Page 1

User Manual

Original Instructions

PanelView Plus 7 Standard Terminals

Catalog Numbers 2711P-T4W21D8S, 2711P-T4W22D8S, 2711P-T4W21D8S-B, 2711P-T4W22D8S-B, 2711P-T6C21D8S,

2711P-T6C22D8S, 2711P-T6C21D8S-B, 2711P-T6C22D8S-B, 2711P-T7C21D8S, 2711P-T7C22D8S, 2711P-T7C21D8S-B,

2711P-T7C22D8S-B, 2711P-T9W21D8S, 2711P-T9W22D8S, 2711P-T9W21D8S-B, 2711P-T9W22D8S-B, 2711P-T10C21D8S,

2711P-T10C22D8S, 2711P-T10C21D8S-B, 2711P-T10C22D8S-B, 2711P-T12W21D8S, 2711P-T12W22D8S, 2711PT12W21D8S-B, 2711P-T12W22D8S-B, 2711P-T15C21D8S, 2711P-T15C22D8S, 2711P-T15C21D8S-B, 2711P-T15C22D8S-B

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Overview About the PanelView Plus 7 Standard Terminals. . . . . . . . . . . . . . . . . 11

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operator Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Software Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PanelView Plus 7 Standard Applications . . . . . . . . . . . . . . . . . . . . . . . . 14

Windows CE Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Open Versus Closed System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Desktop Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Start-up Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

EtherNet/IP Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Typical Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Product Selections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ethernet Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 2

Install the PanelView Plus 7

Standard Terminal

Hazardous Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Considerations for Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Clearances for Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Panel Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Panel Cutout Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Prepare for Panel Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Mount the Terminal in a Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Apply the Static Discharge Warning Label . . . . . . . . . . . . . . . . . . . . . . 34

Remove and Replace Power Terminal Block . . . . . . . . . . . . . . . . . . . . . 35

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connect to a Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Ethernet Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Device Level Ring Network Topology. . . . . . . . . . . . . . . . . . . . . . . 38

Linear Network Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Star Network Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Initial Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Reset the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chapter 3

Configure Terminal Settings FactoryTalk View ME Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Terminal Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Soft Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 3

Page 4

Table of Contents

Load and Run an Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Desktop Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Enable Desktop Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Disable Desktop Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Set a Desktop Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Reset the Desktop Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Configure Start-up Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Disable FactoryTalk View ME Station on Startup . . . . . . . . . . . . 53

Enter Configuration Mode on Startup . . . . . . . . . . . . . . . . . . . . . . 54

Run the Loaded Application on Startup . . . . . . . . . . . . . . . . . . . . . 55

Configure Controller Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Configure Ethernet Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Set the Ethernet Address of the Terminal . . . . . . . . . . . . . . . . . . . . 57

Set the Ethernet Link Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configure the Ethernet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Name the Server Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Modify Device Name of Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Copy Files on Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Delete Files from Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Delete Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Adjust Display Intensity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Configure the Screen Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Disable the Screen Cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Input Device Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Calibrate the Touch Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Set the Double-tap Sensitivity for a Touch Screen . . . . . . . . . . . . 66

Change the Popup for String Entry. . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configure Print Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Configure Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Check Integrity of Application Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

View and Clear the System Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Enable or Disable the Alarm Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Display System Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

View Terminal Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

View FactoryTalk View ME Station Information. . . . . . . . . . . . . 74

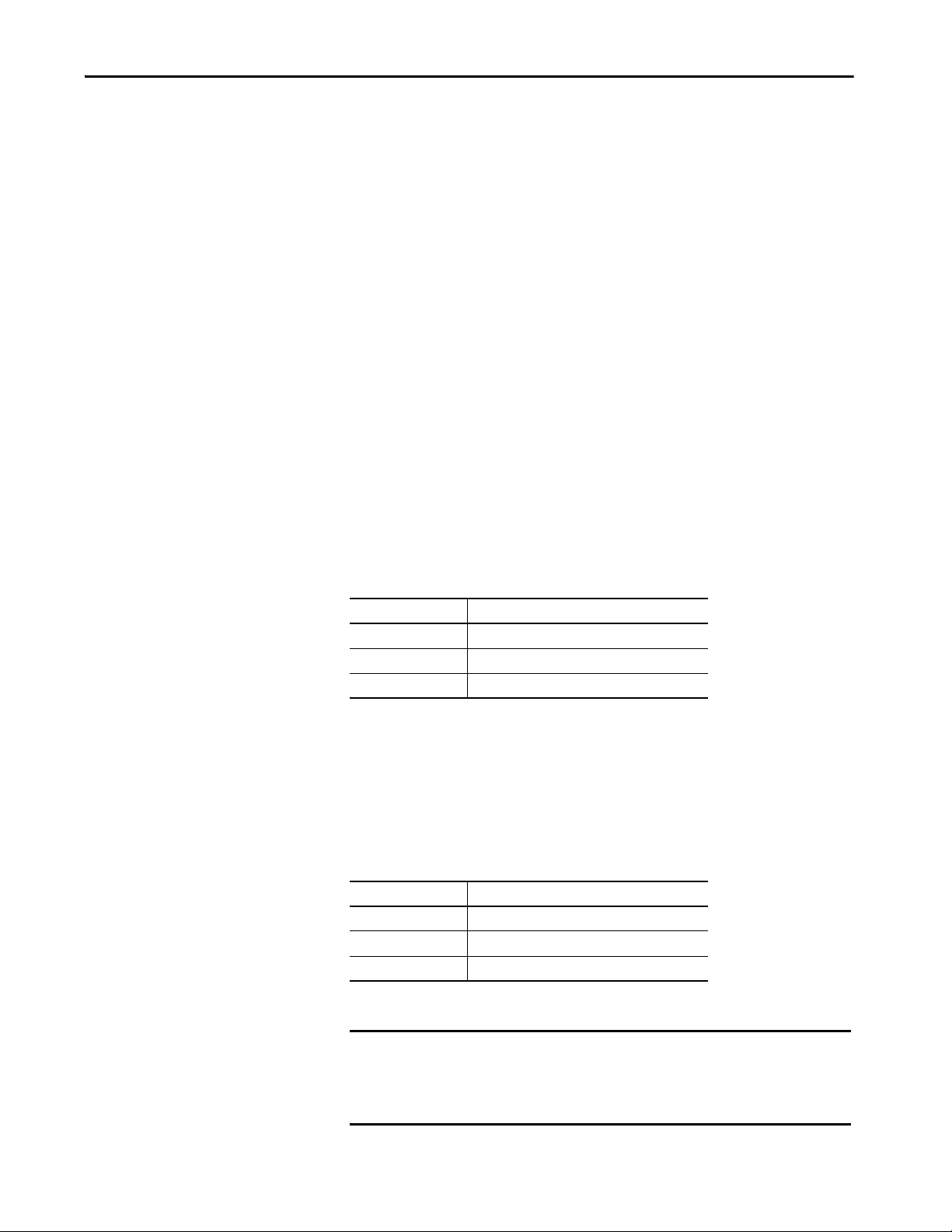

Time and Date Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Change the Time Zone on the Terminal. . . . . . . . . . . . . . . . . . . . . 75

Change the Current Date on the Terminal . . . . . . . . . . . . . . . . . . 76

Change the Current Time on the Terminal . . . . . . . . . . . . . . . . . . 76

Regional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Change the Decimal Separator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Change the Time Format for a Language . . . . . . . . . . . . . . . . . . . . 78

Change the Short Date Format for a Language . . . . . . . . . . . . . . . 79

Change the Long Date Format for a Language. . . . . . . . . . . . . . . . 79

4 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 5

Table of Contents

Chapter 4

Windows Operating System Operating System Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Application Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Scripting Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Network Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Server Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Windows Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Taskbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Soft Input Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Windows Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Backup and Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Perform a Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Restore a Back-up Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Display Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Desktop Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Desktop Appearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Backlight Intensity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Screen Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Cursor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Screen Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Hardware Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Processes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

System Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Logo Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Network Server Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

VNC Server Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Web Server Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

FTP Server Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

File Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

KEPServer Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Startup Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Device Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Double-Tap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

PDF Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Command Prompt Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

. . . . . . . . . . . . . . . . 114

Chapter 5

Install and Replace Components Connect to USB Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

USB Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 5

Page 6

Table of Contents

Install a USB Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Plug-and-Play Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Manual Printer Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Insert an SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Replace the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Install a Protective Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Clean the Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Remove the Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Chapter 6

Update Firmware Terminal Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Download Firmware Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Firmware Upgrade Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Upgrade the Terminal Firmware from a Storage Device. . . . . . . . . . 131

Create a Firmware Upgrade Card . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Upgrade Terminal Firmware by Using a Firmware Upgrade Card.

134

Upgrade Terminal Firmware over the Network . . . . . . . . . . . . . . . . . 135

Chapter 7

Troubleshooting View System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Terminal Does Not Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Terminal Restarts Intermittently . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Touch Screen Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Display Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Ethernet Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Performance Is Slow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Resistance to Chemicals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Clean the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Remove Paint and Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Equipment Wash Downs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Ship the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Maintenance Mode Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Appendix A

Fonts Resident on Terminal TrueType Fonts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

6 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 7

Preface

This manual describes how to install, configure, operate, and troubleshoot the

PanelView™ Plus 7 Standard terminals. It does not provide procedures on how

to create applications that run on the terminals or ladder logic that runs in the

controller.

Other tasks to perform include:

• Create a human machine interface (HMI) application for the terminal

by using FactoryTalk® View Machine Edition (ME) software, version 7.0

or later.

• Create ladder logic for the controller by using the Studio 5000 Logix

Designer® application.

Summary of Changes

Package Contents

This manual contains new and updated information as indicated in the

following table.

Top ic Pag es

Updated the screen and alarm counts for the PanelView Plus 7 Standard terminals. 11, 14

Updated the ATEX, IECEx, and INMETRO information in the Certifications table. 19, 21…23

Added catalog numbers for the new SDHC cards. 17

Added instructions on how to apply the static discharge warning label. 34

This product is shipped with the following items:

• PanelView Plus 7 Standard terminal with FactoryTalk View ME Station

runtime software installed and activated

• Mounting levers for panel installation

• Removable power terminal block

• Secure Digital (SD) card cover

• Product information

• Cutout template

•China RoHS information

• Product Feature Notice

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 7

Page 8

Preface

Product Release Notes

Product release notes are available online within the Product Compatibility

and Download Center.

1. From the Quick Links list on http://www.ab.com

Compatibility and Download Center.

2. From the Compatibility Scenarios tab or the Get Downloads tab, search

for and choose your product.

, choose Product

3. Click the download icon to access product release notes.

8 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 9

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PanelView Plus 7 Standard Terminals Technical Data,

publication 2711P-TD008

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

EtherNet/IP Embedded Switch Technology Application

Guide, publication ENET-AP005

Safety Guidelines for the Application, Installation, and

Maintenance of Solid-State Controls, publication SGI-1.1

Guidelines for Handling Lithium Batteries Technical Data,

publication AG-5. 4

Product Certifications website, rok.auto/certifications

Provides technical specifications, environmental specific ations, and certifications for the PanelView Plus 7 Standard

terminals.

Provides general guidelines for installing a Rockwell Automation industrial system.

Provides information on how to install, configure, and maintain linear and Device Level Ring (DLR) networks using

Rockwell Automation® EtherNet/IP devices with embedded switch technology.

Provides general guidelines for the application, installation, and maintenance of solid-state control in the form of

individual devices or packaged assemblies that use solid-state components.

Provides guidelines to store, handle, install, and dispose of lithium batteries.

Provides declarations of conformity, certificates, and other certification details.

You can view or download publications at

http://www.rockwellautomation.com/global/literature-library/overview.page

.

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 9

Page 10

Preface

Notes:

10 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 11

Chapter 1

Overview

Topic Page Topic Page

About the PanelView Plus 7 Standard Terminals 11 Start-up Options 15

Hardware Features 12 EtherNet/IP Communication 15

Operator Control 13 Typical Configuration 15

Software Support 13 Catalog Number Explanation 16

Windows CE Operating System 14 Product Selections 16

Open Versus Closed System 14 Accessories 17

Desktop Access 15 Ethernet Cables 18

About the PanelView Plus 7 Standard Terminals

The PanelView™ Plus 7 Standard terminals are operator interface devices. They

monitor and control devices that are attached to ControlLogix® 5570 and

CompactLogix™ 5370 controllers on an EtherNet/IP™ network. Animated

graphic and text displays provide operators a view into the operating state of a

machine or process. Operators interact with the control system by using touch

screen input.

The PanelView Plus 7 Standard terminals include these features:

• Terminal functionality permits connection to 1 controller, up to 100

screens, and up to 500 alarms.

• FactoryTalk® View Machine Edition software provides a familiar

environment for creating HMI applications.

• Windows CE operating system with desktop access for configuration

and third-party applications.

• Ethernet communication that supports Device Level Ring (DLR),

linear, and star network topology.

• PDF viewer to access PDF files that are stored on the terminal.

• More screen options including 4-in., 6-in., 7-in., 9-in., 10-in., 12-in., and

15-in. terminals.

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 11

Page 12

Chapter 1 Overview

16

2

3

4

5

6

8

9

7

1

3

2

5

6

4

7

324

Terminals with one Ethernet port.

Terminals with dual Ethernet

ports.

Throughout this user manual, illustrations show the

terminals with dual Ethernet ports.

• Widescreen on three sizes, 4-in., 9-in., and 12-in. terminals.

• Greater screen resolution.

• Terminals are available with Allen-Bradley® branding, or with no

branding for customers that want to put their own branding around the

terminal.

• Certifications including Class I, Div. 2; Class II, Div. 2; Class III;

ATEX, IECEx, and INMETRO Zones 2 and 22.

Hardware Features

16

The PanelView Plus 7 Standard terminal features fixed-hardware

configurations in a range of display sizes with touch screen input.

Table 1 - Hardware Features

Item Feature Description

1 Display/Touch screen TFT color graphic display with a touch screen in a range of sizes:

2 Power 24V DC nom (18…30V DC) nonisolated power input

3Ethernet port

(1 or 2)

4 Mounting slots Mounting levers insert into the slots to mount device in a panel or enclosure. The number of slots varies by terminal size.

5 Universal serial bus (USB)

host port

6 USB device port One USB 2.0 high-speed (type B) device port for connecting a host computer.

12 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

• 4.3-in. wide screen touch (WQVGA)

•5.7-in. touch (VGA)

•6.5-in. touch (VGA)

• 9.0-in. wide screen touch (WVGA)

• 10.4-in. touch (SVGA)

• 12.1-in. wide screen with touch (WXGA)

• 15.0-in. touch (XGA)

• One 10/100Base-T, Auto MDI/MDI-X, Ethernet port for controller communication and IEEE 1588 support for synchronization of

network-connected devices .

• Two 10/100Base-T, Auto MDI/MDI-X, Ethernet ports for controller communication that supports Device Level Ring (DLR) network

topology.

One USB 2.0 high-speed (type A) host port.

Page 13

Table 1 - Hardware Features

Item Feature Description

7SD card slot and

protecti ve cover

8 Battery Battery cover provides access to the lithium battery for replacement.

9 Status indicators Status indicators on the back of the terminal provide status and fault conditions.

• One SD card slot supports catalog number 1784-SDx hot-swappable SD cards for external storage.

• IMPORTANT: ATEX and INMETRO installations:

– Protective cover secures the S D card in the slot, and is required for ATEX, INMETRO, and hazardous location installations.

– See Insert an SD Card

on page 123 for hot-swapping, ATEX, INMETRO, and hazardous location warnings.

Overview Chapter 1

Operator Control

All terminals have a color display with a touch screen for operator control. The

resistive touch screen provides accurate, reliable, and durable touch control for

industrial applications.

ATT EN TI ON : The touch screen accepts input from a finger, stylus, or gloved

hand for operation in dry or wet environments.

The plastic stylus must have a minimum tip radius of 1.3 mm (0.051 in.).

Any other object or tool can damage the touch screen.

Do not conduct multiple operations simultaneously; it can result in unintended

operation. Touch only one operating element on the touch screen with one

finger, at one time.

TIP At runtime, a virtual keyboard or numeric keypad opens on terminal

screens for data entry.

The touch screen supports touch gestures to interact with screen elements

during runtime. Use only these touch gestures on the touch screen:

• Ta p – Briefly touch the target on the terminal screen with your

fingertip.

• Double-tap – Touch the target on the terminal screen twice quickly

with your fingertip.

• Drag – Touch the target on the terminal screen and move your fingertip

across the screen.

• Long press – Touch and hold the target on the terminal screen for

several seconds.

Software Support

For a list of actions you can perform by using touch gestures, refer to the

FactoryTalk View ME help.

IMPORTANT It is the responsibility of the customer to be sure that any third-party

software, updates, patches, or firmware that is installed is free of malicious

bugs, spyware, and so on.

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 13

Page 14

Chapter 1 Overview

Table 2 - PanelView Plus 7 Standard Software Support

Software Description Version

FactoryTalk View ME Station Runtime environment of terminal:

• Runs FactoryTalk View ME applications.

• Provides options to view and configure terminal settings.

Machine Edition Station is preloaded on each terminal and does not require activation.

FactoryTalk View Studio for Machine Edition Software for developing the HMI applications that run on terminal. This software does not run on the

terminal. The HMI applications that are created in this software are loaded onto the terminal.

FactoryTalk ViewPoint A web server application that lets remote users access and control the HMI application that runs on a

terminal by using an internet browser.

A license is embedded with each terminal that suppor ts a client connection to a terminal.

7.0 or later

7.0 or later

1.2 or later

PanelView Plus 7 Standard Applications

Windows CE Operating System

PanelView Plus 7 Standard Machine Edition applications are restricted to these

applications:

• Maximum of 100 screens.

• Maximum of 500 alarm messages.

• One connection or shortcut to a controller by using either RSLinx®

Enterprise or KEPServer Enterprise software.

• Only Ethernet communication is supported.

If RSLinx Enterprise software is used, then Ethernet drivers are

supported.

The terminals run the Windows CE operating system. These devices run HMI

applications and offer a desktop with these capabilities:

• File transfer protocol (FTP) server

• Virtual network computing (VNC) client and server

•ActiveX controls – Refer toView FactoryTalk View ME Station

Information on page 74 to view a list of ActiveX controls installed on

terminal.

TIP For a complete list of ActiveX controls, go to http://

www.rockwellautomation.com/knowledgebase and search the

Knowledgebase for keywords ‘ActiveX Support for PanelView Plus

Ter m in a ls ’.

•PDF reader

•Third-party device support

Open Versus Closed System

You can configure a terminal to run an open or closed desktop environment:

• An open system launches the Windows desktop on startup.

• A closed system launches a FactoryTalk View ME application or

FactoryTalk View ME Station on startup. Desktop access is restricted.

All terminals are shipped as closed systems.

14 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 15

Overview Chapter 1

Desktop Access

Start-up Options

You can allow or restrict access to the Windows desktop on the terminal. From

the desktop, you can perform system and control panel operations or run thirdparty applications. You can even allow access temporarily to perform specific

tasks, then disable desktop access to prevent unauthorized changes.

TIP All terminals are shipped with desktop access disabled.

Refer to Desktop Access

access.

The terminal can perform one of three actions at startup:

• Launch a FactoryTalk View ME HMI application.

• Launch FactoryTalk View ME Station in Configuration mode. This

mode lets you configure terminal settings and start-up options, load

applications to run, and enable or disable desktop access.

• Launch the Windows desktop.

The factory default state and start-up option after a firmware update is to

launch the terminal in Configuration mode. Refer to Configure Start-up

Options on page 53 for details on how to change the start-up option.

on page 48 for details on how to modify desktop

EtherNet/IP Communication

Typical Configuration

PanelView Plus 7 Standard terminals communicate with ControlLogix 5570

and CompactLogix 5370 controllers over an EtherNet/IP connection.

Traditional DLR, linear, and star network topologies are supported. See these

topics for examples:

• Device Level Ring Network Topology

• Linear Network Topology on page 39

• Star Network Topology on page 40

on page 38

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 15

Page 16

Chapter 1 Overview

Catalog Number Explanation

Bulletin Input Type Display Size Display Type Network Power Operating

|| | | | |||

2711P- T = Touch 4 = 4.3-in. C = Color 21 = Single Ethernet port D = DC 8 = Windows CE S = Standard

6 = 5.7-in. W = Wide aspect-ratio color 22 = Embedded switch/DLR

7 = 6.5-in.

9 = 9.0-in.

10 = 10.4-in.

12 = 12.1-in.

15 = 15.0-in.

(1) The standard models support the Windows CE version 6.0 operating system with an FTP server, VNC client server, ActiveX controls, and PDF reader.

Product Selections

See the table for an explanation of the terminal catalog number.

Model - Option

System

Ta b l e 3 provides a description of the product selections.

(1)

- B = No brand

label

Table 3 - PanelView Plus 7 Standard Terminals Product Selections

(1)

Cat. No.

Touch Screen Size Type Aspect

2711P-T4W21D8S 4.3-in. WQVGA

2711P-T4W22D8S •

2711P-T6C21D8S 5.7-in. VGA

2711P-T6C22D8S •

2711P-T7C21D8S 6.5-in. VGA

2711P-T7C22D8S •

2711P-T9W21D8S 9.0-in. WVGA

2711P-T9W22D8S •

2711P-T10C21D8S 10.4-in. SVGA

2711P-T10C22D8S •

2711P-T12W21D8S 12.1-in. WXGA

2711P-T12W22D8S •

2711P-T15C21D8S 15.0-in. XGA

2711P-T15C22D8S •

(1) Add -B to the end of a catalog number to order a terminal without the Allen-Bradley logo and product identification; for example, 2711P-T9W21D8S-B.

Display Input

Ratio

16:9 480 x 272 DC • 512 MB 512 MB nonvolatile

TFT color

4:3 640 x 480 •

TFT color

4:3 640 x 480 •

TFT color

5:3 800 x 480 •

TFT color

4:3 800 x 600 •

TFT color

16:10 1280 x 800 •

TFT color

4:3 1024 x 768 •

TFT color

Pixels

(W x H)

Power

Ethernet Ports Memory

Single DLR RAM Nonvolatile

memory

(Approx. 80 MB free

user memory)

16 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 17

Overview Chapter 1

Accessories

Ta b l e 4 through Ta b l e 9 list accessories for the PanelView Plus 7 Standard

terminals.

Table 4 - Protective Overlays

Cat. No. Display S ize Touch Input Quantity

2711P-RGT4S 4.3-in. • 3

2711P-RGT6S 5.7-in. • 3

2711P-RGT7SP 6.5-in. • 3

2711P-RGT9SP 9.0-in. • 3

2711P-RGT10SP 10.4-in. • 3

2711P-RGT12SP 12.1-in. • 3

2711P-RGT15SP 15-in. • 3

Table 5 - Power Supplies and Power Terminal Blocks

Cat. No. Description Quantity

1606-XLP95E DIN-rail power supply, 24…28V DC output voltage, 95 W 1

1606-XLP100E DIN-rail power supply, 24…28V DC output voltage, 100 W 1

2711P-RSACDIN DIN-rail power supply, AC-to-DC, 85…265V AC, 47…63 Hz 1

2711P-RTBDSP 3-pin DC power terminal block (black with white labels for +, –, and GND) 10

Table 6 - Mounting Hardware

Cat. No. Description Quantity

2711P-RMCS

(1) Catalog number 2711P-RMCS mounting levers are for use only with PanelView Plus 7 Standard terminals. Do not use these

Table 7 - SD Ca rds

Cat. No. Description Quantity

1784-SD1 1 GB SD card 1

1784-SD2 2 GB SD card 1

1784-SDHC8 8 GB High Capacity SD card 1

1784-SDHC32 32 GB High Capacity SD card 1

2711C-RCSD USB to SD adapter for SD card 1

2711P-RCKS SD cover replacement 3

(1) To reduce the chance of corruption when using SD Cards or USB drives with the terminal, Rockwell Automation recommends

(1)

mounting levers with any other PanelView Plus terminals. Do not use black mounting levers; they are not compatible with

PanelView Plus 7 Standard terminals.

that you use SD Card catalog numbers 1784-SD1 or 1784-SD2.

Mounting levers (gray) 12

(1)

Table 8 - USB Programming Cable

Cat. No. Description Length

6189V-USBCBL2 Programming ca ble that connects the device port of the terminal to a

USB host port of a computer

1.8 m (5.9 ft)

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 17

Page 18

Chapter 1 Overview

Table 9 - Battery Replacement

Cat. No. Description Quantity

2711P-RY2032 Lithium coin-cell battery, CR2032 equivalent 1

2711P-RYKS Battery cover replacement 3

Ethernet Cables

See the Industrial Ethernet Media Brochure, publication 1585-BR001B, for

recommended Ethernet cables and media solutions.

See the USB to Serial Adapter Quick Start Guide, publication

GMSC10-QS003

, for information on USB to serial port adapters.

18 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 19

Chapter 2

Install the PanelView Plus 7 Standard Terminal

Top ic P ag e

Hazardous Locations 21

Considerations for Mounting 24

Clearances for Mounting 24

Panel Guidelines 24

Panel Cutout Dimensions 25

Prepare for Panel Mounting 26

Mount the Terminal in a Panel 30

Apply the Static Discharge Warning Label 34

Remove and Replace Power Terminal Block 35

Connect Powe r 36

Connect to a Network 37

Initial Startup 41

Reset the Terminal 41

ATE X:

EN 60079-0, EN 60079-7,

EN 60079-11, and EN 60079-31

II 3 GD

Ex ec ic IIC T4 Gc

Ex ic IIC T4 Gc

Ex tc IIIC T135 °C (275 °F) Dc IP66

Tamb = 0 …55 °C (32…131 °F)

DEMKO 14 ATEX 1302X

ATT EN TI ON : Do not use a PanelView™ Plus 7 Standard terminal for

emergency stops or other controls critical to the safety of personnel or

equipment. Use separate hard-wired operator interface devices that do not

depend on solid-state electronics.

The equipment meets the requirements of the standards and ratings that are

listed in Ta b l e 1 0

Table 10 - ATEX and INMETRO Ratings

IECEx:

IEC 60079-0; IEC 60079-7; IEC 60079-11;

and IEC 60079-31

II 3 GD

Ex ec ic IIC T4 Gc2

Ex tc IIIC T135 °C (275 °F) Dc IP66

Tamb = 0 °C… +55 °C (32 °F…131 °F)

IECEx UL 20.0046X

.

INMETRO:

ABNT NBR IEC 60079-0;

ABNT NBR IEC 60079-11;

ABNT NBR IEC 60079-8;

e ABNT NBR IEC 60079-31

Ex ec ic IIC T4 Gc

Ex ic IIC T4 Gc

Ex tc IIIC T135 °C (275 °F) Dc IP66

Tamb = 0 …55 °C (32…131 °F)

UL-BR 14.0716X

CCC Ex

GB 3836.1-2010; GB 3836.3-2010;

GB 3836.4-2010; GB 12476.1-2013;

GB 12476.5-2013

Ex ec ic IIC T4 Gc

Ex tc IIIC T135 °C (275 °F) Dc IP66

Tamb = 0 °C…+55 °C (32 °F…131 °F)

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 19

Page 20

Chapter 2 Install the PanelView Plus 7 Standard Terminal

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as

defined in IEC 60664-1), at altitudes up to 2000 m (6561 ft) without derating.

The terminals are intended for use with programmable logic controllers.

This equipment is considered Group 1, Class A industrial equipment according to IEC CISPR 11. Without appropriate precautions,

there may be difficulties with electromagnetic compatibility in residential and other environments due to conducted or radiated

disturbances.

Korean Radio Wave Suitability Registration - When so marked this equipment is registered for Electromagnetic

Conformity Registration as business equipment (A), not home equipment. Sellers or users are required to take

caution in this regard.

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판 매자 또는 사용자는 이 점을 주의하시기 바라

며 , 가정외의 지역에서 사용하는 것을 목적으 로 합니다 .

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be accessible only by the use of a tool. The terminals meet specified

NEMA, UL Type, and IEC ratings only when mounted in a panel or enclosure with the equivalent rating. Subsequent sections of

this publication may contain additional information regarding specific enclosure type ratings that are required to comply with

certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by different types of

enclosure

, for additional installation requirements

ATTENTION: Wiring and Safety Guidelines

Use publication NFPA 70E, Electrical Safety Requirements for Employee Workplaces, IEC 60364 Electrical Installations in

Buildings, or other applicable wiring safety requirements for the country of installation when wiring the devices. In addition to

the NFPA guidelines, here are some other guidelines to follow:

• Employ only qualified electricians to wire the device in accordance with local, state, and national codes.

• Connect the device and other similar electronic equipment to its own branch circuit.

• Protect the input power by a fuse or circuit breaker rated at no more than 15 A.

• Route incoming power to the device by a separate path from the communication lines.

• Cross power and communication lines at right angles if they must cross.

• Communication lines can be installed in the same conduit as low-level DC I/O lines (less than 10V).

• Shield and ground cables appropriately to avoid electromagnetic interference (EMI). Grounding minimizes noise from EMI

and is a safety measure in electrical installations.

For more information on grounding recommendations, refer to the National Electrical Code published by the National Fire

Protection Association.

20 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 21

Install the PanelView Plus 7 Standard Terminal Chapter 2

Hazardous Locations

WARNING: EXPLOSION HAZARD

The following information applies when operating this equipment in hazardous locations.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D; Class II, Division 2, Groups F and G; Class III

hazardous locations and nonhazardous locations only.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

• Do not disconnect connections to this equipment unless power has been removed or the area is known to be nonhazardous.

Secure any external connections that mate to this equipment by using screws sliding latches, threaded connectors, or other

means provided with this product.

• When installed in a hazardous location, do not open the enclosure, connect or disconnect equipment unless the area is

known to be non-hazardous.

• Substitution of components can impair suitability for Class I, Division 2.

• Peripheral equipment must be suitable for the location where it is used.

• All wiring must be in accord ance with Cl ass I, Division 2, Class II, Division 2, or Class III wiring methods of Ar ticles 501, 502 or

503, as appropriate, of the National Electrical Code and/or in accordance with Section 18-1J2 of the Canadian Electrical

Code, and in accordance with the authority having jurisdiction.

• When used in Class II and Class III hazardous locations these products must be installed in a dust tight enclosure in

accordance with Articles 502 and 503 of the National Electrical Code.

• For IECEx, ATEX, and INMETRO Zone 2 applications, transient protection shall be provided that is set at a level not exceeding

140% of the peak rated voltage value at the supply terminals to the equipment.

• For IECEx, ATEX, and INMETRO applications, mount the display in environments not subject to UV light exposure.

• USB device port is for maintenance use only, it is not to be used during normal operation of the device.

• Install the display in the cutout of an enclosure by using the provided clamps to compress the bezel gasket to form a seal

against the panel. The gasket seal is permanent for the installation.

• Use field/power wiring that is rated to a minimum of 90 °C (194 °F).

• Install the display in a location that minimizes the risk of impact from other objects. Do not drop, jolt, or impact the display

during installation.

• Mount the display through an enclosure wall with a minimum ingress protection rating of IP54 (Zone 2 applications) and

IP6X (Zone 22 applications), and in an overall environment not exceeding Pollution Degree 2 as defined in IEC 60664-1. The

enclosure must meet Zone 2 and/or Zone 22 ATEX/IECEx requirements depending on area of installation.

The following information applies when operating this equipment in

hazardous locations.

When marked, these products are suitable for use in Class I, Division 2,

Groups A, B, C and D; Class II, Division 2, Groups F and G; Class III

hazardous locations and nonhazardous locations only. Each product is supplied

with markings on the rating nameplate indicating the hazardous location

temperature code. When combining products within a system, the most

adverse temperature code (lowest ‘T’ number) can be used to help determine

the overall temperature code of the system. Combinations of equipment in

your system are subject to investigation by the local authority having

jurisdiction at the time of installation.

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 21

Page 22

Chapter 2 Install the PanelView Plus 7 Standard Terminal

AVERTISSEMENT : RISQUE D’ EXPLOSION

Les informations suivantes s'appliquent lorsque cet équipement fonctionne dans des zones dangereuses.

Cet équipement est utilisable uniquement en Classe I, Division 2, Groupes A, B, C et D ; Classe II, Division 2, Groupes F et G ; Classe

III dangereux et non dangereux.

• Couper le courant ou s'assurer que la zone est classée non dangereuse avant de débrancher l'équipement.

• Couper le courant ou s'assurer que la zone est classée non dangereuse avant de débrancher les connexions de l'équipement.

Fixer tous les connecteurs externes reliés à cet équipement à l'aide de vis, loquets coulissants, connecteurs filetés ou autres

moyens fournis avec ce produit.

• Lorsqu'il est installé dans une zone dangereuse, n'ouvrez pas le boîtier, ne connectez ou déconnectez pas l'équipement à

moins que la zone ne soit connue pour être non dangereuse.

• La substitution de composants peut rendre cet équipement impropre à une utilisation en Classe I, Division 2.

• Les équipements périphériques doivent convenir à l'environnement dans lequel ils sont utilisés.

• Tous les systèmes de câblage doivent être de Classe I, Division 2, Classe II, Division 2, ou Classe III conformément aux

méthodes de câblage indiquées dans les Articles 501, 502 ou 503 du Code Electrique National (National Electrical Code) et/ou

conformément à la Section 18-1J2 du Canadian Electrical Code (Code Electrique Canadien), et en fonction de l'autorité de

juridiction.

• Quand ces produits sont utilisés dans des environnements dangereux de Classe II et Classe III, ils doivent être installés dans

une enceinte étanche aux poussières conformément aux Articles 502 et 503 du Code Electrique National (National Electrical

Code).

• Pour les applications en Zone 2 IECEx, ATEX et INMETRO, une protection contre les transitoires sera fournie pour limiter les

surtensions transitoires à 140 % de la tension de crête assignée au niveau des bornes d'alimentation de l'équipement.

• Pour les applications IECEx, ATEX et INMETRO, installer l'afficheur dans des environnements non exposés aux rayonnements

ultraviolets.

• Le port pour dispositif USB est destiné à la maintenance uniquement, il ne doit pas être utilisé pendant le fonctionnement

normal du dispositif.

• Installer l'afficheur dans la découpe d'une enceinte en utilisant les fixations fournies pour comprimer le joint de

l'encadrement et assurer l'étanchéité avec la paroi. L'étanchéité du joint doit être permanente pour l'installation.

• Utiliser un câblage de terrain/d'alimentation normalisé pour une température minimum de 90°C (194°F).

• Installer l'afficheur dans un emplacement qui minimise le risque de choc par d'autres objets. Pendant l'installation,

l'afficheur ne doit pas tomber, subir des secousses ou des chocs.

• Monter l’écran dans la paroi d’un boîtier ayant un indice de protection minimum IP54 (applications de la zone 2) et IP6X

(applications de la zone 22), et dans un environnement global ne dépassant pas le degré de pollution 2, tel que défini dans la

norme IEC 60664-1. Le boîtier doit répondre aux exigences de la zone 2 et/ou de la zone 22 ATEX/ IECEx, selon la zone

d’installation.

Informations sur l'utilisation de cet équipement en environnements dangereux:

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une

utilisation en environnements de Classe I, Division 2, Groupes A, B, C et D ;

Classe II, Division 2, Groupes F et G ; Classe III dangereux et non dangereux.

Chaque produit est livré avec des marquages sur sa plaque d'identification qui

indiquent le code de température pour les environnements dangereux. Lorsque

plusieurs produits sont combinés dans un système, le code de température le

plus défavorable (code de température le plus faible) peut être utilisé pour

déterminer le code de température global du système. Les combinaisons

d'équipements dans le système sont sujettes à inspection par les autorités locales

qualifiées au moment de l'installation.

22 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 23

Install the PanelView Plus 7 Standard Terminal Chapter 2

As informações a seguir aplicam-se ao operar este equipamento em áreas

classificadas.

Os produtos marcados com “CL I, DIV 2, GP A, B, C, D” são adequados

somente para utilização em áreas classificadas de Classe I, Divisão 2, Grupos A,

B, C e D e em áreas não classificadas. Cada produto é fornecido com marcações

na placa de identificação de classificação que indicam o código de temperatura

da área classificada. Ao combinar produtos em um sistema, o código de

temperatura mais adverso (número ‘T’ mais baixo) pode ser usado para ajudar a

determinar o código de temperatura geral do sistema. As combinações de

equipamentos em seu sistema estão sujeitas à fiscalização das autoridades locais

com jurisdição no momento da instalação.

ATENÇÃO: Risco de explosão

As informações a seguir aplicam-se ao operar este equipamento em áreas classificadas.

Este equipamento é adequado para utilização em áreas classificadas de Classe I, Divisão 2, Grupos A, B, C e D; Classe II, Divisão 2,

Grupos F e G; e Classe III, bem como em áreas não classificadas.

• Não desconecte o equipamento, a não ser que a alimentação tenha sido removida ou a área seja conhecida como não

classificada.

• Não desligue as conexões deste equipamento, a não ser que a alimentação tenha sido removida ou a área seja conhecida

como não classificada. Proteja quaisquer conexões externas a este equipamento utilizando as travas deslizantes, os

conectores com rosca ou outros meios fornecidos com este produto.

• Não abra o invólucro quando instalado em área classificada. Não conecte ou desconecte o equipamento a menos que a área

seja conhecida como área não-classificada.

• A substituição dos componentes pode prejudicar a adequação para a Classe I, Divisão 2.

• Os equipamentos periféricos devem ser adequados para o local onde são utilizados.

• Toda a fiação deve estar em conformidade com os métodos de fiação de Classe I, Divisão 2, Classe II, Divisão 2 ou Classe III do

artigo 501, 502 ou 503 do Código Elétrico Nacional e/ou em conformidade com a Seção 18-1J2 do Código Elétrico Canadense

e em conformidade com a autoridade que tiver jurisdição.

• Quando usados nas áreas classificadas de Classe II e Classe III, esses produtos devem ser instalados em um compartimento

estanque ao pó, de acordo com os artigos 502 e 503 do Código Elétrico Nacional.

• Para aplicações em zona 2 IECEx, ATEX e INMETRO, deverá ser fornecida limitação transiente na aplicação que limitar as

sobretensões transientes a não mais do que 140% acima da tensão aplicada.

• Para aplicações IECEx, ATEX e INMETRO, instale a tela em ambientes onde a luz ultravioleta (UV) não possa influenciar as

partes não metálicas.

• A porta para dispositivo USB destina-se apenas para manutenção e não deve ser utilizada durante a operação normal do

dispositivo.

• Instale a tela no recorte de um gabinete utilizando os grampos fornecidos para comprimir a junta da moldura e formar uma

vedação contra o painel. A junta de vedação é permanente para a instalação.

• Utilize fiação de campo/alimentação que seja classificada para um mínimo de 90 °C (194 °F).

• Instale a tela em um local que minimize o risco de impacto de outros objetos. Não derrube, bata ou cause impacto na tela

durante a instalação.

• O display deve ser montado em um invólucro com grau de proteção mínimo IP54 quando instalado em áreas que requerem

EPL Gc (Zona 2), e IP6X para EPL Dc (Zona 22). O ambiente da instalação não pode exceder Grau de Poluição 2 conforme

definido pela IEC 60664-1. O invólucro deve ser devidamente certificado e atender aos requisitos para EPL Gc (Zona 2) e / ou

EPL Dc (Zona 22), dependendo da instalação.

The terminals have a temperature code of T4 when operating in a

55 °C (131 °F)

maximum ambient temperature. Do not install product in environments where

atmospheric gases have ignition temperatures less than 135 °C (275 °F).

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 23

Page 24

Chapter 2 Install the PanelView Plus 7 Standard Terminal

Considerations for Mounting

Clearances for Mounting

Consider the following items when mounting the terminal:

• Typically, the terminal mounts on the vertical surface of a panel or

enclosure, at a 0° angle, just below eye level.

• Mount the terminal at a height suitable for most operators.

• Mount the terminal in an area that has good lighting.

• Do not mount the terminal where it is exposed to direct sunlight.

Plan for adequate space around the terminal and inside the enclosure for

ventilation and cables. Consider the heat produced by other devices in the

enclosure. The ambient temperature around the terminal must be 0…55 °C

(32…131 °F).

Table 11 - Minimum Required Clearances

Product Area Min Clearance

Top 51 mm (2 in.)

Bottom 51 mm (2 in.)

Side 25 mm (1 in.) on side without an SD card

51 mm (2 in.) on side with SD card

Back 0 mm (0 in.)

Panel Guidelines

Mount the terminals in the door or wall of a NEMA, UL Type, or IP rated

enclosure:

• The enclosure must be of type IP20 or greater protection.

• Panels must have a minimum thickness of 1.5…4.8 mm

(0.060…0.188 in.)

• The material strength and stiffness of the panel must be sufficient to

hold the terminal and maintain an appropriate seal against water and

dust.

• The panel surface must be flat and free of imperfections to maintain an

adequate seal, and NEMA, UL Type, and IP ratings.

.

24 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 25

Install the PanelView Plus 7 Standard Terminal Chapter 2

Panel Cutout Dimensions

Use the template that is shipped with your terminal to mark the cutout

dimensions.

Table 12 - Panel Cutout Dimensions - PanelView Plus 7 Standard Terminals

Terminal Size Input Type Height, mm (in.) Width, mm (in.)

4.3-in. Touch 92 (3.62) 117 (4.61)

5.7-in. Touch 123 (4.84) 156 (6.14)

6.5-in. Touch 142 (5.59) 184 (7.24)

9.0-in. Touch 162 (6.38) 252 (9.92)

10.4-in. Touch 224 (8.82) 269 (10.59)

12.1-in. Touch 218 (8.58) 312 (12.28)

15.0-in. Touch 290 (11.42) 353 (13.90)

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 25

Page 26

Chapter 2 Install the PanelView Plus 7 Standard Terminal

Alignment Marks

Notch

Prepare for Panel Mounting

Before mounting a terminal in a panel, read this section and the entire

installation procedure on page 30

.

IMPORTANT Use catalog number 2711P-RMCS mounting levers (gray) for PanelView

Plus 7 Standard terminals. Do not use these mounting levers with any other

PanelView Plus terminals. Do not use black mounting levers; they are not

compatible with PanelView Plus 7 Standard terminals.

Mounting levers insert into the slots around the bezel to secure the terminal in

the panel. The number of mounting levers varies by terminal size.

Each slot has six notches with alignment marks that are locking positions for a

mounting lever. The thickness of the panel that you mount the terminal in

determines the locking position that is required to maintain a NEMA, UL

Type, and IP seal.

Table 13 - Mounting Lever Locking Positions

Mounting Slot

1

2

3

4

5

6

16

Mounting

Lever Lock

Posit ion

1

2

3

4

5

6

Panel Thickness Range

1.50…2.01 mm (0.060…0.079 in.) 16

2.03…2.64 mm (0.08…0.104 in.) 14

2.67…3.15 mm (0.105…0.124 in.) 12

3.17…3.66 mm (0.125…0.144 in.) 10

3.68…4.16 mm (0.145…0.164 in.) 8/9

4.19…4.80 mm (0.165…0.188 in.) 7

Typic al

Gauge

Always orient a mounting lever vertically before inserting it into a slot. This

method is the only way to slide the mounting lever knob within the slot for

positioning. After sliding the mounting lever to a specific notch, rotate the

mounting lever toward the panel to lock it in position. The flat side of the

mounting lever must come into contact with the panel.

26 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 27

Install the PanelView Plus 7 Standard Terminal Chapter 2

16 1

Flat Side

Knob on reverse side of

mounting lever inserts

into large end of slot.

12 3 4

Inner notch on mounting lever

shows current lever position.

You can use an erasable marker or grease pencil to mark the alignment

marks below the slot for visibility of slot positions.

6

3

2

6

Initially, you secure the terminal in the panel by sliding each mounting lever to

a position that is one or two notches greater than the final lock position. For

example, if the final lock position is 1, slide each mounting lever to position 2

or 3. Follow the sequence specific to the terminal size shown in Figure 2 on

page 29.

TIP If the lock position is 6, slide the mounting lever to the large end of the slot

or insertion hole.

1

Figure 1 on page 28

shows the mounting lever orientation and locking

1

sequence for a 5.7-in. and 10.4-in. terminal. See Figure 2 on page 29

sequence and mounting lever orientations for all terminals.

6

for locking

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 27

Page 28

Chapter 2 Install the PanelView Plus 7 Standard Terminal

The notch shows the locked position.

3101

2

9

4

8

6

7

5

1

3

42

5

6

All mounting levers are locked in position 1.This is appropriate for a

panel thickness of 1.50…2.01 mm (0.060…0.079 in.).

Figure 1 - Mounting Levers Shown in Locked Position

28 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 29

Install the PanelView Plus 7 Standard Terminal Chapter 2

24

6

5

9.0-in. Touch - 8 Levers

3

1

4.3-in. Touch - 4 Levers

5.7-in. Touch - 6 Levers

5

24

8

6.5-in. Touch - 6 Levers

7

6

3

1

2

3

4

3

1

2

4

6

5

1

10

3

29 4

7

5

6

8

10.4-in. and 12.1-in. Touch - 10 Levers

The box indicates that the levers must be rotated in the

orientation that is shown to avoid interference with

ports and cables.

1

IMPORTANT: The mounting lever orientations that are shown are required to maintain

NEMA, UL Type, and IP seals. If you require a NEMA, UL Type, or IP seal, do not use a

mounting lever in another orientation than shown.

15-in. Touch - 12 Levers

11

9

10

12

7

3

5

1

268

4

Figure 2 - Mounting Lever Orientation and Lock Sequence

16

16

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 29

Page 30

Chapter 2 Install the PanelView Plus 7 Standard Terminal

Gasket

Mount the Terminal in a Panel

The terminals were designed for single-person installation. No tools are

required to mount the terminal. Some tools are required to make the panel

cutout.

Follows these steps to mount the terminal in a panel.

ATT EN TI ON :

Disconnect all electrical power from the panel before making the panel cutout.

Make sure that the area around the panel cutout is clear and that the panel is

clean of any debris, oil, or other chemicals.

Make sure that metal cuttings do not enter any components that are already

installed in the panel and that the edges of the cutout have no burrs or sharp

edges.

Failure to follow these warnings can result in personal injury or damage to

panel components.

1. Use the cutout dimensions on page 25

2. Verify that the sealing gasket is present on the terminal.

This gasket forms a compression-type seal. Do not use sealing

compounds.

to cut an opening in the panel.

3. Center the terminal in the panel cutout.

4. See Table 13 on page 26

levers for the panel thickness.

5. See Figure 2 on page 29

and lock sequence for your terminal size.

to get the final lock position of the mounting

to determine the mounting lever orientations

30 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 31

Install the PanelView Plus 7 Standard Terminal Chapter 2

16

16

1 6

6

3

2

6. Secure the terminal in the panel.

TIP The mounting levers for PanelView Plus 7 Standard terminals are gray,

similar to the color of the bezel (catalog number 2711P-RMCS).

Do not use black mounting levers; they are not compatible with PanelView

Plus 7 Standard terminals.

a. Verify the orientation of the mounting lever.

The direction that you rotate each mounting lever is different for

each terminal size.

b. Hold the first mounting lever in the locking sequence vertical to the

slot and insert its knob into the large end of the slot.

c. Slide the mounting lever to a notch that is one or two positions

greater than the final locking position for your panel thickness.

If the final locking position is 1, slide the mounting lever to position 2

or 3.

1

TIP To mark the alignment marks for visibility of the slot positions and

to mark the final lock position, use an erasable marker or grease

pencil.

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 31

Page 32

Chapter 2 Install the PanelView Plus 7 Standard Terminal

1

6

d. Rotate the mounting lever until its flat side comes in contact with the

panel.

IMPORTANT Do not use tools or excessive force to rotate the mounting lever. The

mounting levers are rotated and secured by hand.

TIP A broken mounting lever does not damage the terminal.

If a mounting lever is over torqued, the lever is designed to break

off the pin. This breakage helps to prevent damage to the

terminal bezel. If a pin is broken, turn the mounting lever over

and use the other pin to continue the installation. See Figure 2 on

page 29 for details and restrictions.

6

e. Repeat steps a

through d for the remaining mounting levers.

7. Adjust each mounting lever to its final position by using the same

locking sequence in Figure 2 on page 29

.

a. Unlock mounting lever one in the sequence by rotating it away from

the bezel.

b. With the mounting lever positioned vertically to the slot, slide the

mounting lever to the final locking position in Table 13 on page 26

c. Carefully rotate the mounting lever back toward panel.

d. Repeat steps a

through c to lock the remaining mounting levers in

their final position.

.

32 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 33

Install the PanelView Plus 7 Standard Terminal Chapter 2

6

1

Terminal with dual Ethernet

ports shown.

8. To make sure each is in the correct locked position, inspect all mounting

levers.

ATTENTION: All mounting levers must be in the correct locked

position and follow the correct lever installation sequence to provide

an adequate gasket seal between the terminal and the panel.

Rockwell Automation assumes no responsibility for water or

chemical damage to the terminal or other equipment within the

enclosure because of improper installation.

The notch on the outside of mounting lever shows its locked position.

This view shows that the mounting levers are locked in position 1.

66

6

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 33

Page 34

Chapter 2 Install the PanelView Plus 7 Standard Terminal

Apply the Static Discharge Warning Label

IMPORTANT Rockwell Automation recommends applying the static discharge warning

label for all hazardous location applications according to the instructions

below. If the intended application requires ATEX or IECEx certification, the

static discharge warning label MUST be applied according to the instructions

below.

A static discharge warning label is included in the box with the PanelView Plus

7 Standard terminal. If required for your installation, this label must be affixed

to the panel in a location that is visible to the operator.

Follow these steps to apply the static discharge warning label.

1. Identify a location for the static discharge warning label that is visible to

the operator during operation.

2. Clean the desired install location with isopropyl alcohol.

3. Remove the backing from the static discharge warning label and apply

the label to the desired location.

4. Verify that operator visibility to the static discharge warning label is not

obstructed at any time during operation.

34 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 35

Install the PanelView Plus 7 Standard Terminal Chapter 2

6

66

Terminal with dual Ethernet

ports shown.

Remove and Replace Power Terminal Block

The product has a three-pin terminal block for power connections. You can

remove the terminal block for ease of installation, wiring, and maintenance.

WARNING: Explosion Hazard

If you connect or disconnect wiring while the power is on, an electric arc can

occur. This arc can cause an explosion in hazardous location installations. Make

sure that the power is off and the area is nonhazardous before proceeding.

Failure to turn power off can result in electrical shock or damage to the

terminal.

Use a 0.6 x 3.5-mm flat blade screwdriver for terminal block wiring.

Table 14 - Wire Specifications for Power Input Terminal Block

Wire Type Dual-wire Size

Stranded or solid

Cu 90 °C (194 °F)

(1) Two-wire maximum per terminal.

0.3…1.3 mm

22…16 AWG

(1)

Single-wire Size Strip Length Screw Torque

2

0.3…2.1 mm

(22…14 AWG)

2

7 mm (0.28 in.) 0.56 N•m (5.0 lb•in)

To remove the power terminal block, follow these steps.

1. Loosen the two screws that secure the terminal block.

2. Gently pull the terminal block away from the connector.

To install the power terminal block, follow these steps.

1. Press the terminal block onto the connector until seated.

ATTENTION: Do not use excessive force to press the DC terminal

block into position. The DC terminal block is keyed to fit the DC

connector. If the terminal block does not fit into the connector, verify

that you have the correct DC terminal block. See Table 5 on page 17

2. Tighten the two screws that secure the terminal block to the connector.

.

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 35

Page 36

Chapter 2 Install the PanelView Plus 7 Standard Terminal

7 mm

20 mm

GNDDC+ DC–

Terminal with dual Ethernet

ports shown.

Connect Power

The terminals have a 24-V DC non-isolated power supply at these power

ratings:

• 24V DC nominal (18…30V DC)

• 35 W maximum (1.46A at 24V DC)

ATT EN TI ON : The power supply is internally protected against reverse

polarity. Connecting DC+ or DC- to the earth ground terminal can damage

the terminal. Connecting AC power, or more than 30V DC, can also damage

the terminal.

The terminals support operation from a safety extra low voltage (SELV) or

protective extra-low voltage (PELV) 24V DC power supply. Supported power

supplies include catalog numbers 1606-XLP95E, 1606-XLP100E, and

2711P-RSACDIN.

ATT EN TI ON : Use a SELV or PELV supply as required by local wiring codes for

your installation. The SELV and PELV power sources provide protection so

that under normal and single fault conditions, the voltage between

conductors and earth ground does not exceed a safe value.

To power the terminal from the same power source as other equipment, use a

DC power bus.

To connect the operator terminal to a DC power source, follow these steps.

1. Verify that the wiring is not connected to a power source.

2. Strip 7 mm (0.28 in.) of insulation from your power supply wires.

3. Secure the DC power wires to the marked terminals (+ and –) on the

terminal block.

6

66

4. Secure the earth ground wire to the GND terminal on the terminal

block.

The GND terminal must be connected to a low-impedance earth

ground.

36 Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020

Page 37

Install the PanelView Plus 7 Standard Terminal Chapter 2

Link 2 Link 1

Terminal with dual Ethernet

ports shown.

6

66

Ethernet Ports

Link 1

Link 2

ATTENTION: The earth ground connection to ground is mandatory.

This connection is required for noise immunity, reliability, and

Electromagnetic Compliance (EMC) with the European Union (EU)

EMC Directive for CE marking conformance. This connection is

required for safety by Underwriters Laboratory (UL).

IMPORTANT Secure the power cable to prevent these actions:

• Vibration at the connector.

• Pulling when the panel door is opened and closed, or when

personnel are working inside the panel.

5. Apply power to the operator terminal.

Connect to a Network

The Ethernet port or ports connect to controllers on an EtherNet/IP™

network by using standard Ethernet connections. These types of networks are

supported:

• Device Level Ring Network Topology

on page 38

• Linear Network Topology on page 39

• Star Network Topology on page 40

Each of these EtherNet/IP network topologies supports applications that use

Integrated Motion over an EtherNet/IP network, if necessary. See the

EtherNet/IP Embedded Switch Technology Application Technique,

publication ENET-AP005

, for more information.

IMPORTANT Terminals can have dual Ethernet ports, but only one device IP address.

Ethernet Ports

The Ethernet ports have one or two 10/100Base-T connectors for network

communication and supports MDI/MDI-X connections and DLR network

topology as indicated by the DLR network icon.

The terminal connects to an EtherNet/IP network by using a CAT5, CAT5E,

or CAT6 twisted-pair, Ethernet cable with RJ45 connectors.

Rockwell Automation Publication 2711P-UM007F-EN-P - February 2020 37

Page 38

Chapter 2 Install the PanelView Plus 7 Standard Terminal

1

8

Yel lo w

Status

Indicator

Green

Status

Indicator

IMPORTANT To help prevent accidental disconnection of the Ethernet cable, follow these

steps:

• To minimize vibration at the connector, and reduce the chance that

personnel working inside the panel can accidentally disconnect the

cable, secure the Ethernet cable.

• To prevent pulling on the cable when the panel door is opened and

closed, do not install the Ethernet cable too tightly. Leave some slack in

the cable.

The maximum cable length between the Ethernet ports and a 10/100Base-T

port on an Ethernet hub (without repeaters or fiber) is 100 m (328 ft).

WARNING: Do not connect or disconnect any communication cable with

power applied to this device or any device on the network. An electric arc

can cause an explosion in hazardous location installations. Make sure that

the power is off or the area is nonhazardous before proceeding.

Table 15 - Ethernet Connector Pinout

Connector Pin Pin Name

View of RJ45

Conne ctor

1TD+

2TD-

3RD+

4Unused

5Unused

6RD-

7Unused