Allen-Bradley ControlNet SoftLogix 1789, ControlNet ControlLogix 1756, ControlNet GuardLogix 1756, ControlNet Studio 5000 Logix Emulate, ControlNet CompactLogix 1769 User Manual

...Page 1

User Manual

ControlNet Network Configuration

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789

SoftLogix, Studio 5000 Logix Emulate

Page 2

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/) describes some

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING:

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION:

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

Identifies information about practices or circumstances that can cause an explosion in a hazardous

Identifies information about practices or circumstances that can lead to personal injury or death,

SHOCK HAZARD:

dangerous voltage may be present.

BURN HAZARD:

surfaces may reach dangerous temperatures.

IMPORTANT

Allen-Bradley, ArmorPOINT, CompactLogix, ControlLogix, Data Highway Plus, DriveLogix, FlexLogix, FLEX Ex, FLEX I/O, Logix 5000, PanelView, PanelView Plus, POINT I/O, PowerFlex 700S, Rockwell Software,

Rockwell Automation, RSLinx, RSLinx Classic, RSLogix, RSLogi x 5000, RSNetWorx, RSNetWorx for ControlNe t, RSView, SoftLogix, and TechConnect are tr ademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Identifies information that is critical for successful application and understanding of the product.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

Page 3

Summary of Changes

Updated Information

This document contains new and updated information. Changes are designated

by change bars in the outside margins.

This document contains these changes.

Topic Chapter

Updated supported controller models.

Cover

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 3

Page 4

Summary of Changes

Notes:

4

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016

Page 5

Table of Contents

Preface

ControlNet Overview

Connect a Computer to the

ControlNet Network

Additional Resources ........................................................................................... 7

Chapter 1

Use ControlNet Communication Modules in a Control System ............... 9

Bridge Across Networks ................................................................................... 11

Exchange Information on a ControlNet Network ..................................... 14

ControlNet Network Capacity and Topology ............................................ 21

Chapter 2

Configure the ControlNet Communication Driver

in RSLinx Classic Software .............................................................................. 26

Network Update Time (NUT) ............................................................... 16

Requested Packet Interval (RPI) ............................................................. 17

Actual Packet Interval (API) .................................................................... 17

Schedule the Network ............................................................................... 18

Understand the Network Keeper ........................................................... 19

Default Parameters..................................................................................... 21

Topology ..................................................................................................... 21

Number of Nodes ...................................................................................... 24

Lengths ......................................................................................................... 24

Configure a ControlNet Module

Chapter 3

Use RSLogix 5000 Software ............................................................................ 29

Use RSNetWorx for ControlNet Software .................................................. 44

Configure the I/O Configuration Tree in Your Project ..................... 29

Add a

nd Configure a Local ControlNet Module ................................. 30

Add and Configure a Remote ControlNet Module ............................ 33

Download the Project to the Logix5000 Controller ............................ 36

Electronic Keying. ...................................................................................... 37

Schedule a ControlNet Network for the First Time ........................... 44

Schedule the Network Offline ................................................................. 45

Schedule the Network Online ................................................................. 49

Reschedule a ControlNet Network

that has Previously been Scheduled ......................................................... 53

Page 6

Table of Contents

Control I/O

Produce and Consume Tags

(interlock controllers)

Chapter 4

Set Up the Hardware ......................................................................................... 56

Requested Packet Interval (RPI) ..................................................................... 56

Communication Format .................................................................................. 57

Direct or Rack-optimized Connections .................................................. 58

Ownership ................................................................................................... 61

Add a Remote Adapter ..................................................................................... 63

Add Distributed I/O ......................................................................................... 63

Distributed I/O Communication Formats............................................ 65

Access Distributed I/O ..................................................................................... 65

Validate Connections ........................................................................................ 68

Chapter 5

Terminology ....................................................................................................... 71

Set Up the Hardware......................................................................................... 72

Determine Connections for Produced and Consumed Tags ..................... 73

Organize Tags for Produced or Consumed Data ......................................... 75

Adjust for Bandwidth Limitations .................................................................. 76

Produce a Tag ..................................................................................................... 77

Consume a Tag .................................................................................................. 79

Messaging

Communicate with PanelView

Terminals

Chapter 6

Set Up the Hardware ......................................................................................... 84

Guidelines for MSG Instructions ................................................................... 85

Determine Connections for Messages ............................................................ 86

Guidelines for Caching Message Connections ...................................... 86

Enter Message Logic .......................................................................................... 86

Add the ControlNet Modules and Remote Devices

to the Local Controller’s I/O Configuration ......................................... 87

Enter a Message ........................................................................................... 88

Configure a Message Instruction .................................................................... 88

Stagger the Messages.......................................................................................... 90

Chapter 7

Set Up the Hardware......................................................................................... 92

Determine Connections to PanelView Terminals ....................................... 93

Add a PanelView Terminal .............................................................................. 94

Organize Controller Data for a PanelView Terminal ................................. 96

Index ............................................................................................................................................................................................... 97

6

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016

Page 7

Preface

Additional Resources

This manual describes how you can use ControlNet communication modules

with your Logix5000 controller.

Use this manual if you program applications that use a ControlNet network with

one of these Logix5000 controllers:

CompactLogix controller

•

•

ControlLogix controller

•

PowerFlex 700S with DriveLogix controller

•

SoftLogix5800 controller

Also be familiar with the following:

N

et

working concepts

•

•

RSLogix 5000 software

RSLinx Classic software

•

RSNetWorx for

•

ControlNet software

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

ControlNet Modules Installation Instructions,

publication CNET-IN005

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website,

http://www.ab.com

Describes how to install 1756-CN2, 1756-CN2R,

1756-CN2RXT, 1756-CNB, 1756-CNBR, 1768-CNB,

and 1768-CNBR ControlNet modules.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at http://www.rockwellautomation.com/

literature. To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 7

Page 8

Preface

Notes:

8

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 9

Chapter

Use ControlNet Communication Modules in a Control System

9

1

ControlNet Overview

The ControlNet network provides high-speed transmission of time-critical I/O

and interlocking data and messaging data. This data transfer capability enhances

I/O performance and peer-to-peer communication in any system or application.

The Cont

unaffected as devices are connected or disconnected from it. This ensures

dependable, synchronized, and coordinated real-time performance.

The ControlNet network is most often used in these ways:

This chapter describes how you can use ControlNet modules in a network

control system.

Topic Page

rolNet network is highly deterministic and repeatable and remains

As the default network for the ControlLogix platform

•

•

As a backbone to multiple distributed DeviceNet networks

•

As a peer interlocking network

Use ControlNet

Communication Modules in

a Control System

Bridge Across Networks

Exchange Information on a ControlNet Network

ControlNet Network Capacity and Topology

You can fit various ControlNet modules into your control system.

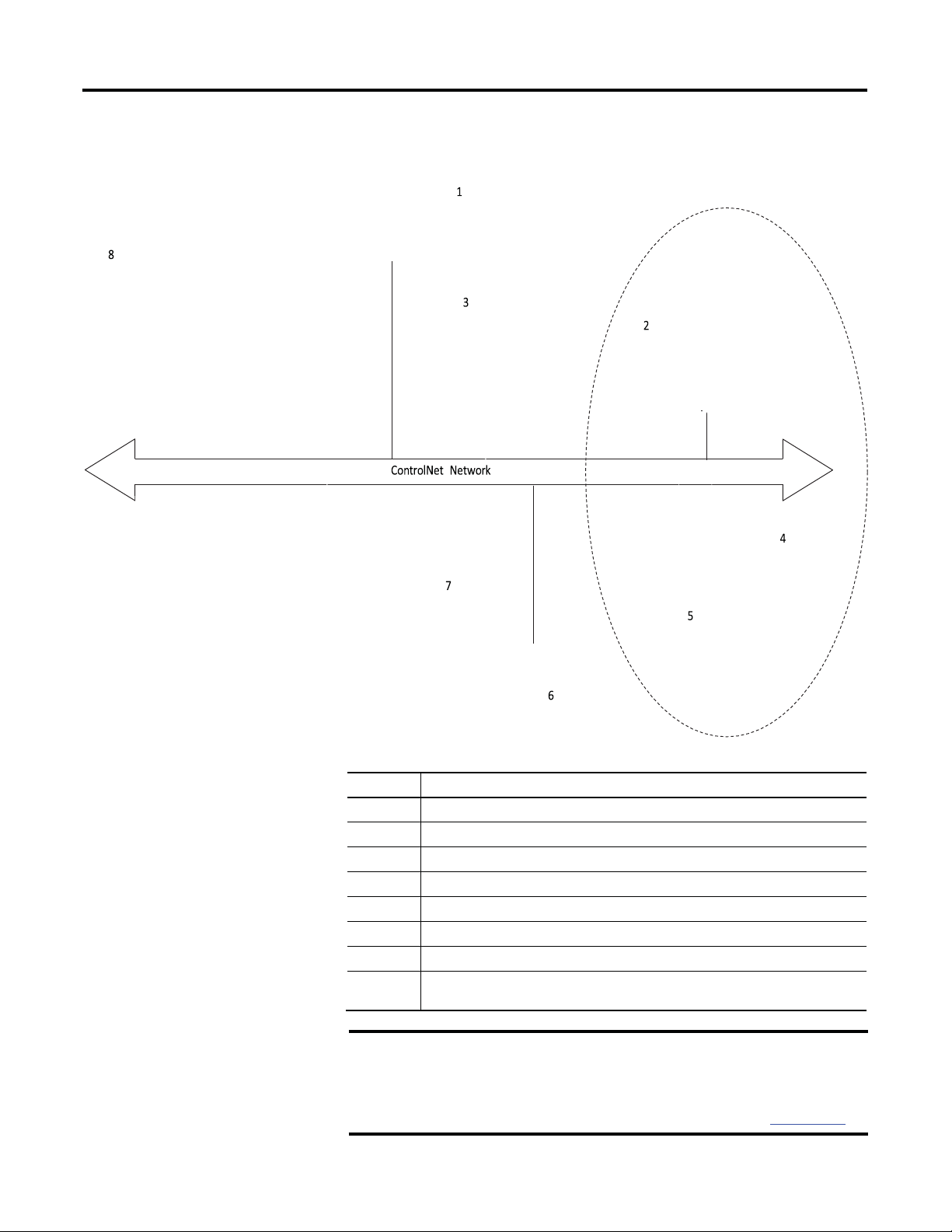

Figure 1 on page 10 shows the following:

•

The controllers produce and consume tags among themselves.

•

The controllers initiate MSG instructions that send/receive data or

configure devices.

•

The computer uploads and downloads projects to the controllers.

The computerconfiguresdevices on the ControlNet network and

•

configures the network itself.

11

14

21

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 9

Page 10

Chapter 1

6 PanelView terminal

ControlNet Overview

Figure 1 - ControlNet Modules and the Control System Overview

10

Item Description

1

2

3

4

5

7

8

IMPORTANT

Rockwell Automation Publication CNET-

Personal computer running SoftLogix5800 controller with 1784-PCICS card

1756-CNB module (as an adapter) with 1756 I/O modules

PowerFlex 700S drive

1794-ACN15 adapter with 1794 I/O modules

1734-ACNR adapter with 1734 I/O modules

CompactLogix 1769-L35CR controller with local 1769 I/O modules

ControlLogix controller with 1756-CN2, 1756-CN2R, 1756-CNB, or 1756-CNBR module

as the scanner

For an enhanced redundancy system, you must use a 1756-CNB,

1756-CNBR, 1756-CN2 series B, or 1756-CN2R series B communication

module. The 1756-CN2 or 1756-CN2R series A module does not support

enhanced redundancy. For more information, refer to the ControlLogix

Enhanced Redundancy System User Manual, publication 1756-UM535.

UM001E-EN-P - June 2016

Page 11

ControlNet Overview

(2)

EtherNet/IP

Yes

Yes

Yes

Yes

Yes

Chapter 1

Bridge Across Networks

Some ControlNet modules support the ability to bridge or route communication

to and from different networks, depending on the capabilities of the platform and

communication devices.

IMPORTANT

You can only bridge across networks to communicate with devices. You

cannot bridge across networks to control I/O, even though RSLogix 5000

software can accept such a configuration in the I/O Configuration folder.

All I/O control must originate and end on the same physical network.

The following table describes how communication can bridge across networks.

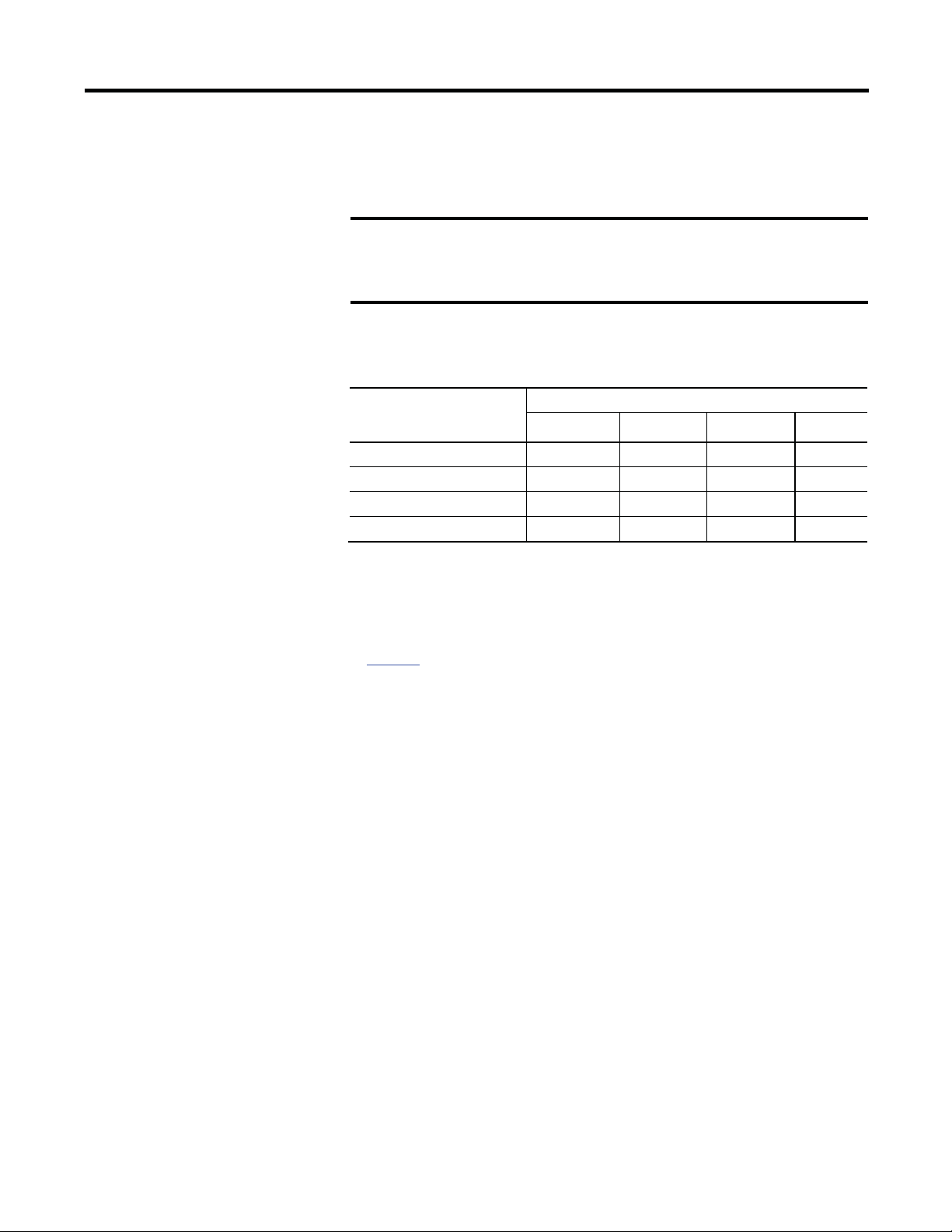

Table 1 - Bridging Across Networks

A device on this network Can communicate with a device on this network

EtherNet/IP ControlNet DeviceNet

ControlNet

DeviceNet No No Yes No

RS-232 Yes

(1) To use RSNetWorx for ControlNet software to configure and schedule a ControlNet network, we recommend

(2) Typically, this is a point-to-point connection between a Logix5000 controller and another device, such as a

Yes Yes Yes Yes

(1)

that you either connect to an EtherNet/IP network and bridge to a ControlNet network or use a 1784-U2CN

cable to connect directly to a ControlNet network.

PanelView Plus operator terminal.

Yes Yes

RS-232

In Figure 2, a workstation configures a drive on the DeviceNet network. The

workstation bridges from the ControlNet network to the DeviceNet network to

reach the drive. The bridge is a ControLogix chassis with ControlNet and

DeviceNet modules.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 11

Page 12

Chapter 1

5

Item Description

Item Description

ControlNet Overview

Figure 2 - Drive Configuration on a DeviceNet Network

2

6

PWR

STS

1

Workstation

2

3

Bridge

IMPORTANT

PanelView terminal

The performance of a CompactLogix controller on a ControlNet network

degrades significantly if you use the controller as a bridge. Target

4

Drive

5

6

DeviceNet network

ControlNet network

bridging over a CompactLogix controller on a ControlNet network toward

applications that are not real-time dependent, such as RSLogix 5000

software program downloads.

In the example shown above, you can transfer messages from the DeviceNet

network through the Logix5000 controller to an RSView32 operator interface.

With a CompactLogix controller as a bridge, you can map the data into the

DeviceNet I/O image and then use RSLinx OPC to send the data to the

Logix5000 controller over the ControlNet network. This method conserves the

limited bridging resources of your CompactLogix controller.

12

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 13

ControlNet Overview

Item Description

Item Description

1 EtherNet/IP network

3 ControlNet Bridge in 1756 system

Destination

Modules for a 1768 CompactLogix

Modules for a 1769 CompactLogix

Modules for a ControlLogix

DeviceNet

•

1768-L43 or 1768-L45 controller

•

1769-L32C or 1769-L35CR controller

•

1756-CN2 module

Chapter 1

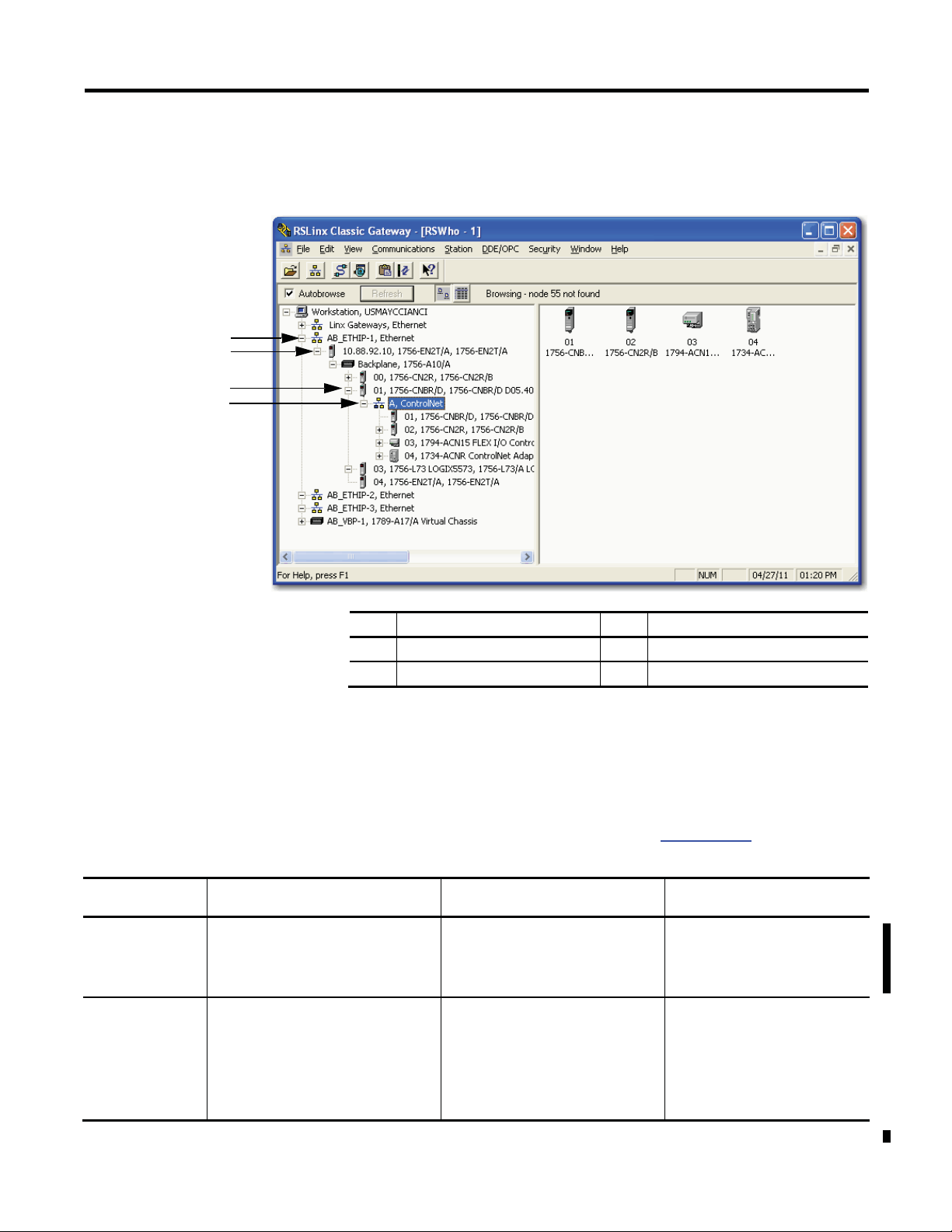

The following example shows how a DeviceNet bridge links to an EtherNet/IP

network in RSLinx software.

Figure 3 - EtherNet/IP Bridge Linking to a ControlNet Network

1

2

3

4

Table 2 - Bridges from a ControlNet Network

Network

EtherNet/IP

System

•

1768-CNB(R) module

•

1769-SDN scanner

•

1768-L43 or 1768-L45 controller

•

1768-CNB(R) module

•

1768-ENBT module

2

EtherNet/IP bridge in 1756 system

4

ControlNet network

The following tables list the possible bridges between communication networks.

Note that you can bridge from a ControlNet network to an Ethernet network

and from an Ethernet network to a ControlNet via a SoftLogix virtual chassis.

However, the products and methods you must use to do so are more detailed than

can be effectively described in the following tables. For more information on how

to bridge from one network to another via a SoftLogix virtual chassis, see the

SoftLogix5800 System User Manual, publication 1789-UM002.

System

•

1769-SDN scanner or 1788-CN2DN

(1)

module

Not applicable

Chassis

•

1756-CN2R module

•

1756-CNB module

•

1756-CNBR module

•

1756-DNB module

•

1756-CN2 module

•

1756-CN2R module

•

1756-CNB module

•

1756-CNBR module

•

1756-ENBT module

•

1756-EN2T module

•

1756-EN2TR module

•

1756-EN3TR module

(1) Can serve as a dedicated standalone bridge from a ControlNet network to a DeviceNet network.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 13

Page 14

Chapter 1

•

1768-L43 or 1768-L45

•

1756-CN2 module

•

1768-L43 or 1768-L45

•

1769-L32E or 1769-L35E

•

1756-DNB module

•

1769-L23E-QB1B controller

ControlNet Overview

Table 3 - Bridges from an EtherNet/IP Network

Destination

Network

ControlNet

DeviceNet

(1) Can serve as a dedicated standalone bridge from an EtherNet/IP network to a DeviceNet network.

Modules for a 1768

CompactLogix System

controller

•

1768-ENBT module

•

1768-CNB(R) module

controller

•

1768-ENBT module

•

1769-SDN scanner

Exchange Information on a ControlNet Network

Modules for a 1769

CompactLogix System

Not applicable

controller

•

1769-SDN scanner or 1788EN2DN module

ControlNet communication modules use a message-based protocol that

implements a relative path to send a message from the producing module in a

system to the consuming modules. This protocol also lets you communicate

(1)

between devices on a ControlNet, DeviceNet, or EtherNet/IP network without

writing additional application code.

Modules for a

ControlLogix Chassis

•

1756-CN2R module

•

1756-CNB module

•

1756-CNBR module

•

1756-ENBT module

•

1756-EN2T module

•

1756-EN2TR module

•

1756-EN3TR module

•

1756-ENBT module

•

1756-EN2T module

•

1756-EN2TR module

•

1756-EN3TR module

Modules for a 1769

CompactLogix Packaged

Controller System

Not applicable

•

1769-L23E-QBFC1B controller

•

1769-L23-QBFC1B controller

•

1769-SDN scanner

With unscheduled data, the device from which a message originates, such as a

Logix5000 controller, contains the path information that makes sure the message

reaches its consumers.

For a full explanation of unscheduled and scheduled data, see Network Update

Time (NUT ) on page 16.

Because the producing module holds this information, other modules along the

path simply pass the information along and do not need to store it. The

significant benefits include the following:

•

You do not need to configure routing tables in the bridging module, which

greatly simplifies maintenance and module replacement.

•

You maintain full control over the route taken by each message, which

enables you to select alternative paths for the same end module.

Scheduled data in Logix-based systems use the producer/consumer networking

model instead of a source/destination (master/slave) model. The producer/

consumer model reduces network traffic and increases transmission speed.

14

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 15

ControlNet Overview

Chapter 1

In traditional I/O systems, controllers poll input modules to obtain their input

status. In a Logix system, digital input modules are not polled by a controller.

Instead, they produce (multicast) their data either upon a change of state (COS)

or periodically. The frequency of update depends upon the options chosen during

configuration and where on the network the input module resides. The input

module, therefore, is a producer of input data and the controller is a consumer of

the data.

The controller can also produce data for other controllers to consume. The

produced and consumed data is accessible by multiple controllers over the Logix

backplane and the ControlNet network. This data exchange conforms to the

producer/consumer model.

A Cont

rolNet network link’s most important function is to transport timecritical control information, such as I/O data and control interlocking. Other

information that is not time-critical, such as program uploads and downloads, is

also transported but does not interfere with time-critical messages because a

ControlNet network can transmit scheduled and unscheduled data.

On a ControlNet network link, nodes transfer information by establishing

connections. Each message sent by a producer contains a Connection ID (CID).

Nodes that have been configured to recognize the CID consume the message,

becoming consumers themselves.

Media access to the network is controlled by a time-slice access algorithm,

Concurrent Time Domain Multiple Access (CTDMA), which regulates a node’s

opportunity to transmit in each network update interval (NUI). You configure

how often the NUI repeats by selecting a network update time (NUT) in

milliseconds.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 15

Page 16

Chapter 1

Parts of NUT

Functions

Scheduled

On a sequential, rotating basis, every scheduled node can transmit data once per

ControlNet Overview

Network Update Time (NUT)

The network update time (NUT) is the shortest interval in which data can be

sent on a ControlNet network. It represents the fastest possible update rate for

scheduled data transfers on that network. For example, a network that runs with a

five ms NUT cannot send scheduled data at a rate faster than five ms. It can,

however, send data at a slower rate. The minimum NUT you can specify is two

ms. The NUT is divided into a three-part structure.

Table 4 - NUT Structure

NUT.

Unscheduled

Maintenance

Time-critical information is sent during this part of the interval.

All nodes transmit on a sequential, rotating basis, the rotation repeating itself

until the time allotted for this portion is used up.

The number of scheduled transmissions determines the time available for

unscheduled transmissions. On a ControlNet network, at least one node can

transmit unscheduled data every NUT.

Information that can be delivered without time constraints is sent during this

part of the interval.

The node with the lowest address transmits information to keep the other nodes

synchronized. This time is automatically subtracted from your NUT. However, the

time required for network maintenance is brief (microseconds) when compared

to that used for the scheduled and unscheduled portions of the NUT.

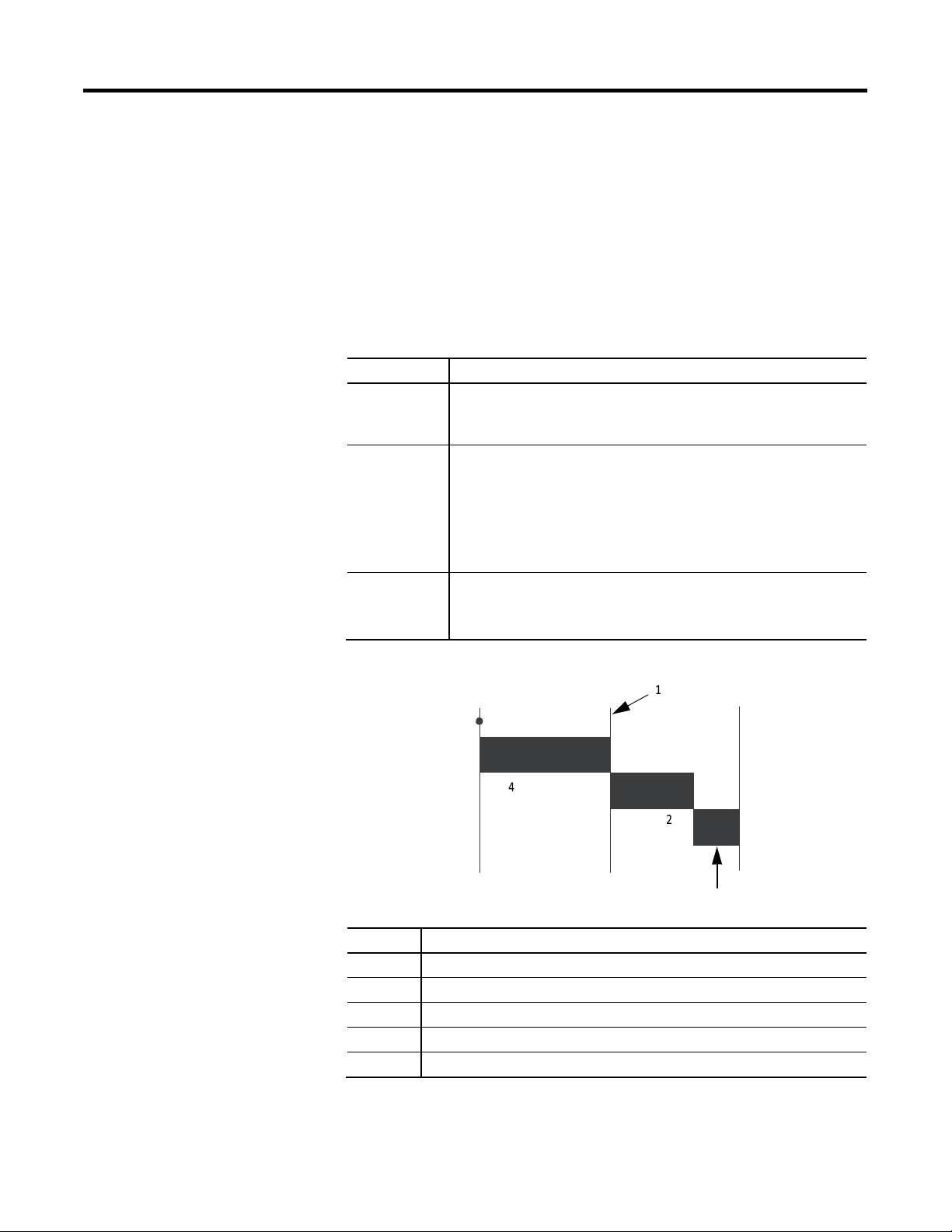

Figure 4 - NUT Structure

5

Item Description

1

2

3

4

5

Start

Boundary moves according to scheduled traffic load

Unscheduled traffic

Network maintenance

Scheduled traffic. Each device transmits only once

3

16

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 17

ControlNet Overview

Chapter 1

Requested Packet Interval (RPI)

The RPI is the update rate specified for a particular piece of data on the network.

By using a rack-optimized connection, the RPI can specify the rate for an entire

rack of I/O. With a direct connection, the RPI can specify the rate for a

particular module or peer-to-peer data. When you add a module to the I/O

configuration of a controller, you must configure the RPI, specifying how often

to produce data for that module. For example, if you specify an RPI of 50 ms,

every 50 ms the I/O module sends its data to the controller or the controller

sends its data to the I/O module.

Set the RPI only as fast as needed by the application. The RPI also determines the

number of packets per second that the module will handle on a connection. Each

module has a limit of how many packets it can handle per second. If you exceed

this limit, the module cannot open any more connections.

A faster RPI consumes more network bandwidth. So, to avoid wasting network

bandwidth, set the RPI only as fast as is necessary. For example, if your

application uses a thermocouple module that has data change every 100 ms, do

not set the RPI for that node at 5 ms because the network bandwidth is used to

transmit mostly old data.

IMPORTANT

You cannot set the RPI to a rate faster than the NUT. The network cannot

send data at a rate that is faster than the NUT.

When you run RSNetWorx for ControlNet software, an Actual Packet Interval

(API) is calculated. The API is equal to or faster than the RPI.

Actual Packet Interval (API)

The API is the actual update rate for a particular piece of data on the network. A

ControlNet network sets this rate equal to or faster than the RPI, based on the

binary multiple of the NUT, which is the next fastest rate at which a module can

send data. If this cannot be done, a ControlNet network provides reports that it

cannot support the configuration.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 17

Page 18

Chapter 1

NUT

Multiple

Rate at Which Module Can

5 ms

1 5 ms

ControlNet Overview

Understand the Effect of the NUT on the API

This e

xample illustrates how the NUT affects the API. A module on the network

can produce data only at binary multiples of the NUT to a maximum of the

NUT multiplied by 128. These multiples are referred to as rates on a ControlNet

network. Therefore, with a NUT of 5 ms, the module can send data at these rates.

Table 5 - NUT Example Data Rates

Send Data

2

4

8

16

32

64

128

In this example, if you specify an RPI of 25 ms, then the network produces an

API of 20 ms, which is the next fastest rate at which the module can send data.

The module places the data on the network at every fourth network update

10 ms

20 ms

40 ms

80 ms

160 ms

320 ms

640 ms

interval to produce the 20 ms API. Similarly, if you specify an RPI of 150 ms, the

network produces an API of 80 ms.

Schedule the Network

Connections over a ControlNet network can be one of the following:

•

Scheduled—Data transferred at specific times.

Unscheduled—Data transferred when the network can accommodate the

•

transfer.

To use scheduled connections, you must schedule the ControlNet network via

RSNetWorx for ControlNet software. For more information on how to schedule

a ControlNet network with RSNetWorx for ControlNet software, see the section

Use R SNetWorx for ControlNet Software on page 44.

You must use RSNetWorx for ControlNet software to enable any connection in a

remote chassis. In addition, RSNetWorx software transfers configuration

information for the remote modules, verifies and saves NUT and other userspecified network parameters, and establishes a schedule that is compliant with

the RPI and other connection options specified for each module.

18

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 19

ControlNet Overview

Chapter 1

IMPORTANT

Control of Scheduled I/O

RSNetWorx for ControlNet software must be run whenever a

scheduled connection is added to, removed from, or changed in your

system.

Scheduled connections let you send and receive data repeatedly at a

predetermined rate. You can use the 1756-CNB or the 1756-CN2 module to

control scheduled I/O when you use it in conjunction with a ControlLogix

controller. When you place the module in the I/O configuration list of a

ControlLogix controller and configure a second ControlLogix chassis with a

remote 1756-CNB or 1756-CN2 module on the same ControlNet network, you

can perform remote control operations on the I/O, or to a second controller in

the second chassis.

In this case, the ControlLogix controller and the 1756-CN2 module in the local

chassis together act as a scanner, while the 1756-CN2 module in the remote

chassis with the I/O plays the role of an adapter.

Understand the Network Keeper

Every ControlNet network requires at least one module to store programmed

parameters for the network and configures the network with those parameters

when the module is started. This module is called a keeper because it keeps the

network configuration. RSNetWorx for ControlNet software configures the

keeper.

To avoid a single point of failure, a ControlNet network supports multiple

redundant keepers. These ControlNet communication modules are keepercapable devices:

•

1756-CN2 and 1756-CN2R modules

•

1756-CNB and 1756-CNBR modules

•

1768-CNB and 1768-CNBR modules

•

1769-L32C and 1769-L35CR controllers

•

1784-PCICS and 1784-PKTCS cards

•

1788-CNx cards

PLC-5C module

•

On a multi-keeper network, any keeper-capable module can keep the network at

any legal node address (01...99). The multi-keeper-capable node with the lowest

node address becomes the active keeper provided it is valid. It has been

configured by RSNetWorx for ControlNet software and that configuration is the

same as that of the first keeper that became active after the network was formed

or reconfigured by RSNetWorx software.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 19

Page 20

Chapter 1

ControlNet Overview

If the active keeper is taken off the network, a valid back-up keeper can take over

for it and continue to act as keeper. As long as at least one valid multi-keeper

device is present on the network, new scheduled connections can be established.

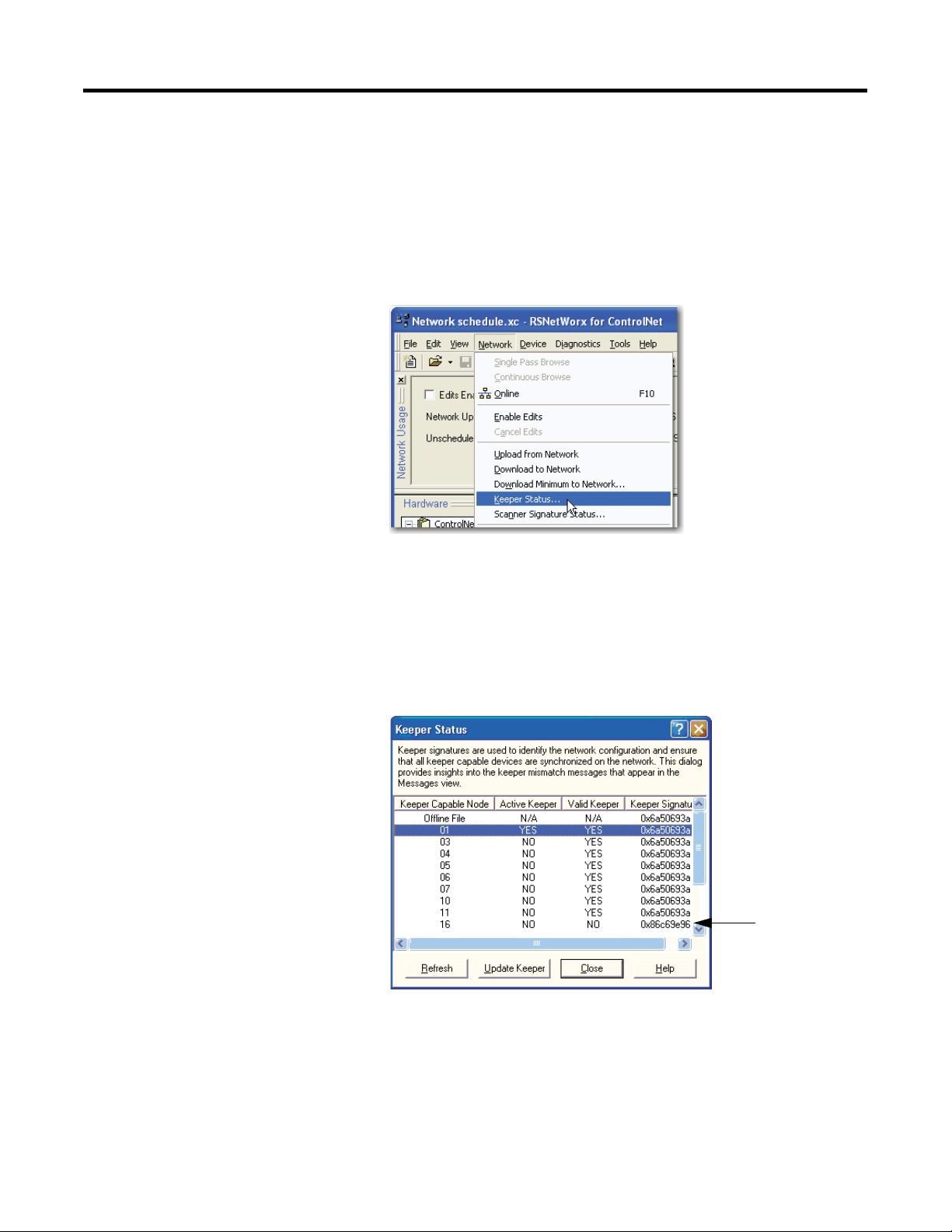

To review the valid keeper devices on your network, follow this procedure in

RSNetWorx for ControlNet software.

1.

From the Network menu, choose Keeper Status.

2.

Review the keeper devices on the Keeper Status dialog box.

On a typical net

•

work, the following must be true:

There must be only one active valid keeper.

All other keepers must be valid. If a keeper is not valid, it cannot

•

perform any scheduled communication. However, all unscheduled

communication occurs as expected.

The keeper signature, shown in hex, must be the same for all nodes.

•

Node 16 is

a valid keeper.

not

20

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 21

ControlNet Overview

Chapter 1

Default Parameters

When a ControlNet network is first established, it relies on a default set of

parameters capable of sending only unscheduled data. Default parameters in all

ControlNet devices include the following:

•

Network Update Time (NUT) = 100 ms

Scheduled MaximumNode Address (SMAX) = 1

•

The SMAX is the highest network address of a node that can use the

scheduled service.

Unscheduled Maximum Node Address (UMAX) = 99

•

The UMAX is the highest network address of a node that can

communicate on a ControlNet network. The UMAX must be set equal to

or higher than the SMAX.

Assumed maximum cable lengths and maximum number of repeaters

•

With this default ControlNet network, you can have unscheduled

communication between the various devices on the network by using

RSLogix 5000 software and RSLinx software.

IMPORTANT

To improve performance, configure a ControlNet network with

RSNetWorx for ControlNet software. We recommend these settings:

•

Set the Unscheduled Maximum Node Address (UMAX) equal to

the highest node address on the network. Leaving this parameter

at the default value of 99 wastes bandwidth and reduces system

performance.

Set the Scheduled Maximum Node Address (SMAX) to a value

•

three or four above the highest scheduled node address, so you

can expand the network in the future.

Also, be aware that each skipped node will subtract a small amount

of bandwidth from the network.

ControlNet Network Capacity and Topology

When planning a ControlNet network, consider these factors:

•

Topology

•

Number of nodes

•

Distances

Connections

•

Topology

A ControlNet network supports a variety of topologies, including trunkline/

dropline, star, tree, and ring redundancy. In its simplest form, a ControlNet

network is a trunkline to which you connect nodes with a tap and a one-meter

dropline.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 21

Page 22

Chapter 1

ControlNet Overview

3

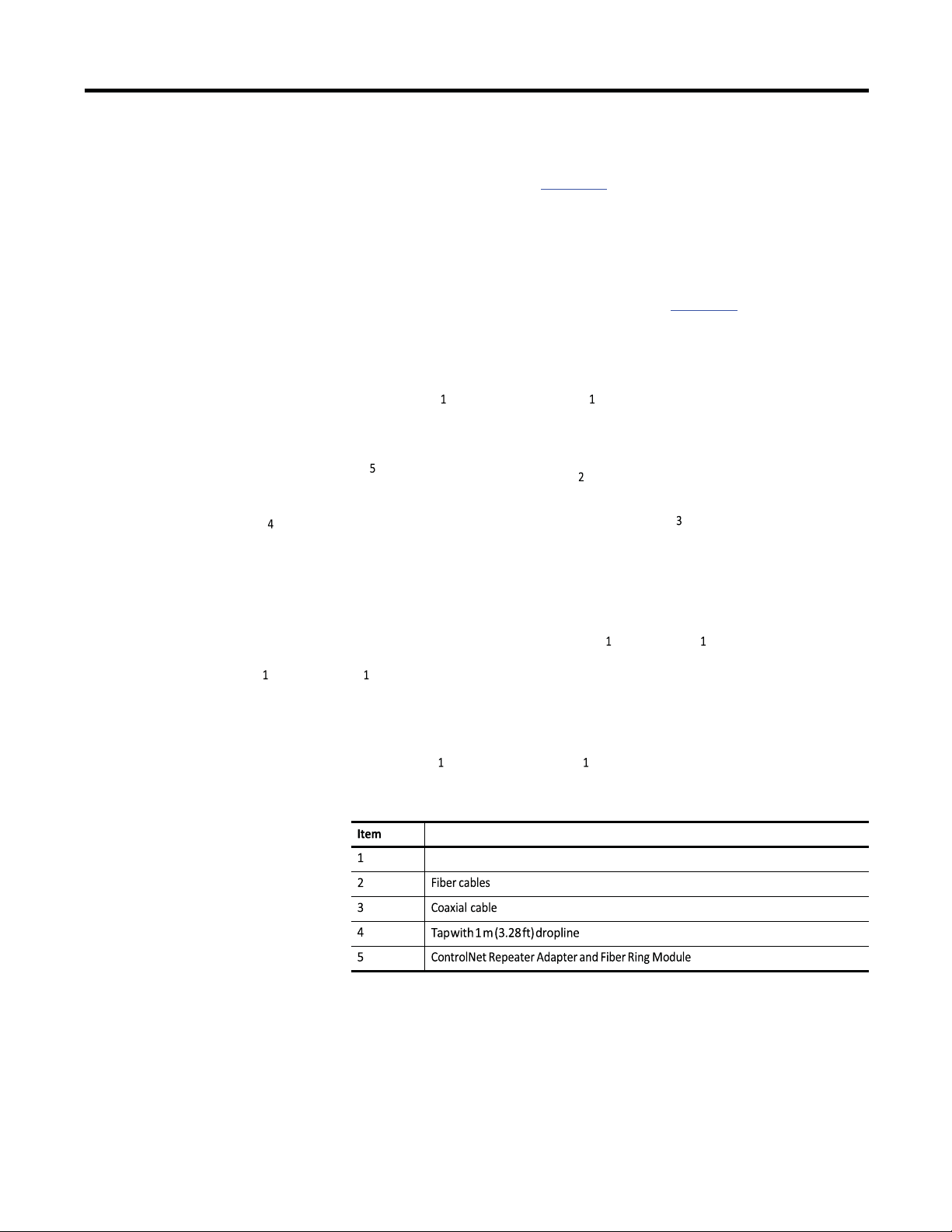

Figure 5 - Example ControlNet Network Trunkline/Dropline Topology

1

2

2

Item Description

1

2

Node

3

Trunkline

Tap with dropline

2

2

Figure 6 - Example ControlNet Network Star Topology

22

Item Description

1

Node

2

3

Rockwell Automation Publication CNET-

Tap with 1 m (3.28 ft) dropline

Coaxial repeater

UM001E-EN-P - June 2016

Page 23

ControlNet Overview

Description

Node

Chapter 1

TIP

Coax repeaters are typically used in trunkline and star topologies. See

the ControlNet Coax Media Planning and Installation Guide,

publication CNET-IN002, for more specific information on coax

topologies you can create.

With fiber media, you can configure your network in trunkline, star,

and ring topologies. Only the 1786-RPFRL and 1786-RPFRXL repeaters

support a ring topology.

For more information, consult the ControlNet Fiber Media Planning

and Installation Guide, publication CNET-IN001.

Figure 7 - Example ControlNet Network Ring Topology

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 23

Page 24

Chapter 1

S

e

g

m

en

t

Le

ng

th

m

(ft

)

ControlNet Overview

Number of Nodes

Each ControlNet network supports up to 99 nodes. Logix5000 controllers

support multiple ControlNet networks, providing the flexibility to add nodes to

a ControlNet network or boost performance.

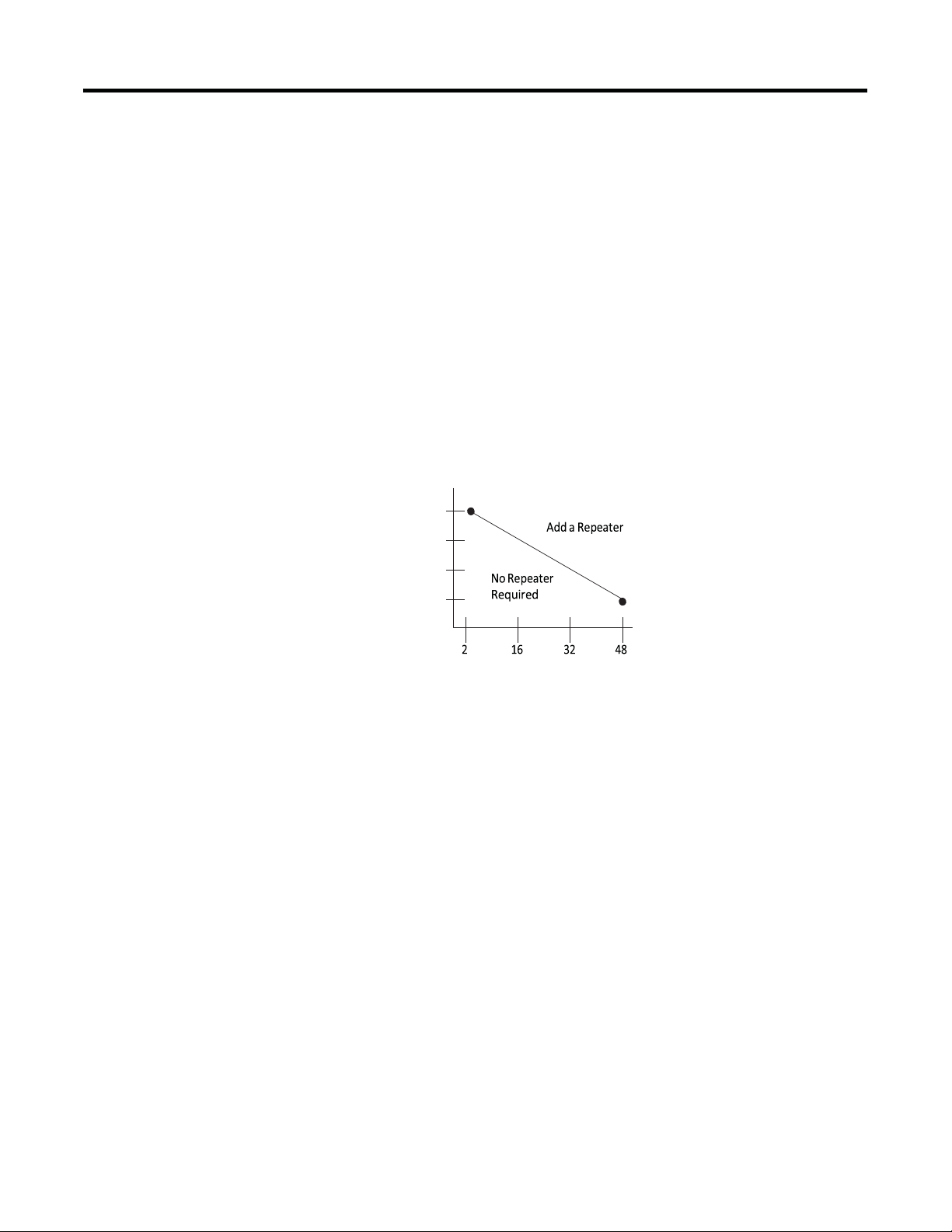

Lengths

In a ControlNet network, the maximum length depends on the number of nodes

on a segment; a segment is a section of trunk between two terminators. Use

repeaters to add segments or increase length.

Figure 8 - Maximum Length of a ControlNet Network

Maximum Allowable Segment Length = 1000 m (3280 ft) - 16.3 m (53.4 ft) X [Number of Taps - 2]

1000 (3280)

750 (2460)

500 (1640)

250 (820)

24

This graph assumes that a 1786-RG6 cable is being used.

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 25

Chapter

Topic

Page

Configure the ControlNet Communication Driver in RSLinx Classic Software

26

2

Connect a Computer to the ControlNet

Network

This chapter explains how to set up a computer to operate on a ControlNet

network.

You need to load a ControlNet communication driver for a computer to

communicate with other devices on a ControlNet network. A computer uses this

driver to do the following:

•

Upload and download controller projects over ControlNet via RSLogix

5000 software.

•

Schedule the ControlNet network via RSNetWorx for ControlNet

software.

•

Operate an HMI type application.

Depending on the connection device, you can use one of these drivers:

•

1784-PCIC or 1784-PCICS card—You must configure the driver in

RSLinx Classic software, as described on page 26

•

USBCIP driver—Use only with a 1784-U2CN USB-to-ControlNet

cable. You are not required to configure the driver in RSLinx Classic

software.

IMPORTANT

After preparing the driver for use, connect the card or cable to the computer, and

then connect the computer to the network.

If you are running RSLinx Classic software, version 2.51, 2.52, or

2.53, you must manually install the USBCIP driver. To obtain the

driver installation package, refer to answer ID 55431 on the

Rockwell Automation Knowledgebase at

http://www.rockwellautomation.com/knowledgebase.

If you are running RSLinx Classic software, version 2.54 or later,

the USBCIP driver is already installed on the computer.

.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 25

Page 26

Chapter 2

Connect a Computer to the ControlNet Network

Configure the ControlNet Communication Driver in RSLinx Classic Software

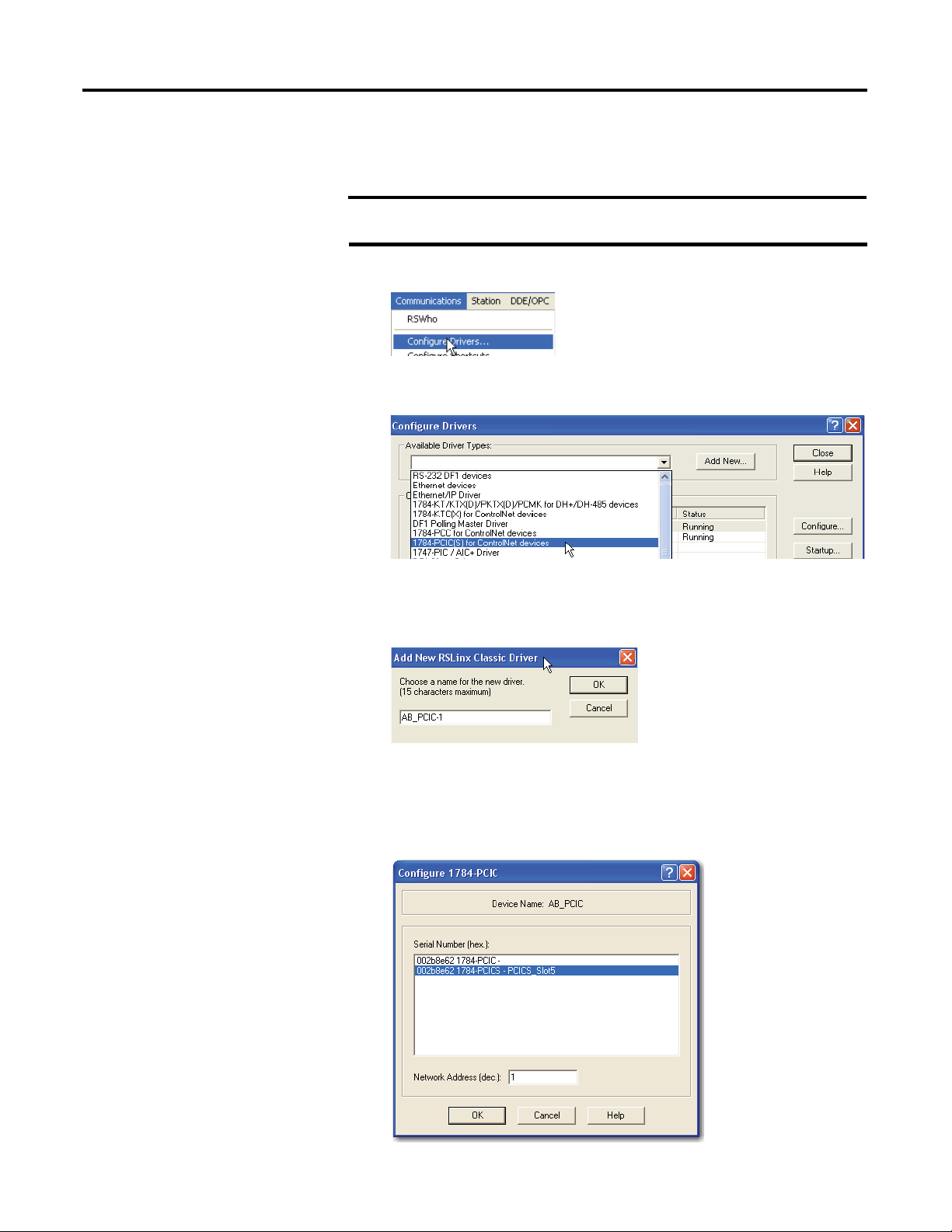

To configure a ControlNet communication driver, perform this procedure in

RSLinx Classic software.

IMPORTANT

1.

From the Communications menu, choose Configure Drivers.

2.

From the Available Driver Types pull-down menu, choose a driver for a

ControlNet devi

3.

Click Add New.

If you are using a 1794-U2CN cable to connect to the network, you are

not required to configure the driver.

ce.

The Add New RSLinx Driver dialog box appears. The driver name

defaults to AB_xxx.

4.

Type the name of the new ControlNet driver.

5.

Click OK.

The Configure Device dialog box appears. The appearance of this screen

varies, depending on the ty

pe of card used.

26

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 27

Connect a Computer to the ControlNet Network

6.

If your computer contains multiple cards, from the Serial Number (hex)

field, choose the co

7.

In the Network Address (dec) box, type the correct network address.

8.

Click OK.

rrect card.

The driver is now available and you can choose the ControlNet port from

Who Active in RS

Logix 5000 software.

Chapter 2

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 27

Page 28

Chapter 2

Connect a Computer to the ControlNet Network

Notes:

28

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 29

Chapter

Topic

Page

Use RSLogix 5000 Software

29

3

Configure a ControlNet Module

This chapter explains how to configure a ControlNet communication module to

operate on a ControlNet network.

Use RSNetWorx for ControlNet Software

IMPORTANT

The example configuration process shown in this chapter uses a

1756-CN2R/B ControlLogix ControlNet bridge module in a

ControlLogix controller project.

However, the overall configuration process, described in

Configure the I/O Configuration Tree in Your Project, generally

applies to any of the ControlNet communication modules covered

in this manual.

44

Use RSLogix 5000 Software

Use RSLogix 5000 software to configure the I/O tree in your project.

Configure the I/O Configuration Tree in Your Project

When y

communication module, you must perform these tasks.

ou use RSLogix 5000 software to configure a ControlNet

1.

Add and Config ure a Local ControlNet Module.

2.

Add and Config ure a Remote ControlNet Module.

IMPORTANT

3.

Download the Project to the Logix5000 Controller.

There are some differences between configuring a local

ControlNet communication module and configuring a remote

ControlNet communication module. Those differences are

covered later in this chapter.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 29

Page 30

Chapter 3

Configure a ControlNet Module

Add and Configure a Local ControlNet Module

After you have started RSLogix 5000 software and created a controller project,

you can add ControlNet communication modules. A local ControlNet module is

a module that resides in the same chassis as the controller.

IMPORTANT

When you create a new RSLogix 5000 project with the CompactLogix

1769-L32C or 1769-L35CR controller, the Controller Organizer creates a

ControlNet port in the local chassis. In this case, you do not need to add a

separate local communication module.

To add a local ControlNet module, follow this procedure.

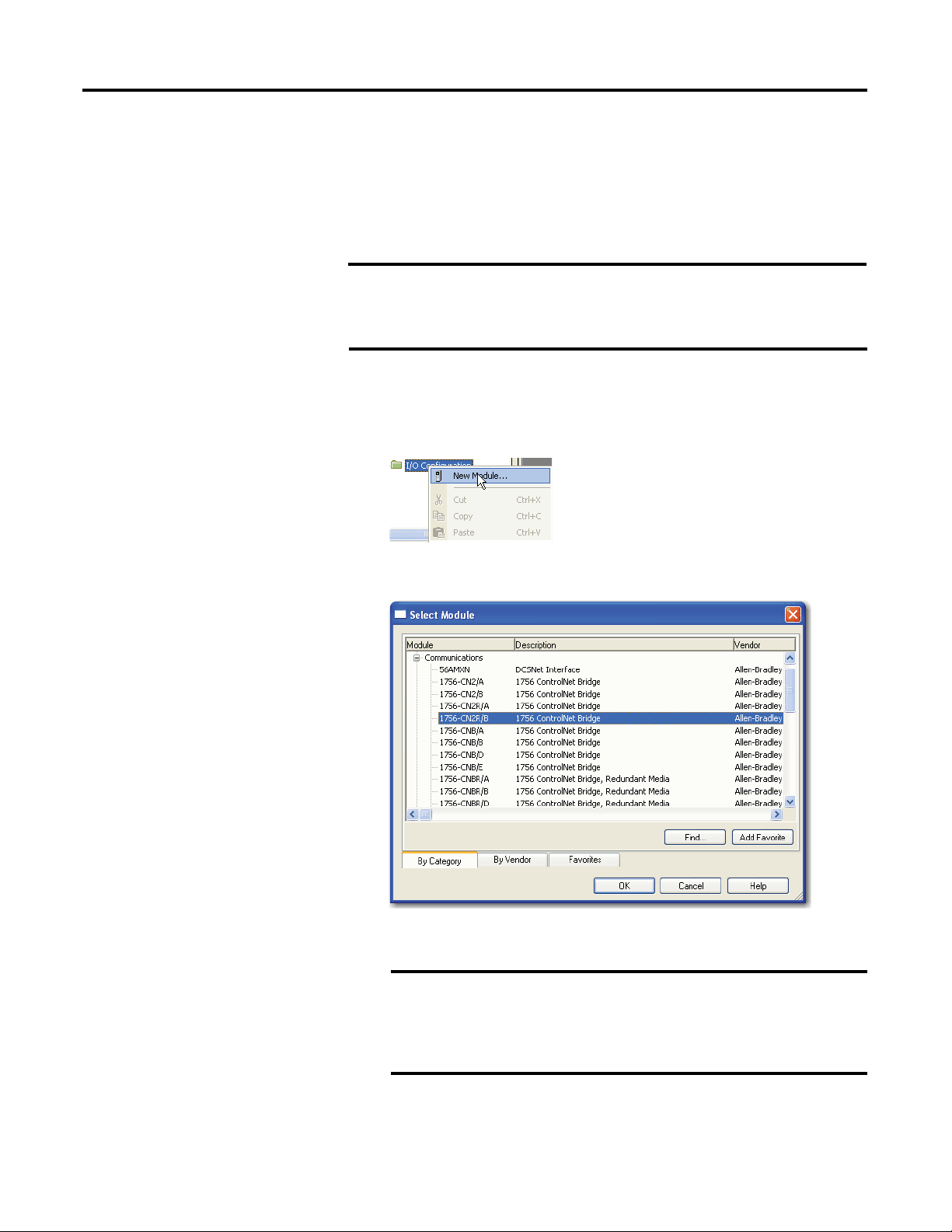

1.

In RSLogix 5000 software, right-click I/O configuration and choose New

Module.

2.

From the Select Module Type dialog box, expand Communications,

choose the local C

ontrolNet communication module, and then click OK.

30

IMPORTANT

Rockwell Automation Publication CNET-

This procedure shows the New Module dialog box for a

1756-CN2R/B. However, various dialogs appear during

configuration depending on the ControlNet module you select. For

help configuring a module, refer to the online help in

RSLogix 5000 software.

UM001E-EN-P - June 2016

Page 31

Configure a ControlNet Module

Field

Action

Name

Type a name for the local ControlNet module.

Logix5000 Controller

Local ControlNet Communication Module

1768 CompactLogix

1768-CNB, 1768-CNBR

1769 CompactLogix

1769-L32C and 1769-L35CR controllers have a built-in ControlNet port

Chapter 3

This table lists the ControlNet communication modules available locally

in the local chassis, computer, or controller with each Logix5000

controller.

Table 6 - ControlNet Communication Modules Available Locally

ControlLogix

SoftLogix

3.

Complete the fields on the New Module dialog box and then click OK.

Node

Description

Slot

Revision

Electronic Keying

Open Module Properties

1756-CN2, 1756-CN2R, 1756-CNB, 1756-CNBR

1784-PCIC, 1784-PCICS

Enter the module’s node number on the network.

Type a description of the local ControlNet module.

Enter the module’s slot number in the chassis.

Choose a major and minor revision of RSLogix 5000 software.

Choose a keying option, as described in Electronic Keying on page 37.

Leave the box checked to configure connection properties in the next

step.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 31

Page 32

Chapter 3

Configure a ControlNet Module

4.

On the Module Properties dialog box, configure the connection properties

and then click A

pply.

Connection Property

Inhibit Module

Major Fault On Controller If

Connection Fails While In Run Mode

Action

If the module does

controller, check the checkbox.

or

If the module needs to communicate with the controller,

leave the checkbox cleared.

IMPORTANT:

leave the checkbox cleared.

If you want the controller to produce a major fault if the

connection to the local communication module fails in Run

mode, check the checkbox.

or

If you want the controller to continue operating if the

connection to the local communication module fails in Run

mode, leave the checkbox cleared. Use ladder logic to

monitor the connection.

not

need to communicate with the

When you test this portion of the system,

32

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 33

Configure a ControlNet Module

Chapter 3

Add and Configure a Remote ControlNet Module

After you have added the local ControlNet communication module, you must

add remote ControlNet communication modules. A remote ControlNet module

is a module that resides in a chassis separate from the controller.

To add a remote ControlNet module, perform this procedure.

1.

In RSLogix 5000 software, right-click the local ControlNet

communication mod

2.

From the Select Module Type dialog box, expand Communications, select

a remote ControlNet co

ule and choose New Module.

mmunication module, and then click OK.

You can connect any remote ControlNet communication module to a

local ControlNet com

munication module.

IMPORTANT

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 33

This procedure shows the New Module dialog box for a

1756-CN2R/B. However, various dialogs appear during

configuration depending on the ControlNet module you select. For

help configuring a module, refer to the online help in

RSLogix 5000 software.

Page 34

Chapter 3

Field

Action

Name

Type a name for the local ControlNet module.

Configure a ControlNet Module

3.

Complete the fields on the New Module dialog box and then click OK.

Node

Description

Chassis Size

Comm Format

Slot

Revision

Electronic Keying

Open Module Properties

Enter the module’s node number on the network.

Type a description of the local ControlNet module.

Enter the total number of slots in the chassis.

Choose a communication format, as described in Communication

Format below.

You do not need to assign a communication format for 1784-PCIC,

1784-PCICS, or 1788-CNx cards.

Enter the module’s slot number in the chassis.

Choose a major and minor revision of RSLogix 5000 software.

Choose a keying option, as described in Electronic Keying on page 37.

Leave the box checked to configure connection properties in the next

step.

34

Communication Format

The communication format determines the following:

•

What configuration options are available

For example, if the module uses None, then you do not have to configure

an RPI rate on the Module Properties dialog box.

•

What type of data is transferred between the owner-controller and I/O

connected via the communication module

•

What tags are generated when configuration is complete

•

The type of connection between the owner-controller and the I/O

connected via the communication module

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 35

Configure a ControlNet Module

Communication Format

Function

Effect on RPI

Rack-optimized

The communication module creates a rack image and

You can specify an RPI that meets this criteria:

0

The communication format setting also affects the RPI rate.

Chapter 3

Table 7 - Communication Formats

Listen-only rack-optimized (not

available on all ControlNet

communication modules)

None

Connection Property

Requested Packet Interval (RPI)

Inhibit Module

Major Fault On Controller If Connection Fails While In

Run Mode

Use Scheduled Connection over ControlNet

Action

returns I/O data in the rack image to the owner-controller.

This option is available only for digital I/O modules.

Remember that diagnostic I/O modules will not return

diagnostic data when you use this format.

The communication module creates a rack image and

returns I/O input data in the rack image to the ownercontroller.

The difference between this choice and rack-optimized is

that the I/O data in the rack image is returned to a

controller that does not control the outputs but is listening

only to its input data.

No RPI is required.

•

Equal to or greater than the NUT

•

4.

On the Module Properties dialog box, configure the connection properties

and then click A

Type the requested packet interval between 2.0…750.0 ms.

If your module uses one of the rack-optimized communication formats, the RPI must be equal

to or greater than the ControlNet Network Update Time (NUT).

If the module does

or

If the module needs to communicate with the controller, leave the checkbox cleared.

IMPORTANT:

If you want the controller to produce a major fault if the connection to the local

communication module fails in Run mode, check the checkbox.

or

If you want the controller to continue operating if the connection to the local communication

module fails in Run mode, leave the checkbox cleared. Use ladder logic to monitor the

connection.

Check the box if you want to explicitly schedule the network connection.

Note the following:

•

The checkbox is enabled when the connection for the module crosses ControlNet and the

module supports unscheduled connections.

•

The checkbox is checked and disabled when the connection to the module crosses

ControlNet, and the module does not support unscheduled connections, and therefore,

must be scheduled.

•

The checkbox is cleared and disabled when the connection to the module does not cross

ControlNet, or the connection crosses ControlNet but does not need to be scheduled.

When you test this portion of the system, leave the checkbox cleared.

pply.

not

need to communicate with the controller, check the checkbox.

In the range permitted by RSLogix 5000 programming

software, for example 2…750 ms

When you set the RPI for a remote ControlNet

communication module, we recommend you use a rate

that is a power of two times the NUT.

For example, if your NUT = 5 ms, we recommend these RPI

values.

NUT = 5m

Optimal RPI

values

The RPI field is dimmed.

x 2

5 ms 10 ms 20 ms 40 ms 80 ms

x 21 x 22 x 23 x 24

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 35

Page 36

Chapter 3

Configure a ControlNet Module

Download the Project to the Logix5000 Controller

IMPORTANT

Before you download your RSLogix 5000 project to your ControlNet

modules, consider whether you will schedule the ControlNet network

offline or online:

•

If you are going to schedule the network offline, complete the

procedure in the section Schedule the Network Offline on page 45.

If you are going to schedule the network online, complete the

•

procedure in this section and then proceed to the section Schedule

the Network Online on page 49.

When you have added the local and remote ControlNet communication modules

to your RSLogix 5000 project, download the new configuration to your

Logix5000 controller.

To download a project to a Logix5000 controller, follow this procedure.

1.

Because you must schedule the ControlNet network before by using the

new configuration, sw

using one of these met

•

itch your Logix5000 controller to Program mode

hods:

Turn the controller keyswitch to PROG.

Turn the controller keyswitch to REM and use RSLogix 5000 software.

•

2.

In RSLogix 5000 software, from the Communications menu, choose Who

Active.

36

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 37

Configure a ControlNet Module

3.

From the Who Active dialog box, browse to and select the controller to

which to download a pr

4.

When the Download dialog box appears, click Download.

oject and click Download.

Chapter 3

Electronic Keying

The electronic keying feature automatically compares the expected module, as

shown in the RSLogix 5000 I/O Configuration tree, to the physical module

before I/O communication begins. You can use electronic keying to help prevent

communication to a module that does not match the type and revision expected.

For each module in the I/O Configuration tree, the user-selected keying option

determines if, and how, an electronic keying check is performed. Typically, three

keying option are available:

•

Exact Match

•

Compatible Keying

Disable Keying

•

You must carefully consider the benefits and implications of each keying option

when selecting between them. For some specific module types, fewer options are

available.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 37

Page 38

Chapter 3

A number that indicates the module’s specific firmware revision. Minor

Configure a ControlNet Module

Electronic keying is based on a set of attributes unique to each product revision.

When a Logix5000 controller begins communicating with a module, this set of

keying attributes is considered.

Table 8 - Keying Attributes

Attribute Description

Vendor

Product Type

Product Code

Major Revision

Minor Revision

You can find revision information on the General tab of a module’s Properties

The manufacturer of the module, for example, Rockwell Automation/AllenBradley.

The general type of the module, for example, communication adapter, AC

drive, or digital I/O.

The specific type of module, generally represented by its catalog number,

for example, 1756-IB16I.

A number that represents the functional capabilities and data exchange

formats of the module. Typically, although not always, a later, that is

higher, Major Revision supports at least all of the data formats supported

by an earlier, that is lower, Major Revision of the same catalog number

and, possibly, additional ones.

Revisions typically do not impact data compatibility but may indicate

performance or behavior improvement.

dialog box.

Figure 9 - General Tab

IMPORTANT

Changing electronic keying selections online may cause the I/O

communication connection to the module to be disrupted and may

Exact Match

result in a loss of data.

Exact Match keying requires all keying attributes, that is, Vendor, Product Type,

Product Code (catalog number), Major Revision, and Minor Revision, of the

physical module and the module created in the software to match precisely in

order to establish communication. If any attribute does not match precisely, I/O

communication is not permitted with the module or with modules connected

through it, as in the case of a communication module.

38

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 39

Configure a ControlNet Module

Chapter 3

Use Exact Match keying when you need the system to verify that the module

revisions in use are exactly as specified in the project, such as for use in highlyregulated industries. Exact Match keying is also necessary to enable Automatic

Firmware Update for the module via the Firmware Supervisor feature from a

Logix5000 controller.

EXAMPLE

In the following scenario, Exact Match keying prevents I/O

communication.

The module configuration is for a 1756-IB16D module with module

revision 3.1. The physical module is a 1756-IB16D module with

module revision 3.2. In this case, communication is prevented because

the Minor Revision of the module does not match precisely.

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 1

Communication is prevented.

IMPORTANT

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

Changing electronic keying selections online may cause the I/O

Communication connection to the module to be disrupted and may

Compatible Keying

result in a loss of data.

Compatible Keying indicates that the module determines whether to accept or

reject communication. Different module families, communication adapters, and

module types implement the compatibility check differently based on the family

capabilities and on prior knowledge of compatible products.

Compatible Keying is the default setting. Compatible Keying allows the physical

module to accept the key of the module configured in the software, provided that

the configured module is one the physical module is capable of emulating. The

exact level of emulation required is product and revision specific.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 39

Page 40

Chapter 3

Configure a ControlNet Module

With Compatible Keying, you can replace a module of a certain Major Revision

with one of the same catalog number and the same or later, that is higher, Major

Revision. In some cases, the selection makes it possible to use a replacement that is

a different catalog number than the original. For example, you can replace a 1756CNBR module with a 1756-CN2R module. Release notes for individual

modules indicate the specific compatibility details.

When a module is created, the module developers consider the module’s

development history to implement capabilities that emulate those of the previous

module. However, the developers cannot know future developments. Because of

this, when a system is configured, we recommend that you configure your module

by using the earliest, that is, lowest, revision of the physical module that you

believe will be used in the system. By doing this, you can avoid the case of a

physical module rejecting the keying request because it is an earlier revision than

the one configured in the software.

EXAMPLE

In the following scenario,

communication:

The module configuration is for a 1756-IB16D module with module

revision 3.3. The physical module is a 1756-IB16D module with

module revision 3.2. In this case, communication is prevented

because the minor revision of the module is lower than expected and

may not be compatible with 3.3.

Compatible Keying prevents I/O

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 3

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

Communication is prevented.

40

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 41

Configure a ControlNet Module

Chapter 3

EXAMPLE

In the following scenario,

Compatible Keying allows I/O

communication:

The module configuration is for a 1756-IB16D module with module

revision 2.1. The physical module is a 1756-IB16D module with

module revision 3.2. In this case, communication is allowed because

the major revision of the physical module is higher than expected and

the module determines that it is compatible with the prior major

revision.

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IB16D

Major Revision = 2

Minor Revision = 1

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

Communication is allowed.

IMPORTANT

Changing electronic keying selections online may cause the I/O

communication connection to the module to be disrupted and may

result in a loss of data.

Disabled Keying

Disa

bled Keying indicates the keying attributes are not considered when

attempting to communicate with a module. Other attributes, such as data size and

format, are considered and must be acceptable before I/O communication is

established. With Disabled Keying, I/O communication may occur with a

module other than the type specified in the I/O Configuration tree with

unpredictable results. We generally do not recommend using Disabled Keying.

ATTENTION:

if used incorrectly, this option can lead to personal injury or death,

property damage, or economic loss.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 41

Be extremely cautious when using Disabled Keying;

Page 42

Chapter 3

Configure a ControlNet Module

If you use Disabled Keying, you must take full responsibility for understanding

whether the module being used can fulfill the functional requirements of the

application.

EXAMPLE

In the following scenario,

communication:

The module configuration is for a 1756-IA16 digital input module. The

physical module is a 1756-IF16 analog input module. In this case,

communication is prevented because the analog module

rejects the data formats that the digital module configuration

requests.

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IA16

Major Revision = 3

Minor Revision = 1

Physical Module

Vendor = Allen-Bradley

Product Type = Analog Input

Module

Catalog Number = 1756-IF16

Major Revision = 3

Minor Revision = 2

Communication is prevented.

Disable Keying prevents I/O

42

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 43

Configure a ControlNet Module

Chapter 3

EXAMPLE

In the following scenario,

Disable Keying allows I/O

communication:

The module configuration is for a 1756-IA16 digital input module. The

physical module is a 1756-IB16 digital input module. In this case,

communication is allowed because the two digital modules share

common data formats.

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IA16

Major Revision = 2

Minor Revision = 1

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input

Module

Catalog Number = 1756-IB16

Major Revision = 3

Minor Revision = 2

Communication is allowed.

IMPORTANT

Changing electronic keying selections online may cause the I/O

communication connection to the module to be disrupted and may

result in a loss of data.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 43

Page 44

Chapter 3

Configure a ControlNet Module

Use RSNetWorx for ControlNet Software

You must use RSNetWorx for Co

order to activate the configured I/O devices in your application. You must also

reschedule the network if a change is made to an already-scheduled network.

Schedule a ControlNet Network for the First Time

RSNetWorx for Co

ControlNet communication modules are keeper-cable devices:

•

1756-CN2 and 1756-CN2R modules

•

1756-CNB and 1756-CNBR modules

•

1768-CNB and 1768-CNBR module

•

1769-L32C and 1769-L35CR controllers

1784-PCICS and 1784-PKTCS cards

•

If you configure a keeper on one network and then use it on another network, the

conflicting information can make it difficult to use RSNetWorx for ControlNet

software to schedule the new network. In extreme cases, it may be difficult to go

online:

•

For more information on the network keeper, see the section Un derstand

the Network Keeper on page 19.

ntrolNet software stores information in keeper devices. These

ntrolNet software to schedule the network in

•

For more information on how to reset valid keepers to an unconfigured

state to resolve mismatches, refer to the RSNetWorx for ControlNet

software online help.

•

For more information on how to clear the memory or keeper information

in a ControlNet communication module, refer to the Knowledgebase at

http://www.rockwellautomation.com/support.

44

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 45

Configure a ControlNet Module

Chapter 3

Schedule the Network Offline

uling a project offline is most useful in the design phase of your project.

Sched

Scheduling off line can be used to predict performance and measure bandwidth.

TIP

Before scheduling a network offline, make sure of the following:

•

To learn more about using RSLogix 5000 and RSNetWorx software

offline to predict performance, refer to answer ID 54793 on the Rockwell

Automation Knowledgebase at http://www.rockwellautomation.com/

knowledgebase.

Your RSLogix 5000 software project uses one controller and one network.

We recommend that you use only one 1756-CN2, 1756-CNB, or 1768-

CNB module in the local chassis when scheduling the network offline.

•

Your RSLogix 5000 software project is complete but has not been

downloaded to the controller.

If your network has already been scheduled and you made a change to it, you

must reschedule it. For more information, refer to Reschedule a ControlNet

Network that has Previously been Scheduled on page 53.

To schedule a network offline, perform this procedure.

1.

In your RSLogix 5000 software project, right-click your local ControlNet

module and choose P

roperties.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 45

Page 46

Chapter 3

Configure a ControlNet Module

2.

From the Module Properties dialog box, click the RSNetWorx tab.

3.

In the ControlNet file field, type a name for a new ControlNet file.

4.

Click Apply.

5.

When a message appears prompting you to create the file, click Yes.

This action creates the file that RSNetWorx for ControlNet software uses

offline to browse and

6.

Click Schedule the ControlNet network.

7.

Click the icon circled below to launch RSNetWorx for ControlNet

schedule the network.

software.

8.

To enable edits in the schedule, in RSNetWorx for ControlNet software,

check Edits Enabled.

46

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 47

Configure a ControlNet Module

This is the node with the highest network address that can use

Max Unscheduled Address

Node with the highest network address that can use unscheduled

Media Redundancy

Designates if the network uses media redundancy.

9.

To change the network properties from default settings to those that best

fit your network, f

10.

On the Network Parameters tab, configure the network parameters, as

described in the ta

Parameter Description

Network Update Time (ms) The smallest user-configurable repetitive time cycle at which data can

Max Scheduled Address

rom the Network menu, choose Properties.

ble below, and click OK.

be sent on a ControlNet network.

scheduled time on a ControlNet link. I/O data is transferred during

scheduled time. RSNetWorx for ControlNet software sets this value.

We recommend that you not change it.

Chapter 3

Network Name

time on a ControlNet link. Messaging data is transferred during

unscheduled time.

Nodes set at addresses higher than the maximum unscheduled node

do not communicate on the network. For example, they will not

display in RSLinx software.

User-defined name of the network.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 47

Page 48

Chapter 3

Configure a ControlNet Module

11.

Click the Media Configuration tab.

Generally, you can use the default media configuration.

12.

Adjust the configuration if your network is longer or uses repeaters.

If the media configuration does not accurately represent the maximum

propagation dela

y between any two nodes, your network may experience

errors.

Default Media Configuration of 1000 m

(3280.84 ft) of RG6 Coaxial Cable

13.

Click OK.

14.

On the Save Configuration dialog box, click Optimize and rewrite the

schedule for all

15.

Click OK.

16.

Return to your RSLogix 5000 software project.

a.

Save your project to update the network file in your RSLogix 5000

connections.

project.

b.

Download your project as described in Download the Project to the

Logix5000 Controller on page 36.

48

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 49

Configure a ControlNet Module

Chapter 3

Schedule the Network Online

Prior to scheduling a network online, make sure that all keepers are unconfigured

or do not conflict with the current network. If your network has already been

scheduled and you made a change to it, you must reschedule it.

Refer to Reschedule a ControlNet Network that has Previously been Scheduled

on page 53 for more information.

To schedule a network online, follow this procedure in RSNetWorx for

ControlNet software.

1.

From the File menu, choose New.

2.

From the New File dialog box, select a ControlNet configuration for the

new file and cl

ick OK.

3.

From the Network menu, choose Online.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 49

Page 50

Chapter 3

Configure a ControlNet Module

4.

From the Browse for Network dialog box, expand the tree to find and

select a communication path to t

he ControlNet network and click OK.

This example uses a previously configured communication path to the

controller. Here, the computer is connected to the ControlNet network via

a 1784-PCIC card. The driver was previously configured via RSLinx

software, as described in Connect a Computer to the ControlNet

Network on page 25.

5.

From the Network menu, choose Single Pass Browse.

6.

Check Edits Enabled.

When you enable edits, RSNetWorx for ControlNet software reads data in

the ControlNet mo

dules and builds a schedule for the network.

50

Rockwell Automation Publication CNET-

UM001E-EN-P - June 2016

Page 51

Configure a ControlNet Module

Parameter

Description

Network Update Time

The smallest user-configurable repetitive time cycle in milliseconds at

7.

To change the network properties from default settings to those that best

fit your network, f

8.

On the Network Parameters tab, configure the network parameters as

described in the tab

rom the Network menu, choose Properties.

le below.

Chapter 3

which data can be sent on a ControlNet link.

Max Scheduled Address

Max Unscheduled Address The node with the highest network address that can use unscheduled

Media Redundancy

Network Name

The node with the highest network address that can use scheduled

time on a ControlNet link. I/O data is transferred during scheduled time.

RSNetWorx for ControlNet software sets this value. We recommend

that you do not change it.

time on a ControlNet link. Messaging data is transferred during

unscheduled time.

Nodes set at addresses higher than the maximum unscheduled node do

not communicate on the network. For example, they will not display in

RSLinx software.

Designates if the network uses media redundancy on any of the

network communication modules.

A user-defined name for the network.

Rockwell Automation Publication CNET-UM001E-EN-P - June 2016 51

Page 52

Chapter 3

Configure a ControlNet Module

9.

Click the Media Configuration tab, modify the settings if needed, and

click OK.

erally, you can use the default media configuration. Adjust the

Gen

configuration if your n

etwork is longer or uses repeaters.

IMPORTANT

10.

From the File menu, choose Save.

11.

From the Save Configuration dialog box, click Optimize and rewrite the

schedule for all

If the media configuration does not accurately represent the

maximum propagation delay between any two nodes, your

network may experience errors.

connections.

52

12.

Click OK.

IMPORTANT

13.

In RSLogix 5000 software, save the online project.

Rockwell Automation Publication CNET-

It is better to optimize connections. However, in some cases

involving multiple controllers, the Merge changes... option is