Page 1

DeviceNet

Modules in

Logix5000™

Control Systems

1734-ADN, 1734-ADNX, 1734-PDN,

1756-DNB, 1769-SDN, 1784-PCIDS,

1788-CN2DN, 1788-DNBO,

1788-EN2DN, 1794-ADN

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the drive to alert

people that dangerous voltage may be present.

Labels may be located on or inside the drive to alert

people that surfaces may be dangerous temperatures.

Page 3

Preface

About This Manual

To: See :

get started with a Logix5000 controller DeviceNet Modules in Logix5000™ Control Systems, publication

Look up abbreviated information and procedures

regarding programming languages, instructions,

communications, and status

program a Logix5000 controller—detailed and

comprehensive information

program a specific Logix5000 programming

instruction

import or export a Logix5000 project or tags from or

to a text file

convert a PLC-5 or SLC 500 application to a

Logix5000 project

control devices over an EtherNet/IP network EtherNet/IP Modules in Logix5000 Control Systems User

control devices over an ControlNet™ network ControlNet Modules in Logix5000 Control Systems User Manual,

You are

here

control devices over an DeviceNet™ network DeviceNet Modules in Logix5000 Control Systems User Manual,

The manual is one of various Logix5000 manuals.

1756-QS001

Logix5000 Controllers System Reference, publication

1756-QR007

Logix5000 Controllers Common Procedures, publication

1756-PM001

• Logix5000 Controllers General Instructions Reference

Manual, publication 1756-RM003

• Logix5000 Controllers Process and Drives Instructions

Reference Manual, publication 1756-RM006

• Logix5000 Controllers Motion Instruction Set Reference

Manual, publication 1756-RM007

Logix5000 Controllers Import/Export Reference Manual,

publication 1756-RM084

Logix5550 Controller Converting PLC-5 or SLC 500 Logic to

Logix5550 Logic Reference Manual, publication 1756-6.8.5

Manual, publication ENET-UM001

publication CNET-UM001

publication DNET-UM004

This manual guides the development of a control system that uses a

Logix5000™ controller and a DeviceNet™ network. A Logix5000

controller is any of the following:

• 1756 ControlLogix® controllers

• 1769 CompactLogix™ controllers

• 1789 SoftLogix5800™ controllers

• 1794 FlexLogix™ controllers

• PoweFlex®700S with DriveLogix™ controllers

1 Publication DNET-UM004A-EN-P - March 2004

Page 4

Preface 2

Who Should Use this

This manual is for those who program or maintain industrial

automation systems.

Manual

To use this manual, you must already have experience with:

• programmable controllers

• industrial automation systems

• personal computers and Windows® 95, Windows 98,

Windows NT®, or Windows 2000 operating system

Conventions in this Manual

Text that is: Identifies: For example: Means:

Italic the actual name of an item that you

see on your screen or in an example

courier information that you must supply

based on your application (a

variable)

enclosed in brackets a keyboard key Press [Enter]. Press the Enter key.

As you use this manual, you will see some terms that are formatted

differently from the rest of the text:

Right-click User-Defined … Right-click on the item that is named

User-Defined.

Right-click

name_of_program …

You must identify the specific program in

your application. Typically, it is a name or

variable that you have defined.

Publication DNET-UM004A-EN-P - March 2004

Page 5

Before You Begin

Configure Your Network Offline

Table of Contents

Chapter 1

What This Manual Covers . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Preliminary Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Choose a Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Bridging Across Networks . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Choose a Baud Rate for the Network . . . . . . . . . . . . . . . . . 1-9

If You Want to Use a Higher Baud Rate… . . . . . . . . . . 1-10

Calculate Scanner Memory Requirements . . . . . . . . . . . . . . 1-11

Check the I/O Limits of the Scanner . . . . . . . . . . . . . . . 1-11

If You Are Using a SoftLogix5800 Controller . . . . . . . . . 1-12

Assign an Address to Each Device . . . . . . . . . . . . . . . . . . . 1-13

Chapter 2

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Create a File for the Network. . . . . . . . . . . . . . . . . . . . . . . 2-3

Create a DeviceNet Configuration File. . . . . . . . . . . . . . 2-3

Give the File a Descriptive Name . . . . . . . . . . . . . . . . . 2-3

Draw Your Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

If Your Device Is Not in the Hardware List… . . . . . . . . 2-4

Configure Each Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Specify the Address of the Device. . . . . . . . . . . . . . . . . 2-6

Configure the Parameters of the Device . . . . . . . . . . . . 2-7

Configure the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Specify the Address of the Scanner . . . . . . . . . . . . . . . 2-9

Define the Properties of the Scanner. . . . . . . . . . . . . . . 2-10

Set the Alignment Option . . . . . . . . . . . . . . . . . . . . . . . 2-11

Clear or Set the Automap on Add Check Box . . . . . . . . 2-12

Build the Scan List . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Manually Assign Each Device to a Memory Location . . . 2-14

Close the Configuration of the Scanner . . . . . . . . . . . . . 2-15

Save the Network File . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Generate an RSNetWorx Report . . . . . . . . . . . . . . . . . . . . . 2-16

Download the Configuration to Network . . . . . . . . . . . . . . 2-17

Before You Download the Configuration . . . . . . . . . . . 2-17

Open the Configuration File for the Network . . . . . . . . 2-17

Go Online to the Network . . . . . . . . . . . . . . . . . . . . . . 2-18

Download the Configuration to the Network. . . . . . . . . 2-19

Chapter 3

Connect a Computer to the System

1 Publication DNET-UM004A-EN-P - March 2004

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Connect a Computer to a Network. . . . . . . . . . . . . . . . . . . 3-2

Configure a Driver for a Network . . . . . . . . . . . . . . . . . . . 3-3

Add the Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Make Sure the Driver Works. . . . . . . . . . . . . . . . . . . . . 3-6

Page 6

Table of Contents 2

Automatically Configure a

DeviceNet Network

Chapter 4

How To Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Determine If You Can Use AutoScan . . . . . . . . . . . . . . . . . 4-1

How AutoScan Effects Your Network. . . . . . . . . . . . . . . . . 4-2

Install the Node Commissioning Tool. . . . . . . . . . . . . . . . . 4-2

Connect Each Device to the Network. . . . . . . . . . . . . . . . . 4-3

Set the Address of a Scanner . . . . . . . . . . . . . . . . . . . . 4-4

Set the Address and Baud Rate of a Device Via Software 4-5

Add the Scanner to the RSLogix 5000 Project . . . . . . . . . . . 4-6

Add the Scanner to the I/O Configuration Folder . . . . . 4-6

Define the Properties of the Scanner. . . . . . . . . . . . . . . 4-7

Turn On AutoScan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Download the RSLogix 5000 Project and Go Online . . . 4-7

Turn On AutoScan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Access Device Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Put the Scanner in Run Mode . . . . . . . . . . . . . . . . . . . . . . 4-11

Additional Information About AutoScan . . . . . . . . . . . . . . . 4-12

Type of Connection that the Scanner Sets Up . . . . . . . . 4-12

Allocating More Memory for Each Device . . . . . . . . . . . 4-12

Connect Each Device to the

Network

Configure Your Network Online

Chapter 5

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Set the Address of a Device . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Set an Address with Software. . . . . . . . . . . . . . . . . . . . . . . 5-3

Procedures for Specific Devices . . . . . . . . . . . . . . . . . . . . . 5-4

ControlLogix Scanner 1756-DNB. . . . . . . . . . . . . . . . . . 5-4

CompactLogix Scanner 1769-SDN . . . . . . . . . . . . . . . . . 5-4

ControlNet to DeviceNet Linking Device 1788-CN2DN 5-5

DriveLogix and FlexLogix Scanner 1788-DNBO . . . . . . . 5-5

EtherNet/IP to DeviceNet Linking Device 1788-EN2DN . 5-6

SoftLogix5800 Scanner 1784-PCIDS . . . . . . . . . . . . . . . . 5-10

Make Sure Your Devices Are on the Network. . . . . . . . . . . 5-11

Chapter 6

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Create a File for the Network. . . . . . . . . . . . . . . . . . . . . . . 6-3

Create a DeviceNet Configuration File. . . . . . . . . . . . . . 6-4

Give the File a Descriptive Name . . . . . . . . . . . . . . . . . 6-4

Go Online to the Network. . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Configure Each Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Upload the Configuration of a Device. . . . . . . . . . . . . . 6-7

Change and Download Parameters . . . . . . . . . . . . . . . . 6-8

Configure the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Publication DNET-UM004A-EN-P - March 2004

Page 7

Control a Device

Table of Contents 3

Upload the Current Configuration of the Scanner . . . . . 6-10

Define the Properties of the Scanner. . . . . . . . . . . . . . . 6-11

Set the Alignment Option . . . . . . . . . . . . . . . . . . . . . . . 6-12

Clear or Set the Automap on Add Check Box . . . . . . . . 6-13

Build the Scan List . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Manually Assign Each Device to a Memory Location . . . 6-15

Download the Configuration to the Scanner . . . . . . . . . 6-16

Upload and Save the Network File. . . . . . . . . . . . . . . . . . . 6-16

Generate an RSNetWorx Report . . . . . . . . . . . . . . . . . . . . . 6-17

Chapter 7

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Before You Use This Chapter . . . . . . . . . . . . . . . . . . . . . . 7-2

Add the Scanner to the I/O Configuration of the Controller 7-3

If You Need to Conserve EtherNet/IP or ControlNet Network

Bandwidth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Add the Scanner to the I/O Configuration Folder . . . . . 7-5

Define the Properties of the Scanner. . . . . . . . . . . . . . . 7-6

Determine the Address of DeviceNet Data . . . . . . . . . . . . . 7-7

If You Have a SoftLogix5800 Controller . . . . . . . . . . . . 7-9

Program Your Logic With Alias Tags . . . . . . . . . . . . . . . . . 7-10

Determine If a Device Has Failed . . . . . . . . . . . . . . . . . . . 7-11

Place the Scanner in Run Mode . . . . . . . . . . . . . . . . . . . . . 7-12

When to Use a MSG Instruction. . . . . . . . . . . . . . . . . . . . . 7-13

Determine the Parameter Number to Access. . . . . . . . . . . . 7-13

Determine the Configuration of the Parameter . . . . . . . . . . 7-14

Test the Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Enter Message Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Define the Source or Destination Data . . . . . . . . . . . . . 7-17

Enter and Configure the MSG Instruction . . . . . . . . . . . 7-18

Set the Communication Path. . . . . . . . . . . . . . . . . . . . . 7-19

Interlock and Share Inputs

Chapter 8

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Interlock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Choose a Master Controller . . . . . . . . . . . . . . . . . . . . . 8-2

Determine How Much Data to Exchange . . . . . . . . . . . 8-2

Enable Slave Mode for the Slave Scanner . . . . . . . . . . . 8-3

Map the Slave Mode Data. . . . . . . . . . . . . . . . . . . . . . . 8-4

Add the Slave to the Scan List of the Master . . . . . . . . . 8-4

Map the Data of the Slave . . . . . . . . . . . . . . . . . . . . . . 8-5

Place Both Scanners In Run Mode . . . . . . . . . . . . . . . . 8-5

Share Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Add the Input to the First Scanner . . . . . . . . . . . . . . . . 8-5

Add the Input to the Second Scanner . . . . . . . . . . . . . . 8-6

Publication DNET-UM004A-EN-P - March 2004

Page 8

Table of Contents 4

Communicate with a PanelView™

Standard Terminal

Map the Input Data in the Second Scanner . . . . . . . . . . 8-7

Chapter 9

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Choose Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Choose an Communication Method . . . . . . . . . . . . . . . . . . 9-2

I/O Slave Communication . . . . . . . . . . . . . . . . . . . . . . 9-2

Explicit Server Communication . . . . . . . . . . . . . . . . . . . 9-3

Explicit Client Communication . . . . . . . . . . . . . . . . . . . 9-3

Plan and Configure I/O Slave Tags . . . . . . . . . . . . . . . . . . 9-4

Use a Word/Bit Format for Each Tag . . . . . . . . . . . . . . 9-5

For Integers, Skip Every Other Word . . . . . . . . . . . . . . 9-5

Configure an I/O Slave Tag . . . . . . . . . . . . . . . . . . . . . 9-6

Set Up the Terminal on the Network . . . . . . . . . . . . . . . . . 9-7

Set the Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Set the Network Address and I/O Sizes. . . . . . . . . . . . . 9-8

Configure the Scanner to Update I/O Slave Tags . . . . . . . . 9-9

Add the Terminal to the Scan List . . . . . . . . . . . . . . . . . 9-9

Edit I/O Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Map Input and Output Data . . . . . . . . . . . . . . . . . . . . . 9-10

Address I/O Slave Tags in the RSLogix 5000 Project . . . . . . 9-11

Plan and Configure Explicit Server Tags . . . . . . . . . . . . . . . 9-13

Assign Assembly Instances . . . . . . . . . . . . . . . . . . . . . . 9-13

For Integers, Skip Every Other Word . . . . . . . . . . . . . . 9-14

Configure an Explicit Server Tag. . . . . . . . . . . . . . . . . . 9-15

Program the Controller to Get/Set Explicit Server Tags . . . . 9-16

Create an Array for the Assembly Instance . . . . . . . . . . 9-16

Enter and Configure the MSG Instruction . . . . . . . . . . . 9-17

Set the Communication Path. . . . . . . . . . . . . . . . . . . . . 9-18

Configure Explicit Client Tags . . . . . . . . . . . . . . . . . . . . . . 9-19

Determine the Parameter Number to Access . . . . . . . . . 9-19

Determine the Configuration of the Parameter. . . . . . . . 9-20

Configure an Explicit Client Tag . . . . . . . . . . . . . . . . . . 9-21

Communicate with an RSView®

Project

Tune the Performance of a

DeviceNet Network

Publication DNET-UM004A-EN-P - March 2004

Chapter 10

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Before You Use This Chapter . . . . . . . . . . . . . . . . . . . . . . 10-2

Create a Topic for the Device . . . . . . . . . . . . . . . . . . . . . . 10-3

Create a Node. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Create a Tag for the Parameter . . . . . . . . . . . . . . . . . . . . . 10-5

Chapter 11

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Factors that Effect Performance . . . . . . . . . . . . . . . . . . . . . 11-2

I/O Parameters of Each Device. . . . . . . . . . . . . . . . . . . 11-3

Page 9

Troubleshoot a DeviceNet

Network

Table of Contents 5

Background Poll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Interscan Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Change the Configuration of the Network . . . . . . . . . . . . . 11-5

Upload the Current Configuration of the Scanner . . . . . 11-5

Set the Interscan Delay and Poll Ratio. . . . . . . . . . . . . . 11-6

Set the I/O Parameters of a Device . . . . . . . . . . . . . . . . 11-6

Download the Configuration to the Scanner . . . . . . . . . 11-8

Save the Network File . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Chapter 12

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Front Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

CompactLogix Scanner 1769-SDN . . . . . . . . . . . . . . . . . 12-1

ControlLogix Scanner 1756-DNB. . . . . . . . . . . . . . . . . . 12-3

ControlNet to DeviceNet Linking Device 1788-CN2DN 12-5

DriveLogix and FlexLogix Scanner 1788-DNBO . . . . . . . 12-7

EtherNet/IP to DeviceNet Linking Device 1788-EN2DN . 12-8

SoftLogix5800 Scanner 1784-PCIDS . . . . . . . . . . . . . . . 12-11

Status Tags in the Controller . . . . . . . . . . . . . . . . . . . . . . 12-13

Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

Status Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

Automate the Replacement of a

Failed Device

Using FLEX™ I/O Modules on a

DeviceNet Network

Chapter 13

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

How to Automate the Replacement of a Failed Device . . . . 13-1

Set Up Automatic Device Recovery . . . . . . . . . . . . . . . . . . 13-3

Choose an Electronic Key Level for a Device . . . . . . . . 13-3

Update the Network Configuration File. . . . . . . . . . . . . 13-4

Define the Electronic Key. . . . . . . . . . . . . . . . . . . . . . . 13-5

Enable Auto-Address Recovery for the Scanner . . . . . . . 13-6

Set the ADR Settings for the Device . . . . . . . . . . . . . . . 13-6

Download the Changes to the Scanner . . . . . . . . . . . . . 13-7

Upload and Save the Network File . . . . . . . . . . . . . . . . 13-7

Chapter 14

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Tally Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . 14-2

Assign an Address to the Adapter . . . . . . . . . . . . . . . . . . . 14-3

If You Configure the Adapter Offline . . . . . . . . . . . . . . . . . 14-3

Set the Address of the Adapter. . . . . . . . . . . . . . . . . . . . . . 14-4

If You Change the Configuration of the Adapter. . . . . . . . . 14-4

Interpret the Status Indicators . . . . . . . . . . . . . . . . . . . . . . 14-5

Publication DNET-UM004A-EN-P - March 2004

Page 10

Table of Contents 6

Using POINT™ I/O Modules on a

DeviceNet Network

Chapter 15

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Choose a Connecting Device . . . . . . . . . . . . . . . . . . . . . . . 15-2

Tally Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . 15-3

POINT I/O 1734-ADN or 1734-ADNX Adapter. . . . . . . . 15-3

POINT I/O 1734-PDN Interface . . . . . . . . . . . . . . . . . . 15-4

Assign Addresses to the Modules . . . . . . . . . . . . . . . . . . . . 15-4

Set the Address of a Module . . . . . . . . . . . . . . . . . . . . . . . 15-5

POINT I/O Interface 1734-PDN . . . . . . . . . . . . . . . . . . 15-5

POINT I/O Module 1734 . . . . . . . . . . . . . . . . . . . . . . . 15-5

POINT I/O Adapter 1734-ADN and 1734-ADNX . . . . . . 15-6

POINTBlock I/O Module 1734D . . . . . . . . . . . . . . . . . . 15-6

Automatically Sequence Point I/O Addresses . . . . . . . . . . . 15-7

Configure a Point I/O Adapter. . . . . . . . . . . . . . . . . . . . . . 15-8

Upload the Configuration of the ADN/ADNX Adapter . . 15-9

Configure the Adapter to Execute an Auto Start. . . . . . 15-10

Create a File for the Subnet . . . . . . . . . . . . . . . . . . . . 15-11

Access the Subnet . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-11

Upload the Subnet Configuration and Save It to a File. 15-12

Specify the Subnet File in the Configuration of the Adapter .

15-12

If You Change the Configuration of the Adapter. . . . . . . . 15-13

Interpret the Status Indicators . . . . . . . . . . . . . . . . . . . . . 15-13

POINT I/O Interface 1734-PDN . . . . . . . . . . . . . . . . . 15-13

POINT I/O Module 1734 . . . . . . . . . . . . . . . . . . . . . . 15-14

POINT I/O Adapter 1734-ADN and 1734-ADNX . . . . . 15-14

POINTBlock I/O Module 1734D . . . . . . . . . . . . . . . . . 15-17

Interpret POINT I/O Data (Data Maps) . . . . . . . . . . . . . . 15-18

1734-IA2 Input Module . . . . . . . . . . . . . . . . . . . . . . . 15-19

1734-IB2 Sink Input Module . . . . . . . . . . . . . . . . . . . . 15-19

1734-IB4 Sink Input Module . . . . . . . . . . . . . . . . . . . . 15-19

1734-IV2 Source Input Module . . . . . . . . . . . . . . . . . . 15-20

1734-IV4 Source Input Module . . . . . . . . . . . . . . . . . . 15-20

1734-OA2 Output Module . . . . . . . . . . . . . . . . . . . . . 15-20

1734-OB2E Electronically Protected Output Module . . 15-21

1734-OB2EP Protected Output Module . . . . . . . . . . . . 15-21

1734-OB4E Electronically Protected Output Module . . 15-21

1734-OV2E Protected Sink Output Module . . . . . . . . . 15-22

1734-OV4E Protected Sink Output Module . . . . . . . . . 15-22

1734-OW2 Relay Sink/Source Output Module . . . . . . . 15-23

1734-OX2 Relay Output Module . . . . . . . . . . . . . . . . . 15-23

1734-IE2C Analog Current Input Module. . . . . . . . . . . 15-23

1734-IE2V Analog Input Module . . . . . . . . . . . . . . . . . 15-24

1734-OE2C Analog Current Output Module. . . . . . . . . 15-25

1734-OE2V Analog Output Module. . . . . . . . . . . . . . . 15-25

1734-IJ Encoder/Counter Module . . . . . . . . . . . . . . . . 15-26

Publication DNET-UM004A-EN-P - March 2004

Page 11

Give a Value Its Own Memory

Location

Table of Contents 7

1734-IK Encoder/Counter Module. . . . . . . . . . . . . . . . 15-26

1734-IM2 Input Module . . . . . . . . . . . . . . . . . . . . . . . 15-27

1734-IR2 RTD Input Module . . . . . . . . . . . . . . . . . . . . 15-27

1734-IT2I Isolated Thermocouple Input Module . . . . . 15-28

1734-VHSC 24V dc High Speed Counter Module . . . . . 15-29

1734-VHSC 5V dc High Speed Counter Module . . . . . . 15-30

1734-SSI Synchronous Serial Interface Absolute

Encoder Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-30

1734-232ASC ASCII Module . . . . . . . . . . . . . . . . . . . . 15-31

Appendix A

When to Use This Appendix . . . . . . . . . . . . . . . . . . . . . . . A-1

Give a Value Its Own Memory Location. . . . . . . . . . . . . . . A-2

Publication DNET-UM004A-EN-P - March 2004

Page 12

Table of Contents 8

Publication DNET-UM004A-EN-P - March 2004

Page 13

Before You Begin

Chapter

1

What This Manual Covers

This manual guides the development of a control system that uses a

Logix5000™ controller and a DeviceNet™ network. This manual

shows how to:

• connect the controller to the network

• establish control of the devices

• interlock and share input data

• access the network via an operator or HMI terminal

• interpret status and diagnostic information

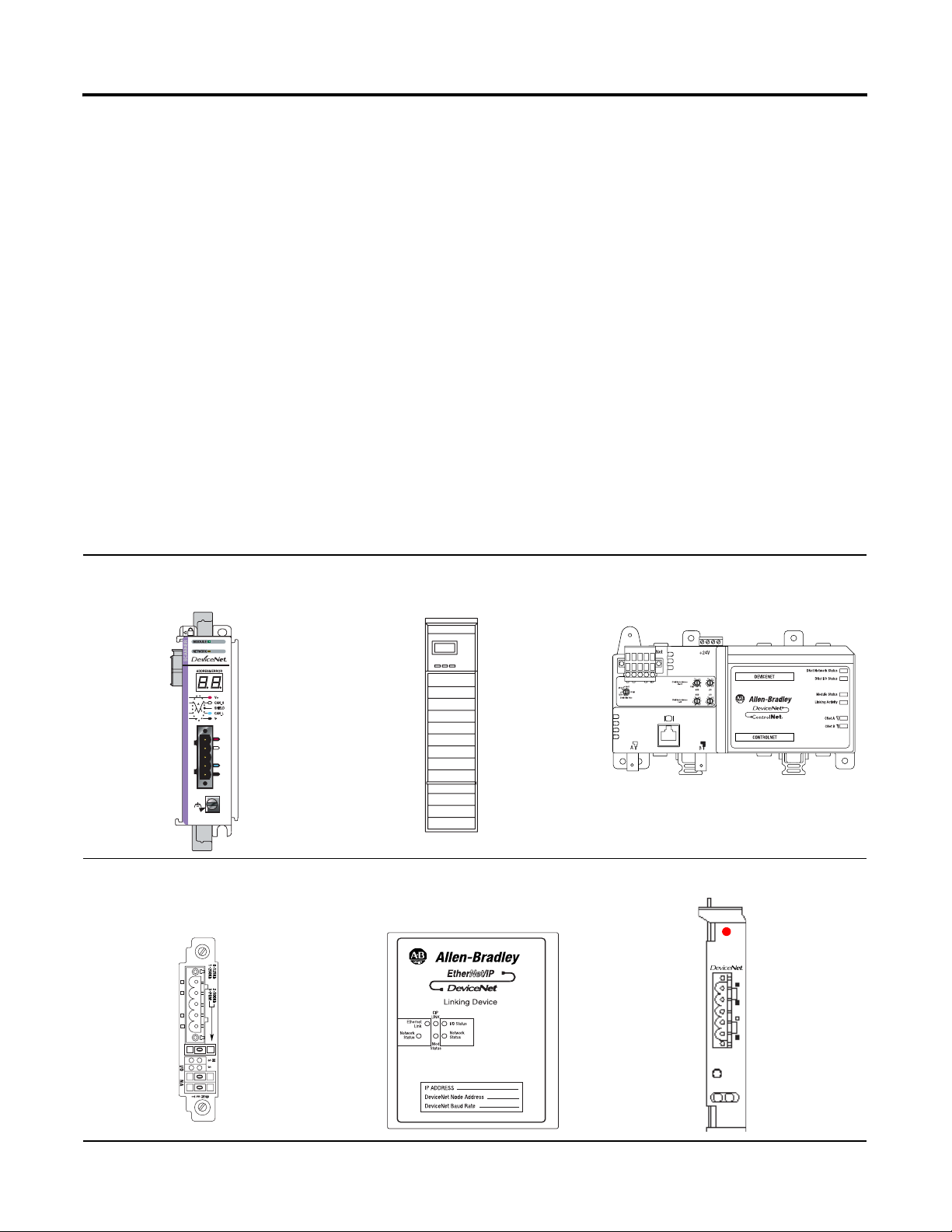

To control the devices on a DeviceNet network, a Logix5000

controller uses one of the following scanners:

CompactLogix™ Scanner 1769-SDN ControlLogix® Scanner 1756-DNB

ControlNet to DeviceNet Linking

Device 1788-CN2DN

DriveLogix™ and FlexLogix™

Communication Card 1788-DNBO

N

31288-M

1 Publication DNET-UM004A-EN-P - March 2004

EtherNet/IP to DeviceNet Linking

Device 1788-EN2DN

SoftLogix™ 5800 Scanner 1784-PCIDS

S

Allen-Bradley

1784-PCIDS

Scanner

I/O

MOD NET

Page 14

1-2 Before You Begin

This manual also provides a basic level of information to use the

following devices on your DeviceNet network.

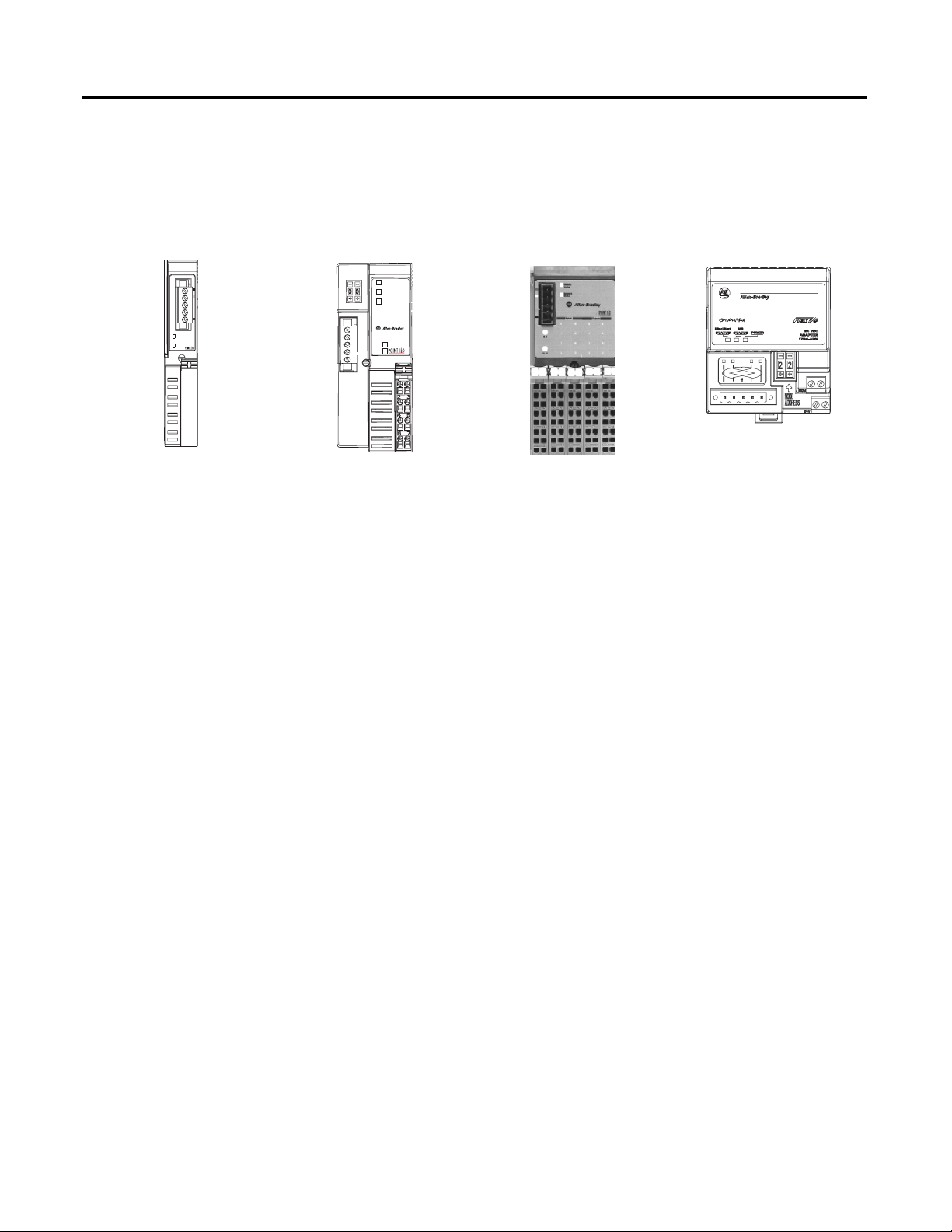

POINT™ I/O Interface

1734-PDN

POINT™ I/O Adapter

1734-ADN and 1734-ADNX

Adapter

Status

DeviceNet

Status

PointBus

Status

1734-ADN

System

Power

DeviceNet

Power

POINT™Block I/O Module

1734D

FLEX™ I/O Adapter

1794-ADN

Publication DNET-UM004A-EN-P - March 2004

Page 15

Before You Begin 1-3

Preliminary Actions

Before you configure and program your DeviceNet network, complete

the following actions:

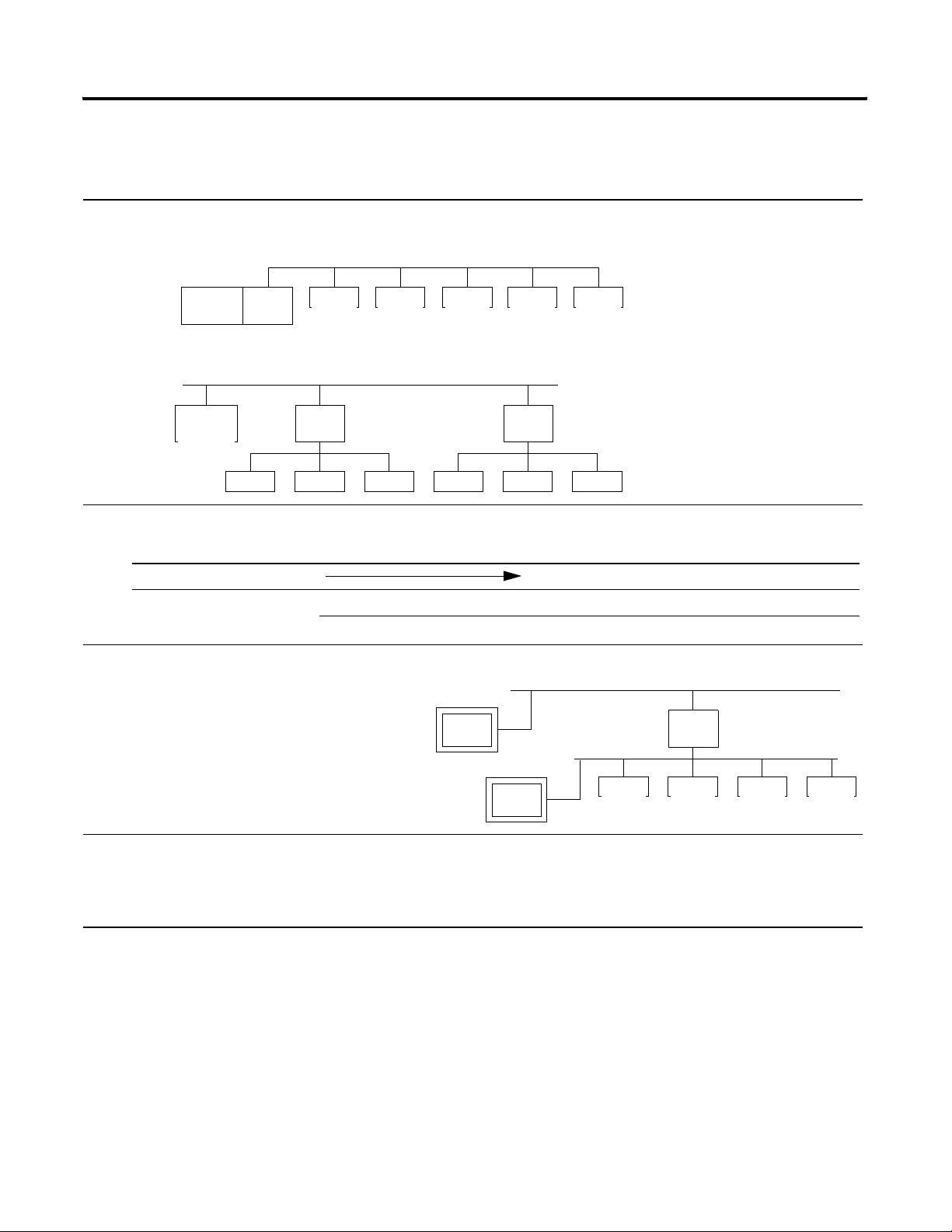

❑

1. Choose whether to use a single network or several distributed networks. (For more information, see page 1-5.)

❑ single network

scannercontroller

device device device device

❑ several smaller distributed networks (subnets)

controller

device

linking

device

device device

❑ 2. Choose a scanner. (For more information, see page 1-5.)

If you are using: And the main network is: Use this scanner:

single network Corresponding scanner for your controller

subnets EtherNet/IP EtherNet/IP to DeviceNet Linking Device 1788-EN2DN

ControlNet™ ControlNet to DeviceNet Linking Device 1788-CN2DN

device

device

linking

device

device device

❑ 3. Choose how to connect your computer to the DeviceNet network. (For more information, see page 1-6.)

Connect to another network and bridge to the

DeviceNet network. Requires a bridge device.

Connect directly to the DeviceNet network. Requires a

device

bridge

device

device device device

DeviceNet interface device.

❑ 4. Choose a baud rate. (For more information, see page 1-9.)

❑ 125K bit/s (default— good starting point)

❑ 250K bit/s

❑ 500K bit/s

Publication DNET-UM004A-EN-P - March 2004

Page 16

1-4 Before You Begin

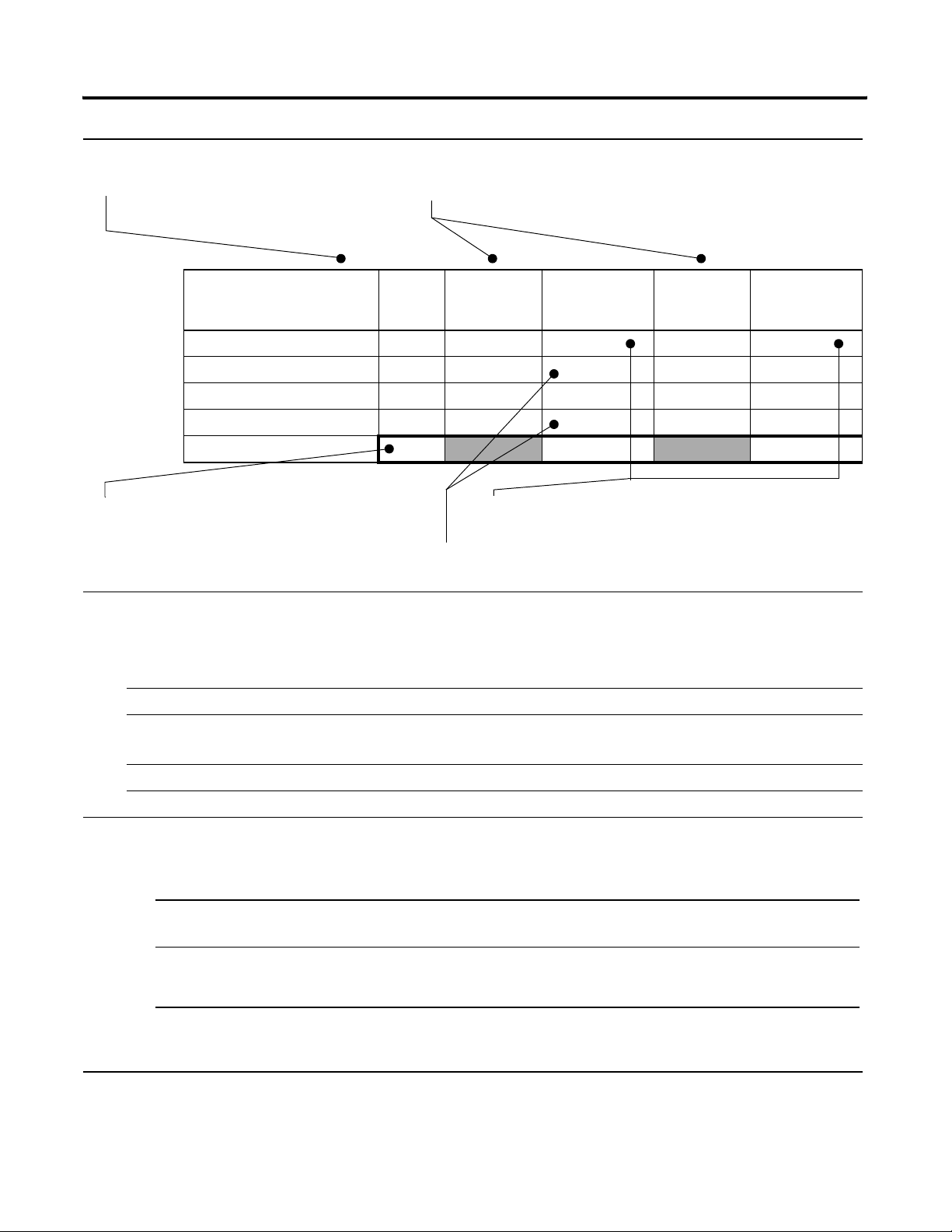

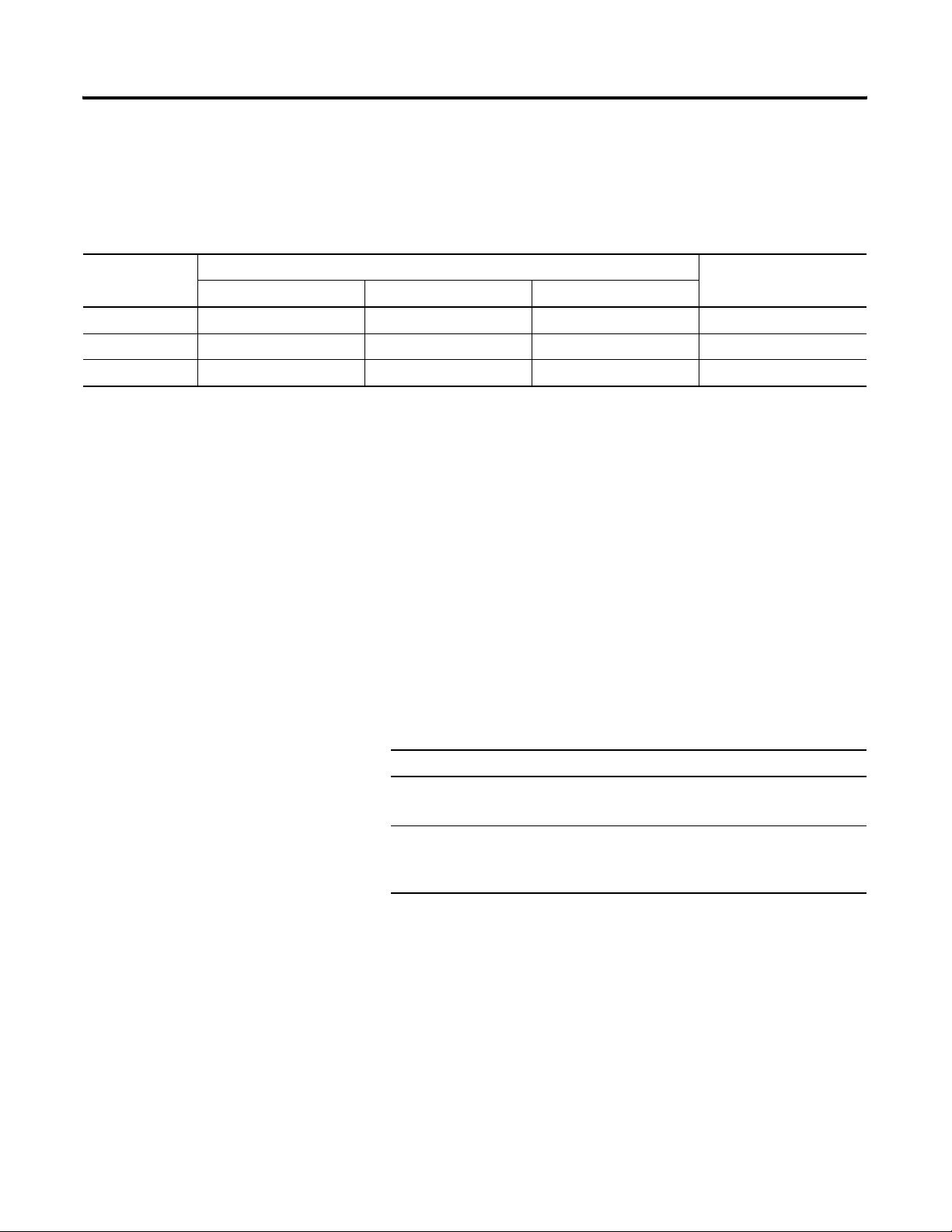

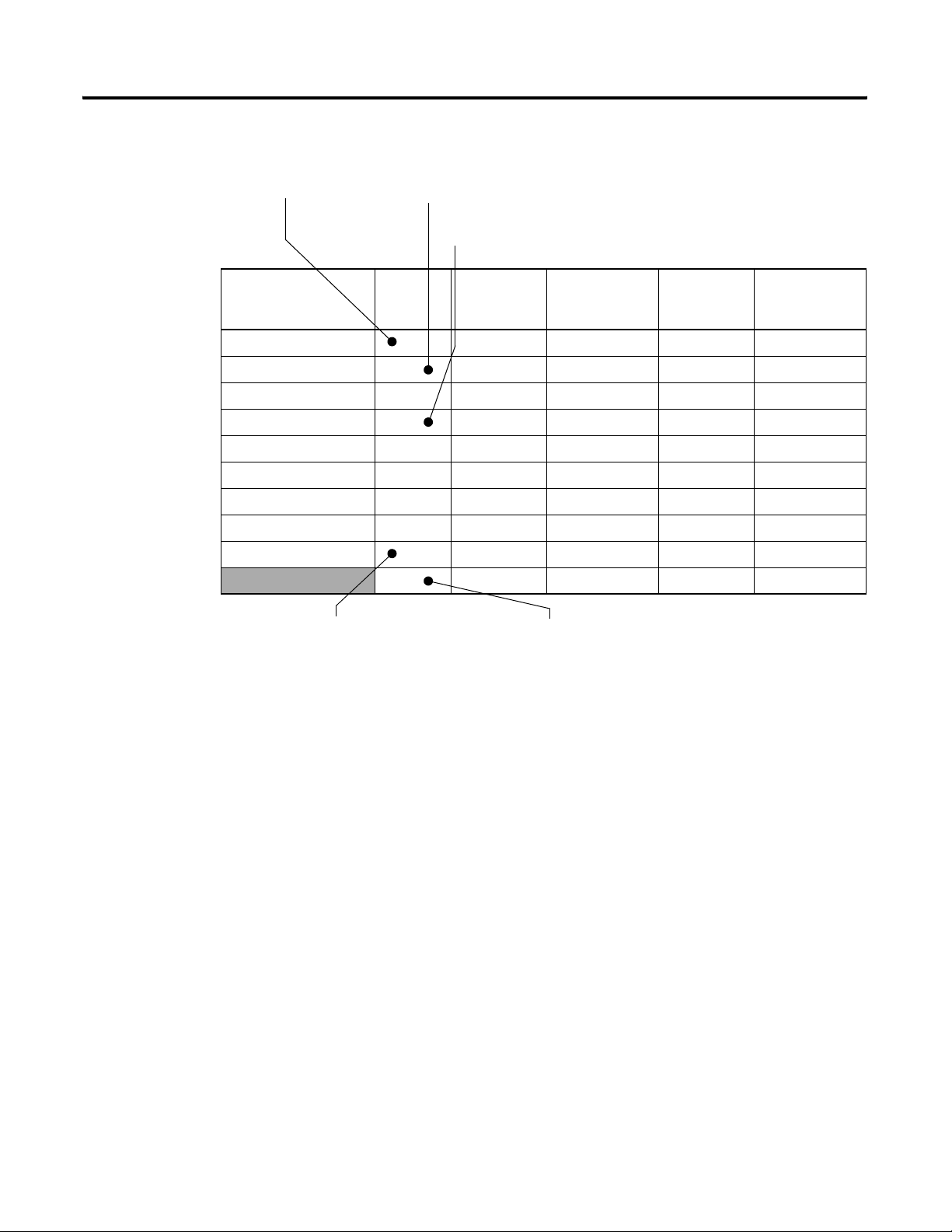

❑ 5. Calculate how much scanner memory you need. (For more information, see page 1-11.)

A. List the devices on your network. B. Record how many bytes each device sends to your control system (input

data) and gets from your control system (output data).

Device Address Input Size of

Device

(bytes)

Input Memory

in Scanner

(DINTs)

Output Size

of Device

(bytes)

Output Memory

in Scanner

(DINTs)

start/stop buttons 1 1 1 1

<empty> 22

I/O adapter w/ modules 9 3 5 2

<empty> 22

E. Total memory that you need in the

scanner.

Total

C. Convert the input and outputs sizes to DINTs, where:

DINTs = (bytes/4) rounded up to an integer.

8 7

D. Add several DINTs between each device in case you want to make

changes later.

❑ 6. Assign an address to each device. The following addresses are recommended but not required. (For more information, see

page 1-13.)

Tip : For flexibility as you develop your system, leave gaps between addresses. Gaps have no effect on system performance.

Give this address: To this device:

0 Scanner

1 to 61 Your devices

Give the lower addresses to devices with 15 bytes or more of input or output data.

62 Computer interface, such as a 1770-KFD or 1784-PCD device

63 Leave open for new or replacement devices.

❑ 7. Make sure you have the required software.

❑ To configure the network:

If: And your scanner is: Configure the network with:

every device on your network (except the scanner)

uses 4 or less bytes of input and output data

some devices use more than 4 bytes of input or

output data

❑ To program the controller, use RSLogix™ 5000 software.

❑ To connect your computer to the network, use RSLinx® software.

Publication DNET-UM004A-EN-P - March 2004

• ControlLogix® 1756-DNB

• FlexLogix™ 1788-DNBO

any RSNetWorx™ for DeviceNet software

RSLogix™ 5000 software (For more

information, see chapter 4.)

(For more information, see chapters 2

and 6.)

Page 17

Before You Begin 1-5

Choose a Scanner

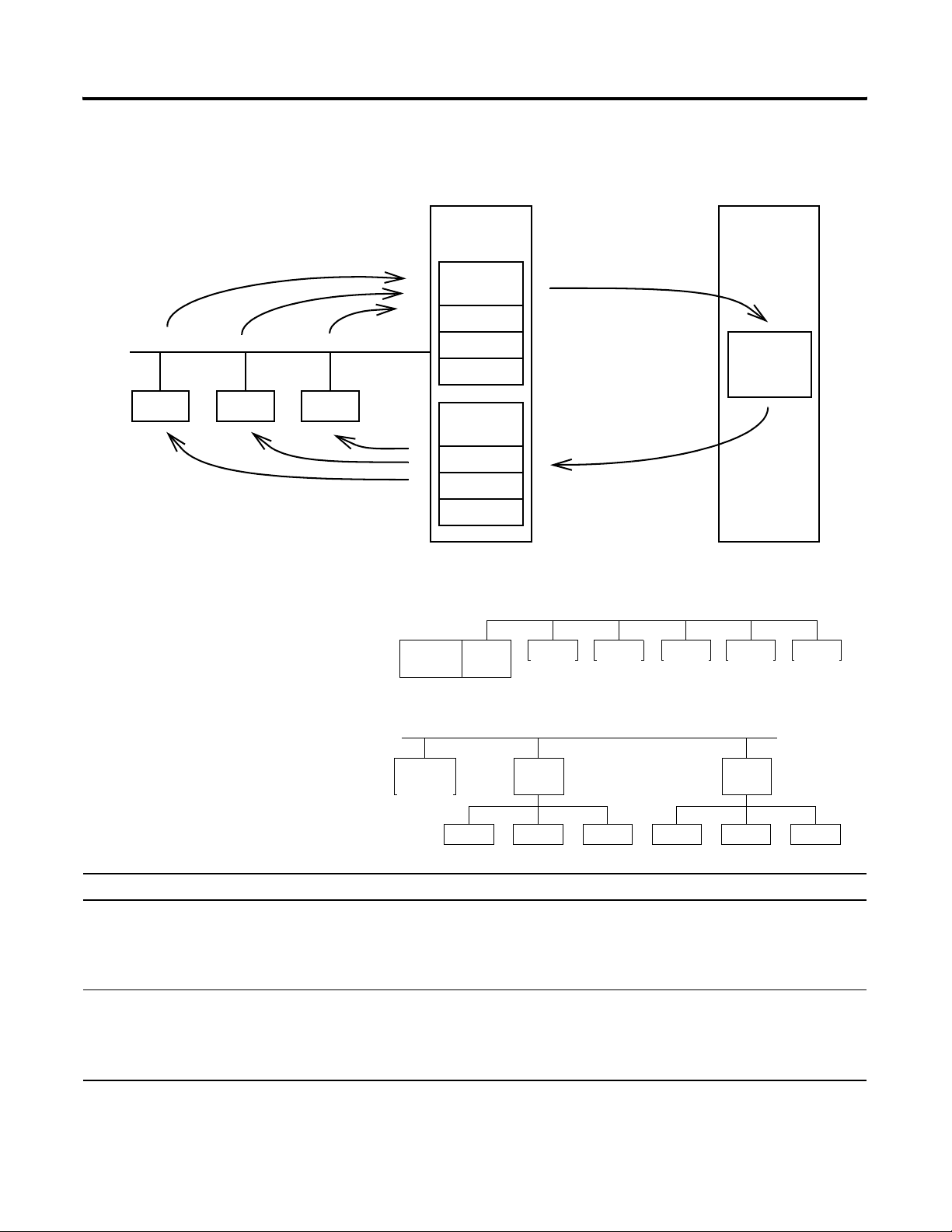

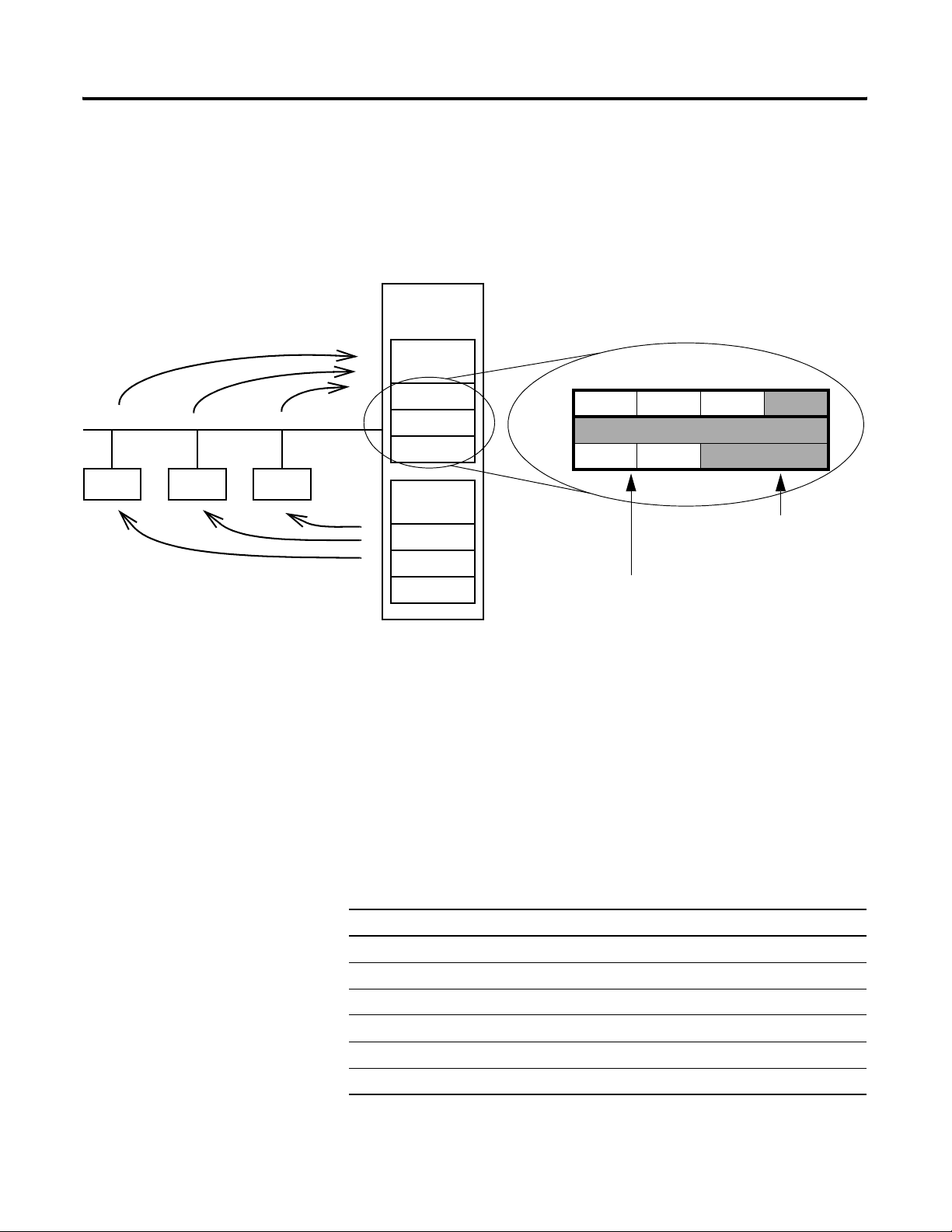

The scanner collects input data from

the devices on the network…

device device device

…and sends the data to the devices.

The DeviceNet scanner connects a controller to the devices on a

DeviceNet network.

scanner

module

Input

Memory

DINT

DINT

DINT

Output

Memory

DINT

DINT

DINT

…and sends the data to

the controller.

The scanner collects output

data from the controller…

controller

controller

data

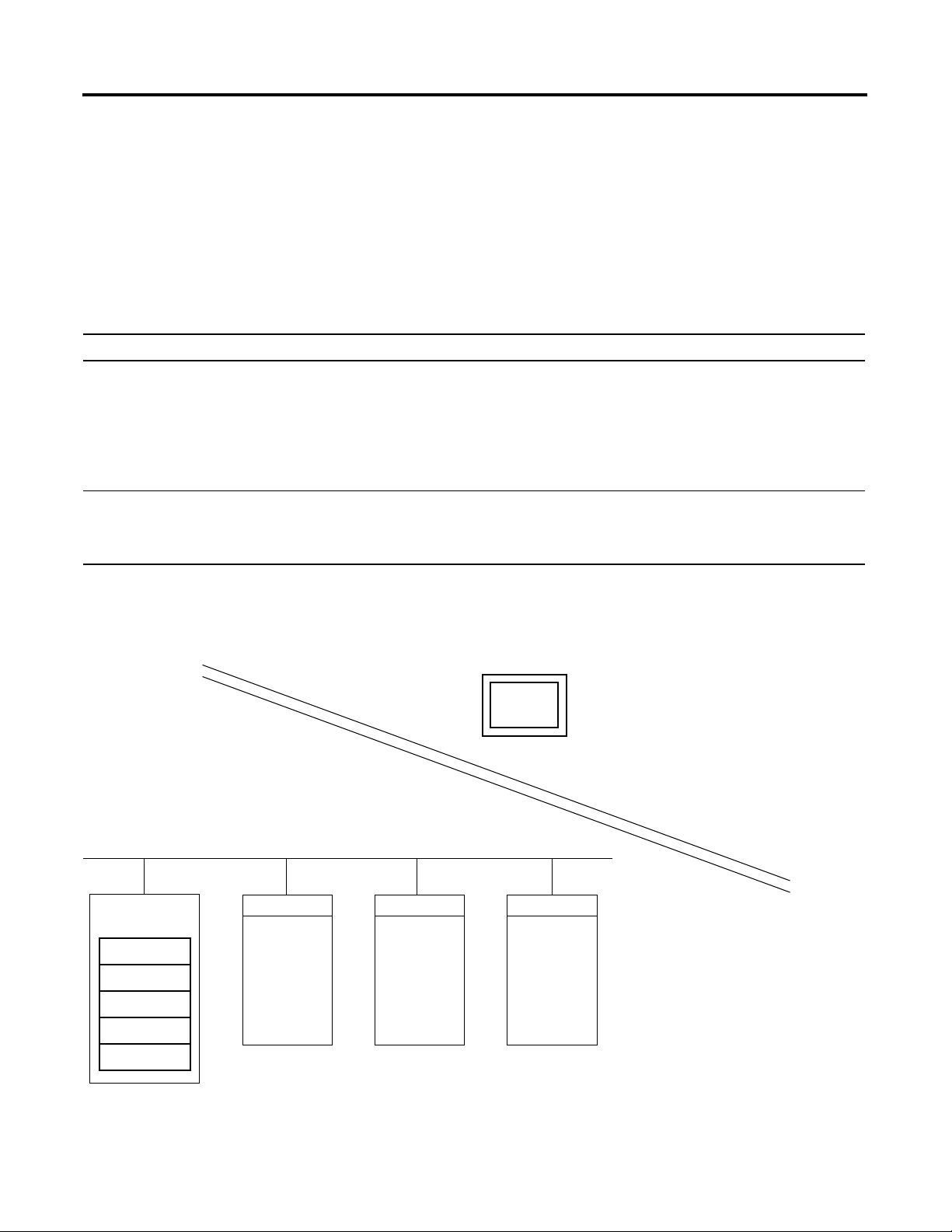

To organize your devices into a DeviceNet network, either:

Place all your devices on a single network and

connect the controller directly to the network via

scannercontroller

device device device device

device

the scanner.

main network

Break up your devices into several smaller

distributed networks (subnets). Place a scanner

(linking device) on each network. Connect the

scanners to the controller via an EtherNet/IP or

controller

linking

device

subnets

ControlNet network (backbone).

device

device device

device

This option: Has these advantages: And these disadvantages:

single network • lower cost

• 1 network to manage

• scanner is local to the controller

• shorter distances

• more devices on the network = slower

performance on that network

• more power supply requirements

subnets • shorter runs on subnets, more total distance

• fewer devices on the subnet = faster performance

on the subnet

• higher cost

• multiple networks to manage

• scanner is remote from the controller

• simpler power supply requirements

linking

device

device device

Publication DNET-UM004A-EN-P - March 2004

Page 18

1-6 Before You Begin

If you are using: And: Use this scanner:

single network CompactLogix™ controller CompactLogix 1769-SDN

subnets EtherNet/IP main network EtherNet/IP to DeviceNet Linking Device 1788-EN2DN

To choose a scanner, use the following table:

ControlLogix® controller ControlLogix 1756-DNB

DriveLogix™ controller DriveLogix and FlexLogix 1788-DNBO

FlexLogix™ controller

SoftLogix™ 5800 controller SoftLogix5800 1784-PCIDS

ControlNet main network ControlNet to DeviceNet Linking Device 1788-CN2DN

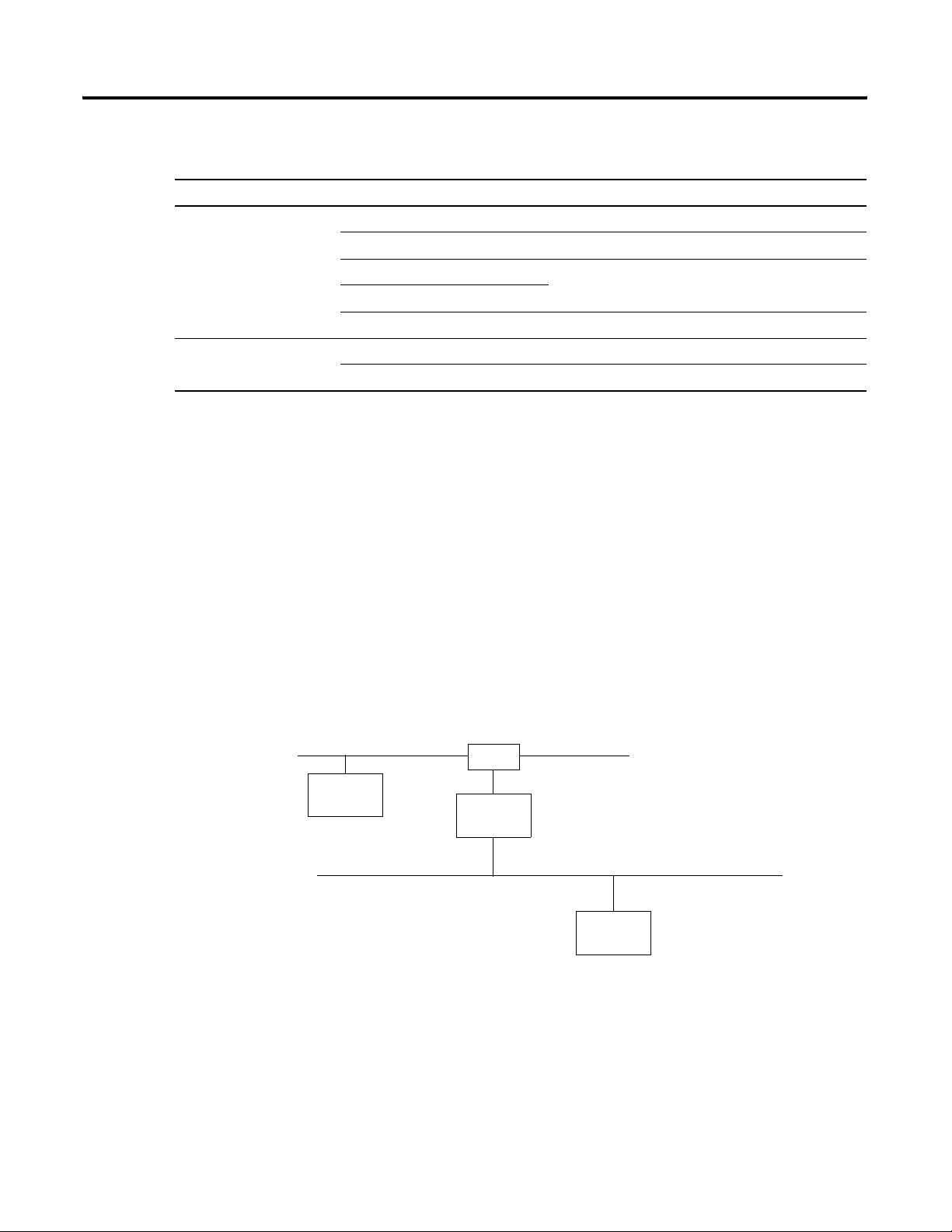

Bridging Across Networks

Device 1

Logix5000™ devices can usually communicate with devices on other

networks with no additional configuration or programming.

• A bridge connects two different networks. The bridge is either:

– single device with communication ports for two different

networks

– separate communication devices in the same chassis

• For example, the bridge device shown below is connected to

both EtherNet/IP and DeviceNet networks. Device 1 on

EtherNet/IP can communicate with Device 2 on DeviceNet

through the bridge.

EtherNet/IP network

switch

bridge

DeviceNet network

Publication DNET-UM004A-EN-P - March 2004

Device 2

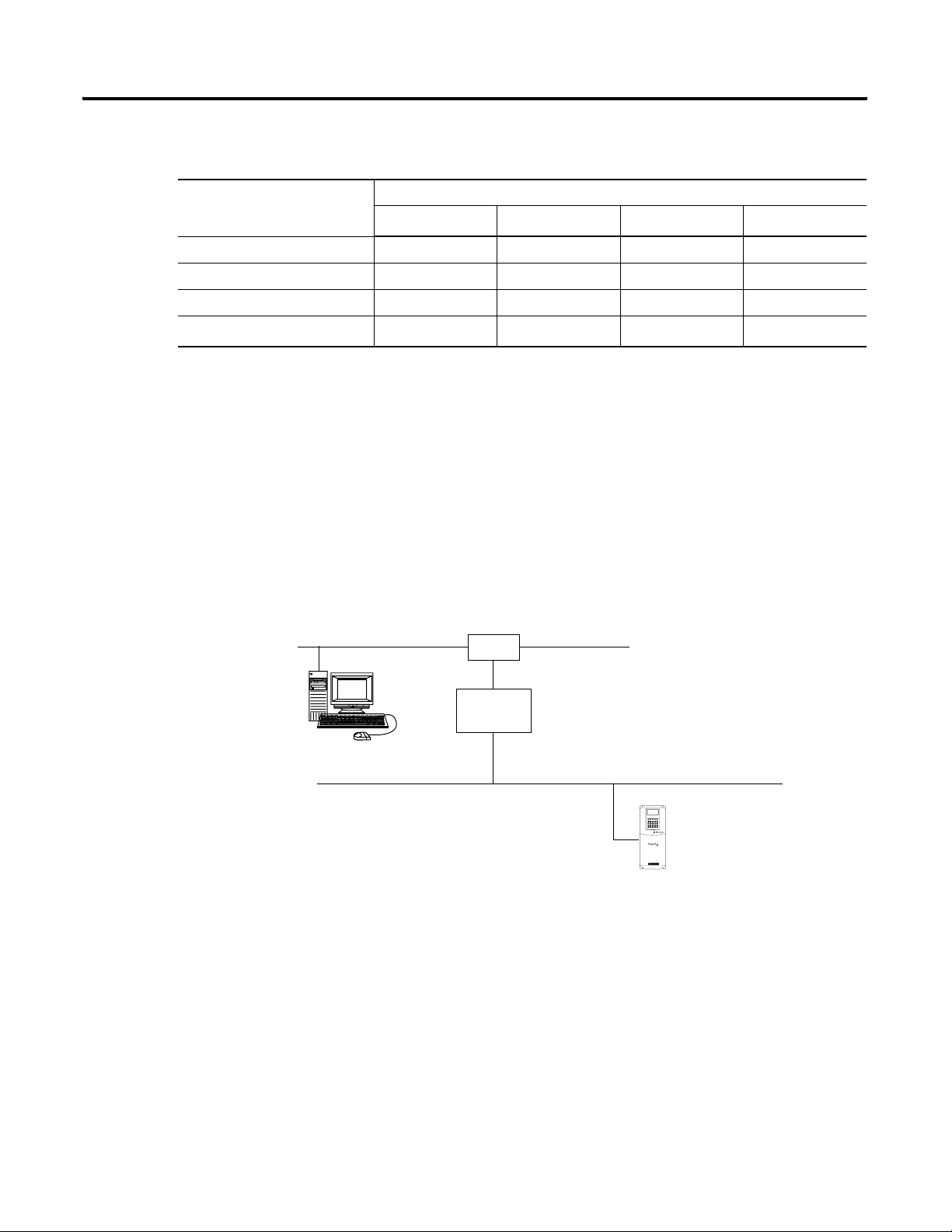

Page 19

Before You Begin 1-7

Communication can bridge these networks:.

A device on this network Can access a device on this network:

EtherNet/IP ControlNet: DeviceNet:

EtherNet/IP yes yes yes yes

ControlNet yes yes yes yes

DeviceNet no no yes no

RS-232 yes

(1)

To use RSNetWorx software to configure and schedule a ControlNet network, we recommend that you either:

yes

(1)

yes yes

• connect to an EtherNet/IP network and bridge to the ControlNet network

• use a 1784-PCC interface device to connect directly to the ControlNet network

(2)

Typically, this is a point-to-point connection between a Logix5000 controller and another device, such as a PanelView™

Plus operator terminal.

RS-232

(2)

:

workstation

In this example, a workstation configures a drive on a DeviceNet

network. The workstation bridges EtherNet/IP to reach the drive.

EtherNet/IP network

switch

bridge

DeviceNet network

PWR

STS

PORT

MOD

Drive

NET A

NET B

Publication DNET-UM004A-EN-P - March 2004

Page 20

1-8 Before You Begin

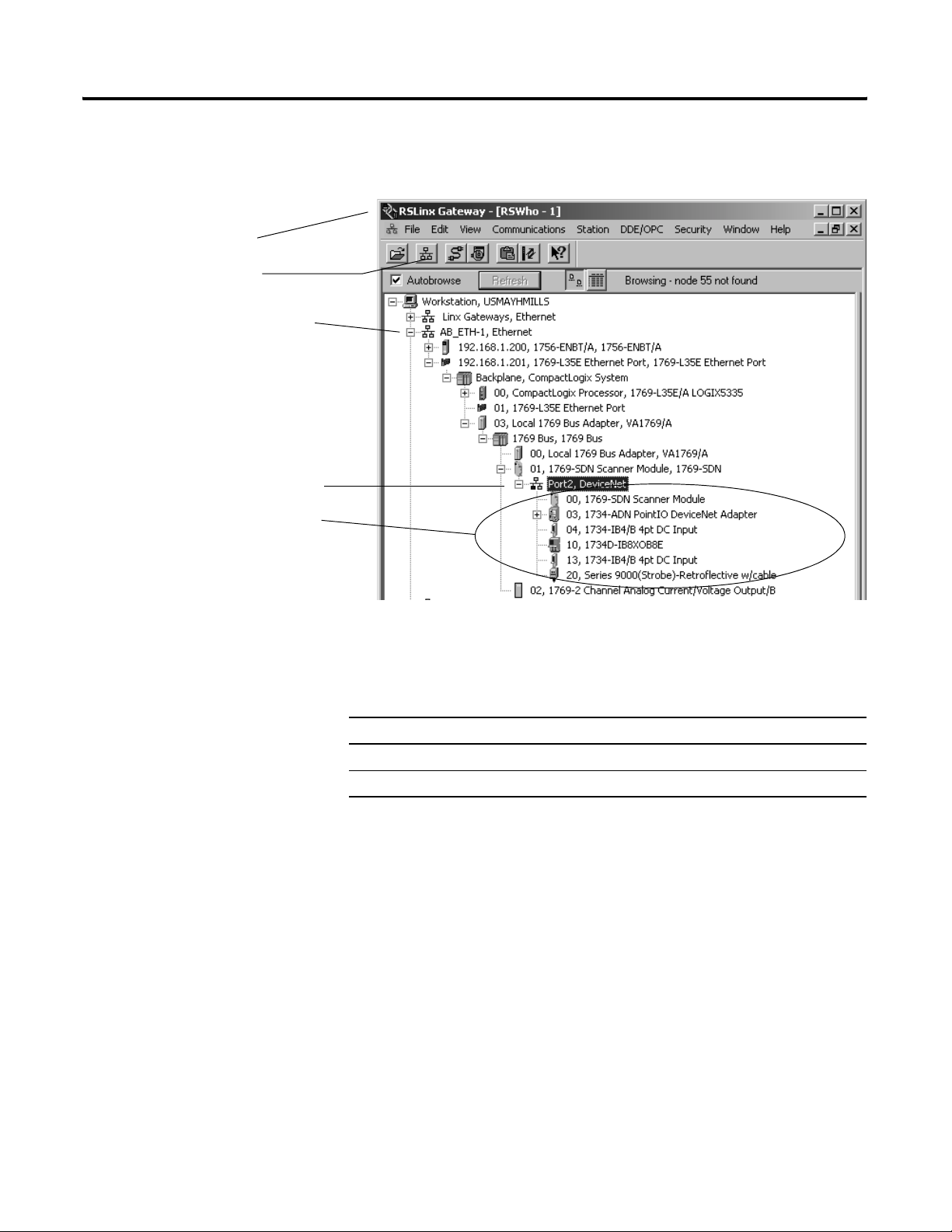

EtherNet/IP network

EtherNet/IP bridge in

1756 system

DeviceNet bridge in

same 1756 system

DeviceNet network

This example RSLinx window shows how the DeviceNet bridge links

to the EtherNet/IP network:

distributed DeviceNet

devices

Publication DNET-UM004A-EN-P - March 2004

Page 21

Before You Begin 1-9

Choose a Baud Rate for the

The default baud rate for a DeviceNet network is 125K bits/s. This is

the easiest baud rate to use and is usually sufficient.

Network

The 2 most common methods to set the baud rate of a device are:

Method: Description:

autobaud feature At power up, the device automatically sets its baud rate to the baud rate of the first device it hears on the network. It

remains set until the device powers up again.

The network requires at least one device with a fixed baud rate so the autobaud devices have something against

which to set. Typically, scanners and network interfaces have a fixed baud rate.

switches or

pushbutton on the

device

software Some devices require a programming device to set its address. For example, you can use your computer and the

Some devices have switches or a pushbutton that set the baud rate.

• The device reads the switch setting at power up.

• Typically, the switch lets you select either:

• autobaud

• fixed baud rate of 125K, 250K, or 500K

• If you change the switch setting, you have to cycle power to the device before the change to takes effect.

There are exceptions. For example, the 1756-DNB module has a pushbutton, which only lets you set the baud rate if

the module is unconnected from the network or network power is off. Once you change the baud rate, the module

automatically resets to the new baud rate.

DeviceNet Node Commissioning tool (software) to set the baud rate of a device. The Node Commissioning tool is

available:

• automatically when you install RSNetWorx for DeviceNet software

• as a separate application on the RSLogix 5000 software CD, revision 13.0 or later

Publication DNET-UM004A-EN-P - March 2004

Page 22

1-10 Before You Begin

If You Want to Use a Higher Baud Rate…

The length of the trunkline and type of cable determines which baud

rates you can use:

Baud rate Maximum distance Cumulative drop line

flat cable thick cable thin cable

125K bit/s 420m (1378 ft) 500m (1640 ft) 100m (328 ft) 156 m (512 ft)

250K bit/s 200m (656 ft) 250m (820 ft) 100m (328 ft) 78m (256 ft)

500K bit/s 75m (246 ft) 100m (328 ft) 100m (328 ft) 39m (128 ft)

If you change the baud rate of your network, make sure that all

devices change to the new baud rate. Mixed baud rates produce

communication errors.

To set the baud rate for the network:

length

1. Connect the network interface to the network and set its baud

rate.

2. Connect the scanner to the network and set its baud rate.

3. For each device that has only fixed baud rates (no autobaud),

set the baud rate and connect it to the network.

4. Connect the remaining devices to the network and enable

autobaud for each of them.

If a device: Then:

has a switch to enable

autobaud

does not have a switch to

enable autobaud

A. Set the switch to autobaud.

B. Connect the device to the network.

A. Connect the device to the network.

B. Use RSNetWorx software to enable

autobaud.

Publication DNET-UM004A-EN-P - March 2004

Page 23

Before You Begin 1-11

Calculate Scanner Memory Requirements

If a device sends input data, it uses

input memory in the scanner.

device device device

If a device gets output data, it uses

output memory in the scanner.

A Logix5000 scanner has fixed sections of memory for the input and

output data of your network. Each device on your network requires

either some input or output memory of the scanner. Some devices

both send and receive data, so they need both input and output

memory.

The memory of a Logix5000 scanner is organized as an array

scanner

module

Input

Memory

DINT

DINT

DINT

Output

Memory

DINT

DINT

DINT

of DINTs (4-byte elements). A Logix5000 system is easier to

program if you give each device its own DINT or DINTs

within the scanner.

byte 3 byte 2 byte 1 byte 0

DINT

DINT

DINT

Some memory may be left

empty (not used).

Device B

The data fills only the portion

of memory that it needs.

Device A

To make sure your network is within limits, calculate the amount of

input and output memory that the scanner needs. This information

will also be very useful when you configure the scanner.

Check the I/O Limits of the Scanner

Once you tally the input and output data for your network, make sure

it is within the limits of the scanner. If they exceed the limits, use

multiple scanners.

Scanner Maximum input data (DINTs) Maximum output data (DINTs)

1756-DNB 124 123

1769-SDN 90 90

1784-PCIDS 124 123

1788-CN2DN 124 123

1788-EN2DN 124 123

1788-DNBO 124 123

Publication DNET-UM004A-EN-P - March 2004

Page 24

1-12 Before You Begin

If You Are Using a SoftLogix5800 Controller

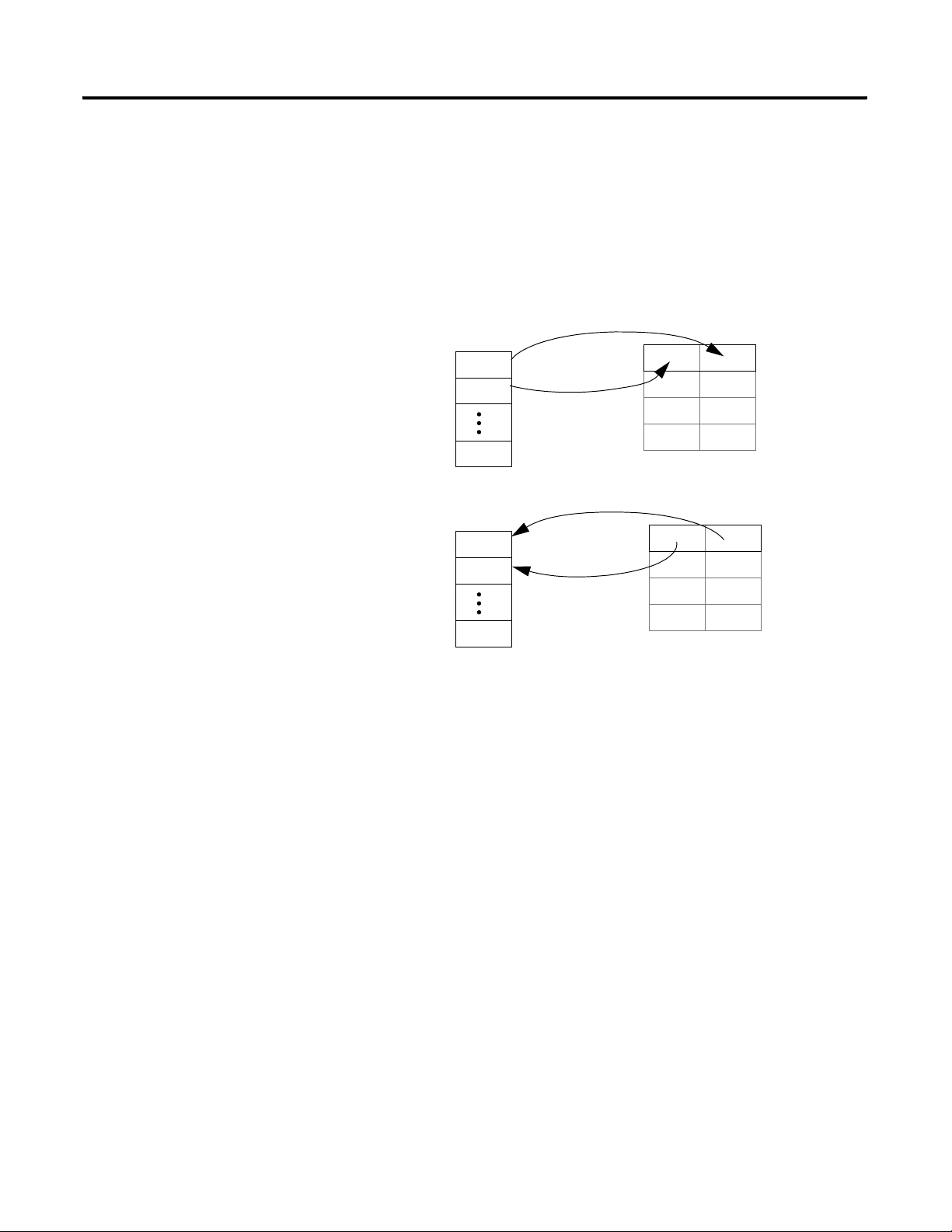

The 1784-PCIDS scanner organizes its input and output memory in

16-bit increments. When you access the data in the controller, the data

is packed into 32-bit increments (DINTs).

Scanner Input Memory

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

Controller Input Data

Controller Output DataScanner Output Memory

A Logix5000 system is easier to program if you give each device its

own DINT or DINTs within the controller. To accomplish this with a

PCIDS scanner:

Publication DNET-UM004A-EN-P - March 2004

• Allocate memory in 4-byte increments.

• This may result in some 16-bit words being left unused.

Page 25

Before You Begin 1-13

Assign an Address to Each

To communicate on the DeviceNet network, each device requires its

own address. In general, a device can use any address between 0 to

Device

Give this device: This address: Notes:

scanner 0 If you have multiple scanners, give them the lowest addresses is sequence (0, 1…).

any device on your network

except the scanner

computer interface to the

network

no device 63 Always leave address 63 open. Out of the box, most DeviceNet devices are preset for

1 to 61 • Give the lower addresses to devices with 15 bytes or more of input or output

62 If you connect a computer directly to the DeviceNet network, use address 62 for the

63. However, we recommend that you follow these guidelines:

data.

• Gaps between addresses are OK and have no effect on system performance. If

you are uncertain of the final lay-out of your system, leave gaps between

addresses. This gives you some flexibility as you develop your system.

computer.

• Many computer interface devices use this address as their default.

• Devices such as a 1770-KFD or 1784-PCD connect a computer directly to a

DeviceNet network.

address 63.

• Some devices have no switches or pushbutton to set the address. They require

software such as RSNetWorx for DeviceNet software to change the address. This

means that you must first place it on the network at its preset address of 63

before you can change the address.

• If another device is already using address 63, there will be an address conflict

and you won’t be able to communicate with the newly connected device.

• Leaving address 63 open makes it possible to configure a new device.

• The auto-address recovery feature also requires address 63 to be open.

Publication DNET-UM004A-EN-P - March 2004

Page 26

1-14 Before You Begin

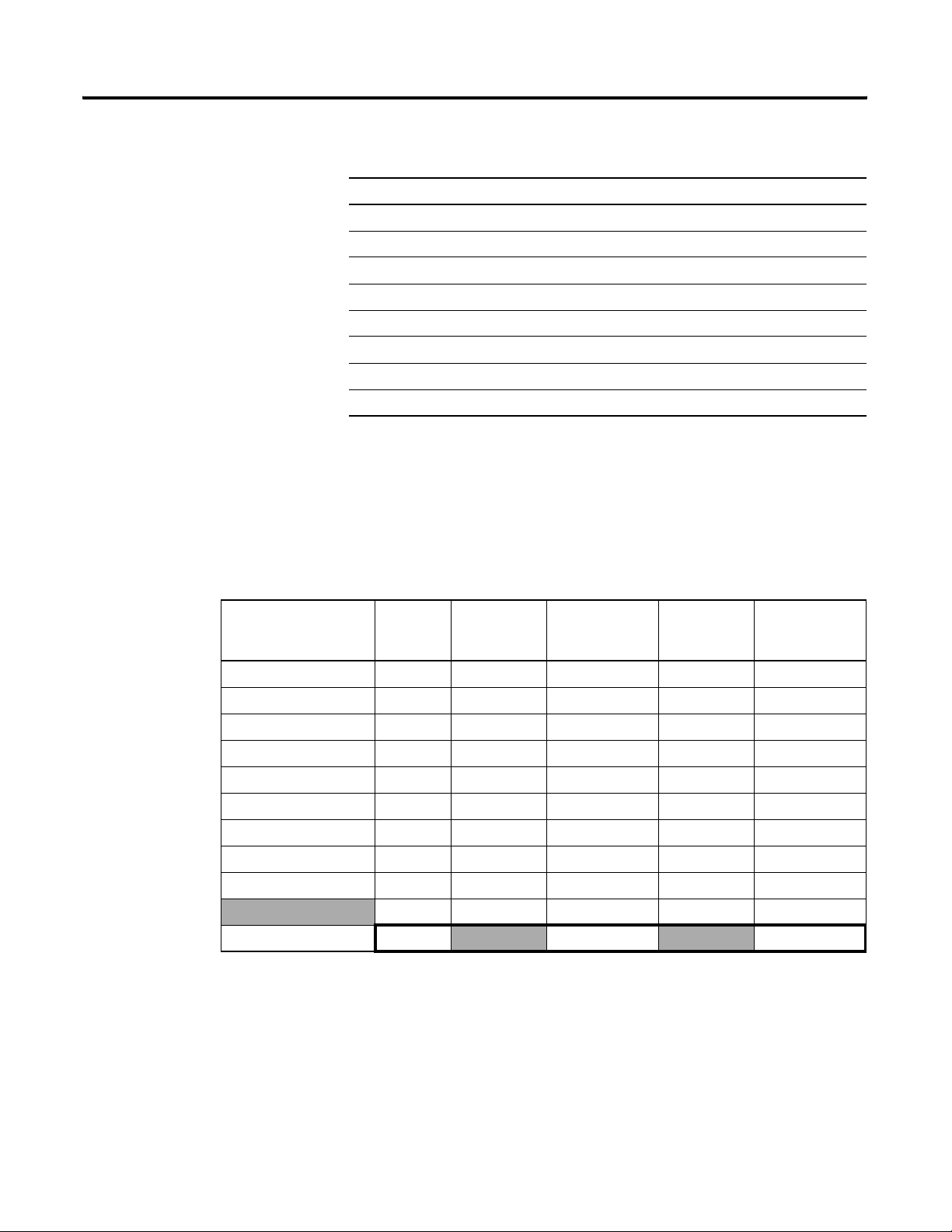

1. Give address 0 to the scanner. 2. Give the lower addresses to devices with 15 bytes or more of input or

Here’s an example:

output data.

3. Gaps in addresses are OK.

Device Address Input Size of

Device

(bytes)

Input Memory

in Scanner

(DINTs)

Output Size

of Device

scanner 0 n/a n/a n/a n/a

PanelView terminal 3 128 32 128 32

<empty> 22

I/O adapter w/ modules 5 9 3 5 2

<empty> 22

drive 74141

<empty> 22

photoeye 9 1 1 0 0

computer interface 62 n/a n/a n/a n/a

63

4. Give address 62 to the computer interface device. 5. Leave address 63 open.

(bytes)

Output Memory

in Scanner

(DINTs)

Publication DNET-UM004A-EN-P - March 2004

Page 27

Configure Your Network Offline

Chapter

2

How to Use This Chapter

To configure your DeviceNet network, you have the following

options:

If: Then configure your network: See:

Any of the following conditions apply:

• The network and devices are not yet installed.

• You do not have access to the network. (I.e., You are

off-site.)

• You prefer to do most of the configuration before you get

on-site with the network.

Both of the following conditions apply:

• The network and devices are already installed.

• You have access to the network. (I.e., You are on-site.)

offline This chapter

online Chapter 6

Offline configuration lets you do most of the DeviceNet configuration

tasks before you connect to the network.

Off-Site

RSNetWorx for DeviceNet software

1. Configure parameters of each device.

2. Configure the scanner to communicate

On-Site

DeviceNet network

Scanner

Scan List

device 1

device 2

device3

…

1 Publication DNET-UM004A-EN-P - March 2004

device 1

parameter 1

parameter 2

parameter 3

…

…

…

device 2

parameter 1

parameter 2

parameter 3

…

…

…

device 3

parameter 1

parameter 2

parameter 3

…

…

…

with the devices on your network.

Page 28

2-2 Configure Your Network Offline

To configure a DeviceNet network while offline:

Step: Page:

❑ Before You Begin 2-2

❑ Create a File for the Network 2-3

❑ Draw Your Network 2-4

❑ Configure Each Device 2-5

❑ Configure the Scanner 2-8

❑ Save the Network File 2-15

❑ Generate an RSNetWorx Report 2-16

❑ Download the Configuration to Network 2-17

Before You Begin

Device Address Input Size of

scanner 0 n/a n/a n/a n/a

PanelView terminal 3 128 32 128 32

<empty> 22

I/O adapter w/ modules 5 9 3 5 2

<empty> 22

drive 74141

<empty> 22

photoeye 9 1 1 0 0

computer interface 62 n/a n/a n/a n/a

Before you configure the network, make sure you have a list of the

devices that you are putting on your network and the address for each

of them.

For example:

63

Total

Device

(bytes)

Input Memory

in Scanner

(DINTs)

43 41

Output Size

of Device

(bytes)

Output Memory

in Scanner

(DINTs)

Publication DNET-UM004A-EN-P - March 2004

Page 29

Configure Your Network Offline 2-3

Create a File for the Network

RSNetWorx software stores information about the configuration of

each device in a file on your computer.

Step: See page:

❑ Create a DeviceNet Configuration File 2-3

❑ Give the File a Descriptive Name 2-3

Create a DeviceNet Configuration File

1. Start RSNetWorx software.

2. Create a file.

3. Select DeviceNet Configuration.

4. Choose OK.

Save the file.

Give the File a Descriptive Name

Since the file stores the configuration of the network, give it a name

that identifies this specific DeviceNet network.

As you work in RSNetWorx software, periodically save your changes

to the file for the network.

Publication DNET-UM004A-EN-P - March 2004

Page 30

2-4 Configure Your Network Offline

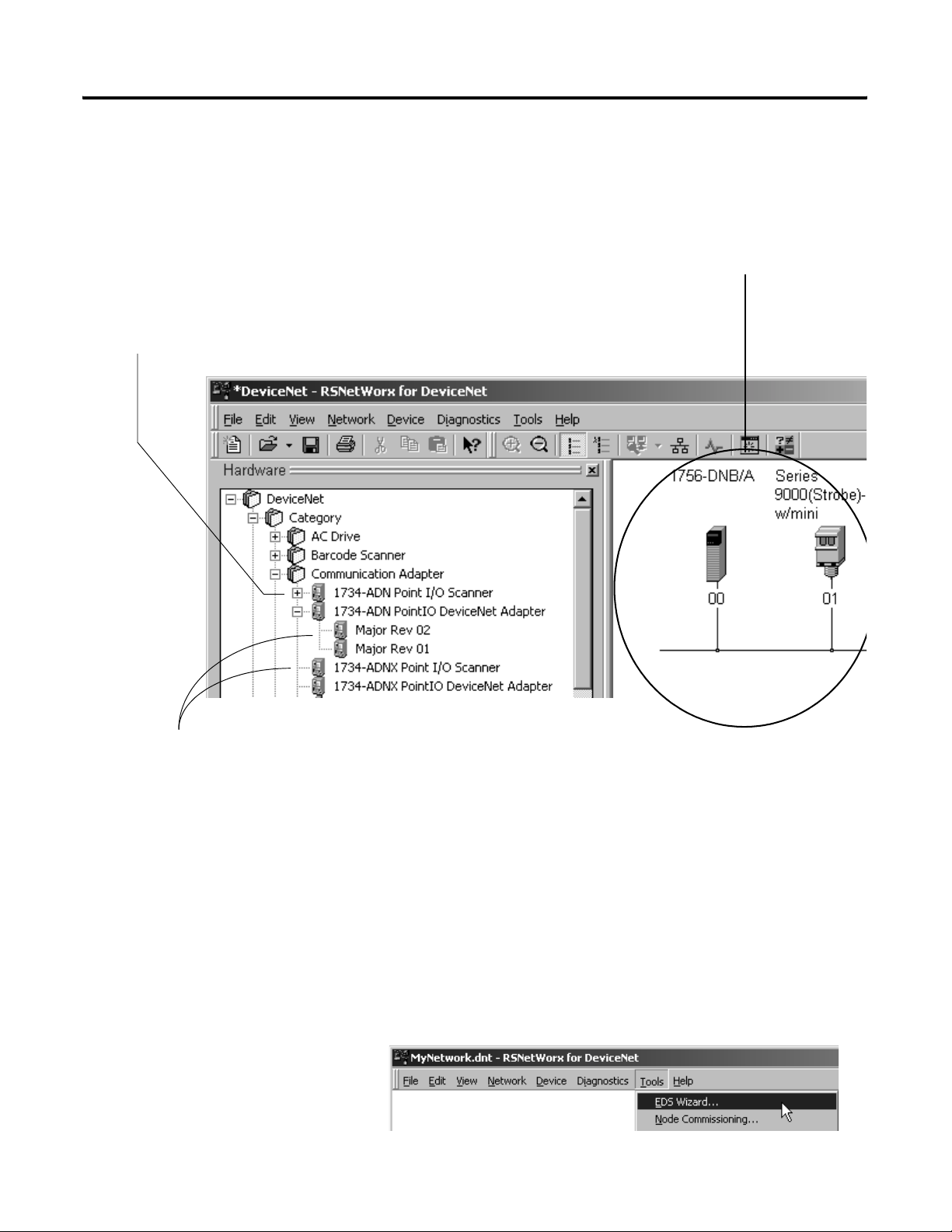

Draw Your Network

1. Browse the hardware list for the device.

2. If there is a [+] sign next to the device, click the [+] sign.

To configure a DeviceNet network, you use RSNetWorx software to

build a graphical picture of your network. To build a graphical picture

of your network, complete the following steps for each of your

devices:

graphical picture of your network

3. Double-click the major revision of the device.

For a device without a list of major revisions (no + or - sign), double-click the device.

Publication DNET-UM004A-EN-P - March 2004

If Your Device Is Not in the Hardware List…

If the hardware list does not show a device, then RSNetWorx requires

the EDS file for the device:

1. To see if an EDS file is available, go to

www.ab.com/networks/eds/

2. Use the EDS wizard of RSNetWorx software to register the file.

Page 31

Configure Your Network Offline 2-5

Configure Each Device

Typically, a DeviceNet device has a set of parameters that define the

behavior of the device.

To configure a device offline:

Step: See page:

❑ Specify the Address of the Device 2-6

❑ Configure the Parameters of the Device 2-7

Publication DNET-UM004A-EN-P - March 2004

Page 32

2-6 Configure Your Network Offline

Specify the Address of the Device

When you are offline, the address on the diagram identifies a device.

It does not set the device to that address. In chapter 5, you will set the

address of each device.

1. Double-click the device.

2. Type or select the DeviceNet address for the

device.

Publication DNET-UM004A-EN-P - March 2004

Page 33

Configure Your Network Offline 2-7

Configure the Parameters of the Device

1. Click the Parameters tab.

2. Set a parameter to the required value:

• Select a new value.

– or –

• Click, type a new value, and press [Enter].

3. Close the dialog box.

Publication DNET-UM004A-EN-P - March 2004

Page 34

2-8 Configure Your Network Offline

Configure the Scanner

Scanner

Scan List

device at address 1

device at address 2

device at address 3

To configure the scanner to communicate with the devices on your

network, you set up a scan list in the scanner. Then you define

memory locations for the data of each device.

scan list – A list in the scanner that identifies the devices with which the

scanner communicates. For each device in its scan list, the scanner sets aside

input and/or output memory for the data of the device.

Output Memory

DINT Input Memory

0

1

2

3

4

5

device at address 1

device at address 2

device at address 3

To configure the scanner offline:

Step: See page:

❑ Specify the Address of the Scanner 2-9

❑ Define the Properties of the Scanner 2-10

❑ Set the Alignment Option 2-11

❑ Clear or Set the Automap on Add Check Box 2-12

❑ Build the Scan List 2-13

❑ Manually Assign Each Device to a Memory Location 2-14

❑ Close the Configuration of the Scanner 2-15

Publication DNET-UM004A-EN-P - March 2004

Page 35

Specify the Address of the Scanner

1. Double-click the scanner.

2. Type or select the DeviceNet address for the

scanner.

Configure Your Network Offline 2-9

Publication DNET-UM004A-EN-P - March 2004

Page 36

2-10 Configure Your Network Offline

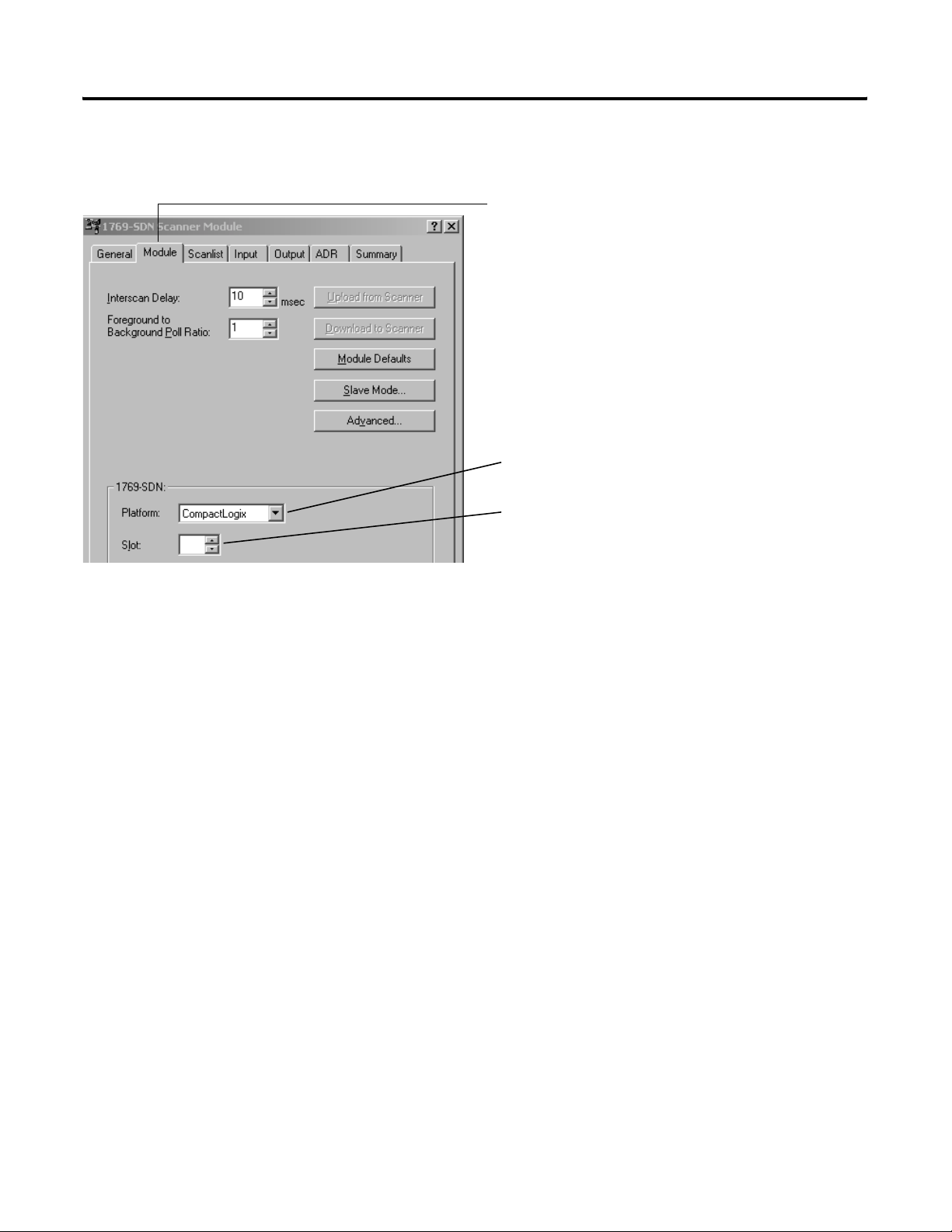

Define the Properties of the Scanner

1. Click the Module tab

2. If this is a CompactLogix scanner (1769-SDN), choose

CompactLogix.

3. If the scanner uses a slot number, type its slot number.

Publication DNET-UM004A-EN-P - March 2004

Page 37

Set the Alignment Option

Configure Your Network Offline 2-11

TIP

The alignment option you choose applies to both the input and

output maps.

1. Click the Input tab.

2. Choose Options.

3. Choose DWord Align.

If You Have a SoftLogix5800 Controller

The SoftLogix5800 scanner 1784-PCIDS organizes its input and output

memory in 16-bit words. For that scanner, choose Word Align.

Publication DNET-UM004A-EN-P - March 2004

Page 38

2-12 Configure Your Network Offline

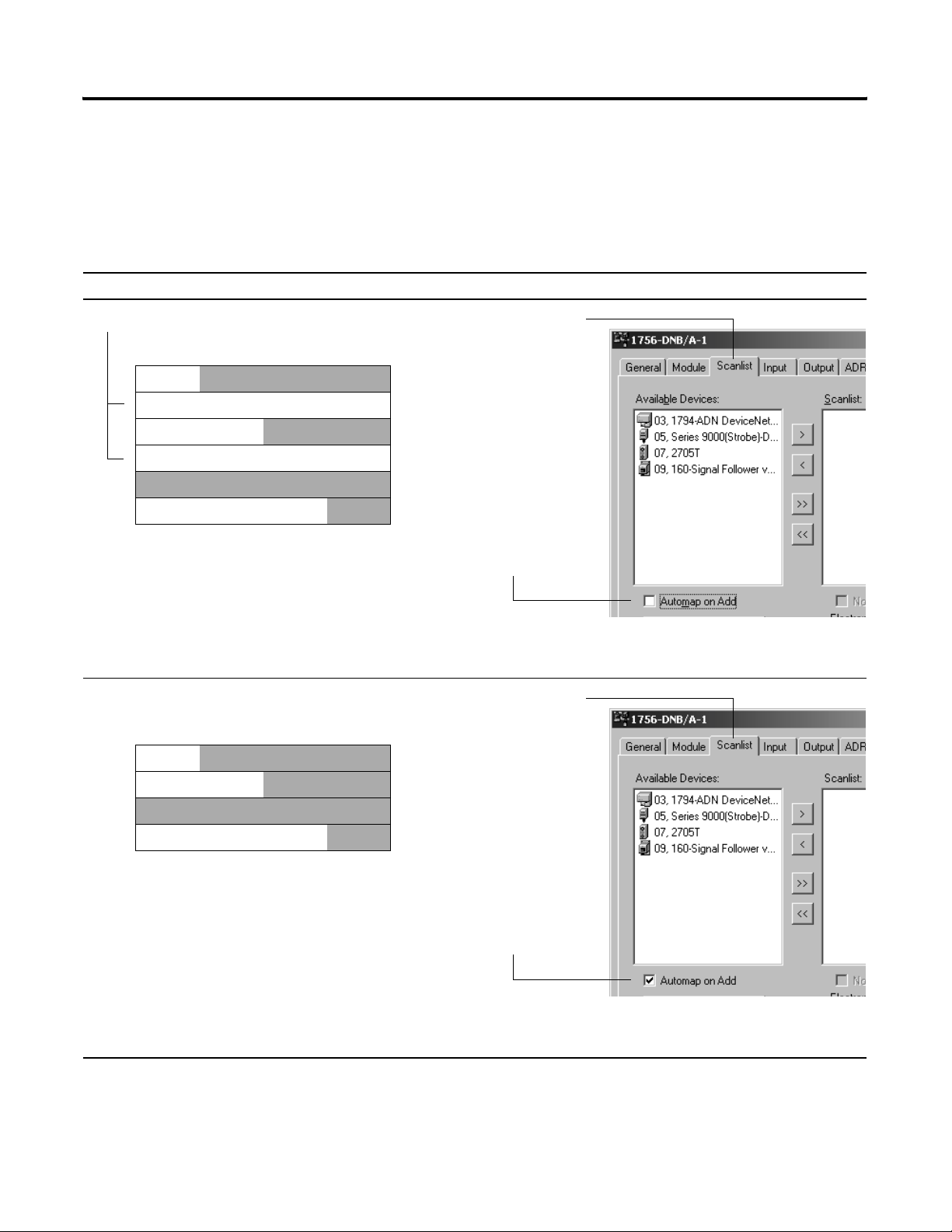

Clear or Set the Automap on Add Check Box

As an option, RSNetWorx software can automatically assign the

memory location for each device. Depending on how you want to

organize the memory, you may or may not want to use this option.

If you want to: Then:

leave gaps between devices

Memory

device at address 1

device at address 2

device at address 3

place devices in sequential DINTs

Memory

device at address 1

1. Click the Scanlist tab

2. Clear (uncheck) the

Automap on Add check box

After you add your devices to the scan list, manually assign the memory location

for each device.

1. Click the Scanlist tab

device at address 2

device at address 3

Publication DNET-UM004A-EN-P - March 2004

2. Set (check) the Automap on

Add check box.

As you add your devices to the scan list, the software automatically assigns the

memory locations for each device.

Page 39

Build the Scan List

Configure Your Network Offline 2-13

1. You should be at the Scanlist tab

If you get the following warning for a device, see Set the I/O

Parameters of a Device on page 11-6

2. Add devices to the scan list.

To add: Do this:

devices one at a

time

all the devices

at once

Select a device and click the >

button.

Click the >> button.

.

Publication DNET-UM004A-EN-P - March 2004

Page 40

2-14 Configure Your Network Offline

Manually Assign Each Device to a Memory Location

IMPORTANT

1. Click the Input tab.

2. Select the device.

If you used Automap on Add (page 2-12).as you built your scan list,

then skip this section. Each device already has a memory location.

3. Type the element number to which you want to assign the data. This is the

starting point for the data. Larger data sizes wrap to several elements.

For example, to start the data in …Data[3], type 3 in the

Start DWord box.

4. Choose AutoMap.

An entry for the device shows up in the input array.

5. Click the Output tab and repeat steps 2 - 4.

Sometimes, a specific input or output value may end up as the upper

bytes of a DINT in the scanner.

To make your programming easier, use advanced mapping to re-map

the value to its own memory location. For more information, see Give

a Value Its Own Memory Location on page A-1.

Publication DNET-UM004A-EN-P - March 2004

Page 41

Configure Your Network Offline 2-15

Close the Configuration of the Scanner

Close the dialog box.

Save the Network File

Save the file.

After you configure each device on your network, including the

scanner, save the file.

Publication DNET-UM004A-EN-P - March 2004

Page 42

2-16 Configure Your Network Offline

Generate an RSNetWorx Report

1. File ⇒ Generate Report.

2. Entire network

An RSNetWorx report shows the following:

• devices on your network

• memory addresses of those devices in the scanner

• configuration of each device

The report is a very useful reference when you program your system.

The report shows up as an

HTML file.

Publication DNET-UM004A-EN-P - March 2004

Page 43

Configure Your Network Offline 2-17

Download the Configuration to Network

After you configure the network offline, you must download the

configuration to the network. Do this after the network and devices

are installed and you have access to the network.

Step: See page:

❑ Before You Download the Configuration 2-17

❑ Open the Configuration File for the Network 2-17

❑ Go Online to the Network 2-18

❑ Download the Configuration to the Network 2-19

Before You Download the Configuration

Before you download the configuration, your computer must be able

to communicate with each device on your DeviceNet network. Make

sure that you have completed the following steps:

Step: See:

Connect a Computer to the System Chapter 3

1. Start RSNetWorx software.

2. Open the dnt file for the network.

Connect Each Device to the Network Chapter 5

Open the Configuration File for the Network

Publication DNET-UM004A-EN-P - March 2004

Page 44

2-18 Configure Your Network Offline

Go Online to the Network

When you go online to a DeviceNet network, RSNetWorx software

looks at the network (browses) one time and shows you the devices

on the network.

• It does not read (upload) or change (download) the parameters

of any of the devices.

• The picture you see remains static. It does not show any changes

since the last browse.

1. Go online.

2. Browse to the DeviceNet network.

3. Choose OK.

The message is telling you that the

software is not going to read or

change the parameters of the

devices. You do that in the next

step.

Publication DNET-UM004A-EN-P - March 2004

4. Check that you are online.

Page 45

Configure Your Network Offline 2-19

Download the Configuration to the Network

IMPORTANT

1. Network ⇒ Download to Network.

2. Yes, download the entire network.

Make sure the scanner is in idle mode. To put the scanner in idle

mode, either:

• Turn off the …O.CommandRegister.Run bit of the scanner.

- or -

• Place the controller in program/remote program mode.

Publication DNET-UM004A-EN-P - March 2004

Page 46

2-20 Configure Your Network Offline

Notes:

Publication DNET-UM004A-EN-P - March 2004

Page 47

Connect a Computer to the System

Chapter

3

How to Use This Chapter

This chapter shows how to connect a computer to your system so you

can:

• configure the devices on the network

• configure network parameters

• upload, download, monitor, and program projects for Logix5000

controllers

Some networks let you browse (bridge) to other networks in your

system. This lets you connect to one network and access devices or

controllers on other networks.

To access your system, choose a network to which to connect and

configure a driver for the network.

For this information: See page:

Connect a Computer to a Network 3-2

Configure a Driver for a Network 3-3

1 Publication DNET-UM004A-EN-P - March 2004

Page 48

3-2 Connect a Computer to the System

Connect a Computer to a Network

IMPORTANT

To access a network, either:

• connect directly to the network

• connect to a different network and browse (bridge) to the

desired network. This requires no additional programming.

To use RSNetWorx software to configure and schedule a ControlNet

network, either:

• connect to an EtherNet/IP network and bridge to the ControlNet

network

• use a 1784-PCC interface device to connect directly to the

ControlNet network

The following diagram shows your options:

ports, cards, or modules in a Logix5000 controller, chassis, or linking device

Logix5000

controller

EtherNet/IP

port

ControlNet

port

DeviceNet

port

ethernet card

serial port

EtherNet/IP network

Laptop Desktop

1784-PCC 1784-PCIC

1770-KFC15 1784-PCICS

1784-KTCX15

1770-KFC15

point-to-point

RS-232

connection

ControlNet network

Laptop Desktop

1784-PCD 1784-PCID

Only lets you access

devices on the

DeviceNet network

DeviceNet network

If you connect directly to a DeviceNet

network, you can access only the devices

on that network.

Publication DNET-UM004A-EN-P - March 2004

1770-KFD 1784-PCIDS

1770-KFD

Page 49

Connect a Computer to the System 3-3

Once you choose a network to which to connect:

• Install the communication card, if required.

• Determine any network parameters for the computer, such as a

network address.

• Connect the computer to the network with the correct cable.

Configure a Driver for a Network

1. Start RSLinx software.

2. Click the Configure Driver button.

3. Add the driver:

For this network: Select this driver:

RS-232 RS-232 DF1 Devices

To communicate over a specific network, configure a driver for the

network.

Add the Driver

ControlNet™ driver that matches your card.

EtherNet/IP Ethernet devices

DeviceNet™ DeviceNet Drivers…

4. Configure the driver.

descriptive name for the network (driver)

configuration (see pages 3-4 to 3-5 for help with specific drivers)

Publication DNET-UM004A-EN-P - March 2004

Page 50

3-4 Connect a Computer to the System

RS-232 DF1 Devices

Important: Make sure no other driver is configured for the

COM port to which you connect the serial cable.

1. Choose the following:

COM port that you are using.

Logix 5550/CompactLogix.

Auto-Configure

5. Wait for the auto-configuration to finish.

Ethernet Devices

1784-PCC

Enter the IP address of the controller or communication

module.

Use the address that the software picks.

Or assign a specific address:

A. Clear this check box.

B. Enter the address that you to use.

Publication DNET-UM004A-EN-P - March 2004

Page 51

1784-PCD

1. Use the default address of 62, if it is

unused.

2. Select the baud rate for the network.

3. OK.

Connect a Computer to the System 3-5

1770-KFD

Important: Make sure no other driver is configured for the COM

port to which you connect the serial cable.

1. Select the COM port to which you connected the 1770-KFD

device.

2. Use the default address of 62, if it is unused.

3. Select the baud rate for the network.

4. OK.

Publication DNET-UM004A-EN-P - March 2004

Page 52

3-6 Connect a Computer to the System

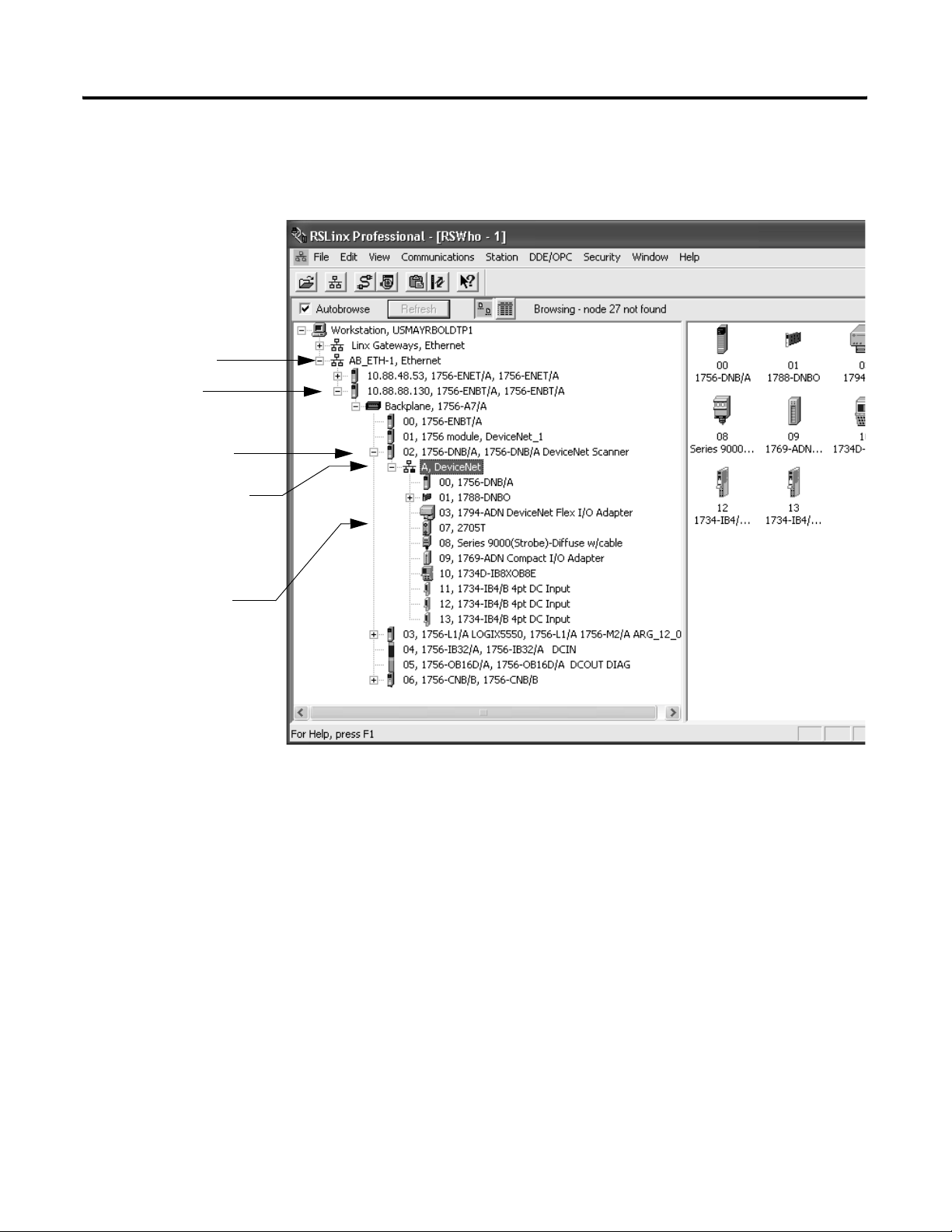

3. Open the RSWho window.

Make Sure the Driver Works

1. Check that the driver is running.

2. Close the dialog box.

4. Double-click the driver to see the network.

Publication DNET-UM004A-EN-P - March 2004

Page 53

Chapter

Automatically Configure a DeviceNet

Network

4

How To Use This Chapter

Before you use this chapter:

Connect your computer to the

system. See chapter 4.

Determine If You Can Use AutoScan

This chapter provides a quick method for configuring a DeviceNet

network. It uses the AutoScan feature to establish communication

between the controller and your devices with minimal steps.

To use the AutoScan feature to configure your network:

Step: Page:

❑ Determine If You Can Use AutoScan 4-1

❑ Review How AutoScan Effects Your Network 4-2

❑ Install the Node Commissioning Tool 4-2

❑ Connect Each Device to the Network 4-3

❑ Add the Scanner to the RSLogix 5000 Project 4-6

❑ Turn On AutoScan 4-7

❑ Access Device Data 4-9

❑ Put the Scanner in Run Mode 4-11

❑ Additional Information About AutoScan 4-12

To use this chapter, make sure your network meets the following

requirements:

Each device on your DeviceNet network (except the scanner):

• sends ≤ 4 bytes of input data

• gets ≤ 4 bytes of output data

You have one of the following DeviceNet scanners:

• ControlLogix 1756-DNB

• FlexLogix 1788-DNBO

Your scanner has the following firmware revision:

This scanner: Requires this firmware:

ControlLogix 1756-DNB revision 5.0 or greater

FlexLogix 1788-DNBO revision 3.0 or greater

You have RSLogix 5000 software revision 13.0 or greater.

If your network does not meet the requirements listed above, then use

chapters 5 to 7 to configure your network and control your devices.

1 Publication DNET-UM004A-EN-P - March 2004

Page 54

4-2 Automatically Configure a DeviceNet Network

How AutoScan Effects Your

As you use AutoScan, keep the following in mind:

Network

Consideration: Description:

1. AutoScan clears the current

configuration.

2. AutoScan allocates a fixed memory

size for each device.

The actual data for the device fills the portion

that it needs and the rest remains unused.

3. New devices are automatically

available.

4. The Automatic Device Recovery

(ADR) option is not available.

With AutoScan, the scanner automatically sets up communication with the devices on your

DeviceNet network. When you turn on the AutoScan option, the scanner removes any

previous configuration that was done to the scanner.

At its default setting, AutoScan allocates 1 DINT of input memory and 1 DINT of output

memory for each device on the DeviceNet network.

While the scanner is in idle mode, AutoScan continues to establish communication with

devices that you connect to the network (as long as the device uses ≤ 4 bytes of input data

and ≤ 4 bytes of output data).

To use the Automatic Device Recovery (ADR) option of a DeviceNet scanner, you have to

use RSNetWorx software to edit the configuration of the scanner. This turns off AutoScan.

DINT Input Memory

0

1

2

device at address 0

device at address 1

device at address 2

Install the Node Commissioning Tool

Use this tool to set the DeviceNet address of a device that has no

switch, pushbutton, or other mechanism for its address.

If all your devices have a switch or pushbutton for their address, then

skip this step. You do not need the Node Commissioning tool.

To install the Node Commissioning tool:

1. Get your RSLogix 5000 software CD.

2. On the CD, find the following folder:

language\Tools\Node Commissioning Tool

where:

language is the language of your software. For example, for

software in English, open the ENU folder.

3. Follow the instructions in the readmefirst file.

Publication DNET-UM004A-EN-P - March 2004

Page 55

Automatically Configure a DeviceNet Network 4-3

Connect Each Device to the

As you connect your devices to the DeviceNet network, follow these

guidelines:

Network

Step: Details:

❑ 1. Assign an address to each

device.

❑ 2. Connect the scanner and any

network interface to the

network.

❑ 3. Connect the rest of your devices

to the network one at a time.

The following addresses are recommended but not required:

Give this address: To this device:

0 scanner

1 to 61 your devices

62 computer interface to the network, such as a 1770-KFD or

63 Leave open. Out of the box, a DeviceNet device is preset for

By first connecting the scanner and/or network interface device to the network, you reduce

the number of baud rate errors as you connect the rest of your devices:

1784-PCD device

address 63. Leaving address 63 open lets you get a new device on

the network without conflicting with another device.

• Scanners and network interface devices use a fixed baud rate.

• Sensors and similar DeviceNet devices use autobaud to set their baud rate. They

wait for another device to communicate. Then they set their baud rate to the same

baud rate as the other device.

• By first placing a scanner or network interface on the network, the other device

have a baud rate against which to set their baud rate.

• Initially, leave the baud rate of the scanner and network interface at the default

setting of 125K bits/s. If you want to change the baud rate, wait until after you

establish communication with all your devices at the default setting (125K).

• To set the DeviceNet address of the scanner, see Set the Address of a Scanner on

page 4-4.

• Out of the box, a DeviceNet device is preset for address 63. To avoid address

conflicts, connect and set the devices one at a time. Otherwise the address conflicts

may prevent communication with them.

• If a device has a switch to set its baud rate, set the switch to autobaud, if available.

Otherwise, set the device to the baud rate of the network.

• After you change the address or baud rate of a device via a switch, cycle power to

the device.

• If a device has no switch or pushbutton for its address or baud rate, see Set the

Address and Baud Rate of a Device Via Software on page 4-5.

• After you set the address of a device, check its network status indicator. Typically, a

solid red or flashing red indicator means an address conflict or problem with the

baud rate.

Publication DNET-UM004A-EN-P - March 2004

Page 56

4-4 Automatically Configure a DeviceNet Network

DeviceNet

TM

MOD/NET I/O OK

1. Connect the device to the network. (If disconnected or the network power is off, the

2. Turn on the power to the device.

3. Press and hold the manual configuration pushbutton until the device displays the desired

4. After the device resets, check the 4-character display on the front of the module:

Set the Address of a Scanner

ControlLogix Scanner 1756-DNB

pushbutton changes the baud rate.)

address.

When you release the button, the device resets to the new address.

If: Then the:

A#address address is OK

Duplicate Node Address address conflicts with another device

DriveLogix and FlexLogix Scanner 1788-DNBO

N

31288-M

1. To change the address, press the button above or below a number.

2. Connect the device to the network.

3. Turn on power to the device.

4. Check the NS (network status) light.

If: Then the:

green (flashing or solid) address is OK

solid red address and/or baud rate conflict with another device

Publication DNET-UM004A-EN-P - March 2004

Page 57

1. Start the Node Commissioning tool.

3. Check this box.

4. Browse to the DeviceNet network.

Automatically Configure a DeviceNet Network 4-5

Set the Address and Baud Rate of a Device Via Software

2. Click Browse.

5. Type the current address for the

device. Out of the box, a device

uses address 63.

7. Type the new address for the device.

8. Select the baud rate for the device.

9. Apply the change.

10. Look for confirmation here.

6. Click OK.

Publication DNET-UM004A-EN-P - March 2004

Page 58

4-6 Automatically Configure a DeviceNet Network

Add the Scanner to the RSLogix 5000 Project

To access the data of your network, add the scanner to the I/O

configuration of the controller. To add a scanner:

Step: See page:

❑ Add the Scanner to the I/O Configuration Folder 4-6

❑ Define the Properties of the Scanner 4-7

Add the Scanner to the I/O Configuration Folder

1. Right-click and choose New Module.

2. Choose the type of scanner.

3. Select the major revision of the scanner.

Publication DNET-UM004A-EN-P - March 2004

Page 59

Automatically Configure a DeviceNet Network 4-7

Define the Properties of the Scanner

1. Type a name for the scanner.

2. Type or select the slot number of

the scanner.

3. Choose Finish.

Turn On AutoScan

1. Save your changes. 2. Download the project to the controller.

To turn on AutoScan:

Step: See page:

❑ Download the RSLogix 5000 Project and Go Online 4-7

❑ Turn On AutoScan 4-8

Download the RSLogix 5000 Project and Go Online

Publication DNET-UM004A-EN-P - March 2004

Page 60

4-8 Automatically Configure a DeviceNet Network

Turn On AutoScan

IMPORTANT

3. Select (check) this check box.

4. Choose OK.

In the following steps, you clear any existing configuration from the

scanner and reconfigure its to communicate with the devices on your

network.

• In the controller, this may change the tag addresses of the devices.

• If you have already programmed your logic, make sure that it still

addresses the correct data.

1. Double-click the scanner.

2. Click the Scan List tab.

Publication DNET-UM004A-EN-P - March 2004

A blue dot indicates a device that the scanner now

controls.

Page 61

Automatically Configure a DeviceNet Network 4-9

Access Device Data

input data from the scanner

output data for the scanner

status data from the scanner

When you add the scanner to the I/O configuration of the controller,

RSLogix 5000 software automatically creates a set of tags for the input,

output, and status data of the network:

The tags for your DeviceNet data follow this format:

location :type .Data [dnet_address] .bit

= Optional

Where: Is:

location location of the scanner in the system

If you have this scanner: In a: Then location is:

ControlLogix 1756-DNB local chassis Local:slot_number_of_scanner

remote chassis adapter:slot_number_of_scanner

where:

adapter is the name of the EtherNet/IP or ControlNet

module in the remote chassis.

FlexLogix 1788-DNBO name of the scanner in the I/O configuration of the controller

type type of data:

Where: Is:

input from a device I

output to a device O

dnet_address address of the device on the DeviceNet network (based on 4 bytes per node)

bit specific bit within the data of the device

Publication DNET-UM004A-EN-P - March 2004

Page 62

4-10 Automatically Configure a DeviceNet Network

While you can use the input and output tags of the scanner directly in

your logic, it is a lot easier to use alias tags.

As an option, create tags that describe each device without pointing them to

the actual addresses of the devices. Later, convert the tags to aliases for the

data of the devices.

alias tag – a tag that represents another tag

• Both tags share the same data.

• When the data changes, both tags change.

• An alias tag provides a descriptive name for

data, such as DeviceNet input or output data.

• If the location of the data changes, simply point

the alias tag lets to the new location without

editing your logic.

1. Enter your logic.

4. Select the Alias button.

5. Select the tag that this alias tag represents.

6. Select the scope for the alias tag.

2. Type a descriptive tag name for the DeviceNet data.

3. Right-click the tag name and choose

New…

7. Choose OK.

Look in the

controller-scoped tags.

Publication DNET-UM004A-EN-P - March 2004

Select the address of the data.

To select a bit, click the ▼.

Page 63

Automatically Configure a DeviceNet Network 4-11

Put the Scanner in Run Mode

To put the scanner in run

mode, turn on this bit.

To run the DeviceNet network:

1. Place the controller in run/remote run mode.

2. Set the following bit of the output structure for the scanner:

If you want to: The set this bit: To:

run the network …O.CommandRegister.Run 1

not run the network (idle mode) …O.CommandRegister.Run 0

fault the network …O.CommandRegister.Fault 1

not fault the network …O.CommandRegister.Fault 0

disable the network …O.CommandRegister.DisableNetwork 1

enable the network …O.CommandRegister.DisableNetwork 0

halt the scanner (ceases all operation) …O.CommandRegister.HaltScanner 1

unhalt the scanner …O.CommandRegister.HaltScanner 0

reset the scanner …O.CommandRegister.Reset 1

resume operation after a reset …O.CommandRegister.Reset 0

3. Check the scanner for run mode:

If you have this scanner: Then this indicator: Displays:

ControlLogix 1756-DNB 4-character display RUN

FlexLogix 1788-DNBO I/O solid green

Publication DNET-UM004A-EN-P - March 2004

Page 64