Page 1

Washer-Extractor

PHM1401C

PHM1401C

Pocket Hardmount

UniLinc Control

Refer to Page 10 for Model Identification

Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

Part No. F8138801R3

September 2009

Page 2

Page 3

Table of

Contents

Safety Information.............................................................................. 4

Explanation of Safety Messages........................................................... 4

Important Safety Instructions ............................................................... 4

Safety Decals........................................................................................ 6

Operator Safety....................................................................... ..... ......... 7

Safe Operating Environment ................................................................ 7

Environmental Conditions ............................................................... 7

Machine Location ............................................ .... ..... ....................... 8

Input and Output Services................................................................ 8

AC Inverter Drive............................................................................ 9

Introduction......................................................................................... 10

Model Identification ............................................................................. 10

Nameplate Location.............................................................................. 11

Replacement Parts ................................................................................ 11

Customer Service.................................................................................. 11

Preliminary Information.................................................................... 13

About the Control............. .................................................................... 13

Power Failure Recovery................................................................... 13

Communications .............................................................................. 13

Audit Information ........................................................................... 13

IR Communications Menu............................................................... 14

IR Communications Error Menu ..................................................... 14

Restore to Factory Defaults ............................................................ 14

Entering Program Mode................................................................... 15

UniLinc Identification........................................................................ 16

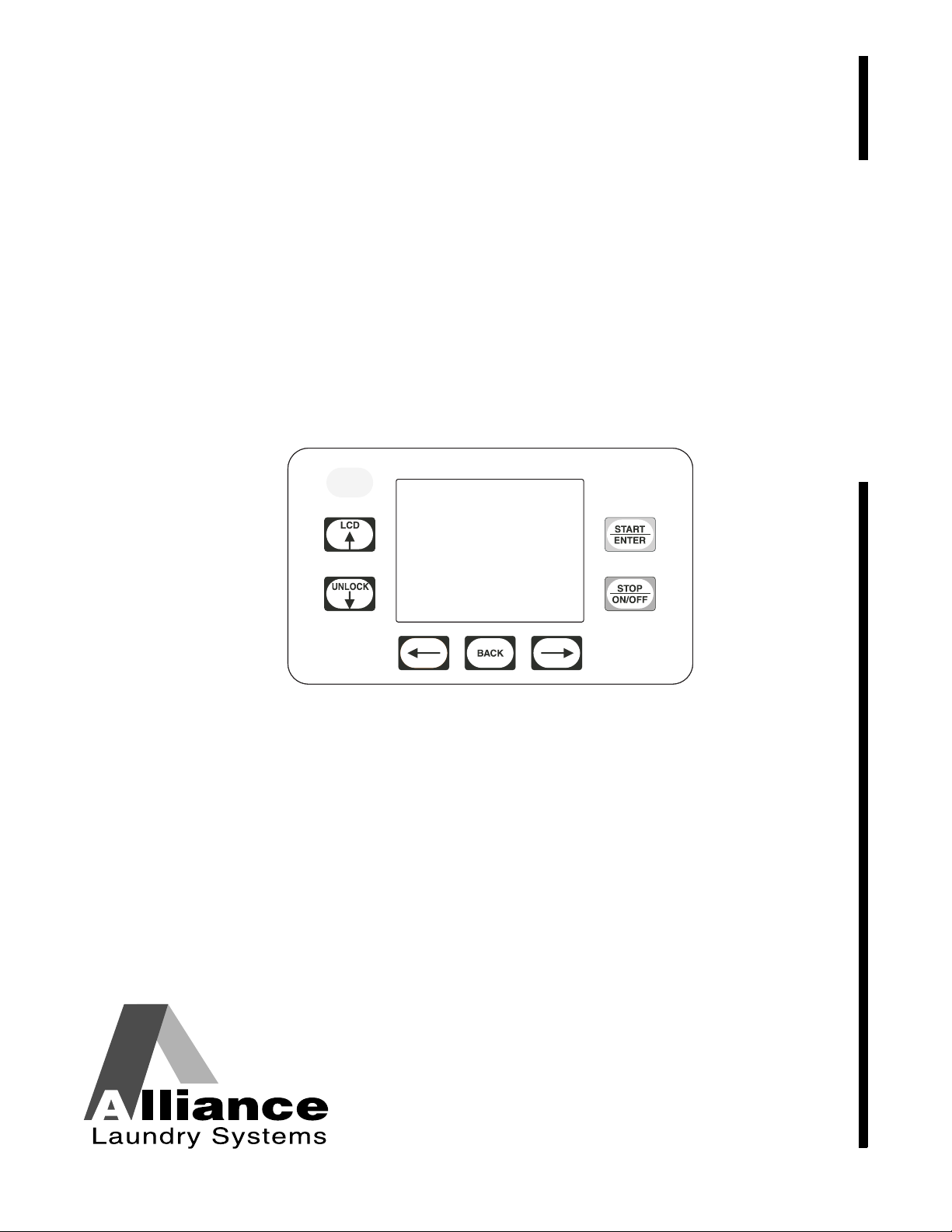

Operational Keypad.............................................................................. 16

Operation Modes .................................................................................. 17

General Modes of Operation............................................................ 17

Power-up Mode................................................................................ 17

Idle Mode......................................................................................... 17

Run Mode......................................................................................... 17

Stop Mode........................................................................................ 17

Error Mode....................................................................................... 17

Delayed Start Countdown Mode...................................................... 17

Communication Mode ..................................................................... 17

Entering Diagnostic Mode From Idle Mode.................................... 17

Machine Cycle Definition and Operation......................................... 18

Machine Cycle Operation..................................................................... 18

Rotation Sensor Equipped Machines.................................................... 18

Delayed Start Feature ........................................................................... 18

Jog Feature UW150 Only..................................................................... 18

Cycle Menu........................................................................................... 18

To Start a Cycle ............................................................................... 19

Run Menu ............................................................................................. 20

Contrast/Backlight Menu...................................................................... 22

Close Door Menu.................................................................................. 22

Lubricate Bearings Menu ............................................................ .... ..... 23

© Copyright 2009, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Run Diagnostic Menu........................................................................... 23

Speed, Temp and Water Level Menu................................................... 24

Cycle Aborted Retry Menu................................................................... 24

Cycle Aborted Fatal Menu.................................................................... 25

Cycle Stopped Menu............................................................................. 25

Delayed Start Menu.............................................................................. 25

Delayed Start Countdown Menu .......................................................... 26

Delayed Start Final Countdown Menu................................................. 26

Menu Navigation................................................................................. 27

The UniLinc................................................. .... ..................................... 27

Menu Navigation on a Single Screen ................................................... 27

Menu Navigation with Parameters ....................................................... 27

Screen to Screen Navigation using the Arrow Keypads....................... 27

Navigation............................................................................................. 27

Display Screen Maps............................................................................ 28

System Menu Map Tree................................................................... 28

Run Menu Map Tree........................................................................ 29

Service Menu Map Tree................................................................... 29

Programming UniLinc ....................................................................... 30

System Menu........................................................................................ 30

Save Changes Menu ............................................................................. 30

Program Menu.................................................................................... 31

Program Menu................................................................................. ..... 31

Modify Cycle........................................................................................ 31

Available Characters........................................................................ 32

Cycle, Segment and Step Programming Flow Diagram....................... 33

Step Menu Navigation ..................................................................... 33

Reuse Fill Step Menu....................................................................... 34

Fill Step Menu.................................................................................. 34

Heater Option................................................................................... 35

Supply A and B Step Menu ............................................................ 35

Agitate Step Menu ........................................................................... 36

Cool Down Step Menu..................................................................... 36

Drain Step Menu ............................................................................. 37

Spray Rinse Extract Step Menu....................................................... 37

Extract Step Menu............................................................................ 38

End of Segment Audio Signal Step Menu....................................... 38

Global Setup........................................................................................ 39

Global Setup Menu............................................................................... 39

Language Menu.................................................................................... 39

Date/Time Menu................................................................................... 39

Water Level Menu................................................................................ 40

Temperature Menu................................................................................ 40

Audio Menu.......................................................................................... 41

Balance Retry Menu............................................................................. 41

Water Management Menu .................................................................... 42

Alarms Program Menu ......................................................................... 44

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 5

Rapid Advance Menu........................................................................... 44

Shakeout Menu..................................................................................... 45

Banners Menu....................................................................................... 45

Factory Defaults Menu......................................................................... 45

Water Level Confirmation Menu.......................................................... 46

Water Temperature Confirmation Menu.............................................. 46

Alarms Confirmation Menu.................................................................. 46

Audio Confirmation Menu ................................................................... 47

Reset All Factory Defaults Confirmation Menu................................... 47

Factory Defaults Second Confirmation Menu...................................... 47

Diagnostic ............................................................................................ 48

Diagnostic Menu................................................................................... 48

Test Menu............................................................................................. 48

Test Cycle ........................................................................................ 49

Factory Valve Purge Menu................................................................... 51

Test Balance Weight Menu .................................................................. 51

Inputs Outputs Menu .............................. ..... ......................................... 52

Water Leak Detection Diagnostic......................................................... 54

Alarms................................................................................................... 55

Machine Identification ....................................................................... 56

Machine Errors ..................................................................................... 56

Door Lock Error .............................................................................. 56

Door Open Error ............................................................................. 56

Drain Alarm Error ........................................................................... 56

Drive Balance Switch Error............................................................. 56

Drive Fault Error.............................................................................. 57

Fill Alarm Error ............................................................................... 57

Frame Balance Switch Error............................................................ 57

Open Temperature Sensor Error ..................................................... 57

Rotation Sensor Error ...................................................................... 57

Shorted Temperature Sensor Error ................................................. 57

SPI Error ............................................ .............................................. 57

Unbalance Error............................................................................... 58

Heat Alarm Error ...................................................... .... ..... .............. 58

Water Level Sensor Error ................................................................ 58

PDA Communications Error............................................................ 58

Water Leak Detection Error............................................................. 58

Slow Drain Detected During A Machine Cycle Error..................... 59

F8138801

Laundry Management........................................................................ 60

Total Number of Machine Cycle Counters........................................... 61

Total Number of Operating Minutes Counters..................................... 61

Last 10 Machine Cycles Rapid Advanced or Stopped ......................... 61

Maintenance........................................................................................ 62

Service Schedule Menu ........................................................................ 62

Daily Menu (Service)....................................................................... 62

Weekly Menu (Service)................................................................... 62

Monthly Menu (Service).................................................................. 63

Quarterly Menu (Service) ................................................................ 63

Cycle Charts........................................................................................ 64

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Explanation of Safety Messages

Precautionary statements (“DANGER,” “W ARNING ,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Important Safety Instructions

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils, drycleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORT ANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable, do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer .

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 7

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer , or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. T o reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

13. Use washer only for its intended purpose,

washing textiles.

14. Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

15. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

16. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

17. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc., or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

18. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

20. Replace worn power cords and/or loose plugs.

21. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

22. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT bypass

the loading door switch by permitting the washer

to operate with the loading door open.

23. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. T o reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

24. Always follow the fabric care instructions

supplied by the textile manufacturer.

25. Never operate the washer with any guards and/or

panels removed.

26. DO NOT operate the washer with missing or

broken parts.

27. DO NOT bypass any safety devices.

28. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a

qualified service person.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Safety Information

This machine must be inst alled, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

WARNING

Ensure that the machine is installed on a

level floor of sufficient strength and that

the recommended clearances for

inspection and maintenance are provided.

Never allow the inspection and

maintenance space to be blocked.

SW020

CAUTION

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

WARNING

Safety Decals

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

To provide person al safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the

manufacturer immediately.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 9

Safety Information

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Never operate the machine with a

bypassed or disconnected balance

system. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

SW039

WARNING

Operator Safety

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locke d

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

Do not bypass any safety devices in the machine.

Safe Operating Environment

Safe operation requires an appropriate operating

environment for both the operator and the machine. If

questions regarding safety arise, contact the

manufacturer immediately.

Environmental Conditions

• Ambient Temperature. Water in the machine will

freeze at temperatures of 32°F (0°C) or below.

Temperatures abov e 120°F (50°C) will result in

more frequent motor overheating and, in some

cases, malfunction or premature damage to solid

state devices that are used in some models.

Special cooling devices may be necessary.

W ater pressure switches are affected by increases

and decreases in temperature. Every 25°F (10°C)

change in temperature will have a 1% effect on

the water level.

• Humidity. Relative humidity above 90% may

cause the machine’s electronics or motors to

malfunction or may trip the ground fault

interrupter. Corrosion problems may occur on

some metal components in the machine.

If the relative humidity is below 30%, belts and

rubber hoses may eventually develop dry rot.

This condition can result in hose leaks, which

may cause safety hazards external to the machine

in conjunction with adjacent electrical

equipment.

• Ventilation. The need for make-up air openings

for such laundry room accessories as dryers,

ironers, water heaters, etc., must be evaluated

periodically . Louvers, screens, or other

separating devices may reduce the available air

opening significantly.

• Radio Frequency Emissions. A filter is available

for machines in installations where floor space is

shared with equipment sensitive to radio

frequency emissions.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

• Elevation. If the machine is to be operated at

elevations of over 3280 feet (1000 m) above sea

level, pay special attention to water levels and

electronic settings (particularly temperature) or

desired results may not be achieved.

• Chemicals. Keep stainless steel surfaces free of

chemical residues.

7

Page 10

Safety Information

Do not place volatile or flammable fluids

in any machine. Do not clean the machine

with volatile or flammable fluids such as

acetone, lacquer thinners, enamel

reducers, carbon tetrachloride, gasoline,

benzene, naptha, etc. Doing so could

result in serious personal injury and/or

damage to the machine.

SW002

DANGER

Replace all panels that are removed to

perform service and maintenance

procedures. Do not operate the machine

with missing guards or with broken or

missing parts. Do not bypass any safety

devices.

SW019

CAUTION

Ensure that a ground wire from a proven

earth ground is connected to the ground

lug near the input power block on this

machine. Without proper grounding,

personal injury from electric shock could

occur and machine malfunctions may be

evident.

SW008

WARNING

• Water Damage. Do not spray the machine with

water. Short circuiting and serious damage may

result. Repair immediately all seepage due to

worn or damaged gaskets, etc.

Machine Location

• Foundation. The concrete floor must be of

sufficient strength and thickness to handle the

floor loads generated by the high extract speeds

of the machine. Refer to Installation manual.

• Service/Maintenance Space. Provide sufficient

space to allow comfortable performance of

service procedures and routine preventive

maintenance.

Consult installation instructions for specific details.

Input and Output Services

• Water Pressure. Best performance will be

realized if water is provided at a pressure of

30 – 80 psi (2.0 – 5.4 bar). Although the machine

will function properly at lower pressure,

increased fill times will occur. Water pressure

higher than 100 psi (6.7 bar) may result in

damage to machine plumbing. Component

failure(s) and personal injury could result.

• Steam Heat (Optional) Pressure. Best

performance will be realized if steam is provided

at a pressure of 30 – 80 psi (2.0 – 5.4 bar). Steam

pressure higher than 125 psi (8.5 bar) may result

in damage to steam components and may cause

personal injury.

For machines equipped with optional steam heat,

install piping in accordance with approved

commercial steam practices. Failure to install the

supplied steam filter may void the warranty.

• Drainage System. Provide drain lines or troughs

large enough to accommodate the total number of

gallons that could be dumped if all machines on

the site drained at the same time from the highest

attainable level. If troughs are used, they should

be covered to support light foot traffic.

• Power. For personal safety and for proper

operation, the machine must be grounded in

accordance with state and local codes. The

ground connection must be to a proven earth

ground, not to conduit or water pipes. Do not use

fuses in place of the circuit breaker. An easyaccess cutoff switch should also be provided.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Always disconnect power and water supplies before a

service technician performs any service procedure.

Where applicable, steam and/or compressed air

supplies should also be disconnected before service is

performed.

F8138801

Page 11

Safety Information

AC Inverter Drive

Machines equipped with the AC inverter drive require

special attention with regard to the operating

environment.

• An especially dusty or linty environment will

require more frequent cleaning of the AC inverter

drive cooling fan filter and of the AC inverter

drive itself.

• Power line fluctuations from sources such as

uninterruptible power supplies (UPS) can

adversely affect machines equipped with the AC

inverter drive. Proper suppression devices should

be utilized on the incoming power to the machine

to avoid problems.

• A clean power supply free from voltage spikes

and surges is absolutely essential for machines

equipped with the AC inverter drive. Nonlinear

inconsistencies (peaks and valleys) in the power

supply can cause the AC inverter drive to

generate nuisance errors.

• Sufficient space to perform service procedures

and routine preventive maintenance is especially

important for machines equipped with the AC

inverter drive.

This manual is designed as a guide to operating and

maintaining the Pocket Hardmount washer-extractor

equipped with the AC inverter drive.

NOTE: All information, illustrations, and

specifications contained in this manual are based

on the latest product information available at the

time of printing. We reserve the right to make

changes at any time without notice.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Introduction

Model Identification

Information in this manual is applicable to these

models:

UW35TV UWL060T3M UWN060T3M UWU060T3M

UW60TV UWL060T3V UWN060T3V UWU060T3V

UW80TV UWL080T3V UWN080T3V UWU080T3V

UW100TV UWL100T3V UWN100T3V UWU100T3V

UW125TV UWL125T3V UWN125T3V UWU125T3V

UW150TV UWL150T3V UWN150T3V UWU150T3V

UWL035T3V UWN035T3V UWU035T3V

UWL060T3L UWN060T3L UWU060T3L

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 13

Introduction

2

1

EXAMPLE OF MACHINE NAMEPLATE LOCATION

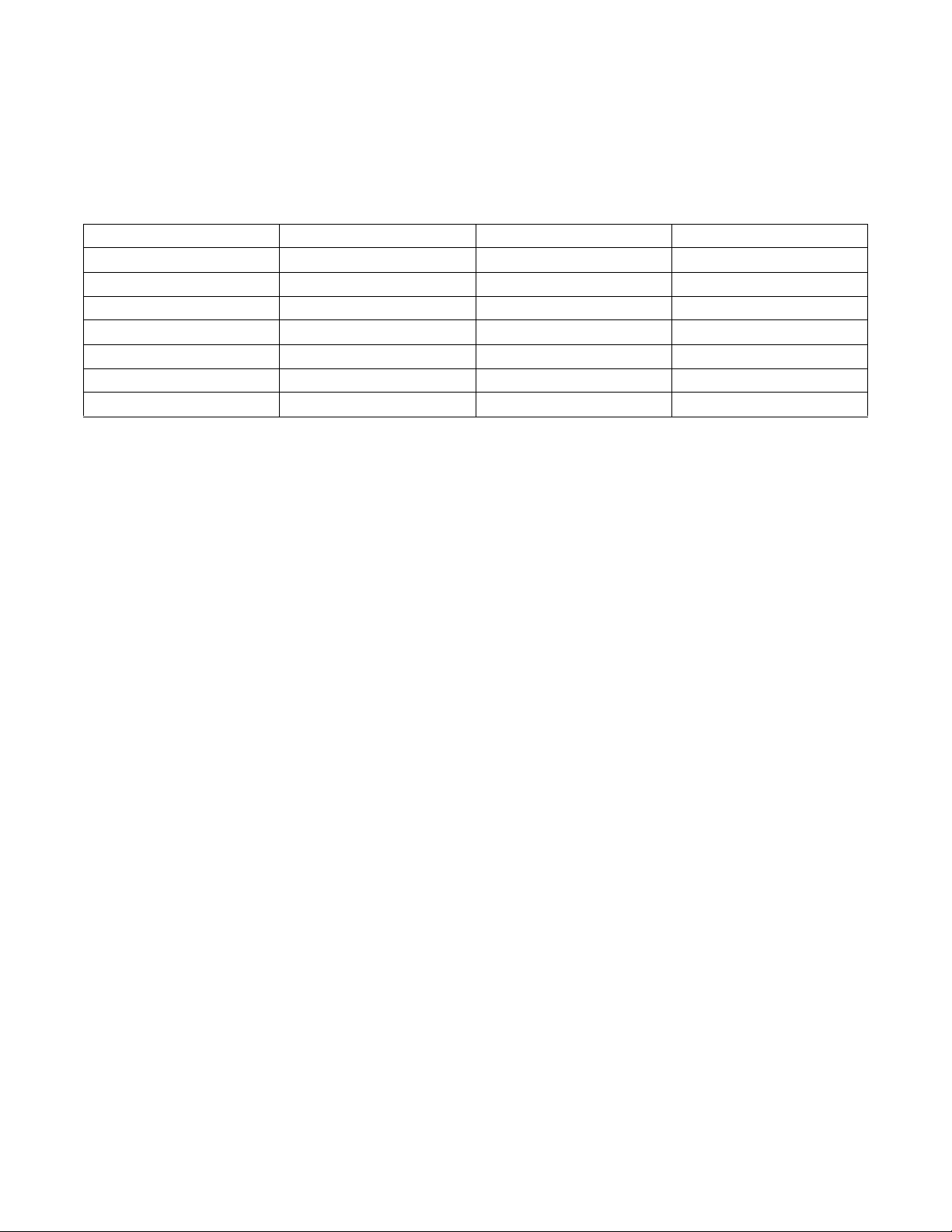

Nameplate Location

The nameplate is located on the back of the machine

and is programmed in the UniLinc Control. To access

Machine ID through the control:

1. Press and hold , then , then

keypads at the same time.

2. Press the keypad until Diagnostic is

highlighted.

3. Press the keypad.

4. Press the keypad until Machine ID is

highlighted.

5. Press the keypad.

Always provide the machine’s serial number and

model number when ordering parts or when seeking

technical assistance. Refer to Figure 1.

Replacement Parts

If literature or replacement parts are required, contact

the source from which the washer-extractor was

purchased or contact Alliance Laundry Systems LLC

at (920) 748-3950 for the name of the nearest

authorized parts distributor. A parts manual may be

ordered by returning the reply card provided with each

washer-extractor.

Customer Service

For technical assistance, contact your local distributor

or call:

(920) 748-3121

Ripon, Wisconsin

A record of each washer-extractor is on file with the

manufacturer. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance. Refer to Figure 1.

1 In UniLinc Control

2 At back of machine

F8138801

Figure 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

PHM1400C

11

Page 14

Introduction

PHM1284R

UWN060T3VXU1001

00000000000

200 – 240

319

HzHz PhasePhase

Supply Water: Supply Water: BARBAR

Number of wires :Number of wires : FLA :FLA : ampsamps

30

Circuit Breaker Size :Circuit Breaker Size : ampsamps

50-60 3

Serial No.Serial No.

Model No.Model No.

VoltageVoltage

60

30 - 85 psi, 2 - 5.7

Max. Load :Max. Load :

Schematic :Schematic :

KGKG

27

LBLB

EXAMPLE OF NAMEPLATE

UW

060

T

V

Q

U1

0001

UW

N

060

T

3

V

X

U1

0

01

Model Number Familiarization Guide - Models through May 3

Sample Model Number: UW060TVQU10001

Model Number Prefix

Washer-Extractor Capacity (60 pounds dry weight of laundry)

Type of Electrical Control T = UniLinc Computer

Washer-Extractor Speed Capabilities V = 8 Speeds

Electrical Characteristics

Design Series

Option Identification (varies from machine to machine)

Model Number Familiarization Guide - Models starting May 4th, 2009

Sample Model Number: UWN060T3VXU1001

Model Number Prefix

Market Approvals

Washer-Extractor Capacity (60 pounds dry weight of laundry)

Type of Electrical Control T = UniLinc Computer

Spray/Dispenser Feature

Washer-Extractor Speed Capabilities V = 8 Speeds

Electrical Characteristics

Design Series

Heat Feature

Option Identification (varies from machine to machine)

rd

, 2009

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

PHM1284R

Figure 2

F8138801

Page 15

Preliminary Information

About the Control

The UniLinc control on the washer-extractor is an

advanced, graphical, programmable computer that lets

the owner control most machine features by

interacting with the control.

UniLinc allows the owner to program custom cycles,

run diagnostic cycles and retrieve audit, error and

bearing information.

Washer-extractors shipped from the factory have

default cycles and wash temperature settings built in.

The owner can change the default cycle, or any cycle.

IMPORTANT: It is extremely important that the

washer-extractor has a positive ground and that all

mechanical and electrical connections are made

before applying power to or operating the washerextractor.

Power Failure Recovery

If a cycle is in progress when the power fails, and if

the power outage lasts three or more seconds, the cycle

is lost and cannot be resumed when power recovers. If

the power outage lasts less than three seconds, the

control will resume the cycle when the power

recovers.

Audit Information

The control collects and stores audit information,

which can be accessed with a PDA. Refer to the

following list for available audit information with a

PDA. Refer to UniLinc PC and PDA Application

User Instructions.

• Total Number of Individual Cycle Counters

• Last 25 Machine Cycles

• Service History

• Machine Errors Audit Data

• Communication Audit Data

• Re-Programming Audit Data

• Power Failures Audit Data

• Average Fill Time Audit Data

• Average Drain Time Audit Data

• Power Failure Audit Data

The PDA can receive audit and program data from the

control, and send programming data and diagnostic

commands to the control. Refer to UniLinc PC and

PDA Application User Instructions for additional

information on using a PDA.

Communications

The control has the ability to communicate with a

PDA or a laptop with an IrDA device running the

UniLinc software. Devices such as PDAs and laptops

that are IrDA capable (able to transmit information to

machine) that have been tested and approved for use

with the UniLinc software can be used as a tool for

managing the machine.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Preliminary Information

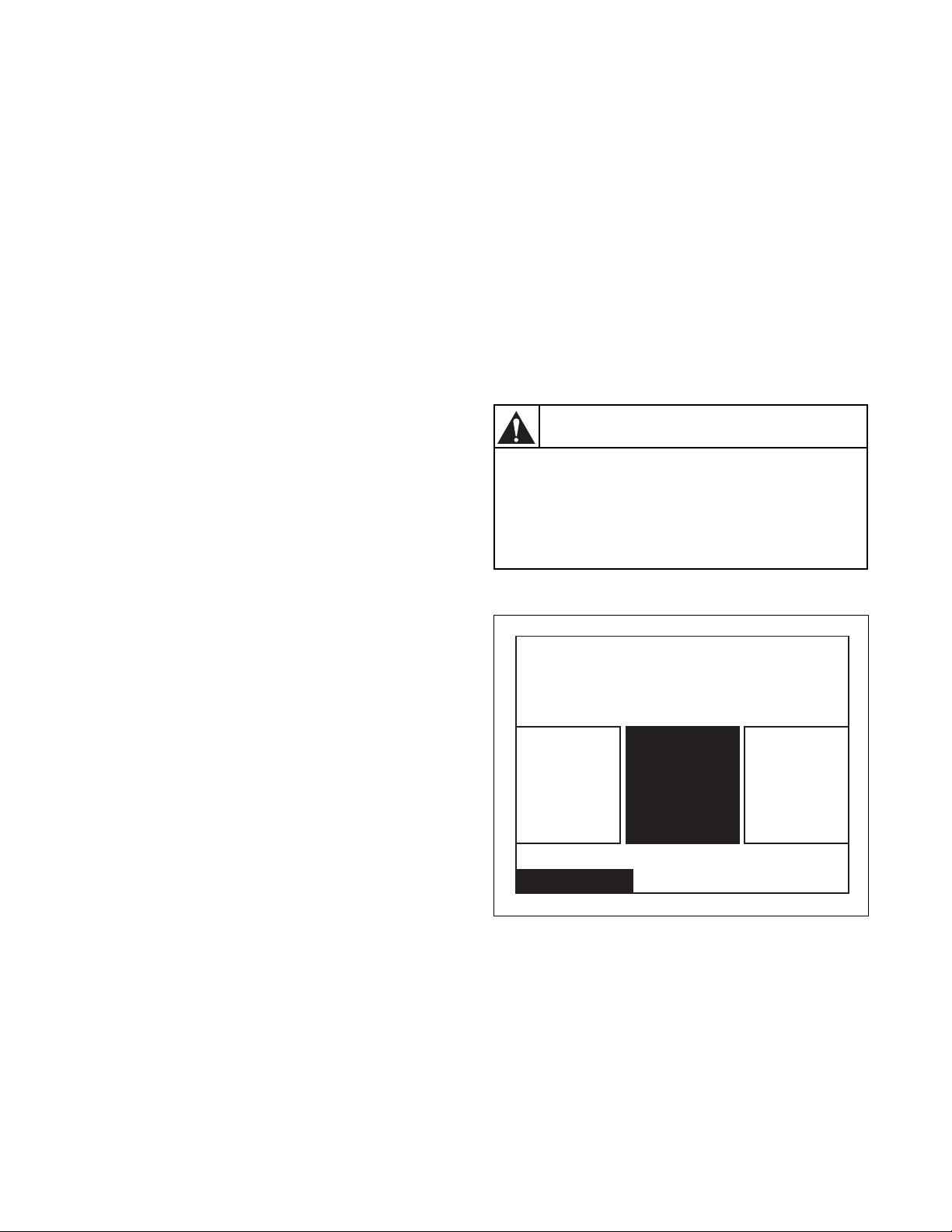

Invalid Data

IR Communications Menu

PHM1003R

Figure 3

The IR Communications Menu displays while the

control is communicating with a PDA. The control

will jump back to the previous page when the

communication is complete.

IR Communications Error Menu

Restore to Factory Defaults

When the user selects Restore All Cycles And Global

Settings To Factory-Defaults, the control resets all of

the default values. The control also resets Machine

Cycles #1 through #41. The control will also reset the

following to factory-defaults:

Default Washer-Extractor Settings

Language = English

Maximum Balance Retries = 3

Water Reuse = Disabled

Rapid Advance = Enabled

Water Recirculation = Disabled

External Dispenser Pause = Disabled

Shakeout = 40 seconds

Banner # 1 = Blank

Banner # 2 = Blank

Daylight Saving = Enabled

Water Levels

PHM1004N

Figure 4

The IR Communications Error Menu displays after the

control had an error communicating with a PDA. The

control will return to previous page after 3 seconds.

High = 27

Medium = 15

Low = 3

Water Temperature

Hot = 140 F

Warm = 100 F

Cold = 35 F

Cooldown = 110 F

Temperature Controlled Fill = Disabled

Audio Signal External Signal = Disabled

Keypad Signal (beep) = Enabled

End of Cycle / Segment Sound = Enabled Low, 5

second duration

Alarms

Fill = 5 minutes

Drain = 2 minutes

Heat = 1 hour 30 minutes

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 17

*Manual Programming = Enabled

*If manual programming is disabled, programmin g

changes to UniLinc can only be made with an external

communication device. Refer to UniLinc PC and

PDA Applications User Instructions.

Refer to Factory Defaults, Menu section for

information on Restoring Factory Defaults.

Entering Program Mode

1. Press and hold , then , then to

enter the System Menu. Select Program to enter

programming options.

Preliminary Information

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

UniLinc Identification

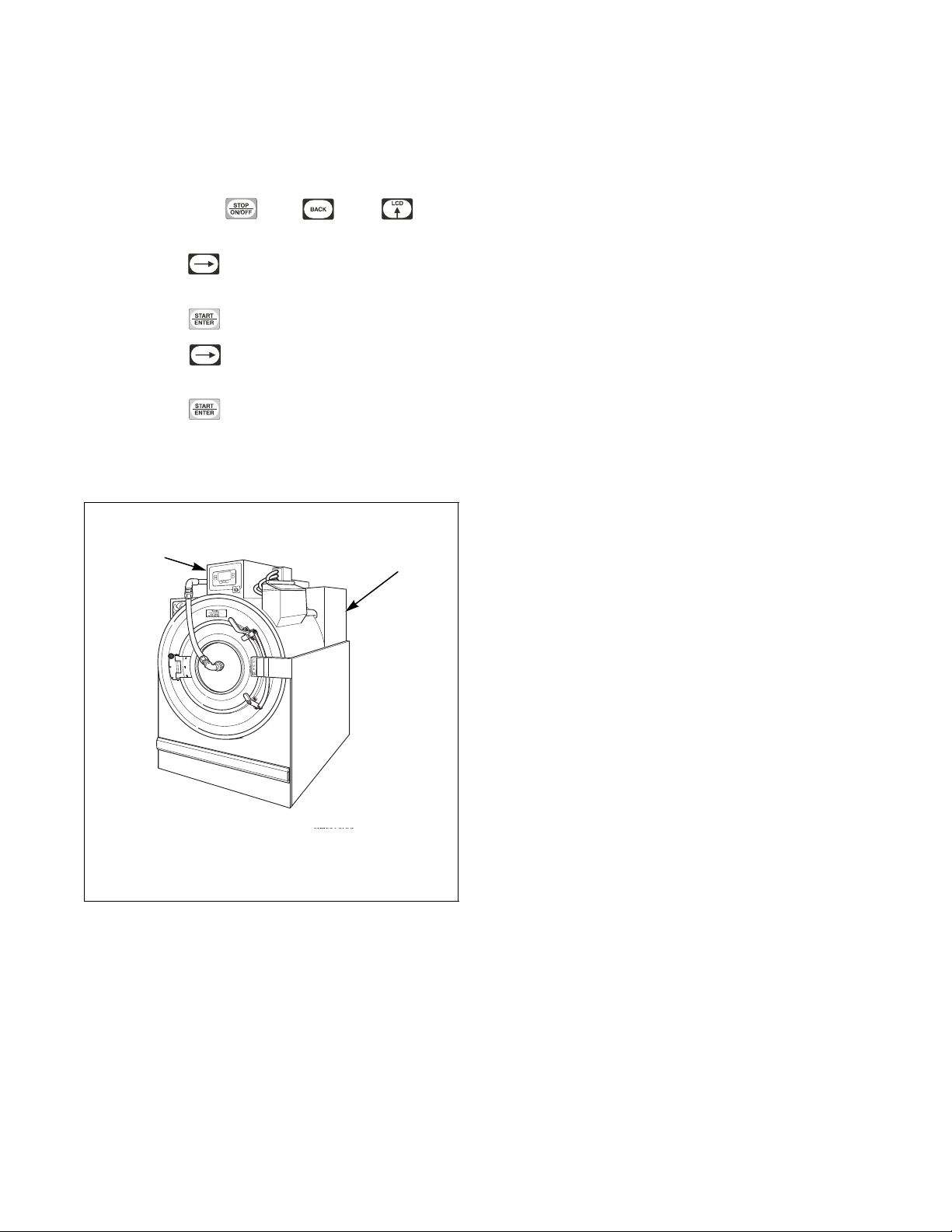

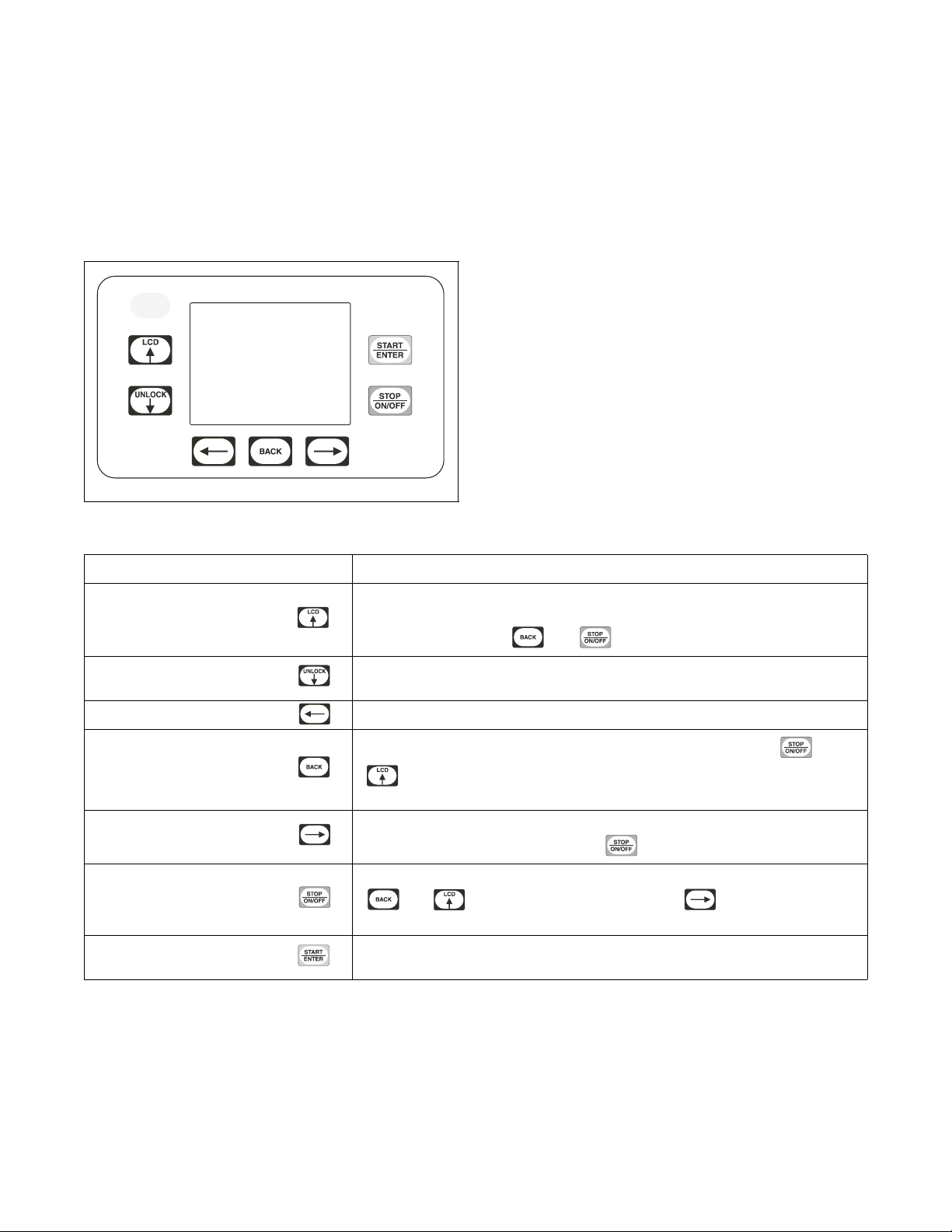

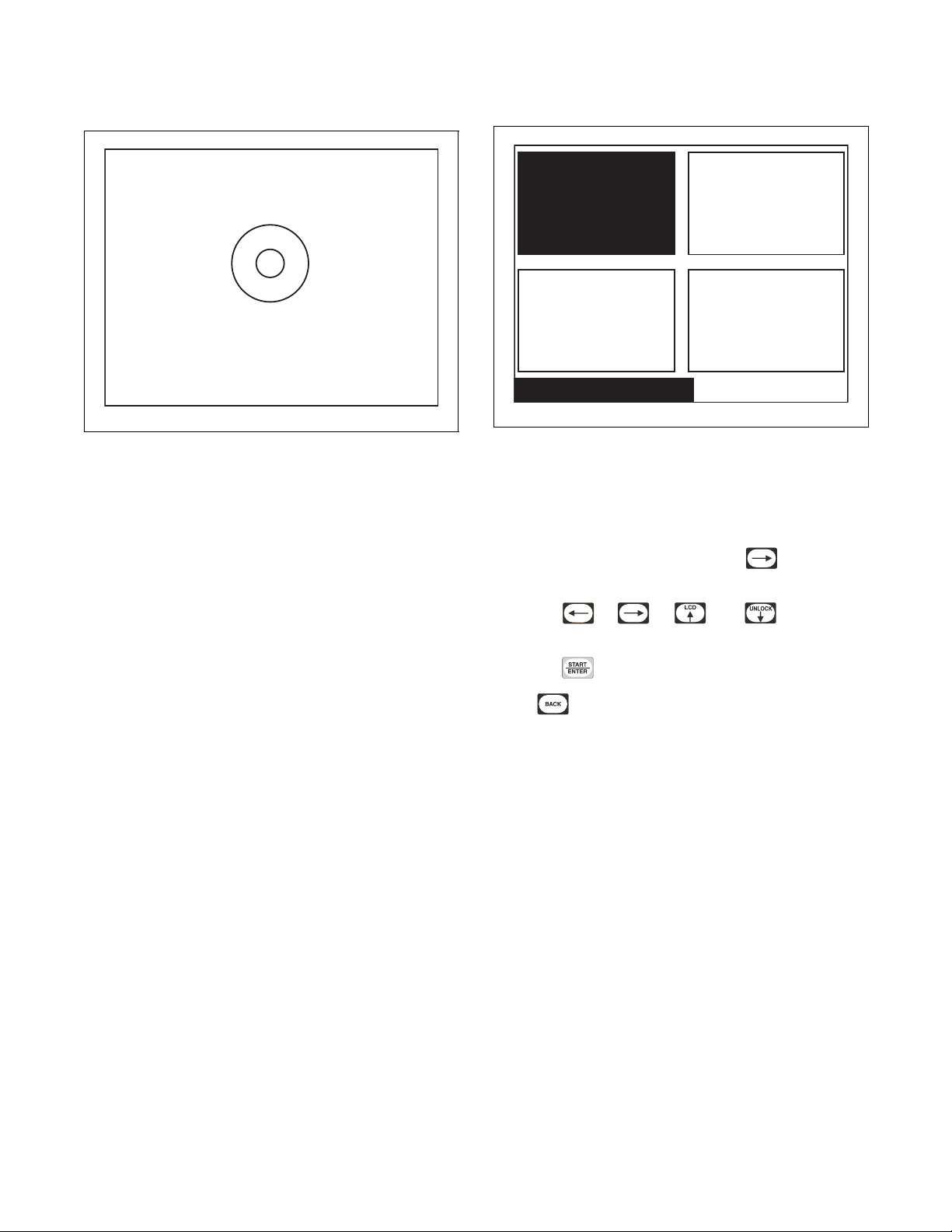

Operational Keypad

The control includes seven keypads. These functions

are available to the operator and are intended to

control and manage operation of the washer-extractor.

Refer to Figure 5 and Table 1.

PHM1401C

Figure 5

Keypad Description

LCD/UP ARROW

UNLOCK/DOWN ARROW

LEFT ARROW

BACK

RIGHT ARROW

STOP/ON/OFF

START/ENTER

Press to move the cursor on display to edit programming values. Also, press

while in Cycle Menu or Run Menu to change to the

Menu. Also, press with and to enter System Menu.

Press to move the cursor on display, edit programming values, or unlock door.

The door can only be unlocked while the machine is idle.

Press to move cursor on display.

Press to move back to the previous display menu. Also, press with and

to enter System Menu. Also, back from the Cycle Menu to enter the

Service Schedule Menu.

Press to move cursor on display. Press while running a cycle to get to Run

Diagnostic Menu. Press and hold with to enter Delayed Start Menu.

Press to stop and abort a machine cycle during Run Mode. Also press with

and to enter System Menu. Press with to enter Delayed Start

Menu.

Press to start or rapid advance a machine cycle during Run Mode. Also, press to

save edited programming values when used in programming menus.

Table 1

Contrast Adjust/Backlight

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 19

UniLinc Identificatio n

Operation Modes

General Modes of Operation

In each mode of operation, the user may press keyp ads

or communicate with the control to change the

displayed menu.

Power-up Mode

The control enters this mode at power-up. After the

control completes operation in the Power-up Mode it

will enter Idle Mode. The display is blank during

Power-up Mode.

Idle Mode

Control is ready for operation in Idle Mode. Control

can display different menus depending on user input

(keypad press, opening or closing the loading door, or

PDA communication). If there is no user input for one

minute, control will turn off the LCD backlight.

Control will light when there is user input. If there is

no user input for 10 minutes, display will go blank.

If control is in Idle Mode, Cycle Menu is displayed,

loading door closed, and the keypad is pressed,

control will enter Run Mode.

Run Mode

Control enters Run Mode during a cycle. Display

shows machine cycle time remaining, the colon

flashing one second on/one second off indicating that

the cycle time is counting down, and the display will

indicate the current cycle step. Loading door is closed

and locked during Run Mode. Press keypad to

end cycle and enter Stop Mode. Press keypad to

Rapid Advance to the next cycle step (if the Rapid

Advance feature is enabled. The Rapid Advance

feature is enabled by default.) Control enters Error

Mode if loading door unlocks or opens.

Stop Mode

If keypad is pressed before cycle ends, control

enters Stop Mode and performs the following steps:

• Displays a hourglass.

• Turns off all outputs.

• Verifies water is drained.

• Verifies motor is stopped by either rotation

sensor or time.

• The control will display the unlock door screen.

The user must unlock and open the door to return

to the Cycle Menu.

Error Mode

This mode will be entered to display all alarms and

machine errors.

Delayed Start Countdown Mode

Delayed Start Countdown Menu is entered after

delayed start is activated. The display will show the

hours and minutes remaining until the machine will

automatically start.

The Delayed Start Final Countdown Menu is entered

during the last sixty seconds before the control is

automatically started. The keypad will start the

selected cycle immediately. Press to return to the

Cycle Menu.

Communication Mode

This mode is entered whenever the control is

communicating with a PDA. Refer to UniLinc PC and

PDA Applications User Instructions.

Entering Diagnostic Mode From Idle Mode

When entered from the Idle Mode, the control will be

running a test selected by the user via keypad presses

or communication with a device. The diagnostic tests

available from the Idle Mode are the Test Cycle, Test

Balance Weight, and Inputs Outputs Menus.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Machine Cycle Definition and Operation

WARNING

To avoid personal injury, do NOT reach

into the basket while it is rotating. Keep

all personnel at a safe distance from the

machine while using the basket Jog

Feature.

W641

For Technical Service

Distributor ABC

1-800-555-5555

Cycle41:

Supply Set

Up

Cycle02:

Towels White

Cycle01:

Towels

White

Bleach

Cycle Menu

There are 41 machine cycles which can be selected

and run. Machine cycles can be modified or made

“unavailable” by manually editing them in Modify

Cycle Menu or by using the PDA to download a

modified machine cycle into the control. Machine

cycles cannot be deleted, but can be made

“unavailable” so that they are not visible from the

Cycle Menu. New machine cycles cannot be created,

but existing machine cycles that have been edited to be

“unavailable” may be re-edited to be available again.

Machine Cycle Operation

When a cycle is run, the control runs the cycle

segment by segment and step by step in a sequence.

The first segment can be programmed to “Off”,

“Prewash”, “Wash” or “Rinse”. If the segment is

programmed to “Off”, control skips to the next

segment. If the segment is not programmed to “Off”,

the first segment step (Reuse Fill step) is examined to

see if it is programmed on. If the segment step is

programmed on, it is executed and the next step

follows until the segment is complete. Any segment

steps programmed to “Off” are skipped.

At the start of a machine cycle, the control displays a

Total Remaining Cycle time. This time is taken from

the audit data for this cycle where there is stored an

average time elapsed for the last three of these cycles

that had been completed. The Total Remaining Cycle

Time begins to count down as soon as the cycle is

started. Since there will be differences between the

average elapsed cycle time and the actual elapsed

cycle time, the T otal Remaining Cycle T ime displ ayed

is corrected at the start of the cycle’s final enabled step

that has programmed time duration.

Delayed Start Feature

The user can select a machine cycle to run at a later

time. Refer to Delayed Start Menu Section.

Jog Feature UW150 Only

The user can use Jog Feature from the Cycle Menu in

Idle Mode, while the machine door is open. When the

control detects that the jog buttons are pressed, the

control will wake up and start a five second sound,

turn the beeper on and off for five seconds and then the

motor will turn in reverse direction at a reduced speed.

Cycle Menu

Rotation Sensor Equipped

Machines

On machines equipped with rotation sensors and a

rotation sensor error has not occurred, the control

monitors the rotation sensor. The control will never

send a new motor output which would reverse the

motor direction or force the motor to run at a lower

speed if the rotation sensor input indicates that the

machine basket is rotating. The control will wait for

the rotation to stop before sending the motor

command.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

PHM702N

Figure 6

The Cycle Menu is the first menu displayed by the

control at power-up. The Cycle Menu allows the user

to select one of the 41 machine cycles. Machine cycles

that are turned off will not be displayed in the Cycle

Menu. As a default, the last run cycle will be displayed

in the center, highlighted position. The factory default

cycle will be Cycle01.

F8138801

Page 21

Machine Cycle Definition and Operation

To Start a Cycle

1. Press the or keypad to change cycles.

2. Press the keypad to move the cycle in the

rightmost menu box to the center, highlighted

position.

3. Press the keypad to move the cycle in the

leftmost menu box to the center, highlighted

position.

4. Moving the and keypads allows the

Cycle Menu to scroll through the center,

highlighted position.

5. Press to start selected cycle.

NOTE: Press and hold or keypad to

make highlighted area move rapidly.

NOTE: If door is not closed when the keypad

is pressed, display will jump to the Close Door

Menu.

NOTE: If the machine has operated over 200 hours

and the Lubricate Bearings has not been reset from

the System Menu the Global Settings, a reminder

screen will pop up. The Lubricate Bearings Menu

will be display for five seconds and the Cycle Menu

will display for five seconds. This will occur until

the Bearing Timer is reset in the System Menu. The

Lubricate Bearings Menu will only be shown

during the Cycle Menu.

Press any keypad to clear the menu and enter Cycle

Menu.

Optional settings are performed by either pressing a

keypad or by a combination of keypad presses:

• Press the keypad to jump control to the

Contrast Adjust/Backlight Menu.

• Press the keypad to enter the Service

Schedule Menu.

• Press and hold then to enter Delayed

Start Menu.

• Press and hold then then to

enter the System Menu.

• Press the keypad on the Cycle Menu to

unlock door.

A Banner is displayed above the Cycle Selections in

the Cycle Menu. If Banner 1 and Banner 2 are

programmed, Banner 1 displays for ten (10) seconds

and Banner 2 displays for ten (10) seconds. If only one

Banner is programmed it will be the only one shown.

Refer to Banner Menu Section.

During communication with the PDA, all menus enter

IR Communications Menu.

Every night at midnight the control will enter Service

Schedule Menu if the machine is in idle mode on the

Cycle Menu.

When a keypad is pressed or the door is opened or an

IR communication takes place the control will turn the

LCD contrast on and the backlight back on (if

programmed).

Control will also enter specific service sub-menu for

that day.

Quarterly Menu displays on the first day of the month

for January, April, July and October.

Monthly Menu displays on all other first days of the

month.

Weekly Menu displays on a Monday not on the first

day of the month. All other days the control will

display the Daily Menu.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Machine Cycle Definition and Operation

Cycle01: Towels White Bleach

Segment06: Rinse

Extract

Extract Speed

Very High

Run Menu

PHM1007R

05:30

Cycle01: Towels White Bleach

Segment01: Wash

Drain

Run Menu

PHM1005R

35:02

HOT LOW

Cycle01: Towels White Bleach

Segment01: Wash

Agitate

Agitate Type

18F/3P/18R

Run Menu

PHM1006R

38:14

HOT LOW

Cycle01: Towels White Bleach

Segment01: Wash

Fill

Run Menu

PHM1071R

41:43

ESI

SI

S2 S3 S4 S5

ES2

ES3

ES4

ES5

ES6

ES7

ES8

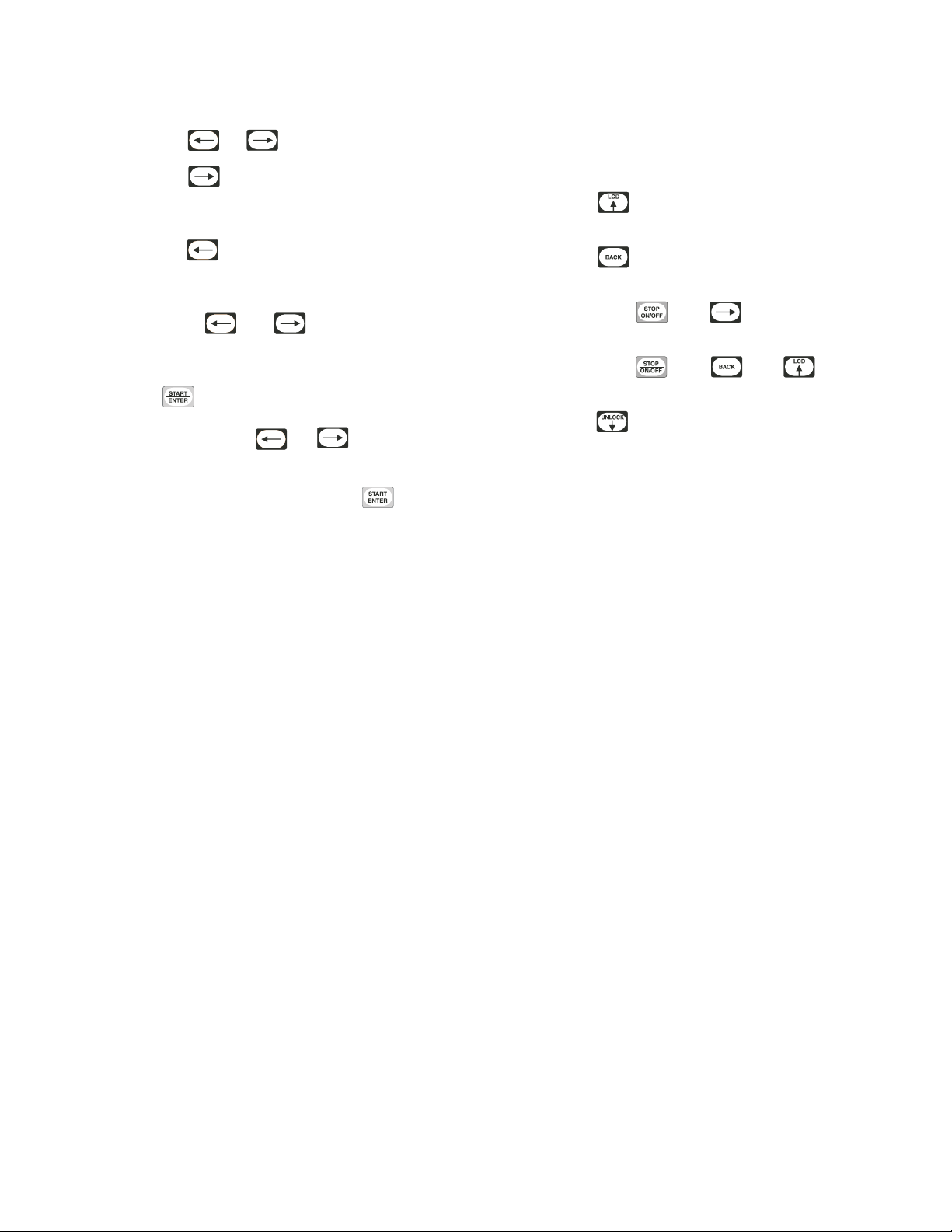

PHM1071R PHM1006R

PHM1005R PHM1007R

Run Menu

Run Menu provides cycle, segment, and step

information while the machine is operating. Refer to

Figure 7.

Supplies are only shown during the fill and supply

steps.

During the agitate steps the type of agitation is shown.

During the extract steps, the extraction speed displays.

20

Figure 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 23

Machine Cycle Definition and Operation

HOT LOW

Cycle01: Towels White Bleach

Segment01: Wash

Fill

Run Menu

PHM1071R

41:43

ESI

SI

S2 S3 S4 S5

ES2

ES3

ES4

ES5

ES6

ES7

ES8

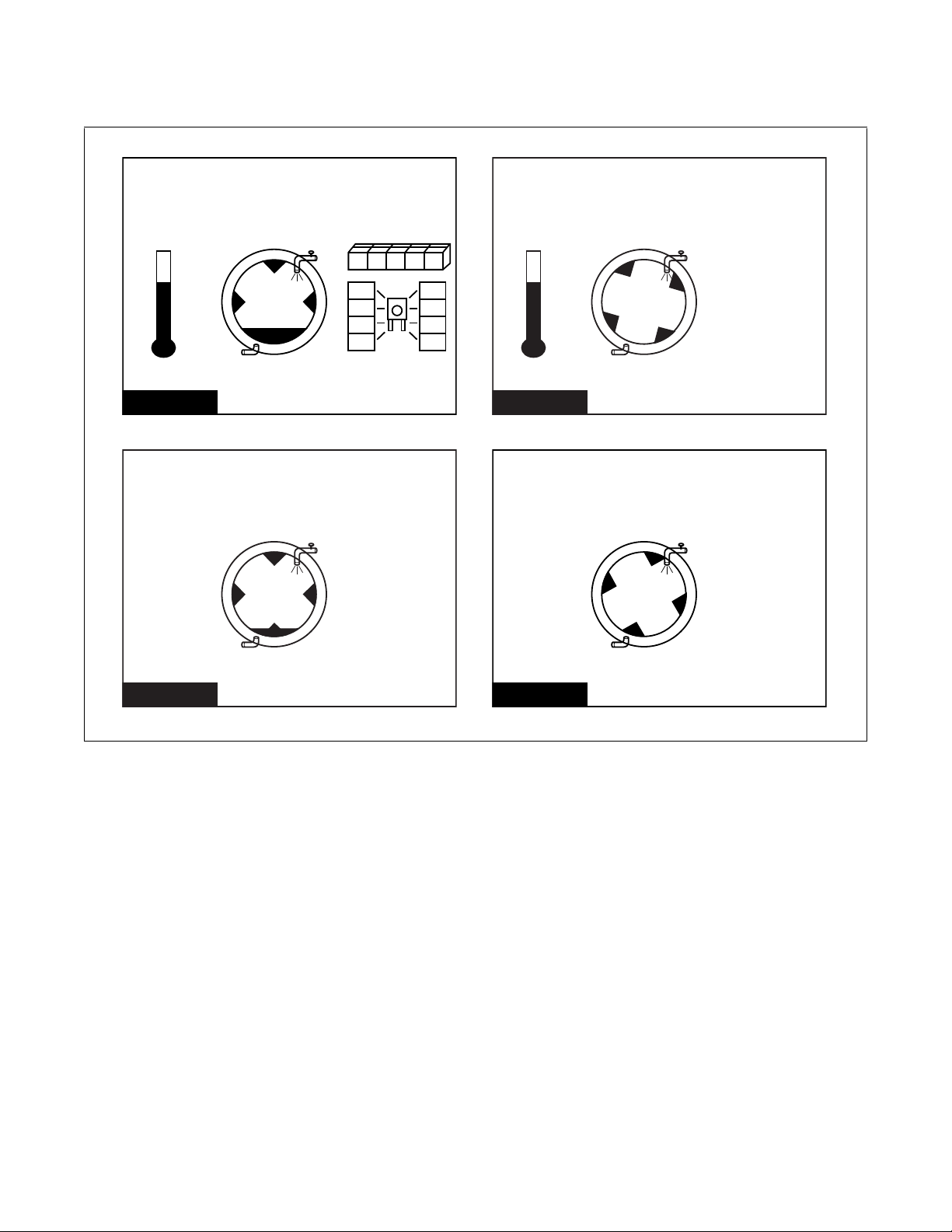

1

2

3

4

5

6

7

8

9

10

11

PHM1071N

1 Cycle Name 6 Water Level – OVFL, HIGH, MED, LOW

2 Segment Name 7 Water Level – Graphical Value/Action graphic

3 Step Name 8 Internal Supply Indicators

4 Programmed Water Temperature - 9 External Supply Indicators

HOT, WARM, COLD or actual temperature 10 Run Screen Indicator

5 Actual Temperature – range of 32-212F 11 Countdown Timer

The Run Menu cannot be navigated by manipulating

the arrow keypads. Press keypad to advance the

cycle one step. The Control cannot advance into a

Spray Rinse Extract or an Extract Cycle Step.

Advancing the steps within a cycle also depends on

whether the option has been toggled on or off in the

Rapid Advance Menu.

The Run menus include the Run Menu, the Run

Diagnostic Menu, and the various sub-screens of the

Run Diagnostic Menu. Press the keypad to jump

to the Run Diagnostic Menu.

Press the keypad to stop the cycle in any of the

Run menus.

When the keypad is pressed, the display will

jump to the Cycle Stopped Menu showing an

hourglass.

Figure 8

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Machine Cycle Definition and Operation

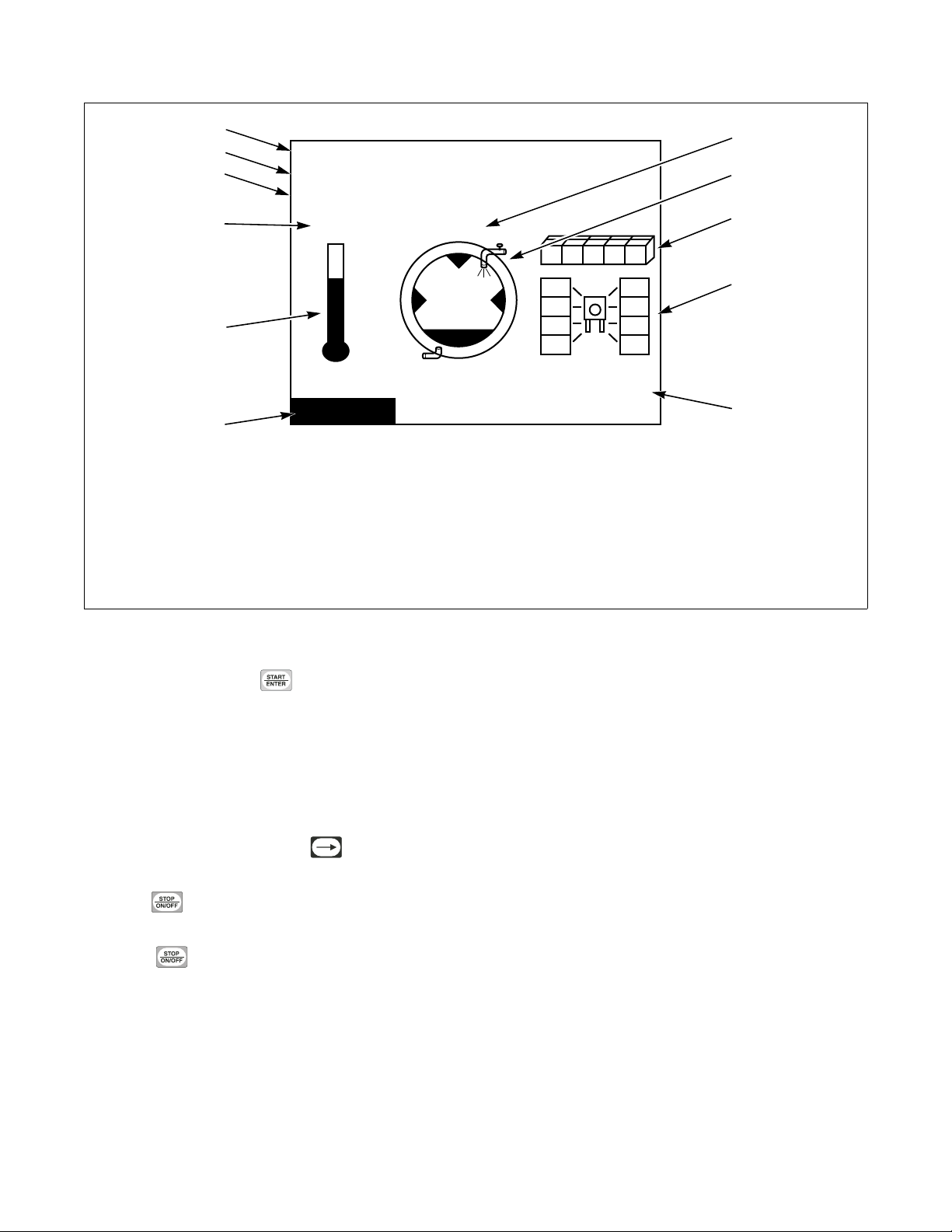

Contrast / Backlight Menu

Contrast Backlight

Contrast/Backlight Menu

PHM1008R

Figure 9

Press the keypad from Cycle Menu or Run

Menu to enter the Contrast Adjust/Backlight Menu.

The Contrast Adjust/Backlight Menu allows the user

to adjust contrast and turn the backlight on or off.

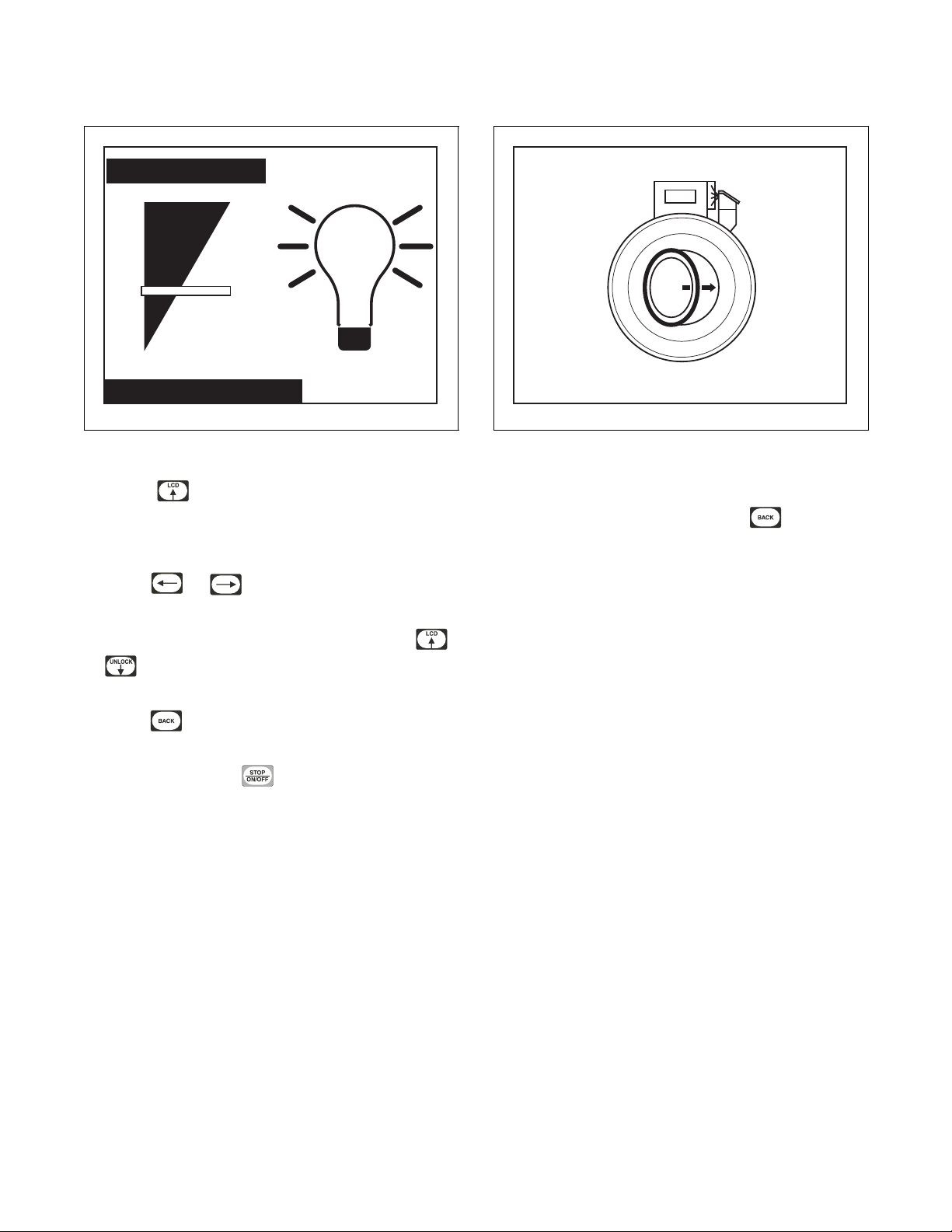

Close Door Menu

PHM706N

Figure 10

The Close Door Menu displays when loading door on

the machine is open and needs to be closed.

Close door to start cycle or press the keypad to

return to Cycle Menu.

Press the or keypad to highlight “Contrast”

or “Backlight” menu items.

Once the menu item has been selected, press the

or keypad to change contrast. The backlight is

either on or off and will have a factory default of on.

Press the keypad to enter the previous page.

If the Contrast Adjust/Backlight Menu is selected from

the Run Menu and the keypad is pressed, the

Cycle is aborted.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 25

Machine Cycle Definition and Operation

Lubricate Bearings!

200 Hours Have Elapsed

Alarms

Run Diagnostic Menu

Machine ID

Inputs and

Outputs

Speed, Temp

and Level

Lubricate Bearings Menu

PHM1009R

Figure 11

The Lubricate Bearings Menu displays when the

machines has run for 200 hours and the bearing is the

type that can be lubricated. The Lubricate Bearings

Menu displays during Idle Mode when the Cycle

Menu is displayed. The Lubricate Bearing Menu and

Cycle Menu will alternate being displayed.

To remove the Lubricate Bearings Menu from being

shown during Idle Mode, the user must reset the

bearing timer by navigating to the System Menu and

reset the bearing timer. Press any keypad to display

Cycle Menu while viewing Lubricate Bearings Menu.

Run Diagnostic Menu

PHM1010R

Figure 12

The Run Mode Diagnostic Menu allows user to access

diagnostic information of the cycle currently running.

The menu contains speed, temperature, water level,

inputs and outputs, alarms, and machine ID.

While machine is running, press the keypad to

enter Run Diagnostic Menu.

Press the , , , or keypad to

navigate the menu.

Press the keypad to choose selection.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

If the keypad is pressed, display enters Run

Menu. If nothing is selected for 15 seconds, the

display will return to Run Menu.

23

Page 26

Machine Cycle Definition and Operation

9

7

11

3

1

6

2

5

8

10

4

12

Cycle Stopped

Heater Alarm Time Exceeded

Press START Key to Retry

Press STOP Key to Abort Cycle

Speed, Temp and Water Level Menu

Cycle01: Towels White Bleach

Segment01: Wash

Fill

01:42

01:42

Temp

Actual

138 F

140 FProgram

Run Menu

1 Cycle Name 7 Programmed Water Temperature

2 Segment Name 8 Actual Water Level

3 Step Name 9 Programmed Water Level

4 Segment Time Elapsed 10 Actual RPM

5 Step Time Remaining 11 Run Screen Indicator

6 Actual Water Temperature 12 Cycle Time Remaining

Figure 13

The Speed, Temp, and Level Menu will display the

Level

01

01

Cycle Aborted Retry Menu

RPM

40

PHM1083R

actual RPM, temperature and level, and program

values of the temperature and level during run mode.

The top portion of the display contains the same

information listed in the Run Menu detailing Cycle,

Segment, and Step operation.

PHM1083R

Press keypad to enter Run Mode Diagnostic

Menu. Press keypad to stop the cycle, the

control will enter Cycle Stopped if there is rotation or

the Unlock Door page if there is not rotation. Press the

keypad to advance the cycle one step. The

Control cannot advance into a Spray Rinse Extract or

an Extract Cycle Step. Advancing the steps within a

cycle also depends on whether this option has been

changed to on or off in the Rapid Advance Menu.

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

PHM1011R

Figure 14

The Cycle Aborted Retry Menu will be displayed for a

fill, drain or heater alarm time error. The display will

toggle this page with the Run Menu every three

seconds. Press to resume the cycle.

F8138801

Page 27

Machine Cycle Definition and Operation

Cycle Aborted

Water Level Sensor Error

Press BACK Key to

Return to Cycle Menu

Delayed Start Menu

Cycle01: Towels White Bleach

Hour1

Press keypad to abort the cycle. After two

minutes without a keypad press the control will abort

the cycle and go to the Cycle Aborted Fatal Menu.

Cycle Aborted Fatal Menu

PHM1012R

Figure 15

The Cycle Aborted Fatal Menu will be displayed

during any fatal errors or if the cycle is aborted from

the Cycle Aborted Retry Menu. Press the

keypad to exit the menu. Control will go to the Cycle

Stopped Menu or the Unlock Door Menu (depending

on if there is rotation or water present).

Cycle Stopped Menu

Delayed Start Menu

PHM1014R

Figure 17

The Delayed Start Menu allows user to select in how

many hours the cycle should start.

Delayed Start Menu is only available from the Cycle

Menu.

If the loading door is opened, if the keypad is

pressed, or if there is a power failure during the delay,

the Delayed Start is aborted and is recorded as an

aborted cycle in the Last 10 Cycles Rapid Advance or

Stopped Audit Queue.

NOTE: 16 hours is the maximum delayed start

time.

The Cycle Stopped Menu is displayed while the

control is waiting for the basket to stop spinning. After

rotation is complete and the water has drained from the

machine the control will go to the Unlock Door Menu.

Figure 16

F8138801

To activate a dela yed start cycle:

1. Select the desired cycle for delayed start.

2. Press and hold and keypads. The

cycle that was selected will display with the

Delayed Start Menu.

3. Press the or keypad to alter the

number of hours.

4. Press the keypad to go back to Cycle Menu.

5. Press the keypad to enter Delayed Start

Countdown Time Menu.

PHM1013R

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Machine Cycle Definition and Operation

Delayed Start

Cycle01: Towels White Bleach

hh mm

Press Start to Run Cycle

Press Stop to Abort

Delayed Start Activated

059:

Delayed Start

Cycle01: Towels White Bleach

Press Start to Run Cycle

Press Stop to Abort

Machine Will Start

Automatically in

59

Seconds

Delayed Start Countdown Menu

PHM1015R

Figure 18

The Delayed Start Countdown Menu will be shown

after the delayed start feature has been activated.

Press keypad to return to the Cycle Menu. When

there is sixty seconds left on the countdown, control

will enter the Delayed Start Final Countdown Menu.

Delayed Start Final Countdown

Menu

PHM1016R

Figure 19

The Delayed Start Final Countdown Menu is

displayed during the last sixty seconds before the

control is automatically started. The audio signal will

sound one second on and one second off.

The keypad will start the selected cycle

immediately . The keypad will jump to the Cycle

Menu.

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 29

Menu Navigation

The UniLinc

The front-end control allows the user to control

machine operation by pressing keypads to select

options on the display menus and by navigating

between display menus.

The control has four ways to navigate to program, edit,

and select items in menus

Menu Navigation on a Single Screen

The Menu Navigation on a single screen displays a list

of items arranged either left to right and/or top to

bottom on the screen. A highlighted box shows the

selected item in the menu. Press the directional arrow

keypads to move the highlighted box between choices.

Press the keypad to select an item. Press

the keypad to turn an item on or off.

NOTE: In Cycle Menu, the highlighted box

remains in the center, and the cycles scroll as the

directional keypads are pressed.

Menu Navigation with Parameters

Another type of menu similar is a menu with

modifiable parameters. The and keypads

are used to navigate through the screens. The

and keypads are used to change the valve of the

highlighted item.

An example is the Temperature Menu under Global

Setup. The menu items are positioned vertically, but

the and keypads are used to navigate

through the different items while the and

keypads are used to adjust the values.

Screen to Screen Navigation using

the Arrow Keypads

In Screen to Screen Navigation, the or

keypad are used to go from one menu page to the next

(i.e., moving from Alarms [1 of 3] Menu to Alarms

[2 of 3] or Alarms [3 of 3] menus), if a menu cannot fit

entirely on the same page. The Laundry Management

Menu uses this navigation method.

Navigation

The Edit Mode is used when a letter or numeric value

has to be modified or created. The highlighted box is

moved over the editable item and the keypad is

pressed. The mode can be verified by seeing the first

character in the item with a blinking underscore

underneath. The character can then be changed by

using the and keypads.

For example, the Cycle Name can contain the capital

letters “A” through “Z”, small letters “a” through “z”,

the numbers “0” through “9”, and special characters.

The user can go forward to the next character in the

item by using the keypad. Press the

keypad to go backward a character. If the first

character in the item is selected and the keypad

is pressed, the cursor will go to the last character of the

item. Thus, the cursor will move only within the item

when the horizontal keypads are pressed.

Another example of the edit mode is when the user is

programming the time. In the edit mode when

programming a time, the only characters that can be

selected are “0” through “9” when using the

or keypad.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Menu Navigation

Cycle Menu

System Menu

Diagnostic Menu

Run Menu Service Menu

Contrast Adjust Menu

Auto - Leak Detect Menu

Close Door Menu

Lube Bearing Menu

Delayed Start Menu

. . . . . .

Program Menu

Laundry Management

Menus

Machine ID Menu

Alarms Menu

Water Leak Detection Menu

Factory Valve Purge

Balance Weight Test

Inputs Outputs

Test Cycle

Save Changes Menu

(After all Step Menus

and Global Menus

except Factory

Defaults)

Global Setup

Language Menu

Date/ Time Menu

Water Level Menu

Audio/ Ext Signl Menu

Balance Retry Menu

Water Mgmt Menu

Alarms Prog Menu

Rapid Advance

Shake Out Menu

Temperature Menu

Banners Menu

Test Menu

Modify Cycle Menu

Reuse Step Menu

Supply A & B Step Menus

Cool Down Step Menu

Drain Step Menu

Spray Rinse Extract Step Menu

Extract Step Menu

EOS Audio Signal Step Menu

All Defaults Confirmation

Factory Defaults Menu

Agitate Step Menu

Fill Step Menu

Second

Confirmation

Water Level Confirmation

Temperature Confirmation

Alarms Confirmation

Audio Confirmation

PHM1264R

Display Screen Maps

Refer to the following charts for maps of all of the

display menus.

System Menu Map Tree

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 20

F8138801

Page 31

Run Menu Map Tree

Cycle Menu

Run Menu Service Menu System Menu

Contrast Adjust Menu

Close Door Menu

Lube Bearing Menu

Delayed Start Menu

Auto - Leak Detect Menu

. . . . . .

Contrast Adjust Menu

Unlock Door

Cycle Stopped

Cycle Aborted Retry Menu

Cycle Aborted Fatal Menu

Run Diagnostic

Speed, Temp, Level Menu

Run Alarms Menu

Machine ID Menu

Run Mode Inputs Outputs

PHM1271R

Cycle Menu

Service Menu Run Menu System Menu

Contrast Adjust Menu

Close Door Menu

Lube Bearing Menu

Delayed Start Menu

Auto - Leak Detect Menu

. . . . . .

Daily Menu

Monthly Menu

Quarterly Menu

Weekly Menu

PHM1272R

Menu Navigation

Figure 21

Service Menu Map Tree

Figure 22

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Programming UniLinc

Laundry

Management

System Menu

Reset Bearing

Timer

DiagnosticProgram

Save Changes?

NoYe s

System Menu

PHM1020R

Figure 23

The System Menu allows the user to access: cycle

programming, diagnostics, laundry management,

bearing timer reset/reset bearing timer.

Press and hold , then, , then to enter

the System Menu.

The System Menu is a submenu of the Cycle Menu.

The navigation of the System Menu is different from

the Cycle Menu. In the Cycle Menu, the highlighted

text box was stationary. In the System Menu, the

ARROW keypads control the location of the

highlighted text box. Text will remain at the same

location but the highlighted box will move when the

text box when the , , , and

keypads are pressed.

Save Changes Menu

PHM1021R

Figure 24

The Save Changes Menu is used to confirm

programming changes when modifying a cycle or the

parameters of the Global Settings. The Save Changes

Menu will default to Yes. Using the or

keypad will move the cursor between Yes or No. Press

the keypad to make a selection. Once the

keypad is pressed, the display will either return to the

Modify Cycle Menu or the Global Setup Menu

depending in which submenu the display was in.

Press the keypad to enter selected menu.

Press the keypad to return to the Cycle Menu

screen.

If the user highlights Reset Bearing Timer an d pres ses

the keypad, the text changes to Bearing Timer

Reset and the control resets the total operation time

since the bearings were last serviced. This menu item

will not be an option on machines that do not have a

greasable bearing.

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 33

Program Menu

Program Menu

Modify Cycle Global Setup

Modify Cycle

Cycle01: Towels White Bleach

Segment01: Prewash

Program Menu

PHM1022R

Figure 25

In System Menu, select Program and press .

To program cycles, select Modify Cycle and

press .

To change properties that will affect the machine

globally, select Global Setup (i.e., water temperature

Cold to 35°F, will make the cold water temp 35°F for

all cycles) and press .

Press the keypad to return to System Menu.

Modify Cycle

The Modify Cycle Menu is used to program the

cycles. For programming steps, the Modify Cycle

Menu changes to the Step Menu.

The Cycle Number will be highlighted when the

Modify Cycle is first displayed.

Press the or keypad to change cycle

selections.

The cycle can be turned on and off by pressing

the keypad. If the cycle is turned off, the Cycle

Name will display “Off” and the user will not be able

to make any changes to the cycle.

Press the keypad to make the highlighted box

move to the cycle name to the right of the cycle

number.

Press the keypad to make the display jump to

the End of Segment (EOS) Audio Signal Step Menu of

the last segment of that cycle which is programmed

“On”.

NOTE: All segments and available steps have to be

scrolled through even though they may be shut off.

Figure 27 illustrates the flow of the cursor during

the programming of a cycle.

To edit a cycle name, select the cycle name and press

the keypad.

The first character of the Cycle Name will have a

blinking underscore underneath to display it is ready

for editing. Use the and keypads to select

the different characters. After the desired character has

been selected, press the keypad to save the

character and move to the next character in the string.

The user may press the keypad to go back a

Figure 26

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

PHM1023R

character. Pressing the keypad when located on

the first character will take the user to the last

character of the string, which may be a blank space.

Continue pressing the keypad to move to

desired character. The blinking underscore is under the

last character of the string and the keypad is

pressed, the blinking underscore will move to the first

character of the string.

Press the keypad to exit string edit mode.

31

Page 34

Program Menu

NOTE: Refer to Table 2 for a chart of available

letters, numbers and symbols.

Press the keypad to move highlighted box to

Segment Number or press the keypad to move

the highlighted box back to the Cycle Number. While

the Segment Number is highlighted, the Segment

pressing the or keypad. The Segment

Name choices are Prewash, Wash, and Rinse.

NOTE: OFF may also be displayed in the Segment

Name position if the segment number had been

turned off previously, but is not a menu choice.

Press the keypad to move highlighted box back

Number can be turned on or off by using the

keypad. If turned off, all sub programming steps will

become inaccessible.

to the Segment Number. Press the keypad to

move into step menus of cycle segment. Steps have

separate menus (different screens) from the Modify

Press the or keypad to change segment

selections.

Press the keypad to move the highlighted text

Cycle Menu. However, when the highlighted cursor is

on the Step Name and the keypad is pressed, the

display will jump back to the Modify Cycle Menu and

the Segment Name will be highlighted.

box to the Segment Name.

While the Segment Name is selected, the user selects

the Segment Name from a list of three choices by

Press the keypad to jump to the Save Changes

Menu.

Available Characters

ABCDEFGH I JKLMNOP

QRSTUVWXYZabcdef

ghi jklmnopqr s tuv

wxyz0123456789!"

#$%&'()*+,-./:;<

=>?@[\]^_`{|}~€‚

ƒ„…†‡ˆ‰Š‹ŒŽ‘’“”•

–—˜™š›œžŸ ¡¢£¤¥ ¦

§¨©ª«¬-®¯°±²³´µ¶

· ¸ ¹ º »¼½¾¿ АБВГДЕЖ

ЗИЙКЛМНОПРСТУФХЦ

ЧШЩЪЫЬЭЮ Я абвгдеж

зийклмнопрстуфхц

чшщъыьэюя

32

Table 2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8138801

Page 35

Cycle, Segment and Step

Cycle NameCycle Number

Segment Name

Reuse Fill Step

Fill Step

Segment Number

Supply A Step

Supply B Step

Agitate Step

Cooldown Step

Drain Step

Spray Rinse Extract Step

Extract Step

EOS Audio Signal Step

PHM1024R

1

Reuse Fill Step is not used unless active in the Global Settings.

2

Supply B Step will not be shown if Supply A step is turned off.

PHM1024R

Programming Flow Diagram

Program Menu

Step Menu Navigation

Step Menus are a subgroup of the Modify Cycle Menu

and the navigation is very similar to the navigation of

the Modify Cycle Menu. When a step menu is first

displayed, the step name will be highlighted. While the

step name is highlighted, it can be toggled on or off by

pressing the keypad. If the Step is toggled from

OFF to ON, then the last programmed parameters will

be displayed. The programmable parameters (i.e.,

water temperature, water level, time, etc.) are based on

the step being programmed. For instance, the water

temperature is available in the Fill Step but not the

Reuse Fill Step, so, the water temperature parameter

will not be shown in the Reuse Fill Step.

F8138801

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 27

NOTE: Reuse Fill Step is only available when the

different Step parameters can be selected.

Press the or keypad. To view all steps of a