Page 1

Installation Instructions

Original Instructions

Elf and Cadet 3 Tongue Interlock Switches

Catalog Numbers 440K-C21048, 440K-C21050, 440K-C21052, 440K-C21054, 440K-C21055, 440K-C21057, 440K-C21058, 440K-C21060,

440K-C21061, 440K-C21062, 440K-C21065, 440K-C21067, 440K-C21068, 440K-C21070, 440K-C21074, 440K-C21080, 440K-C21088, 440K-C21089,

440K-C21090, 440K-C21091, 440K-C21092, 440K-C21093, 440K-C21094, 440K-C21095, 440K-C21096, 440K-C21097, 440K-C21098,

440K-E2NNAPS, 440K-E2NNFPS, 440K-E33014, 440K-E33024, 440K-E33025, 440K-E33029, 440K-E33030, 440K-E33031, 440K-E33034,

440K-E33036, 440K-E33037, 440K-E33040, 440K-E33041, 440K-E33045, 440K-E33046, 440K-E33047, 440K-E33053, 440K-E33074,

440K-E33075, 440K-E33077, 440K-E33078, 440K-E33079, 440K-E33080

Summary of Changes

This publication contains new and updated information as indicated in the

following table.

Top ic Pa ge

Updated Specifications table 1

Added UL 508 Information section 2

Added Attention table 3

Installation

Installation of the Elf™ and Cadet™ 3 Tongue Interlock Switches must be in

accordance with the following steps and stated specifications and should be

carried out by suitably competent personnel. The unit is not to be used as a

mechanical stop. Guard stops and guides must be mounted.

Adherence to the recommended maintenance instructions forms part of the

warranty.

ATTENTION: The presence of spare actuators can

compromise the integrity of the safety systems. Personal

injury or death, property damage or economic loss can result.

Appropriate management controls, working procedures, and

alternative protective measures should be introduced to

control their use and availability.

Attribute Value

A600/AC-15 240V/3 A, 120V/6 A, N150/DC13 24V/2 A

Contact rating

Input 240V, 24V, 250V, 60V, 30V, 30V

Ingress protection rating IP67

Operating temperature -20…+80 °C (-4…+176 °F)

Mechanical life 1,000,000 operations

Torque settings, max

M12 QD (4-pin): 250V/4 A

M12 QD (5-pin): 60V/4 A

M12 QD (6-pin): 30V/2 A

M12 QD (8-pin): 30V/2 A

1.4 N•m (12.39 lb•in) mounting bolts

1.2 N•m (10.62 lb•in) lid screws

1.0 N•m (8.85 lb•in) terminal screws

0.57 N•m (5.04 lb•in) head bolts

Maintenance

Every week, check the alignment of the actuator to the switch and the correct

operation of the switching circuit. Also check for signs of abuse or interference.

Inspect the switch casing and actuator for damage. Replace if needed.

At least every six months, isolate all power. Remove the lid and end cover. Inspect

all terminals for tightness. Clean out any accumulation of fine dirt. Check for any

sign of wear of damage, for instance, actuator wear, cam assembly wear, contact

oxidization and replace if needed. Replace cover and tighten screws to specified

settings. Reinstate the power and check for correct operation. Reapply tamper

evident varnish or similar compound for mountings.

WAR N IN G : Do not defeat, tamper, remove, or bypass this unit.

Severe injury to personnel could result.

Specifications

Attribute Value

Safety contacts (Elf)

Safety contacts (Cadet 3)

Thermal current 10 A

Auxiliary contacts 1 N.O.

Switching current/

voltage

1 N.C. or 2 N.C. direct opening action

2 N.C. or 3 N.C. direct opening action

3 mA/18V, min

Repair

If there is any malfunction or damage, no attempts at repair should be made. The

unit should be replaced before machine operation is allowed. DO NOT DISMANTLE

THE UNIT.

IMPORTANT

2

After installation and commissioning, the actuator,

switch, and switch lid mounting screws should be

coated with tamper evident varnish or similar

compound.

Page 2

Elf and Cadet 3 Tongue Interlock Switches Installation Instructions

1 x M16

2 x M5

2 x M4

1.4 N•m

(12.39 lb•in)

6 (0.24)

7.5 (0.29)

1 (0.04)

2.5 (0.098)

1 (0.04)

2.5 (0.098)

8.75 (0.34)

18.25 (0.72)

M4

23 (0.91)

1 (0.04)

3 (0.12)

29 (1.14)

8 (0.31)

3 (0.12)

7.5 (0.3)

24 (0.94)

12

(0.47)

Cat. No. 440K-A21006

The products shown in this document, conform with the Essential

lth and Safety Requirements (EHSRs) of the European Machinery

Hea

Directive. These products are third-party certified to EN 60947-5-1 and

EN ISO 14119.

Declaration of Conformity and certification: rok.auto/certifications

.

ISO 14119 defines types of interlocking devices and coding.

Product Type Coding

440K 2 Low

ATTENTION: Discard the plastic transit plugs (shipped with

select conduit models only) at installation and replace with

UL Listed outlet box plugs or the equivalent.

UL 508 Information

• When used in elevated ambients, temperature rating of field wiring shall

not be less than ambient.

• Use copper conductors only.

• Use polymeric conduit only. End of line device.

• Use only one conduit entrance for field connections.

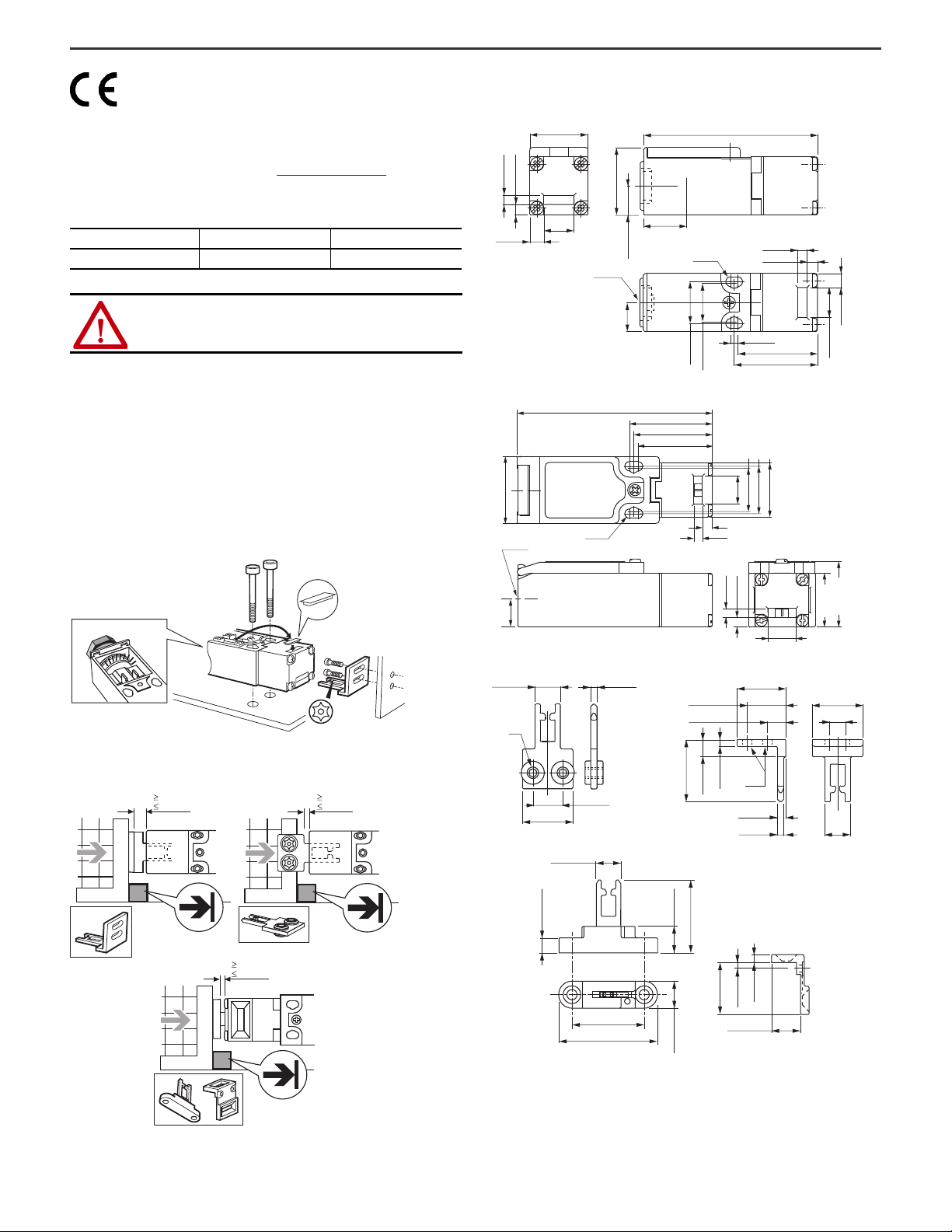

Mounting

Approximate Dimensions

Figure 1 - Elf Tongue Interlock Switch Dimensions [mm (in.)]

25 (0.98) 75 (2.95)

4 (0.16)

4.5 (0.18)

6 (0.24)

13 (0.51)

Figure 2 - Cadet 3 Tongue Interlock Switch Dimensions [mm (in.)]

31 (1.22)

1 x M16

1 x M16

90.5 (3.56)

2 x M4

29 (1.14)

12.5 (0.49)

12.5

(0.49)

17.5 (0.69)

38.4 (1.51)

36.4 (1.43)

34.4 (1.35)

2 x M4

18 (0.71)

16.5 (0.65)

13

(0.51)

3 (0.12)

4.5 (0.18)

4 (0.16)

4 (0.16)

4.5 (0.18)

34.5 (1.36)

36 (1.42)

20 (0.79)

22 (0.87)

25 (0.98)

6 (0.24)

13 (0.51)

Key Placement

13

(0.51)

Figure 3 - Key Dimensions [mm (in.)]

12 (0.47)

M4

25 (0.59)

Cat. No. 440K-A21014

12 (0.47)

8.5 (0.33)

Cat. No. 440K-A21030

3 (0.12)

15 (0.98)

40 (1.57)

55.5 (2.19)

14 (0.55)

40 (1.57)

15.5 (0.61)

4 (0.16)

4.5 (0.18)

25 (0.98)

3 (0.12)

13.5 (0.53)

4 (0.16)

13 (0.51)

30.4 (1.2)

25 (0.98)

2 Rockwell Automation Publication 440K-IN001D-EN-P - July 2020

Page 3

Head Rotation

0.57 N•m (5.04 lb•in)

B

D

C

A

1112

2324

2

1

1

3

2

4

3

4

1112

2122

2

1

1

3

2

4

3

4

1112

2122

3334

1

5

1

5

2

6

3

4

6

2

4

3

1112

2122

3132

1

5

2

6

3

4

1

5

6

2

4

3

Elf QD Elf QD Cadet 3 QD Cadet 3 QD

1112

2324

1112

2122

1112

2122

3334

1112

2122

3132

Cadet 3Elf Cadet 3Elf

1112

2122

1

2

4

5

1112

2122

1

2

4

5

3132

Safety C

2

5

1

3

4

Safety A

Safety A

N/A

Safety B

Safety B

5-pin Micro (M12)

for ArmorBlock® Guard I/O™

Cadet 3Elf

=

=

3.8

4.2

11/12

23/24

0 mm6

=

=

4

11/12

21/22

0 mm6

=

=

3.8

11/12

21/22

0 mm

4.5

33/34

=

=

3.8

11/12

21/22

0 mm

3.3

33/34

=

=

3.8

11/12

21/22

0 mm

31/32

Cadet 3Elf Cadet 3 Cadet 3Elf

Pinouts

Elf and Cadet 3 Tongue Interlock Switches Installation Instructions

Wiring

ATTENTION: Improper selection or installation of the devices affects the integrity of the safety systems.

Personnel injury or death, property damage or economic loss can result.

Comply with ISO 14119 including selection, accessibility to the installation, arrangement and fastening, possible substitute actuation, motivation to

defeat, and actuation mode.

Management controls, working procedures, training, and additional protective measures should be used to minimize the motivation to defeat and to

manage the use and availability of spare actuators.

Comply with IEC 62061 or ISO 13849-1 and ISO 13849-2 for functional safety.

Comply with ISO 13857 and ISO 13855 for guard openings and minimum (safe) distances.

Rockwell Automation Publication 440K-IN001D-EN-P - July 2020 3

Page 4

Rockwell Automation Support

Use these resources to access support information.

Technical Support Center Find help with how-to videos, FAQs, chat, user forums, and product notification updates. rok.auto/support

Knowledgebase Access Knowledgebase articles. rok.auto/knowledgebase

Local Technical Support Phone Numbers Locate the telephone number for your country. rok.auto/phonesupport

Literature Library Find installation instructions, manuals, brochures, and technical data publications. rok.auto/literature

Product Compatibility and Download Center

(PCDC)

Download firmware, associated files (such as AOP, EDS, and DTM), and access product

release notes.

rok.auto/pcdc

Documentation Feedback

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback.

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec.

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback.

For technical support, visit rok.auto/support.

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400 EEE Yönetmeliğine Uygundur

Allen-Bradley, ArmorBlock, expanding human possibility, Cadet, Elf, Guard I/O, Guardmaster, and Rockwell Automation are trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 440K-IN001D-EN-P - July 2020 | Supersedes Publication 440K-IN001C-EN-P-August 2019

Copyright © 2020 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

PN-462122

W21687 Ver 09

Loading...

Loading...