Page 1

This manual links to Knowledgebase Article Logix 5000 Controller Fault

Codes for fault codes; download the spreadsheets now for offline access.

ControlLogix 5580 and

GuardLogix 5580 Controllers

Bulletin 1756

User Manual

Original Instructions

Page 2

ControlLogix 5580 and GuardLogix 5580 Controllers User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WA RN I NG : Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential

Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory

requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 3

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

ControlLogix and GuardLogix

Systems

Minimum Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ControlLogix Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ControlLogix No Stored Energy (NSE) Controllers . . . . . . . . . . 16

ControlLogix-XT Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Process Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Conformal Coated Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ControlLogix Redundant Controllers . . . . . . . . . . . . . . . . . . . . . . . 17

ControlLogix System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Standalone Controller and I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Multiple Controllers in One Chassis . . . . . . . . . . . . . . . . . . . . . . . . 19

Multiple Devices Connected via Multiple Networks. . . . . . . . . . 20

GuardLogix System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Design the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CIP Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Secure Controller Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

ControlLogix 5580 Controller Features. . . . . . . . . . . . . . . . . . . . . . . . . 25

GuardLogix 5580 Controller Features . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Features Supported By GuardLogix 5580 Controllers Via t

he Safety Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 2

Safety Concept of GuardLogix

Controllers

Communication Networks

Functional Safety Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Safety Network Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Safety Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Distinguish between Standard and Safety Components. . . . . . . . . . . 31

Controller Data-flow Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Safety Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 3

Networks Available. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

EtherNet/IP Network Communication. . . . . . . . . . . . . . . . . . . . . . . . . 37

EtherNet/IP Link Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

EtherNet/IP Communication Modules . . . . . . . . . . . . . . . . . . . . . 40

Double Data Rate (DDR) Backplane Communication for

ControlLogix Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ControlNet Network Communication . . . . . . . . . . . . . . . . . . . . . . . . . 41

GuardLogix ControlNet Example . . . . . . . . . . . . . . . . . . . . . . . . . . 42

ControlNet Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 3

Page 4

Table of Contents

DeviceNet Network Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DeviceNet Bridge Module and Linking Devices . . . . . . . . . . . . . . 45

Connections Over DeviceNet Networks . . . . . . . . . . . . . . . . . . . . 45

Data Highway Plus (DH+) Network Communication . . . . . . . . . . . 45

Communicate Over a DH+ Network . . . . . . . . . . . . . . . . . . . . . . . 46

Universal Remote I/O (RIO) Communication . . . . . . . . . . . . . . . . . . 47

Communicate Over a Universal Remote I/O Network . . . . . . . 48

Foundation Fieldbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 49

HART Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Chapter 4

Connect to a Controller

Start Using the Controller

Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Other Methods to Set the IP Address . . . . . . . . . . . . . . . . . . . . . . . 52

Duplicate IP Address Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Duplicate IP Address Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

DNS Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Update Controller Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Firmware Upgrade Guidelines for Safety Controllers . . . . . . . . . 55

Determine Required Controller Firmware. . . . . . . . . . . . . . . . . . . 56

Obtain Controller Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Use ControlFLASH Plus or ControlFLASH Software to

Update Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Use AutoFlash to Update Firmware. . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 5

Create a Logix Designer Application Project. . . . . . . . . . . . . . . . . . . . . 61

Additional Configuration for a GuardLogix Controller. . . . . . . . . . . 62

Set the Safety Level for a GuardLogix Controller . . . . . . . . . . . . . 62

Passwords for Safety-locking and Unlocking . . . . . . . . . . . . . . . . . 63

Protect the Safety Signature in Run Mode . . . . . . . . . . . . . . . . . . . 64

Assign the Safety Network Number (SNN). . . . . . . . . . . . . . . . . . 65

Copy and Paste a Safety Controller Safety Network Number. . 69

Go Online with the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Use RSWho. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Use a Recent Communication Path . . . . . . . . . . . . . . . . . . . . . . . . . 72

Additional Considerations for Going Online with a GuardLogix

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Match Project to Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Firmware Revision Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Safety Status/Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Safety Signature and Safety-locked and -unlocked Status . . . . . . 75

Checks for Going Online with a GuardLogix Controller. . . . . . 76

Download to the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Use Who Active. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Use the Controller Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 5

Table of Contents

Additional Considerations for Download to a

GuardLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Upload from the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Use Who Active. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Use the Controller Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Additional Considerations for Upload from a

GuardLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Choose the Controller Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . 83

Use the keyswitch to Change the Operation Mode . . . . . . . . . . . 84

Use the Logix Designer Application to Change the

Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Reset Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Stage 1 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Stage 2 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Safety Partner Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter 6

Use the Secure Digital Card

Manage Controller

Communication

Considerations for Storing and Loading a Safety Project . . . . . . . . . . 93

Store to the SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Load from the SD Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Controller Power-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

User-initiated Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Other Secure Digital Card Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Chapter 7

Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Nodes on an EtherNet/IP Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Devices Included in the Node Count. . . . . . . . . . . . . . . . . . . . . . . 102

Devices Excluded from the Node Count. . . . . . . . . . . . . . . . . . . . 103

Controller Communication Interaction with Control Data. . . . . . 104

Produce and Consume (Interlock) Data. . . . . . . . . . . . . . . . . . . . . . . . 105

Requested Packet Interval (RPI) of Multicast Tags . . . . . . . . . . 106

Send and Receive Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Determine Whether to Cache Message Connections . . . . . . . . 108

Socket Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Simple Network Management Protocol (SNMP) . . . . . . . . . . . . . . . 109

Use a CIP Generic MSG to Enable SNMP on the Controller. 109

Use a CIP Generic MSG to Disable SNMP on the Controller 111

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 5

Page 6

Table of Contents

Chapter 8

Standard I/O Modules

Safety I/O Devices

Selecting ControlLogix

I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Add Local I/O to the I/O Configuration . . . . . . . . . . . . . . . . . . . 115

Remote I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Add Remote I/O to the Ethernet Port on the Controller . . . . 121

Add Remote I/0 to a Local Communication Module . . . . . . . . 123

Add to the I/O Configuration While Online . . . . . . . . . . . . . . . . . . . 127

Modules and Devices that Can be Added While Online . . . . . 128

Determine When Data is Updated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Input Data Update Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Output Data Update Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Chapter 9

Add Safety I/O Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Configure Safety I/O Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Using Network Address Translation (NAT) with

CIP Safety Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Set the SNN of a Safety I/O Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Change a Safety I/O Device SNN. . . . . . . . . . . . . . . . . . . . . . . . . . 136

Copy and Paste a Safety I/O Device SNN . . . . . . . . . . . . . . . . . . 138

Connection Reaction Time Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Safety I/O Device Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Configuration via the Logix Designer Application. . . . . . . . . . . 141

Different Configuration Owner (data-only connection) . . . . . 142

Reset Safety I/O Device to Out-of-box Condition. . . . . . . . . . . 143

I/O Device Address Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Monitor Safety I/O Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Replace a Safety I/O Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Configuration Ownership. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Replacement Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Replacement with ‘Configure Only When No Safety Signature

Exists’ Enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Replacement with ‘Configure Always’ Enabled. . . . . . . . . . . . . . 152

Chapter 10

Develop Standard Applications

6 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Elements of a Control Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Task Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Scheduled and Unscheduled Programs . . . . . . . . . . . . . . . . . . . . . 159

Routines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Parameters and Local Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Program Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Page 7

Develop Safety Applications

Table of Contents

Programming Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Extended Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Access the Module Object from an Add-On Instruction . . . . . . . . . 165

Monitor Controller Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Monitor I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Determine If I/O Communication Has Timed Out . . . . . . . . . 167

Determine if I/O Communication to a Specific I/O Module

has Timed Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Automatic Handling of I/O Module Connection Faults . . . . . 168

Sample Controller Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Chapter 11

Safety Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Safety Task Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Safety Task Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Safety Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Safety Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Safety Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Safety Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Valid Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Program Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Produced/Consumed Safety Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Configure the SNN for a Peer Safety Controller Connection. 178

Produce a Safety Tag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Consume Safety Tag Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Safety Tag Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Create Tag Mapping Pairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Monitor Tag Mapping Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Safety Application Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Safety-lock the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Set Passwords for Safety-locking and Unlocking. . . . . . . . . . . . . 191

Generate a Safety Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Programming Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Monitor Safety Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

View Status via the Online Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

View Status via the Safety Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Monitor Safety Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Utilizing Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Safety Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Nonrecoverable Controller Faults. . . . . . . . . . . . . . . . . . . . . . . . . . 201

Nonrecoverable Safety Faults in the Safety Application . . . . . . 201

Recoverable Faults in the Safety Application . . . . . . . . . . . . . . . . 202

View Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 7

Page 8

Table of Contents

Develop Secure Applications

Develop a Fault Routine for Safety Applications . . . . . . . . . . . . . . . . 204

Use GSV/SSV Instructions in a Safety Application. . . . . . . . . . . . . . 205

Chapter 12

Controller Security Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

System-level Security Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Controller-specific Security Features . . . . . . . . . . . . . . . . . . . . . . . 211

Verification of Security Implementation. . . . . . . . . . . . . . . . . . . . 212

Configure Trusted Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Configure User-definable Major Faults. . . . . . . . . . . . . . . . . . . . . . . . . 214

Create a Fault Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Configure the Program to Use the Fault Routine. . . . . . . . . . . . 214

Jump to the Fault Routine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

License-based Source and Execution Protection. . . . . . . . . . . . . . . . . 216

Enable License-based Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Configure Change Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Controller Audit Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Disable the Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Disable the Ethernet Port on the Port Configuration Tab. . . . 222

Disable the Ethernet Port with a MSG Instruction . . . . . . . . . . 223

Disable the CIP Security Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Disable the USB Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Disable the SD Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Disable the 4-character Status Display. . . . . . . . . . . . . . . . . . . . . . . . . . 232

Disable All Categories of Messages . . . . . . . . . . . . . . . . . . . . . . . . . 232

Disable Individual Categories of Messages . . . . . . . . . . . . . . . . . . 234

Disable the Controller Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Studio 5000 Logix Designer Application Version 33.00.00

and Later . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Studio 5000 Logix Designer Application Version 32.00.00 or Earlier

236

Controller Web Page Default Settings. . . . . . . . . . . . . . . . . . . . . . 237

Use a CIP Generic MSG to Disable the Controller Web Pages 238

Use a CIP Generic MSG to Enable the Controller Web Pages 240

Chapter 13

Develop Motion Applications

Motion Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Program Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Obtain Axis Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Chapter 14

Troubleshoot the Controller

8 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Automatic Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Considerations for Communication Loss Diagnostics . . . . . . . . . . . 250

Controller Diagnostics with Logix Designer . . . . . . . . . . . . . . . . . . . . 251

I/O Module Properties Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Notification in the Tag Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Page 9

Table of Contents

Enable Major Fault on Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Port Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Advanced Time Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Controller Diagnostics with Linx-based Software . . . . . . . . . . . . . . . 260

Controller Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Home Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Faults Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Tasks Webpage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Browse Chassis Webpage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Appendix A

Status Indicators

Change Controller Type

Status Display and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

General Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

GuardLogix Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Safety Partner Status Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Major Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

I/O Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Controller Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

RUN Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

FORCE Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

SD Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

OK Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Safety Partner OK Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

EtherNet/IP Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Thermal Monitoring and Thermal Fault Behavior . . . . . . . . . . . . . . 277

Appendix B

Change from a Standard to a Safety Controller . . . . . . . . . . . . . . . . . 279

Change from a Safety to a Standard Controller . . . . . . . . . . . . . . . . . 280

Change Safety Controller Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 9

Page 10

Table of Contents

Notes:

10 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 11

Preface

Catalog Numbers

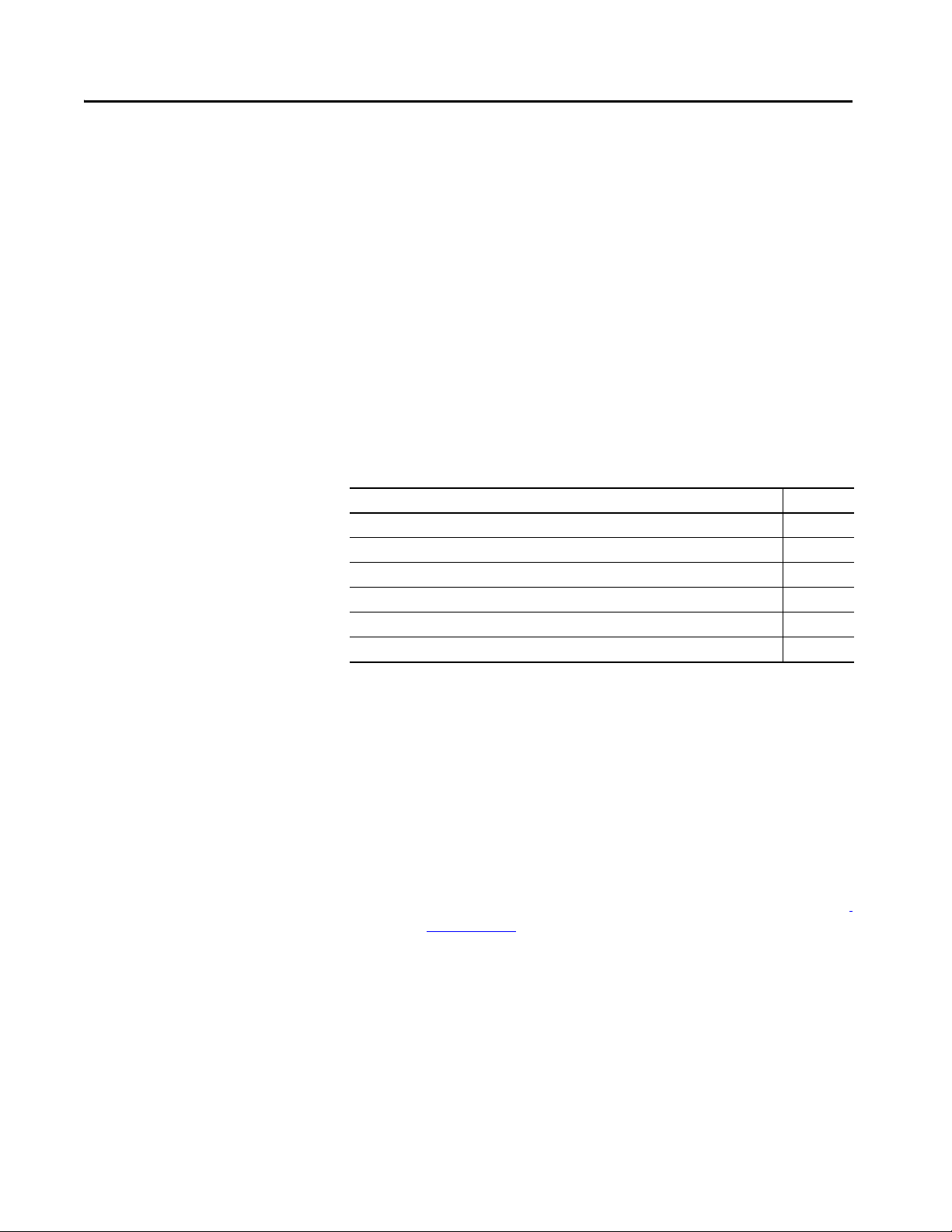

This publication is applicable to these controllers:

Standard Catalog Numbers: 1756-L81E, 1756-L81EK, 1756-L82E, 1756-L82EK, 1756-L83E, 1756-L83EK, 1756-L84E,

1756-L84EK, 1756-L85E, 1756-L85EK

No Stored Energy (NSE) Catalog Numbers: 1756-L81E-NSE, 1756-L82E-NSE, 1756-L83E-NSE, 1756-L84E-NSE, 1756-L85E-NSE

ControlLogix-XT Catalog Numbers: 1756-L81EXT, 1756-L82EXT, 1756-L83EXT, 1756-L84EXT, 1756-L85EXT

Process Catalog Numbers: 1756-L81EP, 1756-L83EP, 1756-L85EP

GuardLogix Catalog Numbers 1756-L81ES, 1756-L81ESK, 1756-L82ES, 1756-L82ESK, 1756-L83ES, 1756-L83ESK,

1756-L84ES, 1756-L84ESK, 1756-L8SP, 1756-L8SPK

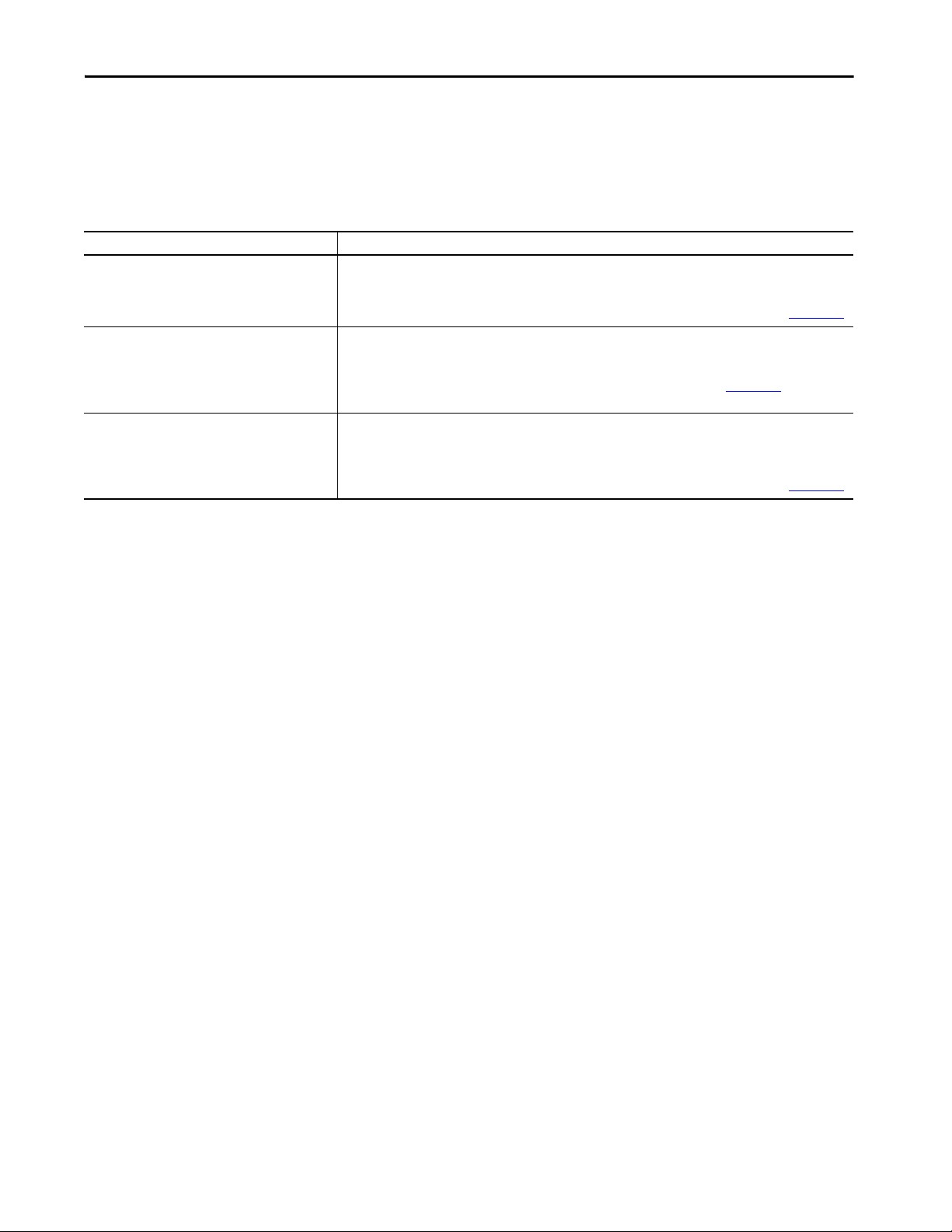

Summary of Changes

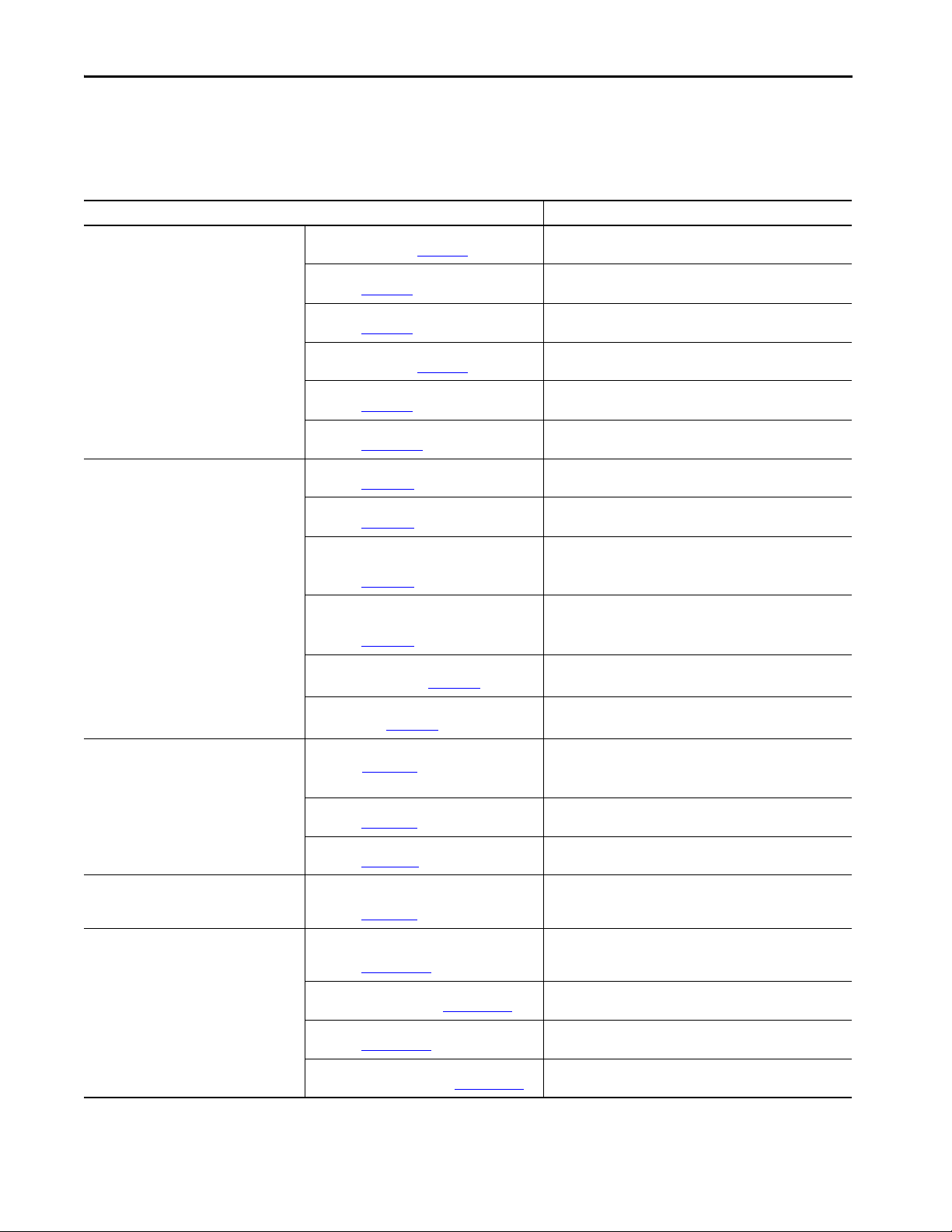

This manual contains new and updated information as indicated in the

following table.

Top ic Pag e

Added ControlLogix NSE, ControlLogix-XT, and ControlLogix Process controllers. Throughout.

Updated safety signature definition. 30

Updated behavior of controller status indicators while loading a project from the SD card. 100

Added Simple Network Management Protocol (SNMP). 109

Added Automatic Diagnostics. 249

Added Considerations for Communication Loss Diagnostics. 250

Overview

This manual provides information about designing a system, operating a

ControlLogix® or GuardLogix®-based controllers system, and developing

applications.

You must be trained and experienced in the creation, operation, and

maintenance of safety systems.

For information on Safety Integrity Level (SIL) and Performance Level (PL)

requirements and safety application requirements, see the GuardLogix 5580

and Compact GuardLogix 5380 Controller Systems Safety Reference Manual,

publication 1756-RM012.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 11

Page 12

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Table 1 - Additional Resources

Resource Description

Hardware Installation ControlLogix 5580 Controllers Installation

Technical Data 1756 ControlLogix Controllers Technical Data,

Networks (ControlNet, DeviceNet, EtherNet/IP) EtherNet/IP Network Devices User Manual,

Safety application requirements GuardLogix 5580 and Compact GuardLogix 5380

Motion Integrated Motion on the EtherNet/IP Network

Instructions, publication 1756-IN043

GuardLogix 5580 Controllers Installation Instructions,

publication 1756-IN048

ControlLogix Power Supply Installation Instructions,

publication 1756-IN619

ControlLogix Redundant Power Supply Installation

Instructions, publication 1756-IN620

ControlLogix Chassis Installation Instructions,

publication 1756-IN621

Replacement door labels for the 1756 I/O modules,

publication IASIMP-SP021

publication 1756-TD001

1756 ControlLogix I/O Specifications Technical Data,

publication 1756-TD002

1756 ControlLogix Communications Modules

Specifications Technical Data,

publication 1756-TD003

1756 ControlLogix Integrated Motion Modules

Specifications Technical Data,

publication 1756-TD004

1756 ControlLogix Power Supplies Specifications

Technical Data, publication 1756-TD005

1756 ControlLogix Chassis Specifications Technical

Data, publication 1756-TD006

publication ENET-UM006

ControlNet Network Configuration User Manual,

publication CNET-UM001

DeviceNet Media Design Installation Guide,

publication DNET-UM072

Controller Systems Safety Reference Manual,

publication 1756-RM012

Configuration and Startup User Manual,

publication MOTION-UM003

Integrated Motion on the EtherNet/IP Network

Reference Manual, publication MOTION-RM003

Motion Coordinate System User Manual,

publication MOTION-UM002

SERCOS and Analog Motion Configuration and

Startup User Manual, publication MOTION-UM001

Provides installation instructions for ControlLogix 5580 controllers.

Provides installation instructions for GuardLogix 5580 controllers.

Describes how to install standard power supplies.

Describes how to install redundant power supplies.

Describes how to install ControlLogix chassis.

Contains door labels for the 1756 I/O modules that are available to

print.

Provides specifications for ControlLogix controllers.

Provides specifications for ControlLogix I/O modules.

Provides specifications for ControlLogix Communications Modules.

Provides specifications for ControlLogix Integrated Motion Modules.

Provides specifications for ControlLogix Power Supplies.

Provides specifications for ControlLogix Chassis.

Describes how to configure and use EtherNet/IP™ devices with a Logix

5000™ controller and communicate with various devices on the

Ethernet network.

Provides information about ControlNet® networks.

Provides information about DeviceNet® networks.

Contains detailed requirements for achieving and maintaining

SIL 2/PLd and SIL 3/PLe with the GuardLogix 5580 controller system,

using the Studio 5000 Logix Designer® application.

Details how to design your ControlLogix system for Integrated Motion

on the EtherNet/IP network applications.

Detailed information on axis control modes and attributes for

Integrated Motion on EtherNet/IP networks.

Details how to create and configure a coordinated motion application

system.

Details how to configure a Sercos motion application system.

12 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 13

Table 1 - Additional Resources (continued)

Resource Description

Design Considerations Logix 5000 Controllers Design Considerations

Reference Manual, publication 1756-RM094

High Availability System Reference Manual,

publication HIGHAV-RM002

Ethernet Design Considerations Reference Manual,

publication ENET-RM002

FOUNDATION Fieldbus Design Considerations

Reference Manual, PROCES-RM005

Using Logix 5000 Controllers as Masters or Slaves on

Modbus Application Solution, publication CIG-AP129

Programming Tasks and Procedures Logix 5000 Controllers Common Procedures

Programming Manual, publication 1756-PM001

Logix 5000 Controllers General Instructions

Reference Manual, publication 1756-RM003

GuardLogix Safety Application Instruc tion Set

Reference Manual, publication 1756-RM095

Product Certifications Product Certifications website,

https://www.rockwellautomation.com/global/

certification/overview.page

Provides information to help design and plan Logix 5000 systems.

Provides information to help design and plan high availability

systems.

Provides additional information about network design for your

system.

This document provides design choices and best practices for

implementing a FOUNDATION Fieldbus network with the

1788-EN2FFR or 1788-CN2FFR linking devices.

For more information about using Modbus sample programs.

Provides access to the Logix 5000 Controllers set of programming

manuals. The manuals cover such topics as how to manage project

files, organize tags, program logic, test routines, handle faults, and

more.

Provides information on the programming instructions available to

use in Logix Designer application projects.

Provides information on the GuardLogix Safety application instruction

set.

Provides declarations of conformity, certificates, and other

certification details.

Preface

You can view or download publications at rok.auto/literature.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 13

Page 14

Notes:

Preface

14 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 15

Chapter 1

ControlLogix and GuardLogix Systems

This chapter describes features and functions that are associated with the

ControlLogix® 5580 and GuardLogix® 5580 controllers.

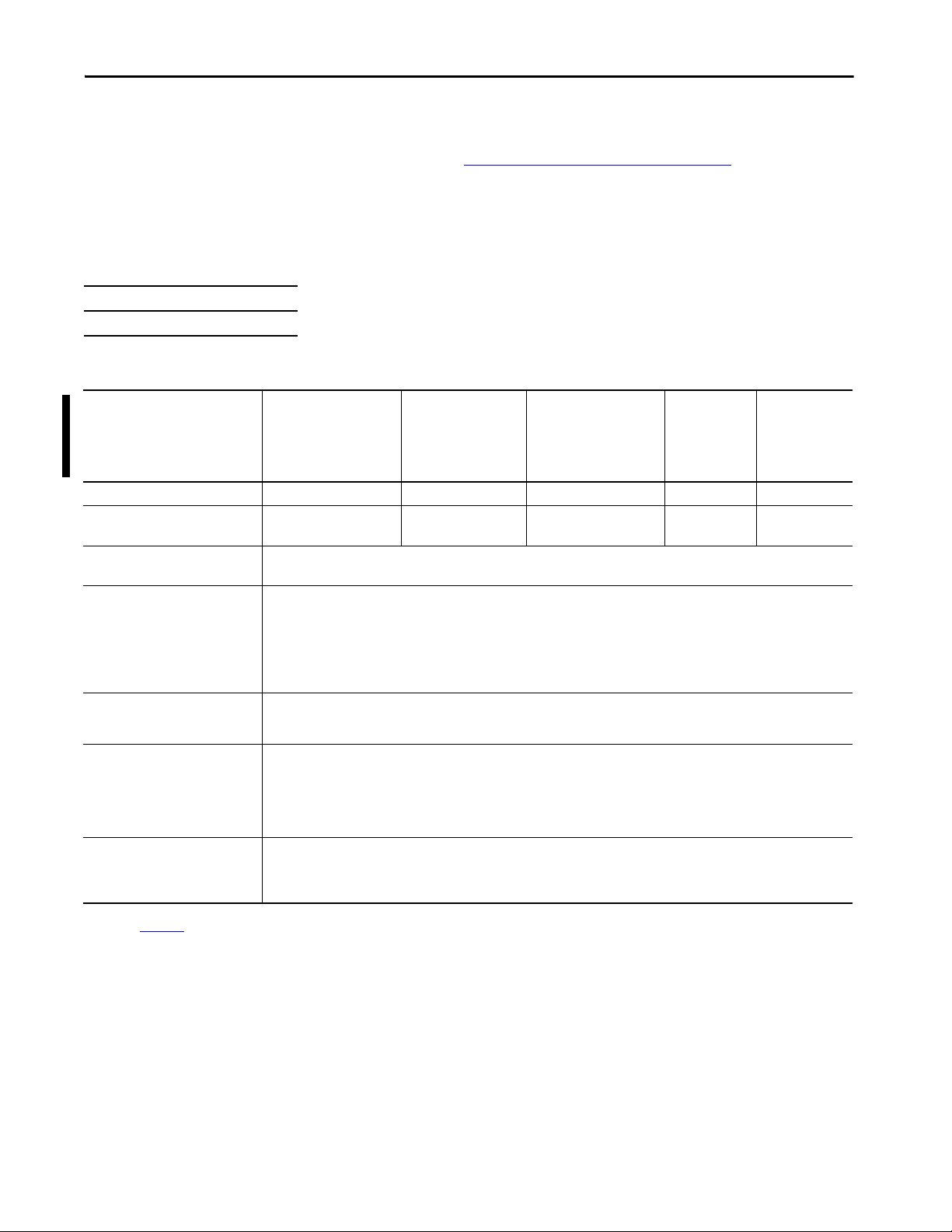

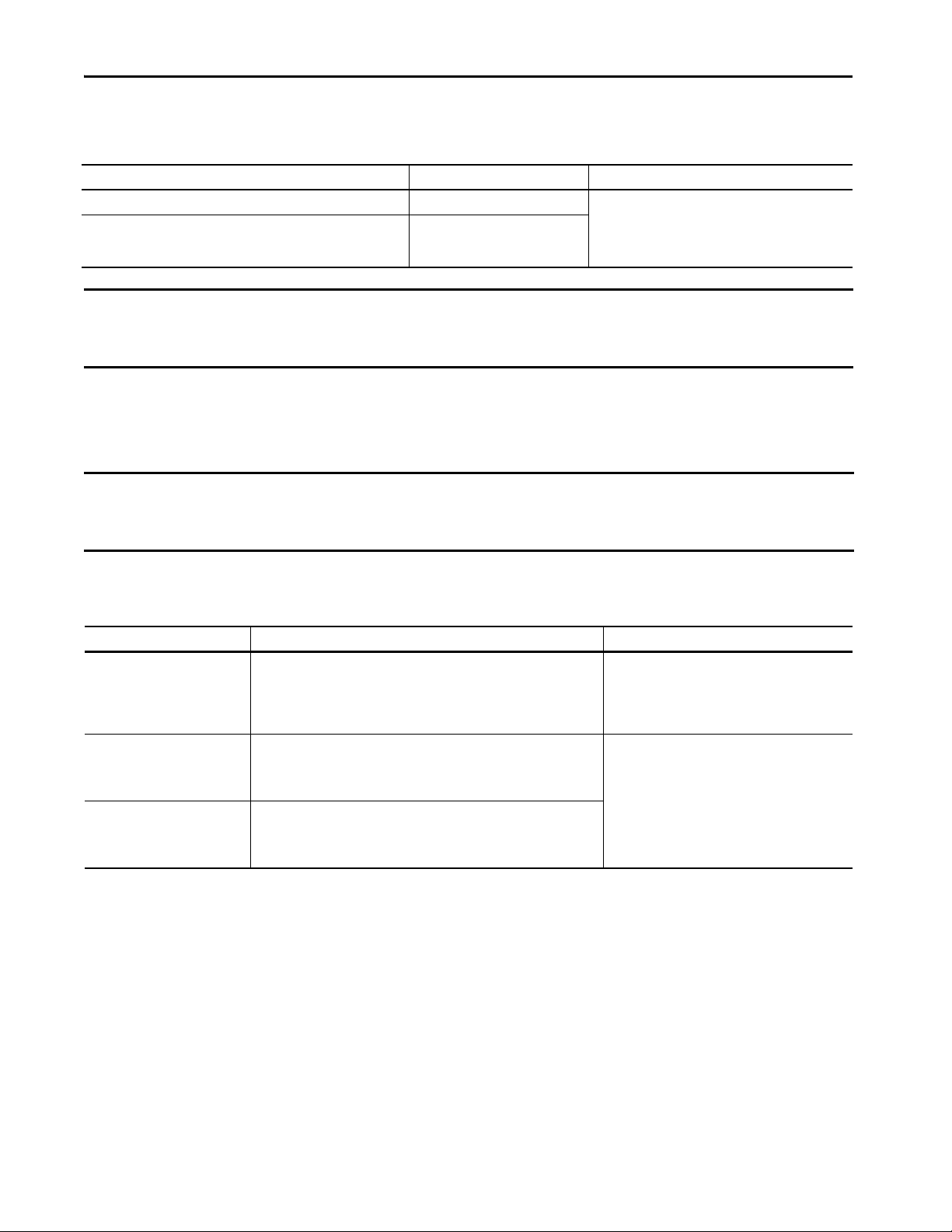

Top ic Pag e

Minimum Requirements 15

ControlLogix System 18

GuardLogix System 21

Design the System 24

CIP Security 24

Secure Controller Systems 25

ControlLogix 5580 Controller Features 25

Minimum Requirements

Applies to these controllers:

ControlLogix 5580

GuardLogix 5580

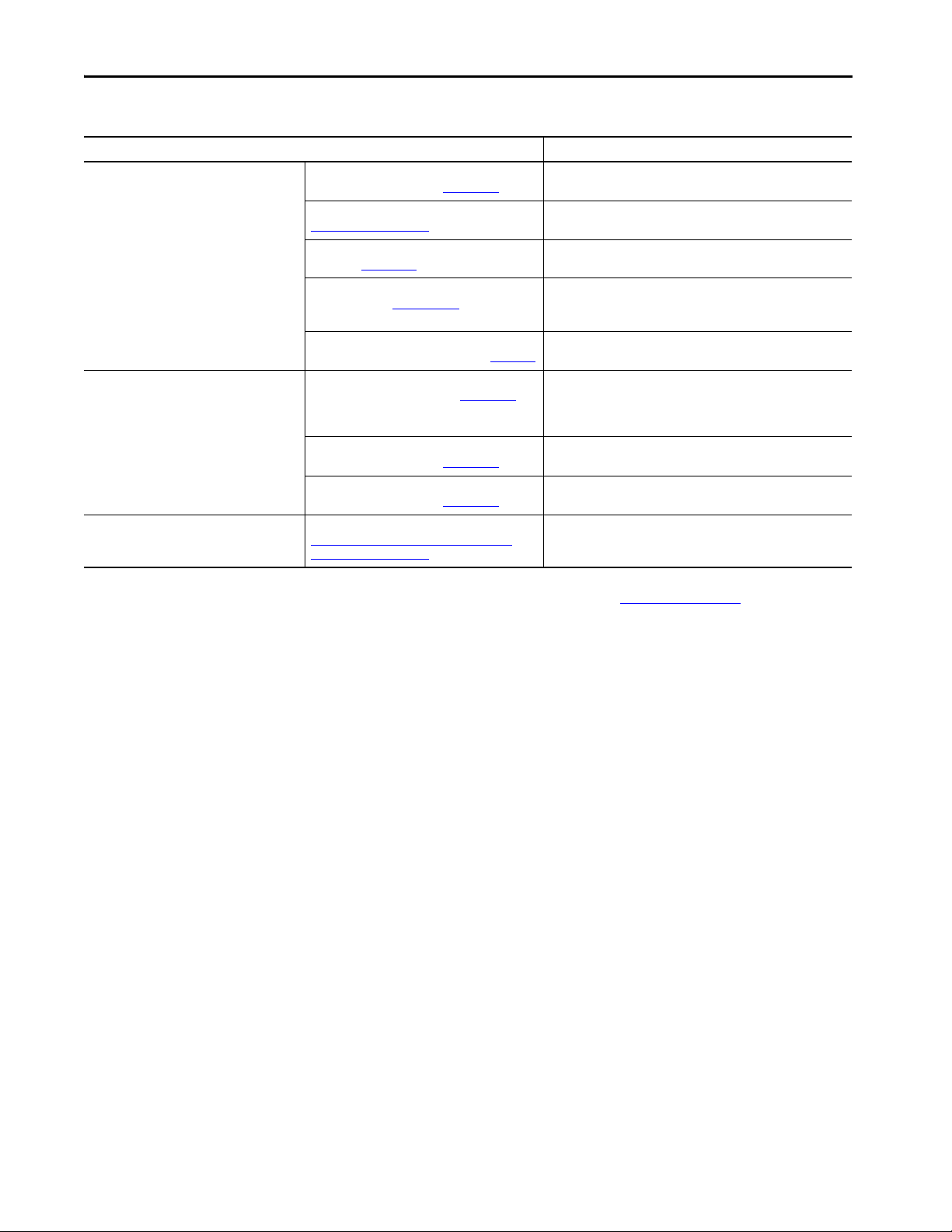

The controllers have these minimum requirements.

• ControlLogix Chassis, Series C (Series B chassis function within a

derated temperature range)

• ControlLogix Chassis Power Supply

• Programming software

System Cat. No. Studio 5000 Logix Designer®

ControlLogix 1756-L83E, 1756-L83EK

1756-L81E, 1756-L81EK, 1756-L82E, 1756-L82EK,

1756-L84E, 1756-L84EK

1756-L81E-NSE, 1756-L82E-NSE, 1756-L83E-NSE,

1756-L84E-NSE, 1756-L85E-NSE, 1756-L81EXT,

1756-L82EXT, 1756-L83EXT, 1756-L84EXT, 1756-L85EXT,

1756-L81EP, 1756-L83EP, 1756-L85EP

GuardLogix 1756-L81ES, 1756-L81ESK, 1756-L82ES, 1756-L82ESK,

1756-L83ES, 1756-L83ESK, 1756-L84ES,1756-L84ESK,

1756-L8SP, 1756-L8SPK

(1) Catalog numbers followed by a “K” indicate a conformal coating option.

(2) For compatible Linx-based communication software, and ControlFLASH Plus™ and ControlFLASH™ software, see the

Product Compatibility and Download Center (PCDC)

(3) Studio 5000 Logix Designer Professional, Full Edition, or a separately licensed GuardLogix Safety Editor must be present on the

workstation in order to edit a GuardLogix project.

(1)

, 1756-L85E, 1756-L85EK

.

Version 28.00.00 or later

Version 29.00.00 or later

Version 33.00.00 or later

Version 31.00.00 or later

(2)

(3)

IMPORTANT If safety connections or safety logic are required for your application, then

you must use a GuardLogix 5580 controller.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 15

Page 16

Chapter 1 ControlLogix and GuardLogix Systems

ControlLogix Controllers

The controllers are available with different functionality based on your

application.

ControlLogix No Stored Energy (NSE) Controllers

The NSE controller is intended for use in applications that require the installed

controller to deplete its residual stored energy to specific levels before

transporting it into or out of your application.

The residual stored energy of the NSE controller depletes to 400μJ or less in 40

seconds.

WARNING: If your application requires the NSE controller to deplete its

residual stored energy to 400 µJ or less before you transport it into or out of

the application, complete these steps before you remove the controller.

1. Turn off power to the chassis.

After you turn off power, the controller’s OK status indicator transitions

from Green to Solid Red to OFF.

2. Wait at least 40 seconds for the residual stored energy to decrease to

400 µJ or less before you remove the controller.

There is no visual indication of when the 40 seconds has expired. You m ust

track that time period.

IMPORTANT The Real Time Clock (RTC) does not retain its time and date when the power

is off.

Some applications require that the installed controller to deplete its residual

stored energy to specific levels before transporting it into or out of your

application. This requirement can include other devices that also require a wait

time before removing them. See the documentation of those products for more

information.

ControlLogix-XT Controllers

The ControlLogix-XT ™ (Extended Temperature) controllers function in the

same way as the traditional ControlLogix controllers, with an extended

temperature range, and have the same features as the ControlLogix standard

controllers.

The ControlLogix-XT controllers are conformal coated to add a layer of

protection when exposed to harsh, corrosive environments. While the standard

ControlLogix system can withstand temperatures from 0…60 °C (33…140 °F),

the ControlLogix-XT system can withstand temperatures from -25…+70 °C

(-13…+158 °F).

16 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 17

ControlLogix and GuardLogix Systems Chapter 1

Process Controllers

The process controller is an extension of the Logix 5000 controller family that

focuses on plantwide process control. The process controller comes configured

with a default process tasking model and dedicated PlantPAx process

instructions optimized for process applications and that improve design and

deployment efforts.

The ControlLogix process controller hardware is also conformal coated to add

a layer of protection when exposed to harsh, corrosive environments, and can

be used in temperature extremes from -25…+70 °C (-13…+158 °F) when

deployed as part of a Logix-XT system.

Conformal Coated Products

ATT EN TI ON : Conformal coated products are shipped with port protection

plugs installed to provide a layer of protection from corrosive environments.

In order to meet the corrosive atmosphere rating of the product, port plugs

need to be installed in unused ports at all times during storage and

operation. If temporary access is required, plugs can be removed, and should

be reinserted after temporary access is complete.

ControlLogix Redundant Controllers

You can use ControlLogix 5580 controllers in redundant applications with the

Studio 5000 Logix Designer application, version 33.00.00 or later.

For information, see these publications:

• High Availability System Reference Manual, publication

HIGHAV-RM002

• ControlLogix 5580 Redundant Controller User Manual, publication

1756-UM015

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 17

Page 18

Chapter 1 ControlLogix and GuardLogix Systems

ControlLogix System

Applies to these controllers:

ControlLogix 5580

The ControlLogix system is chassis-based, which provides options for

configuring a variety of communications and I/O capabilities. The

ControlLogix controllers support multiple programming languages that enable

sequential, process, motion, and drive control.

A variety of system configuration options are described in the following

sections.

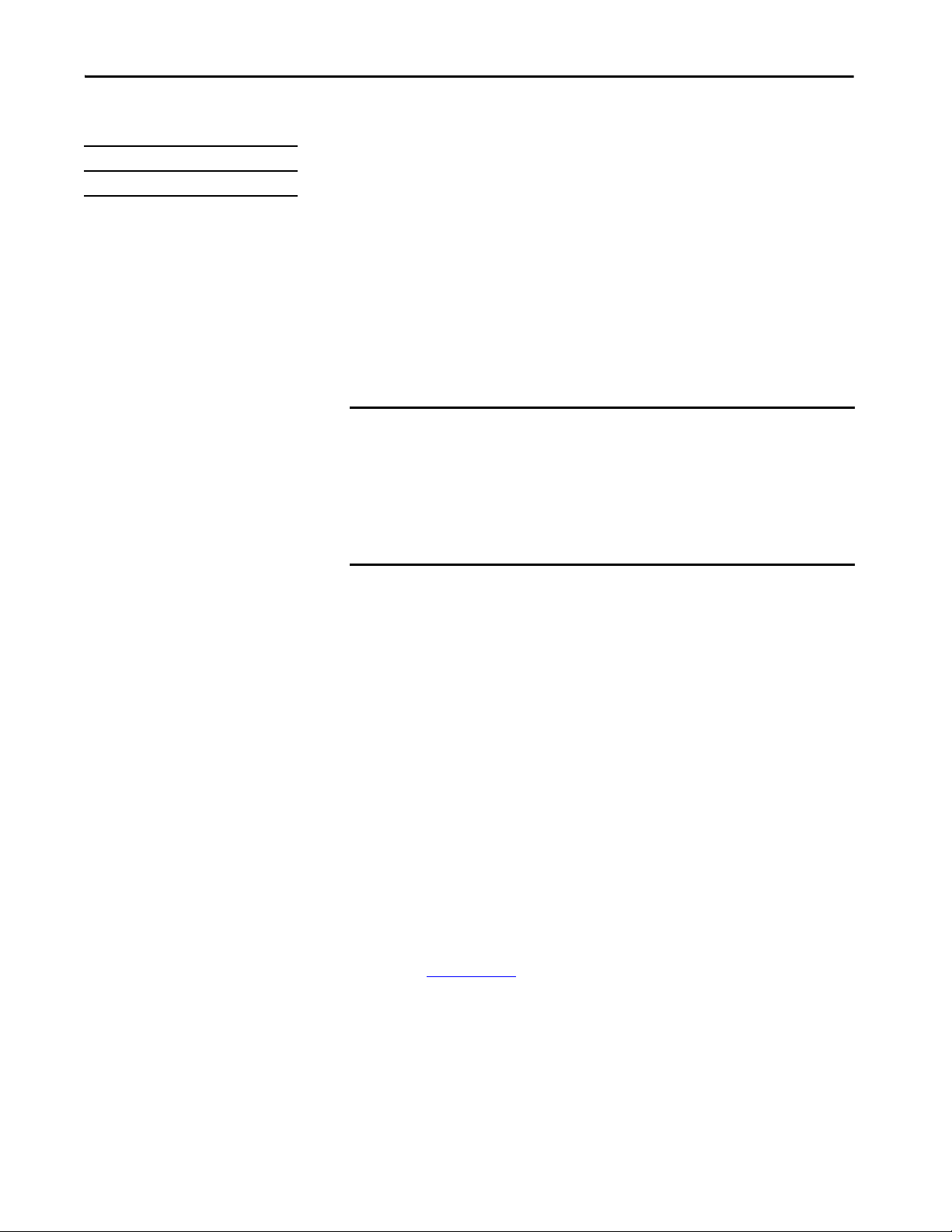

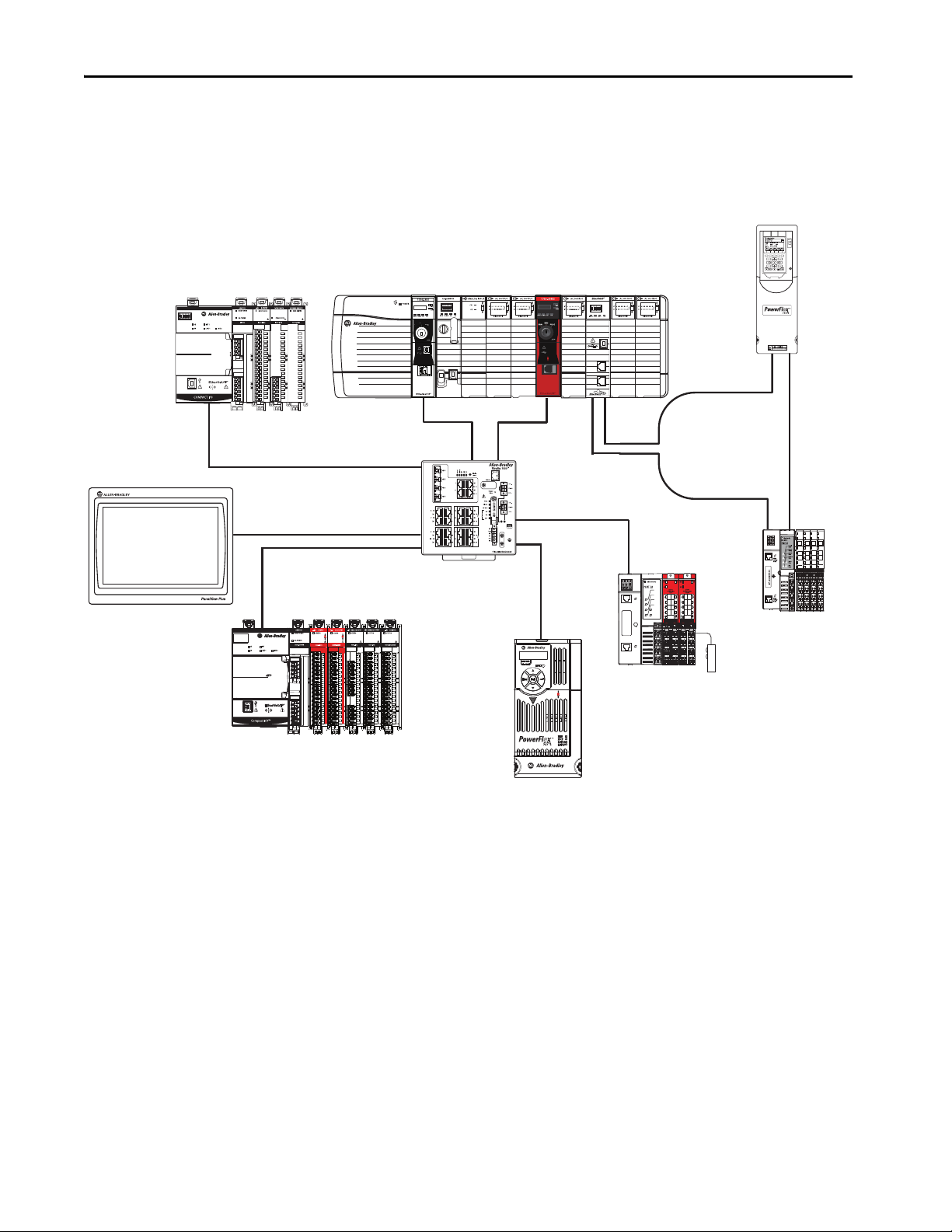

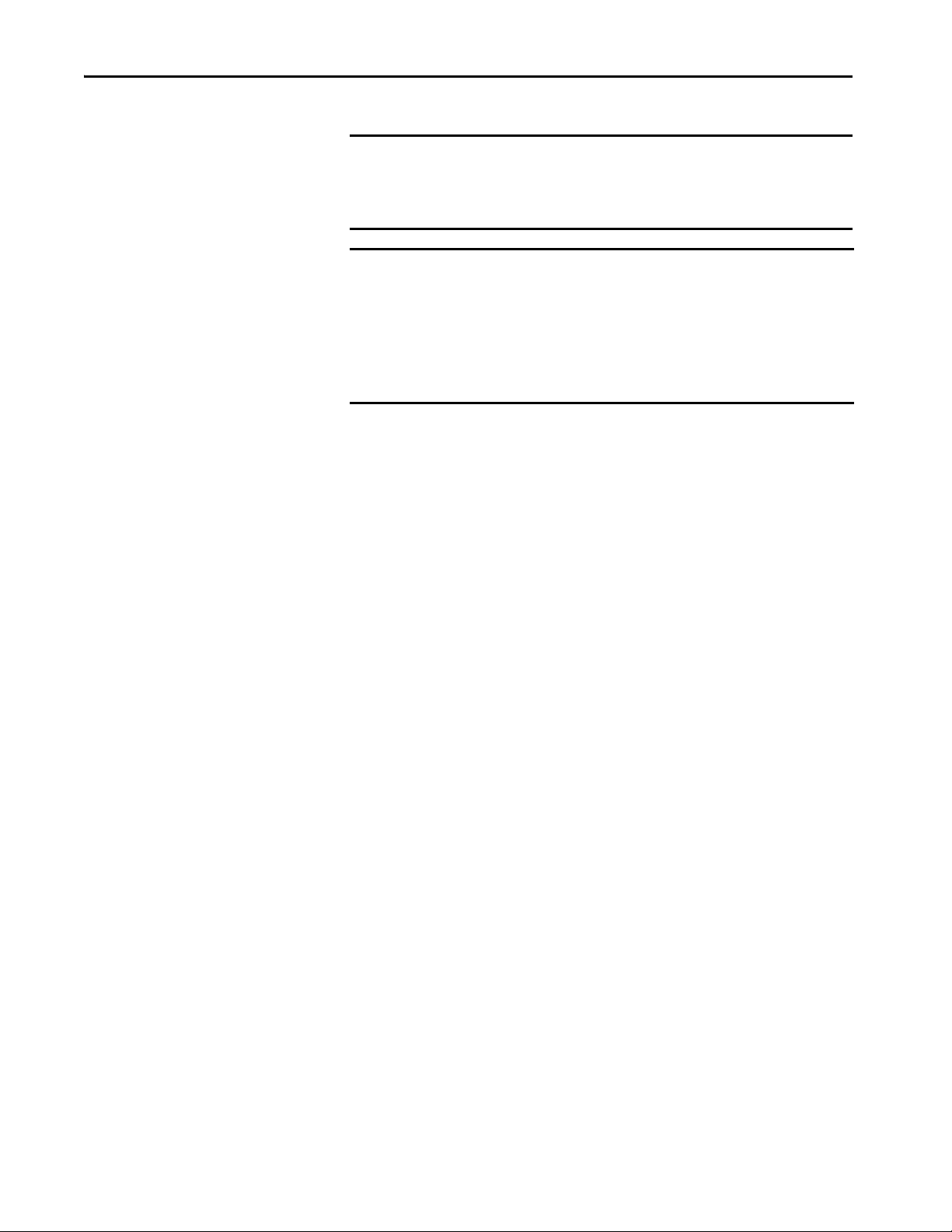

Standalone Controller and I/O

One of the simplest controller configurations is a standalone controller with

I/O assembled in one chassis.

Figure 1 - Standalone Controller and I/O

18 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 19

ControlLogix and GuardLogix Systems Chapter 1

Panel View™ Pl us 7

Stratix® 5400

5069-AEN2TR

Compact 5000 Safety I/O Modules

Compact 5000 I/O Modules

PowerFlex® 755 Drive

1 Gbps

1 Gbps

100 Mbps

100 Mbps

1734-AENTR

1734 POINT I/O™

100 Mbps

1734-AENTR EtherNet/IP Adapter

1734 POINT Guard I/O™

Safety Device

1 Gbps

PowerFlex 527 Drive

(CIP Safety™ enabled)

100 Mbps

1 Gbps

5069-AEN2TR

Compact 5000™ I/O modules

1756-EN2TR

1756-L84ES

1756-L85E

1756-L72

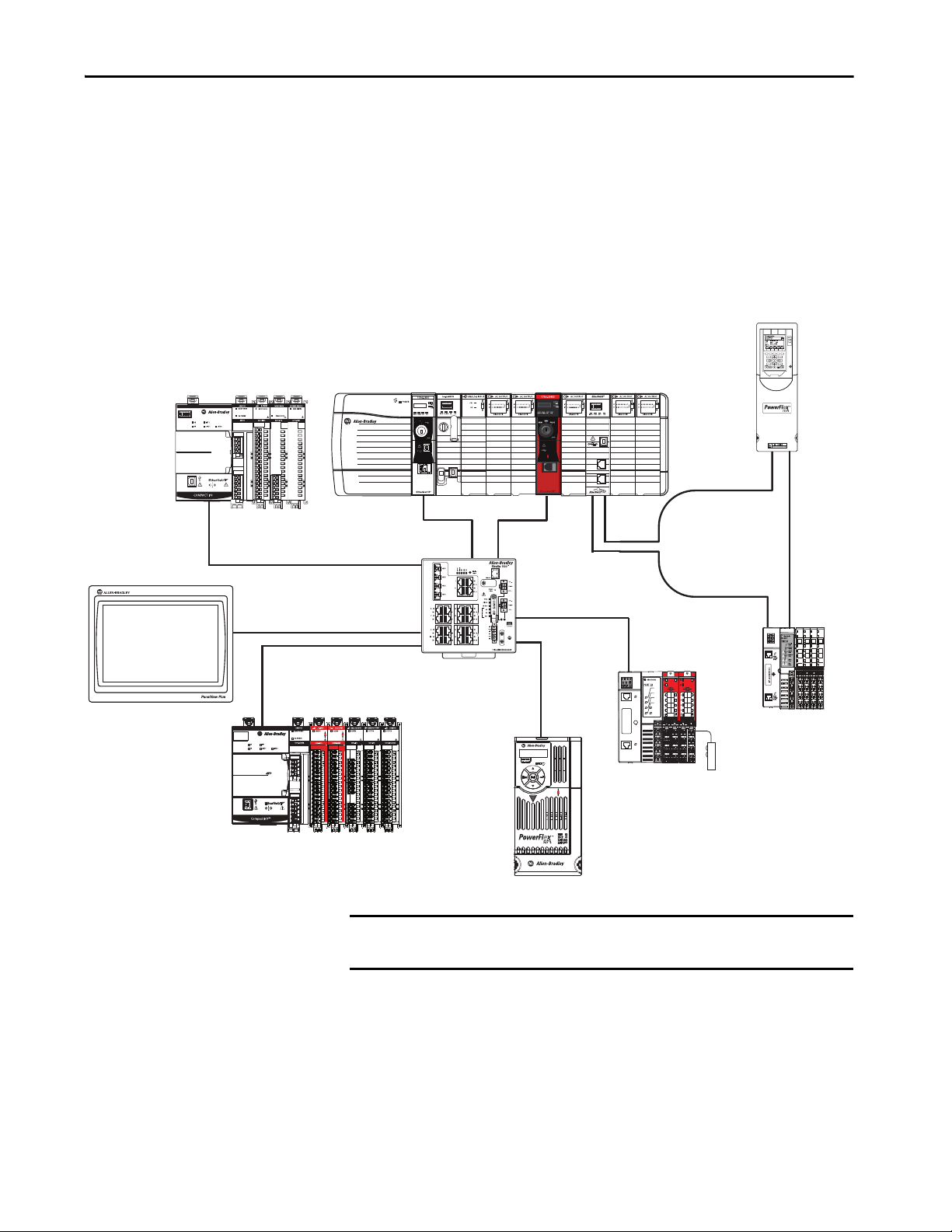

Multiple Controllers in One Chassis

You can use multiple controllers in one ControlLogix chassis. This example

shows a ControlLogix 5580 controller (slot 0) connected directly to the

EtherNet/IP™ network, a ControlLogix 5570 controller (slot 1) connected to

the network through a 1756-EN2TR module (slot 7), and a GuardLogix 5580

controller in a SIL 2/PLd configuration (slot 5) connected directly to the

EtherNet/IP Network.

Figure 2 - Multiple Controllers in One Chassis

IMPORTANT You cannot bridge through the Ethernet (front) port of another controller to

add remote I/O.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 19

Page 20

Chapter 1 ControlLogix and GuardLogix Systems

PowerFlex Drive

DeviceNet

FLEX™ I/O

Control Net

Ethernet Device-level

Ring Network

Ethernet

HART

Endress + Hauser Flowmeters

Fac toryTa lk® Ser ver

POINT I/O

1756-L85E

1756-DNB

1756-CN2R

1756-EN2TR

1756-EN2T

1756-IF8H

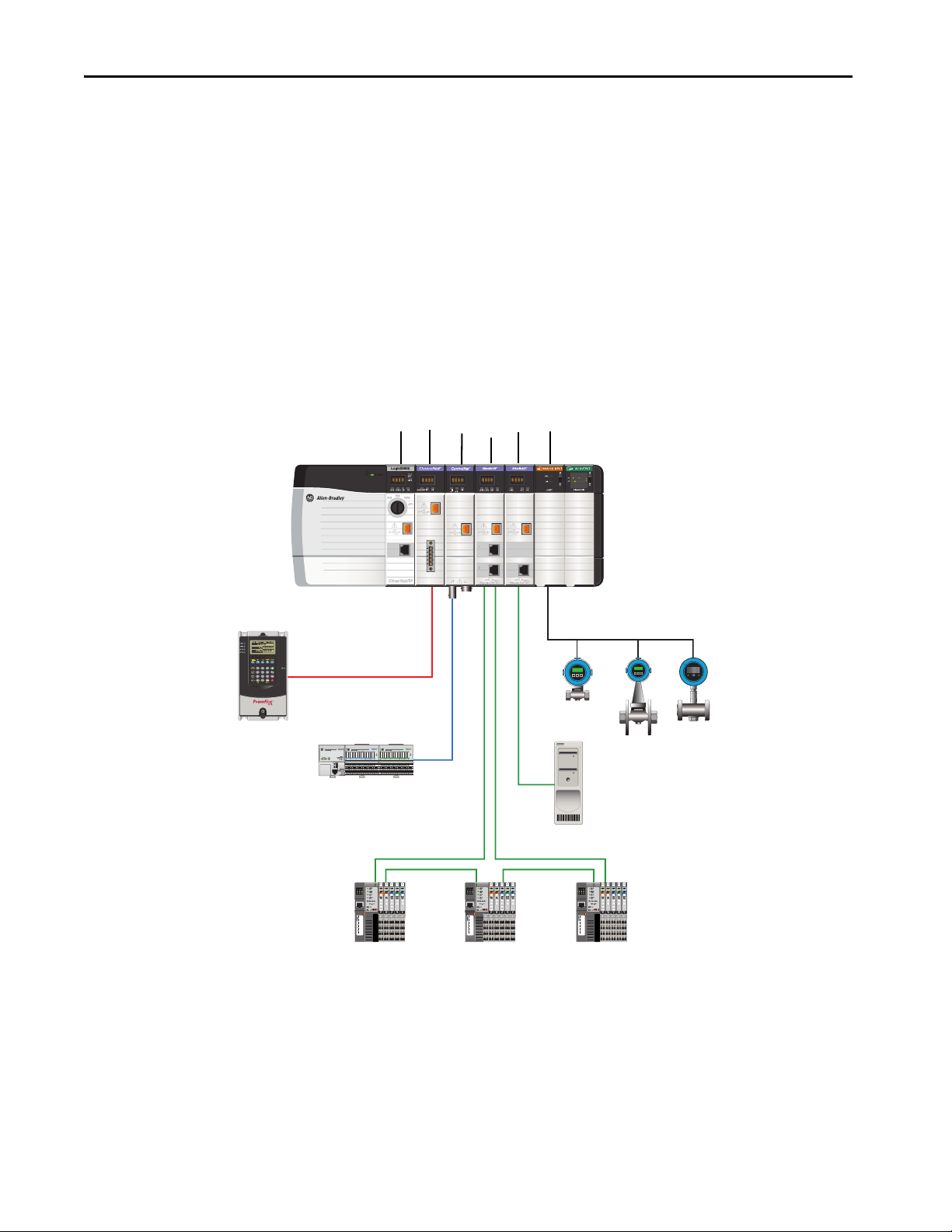

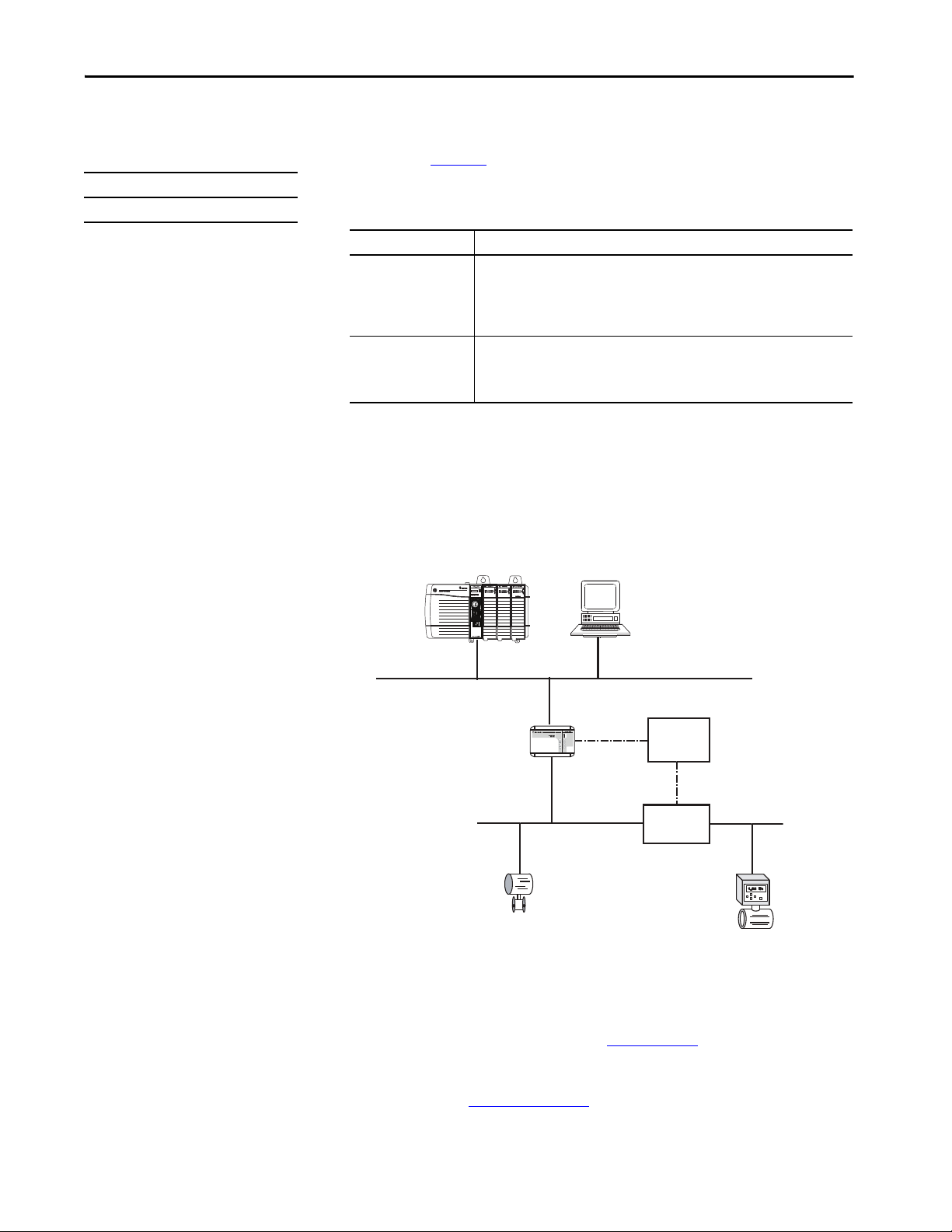

Multiple Devices Connected via Multiple Networks

For some applications, various devices can be connected to the ControlLogix

chassis via multiple communication networks. For example, a system can be

connected to the following:

• Distributed I/O via an Ethernet network

• A PowerFlex drive connected via a DeviceNet® network

• Distributed I/O via a ControlNet® network.

• Flowmeters that are connected via a HART connection

Figure 3 - Multiple Devices Connected Via Multiple Networks

20 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 21

ControlLogix and GuardLogix Systems Chapter 1

GuardLogix System

Applies to these controllers:

GuardLogix 5580

The GuardLogix system can communicate with safety I/O devices via

CIP Safety over an EtherNet/IP network (Guard I/O™ modules, integrated

safety drives, integrated safety components).

For a GuardLogix controller, you can interface to local standard I/O in the

backplane via standard tasks while you interface with remote safety I/O

through the EtherNet/IP port.

The GuardLogix system supports up to SIL 3 and PLe safety applications.

• Without a safety partner installed, you can achieve SIL 2/PLd

(Category 3) with the use of the safety task and safety I/O.

• With the use of the safety task and a safety partner installed, you can

achieve SIL 3/PLe (Category 4) capability.

IMPORTANT For the safety task, GuardLogix controllers support Ladder Diagram only.

For standard tasks, GuardLogix controllers support:

• Ladder Diagram (LD)

• Structured Text (ST)

• Function Block Diagram (FBD)

• Sequential Function Chart (SFC)

For SIL 3 safety applications, the GuardLogix system is composed of a primary

GuardLogix controller and a safety partner that function together in a 1oo2

architecture.

• The primary controller is the processor that performs standard and

safety functions and communicates with the safety partner for safetyrelated functions in the GuardLogix control system.

• The safety partner is a co-processor that provides an isolated second

channel for safety-related functions in the system. The safety partner

does not have a key switch or communication port. The primary

controller controls the configuration and operation of the safety partner.

• The safety partner must be installed in the slot immediately to the right

of the primary controller. The firmware major and minor revisions of

the primary controller and safety partner must match exactly to establish

the control partnership that is required for safety applications

For information on Safety Integrity Level (SIL) and Performance Level (PL)

requirements and safety application requirements, see the GuardLogix 5580

and Compact GuardLogix 5380 Controller Systems Safety Reference Manual,

publication 1756-RM012

.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 21

Page 22

Chapter 1 ControlLogix and GuardLogix Systems

MOD

NET

MOD

NET

MOD

NET

MOD

NET

2

1

1

1

4

I/O

I/O

6

5

10

2

1

2

1

2

1

1

I/O-A

6

510

1

I/O-B

6

510

1

I/O-A61I/O-B

6

510510

UFB

UFB-A UFB-B

UFB-A UFB-B

D+D-D+

D-

D+

D-

MF-A MF-B MF-A MF-B

D+

D-

MBRK

+

-

5069-IB8S

5069-OBV8S

GuardLogix 5580 Safety Controller

GuardLogix 1756-L8SP Safety Partner

Studio 5000 Logix Designer

Application

(version 31.00 or later)

Kinetix® 5700 Servo Drive System

Digital Inputs to Sensors and Control String

Kinetix VP

Servo Motors

2198-CAPMOD-2240

Capacitor Module

(optional component)

1783-BMS

Stratix 5700 Switch

Module Definition

Configured with

Motion and Safety

Conne ction

5069-AEN2TR

Compact 5000 Safety I/O modules

Compact 5000 I/O modules

Safety Device

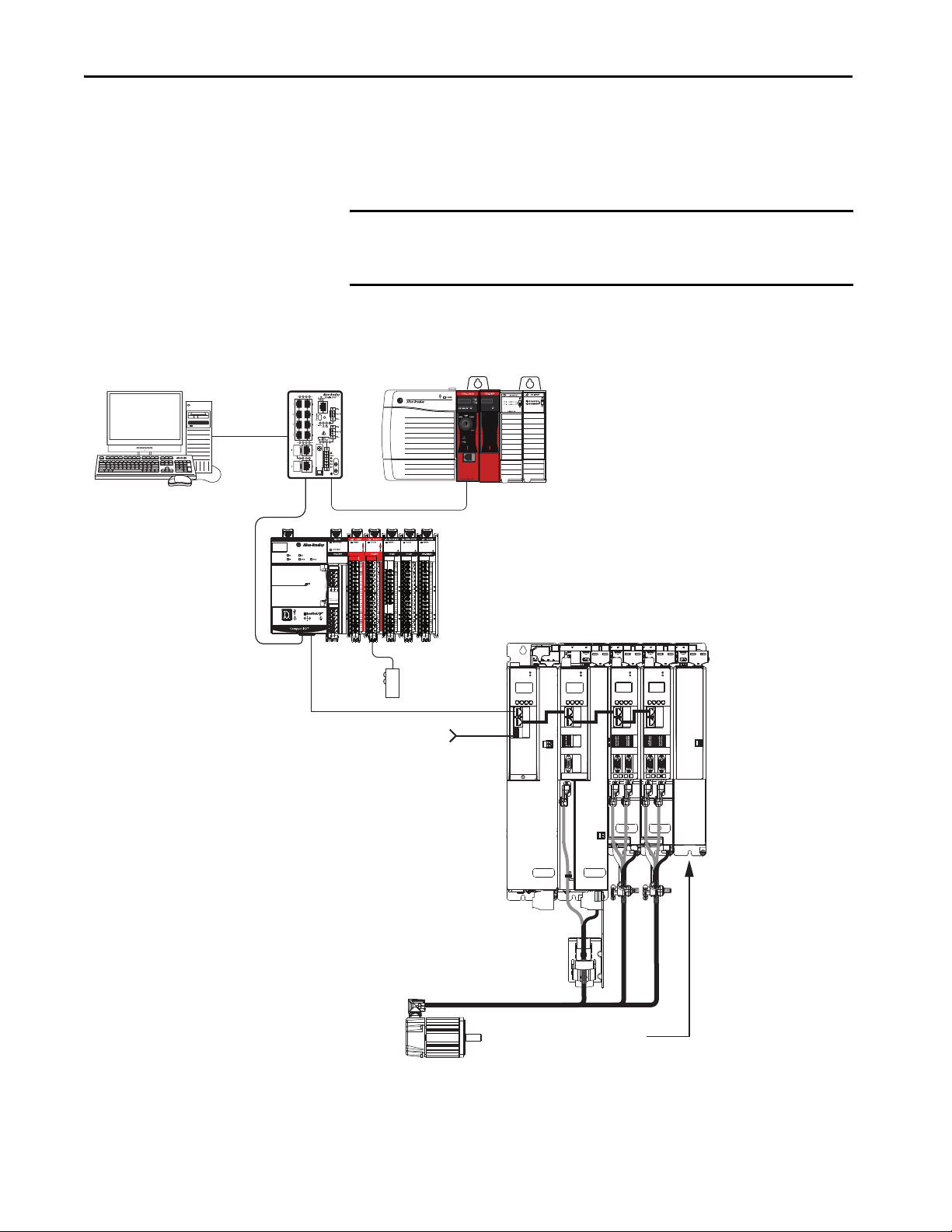

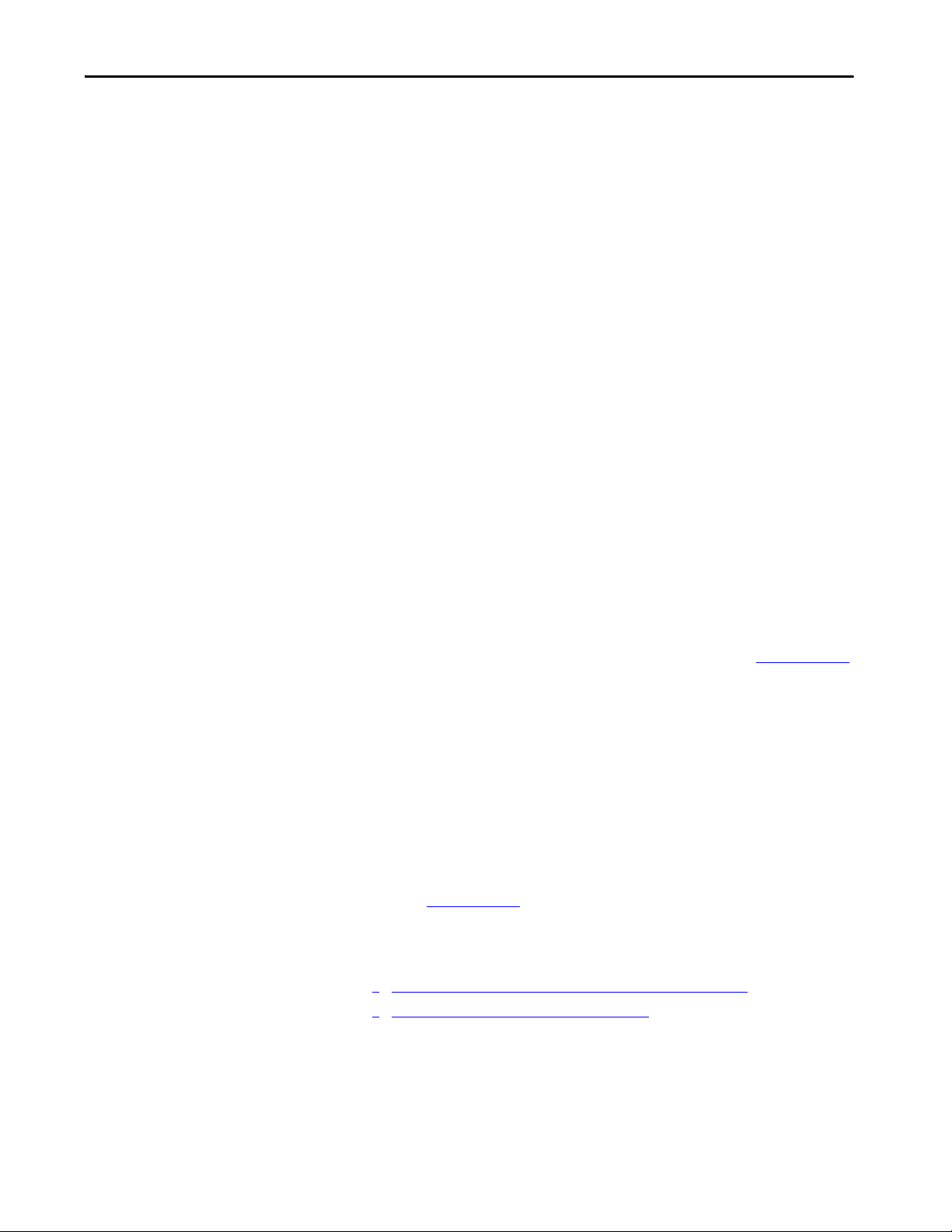

GuardLogix with Safety I/O and Integrated Safety Drives

In this example, a single GuardLogix safety controller makes the Motion and

Safety connections.

IMPORTANT If only one controller is used in an application with Motion and Safety

connections, it must be a safety controller such as the GuardLogix 5580

controller.

Figure 4 - Motion and Safety Configuration (single controller)

22 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 23

ControlLogix and GuardLogix Systems Chapter 1

GuardLogix 5580 Safety Controller

GuardLogix 1756-L8SP Safety Partner

Studio 5000 Logix Designer

Application

(version 31.00 or later)

Kinetix 5700 Servo Drive System

Digital Inputs to Sensors and Control String

Kinetix VP

Servo Motors

2198-CAPMOD-2240

Capacitor Module

(optional component)

1734-AENTR

POINT Guard I/O

EtherNet/IP Adapter

1783-BMS

Stratix 5700

Switch

ControlLogix 5580 Controller

Motion Program

Module Definition Configured with

Motion only Connection

Safety Program

Module Definition Configured

with Safety only Connection

Safety

Device

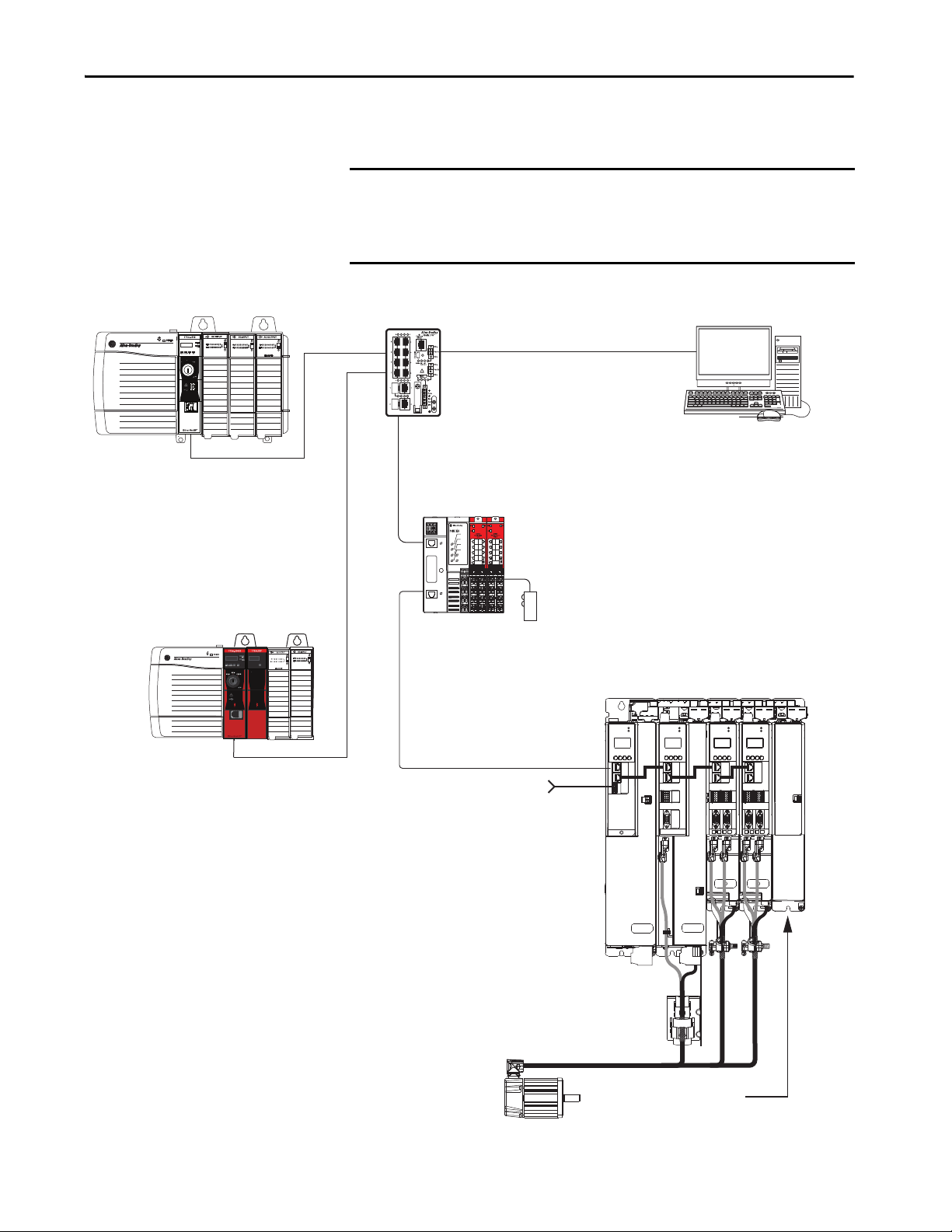

In this example, a standard controller makes the Motion-only connection and a

separate GuardLogix 5580 controller makes the safety-only connection.

IMPORTANT If two controllers are used in an application with motion-only and safety-

only connections, the safety-only connection must be a GuardLogix

controller while the motion-only connection can be made by either a

standard or a safety controller.

Figure 5 - Motion and Safety Configuration (multi-controller)

MOD

MOD

NET

2

1

1

4

I/O

MOD

NET

2

1

I/O

1

6

5

10

UFB

D-

-

MBRK

+

NET

2

2

1

1

I/O-A

I/O-B

1

6

1

6

1

510

510

510510

UFB-A UFB-B

D+D-D+

D+

D-

MF-A MF-B MF-A MF-B

I/O-A61I/O-B

UFB-A UFB-B

MOD

NET

6

D+

D-

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 23

Page 24

Chapter 1 ControlLogix and GuardLogix Systems

Design the System

Applies to these controllers:

ControlLogix 5580

GuardLogix 5580

When you design a a system, there are several system components to consider

for your application:

• I/O devices

• Motion control axes and drives

• Communication modules

•Controllers

• Chassis

•Power supplies

• Studio 5000 Logix Designer Application

In addition, safety systems have also have components to consider:

•Safety Controller

• Safety Partner (for SIL 3/PLe applications)

•Safety I/O

•Safety Devices

For more information to design and select components for your system, see:

• 1756 ControlLogix Controllers Technical Data,

publication 1756-TD001

• 1756 ControlLogix I/O Specifications Technical Data,

publication 1756-TD002

• GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems

Safety Reference Manual,

publication 1756-RM012

CIP Security

CIP Security™ is a standard, open-source communication method that helps to

provide a secure data transport across an EtherNet/IP network.

The secure data transport is used between certain connected devices to help

protect the devices from threats posed by unauthorized users with malicious

intent.

Rockwell Automation uses the following products to implement CIP Security:

• FactoryTalk Policy Manager

•FactoryTalk Linx

• Studio 5000® Design Environment

• CIP Security-enabled products from Rockwell Automation, for

example, the products described in this publication

For more information on CIP Security, including which products support CIP

Security, see the CIP Security Application Technique, publication SECURE-

AT001.

24 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 25

ControlLogix and GuardLogix Systems Chapter 1

Secure Controller Systems

The ControlLogix 5580 controller, firmware revision 32 supports

IEC-62443-4-2 SL 1 requirements. For security features and system

requirements, see Develop Secure Applications

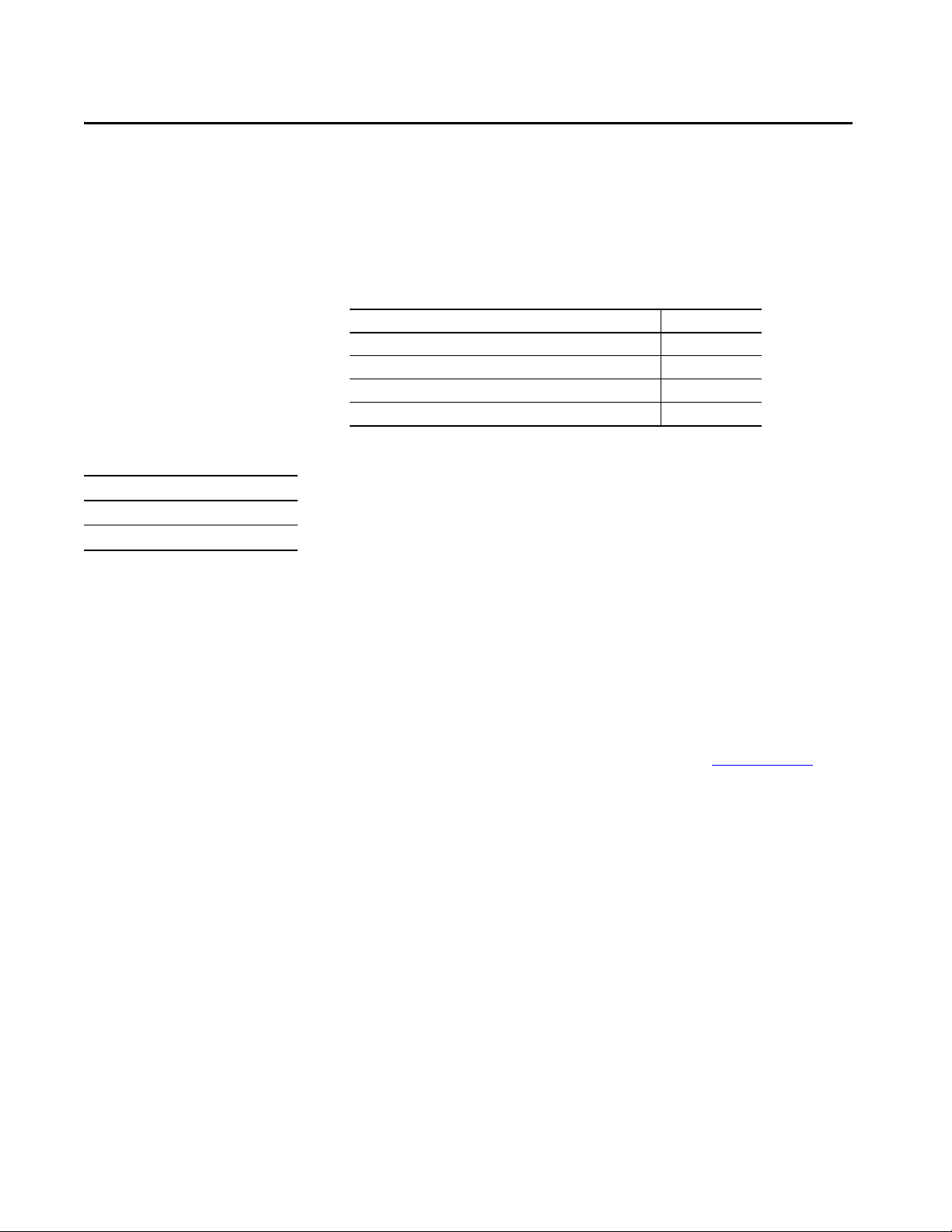

ControlLogix 5580 Controller Features

Applies to these controllers:

ControlLogix 5580

Table 1 - ControlLogix 5580 Controller Features

Feature 1756-L81E, 1756-L81EK,

1756-L81E-NSE,

1756-L81EXT, 1756-L81EP

User Memory 3 MB 5 MB 10 MB 20 MB 40 MB

60 nodes

EtherNet/IP nodes supported, max

Communication ports 1 - USB port, 2.0 full-speed, Type B

Communication options • EtherNet/IP

Controller tasks • 32 tasks

Integrated motion • Integrated Motion on the EtherNet/IP network

Programming languages • Ladder Diagram (LD)

(1) A node is an EtherNet/IP device that you add directly to the I/O configuration, and counts toward the node limits of t he controller. For more information on EtherNet/IP nodes, see the ControlLogix 5580 Controllers User Manual,

publication1756-UM543

(2) With Studio 5000 Logix Designer Application Version 31 or greater.

(3) With Studio 5000 Logix Designer Application Version 28 and Version 29.

(4) With Studio 5000 Logix Designer Application Version 29.

(5) With Studio 5000 Logix Designer Application Version 30 or greater.

(6) With Studio 5000 Logix Designer Application Version 28 or greater.

.

(1)

100 nodes

1 - EtherNet/IP port: 10 Mbps, 100 Mbps, 1 Gbps link speeds

•ControlNet

• DeviceNet

• Data Highway Plus™

• Remote I/O

•SynchLink™

• Third-party process and device networks

• 1000 programs/task

• Event tasks: all event triggers

• Sercos interface

• Analog options

–Encoder input

– Linear displacement transducer (LDT) input

– Serial Synchronous Input (SSI)

• Structured Text (ST)

• Function Block Diagram (FBD)

• Sequential Function Chart (SFC)

This table lists the system, communication, and programming features

available with ControlLogix 5580 controllers.

1756-L82E, 1756L82EK, 1756-L82E-NSE,

1756-L82EXT

(4)

(5)

(2)

(2)

:

80 nodes

175 nodes

(4)

(5)

1756-L83E, 1756-L83EK,

1756-L83E-NSE,

1756-L83EXT, 1756-L83EP

(3)

100 nodes

(5)

250 nodes

on page 207.

1756-L84E,

1756-L84EK,

1756-L84E-NSE,

1756-L84EXT

(4)

150 nodes

(5)

250 nodes

1756-L85E,

1756-L85EK,

1756-L85E-NSE,

1756-L85EXT,

1756-L85EP

(6)

300 nodes

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 25

Page 26

Chapter 1 ControlLogix and GuardLogix Systems

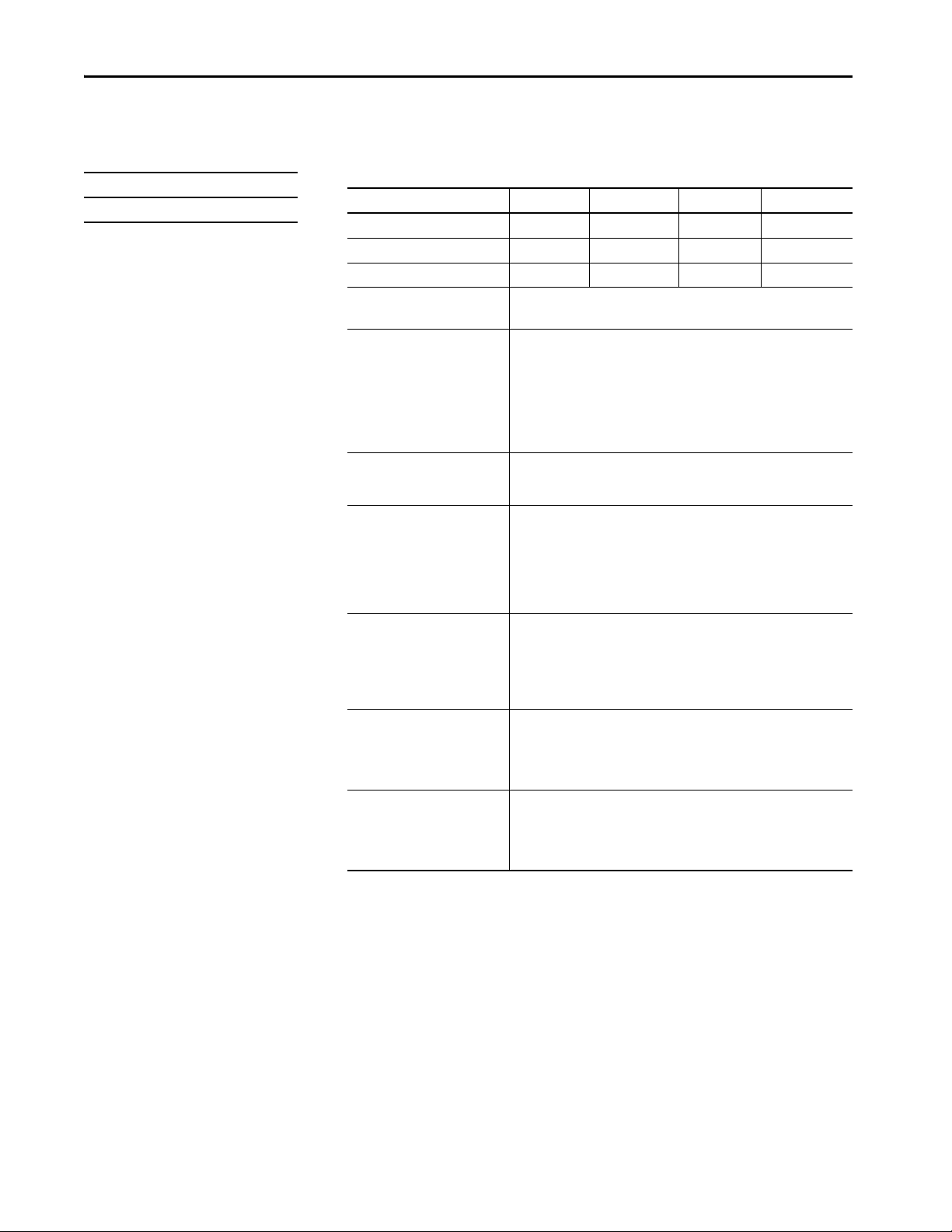

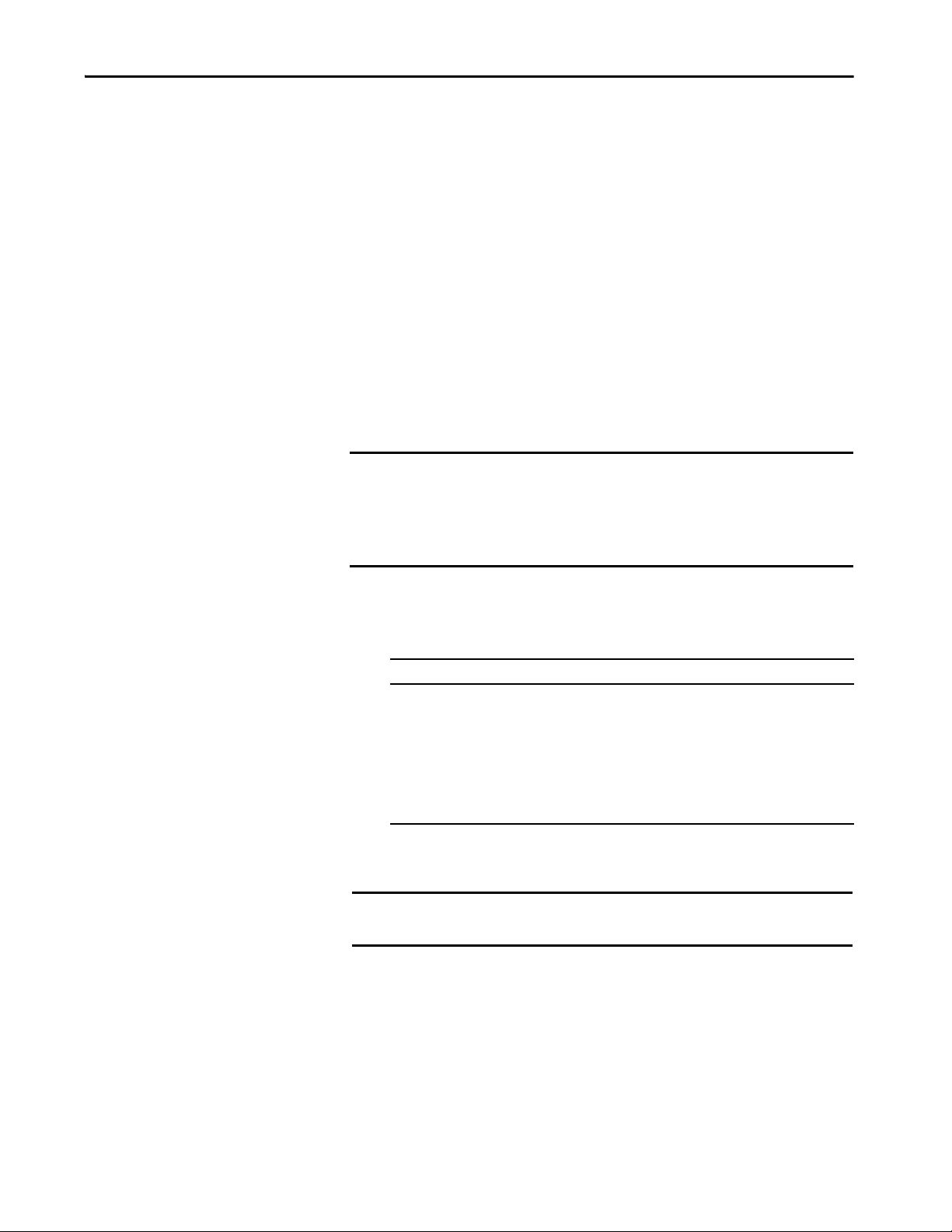

GuardLogix 5580 Controller Features

Applies to these controllers:

GuardLogix 5580

This table lists the system, communication, and programming features

available with GuardLogix 5580 controllers.

Table 2 - GuardLogix 5580 Controller Features

Feature 1756-L81ES 1756-L82ES 1756-L83ES 1756-L84ES

User Memory 3 MB 5 MB 10 MB 20 MB

Safety Memory 1.5 MB 2.5 MB 5 MB 6 MB

EtherNet/IP nodes supported, max 100 175 250 250

Communication ports 1 - USB port, 2.0 full-speed, Type B

1 - EtherNet/IP port: 10 Mbps, 100 Mbps, 1 Gbps link speeds

Communication options • EtherNet/IP (1756-EWEB cannot be used for safety connections)

• Support for Network address translation (NAT)

• ControlNet

• DeviceNet

• Data Highway Plus

• Remote I/O

•SynchLink

• Third-party process and device networks

Controller tasks • 31 standard tasks, 1 safety task

• 1000 programs/task

• Event tasks: all event triggers

Integrated motion Integrated motion is supported in standard task only.

• Integrated Motion on the EtherNet/IP network

• Sercos interface

•Analog options:

– Encoder input

– Linear displacement transducer (LDT) input

– Serial Synchronous Input (SSI)

Programming languages • For the safety task, GuardLogix controllers support Ladder Diagram only.

• For standard tasks, GuardLogix controllers support:

– Ladder Diagram (LD)

– Structured Text (ST)

– Function Block Diagram (FBD)

– Sequential Function Chart (SFC)

Integrated safety • Integrated safety on the EtherNet/IP network (Kinetix drives, PowerFlex

drives, safety components)

• Distribute and control safety I/O (over EtherNet/IP and DeviceNet networks

only)

• Produce and consume safety tag data.

Controller Features • Data access control

• Firmware supervisor

• Secure Digital (SD) card

• Safety Connections

• Standard Connections

26 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 27

ControlLogix and GuardLogix Systems Chapter 1

Features Supported By GuardLogix 5580 Controllers Via the Safety Task

In the Logix Designer application, version 31 or later, the Safety task supports a

subset of features that are supported in the standard task as listed in this table.

Feature Studio 5000 Logix Designer Application,

Safety Task Standard Task

Add-on instructions X X

Instruction-based alarms and events — X

Tag-based alarms — X

Controller logging X X

Event task s

Function block diagrams (FBD) — X

Integrated motion X

Analog motion — X

Sercos motion — X

Drive Safety Instructions X —

Ladder Diagram (LD) X X

Language switching X X

License-based source protection — X

Online import of program components — X

Online export of program components X X

Sequential function chart (SFC) routines — X

Structured Text (ST) — X

(1) While the safety task cannot be an Event task, standard Event tasks can be triggered with the use of the Event instruction in the

(2) Limited to the use of Drive Safety Instructions wi th Kinetix 5700 ERS4 drives.

(1)

safety task.

Version 31 or Later

—X

(2)

X

IM PORTANT Safety Consideration

GuardLogix 5580 controllers can produce standard tags as unicast or multicast, but they can only

produce safety tags as unicast. The controllers can consume safety tags as either unicast or multicast.

When you configure a produced safety tag, you are only allowed to configure unicast connection

options. Logix Designer does not allow you to configure multicast connection options.

When you configure a consumed tag, you must consider the capabilities of the producer:

• If the producer in the I/O tree of this controller is a GuardLogix 5580 or Compact GuardLogix 5380

controller, and you are consuming a safety tag, you must configure the consumed tag to use unicast.

• If the producer in the I/O tree of this controller is a GuardLogix 5570 or 5560, or a Compact

GuardLogix 5370, the safety consumed tag can be configured as either unicast or multicast.

• GuardLogix 5580 controllers do not produce safety tags to GuardLogix 5570 (firmware revision 30

and earlier) controllers in the same chassis, because GuardLogix 5580 controllers can only produce

safety tags as unicast, and GuardLogix 5570 (firmware revision30 and earlier) controllers cannot

configure consumed tags as unicast. This restriction does not apply over EtherNet/IP, as consumed

tags can be configured for unicast.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 27

Page 28

Chapter 1 ControlLogix and GuardLogix Systems

Notes:

28 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 29

Chapter 2

Safety Concept of GuardLogix Controllers

Top ic Pag e

Functional Safety Capability 29

Safety Network Number 30

Safety Signature 30

Distinguish between Standard and Safety Components 31

Controller Data-flow Capabilities 32

Safety Terminology 33

Functional Safety Capability

Applies to these controllers:

GuardLogix 5580

The GuardLogix® 5580 controller system is certified for use in safety

applications up to and including SIL 2/PLd and SIL 3/PLe where the

de-energized state is the safe state.

For SIL 3/PLe safety applications, the GuardLogix system is made up of a

primary controller and a safety partner, that function together in a 1oo2

architecture.

For SIL 2/PLd and SIL 3/PLe safety system requirements, including

functional validation test intervals, system reaction time, and PFD/PFH

calculations, see the GuardLogix 5580 and Compact GuardLogix 5380

Controller Systems Safety Reference Manual, publication 1756-RM012

.

You must read, understand, and fulfill these requirements before you operate a

GuardLogix SIL 2/PLd or SIL 3/PLe safety system.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 29

Page 30

Chapter 2 Safety Concept of GuardLogix Controllers

Safety Network Number

The safety network number (SNN) uniquely identifies CIP Safety™ subnets

within a routable safety network. The combination of the SNN + Node

Address uniquely identifies each CIP Safety port on each device in the routable

safety network.

The GuardLogix 5580 controllers require two safety network numbers: one

for the Ethernet port, and one for the backplane.

Safety Signature

For an explanation of the Safety Network Number, see the GuardLogix 5580

and Compact GuardLogix 5380 Controller Systems Safety Reference Manual,

publication 1756-RM012.

For information on how to assign the SNN, see Assign the Safety Network

Number (SNN) on page 65.

The safety signature is composed of a safety signature ID (identification

number), and a timestamp (date and time). The safety signature ID applies to

the entire safety portion of the controller and uniquely identifies each project,

including its logic, data, and configuration.

The GuardLogix system uses the safety signature to determine project integrity

and to let you verify that the correct project is downloaded to the target

controller. The ability to create, record, and verify the safety signature is a

mandatory part of the safety-application development process.

The safety signature must be present to operate as a SIL 2/PLd or SIL 3/PLe

safety controller.

See Generate a Safety Signature

on page 192 for more information.

30 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 31

Safety Concept of GuardLogix Controllers Chapter 2

Distinguish between Standard and Safety Components

Slots of a GuardLogix system chassis that are not used by the safety function

can be populated with other ControlLogix® modules that are certified to the

Low Voltage and EMC Directives. See the Rockwell Automation Product

Certifications page (

certification/overview.page?)

Product Family, and determine the modules that are certified.

You must create and document a clear, logical, and visible distinction between

the safety and standard portions of the controller project. As part of this

distinction, the Studio 5000 Logix Designer® application features safety

identification icons to identify the safety task, safety programs, safety routines,

and safety components.

In addition, the Logix Designer application uses a safety class attribute that is

visible whenever safety task, safety programs, safety routine, safety tag, or safety

Add-On Instruction properties are displayed.

http://www.rockwellautomation.com/global/

to find the CE certificate for the ControlLogix

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 31

Page 32

Chapter 2 Safety Concept of GuardLogix Controllers

GuardLogix Controller

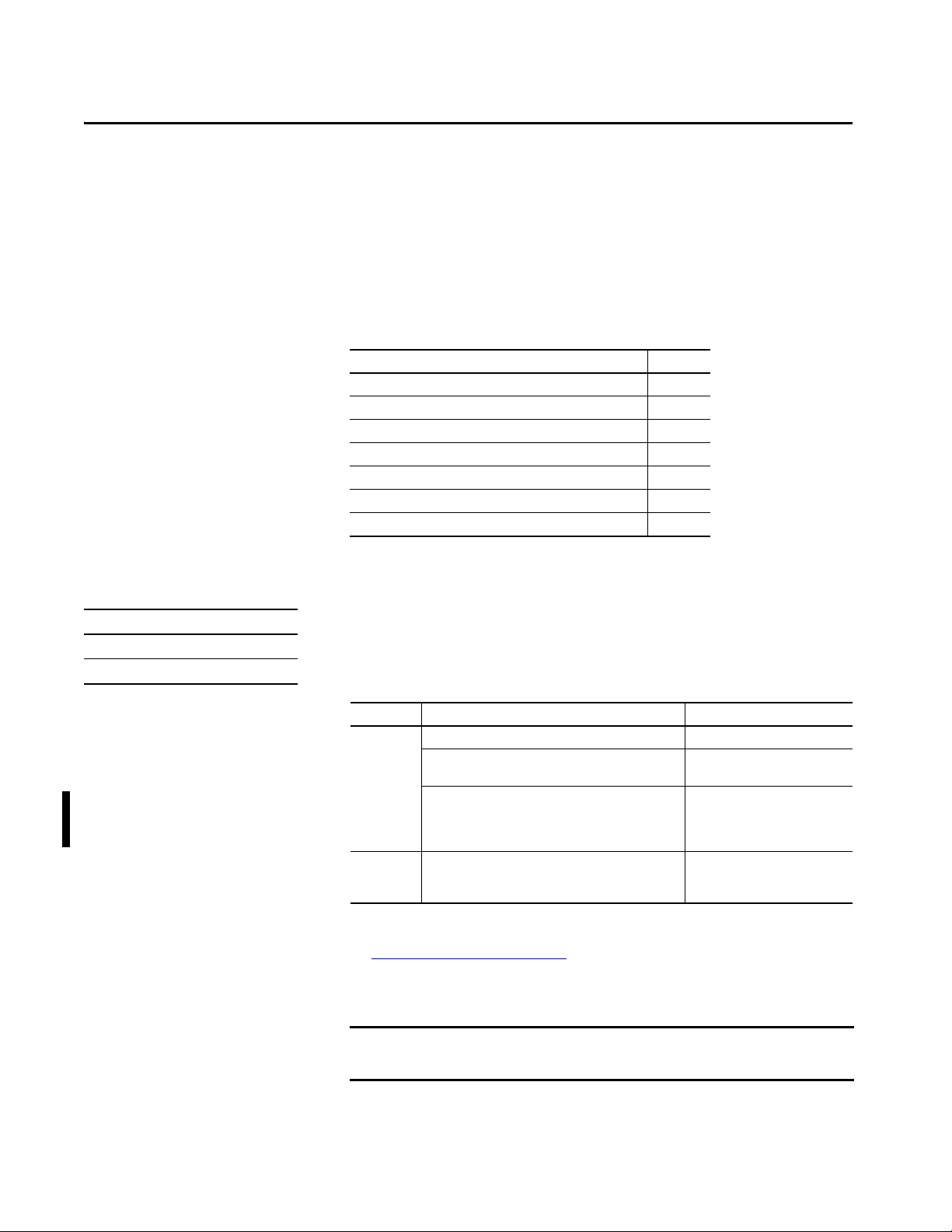

Controller Data-flow Capabilities

This illustration explains the standard and safety data-flow capabilities of the

GuardLogix controller.

Figure 6 - Data-flow Capabilities

Standard Safety

Standard Tasks

Standard Programs

Standard Routines

Program Data

Controller Standard Tags

Safety Task

Safety Programs

Safety Routines

Program Safety Data

Controller Safety Tags

No. Description

1 Standard tags and logic behave the same way that they do in a standard ControlLogix controller.

2 Standard tag data, program- or controller-scoped, can be exchanged with external HMI devices,

personal computers, and other controllers.

3 GuardLogix controllers are integrated controllers with the ability to move (map) standard tag data into

safety tags for use within the safety task. This is the only way to get standard tag data in to the safety

task. Safety logic in the safety task cannot read or write the standard tag that is the source in the tag

mapping data transfer; it can only reference the safety tag destination of the mapping. But, it can read

and write that safety tag.

ATT EN TI ON : Mapped tag data must not be used to control a SIL 2/PLd or

SIL 3/PLe output directly.

4 Controller-scoped safety tags can be read directly by standard logic.

5 Safety tags can be read or written by safety logic.

6 Safety tags can be exchanged between safety controllers over Ethernet or ControlNet® networks,

including 1756 and 5069 GuardLogix controllers.

7 Safety tag data, program- or controller-scoped, c an be read by external devices, such as HMI devices,

personal computers, or other standard controllers. External devices cannot write to safety tags

(whether the controller is protected or not).

Once this data is read, it is considered standard data, not SIL 3/PLe data.

32 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 33

Safety Concept of GuardLogix Controllers Chapter 2

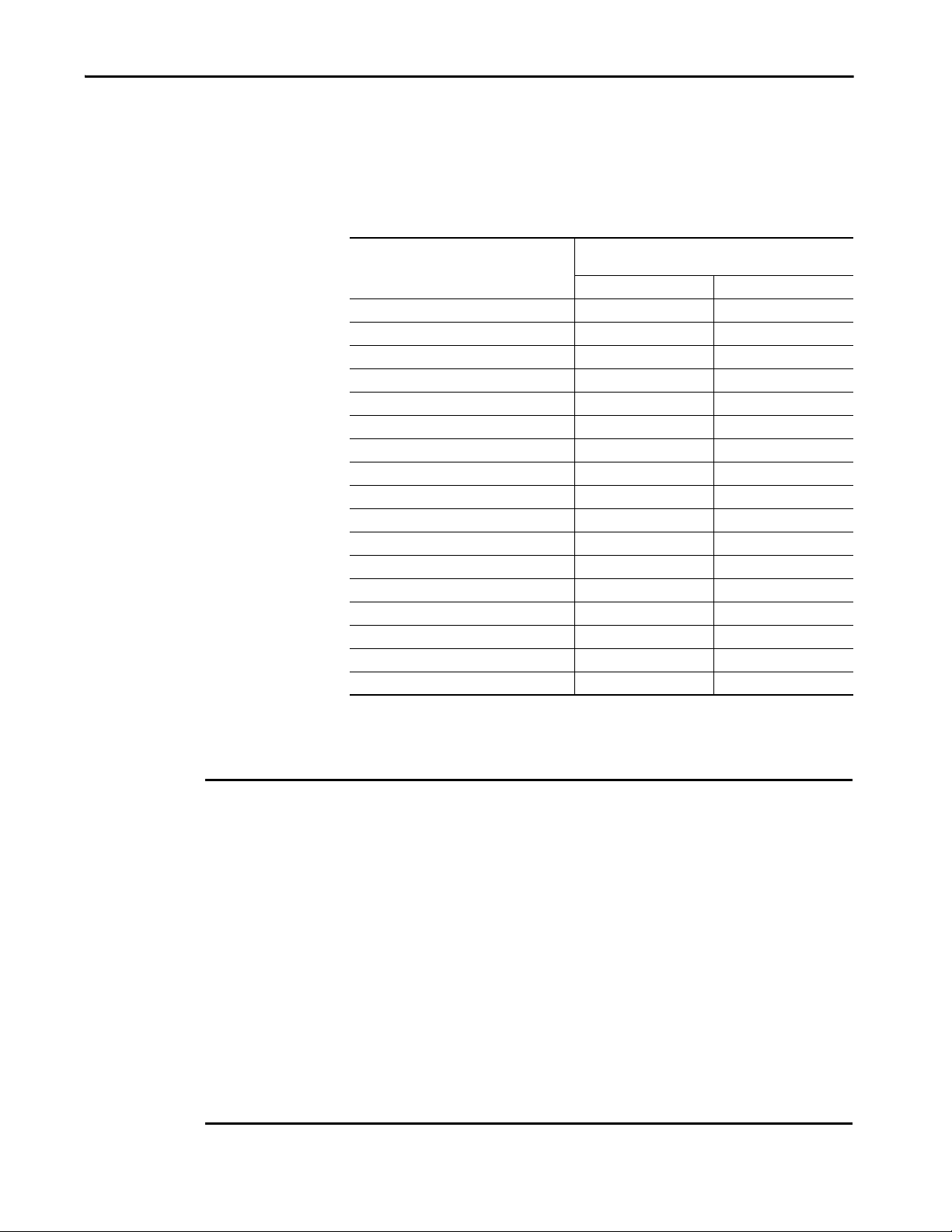

Safety Terminology

This table defines safety terms that are used in this manual.

Table 3 - Safety Terms and Definitions

Abbreviation Full Term Definition

1oo1 One Out of One Identifies the programmable electronic controller architecture. 1oo1 is a single-channel system.

1oo2 One Out of Two Identifies the programmable electronic controller architecture. 1oo2 is a dual-channel system.

CIP Safety Common Industrial Protocol – Safety Certified SIL 3/PLe-rated version of CIP™.

DC Diagnostic Coverage The ratio of the detected failure rate to the total failure rate.

PFD Probability of Failure on Demand The average probability of a system to fail to per form its design function on demand.

PFH Probability of Failure per Hour The probability of a system to have a dangerous failure occur per hour.

PL Performance Level ISO 13849-1 safety rating.

SIL Safety Integrity Level A relative level of risk-reduction provided by a safety function, or to specify a target level of risk reduction .

SIL CL SIL Claim Limit The maximum safety integrity level (SIL) that can be achieved.

SNN Safety Network Number A unique number that identifies a section of a safety network.

UNID Unique Node ID (also called unique node

referenc e)

The unique node reference is a combination of a safe ty network number (SNN) and the node address of the

node.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 33

Page 34

Chapter 2 Safety Concept of GuardLogix Controllers

Notes:

34 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 35

Communication Networks

Several communication networks are available.

Top ic Pag e

Networks Available 35

EtherNet/IP Network Communication 37

Double Data Rate (DDR) Backplane Communication for ControlLogix

Control lers

ControlNet Network Communication 41

DeviceNet Network Communication 44

Data Highway Plus (DH+) Network Communication 45

Universal Remote I/O (RIO) Communication 47

Foundation Fieldbus Communication 49

HART Communication 50

Chapter 3

40

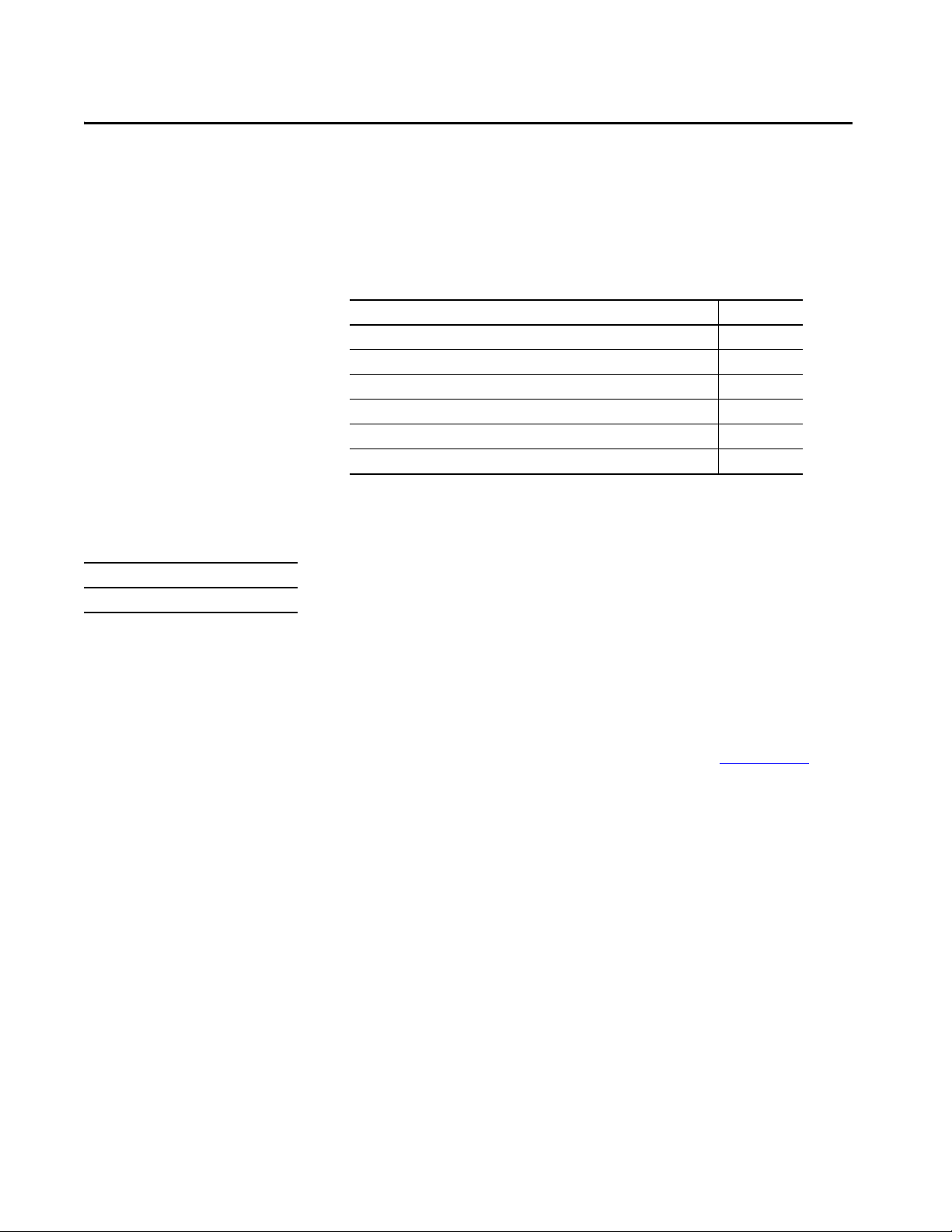

Networks Available

Ta b l e 4 describes typical application features that are used with ControlLogix®

and GuardLogix® systems, and lists the networks available to support such

application features.

Table 4 - Applications and Supported Networks

Application Features ControlLogix and GuardLogix Supported

Integrated Motion

Time synchronization EtherNet/IP EtherNet/IP

Control of distributed I/O • EtherNet/IP

Produce/consume data between controllers • EtherNet/IP

Messaging to and from other devices, including access to

the controller via the Studio 5000 Logix Designer®

application

(1) The controllers also support analog and Sercos motion interfaces. For more information, See Develop Motion Applications on page 243.

(1)

Networks for Standard Communications

EtherNet/IP™ EtherNet/IP

• DeviceNet®

• ControlNet®

• Foundation Fieldbus

•HART

• Universal remote I/O

•ControlNet

• EtherNet/IP

•ControlNet

• DeviceNet (only to devices)

• Data Highway Plus™ (DH+™)

• DH-485

GuardLogix Supported Networks for

CIP Safety™ Communications

Time synchronization does not use the safety protocol.

•EtherNet/IP

•ControlNet

Messaging does not use the safety protocol.

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 35

Page 36

Chapter 3 Communication Networks

For more information about using EtherNet/IP modules, see these

publications:

• EtherNet/IP Modules in Logix 5000 Control Systems User Manual,

publication ENET-UM001

• EtherNet/IP Communication Modules in 5000 Series Systems,

publication ENET-UM004

For more information about network design, see these publications;

• Ethernet Design Considerations Reference Manual,

publication ENET-RM002

.

• ControlNet Network Configuration User Manual,

publication CNET-UM001

• DeviceNet Media Design Installation Guide,

publication DNET-UM072

• FOUNDATION Fieldbus Design Considerations Reference Manual,

publication PROCES-RM005

36 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 37

Communication Networks Chapter 3

Workstation

5069-AEN2TR Adapter

Compact 5000 I/O Modules

5069-AEN2TR Adapter

Compact 5000 I/O Modules

5069-AEN2TR Adapter

Compact 5000 I/O Modules

Stratix® switch with

Gigabit copper ports

ControlLogix 5580 Controller or GuardLogix 5580 Controller

1756 I/O Modules

1 Gbps

1 Gbps

1 Gbps

1 Gbps

EtherNet/IP Network Communication

Applies to these controllers:

ControlLogix 5580

GuardLogix 5580

The EtherNet/IP network offers a full suite of control, configuration, and data

collection services by layering the Common Industrial Protocol (CIP™) over

the standard Internet protocols, such as TCP/IP and UDP. This combination

of well-accepted standards provides the capability that is required to support

information data exchange and control applications.

IMPORTANT You cannot bridge through the Ethernet (front) port of another controller to

add remote I/O.

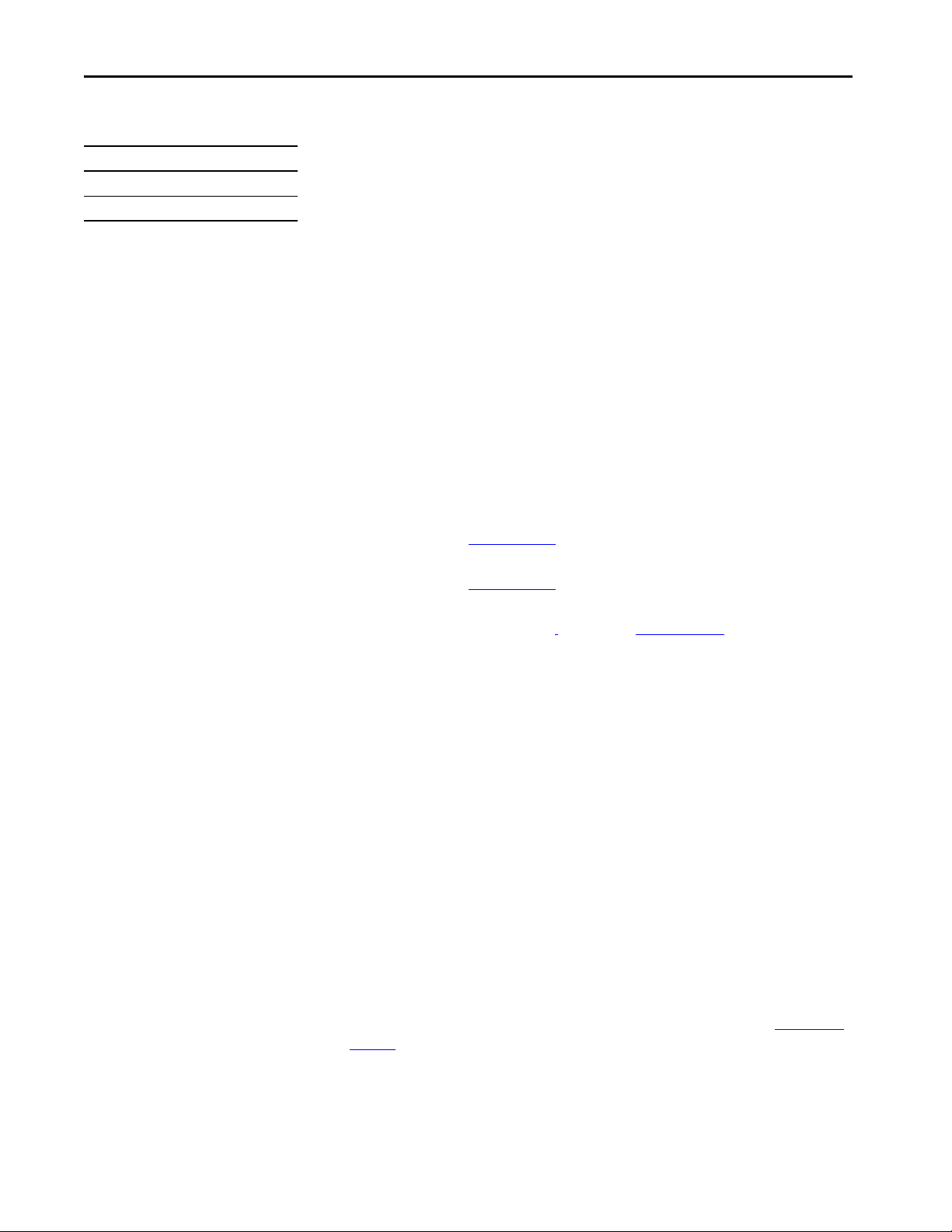

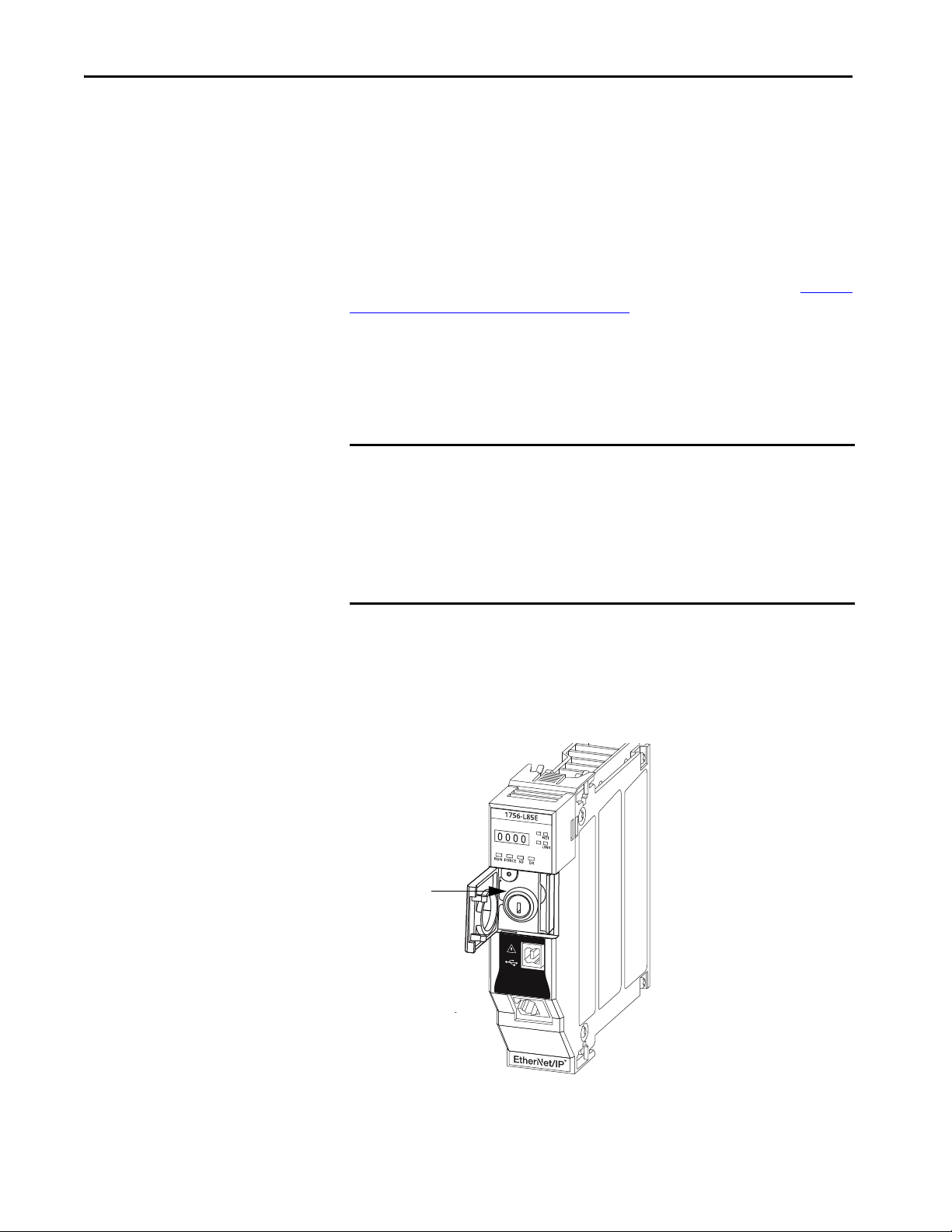

EtherNet/IP Link Speeds

The controller supports10 Mbps/100 Mbps/1 Gbps EtherNet/IP link speeds.

Network performance in a the controller system is optimal if the 1 Gbps link

speed is used. However, legacy Ethernet devices do not support the 1 Gbps link

speed. Instead, they support a maximum rate of 100 Mbps.

The difference in maximum link speeds impacts your controller system and, in

some applications, restricts you from using the 1 Gbps link speeds on a

controller.

When you design a controller system and consider using the 1 Gbps rate on the

controller, remember the following:

• You can use the 1 Gbps link speed on the controller port when all

network devices support 1 Gbps, for example, 5069-AEN2TR adapters

with Compact 5000™ I/O modules.

When switches are used in a star topolog y, configure the controller ports

to use Auto Negotiate.

Figure 7 - 1 Gb EtherNet/IP Network Example

Rockwell Automation Publication 1756-UM543K-EN-P - August 2020 37

Page 38

Chapter 3 Communication Networks

Panel View™ Pl us 7

Stratix® 5400

5069-AEN2TR

Compact 5000 Safety I/O Modules

Compact 5000 I/O Modules

PowerFlex® 755 Drive

1 Gbps

1 Gbps

100 Mbps

100 Mbps

1734-AENTR

1734 POINT I/O™

100 Mbps

1734-AENTR EtherNet/IP Adapter

1734 POINT Guard I/O™

Safety Device

1 Gbps

PowerFlex 527 Drive

(CIP Safety™ enabled)

100 Mbps

1 Gbps

5069-AEN2TR

Compact 5000™ I/O modules

1756-EN2TR

1756-L84ES

1756-L85E

1756-L72

• You can use the 1 Gbps link speed on the controller port when some

network devices support a maximum link speed of 100 Mbps. However,

the controller must be connected to those devices through a managed

switch.

38 Rockwell Automation Publication 1756-UM543K-EN-P - August 2020

Page 39

Communication Networks Chapter 3

1756-L85E

1756 I/O

CompactLogix 5570

PowerFlex 700S

Switch

1794-AENT

1756-EN2T

Remote I/O

1734-AENT

Wor kst ati on

Device Level Ring (DLR) Topology

connected via 1783-ETAP with tap

100 Mbps

100 Mbps

100 Mbps

100 Mbps

100 Mbps

100 Mbps

100 Mbps

• Do not mix 1 Gbps and 100 Mbps link speeds within a single DLR ring

or linear network.