XS / L3 Features .......................................................................................................................................16

AT-DC2552XS/L3 Functions.................................................................................................................................16

System Capacity ...................................................................................................................................................16

AT-DC2552XS/L3 Physical Description ................................................................................................................19

LEDs.............................................................................................................................................................................24

SFP+ Slot LED ......................................................................................................................................................24

QSFP+ Slot LEDs .................................................................................................................................................25

Power/Fault LED ...................................................................................................................................................26

NET MGMT LED ...................................................................................................................................................27

FAN Status LEDs ..................................................................................................................................................28

AC Power LED ......................................................................................................................................................29

Console Port.................................................................................................................................................................30

AT-PWR06 Power Supply Module ...............................................................................................................................31

AT-FAN06 Fan Module ................................................................................................................................................33

Chapter 2: VCStack Overview ........................................................................................................................................ 35

VCStack Introduction....................................................................................................................................................36

Features of Virtual Chassis Stacking ....................................................................................................................36

VCStack Capable Switches ..................................................................................................................................36

The Physical Stack................................................................................................................................................37

Resilient Stacked Topology...................................................................................................................................38

Stack Formation ...........................................................................................................................................................42

The Role of the Stack Master................................................................................................................................42

Chapter 3: Beginning the Installation ............................................................................................................................ 45

Installation Overview ....................................................................................................................................................46

Reviewing Safety Precautions......................................................................................................................................47

Planning the Installation ...............................................................................................................................................52

Unpacking the Switch...................................................................................................................................................53

AT-DC2552XS/L3 Switch......................................................................................................................................53

AT-PWR06 Power Supply.....................................................................................................................................54

AT-FAN06 Fan Module .........................................................................................................................................55

Chapter 4: Installing the Switch and Modules .............................................................................................................. 57

Installing the Switch on a Desktop ...............................................................................................................................58

Installing the Switch in an Equipment Rack.....................................................................................

Installing and Replacing AT-PWR06 Power Supply Module ........................................................................................62

Installing Power Supply Module ............................................................................................................................62

Replacing Power Supply Module ..........................................................................................................................64

Installing Power Supply Blank Cover ....................................................................................................................65

Installing and Replacing AT-FAN06 Fan Module .........................................................................................................66

Installing Fan Module ............................................................................................................................................66

Replacing Fan Module ..........................................................................................................................................68

.............................59

Chapter 5: Installing the SFP+ and QSFP+ Transceivers and Cables ........................................................................ 69

Installing SFP+ Transceivers and Cables ....................................................................................................................70

General Guidelines ...............................................................................................................................................70

Installing SFP+ Transceiver ..................................................................................................................................71

5

Page 6

Contents

Installing an SFP+ Direct Attach Cable ................................................................................................................ 73

Installing QSFP+ Transceivers and Cables ................................................................................................................. 75

Installing a QSFP+ Transceiver............................................................................................................................ 75

Installing a QSFP+ MTHTP Cable........................................................................................................................ 77

Chapter 6: Powering the Switch ..................................................................................................................................... 79

Powering On the Switch .............................................................................................................................................. 80

Turning Off the Switch ................................................................................................................................................. 82

Chapter 7: Managing the Switch .................................................................................................................................... 83

Local Management ...................................................................................................................................................... 84

Connecting the Console Port ............................................................................................................................... 84

Remote Network Management .................................................................................................................................... 86

NET MGMT Cable Installation.............................................................................................................................. 86

Chapter 8: Troubleshooting ............................................................................................................................................ 89

Appendix A: Technical Specifications ........................................................................................................................... 93

Physical Specifications ................................................................................................................................................ 93

Environmental Specifications....................................................................................................................................... 94

Power Specifications ................................................................................................................................................... 94

Certifications................................................................................................................................................................ 94

Console Port Pinouts................................................................................................................................................... 95

RJ-45 Twisted Pair Port Pinouts.................................................................................................................................. 96

6

Page 7

Figures

Figure 1: AT-DC2552XS / L3 Front Panel ............................................................................................................................19

Figure 2: AT-DC2552XS / L3 Rear Panel View....................................................................................................................22

Figure 3: SFP+ Slot LEDs ....................................................................................................................................................24

Figure 4: QSFP+ LEDs.........................................................................................................................................................25

Figure 5: Power/Fault LED ...................................................................................................................................................26

Figure 6: NET MGMT LEDs..................................................................................................................................................27

Figure 7: FAN Status LEDs ..................................................................................................................................................28

Figure 8: AC Power LED ......................................................................................................................................................29

Figure 9: AT-PWR06 Power Supply Module ........................................................................................................................31

Figure 10: AT-FAN06 Fan Module........................................................................................................................................33

Figure 11: Stacking Ports .....................................................................................................................................................37

Figure 12: AT-DC2552XS / L3 Stacking Configuration Example..........................................................................................38

Figure 13: VCStack Resilient Stacked Topology Example ...................................................................................................39

Figure 14: Resiliency Link Connecting to Switch Ports Over the Resiliency Link VLAN......................................................40

Figure 15: Resiliency Link Connecting to Switch Ports Over the Resiliency Link VLAN Using a Network Hub ...................41

Figure 16: Stacking Ports .....................................................................................................................................................42

Figure 17: Contents of the AT-DC2552XS / L3 Shipping Box ..............................................................................................53

Figure 18: Contents of the AT-PWR06 Power Supply Module Shipping Box.......................................................................54

Figure 19: Contents of the AT-FAN06 Fan Module Shipping Box ........................................................................................55

Figure 20: Attaching the Rubber Feet ..................................................................................................................................58

Figure 21: Possible Bracket Locations .................................................................................................................................59

Figure 22: Attaching the Brackets to Switch.........................................................................................................................60

Figure 23: Mounting the Switch in an Equipment Rack ........................................................................................................61

Figure 24: Loosen Power Supply Captive Screws................................................................................................................62

Figure 25: Insert AT-PWR06 Module Into Chassis...............................................................................................................63

Figure 26: Tighten AT-PWR06 Captive Screws ...................................................................................................................64

Figure 27: Loosen Screws on Fan Blank Cover ...................................................................................................................66

Figure 28: Insert AT-FAN06 Module Into Chassis ................................................................................................................66

Figure 29: Tighten AT-FAN06 Captive Screws.....................................................................................................................67

Figure 30: Removing the Dust Plug from an SFP+ Slot .......................................................................................................71

Figure 31: Handle on SFP Transceiver ................................................................................................................................72

Figure 32: Installing an SFP+ Transceiver ......................................................................................

Figure 33: Removing SFP+ Dust Cover ...............................................................................................................................72

Figure 34: Attaching a Fiber Optic Cable to an SFP+ Transceiver.......................................................................................73

Figure 35: Removing the Dust Plug from an SFP+ Slot .......................................................................................................73

Figure 36: Installing an SFP+ Direct Attach Cable ...............................................................................................................74

Figure 37: Removing QSFP+ Slot Dust Cover .....................................................................................................................76

Figure 38: Installing a QSFP+ Transceiver...........................................................................................................................76

Figure 39: Removing QSFP+ Dust Cover ............................................................................................................................77

Figure 40: Attaching a Fiber Optic Cable to a QSFP+ Transceiver ......................................................................................77

Figure 41: Removing QSFP+ Slot Dust Cover .....................................................................................................................78

Figure 42: Installing a QSFP+ MTHTP Cable.......................................................................................................................78

Figure 43: Connecting the Management Cable to the Console Port ....................................................................................84

Figure 44: Connecting the Twisted Pair Cable into the NET MGMT port .............................................................................87

Figure 45: USB Console Connector and Port Pin Layout.....................................................................................................95

Figure 46: RJ-45 Connector and Port Pin Layout.................................................................................................................96

.....................................72

7

Page 8

Figures

8

Page 9

Table s

Table 1: Twisted Pair Cable Specifications for the NET MGMT Port ..................................................................................21

Table 2: SFP+ Slot LED ......................................................................................................................................................24

Table 3: QSFP+ LED ...........................................................................................................................................................25

Table 4: Power/Fault LED Description .................................................................................................................................26

Table 5: NET MGMT LED Descriptions ...............................................................................................................................27

Table 6: FAN Status LED Descriptions ................................................................................................................................28

Table 7: AC Power LED Description ....................................................................................................................................29

Table 8: Installation Procedures ..........................................................................................................................................46

Table 9: SFP+ Cables .........................................................................................................................................................71

Table 10: QSFP+ Cables .....................................................................................................................................................75

Table 11: Product Dimensions .............................................................................................................................................93

Table 12: Product Weights ..................................................................................................................................................93

Table 13: Environmental Specifications ...............................................................................................................................94

Table 14: AT-PWR06 Input Specifications ..........................................................................................................................94

Table 15: Product Certifications ...........................................................................................................................................94

Table 16: Console Pinouts ..................................................................................................................................................95

Table 17: Pin Signals for 10 and 100 Mbps .........................................................................................................................96

Table 18: Pin Signals - 1000 Mbps ......................................................................................................................................97

9

Page 10

Tables

10

Page 11

Preface

This guide contains instructions on how to install the AT-DC2552XS / L3

Enterprise Core Switch and the associated power supply and fan modules

on a desktop or in a 19 inch equipment rack.

This preface contains the following sections:

“Document Conventions” on page 12

“Contacting Allied Telesis” on page 13

11

Page 12

Preface

Note

Caution

Warning

Document Conventions

This document uses the following conventions:

Notes provide additional information.

Cautions inform you that performing or omitting a specific action

may result in equipment damage or loss of data.

Warnings inform you that performing or omitting a specific action

may result in bodily injury.

12

Page 13

Contacting Allied Telesis

If you need assistance with this product, you may contact Allied Telesis

technical support by going to the Support & Services section of the Allied

Telesis web site at www.alliedtelesis.com/support. You can find links for

the following services on this page:

24/7 Online Support — Enter our interactive support center to

search for answers to your product questions in our knowledge

database, to check support tickets, to learn about RMAs, and to

contact Allied Telesis technical experts.

USA and EMEA phone support — Select the phone number that

best fits your location and customer type.

Hardware warranty information — Learn about Allied Telesis

warranties and register your product online.

Replacement Services — Submit a Return Merchandise

Authorization (RMA) request via our interactive support center.

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Documentation — View the most recent installation and user

guides, software release notes, white papers, and data sheets for

your products.

Software Downloads — Download the latest software releases for

your managed products.

For sales or corporate information, go to www.alliedtelesis.com/

purchase and select your region.

13

Page 14

Preface

14

Page 15

Chapter 1

Overview

This chapter contains the following sections:

“AT-DC2552XS / L3 Features” on page 16

“LEDs” on page 24

“Console Port” on page 30

“AT-PWR06 Power Supply Module” on page 31

“AT-FAN06 Fan Module” on page 33

15

Page 16

Chapter 1: Overview

Note

AT-DC2552XS / L3 Features

The AT-DC2552XS / L3 Enterprise Core Switch has a high-density

switching fabric (1280 Gbps) in a compact 1 RU chassis. The switch’s

functions and physical description are described in the following sections:

AT-DC2552XS/

A list of the AT-DC2552XS / L3 switch’s functions is as follows:

L3 Functions

Ports

You will find the following network and management ports on the

AT-DC2552XS / L3:

48 SPF+ slots

4 QSFP+ slots

1 Console port (USB)

1 NET MGMT port (RJ-45)

Refer to Table 16 on page 95 for the Console connector pinout

functions.

System Capacity Here are the basic features of the AT-DC2552XS / L3 Enterprise Core

Switch:

System Capacity

16

2GB RAM size

128MB flash memory

9MB packet buffer

128K MAC addresses

4094 VLAN IDs (802.1Q)

1K MAC-based VLAN

512 ACL profiles with 256 ACL rules/profile

8 QoS queues per port

255 Layer 2 multicast groups

Maximum jumbo frames 12k bytes

32 Link Aggregation group (member 8)

Port Mirroring

Page 17

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Note

Note

Note

Installation Options

The AT-DC2552XS / L3 Enterprise Core Switch is designed to be installed

in one of two ways:

On a desktop.

In a 19-inch equipment rack.

Power Supply/Fan Modules

The AT-DC2552XS / L3 must have two fan modules and at least one

power supply module installed. You may elect to install a second power

supply module for redundancy. The power supply and fan modules are:

AT-PWR06 power supply module

AT-FAN06 fan module

The AT-DC2552XS / L3 must have two fan modules and at least one

power supply module installed before you power the unit on. You

may elect to install a second power supply module for redundancy.

The AT-PWR06 power supply module and AT-FAN06 fan module

are sold separately from the AT-DC2552XS / L3 Enterprise Core

Switch. Contact your local Allied Telesis representative for more

information.

Optional SFP+ Transceivers

The following SFP+ transceivers and direct attach cable assemblies have

been approved by Allied Telesis and may be installed in the

AT-DC2552XS / L3 chassis:

The SFP+ transceivers and direct attach cable assemblies are sold

separately from the AT-DC2552XS / L3 Enterprise Core Switch.

Contact your local Allied Telesis representative for more information.

AT-SP10SR (10GBASE-SR LC Ren (2))

AT-SP10LR (10GBASE-LR LC Ren (2))

AT-SP10TW1 (SFP + Direct Attach Cable (1m))

AT-SP10TW3 (SFP + Direct Attach Cable (3m))

AT-SP10TW7 (SFP + Direct Attach Cable (7m))

17

Page 18

Chapter 1: Overview

Note

Note

Optional QSFP+ Transceivers

The following QSFP+ transceivers direct attach cable assemblies have

been approved by Allied Telesis and may be installed in the

AT-DC2552XS / L3 chassis:

The QSFP+ transceivers and direct attach cable assemblies are

sold separately from the AT-DC2552XS / L3 Enterprise Core Switch.

Contact your local Allied Telesis representative for more information.

AT-QSFPSR (40GBASE-SR4 (MPO))

QSFP+ Direct Attach Cables

- AT-QSFP1CU (QSFP + Direct Attach Cable (1m))

- AT-QSFP3CU (QSFP + Direct Attach Cable (3m))

Fiber-Optic Cable for AT-QSFPSR

- ET3-MPO12-1 (1m)

- ET3-MPO12-5 (5m)

Management Software and Interfaces

Here are the management software and the management interfaces:

AlliedWare Plus Management Software

Command line interface

SNMP V1, V2 and V3

Refer to the AT-DC2552XS / L3 Management Software Command

Line Interface User’s Guide for information concerning specific

commands.

Management Methods

Here are the methods for managing the switches:

Local management through the Console port

Telnet client on a network or NET MGMT port

Secure Shell with telnet client on a network (SSH) port

SNMPv1, v2c, and v3 on a network or NET MGMT port

18

Page 19

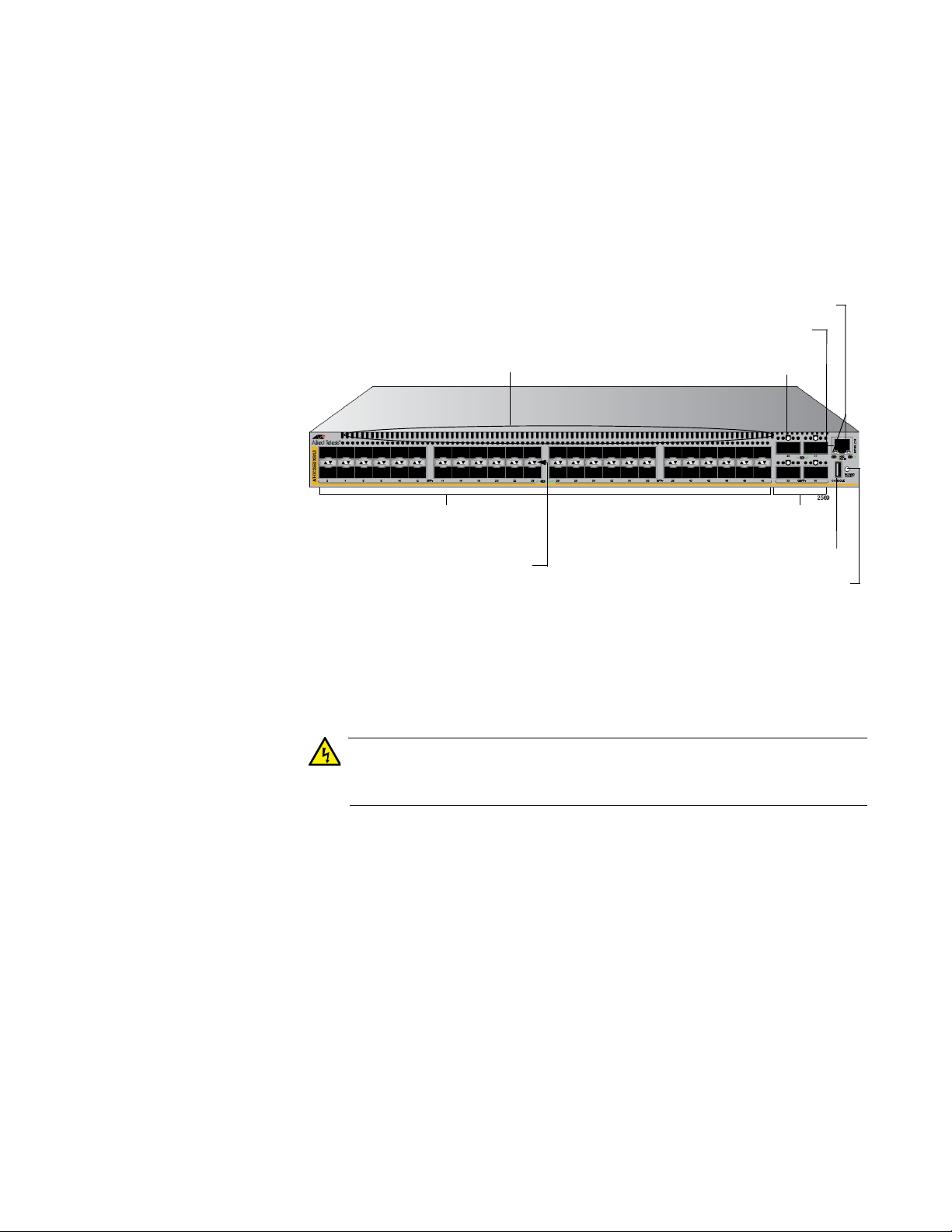

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Warning

NET MGMT Port LEDs

NET MGMT Port

4 QSFP+ Slots

QSFP+ Slot LEDs

Console Port

Power/Fault LED

48 SFP+ Slots

SFP+ Slot LEDs

Exhaust Air Vents

[Top of Chassis]

(Ports 1 - 48)

(Ports 49 - 64)

(ETH0)

AT-DC2552XS/

L3 Physical

Description

The AT-DC2552XS / L3 Enterprise Core Switch physical description is as

follows:

AT-DC2552XS / L3 Front Panel

The front panel of the AT-DC2552XS / L3 is shown in Figure 1.

Figure 1. AT-DC2552XS / L3 Front Panel

Exhaust Air Vents - Air is forced through the chassis by the fan

modules and power supply modules and exits through the exhaust

air vents on the top of the front panel.

Air vents must not be blocked and must have free access to the

room ambient air for cooling. E6

SFP+ Slots - There are 48 SPF+ slots (ports 1 - 48) on the front

panel. Each port supports communication speeds up to 10Gbps.

The switch supports a variety of 10G SFP+ transceivers and direct

attach cables.

The AT-DC2552XS / L3 Enterprise Core Switch only supports

SFP+ transceivers in this product. Refer to “Installing SFP+

Transceivers and Cables” on page 70 for installation instructions of

the SFP+ transceivers.

19

Page 20

Chapter 1: Overview

Note

Note

Note

Note

Each SFP+ slot has a dust cover installed at the factory which

should be left in place until an SFP+ transceiver is installed.

SFP+ Slot LEDs - Each SFP+ slot has a corresponding LED which

displays the link and activity status of the port. See Figure 3 on

page 24 for the location of these LEDs and Table 2 on page 24 for

their functional description.

QSFP+ Slots - There are four QSFP+ slots which support

communication speeds up to 40 GB. These slots are numbered 49,

53, 57 and 61. Each slot may be configured as one 40 GB port or 4

X 10GB ports in the management software. See Figure 4 on page

25 for the location of these LEDs and Table 3 on page 25 for their

functional description. Refer to “Installing QSFP+ Transceivers and

Cables” on page 75 for installation instructions.

Each QSFP+ slot has a dust cover installed at the factory which

should be left in place until a QSFP+ transceiver is installed.

QSFP+ transceivers must be purchased separately. For more

information about the list of supported QSFP+ transceivers, refer to

“Optional SFP+ Transceivers” on page 17.

QSFP+ Slot LEDs - Each QSFP+ slot has a corresponding QSFP+

LED which displays the link and activity status of the QSFP + slots.

Refer to “QSFP+ Slot LEDs” on page 25 for the functional

description.

Power/Fault LED - The Status LED displays the overall status of

the chassis, power supply modules and fan modules. Refer to

“Power/Fault LED” on page 26 for the functional description.

Console Port - The console port is a standard RS-232 interface

using an USB interface. This port provides the capability to

manage the configuration and firmware of the switch locally

independent from the Ethernet network. Refer to “Connecting the

Console Port” on page 84 for more information.

An RS-232 cable (female USB / D-Sub 9 pin) cable is included with

the AT-DC2552XS / L3 shipping container.

20

Page 21

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

NET MGMT Port - This 10/100/1000BASE-T RJ-45 Ethernet port

provides the capability to manage the configuration and firmware of

the switch. You can obtain or forward information via the command

line interface (CLI) or SNMP interface. The port features auto MDI/

MDI-X and auto negotiation.

The cable requirements of the NET MGMT port are given in

Table 1.

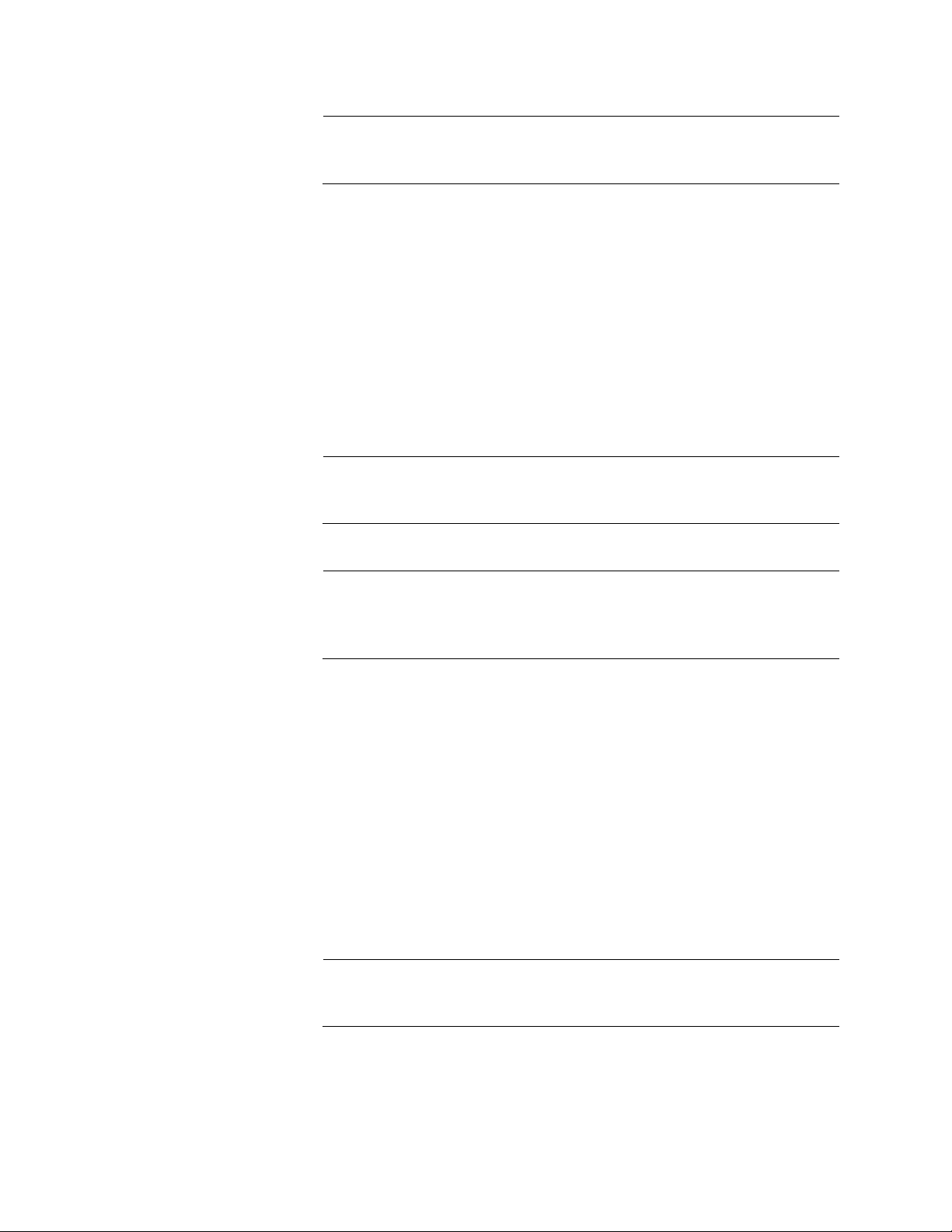

Table 1. Twisted Pair Cable Specifications for the NET MGMT Port

Cable Type 10Mbps 100Mbps 1000Mbps

Standard TIA/EIA 568-B-

Yes Yes No

compliant Category 3 shielded

or unshielded cabling with 100

ohm impedance and a

frequency of 16 MHz.

Standard TIA/EIA 568-A-

Yes Yes Yes

compliant Category 5 or TIA/

EIA 568-B-compliant Enhanced

Category 5 (Cat 5e) shielded or

unshielded cabling with 100

ohm impedance and a

frequency of 100 MHz.

Standard TIA/EIA 568-B-

Yes Yes Yes

compliant Category 6 or 6a

shielded cabling.

NET MGMT Port LEDs - These two LEDs display the speed, link

and activity status of the NET MGMT Port. Refer to “NET MGMT

LED” on page 27 for more information.

21

Page 22

Chapter 1: Overview

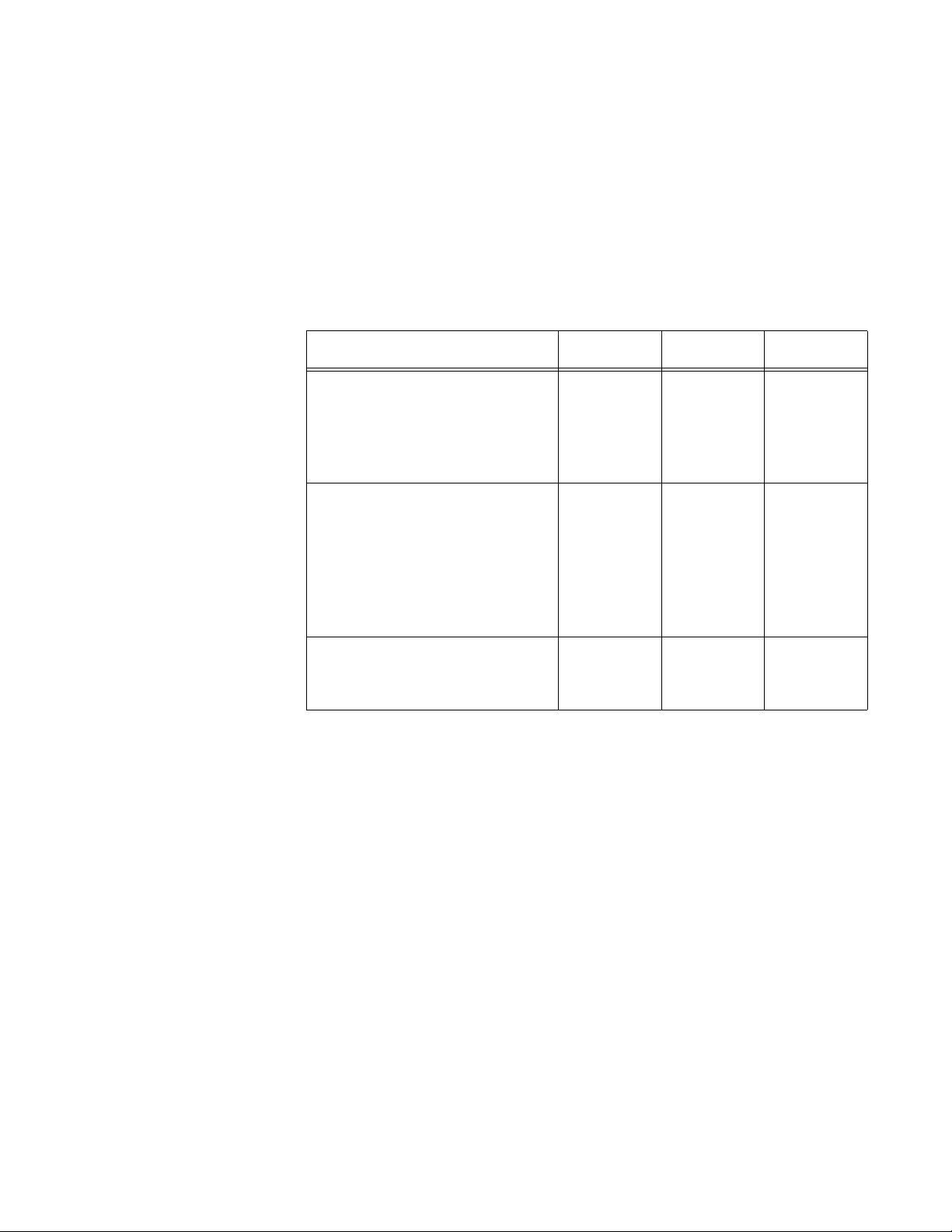

Warning

Note

PS 1 FAN 1 FAN 2 PS 2

Blank

Covers

Slot Slot Slot Slot

Fan 1

LED

Fan 2

LED

[Top of Chassis]

AT-DC2552XS / L3 Rear Panel

The rear panel of the AT-DC2552XS / L3 is shown in Figure 2.

Figure 2. AT-DC2552XS / L3 Rear Panel View

Blank Covers - When the switch is shipped from the factory, four

blank covers are installed.

- Two blank covers for the power supply slots (PS 1/PS 2)

- Two blank covers for the two fan module slots (FAN 1/FAN 2)

To insure proper cooling and air flow within the chassis, the blank

covers should not be removed unless the modules are installed in

their place. E76

The power unit slots (PS 1/PS 2) are for the installation of the AT-

PWR06 power supply module. These slots are located on the far

right and far left sides of the chassis.

A second AT-PWR06 power supply module may be installed for

redundancy, but is not required for normal operation of the switch.

With a redundant power supply configuration, you can replace one

of the two power supply modules without turning off the primary

power supply. Each AT-PWR06 power supply module that is

installed in the chassis is hot-swappable. Refer to “Installing and

Replacing AT-PWR06 Power Supply Module” on page 62 for the

installation procedure.

The AT-PWR06 power supply module is sold and packaged

separately from the AT-DC2552XS / L3 Enterprise Core Switch.

22

Page 23

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Note

The fan module slots (FAN 1/FAN 2) are for the installation of the

AT-FAN06 fan module. These slots are located on the center right

and center left of the chassis.

Two AT-FAN06 fan modules are required in the chassis for normal

operation of the switch. Refer to “Installing and Replacing ATFAN06 Fan Module” on page 66 for the installation procedure.

The AT-FAN06 fan module is sold and packaged separately from

the AT-DC2552XS / L3 Enterprise Core Switch.

Fan LEDs - The fan LEDs FAN 1 (upper LED) / FAN 2 (lower LED)

display the status of the fan modules. They are located in the

center of the chassis between the fan module slots. Refer to

Table 6 on page 28 for the functional description of these LEDs.

23

Page 24

Chapter 1: Overview

LED Upper

L/A LED

Lower SFP+

Slot

Upper SFP+

Slot

LEDs

Here are the descriptions of the switch’s LEDs.

SFP+ Slot LED Each SFP+ slot has one Link/Activity LED. The LED is triangular in shape.

The triangle LED pointing up shows the status of the upper SFP+ slot

while the triangle LED pointing down shows the status of the lower SFP+

slot. These SFP+ slot LEDs are shown in Figure 3.

Figure 3. SFP+ Slot LEDs

The SFP+ slot LEDs are described in Table 2.

Table 2. SFP+ Slot LED

LED State Description

Solid green The SFP+ transceiver has established a

link to a network device.

Link/Activity

Flashing

green

Off

The SFP+ transceiver is receiving or

transmitting packets to a network device.

The SFP+ slot is empty or the SFP+

transceiver has not established a link to a

network device.

24

Page 25

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

QSFP+ LEDs

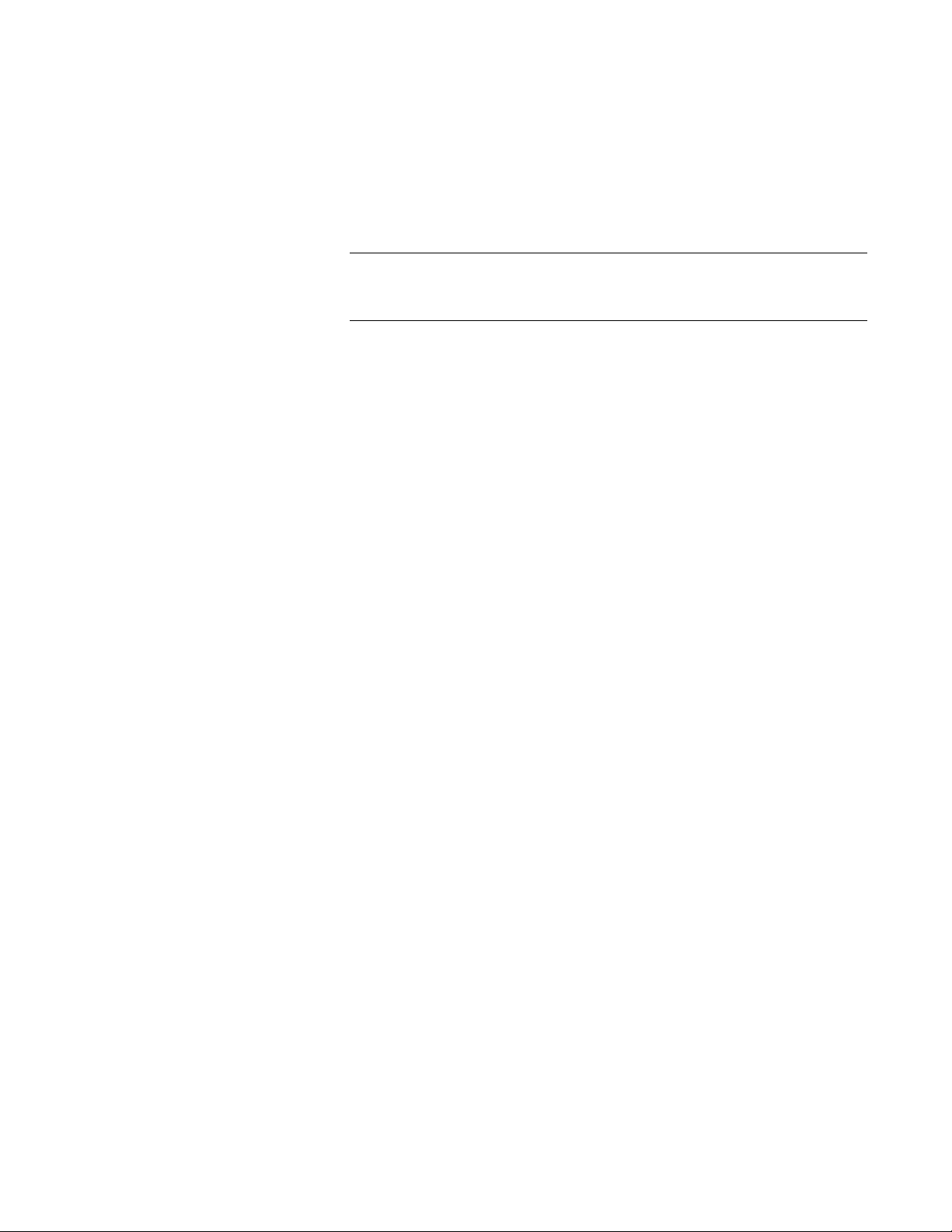

QSFP+ Slot LEDs Each QSFP+ port has one link/activity LED labeled LINK/ACT. These

LEDs are shown in Figure 4.

Figure 4. QSFP+ LEDs

The QSFP+ LED is described in Table 3.

Table 3. QSFP+ LED

LED State Description

Solid green The QSFP+ transceiver has established a

link to a network device.

Link/Activity

Flashing

green

The QSFP+ transceiver is receiving or

transmitting packets to a network device.

The QSFP+ slot is empty or the QSFP+

Off

transceiver has not established a link to a

network device.

25

Page 26

Chapter 1: Overview

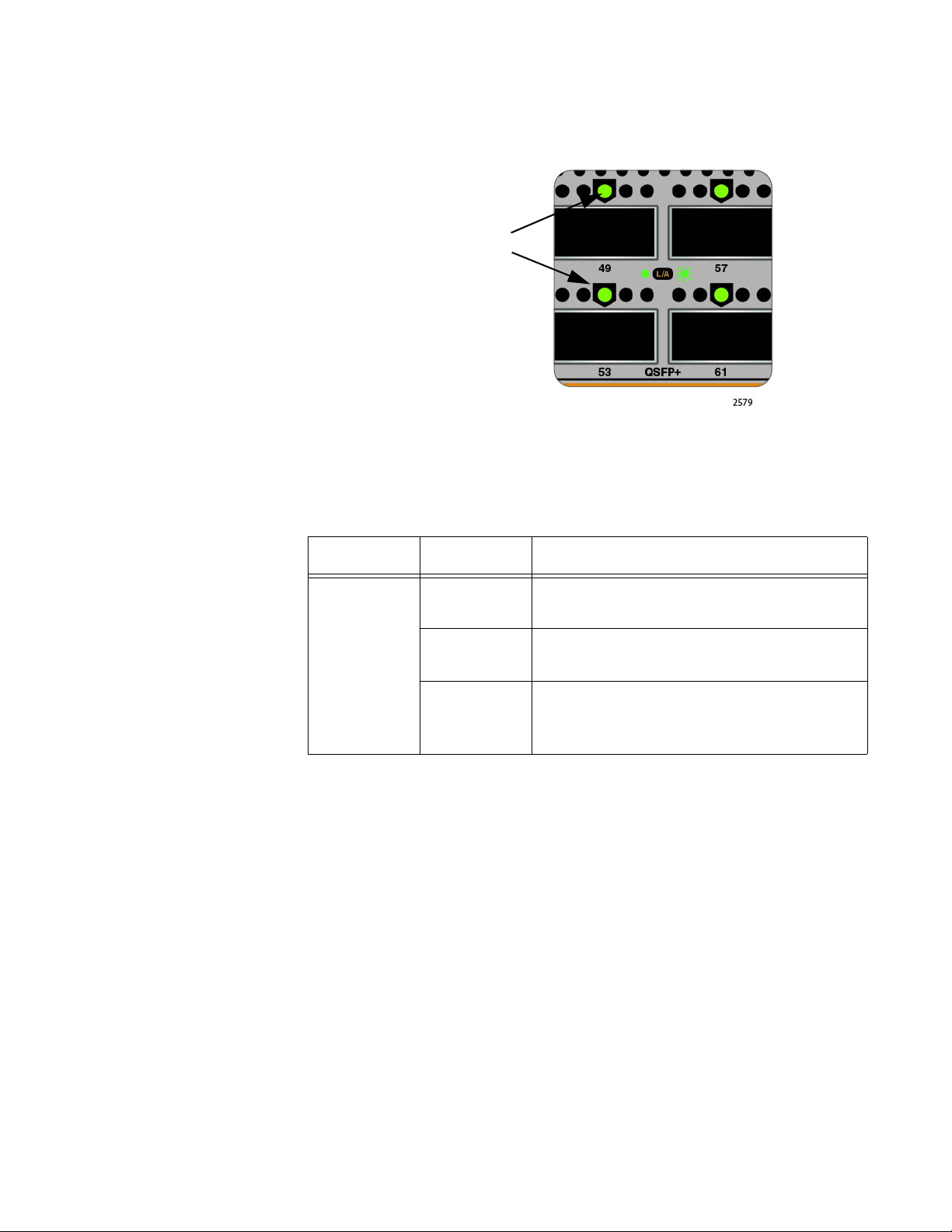

Power/Fault LED The Power/Fault LED is shown in Figure 5.

Figure 5. Power/Fault LED

The Power/Fault LED is described in Table 4.

Table 4. Power/Fault LED Description

Location LED State Description

Front

Panel

POWER

/FAULT

Solid green Power is being supplied and the chassis is

operating normally.

Flashing

System is booting up.

green

Solid yellow Failure of one or more power supply fans.

Flashing

Only one PSU is powered up.

yellow

Off No power.

26

Page 27

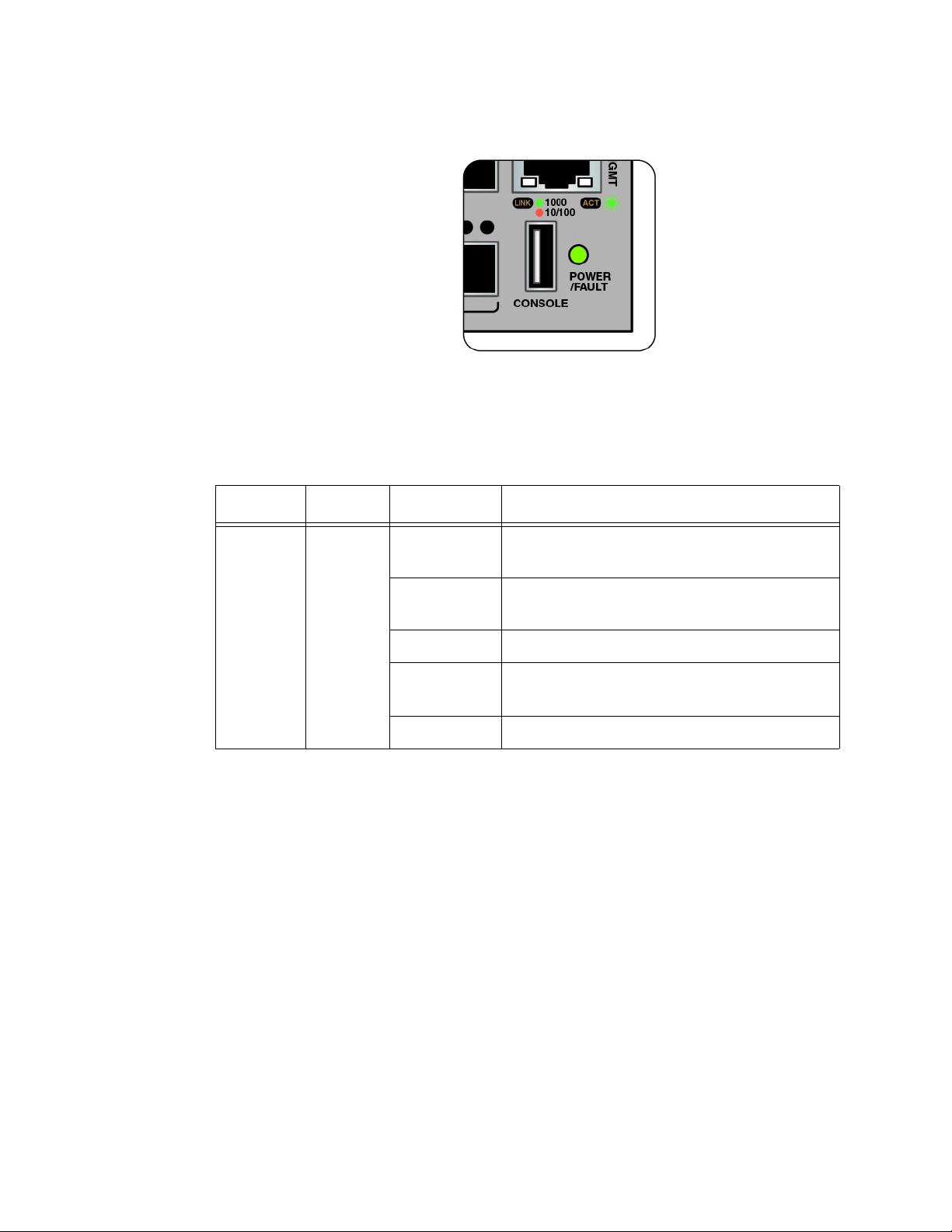

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

LINK

LED

ACT

LED

NET MGMT

The NET MGMT LEDs are shown in Figure 6.

LED

Figure 6. NET MGMT LEDs

The NET MGMT LEDs are described in Table 5.

Table 5. NET MGMT LED Descriptions

Location LED State Description

The NET MGMT port has established a link to

Front

Panel

ACT

(Right LED)

Solid green

Flashing

green

Off The NET MGMT port established a link to a

a network device, but no packets are being

transmitted or received.

The NET MGMT port is receiving or

transmitting packets to a network device.

network device.

LINK

(Left LED)

Solid green A valid 1G link is established on the port.

Solid yellow A valid 10/100M link is established on the port.

Off No link is established on the port.

27

Page 28

Chapter 1: Overview

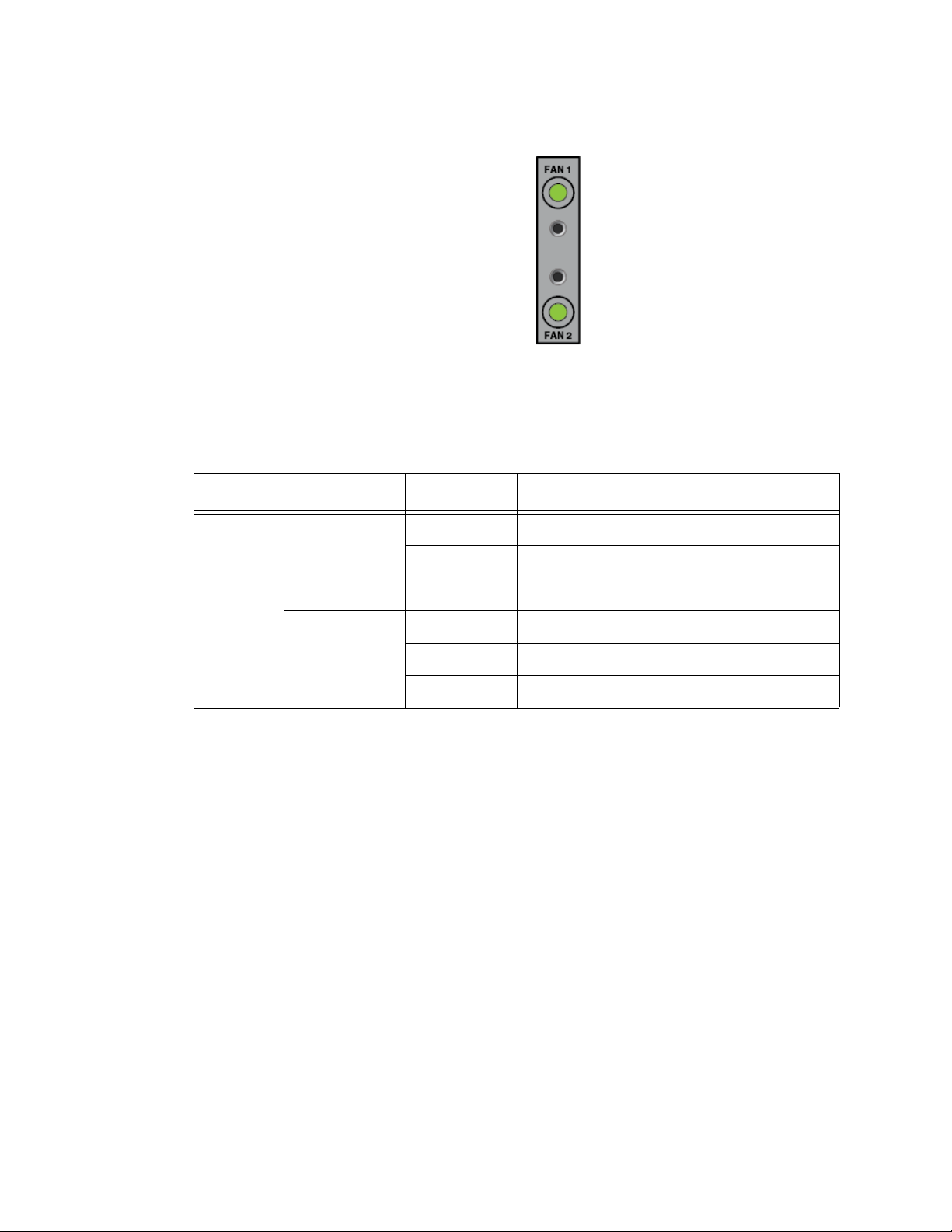

FAN Status LEDs The fan status LEDs are shown in Figure 7.

Figure 7. FAN Status LEDs

The fan status LEDs are described in Table 6.

Table 6. FAN Status LED Descriptions

Location LED State Description

Rear

Panel

FAN1

(top LED)

FAN2

(bottom LED)

Solid Green Fan operating normally.

Solid Red Fan is in failure mode.

Off No power is supplied to the fan module.

Solid Green Fan operating normally.

Solid Red Fan is in failure mode.

Off No power is supplied to the fan module.

28

Page 29

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

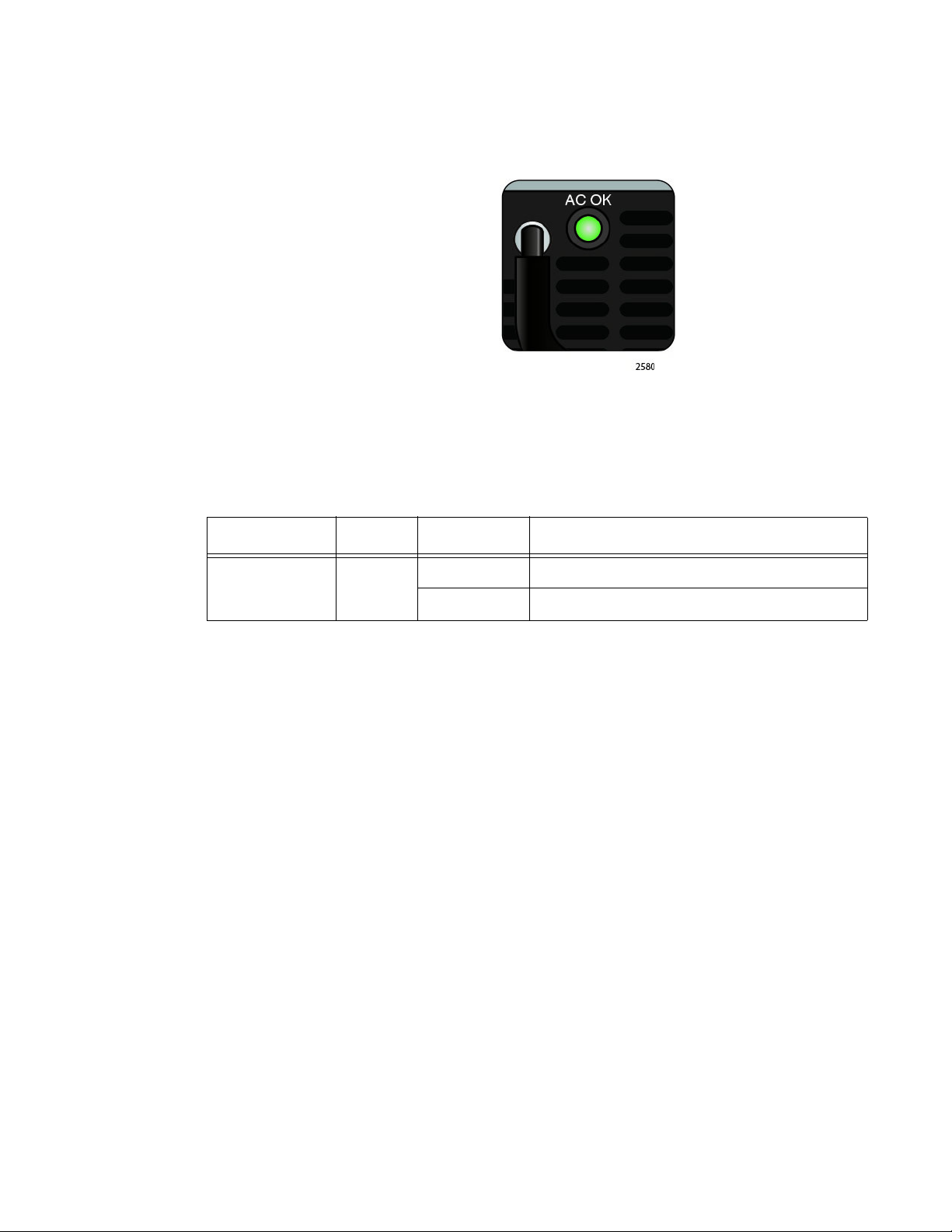

AC Power LED Each AT-PWR06 power supply module has an AC power (AC OK) LED.

This LED is shown in Figure 8.

Figure 8. AC Power LED

The AC Power LED is described in Table 7.

Table 7. AC Power LED Description

Location LED State Description

Power Supply

Module Panel AC OK

Solid Green AC power is supplied to power supply.

Off No AC power is supplied to power supply.

29

Page 30

Chapter 1: Overview

Note

Note

Console Port

The Console port is a USB connector located on the front panel. See

Figure 1 on page 19 for its location. It is used to locally configure the

features and parameter settings of the switch. This type of management

uses the RS-232 serial communications protocol. It is commonly referred

to as local or out-of-band management because it is not connected over

an Ethernet network. To perform local management, you must be at the

location of the switch and must use the management cable included with

the switch.

Refer to “Console Port Pinouts” on page 95 for USB pin orientation

and the signal functions assigned to each pin.

To establish a local management session with the switch, connect a

terminal or a personal computer with a terminal emulation program to the

Console port using the management cable provided with the switch. This

cable has a USB connector on one end and a DB-9 (D-sub 9-pin)

connector on the other.

The Console port is configured at the factory to the following

specifications:

Default baud rate: 9600 bps (Range is 9600 to 115200 bps)

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

These settings are for a DEC VT100 or ANSI terminal, or an

equivalent terminal emulation program.

30

Page 31

AT-PWR06 Power Supply Module

Warning

Warning

Captive Intake

Handle

Power

Connector

AC Power

LED

Screws

Air Vents

The AT-DC2552XS / L3 Enterprise Core Switch is powered by one ATPWR06 power supply module. A second AT-PWR06 power supply module

may be installed for redundancy. The power supply module has an AC

connector on the power supply module panel and is installed by the user in

slot PS1 or slot PS2. The location of these slots is shown in Figure 2 on

page 22.

When two power supplies are installed and operating, only one power

supply is active at a time. The second power supply operates in a

redundant state and is automatically activated by the switch if the active

power supply loses power or fails. The change-over is instantaneous and

has no effect on the Ethernet data being passed through the chassis.

Power cord is used as a disconnection device. To de-energize

equipment, disconnect the power cord. E3

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

This unit might have more than one power cord. To reduce the risk of

electric shock, disconnect all power cords before servicing the unit.

E30

Refer to “Power Specifications” on page 94 for the input power

specifications.

A view of the AT-PWR06 power supply module is shown in Figure 9.

Figure 9. AT-PWR06 Power Supply Module

31

Page 32

Chapter 1: Overview

Warning

The components of the AT-PWR06 power supply module (see Figure 9 on

page 31) are as follows:

Power connector - The AC power cable plugs into this connector.

Regional AC power cables are provided in the AT-PWR06 power

supply module shipping box. Refer to “Powering On the Switch” on

page 80 and “Turning Off the Switch” on page 82.

AC Power LED - This LED displays the status of the power supply

module. Refer to “AC Power LED” on page 29 for a functional

description of this LED.

Intake Air Vents - The AT-PWR06 power supply module has two

fans which pull air into the power supply module through the intake

air vents to cool the power supply and the chassis components.

The air is discharged through the exhaust air vents on the top of

the chassis front panel. See Figure 1 on page 19 for the location of

the exhaust vents.

Air vents must not be blocked and must have free access to the

room ambient air for cooling. E6

Captive screws - These two screws secure the power supply

module to the chassis frame. Refer to “Installing and Replacing

AT-PWR06 Power Supply Module” on page 62 for the power

supply installation procedure.

Handle - The handle is used to physically push or pull the AT-

PWR06 power supply module when it is inserted or removed.

Refer to “Installing and Replacing AT-PWR06 Power Supply

Module” on page 62 for the power supply installation procedure.

32

Page 33

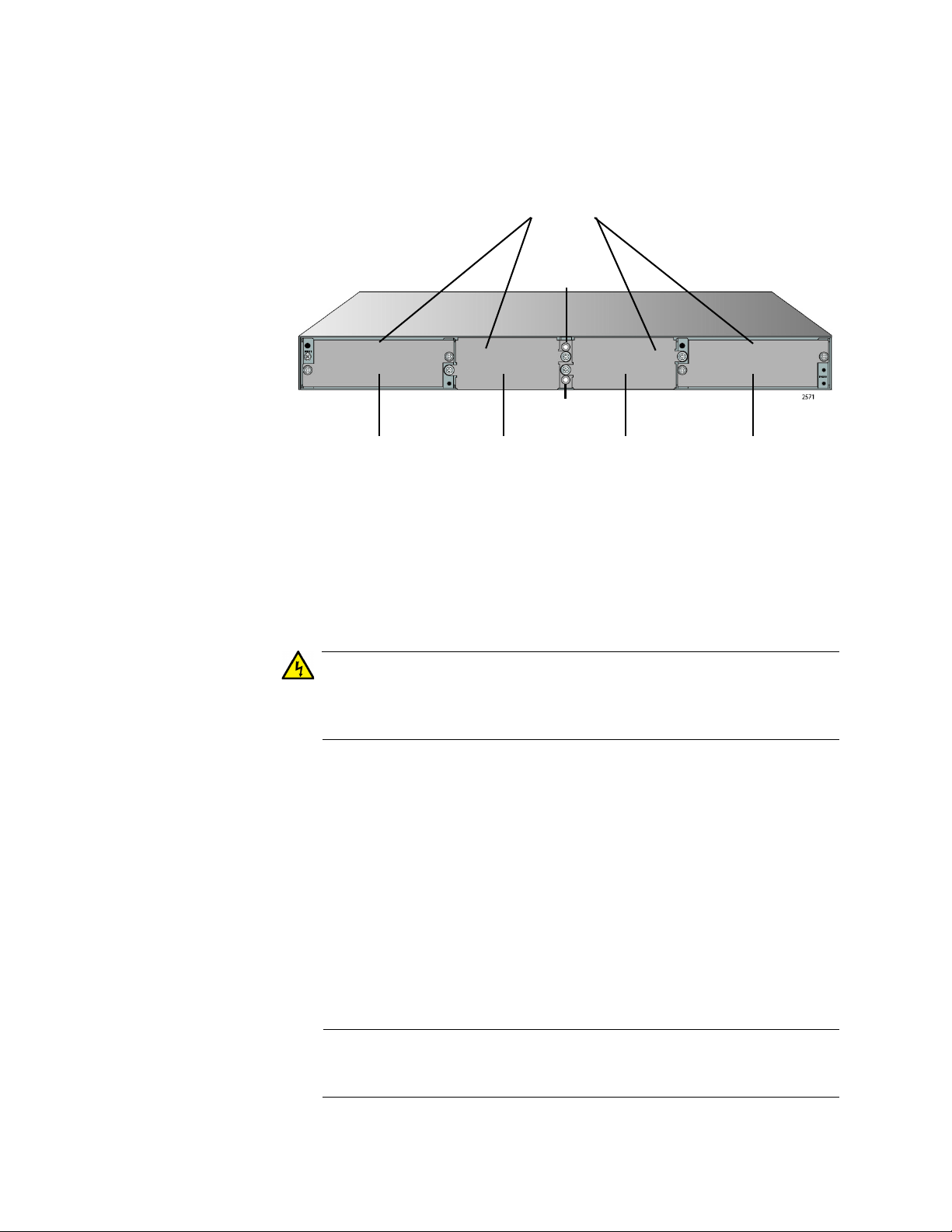

AT-FAN06 Fan Module

Warning

Captive Screws

Intake Air VentsHandles

Installation of two AT-FAN06 fan modules are required in the

AT-DC2552XS / L3. Refer to “Installing and Replacing AT-FAN06 Fan

Module” on page 66 for the fan installation procedure.

Each AT-FAN06 fan module is equipped with two forced-air cooling fans

The fans push air through the chassis from the rear to the front. The ATFAN06 fan module is ordered and shipped separately from the

AT-DC2552XS / L3 Enterprise Core Switch.

A view of the AT-FAN06 fan module is shown in Figure 10.

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Figure 10. AT-FAN06 Fan Module

The components of the AT-FAN06 fan module are as follows:

Captive screws - The two captive screws secure the fan module to

the chassis frame.

Handles - The two handles are used to physically push or pull the

AT-FAN06 fan module into and out of the chassis.

Intake Air Vents - The AT-FAN06 fan module has two fans which

pull air through the intake air vents to cool the chassis components.

The air is discharged through the front panel exhaust air vents. See

Figure 1 on page 19 for the location of the exhaust vents.

Air vents must not be blocked and must have free access to the

room ambient air for cooling. E6

33

Page 34

Chapter 1: Overview

34

Page 35

Chapter 2

VCStack Overview

The chapter contains the following sections:

“VCStack Introduction” on page 36

“Stack Formation” on page 42

35

Page 36

Chapter 2: VCStack Overview

Caution

VCStack Introduction

This chapter describes Virtual Chassis Stacking (VCStack), its features,

and basic connection examples.

VCStack is a group of physically separate switches that are configured to

operate as a single logical switch. In order to function as a VCStack, its

component switches are connected using high-speed stacking links.

Features of

Virtual Chassis

Stacking

Creating a VCStack greatly eases network management, because you

can configure all the stacked devices via a single IP address. Creating a

VCStack will often eliminate your need to configure protocols such as

VRRP and Spanning Tree. VCStack also enables you to create highly

resilient networks. This resiliency can be applied in several ways.

Within the stack itself, switch interconnection is via two links. The second

link is able to provide an alternative data path, thus the stack will continue

to function if a single switch fails. Degraded performance might occur

however, due to the reduced VCStack bandwidth.

User ports can also be made extremely resilient by utilizing link

aggregation. Aggregated links can span ports, modules, and even

switches within the stack. Creating aggregated links that span multiple

switches within a stack creates an extremely resilient configuration.

Communication will still exist even if a switch and its aggregated ports fail.

See Figure 13 on page 39.

Stack operation is only supported if STACK VIRTUAL-MAC is

enabled.

E72

For more information, refer to the STACK VIRTUAL-MAC command

in the AT-DC2552XS / L3 Management Software Command Line

Interface User’s Guide.

VCStack Capable

36

Switches

VCStack is supported on the following Allied Telesis switch types:

SwitchBlade® x8100 Series (VCStack Plus)

x900-24XT, x900-24XS, x900-24XT-N

x900-12XT/s

SwitchBlade® x908

AT-DC2552XS / L3

x610 Series

x510 Series

IX5-28GPX

Page 37

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Note

x310 Series

You can only create VCStacks using switches from within the same

product group, for example, all AT-DC2552XS / L3 switches, or all

x610 Series switches.

Stacking connectivity and functionality varies slightly between switch

types. Your AT-DC2552XS / L3 switch can support a maximum of two

devices per stack. Consult the appropriate software reference for stacking

functionality of other Allied Telesis switches.

The Physical

Stack

A VCStack can consist of a maximum of two individual AT-DC2552XS / L3

switches, interconnected via high-speed stacking links (QSFP+ ports 49,

53, 57, or 61). A stack always has a primary stack member called the

stack master (displayed in the show commands as the active master). The

remaining switch then becomes an ordinary member of the stack, and is

referred to as the backup member.

VCStack Cables and Connections

Stack members are interconnected via the QSFP+ ports 49, 53, 57, or 61.

These ports are shown in Figure 11.

Figure 11. Stacking Ports

The stacking cables must connect ports that have the same port number.

A stack will form regardless of which port numbers are used for linking, as

long as the same numbers are linked together. This means that you can

connect your stack using any two of the following pairs of ports:

port 49 connected to port 49

port 53 connected to port 53

port 57 connected to port 57

port 61 connected to port 61

37

Page 38

Chapter 2: VCStack Overview

Figure 12 shows an example configuration. In this example, the QSFP+

stacking ports labeled 49 and 61 on one member are connected to the

QSFP+ stacking ports labeled 49 and 61 on the other stack member,

respectively.

Figure 12. AT-DC2552XS / L3 Stacking Configuration Example

Resilient Stacked

Topology

Where network connectivity uptime is a major criteria, you can use virtual

chassis stacking to create highly reliable network configurations. The

network shown in Figure 13 on page 39 employs redundant links and

switches to create a stacked network that offers extremely reliable user

connectivity.

Employing link aggregation, rather than spanning tree, to manage the

parallel paths enables the bandwidth of both data links to be utilized under

normal conditions while enabling a single data link to operate should its

partner link fail.

38

Page 39

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Note

Figure 13. VCStack Resilient Stacked Topology Example

The network depicted in Figure 13 employs two SwitchBlade® x908

switches to form an expandable network core. These switches are stacked

and so appear as a single logical switch

Smaller switches, such as the AT-DC2552XS / L3, can be also be

used to form the stacked core or stacked distribution.

This network topology supplies multiple dual connections to a number of

downstream distribution switches that can in turn connect to user devices.

Similarly, the dual network paths provide very reliable connectivity to the

servers portion of the network.

39

Page 40

Chapter 2: VCStack Overview

DC2552XS/L3

DC2552XS/L3

DC2552XS/L3

DC2552XS/L3

Resiliency Link

The resiliency link carries no network data. Its function is to provide

additional stack status information to enable the stack members to more

accurately decide whether it is appropriate for one of them to take over the

role of stack master if the existing master fails.

A resiliency link can be created using a single physical connection

between two eth0 (NET MGMT) ports, or it can use a VLAN (resiliency link

VLAN) to which the switch ports can be attached.

To create a resiliency link using eth0 (NET MGMT) ports, connect a

standard twisted pair LAN cable (either straight through, or crossover—

MDI-MDIX negotiation is supported on these ports) between the two eth0

(NET MGMT) ports on both devices. Once you have connected the cable,

you can run the STACK RESILIENCYLINK command to create the

resiliency link.

Resiliency Link Configurations via Switch Ports

Two resiliency-link configurations that use switch ports are shown below.

Figure 14 shows the resiliency link connecting in a ring topology, while

Figure 15 on page 41 shows the resiliency link connecting to the switch

ports via a network hub. In both configurations, the resiliency link

connections are made using a designated VLAN running over switch-port

connections between each stack member. For more information on using

the resiliency link commands, refer to the STACK RESILIENCYLINK and

SWITCHPORT RESILIENCYLINK commands in the AT-DC2552XS / L3

Management Software Command Line Interface User’s Guide.

40

Figure 14. Resiliency Link Connecting to Switch Ports Over the Resiliency

Link VLAN

Page 41

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

DC2552XS/L3

Switches

DC2552XS/L3

Switches

Figure 15. Resiliency Link Connecting to Switch Ports Over the Resiliency

Link VLAN Using a Network Hub

41

Page 42

Chapter 2: VCStack Overview

Stack Formation

As previously mentioned, a VCStack always contains a stack (active)

master and a stack member (backup). To be part of a stack, a switch must

connect to the other potential stack member via dedicated stacking ports.

See Figure 16.

Figure 16. Stacking Ports

The Role of the

Stack Master

Once the switches have been physically connected, powering the

members on sets off a number of automatic processes that enable the

stack members to detect the presence of one another and form

themselves into a VCStack.

Long-Distance Stacking

You can extend the distance between stacked units up to the maximum

distance supported by the particular QSFP+ port you are using. This

capability enables you to create a stack of 2 geographically separated

switches as a single stack.

In addition to being a member of its VCStack, the stack master manages

functions such as software version control and distribution, routing

processing, and network management.

Selecting the Stack Master

The stack members are able to automatically select which switch will

become the stack master. This selection is based on two components:

1. The stack member’s priority setting.

42

2. The stack member’s MAC address.

For both components, the lower the number, the higher the priority will be.

To set the stack priority, run the STACK PRIORITY command. Note that

changes to these settings will not take effect until the next master reelection. To display these components run the SHOW STACK command.

Page 43

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Note

Note

Note

The master is the switch with the lowest priority setting, or if the priority

settings are equal, the switch with the lowest MAC address will become

the stack master. When a stack member is initially booted, its priority value

defaults to 128. Therefore, if both switches retain their defaults, then the

stack master will be determined by MAC address comparison.

The stack also assigns a stack ID number to each member. This number

provides a unique reference number for switches within the stack; it plays

no part in selecting the stack master. The stack ID is used as the first digit

of the three component port identifier numbers. For example, port number

2.0.14 has the stack ID of 2.

The stack ID number assignment is important to remember when

using configuration scripts. You should ensure that you modify your

configuration scripts to match any changes you have made to the

stack ID assignments.

The ability to independently set both a stack member’s priority and

its ID means that the stack master does not need to have an ID of 1;

although configuration is simplified by arranging for ID 1 to be the

device with the lowest priority value - and thereby forcing it to be the

stack master. If you create a stack using new switches, the following

(simplified) process should ensure that the master member has an

ID of 1.

New switches are shipped with a Stack Member ID of 1 and a

priority of 128. If two such switches are created as a stack, the

switch with the lowest MAC address will be selected to be the stack

master (because all priority settings are 128). The remaining stack

member device will then reboot. The stack master does not reboot

and retains its Stack Member ID of 1.

You can change the stack ID by using the command stack renumber.

Common Stack Configuration

Once the switches have configured themselves into a VCStack, they all

share the same configuration information and startup scripts.

43

Page 44

Chapter 2: VCStack Overview

44

Page 45

Chapter 3

Beginning the Installation

The chapter contains the following sections:

“Installation Overview” on page 46

“Reviewing Safety Precautions” on page 47

“Planning the Installation” on page 52

“Unpacking the Switch” on page 53

45

Page 46

Chapter 3: Beginning the Installation

Installation Overview

Table 8 lists the installation procedures for the AT-DC2552XS / L3

Enterprise Core Switch. The procedures should be performed in the order

presented in the table.

1 “Reviewing Safety Precautions” on page 47

2 “Planning the Installation” on page 52

3 “Unpacking the Switch” on page 53

4 “Installing the Switch on a Desktop” on page 58 OR

5 “Installing Power Supply Module” on page 62

Table 8. Installation Procedures

Step Procedure

“Installing the Switch in an Equipment Rack” on page 59

6 “Installing Fan Module” on page 66

7 “Installing SFP+ Transceivers and Cables” on page 70

8 “Installing QSFP+ Transceivers and Cables” on page 75

9 “Powering On the Switch” on page 80

10 “Managing the Switch” on page 83

46

Page 47

Reviewing Safety Precautions

Note

Warning

Warning

Warning

Warning

Warning

Please review the following safety precautions before you begin to install

the switch.

The indicates that a translation of the safety statement is

available in a PDF document titled Translated Safety Statements on

the Allied Telesis website at www.alliedtelesis.com/support.

Class 1 Laser product. L1

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Do not stare into the laser beam. L2

Do not look directly at the fiber optic cable ends or inspect the cable

ends with an optical lens. L6

Laser Safety: EN60825-1 L7

To prevent electric shock, do not remove the cover. No userserviceable parts inside. This unit contains hazardous voltages and

should only be opened by a trained and qualified technician. To

avoid the possibility of electric shock, disconnect electric power to

the product before connecting or disconnecting the LAN cables.

E1

47

Page 48

Chapter 3: Beginning the Installation

Warning

Warning

Warning

Note

Caution

Warning

Note

Do not work on equipment or cables during periods of lightning

activity. E2

Power cord is used as a disconnection device. To de-energize

equipment, disconnect the power cord. E3

Class I Equipment. This equipment must be earthed. The power

plug must be connected to a properly wired earth ground socket

outlet. An improperly wired socket outlet could place hazardous

voltages on accessible metal parts. E4

Pluggable Equipment. The socket outlet shall be installed near the

equipment and shall be easily accessible. E5

Air vents must not be blocked and must have free access to the

room ambient air for cooling. E6

Operating Temperature. This product is designed for a maximum

ambient temperature of 40° degrees C. E7

All Countries: Install product in accordance with local and National

Electrical Codes. E8

48

Page 49

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Warning

Note

Caution

Warning

Note

Caution

Only trained and qualified personnel are allowed to install or replace

this equipment. E14

Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect that

overloading of circuits might have on overcurrent protection and

supply wiring. Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern. E21

Risk of explosion if battery is replaced by an incorrect type. Replace

only with the same or equivalent type recommended by the

manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

Attention: Le remplacement de la batterie par une batterie de type

incorrect peut provoquer un danger d’explosion. La remplacer

uniquement par une batterie du même type ou de type équivalent

recommandée par le constructeur. Les batteries doivent être

éliminées conformément aux instructions du constructeur. E22

Mounting of the equipment in the rack should be such that a

hazardous condition is not created due to uneven mechanical

loading. E25

Use dedicated power circuits or power conditioners to supply reliable

electrical power to the device. E27

The chassis may be heavy and awkward to lift. Allied Telesis

recommends that you get assistance when mounting the chassis in

an equipment rack. E28

49

Page 50

Chapter 3: Beginning the Installation

Warning

Note

Caution

Warning

Caution

Warning

This unit might have more than one power cord. To reduce the risk

of electric shock, disconnect all power cords before servicing the

unit. E30

If installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater than

the room ambient temperature. Therefore, consideration should be

given to installing the equipment in an environment compatible with

the manufacturer’s maximum rated ambient temperature (Tmra).

E35

Installation of the equipment in a rack should be such that the

amount of air flow required for safe operation of the equipment is not

compromised. E36

Reliable earthing of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections other than

direct connections to the branch circuits (e.g., use of power strips).

E37

The unit does not contain serviceable components. Please return

damaged units for servicing. E42

When you remove an SFP module from this product, the case

temperature of the SFP may exceed 40° C (158° F). Exercise

caution when handling with unprotected hands. E43

50

Page 51

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Caution

Caution

Warning

Warning

Warning

Warning

To insure proper cooling and airflow within the chassis, a blank

cover should be installed if a module is not present in the chassis

E70

Stack operation is only supported if STACK VIRTUAL-MAC is

enabled. E72

To operate this product, two fan modules must be installed.

Operation with one fan module will cause the chassis to overheat.

E73

To insure proper cooling and air flow within the chassis, the blank

covers should not be removed unless the modules are installed in

their place. E76

In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

E84

A transceiver can be damaged by static electricity. Be sure to

observe all standard electrostatic discharge (ESD) precautions,

such as wearing an antistatic wrist strap, to avoid damaging the

device. E92

51

Page 52

Chapter 3: Beginning the Installation

Planning the Installation

The AT-DC2552XS / L3 Enterprise Core Switch can be installed on a

desktop or in a 19 inch equipment rack. Observe these general

requirements when planning the installation of the switch.

Check that the power outlets for the switches are located near the

Verify that the site provides easy access to the ports on the front of

Check that the site allows for adequate air flow around the units

Do not place objects on top of the switch.

Do not expose the switch to moisture or water.

devices and are easily accessible.

the switch. This will make it easy for you to connect and disconnect

cables, as well as view the port LEDs.

and through the cooling vents on the front and rear panels. (The

airflow direction is from fan modules on the rear panel through the

unit to the port side on the front panel.)

Make sure the site is a dust-free environment.

Use dedicated power circuits or power conditioners to supply

reliable electrical power to the network devices.

Do not install the switch in a wiring or utility box because it will

overheat and fail from inadequate airflow.

If the unit is to be installed in an equipment rack, check that the

rack is safely secured and will not tip over. Devices in a rack

should be installed starting at the bottom, with the heavier devices

near the bottom of the rack.

52

Page 53

Unpacking the Switch

Note

Note

One AT-DC2552XS / L3 switch

Two rack mounting brackets with

eight bracket screws

Desktop mounting feet

One 2 m (6.6 ft) local management cable with

USB and DB-9 (D-sub 9-pin) connectors.

Refer to the following figures in this section to verify the contents of the

shipping containers:

”AT-DC2552XS/L3 Switch”

“AT-PWR06 Power Supply” on page 54

“AT-FAN06 Fan Module” on page 55

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

If any item in a shipping container is missing or damaged, contact

your Allied Telesis sales representative for assistance.

AT-DC2552XS/

L3 Switch

The contents of the AT-DC2552XS / L3 shipping box are listed in Figure

17.

Figure 17. Contents of the AT-DC2552XS / L3 Shipping Box

You should retain the original packaging material in the event you

need to return the unit to Allied Telesis.

53

Page 54

Chapter 3: Beginning the Installation

Note

Note

Note

One AT-PWR06 Power Supply Module

One regional AC power cord

AT-PWR06

Power Supply

The contents of the AT-PWR06 power supply module shipping box are

listed in Figure 18.

Figure 18. Contents of the AT-PWR06 Power Supply Module Shipping

Box

The AT-DC2552XS / L3 switch can operate with one power supply

module installed. You may elect to install a second power supply

module for redundancy.

The AT-PWR06 power supply module is sold and packaged

separately from the AT-DC2552XS / L3 Enterprise Core Switch.

Contact your local Allied Telesis representative for more information.

You should retain the original packaging material in the event you

need to return the unit to Allied Telesis.

54

Page 55

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Note

Note

Note

One AT-FAN06 FAN Module

AT-FAN06 Fan

Module

The contents of the AT-FAN06 fan module shipping box is shown in Figure

19.

Figure 19. Contents of the AT-FAN06 Fan Module Shipping Box

The AT-DC2552XS / L3 switch must have two fan modules installed

for proper operation.

The AT-FAN06 fan module is sold and packaged separately from

the AT-DC2552XS / L3 Enterprise Core Switch. Contact your local

Allied Telesis representative for more information.

You should retain the original packaging material in the event you

need to return the unit to Allied Telesis.

55

Page 56

Chapter 3: Beginning the Installation

56

Page 57

Chapter 4

Installing the Switch and Modules

You may install the AT-DC2552XS / L3 Switch on a desktop or in a

standard 19 inch equipment rack. In addition, you must install at least one

AT-PWR06 power supply module and two AT-FAN06 fan modules in the

switch chassis.

Here are the installation procedures in this chapter:

“Installing the Switch on a Desktop” on page 58

“Installing the Switch in an Equipment Rack” on page 59

“Installing and Replacing AT-PWR06 Power Supply Module” on

page 62

“Installing and Replacing AT-FAN06 Fan Module” on page 66

57

Page 58

Chapter 4: Installing the Switch and Modules

Note

[Bottom of Switch]

Installing the Switch on a Desktop

To install the switch on a desktop, perform the following procedure:

To install the switch in a rack, refer to “Installing the Switch in an

Equipment Rack” on page 59.

1. Remove all equipment from the package and store the packaging

material in a safe place.

2. Turn the switch over and place it on a table.

3. Remove the adhesive backing from the rubber feet.

4. Four rubber feet are provided in the switch shipping container, see

Figure 17 on page 53. Attach the feet to the bottom of the switch in the

corners as shown in Figure 20.

58

Figure 20. Attaching the Rubber Feet

5. Turn the switch over again and place it on a flat, secure surface (such

as a desk or table) leaving ample space around the unit for ventilation.

6. The next step in the installation process is installing the power supply

module(s). Go to “Installing Power Supply Module” on page 62 for the

installation procedure.

Page 59

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

Note

Installing the Switch in an Equipment Rack

To install the switch on a desktop, refer to “Installing the Switch on a

Desktop” on page 58.

When installing the AT-DC2552XS / L3 switch in a 19 inch rack, it must

always be mounted horizontally with the top side up; see Figure 1 on page

19 and Figure 2 on page 22. The switch can be oriented and positioned in

the rack in four different ways. This is determined by where you install the

two rack mount brackets that are provided. The four possible positions for

the brackets are:

Flush with the rear of chassis so the rear of the chassis is even

with the vertical rack rails.

Offset by 17.5 cm from the rear of the chassis so that the rear of

the chassis protrudes beyond the vertical rack rails by 17.5 cm.

Flush with the front of chassis so the front of the chassis is even

with the vertical rack rails.

Offset by 17.5 cm from the front of the chassis so that the front of

the chassis protrudes beyond the vertical rack rails by 17.5 cm.

These four possible bracket locations are illustrated in Figure 21.

Figure 21. Possible Bracket Locations

59

Page 60

Chapter 4: Installing the Switch and Modules

Note

Caution

This procedure requires the following items:

Perform this procedure to install the switch in a 19-inch equipment rack:

1. Secure the two rack mount brackets to the sides of the switch using

Eight bracket screws (included with the switch)

Two equipment rack brackets (included with the switch)

Cross-head screwdriver (not provided)

Four standard equipment rack screws (not provided)

If you have installed the rubber feet, remove the rubber feet by

prying them off the bottom of the chassis with a flat-bladed tool.

the eight bracket screws provided. Figure 22 shows an example of

mounting the rack mount bracket on the rear of the chassis and with

the bracket flush to the rear panel. See Figure 21 on page 59 for other

possible bracket mounting positions on the chassis.

60

Figure 22. Attaching the Brackets to Switch

The chassis may be heavy and awkward to lift. Allied Telesis

recommends that you get assistance when mounting the chassis in

an equipment rack. E28

Page 61

AT-DC2552XS / L3 Enterprise Core Switch Installation Guide

2. Have another person hold the switch in the equipment rack while you

secure it using standard rack mount screws (not provided).

Figure 23. Mounting the Switch in an Equipment Rack

61

Page 62

Chapter 4: Installing the Switch and Modules

Installing and Replacing AT-PWR06 Power Supply Module

The AT-PWR06 power supply module may be installed in one of the two

power supply slots - PSU1 or PSU2. See Figure 2 on page 22 for the

location of these slots.

The AT-DC2552XS / L3 Enterprise Core Switch can operate under full

load with one power supply module installed. However, if you want power

supply redundancy, a second power supply may be installed.

There is no functional difference between the two available power supply

slots. Operation of the AT-DC2552XS / L3 is the same when installed in

either slot. If you want to use only one power supply, Allied Telesis

recommends that you install it in the PSU1 slot.

The following procedures are included in this section:

“Installing Power Supply Module”

“Replacing Power Supply Module” on page 64

Installing Power

Supply Module

“Installing Power Supply Blank Cover” on page 65

Install the AT-PWR06 power supply module by performing the following