Allied 4SCU16LS PRODUCT SPECIFICATIONS

4SCU16LS

PRODUCT SPECIFICATIONS

16 SEER SPLIT SYSTEM

TWO-STAGE AIR CONDITIONER

FORM NO. 4SCU16LS-100 (01/2021)

COMPONENTS

• Communicating capable control board works with Comfort Sync®

thermostat (or conventional thermostat)

• Self diagnostics control board for quick trouble shooting; saves

up to 10 fault codes regardless of power interrupt

• Factory installed high and low pressure switches

• Thread-on type pressure switches with valve core for quick

service

• Service valves mounted for easy brazing and service

• Factory installed crankcase heater

• Factory installed TXV for excellent refrigeration control

• Fan orifice for sound reduction and efficient performance

• Charged for 15 feet of line set

• Can be matched with Comfort Sync® enabled or conventional

indoor unit

COMMUNICATING THERMOSTAT ENABLED

COMPRESSOR

• High-efficiency 2 stage Copeland UltraTech™ scroll compressor

• R410a refrigerant

• Heavy-duty compressor sound blanket for quiet operation

• Internally protected against high temperature motor overload

conditions

CABINET

• Four metal louvered panels easily removable for coil cleaning and

service

• Corner-mounted controls for easy service

• Rounded corner posts for safety and attractive appearance

• Baked polyester paint finished over galvanized steel for maximum

durability

• Removable PVC coated wire fan discharge grill

• External gauge ports for easy service

WARRANTY

10 year limited warranty on compressor

10 year limited warranty on all parts, extended warranty available*

*Warra nty provides for a total of 10 years of limited warrant y coverage (Standard

5-yea r limited p arts warranty plus an add itional 5 -year limited ex tended p arts

warrant y). Warrant y must be registered online within 60 day s of installation to

qualif y for 10 -year coverage. Unregistere d equipment defaults to 5-year cove rage.

See full warranty at www.allied air.com for terms, conditio ns and exclusions .

COILS

• Enhanced tube-and-fin coil design featuring MHT™ Technology

• Raised coil prevents debris from impeding airflow

DESIGN

• Designed to perform in temperatures up to 125 degrees F

* Check that equipment complies with all applicable building codes, laws, and regulations for its intended use prior to installation.

Page 1

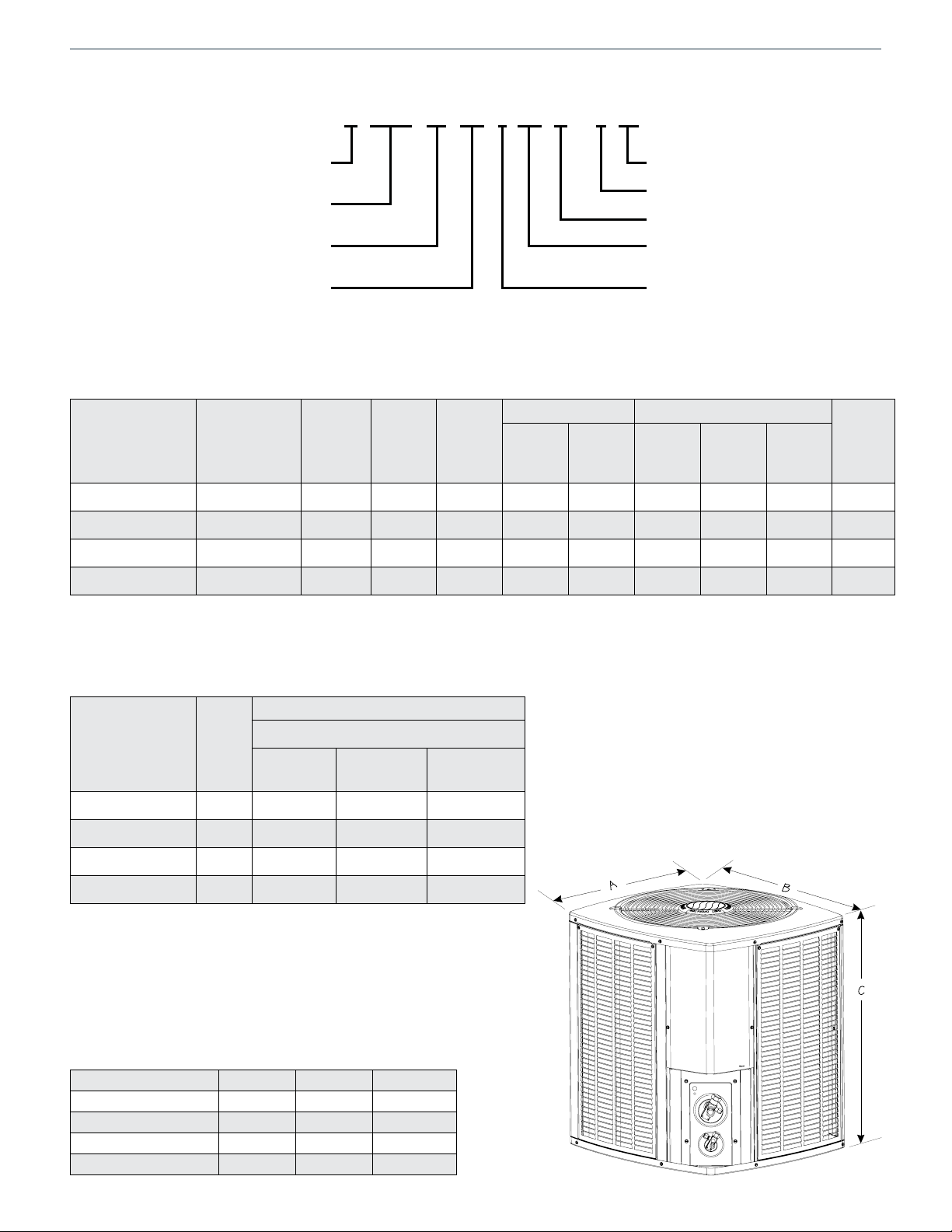

ENHANCED SPLIT SYSTEM 4SCU16LS

MODEL NUMBER GUIDE

4 SCU 16 LS 1 36 P - 3 A4 SCU 16 LS 1 36 P - 3 A

REFRIGERANT

4 = R410A

SCU

SPLIT CONDENSING UNIT

16

16 SEER NOMINAL

LS

LOUVERED TWO-STAGE

COMMUNICATING ENABLED

MINOR REVISION CODE

MAJOR REVISION CODE

1-PHASE, 60 HZ

NOMINAL CAPACITY

36 - 36,000 BTUH

REGION RESTRICTIONS

STANDARD MODEL

PHYSICAL AND ELECTRICAL

Max.

Model

Voltage/Hz/

Phase

Voltage

Range

Min.

Circuit

Amp.

Over

Current

Device

(amps)

4SCU16LS124P-3 208-230/60/1 197-253 15.7 25 11.7 58 1.0 1/6 825 212

4SCU16LS136P-3 208-230/60/1 197-253 20.2 35 15.3 83 1.1 1/6 825 245

4SCU16LS148P-3 208-230/60/1 197-253 28.2 45 21.2 104 1.1 1/6 825 287

4SCU16LS160P-3 208-230/60/1 197-253 35.6 60 27.1 153 1.7 1/4 825 332

Note: Weig hts listed are unit weights with pa ckaging

Compressor Fan Motor

Rated

Load

(amps)

Locked

Rotor

(amps)

Rated

Load

(amps)

Rated HPNom.

RPM

Weight

(lbs.)

UNIT SOUND RATINGS

Estimated Sound Pressure (dBA)

Model

Sound

Power

1

One Meter

(3.3 feet)

Approximate Distance

Two Meters

(6.6 feet)

3

Three Meters

(9.8 feet)

4SCU16LS124P-3 74 66 60 56

4SCU16LS136P-3 74 66 60 56

4SCU16LS148P-3 76 68 62 58

4SCU16LS160P-3 76 68 62 58

1 Rated in accordance with AHRI standard 270 (2015)

2 Rated in accordance with AHRI standard 275 (2010)

3 Based only on distance factor; other factors may change this value such as:

• Unit location (reflective surfaces adjacent to the unit)

• Barrier shielding sources

• Sound path/elevation

• Outside noise sources

DIMENSIONS (IN.)

Model No. A - Width B - Depth C - Height

4SCU16LS124P-3 29.25 31.25 43.75

4SCU16LS136P-3 29.25 31.25 29.75

4SCU16LS148P-3 29.25 31.25 37. 75

4SCU16LS160P-3 35.75 37.75 43.75

2

Page 2

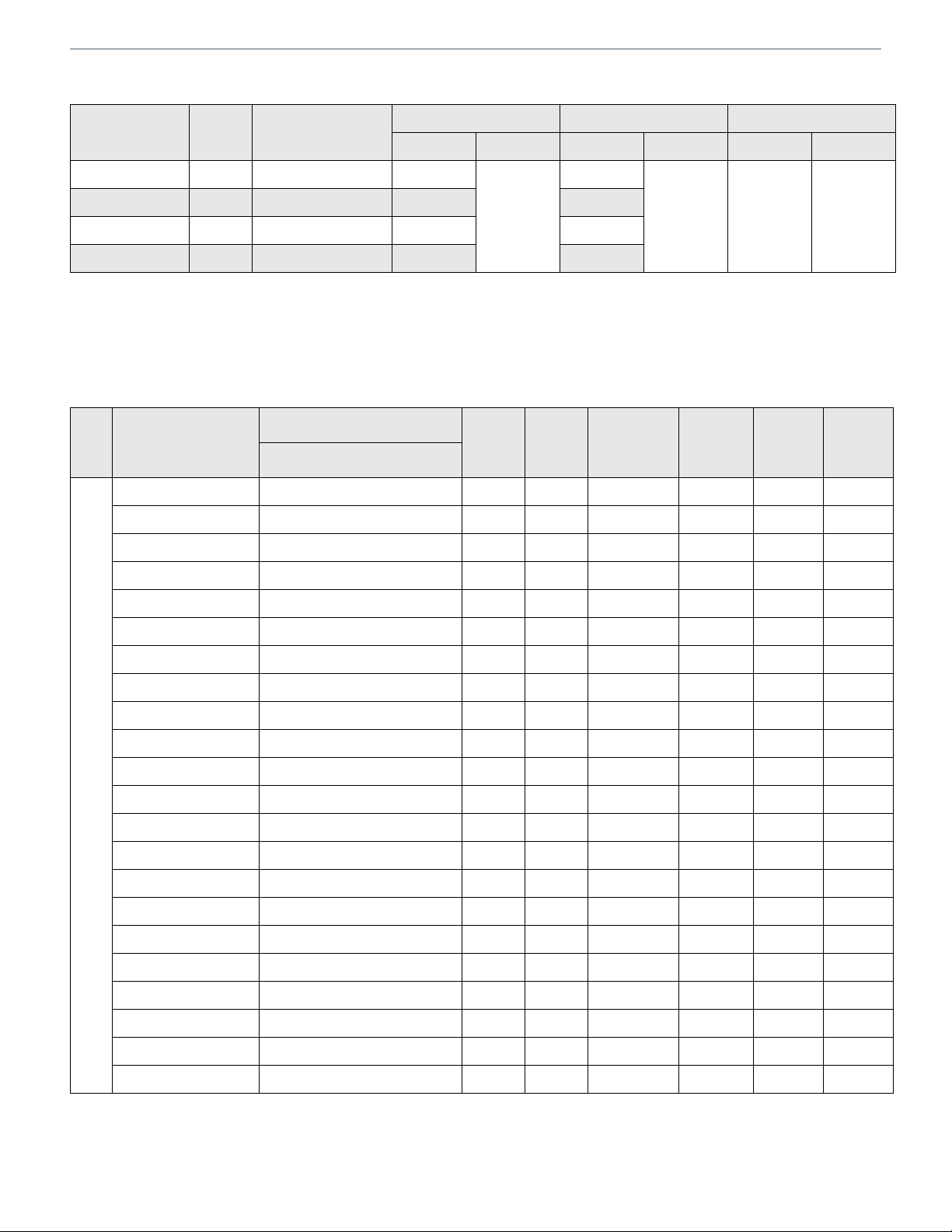

ENHANCED SPLIT SYSTEM 4SCU16LS

REFRIGERATION DATA

Model

System

Charge

(oz.) *

Indoor TXV

Refrigerant Line Size Outdoor Unit Connection Indoor Unit Connection

Suction Liquid Suction Liquid Suction Liquid

4SCU16LS124P-3 117 A4TXV01/H4TXV01 3/4

4SCU16LS136P-3 137 A4TXV01/H4TXV02 7/8 7/ 8

3/8

4SCU16LS148P-3 180 A4TXV02/H4TXV02 7/ 8 7/8

4SCU16LS160P-3 214 A4TXV02/H4TXV03 1 1/8 7/ 8

* Factory charged for 15 fe et of line set ; adjust 0 .6 oz per foot (see installation instructi ons).

COOLING PERFORMANCE WITH AIR HANDLERS & FURNACES

Indoor Model

SEER EER

Evap. Coil or Air Handler

3

BCE4M24S* 15.10 12.20 24000 17,800 850 650

BCE4M30S* 15.10 12.20 24000 17,800 850 650

Model

Outdoor

Variable Speed

Furnace

BCS2M36V00NA1P+A4TXV01 15.10 12.20 24000 17,800 800 600

3/4

AHRI Rate

Capacity1

BTUH

3/8

Sensible

Rated

Capacity

VARIES

BASED

ON COIL

MATCH

CFM

High

3/8

CFM

Low

EFV08BC E*1P36B+A4TXV01+TDR 15.10 12.20 24000 17,800 850 650

A80US2V070A12 E*1P19A+A4TXV01+TDR 16.00 13.00 24000 17,800 820 650

A80US2V070A12 E*1P23A+A4TXV01+TDR 16.00 13.00 24000 17,800 820 650

A80US2V070A12 E*1P29A+A4TXV01+TDR 16.00 13.00 24000 17,800 780 495

A80US2V070A12 E*1P36A+A4TXV01+TDR 16.00 13.00 24000 17,800 780 495

A80US2V090B12 E*1P23B+A4TXV01+TDR 15.10 13.00 24000 17,800 780 495

A80US2V090B12 E*1P29B+A4TXV01+TDR 16.00 13.00 24000 17,800 780 495

A80US2V090B12 E*1P30B+A4TXV01+TDR 16.00 13.00 24000 17,800 800 500

A80US2V090B12 E*1P36B+A4TXV01+TDR 15.10 12.50 24000 17,800 780 495

A80DS2V070A12 E*1P36A+A4TXV01+TDR 14.50 12.20 22000 16,300 800 575

4SCU16LS124P-3

A96US2V045B12 E*1P23B+A4TXV01+TDR 16.00 13.00 24000 17,800 815 540

A96US2V045B12 E*1P29B+A4TXV01+TDR 16.00 13.00 24000 17,800 815 540

A96US2V045B12 E*1P30B+A4TXV01+TDR 16.00 13.00 24000 17,800 815 540

A96US2V045B12 E*1P36B+A4TXV01+TDR 16.00 13.00 24000 17,800 815 540

A96US2V070B12 E*1P23B+A4TXV01+TDR 16.00 13.00 24000 17,800 800 600

A96US2V070B12 E*1P29B+A4TXV01+TDR 16.00 13.00 24000 17,800 800 600

A96US2V070B12 E*1P30B+A4TXV01+TDR 16.00 13.00 24000 17,800 800 600

A96US2V070B12 E*1P36B+A4TXV01+TDR 16.00 13.00 24000 17,800 800 600

A96US2V090C12 E*1P30C+A4TXV01+TDR 16.00 13.00 24000 17,800 800 600

Note:

1 Certified in ac cordan ce with Unitary Air Conditioner Ce rtific ation Pro gram, which is based on AH RI Stan dard 21 0/240

2 Required to achieve AHR I rating. If NA (Not Applic able) is in the piston column, the n TX V is required

3 A blower tim e delay relay is required to achieve AHRI rating. This featu re is stand ard on all Allied Air Enterprises Furna ce and AH p roducts

Page 3

Loading...

Loading...