Alliance Laundry Systems SVN255P, UVN255P User Manual

Models From serial #

UVN255P

SVN255P

1520001

Operation Instructions

for washers

MICROPROCESSOR

CONTROL

MICROPROCESSOR

Control

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Safety instructions 2

DANGER!

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock or injury to persons when using the washer, follow basic

precautions, including the following:

1. READ all instructions before using the washer and KEEP them in a prominent location for customer use .

2. Do not wash articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline,

dry cleaning solvents, and other flammable or explosive substances as they GIVE OFF VAPOURS that

could ignite or explode. These substances GIVE OFF VAPOURS that could ignite or explode.

3. DO NOT ADD gasoline, dry-cleaning solvents, or other flammable or explosive substances to the was h

water. These substances give off vapours that could ignite or explode.

4. Under certain conditions, hydrogen gas may be produced in a hot water system that has not been used for

two weeks o r m ore. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has not been used for suc h

a period, before using the washing machine, turn on all hot water faucets and let the water flow from each

for several minutes. This will release any accumulated hydrogen gas. As the gas is flammable, do not

smoke or use an open flame during this time.

5. Do not allow children to play on or in the washer. CLOSE SUPERVISION of children is necessary when

the washer is used near children.

6. Before the washer is removed from service or discarded, REMOVE the door.

7. DO NOT TRY TO OPEN THE WASHER’S DOOR if the drum is moving.

8. Do not install or store the washer where it will be exposed to the WEATHER or near possible water

splashes.

9. DO NOT TAMPER with controls.

10. DO NOT REPAIR OR REPLACE any part of the washer or attempt any servicing, unless specifically

recommended in the user instructions or in published user-repair instructions that you understand and have

the skills to carry out. DO NOT BY-PASS any safety device.

11. It is NOT ACCEPTED ANY electric or mechanic MODIFICATION OR MANIPULATION. DO NOT

INSTALL foreign components inside the machine.

12. All SAFETY INSTRUCTIONS included in the Instruction Handbooks, should be repri nted and post ed in the

laundry ro om.

13. Failure to install and operate this machine according to the Instruction Handbooks or to work saf ety and

hygiene standards and common sense, may result in conditions which CAN PRODUCE bodily inju ry or

loss of life.

14. The DANGER, WARNING, CAUTION and IMPORTANT instructions appearing in the Instruction

Handbooks are not meant to cover all possible conditions and situations that may occur. It must be

understood that common sense, caution and carefulness are factors which cannot be built into this

machine. These factors MUST BE supplied by the person(s) transporting, installing, maintaining, or

operating the machine.

15. All connections for electrical power and plumbing MUST comply with the statutory safety standards

applicable to each country, and be made by Licensed Installers only (refer to note 3).

Cod. G522441

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Safety instructions 3

16. WARNING!

MACHINE INSPECTION, FILTER CLEANING, MAINTENANCE, SERVICE OR PARTS REPLACEMENT.

Before attempting any service or inspection of the washing machine:

Close and mechanically interlock the water supply valves and check that machine has COMPLETELY

drained, parts have cooled down and that no pieces are in movement through inertia.

To reduce the risk of electrical shock:

COMPLETELY disconnect the machine from the original power source and check for accidental

reconnection. MOVING THE ON SWITCH TO THE OFF POSITION IS NOT SUFFICIENT.

Disconnect the electrical power of the external dosing to the washing machine. These circuits are

independent of the washer’s supply.

Wait a minimum of (5) five minutes after disconnection to ensure the elimination of residual voltage

within the machine.

Failure to comply with this warning may result in serious injury.

17. NEVER START THE MACHINE NOR USE IT IN THE ABSENCE, INCORRECT POSITION OR

MALFUNCTION OF:

COVERS ( GUARDS) AND PROTECTIONS

SAFETY DEVICES

CONTROL ELEMENT

18. The room MUST comply with the environment conditions (air venting, temperature, humidity...) specified in

the Installation Instruction Handbook. NEVER INSTALL THE WASHING MACHINE in very humid

environments or with water splashes.

19. DO NOT OPERATE the machine if it is suspected to be faulty, either visually, by noise or smell, or with

missing or broken parts.

20. Machine start-up SHALL be made by Authorised Service Technicians (refer to note 2).

21. Machine SHALL BE USED by qualified personnel (refer to note 1), wholly familiar with the machine’s

operation.

22. DO NOT allow children or people with handicaps incompatible to machine use to operate machine.

23. Every machine working with temperature has a fire hazard, take SPECIAL care. KEEP appliance area free

from combustible materials and fire extinguishers should be PLACED near the machines and should be

easily accessible to all laundry staff.

24. Delimitate danger areas and PREVENT public access to them with machine in operation. Do not expose

yourself to the dispenser, drain and rear overflow steam exhaust

25. On completion of the day's work, TURN OFF t he manual supply v alves and DISCONNECT the electrical

power by the External Automatic Switch.

26. Always CONTACT an Authorised Service Tec hnicia n or Lic ensed I nstalle r (refer to notes 2 & 3) about any

problems or conditions you do not understand.

27. For a safe operation, machine MUST be kept in a good environment, used and maintained properly. We

recommend asking annually the Authorised Technical Service for a thorough overhaul (refer to note 2).

28. The Distributor (seller) IS OBLIGED to thoroughly train the operator during the starting-up.

THE MANUFACTURER REFUSES ANY RESPONSIBILITY IF THESE SAFETY INSTRUCTIONS AND ALL

INFORMATION IN THE CORRESPONDING HANDBOOKS ARE NOT FOLLOWED.

SAVE THESE INSTRUCTIONS

NOTES:

(1) Qualified Personnel refers to anyone who has read the Instructions Handbooks, has been trained and has a thorough understanding

of the machine’s operation

(2) An Authorised Service Technician (AST) is one that has successfully completed training on the product by the manufacturer or a

manufacturer Distributor.

(3) An Authorised Licensed Installer is one that is suitably qualified in the procedures and regulations applicable in that country.

.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Safety instructions 4

HAZARD SYMBOLS USED ON WASHER LABELS:

Electric risk

Protection guard for electr ic component s .

Mechanical risk

Protectio n gu ard for moving pa r t s

SYMBOLS USED IN THIS MANUAL

This symbol alerts you to potential

hazards for the user, the machine or the

fabric.

Replacement Parts

If literature or replacement parts are required, contact the source from which the washer-extractor was

purchased or contact Alliance Laundry Systems LLC at (920) 748-3950 for the name of the nearest authorized

parts distributor. A parts manual may be ordered by returning the reply card provided with each washerextractor.

Customer Service

For technical assistance, contact your local distributor or call: (920) 748-3121 Ripon, Wisconsin

A record of each washer-extractor is on file with the manufacturer. Always provide the machine’s serial number

and model number when ordering parts or when seeking technical assistance. Serial plat e is located at the rear

side.

Copyright 2009, Alliance Laundry System LLC

All rights reserved. No parts of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher

High temperature risk

Operate with caution.

Use appropriate protections.

Risk of harmful vapours inhalation

Keep dispenser box closed.

Use appropriate protections.

This symbol is used to give relevance to

any precise explanation

.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Safety instructions 5

IMPORTANT INSTRUCTIONS FOR USE AND CONSERVATION

1. EXPECTED MACHINE USE AND DON’TS. This machine has been made and designed for industrial

washing or cleansing in a water bath of linen and textile materials only. Linen and textile materials must be

free from solvent impregnation or explosives. Any other use will be considered contraindicated without the

written authorization of the manufacturer.

Under-loading as well as overloading is not recommended. Always endeavour to meet the capacity of the

machine.

It is not recommended to wash the linen inside bags. Should it be necessary, load the machine up to its

nominal value.

It is not recommended to spin carpeting, canvas or waterproof fabrics.

2. Machine MATERIALS in contact with wash products are:

Stainless Steel AISI-304 L

Aluminium in models HS-6008 & MS-610 (EH020 & EM025)

EPOXY coating on steel (in some models)

Polypropylene PP

EPDM and NBR

Borosilicate glass

3. The user must inquire the chemical product supplier about the risks of chemicals and its combination. The

user is responsible to assure that products ARE COMPATIBLE and will not produce machine oxidation or

damage either to people or to the washer.

Notice that the hypochlorite (bleach), in certain conditions of use, generates chlorine gas.

The chlorine is a corrosive and oxidizing substance that, in elevated concentrations and temperature,

deteriorates the stainless steel and elastomers.

There are other highly oxidizing agents, such as the ozone, that can cause the same effect.

4. Periodically CLEAN the machine. You will prevent metallic parts corrosion and produce higher output and

have a longer life. To clean the washing machine, use water and detergent, rinse with a damp cloth, and

dry. Cleaning with water jet or pressure steam is forbidden.

5. Once the wash cycle has finished, THE WASHER DOOR SHOULD REMAIN OPEN.

Allows for the ventilation of the washer interior

Avoids the appearance of harmful micro organisms

Extends the lifetime of the door joint

6. NEVER use harsh products to clean the machine and laundry room. There are products on the market,

which are highly corrosive.

7. If machine is left idle for long periods of time, it must be PROTECTED from humidity and temperature

variations.

8. FOLLOW the fabric care instructions supplied by the manufacturer. THE MANUFACTURER REFUSES

ANY RESPONSIBILITY IN CASE OF TEXTILE WEAR AND TEAR.

9. Failure due t o im pr oper machine operation may VOID WARRANTY.

10. Replacing any part of the washer can affect the machine’s security.

Examples:

Just a screw or bolt of insufficient strength could cause dangerous damage.

A heater without an internal fuse could provoke a fire.

An inadequate clamp can be the caus e o f wat er leaks and short circuits, et c.

The reason for which ONLY ORIGINAL SPARE PARTS MUST BE USED

The incompliance of this precaution may result in a washer breakdown, a serious accident, and loss of the

warranty.

11. When asking for information on your machine, MENTION model and serial number (SERIAL PLATE is

located at the rear side).

12. THE ELECTRICAL DIAGRAM IS LOCATED IN THE UNDERSIDE OF THE WASHER’S TOP COVER.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Index 6

SAFETY INSTRUCTIONS .......................... ................................................................ ...............................2

INDEX .................................................................................... ................................................................. 7

1. DESCRIPTION.......................................................................................................................................8

1.1. Characteristics.............................................................. ...................................................................8

1.2. Protection, safety and control elements...........................................................................................8

1.3. Safety functions ...............................................................................................................................9

2. CONTROL PANEL..................................................... ............................................................................9

2.1. Connection and stop devices...........................................................................................................9

2.2. Screen .............................................................................................................................................9

2.3. Keyboards......................................................................................................................................10

2.4. Card reader.............................. ......................................................................................................10

3. MAIN MENU. INTERVENTION MODES...............................................................................................11

4. EXECUTING PROGRAMS...................................................................................................................12

4.1. Starting the washing machine. Main menu.....................................................................................12

4.2. Selecting and starting a wash program.................... ..... .... ......... ..... .... ..... ......... ..... .... ......... ..... ......12

4.3. Information about functions. Description of the screens............. ..... ..... .... ......... ..... .... ..... ..... .... ......13

4.4. Modifying the duration of a program...............................................................................................14

4.5. Info screen.....................................................................................................................................14

4.6. Crease-guard stop. Rinse hold function.........................................................................................14

4.7. Stop and door opening modes.......................................................................................................15

4.8. Delayed start of a wash program.................................................................................... ...............15

4.9. Unbalance control..........................................................................................................................16

4.10. Machines with tilt system ............ ......... .... ..... ......... ..... .... ..... ......... ..... .... ......... ..... .... ....................16

4.10.1. Tilt system control panel.................................................... ......... ..... ..... .... ......... ..... .... ...........17

4.10.2. Using the tilt system.... ......... .... ..... ..... ........ ..... ..... .... ......... ..... .... .......... .... ..... .... ....................18

4.11. Machines with easy-load system..................................................................... .............................19

4.11.1. Easy-load system control panel ............................................................................................19

4.11.2. Using the easy-load system.............................................. ..... ......... ..... .... ..... ......... .... ..... ......20

5. PRE-SET PROGRAMS........................................................................................................................21

5.1. Table summarizing the pre-set programs.......................................................................................21

5.2. Interpreting the icons in the tables of pre-set programs .................................................................22

5.3. Contents of pre-set programs........................................................................................................23

6. PROGRAMMING MODE......................................................................................................................25

6.1. Defining programming concepts.....................................................................................................25

6.2. Programming mode menus............................................................................................................25

7. PROGRAMMING A NEW WASH PROGRAM......................................................................................26

7.1. Access to programming a new program.........................................................................................27

7.2. Identifying the new program................... .................................................. ......................................27

7.3. Programming a program phase......................................................................... .............................28

7.3.1. Water inlet..................................................... ..........................................................................28

7.3.2. Bath level................................................................................................................................29

7.3.3. Bath temperature – Heating....................................................................................................29

7.3.4. Heating gradient ................... .............................................................................................30

7.3.5. Product dosing........................................................................................................................30

7.3.6. Duration of the dosing. ..................... ................................................... .................................31

7.3.7. Rotation. Start – Stop Sequence.............................................................................................31

7.3.8. Rotation speed. ...................................................................................................................32

7.3.9. Rotation time....... ....................................................................................................................32

7.3.10. Gradual cooling . .......... .... ..... .... ......... ..... ..... .... ......... ..... .... ..... ......... ..... .... ......... ..... ............. ..32

7.3.11. Cooling gradient. .................................................. ......... ..... ..... ......... .... ..... ......... .... ...........33

7.3.12. Draining................................................................ .... ..... ......... ..... .... ......... ..... .... ....................33

7.3.13. Draining speed....... ..... .... ......... ..... .... ......... ..... ..... .... ......... ..... .... .......... .... ..... .... ....................34

7.3.14. Spin time.................................. ..... ......... ..... .... ......... ..... .... .......... .... ..... .... ......... .................. ..35

7.3.15. Buzzer............................. ......... ..... .... .......... .... ..... ......... .... ..... ..... ......... .... ..... ...................... ..35

7.3.16. End of phase or program.......................................................................................................35

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Index 7

8. MODIFYING PROGRAMS................................................................................... .................................36

8.1. Modifying a program................................................ ......................................................................36

8.1.1. Selecting a program and modifying the name.........................................................................36

8.1.2. Selecting phase and intervention............................................................................................37

8.1.3. Modifying and viewing the content of a phase .........................................................................37

8.1.4. Inserting a phase.....................................................................................................................38

8.1.5. Erasing the phase selected............................................................................. ........................38

8.2. Copying a program into an empty program................................................................ ....................38

8.3. Blocking and unblocking the use of a program...............................................................................39

8.4. Erasing a program............................ ..... .... .......... .... ..... ......... .... ..... ..... ......... .... ..... ........................39

8.5. Modifying the name and viewing the content of pre-set programs (from numbers 1 to 20) ............39

9. USING THE CARD..................................................... ..........................................................................40

9.1. Copying from machine to card........................................................ ...............................................41

9.2. Copying from card to machine.......................................................................................................41

9.3. Consulting the card content and changing the program name............................................ ...........42

9.4. Erasing a program on the card.......................................................................................................42

10. SYSTEM TOOLS................................................. .... ..... ......... ..... .... ......... ..... ..... .... ......... ....................43

10.1. Configuration menu. Presentation and access................ .............................................................43

10.2. Configuring operation and programming parameters............................................................. ......44

10.2.1. Operation parameters............................................................ ..... .... ......... ..... .... ..... ...............44

10.2.2. Advanced programming options............................................................................................47

10.2.3. Modifiable values tables........................................... ......... ..... .... .......... .... ..... ......... .... ...........48

10.3. Setting the clock...........................................................................................................................50

10.4. Initializing the card................................................................... ..... ..... ......... .... ..... ........................50

10.5. Managing access codes..................................... .... ......... ..... .... ..... ......... ..... .... ......... ..... ...............51

11. INFORMATION MENU........................................ ..... ......... .... ..... .... .......... .... ..... ......... .... ..... ...............52

11.1. General information. Content.......................................................................................................52

11.2. Operation counters.................................. ..... ......... ..... .... ......... ..... .... ..... ......... ..... .... ....................52

11.3. Alarm counters....................... ......... ..... .... .......... .... ..... .... ......... ..... ..... ......... .... ..... .... ....................53

11.4. Executed program counters................................................................................. ........................54

11.5. Load counters. ..... ......... ..... .... ..... ......... .... ..... ......... ..... .... ..... ......... .... ..... ......... ..... .... ....................54

12. TEXT MESSAGES....................................................... ..... .... ......... ..... ..... ......... .... ..... .... ....................54

12.1. Programming messages and moment of display..........................................................................54

13. TROUBLESHOOTING ............................... .... ..... ......... ..... .... ......... ..... ..... ......... .... ..... .... ....................55

13.1. Freeing a trapped person................................................................... .......................................... 55

13.2. Manually releasing of the security lock............................................... .... ..... ......... .... ..... .... ...........55

13.3. What to do when…......................... .............................................................................................56

13.4. System alarms......................................................................... .......... .... ..... ......... .... ....................57

14. MAINTENANCE......................................... ......... ..... .... ..... ......... .... ..... ......... ..... .... ..... ........................60

14.1. Operations described.................. .... ..... .... .......... .... ..... ......... .... ..... ..... ......... .... ..... ......... ...............60

14.2. Washing machine cleaning..........................................................................................................60

14.3. Door seal cleaning............................................................... .... .......... .... ..... .... ......... ......... ...........60

14.4. Cleaning the electro valve filters............................ ..... ......... .... ..... ......... ..... .... ..... ......... ...............60

14.5. Cleaning the dispenser ............... .... .......... .... .... .......... .... ..... .... ......... ..... ..... ......... .... ..... ...............61

14.6. Revising the safety mechanisms.......... .... ..... .... .......... .... ..... .... ..... ......... ..... .... ..... ......... .... ...........62

14.7. General revision.............................. ..... ......... ..... .... ......... ..... .... .......... .... ..... .... ......... .............. ......63

15. SERVICE REMOVAL............... .... ..... ......... .... ..... ......... ..... .... ......... ..... ..... ......... .... ..... .... ....................63

15.1. Dismantling..... ..... ......... ..... .... ......... ..... .... ......... ..... ..... .... ......... ..... .... .......... .... ..... ........................63

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Description 8

1. DESCRIPTION

WASHER EXTRACTOR DESIGNED TO WASH OR TREAT FABRIC IN A WATER BATH.

1.1. Characteristics

Construction characteristics:

Washers, capable of extracting with speeds above 350G without having to be bolted down. The design of its

suspension system: multi-directional springs and shock absorbers to cushion up to 95% of the vibrations

produced during the spin cycle.

Stainless steel inner and outer drum. The openings in the drum blades promote the uniform distribution of

bath water and improve the yield of the washer both during the wash and the rinse cycles.

The drum rotation is produced by an asynchronous motor of alternating current controlled by inverter.

Hot and cold water connections with a safety mechanism to prevent contaminating by back-flowing into the

general potable water system.

Large capacity drain valve.

Water inlets and all product dispensers done using a common collector with an anti-siphon mechanism.

Option for heating the bath using electric heaters or steam injection.

Functional characteristics

Operation control of the washer by microprocessor.

Operation of the washer adaptable to the possibilities of the installation and the needs of the user.

Temperature control mixes hot and cold water in accordance with the programmed temperature and the

activation of the heating system. Precision of +/- 2º C (+/- 3.5ºF) .

Level control done with an electronic pressure transmitter.

Serial communication between the washer microprocessor and the inverter control of the motor. This

communication takes advantage of all the features offered by inverter technology which results in a

significant energy savings and an optimal management of the spin cycle. This in turn implies a significant

reduction in noise, vibration and wear on the washer components.

Washing programs: availability of twenty pre-programmed programs.

Seventy-nine free programs, programmable by the user.

Programming, copying, modifying and erasing menus. These menus are viewed in graphic mode. This type

of viewing facilitates understanding the different operations.

Memory card that allows storing programs from the washing machine memory and later introducing them

into other machines Thanks to its programming system, the programs programmed into a washing machine

with Microprocessor Control are usable in any washing machine with the same control.

Multiple controls that assure the safe use of the washer.

1.2. PROTECTION, SAFETY AND CONTROL ELEMENTS

Fixed guards: Covers. Protect the user from the contact with dangerous points and accidental machine

spattering.

Moving guards:

Dispenser cover.

TILT models. Covers allowing tilting mov ements of the washer.

Door with interlock microswitch, door lock and delayed opening.

Unbalance microswitch. Additional electromechanical safety to protect against unbalance of drum load

during the spin cycle.

Overflow. When the bath level is exceeded by electrovalve failure, the bath is drained through the drain

outlet

Thermal fuse to protect the electric heaters.

:

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Control panel 9

1.3. SAFETY FUNCTIONS

Bath level control. Allows selecting different bath levels during the wash cycle and controls the overflow

safety and minim level of connection to the heating system and door opening.

Temperature control. Allows selecting the bath temperature during the wash cycle and controls the bath

insufficient temperature and overheat safeties.

Unbalance control. Repositioning of the washer's load if the inverter power control detects unbalance.

Door opening safety. Allows the opening of the door in safety conditions.

2. CONTROL PANEL

The Microprocessor Control offers different user intervention devices upon the washing machine.

2.1. CONNECTION AND STOP DEVICES

General switch. Switch disconnect or located on the re ar

part of the washing machine. Totally disconnects the

electric supply from the machine.

ON switch (A): Switch installed on the front piece of the

washing machine.

Emergency stop (B): (only on washing machines with

capacity over 150dm

a visible and accessible place on the washing

machine.

STOP key (C): key on the numerical keyboard.

2.2. SCREEN

Allows viewing the different operations that the washing machine and/or the user execute by means of easily

understandable graphic icons

1 2 3

4

Screen in graphic mode. In graphic visualization, the

screen is divided into different parts.

1) Function icon

2) Program and phase numbers

3) System time

4) Central screen

5) Function of the multi-function keys

6) Multi-function keyboard

5 5 5 5

6 6 6 6

Screen in text mode. Used in the CONFIGURATION

mode menus and the TECHNICAL ASSISTANCE area.

The screen displays messages written in different

languages.

3

). Red button with lock located in

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

2.3. KEYBOARDS

Control panel 10

Numerical keyboard: Used for selecting programs, introducing values...

Numerical keys: Allows introducing numerical values for selecting

0 ... 9

programs, programming, configuration, access codes...

T T T T

2.4. CARD READER

4

C

STOP

The keys with vertical and horizontal arrow symbols allow

inserting text.

C key: Accesses the delayed start of a program and erases

written characters.

STOP key: cancels a wash cycle and other functions depending

on the one currently in use.

Multi-function keyboard (T). Made up of four keys that

execute different orders depending on what is currently in use.

The function of each key is displayed on the graphic screen

.

The Microprocessor Control allows storing wash programs on a memory card

and copying them onto other washing machines that use the same control. The

card has a maximum capacity of 25 programs. Depending on the length of the

program, this quantity can be reduced.

Cod. G522441

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Main menu 11

3. MAIN MENU. INTERVENTION MODES

The Microprocessor Control is divided into THREE MAJOR OPERATION AREAS or user INTERVENTION

MODES. Each of the three modes is accessed through the MAIN MENU made up of three icons identifying

each of the modes.

PROGRAM EXECUTION MODE

Covers the functions or interventions destined to:

Selecting and executing the different wash programs

Programming the delayed start of a program

Accessing information about the different functions that the washing machine is

executing

Small specific modifications of the program being executed

All the information that appears on the screen during the execution of a program is in

graphic mode.

Information regarding this intervention mode: chapter 4 in this manual.

PROGRAMMING MODE

Covers the functions or interventions destined to:

Knowing the content of the PRE-SET program in the washing machine’s memory

Creating a new wash program, whether it is a new program or copying an already

existent program

Eliminating programs from the washing machine’s memory

Using the resources that the card holds

All the information that appears on the screen in the program management menu is in

graphic mode.

Information regarding this intervention mode: chapters 5 to 9 of this manual.

SYSTEM TOOLS MODE

This area offers specific menus for CONFIGURING THE SYSTEM.

Among other features:

Configuring operation parameters

Setting the clock of the system

Controlling security codes

It also provides a lot of information about the characteristics and life of the washing

machine.

The information in this area is in text mode.

Information regarding this intervention mode: chapter 10 in this manual.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Executing programs 12

4. EXECUTING PROGRAMS

4

OK

4.2. SELECTING AND STARTING A WASH PROGRAM

Select the icon of the program to be executed. Use the ----- ---4-- keys on the multifunction keyboard.

Confirm the selection with the OK.key.

Possible icons:

Door closed.

Before starting a wash program, opening the washing machine door is imperative.

Group the fabrics to be washed in homogeneous loads, trying to reach the nominal value of the

load. Empty all pockets, fasten buttons, close zippers and remove accessories that are not

machine-washable. It is not recommend mixing whites with other colours.

Open the door and load the machine. The LED of washer loading and program selection blinks.

Washer load recommendations according to the type of fabric to wash:

- Cotton fabrics: nominal load

- Synthetic fabrics: between 80% & 90% nominal load

- Delicate fabrics: between 35% & 50% nominal load

Do not overload the machine; the door must be able to close easily.

While door is open the icon indicating door open is displayed on the screen.

Close the door The last five executed programs are displayed on the screen.

Select program desired. Use either the multi-function keys or the numerical keyboard.

To start a wash cycle, press the START key on the multi-function keyboard.

4.1. STARTING THE WASHING MACHINE.

MAIN MENU

Open the manual water inlet valves.

Open the manual steam inlet valves (steam heated

washing machines).

Connect the general switch of the washing

machine. Activate the ON switch: position I.

On the screen, the initialising logo will appear and

then the MAIN MENU.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Executing programs 13

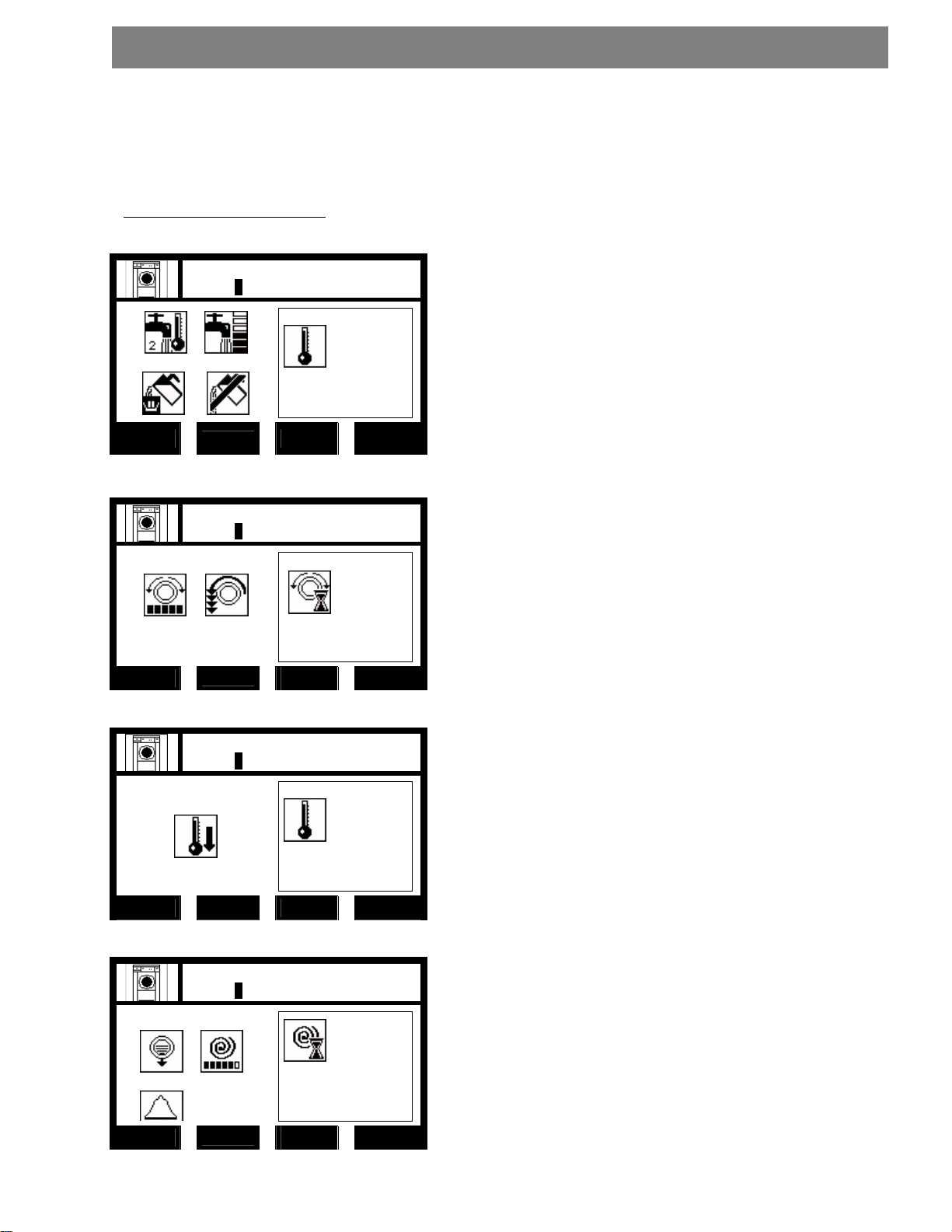

4.3. INFORMATION ABOUT FUNCTIONS. DESCRIPTION OF THE SCREENS

During the course of the wash program, a series of informative screens about functions that the washing

machine is executing will appear on the screen.

Information about functions is displayed through icons. To know the meaning of each icon, consult

Programming a program phase

Below, the most frequent screens and their meaning are shown.

PROG. 36

PHAS. 1 2 3 4 5 6 7 8

i

RH-OFF

PROG. 36

PHAS. 1 2 3 4 5 6 7 8

i

RH-OFF

PROG. 36

PHAS. 1 2 3 4 5 6 7 8

(section 7.3).

16:43

80ºC

65ºC

4

16:55

8 min

+

16:64

Bath management screen

Information about:

Ty pe of water

Bath level

Dosings

Programmed temperature (example: 80ºC)

Bath temperature (example 65ºC)

(Consult the meaning of icons in sections

7.3.1...7.3.5)

Function of the multi-function keyboard: refer to

section 4.4.

Rotation screen

Information about:

Type of rotation

Dr um s peed

Rotation time

(Consult the meaning of icons in sections

7.3.7...7.3.9)

Progressive cooling screen

Information about:

Temperature of the bath

(Consult t he meaning of icons in sections 7.3.10)

i

RH-OFF

PROG. 36

PHAS. 1 2 3 4 5 6 7 8

i

RH-OFF

65ºC

4 min

+

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

4

16:64

Bath drainage screen

Information about:

Drum speed during the bath drainage cycle

Spin time

Buzzer

(Consult the m ea ning of icons in sec t i o ns

7.3.12...7.3.15)

Cod. G522441

Executing programs 14

4.4. MODIFYING THE DURATION OF A PROGRAM

Once a program is started, the user can modify the rotation and/or spin time. This intervention will always be

possible if the time icon associated with the rotation or spin function appears.

Advancing the program and accessing in order to execute the functions on the following screen is also possible.

Intervention keys on the multi-function keyboard

Increase the rotation or spin times

+

Decrease the rotation or spin times

Key for adva ncing to the following func tion screen

44

4.5. INFO SCREEN

Screen that gives diverse information to the user.

This screen is accessed by pressing the key ---i--- on the multi-function keyboard. After a few seconds,

the screen returns to the previous configuration.

Content of information:

Time remaining in the program. Calculation estimated in washing machines without heating systems and

normal water pressure conditions.

Bath level [mm]. Column of bath detected by pressure switch.

Temperature of the bath. Value in centigrade or Fahrenheit according to the washing machine

configuration.

Temperature programmed in the phase. Value in centigrade or Fahrenheit according to the washing

machine configuration.

Level of unbalance (visible during the spin cycle).

Level of power absorbed by the motor.

4.6. CREASE-GUARD STOP. RINSE HOLD FUNCTION

This function allows interrupting the program from advancing before the final spin cycle of the program starts.

During the interruption time, the washing machine stops the movement of the drum, except for short rotation

movements at very large intervals, keeping the drain closed and the bath inside.

Possible interventions:

The function is activated by the keys on the multi-function keyboard.

To activate the function, press the RH-OFF key FOR SOME SECONDS. The key message will change to

RH-ON.

Once program interruption is activated, the CONT key will blink. Press this key in order to resume the

program.

To deactivate the function before the program is interrupted, press the RH-ON key. The key message will

change to RH-OFF.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Executing programs 15

4.7. STOP AND DOOR OPENING MODES

Description of the distinct stop modes of the washing machine.

End of cycle. Stoppage of the washing machine functions after the wash cycle ends. The washing machine

control circuit remains in operation.

Door opening. After the bath has been drained and the drum rotation has ended, the door lock is unblocked

allowing for the opening of the door.

STOP key. Interrupts the wash cycle in operation and opens the drain of the washing machine. The washing

machine control circuit remains in operation.

Door opening. After the bath has been drained and the drum rotation has ended, the door lock is unblocked

allowing for the opening of the door.

NORMAL STOP switch. Switch installed on the front piece of the washing machine. Disconnect the washing

machine control circuit. DOES NOT DISCONNECT the entire electric circuit of the machine.

Door opening:

Models with safety delay by means of thermal device (HS-6013, HS-6017, EH030 and EH040). After a

maximum safety time (at times surpassing 3 minutes), the washing machine lock is unblocked.

Other models : Connect the ON switch again. After a maximum safety time (at times surpassing 3 minutes),

the washing machine lock is unblocked. In NORMAL STOP condition the door is not unblocked.

Emergency stop. Red button with lock located in a visible and accessible place on the washing machine. It

interrupts the operation of the washing machine. Once the switch is unblocked, the wash program resumes

by pressing the PROG key of the multi-function keyboard; the STOP key cancels de program.

Door opening:

Pushing the STOP key and after a maximum safety time (at times surpassing 3 minutes), the washing

machine lock is unblocked.

General stop. General switch located on the rear part of the washing machine. TOTALLY disconnects the

electric supply of the machine. Suitable for maintenance interventions and in situations of prolonged machine

stoppage.

Door opening:

Models with safety delay by means of thermal device (HS-6013, HS-6017, EH030 and EH040). After a

maximum safety time (at times surpassing 3 minutes), the washing machine lock is unblocked.

Other models: In GENERAL STOP condition the door is not unblocked. If the washer's electrical supply can

not be connected, the safety lock will have to be manual unblocked. Refer to chapter 14.

4.8. DELAYED START OF A WASH PROGRAM

Allows the user to program the start time of a wash cycle.

Programming the start time:

Load the washing machine, close the door and select the wash program.

Press the C key on the numerical keyboard. On the screen, the current time will appear. Format of 24 hours.

The ------ ---4--- keys of the multi-function keyboard allow selecting minutes / hours. The value being

selected blinks.

Program the desired starting time on the numerical keyboard and confirm with the START key. The start

time remains on the screen.

The STOP keys or the ------ on the multi-function keyboard cancel the delayed start.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Executing programs 16

4.9. UNBALANCE CONTROL

Before star ting spin, the electronic control of the washing machine checks the correct distribution of the load.

If it detects that the load is not well distributed and that can cause an excessive unbalance during the spin, a new

positioning of the clothes will be carried out.

If there’s still unbalance during the spin of the last phase, the washer can end the washing cycle reducing the

spin speed.

Three unbalance levels, which cause different reactions in the washing machine, have been established.

The unbalance level detected is viewed on the INFO screen when the washing machine executes the spin cycle.

NO unbalance:........ ...allows any spin cycle

LOW unbalance:........allows medium speed spin cycles and high speed spin cycles after a certain number

of attempts.

MEDIUM unbalance:..allo ws medium speed spin cycles; after a certain number of att empts, it reduces the

speed of the high spin cycles

HIGH unbalance:.......does not allow the spin cycle

As a safety feature, a microswitch monitors the movement of the washer suspended group. It is only activated in

cases of extreme unbalance. This device prevents executing spin cycles.

To improve the efficiency of the spin of the washer it’s advisable to:

Load the washing machine up to its nominal value, using the total capacity of the drum.

Load the washer with homogeneous loads

4.10. MACHINES WITH TILT SYSTEM

The TILT SYSTEM is made up of a pneumatic actuators system and an auxiliary electric control that allows the

tilting of the washer forwards and backwards to assist loading and unloading while the door of the machine is

open.

At the same t i me, operatin g the corresponding control devices, the drum rotation at low speed can be started.

With the machine at the loading position, a water inlet can be opened (cold or hot) to soak the dry linen and

reduce its volume. The maximum water level allowed in this situation is limited by program. The water used

during this process will be kept inside the washer when a new cycle is started. To drain the water used during

the loading process, turn off and on again the O/I switch on the control panel of the machine.

To use the TILT system control, the optionalA10 (TILT) board must be installed and approp riately ac tivat ed on

the SETUP menu.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Executing programs 17

ATTENTION!

Because of the washer's tilting movement, there is crushing and shearing hazard between the tilting

elements and the building elements.

To prevent them, please follow these instructions:

Keep away from the rear of the washer during the tilt movement.

The TILT SYSTEM has JUST been designed as a system to facilitate the washer's loading and unloading

operations.

DO NOT USE the washer until all the guards are properly located and adjusted

In particular take special care to the tilt hinge guards.

DO NOT MISLEAD NOR CANCEL THE POSITION DETECTORS located on the machine brackets.

DO NOT MISLEAD NOR CANCEL THE PUSH-BUTTON that activate the drum's rotation with the door

open.

The pressure of the pneumatic circuit specific for tilting is controlled by a pressure regulator located on the

electrical panel, with a fixed adjustment of 5 kg/cm

REGULATOR.

TO AVOID THE RISK OF DRAGGING, NOBODY MUST TOUCH THE LINEN WHILE ACTIVATING THE

DRUM ROTATION DEVICE

Because of the facility of rotating the drum with door open, during loading and unloading operations NEVER

MORE THAN ONE PERSON WILL OPERATE WITH THE MACHINE.

The washer is protected against possible incorrect handling, so machine must be in horizontal position

before selecting a tilting movement or starting a wash program.

To prevent accidents resulting from getting trapped between the door and the opening for loading,

before any tilting movement is started, secure the washing machine’s door by means of the hook

located on its right side.

2

(71 PSI). DO NOT MODIFY NOR MANIPULATE THIS

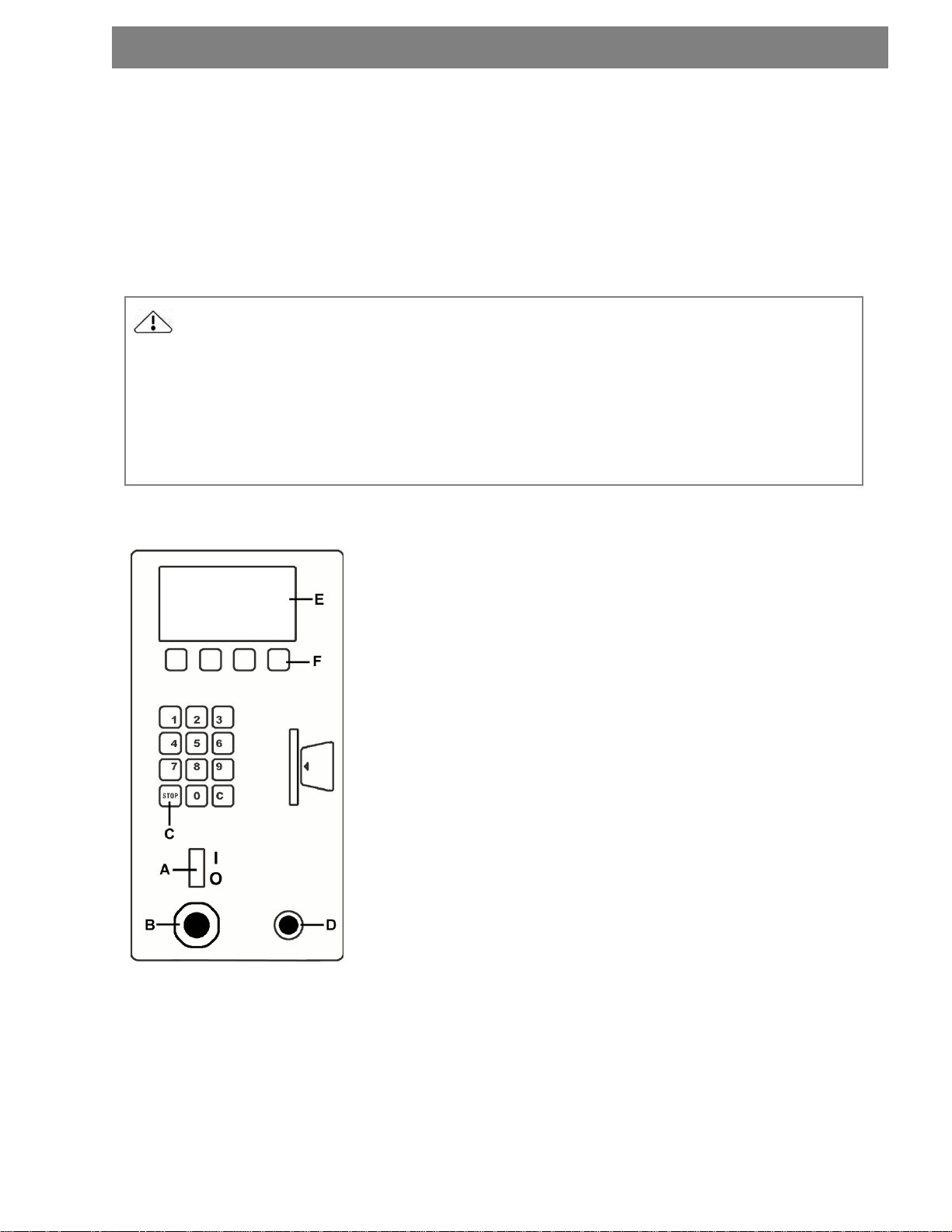

4.10.1. TILT SYSTEM control panel

Control panel devices

ON switch (A): Switch installed on the front piece of the washing

machine.

Emergency stop (B): Red button with lock located in a visible and

accessible place on the washing machine.

STOP key (C): key on the numerical keyboard.

DRUM ROTATION push-button (D): Activates the drum rotation options

of the multi-function keyboard.

Graphics screen (E): It displays the different operations by means of

graphic icons.

Multi-function keyboard (F). It allows executing the TILT system options.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Executing programs 18

4.10.2. Using the TILT SYSTEM

Open the washing machine’s door and secure it using the right side hook. If the main menu window is

displayed, go to PROGRAM EXECUTION MODE.

Execute the desired option by pressing the corresponding key from the multi-function keyboard:

Loading and unloading functions

Loading position. It tilts the washer backwards. When it reaches the final tilt position, the loading

and unloading functions screen can be accessed.

On the multi-function keyboard, press the key corresponding to the icon to tilt the washer to the

loading position.

Unloading position. It tilts the washer forwards. When it reaches the final tilt position, the loading

and unloading functions screen can be accessed.

On the multi-function keyboard, press the key corresponding to the icon to tilt the washer to the

unloading position.

Cold water inlet. Only in loading position.

ON: open valve; OFF: close valve (if OFF is not pressed, the valve closes automatically when it

reaches a preset level).

Water inlet A2 (hot and cold water depending on the washer connections.) Only in loading

position.

ON: open valve; OFF: close valve (if OFF is not pressed, the valve closes automatically when it

reaches a preset level).

Right rotation. Press the DRUM ROTATION push-button on the control board to activate the

multi-function keyboard.

On the multi-function keyboard press the key which corresponds to the picture in the screen. The

drum will turn clockwise at low speed.

Left rotation. Press the DRUM ROTATION push-button on the control board to activate the multifunction keyboard.

On the multi-function keyboard press the key which corresponds to the picture in the screen. The

drum will turn clockwise at low speed.

End of TILT System operation

The STOP key on the alphanumeric keyboard closes the loading and unloading functions

STOP

screen. The return to horizontal position screen is displayed.

If water has been allowed in the loading position, this water will be kept into the washer when a

new cycle is started.

Return to horizontal position.

Press, on the multi-function keyboard, the key corresponding to the icon to tilt washer in

horizontal position. If water has been allowed in the loading position, this water will be kept into

the washer when a new cycle is started.

Close the door. The action of closing the door finishes the loading and unloading state, as well.

This action does not open the drain valve. If water has been allowed in the loading position, this

water will be ke pt in t o th e was h e r when a new cycle is st ar t e d.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Executing programs 19

4.11. MACHINES WITH EASY-LOAD SYSTEM

The EASY-LOAD SYSTEM is made up of an auxiliary electronic control allowing the start of the drum rotation at

low speed to assist loading and unloading while the door of the machine is open.

At the same time, operating the corresponding control devices, a water inlet can be opened (cold or hot) to soak

the dry linen an d reduce its volume. The maximum water l evel allowed in this situation is limi ted by program.

The water used during this process will be kept inside the washer when a new cycle is started. To drain the

water used during the loading process, turn off and on again the O/I switch on the control panel of the machine.

To use the EASY-LOAD system control, the optional A10 (TILT) board must be installed and appropriately

activated on the SETUP menu.

IMPORTANT SAFETY INSTRUCTIONS SPECIFIC FOR EASY-LOAD SYSTEM

The EASY-LOAD SYSTEM has JUST been designed to facilitate the washer's loading and unloading

operations. Therefore:

DO NOT MISLEAD NOR CANCEL THE PUSH-BUTTON that activate the drum's rotation with the door

open.

TO AVOID THE RISK OF DRAGGING, NOBODY MUST TOUCH THE LINEN WHILE ACTIVATING T HE

DRUM ROTATION DEVICE

Because of the facility of rotating the drum with door open, during loading and unloading operations

NEVER MORE THAN ONE PERSON WILL OPERATE WITH THE MACHINE.

4.11.1. EASY-LOAD SYSTEM control panel

Control panel devices

ON switch (A): Switch installed on the front piece of the washing

machine.

Emergency stop (B): Red button with lock located in a visible and

accessible place on the washing machine.

STOP key (C): key on the numerical keyboard.

DRUM ROTATION push-button (D): Activates the drum rotation options

of the multi-function keyboard.

Graphics screen (E): it displays the different operations by means of

graphic icons.

Multi-function keyboard (F). It allows executing the TILT system options.

© Copyright 2009, Alliance Laundry System LLC – DO NOT COPY OR TRANSMIT Rev. 02/0510

Cod. G522441

Loading...

Loading...