Allen-Bradley Kinetix 350, Compact GuardLogix, ControlLogix, CompactLogix, Kinetix 5500 User Manual

...Page 1

User Manual

Original Instructions

Integrated Motion on the EtherNet/IP Network: Configuration and Startup

ControlLogix, CompactLogix, GuardLogix, Compact GuardLogix, Kinetix 350, Kinetix 5500, Kinetix 5700, Kinetix 6500,

PowerFlex 527, PowerFlex 755

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Components of a Motion System Controller, Communication, Drive, and Software Options . . . . . . . 11

Controller and Ethernet Communication

Module Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Integrated Motion on EtherNet/IP Drive

Software Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Integrated Motion on EtherNet/IP Drives . . . . . . . . . . . . . . . . . . . . . . 13

Options for PowerFlex 755 Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configuration and Startup Scenarios. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Help for Selecting Drives and Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 2

Create a Project for Integrated

Motion on the EtherNet/IP

Network

Create a Controller Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Set Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Add an Ethernet Communication Module . . . . . . . . . . . . . . . . . . . . . . 26

Configure Integrated Motion

Control Using Kinetix Drives

Chapter 3

Add a Kinetix EtherNet/IP Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Configure the Safety Category - Kinetix 5500 Drives . . . . . . . . . 36

Configure the Power Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configure Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Create an Associated Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Create an Axis for a Kinetix Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Establish Feedback Port Assignments . . . . . . . . . . . . . . . . . . . . . . . 41

Create a Motion Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Set the Base Update Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Configure the Axis Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Configure the Associated Axis and Control Mode . . . . . . . . . . . . . . . 47

Specify the Motor Data Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Choose the Catalog Number as the Motor Data Source. . . . . . . 51

Choose Nameplate as the Motor Data Source . . . . . . . . . . . . . . . . 52

Choose Motor NV as the Motor Data Source . . . . . . . . . . . . . . . . 53

Display Motor Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Assign Motor Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configure the Load Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Configure the Master Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Configure Feedback Only Axis Properties . . . . . . . . . . . . . . . . . . . . . . . 57

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 3

Page 4

Table of Contents

Chapter 4

Configure Integrated Motion

Control Using Kinetix 5700 Drives

Add a Kinetix 5700

EtherNet/IP Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Configure the DC-bus Power Supply and Associate an Axis . . . 60

Configure the Regenerative Bus Supply. . . . . . . . . . . . . . . . . . . . . . 64

Continue Inverter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Configure the Inverter Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Create an Associated Axis and Establish Feedback

Assignments for an Inverter Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Create a Motion Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Set the Base Update Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Configure the Axis Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Configure the Associated Axis and Control Mode . . . . . . . . . . . . . . . 88

Specify the Motor Data Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Choose the Catalog Number as the Motor Data Source. . . . . . . 91

Choose Nameplate as the Motor Data Source . . . . . . . . . . . . . . . . 93

Choose Motor NV as the Motor Data Source . . . . . . . . . . . . . . . . 94

Display Motor Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Assign Motor Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Configure the Load Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Configure the Master Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Configure Integrated Motion

Using a PowerFlex 755 Drive

Chapter 5

Add a PowerFlex 755 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Select a Peripheral Feedback Device and Slot Assignment . . . . 101

Select an I/O Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Assign a Power Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Configure Power Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Configure Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configure Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Create an Associated Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Create an Axis for a PowerFlex 755 Drive. . . . . . . . . . . . . . . . . . . 109

Establish Feedback Port Assignments . . . . . . . . . . . . . . . . . . . . . . 110

Create a Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Set the Base Update Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Configure the Axis Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Configure the Associated Axis and Control Mode . . . . . . . . . . . . . . 116

Specify the Motor Data Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Choose Catalog Number as the Motor Data Source . . . . . . . . . 119

Choose Nameplate as the Motor Data Source . . . . . . . . . . . . . . . 121

Choose Drive NV as the Motor Data Source. . . . . . . . . . . . . . . . 122

Display Motor Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Assign Motor Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

4 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 5

Chapter 6

Table of Contents

Configure Integrated Motion

Using a PowerFlex 527 Drive

Set the Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Add a PowerFlex 527 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Configure the PowerFlex 527 Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configure the Drive with Hard-wired Safety Connections . . . 132

Configure the Drive with Integrated Safety Connections . . . . 134

Configure Power Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Configure Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Create an Axis for a PowerFlex 527 Drive . . . . . . . . . . . . . . . . . . . . . . 138

Create the Motion Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Configure the Axis Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Configure the Associated Axis and Control Mode . . . . . . . . . . . . . . 142

Chapter 7

Axis Scheduling About Axis Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Timing Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

One Cycle Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Two Cycle Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Axis Scheduling Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Configure the Update Periods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Motion Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Configuration Examples for a

Kinetix Drive

Axis Configuration Examples for

the PowerFlex 755 Drive

Chapter 8

Example 1: Position Loop with Motor Feedback Only. . . . . . . . . . . 159

Example 2: Position Loop with Dual Feedback . . . . . . . . . . . . . . . . . 163

Example 3: Feedback Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Example 4: Kinetix 5500 Drive, Velocity Loop

with Motor Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Example 5: Kinetix 350 Drive, Position Loop

with Motor Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Example 6: Kinetix 5700 Drive, Frequency Control

with No Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Example 7: 842E-CM Integrated Motion Encoder

with Master Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Chapter 9

Example 1: Position Loop with Motor Feedback Via a

UFB Feedback Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Example 2: Position Loop with Dual Motor Feedback Via a

UFB Feedback Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Example 3: Velocity Loop with Motor Feedback Via a

UFB Feedback Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Example 4: Velocity Loop with No Feedback . . . . . . . . . . . . . . . . . . . 199

Example 5: Frequency Control with No Feedback . . . . . . . . . . . . . . 202

Example 6: Torque Loop with Feedback . . . . . . . . . . . . . . . . . . . . . . . 206

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 5

Page 6

Table of Contents

Chapter 10

Axis Configuration Examples for

the PowerFlex 527 Drive

Example 1: Frequency Control with No Feedback . . . . . . . . . . . . . . 210

Example 2: Velocity Control with Motor Feedback . . . . . . . . . . . . . 214

Example 3: Position Control with Motor Feedback . . . . . . . . . . . . . 217

Chapter 11

Commission an Axis Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Direct Coupled Rotary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Direct Coupled Linear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Rotary Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Linear Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Changing Scaling Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Hookup Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Run a Motor and Feedback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Run a Motor Feedback Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Run a Marker Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Applying the Commutation Hookup Test . . . . . . . . . . . . . . . . . . . . . 232

Unknown Commutation Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Verification of Known Commutation Offset . . . . . . . . . . . . . . . 233

Non-standard or Incorrect Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 233

Run a Commutation Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Polarity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Autotune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Load Observer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Benefits of Load Observer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

How Load Observer Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Load Observer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Adaptive Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Benefits of Adaptive Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

How Adaptive Tuning Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Adaptive Tuning Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Status Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Load Ratio Data from Motion Analyzer. . . . . . . . . . . . . . . . . . . . . . . . 249

Test an Axis with Motion Direct Commands. . . . . . . . . . . . . . . . . . . 249

Access Motion Direct Commands for an Axis or Group . . . . . 250

Understanding STO Bypass When Using

Motion Direct Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

6 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 7

Table of Contents

Chapter 12

Homing Guidelines for Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Active Homing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Passive Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Active Homing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Passive Homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Absolute Position Recovery (APR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

APR Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Position Recovery Considerations for Logix5000

Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Absolute Feedback Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

SERCOS Versus Integrated Motion on Ethernet Networks . . 263

APR Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

APR Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

APR Fault Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

APR Fault Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Online Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Resetting an APR Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Absolute Position Loss without APR Faults. . . . . . . . . . . . . . . . . 273

Behavior of APR for Incremental Encoders . . . . . . . . . . . . . . . . . 274

Saving an ACD File Versus Upload of a Project . . . . . . . . . . . . . 274

Chapter 13

Manual Tune When to Manually Tune an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Axis Configuration Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Current Tuning Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Loop Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Motion Generator and Motion Direct Commands . . . . . . . . . . 279

Additional Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Feedforward Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Compensation Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Filters Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Limits Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Planner Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Configure Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Monitor Tags with the Quick Watch Window . . . . . . . . . . . . . . . . . 285

Use Motion Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 7

Page 8

Table of Contents

Chapter 14

Status, Faults, and Alarms Faults and Alarms Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

QuickView Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Data Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Drive Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Connection Faults and Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Troubleshoot Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Manage Motion Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Configure the Exception Actions for AXIS_CIP_DRIVE . . . . . . . 294

Inhibit an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Example: Inhibit an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Example: Uninhibit an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Digital I/O Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Appendix A

Parameter Group Dialog Boxes Parameter Dialog-box Listings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Out of Box Configuration for

PowerFlex Drives

Appendix B

Program a Velocity Profile and Jerk Rate . . . . . . . . . . . . . . . . . . . . . . . 305

Definition of Jerk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Choose a Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Use % of Time for the Easiest Programming of Jerk. . . . . . . . . . 307

Velocity Profile Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Jerk Rate Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Profile Operand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Enter Basic Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Example Motion Control Program. . . . . . . . . . . . . . . . . . . . . . . . . 317

Download a Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Choose a Motion Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

Troubleshoot Axis Motion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

Why Does My Axis Accelerate When I Stop It? . . . . . . . . . . . . . 321

Why Does My Axis Overshoot Its Target Speed?. . . . . . . . . . . . 322

Why Is There a Delay When I Stop and

Then Restart a Jog? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Why Does The Axis Reverse Direction

When Stopped and Started? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Programming with the MDSC Function . . . . . . . . . . . . . . . . . . . . . . . 329

PowerFlex Out-of-Box Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . 332

Recommended Out-of-Box Settings. . . . . . . . . . . . . . . . . . . . . . . . 332

Setting the ACO/AVO Attributefor PF527 Drives Only. . . . . . . . 336

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

8 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 9

Preface

Use this manual to configure an integrated motion on the EtherNet/IP™

network application and to start up your motion solution with a Logix

controller-based system.

This manual is designed to give you a straightforward approach to an

integrated motion control solution. If you have any comments or suggestions,

see Documentation Feedback

on the back cover of this manual.

Summary of Changes

This manual contains new and updated information as indicated in the

following table and the change bars throughout.

Top ic Pag e

Integrated Motion on EtherNet/IP Drives 13

Add a Kinetix EtherNet/IP Drive 36

Configure the Regenerative Bus Supply 64

Additional Resources

Create an Associated Axis and Establish Feedback

Assignments for an Inverter Drive

Absolute Position Recovery (APR) 262

These resources contain information about related products from Rockwell

88

Automation®.

Table 1 - Publications About Related Products

Resource Description

842E-CM Integrated Motion Encoder on EtherNet/IP User Manual,

publication 842E-UM002

ControlLogix 5580 Controllers Migration Guide, publication 1756-RM100 Provides information about the features and functions of the ControlLogix® 5580

ControlLogix 5580 and GuardLogix 5580 Controllers User Manual,

publication 1756-UM543

CompactLogix 5380 and Compact GuardLogix 5380 Controllers User Manual,

publication 5069-UM001

ControlLogix System User Manual, publication 1756-UM001 Describes the necessary tasks to install, configure, program, and operate a

EtherNet/IP Network Configuration User Manual, publication ENET-UM001

GuardLogix 5570 Controllers User Manual, publication 1756-UM022

GuardLogix 5570 and Compact GuardLogix 5370 Controller Systems Safety Reference

Manual, publication 1756-RM099

GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems Safety Reference

Manual, publication 1756-RM012

Integrated Motion on the EtherNet/IP Network Reference Manual,

publication MOTION-RM003

Kinetix 350 Single-axis EtherNet/IP Servo Drive User Manual, publication 2097-UM002

Describes the necessary tasks to install, wire, and troubleshoot your encoder.

controllers.

Provides information on how to install, configure, program, and operate

ControlLogix 5580 and GuardLogix® 5580 controllers.

Provides information on how to install, configure, program, and operate

CompactLogix™ 5380 and Compact GuardLogix 5380 controllers.

ControlLogix system.

Describes Ethernet network considerations, networks, and setting IP addresses.

Provides information on how to install, configure, and operate GuardLogix 5570

controllers in Studio 5000 Logix Designer® projects, version 21 or later.

Provides information on how to meet safety application requirements for

GuardLogix 5570 controllers in Studio 5000 Logix Designer projects, version 21 or later.

Describes the necessary tasks to install, configure, program, and operate a

ControlLogix system.

Provides a programmer with details about the Integrated Motion on the EtherNet/IP

network Control Modes, Control Methods, and AXIS_CIP_DRIVE Attributes.

Provides detailed information on wiring, power, troubleshooting, and integration with

ControlLogix, or CompactLogix controller platforms.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 9

Page 10

Preface

Table 1 - Publications About Related Products (continued)

Resource Description

Kinetix 5500 Servo Drives Installation Instructions, publication 2198-IN001 Provides installation instructions for the Kinetix® 5500 Integrated Axis Module and

Kinetix 5500 Servo Drives User Manual, publication 2198-UM001

Kinetix 5700 Servo Drives User Manual, publication 2198-UM002 Provides information on installing, configuring, start up, troubleshooting, and

Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drives User Manual,

publication 2094-UM002

Logix 5000 Controllers Motion Instructions Reference Manual,

publication MOTION-RM002

Logix 5000 Controllers Common Procedures, publication 1756-PM001

Logix 5000 Controllers General Instructions Reference Manual, public ation 1756-RM003 Provides a programmer with details about general instructions for a Logix-based

LOGIX 5000 Controllers Advanced Process Control and Drives and Equipment Phase and

Sequence Instructions Reference Manual, publication 1756-RM006

Logix 5000 Controllers Quick Start, publication 1756-QS001

Motion System Tuning Application Technique, publication MOTION-AT005 Provides detailed information on motion system tuning.

PowerFlex 527 Adjustable Frequency AC Drive User Manual, publication 520-UM002 Provides information on installation, configuration, start up, troubleshooting, and

PowerFlex 750-Series AC Drives Programming Manual, publication 750-PM001

PowerFlex 750-Series AC Drives Reference Manual, publication 750-RM002 Provides detailed drive information including operation, parameter descriptions, and

PowerFlex 755 Drive Embedded EtherNet/IP Adapter User Manual,

publication 750COM-UM001

PowerFlex 750-Series Safe Speed Monitor Option Module Safety Reference Manual,

publication 750-RM001

PowerFlex 750-Series Safe Torque Off Option Module User Manual,

publication 750-UM002

PowerFlex 755 Integrated Safety - Safe Torque Off Option Module User Manual,

publication 750-UM004

PowerFlex 755/755T Integrated Safety Functions Option Module User Manual,

publication 750-UM005

The Integrated Architecture and CIP Sync Configuration Application Technique,

publication IA-AT003

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website, www.rok.auto/certifications

Network specifications details, http://www.odva.org

Axis Module components.

Provides information on installation, configuration, start up, troubleshooting, and

applications for the Kinetix 5500 servo drive systems.

applications for the Kinetix 5700 servo drive systems.

Provides information on installation, configuration, start up, troubleshooting, and

applications for the Kinetix 6200 and Kinetix 6500 servo drive systems.

Provides a programmer with details about motion instructions for a Logix-based

controller.

Provides detailed and comprehensive information about how to program a Logix

5000™ controller.

controller.

Provides a programmer with details about process and drives instructions for a Logixbased controller.

Describes how to get started programming and maintaining Logix5000 controllers.

applications for the PowerFlex® 527 drive.

Provides information that is necessary to install, start-up, and troubleshoot PowerFlex

750-Series Adjustable Frequency AC Drives.

programming of the AC drive.

Provides information on installation, configuration, start up, troubleshooting, and

applications for the PowerFlex 755 Drive Embedded EtherNet/IP Adapter.

These publications provide detailed information on installation, setup, and operation

of the 750-Series safety option modules.

Provides detailed configuration information on CIP™ Sync technology and time

synchronization.

Provides general guidelines for installing a Rockwell Automation® industrial system.

Provides declarations of conformity, certificates, and other certification details.

ODVA is the organization that supports network technologies that are built on the

Common Industrial Protocol (CIP) — DeviceNet™, EtherNet/IP, CompoNet™, and

ControlNe t™.

You can view or download publications at

http://www.rockwellautomation.com/literature/. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative

10 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 11

Components of a Motion System

Top ic Pag e

Controller, Communication, Drive, and Software Options 11

Integrated Motion on EtherNet/IP Drives 13

Configuration and Startup Scenarios 18

Help for Selecting Drives and Motors 20

Chapter 1

Controller, Communication, Drive, and Software Options

You need a Logix 5000™ controller with a connection to the EtherNet/IP™

network (either via an embedded Ethernet port or an Ethernet communication

module). You also need an Ethernet adapter for the controller (if the controller

does not have embedded Ethernet), an Integrated Motion drive (see Ta b l e 4

),

and configuration and programming software.

TIP ControlLogix® 5560 and GuardLogix® 5560 controllers are not supported in

Studio 5000 Logix Designer® application, version 21.00.00 and later.

Controller and Ethernet Communication Module Options

A GuardLogix or Compact GuardLogix safety controller is required for

motion and safety applications.

Ta b l e 2

Studio 5000 Logix Designer application.

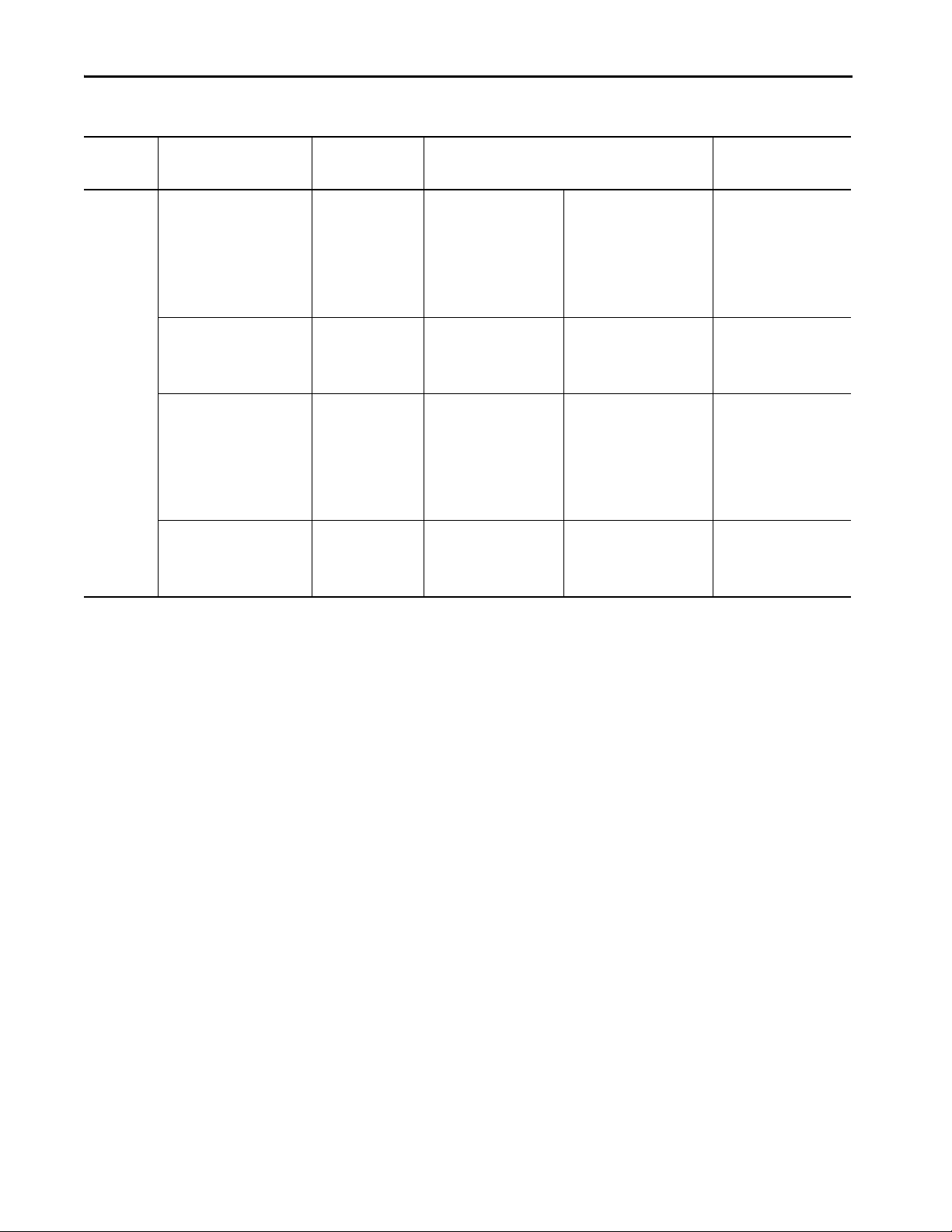

Table 2 - Controllers and Required Software Versions

lists the available controllers and minimum required version of the

Controller Studio 5000 Logix Designer Version

ControlLogix 5580 controllers Version 28 or later

GuardLogix 5580 controllers Version 31 or later

CompactLogix 5380 controllers Version 30 or later

Compact GuardLogix 5380

controllers

ControlLogix 5570 controllers Version19 or later

GuardLogix 5570 controllers Version 20 or later

CompactLogix 5370 controllers Version 20 or later

Compact GuardLogix 5370

controllers

Vers ion 3 1 or la ter

Vers ion 2 8 or la ter

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 11

Page 12

Chapter 1 Components of a Motion System

Ta b l e 3 provides information on how many motion axes are supported

depending on the hardware that is used in your application and the

configuration of your axes. For example, you can have eight Position Loop axes

per 1756-EN2T module. Each drive requires one TCP and one CIP™

connection. If you have other devices that consume TCP connections on the

module, it reduces the number of drives you can support. Only the drives and

axes that are configured for Position Loop are limited. Frequency Control,

Velocity Loop, and Torque Loop configured drives and axes are not limited.

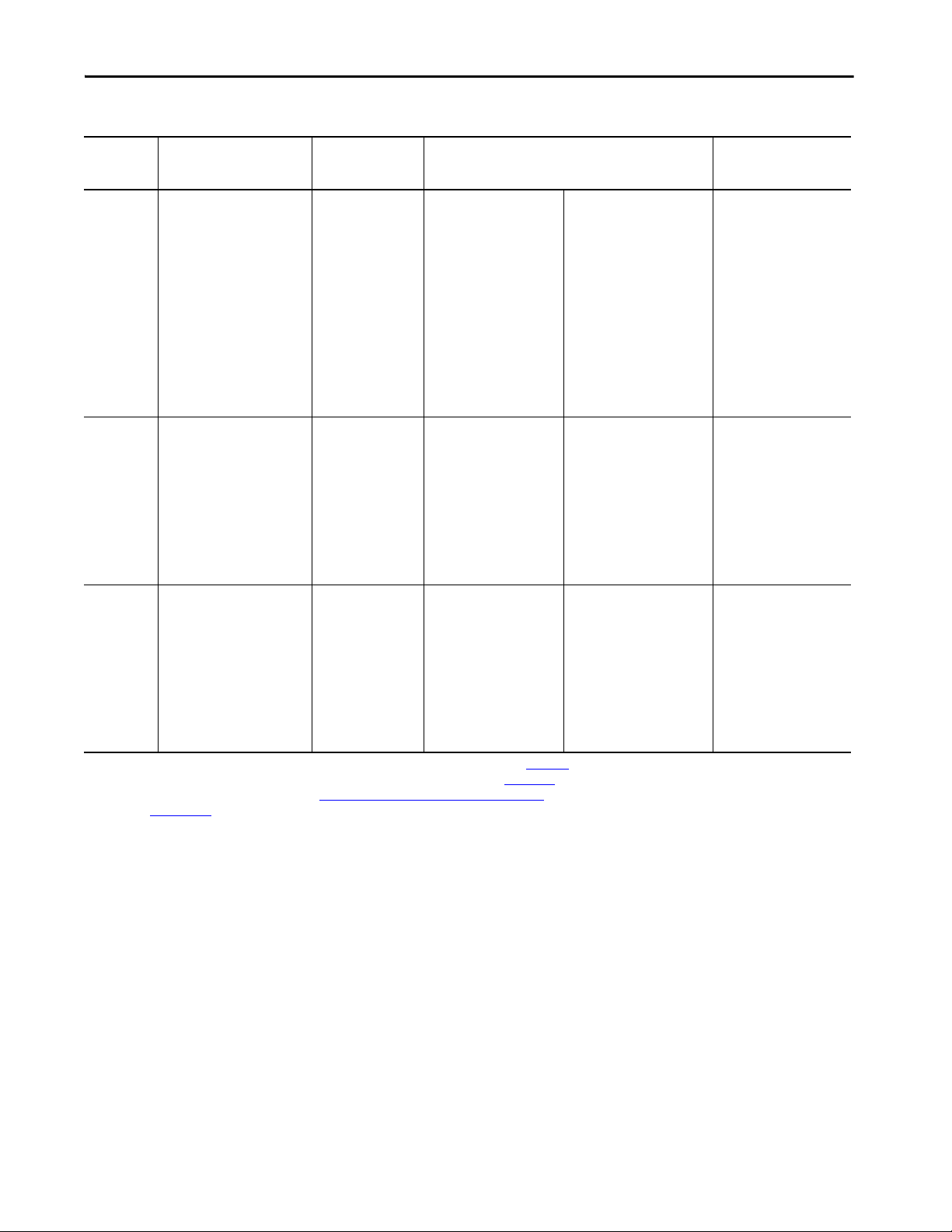

Table 3 - Supported Axes by Controller Type

Controller Communication

ControlLogix 5560, GuardLogix 5560,

ControlLogix 5570,GuardLogix 5570

Armor™ ControlLogix 5570, Armor™ GuardLogix 5570

ControlLogix 5580, GuardLogix 5580

ControlLogix 5580,

GuardLogix 5580

CompactLogix 5380,

Compact GuardLogix 5380

CompactLogix 5370,

Compact GuardLogix 5370,

Armor CompactLogix 5370,

Armor Compact

GuardLogix 5370

1756-L81E, 1756-L81ES Embedded Ethernet

1756-L82E, 1756-L82ES Embedded Ethernet

1756-L83E, 1756-L83ES

1756-L84E, 1756-L84ES

1756-L85E Embedded Ethernet 256 Up to 256 300 max nodes

5069-L306ERM, 5069-L306ERMS2 Embedded Ethernet 2 Up to 256 16 max nodes

5069-L310ERM, 5069-L310ERMS2 Embedded Ethernet 4 Up to 256 24 max nodes

5069-L320ERM, 5069-L320ERMS2 Embedded Ethernet 8 Up to 256 40 max nodes

5069-L330ERM, 5069-L330ERMS2 Embedded Ethernet 16 Up to 256 Version 30 and earlier: 50 max

5069-L340ERM, 5069-L340ERMS2 Embedded Ethernet 20 Up to 256 Version 30 and earlier: 55 max

5069-L350ERM, 5069-L350ERMS2 Embedded Ethernet 24 Up to 256 Version 30 and earlier: 60 max

5069-L380ERM, 5069-L380ERMS2 Embedded Ethernet 28 Up to 256 Version 30 and earlier: 70 max

5069-L3100ERM,

5069-L3100ERMS2

1769-L18ERM Embedded Ethernet 2 Up to 100 8 max nodes

1769-L27ERM Embedded Ethernet 4 Up to 100 16 max nodes

1769-L30ERM, 1769-L30ERMS Embedded Ethernet 4 Up to 100 16 max nodes

1769-L33ERM, 1769-L33ERMS

1769-L33ERMO, 1769-L33ERMOS

1769-L36ERM, 1769-L36ERMS

1769-L36ERMO, 1769-L36ERMOS

1769-L37ERM, 1769-L37ERMS,

1769-L37ERMO, 1769-L37ERMOS,

1769-L38ERM, 1769-L38ERMS

1769-L38ERM0, 1769-L38ERM0S

(1)

Modules

1756-EN2T and 1756-EN2TF 8 Up to 100 —

1756-EN3TR 100 Up to 100 —

1756-EN2TR 8 Up to 100 —

1756-EN2T and 1756-EN2F 8 Up to 100 —

1756-EN2TP 8 Up to 100 —

1756-EN3TR 100 Up to 256 —

1756-EN2TR 8 Up to 256 —

Embedded Ethernet

Embedded Ethernet 32 Up to 256 Version 30 and earlier: 80 max

Embedded Ethernet 8 Up to 100 32 max nodes

Embedded Ethernet 16 Up to 100 64 max nodes

Embedded Ethernet 16 Up to 100 64 max nodes

Embedded Ethernet 16 Up to 100 80 max nodes

Supported Axes

Position Loop

(2)

(2)

(2)

256 Up to 256 100 max nodes

256 Up to 256 175 max nodes

256 Up to 256 250 max nodes

(3)

(4)

Other Loop Types Integrated Motion Drives

nodes

Version 31 and later: 60 max

nodes

nodes

Version 31 and later: 90 max

nodes

nodes

Version 31 and later: 120 max

nodes

nodes

Version 31 and later: 150 max

nodes

nodes

Version 31 and later: 180 max

nodes

(5)

12 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 13

Components of a Motion System Chapter 1

(1) For more information on Ethernet communication modules, see 1756 ControlLogix Communication Modules Specifications Technical Data, publication 1756-TD003.

(2) ControlLogix 5580 and GuardLogix 5580 can also use Ethernet communication modules to communicate on the EtherNet/IP network.

(3) Multiple controllers can control drives on a common 1756-ENxTx module, so based on the TCP connection limit, up to 128 can be supported.

(4) Only the drives/axes configured for Position Loop are limited. Frequency Control, Velocity Loop, and Torque Loop configured drives/axes are not limited.

(5) If more than the maximum number of I/O modules are configured under the embedded Ethernet Port, a Project Verify error notifies you that the maximum number of nodes on the local Ethernet Port

has been exceeded.

Integrated Motion on EtherNet/IP Drive Software Options

The following software is required for use with your system:

• Studio 5000 Logix Designer application (see Table 2 on page 11

minimum versions for controllers and Ta b l e 4

for minimum versions for

drives)

•RSLinx® Classic software, version 3.51.00 or later

• For PowerFlex® 755 drives, you need the Add-on Profile, V18 or later.

for

Integrated Motion on

Ta b l e 4 lists the EtherNet/IP drives available for integrated motion.

EtherNet/IP Drives

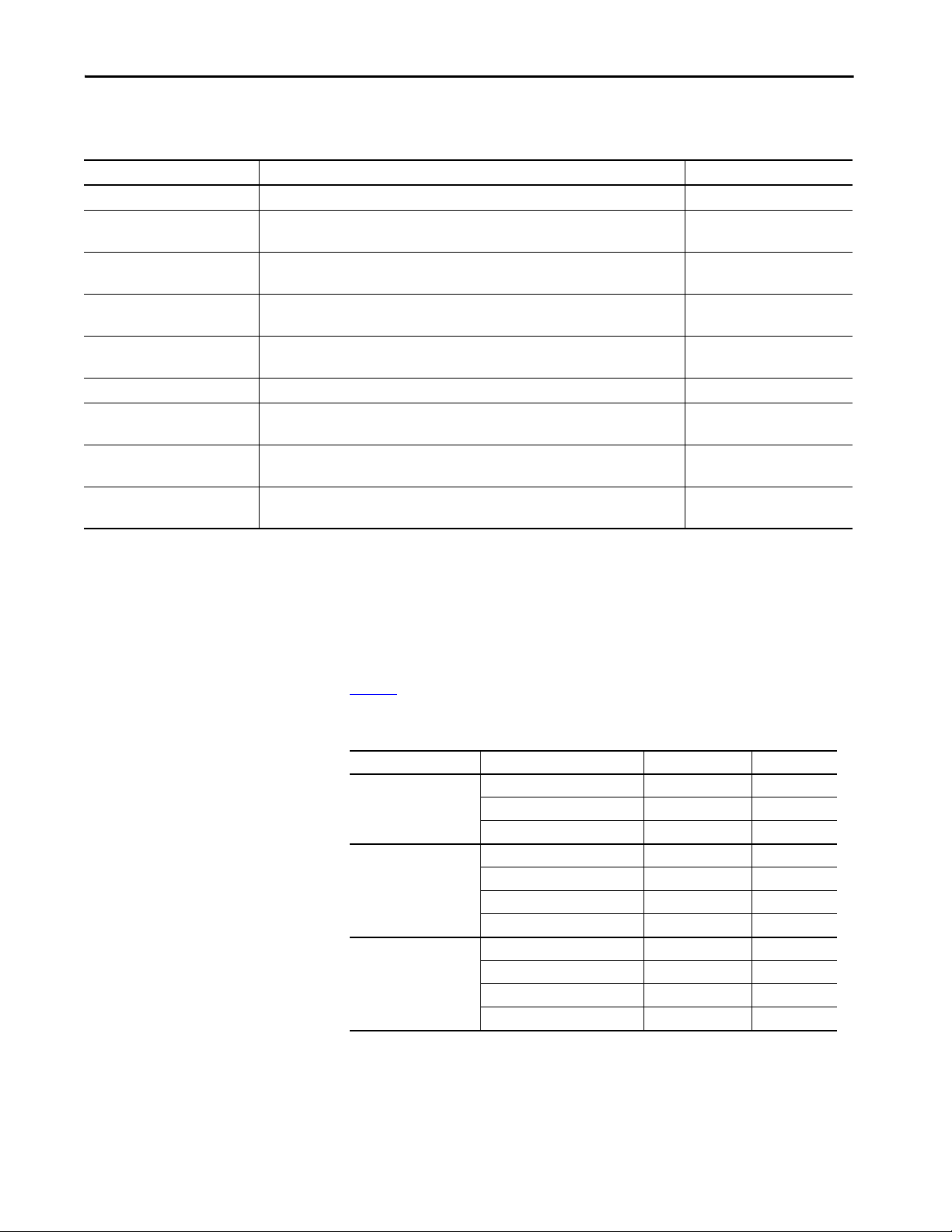

Table 4 - Integrated Motion EtherNet/IP Drives

Drive Description Supported Axis

842E-CM The 842E-CM is an ultra-high

Kinetix®

(1)

350

Kinetix

(1)

5500

resolut ion encoder with

EtherNet/IP interface with time

synchronization for motion

control. These encoders provide

18-bit single-turn resolution and

30-bit multi-turn resolution.

The Kinetix 350 drive is a singleaxis EtherNet/IP servo drive with

Safe Torque Off (STO) functional

safety that supports the

Integrated Motion on

EtherNet/IP network.

The Kinetix 5500 servo drives

support the Integrated Motion

on EtherNet/IP network. Singleaxis and multi-axis, AC, DC,

AC/DC, and AC/DC hybrid bu ssharing configurations are

possible.

2198-Hxxx-ERS servo drives

support hardwired STO with

connections to safety inputs.

2198-Hxxx-ERS2 servo drives

support integrated STO with

connections to the safety

controller.

Configurations

Feedback Only 10…30V 21.00.00

Posi tion

Velo cit y

Tor qu e

Frequency Control

Posi tion

Velo cit y

Tor qu e

Power Ratings Minimum Version of the

(3)

Voltag e Ranges

100V AC 1-phase

200V AC 1-phase

200V AC 3-phase

400V AC 3-phase

Voltag e Ranges

195…264V AC rms 1-phase

195…264V AC rms 3-phase

324…528V AC rms 3-phase

Output Power

0.4…0.8 kW

0.5…3 kW

0.5…3 kW

1…3 kW

Output Power

0.2…1.0 kW

0.3…7.2 kW

0.6…14.9 Kw

Studio 5000 Logix

Designer Application

21.00.00

21.00.00

24.00.00

(4)

(5)

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 13

Page 14

Chapter 1 Components of a Motion System

Table 4 - Integrated Motion EtherNet/IP Drives (continued)

Drive Description Supported Axis

Configurations

Kinetix

5700

(1)

2198-Sxxx-ERS3 (single-axis)

and 2198-Dxxx-ERS3 (dual-axis)

series A support hardwired and

integrated STO with connections

to the safety controller

(Version26). Series B also

Frequency Control

Feedba ck Only

Position Loop

Velo city Loop

Tor que Loo p

support integrated Timed SS1

safety function and (Version 31).

2198-Pxxx Non-Regenerative

AC/DC Conver ter

2198-Sxxx-ERS4 (single-axis)

and 2198-Dxxx-ERS4 (dual-axis)

(Version 31) support integrated

safe monitor functions with

connection to the safety

controller.

Frequency Control

Feedba ck Only

Position Loop

Velo city Loop

Tor que Loo p

2198-RPxxx Regenerative AC/DC

Converter

Power Ratings Minimum Version of the

(3)

Studio 5000 Logix

Designer Application

Input Voltage Range

324…528V AC rms,

Output Voltage Range

3-phase

Output Power

1.6…112 kW

For 1.6…60kW

26.00.00

For 90…112kW

32.00.00

480V AC rms nominal

Current Range

2.5…192 A

Input Voltage Range

26.00.00

324…528V

Current Range

10…69 A

Input Voltage Range

324…506V AC rms,

Output Voltage Range

3-phase

Output Power

1.6…112 kW

For 1.6…60kW

31.00.00

For 90…112kW

32.00.00

480V AC nominal

Current Range

2.5…192 A

Input Voltage Range

324…528V

Output Power

24…140 kW

32.00.00

Current Range

35.3/88.0…207.0/312.0 A

(6)

(7)

14 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 15

Table 4 - Integrated Motion EtherNet/IP Drives (continued)

Components of a Motion System Chapter 1

Drive Description Supported Axis

Configurations

Kinetix

6500

(1)

The Kinetix 6500 drive is a

closed-loop modular servo drive.

It consists of an integrated axis

(IAM) power module and up to

seven axis (AM) power modules,

Feedba ck Only

Posi tion

Velo cit y

Tor qu e

Power Ratings Minimum Version of the

(3)

Voltag e Range

324…528V AC rms 3-phase

each coupled with a Kinetix 6500

control module.

The IAM and AM power modules

provide power for up to eight

axes.

The 2094-EN02D-M01-S0 control

modules support Safe Torque Off

and 2094-EN02D-M01-S1 control

modules support safe-speed

monitoring.

Power Flex

(2)

527

The PowerFlex 527 is a singleaxis EtherNet/IP AC drive with

STO feature that supports the

Integrated Motion on

Frequency Control

Posi tion

Velo cit y

Input Power

100…600V AC

EtherNet/IP network. Hardwired

STO and Integrated STO are

supported.

It consists of an integrated axis

power module and incremental

encoder feedback (sold

separately).

Power Flex

(2)

755

The PowerFlex 755 Drive

EtherNet/IP AC drive is a closed

loop drive. It consists of an

integrated axis power module

with five option slots for

communication, I/O, feedback,

Frequency Control

Posi tion

Velo cit y

Tor qu e

Input Power

400V AC

480V AC

600V AC

690V AC

safety, and auxiliary control

power (sold separately).

The PowerFlex 755 drive can

control a motor in closed loop

and open loop mode.

(1) For more information on Kinetix servo drives, see Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003.

(2) For more information on PowerFlex drives, see PowerFlex Low Voltage Drives Selection Guide, publication PFLEX-SG002

(3) For more information about the configuration types, see Configure the Associated Axis and Control Mode on page 47

publication MOTION-RM003

(4) Drives with catalog numbers ending in ERS.

(5) Drives with catalog numbers ending in ERS2.

(6) Drives with catalog numbers ending in ERS3.

(7) Drives with catalog numbers ending in ERS4.

.

.

and the Integrated Motion on the EtherNet/IP Network Reference Manual,

Continuous Output Power

6.0…45 kW

Output Power

0.4...22 kW/0.5...30 Hp /

0.9...62.1 A

Output Power:

0.75…1250 kW/2.1…2150 A

1...1750 Hp/2.1...2070 A

1...1400 Hp/1.7...1430 A

7.5...1400 kW/12...1400 A

Studio 5000 Logix

Designer Application

21.00.00

24.00.00

RSLogix 5000

®, version

19.00.00 or later

Studio 5000 Logix Designer

application, version 21.00.00

or later

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 15

Page 16

Chapter 1 Components of a Motion System

Options for PowerFlex 755 Drives

When a PowerFlex 755 drive is used in Integrated Motion on EtherNet/IP

mode, the Logix controller and Studio 5000 Logix Designer application are the

exclusive owners of the drive (same as Kinetix). An HIM or other drive

software tools, such as DriveExplorer™ and DriveTools™ SP, cannot be used to

control the drive or change configuration settings. These tools can only be used

for monitoring.

The PowerFlex 755 drive contains an EtherNet/IP adapter that is embedded

on the main control board. This embedded adapter lets you easily configure,

control, and collect drive data over Ethernet networks. The drive can operate

also in the integrated motion mode or the existing I/O mode.

The PowerFlex 755 drive has five option ports that can accept a combination of

options for control, communication, I/O, feedback, safety, and auxiliary

control power. Only one safety option module can be installed on a drive.

There are seven types of peripherals:

•HIM

•I/O

• Communications, Ethernet Standard

•Aux Power

•Safety

•Encoder Interface

•Universal Feedback

(1)

(2)

(3)

(3)

Ta b l e 5 lists valid peripheral devices and ports for various PowerFlex 755

drives.

(1) Aux power is not supported for Integrated Motion.

(2) Only one safety option module can be installed on a drive.

(3) See Tab le 6

for supported feedback module combinations.

16 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 17

Components of a Motion System Chapter 1

Table 5 - Peripheral Devices and Ports for PowerFlex 755 Devices That Support Integrated Motion on Ethernet Networks

Drive Catalog Number Description Ports

PowerFlex 755-EENET-CM PowerFlex 755 AC Drive via Embedded Ethernet 4, 5, 6, 7, 8

PowerFlex 755-EENET-CM-S PowerFlex 755 AC Drive via Embedded Ethernet - Safe Torque Off Option 4 and 5

6 is reserved for safety

PowerFlex 755-EENET-CM-S1 PowerFlex 755 AC Drive via Embedded Ethernet - Safe Speed Monitor Option 4 and 5

6 is reserved for safety

PowerFlex 755-EENET-CM-S3

PowerFlex 755-HiPwr-EENET-S4

(1)

PowerFlex 755 AC Drive via Embedded Ethernet - Integrated Safe Torque Off Option

(1)

PowerFlex 755 AC Drive via Embedded Ethernet - Integrated Safety Functions Option

PowerFlex 755-HiPwr-EENET-CM PowerFlex 755 High-power AC Drive via Embedded Ethernet 4, 5, 6, 7, 8

PowerFlex 755-EENET-CM-S PowerFlex 755 High-power AC Drive via Embedded Ethernet - Safe Torque Off Option 4 and 5

PowerFlex 755-EENET-CM-S1 PowerFlex 755 High-power AC Drive via Embedded Ethernet - Safe Speed Monitor Option 4 and 5

PowerFlex 755-HiPwr-EENET-CM-S3 PowerFlex 755 High-power AC Drive via Embedded Ethernet - Integrated Safe Torque Off Option 4 and 5

(1) PowerF lex Drive firm ware revision 1 4 or later requ ired.

(2) Safe Torque Off option module is only available when used with GuardLogix 5580 and Compact GuardLogix 5380 safety controllers.

(3) Integrated Motion support of the Integrated Safety Functions option module is only available when used with GuardLogix 5580 and Compact GuardLogix 5380 safety controllers.

(2)

4 and 5

6 is reserved for safety

(3)

4 and 5

6 is reserved for safety

6 is reserved for safety

6 is reserved for safety

6 is reserved for safety

See the manual for your PowerFlex 755 AC Drive safety or communication

option for more information on using your specific peripheral device.

Ta b l e 6

Table 6 - Supported Feedback Module Combinations

(1) The safe speed monitor option module must be used with the 20-750-DENC-1 Dual Incremental Encoder module or the

shows the feedback module combinations that are supported.

Option Supported Module Catalog Number Valid Ports

Two Feedback Options Single Incremental Encoder 20-750-ENC-1 4…8

Dual Incremental Encoder 20-750-DENC-1 4…8

Universal Feedback Card 20-750-UFB-1 4…6

Two Feedback Options and

One Safe Torque Off Option

Two Feedback Options and

One Safe Speed Monitor

(1)

Option

20-750-UFB-1 Universal Feedback module.

Single Incremental Encoder 20-750-ENC-1 4 and 5

Dual Incremental Encoder 20-750-DENC-1 4 and 5

Universal Feedback 20-750-UFB-1 4 and 5

Safe Torque Off 20-750-S 6

Single Incremental Encoder 20-750-ENC-1 4 and 5

Dual Incremental Encoder 20-750-DENC-1 4 and 5

Universal Feedback 20-750-UFB-1 4 and 5

Safe Speed Monitor 20-750-S1 6

For more information, see the Installation Instructions for your PowerFlex

750-Series AC Drive.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 17

Page 18

Chapter 1 Components of a Motion System

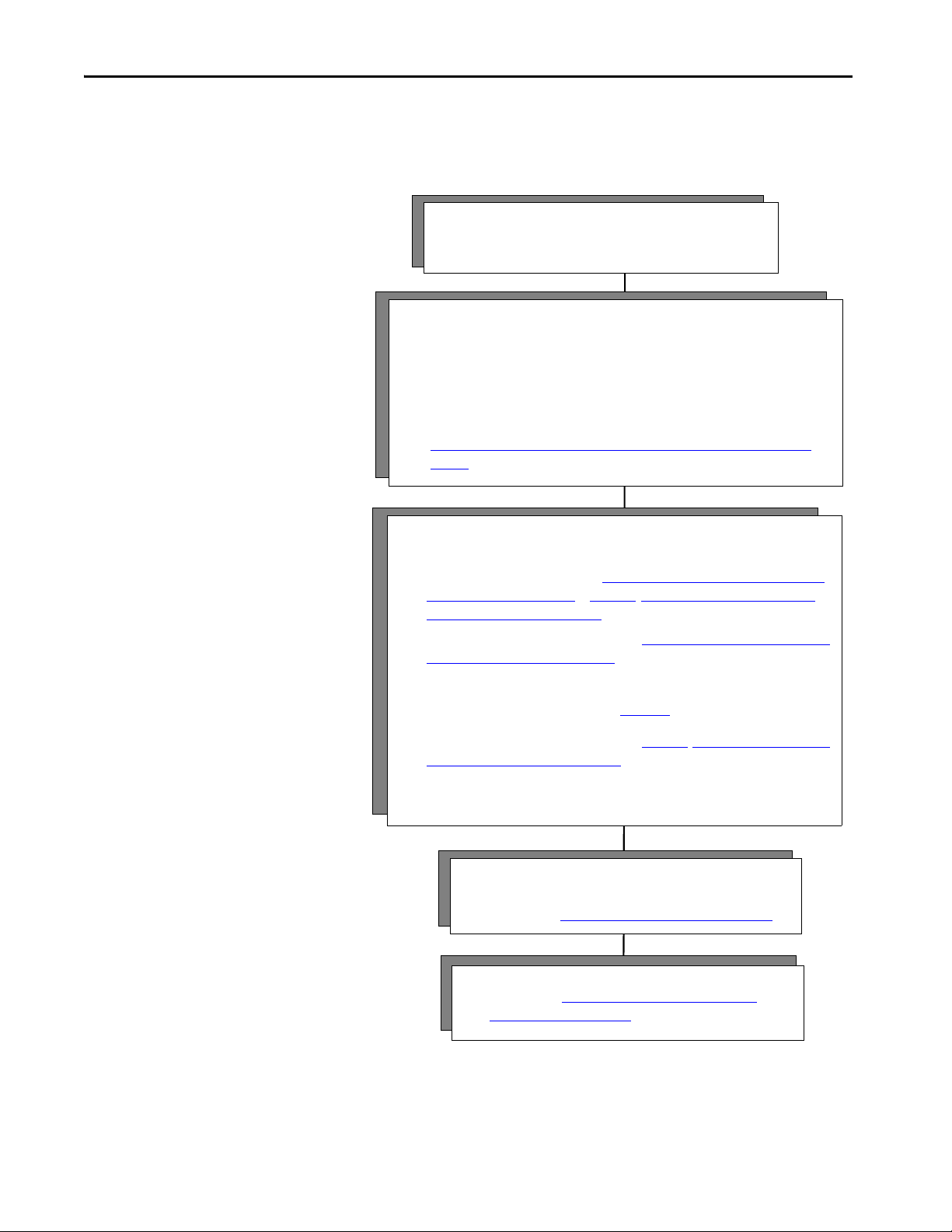

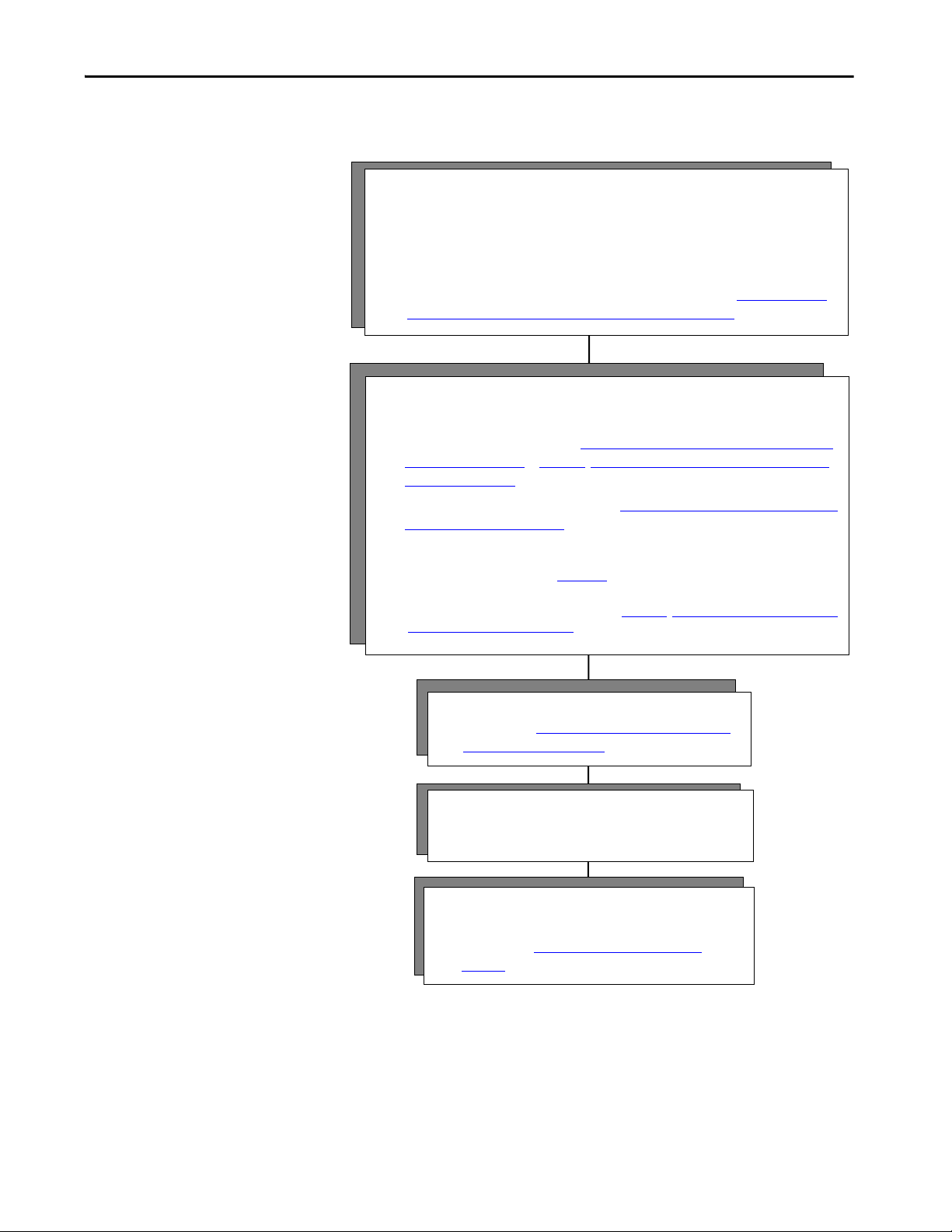

4 - Commission

• Download project.

• Follow steps in Chapter 11, Commission an Axis on page 221

.

Connect Hardware First

5 - Program

• Follow steps in Appendix B, Out of Box Configuration for

PowerFlex Drives on page 305.

3 - Configure the drive module and an axis.

Check drive firmware for the latest revisions and update if needed.

• For Kinetix drives, follow the steps in Chapter 3,Configure Integrated Motion Control

Using Kinetix Drives on page 31 or Chapter 4, Configure Integrated Motion Control

Using Kinetix 5700 Drives on page 59.

• For a PowerFlex 755 drive, follow the steps in Chapter 5, Configure Integrated Motion

Using a PowerFlex 755 Drive on page 99.

If you are using a PowerFlex 755 drive and are unfamiliar with the integrated motion interface

and attributes, see the Integrated Motion on EtherNet/IP appendix in the PowerFlex 750-Series

AC Drives Programming Manual, publication 750-PM001.

• For a PowerFlex 527 drive, follow the steps in Chapter 6, Configure Integrated Motion

Using a PowerFlex 527 Drive on page 129.

2 - Configure the controllers and communication modules.

• Open the Logix Designer application.

• Check software and firmware for the latest revisions and update if needed.

• You must configure the controllers and communication modules for time

synchronization and motion.

• To configure a project and enable time synchronization, follow the steps in

Chapter 2, Create a Project for Integrated Motion on the EtherNet/IP Network on

page 21.

1 - Connect

• Install modules and drives.

• Check software and firmware for the latest revisions.

Configuration and Startup Scenarios

The two ways to get an integrated motion on the EtherNet/IP network

solution to run are to connect the hardware first or configure the software first.

18 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 19

Configure Software First

3 - Program

• Follow steps in Appendix B, Out of Box Configuration for

PowerFlex Drives on page 305.

4 - Connect

• Install modules and drives.

• Check software and firmware for the latest revisions.

1 - Configure the controllers and communication modules.

• Open the Logix Designer application.

• Check software and firmware for the latest revisions and update if needed.

• You must configure the controllers and communication modules for time synchronization

and motion.

• To build a project and enable time synchronization, follow the steps in Chapter 2, Create a

Project for Integrated Motion on the EtherNet/IP Network on page 21.

2 - Configure the drive module and configure an axis.

Check drive firmware for the latest revisions and update if needed.

• For Kinetix drives, follow the steps in Chapter 3,Configure Integrated Motion Control Using

Kinetix Drives on page 31 or Chapter 4, Configure Integrated Motion Control Using Kinetix

5700 Drives on page 59.

• For a PowerFlex 755 drive, follow the steps in Chapter 5, Configure Integrated Motion Using

a PowerFlex 755 Drive on page 99.

If you are using a PowerFlex 755 drive and are unfamiliar with the integrated motion interface and

attributes, see the Integrated Motion on EtherNet/IP appendix in the PowerFlex 750-Series AC Drives

Programming Manual, publication 750-PM001.

For a PowerFlex 527 drive, follow the steps in Chapter 6, Configure Integrated Motion Using

a PowerFlex 527 Drive on page 129.

5 - Commission

• Download project.

• Follow steps in Chapter 11, Commission an Axis on

page 221.

Components of a Motion System Chapter 1

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 19

Page 20

Chapter 1 Components of a Motion System

Help for Selecting Drives and Motors

Motion Analyzer helps you select the appropriate Allen-Bradley® drives and

motors that are based on your load characteristics and typical motion

application cycles. The software guides you through wizard-like screens to

collect information specific to your application.

After you enter the information for your application, such as, load inertia,

gearbox ratio, feedback device, and brake requirements, the software generates

an easy-to-read list of recommended motors, drives, and other support

equipment.

You can access Motion Analyzer at

https://motionanalyzer.rockwellautomation.com

.

20 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 21

Chapter 2

Create a Project for Integrated Motion on the

EtherNet/IP Network

Top ic Pag e

Create a Controller Project 21

Set Time Synchronization 24

Add an Ethernet Communication Module 26

This chapter describes how to configure an integrated motion project in the

Logix Designer application.

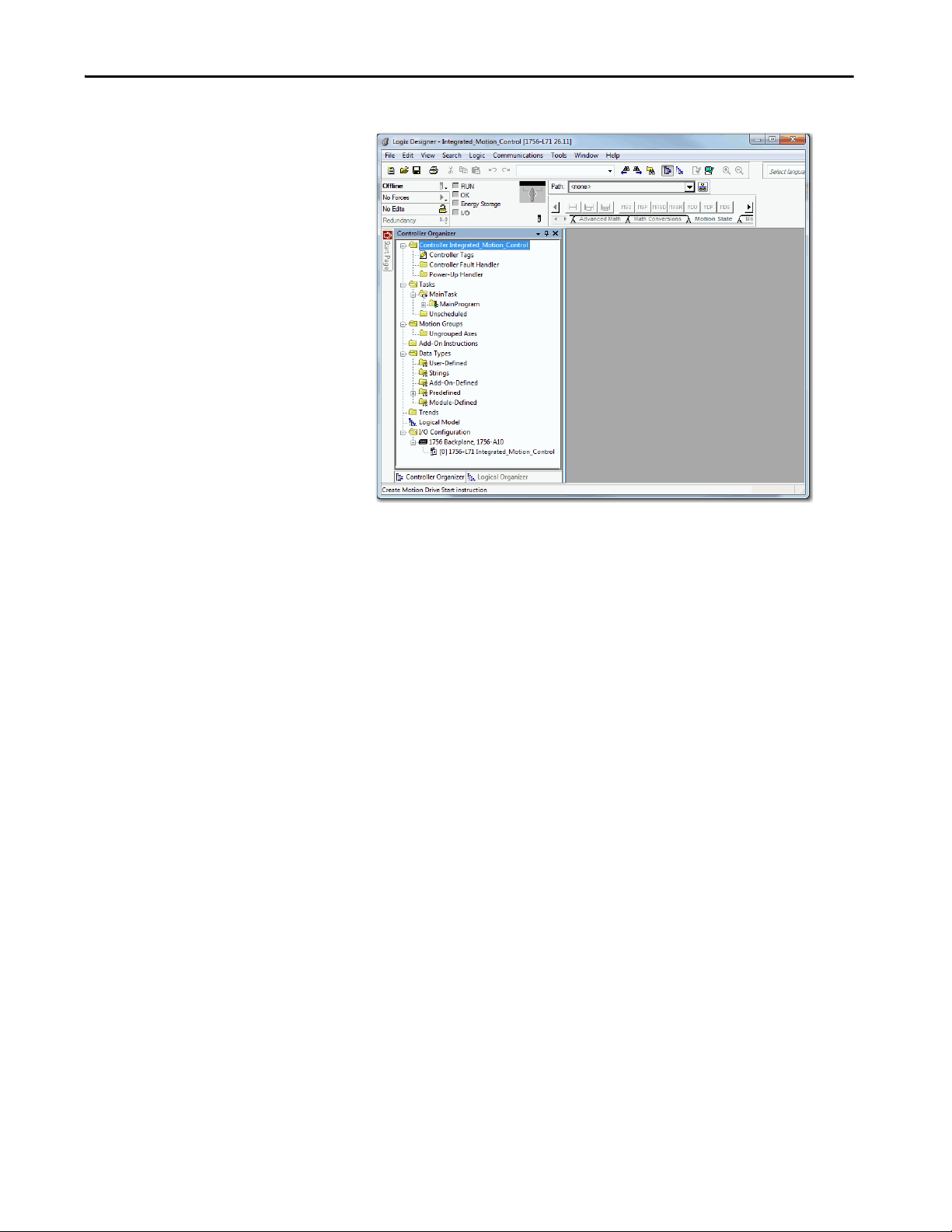

Create a Controller Project

IMPORTANT For Motion and Safety applications, you must use a GuardLogix® or Compact

GuardLogix controller.

Follow these instructions to create a project.

1. On the Studio 5000® dialog box, choose Create New Project.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 21

Page 22

Chapter 2 Create a Project for Integrated Motion on the EtherNet/IP Network

2. Choose a controller, type a name, and click Next.

3. Type a Name for the controller.

4. Assign a location (optional).

5. Click Next.

The Project Configuration dialog box appears.

6. Choose the chassis type.

7. Assign the slot location of the controller.

8. Assign the Security Authority.

9. Type a description (optional).

10. Click Finish.

22 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 23

Create a Project for Integrated Motion on the EtherNet/IP Network Chapter 2

The Logix Designer application opens with new project.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 23

Page 24

Chapter 2 Create a Project for Integrated Motion on the EtherNet/IP Network

EtherNet/IP™

Logix5563

EtherNet/IP™

EtherNet/IP™

SOE INTPUTSOE INTPUT SOE INTPUT SOE INTPUT SOE INTPUT SOE INTPUT

EtherNet/IP™

SOE INTPUTSOE INTPUT SOE INTPUT SOE INTPUT SOE INTPUT SOE INTPUT

Logix5563

EtherNet/IP™

SOE INTPUT SOE INTPUT SOE INTPUT SOE INTPUT

S

P2=1

P2=2

GM

CIP Sync

CIP Sync

CIP Sync

L

7

X

S

O

E

S

O

E

S

O

E

S

O

E

E

N

2

T

S

O

E

S

O

E

S

O

E

S

O

E

S

O

E

S

O

E

E

N

2

T

E

N

2

T

S

O

E

S

O

E

S

O

E

S

O

E

S

O

E

S

O

E

E

N

2

T

E

N

2

T

D

I

O

D

I

O

D

I

O

D

I

O

D

I

O

L

7

X

CIP Sync

S

M

S

S S S

CIP Sync

S

M

S

S

S

S

S

CIP Sync

S

M

S

S

S

S

S

CIP Sync

M

S

CIP Sync

Com

IN2

IN1

Ref

M

NTP

MOD

NET

MOD

NET

MOD

NET

MOD

NET

2

1

1

1

4

I/O

I/O

6

5

10

2

1

2

1

2

1

1

I/O-A

6

510

1

I/O-B

6

510

1

I/O-A61I/O-B

6

510510

UFB

UFB-A UFB-B

UFB-A UFB-B

D+D-D+

D-

D+

D-

MF-A MF-B MF-A MF-B

D+

D-

MBRK

+

-

MOD

NET

2

1

1

I/O-A61I/O-B

6

510510

UFB-A UFB-B

D+

D-

MF-A MF-B

D+

D-

5700

5700

5700

5700

5700

S

S

S

S

M

350

MEM

A=ENABLE

B= REGEN

C=DATA ENTRY

D=FAULT

E=COM ACTIVITY

24VDC

INPUT

BRAKE/

DC BUS

AB D

E

C

ETHERNET

MORTOR FEEDBACK

S

S

CIP Sync

S

Com

IN2

IN1

Ref

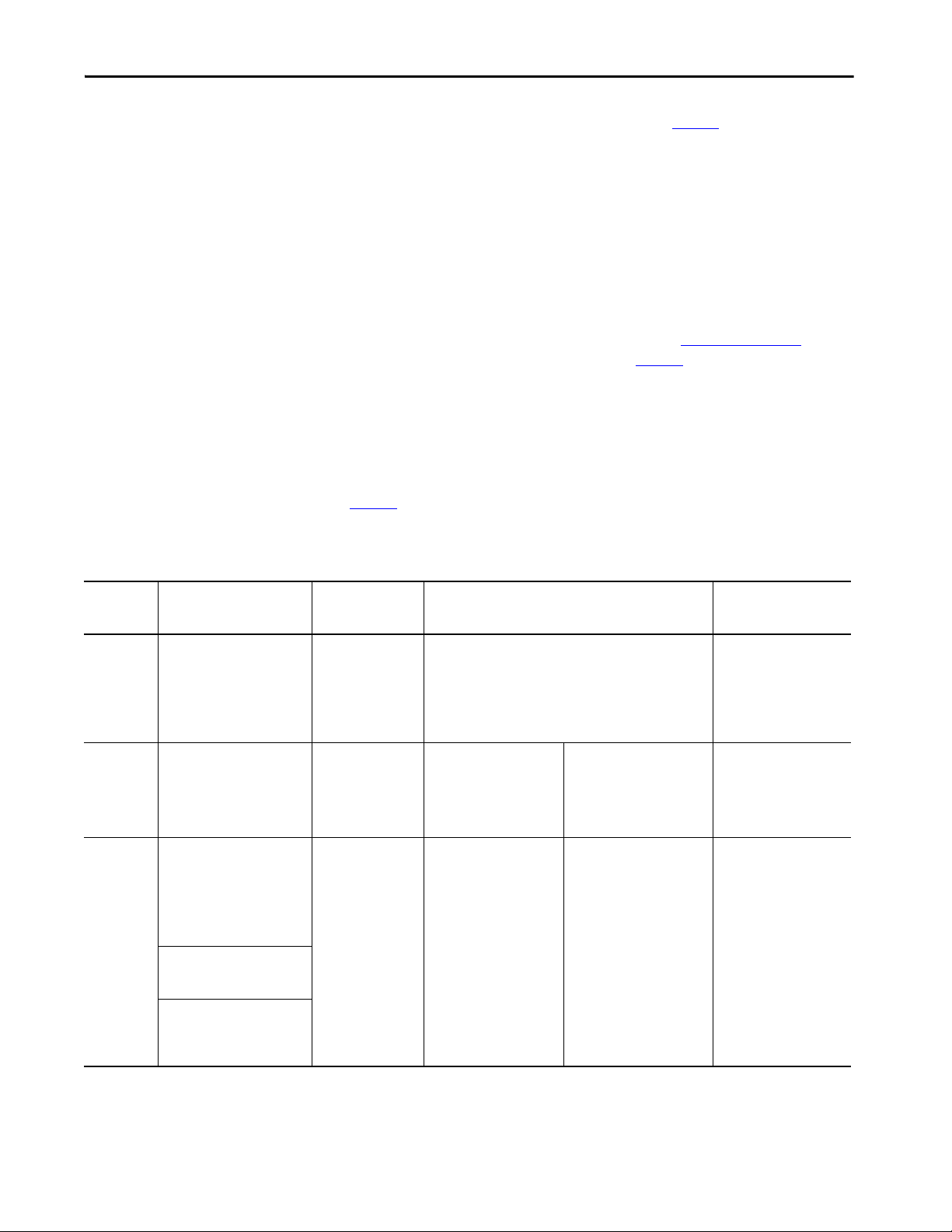

GM = Grandmaster (time source)

M = Master

S = Slave

P1 and P2 = Priorities Priorities are automatically assigned based on their clock quality, which the Best Clock Algorithm determines. In this example, P2=1 is the

best quality so it becomes the Grandmaster. If the P2=1 device loses clock quality for some reason, then P2=2 would become the

Grandmaster for the system.

Supervisory

Stratix® 5700

Stratix 5700

HMI

PowerFlex 527

Kinetix® 350

EtherNet/IP

Kinetix 5500

PowerFlex® 755

Kinetix® 5700

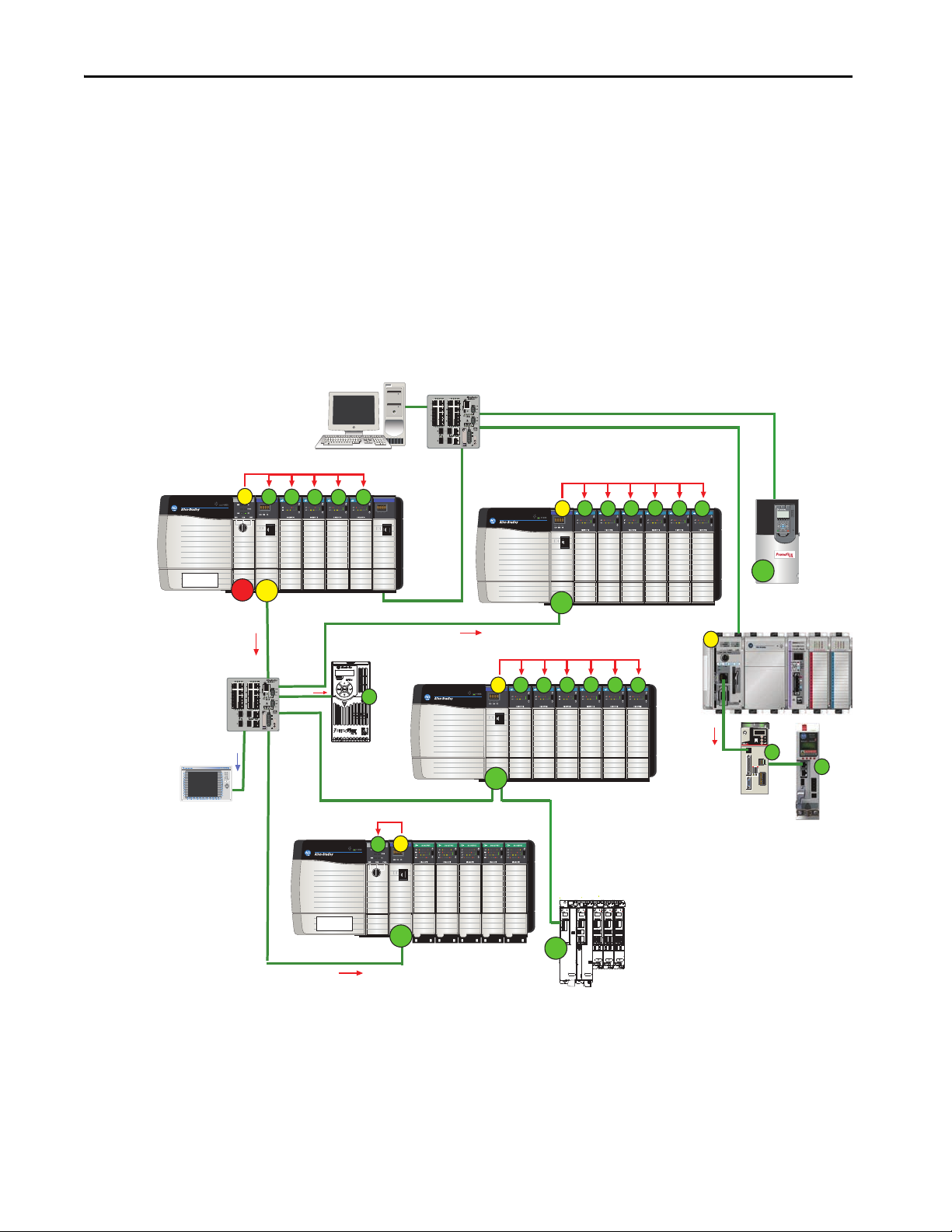

Set Time Synchronization

This technology supports highly distributed applications that require time

stamps, sequence of events records, distributed motion control, and increased

control coordination. All controllers and communication modules must have

time synchronization that is enabled for applications that use integrated

motion on the EtherNet/IP™ network.

Time synchronization in the Logix system is called CIP Sync. CIP Sync

provides a mechanism to synchronize clocks between controllers, I/O, and

other devices that are connected over CIP™ networks and the ControlLogix® or

CompactLogix™ backplane. The device with the best clock becomes the

Grandmaster time source for your system.

Figure 1 - Star Topology with the ControlLogix Controller as the Grandmaster

24 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 25

Create a Project for Integrated Motion on the EtherNet/IP Network Chapter 2

The Best Master Clock algorithm determines what device has the best clock.

The device with the best clock becomes the Grandmaster time source for your

system. All controllers and communication modules must have time

synchronization that is enabled to participate in CIP Sync.

See the Integrated Architecture and CIP Sync Configuration Application

Te ch ni qu e , p ub lica ti o n

IA-AT003

, for detailed information.

You must enable time synchronization for motion applications. Follow these

instructions to enable time synchronization.

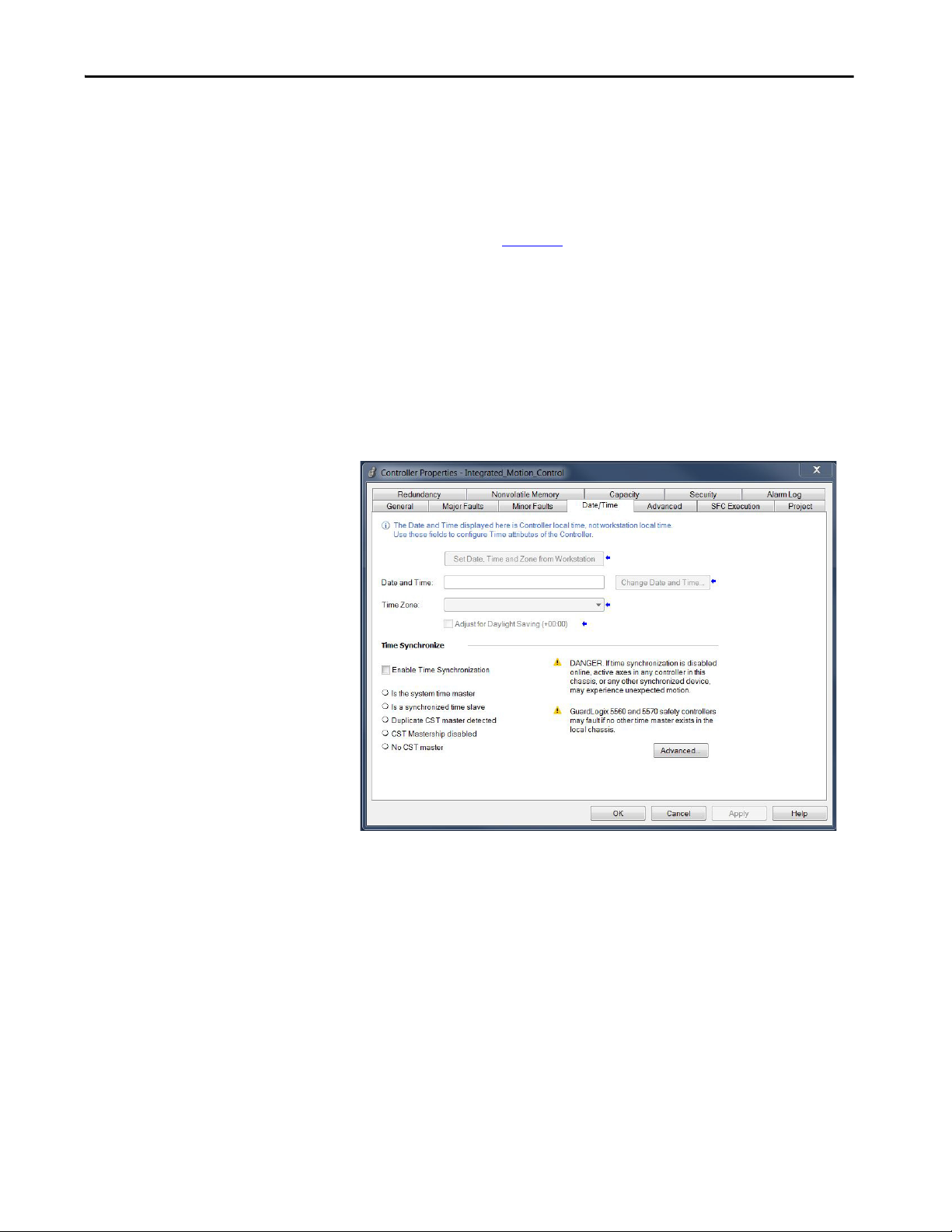

1. In the Controller Organizer, right-click the controller and choose

Properties.

2. Click the Date/Time tab.

3. Check Enable Time Synchronization.

4. Click OK.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 25

Page 26

Chapter 2 Create a Project for Integrated Motion on the EtherNet/IP Network

Add an Ethernet Communication Module

Although ControlLogix 5580 and GuardLogix 5580 controllers can use

Ethernet communication modules, only ControlLogix 5560 and 5570 and

GuardLogix 5560 and 5570 controllers require an Ethernet communication

module for connection to the Ethernet network. See Controller,

Communication, Drive, and Software Options on page 11 for more

information.

Follow these instructions to add an Ethernet communication module to your

project if needed.

IMPORTANT For all communication modules, use the firmware revision that goes with

the firmware revision of your controller. See the release notes for the

firmware of your controller.

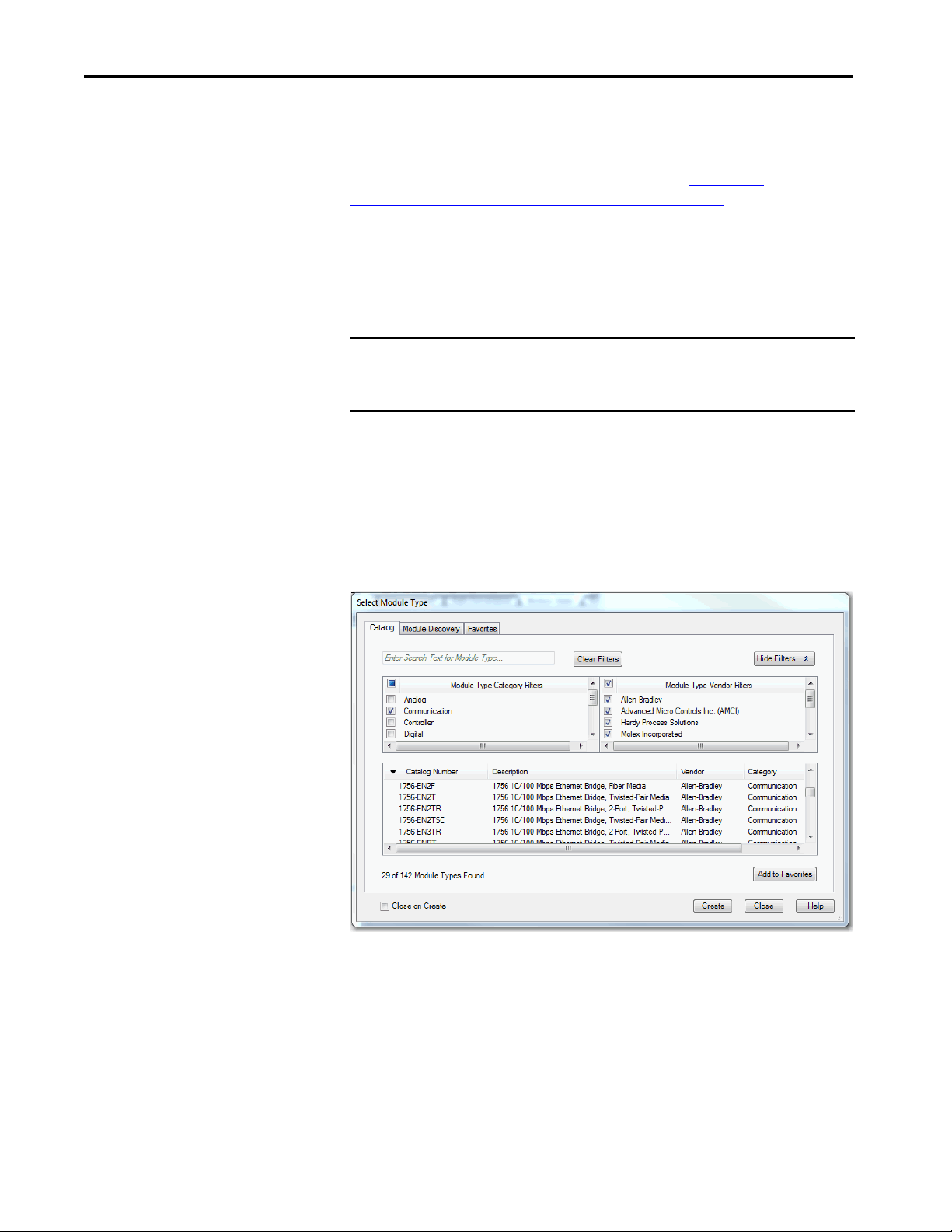

1. To add a module, right-click the backplane and choose New Module.

2. Clear the Module Type Category Filters select all checkbox.

3. Check the Communication checkbox.

On the Select Module Type dialog box, you can filter to the exact type of

module you are looking for, which makes your search faster.

4. Under Communications, select the Ethernet module and click Create.

26 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 27

Create a Project for Integrated Motion on the EtherNet/IP Network Chapter 2

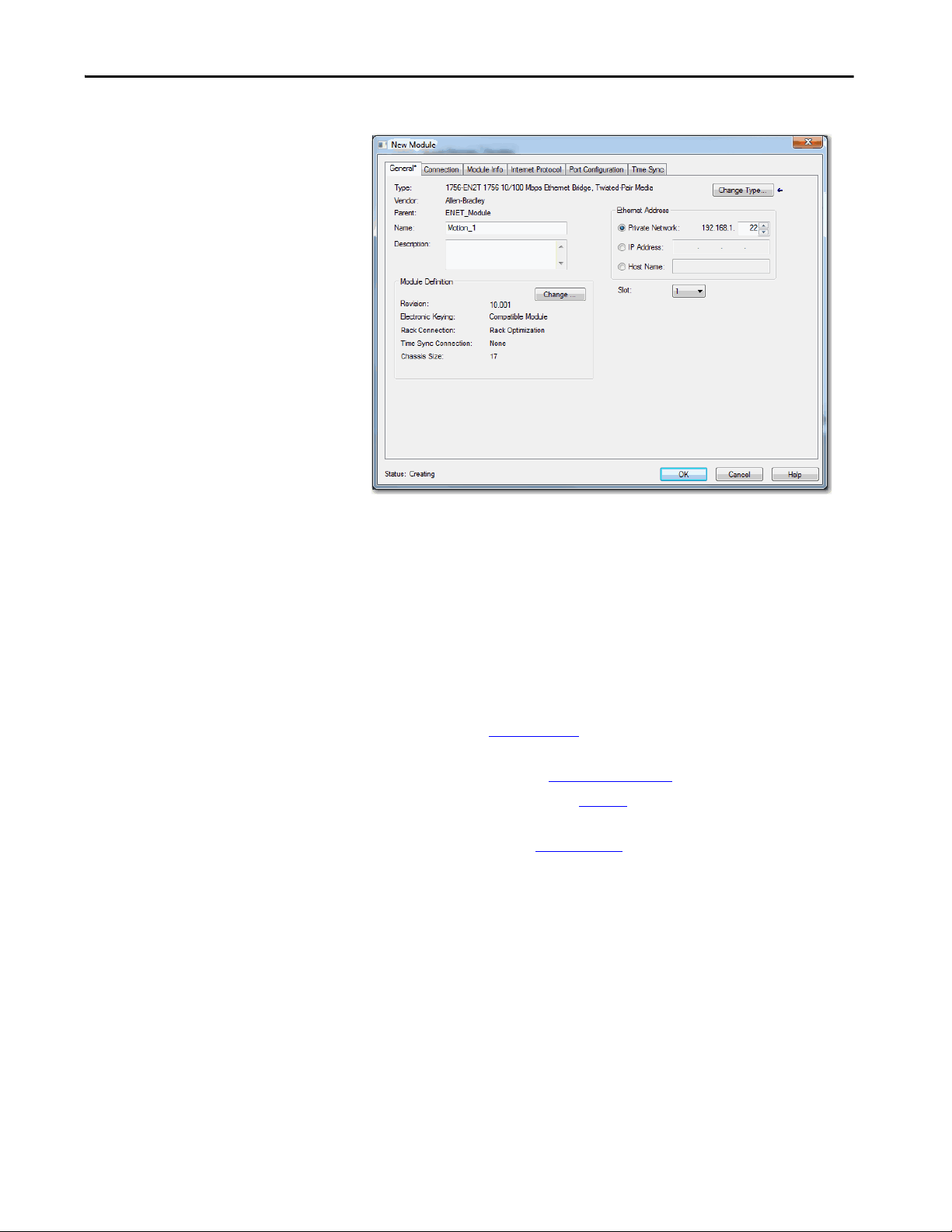

The New Module configuration tabs appear.

5. Type a name for the module.

6. If you want, type a description.

7. Assign the EtherNet/IP address of the Ethernet module.

For information on how to create an Ethernet network and setting IP

addresses for the communication and motion modules, see these

manuals:

– EtherNet/IP Network Configuration User Manual,

publication

ENET-UM001

– PowerFlex® 755 Drive Embedded EtherNet/IP Adapter User

Manual, publication, 750COM-UM001

– Knowledgebase Technote

# 66326

– Converged Plantwide Ethernet (CPwE) Design and Implementation

Guide, publication

ENET-TD001

8. Assign the slot for the module.

9. In the module definition area, click Change.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 27

Page 28

Chapter 2 Create a Project for Integrated Motion on the EtherNet/IP Network

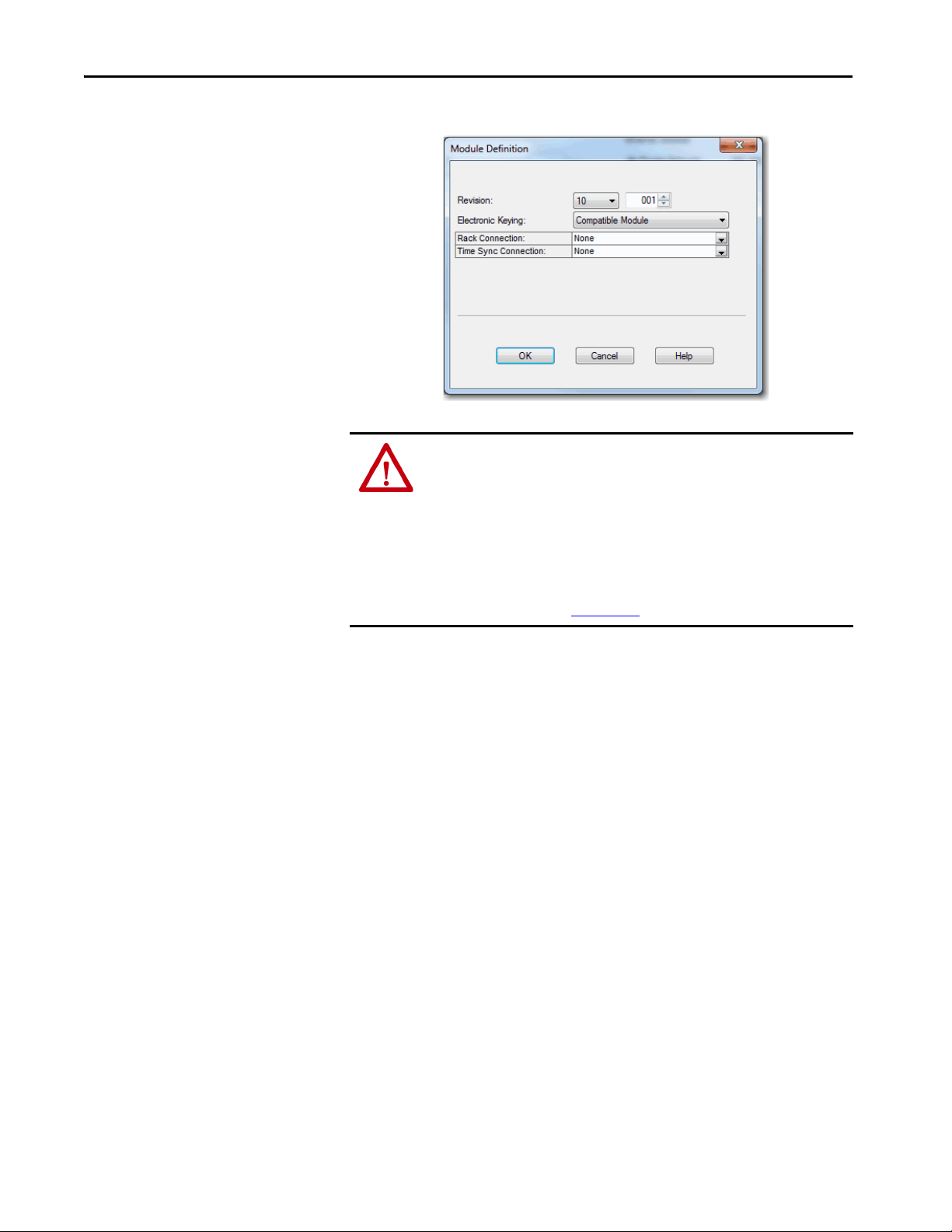

10. Choose an Electronic Keying option.

ATT EN TI ON : The electronic keying feature automatically compares the

expected module, as shown in the configuration tree, to the physical module

before communication begins.

When you are using motion modules, set the electronic keying to either `Exact

Match‘ or `Compatible Keying‘.

Never use `Disable Keying’ with Ethernet communication and motion modules.

For more information about electronic keying, see the ControlLogix Controller

User Manual, publication 1756-UM001

.

28 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 29

Create a Project for Integrated Motion on the EtherNet/IP Network Chapter 2

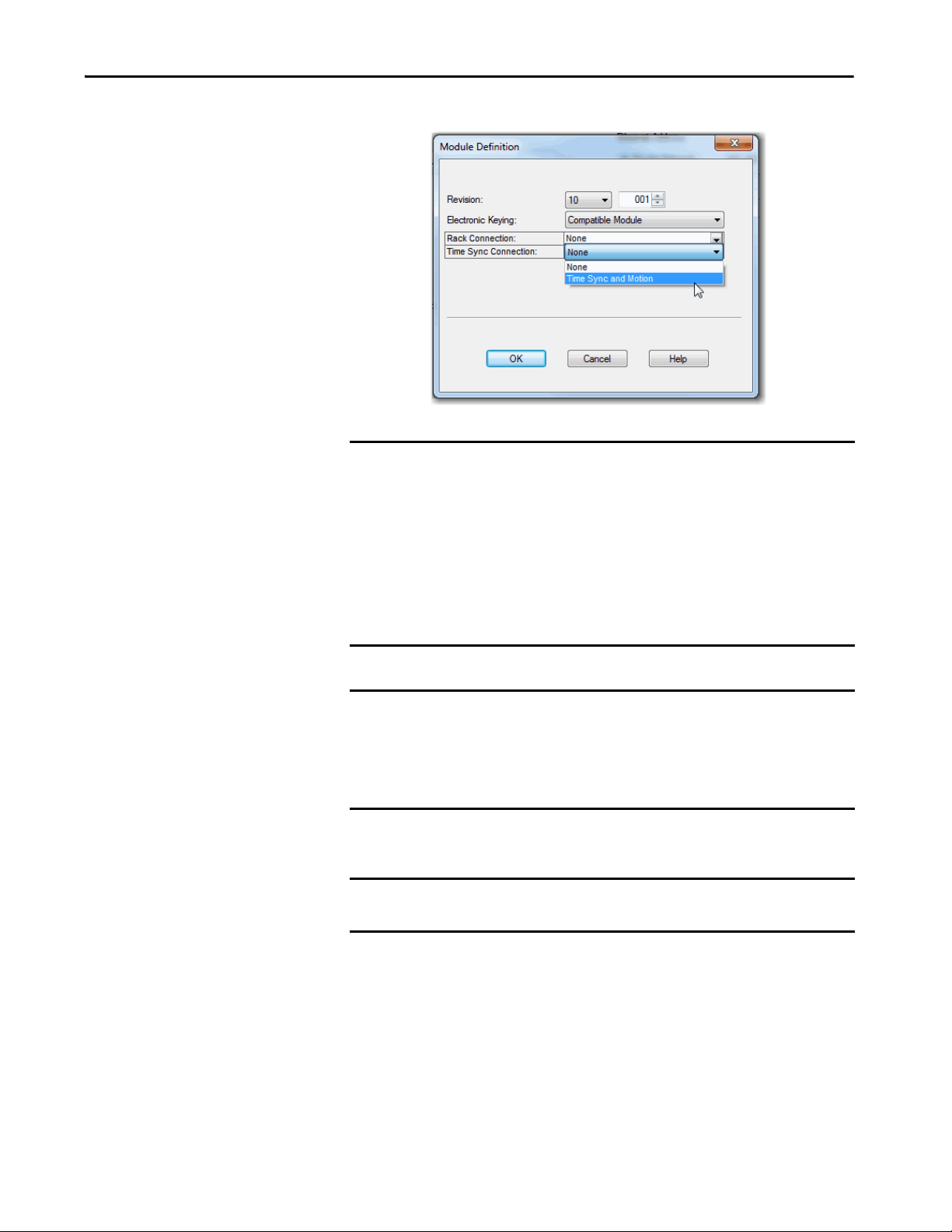

11. Choose Time Sync and Motion.

IMPORTANT For CIP Sync time coordination to work in motion control, you must set the

Time Sync Connection to Time Sync and Motion on all Ethernet

communication modules. The CIP Sync protocol is what enables motion

control on the EtherNet/IP network.

The Time Sync and Motion selection is available only for firmware revision 3

and later. You must be offline to change the Time Sync and Motion selection.

If you are online at a major revision of 1 or 2, you can only change the

revision to a 1 or 2. You must go offline to change the module to revision 3 or

4 and return to revision 1 or 2.

IMPORTANT For CompactLogix 5370 and Compact GuardLogix 5370 controllers, the

embedded dual-port Ethernet is automatically set with Time Sync

Connection= Time Sync and Motion.

To enable Integrated Motion, check the `Enable Time Synchronization’

checkbox on the controller time/date tab.

12. Click OK.

IMPORTANT If you have not enabled time synchronization, you get errors when you try to

associate an axis.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 29

Page 30

Chapter 2 Create a Project for Integrated Motion on the EtherNet/IP Network

Notes:

30 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 31

Chapter 3

Configure Integrated Motion Control Using

Kinetix Drives

Top ic Pag e

Add a Kinetix EtherNet/IP Drive 32

Create an Associated Axis 40

Create a Motion Group 42

Configure the Axis Properties 46

Configure the Associated Axis and Control Mode 47

Specify the Motor Data Source 50

Display Motor Model Information 54

Assign Motor Feedback 54

Configure the Load Feedback 55

Configure the Master Feedback 57

This chapter provides procedures on how to configure integrated motion

control by using the Kinetix® 350, Kinetix 5500, and Kinetix 6500 drives. The

basic configuration for an integrated motion solution is to associate a drive

with motor feedback and an axis configuration type.

For the examples in this chapter, the Kinetix 6500 drive is used and the

exceptions for the Kinetix 350, Kinetix 5500 drives noted. See Chapter 4

Configure Integrated Motion Control Using Kinetix 5700 Drives

,

, for Kinetix

5700 configuration information.

See Chapter 8

, Configuration Examples for a Kinetix Drive, for examples of

axis and feedback configurations.

For information about what attributes are replicated in the drive, see the

Integrated Motion on the EtherNet/IP™ network Reference Manual,

publication MOTION-RM003

.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 31

Page 32

Chapter 3 Configure Integrated Motion Control Using Kinetix Drives

Add a Kinetix EtherNet/IP Drive

See Tab le 2 o n p ag e 11 to determine the minimum version of the Studio 5000

Logix Designer® application that is required for your drive.

IMPORTANT • For complete information on how to configure Kinetix 5500 drives,

including drives with integrated safety connections, see the Kinetix 5500

Servo Drives User Manual, publication 2198-UM001

.

• For complete information about how to configure the Kinetix 350 drives,

see the Kinetix 350 Single-axis EtherNet/I/P Servo Drive User Manual,

publication 2097-UM002

.

• For complete information about to configure the Kinetix 6500 drives, see

the Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drives User

Manual, publication 2094-UM002

.

Follow these instructions to add a Kinetix drive your project.

1. Right-click the Ethernet network (node) and choose New Module.

2. To filter the selections, check the Motion checkbox.

3. Choose the Kinetix 350, Kinetix 5500, or Kinetix 6500 drive.

4. Click Create.

32 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 33

Configure Integrated Motion Control Using Kinetix Drives Chapter 3

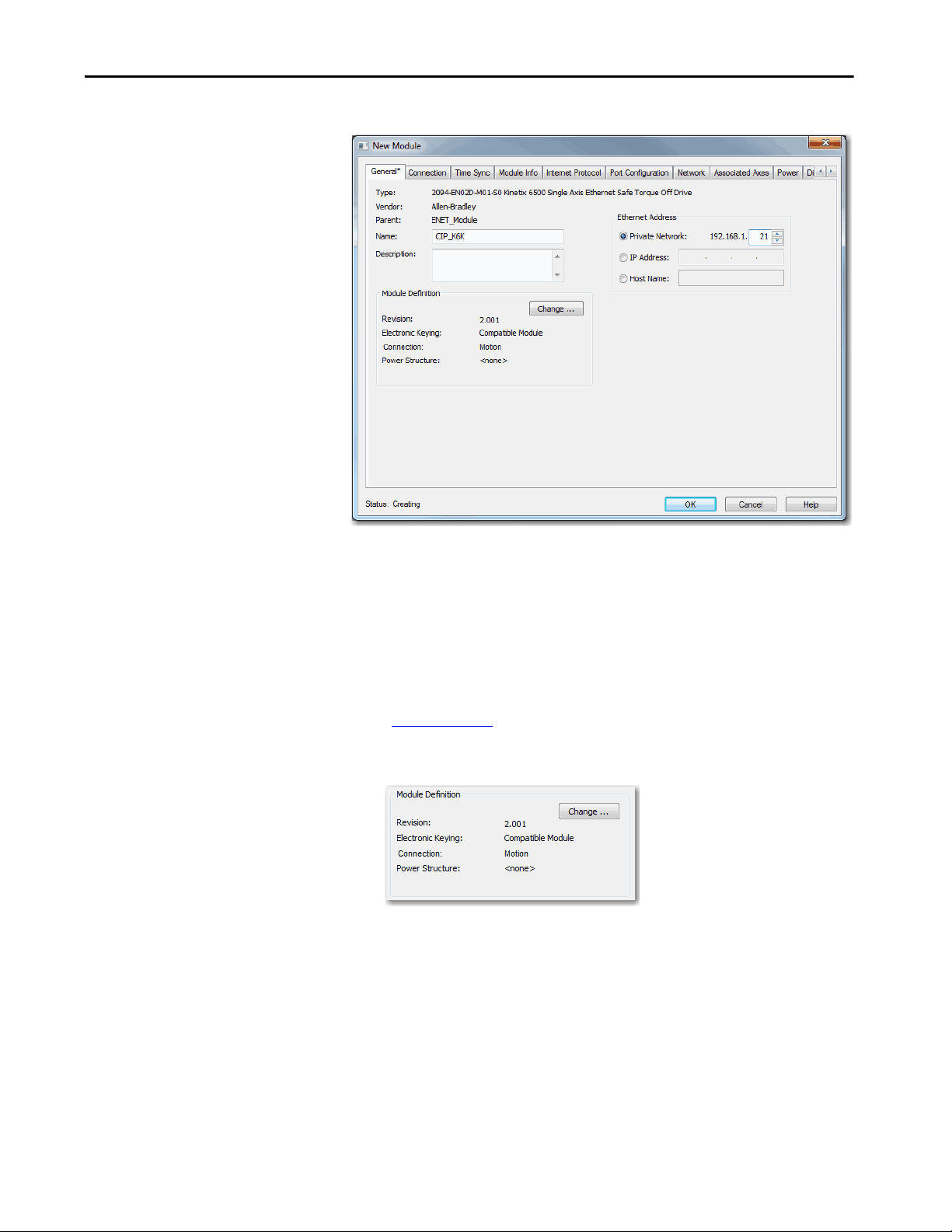

5. Type a Name for the module.

6. Type a description, if desired.

7. Assign an EtherNet/IP address.

You can establish the Node address of the drive by entering a private IP

address via a thumbwheel switch on the drive for Private Network

segments. Use the format 192.168.1.xxx, where the last octet, xxx, is the

switch setting.

See the EtherNet/IP Network Configuration User Manual, publication

ENET-UM001

, for information on setting IP addresses and other

Ethernet network considerations.

8. Under Module Definition, click Change.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 33

Page 34

Chapter 3 Configure Integrated Motion Control Using Kinetix Drives

9. Choose an Electronic Keying option.

The Module Definition dialog box appears.

ATTENTION: The electronic keying feature automatically compares

the expected module, as shown in the configuration tree, to the

physical module before communication begins.

When you are using motion modules, set the electronic keying to either

`Exact Match‘ or `Compatible Keying‘.

Never use `Disable Keying’ with motion modules.

For more information about electronic keying, see the Electronic Keying

in Logix 5000™ Control Systems Application Technique, publication

LOG IX-AT 001

.

34 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 35

Configure Integrated Motion Control Using Kinetix Drives Chapter 3

10. Assign the appropriate Power Structure.

When you select a Kinetix 6500 drive catalog number, you are specifying

only a Control Module. To specify the drive, you must assign a power

structure. Some of the drives do not require a power structure.

TIP You can locate the power-structure reference numbers by doing the

following:

• Check the hardware

• See the device documentation

• Reviewing the purchase order or the bill of materials.

You assign the power structure for the Kinetix 6500 drive only.

Kinetix 350 and Kinetix 5500 drives auto-populate the only power

structure available.

11. Check the checkbox if you want to verify the power rating on

connection.

12. Click OK.

When you change the Module Definition, related parameters also

change. By changing the major revision or power structure, the identity

of the drive changes. If your drive is associated to an axis, these changes

disassociate the axis.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 35

Page 36

Chapter 3 Configure Integrated Motion Control Using Kinetix Drives

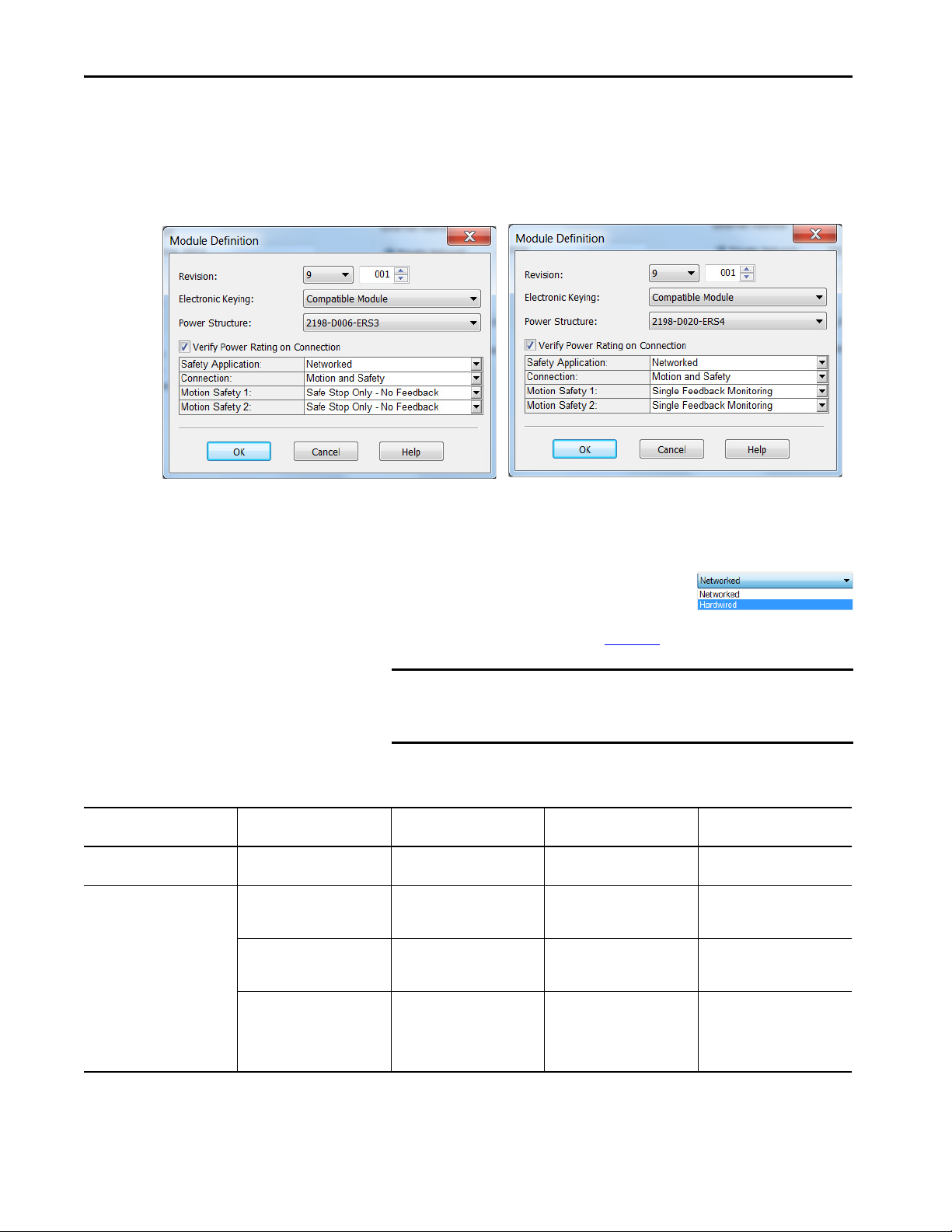

Configure the Safety Category - Kinetix 5500 Drives

The Safety tab provides you with information about the connection between

the owner and the 2198-Hxxx-ERS2 servo drive. The information comes from

the controller.

The connection between the owner and the 2198-Hxxx-ERS2 servo drive is

based on the following:

• Servo drive catalog number must be 2198-Hxxx-ERS2 (integrated)

• Servo drive safety network number

•GuardLogix® slot number

• GuardLogix safety network number

• Path from the GuardLogix controller to the 2198-Hxxx-ERS2 drive

• Configuration signature

The connection between the GuardLogix controller and the 2198-Hxxx-ERS2

drive is lost if any differences are detected. The yellow yield icon also appears in

the controller project tree after you download the program.

For complete information on how to configure a drive with integrated safety

connections, see the Kinetix 5500 Servo Drives User Manual,

publication 2198-UM001

.

36 Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019

Page 37

Configure Integrated Motion Control Using Kinetix Drives Chapter 3

Configure the Power Options

1. Click the Power tab.

IMPORTANT Single-phase operation is possible only when Module Properties >

Power tab > Bus Configuration is configured as Standalone and Voltage

is configured as 200…240V AC.

IMPORTANT The Logix Designer application enforces shared-bus configuration rules

for Kinetix 5500 drives, except for shared AC configurations.

2. From the pull-down menus, choose the power options appropriate for

your actual hardware configuration.

ATTENTION: To avoid damage to equipment, make sure the AC input

voltage that is configured in the Logix Designer application matches

the actual hardware being configured.

Attribute Menu Description

Vol tag e

AC Input Phasing

Bus Configuration

(1)

400-480 VAC 324…528 AC rms input voltage

200-240 VAC 195…264 AC rms input voltage

• Three Phase

• Single Phase

Standalone

Shared AC/DC

Shared DC

Input power phasing. Kinetix 5500 drives with

single-phase operation is limited to 2198-H003ERSx, 2198-H008-ERSx, and 2198-H015-ERSx.

Applies to single-axis drives and drives with

Shared AC input configurations.

Applies to converter drives with Shared AC/DC

and Shared AC/DC Hybrid input configurations.

Applies to inverter drives with Shared DC input

(common-bus) configurations.

Rockwell Automation Publication MOTION-UM003K-EN-P - January 2019 37

Page 38

Chapter 3 Configure Integrated Motion Control Using Kinetix Drives

Attribute Menu Description

Standalone Applies to standalone bus configurations.

Bus-sharing Group

•Group1

•Group2

Applies to any bus-sharing configuration.

(2)

•Group3…

Disables the internal shunt resistor and external

shunt option.

Shunt Regulato r Action

Disabled

Shunt Regulator Enables the internal and external shunt options.

Internal

Shunt Regulator Resistor Type

External

External Shunt

(3)

•None

• 2097-R6

• 2097-R7

(1) Bus Configuration selection is not applicable to all EtherNet/IP drives.

(2) All drives physically connected to the same shared-bus connection system must be part of the same bus-sharing

group in the Logix Designer application.

(3) See the Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003

Bulletin 2097 external shunt resistors.

Enables the internal shunt (external shunt option

is disabled).

Enables the external shunt (internal shunt

option is disabled).

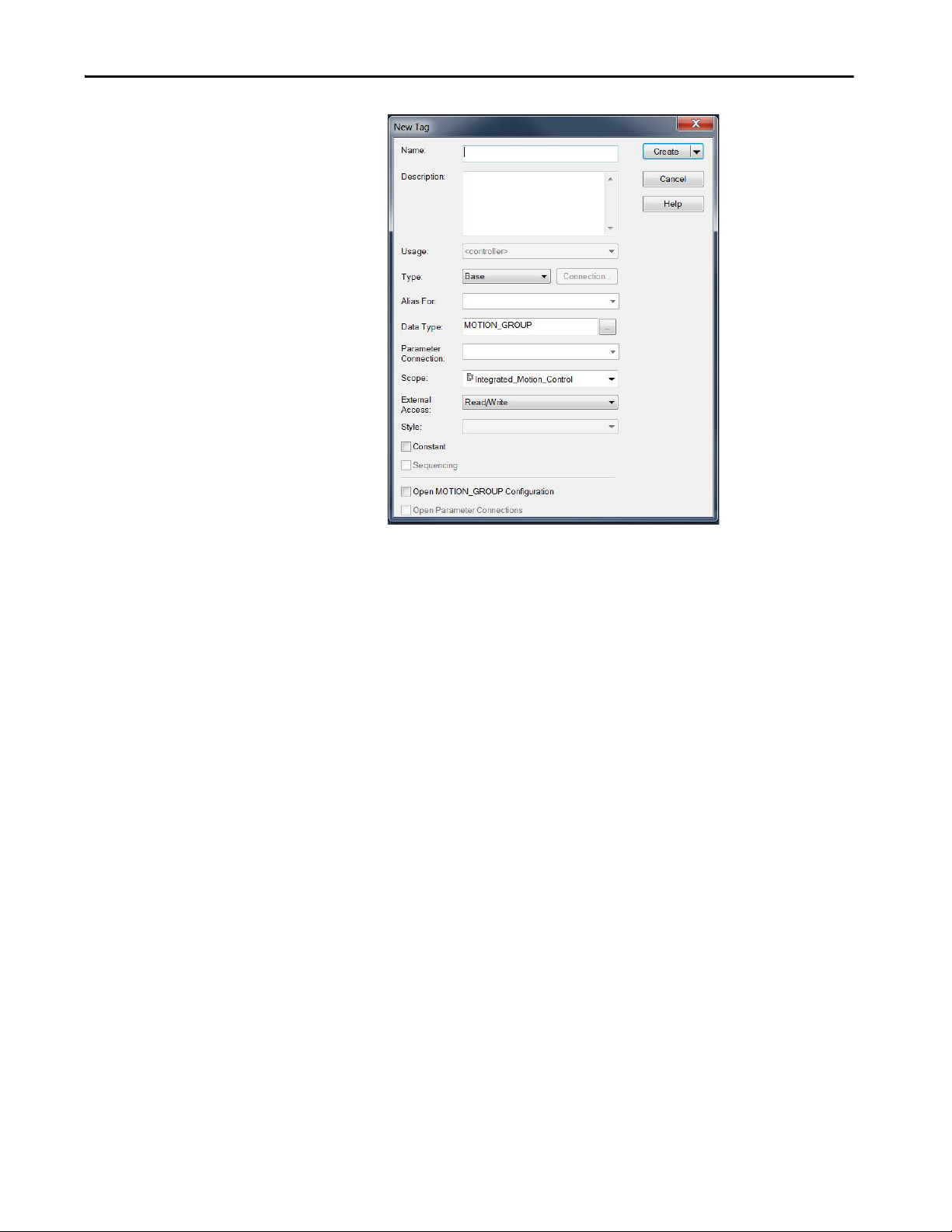

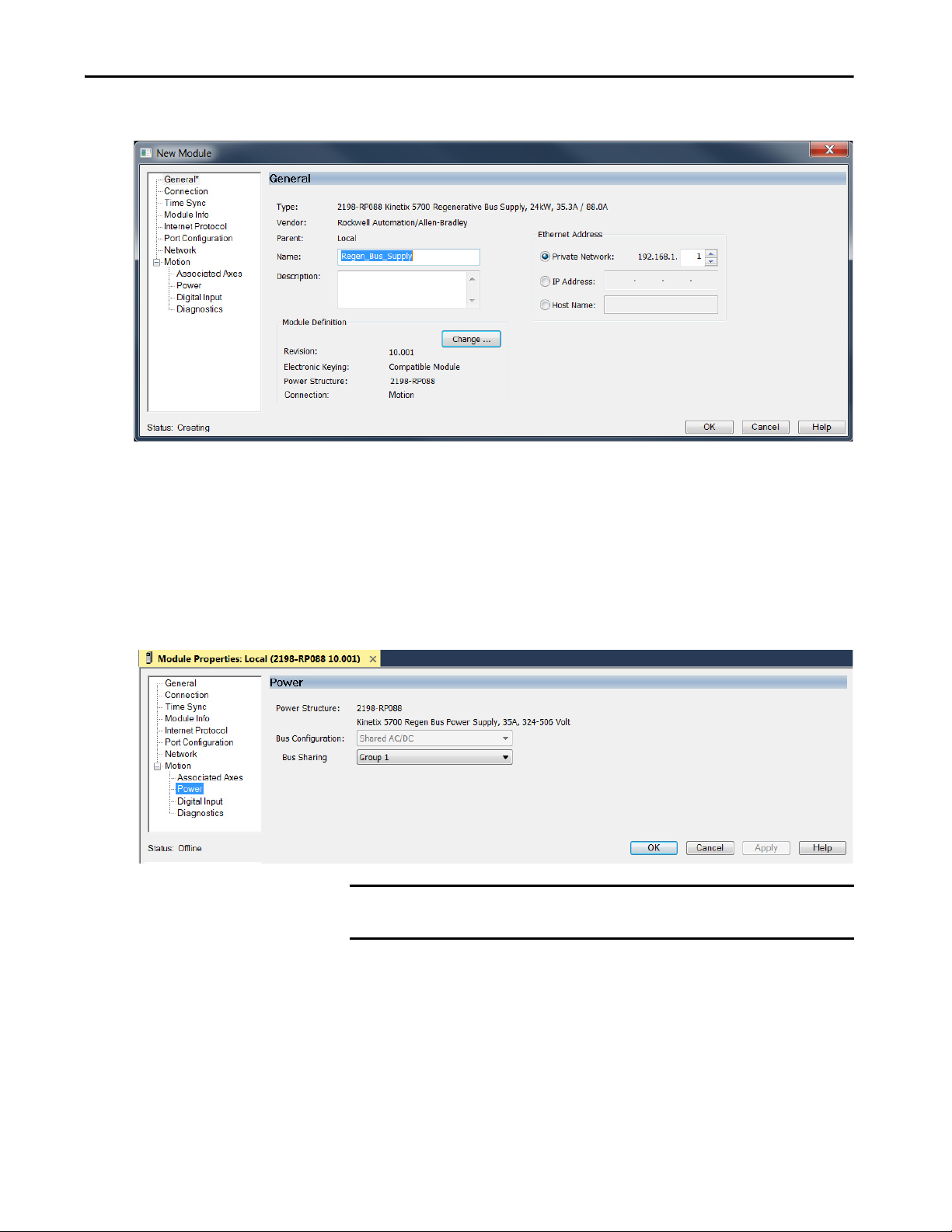

Selects external shunt option. Only the shunt