Allen-Bradley 1756 GuardLogix, 5069 CompactLogix, 1789 SoftLogix, 1756 ControlLogix, 5069 Compact GuardLogix Reference Manual

...Page 1

Reference Manual

Logix 5000 Advanced Process Control and Drives and

Equipment Phase and Sequence Instructions

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789

SoftLogix, 5069 CompactLogix, Emulate 5570

Page 2

Important user information

ies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this equipment

before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring instructions

in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried out by

suitably trained personnel in accordance with applicable code of practice. If this equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated

with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identif

personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Important:

Labels may also be on or inside the equipment to provide specific precautions.

Identifies information that is critical for successful application and understanding of the product.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be

present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc

Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work

practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their resp ective companies.

Page 3

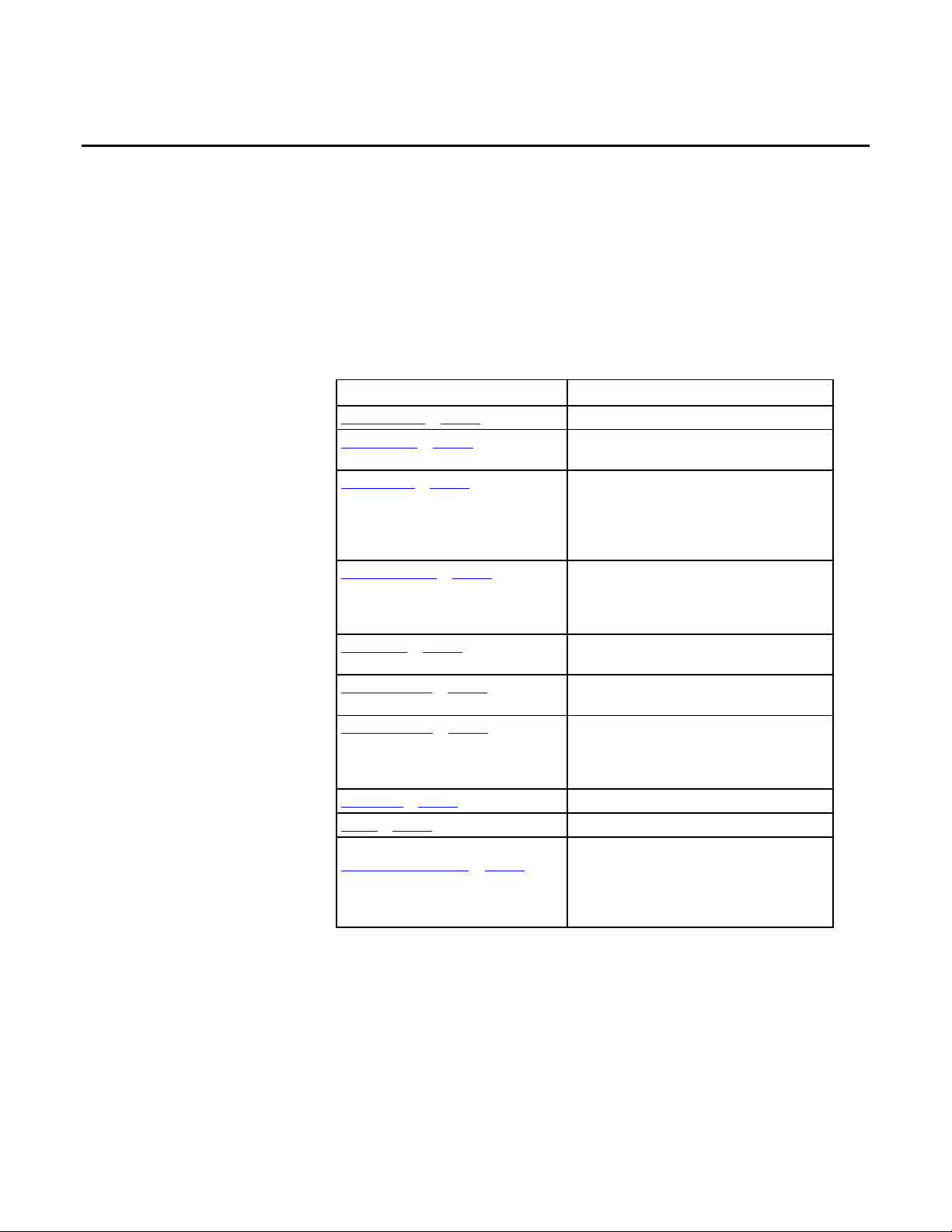

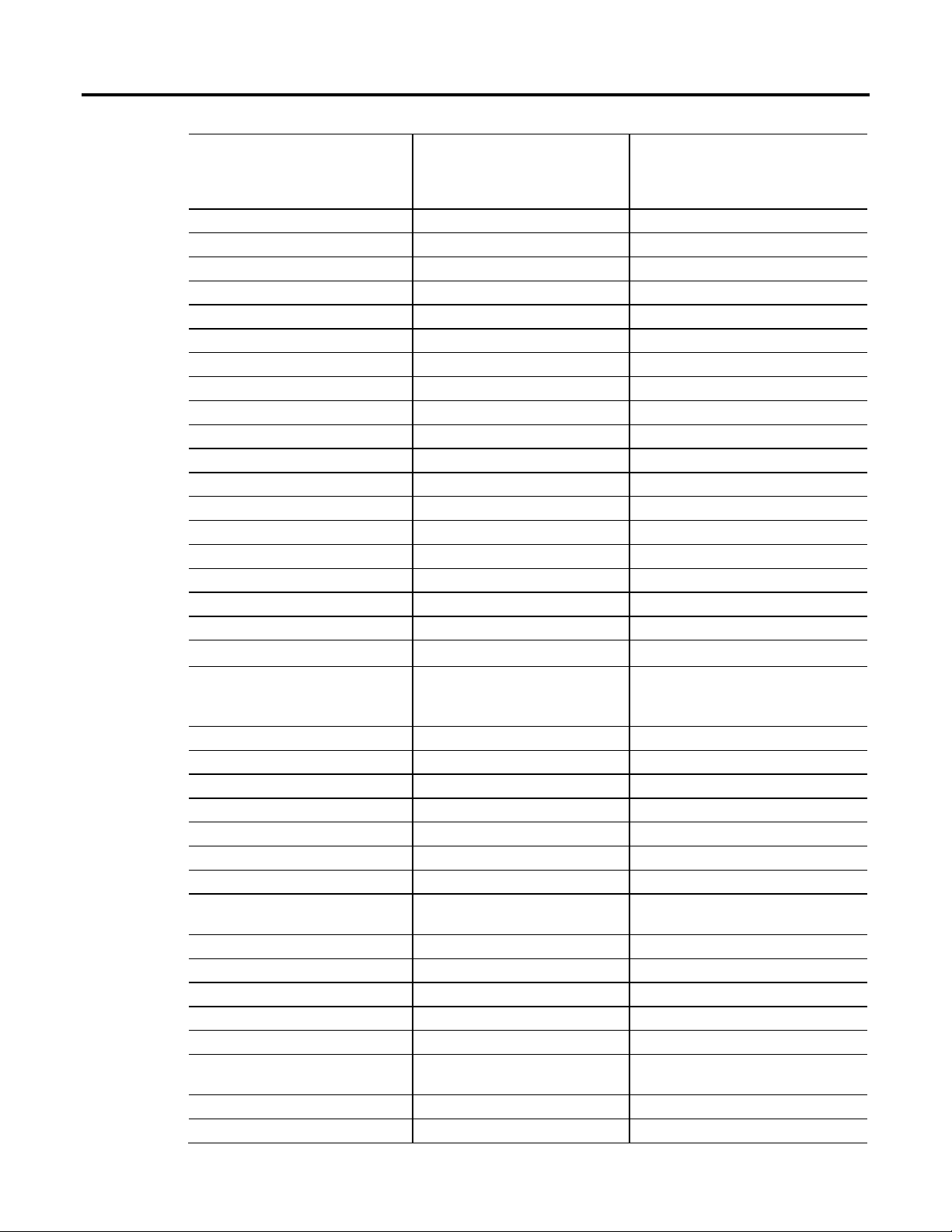

Summary of changes

This manual includes new and updated information. Use these reference tables to

locate changed information.

Global changes

None for this release.

New or enhanced features

Subject Reason

Common Attributes on page 537 Added link to the Elementary Data Types topic

Immediate values on page 540 Added Integer Immediate Values and Floating Point

Immediate Values tables.

Data Conversions on page 541 Changed Optimal data types to intermediate data types and

included extended data types USINT, INT, UINT, UDINT,

ULINT, LREAL. In the Convert SINT or INT to DINT section,

added converting DINT to LINT. Included converting data

for 32 and 64 bits.

Elementary data types on page 545 Changed the topic title from Data Types to Elementary Data

Types. Added LINT, USINT, UINT, UDINT, ULINT, REAL, and

LREAL.

LINT data types on page 548 Added a list of applicable controllers that support LINT data

types used in instructions.

Floating Point Values on page 548 Added a list of applicable controllers. Added LREAL tag

description.

Index Through Arrays on page 551 Added two new tips explaining Logix Designer allows

subscripts that are extended data type tags only. Also

explained using all available integer elementary data types

as a subscript index.

Bit Addressing on page 552 Added new definitions.

FOR_DO on page 525 Updated the description for loop ends.

Equipment Phase Instructions on page 415

The controllers that support Equipment Phase instructions

expanded to include the CompactLogix 5370 and

CompactLogix 5380, ControlLogix 5570 and ControlLogix

5580, and Compact GuardLogix 5370 and Compact

GuardLogix 5380 controllers.

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 3

Page 4

Page 5

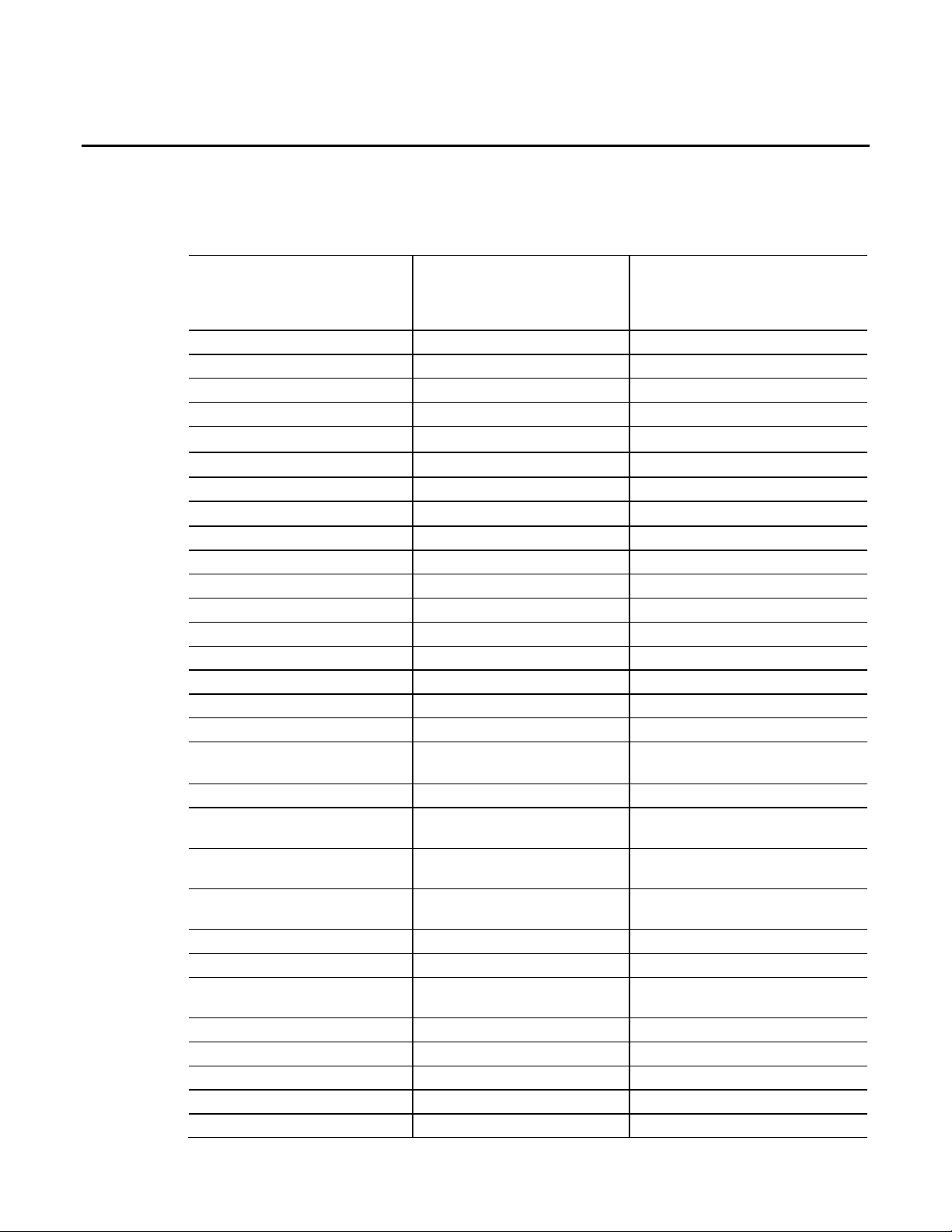

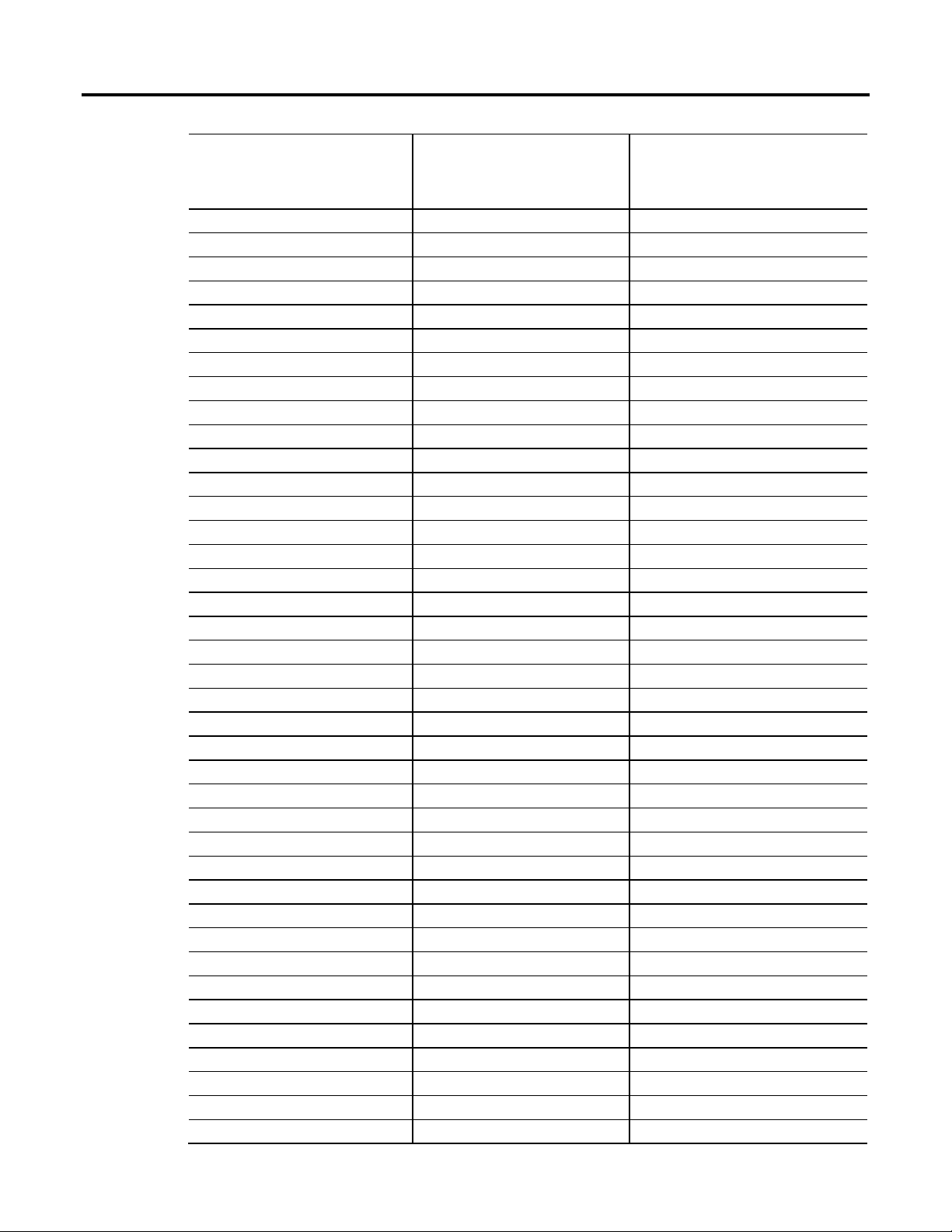

Instruction Locator

Use this locator to find the applicable Logix5000 controllers instruction manual

for each instruction.

Logix5000 Controllers General Instructions

Reference Manual 1756-RM003

Absolute Value (ABS) Alarm (ALM) Master Driven Coordinated Control (MDCC)

Add (ADD) Attach to Equipment Phase (PATT) Motion Apply Axis Tuning (MAAT)

Analog Alarm (ALMA) Attach to Equipment Sequence (SATT) Motion Apply Hookup Diagnostics (MAHD)

Always False (AFI) Coordinated Control (CC) Motion Arm Output Cam (MAOC)

Arc Cosine (ACS, ACOS) D Flip-Flop (DFF) Motion Arm Registration (MAR)

Arc Sine (ASN, ASIN) Deadtime (DEDT) Motion Arm Watch (MAW)

Arc Tangent (ATN, ATAN) Derivative (DERV) Motion Axis Fault Reset (MAFR)

ASCII Chars in Buffer (ACB) Detach from Equipment Phase (PDET) Motion Axis Gear (MAG)

ASCII Clear Buffer (ACL) Detach from Equipment Sequence (SDET) Motion Axis Home (MAH)

ASCII Handshake Lines (AHL) Discrete 3-State Device (D3SD) Motion Axis Jog (MAJ)

ASCII Read (ARD) Discrete 2-State Device (D2SD) Motion Axis Move (MAM)

ASCII Read Line (ARL) Enhanced PID (PIDE) Motion Axis Position Cam (MAPC)

ASCII Test for Buffer Line (ABL) Enhanced Select (ESEL) Motion Axis Stop (MAS)

ASCII Write (AWT) Equipment Phase Clear Failure (PCLF) Motion Axis Time Cam (MATC)

ASCII Write Append (AWA) Equipment Phase Command (PCMD) Motion Axis Shutdown (MASD)

Bit Field Distribute (BTD) Equipment Phase External Request (PXRQ) Motion Axis Shutdown Reset (MASR)

Bit Field Distribute with Target (BTDT) Equipment Phase Failure (PFL) Motion Calculate Cam Profile (MCCP)

Bit Shift Left (BSL) Equipment Phase New Parameters (PRNP) Motion Coordinated Path Move (MCPM)

Logix5000 Controllers Advanced Process

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Reference Manual MOTION-RM002

Bit Shift Right (BSR) Equipment Phase Override Command (POVR) Motion Calculate Slave Values (MCSV)

Bitwise And (AND) Equipment Phase Paused (PPD) Motion Coordinated Transform with Orientation

(MCTO)

Bitwise (NOT) Equipment Sequence Assign Sequence Identifier

(SASI)

Bitwise (OR) Equipment Sequence Clear Failure (SCLF) Motion Calculate Transform Position with

Boolean AND (BAND) Equipment Sequence command (SCMD) Motion Change Dynamics (MCD)

Boolean Exclusive OR (BXOR) Equipment Sequence Override (SOVR) Motion Coordinated Change Dynamics (MCCD)

Boolean NOT (BNOT) Function Generator (FGEN) Motion Coordinated Circular Move (MCCM)

Boolean OR (BOR) High Pass Filter (HPF) Motion Coordinated Linear Move (MCLM)

Break (BRK) High/Low Limit (HLL) Motion Coordinated Shutdown (MCSD)

Breakpoints (BPT) Integrator (INTG) Motion Coordinated Shutdown Reset (MCSR)

Clear (CLR) Internal Model Control (IMC) Motion Coordinated Stop (MCS)

Compare (CMP) JK Flip-Flop (JKFF) Motion Coordinated Transform (MCT)

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 5

Motion Calculate Transform Position (MCTP)

Orientation (MCTPO)

Page 6

Instruction Locator

Logix5000 Controllers General Instructions

Reference Manual 1756-RM003

Convert to BCD (TOD) Lead-Lag (LDLG) Motion Direct Drive Off (MDF)

Convert to Integer (FRD) Low Pass Filter (LPF) Motion Direct Drive On (MDO)

Copy File (COP), Synchronous Copy File (CPS) Maximum Capture (MAXC) Motion Direct Start (MDS)

Cosine (COS) Minimum Capture (MINC) Motion Disarm Output Cam (MDOC)

Compute (CPT) Modular Multivariable Control (MMC) Motion Disarm Registration (MDR)

Count down (CTD) Moving Average (MAVE) Motion Disarm Watch (MDW)

Count up (CTU) Moving Standard Deviation (MSTD) Motion Group Shutdown (MGSD)

Count up/down CTUD Multiplexer (MUX) Motion Group Shutdown Reset (MGSR)

Data Transition (DTR) Notch Filter (NTCH) Motion Group Stop (MGS)

Degrees (DEG) Phase State Complete (PSC) Motion Group Strobe Position (MGSP)

Diagnostic Detect (DDT) Position Proportional (POSP) Motion Redefine Position (MRP)

Digital Alarm (ALMD) Proportional + Integral (PI) Motion Run Axis Tuning (MRAT)

DINT To String (DTOS) Pulse Multiplier (PMUL) Motion Run Hookup Diagnostics (MRHD)

Divide (DIV) Ramp/Soak (RMPS) Motion Servo Off (MSF)

End of Transition (EOT) Rate Limiter (RLIM) Motion Servo On (MSO)

Equal to (EQU) Reset Dominant (RESD)

File Arithmetic (FAL) Scale (SCL)

File Bit Comparison (FBC) S-Curve (SCRV)

FIFO Load (FFL) Second-Order Controller (SOC)

FIFO Unload (FFU) Second-Order Lead Lag (LDL2)

Logix5000 Controllers Advanced Process

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Reference Manual MOTION-RM002

File Average (AVE) Select (SEL)

File Standard Deviation (STD) Selected Negate (SNEG)

File Fill (FLL) Selected Summer (SSUM)

File Sort (SRT) Set Dominant (SETD)

Find String (FIND) Split Range Time Proportional (SRTP)

For (FOR) Totalizer (TOT)

File Search and Compare (FSC) Up/Down Accumulator (UPDN)

Get System Value (GSV) and Set System Value

(SST)

Greater Than or Equal to (GEQ)

Greater than (GRT)

Insert String (INSERT)

Immediate Output (IOT)

Jump to Label (JMP) and Label (LBL)

Jump to Subroutine (JSR), Subroutine (SBR), and

Return (RET)

Jump to External Routine (JXR)

Less Than (LES)

6 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 7

Instruction Locator

Logix5000 Controllers General Instructions

Reference Manual 1756-RM003

Less Than or Equal to (LEQ)

LIFO Load (LFL)

LIFO Unload (LFU)

License Validation (LV)

Limit (LIM)

Log Base (LOG)

Lower to Case (LOWER)

Masked Move (MVM)

Masked Move with Target (MVMT)

Master Control Reset (MCR)

Masked Equal to (MEQ)

Message (MSG)

Middle String (MID)

Modulo (MOD)

Move (MOV)

Multiply (MUL)

Natural Log (LN)

Negate (NEG)

Not Equal to (NEQ)

No Operation (NOP)

One Shot (ONS)

One Shot Falling (OSF)

One Shot Falling with Input (OSFI)

One Shot Rising (OSR)

One Shot Rising with Input (OSRI)

Output Energize (OTE)

Output Latch (OTL)

Output Unlatch (OTU)

Proportional Integral Derivative (PID)

Radian (RAD)

Real to String (RTOS)

Reset (RES)

Reset SFC (SFR)

Return (RET)

Retentive Timer On (RTO)

Retentive Timer On with Reset (RTOR)

Pause SFC (SFP)

Size In Elements (SIZE)

Sequencer Input (SQI)

Logix5000 Controllers Advanced Process

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Reference Manual MOTION-RM002

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 7

Page 8

Instruction Locator

Logix5000 Controllers General Instructions

Reference Manual 1756-RM003

Sequencer Load (SQL)

Sequencer Output (SQO)

Sine (SIN)

Square Roost (SQR/SQRT)

String Concatenate (CONCAT)

String Delete (DELETE)

String to DINT (STOD)

String to REAL (STOR)

Swap Byte (SWPB)

Subtract (SUB)

Tangent (TAN)

Timer Off Delay (TOF)

Timer Off Delay with Reset (TOFR)

Timer On Delay (TON)

Timer On Delay with Reset (TONR)

Temporary End (TND)

Tracepoints (TPT)

Trigger Event Task (EVENT)

Truncate (TRN)

Unknown Instruction (UNK)

Upper Case (UPPER)

User Interrupt Disable (UID)/User Interrupt Enable

(UIE)

X to the Power of Y (XPY)

Examine if Closed (XIC)

Examine If Open (XIO)

Bitwise Exclusive (XOR)

Logix5000 Controllers Advanced Process

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Reference Manual MOTION-RM002

8 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 9

Preface

Process Control Instructions

Table of contents

Studio 5000 environment................................................................................................. 15

Additional resources .......................................................................................................... 16

Purpose of this manual ...................................................................................................... 16

Legal Notices ....................................................................................................................... 16

Chapter 1

Process Control Instructions ........................................................................................... 19

Alarm (ALM) ...................................................................................................................... 20

Discrete 3-State Device (D3SD) ..................................................................................... 26

Discrete 2-State Device (D2SD) ..................................................................................... 41

Deadtime (DEDT) ............................................................................................................ 51

Function Generator (FGEN) .......................................................................................... 56

Lead-Lag (LDLG) .............................................................................................................. 62

Enhanced PID (PIDE) ...................................................................................................... 67

Position Proportional (POSP) ...................................................................................... 102

Ramp/Soak (RMPS) ....................................................................................................... 111

Scale (SCL) ........................................................................................................................ 125

Split Range Time Proportional (SRTP) ...................................................................... 130

Totalizer (TOT) .............................................................................................................. 137

Coordinated Control (CC) ........................................................................................... 147

CC Function Block Configuration ...................................................................... 181

CC Function Block Model Initialization ............................................................ 182

CC Function Block Tuning ................................................................................... 183

CC Function Block Tuning Errors ...................................................................... 183

CC Function Block Tuning Procedure ............................................................... 184

Internal Model Control (IMC) .................................................................................... 184

IMC Fun

IMC Function Block Model Initialization ......................................................... 202

IMC Function Block Tuning ................................................................................ 202

IMC Function Block Tuning Errors .................................................................... 203

IMC Function Block Tuning Procedure ............................................................. 204

Modular Multivariable Control (MMC) .................................................................... 204

MMC Function Block Configuration ................................................................. 243

MMC Function Block Model Initialization....................................................... 245

MMC Function Block Tuning .............................................................................. 245

Use an MMC Function Block for Splitter Control .......................................... 246

MMC Function Block Tuning Errors ................................................................. 246

MMC Function Block Tuning Procedure .......................................................... 247

Current SP

Use the Coordinated Control Function Block to Control ............................. 248

CV High/Low Limiting ................................................................................................. 250

CV Percent Limiting ....................................................................................................... 251

CV Rate-of-Change Limiting ........................................................................................ 252

ction Block Configuration .................................................................... 201

......................................................................................................................... 248

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 9

Page 10

Table of contents

Drives

Filter

Select_Limit Instructions

CV Windup Limiting ..................................................................................................... 253

Execution ........................................................................................................................... 254

Switch Between Program Control and Operator Control .............................. 254

Operating Modes ...................................................................................................... 255

Convert the PV and SP Values to Percent .......................................................... 257

Primary Loop Control ............................................................................................ 257

Processing Faults ....................................................................................................... 259

Select the Control Variable .................................................................................... 259

Update the CVOper and CVProg Values ........................................................... 260

Select the Setpoint .................................................................................................... 260

SP High/Low Limiting ........................................................................................... 261

Chapter 2

Drives Instructions .......................................................................................................... 263

Integrator (INTG) ........................................................................................................... 264

Proportional + Integral (PI) .......................................................................................... 270

Pulse Multiplier (PMUL) ............................................................................................... 281

S-Curve (SCRV) .............................................................................................................. 289

Second-Order Controller (SOC) ................................................................................. 298

Up/Down Accumulator (UPDN) ............................................................................... 308

HMI Button Control (HMIBC) ................................................................................. 312

Chapter 3

Filter Instructions ............................................................................................................ 319

Derivative (DERV) .......................................................................................................... 320

High Pass Filter (HPF) ................................................................................................... 324

Low Pass Filter (LPF) ...................................................................................................... 330

Notch Filter (NTCH) .................................................................................................... 336

Second-Order Lead Lag (LDL2) ................................................................................... 341

Chapter 4

Select/Limit Instructions ............................................................................................... 349

Enhanced Select (ESEL) ................................................................................................. 350

High/Low Limit (HLL) ................................................................................................. 357

Multiplexer (MUX) ......................................................................................................... 362

Rate Limiter (RLIM) ....................................................................................................... 365

Select (SEL) ....................................................................................................................... 370

Selected Negate (SNEG) ................................................................................................ 373

Selected Summer (SSUM) ............................................................................................. 376

10 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 11

Table of contents

Statistical Instructions

Logical and Move

Equipment Phase

Equipment Sequence

Chapter 5

Instructions

Statistical Instructions ..................................................................................................... 381

Moving Average (MAVE) .............................................................................................. 382

Maximum Capture (MAXC) ........................................................................................ 388

Minimum Capture (MINC) ......................................................................................... 392

Moving Standard Deviation (MSTD) ......................................................................... 395

Chapter 6

Logical and Move Instructions ...................................................................................... 401

D Flip-Flop (DFF) ........................................................................................................... 401

JK Flip-Flop (JKFF) ......................................................................................................... 404

Reset Dominant (RESD) ................................................................................................ 407

Set Dominant (SETD) .................................................................................................... 411

Chapter 7

Equipment Phase Instructions ...................................................................................... 415

Attach to Equipment Phase (PATT) ........................................................................... 416

Detach from Equipment Phase (PDET) ..................................................................... 421

Equipment Phase Clear Failure (PCLF) ..................................................................... 424

Equipment Phase Command (PCMD) ...................................................................... 427

Equipment Phase External Request (PXRQ)............................................................. 433

Equipment Phase Failure (PFL) .................................................................................... 443

Equipment Phase New Parameters (PRNP) .............................................................. 448

Equipment Phase Override Command (POVR) ...................................................... 451

Equipment Phase Paused (PPD) ................................................................................... 455

Phase State Complete (PSC) ......................................................................................... 460

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 11

Chapter 8

Equipment Sequence instructions ................................................................................ 465

Attach to Equipment Sequence (SATT) .................................................................... 465

Detach from Equipment Sequence (SDET)............................................................... 468

Equipment Sequence Assign Sequence Identifier (SASI) ........................................ 470

Equipment Sequence Clear Failure (SCLF) ............................................................... 471

Equip

ment Sequence command (SCMD) .................................................................. 473

Equipment Sequence Diagram instructions ............................................................... 476

Equipment Sequence Override (SOVR) ..................................................................... 476

Guidelines for SATT instructions ................................................................................ 479

Guidelines for SCMD instructions .............................................................................. 480

Guidelines for SOVR instructions ................................................................................ 480

Result codes for SATT instructions ............................................................................. 481

Result codes for SCLF instructions .............................................................................. 482

Page 12

Table of contents

Function Block Attributes

Structured Text

Result codes for SCMD instructions ........................................................................... 483

Result codes for SOVR instructions ............................................................................. 484

SASI instruction examples ............................................................................................. 485

SATT instruction examples ........................................................................................... 486

SCLF instruction examples ............................................................................................ 486

SCMD instruction examples ......................................................................................... 487

SDET instruction examples ........................................................................................... 487

SOVR instruction examples ........................................................................................... 488

When should I use an SOVR instruction instead of an SCMD instruction? ...... 489

Chapter 9

Programming

Choose the Function Block Elements.......................................................................... 492

Latching Data.................................................................................................................... 493

Function Block Responses to Overflow Conditions ................................................ 494

Order of Execution .......................................................................................................... 495

Timing Modes .................................................................................................................. 499

Program/Operator Control ........................................................................................... 502

Function Block States ...................................................................................................... 505

Chapter 10

Structured Text Syntax ................................................................................................... 508

Structured Text Components: Comments ................................................................ 509

Structured Text Components: Assignments .............................................................. 510

Specify a non-retentive assignment ....................................................................... 511

Assign an ASCII character to a string data member ......................................... 512

Structured Text Components: Expressions ................................................................ 513

Use arithmetic operators and functions .............................................................. 514

Use bitwise operators ............................................................................................... 516

Use logical operators ................................................................................................ 516

Use relational operators .......................................................................................... 517

Structured Text Components: Instructions ............................................................... 519

ured Text Components: Constructs ................................................................. 520

Struct

Character string literals ................................................................................................... 521

String Types ............................................................................................................... 522

CASE_OF ......................................................................................................................... 523

FOR_DO ........................................................................................................................... 525

IF_THEN .......................................................................................................................... 527

REPEAT_UNTIL ........................................................................................................... 530

WHILE_DO .................................................................................................................... 533

Structured Text Attributes............................................................................................. 535

12 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 13

Common Attributes for

Index

Advanced Process Control

and Drives Instructions

Table of contents

Chapter 11

Common Attributes ........................................................................................................ 537

Math Status Flags ............................................................................................................. 537

Immediate values .............................................................................................................. 540

Data Conversions ............................................................................................................. 541

Elementary data types ...................................................................................................... 545

LINT data types ............................................................................................................... 548

Floating Point Values ...................................................................................................... 548

Index Through Arrays ..................................................................................................... 551

Bit Addressing ................................................................................................................... 552

Function Block Faceplate Controls .............................................................................. 552

Faceplate Control Properties Dialog - General Tab ................................................. 553

Faceplate Control Properties Dialog - Display Tab .................................................. 554

Faceplate Control Properties Dialog - Font Tab ....................................................... 555

Faceplate Control Properties Dialog - LocaleTab ..................................................... 556

ASCII Character Codes .................................................................................................. 557

ASCII character codes ..................................................................................................... 557

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 13

Page 14

Page 15

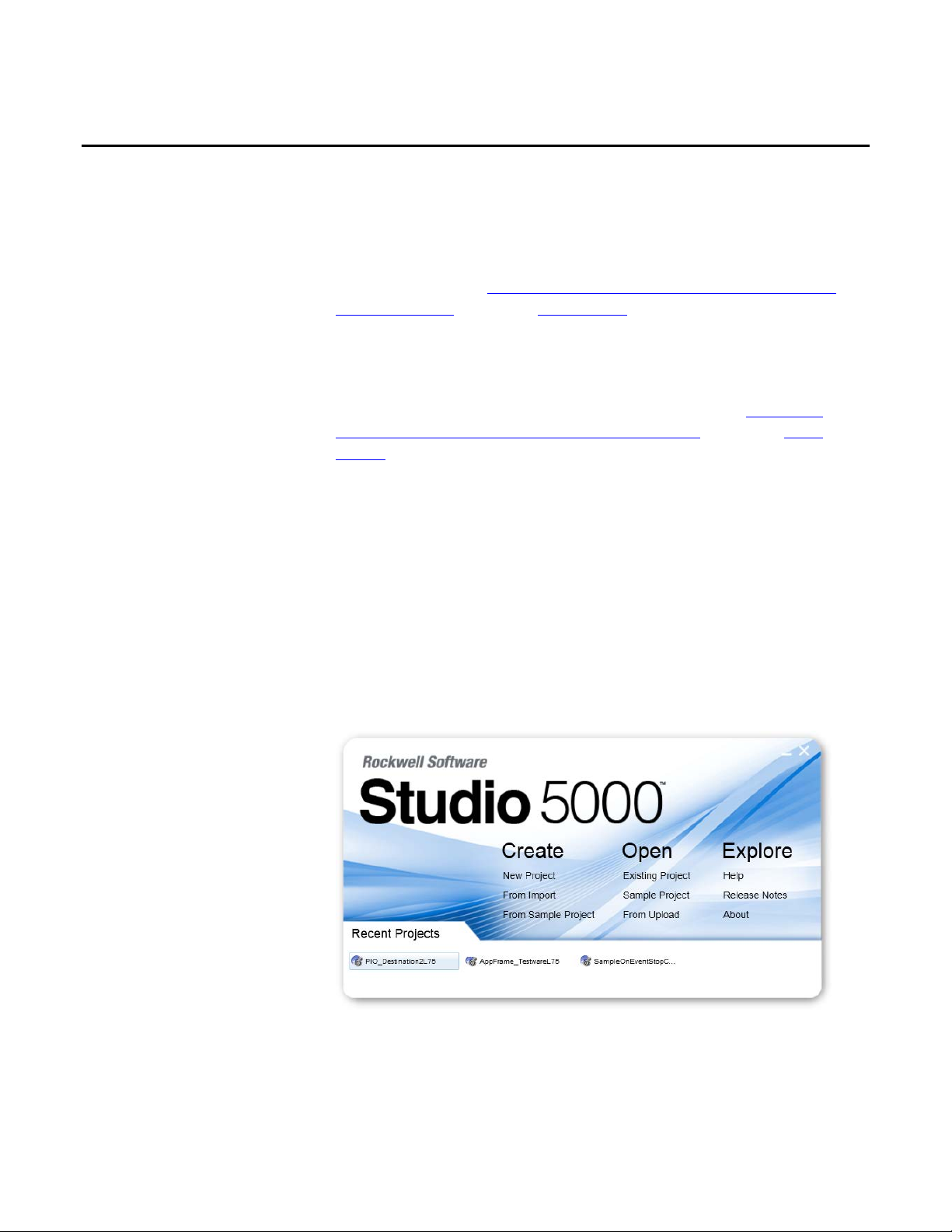

Studio 5000 environment

Preface

This manual provides a programmer with details about the available General,

Motion, Process, and Drives instruction set for a Logix-based controller.

If you design, program, or troubleshoot safety applications that use GuardLogix

controllers, refer to the

Reference Manual, publication 1756-RM095.

This manual is one of a set of related manuals that show common procedures for

programming and operating Logix 5000 controllers.

GuardLogix Safety Application Instruction Set Safety

For a complete list of common procedures manuals, refer to the

Controllers Common Procedures Programming Manual, publication 1756-

PM001 .

The term Logix 5000 controller refers to any controller based on the Logix 5000

operating system.

The Studio 5000 Automation Engineering & Design Environment® combines

engineering and design elements into a common environment. The first element is

the Studio 5000 Logix Designer® application. The Logix Designer application is

the rebranding of RSLogix 5000® software and will continue to be the product to

program Logix 5000™ controllers for discrete, process, batch, motion, safety, and

drive-based solutions.

Logix 5000

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 15

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio 5000

environment is the one place for design engineers to develop all elements of their

control system.

Page 16

Preface

Additional resources

Purpose of this manual

Legal Notices

These documents contain additional information concerning related Rockwell

Automation products.

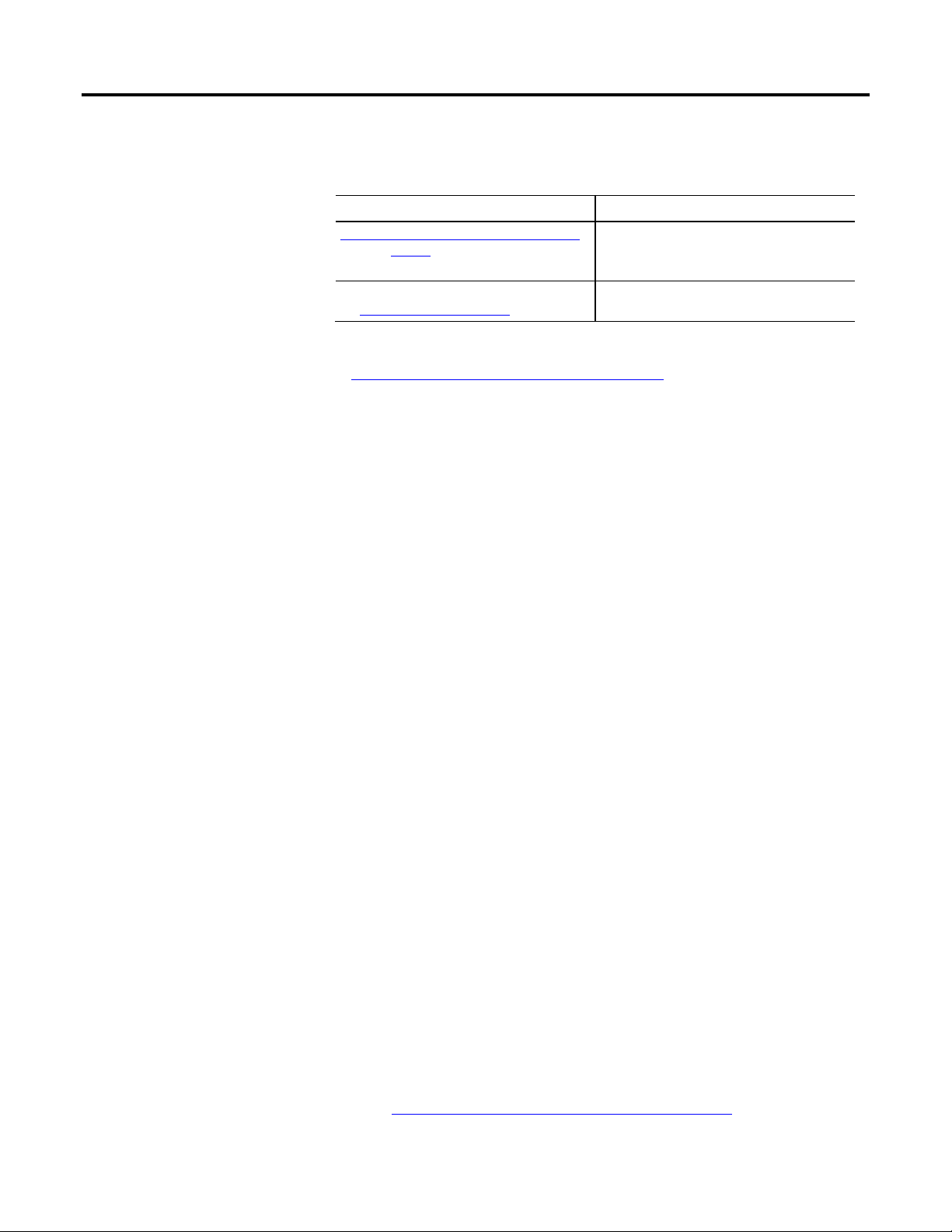

Resource Description

Industrial Automation Wiring and Grounding Guidelines ,

publication 1770-4.1

Provides general guidelines for installing a Rockwell

Automation industrial system.

Product Certifications webpage, available

at http://ab.rockwellautomation.com

Provides declarations of conformity, certificates, and other

certification details.

View or download publications

at http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact the local Rockwell Automation distributor or

sales representative.

This manual provides a programmer with details about each available instruction

for a Logix-based controller. This manual also gives you guidance and examples to

use equipment phase instructions to transition to different state, handle faults, set

up break points, and so forth.

Copyright Notice

Copyright © 2019 Rockwell Automation Technologies, Inc. All Rights Reserved.

Printed in USA.

This document and any accompanying Rockwell Software products are

copyrighted by Rockwell Automation Technologies, Inc. Any reproduction

and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement for

details.

16 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement ("EULA")

by opening the License.rtf file located in your product's install folder on your hard

drive.

Open source licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source packages

included in this product are located at their respective web site(s).

Alternately, obtain complete Corresponding Source code by contacting Rockwell

Automation via the Contact form on the Rockwell Automation

website:

http://www.rockwellautomation.com/global/about-

Page 17

Preface

us/contact/contact.page

Please include "Open Source" as part of the request text.

A full list of all open source software used in this product and their corresponding

licenses can be found in the OPENSOURCE folder

included with the Release

Notes. The default installed location of these licenses is C:\Program Files

(x86)\Common

Files\Rockwell\Help\

<Product>\ReleaseNotes\OPENSOURCE\index.htm.

Trademark Notices

Allen-Bradley, ControlBus, ControlFLASH, Compact GuardLogix, Compact

I/O, ControlLogix, CompactLogix, DCM, DH+, Data Highway Plus,

DriveLogix, DPI, DriveTools, Explorer, FactoryTalk, FactoryTalk Administration

Console, FactoryTalk Alarms and Events, FactoryTalk Batch, FactoryTalk

Directory, FactoryTalk Security, FactoryTalk Services Platform, FactoryTalk

View, FactoryTalk View SE, FLEX Ex, FlexLogix, FLEX I/O, Guard I/O, High

Performance Drive, Integrated Architecture, Kinetix, Logix5000, Logix 5000,

Logix5550, MicroLogix, DeviceNet, EtherNet/IP, PLC-2, PLC-3, PLC-5,

PanelBuilder, PowerFlex, PhaseManager, POINT I/O, PowerFlex, Rockwell

Automation, RSBizWare, Rockwell Software, RSEmulate, Historian,

RSFieldbus, RSLinx, RSLogix, RSNetWorx for DeviceNet, RSNetWorx for

EtherNet/IP, RSMACC, RSView, RSView32, Rockwell Software Studio 5000

Automation Engineering & Design Environment, Studio 5000 View Designer,

SCANport, SLC, SoftLogix, SMC Flex, Studio 5000, Ultra 100, Ultra 200,

VersaView, WINtelligent, XM, SequenceManager are trademarks of Rockwell

Automation, Inc.

Any Rockwell Automation logo, software or hardware product not mentioned

herein is also a trademark, registered or otherwise, of Rockwell Automation, Inc.

Other Trademarks

CmFAS Assistant, CmDongle, CmStick, CodeMeter, CodeMeter Control

Center, and WIBU are trademarks of WIBU-SYSTEMS AG in the United States

and/or other countries.

All other trademarks are the property of their respective holders and are hereby

acknowledged.

Warranty

This product is warranted in accordance with the product license. The product’s

performance may be affected by system configuration, the application being

performed, operator control, maintenance, and other related factors. Rockwell

Automation is not responsible for these intervening factors. The instructions in

this document do not cover all the details or variations in the equipment,

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 17

Page 18

Preface

procedure, or process described, nor do they provide directions for meeting every

possible contingency during installation, operation, or maintenance. This

product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the

accompanying software may have changed since the release. Rockwell Automation,

Inc. reserves the right to change any information contained in this document or

the software at any time without prior notice. It is your responsibility to obtain the

most current information available from Rockwell when installing or using this

product.

Environmental Compliance

Rockwell Automation maintains current product environmental information on

its website at

http://www.rockwellautomation.com/rockwellautomation/about-

us/sustainability-ethics/product-environmental-compliance.page

Contact Rockwell

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/

18 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 19

Process

Process Control

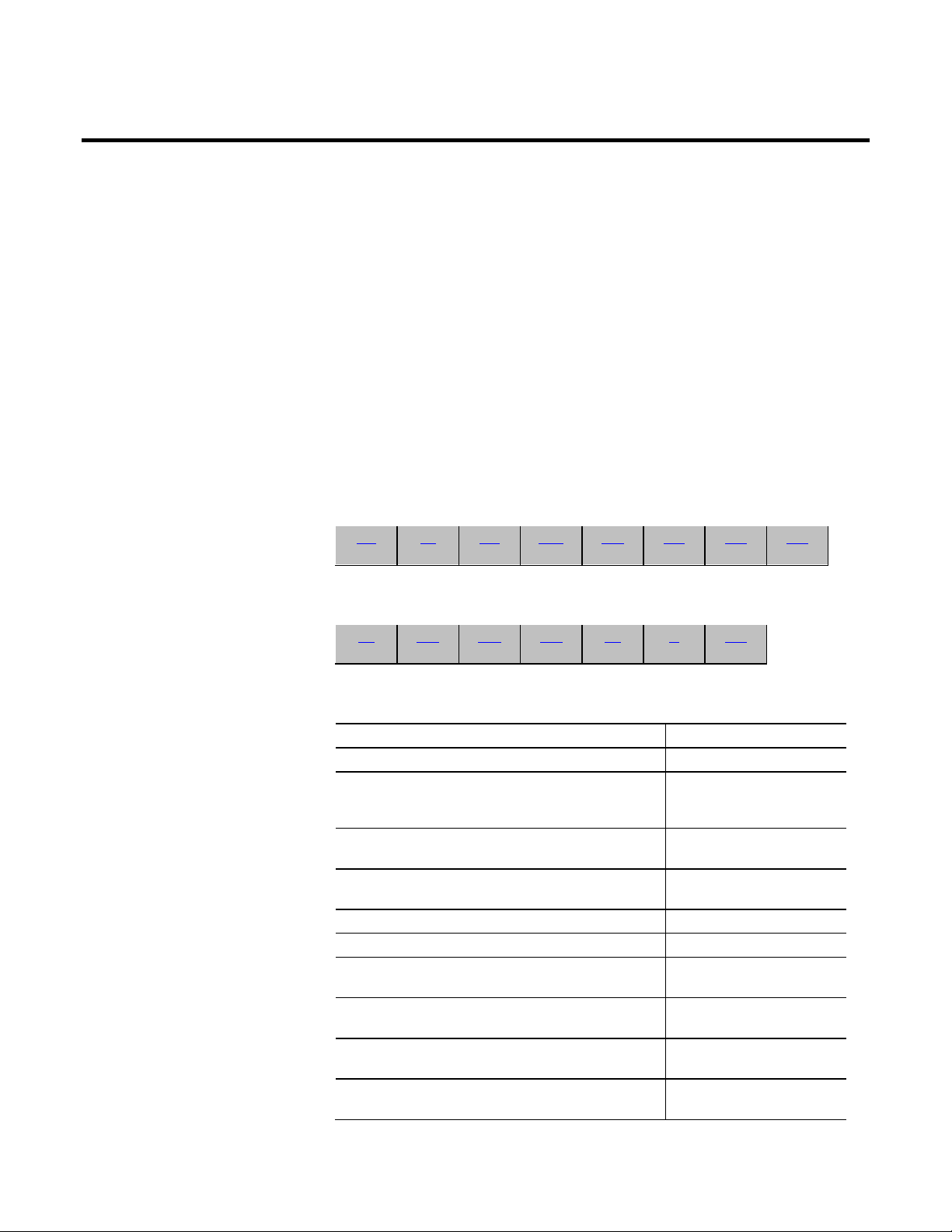

The Process Control instructions include these instructions:

Chapter 1

Instructions

Available Instructions

Ladder Diagram

Not available

Function Block and Structured Text

ALM SCL PIDE RMPS POSP SRTP LDLG FGEN

TOT DEDT D2SD D3SD IMC CC MMC

If you want to Use this instruction

Provide alarming for any analog signal. ALM

Control discrete devices, such as solenoid valves, pumps, and motors, that

have only two possible states (e.g., on/off, open/closed, etc.).

D2SD

Control discrete devices, such as high/low/off feeders that have three

possible states (e.g., fast/slow/off, forward/stop/reverse, etc.).

Perform a delay of a single input. You select the amount of deadtime

delay.

Convert an input based on a piece-wise linear function. FGEN

Provide a phase lead-lag compensation for an input signal. LDLG

Regulate an analog output to maintain a process variable at a certain

setpoint, using a PID algorithm.

Raise/lower or open/close a device, such as a motor-operated valve, by

pulsing open or close contacts.

Provide for alternating ramp and soak periods to follow a temperature

profile.

Convert an unscaled input value to a floating point value in engineering

units.

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 19

D3SD

DEDT

PIDE

POSP

RMPS

SCL

Page 20

Chapter 1

Process Control Instructions

Take the 0-100% output of a PID loop and drive heating and cooling

Alarm (ALM)

digital output contacts with a periodic pulse.

SRTP

Provide a time-scaled accumulation of an analog input value, such as a

volumetric flow.

Control a single process variable by maintaining a single controller output. IMC

Control a single process variable by manipulating as many as three

different control variables.

Control two process variables to their setpoints using up to three control

variables.

TOT

CC

MMC

See also

Filter Instructions on page 319

Logical and Move Instructions on page 401

Drives Instructions on page 263

Select/Limit Instructions on page 349

Statistical Instructions on page 381

This information applies to the CompactLogix 5370, ControlLogix 5570,

Compact GuardLogix 5370, GuardLogix 5570, Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix

5580 controllers.

The ALM instruction provides alarming for any analog signal.

Available Languages

Ladder Diagram

This instruction is not available in ladder diagram logic.

20 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 21

Process Control Instructions

Chapter 1

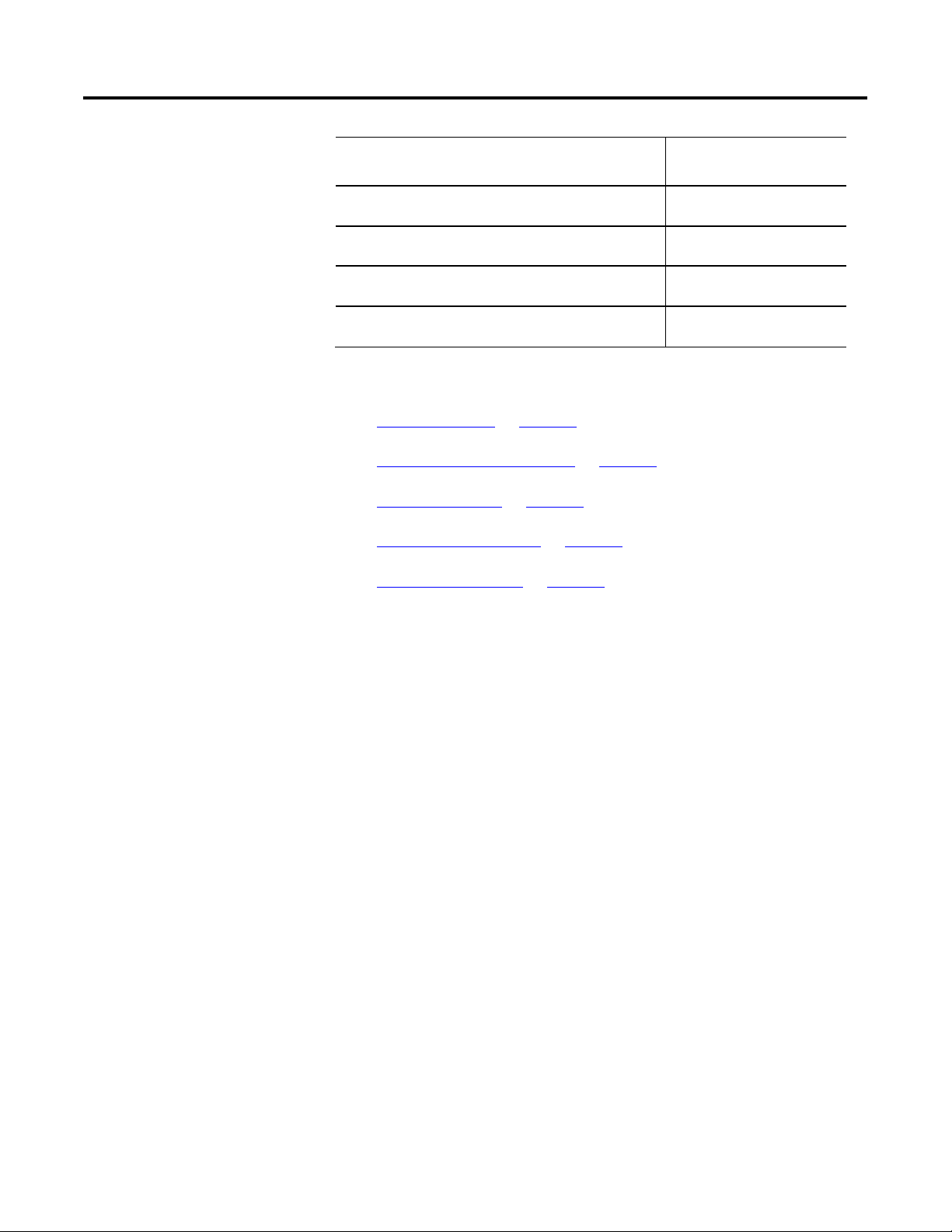

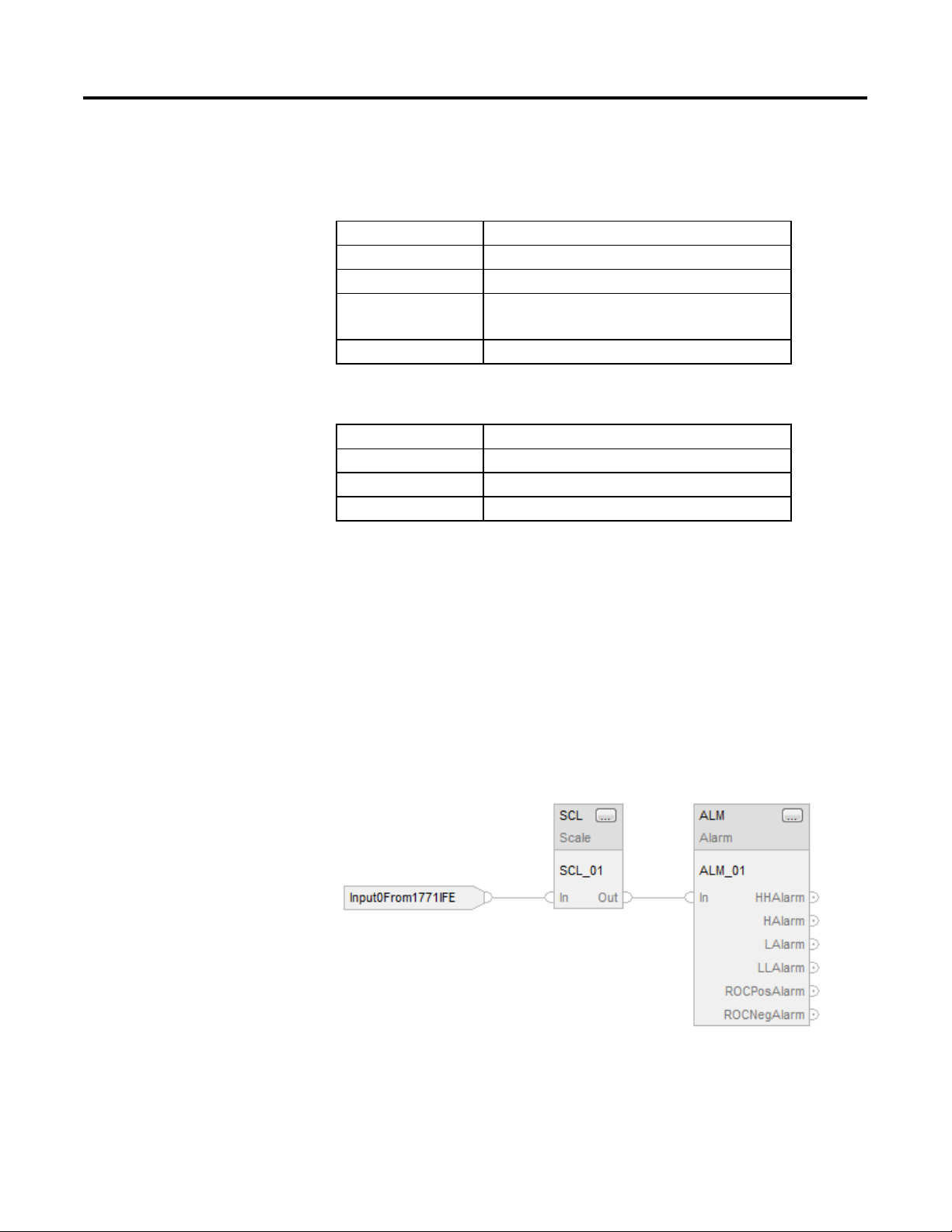

Function Block

Structured Text

ALM(ALM_tag)

Operands

Function Block

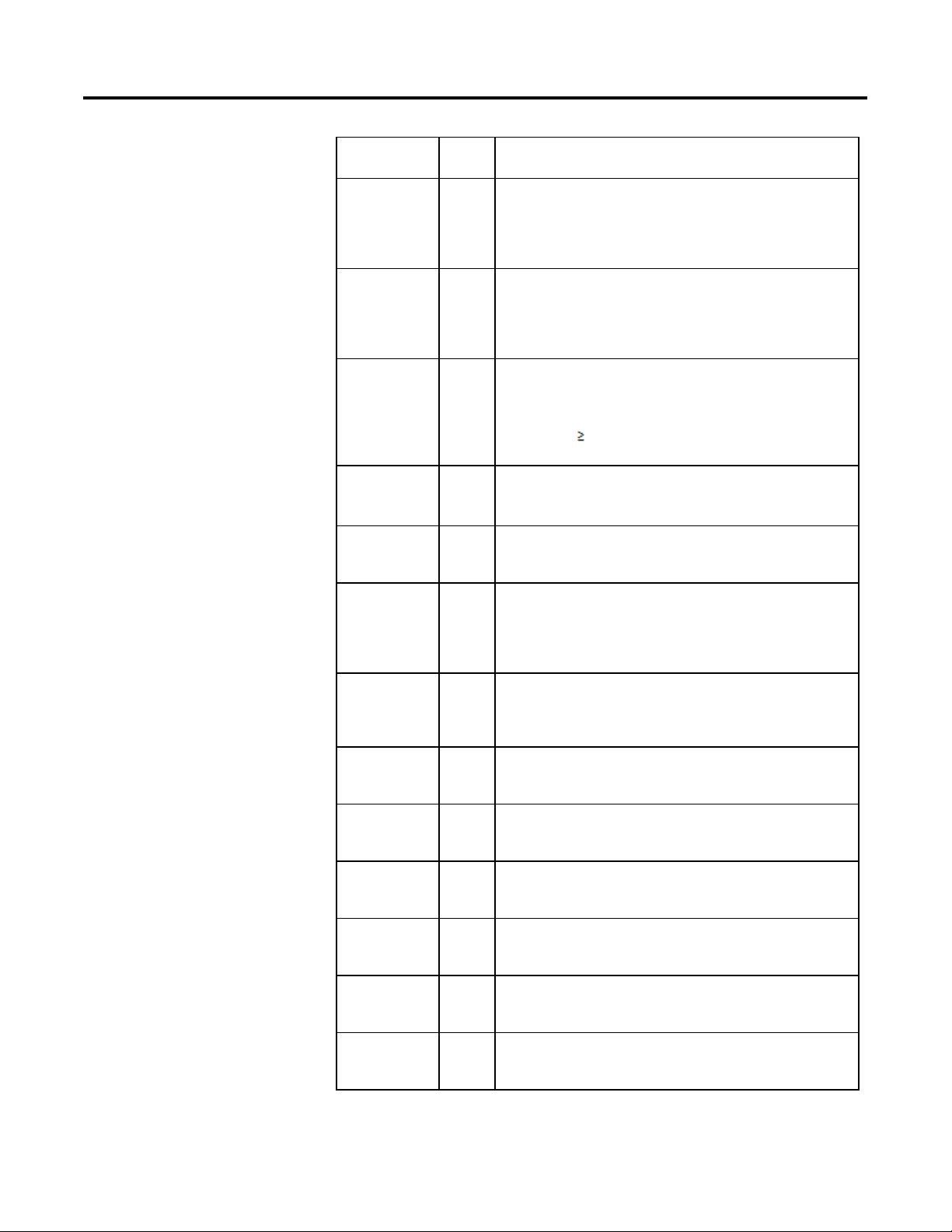

Operand Type Format Description

ALM tag ALARM structure ALM structure

Structured Text

Operand Type Format Description

ALM tag ALARM structure ALM structure

See Structured Text Syntax for more information on the syntax of expressions

within structured text.

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 21

Page 22

Chapter 1

Process Control Instructions

ROC negative alarming. If invalid, the instruction assumes a value of

ALARM Structure

Input Parameter Data Type Description

EnableIn BOOL Enable input. If false, the instruction does not execute and outputs

are not updated.

Default is true.

In REAL The analog signal input.

Valid = any float

Default = 0.0

HHLimit REAL The high-high alarm limit for the input.

Valid = any real value

Default = maximum positive value

HLimit REAL The high alarm limit for the input.

Valid = any real value

Default = maximum positive value

LLimit REAL The low alarm limit for the input.

Valid = any real value

Default = maximum negative value

LLLimit REAL The low-low alarm limit for the input.

Valid = any real value

Default = maximum negative value

Deadband REAL The alarm deadband for the high-high to low-low limits

Valid = any real value 0.0

Default = 0.0

ROCPosLimit REAL The rate-of-change alarm limit in units per second for a positive

(increasing) change in the input. Set ROCPosLimit = 0 to disable

ROC positive alarming. If invalid, the instruction assumes a value of

0.0 and sets the appropriate bit in Status.

Valid = any real value 0.0

Default = 0.0

ROCNegLimit REAL The rate-of-change alarm limit in units per second for a negative

(decreasing) change in the input. Set ROCNegLimit = 0 to disable

ROCPeriod REAL Time period in seconds for calculation (sampling interval) of the

22 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

0.0 and sets the appropriate bit in Status.

Valid = any real value 0.0

Default = 0.0

rate of change value. Each time the sampling interval expires, a

new sample of In is stored, and ROC is re-calculated. Instead of an

enable bit like other conditions in the analog alarm, the rate-ofchange detection is enabled by putting any non-zero value in the

ROCPeriod.

Valid = 0.0 to 32767.0

Default = 0.0.

Page 23

Process Control Instructions

Chapter 1

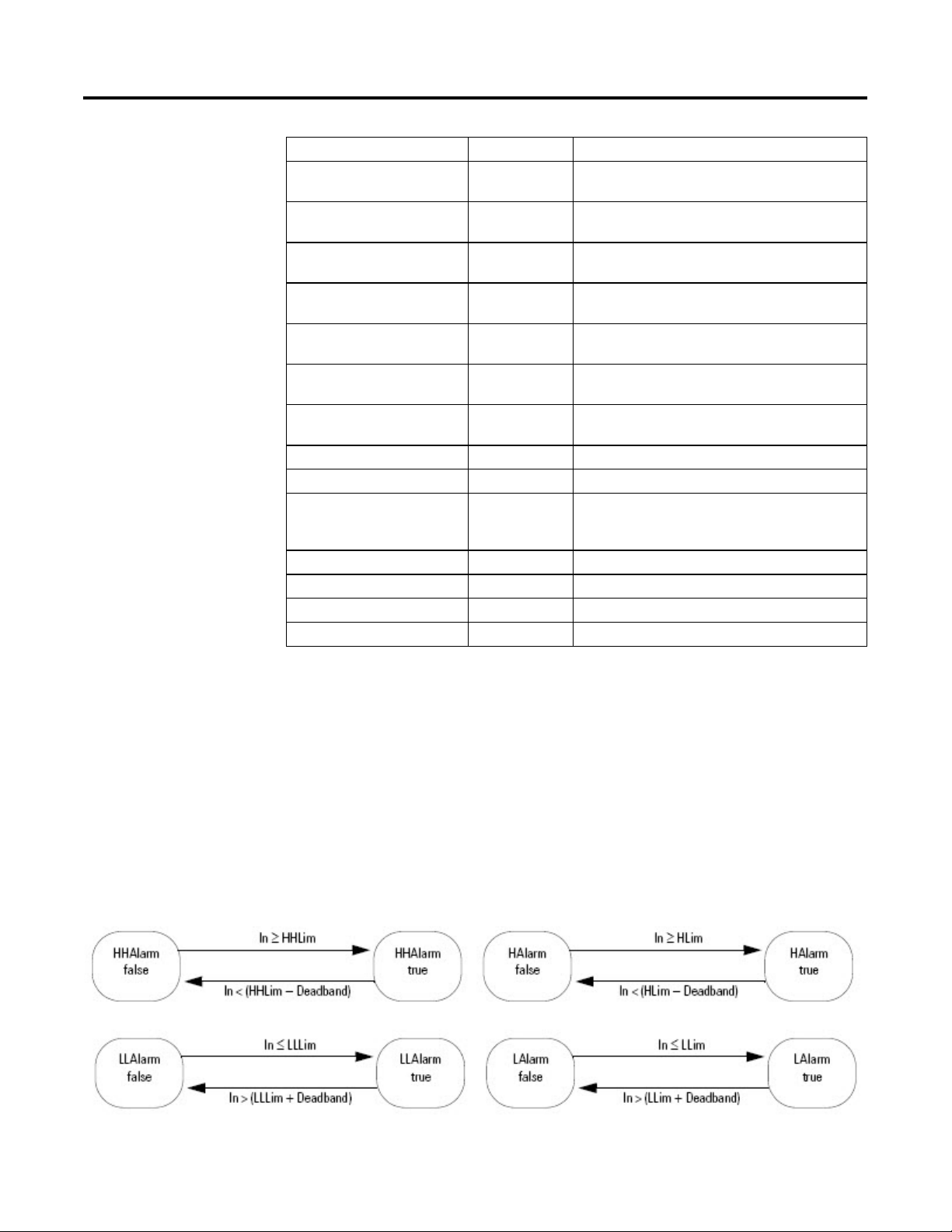

Output Parameter Data Type Description

EnableOut BOOL Indicates if instruction is enabled. Cleared to false if ROC

overflows.

HHAlarm BOOL The high-high alarm indicator.

Default = false

HAlarm BOOL The high alarm indicator.

Default = false

LAlarm BOOL The low alarm indicator.

Default = false

LLAlarm BOOL The low-low alarm indicator.

Default = false

ROCPosAlarm BOOL The rate-of-change positive alarm indicator.

Default = false

ROCNegAlarm BOOL The rate-of-change negative alarm indicator.

Default = false

ROC REAL The rate-of-change output.

Status DINT Status of the function block.

InstructFault (Status.0) BOOL The instruction detected one of the following execution errors.

This is not a minor or major controller error. Check the remaining

status bits to determine what occurred.

DeadbandInv (Status.1) BOOL Invalid Deadband value.

ROCPosLimitInv (Status.2) BOOL Invalid ROCPosLimit value.

ROCNegLimitInv (Status.3) BOOL Invalid ROCNegLimit value.

ROCPeriodInv (Status.4) BOOL Invalid ROCPeriod value.

Description

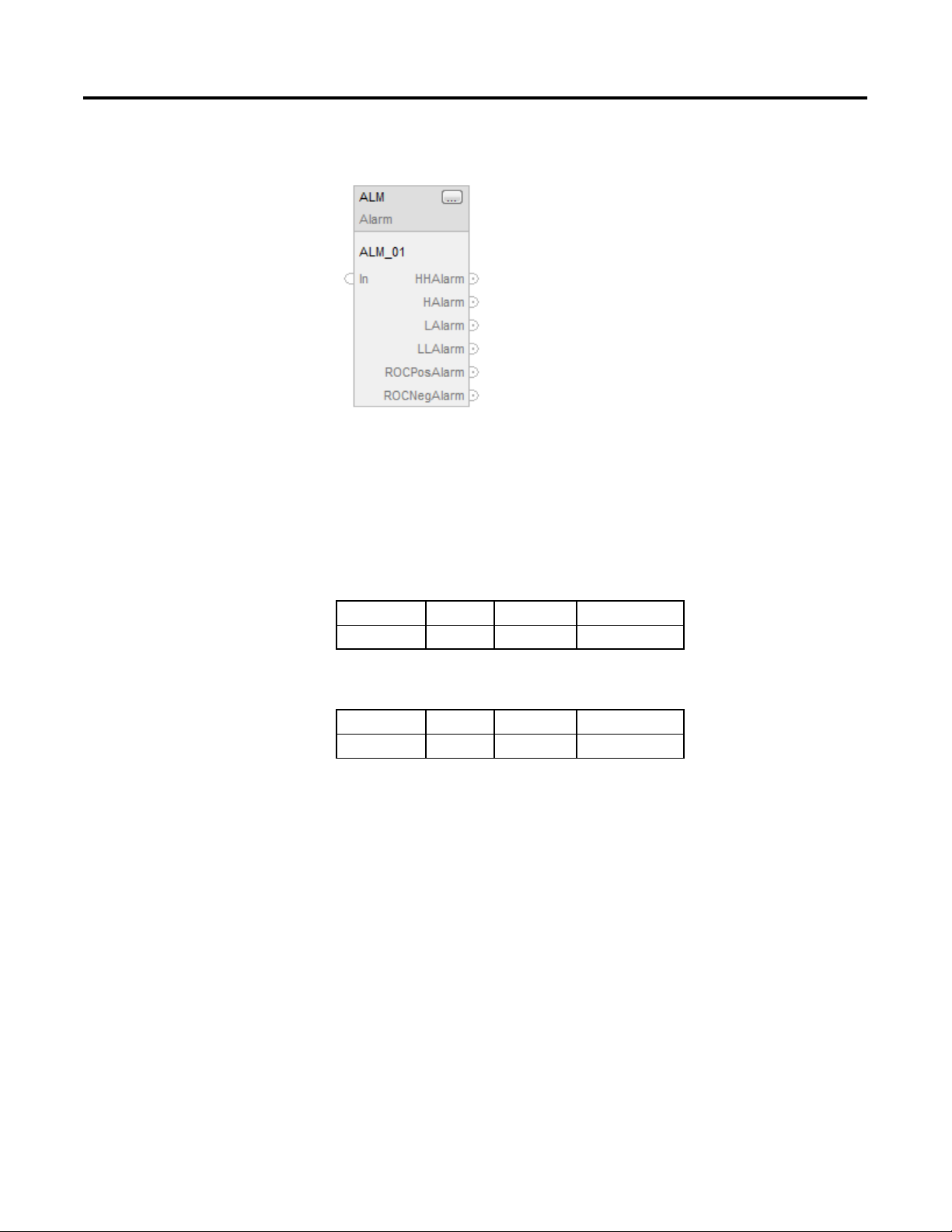

The ALM instruction provides alarm indicators for high-high, high, low, low-low,

rate-of-change positive, and rate-of-change negative. An alarm deadband is

available for the high-high to low-low alarms. A user-defined period for

performing rate-of-change alarming is also available.

High-high to Low-low Alarm

The high-high and low-low alarm algorithms compare the input to the alarm limit

and the alarm limit plus or minus the deadband.

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 23

Page 24

Chapter 1

Process Control Instructions

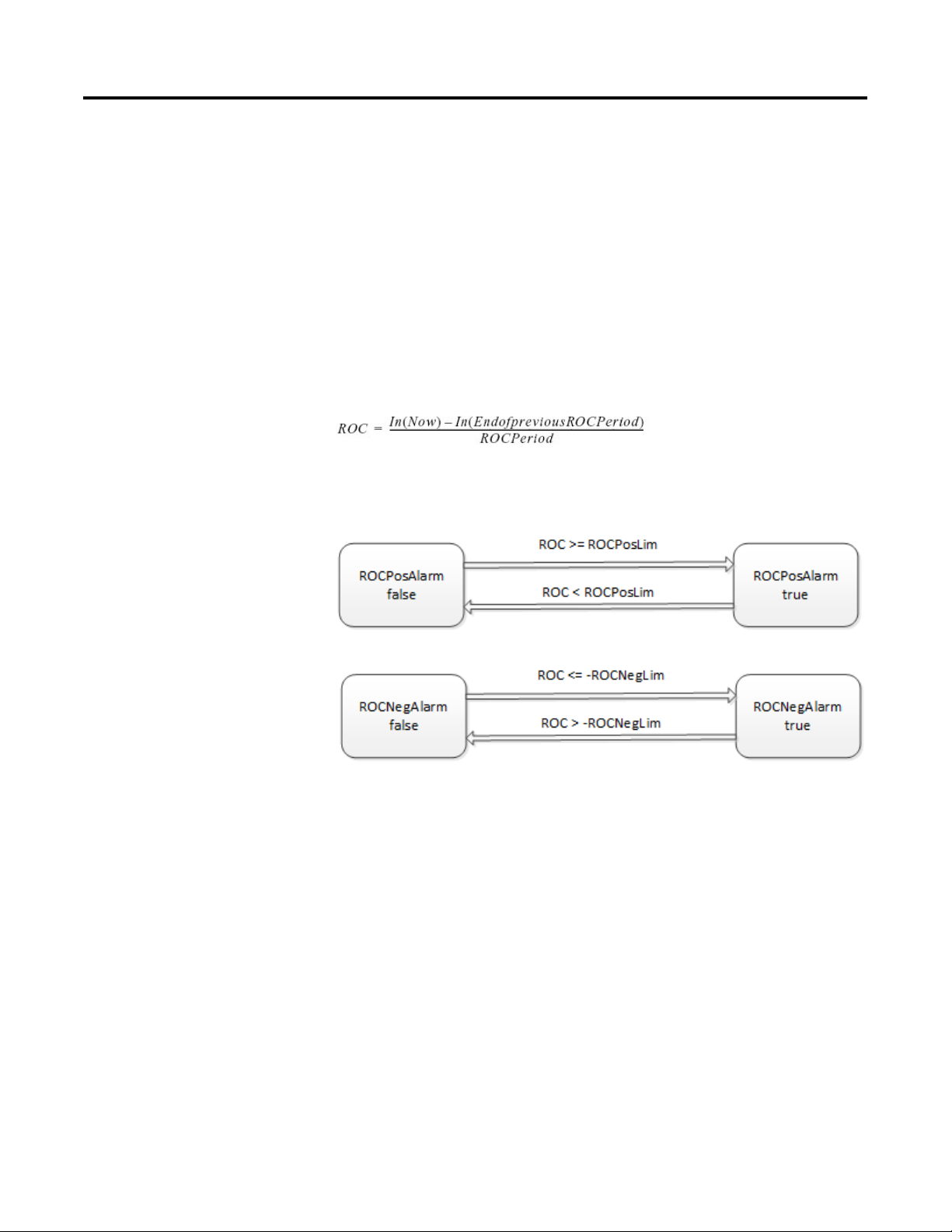

Rate-of-change Alarm

The rate-of-change (ROC) alarm compares the change of the input over the

ROCPeriod to the rate-of-change limits. The ROCPeriod provides a type of

deadband for the rate-of-change alarm. For example, define an ROC alarm limit of

O

F/second with a period of execution of 100 ms. If you use an analog input

2

module with a resolution of 1

O

F, every time the input value changes, an ROC

alarm is generated because the instruction calculates an effective rate of

10°F/second. However, enter an ROCPeriod of 1 sec and the instruction only

O

generates an alarm if the rate truly exceeds the 2

F/second limit.

The ROC alarm calculates the rate-of-change as:

The instruction performs this calculation when the ROCPeriod expires. Once the

instruction calculates the ROC, it determines alarms as:

Monitoring the ALM Instruction

There is an operator faceplate available for the ALM instruction.

Affects Math Status Flags

No

Major/Minor Faults

None specific to this instruction. See Common Attributes for operand-related

faults.

24 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 25

Process Control Instructions

Chapter 1

Execution

Function Block

Condition/State Action Taken

Prescan Rung-condition-in bits are cleared to false.

Rung-condition-in is false Rung-condition-in bits are cleared to false.

Rung-condition-in is true Rung-condition-in bits are set to true.

The instruction executes.

Postscan Rung-condition-in bits are cleared to false.

Structured Text

Condition/State Action Taken

Prescan See Prescan in the Function Block table.

Normal Execution See Rung-condition-in is true in the Function Block table.

Postscan See Postscan in the Function Block table.

Example

The ALM instruction is typically used either with analog input modules (such as

1771 I/O modules) that do not support on-board alarming, or to generate alarms

on a calculated variable. In this example, an analog input from a 1771-IFE module

is first scaled to engineering units using the SCL instruction. The Out of the SCL

instruction is an input to the ALM instruction to determine whether to set an

alarm. The resulting alarm output parameters could then be used in your program

and/or viewed on an operator interface display.

Function Block

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 25

Structured Text

SCL_01.IN := Input0From1771IFE;

Page 26

Chapter 1

Process Control Instructions

SCL(SCL_01);

Discrete 3-State Device

ALM_01.IN := SCL_01.Out;

ALM(ALM_01);

See also

(D3SD)

Common Attributes on page 537

Structured Text Syntax on page 508

Function Block Faceplate Controls on page 552

This information applies to the CompactLogix 5370, ControlLogix 5570,

Compact GuardLogix 5370, GuardLogix 5570, Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix

5580 controllers.

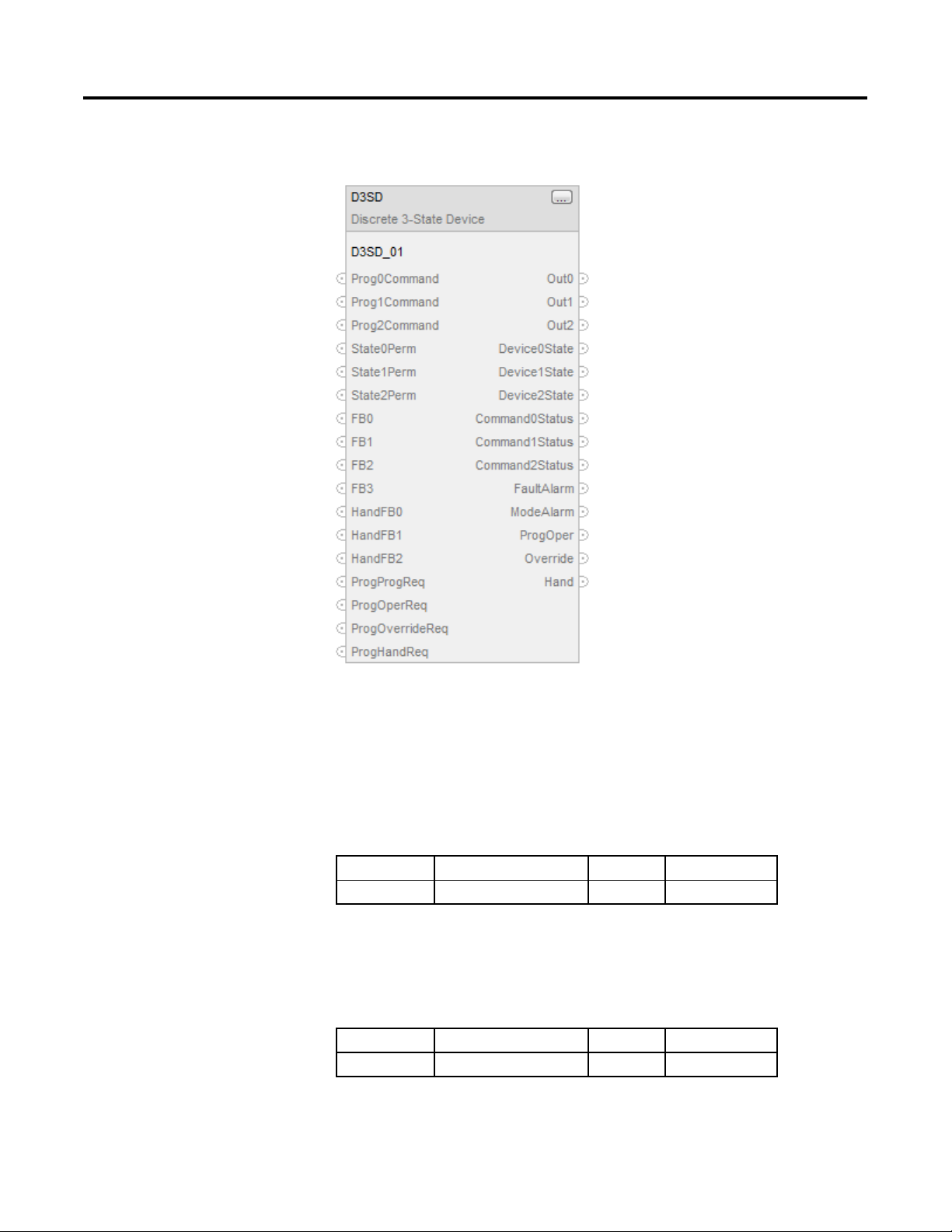

The D3SD instruction controls a discrete device having three possible states, such

as fast/slow/off or forward/stop/reverse.

Available Languages

Ladder Diagram

This instruction is not available in ladder diagram logic.

26 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 27

Process Control Instructions

Chapter 1

Function Block

Structured Text

D3SD(D3SD_tag)

Operands

Structured Text

Operand Type Format Description

D3SD tag DISCRETE_3STATE structure D3SD structure

See Structured Text Syntax for more information on the syntax of expressions

within structured text.

Function Block

Operand Type Format Description

D3SD tag DISCRETE_3STATE structure D3SD structure

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 27

Page 28

Chapter 1

Process Control Instructions

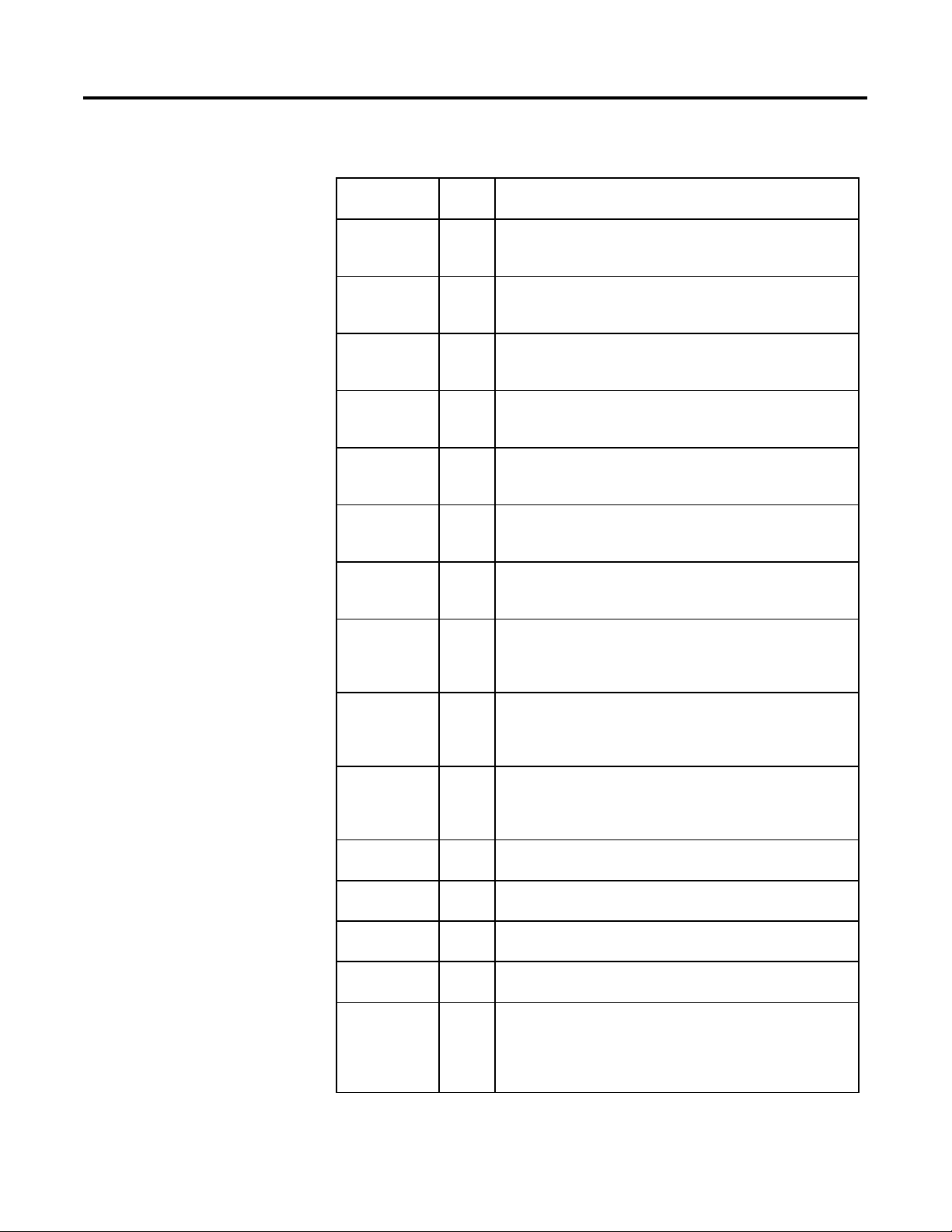

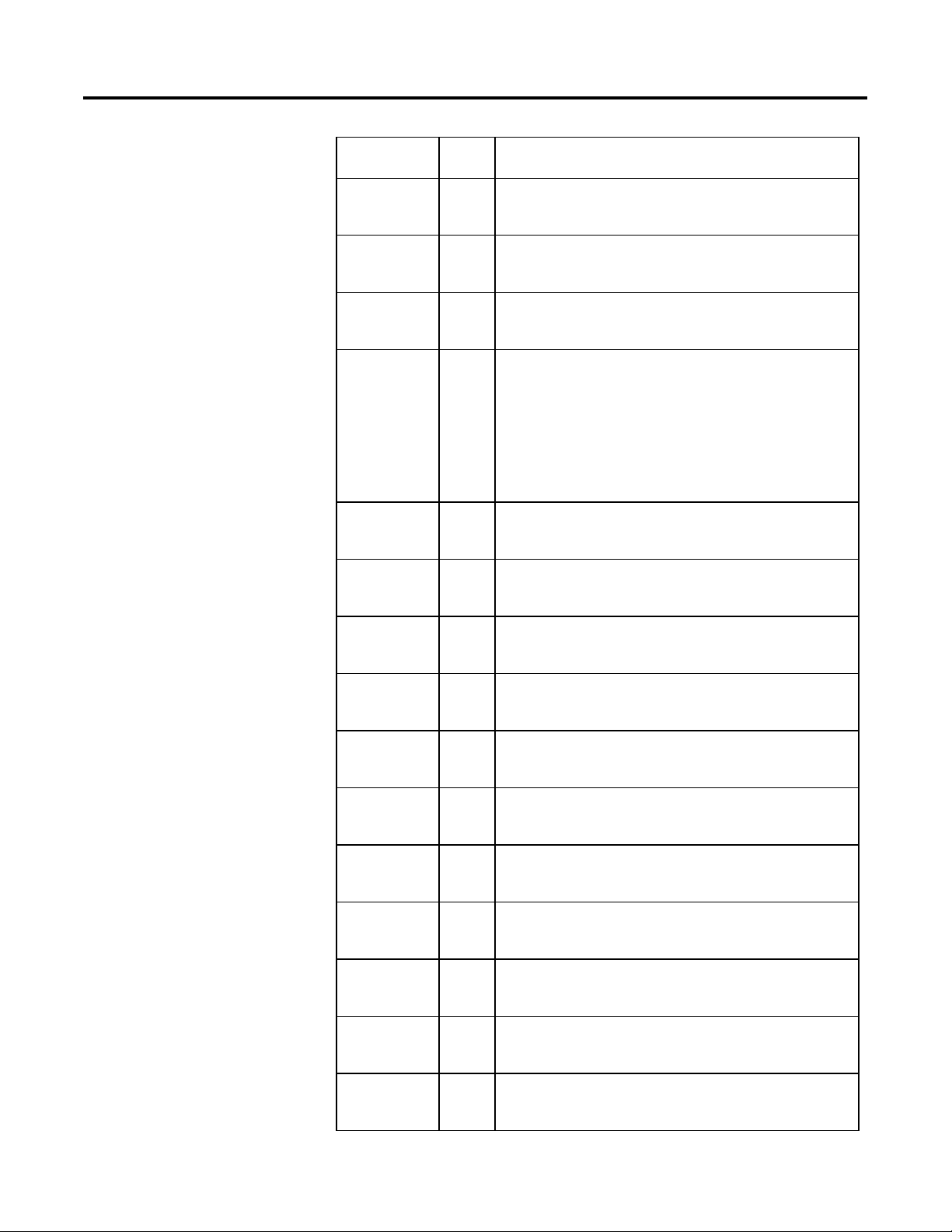

DISCRETE_3STATE Structure

Input Parameter Data

Type

EnableIn BOOL Enable input. If false, the instruction does not execute and outputs are not

Prog0Command BOOL Program state 0 command. This input determines the device state when the

Prog1Command BOOL Program state 1 command. This input determines the device state when the

Prog2Command BOOL Program state 2 command. This input determines the device state when the

Oper0Req BOOL Operator state 0 request. Set to true by the operator interface to place the device

Oper1Req BOOL Operator state 1 request. Set true by the operator interface to place the device into

Oper2Req BOOL Operator state 2 request. Set to true by the operator interface to place the device

State0Perm BOOL State 0 permissive. Unless in Hand or Override mode, this input must be true for

State1Perm BOOL State 1 permissive. Unless in Hand or Override mode, this input must be true for

State2Perm BOOL State 2 permissive. Unless in Hand or Override mode, this input must be true for

FB0 BOOL The first feedback input available to the instruction.

FB1 BOOL The second feedback input available to the instruction.

FB2 BOOL The third feedback input available to the instruction.

FB3 BOOL The fourth feedback input available to the instruction.

HandFB0 BOOL Hand feedback state 0. This input from a field hand/off/auto station shows the

Description

updated.

Default is true.

device is in Program control. If true, the device is commanded to the 0 state.

Default is false.

device is in Program control. If true, the device is commanded to the 1 state.

Default is false.

device is in Program control. If true, the device is commanded to the 2 state.

Default is false.

into the 0 state when the device is in Operator control.

Default is false.

the 1 state when the device is in Operator control.

Default is false.

into the 2 state when the device is in Operator control.

Default is false.

the device to enter the 0 state. This input has no effect if the device is already in

the 0 state.

Default is true.

the device to enter the 1 state. This input has no effect if the device is already in

the 1 state.

Default is true.

the device to enter the 2 state. This input has no effect if the device is already in

the 2 state.

Default is true.

Default is false.

Default is false.

Default is false.

Default is false.

requested state of the field device. True indicates the field device is being

requested to enter the 0 state; false indicates the field device is being requested to

enter some other state.

Default is false.

28 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 29

Process Control Instructions

Chapter 1

Input Parameter Data

Type

HandFB1 BOOL Hand feedback state 1. This input from a field hand/off/auto station shows the

HandFB2 BOOL Hand feedback state 2. This input from a field hand/off/auto station shows the

FaultTime REAL Fault time value. Configure the value in seconds of the time to allow the device to

FaultAlarmLatch BOOL Fault alarm latch input. When true and FaultAlarm is true, latch FaultAlarm. To

FaultAlmUnLatch BOOL Fault alarm unlatch input. Set this input to true when FaultAlarmLatch is set to

OverrideOnInit BOOL Override on initialization request. If this bit is true, then during instruction first

OverrideOnFault BOOL Override on fault request. Set this value to true if the device should go to Override

Out0State0 BOOL Output 0 state 0 input. This value determines the value of Output0 when the

Out0State1 BOOL Output 0 state 1 input. This value determines the value of Output0 when the

Out0State2 BOOL Output 0 state 2 input. This value determines the value of Output0 when the

Out1State0 BOOL Output 1 state 0 input. This value determines the value of Output1 when the

Out1State1 BOOL Output 1 state 1 input. This value determines the value of Output1 when the

Out1State2 BOOL Output 1 state 2 input. This value determines the value of Output1 when the

Description

requested state of the field device. True indicates the field device is being

requested to enter the 1 state; false indicates the field device is being requested to

enter some other state.

Default is false.

requested state of the field device. True indicates the field device is being

requested to enter the 2 state; false indicates the field device is being requested to

enter some other state.

Default is false.

reach a newly commanded state. Set FaultTime = 0 to disable the fault timer. If

this value is invalid, the instruction assumes a value of zero and sets the

appropriate bit in Status.

Valid = any float 0.0

Default = 0.0

unlatch FaultAlarm, set FaultAlmUnlatch to true or clear FaultAlarmLatch to false.

Default is false.

unlatch FaultAlarm. The instruction clears this input to false.

Default is false.

scan, the instruction is placed in Operator control with Override true and Hand

false. If ProgHandReq is true, then Override is cleared to false and Hand is set to

true.

Default is false.

mode and enter the Override State on a fault alarm. After the fault alarm is

removed, the instruction is placed in Operator control.

Default is false.

device is in the 0 state.

Default is false.

device is in the 1 state.

Default is false.

device is in the 2 state.

Default is false.

device is in the 0 state.

Default is false.

device is in the 1 state.

Default is false.

device is in the 2 state.

Default is false.

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 29

Page 30

Chapter 1

Process Control Instructions

Input Parameter Data

Type

Out2State0 BOOL Output 2 state 0 input. This value determines the value of Output2 when the

Out2State1 BOOL Output 2 state 1 input. This value determines the value of Output2 when the

Out2State2 BOOL Output 2 state 2 input. This value determines the value of Output2 when the

OverrideState DINT Override state input. Set this input to indicate the state of the device when in

FB0State0 BOOL Feedback 0 state 0 input. This value determines the expected value of FB0 when

FB0State1 BOOL Feedback 0 state 1 input. This value determines the expected value of FB0 when

FB0State2 BOOL Feedback 0 state 2 input. This value determines the expected value of FB0 when

FB1State0 BOOL Feedback 1 state 0 input. This value determines the expected value of FB1 when

FB1State1 BOOL Feedback 1 state 1 input. This value determines the expected value of FB1 when

FB1State2 BOOL Feedback 1 state 2 input. This value determines the expected value of FB1 when

FB2State0 BOOL Feedback 2 state 0 input. This value determines the expected value of FB2 when

FB2State1 BOOL Feedback 2 state 1 input. This value determines the expected value of FB2 when

FB2State2 BOOL Feedback 2 state 2 input. This value determines the expected value of FB2 when

FB3State0 BOOL Feedback 3 state 0 input. This value determines the expected value of FB3 when

FB3State1 BOOL Feedback 3 state 1 input. This value determines the expected value of FB3 when

Description

device is in the 0 state.

Default is false.

device is in the 1 state.

Default is false.

device is in the 2 state.

Default is false.

Override mode.

2 = Device should go to the 2 state

1 = Device should go to the 1 state

0 = Device should go to the 0 state

An invalid value sets the appropriate bit in Status.

Valid = 0 to 2

Default = 0

the device is in the 0 state.

Default is false.

the device is in the 1 state.

Default is false.

the device is in the 2 state.

Default is false.

the device is in the 0 state.

Default is false.

the device is in the 1 state.

Default is false.

the device is in the 2 state.

Default is false.

the device is in the 0 state.

Default is false.

the device is in the 1 state.

Default is false.

the device is in the 2 state.

Default is false.

the device is in the 0 state.

Default is false.

the device is in the 1 state.

Default is false.

30 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 31

Process Control Instructions

Chapter 1

Input Parameter Data

Type

FB3State2 BOOL Feedback 3 state 2 input. This value determines the expected value of FB3 when

ProgProgReq BOOL Program program request. Set to true by the user program to request Program

ProgOperReq BOOL Program operator request. Set to true by the user program to request operator

ProgOverrideReq BOOL Program override request. Set to true by the user program to request the device to

ProgHandReq BOOL Program hand request. Set to true by the user program to request the device to

OperProgReq BOOL Operator program request. Set to true by the operator interface to request

OperOperReq BOOL Operator operator request. Set to true by the operator interface to request

ProgValueReset BOOL Reset program control values. When true, all the program request inputs are

Description

the device is in the 2 state.

Default is false.

control. Ignored if ProgOperReq is true. Holding this true and ProgOperReq false

locks the instruction in Program control.

Default is false.

control. Holding this true locks the instruction in Operator control.

Default is false.

enter Override mode. Ignored if ProgHandReq is true.

Default is false.

enter Hand mode.

Default is false.

Program control. The instruction clears this input to false.

Default is false.

Operator control. The instruction clears this input to false.

Default is false.

cleared to false at each execution of the instruction.

Default is false.

Output Parameter Data Type Description

EnableOut BOOL Indicates if instruction is enabled.

Out0 BOOL The first output of the instruction.

Out1 BOOL The second output of the instruction.

Out2 BOOL The third output of the instruction.

Device0State BOOL Device state 0 output. True when the device

is commanded to the 0 state and the

feedback indicates the device really is in the

0 state.

Device1State BOOL Device state 1 output. True when the device

is commanded to the 1 state and the

feedback indicates the device really is in the

1 state.

Device2State BOOL Device state 2 output. True when the device

is commanded to the 2 state and the

feedback indicates the device really is in the

2 state.

Command0Status BOOL Device state 0 command status. True when

the device is being commanded to the 0

state; false when the device is being

commanded to some other state.

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 31

Page 32

Chapter 1

Process Control Instructions

Command1Status BOOL Device state 1 command status. True when

the device is being commanded to the 1

state; false when the device is being

commanded to some other state.

Command2Status BOOL Device state 2 command status. True when

the device is being commanded to the 2

state; false when the device is being

commanded to some other state.

FaultAlarm BOOL Fault alarm output. True if the device has

been commanded to a new state, and the

FaultTime has expired without the feedback

indicating that the new state has actually

been reached. Also set to true if, after

reaching a commanded state, the feedbacks

suddenly indicate that the device is no

longer in the commanded state.

ModeAlarm BOOL Mode alarm output. True if the device is in

operator control and a ProgxCommand input

requests a state which is different from the

state currently commanded by the operator.

This alarm is intended as a reminder that a

device was left in Operator control.

ProgOper BOOL Program/operator control indicator. True

when in Program control. False when in

Operator control.

Override BOOL Override mode. True when the device is in

the Override mode.

Hand BOOL Hand mode. True when the device is in the

Hand mode.

Status DINT Status of the function block.

InstructFault (Status.0) BOOL The instruction detected one of the following

execution errors. This is not a minor or major

controller error. Check the remaining status

bits to determine what occurred.

FaultTimeInv (Status.1) BOOL Invalid FaultTime value. The instruction sets

FaultTime = 0.

OverrideStateInv (Status.2) BOOL The Override value is out of range. It

prevents the instruction from entering the

Override state.

ProgCommandInv (Status.3) BOOL Multiple program state command bits are set

at the same time. Refer to Commanded State

in Program Control section.

OperReqInv (Status.4) BOOL Multiple operator state request bits are set at

the same time. Refer to Commanded State in

Program Control section.

32 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

HandCommandInv (Status.5) BOOL Multiple hand feedback state request bits are

set at the same time.

Page 33

Process Control Instructions

Chapter 1

Description

The D3SD instruction controls a discrete device having three possible states, such

as fast/slow/off or forward/stop/reverse. Typical discrete devices of this nature

include feeder systems, and reversible motors.

Affects Math Status Flags

No

Major/Minor Faults

None specific to this instruction. See Common Attributes for operand-related

faults.

Execution

Function Block

Condition/State Action Taken

Prescan EnableIn and EnableOut bits are cleared to false.

Tag.EnableIn is false EnableIn and EnableOut bits are cleared to false.

Tag.EnableIn is true EnableIn and EnableOut bits are set to true.

The instruction executes

Instruction first run Set ProgOper to Operator Mode.

Set Command0Status to True.

Set Command1Status to False.

Set Command2Status to False.

Instruction first scan The fault timer is cleared.

ModeAlarm is cleared to false.

All the operator request inputs are cleared to false.

If ProgValueReset is true, all the program request inputs are

cleared to false.

When OverrideOnInit is true, ProgOper is cleared to false(Operator

control).

If ProgHandReq is false and OverrideOnInit is true, Hand is cleared

to false and Override is set to true (Override mode).

If ProgHandReq is true, Hand is set to true and Override is cleared

to false(Hand mode).

Postscan EnableIn and EnableOut bits are cleared to false.

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 33

Page 34

Chapter 1

Process Control Instructions

Structured Text

In Structured Text, EnableIn is always true during normal scan. Therefore, if the

instruction is in the control path activated by the logic it will execute.

Condition/State Action Taken

Prescan See Prescan in the Function Block table.

Normal Execution See Tag.EnableIn is true in the Function Block table.

Postscan See Postscan in the Function Block table.

Examples

The D3SD instruction is typically used to control 3-state devices such as

high/low/off feed systems. In this example, the D3SD instruction controls a feed

system consisting of a pair of solenoid valves adding vegetable oil to a batch tank.

One of the valves is on a large diameter feed pipe into the batch tank, and the

other valve is plumbed in parallel on a small diameter feed pipe. When oil is first

added, the D3SD instruction is commanded to the fast feed state (state 2) where

both valves are opened. When the oil added approaches the target amount, the

D3SD instruction is commanded to the slow feed state (state 1) where the "large

valve" is closed and the "small valve" is kept open. When the target is reached, the

D3SD instruction is commanded to go to the off state (state 0) and both valves are

closed. As long as the D3SD instruction is in Program control, the valves open

according to the CloseOilFeed, SlowOilFeed, and FastOilFeed inputs. The

operator can also take Operator control of the feed system if necessary. The

solenoid valves in this example have limit switches which indicate when the valves

are fully closed or opened. These switches are wired into the FB0, FB1, FB2, and

FB3 feedback inputs. This allows the D3SD instruction to generate a FaultAlarm

if the solenoid valves do not reach their commanded states within the configured

FaultTime.

34 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 35

Process Control Instructions

Chapter 1

Function Block

Structured Text

OilFeedController.Prog0Command := ClosedOilFeed;

OilFeedController.Prog1Command := SlowOilFeed;

OilFeedController.Prog1Command := FastOilFeed;

OilFeedController.FB0 := SmallOilValveClosed;

OilFeedController.FB1 := SmallOilValveOpened;

OilFeedController.FB2 := LargeOilValveClosed;

OilFeedController.FB3 := LargeOilValveOpened;

D3SD(OilFeedController);

SmallOilValve := OilFeedController.Out0;

LargeOilValve := OilFeedController.Out1;

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 35

Page 36

Chapter 1

Process Control Instructions

Switch Between Program Control and Operator Control

The following diagram shows how the D3SD instruction changes between

Program control and Operator control.

(1) The instruction remains in Operator control mode when ProgOperReq is

true.

Commanded State in Program Control

The following table shows how the D3SD instruction operates when in Program

control.

Prog0

Command

false false true either either true Command0Status is cleared to false

false true false either true either Command0Status is cleared to false

true false false true either either Command0Status is set to true

Prog1

Command

Prog2

Command

State0

Perm

State1

Perm

State2

Perm

Description

Command1Status is cleared to false

Command2Status is set to true

Command1Status is set to true

Command2Status is cleared to false

Command1Status is cleared to false

Command2Status is cleared to false

If more than one program command input is true:

• The instruction sets the appropriate bit in Status

36 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

• If Override and Hand are cleared to false, the instruction holds the previous

state

Page 37

Process Control Instructions

Chapter 1

Commanded State in Operator Control

The following table shows how the D3SD instruction operates when in Operator

control.

State1

Oper0Req Oper1Req Oper2Req State0 Perm

false false true either either true Command0Status is cleared to false

false true false either true either Command0Status is cleared to false

true false false true either either Command0Status is set to true

Perm State2 Perm Description

Command1Status is cleared to false

Command2Status is set to true

Command1Status is set to true

Command2Status is cleared to false

Command1Status is cleared to false

Command2Status is cleared to false

If more than one operator command input is true:

• The instruction sets the appropriate bit in Status

• If Override and Hand are cleared to false, the instruction holds the previous

state

After every instruction execution, the instruction:

• Clears all the operator request inputs

• If ProgValueReset is true, clears all the program request inputs to false

Hand Mode or Override Mode

The following table describes how the D3SD instruction determines whether to

operate in Hand or Override mode.

ProgHandReq ProgOverrideReq FaultAlarm and OverrideOnFault Description

true either either Hand mode

Hand is set to true

Override is cleared to false

false true either Override mode

Hand is cleared to false

Override is set to true

false either true Override mode

Hand is cleared to false

Override is set to true

When Override is set, it takes precedence over Program and Operator control.

The following table describes how the Override mode affects the commanded

state.

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 37

Page 38

Chapter 1

Process Control Instructions

Override Override State Description

true 2 Command0Status is cleared to false

Command1Status is cleared to false

Command2Status is set to true

true 1 Command0Status is cleared to false

Command1Status is set to true

Command2Status is cleared to false

true 0 Command0Status is set to true

Command1Status is cleared to false

Command2Status is cleared to false

If OverrideState is invalid, the instruction sets the appropriate bit in Status and

does not enter the override state.

When Hand is true, it takes precedence over Program and Operator control. The

following table describes how the Hand mode affects the commanded state.

Hand HandFB0 HandFB1 HandFB2 Description

true false false true Command0Status is cleared to false

Command1Status is cleared to false

Command2Status is set to true

true false true false Command0Status is cleared to false

Command1Status is set to true

Command2Status is cleared to false

true true false false Command0Status is set to true

Command1Status is cleared to false

Command2Status is cleared to false

If more than one HandFB input is true, the instruction sets the appropriate bit in

Status and, if Hand is true, the instruction holds the previous state.

38 Rockwell Automation Publication 1756-RM006K-EN-P - November 2018

Page 39

Process Control Instructions

Chapter 1

Output State

The D3SD output state is based on the state of the command status.

CommandStatus Output State

Command0Status is true Out0 = Out0State0

Out1 = Out1State0

Out2 = Out2State0

Command0Status is true and

FB0 = FB0State0 and

FB1 = FB1State0 and

FB2 = FB2State0 and

FB3 = FB3State0

Command1Status is true Out0 = Out0State1

Command1Status is true and

FB0 = FB0State1 and

FB1 = FB1State1 and

FB2 = FB2State1 and

FB3 = FB3State1

Command2Status is true Out0 = Out0State2

Command2Status is true and

FB0 = FB0State2 and

FB1 = FB1State2 and

FB2 = FB2State2 and

FB3 = FB3State2

Stop and clear the fault timer.

Device0State is set to true

Out1 = Out1State1

Out2 = Out2State1

Stop and clear the fault timer.

Device1State is set to true

Out1 = Out1State2

Out2 = Out2State2

Stop and clear the fault timer.

Device2State is set to true

Fault Alarm Conditions

The D3SD instruction checks for these fault alarm conditions.

Fault alarm condition resulting from Rules

Device state was commanded to change,

but the feedback did not indicate that the

desired state was actually reached within

the FaultTime

The device unexpectedly left a state

(according to the feedback) without

being commanded to

Rockwell Automation Publication 1756-RM006K-EN-P - November 2018 39