Page 1

User Manual

Original Instructions

ControlLogix System

Catalog Numbers 1756-L61, 1756-L62, 1756-L63, 1756-L63XT, 1756-L64, 1756-L65, 1756-L71, 1756-L72, 1756-L73,

1756-L73XT, 1756-L74, 1756-L75, 1756-L72EROM, 1756-L73EROM

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ControlLogix Controllers Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Standard ControlLogix Controllers . . . . . . . . . . . . . . . . . . . . . . . . . 10

Redundant ControlLogix Controllers . . . . . . . . . . . . . . . . . . . . . . . 11

Extreme Environment ControlLogix Controllers . . . . . . . . . . . . 11

Armor ControlLogix Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Required Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 1

Install the 1756-L7x Controller Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1756-L7x Controller Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Parts Included with the 1756-L7x Controller . . . . . . . . . . . . . . . . 19

Parts Available for Use with the 1756-L7x Controller . . . . . . . . 20

1756-L7x Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Insert the Controller into the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Insert the Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Install the SD Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Remove the SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Install the ESM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Uninstall the ESM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 2

Install the 1756-L6x Controller Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1756-L6x Controller Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Parts Not Included with the 1756-L6x Controller. . . . . . . . . . . . 33

1756-L6x Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

CompactFlash Card Installation and Removal . . . . . . . . . . . . . . . . . . . 34

Battery Connection and Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Insert the Controller into the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Remove the Controller from the Chassis . . . . . . . . . . . . . . . . . . . . . . . . 42

Chapter 3

Start Using the Controller Make Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1756-L7x Connection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1756-L6x Connection Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Connect to the 1756-L7x Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Configure the USB Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Connect to the 1756-L6x Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Configure the Serial Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Upgrade Controller Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Determine Required Controller Firmware . . . . . . . . . . . . . . . . . . . 51

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 3

Page 4

Table of Contents

Obtain Controller Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Use ControlFLASH Software to Upgrade Firmware . . . . . . . . . 52

Use AutoFlash to Upgrade Firmware. . . . . . . . . . . . . . . . . . . . . . . . 57

Set the Communication Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Go Online with the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Download to the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Use the Who Active Dialog Box to Download . . . . . . . . . . . . . . . 62

Use the Controller Status Menu to Download . . . . . . . . . . . . . . . 63

Upload from the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Use the Who Active Dialog Box to Upload . . . . . . . . . . . . . . . . . . 63

Use the Controller Status Menu to Upload . . . . . . . . . . . . . . . . . . 64

Choose the Controller Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . 65

Use the Mode Switch to Change the Operation Mode . . . . . . . . 65

Use Logix Designer to Change the Operation Mode. . . . . . . . . . 67

Load or Store to the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Store to the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Load from the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Other Memory Card Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Use ControlLogix Energy Storage Modules (ESMs) . . . . . . . . . . . . . . 73

Save the Program to On-board NVS Memory . . . . . . . . . . . . . . . . 74

Clear the Program from On-board NVS Memory . . . . . . . . . . . . 74

Estimate the ESM Support of the WallClockTime . . . . . . . . . . . . . . . 75

Maintain the Battery (Only 1756-L6x Controllers) . . . . . . . . . . . . . . 75

Check the Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

1756-BA1 or 1756-BATA Battery Life . . . . . . . . . . . . . . . . . . . . . . 76

1756-BATM Battery Module and Battery Life . . . . . . . . . . . . . . . 77

Estimate 1756-BA2 Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Estimate 1756-BA2 Battery Life After Warnings . . . . . . . . . . . . . 79

Battery Storage and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Chapter 4

ControlLogix System and

Controllers

4 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

ControlLogix System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Design a ControlLogix System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

ControlLogix Controller Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

System, Communication, and Programming Features. . . . . . . . . 85

Memory Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Page 5

Table of Contents

Chapter 5

Communication Networks Networks Available. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

EtherNet/IP Network Communication. . . . . . . . . . . . . . . . . . . . . . . . . 90

ControlLogix EtherNet/IP Module Features . . . . . . . . . . . . . . . . 91

ControlLogix EtherNet/IP Communication Modules. . . . . . . . 91

Software for EtherNet/IP Networks . . . . . . . . . . . . . . . . . . . . . . . . 92

Connections Over an EtherNet/IP Network. . . . . . . . . . . . . . . . . 92

Double Data Rate (DDR) Backplane Communication . . . . . . . 92

ControlNet Network Communication . . . . . . . . . . . . . . . . . . . . . . . . . 93

ControlLogix ControlNet Module Features . . . . . . . . . . . . . . . . . 94

ControlLogix ControlNet Modules. . . . . . . . . . . . . . . . . . . . . . . . . 95

Software for ControlNet Networks . . . . . . . . . . . . . . . . . . . . . . . . . 95

Connections Over a ControlNet Network. . . . . . . . . . . . . . . . . . . 96

DeviceNet Network Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . 96

ControlLogix DeviceNet Module Features . . . . . . . . . . . . . . . . . . 97

ControlLogix DeviceNet Bridge Module and Linking Devices. 98

Software for DeviceNet Networks . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Connections Over DeviceNet Networks . . . . . . . . . . . . . . . . . . . . 98

ControlLogix DeviceNet Module Memory . . . . . . . . . . . . . . . . . . 98

Data Highway Plus (DH+) Network Communication . . . . . . . . . . . 99

Communicate Over a DH+ Network . . . . . . . . . . . . . . . . . . . . . . 100

Universal Remote I/O (RIO) Communication . . . . . . . . . . . . . . . . . 101

Communicate over a Universal Remote I/O Network . . . . . . . 102

Foundation Fieldbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . 102

HART Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Serial Communication on

1756-L6x Controllers

Chapter 6

1756-L6x Controller Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

ControlLogix Chassis Serial Communication Options. . . . . . . 106

Communication with Serial Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

DF1 Master Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

DF1 Point to Point Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

DF1 Radio Modem Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

DF1 Radio Modem Advantages. . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

DF1 Radio Modem Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

DF1 Radio Modem Protocol Parameters . . . . . . . . . . . . . . . . . . . 109

DF1 Slave Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

DH-485 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

ASCII Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Configure the 1756-L6x Controller for Serial Communication . . 112

Broadcast Messages Over a Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . 114

Configure Controller Serial Port Properties. . . . . . . . . . . . . . . . . 115

Program the Message Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Modbus Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 5

Page 6

Table of Contents

Chapter 7

Manage Controller

Communication

Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Produce and Consume (Interlock) Data. . . . . . . . . . . . . . . . . . . . . . . . 118

Connection Requirements of a Produced or Consumed Tag . 118

Send and Receive Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Determine Whether to Cache Message Connections . . . . . . . . 120

Calculate Connection Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Local Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Remote Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Connections Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Chapter 8

I/O Modules Selecting ControlLogix I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Add Local I/O to the I/O Configuration . . . . . . . . . . . . . . . . . . . 126

Remote I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Add Remote I/O to the I/O Configuration. . . . . . . . . . . . . . . . . 128

Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Add Distributed I/O to the I/O Configuration . . . . . . . . . . . . . 132

Reconfigure an I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Reconfigure an I/O Module Via the Module Properties. . . . . . 135

Reconfigure an I/O Module Via a Message Instruction . . . . . . 136

Add to the I/O Configuration While Online . . . . . . . . . . . . . . . . . . . 136

Modules and Devices That Can Be Added While Online . . . . 137

Online Additions - ControlNet Considerations. . . . . . . . . . . . . 137

Online Additions—EtherNet/IP Considerations . . . . . . . . . . . 140

Determine When Data Is Updated . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Chapter 9

Develop Motion Applications Motion Control Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Motion Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Obtain Axis Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Program Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

6 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 7

Table of Contents

Chapter 10

Develop Applications Elements of a Control Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Task Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Scheduled and Unscheduled Programs . . . . . . . . . . . . . . . . . . . . . 153

Routines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Parameters and Local Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Extended Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Access Extended Properties in Logic. . . . . . . . . . . . . . . . . . . . . . . . 156

Programming Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Access the Module Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Create the Add-On Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Monitoring Controller Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Monitoring I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Determine If I/O Communication Has Timed Out . . . . . . . . . 163

Determine If I/O Communication to a Specific I/O

Module Has Timed Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Interrupt the Execution of Logic and Execute the

Fault Handler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

System Overhead Time Slice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Configure the System Overhead Time Slice. . . . . . . . . . . . . . . . . 166

Sample Controller Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Chapter 11

Using the PhaseManager Tool PhaseManager Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Minimum System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

State Model Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

How Equipment Changes States. . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Manually Change States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

PhaseManager Tool versus Other State Models . . . . . . . . . . . . . . . . . 174

Equipment Phase Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Chapter 12

Redundant Systems ControlLogix Redundancy Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 175

System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

System Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Enhanced Versus Standard Redundancy . . . . . . . . . . . . . . . . . . . . 179

Build a Redundant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

ControlNet Considerations in Redundant Systems . . . . . . . . . . . . . 180

EtherNet/IP Considerations in Redundant Systems. . . . . . . . . . . . . 180

IP Address Swapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Redundancy and Scan Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 7

Page 8

Table of Contents

Appendix A

Troubleshoot the Module Use Logix Designer Application for Troubleshooting . . . . . . . . . . . 183

Fault Type Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

1756-L7x Controller Status Display and Indicators . . . . . . . . . . . . . 186

1756-L7x Controller Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

General Status Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Major Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

I/O Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

1756-L7x Controller Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 194

RUN Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

FORCE Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

SD Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

OK Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

1756-L6x Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

RUN Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

I/O Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

FORCE Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

RS232 Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

BAT Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

OK Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

8 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 9

Preface

This publication provides this information:

• Design and planning considerations

• Installation procedures

• Configuration procedures

• Maintenance and troubleshooting methods

This publication is designed for use by anyone responsible for planning and

implementing a ControlLogix® system:

• Application engineers

• Control engineers

• Instrumentation technicians

The contents of this publication are for anyone who already has an

understanding of Logix5000™ control systems, programming techniques, and

communication networks.

Summary of Changes

ControlLogix Controllers Overview

We’ve added the 1756-L72EROM and 1756-L73EROM Armor™

ControlLogix controllers to this user manual.

There are five types of ControlLogix controllers available. These types include

the following:

• Standard ControlLogix controllers

• Extreme environment ControlLogix controllers

• Armor ControlLogix controllers

• Standard GuardLogix® controllers

• Armor GuardLogix controllers

This manual explains how to use standard, extreme environment, and Armor

ControlLogix controllers.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 9

Page 10

Preface

For detailed information about GuardLogix and Armor GuardLogix safety

controllers, see the following publications.

Resource Description

GuardLogix 5570 Controllers User Manual,

publication

GuardLogix 5570 and Compact GuardLogix 5370

Controller Systems Reference Manual, publication

1756-RM099

GuardLogix Controllers User Manual, publication

1756-UM020

GuardLogix Controller Systems Safety Reference

Manual, publication

GuardLogix Safety Application Instruction Set Safety

Reference Manual, publication

1756-UM022

1756-RM093

1756-RM095

Provides information on how to install, configure, and

operate GuardLogix 5570 controllers in Studio 5000®

projects, version 21 or later.

Provides information on how to meet safety application

requirements for GuardLogix 5570 controllers in

Studio 5000 projects, version 21 or later.

Provides information on how to install, configure, and

operate GuardLogix 5560 and GuardLogix 5570 controllers

in RSLogix 5000® projects, version 20 or earlier.

Provides information on how to meet safety application

requirements for GuardLogix 5560 and GuardLogix 5570

controllers in RSLogix 5000 projects, version 20 or earlier.

Provides programmers with details about the GuardLogix

safety application instruction set.

Standard ControlLogix Controllers

Two lines of standard ControlLogix controllers are now available. These

controllers are identified as 1756-L6x controllers and 1756-L7x controllers

according to abbreviations of their full catalog numbers.

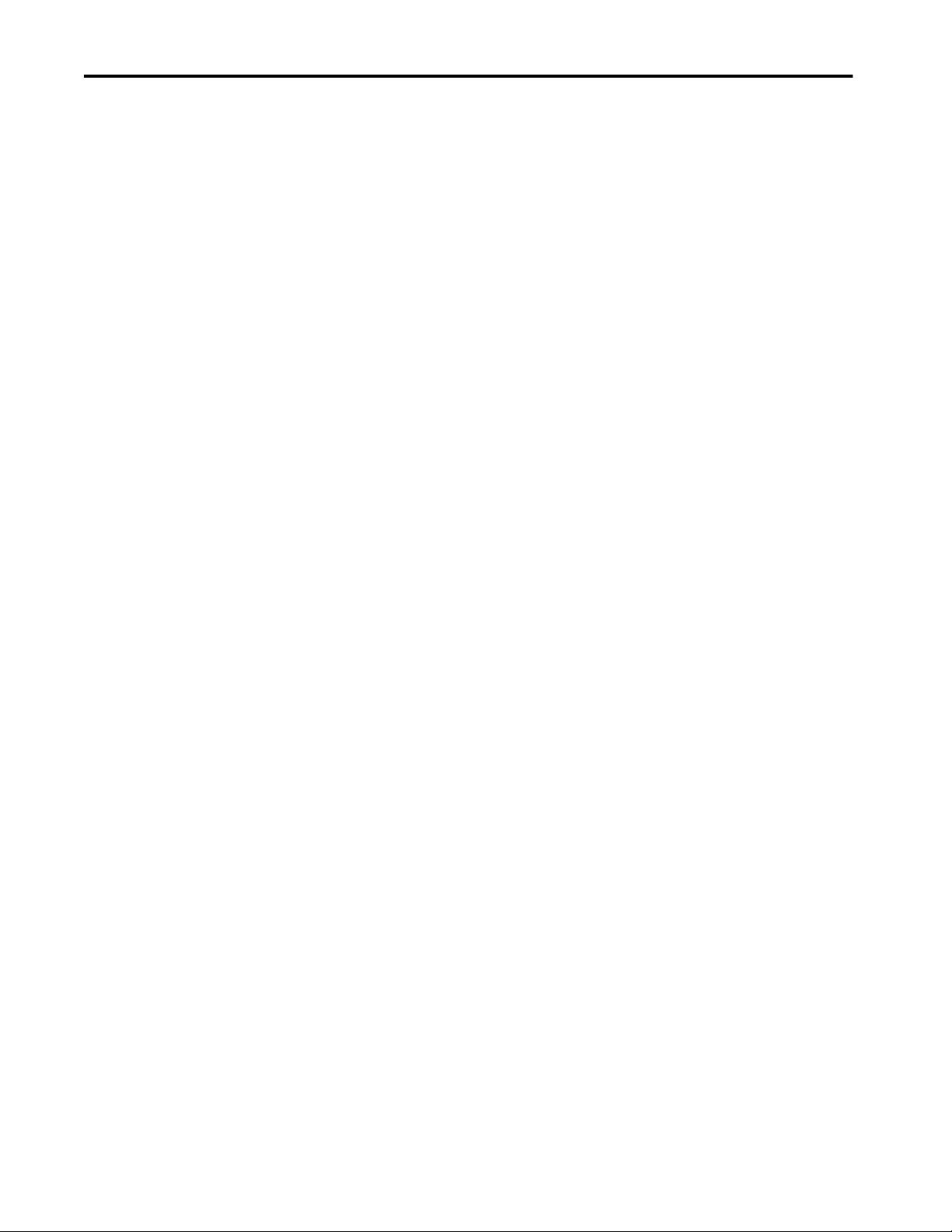

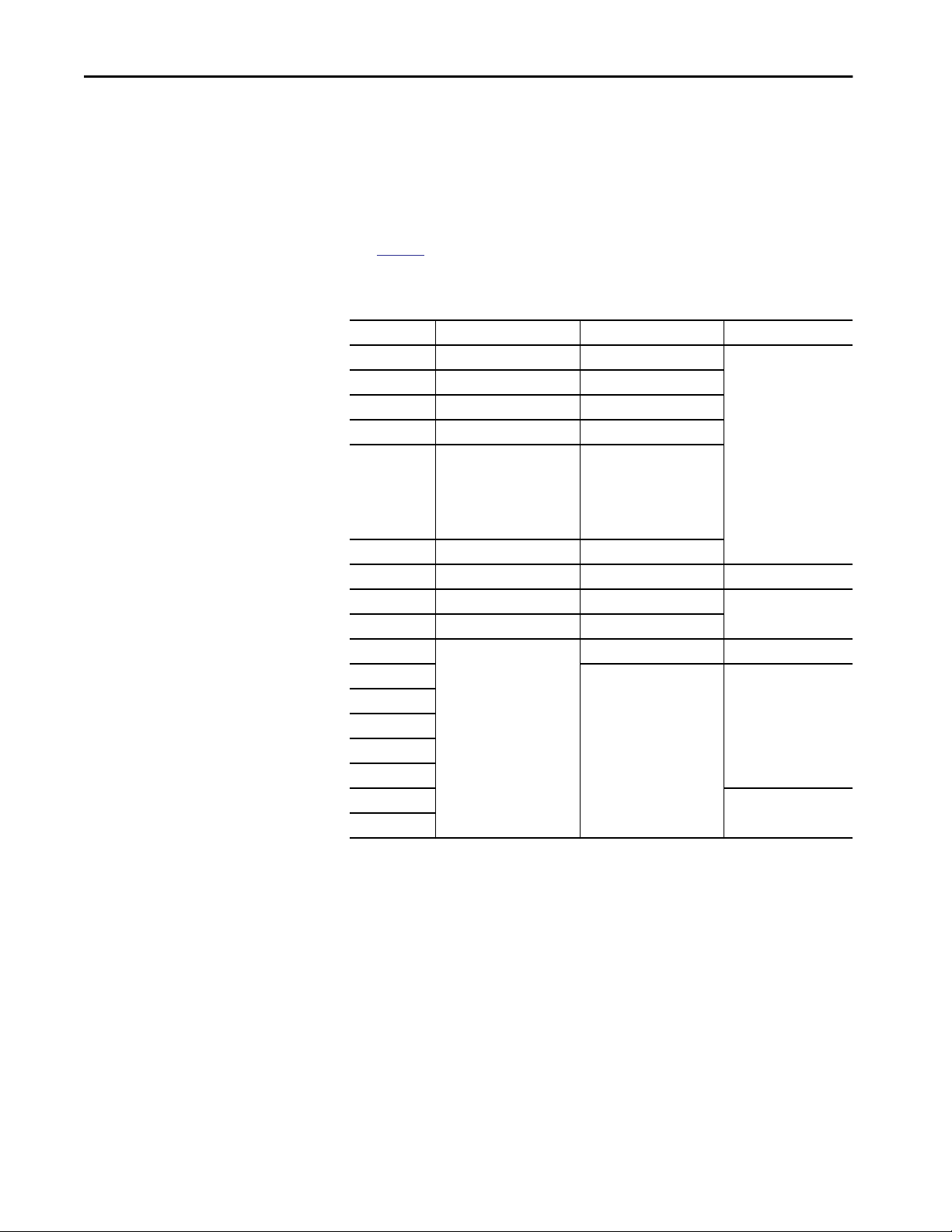

Table 1 - ControlLogix Catalog Numbers

Abbreviated Cat. No. Cat. No.

1756-L6x 1756-L61, 1756-L62,1756-L63, 1756-L64,1756-L65

1756-L7x 1756-L71, 1756-L72, 1756-L73,1756-L74, 1756-L75

The standard ControlLogix controllers share many similar features, but also

have some differences. Table 2 provides a brief overview the differences

between the controllers. For further details about these features and

differences, see the appropriate chapters of this manual.

Table 2 - Differences between 1756-L7x and 1756-L6x Controllers

Feature 1756-L7x 1756-L6x

Clock support and backup used for

memory retention at powerdown

Communication ports (built-in) USB Serial

Connections, controller 500 250

Memory, nonvolatile Secure Digital (SD) card CompactFlash card

Status display and status indicators Scrolling status display and four

Unconnected buffer defaults 20 (40, max) 10 (40, max)

Energy Storage Module (ESM) Battery

Six status indicators

status indicators

For information on using ControlLogix controllers in SIL 2 applications, see

the Using ControlLogix in SIL 2 Applications Safety Reference Manual,

publication

10 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

1756-RM001.

Page 11

Preface

Redundant ControlLogix Controllers

Certain ControlLogix controllers are also supported for use in redundant

systems. For more information about controllers and redundant systems, see

Chapter 12.

Extreme Environment ControlLogix Controllers

The extreme environment ControlLogix controllers, catalog numbers

1756-L73XT and 1756-L63XT, provide the same functionality as the 1756L73 and 1756-L63 controllers, but are designed to withstand temperatures

-25…+70 °C (-13…+158 °F).

Armor ControlLogix Controllers

The Armor ControlLogix controller combines a 1756-L72 or 1756-L73

ControlLogix controller with two EtherNet/IP DLR-capable 1756-EN3TR

communication modules in an IP67-rated housing for mounting on a machine.

For more information about the Armor ControlLogix controllers, catalog

numbers 1756-L72EROM and 1756-L73EROM, refer to the Armor

ControlLogix Controller Installation Instructions, publication

1756-IN061.

Though the 1756-L72EROM and 1756-L73EROM controllers have

functionality identical to that of the 1756-L72 and 1756-L73 controllers, the

Armor controller energy storage modules (ESM) cannot be removed or

replaced.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 11

Page 12

Preface

Before You Begin

Before you begin using your ControlLogix controller, verify that you have the

applications that are required to configure and program the controller.

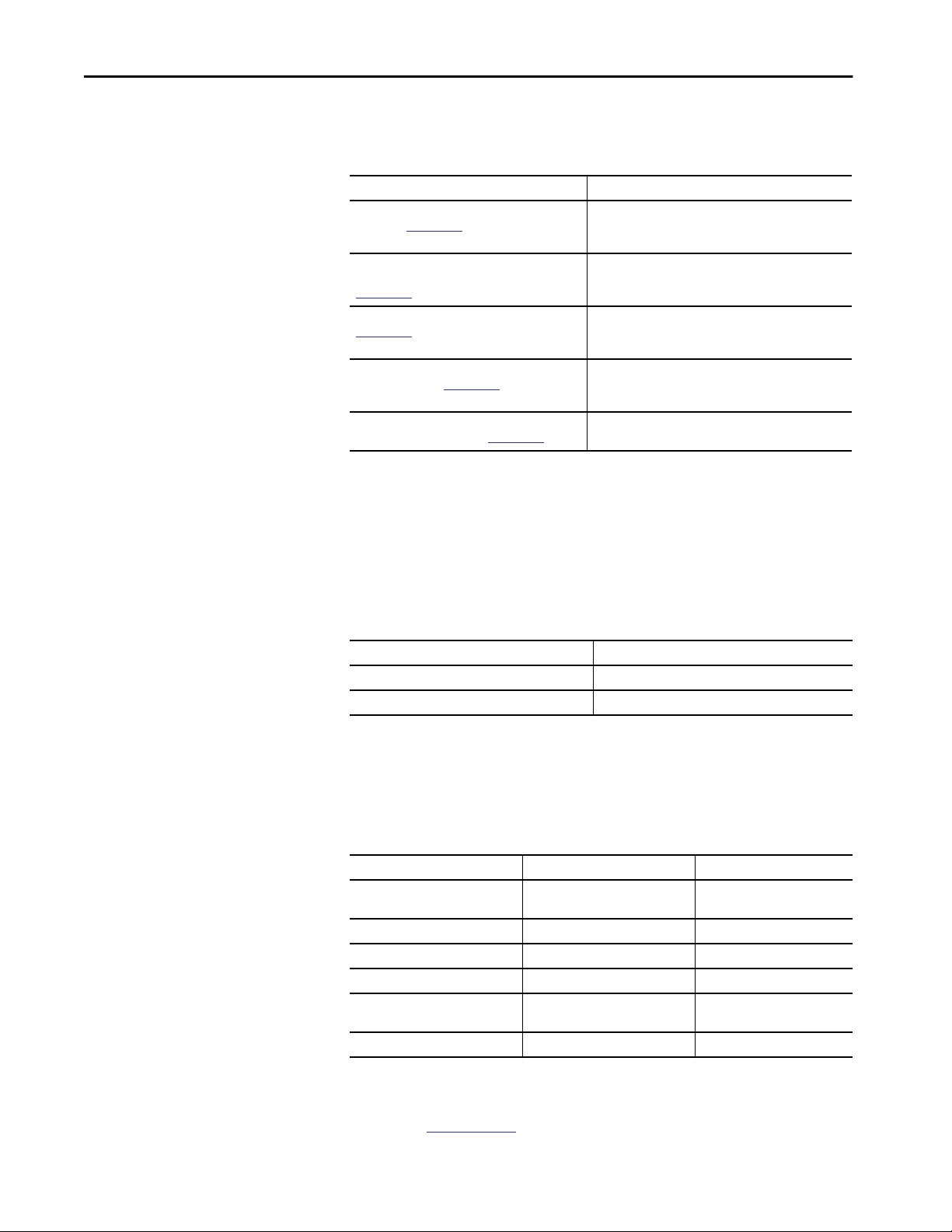

Required Software

Use Table 3 to identify the minimum software versions that are required to use

your ControlLogix controller.

Table 3 - Required Software for Controller Use

Cat. No. Studio 5000 Environment RSLogix 5000 Software RSLinx® Classic

1756-L61/A — Version 12.06.00 or later Any version

1756-L61/B — Version 13.04.00 or later

1756-L62/A — Version 12.06.00 or later

1756-L62/B — Version 13.04.00 or later

1756-L63/A — • If not using a CompactFlash

card, version 10.07.00 or

later

• If using a CompactFlash

card, version 11.16.00 or

later

1756-L63/B — Version 13.04.00 or later

1756-L63XT/B — Version 13.04.00 or later Version 2.55.00 or later

1756-L64/B — Version 16.03.00 or later Any version

1756-L65/B — Version 17.01.02 or later

1756-L71 Version 21.00.00 or later Version 20.01.02 Version 2.59.00 or later

1756-L72 Version 19.01.00 or later Version 2.57.00 or later

1756-L73

1756-L73XT

1756-L74

1756-L75

1756-L72EROM 2.59.02 or later

1756-L73EROM

12 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 13

Preface

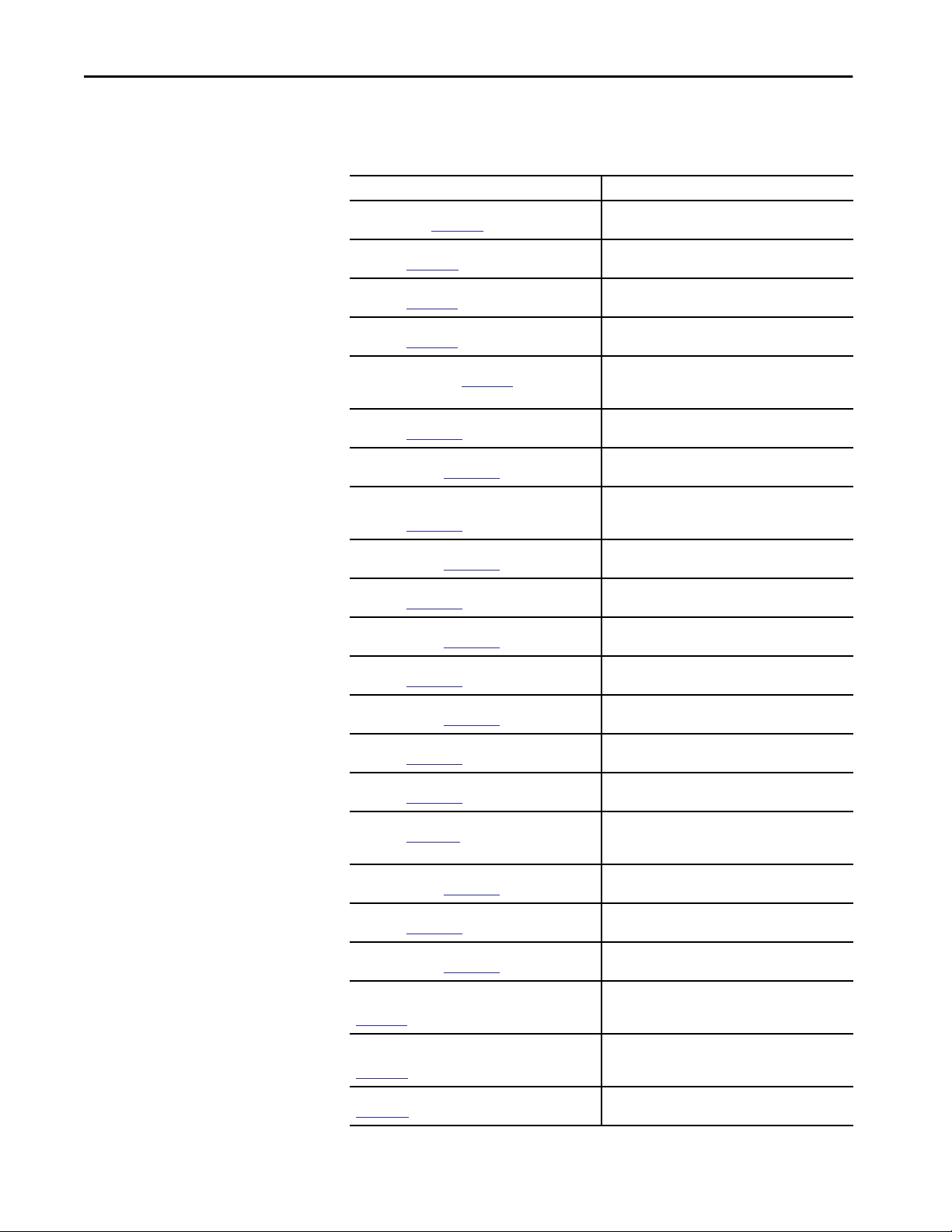

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

1756 ControlLogix and GuardLogix Controllers Technical

Data, publication

1756 ControlLogix I/O Specifications Technical Data,

publication

Armor ControlLogix Controllers Installation Instructions,

publication

ControlLogix Battery Module Installation Instructions,

publication

ControlLogix Chassis and Power Supply Installation

Instructions, publication

ControlLogix Analog I/O Modules User Manual,

publication

ControlLogix Configurable Flowmeter Module User

Manual, publication

ControlLogix Data Highway Plus-Remote I/O

Communication Interface Module User Manual,

publication

ControlLogix DH-485 Communication Module User

Manual, publication

ControlLogix Digital I/O Modules User Manual,

publication

ControlLogix Enhanced Redundancy System User

Manual, publication

ControlLogix HART Analog I/O Modules User Manual,

publication

ControlLogix High-speed Analog I/O Module User

Manual, publication

ControlLogix High-speed Counter Module User Manual,

publication

ControlLogix Low-speed Counter Module User Manual,

publication

ControlLogix Peer I/O Control Application Technique,

publication

ControlLogix Programmable Limit Switch Module User

Manual, publication

ControlLogix Redundancy System User Manual,

publication

ControlLogix Remote I/O Communication Module User

Manual, publication

ControlLogix SIL2 System Configuration Using RSLogix

5000 Subroutines Application Technique, publication

1756-AT010

ControlLogix SIL2 System Configuration Using SIL2

Add-On Instructions Application Technique, publication

1756-AT012

ControlLogix System Selection Guide, publication

1756-SG001

1756-TD001

1756-TD002

1756-IN061

1756-IN576

1756-IN005

1756-UM009

1756-UM010

1756-UM514

1756-UM532

1756-UM058

1756-UM535

1756-UM533

1756-UM005

1756-UM007

1756-UM536

1756-AT016

1756-UM002

1756-UM523

1756-UM534

Provides specifications for ControlLogix and GuardLogix

controllers.

Provides specifications for ControlLogix I/O modules.

Provides information about how to install the Armor

ControlLogix controllers.

Provides information for battery module installation.

Describes how to install and troubleshoot standard and

ControlLogix-XT™ versions of the 1756 chassis and

power supplies, including redundant power supplies.

Provides information about analog I/O module

configuration properties.

Provides information about configurable flowmeter

configuration properties.

Provides information about Data Highway Plus™

communication and remote I/O communication module

configuration properties.

Describes how to connect a 1756-DH485 module to a

DH-485 network with multiple controllers.

Provides information about digital I/O module

configuration properties.

Provides detailed information about ControlLogix

redundancy systems.

Describes how to use HART analog I/O modules.

Provides information about high-speed analog I/O

module configuration properties.

Provides information about high-speed counter-module

configuration properties.

Provides information about low-speed counter-module

configuration properties.

Describes typical peer control applications and provides

details about how to configure I/O modules for peer

control operation.

Provides information about programmable limit switch

configuration properties.

Provides information ControlLogix standard redundancy

systems.

Provides information for remote I/O network

communication configuration.

Provides information about ControlLogix SIL2- certified

fault-tolerant systems.

Provides information about ControlLogix SIL2- certified

fault-tolerant systems.

Describes how to design and select components for your

ControlLogix system.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 13

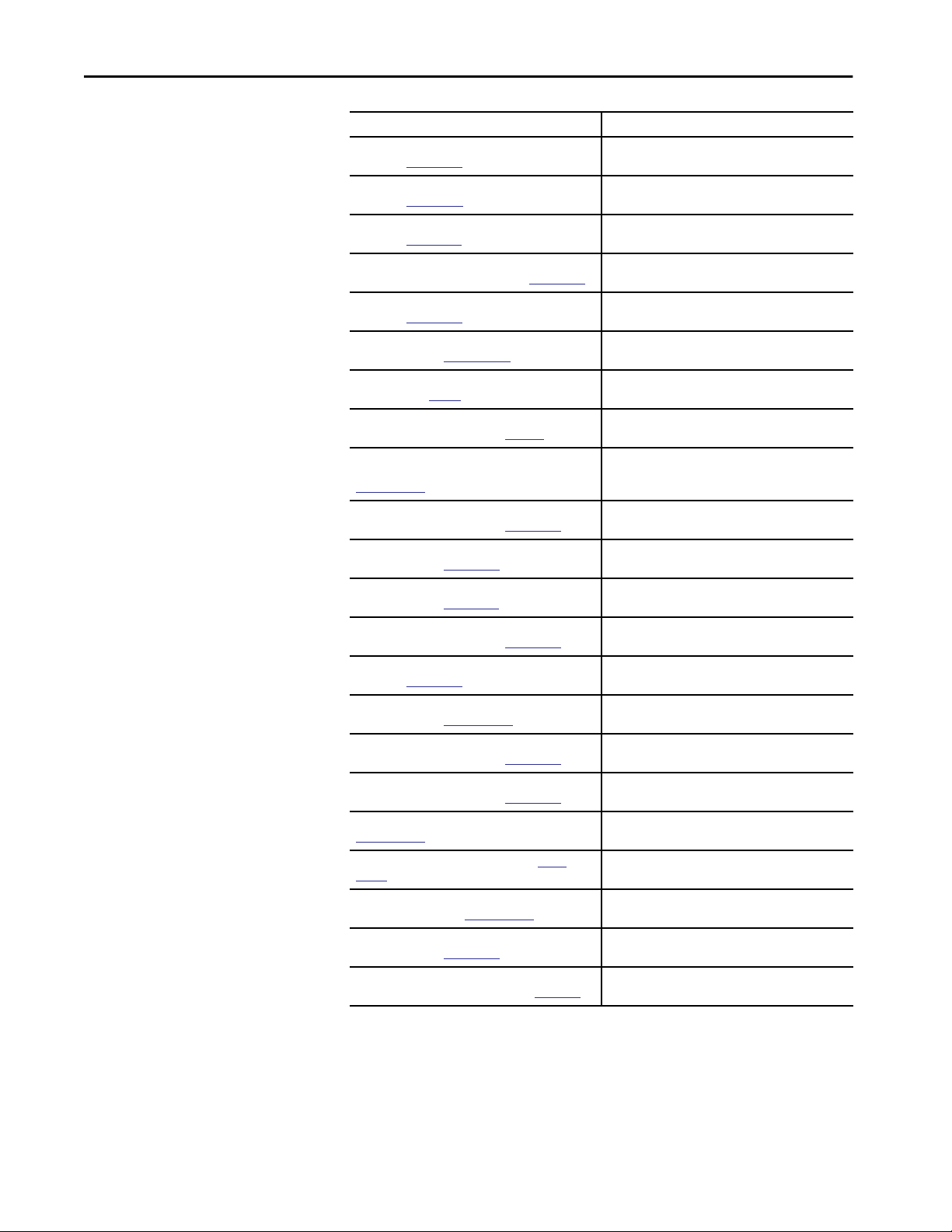

Page 14

Preface

Resource Description

ControlNet Network Configuration User Manual,

publication

DeviceNet Network Configuration User Manual,

publication

Ethernet Design Considerations Reference Manual,

publication

EtherNet/IP and ControlNet to FOUNDATION Fieldbus

Linking Device User Manual, publication

EtherNet/IP Network Configuration User Manual,

publication

FOUNDATION Fieldbus Design Considerations Reference

Manual, publication

Guidelines for Handling Lithium Batteries Technical

Data, publication

Integrated Architecture and CIP Sync Configuration

Application Technique, publication

Integrated Motion on the EtherNet/IP Network

Configuration and Startup User Manual, publication

MOTION-UM003

Logix5000 Controllers Add-On Instructions

Programming Manual, publication

Logix5000 Controllers General Instructions Reference

Manual, publication

Logix5000 Controllers I/O and Tag Data Programming

Manual, publication

Logix5000 Controllers Major, Minor and I/O Faults

Programming Manual, publication

Logix5000 Controllers Messages Programming Manual,

publication

Logix5000 Controllers Motion Instructions Reference

Manual, publication

Logix5000 Controllers Nonvolatile Memory Card

Programming Manual, publication

Logix5000 Controllers Produced and Consumed Tags

Programming Manual, publication

Motion Coordinate System User Manual, publication

MOTION-UM002

PhaseManager™ User Manual, publication

UM001

SERCOS and Analog Motion Configuration and Startup

User Manual, publication

Using ControlLogix in SIL2 Applications Safety Reference

Manual, publication

Using Logix5000 Controllers as Masters or Slaves on

Modbus Application Solution, publication

CNET-UM001

DNET-UM004

ENET-RM002

1788-UM057

ENET-UM001

PROCES-RM005

AG-5.4

IA-AT003

1756-PM010

1756-RM003

1756-PM004

1756-PM014

1756-PM012

MOTION-RM002

1756-PM017

1756-PM011

LOGIX-

MOTION-UM001

1756-RM001

CIG-AP129

Describes how to use ControlNet modules.

Provides information about DeviceNet modules and

devices.

Provides additional information about network design

for your system.

Describes in detail how to use the available Foundation

Fieldbus devices.

Provides information about EtherNet/IP communication

modules.

Describes in detail how to use the available Foundation

Fieldbus devices.

Describes how to store, handle, transport, and dispose

of lithium batteries.

Describes how to configure CIP Sync with Integrated

Architecture® products and applications.

Details how to design your ControlLogix system for

Integrated Motion on the EtherNet/IP network

applications.

Describes in detail how to use add-on instructions.

Provides more information about GSV instructions, SSV

instructions, objects, and attributes.

Describes how to create and configure program tags for

optimal task and program execution.

Provides more information for I/O faults.

Provides information for controller messages.

Provides programmers with details about the motion

instructions that are available for a Logix5000 controller.

Provides information about changing the project that is

available to load from nonvolatile memory,

Provides more information for produced and consumed

tags.

Details how to create and configure a coordinated

motion application system.

Provides more information about instructions for use

with equipment phases.

Details how to configure a sercos motion application

system.

Provides specific configuration and programming

considerations.

Describes how to use Modbus sample programs.

14 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

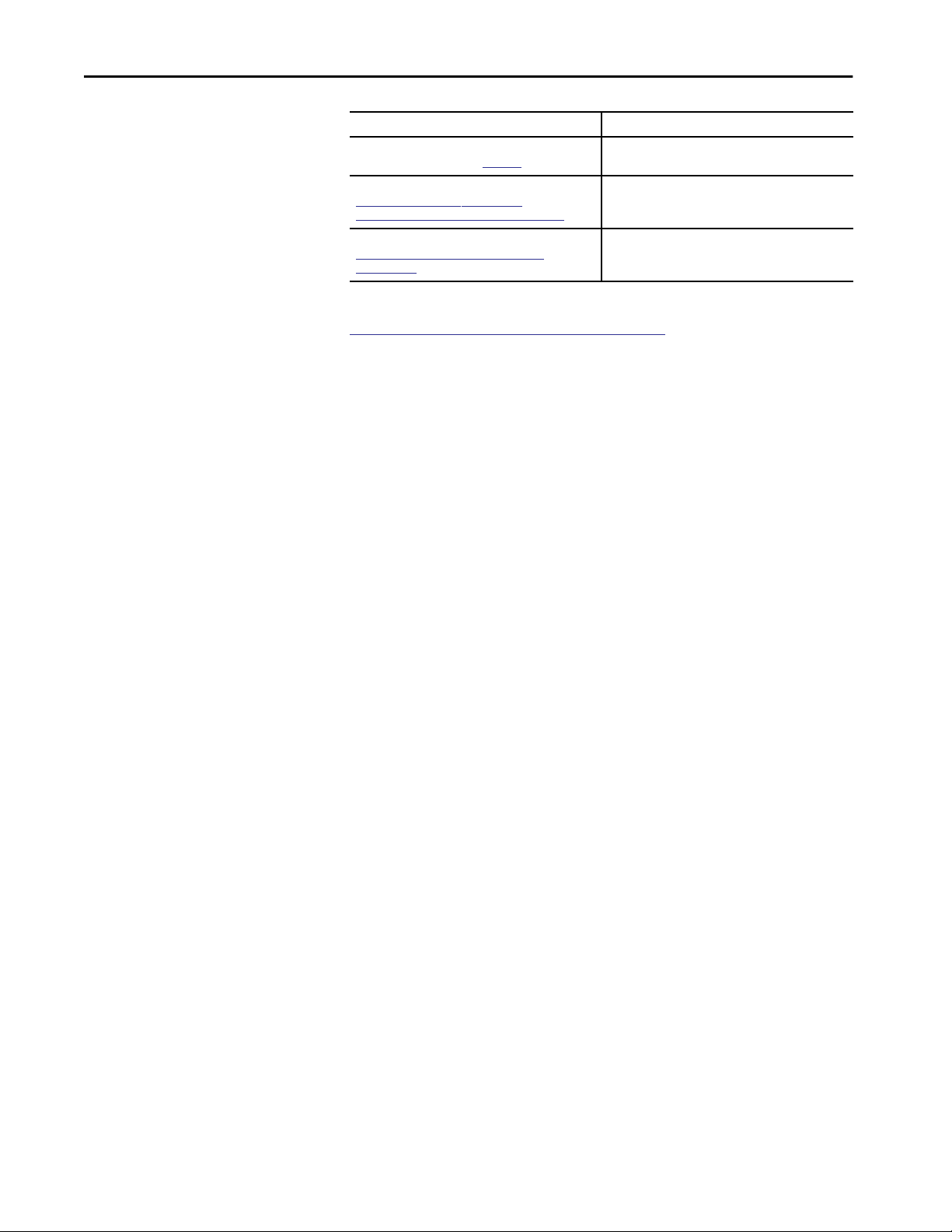

Page 15

Preface

Resource Description

Industrial Automation Wiring and Grounding Guidelines

Application Data, publication 1770-4.1

Product Certifications website,

http://www.rockwellautomation.com/

rockwellautomation/certification/overview.page

Programmable Controllers Battery Reference,

http://www.ab.com/programmablecontrol/

batteries.html

Provides general guidelines to install a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and

other certification details.

Provides Material Safety Data Sheets (MSDS) for

individual replacement batteries.

You can view or download publications at

http://www.rockwellautomation.com/literature/. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 15

Page 16

Preface

Notes:

16 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 17

Install the 1756-L7x Controller

Topic Page

Before You Begin 19

1756-L7x Controller Parts 19

1756-L7x Controller Installation 20

Insert the Controller into the Chassis 21

Insert the Key 22

Install the SD Card 23

Remove the SD Card 25

Install the ESM 26

Uninstall the ESM 27

Chapter 1

ATTENTION: Personnel responsible for the application of safety-related programmable electronic systems (PES) shall be aware

of the safety requirements in the application of the system and shall be trained in using the system.

Table 4 - Environment and Enclosure

ATTENTION:

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications

(as defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio

communication services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, Rockwell Automation publication

requirements

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosure

1770-4.1, for additional installation

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 17

Page 18

Chapter 1 Install the 1756-L7x Controller

Table 5 - North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I Division 2

Groups A, B, C, D, Hazardous Locations and nonhazardous locations only. Each product is

supplied with markings on the rating nameplate indicating the hazardous location

temperature code. When combining products within a system, the most adverse

temperature code (lowest "T" number) may be used to help determine the overall

temperature code of the system. Combinations of equipment in your system are subject

to investigation by the local Authority Having Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has been removed or

the area is known to be nonhazardous.

• Do not disconnect connections to this equipment unless power

has been removed or the area is known to be nonhazardous.

Secure any external connections that mate to this equipment by

using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Substitution of components may impair suitability for Class I,

Division 2.

• If this product contains batteries, they must only be changed in

an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une utilisation en

environnements de Classe I Division 2 Groupes A, B, C, D dangereux et non dangereux.

Chaque produit est livré avec des marquages sur sa plaque d'identification qui

indiquent le code de température pour les environnements dangereux. Lorsque

plusieurs produits sont combinés dans un système, le code de température le plus

défavorable (code de température le plus faible) peut être utilisé pour déterminer le

code de température global du système. Les combinaisons d'équipements dans le

système sont sujettes à inspection par les autorités locales qualifiées au moment de

l'installation.

WARNING: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que l'environnement est classé

non dangereux avant de débrancher l'équipement.

• Couper le courant ou s'assurer que l'environnement est classé

non dangereux avant de débrancher les connecteurs. Fixer tous

les connecteurs externes reliés à cet équipement à l'aide de vis,

loquets coulissants, connecteurs filetés ou autres moyens fournis

avec ce produit.

• La substitution de composants peut rendre cet équipement

inadapté à une utilisation en environnement de Classe I,

Division 2.

• S'assurer que l'environnement est classé non dangereux avant

de changer les piles.

Table 6 - European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to comply with the Essential Health

and Safety Requirements relating to the design and construction of Category 3 equipment intended for use in Zone 2 potentially explosive atmospheres, given in Annex II to this

Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

WARNING:

• This equipment shall be mounted in an ATEX certified enclosure with a minimum ingress protection rating of at least IP54

(as defined in IEC60529) and used in an environment of not more than Pollution Degree 2 (as defined in IEC 60664-1) when

applied in Zone 2 environments. The enclosure must utilize a tool removable cover or door.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• This equipment must be used only with ATEX certified Rockwell Automation backplanes.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

18 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 19

Install the 1756-L7x Controller Chapter 1

Before You Begin

1756-L7x Controller Parts

See 1756-IN005 to install a ControlLogix® chassis and power supply before

you install your controller and power supply.

These sections describe parts that are included with the L7x controllers and

available accessory parts.

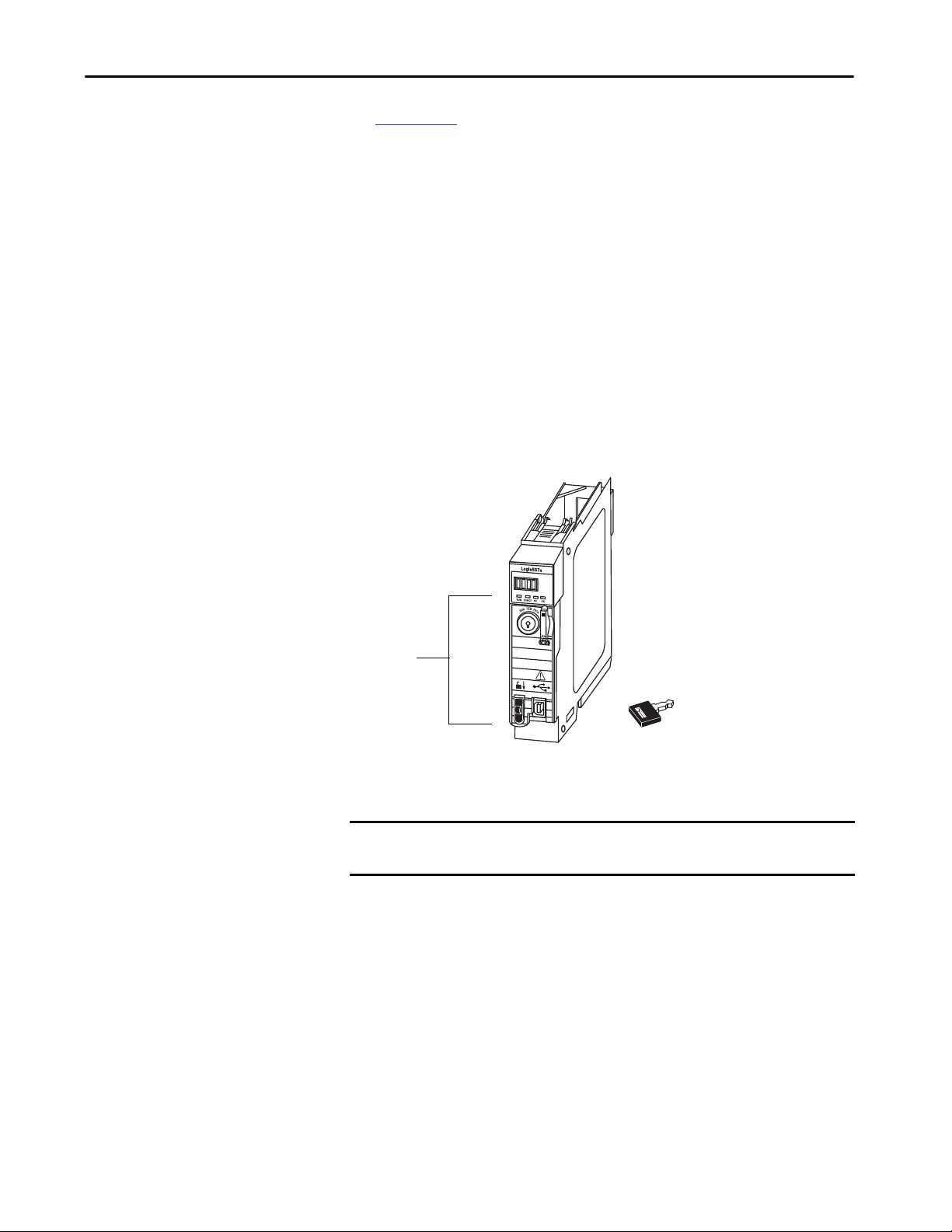

Parts Included with the 1756-L7x Controller

These parts are included with the controller:

• 1756-ESMCAP capacitor-based energy storage module (ESM)

• 1784-SD1 Secure Digital (SD) card, 1 GB

• 1747-KY controller key

Figure 1 - Parts with the 1756-L7x Controller

SD Card (installed)

1756-ESMCAP

(installed)

1747-KY Key

IMPORTANT The 1756-L7x controllers ship with an SD card installed. We recommend that

you leave the SD card installed.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 19

Page 20

Chapter 1 Install the 1756-L7x Controller

Parts Available for Use with the 1756-L7x Controller

You can choose to use the parts included with the controller and these parts

specific to your application.

If your application requires Then use this part

USB connection from a computer to the controller USB cable

Nonvolatile memory 1784-SD1 (1 GB) or 1784-SD2 (2 GB)

ESM without WallClockTime back-up power 1756-ESMNSE

ESM that secures the controller by blocking the USB

connection and SD card use

This ESM provides your application an enhanced degree

of security.

(1) The USB port is intended only for temporary local programming purposes and not intended for permanent connection. The USB

cable is not to exceed 3.0 m (9.84 ft) and must not contain hubs.

(2) For information about the hold-up time of the ESMs, see Estimate the ESM Support of the WallClockTime on page 75 and stored

energy depletion rate on page 27.

(2)

(1)

This ESM does not have WallClockTime back-up power.

Use this ESM if your application requires that the

installed ESM deplete its residual stored energy to 40 μJ

or less before transporting it into or out of your

application.

only a 1756-L73 (8 MB) or smaller memory-sized

controller.

1756-ESMNRM

(2)

Additionally, you can use this ESM with

1756-L7x Controller Installation

WARNING: Do not use the USB port in hazardous locations.

.

ATTENTION:

• The USB port is intended only for temporary local programming purposes

and not intended for permanent connection.

• The USB cable is not to exceed 3.0 m (9.84 ft) and must not contain hubs.

These sections explain how to install the 1756-L7x controller. To install the

1756-L7x controller, complete the tasks summarized in this table.

Task Page

Insert the Controller into the Chassis 21

Insert the Key 22

Install the SD Card 23

Remove the SD Card 25

Install the ESM 26

20 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 21

Install the 1756-L7x Controller Chapter 1

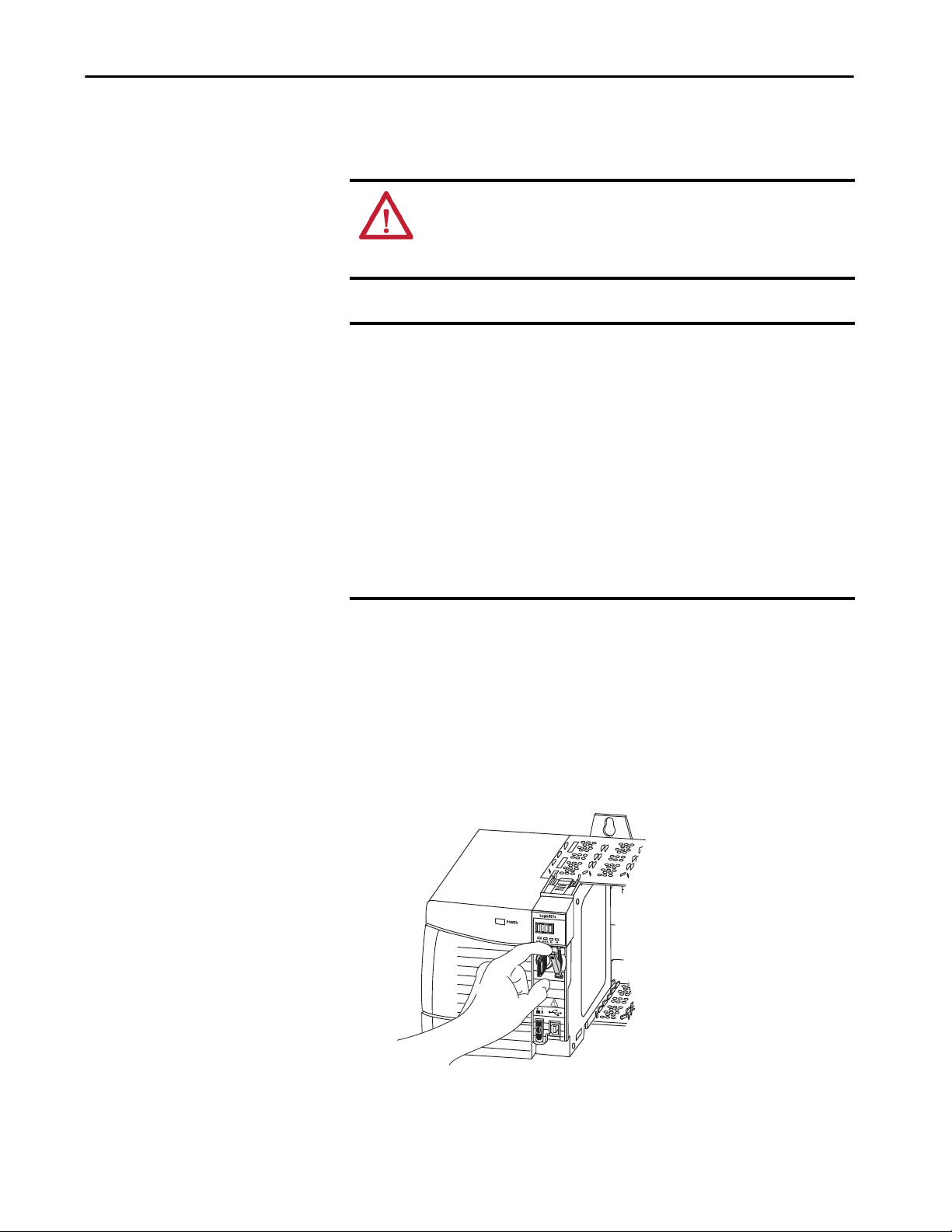

Insert the Controller into the Chassis

When installing a ControlLogix controller, you can do the following:

• Place the controller in any slot.

• Use multiple controllers in the same chassis.

You can install or remove a ControlLogix controller while chassis power is on

and the system is operating.

WARNING: When you insert or remove the module while backplane power

is on, an electrical arc can occur. This could cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the

controller and its mating connector on the chassis. Worn contacts may create

electrical resistance that can affect controller operation.

Table 7 - Prevent Electrostatic Discharge

ATTENTION: This equipment is sensitive to electrostatic discharge, which

can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

IMPORTANT The ESM begins charging when one of these actions occurs:

• The controller and ESM are installed into a powered chassis.

• Power is applied to the chassis that contains a controller with the ESM

installed.

• An ESM is installed into a powered controller.

After power is applied, the ESM charges for up to two minutes as indicated

by CHRG or ESM Charging on the status display.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 21

Page 22

Chapter 1 Install the 1756-L7x Controller

1. Align the circuit board with the top and bottom guides in the chassis.

Top Circuit Board

Aligned

Bottom Circuit Board

Aligned

31997-M

2. Slide the module into the chassis until it snaps into place.

3. Verify that the controller is flush with the power supply or other

installed modules.

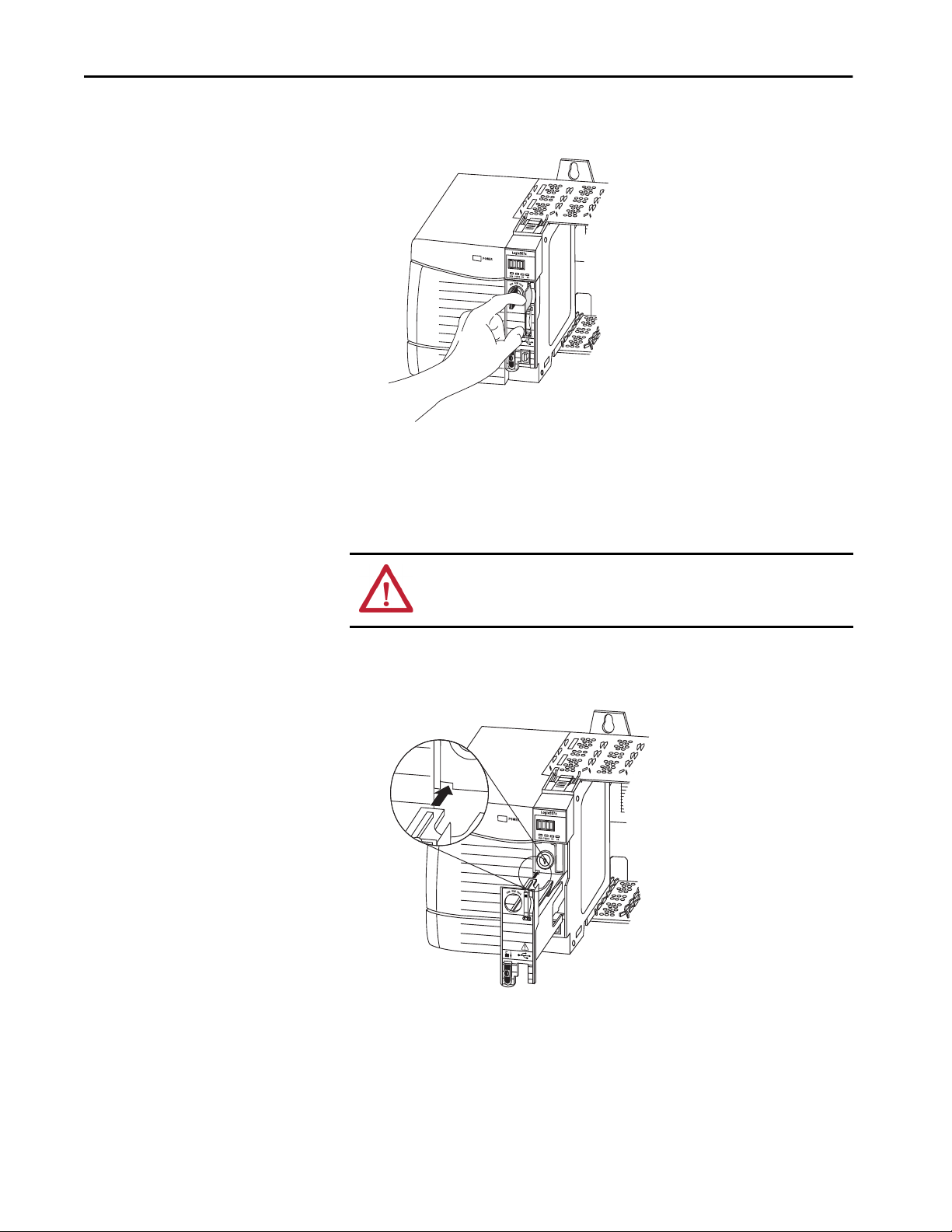

Insert the Key

After you have inserted the controller into the chassis, reference the

Troubleshoot the Module on page 183 for information to interpret the status

indicators.

After the controller is installed, insert the key.

32001-M

22 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 23

Install the 1756-L7x Controller Chapter 1

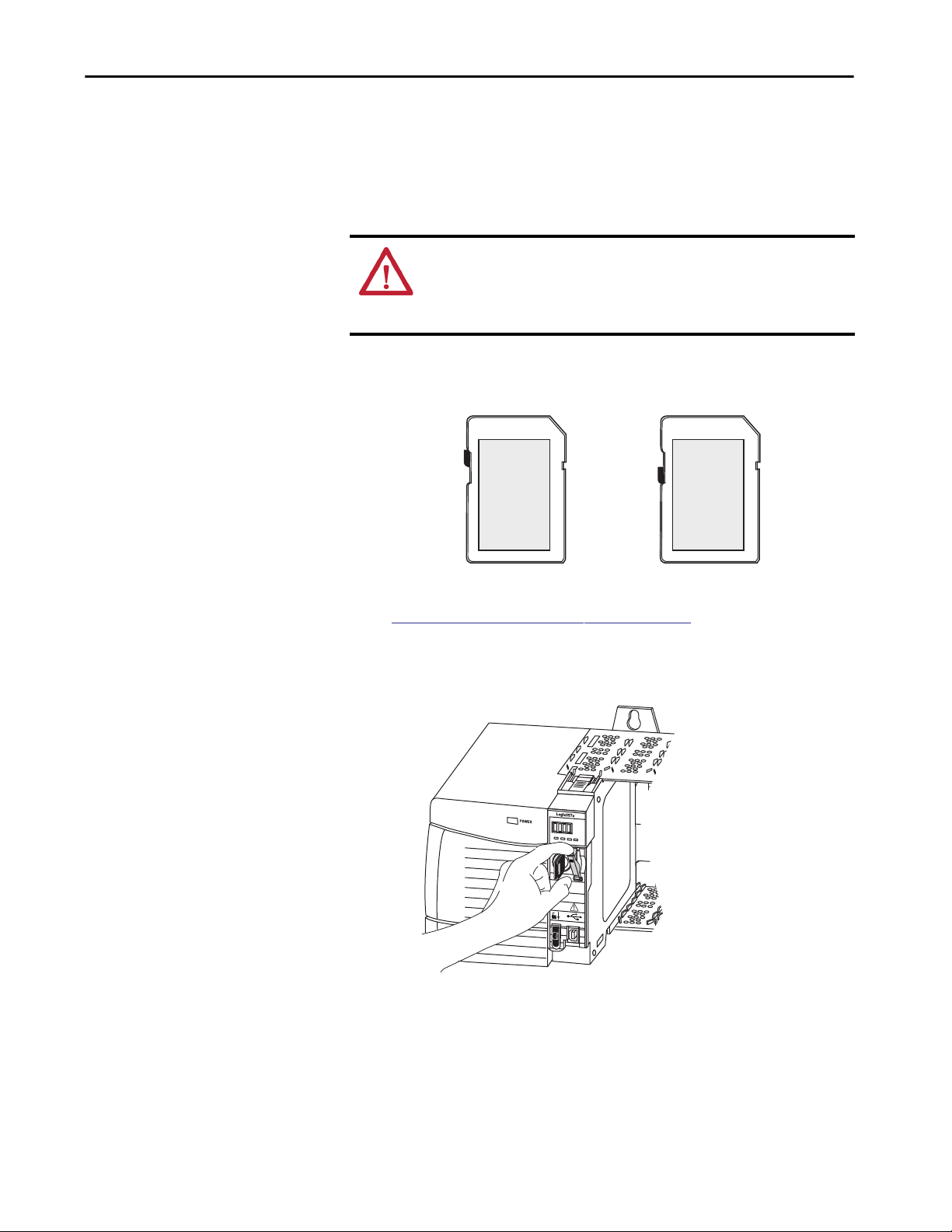

Install the SD Card

Complete these steps to install the SD card in the 1756-L7x controllers.

We recommend that you leave the SD card in the controller, even when it is not

used. If the controller experiences a major nonrecoverable fault, fault

information is saved to the card.

WARNING: When you insert or remove the Secure Digital (SD) memory card

while power is on, an electrical arc can occur. This could cause an explosion in

hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

1. Verify that the SD card is locked or unlocked according to your

preference.

Unlocked

Locked

For more information about the lock/unlock memory settings, see the

Load or Store to the Memory Card on page 68.

2. Open the door for the SD card.

RU

N

FO

RCE

S

D

O

K

3. Insert the SD card into the SD card slot.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 23

Page 24

Chapter 1 Install the 1756-L7x Controller

4. Gently press the card until it clicks into place.

5. Close the SD card door.

Log

ix 55

xx

RUN

FORCE

SD

OK

24 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 25

Install the 1756-L7x Controller Chapter 1

Remove the SD Card

The 1756-L7x controller ships with an SD card installed. Complete these steps

to remove the SD card from the 1756-L7x controller.

WARNING: When you insert or remove the Secure Digital (SD) memory card

while power is on, an electrical arc can occur. This could cause an explosion in

hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

IMPORTANT • Verify that the SD card status indicator is off and that the card is not in

use before removing it.

• We recommend that you do the following:

– Leave an SD card installed.

– Use the SD cards available from Rockwell Automation

(catalog number 1784-SD1 or 1784-SD2).

• While other SD cards can be used with the controller,

Rockwell Automation has not tested the use of those cards with the

controller. If you use an SD card other than those cards that are available

from Rockwell Automation, you can experience data corruption or loss.

• Also, SD cards that are not provided by Rockwell Automation do not have

the same industrial, environmental, and certification ratings as those

cards that are available from Rockwell Automation.

1. Verify that the SD card is not in use by checking to be sure that the

SD indicator is Off.

TIP You can also put the controller into Hard Run mode to keep the controller

from writing to the SD card while it is removed.

2. Open the door to access the SD card.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 25

Page 26

Chapter 1 Install the 1756-L7x Controller

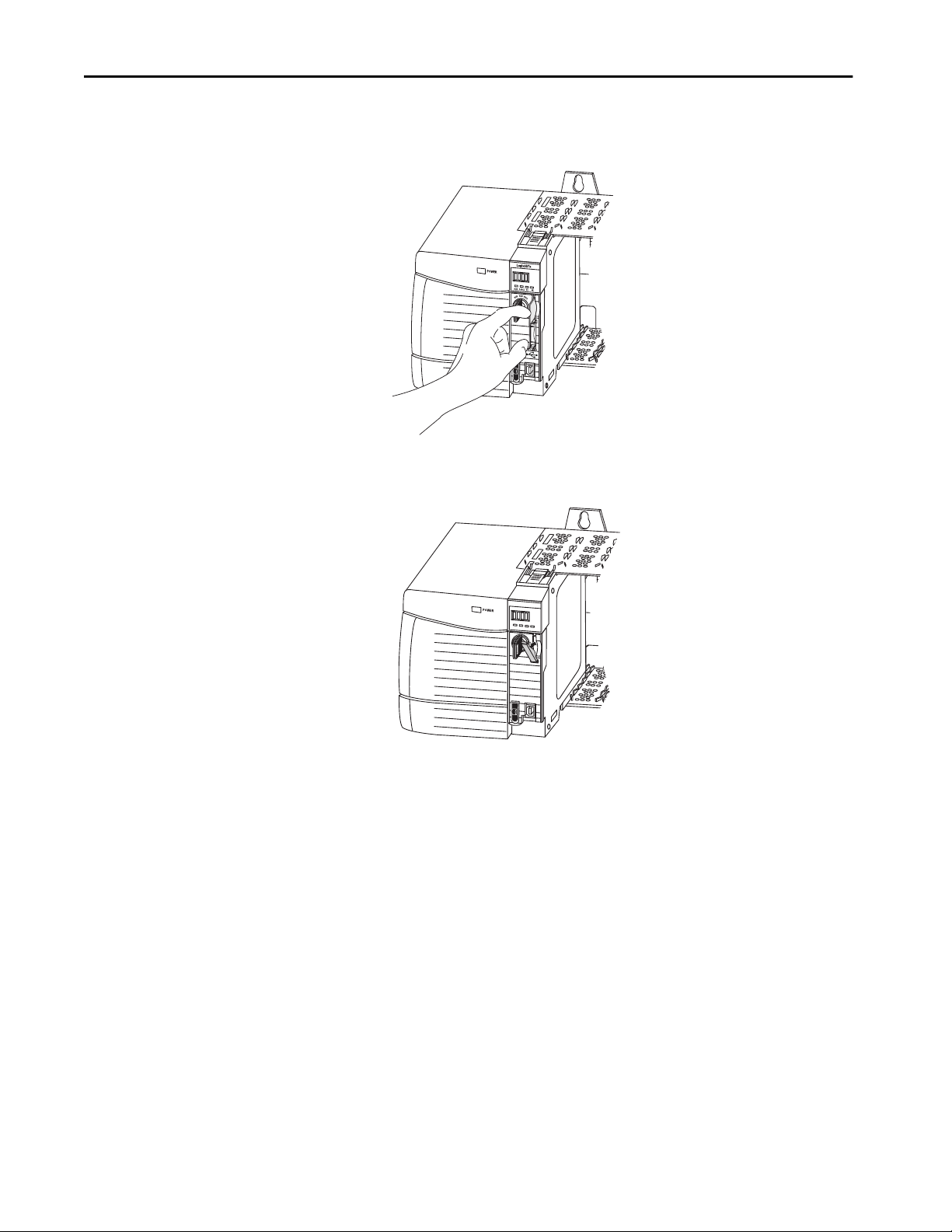

3. Press and release the SD card to eject it.

4. Remove the SD card and close the door.

Install the ESM

To install an ESM in the 1756-L7x controller, complete these steps.

ATTENTION: To avoid potential damage to the product when inserting the

ESM, align it in the track and slide forward with minimal force until the ESM

snaps into place.

1. Align the tongue-and-groove slots of the ESM and controller.

2. Slide the ESM back until it snaps into place.

The ESM begins charging after installation. The following status

messages indicate charging status:

•ESM Charging

•CHRG

26 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 27

Uninstall the ESM

Install the 1756-L7x Controller Chapter 1

After you install the ESM, it can take up to 15 seconds for the charging

status messages to display.

.

IMPORTANT Allow the ESM to finish charging before removing power from the controller.

Failure to do so can result in the loss of the application program. A type 1,

code 40 major fault is logged on powerup.

To verify that the ESM is fully charged, check the status display to confirm

that messages CHRG or ESM charging are no longer indicated.

TIP We recommend that you check the WallClockTime object attributes after

installing an ESM to verify that time of the controller is correct.

The ESM contains a real-time clock. If the ESM is new or came from another

controller, the WallClockTime object attributes for your controller can

change.

WARNING: If your application requires the ESM to deplete its residual stored

energy to 40 μJ or less before you transport it into or out of the application,

use only the 1756-(SP)ESMNSE(XT) module. In this case, complete these

steps before you remove the ESM.

• Turn power off to the chassis.

After you turn power off to the chassis, the controller’s OK status indicator

transitions from green to solid red to OFF.

• Wait at least 20 minutes for the residual stored energy to decrease to

40 μJ or less before you remove the ESM.

There is no visual indication of when the 20 minutes has expired. You must

track that time period.

WARNING: When you insert or remove the energy storage module while

backplane power is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the module

and its mating connector.

IMPORTANT Before you remove an ESM, make necessary adjustments to your program to

account for potential changes to the WallClockTime attribute.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 27

Page 28

Chapter 1 Install the 1756-L7x Controller

Consider these points before removing the ESM:

• The following ESM modules can be currently installed in your

1756-L7x or 1756-L7xXT controller:

– 1756-ESMCAP

– 1756-ESMNSE

– 1756-ESMCAPXT

– 1756-ESMNSEXT

• The 1756-L7x controllers come with the 1756-ESMCAP module

installed. The 1756-L7xXT extreme temperature controller ships with a

1756-ESMCAPXT module installed. For more information on how to

use a 1756-ESMNSE, 1756-ESMNRM, 1756-ESMNSEXT, or

1756-ESMNRMXT module, see

page 26.

• After the 1756-L7x or 1756-L7xXT controllers lose power, because the

chassis power is turned off or the controller has been removed from a

powered chassis, do not immediately remove the ESM.

Wait until the OK status indicator on the controller transitions from

Green to Solid Red to OFF before you remove the ESM.

• You can use the 1756-ESMNSE module with only a 1756-L73 (8 MB)

or smaller memory-sized controller.

• Use the 1756-ESMNSE module if your application requires that the

installed ESM deplete its residual stored energy to 40 μJ or less before

transporting it into or out of your application.

• Once it is installed, you cannot remove the 1756-ESMNRM or

1756-ESMNRMXT module from a 1756-L7x or 1756-L7xXT

controller.

• The Armor™ controller energy storage modules (ESM) cannot be

removed or replaced.

28 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 29

Install the 1756-L7x Controller Chapter 1

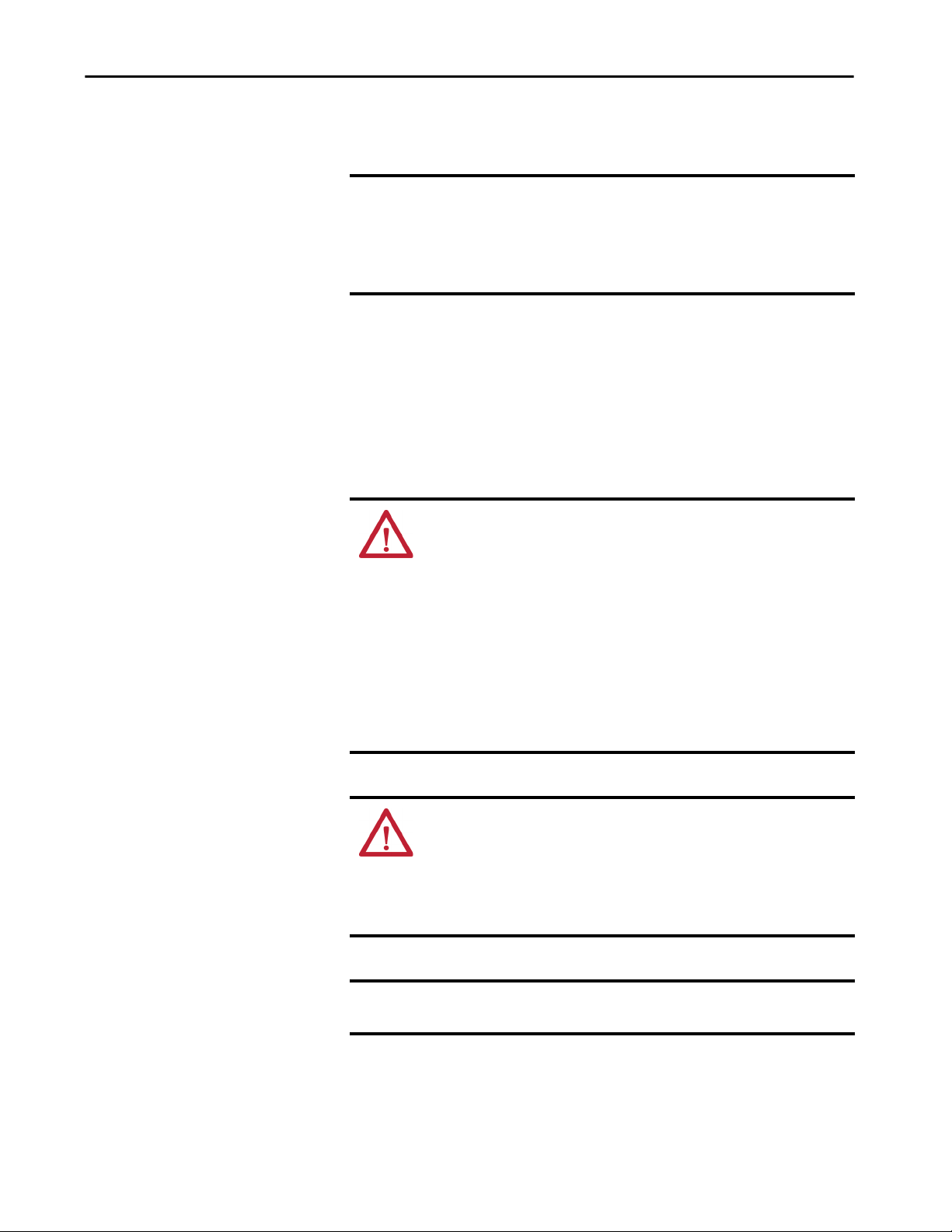

Complete these steps to remove an ESM module from the controller.

1. Remove the key from the mode switch.

IMPORTANT The next step depends on which of the following conditions applies to your

application.

• If you are removing the ESM from a powered 1756-L7x controller, go to

step 2.

• If you are removing the ESM from a 1756-L7x controller that is not

powered, because the chassis power is turned off or the controller has

been removed from a powered chassis, do not immediately remove

the ESM.

Wait until the OK status indicator on the controller transitions from Green to

Solid Red to OFF before you remove the ESM.

After the OK status indicator transitions to Off, go to

step 2.

2. Use your thumb to press down on the black release and pull the ESM

away from the controller.

Log

ix 55

xx

RUN

FORCE

SD

OK

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 29

Page 30

Chapter 1 Install the 1756-L7x Controller

Notes:

30 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 31

Install the 1756-L6x Controller

Topic Page

Before You Begin 33

1756-L6x Controller Parts 33

1756-L6x Controller Installation 34

CompactFlash Card Installation and Removal 34

Battery Connection and Replacement 38

Insert the Controller into the Chassis 40

Remove the Controller from the Chassis 42

Chapter 2

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

Table 8 - Environment and Enclosure

ATTENTION:

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications

(as defined in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio

communication services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, Rockwell Automation publication

requirements

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosure

1770-4.1, for additional installation

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 31

Page 32

Chapter 2 Install the 1756-L6x Controller

Table 9 - North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I Division 2

Groups A, B, C, D, Hazardous Locations and nonhazardous locations only. Each product is

supplied with markings on the rating nameplate indicating the hazardous location

temperature code. When combining products within a system, the most adverse

temperature code (lowest "T" number) may be used to help determine the overall

temperature code of the system. Combinations of equipment in your system are subject

to investigation by the local Authority Having Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD

• D o not disconnect equipment unless power has been removed or

the area is known to be nonhazardous.

• Do not disconnect connections to this equipment unless power

has been removed or the area is known to be nonhazardous.

Secure any external connections that mate to this equipment by

using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Substitution of components may impair suitability for Class I,

Division 2.

• If this product contains batteries, they must only be changed in

an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une utilisation en

environnements de Classe I Division 2 Groupes A, B, C, D dangereux et non dangereux.

Chaque produit est livré avec des marquages sur sa plaque d'identification qui

indiquent le code de température pour les environnements dangereux. Lorsque

plusieurs produits sont combinés dans un système, le code de température le plus

défavorable (code de température le plus faible) peut être utilisé pour déterminer le

code de température global du système. Les combinaisons d'équipements dans le

système sont sujettes à inspection par les autorités locales qualifiées au moment de

l'installation.

WARNING: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que l'environnement est classé

non dangereux avant de débrancher l'équipement.

• Couper le courant ou s'assurer que l'environnement est classé

non dangereux avant de débrancher les connecteurs. Fixer tous

les connecteurs externes reliés à cet équipement à l'aide de vis,

loquets coulissants, connecteurs filetés ou autres moyens fournis

avec ce produit.

• La substitution de composants peut rendre cet équipement

inadapté à une utilisation en environnement de Classe I,

Division 2.

• S'assurer que l'environnement est classé non dangereux avant

de changer les piles.

Table 10 - European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to comply with the Essential Health

and Safety Requirements relating to the design and construction of Category 3 equipment intended for use in Zone 2 potentially explosive atmospheres, given in Annex II to this

Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

WARNING:

• This equipment shall be mounted in an ATEX certified enclosure with a minimum ingress protection rating of at least IP54

(as defined in IEC60529) and used in an environment of not more than Pollution Degree 2 (as defined in IEC 60664-1) when

applied in Zone 2 environments. The enclosure must utilize a tool removable cover or door.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• This equipment must be used only with ATEX certified Rockwell Automation backplanes.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

32 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 33

Install the 1756-L6x Controller Chapter 2

Before You Begin

1756-L6x Controller Parts

See 1756-IN005 to install a ControlLogix® chassis and power supply before

you install your controller and power supply.

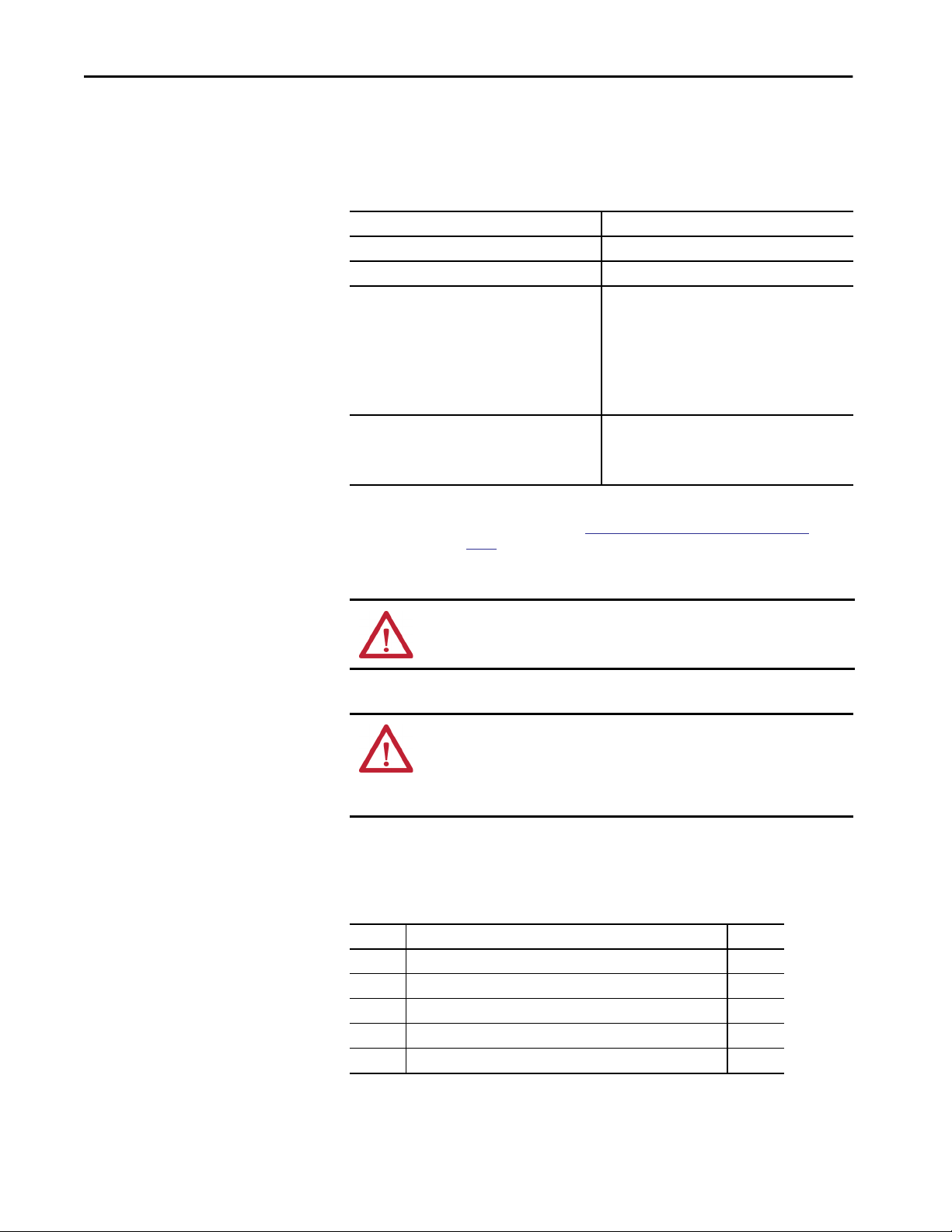

These sections describe parts that are included with the 1756-L6x controllers

and available accessory parts:

• One of the following batteries is included with your controller:

– For series A controllers, catalog number 1756-BA1

– For series B controllers, catalog number 1756-BA2

• Key, catalog number 1747-KY

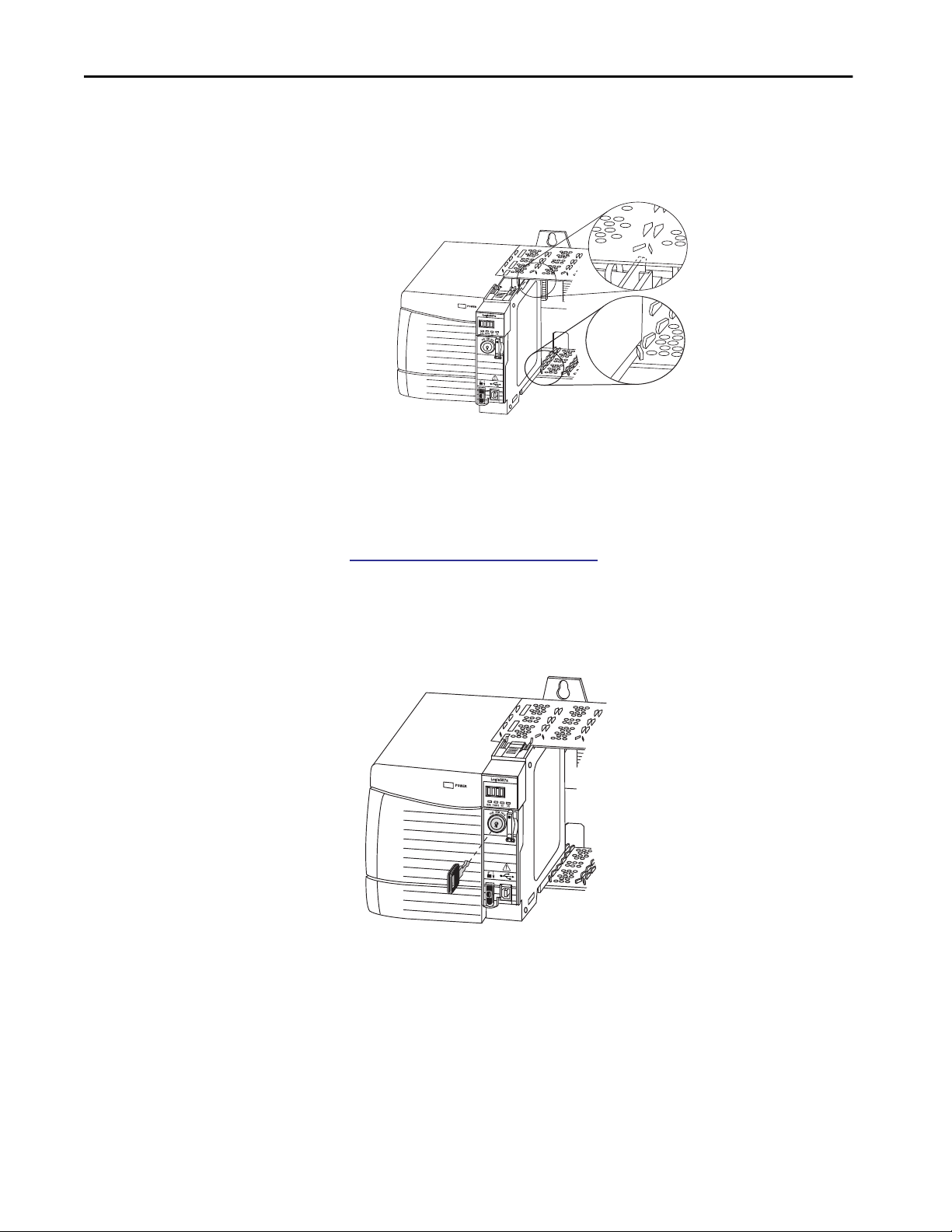

Figure 2 - Parts Included with the 1756-L6x Controller

1756-L6x Controller

1756-BA1 or 1756-BA2

Logix 5563

RUN

I/O

FORCE

RS232

BAT

OK

RUN

REM

PROG

1747-KY Key

Parts Not Included with the 1756-L6x Controller

You can choose to use the parts included with the controller and these parts

specific to your application.

If your application requires Then use this component

RS-232 connection to the controller 1756-CP3 serial cable

Nonvolatile memory 1784-CF128 CompactFlash card

Expanded battery life for extended memory retention 1756-BATM battery module

(1) The 1756-BATM can be used with series A controllers, but it cannot be used with series B controllers. Series B controllers use

battery power differently than previous controllers and therefore battery considerations for this series controller vary. For more

information to determine what battery to use, see the ControlLogix Controllers Selection Guide, publication 1756-SG001.

(1)

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 33

Page 34

Chapter 2 Install the 1756-L6x Controller

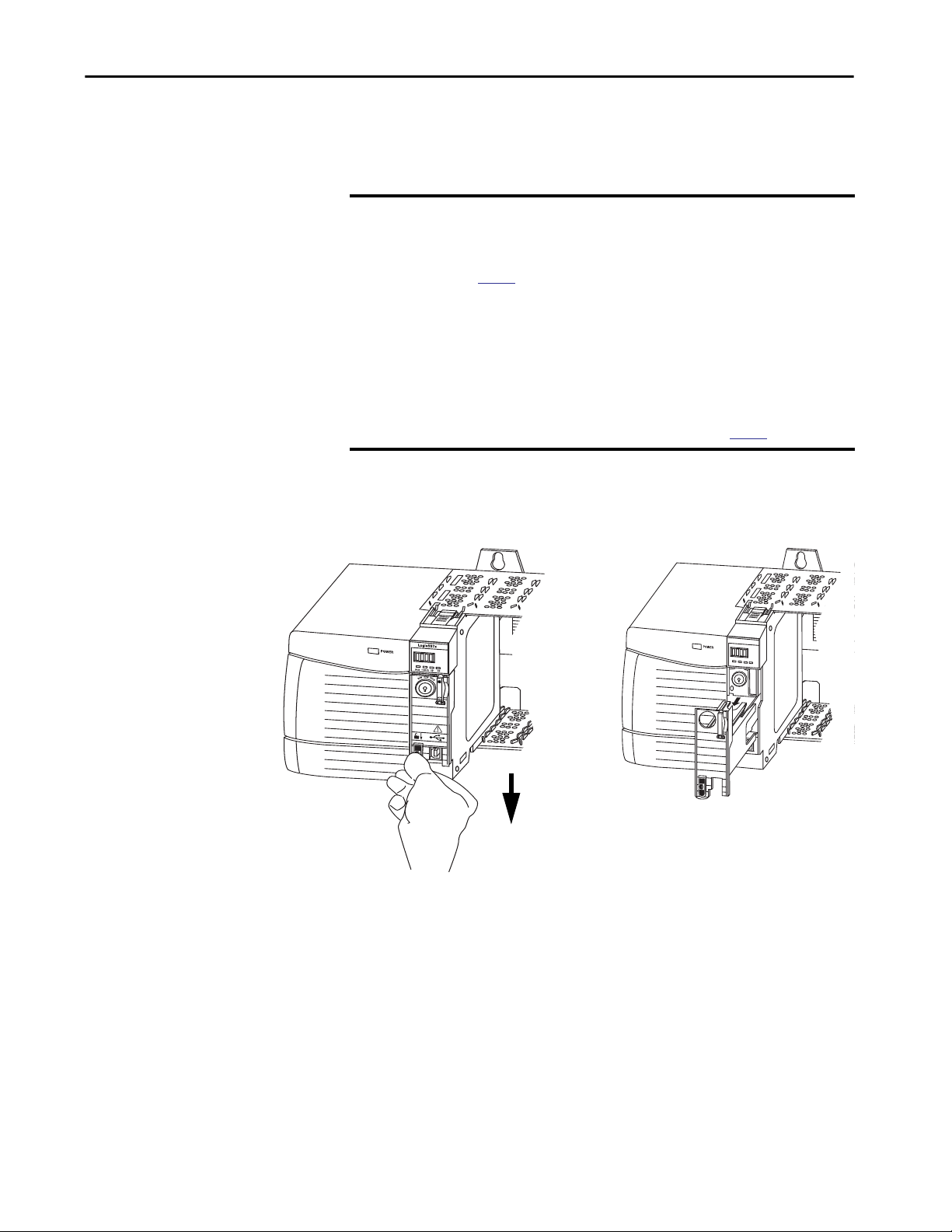

1756-L6x Controller Installation

CompactFlash Card Installation and Removal

These sections explain how to install a 1756-L6x controller. To install the

1756-L6x controller, complete the tasks summarized in this table.

Task Page

CompactFlash Card Installation and Removal 34

Battery Connection and Replacement 38

Insert the Controller into the Chassis 40

Remove the Controller from the Chassis 42

The installation and removal of a CompactFlash card depends on the

controller.

WARNING: When you insert or remove the CompactFlash card while power

is on, an electrical arc can occur. This could cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

• If you are using a series A controller, reference these sections:

–

Install a CompactFlash Card in a Series A Controller on page 35.

–

Remove a CompactFlash Card from a Series A Controller on

page 35.

• If you are using a series B controller, reference these sections:

–

Install a CompactFlash Card in a Series B Controller on page 36.

–

Remove a CompactFlash Card from a Series B Controller on

page 37.

34 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 35

Install the 1756-L6x Controller Chapter 2

Install a CompactFlash Card in a Series A Controller

Complete these steps to install a CompactFlash card in a series A controller.

.

2

4

1

3

1. Lay the controller on its side with the front facing to the left.

2. Raise the locking clip.

3. Insert the CompactFlash card into the slot at the bottom of the

controller.

4. Pull the clip forward and downward until it snaps into place over the

card.

Remove a CompactFlash Card from a Series A Controller

Complete these steps to remove a CompactFlash card from a series A

controller.

2

1

3

1. Lay the controller in its side with the mode switch facing left.

2. Raise the locking clip.

3. Gently pull the card out of the slot.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 35

Page 36

Chapter 2 Install the 1756-L6x Controller

Install a CompactFlash Card in a Series B Controller

Complete these steps to install a CompactFlash card in a series B controller.

1

2

4

3

1. Open the door of the controller and push the CompactFlash latch to the

left.

2. Insert the CompactFlash card with the Allen-Bradley® logo pointing left.

3. Release the latch and secure it over the CompactFlash card.

36 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 37

Install the 1756-L6x Controller Chapter 2

Remove a CompactFlash Card from a Series B Controller

Complete these steps to remove a CompactFlash card from a series B

controller.

1

3

2

1. Verify that the OK indicator is solid green and open the door of the

controller.

2. Push and hold the CompactFlash latch to the left.

3. Push the eject button and remove the card.

4. Release the latch.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 37

Page 38

Chapter 2 Install the 1756-L6x Controller

Battery Connection and Replacement

This product contains a hermetically-sealed lithium battery that may need to be

replaced during the life of the product.

At the end of its life, the battery contained in this product should be collected

separately from any unsorted municipal waste.

The collection and recycling of batteries helps protect the environment and

contributes to the conservation of natural resources as valuable materials are

recovered.

WARNING: When you connect or disconnect the battery an electrical arc can

occur. This could cause an explosion in hazardous location installations. Be

sure that power is removed or the area is nonhazardous before proceeding.

For safety information on the handling of lithium batteries, including handling

and disposal of leaking batteries, see Guidelines for Handling Lithium Batteries,

publication

AG-5.4.

IMPORTANT To prevent program loss, replace a 1756-BA1 or 1756-BA2 battery according

to the following schedule even if the BAT status indicator is Off.

If the temperature 2.54 cm (1 in.)

below the chassis is

-25…+35 °C (-13…+95 F) No replacement required

36…40 °C (96.8…104 F) 3 years

41…45 °C (105.8…113 F) 2 years

46…50 °C (114.8…122 F) 16 months

51…55 °C (123.8…131 F) 11 months

56…70 °C (132.8…158F) 8 months

Replace the battery within

ATTENTION: Store batteries in a cool, dry environment. We recommend

25

C (77 F) with 40…60% relative humidity. You can store batteries for up

to 30 days between -45…+85

C (-49…+185F), such as during

transportation. To avoid leakage or other hazards, do not store batteries

above 60

C (140 F) for more than 30 days.

Connection of the battery varies depending on your controller series:

• If you are using a series A controller, see

• If you are using a series B controller, see

38 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

page 39.

page 40.

Page 39

Install the 1756-L6x Controller Chapter 2

Install the Battery on a Series A Controller

Complete these steps to install a 1756-BA1 battery on a series A controller.

For information to install a 1756-BATM battery module or replace a

1756-BATM assembly, see the ControlLogix Battery Module Installation

Instructions, publication

ATTENTION: For a series A controller, connect only a 1756-BA1 battery or a

1756-BATM battery module. The use of other batteries can damage the

controller.

1756-IN576.

DATE

Wire Terminal Location Connected Wire

Top No connection

Middle Black lead (-)

Bottom Red lead (+)

1. Connect the battery connector to the port to the right of the battery

slot.

2. Snap the battery into the battery slot.

3. Write the date on the battery label.

4. Attach the label to the inside of the controller door.

Rockwell Automation Publication 1756-UM001P-EN-P - May 2017 39

Page 40

Chapter 2 Install the 1756-L6x Controller

Install the Battery on a Series B Controller

Complete these steps to install the battery on a series B controller.

ATTENTION: For a series B controller, connect only a 1756-BA2 battery.

The use of other batteries can damage the controller.

Insert the Controller into the Chassis

DATE

1. Plug the battery connector into the battery port (+ Red, - Black).

2. Insert the battery, with the arrow pointing up, into the battery slot.

3. Write the date on the battery label.

4. Attach the label to the inside of the controller door.

When installing a ControlLogix controller, you can do the following:

• Place the controller in any slot.

• Use multiple controllers in the same chassis.

You can install a ControlLogix controller while chassis power is on and the

system is operating.

WARNING: When you insert or remove the module while backplane power

is on, an electrical arc can occur. This could cause an explosion in hazardous

location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the

controller and its mating connector on the chassis. Worn contacts may create

electrical resistance that can affect controller operation.

40 Rockwell Automation Publication 1756-UM001P-EN-P - May 2017

Page 41

Table 11 - Prevent Electrostatic Discharge