Allied Autovent 2000, Autovent 3000 User manual

OPERATING

AutoVent

ea-

CCR

Time

ventilator

CR

cycied,

for

Version

AE

ZA

人

constant

Emergency

flow,

MANUAL

1.5

本 本 4

gos

powcred

Medical

Service.

:

>

É

AutoVent55S2/3S52

A

TABLE

OF

CONTENTS

Section

INTRODUCTION

GENERAL

USE OF

Design

DESCRIPTION

THE

Explanation

PERFORMANCE

PATIENT

Visual

Pressure

Source

Exhalation

CONTROL

Source

Patient

Breaths

Tidal

Inspiratory

Patient

Non-Rebreathing

OPERATING

of

Warnings/Cautions/Notes

CHARACTERISTICS

VALVE

Indicator

Limit

Alarm

Gas

Inlets

MANUAL

ASSEMBLY

Module

Valve

MODULE

Gas

Inlet

Valve

Outlets

Per

Minute

Volume

Time

Valve

(BPM)

(V+)

(Ti)

Supply

Tubing

Valve

and

and

Corrugated

AND

FEATURES

Oxygen

Line

Hose

Page

Number

1

1

2

3

3

5

UNPACKING

AUTOVENT

OPERATING

Instructions

2000/3000

with

Oxygen

Regulator

Control

Instructions

with a Wall

Instructions

with

an

Ventilator

PATIENT

MAINTENANCE

USE

Cleaning

Cleaning

Cleaning

Cleaning

STORAGE

TROUBLESHOOTING

LSP

AUTOVENT

OF

AND

INSPECTION

INSTRUCTIONS

for

Use

of

Cylinders

Attachment

Module

for

Use

of

Outlet

for

use

of

Air/Oxygen

Check

out

OF

THE

and

Disinfecting

and

Disinfecting

and

Disinfecting

the

Non-Rebreathing

THE

LSP

2000/3000

OF

the

AutoVent

2000/3000

Attachment

the

AutoVent

2000/3000

Employing a Quick

the

AutoVent

2000/3000

Blender

LSP

AUTOVENT

Equipment

the

Control

the

Patient

Valve

AUTOVENT

GUIDE

FOR

2000/3000

THE

THE

Valve

Connection

2000/3000

Module

Assembly

8

8

Adapter

12

14

16

16

WARRANTY

APPENDIX

INFORMATION

A:

Support

B:

Patient

C:

Control

D:

Oxygen

E:

AutoVent

F:

AutoVent

Equipment

Valve

Specifications

Module

Pressure

Specifications

Re

2000/3000

2000/3000

ulator

Specifications

Altitude

Oxygen

Conversion

Cylinder

18

20

Chart

Depletion Chart

AutoVe:

INTRODUCTION

THE

AUTOVENT

2000/3000

Long

an

innovator

emergency

medicine,

Products

primary

oxygen

field

States

1979.

manufacturer

range

rescue

and

Life

Support

has

been

manufacturer

delivery

use

in

the

and

worldwide

LSP

is

also

of a wide

of

trauma,

devices.

trauma

a

of

devices

United

a

burn

in

for

since

and

Specifications

LSP

AutoVent

including

Assembly,

and

Regulators

for

use

included

of

this

manual.

The

Life

AutoVent

represent a major

breakthrough

2000/3000,

the

Patient

Control

with

this

in

the

Appendix

Support

2000/3000

in

intended

device,

Products

pneumatic

for

the

Valve

Module,

are

technology.

intended

assistance

following

near

drowning,

paramedical

other

circumstances

requiring

assistance.

They

for

the

of

cardiac

transport,

ventilatory

are

ventilatory

patients

arrest,

trauma,

and

GENERAL DESCRIPTION

The

LSP

Automatic

Ventilator

2000/3000)

constantflow,

ventilators

ventilation

to

20

(BPM)

2000

breaths

AutoVent

The

Assembly

to

draw

flow

spontaneous

Designed

emergency

the

from

volume.

3000

1200

(AutoVent

time-cycled,

gas-powered

offer

at

rates

breaths

in

version,

attached

the

per

3000

per

AutoVent

and 8 to

minute

Patient

allows a patient

supplemental

(up

to

48

LPM)

effort.

for

transport

medical

AutoVent

400

delivers

ml

2000

ml

to

The

AutoVent

in

volume.

from

controlled

from

8

minute

27

in

the

version.

Valve

gas

with

and

use,

delivers

1200

ml

200

to

peak

60+5

flow

liters

They

units

Both

pressures

em

rates

per

are

ideally

AutoVents

H20

from

minute

small,

emergency

situations

extremes

125°F.

power

standard

gas.

assemble

and

easily

Ventilators

exceed

Heart

guidelines

resuscitation.

An

sounds

at

from

Operating

is

obtained

50

They

are

and

their

functions

understood.

meet

the

Association

for

Audible

whenever

deliver

up

to

at

flow

16

to

(LPM).

compact

suited

and

temperature

for

transport

O°F

to

from

psi

source

simple

operate,

are

The

or

American

(AHA)

alarm

48

to

ventilatory

approach

pressure

the

operator.

will

continue

until

drops

cycles

phase.

WARNING:

as

directed.

usage

modification

product

user

the

limit,

the

airway

or

the

to

the

or

unauthorized

may

or

patient

pressures

preset

alerting

This

alarm

to

sound

pressure

system

expiratory

Use

only

Improper

of

this

result

injury.

in

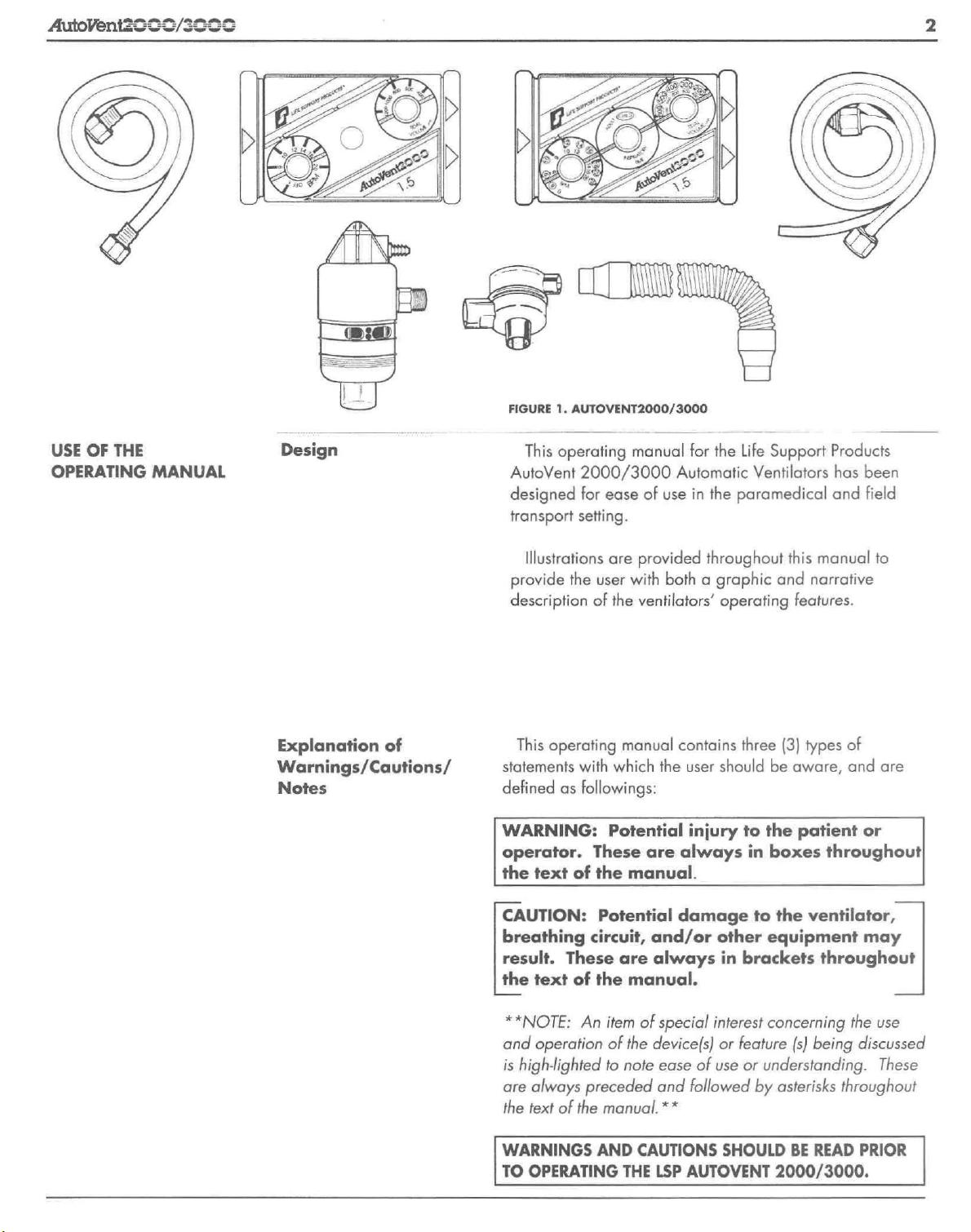

AutoVent2SSS/200€

FIGURE

1.

AUTOVENT2000/3000

USE

OF

THE

OPERATING

MANUAL

This

operating

AutoVent

designed

transport

2000/3000

for

setting.

manual

ease

Automatic

of

use

for

in

the

the

Life

Support

Ventilators

paramedical

Products

has

and

been

field

Illustrations

provide

description

This

Explanation

Warnings/Cautions/

Notes

of

operating

statements

defined

WARNING:

operator.

the

CAUTION:

breathing

result.

the

**NOTE:

and

is

are

the

WARNINGS

TO

as

text

text

operation

high-lighted

always

text

of

OPERATING

are

provided

the

user with

of

the

ventilators’

manual

with

which

followings:

Potential

These

of

the

manual.

Potential

circuit,

These

are

of

the

An

item

of

the

to

note

preceded

the

manual.

AND

THE

manual.

of

CAUTIONS

throughout

both a graphic

operating

contains

the

user

should

injury

are

always

damage

and/or

always

special

device(s)

ease

and

**

LSP

other

in

interest

or

of

use

followed

SHOULD

AUTOVENT

this

manual

and

narrative

features.

three

(3)

types

be

aware,

to

the

patient

in

boxes

to

the

equipment

brackets

concerning

feature

or

understanding.

by

asterisks

2000/3000.

throughout!

ventilator,

throughout

(s)

being

BE

READ

to

of

and

are

or

may

the

use

discussed

These

throughout

PRIOR

AutoVentZSS5/SSSS

PERFORMANCE

CHARACTERISTICS

AND

FEATURES

The

AutoVent

flow,

gas

powered

ventilators’

to

20

version,

Should

obtained

patient

automatic

breaths

per

and 8 to

the

patient

on

demand

valve.

2000/3000

ventilators.

rate

to

minute

27

(BPM),

BPM

in

require

additional

by

making

are

time

This

be

set

in

the

AutoVent

an

cycled,

feature

by

the

the

AutoVent

breaths,

inspiratory

constant

allows

operator

3000

these

effort

the

from

8

2000

version.

can

be

on

the

PATIENT

ASSEMBLY

VALVE

The

patient

both

controlled

spontaneous

patient.

demand

indicator,

alarm,

valve.

15mm.

diameter/22mm.

diameter

valve

breaths

It

consists

valve, a visual

pressure

and

exhalation

It

has a standard

inside

adapter,

delivers

and

of

limit

outside

which

WI

to

a

the

is

<

compatible

other

airway

The

patient

spontaneous

upon

demand

makes

an

inspiratory

of

-2

cm.

HO.

control

the

for

____—

may

"O"

position

this

purpose.)

VISUAL

INDICATOR

with

masks

devices.

valve

allows

breathing

if

the

patient

(The

be

turned

if

desired

NI

X

and

effort

BPM

to

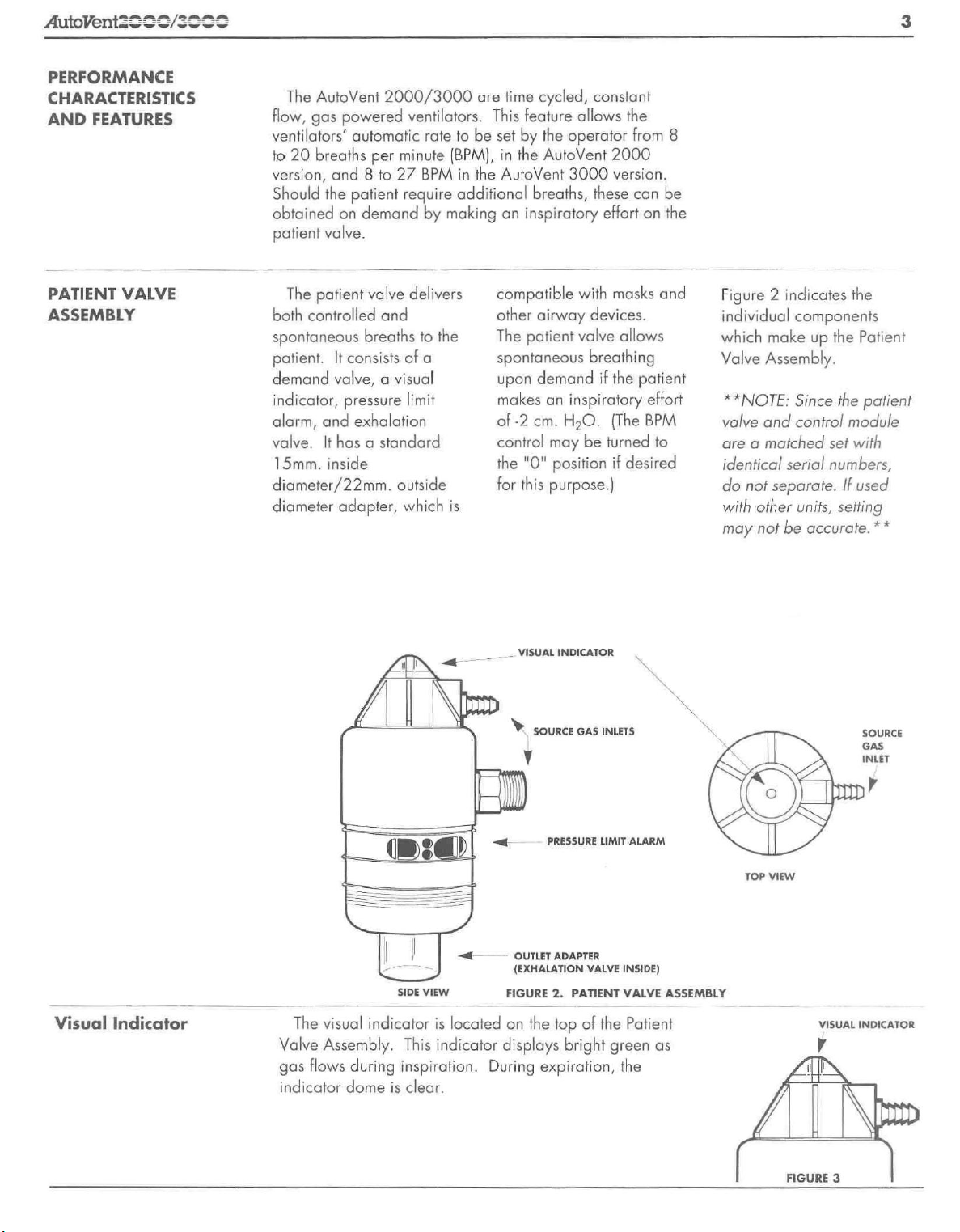

Figure 2 indicates

individual

which

Valve

**NOTE:

valve

are a matched

identical

do

with

may

components

make

Assembly.

Since

and

control

serial

not

separate.

other

units,

not

be

the

up

the

the

module

set

with

numbers,

If

used

setting

accurate.

Patient

patient

**

SOURCE

GAS

INLET

Visual

Indicator

The

visual

Valve

Assembly.

gas

flows

during

indicator

dome

SIDE

VIEW

indicator

is

This

indicator

inspiration.

is

clear.

FIGURE

located

on

displays

During

PRESSURE

OUTLET

ADAPTER

(EXHALATION

2.

PATIENT

the

top

bright

expiration,

VALVE

of

LIMIT

ALARM

INSIDE)

VALVE

the

Patient

green

the

ASSEMBLY

as

hy

TOP

VIEW

VISUAL

INDICATOR

y

il

/

[

FIGURE

п

3

AutoVent5222/5522

Pressure

Module

Limit

Alarm

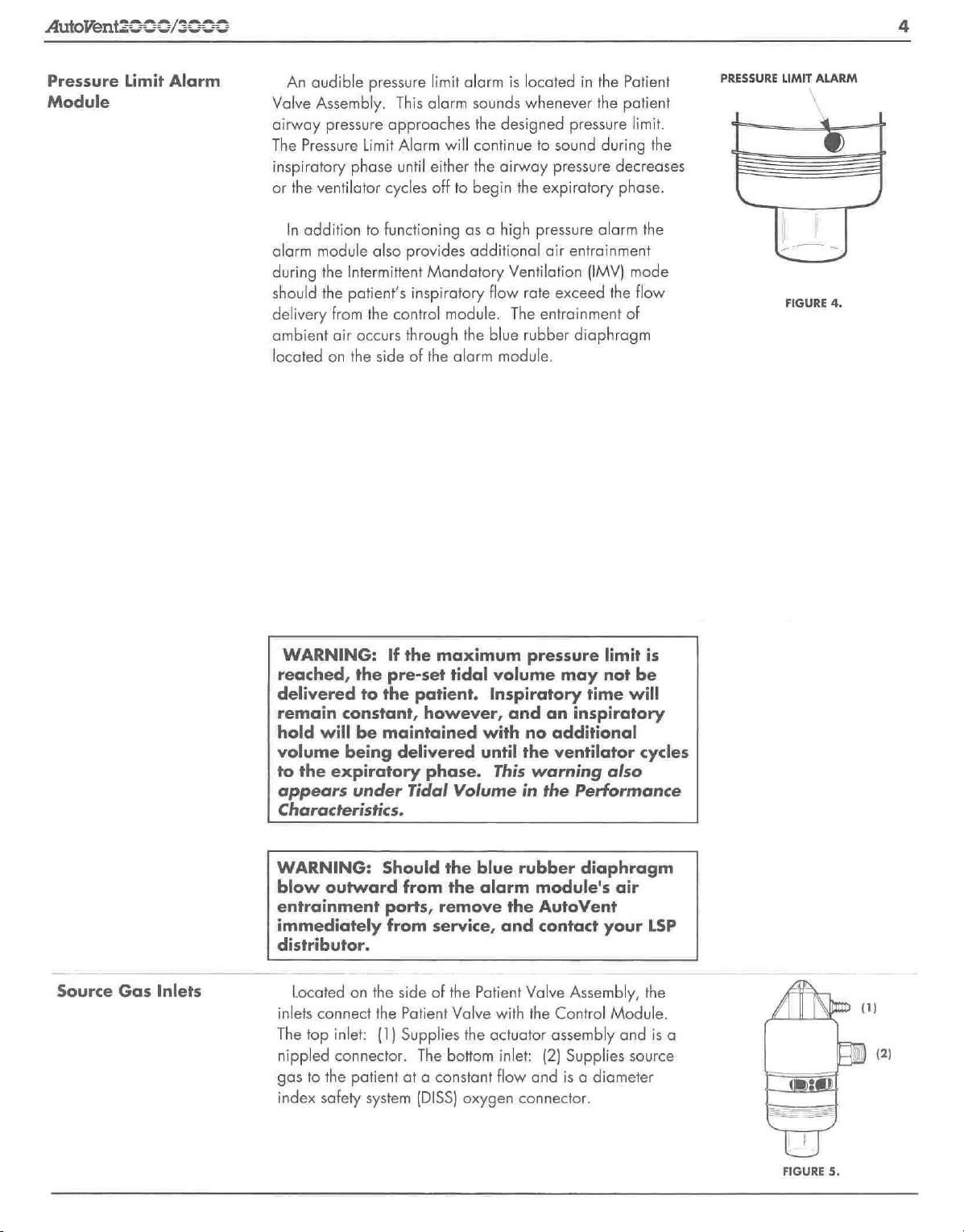

An

audible

Valve

Assembly.

airway

The

inspiratory

or

alarm

during

should

delivery

ambient

located

pressure

Pressure

the

ventilator

In

addition

module

the

the

from

air

on

phase

Intermittent

patient's

occurs

the

pressure

This

limit

alarm

approaches

Limit

Alarm

until

either

cycles

off

to

functioning

also

provides

Mandatory

inspiratory

the

control

through

side

of

the

alarm

sounds

the

designed

will

continue

the

airway

to

begin

as a high

additional

flow

module.

the

blue

alarm

module.

is

located

whenever

in

the

the

pressure

to

sound

during

pressure

the

expiratory

pressure

air

Ventilation

rate

The

entrainment

rubber

alarm

entrainment

(IMV)

exceed

diaphragm

Patient

patient

limit.

the

decreases

phase.

the

mode

the

flow

of

PRESSURE

LIMIT

FIGURE

ALARM

4.

Source

Gas

Inlets

WARNING:

reached,

delivered

remain

hold

will

volume

to

the

expiratory

appears

Characteristics.

WARNING:

blow

outward

entrainment

immediately

distributor.

Located

inlets

connect

The

top

inlet:

nippled

gas

index

connector.

to

the

safety

If

the

pre-set

to

the

constant,

be

maintained

being

under

Should

ports,

from

on

the

the

(1)

patient

system

the

maximum

tidal

patient.

however,

with

delivered

phase.

Tidal

from

service,

side

of

Patient

Supplies

The

at a constant

(DISS)

until

Volume

the

blue

the

alarm

remove

the

Patient

Valve

the

bottom

oxygen

pressure

volume

Inspiratory

and

This

the

and

with

actuator

inlet:

flow

may

an

inspiratory

no

additional

the

ventilator

warning

in

the

Performance

rubber

Valve

the

and

connector.

diaphragm

module's

AutoVent

contact

Assembly,

Control

assembly

(2)

Supplies

is a diameter

limit

not

time

also

air

your

Module.

is

be

will

cycles

LSP

the

and

is

source

a

FIGURE

5.

AutoVent20

Exhalation

Valve

99/3000

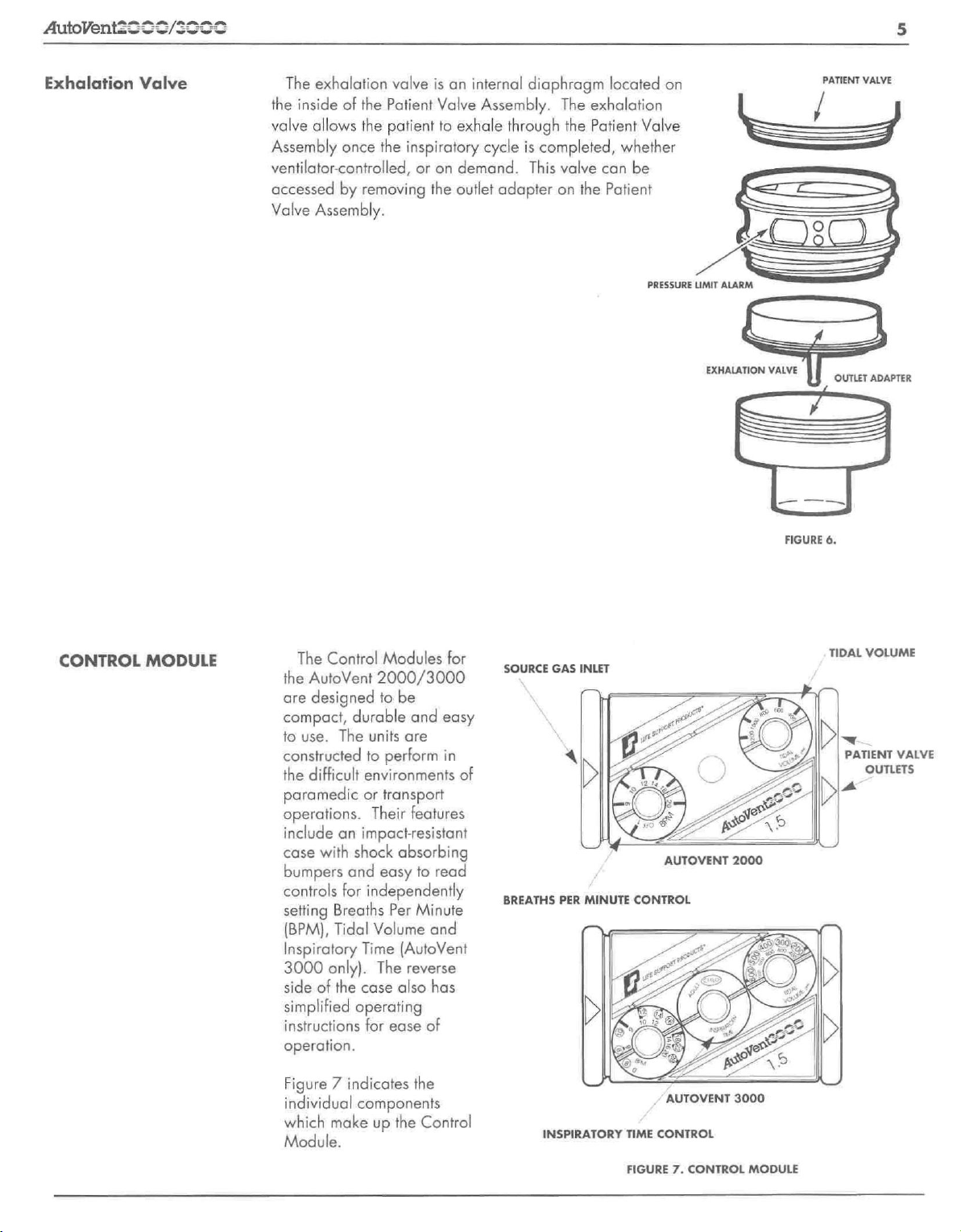

The

exhalation

the

inside

of

valve

allows

Assembly

ventilator-controlled,

accessed

Valve

once

by

Assembly.

valve

the

Patient

the

patient

the

inspiratory

or

removing

is

Valve

to

on

the

an

internal

diaphragm

Assembly.

exhale through

cycle

is

completed,

demand.

outlet

This

adapter

The

exhalation

the

Patient

valve

can

on

the

Patient

located

on

Valve

whether

be

PATIENT

/

VALVE

CONTROL

MODULE

The

Control

the

AutoVent

are

designed

compact,

to

use.

constructed

the

difficult

paramedic

operations.

include

case

with

bumpers

controls

setting

(BPM),

Inspiratory

3000

side

simplified

instructions

operation.

Breaths

Tidal

only).

of

Modules

2000/3000

to

durable

The

units

to

perform

environments

or

transport

Their

an

impactresistant

shock

and

easy

for

independently

Volume

Time

The reverse

the

case

operating

for

for

be

and

easy

are

in

of

features

absorbing

to

read

Per

Minute

and

(AutoVent

also

has

ease

of

SOURCE

BREATHS

GAS

PER

INLET

MINUTE

PRESSURE

AUTOVENT

CONTROL

A

LIMIT

ALARM

EXHALATION

2000

VALVE

—

——

FIGURE

OUTLET

6.

TIDAL

>

PATIENT

M

ADAPTER

VOLUME

VALVE

OUTLETS

Figure 7 indicates

individual

which

components

make

Module.

up

the

the

Control

INSPIRATORY

TIME

FIGURE

AUTOVENT

CONTROL

7.

CONTROL

3000

MODULE

AutoVent2522/552S

Source

Patient

Gas

Valve

Inlet

Outlets

located

marked

diameter

When a high

gas

delivered

the

An

this

a

specified

**NOTE:

prior

desired

located

and

the

top

Assembly

system

Supplies

inch

on

with

index

from a cylinder

to

the

Patient

Valve

Air/Oxygen

system,

between

oxygen

Use

to

patient

oxygen

on

marked

Control

outlet

Module

(1)

at a constant

(DISS)

the

threaded

the

left

side

an

arrow,

safety

pressure

Control

the

system

line

or

bulk

Module

Assembly.

Blender

the

source

concentration.

of

an

Oxygen

use

in

order

concentration

the

right

side

with

arrows,

with

the

Supplies

oxygen

Patient

female

source

flow

connector.

Valve

connecior.

of

the

Control

source

(DISS)

is

attached

oxygen

and

can

also

and

Analyzer

to

accurately

to

be

of

the

Control

the

patient

Patient

gas

and

is a diameter

Actuator

Module

gas

inlet

is a standard

male

oxygen

to a 50

source,

be

the

this

cycled

for

inserted

ventilator,

is

recommended

measure

delivered.

Module

valve

outlets

Valve

Assembly.

to

the

Patient

The

bottom

and

is a unique

and

connector.

psi

source

gas

is

delivery

in

line

with

to

deliver

the

**

body

connect

The

Valve

index

safety

outlet:

(2)

7/16

to

SOURCE

GAS

INLET

FIGURE

FIGURE

8.

9.

Breaths

(BPM)

Tidal

Volume

Per

Minute

(Vi)

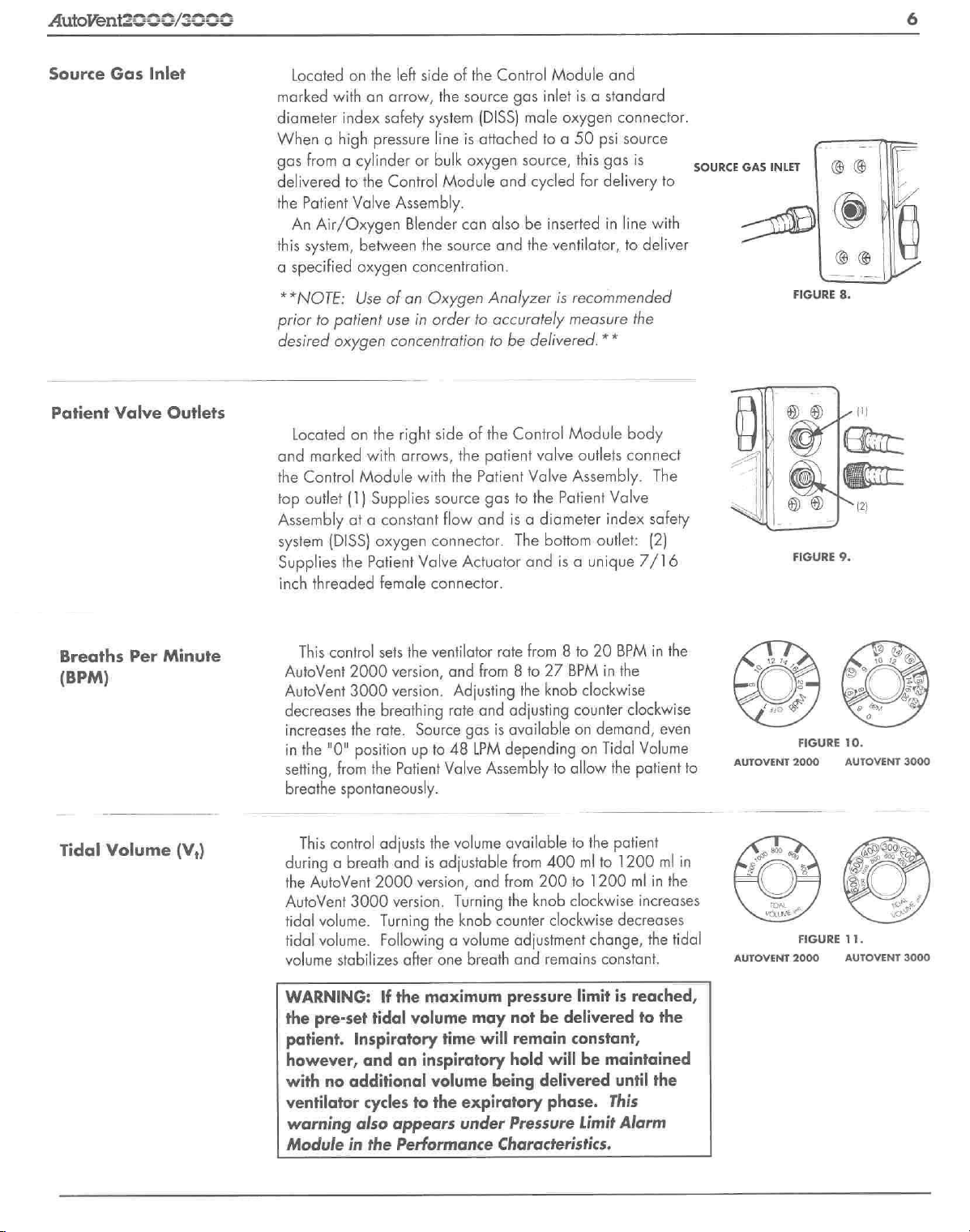

This

control

AutoVent

AutoVent

decreases

increases

in

setting,

breathe

This

2000

3000

the

the

rate.

the

"O"

position

from

the

spontaneously.

control

during a breath

the

AutoVent

AutoVent

tidal

volume.

tidal

volume.

volume

2000

3000

stabilizes

WARNING:

the

pre-set

patient.

however,

with

ventilator

warning

Module

tidal

Inspiratory

and

no

additional

cycles

also

in

the

sets

the

ventilator

version,

and

version.

breathing

Source

up

to

Patient

adjusts

and

version.

Turning

Valve

the

is

adjustable

version,

the

rate

from 8 to

Adjusting

rate

and

adjusting

gas

is

available

48

LPM

depending

Assembly

volume

Turning

and

knob

counter

available

from

the

Following a volume

after

one

breath

If

the

maximum

volume

time

an

inspiratory

volume

to

the

appears

Performance

pressure

may

will

being

expiratory

under

Pressure

Characteristics.

from 8 to

the

27

BPM

knob

clockwise

20

counter

on

demand,

on

to

allow

to

the

from

400

ml

to

200

to

1200

knob clockwise

clockwise

adjustment

and

change,

remains

limit

not be

remain

hold

delivered

constant,

will

be

delivered

phase.

Limit

BPM

in

the

in

the

clockwise

even

Tidal

Volume

the

patient

patient

1200

ml

in

ml

in

the

increases

decreases

the

tidal

constant.

is

reached,

to

the

maintained

until

the

This

Alarm

to

AUTOVENT

AUTOVENT

FIGURE

2000

FIGURE

2000

10.

AUTOVENT

11.

AUTOVENT

3000

3000

AutoVent2552/5555

Tidal

Volume

(Continued)

Inspiratory

Time

(Vi)

(Ti)

**NOTE:

the

AutoVent

with

pressure alarm

This

allows

settings

respectively.

setting

corresponds

Volume

setting

corresponds

control

of

approximately

CAUTION:

center

either

WARNING:

3000

Tidal

It

is

2000/3000

the

patient

control

knob

adjustment

allow

selection

The

is

approximately

fo

control

is

approximately

to

knobs.

control

of

the

be

adjusted

Volume

recommended

circuit

near

limit.**

in

the

center position

of

the

patient's

of

Adult

inspiratory

.75

seconds

the

circled

orange

knobs.

the

The

When

The

1.5

white

settings

AutoVent

1.5

seconds.

you

knob

end

stops.

Should

settings.

the

after

inspiratory

seconds

to

that

you

during

time

2000

select

maintenance

the

outlet

of

inspiratory

and

Child

for

the

circled

and

settings

time

and

on

the

BPM

has a pre-set

either

the

appropriate

inspiratory

initial

setup,

periodically

by

placing a pressure

to

verify

inspiratory

the

AutoVent

time.

The

two

inspiratory

when

on

the

for

when

and

time

orange

selected

the

selected

Adult

time

child

BPM

and

white

Tidal

Volume

inspiratory

or

setting

control

it

will

check

3000

Tidal

Adult

time

Child

and

alter

the

performance

pressures

setting,

knob

the

and

position

on

patient's

characteristics

manometer

the

accuracy

C

^

FIGURE

11A.

rotate

the

the

it

against

AutoVent

BPM

and

in

li

line

of

the

of

Patient

Tubing

Line

Non-Rebreathing

Valve

Hose

Valve

and

and

Corrugated

Supply

Oxygen

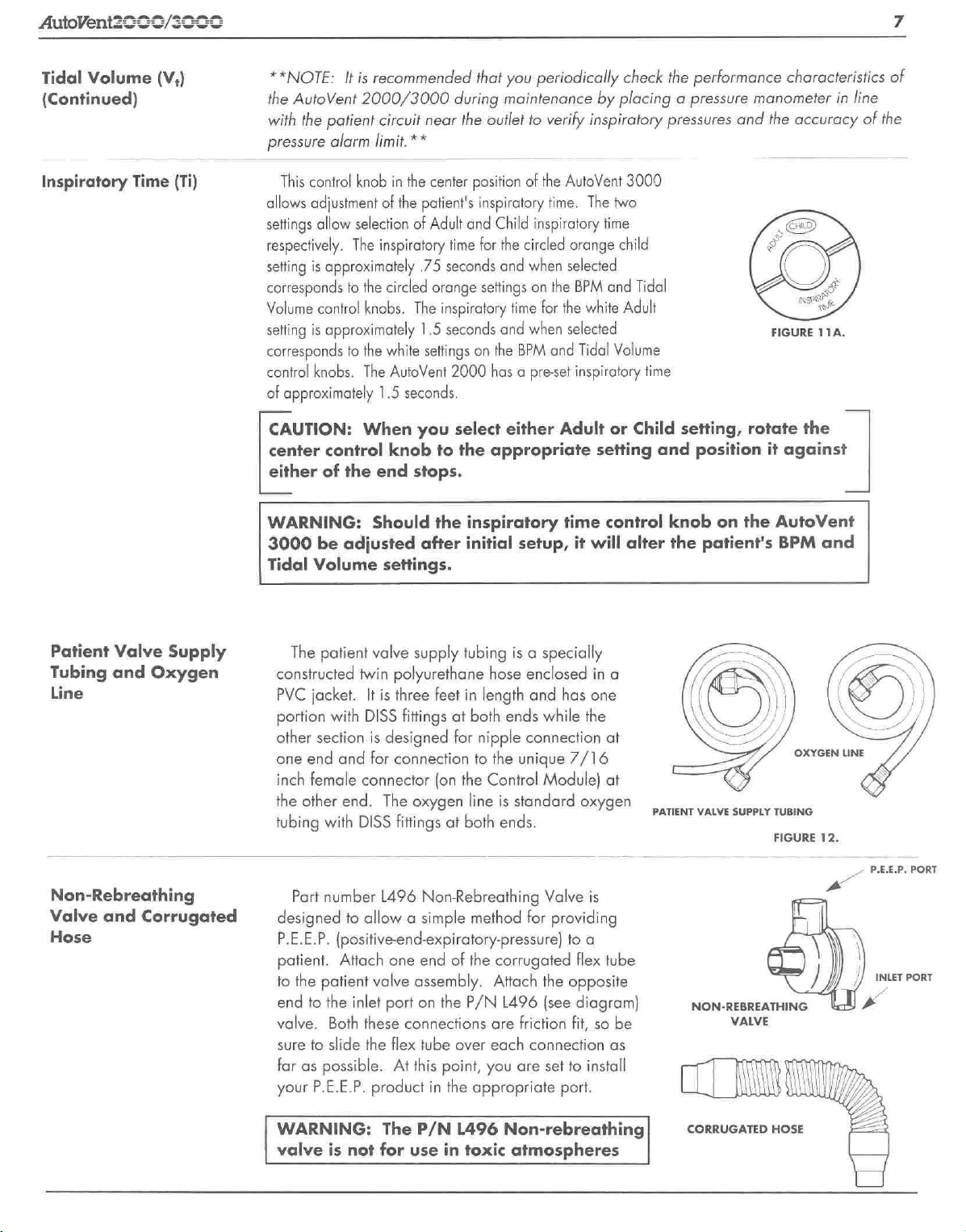

The

patient

constructed

PVC

jacket.

portion

other

one

inch

the

tubing

designed

P.E.E.P.

patient.

to

end

valve.

sure

far

your

WARNING:

valve

with

section

end

and

female

other

end.

with

Part

number

(positive-end-expiratory-pressure]

Attach

the

patient

to

the

Both

to

slide

as

possible.

P.E.E.P.

is

valve

supply

twin

polyurethane

It

is

three

DISS

fittings

is

designed

for

connection

connector

The

oxygen

DISS

fittings

L496

Non-Rebreathing

to

allow a simple

one end

valve

assembly.

inlet

port

on

these

connections

the

flex

tube

At

this

product

not

for

The

in

P/N

use

tubing

hose

feet

in

length

at

both

for

nipple

to

(on the

Control

line

at

both

method

of

the

the

P/N

are

over

each

point,

you

the

appropriate

L496

in

toxic

is a specially

enclosed

and

ends

while

connection

the

unique

Module)

is

standard

ends.

Valve

for

corrugated

Attach

the

L496

(see

friction

connection

are

set

Non-rebreathing

atmospheres

in

a

has

one

the

at

7/16

at

oxygen

is

providing

to

a

flex

tube

opposite

diagram)

fit,

so

as

to

install

port.

be

PATIENT

VALVE

SUPPLY

NON-REBREATHING

VALVE

CORRUGATED

TUBING

FIGURE

12.

P.E.E.P.

PORT

As

HOSE

Loading...

Loading...