Allen-Bradley ControlLogix 5580, CompactLogix 5380, Logix 5000, CompactLogix 5370, Compact GuardLogix 5370 Reference Manual

...

Reference Manual

Original Instructions

Replacement Guidelines: Logix 5000 Controllers

ControlLogix 5570 to ControlLogix 5580

GuardLogix 5570 to GuardLogix 5580

CompactLogix 5370 to CompactLogix 5380

Compact GuardLogix 5370 to Compact GuardLogix 5380

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

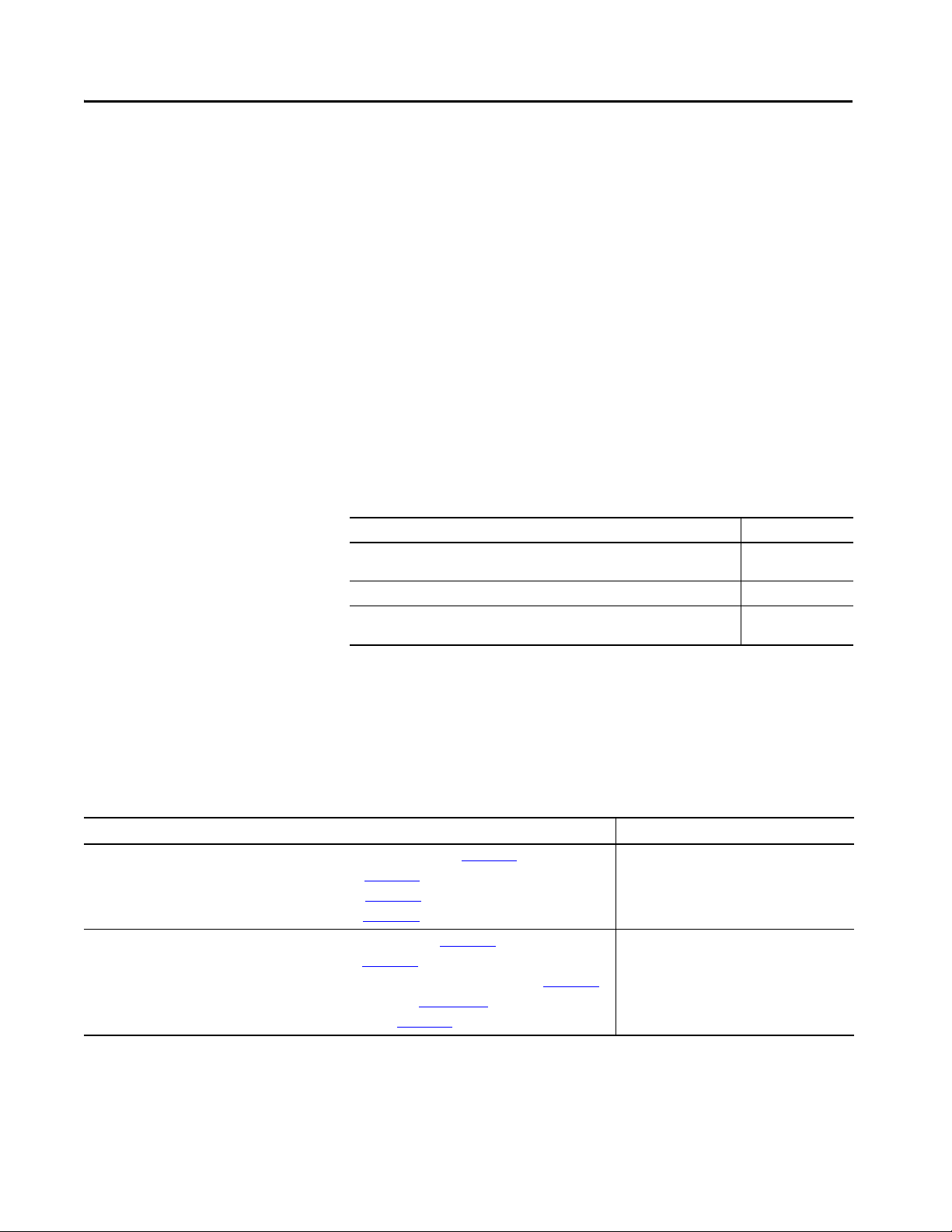

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Websites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Before You Begin a Migration Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

New and Future Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Integrated Architecture Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Migration Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Replacement Considerations

with ControlLogix 5580 and

GuardLogix 5580 Systems

Minimum Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

GuardLogix Controllers Minimum Requirements. . . . . . . . . . . . 18

Product Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ControlLogix Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

GuardLogix Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

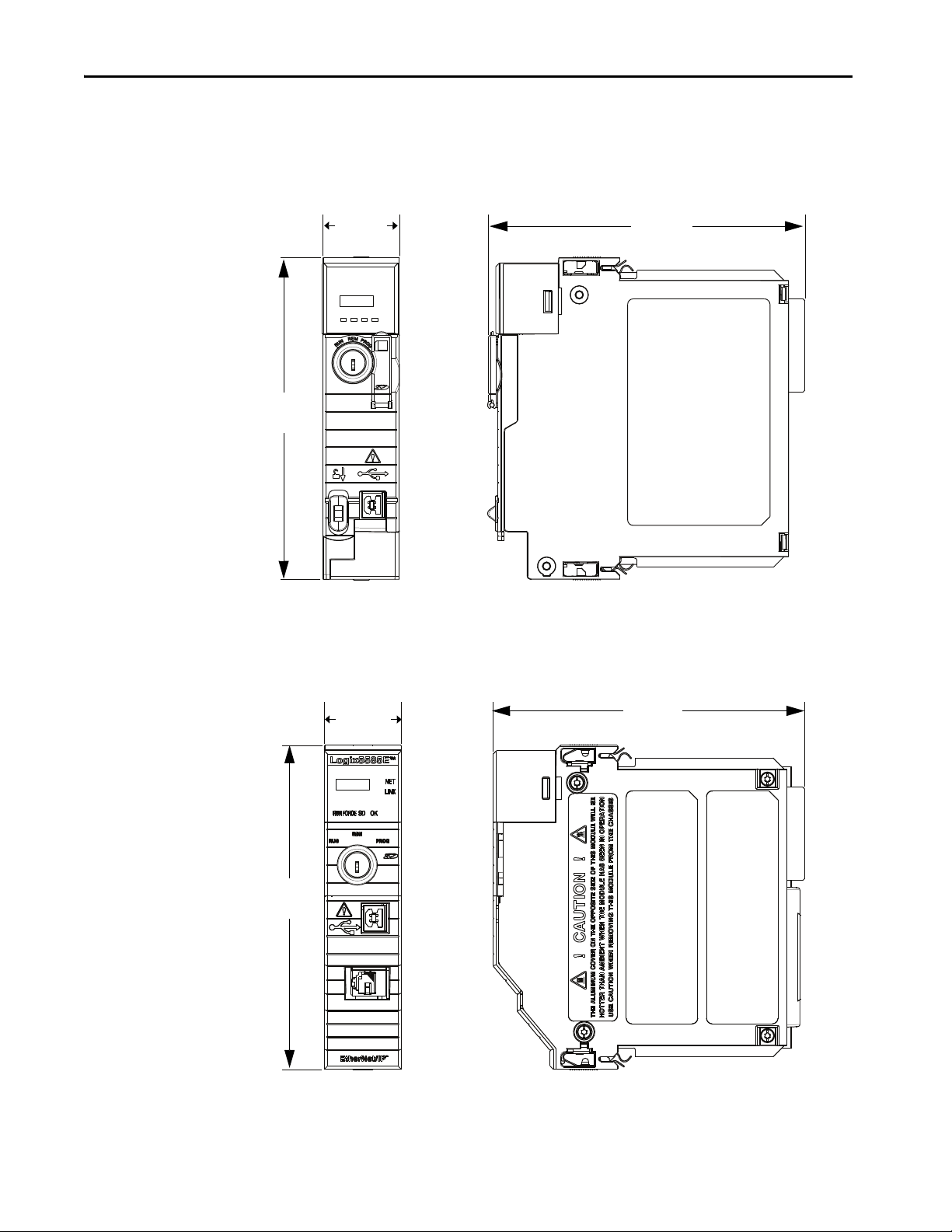

Controller Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ControlLogix 5570 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ControlLogix 5580 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

GuardLogix 5570 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

GuardLogix 5580 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connectors and Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Project Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configure the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connections Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Nodes on an EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . . . . . 27

New Project Dialog Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Controller Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Controller Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5570 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5580 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SD Card Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Communication Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Download the Program to the Controller . . . . . . . . . . . . . . . . . . . . . . . 41

Build Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Downloading Workflow Change . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Upload Fidelity Change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Thermal Monitoring and Thermal Fault Behavior . . . . . . . . . . . . . . . 43

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 3

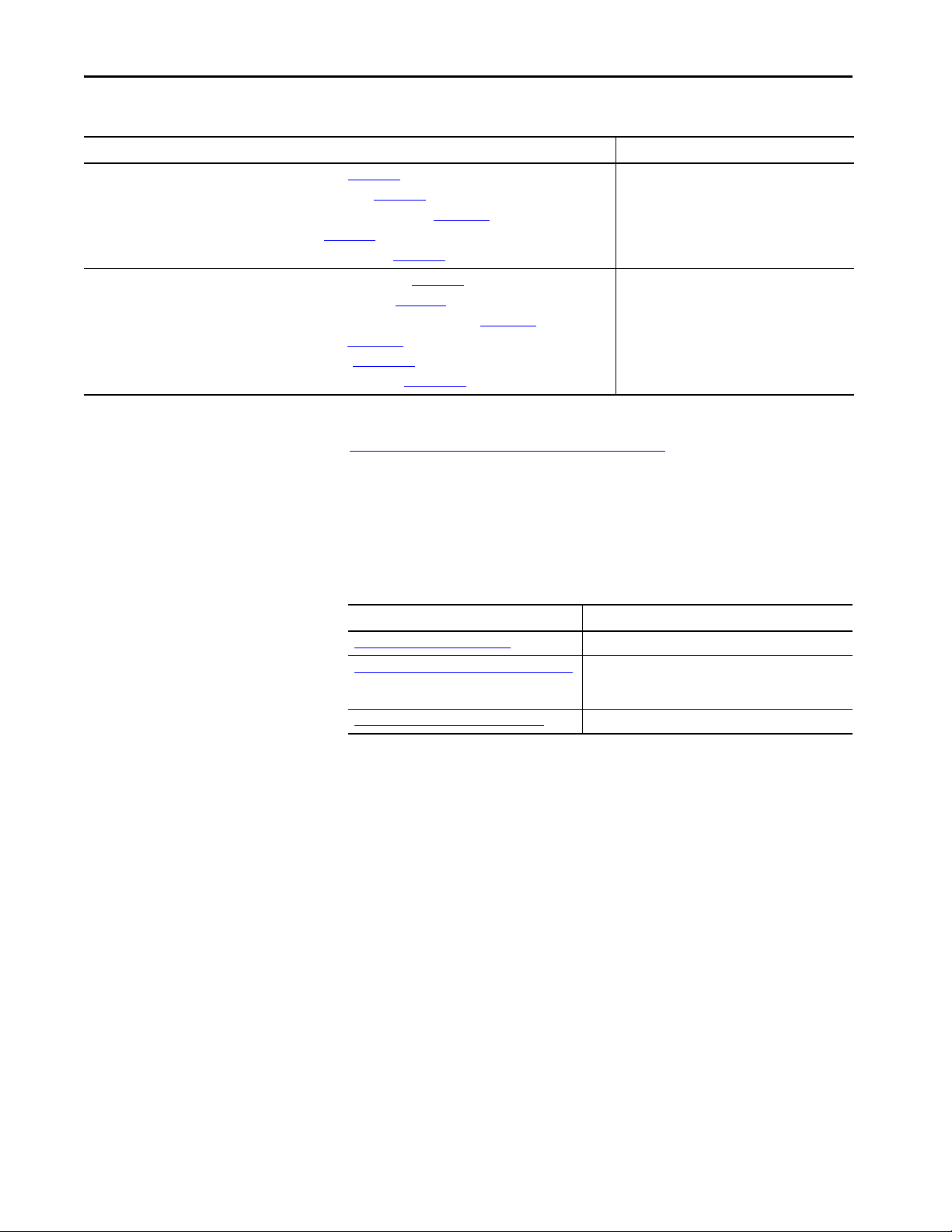

Table of Contents

Chapter 3

Replacement Considerations

with CompactLogix and Compact

GuardLogix Systems

Minimum Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

CompactLogix Controllers Minimum Requirements . . . . . . . . . 46

Compact GuardLogix Controllers Minimum Requirements . . 46

Product Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CompactLogix Controllers Product Comparison . . . . . . . . . . . . 47

Compact GuardLogix Controllers Product Comparison . . . . . . 49

Controller Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CompactLogix 5370 L3 and Compact GuardLogix 5370 L3

Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CompactLogix 5380 Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Compact GuardLogix 5380 Spacing. . . . . . . . . . . . . . . . . . . . . . . . . 52

Controller Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

CompactLogix 5370 L3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 53

CompactLogix 5380 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Compact GuardLogix 5370 Dimensions. . . . . . . . . . . . . . . . . . . . . 54

Compact GuardLogix 5380 Dimensions. . . . . . . . . . . . . . . . . . . . . 54

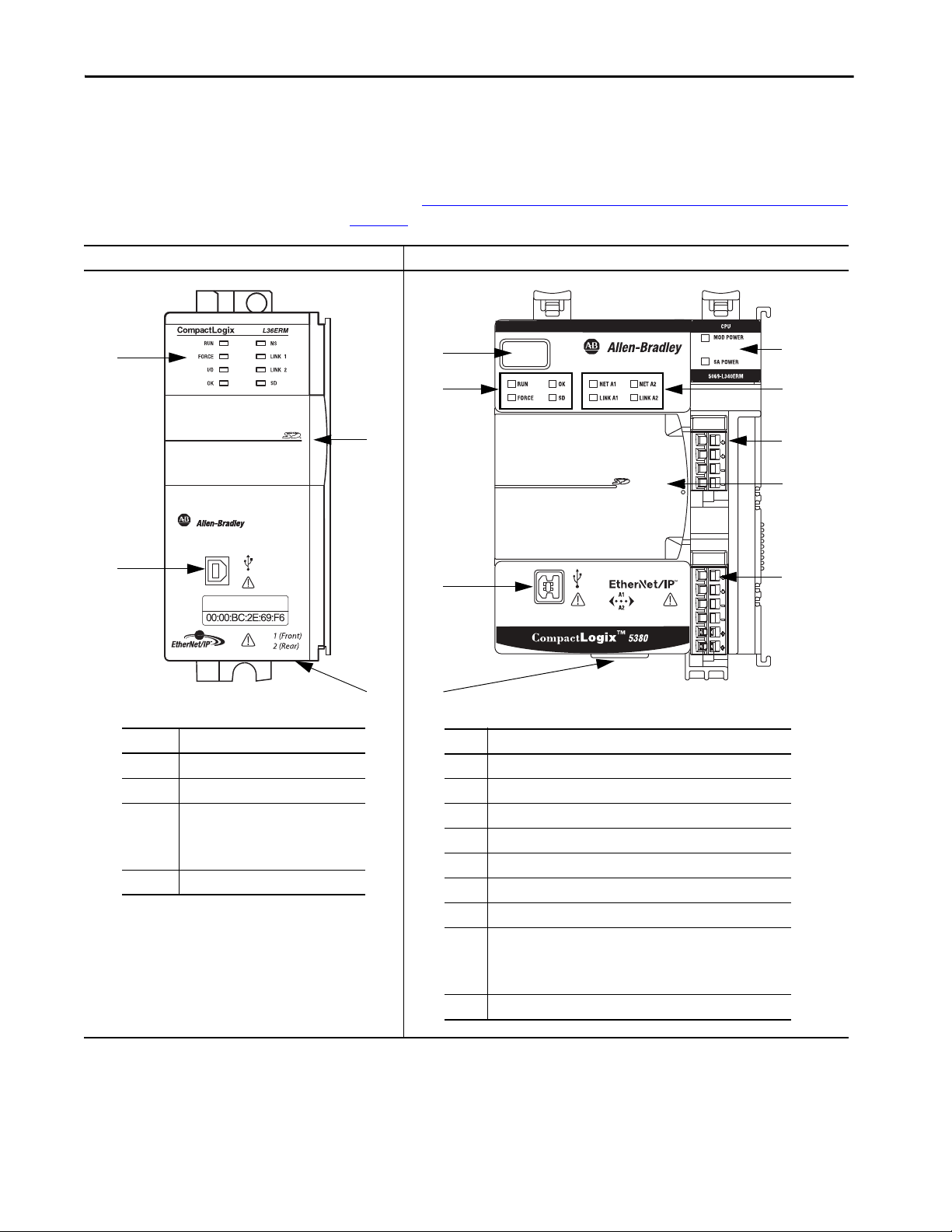

Connectors and Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Power the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Project Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configure the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Connections Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Nodes on an EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . . . . . 59

New Project Dialog Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Controller Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Controller Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

SD Card Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Communication Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

EtherNet/IP Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Dual-IP Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Linear/DLR Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Use I/O Modules in CompactLogix Systems . . . . . . . . . . . . . . . . . . . . 74

CompactLogix 5370 L3 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

CompactLogix 5380 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Local I/O Module Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Event Task Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Scheduled Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Download the Program to the Controller . . . . . . . . . . . . . . . . . . . . . . . 79

Build Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Downloading Workflow Change . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Upload Fidelity Change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Thermal Monitoring and Thermal Fault Behavior . . . . . . . . . . . . . . . 81

4 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Chapter 4

Table of Contents

Replacement Considerations

with Safety Applications

Perform Risk Assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Applications with

1734-AENTR Series A Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Safety Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

GSV of Safety Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Safety Network Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Produce/Consume Safety Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

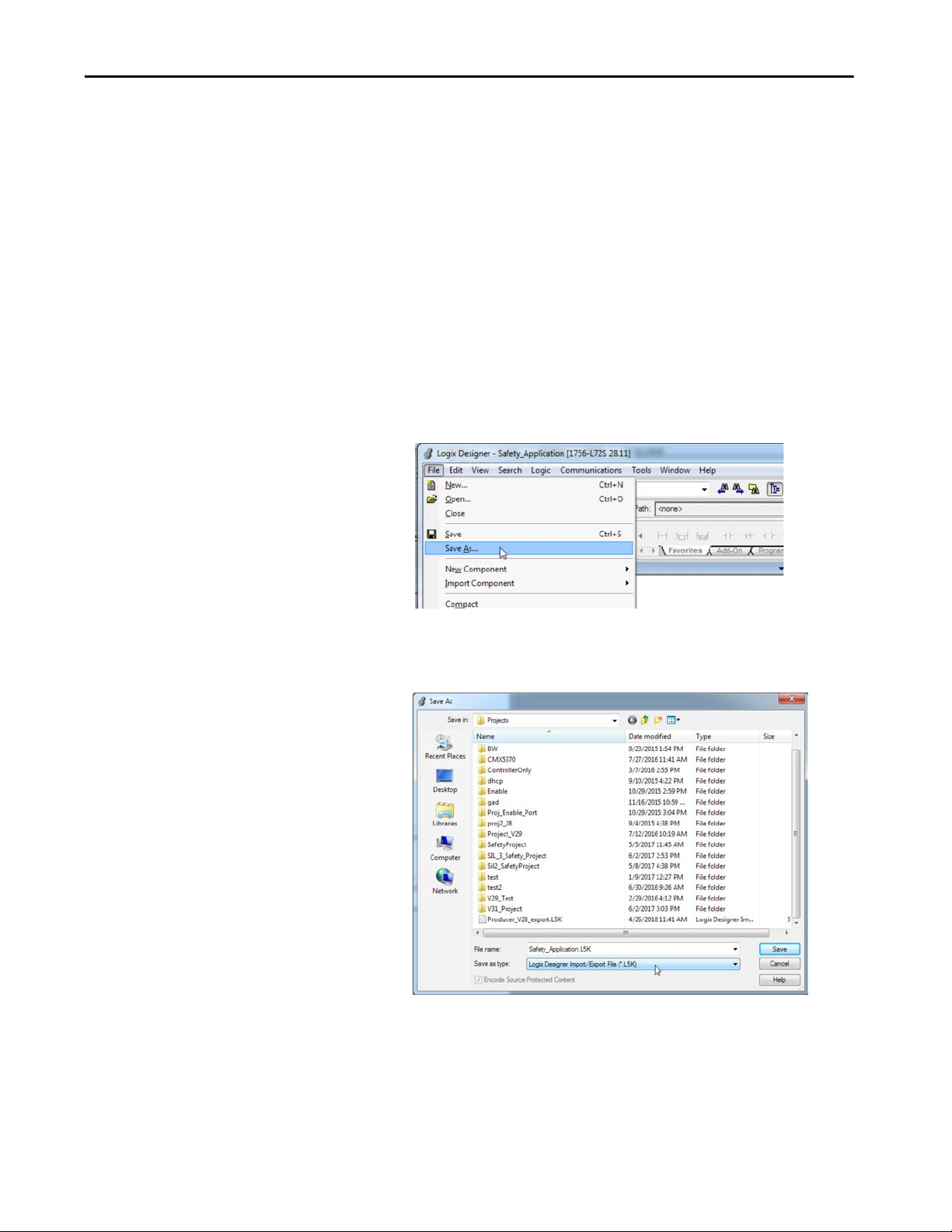

Safety Application Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Exporting and importing Safety Add-on Instructions . . . . . . . . . 88

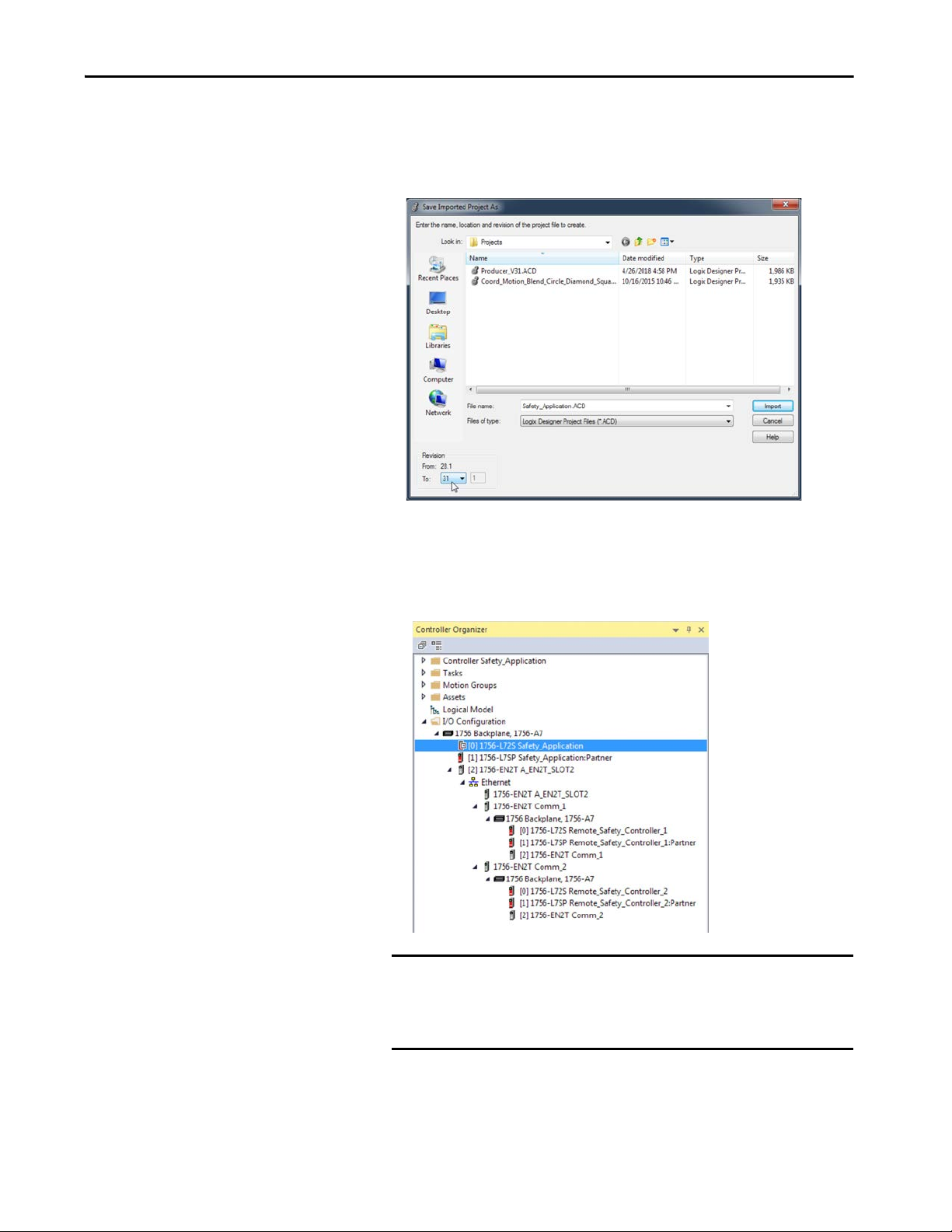

Convert a Safety Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Replace Producer Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Chapter 5

Standard Application Conversion Converting Logix Designer Projects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Produce and Consume Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

RPI of Multicast Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Data Structures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Late Binding of I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Standard Native I/O Data Types and Tags . . . . . . . . . . . . . . . . . 103

I/O Data Manipulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Motion Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

ControlLogix 5580 and GuardLogix 5580 Controllers . . . . . . 105

CompactLogix 5380 and Compact GuardLogix 5380

Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Axis Position References in Move Instructions . . . . . . . . . . . . . . 107

Pending Edits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

AXIS_CIP_Drive Data Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Chapter 6

Instruction Execution Math-related Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

TRN Instruction Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Improved Math Instruction Accuracy . . . . . . . . . . . . . . . . . . . . . . 111

SQR/SQRT Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

X Mod 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

AND, NOT, OR, and XOR Support for REAL. . . . . . . . . . . . . 112

Floating Point Literals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

XPY Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

0.0 div 0.0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Structural Changes to Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

JSR Nesting Level Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Max Number of Inputs or Outputs for a Program JSR/RET . 117

Max Number of InOut Parameters for an

Add-On Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Jump to Label Must Be Present . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

MCR Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 5

Table of Contents

Data Alignment and Memory Allocation Rules for

User-defined Data Types (UDTs) That Contain LINTs. . . . . 120

Instruction Error and Fault Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Subscript Expressions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

TRN Operator and Math Status Flags. . . . . . . . . . . . . . . . . . . . . . 124

Math Status Flags are Valid Only in One Rung. . . . . . . . . . . . . . 125

AVE and STD Instruction Accuracy . . . . . . . . . . . . . . . . . . . . . . . 126

BTD, FAL, FSC, and CMP No Longer Generate

Math Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Math Status Flags Not Permitted in Structured Text . . . . . . . . 127

Minor Fault on Overflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Manually Set Math Overflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

TOD Instruction Flags and Math Status Flags . . . . . . . . . . . . . . 130

Add-On Instructions Do Not Propagate Math Status Flags . . 130

Subroutines Do Not Affect Math Status Flags . . . . . . . . . . . . . . 131

Carry Flag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Store NAN in an Integer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Compare NAN Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Operand Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Converting +/- Infinity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Copy/File Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

COP and CPS Into Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

JSR and RET Parameters Passing Into Structures. . . . . . . . . . . . 136

JSR passing Atomic Data type into an Array or Structure . . . . 137

Instructions That Operate On Arrays . . . . . . . . . . . . . . . . . . . . . . 139

GSV/SSV Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

MCT/MCTP Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Chapter 7

Diagnostics and Status Indicators

with ControlLogix Systems

6 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Controller Status Display and Indicators . . . . . . . . . . . . . . . . . . . . . . . 141

4-Character Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Ethernet Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Controller Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Home Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Tasks Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Diagnostics Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Advanced Diagnostics Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . 146

Browse Chassis Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Chapter 8

Table of Contents

Diagnostics and Status Indicators

with CompactLogix Systems

Controller Status Display and Indicators . . . . . . . . . . . . . . . . . . . . . . . 150

4-Character Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Controller Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

EtherNet/IP Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Power Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Controller Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Differences Between 5380 and 5370 Controllers . . . . . . . . . . . . 155

EtherNet/IP Mode Affect on 5380 Controller Web Pages . . . 155

Home Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Tasks Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Diagnostics Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Ethernet Port A1/A2 Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Advanced Diagnostics Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . 160

Browse Chassis Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 7

Table of Contents

Notes:

8 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Preface

This manual is intended to offer guidelines when you replace the following:

• ControlLogix® 5570 controller with a ControlLogix® 5580 controller.

Guidelines that reference a ControlLogix 5570 controller also apply to a

ControlLogix 5560 controller.

• CompactLogix™ 5370 L3 controller with a CompactLogix 5380

controller

• GuardLogix® 5560 or GuardLogix 5570 controller with a GuardLogix

5580 controller.

• Compact GuardLogix 5370 L3 controller with a Compact GuardLogix

5380 controller

Summary of Changes

This manual contains new and updated information as indicated in the

following table.

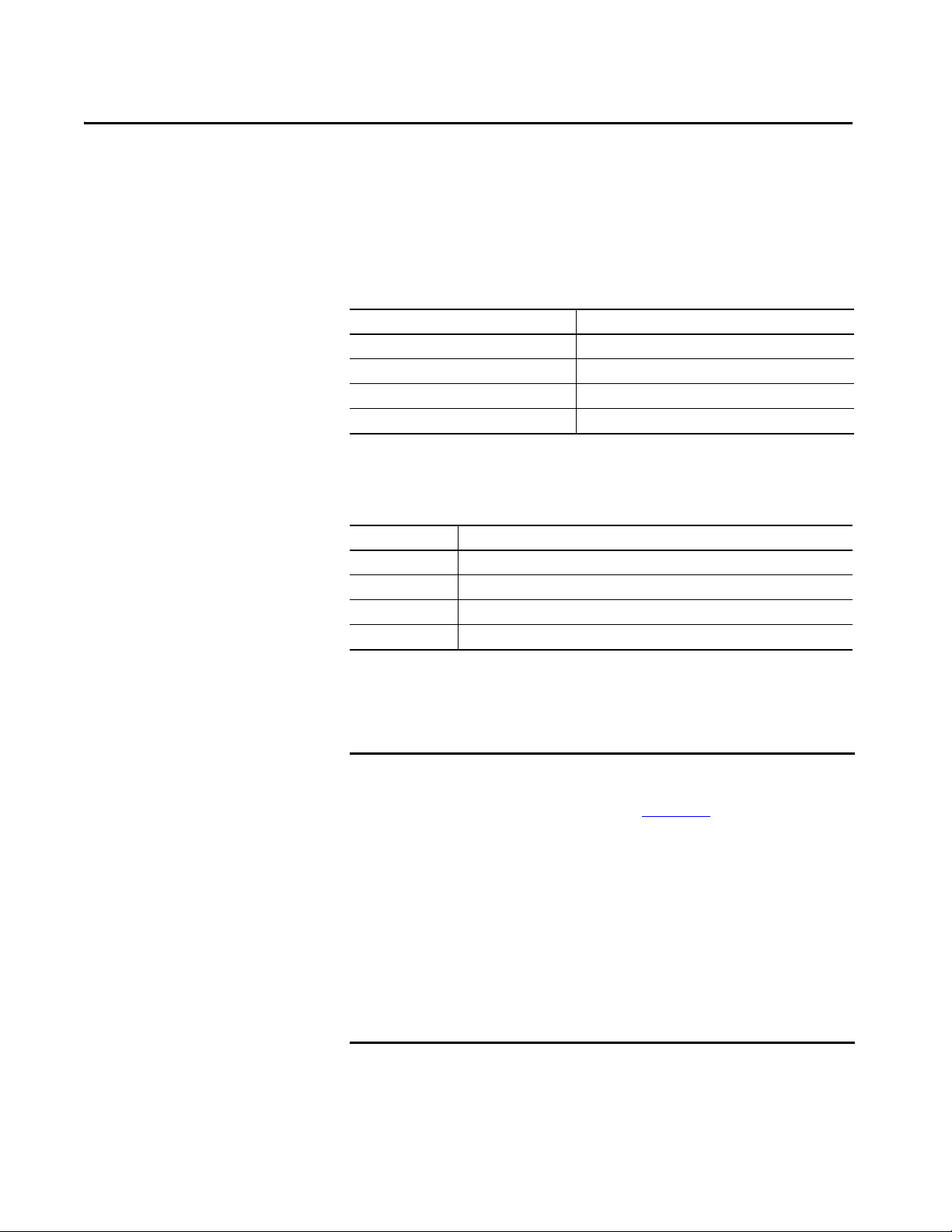

Top ic Pa ge

Added information regarding GuardLogix 5580 and Compact GuardLogix 5380

controllers.

Added Chapter 4: Replacement Considerations with Safety Applications 83

Added information on the AXIS_CIP_Drive Data Type for Studio 5000 Logix Designer®

V31.00.00

Additional Resources

These resources contain information about related products from

Rockwell Automation.

These documents contain more information about Logix 5000™ controllers.

Table 1 - Additional Resources

Resource Description

• EtherNet/IP™ Communication Modules in Logix 5000™ Control Systems, publication ENET-UM004

• EtherNet/IP Network Configuration User Manual, publication ENET-UM001

• ControlNet® Network Configuration User Manual, publication CNET-UM001

• DeviceNet® Network Configuration User Manual, publication DNET-UM004

• Logix 5000 Controllers Common Procedures Programming Manual, publication 1756-PM001

• Logix Controllers Instructions Reference Manual, publication 1756-RM009

• Logix 5000 Controllers Advanced Process Control and Drives Instructions Reference Manual, publication 1756-RM006

• Logix 5000 Controllers Motion Instructions Reference Manual, publication MOTION-RM002

• Logix 5000 Controllers Import/Export Reference Manual, publication 1756-RM084

Networks

Logix 5000 Software and Programming

Through out

108

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 9

Preface

Table 1 - Additional Resources

Resource Description

• 1756 ControlLogix Controllers Technical Data, publication 1756-TD001

• ControlLogix 5580 Controllers Product Information, publication 1756-PC405

• ControlLogix 5580 and GuardLogix 5580 Controllers User Manual, publication 1756-UM543

• ControlLogix Chassis and Power Supply, publication 1756-IN005

• 1756 ControlLogix Chassis Specifications Technical Data, publication 1756-TD006

• CompactLogix 5380 Controller Specifications Technical Data, publication 5069-TD002

• CompactLogix 5380 Controllers Installation Instructions, publication 5069-IN013

• CompactLogix 5380 and Compact GuardLogix 5380 Controllers User Manual, publication 5069-UM001

• CompactLogix 5370 Controllers User Manual, publication 1769-UM021

• CompactLogix 5370 L3 Controllers Quick Start, publication IASIMP-QS023

• CompactLogix Performance and Capacity Quick Reference, publication IASIMP-QR007

ControlLogix Controllers, Chassis, and Power Supply

CompactLogix Controllers

You can view or download publications at

http://www.rockwellautomation.com/literature/

To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

.

Websites

Resource Description

https://ab.rockwellautomation.com/ Product Selection Information

Product Compatibility and Download Center (PCDC) Product-relate d downloads including firmware, release

http://samplecode.rockwellautomation.com Studio 5000 Logix Designer Sample Code

notes, associated software, drivers, tools, and utilities

(produc t serial nu mber required)

10 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Chapter 1

Before You Begin a Migration

Topic Page

Considerations 12

New and Future Features 13

Integrated Architecture Tools 15

Migration Services 15

This publication features these controllers, and where applicable, the

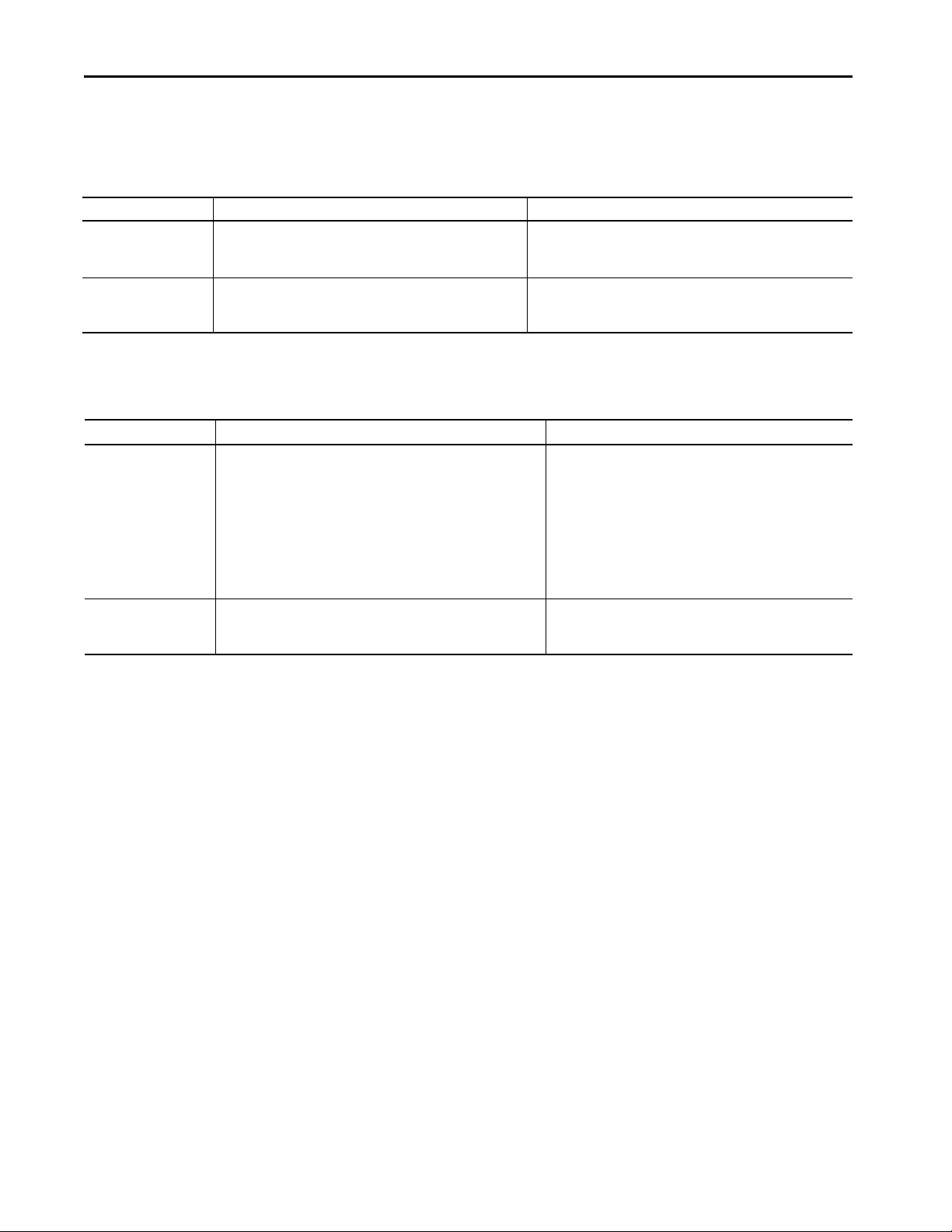

controllers are known as:

Controller Family Includes these controllers

5580 controllers ControlLogix® 5580 and GuardLogix® 5580 controllers

5380 controllers CompactLogix™ 5380 and Compact GuardLogix 5380 controllers

5570 controllers ControlLogix 5570 and GuardLogix 5570 controllers

5370 controllers CompactLogix 5370 and Compact GuardLogix 5370 controllers

This publication provides a reference to controller capabilities and how the

5580/5380 controller capabilities differ from the 5570/5370 controllers.

IMPORTANT Any user or third-party developer of communications software to a

ControlLogix or CompactLogix controller must fully follow the Logix 5000™

Data Access Programming Manual, 1756-PM020

.

Beginning with Logix controller families 5380 and 5580, the full

implementation and enforcement of the CIP™ specification standard for

ANSI Extended Symbolic 0x91 is required, as documented in the above

referenced publication and the ODVA CIP specification.

Any custom or 3rd party communications software, which previously only

supported ANSI Extended Symbolic 0x61, will need to be updated to

communicate to these new controllers.

Previous Logix controller families CompactLogix L1, L2, L3, 5370 and

ControlLogix 5550, 5560, 5570 continue to support both the 0x91 CIP

Standard and the older, no longer in use, 0x61.

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 11

Chapter 1 Before You Begin a Migration

Considerations

Throughout this manual, the following apply:

• Guidelines that reference a ControlLogix 5570 controller also apply to a

ControlLogix 5560 controller.

• There are references to controller project versions. Controller project

versions 20 or earlier are created in RSLogix 5000® software. Controller

project versions 21 or later are created in the Studio 5000 Logix

Designer® environment, referred to as the Logix Designer application

throughout this publication.

• Not all controllers are available with all versions of RSLogix 5000

software or the Logix Designer application.

For example, CompactLogix 5370 L3 controllers are available in

RSLogix 5000 software, version 20 and the Logix Designer application,

version 21 or later.

• Unless otherwise indicated, the graphics that are used throughout

manual are the same for 5380 and 5580 controllers.

Product compatibility information and release notes are available online

within the Product Compatibility and Download Center at

http://www.rockwellautomation.com/rockwellautomation/support/

pcdc.page.

12 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Before You Begin a Migration Chapter 1

New and Future Features

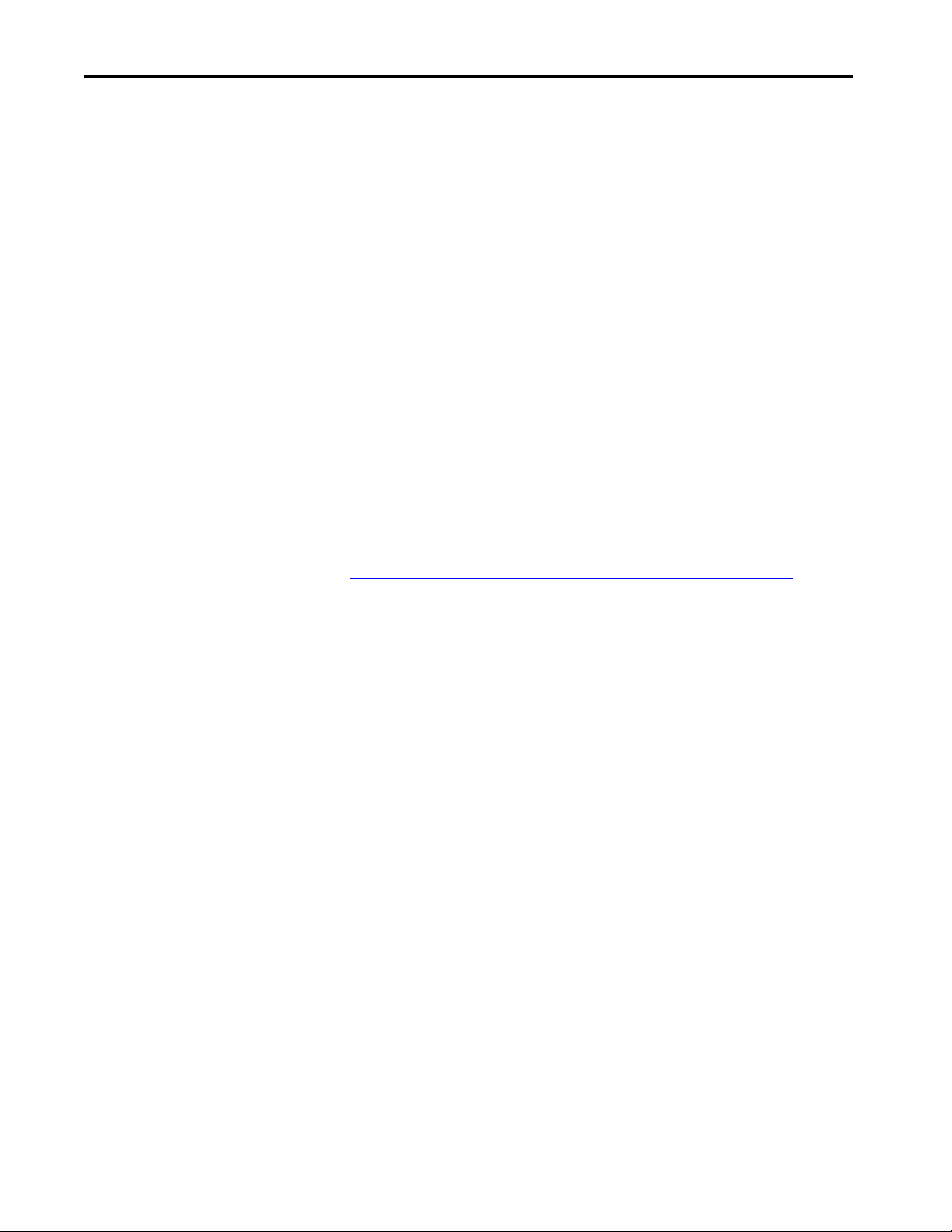

The following table indicates the Studio 5000 Logix Designer environment

version in which product features are available.

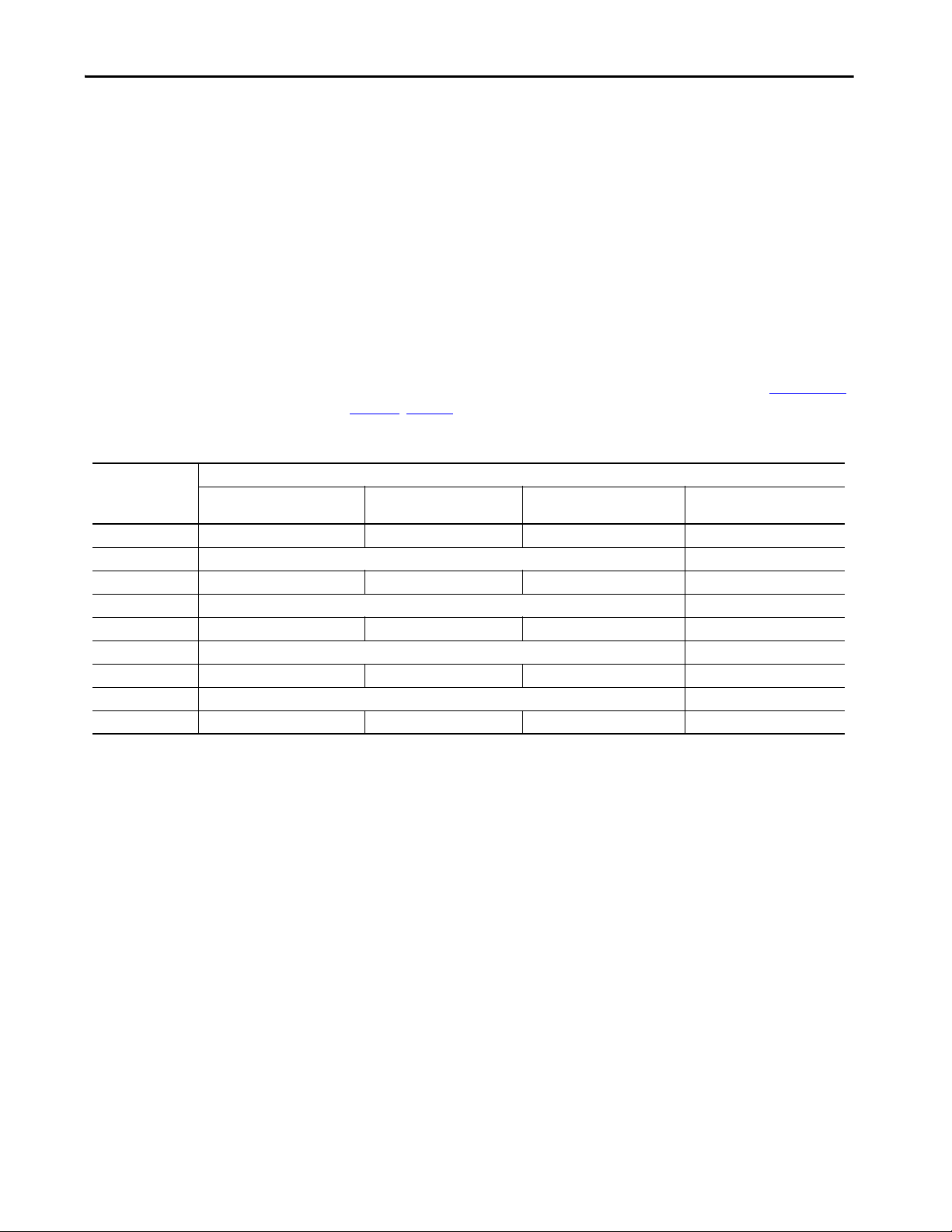

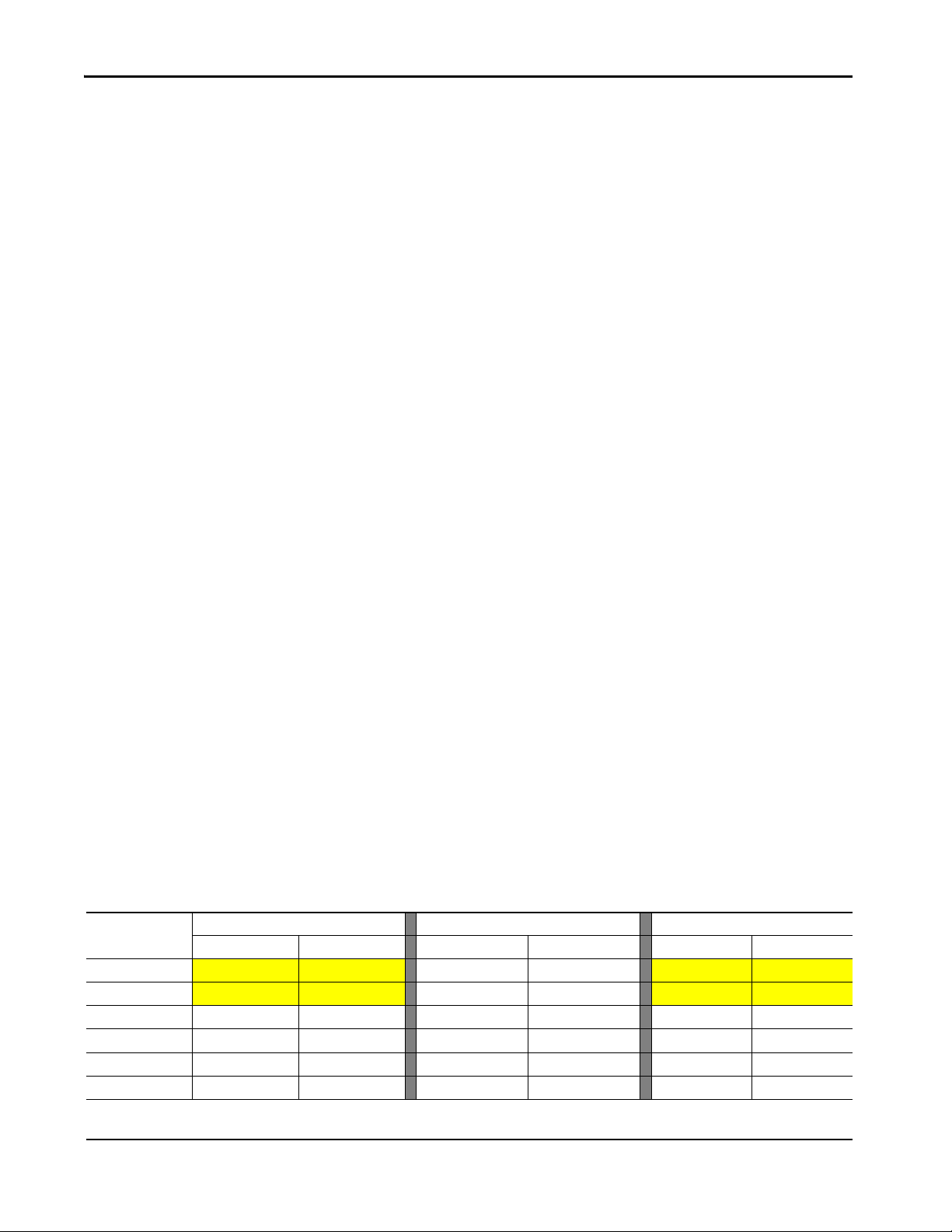

Table 2 - New and Future Features

Feature ControlLogix Controllers CompactLogix Controllers

ControlLogix 5570

GuardLogix 5570

Hardware support No new controllers in

1 Gbps Ethernet port Not applicable Single embedded Ethernet

EtherNet/IP™ modes:

• Dual-IP mode

•DLR/Linear mode

Instruction-based alarms (ALMA, ALMD) All versions Version 29 or later All versions Version 29 or later

Tag-based Alarms Not applicable Version 31 or later Not applicable Version 31 or later

Integrated Motion on EtherNet/IP All versions Version 28 or later All versions

SERCOS motion All versions Version 31 or later Not supported Not supported

Analog motion All versions Version 31 or later Not supported Future

versions 28, 29, or 30

Not applicable Not supported DLR/Linear mode in all versions

ControlLogix 5580

GuardLogix 5580

New controllers in version 28:

• 1756-L83E

• 1756-L85E

New controllers in version 29:

• 1756-L81E

• 1756-L82E

• 1756-L84E

New controllers in version 31:

• 1756-L81ES

• 1756-L82ES

• 1756-L83ES

• 1756-L84ES

port that supports up to 1

Gbps communication rate

CompactLogix 5370 L3

Compact GuardLogix 5370 L3

New controllers in version 28:

• 1769-L30ERMS

• 1769-L33ERMS

• 1769-L36ERMS

New controllers in version 31:

• 1769-L37ERM

• 1769-L37ERMS

• 1769-L38ERM

• 1769-L38ERMS

• 1769-L38ERMO

• 1769-L38ERMOS

Not supported Dual, embedded Ethernet ports

that support CompactLogix 5370

L3 controllers

(3)

CompactLogix 5380

Compact GuardLogix 5380

New controllers in version 28:

• 5069-L320ER

• 5069-L340ERM

New controllers in version 29:

• 5069-L306ER,

5069-L306ERM

• 5069-L310ER,

5069-L310ER-NSE,

5069-L310ERM

• 5069-L320ERM

• 5069-L330ER,

5069-L330ERM

• 5069-L340ER

• 5069-L350ER

New controllers in version 30:

• 5069-L350ERM

• 5069-L380ERM

• 5069-L3100ERM

New controllers in version 31:

• 5069-L306ERS2

• 5069-L306ERMS2

• 5069-L310ERS2

• 5069-L310ERMS2

• 5069-L320ERS2

• 5069-L320ERMS2

• 5069-L330ERS2

• 5069-L330ERMS2

• 5069-L340ERS2

• 5069-L340ERMS2

• 5069-L350ERS2

• 5069-L350ERMS2

• 5069-L380ERS2

• 5069-L380ERMS2

• 5069-L3100ERS2

• 5069-L3100ERMS2

that each support up to 1 Gbps

communication rate

CompactLogix 5380 Controllers

Version 28 or later DLR/Linear mode

CompactLogix 5380 Controllers

Version 29 or later Dual-IP mode and DLR/Linear

Compact GuardLogix 5380

Controllers Version 31or later Dual-IP mode and DLR/Linear

Vers ion 2 8 or la ter

(3)

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 13

Chapter 1 Before You Begin a Migration

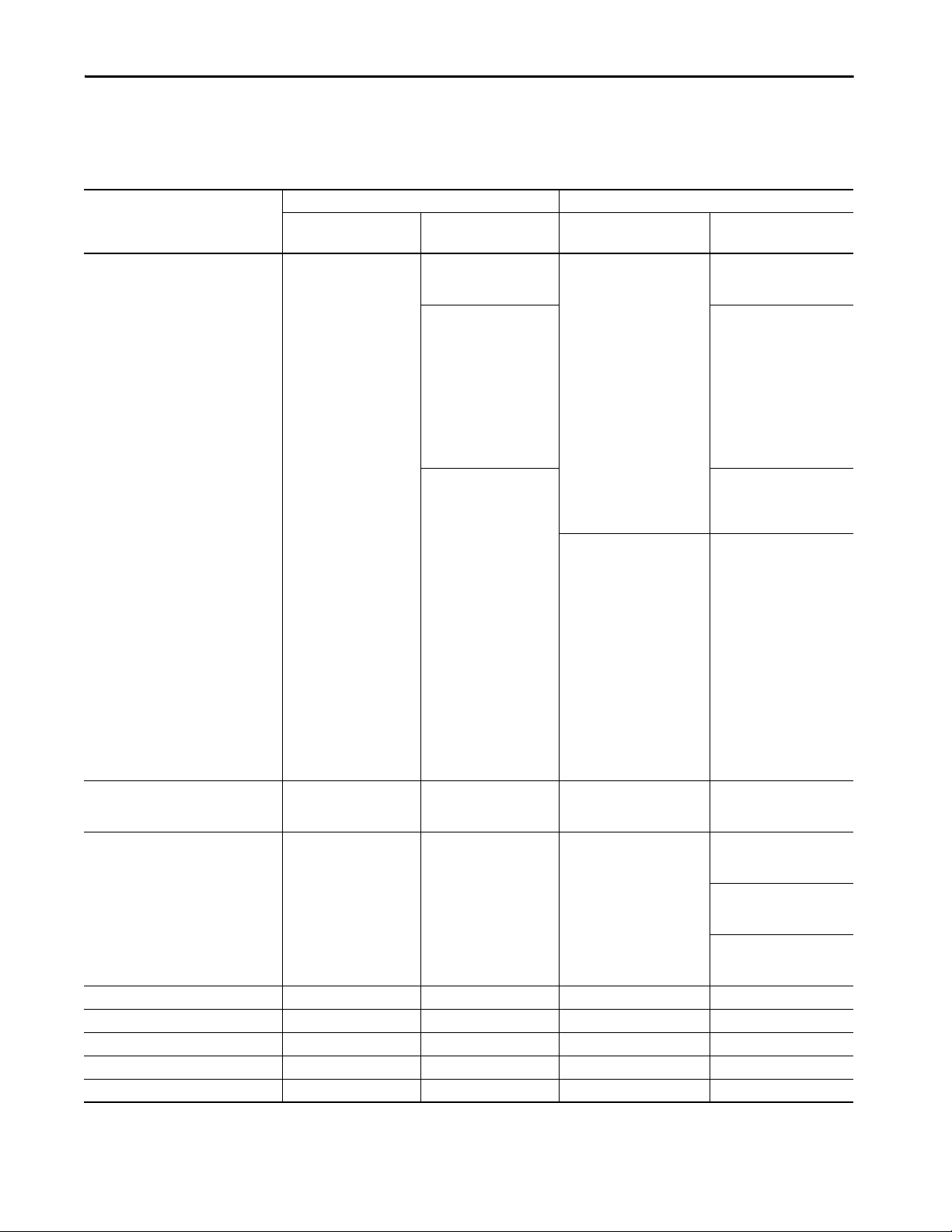

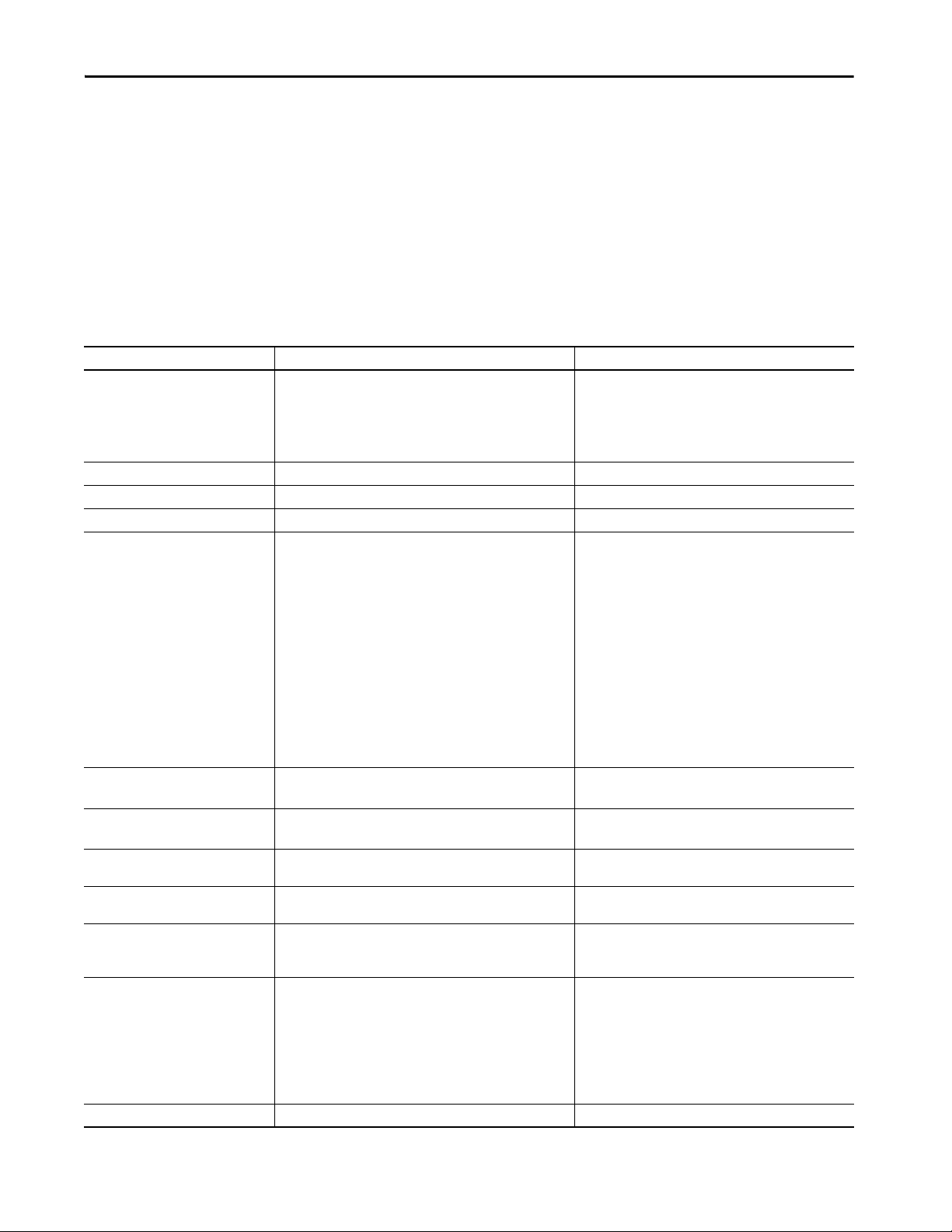

Table 2 - New and Future Features

Feature ControlLogix Controllers CompactLogix Controllers

ControlLogix 5570

GuardLogix 5570

Integrated safety SIL 2/PLd Version 28 or later for

ControlLogix 5570 controllers

only, along with components

of the ControlLogix system

that are type-approved and

certified for use in SIL 2

applications, according to IEC

(2)

61508.

For more information, see the

Using ControlLogix in SIL 2

Applications Safety Reference

Manual, publication

1756-RM001.

Integrated safety SIL 3/PLe Version 28 or later with these

GuardLogix 5570 controllers

and safety partner:

• 1756-L71S and

1756-L7SP

• 1756-L72S and

1756-L7SP

• 1756-L73S and

1756-L7SP

PanelView™ 5000 graphic terminal support Version 27 or later Version 29 or later Version 27 or later Version 29 or later

Redundancy ControlLogix 5570 controllers

- Versions 19, 20, and 24

ControlLogix 5560 controllers

- Versions 19 and 20

PhaseManager™ All versions Future All versions Future

SequenceManager™ Version 28 or later Future Version 28 or later Future

Drive-based CIP Safety stopping functions

(1)

, monitored/timed SS1)

(STO

Controller-based CIP Safety stopping and

Version 30 or later Version 31 or later Version 30 or later Version 31 or later

Not applicable Version 31 or later Not applicable Version 31 or later

monitoring functions

(SS1, SS2, SOS, SLS, SLP, SDI)

Secured Data Exchange Version 30 or later Future Version 30 or later Future

Controller-based Audit Log Version 30 or later Future Version 30 or later Future

Component Change Detection Version 30 or later Future Version 30 or later Future

Emulate All versions Future All versions Future

(1) Only the GuardLogix 5570, GuardLogix 5580, Compact GuardLogix 5370, and Compact GuardLogix 5380 controllers support the CIP Safety™ protocol that is needed for the Safe To rque Off (STO)

function.

(2) This type of SIL 2 application is not supported by ControlLogix 5580 controllers.

(3) Not all CompactLogix 5370 L3 or CompactLogix 5380 controllers support Integrated Motion on an EtherNet/IP network.

ControlLogix 5580

GuardLogix 5580

Version 31 or later with these

GuardLogix 5580 controllers:

• 1756-L81ES

• 1756-L82ES

• 1756-L83ES

• 1756-L84ES

Achieve SIL 2/PLd with the

use of a primary safety

controller, the safety task, and

safety I/O.

CompactLogix 5370 L3

Compact GuardLogix 5370 L3

CompactLogix 5380

Compact GuardLogix 5380

Not supported Version 31 or later with these

Compact GuardLogix 5380

controllers:

• 5069-L306ERS2

• 5069-L306ERMS2

• 5069-L310ERS2

• 5069-L310ERMS2

• 5069-L320ERS2

• 5069-L320ERMS2

• 5069-L330ERS2

• 5069-L330ERMS2

• 5069-L340ERS2

• 5069-L340ERMS2

• 5069-L350ERS2

• 5069-L350ERMS2

• 5069-L380ERS2

• 5069-L380ERMS2

• 5069-L3100ERS2

• 5069-L3100ERMS2

Achieve SIL 2/PLd with the use

of the SIL2/PLd capable safety

controller, the safety task, and

safety I/O.

Version 31 or later with these

GuardLogix 5580 controllers

and safety partner:

• 1756-L81ES

• 1756-L82ES

• 1756-L83ES

• 1756-L84ES

• 1756-L8SP

Version 28 or later with these

Compact GuardLogix 5370 L3

controllers:

• 1769-L30ERMS

• 1769-L33ERMS

• 1769-L36ERMS

• 1769-L36ERMOS

• 1769-L37ERMS

Future

• 1769-L37ERMOS

• 1769-L38ERMS

• 1769-L38ERMOS

Future Not supported Not supported

14 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Before You Begin a Migration Chapter 1

Integrated Architecture Tools

Migration Services

The Integrated Architecture® system can help you plan and configure a system,

and migrate system architectures. For more information, go to:

http://www.rockwellautomation.com/rockwellautomation/productstechnologies/integrated-architecture/tools/overview.page?

Rockwell Automation can help you in the following ways:

• To get the most out of your current equipment.

• To determine your next steps.

• To plan for the transition to newer technology.

You can migrate all at once or use our unique, phased approach. The phased

approach helps you minimize the costs, risks, and complexities that are present

when you manage legacy products and systems. Regardless of the migration

approach that you take, Rockwell Automation has the tools and the experience

to guide you through the transition.

For more information, see Migration Solutions Brochure,

publication MIGRAT-BR002

.

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 15

Chapter 1 Before You Begin a Migration

Notes:

16 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Chapter 2

Replacement Considerations with ControlLogix

5580 and GuardLogix 5580 Systems

Topic Page

Minimum Requirements 18

Product Comparison 19

Controller Dimensions 22

Connectors and Status Indicators 24

Project Size 26

Configure the Controller 26

Controller Res et 37

SD Card Behavior 38

Communication Options 39

Download the Program to the Controller 41

Thermal Monitoring and Thermal Fault Behavior 43

This chapter describes features and functions that are associated with the

ControlLogix® 5580 and GuardLogix® 5580 controllers.

This chapter features these controllers, and where applicable, the controllers

are known as:

Controller Family Includes these controllers

5580 controllers ControlLogix 5580 and GuardLogix 5580 controllers

5570 controllers ControlLogix 5570 and GuardLogix 5570 controllers

It is not an exhaustive list of the features and functions available with the

controllers. Instead, the list indicates what is new or changed in the controller

at this release:

• Embedded 10/100/1000 Mbps Ethernet port

• Higher performance and capacity including :

– Motion Processing: 256 total axes

– Total I/O packets processing: 128,000 pps

– 320 unconnected message buffers

– 256 simultaneous cached message instructions in the running state

– Support for up to 300 EtherNet/IP™ nodes

• Support for Compact 5000™ I/O over an EtherNet/IP network

• Change Ethernet port speed without a module reset

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 17

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

Minimum Requirements

The 5580 controllers have these minimum requirements.

ControlLogix Controllers Minimum Requirements

Requirement, Minimum ControlLogix 5570 Controller ControlLogix 5580 Controller

Chassis 1756-A4, 1756-A7, 1756-A10, 1756-A13, 1756-A17

Series A, Series B, and Series C

Programming Software Studio 5000 Automation Engineering & Design Environment®,

Version 21.00.00 or later

RSLogix 5000® Software Version 20.00.00 or later

1756-A4, 1756-A7, 1756-A10, 1756-A13, 1756-A17

0 °C < Ta < +60 °C (+32 °F < Ta < +140 °F) for Series C Chassis

0 °C < Ta < +50 °C (+32 °F < Ta < +122 °F) for Series B Chassis

Studio 5000 Logix Designer® Application Version 28.00.00 or later

GuardLogix Controllers Minimum Requirements

Requirement, Minimum GuardLogix 5570 Controller GuardLogix 5580 Controller

Chassis 1756-A4, 1756-A7, 1756-A10, 1756-A13, 1756-A17

Series A, Series B, and Series C

Programming Software Studio 5000 Automation Engineering & Design Environment,

Version 21.00.00 or later

RSLogix 5000 Software Version 20.00.00 or later

1756-A4, 1756-A7, 1756-A10, 1756-A13, 1756-A17

Operating in SIL 2/PL d Configuration:

0 °C < Ta < +60 °C (+32 °F < Ta < +140 °F) for Series C Chassis

Note: If operating above +55 °C (+131 °F), modules greater than

6.2 W shall not be installed in slots adjacent to the controller.

Operating in SIL 3/PL e Configuration:

0 °C < Ta < +60 °C (+32 °F < Ta < +140 °F) for Series C Chassis

0 °C < Ta < +50 °C (+32 °F < Ta < +122 °F) for Series B Chassis

Studio 5000 Logix Designer Application Version 31.00.00 or later

18 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

Product Comparison

This section compares:

• ControlLogix 5580 controllers to ControlLogix 5570 controllers

• GuardLogix 5580 controllers to GuardLogix 5570 controllers

ControlLogix Controllers

The ControlLogix 5580 controllers operate similarly to the

ControlLogix 5570 controllers, with these differences.

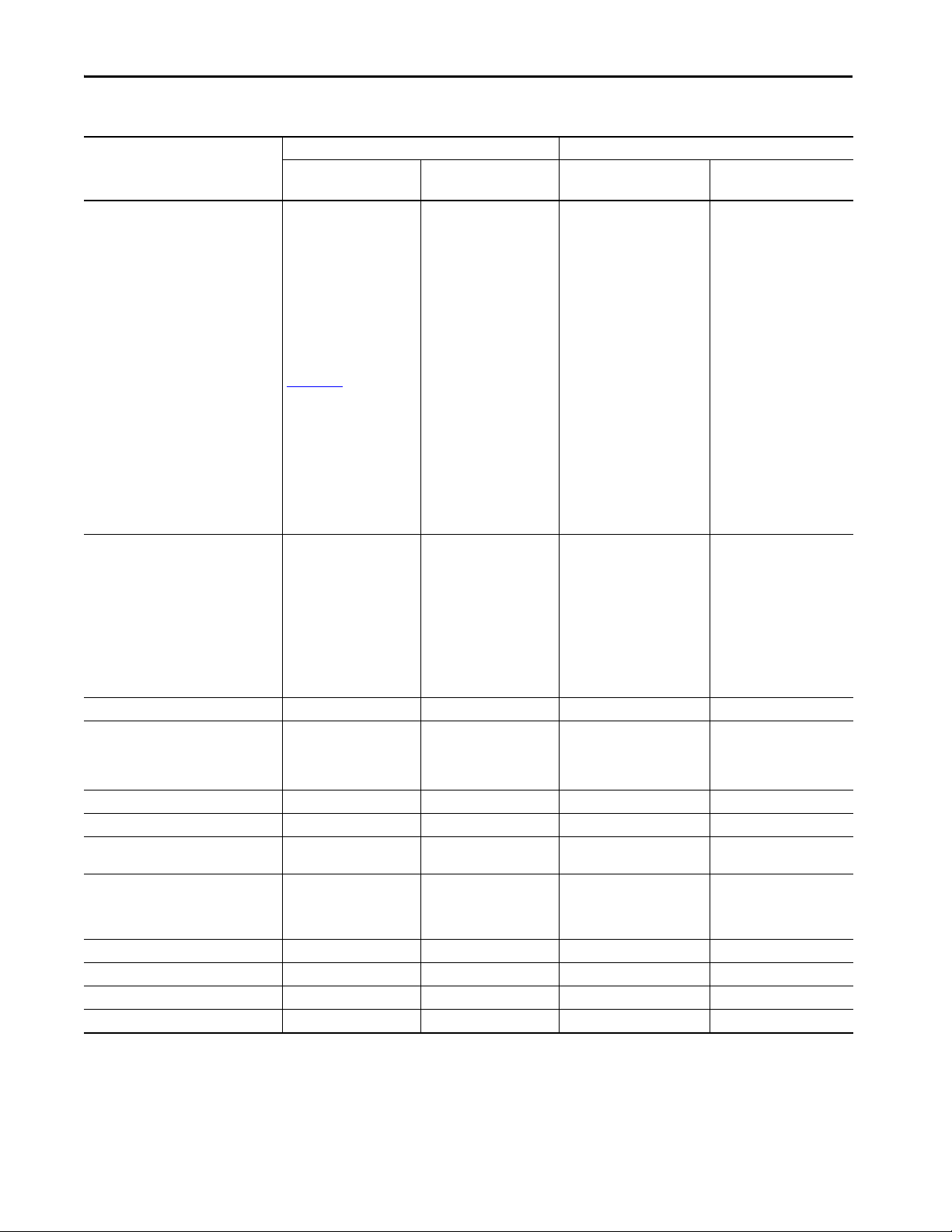

Table 3 - Technical Specifications

Attribute ControlLogix 5570 Controller ControlLogix 5580 Controller

Memory 4…32 MB user memory 1756-L81E: 3 MB

1756-L82E: 5 MB

1756-L83E: 10 MB

1756-L84E: 20 MB

1756-L85E: 40 MB

I/O Memory 0.98 MB Not applicable

Compact 5000 I/O modules supported Not supported Full support

Embedded Ethernet Not applicable 10/100/1000 Mbps

Ethernet nodes Controller connections: a total of 500 connections used for Ethernet

I/O and Ethernet Messaging.

Logix Designer application, version 28:

• 1756-L83E: 100 EtherNet/IP nodes, max

• 1756-L85E: 300 EtherNet/IP nodes, max

Logix Designer application, version 29:

• 1756-L81E: 60 EtherNet/IP nodes, max

• 1756-L82E: 80 EtherNet/IP nodes, max

• 1756-L83E: 100 EtherNet/IP nodes, max

• 1756-L84E: 150 EtherNet/IP nodes, max

• 1756-L85E: 300 EtherNet/IP nodes, max

(2)

Logix Designer application, version 30 or later:

• 1756-L81E: 100 EtherNet/IP nodes, max

• 1756-L82E: 175 EtherNet/IP nodes, max

• 1756-L83E: 250EtherNet/IP nodes, max

• 1756-L84E: 250 EtherNet/IP nodes, max

• 1756-L85E: 300 EtherNet/IP nodes, max

Ethernet performance Not applicable Ethernet I/O (Class 0/1): 128,000 packets per second

Ethernet Messaging (Class 3): 2000 messages per second

Unconnected message buffers 20 outgoing buffers, configurable to 40

4 incoming buffers

Concurrent cached message instructions

in the running state

HMI and Messaging (Class 3) Drawn from the 500 total connections supported by the controller. 512 dedicated messages (256 incoming messages and 256

Integrated motion • SERCOS interface

Motion axes 128, any combination of these supported axis types:

Axes/ms over backplane 8 19

32, drawn from the 500 total connections supported by the

controller.

• Analog options (encoder input, LDT input, SSI input)

•EtherNet/IP network

• CIP™

• Consumed

• Virtual

• Position loop drives

•Servo

•Servo drive

• Generic

320 - Any combination of outgoing or incoming unconnected

buffers.

256 dedicated buffers.

outgoing messages)

• EtherNet/IP network

• SERCOS interface

• Analog options (encoder input, LDT input, SSI input)

256, any combination of these supported axis types:

•CIP

• Consumed

•Virtual

• Position loop drives

(4)

(4)

(3)

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 19

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

Table 3 - Technical Specifications

Attribute ControlLogix 5570 Controller ControlLogix 5580 Controller

Axes/ms over EtherNet/IP port Not applicable 32 when you use the built-in EtherNet/IP port at 1 Gbps.

Rockwell Automation recommends that you use the built-in

EtherNet/IP port for high-performance motion applications.

Voltage and current ratings 800 mA @ 5.1V DC

5.0 mA @ 1.2V DC

Energy storage module • 1756-ESMCAP capacitor energy storage module (removable)

• 1756-ESMNSE capacitor energy storage module (removable)

• 1756-ESMNRM capacitor energy storage module

(nonremovable)

Weight, approx 0.25 kg (0.55 lb) 0.394 kg (.868 lb)

Wire ca tegory

(1)

3 - on USB port 3 - on USB port

Wire si ze Not applicable Ethernet cabling and installation according to

Reset Button Not applicable A stage 1 reset clears the user application program and

(1) Use this conductor category information for planning conductor routing. See the Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1.

(2) The 5580 controllers allocate memory as needed, so there is no dedicated I/O memory space.

(3) Data size = 32-bits / 1-DINT

(4) With Studio 5000 Logix Designer Application Ve rsion 31.00.00 or later.

1.2 A @ 5.1V DC

5.0 mA @ 1.2V DC

Embedded in controller, nonremovable

2 - on Ethernet port

IEC 61918 and IEC 61784-5-2

memory, but retains the controller IP address.

A stage 2 reset returns the controller to out-of box settings

(including firmware), and clears all network settings.

GuardLogix Controllers

The GuardLogix 5580 controllers operate similarly to the GuardLogix 5570

controllers, with some differences.

Table 4 - Features and Specifications

Attribute GuardLogix 5570 Controller GuardLogix 5580 Controller

Instruction-based alarms (ALMA,

ALMD)

Tag based alarms Not applicable Yes

PanelView™ 5000 Not supported Full support

User and Safety Memory 1756-L71S: 2 MB + 1 MB Safety

I/O Memory 0.98 MB Not applicable

Compact 5000 I/O modules supported Not supported Full support

Embedded Ethernet Not applicable 10/100/1000 Mbps

Ethernet nodes

(1)

Ethernet performance Not applicable Ethernet I/O (Class 0/1): 128,000 packets per second

Yes Yes

1756-L81ES: 3 MB + 1.5 MB Safety

1756-L72S: 4 MB + 2 MB Safety

1756-L73S: 8 MB + 4 MB Safety

1756-L82ES: 5 MB + 2.5 MB Safety

1756-L83ES: 10 MB + 5.0 MB Safety

1756-L84ES: 20 MB + 6.0 MB Safety

Controller connections: a total of 500 connections used for

Ethernet I/O and Ethernet Messaging.

• 1756-L81ES: 100 EtherNet/IP nodes, max

• 1756-L82ES: 175 EtherNet/IP nodes, max

• 1756-L83ES: 250 EtherNet/IP nodes, max

• 1756-L84ES: 250 EtherNet/IP nodes, max

Ethernet Messaging (Class 3): 2000 messages per second

(3)

(4)

20 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

Table 4 - Features and Specifications

Attribute GuardLogix 5570 Controller GuardLogix 5580 Controller

Unconnected message buffers 20 outgoing buffers, configurable to 40

4 incoming buffers

Concurrent cached message

32, drawn from the 500 total connections supported by the controller. 256 dedicated buffers.

instructions in the running state

HMI and Messaging (Class 3) Drawn from the 500 total connections supported by the controller. 512 dedicated messages (256 incoming messages and 256

Integrated motion • SERCOS interface

• Analog options (encoder input, LDT input, SSI input)

• EtherNet/IP network

Drive Safety Instructions with

Not applicable Yes

Kinetix® 5700 ERS4 Drives

Networked Safe Torque Off for Drives

Full support Full support

(CIP Mode/IO Mode)

Networked Safe Torque Off for Kinetix

Full support Full support

(CIP Mode)

Motion axes 100, any combination of these supported axis types:

•CIP

•Consumed

• Virtual

• Position loop drives

•Servo

•Servo drive

Generic

Axes/ms over backplane 8 19

Axes/ms over EtherNet/IP port Not applicable 32 when you use the built-in EtherNet/IP port at 1 Gbps.

Voltage and current ratings 800 mA @ 5.1V DC

5.0 mA @ 1.2V DC

Energy storage module • 1756-ESMCAP capacitor energy storage module (removable)

• 1756-ESMNSE capacitor energy storage module (removable)

• 1756-ESMNRM capacitor energy storage module (nonremovable)

Weight, approx 0.25 kg (0.55 lb) 0.394 kg (.868 lb)

Wire ca tegory

(2)

3 - on USB port 3 - on USB port

Wire si ze Not applicable Ethernet cabling and installation according to

Reset Button Not applicable • A controller stage 1 reset clears the user application

(1) For more information on Ethernet nodes, see Nodes on an EtherNet/IP Network on page 27.

(2) Use this conductor category information for planning conductor routing. See the Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

(3) The 5580 controllers allocate memory as needed, so there is no dedicated I/O memory space.

(4) Data size = 32-bits / 1-DINT

320 - Any combination of outgoing or incoming unconnected

buffers.

outgoing messages)

• SERCOS interface

• Analog options (encoder input, LDT input, SSI input)

• EtherNet/IP network

256, any combination of these supported axis types:

•CIP

• Consumed

• Virtual

• Position loop drives

Rockwell Automation recommends that you use the built-in

EtherNet/IP port for high-performance motion applications.

1.2 A @ 5.1V DC

5.0 mA @ 1.2V DC

Embedded in controller, nonremovable

2 - on Ethernet port

IEC 61918 and IEC 61784-5-2

program and memory, but retains the controller IP address.

• A controller st age 2 reset returns the control ler to out-o f

box settings (including firmware), and clears all network

settings. On a GuardLogix 5580 controller, the stage 2 reset

also clears safety settings and the safety signature/safety

locked state.

• The Safety Partner reset returns the 1756-L8SP Safety

Partner to the out-of box settings (including firmware).

• In a SIL 3 application, when you reset the GuardLogix

Controller you must also reset the 1756-L8SP Safety

Part ner.

.

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 21

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

145.20 mm

(5.72 in.)

142.94 mm

(5.63 in.)

34.55 mm

(1.36 in.)

145.20 mm

(5.72 in.)

136.60 mm

(5.50 in.)

34.55 mm

(1.36 in.)

Controller Dimensions

This section shows dimensional differences.

ControlLogix 5570 Dimensions

Logix5572™

RUN FORCE SD OK

ControlLogix 5580 Dimensions

22 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

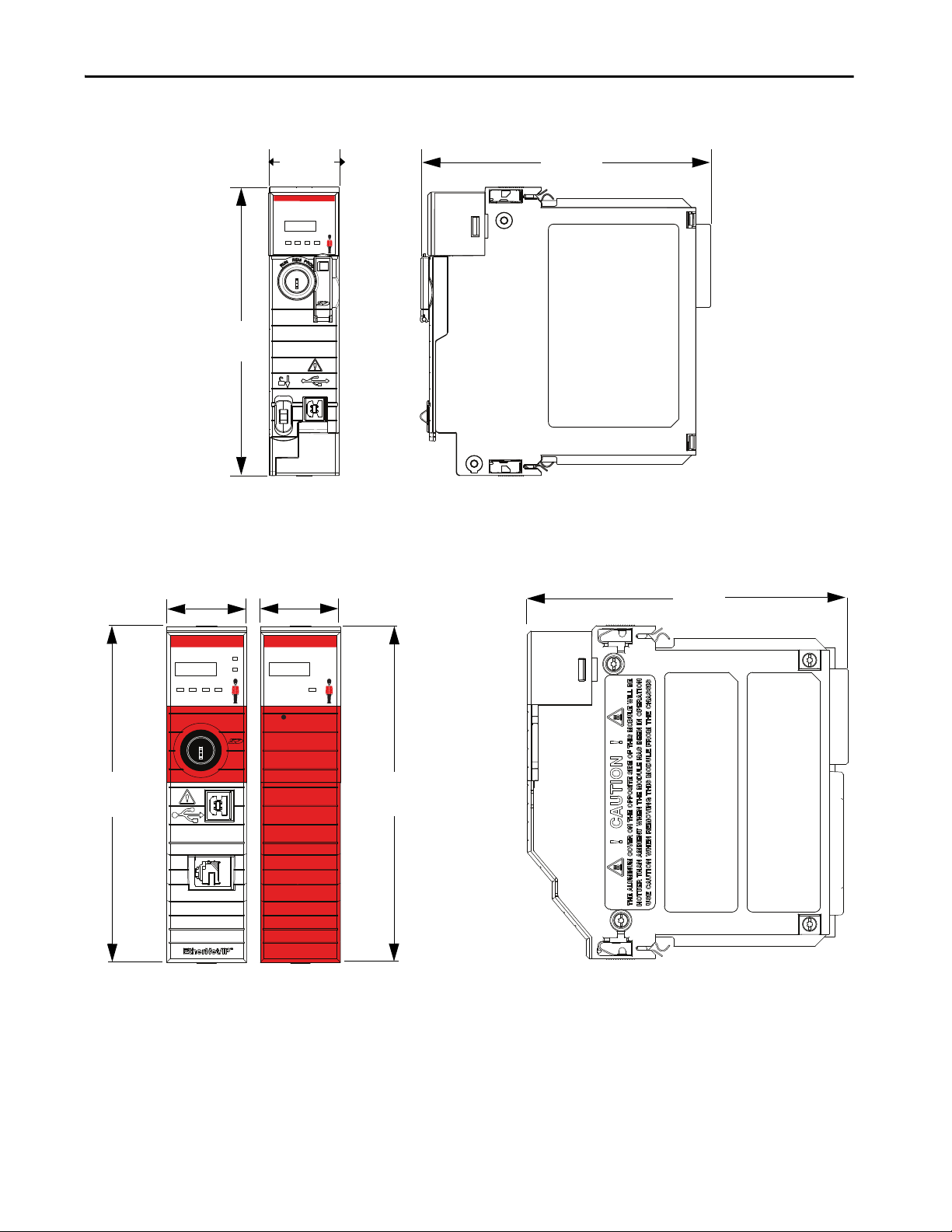

Logix5572S™

145.20 mm

(5.72 in.)

142.94 mm

(5.63 in.)

34.55 mm

(1.36 in.)

139.6 mm

(5.50 in.)

34.55 mm

(1.360 in.)

145.2 mm

(5.717 in.)

Front view: GuardLogix 5580 Controller, GuardLogix 5580 Safety Partner

Side view: GuardLogix 5580 Controller, GuardLogix 5580 Safety Partner

34.55 mm

(1.360 in.)

145.2 mm

(5.717 in.)

RUN FORCE SD OK

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

GuardLogix 5570 Dimensions

Logix5584ES™

RUN

RUN

FORCE SD OK

REM

GuardLogix 5580 Dimensions

Logix55L8SP™

NET

LINK

OK

PROG

32714-M

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 23

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

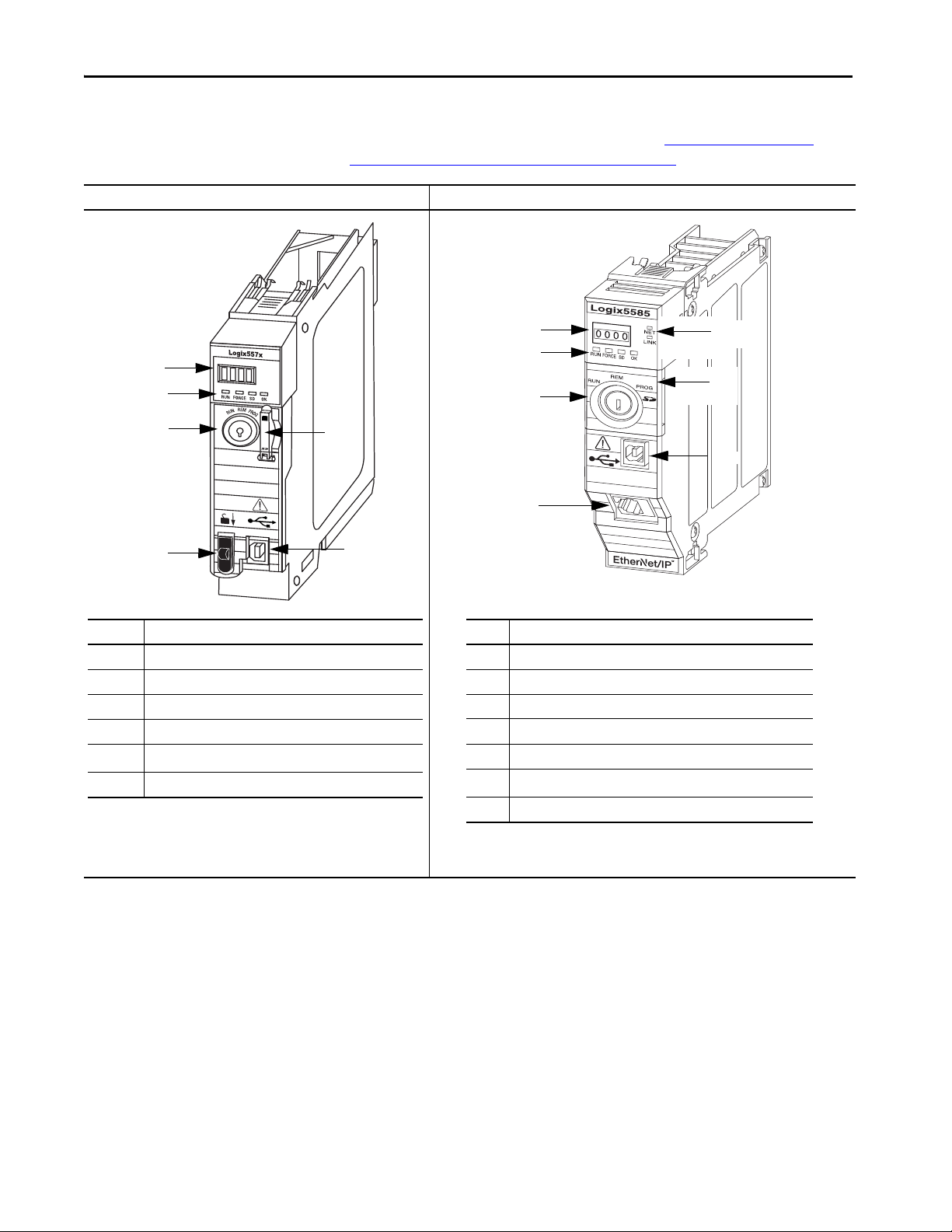

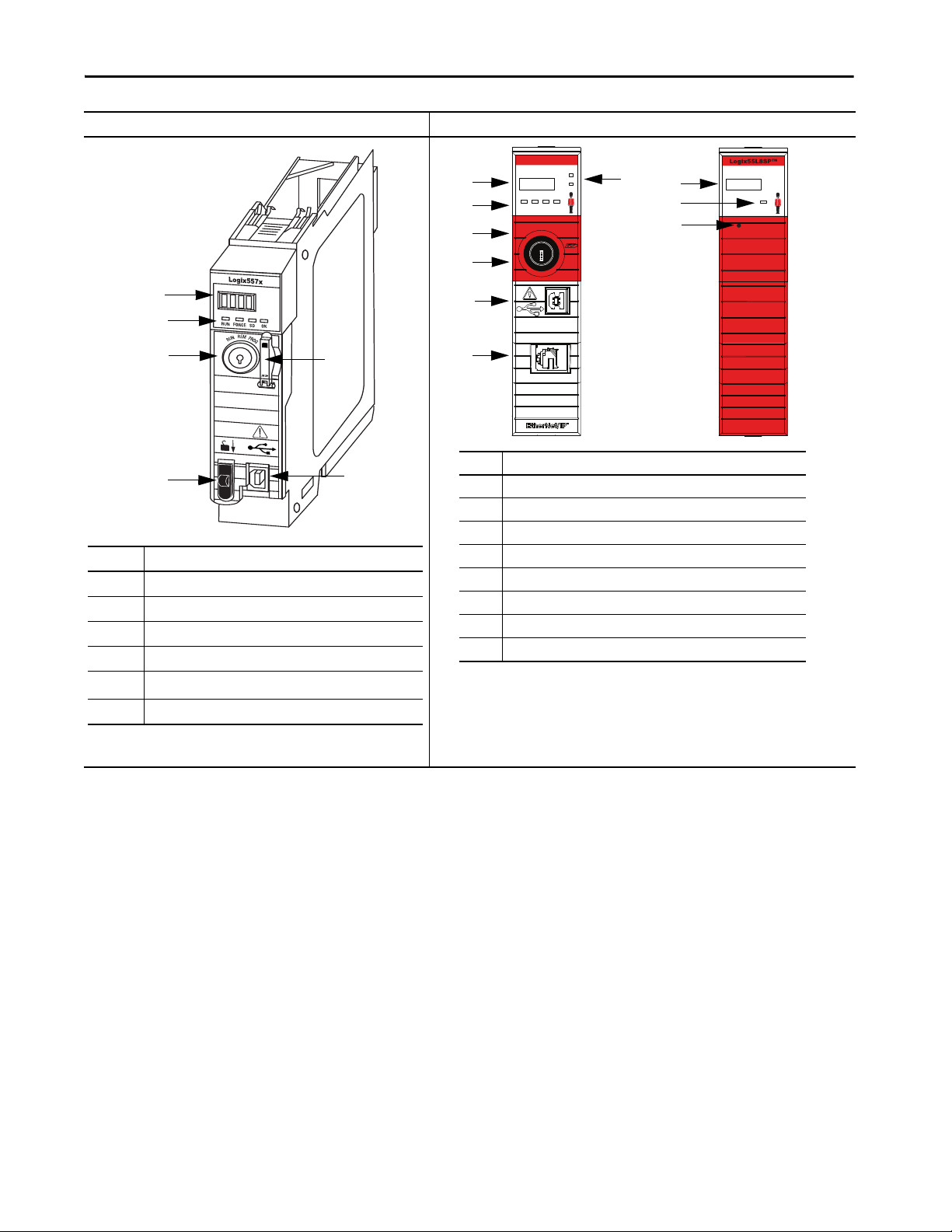

Item Description

14-character Display

2 Status Indicators

3REM RUN PROG Key

4 Energy Storage Module Release

5

SD Card slot behind the door

(1)

(1) The door opens from top to bottom.

6USB Port

1

2

3

5

6

4

1

7

4

3

5

6

2

Item Description

14-character Display

2 Status Indicators

3REM RUN PROG Key

4 Ethernet Port

5 Ethernet Status Indicators

6

SD Card slot and Reset button are behind the door.

(1)

(1) First remove the key, then open the door from right to left.

7USB Port

Connectors and Status Indicators

ControlLogix 5570 ControlLogix 5580

This section shows the front plate differences. For more information on the

status indicators and reset button, see Chapter 7, Diagnostics and Status

Indicators with ControlLogix Systems on page 141.

24 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

32511-M

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

Item Description

14-character Display

2 Status Indicators

3REM RUN PROG Key

4 Energy Storage Module Release

5

SD Card slot behind the door

(1)

(1) The door opens from top to bottom.

6USB Port

1

2

3

5

6

4

1

5

3

7

2

Item

Description

14-character display

2 Status Indicators

3 Mode switch (Remote, Run, Program)

4 SD card slot and Reset Button behind the door

(1)

(1) First remove the key, then open the door from right to left.

5USB Port

6Ethernet Port

7Ethernet Status Indicators

8 Safety Partner Reset Button

6

4

1

2

8

GuardLogix 5570 GuardLogix 5580 and Safety Partner

Logix5584ES™

NET

LINK

RUN

FORCE SD OK

REM

RUN

PROG

OK

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 25

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

Project Size

Configure the Controller

The size of the .ACD file does not reflect the size of your project that

downloads to the controller. The .ACD file contains multiple components.

Not all components are downloaded to the controller.

You must consider how to best use controller resources when ControlLogix

controllers communicate over an EtherNet/IP network. There are limitations

concerning how much EtherNet/IP communication the controller supports.

Consider the following:

•Connections

•Ethernet Nodes

Connections Overview

A Logix 5000™ controller provides connection resources whenever

communications are established between two devices.

Connections are used when the system contains the following conditions

or activities:

• I/O modules, communication modules, and adapters are present in the

I/O configuration of the user project

• Produced or Consumed tags are configured in the user project

• Connected Messages are executed in the user application

• External devices, programming terminals, or HMIs communicate with

the controller

You must track the number of connections that are used when you configure a

ControlLogix 5570 control system.

26 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

Nodes on an EtherNet/IP Network

When used in a Logix Designer application project, version 28 or later,

5580 controllers offer a simplified method for counting controller resources.

When you configure a 5580 control system, you simply count the number of

Ethernet nodes that you include in the I/O configuration section of your Logix

Designer application project.

On the Controller Properties dialog box, the Logix Designer application

project displays the updated number of nodes that are used as you add Ethernet

nodes to the project.

To see an example of how the project displays the node count, see Figure 3 on

page 32. Ta b l e 5 lists the EtherNet/IP node limits for 5580 controllers.

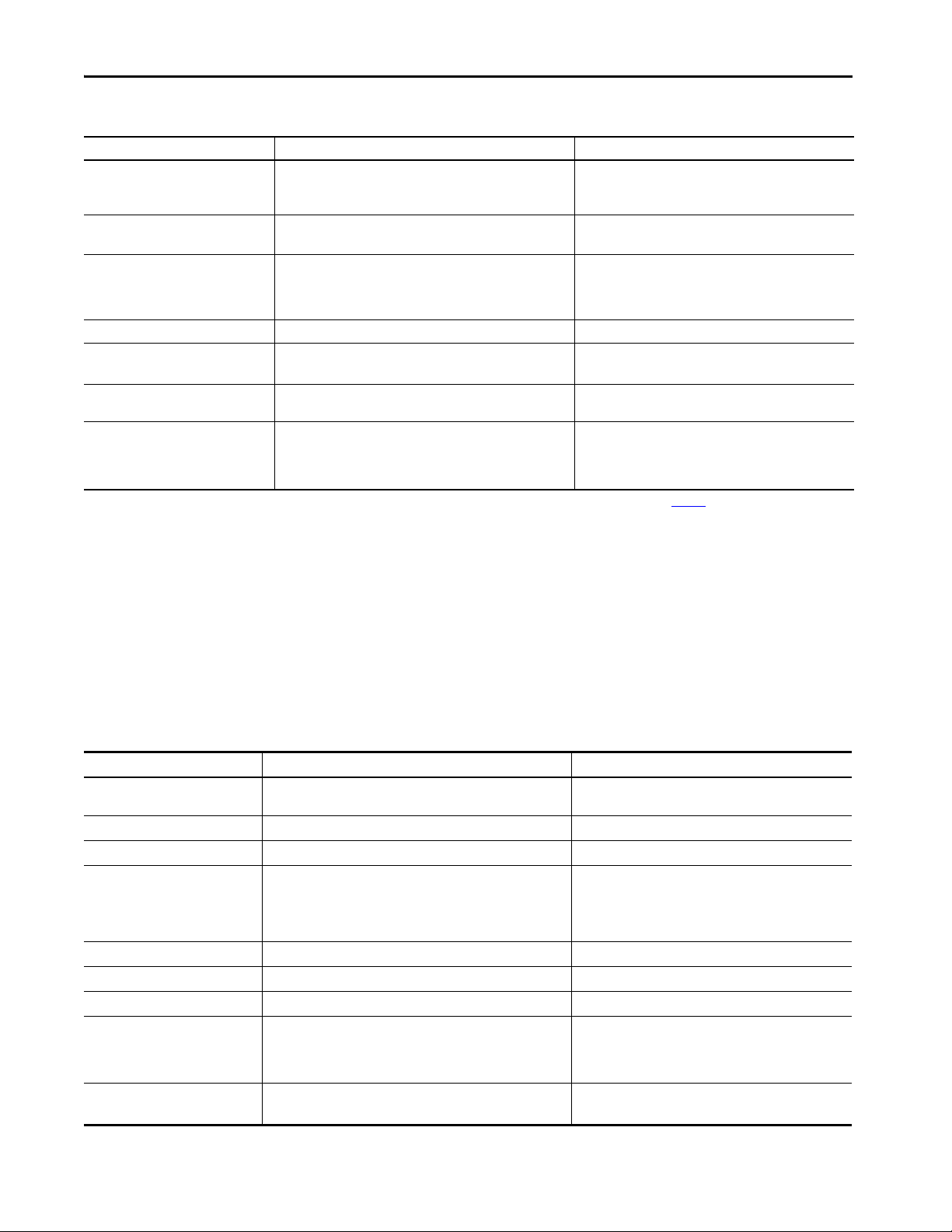

Table 5 - 5580 Controller EtherNet/IP Node Guidelines

Cat. No. Maximum Number of EtherNet/IP Nodes Supported

Logix Designer Application,

Versi on 28

1756-L81E Not applicable 60 100 100

1756-L81ES Not applicable 100

1756-L82E Not applicable 80 175 175

1756-L82ES Not applicable 175

1756-L83E 100 100 250 250

1756-L83ES Not applicable 250

1756-L84E Not applicable 150 250 250

1756-L84ES Not applicable 250

1756-L85E 300 300 300 300

Logix Designer Application,

Versi on 29

Logix Designer Application,

Version 3 0

Logix Designer Application,

Version 31 or later

Devices Included in the Node Count

Any devices that you add directly to the I/O configuration section are counted

toward the node limits of the controller. The following are example devices

that must be counted:

• Remote communication adapters

• Devices with an embedded EtherNet/IP port, such as I/O modules,

drives, and linking devices

• EtherNet/IP devices that are connected to a communication module in

the local chassis

• Remote controllers when a produce/consume connection is established

between the two controllers

• HMI devices that are included in the I/O configuration tree

• Third-party devices that are directly connected to the EtherNet/IP

network

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 27

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

Devices Excluded from the Node Count

Ethernet devices that exist on the EtherNet/IP network but are not added to

the I/O configuration of the project do not count as nodes. These items are not

added to the I/O configuration and are not considered nodes:

•Computer

• EtherNet/IP communication modules that reside in the local chassis

with the controller

• HMI that is not added to the I/O configuration section

•MSG instruction

• Standard Ethernet devices for which the controller uses a socket

interface to communicate

New Project Dialog Box

When you create a project with a 5580 controller, the Module Definition

dialog box appears. The dialog box provides standard controller settings, along

with additional security settings. The information that is entered in this dialog

box displays on the Controller Properties General tab and Security tab.

28 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

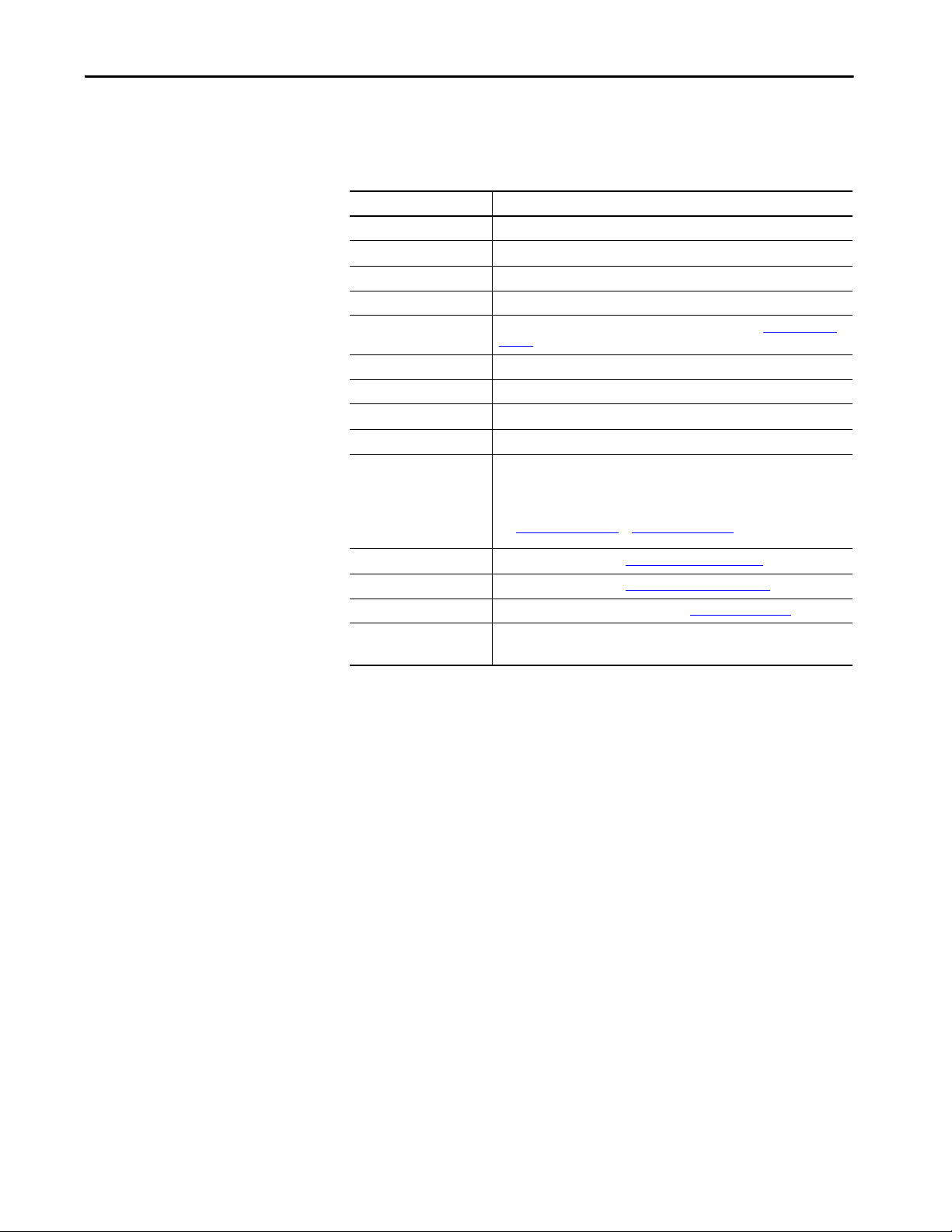

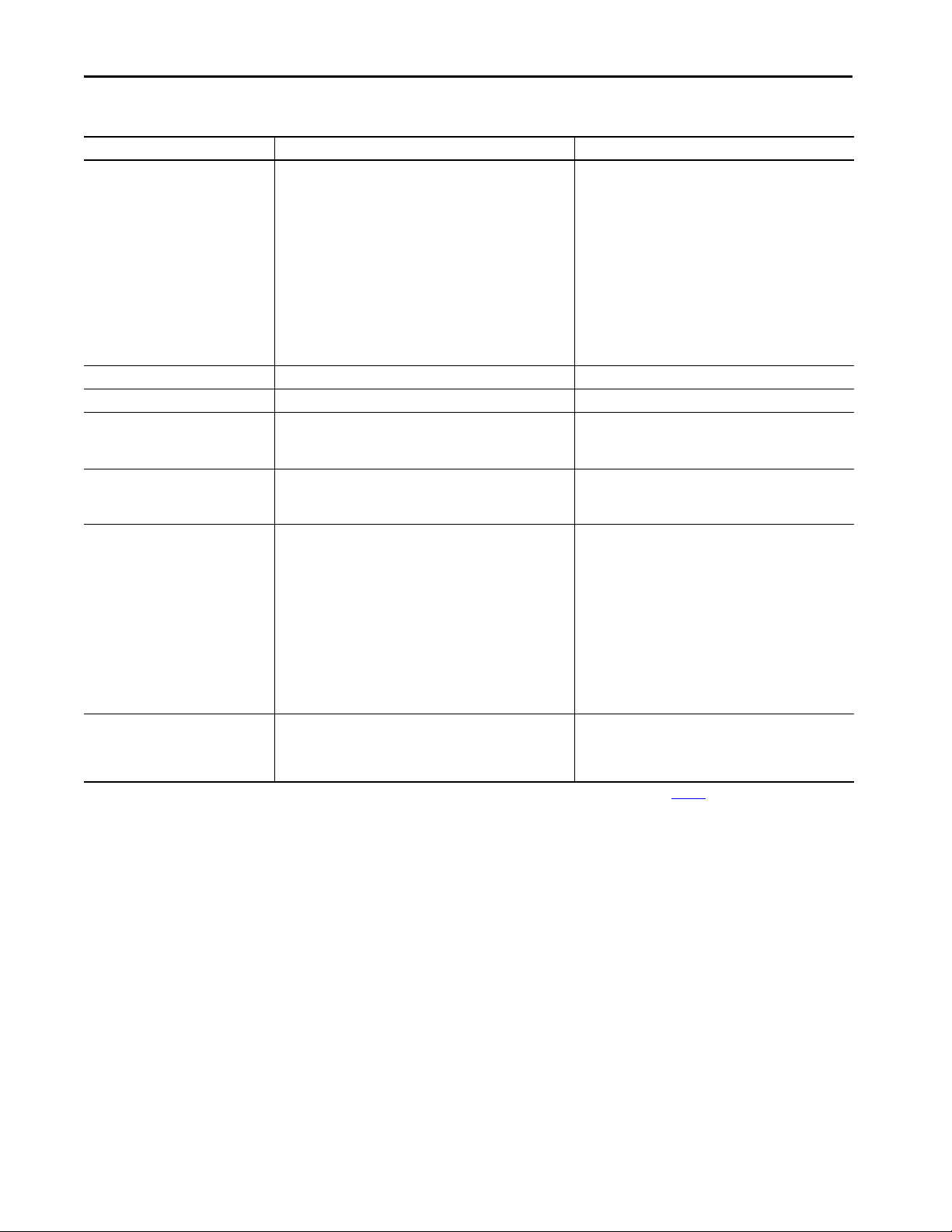

Controller Properties

This table compares the Controller Properties Tab.

Controller Properties Tab Comments

General Same functionality as 5570 controllers.

Major Faults Same functionality as 5570 controllers.

Minor Faults Same functionality as 5570 controllers.

Date/Time Same functionality as 5570 controllers.

Advanced New parameter to enable Minor Overflow fault reporting. See Advanced Tab on

SFC Execution Same functionality as 5570 controllers.

Project Same functionality as 5570 controllers.

Redundancy Currently not available for 5580 controllers.

Nonvolatile Memory Same functionality as the 5570 controllers.

Memory (Logix Designer

application, version 28)

Capacity (Logix Designer

application, version 29 and

later)

Internet Protocol New for 5580 controllers. See Internet Protocol Tab on page 34

Port Configuration New for 5580 controllers. See Port Configuration Tab on page 35.

Security Now has additional security parameters. See Security Tab on page 36

Alarm Log Not available for 5580 controllers in version 28.

page 30

The tabs indicate the same information but are named differently between the

Logix Designer application versions.

Indicates data usage. Data usage is indicated with one value that combines Data

and Logic memory usage and I/O memory usage.

See Memory Tab on page 31

Available in version 29 or later with the same functionality as the 5570 controllers.

or Capacity Tab on page 32.

.

.

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 29

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

Report Overflow Faults is ena bled by default when

morphing a legacy projec t, but defaults to disabled

when creating a ControlLogix 5580 project.

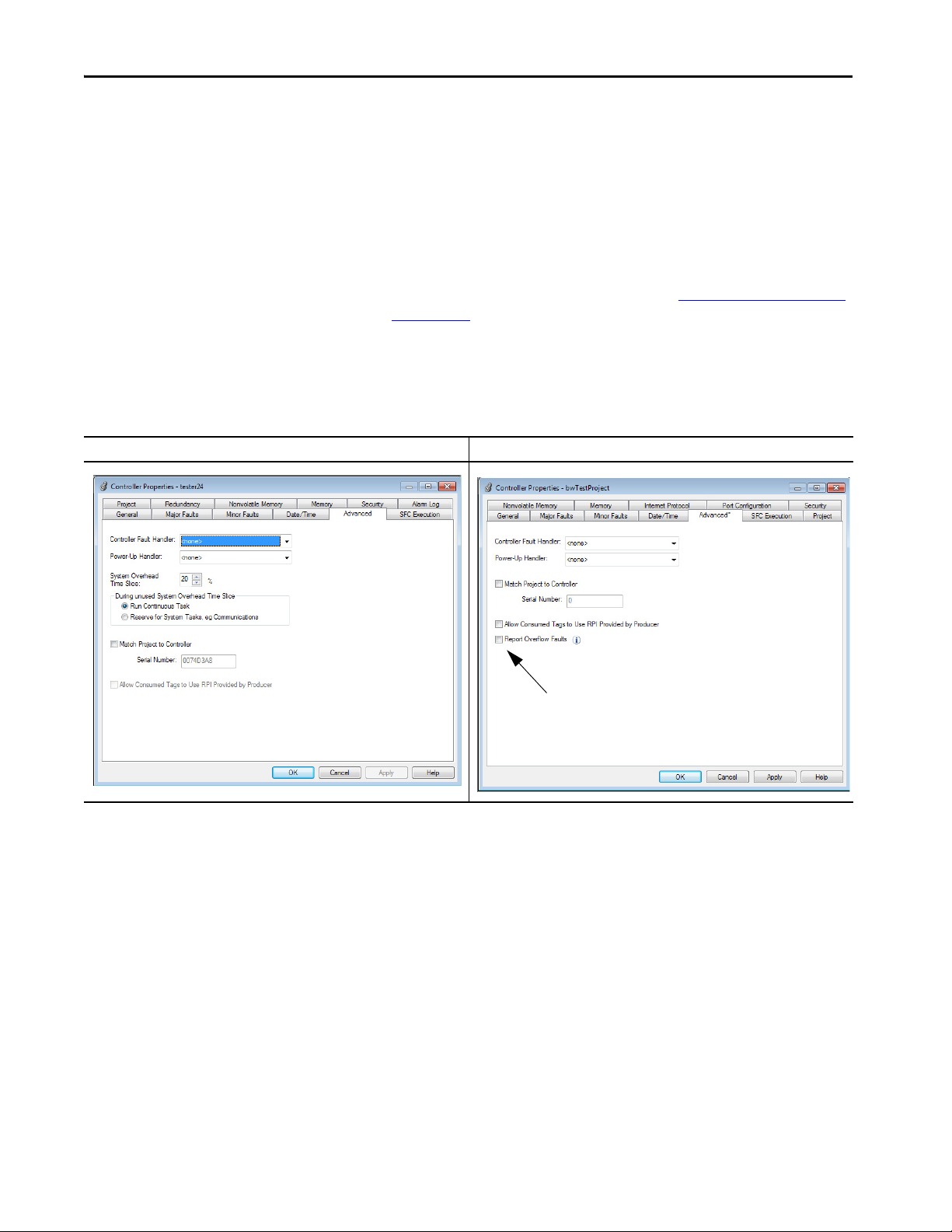

Advanced Tab

The Advanced tab provides a way to assign the Controller Fault Handler and

Power-up Handler. You can also match a project to a specific controller by

serial number.

• Report Overflow Faults is a new parameter that lets you control Minor

Overflow fault reporting. When you create a project, the default setting

is disabled. When you import or open a legacy project, the default

setting is enabled. For more information, see Minor Fault on Overflow

on page 128.

• System Overhead Time Slice is no longer required for 5580 controllers,

and the parameter is removed.

Figure 1 - Controller Properties Dialog Box - Advanced Tab

5570 Controllers Example 5580 Controllers Example

30 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

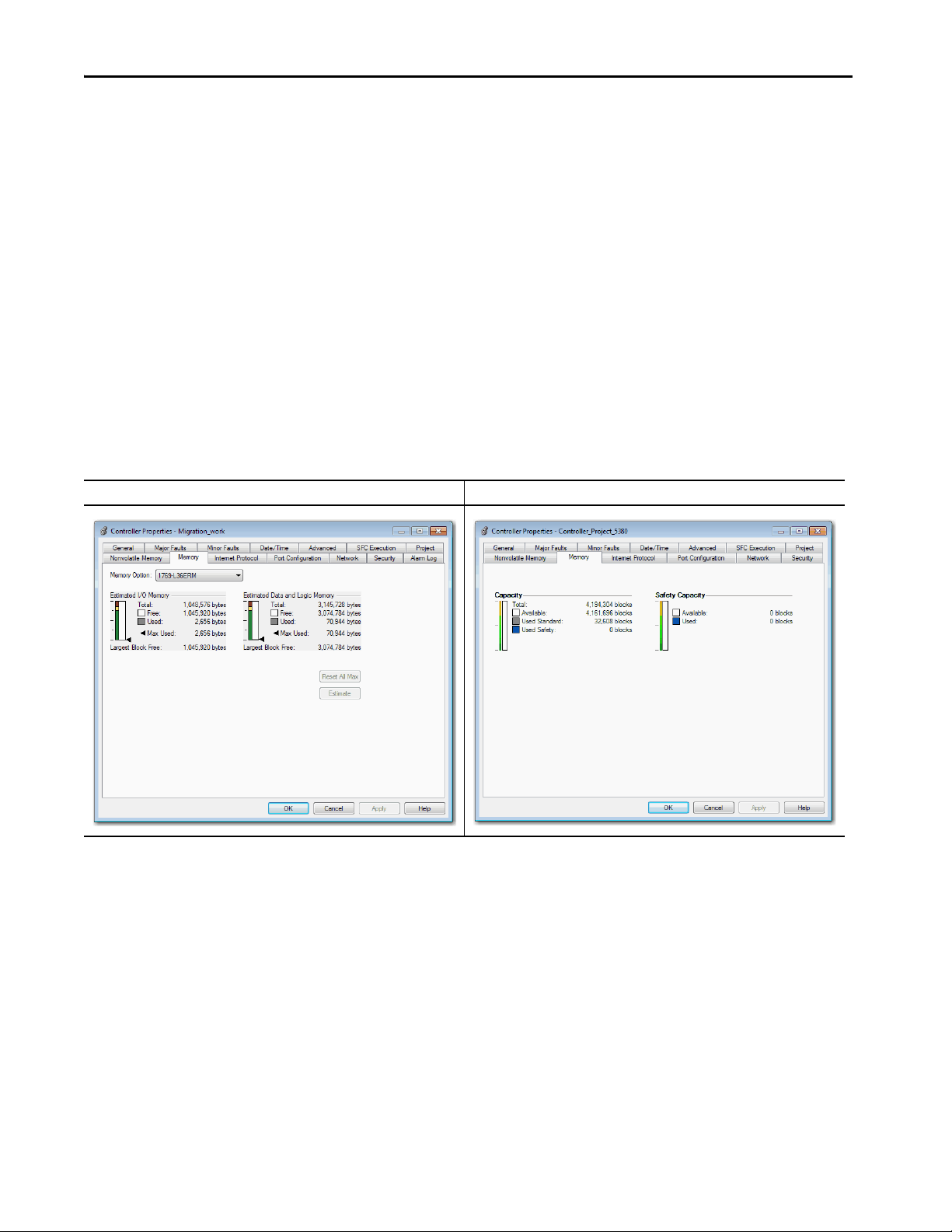

Memory Tab

In the Logix Designer application, version 28 or earlier, the Memory tab

indicates data usage.

• 5570 controllers - Data usage is indicated with two values. The tab

shows I/O memory and Data and Logic memory separately.

As you change the project, you can click Estimate to see the estimated

memory usage and remaining available memory.

• 5580 controllers - Data usage is indicated with one value that combines

Data and Logic memory usage and I/O memory usage.

As you change the project, the data values are automatically updated to

indicate the estimated memory usage and remaining available memory.

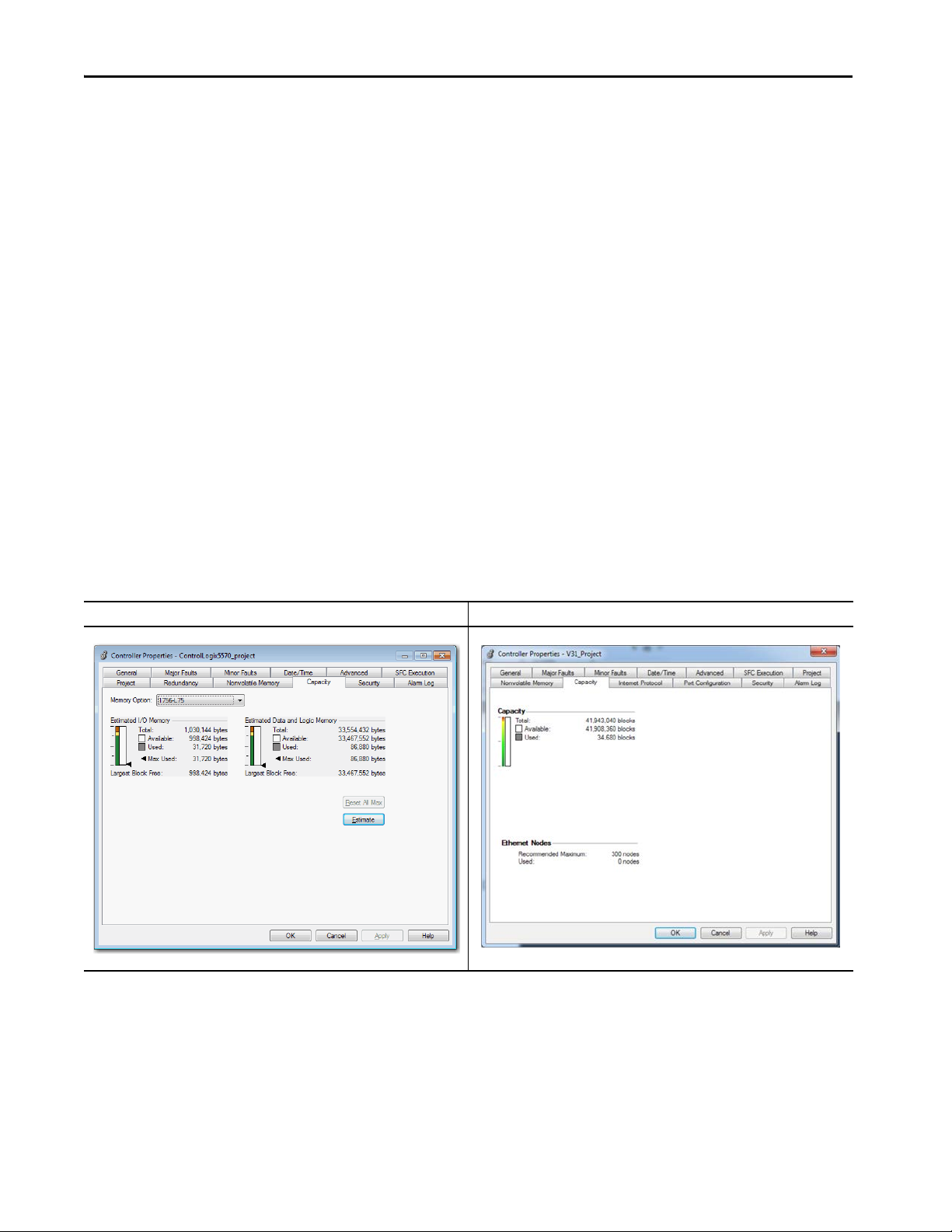

Figure 2 - ControlLogix Controller Properties Dialog Box - Memory Tab

ControlLogix 5570 Version 28 Example ControlLogix 5580 Version 28 Example

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 31

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

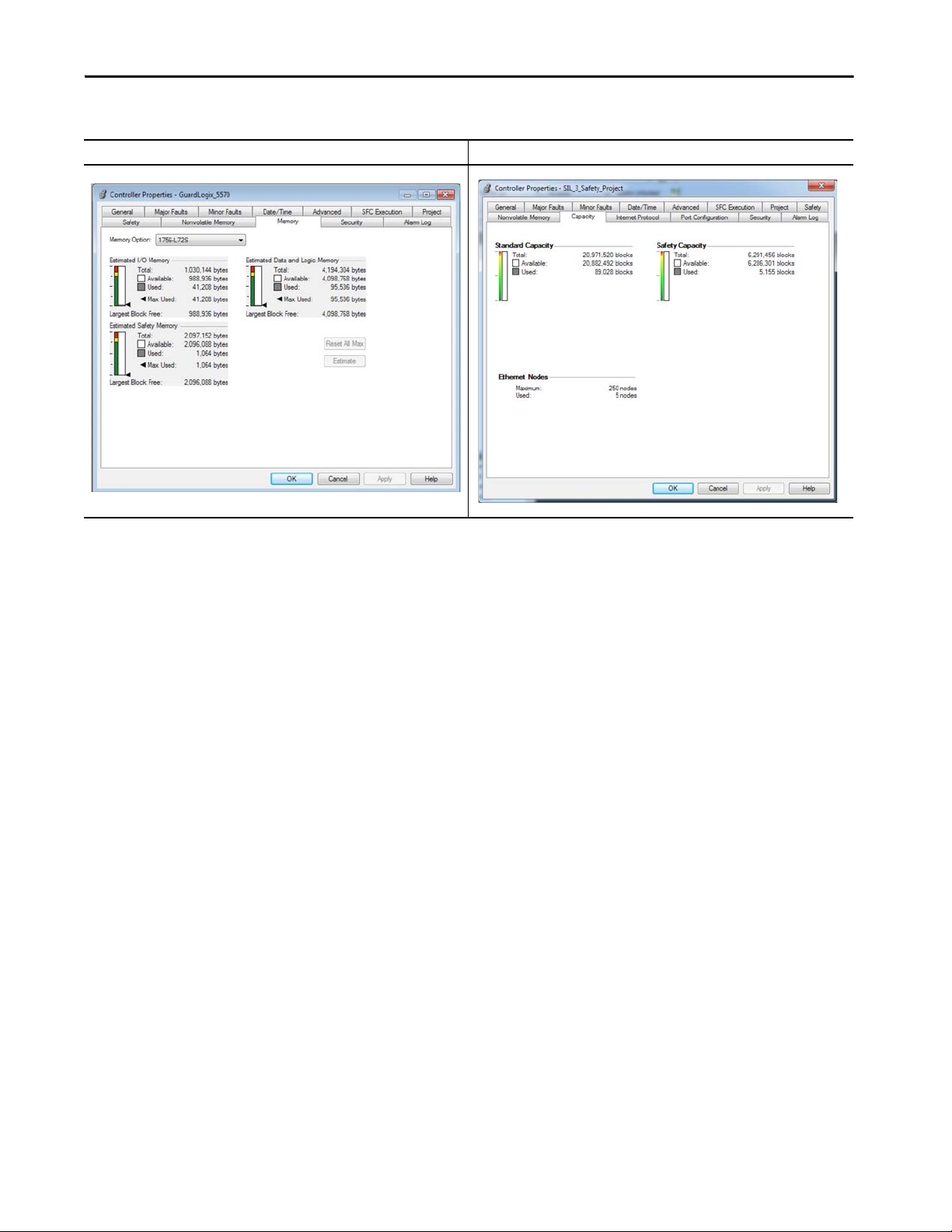

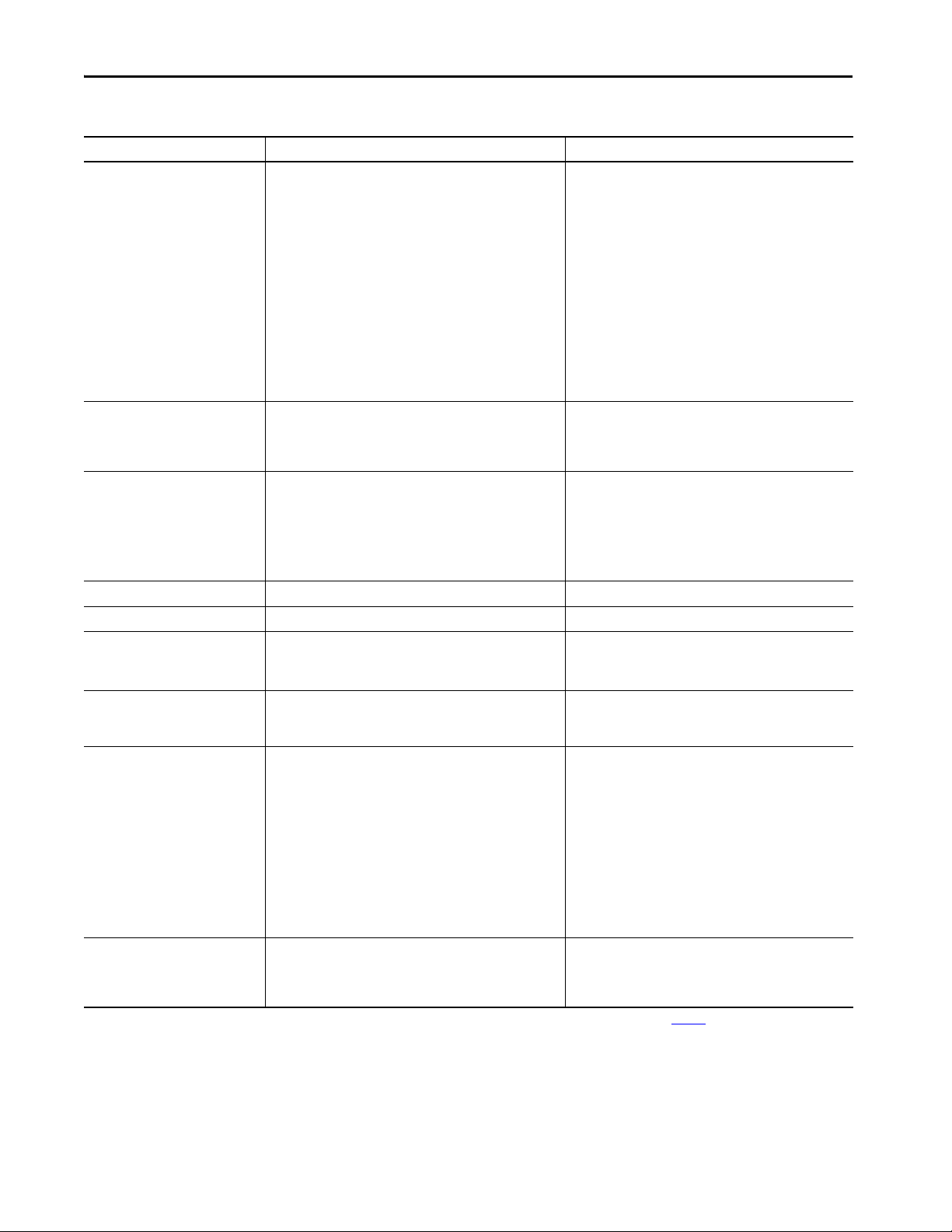

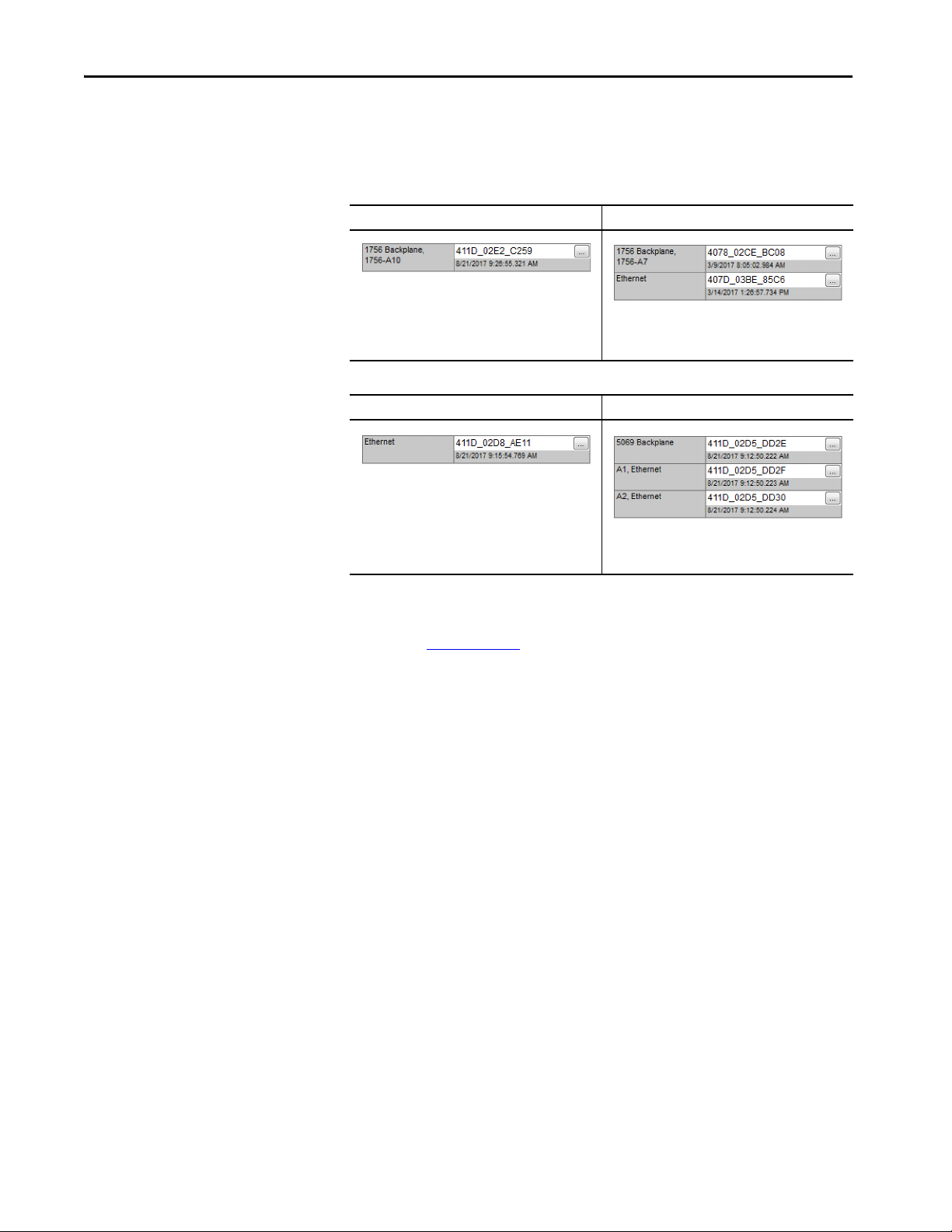

Capacity Tab

In the Logix Designer application, version 29 or later, the Capacity tab

indicates data usage.

• 5570 controllers - Data usage is indicated with two values. The tab

shows I/O memory and Data and Logic memory separately.

GuardLogix 5570 controllers also show the Safety memory.

As you change the project, you can click Estimate to see the estimated

memory usage and remaining available memory.

• 5580 controllers - Data usage is indicated with one value that combines

Data and Logic memory usage and I/O memory usage. The tab also

shows the number of Ethernet nodes that are used. GuardLogix 5580

controllers also show the Safety capacity.

As you change the project, the data values are automatically updated to

indicate the estimated memory usage and remaining available memory.

The number of Ethernet nodes is also updated automatically.

As you change the project, the data values are automatically updated.

Figure 3 - ControlLogix Controller Properties Dialog Box Version 29 or later- Capacity Tab

ControlLogix 5570 Example ControlLogix 5580 Example

32 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

Figure 4 - GuardLogix Controller Properties Dialog Box - Capacity Tab

GuardLogix 5570 Version 28 Example GuardLogix 5580 Version 31 or later Example

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 33

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

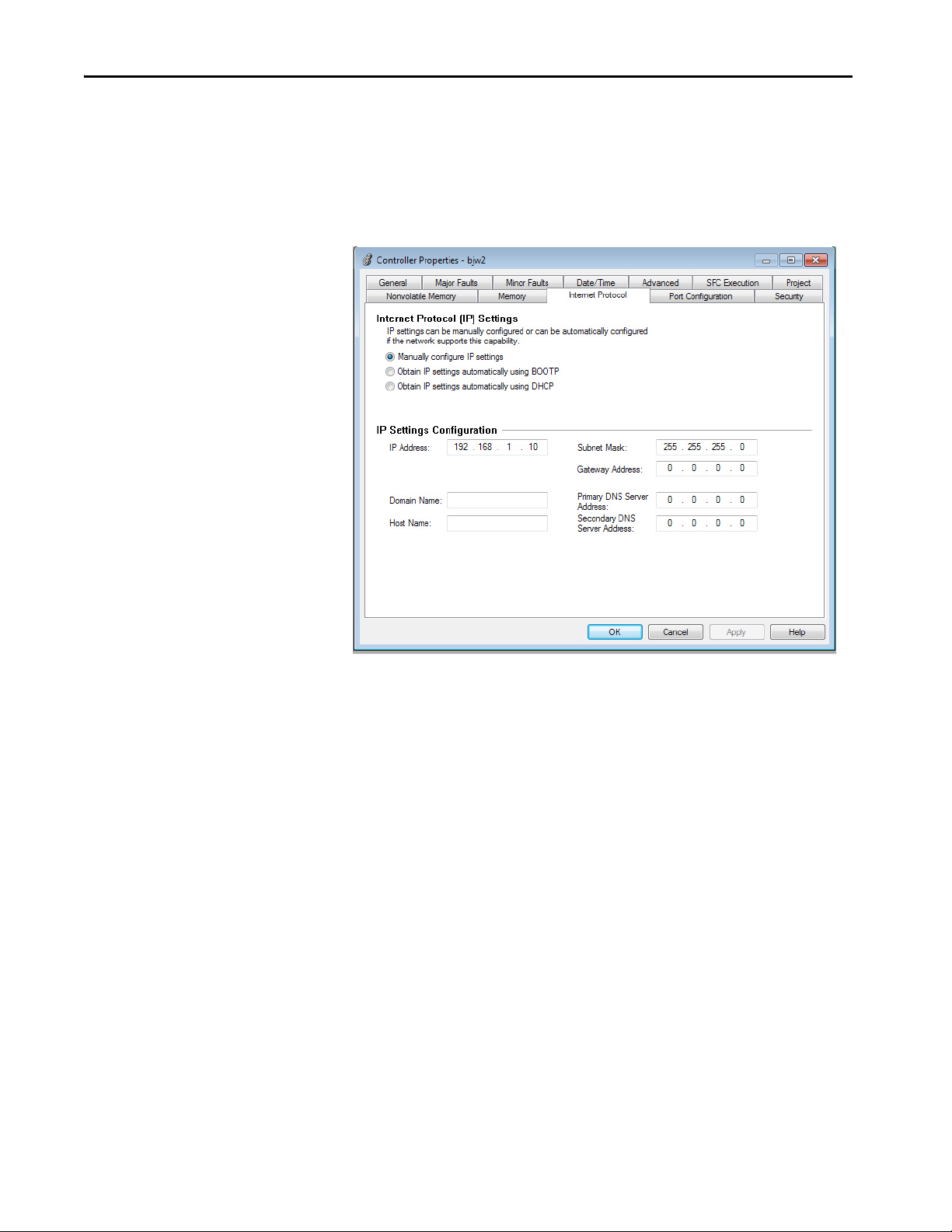

Internet Protocol Tab

When online with the controller, the Internet Protocol tab lets you configure

the IP Settings. These settings are not available offline.

Figure 5 - Controller Properties Dialog Box - Internet Protocol Tab - Online

When online, configurable settings include the following:

• Source of IP Settings (DHCP, BOOTP, or manual configuration)

• Physical Module IP Address

•Subnet Mask

• Gateway Address

•Domain Name

•Host Name, Primary DNS Server Address

•Secondary DNS Server Address

34 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

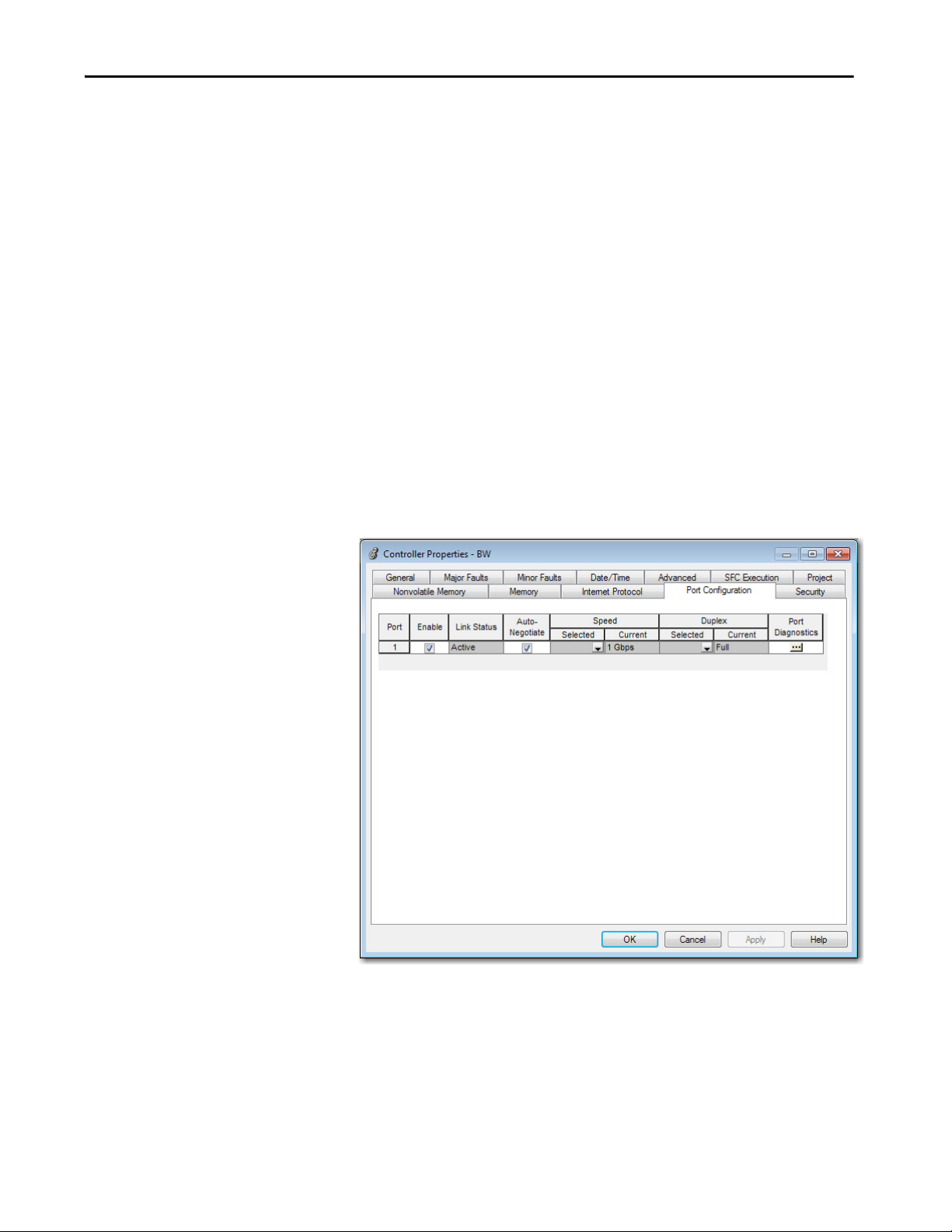

Port Configuration Tab

When online, the Port Configuration tab lets you view and configure the

Ethernet port settings:

•View Link Status

• Enable/Disable the Ethernet port

• Configure Auto-Negotiate

• Configure Selected Speed up to 1 Gbps (or set to auto-negotiate)

•View Current Speed

• Configure Selected Duplex

The 5580 controllers only support full-duplex.

•View Current Duplex

• Access the Port Diagnostics dialog

You can change the Port Configuration parameters without resetting

the controller.

Figure 6 - Controller Properties Dialog Box - Port Configuration Tab

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 35

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

Port Diagnostics

On the Port Configuration category, click the Port Diagnostics button to view

information for the Ethernet port. For parameter descriptions, see the

ControlLogix 5580 and GuardLogix 5580 Controllers User Manual,

publication 1756-UM543

.

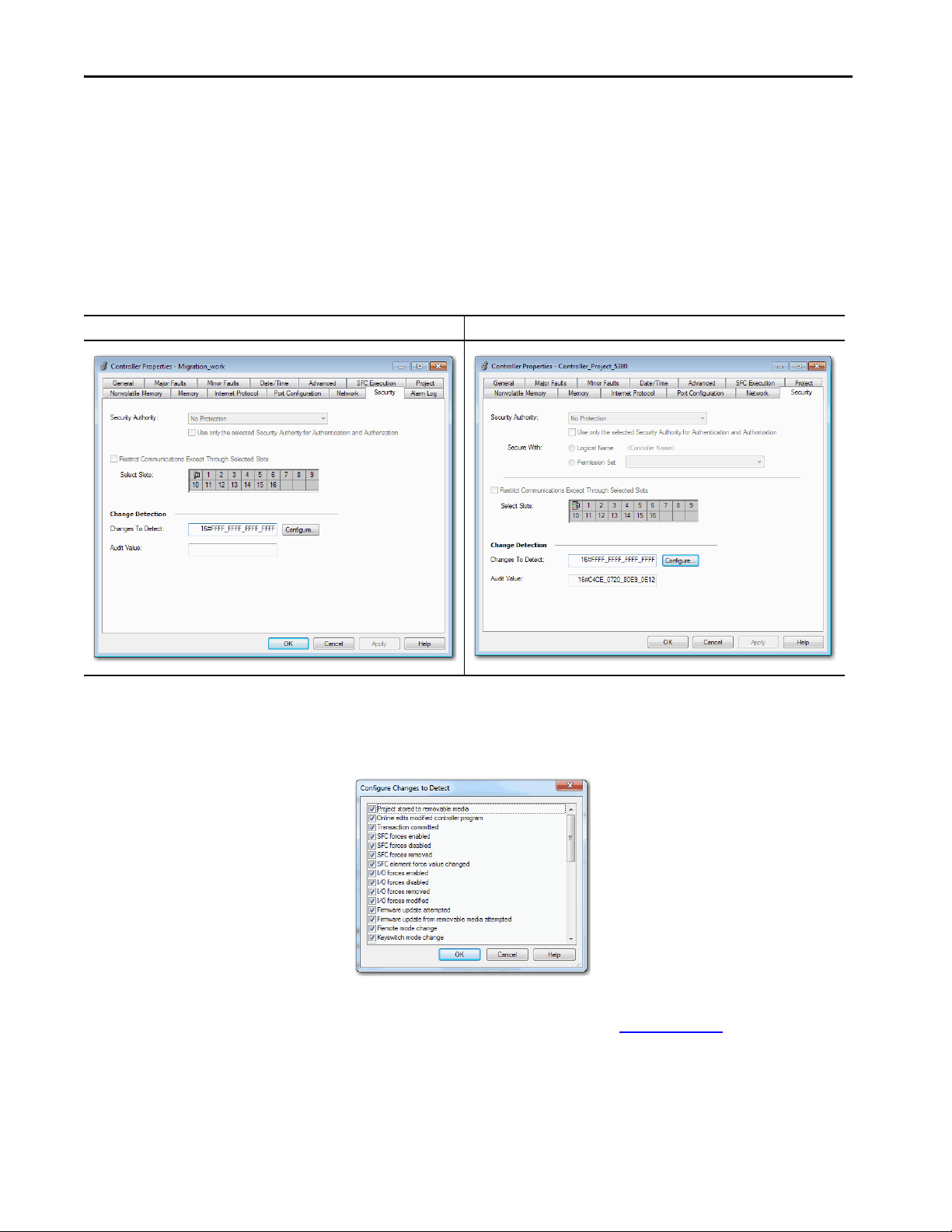

Security Tab

The Security Tab lets you see the controller security settings, for example, the

Security Authority choice. Security settings are configured when you create the

project.

With the Logix Designer application, version 28 or later, the 5580 controllers

support additional parameters in the Security Authority section.

Figure 7 - Controller Properties Dialog Box - Security Tab

5570 Controllers Example 5580 Controllers Example

36 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

ControlLogix and GuardLogix 5580

controllers Reset Button

OK

1756-L8SP Safety Partner

Reset Button

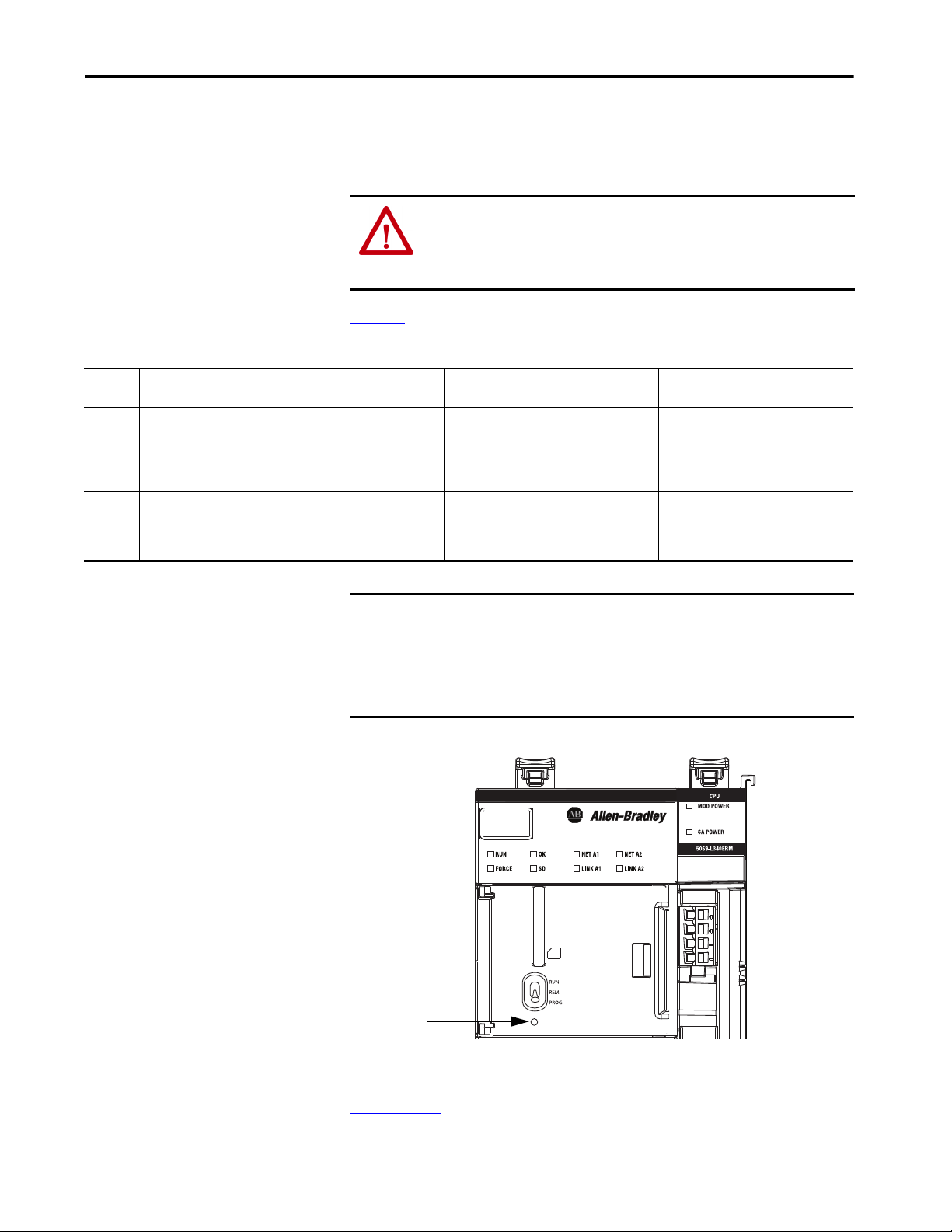

Controller Reset

You can clear the program from memory on the 5570 controllers. On 5580

controllers, you can clear the program from memory and reset the controller to

factory default settings.

5570 Controllers

Clearing the program from the on-board NVS memory on the

5570 controllers and the 1756-L7SP Safety Partner, involves removing the

Energy Storage Module.

For information on how to perform this procedure, see Knowledgebase

Answer ID 450803, 1756-L7x: Clearing Memory/Resetting Processor to

Factory Default, accessible at https://rockwellautomation.custhelp.com

'

IMPORTANT When you clear the program on a GuardLogix 5570 Controller, you must also

clear the 1756-L7SP Safety Partner.

5580 Controllers

You can clear the program from memory and reset the 5580 controllers and the

1756-L8SP Safety Partner with the reset button.

For information on how to use the reset button, see the ControlLogix 5580

and GuardLogix 5580 Controllers User Manual, publication 1756-UM543

WARNING: When you press the reset button while power is on, an Electric

Arc can occur. This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous

.

before proceeding.

IMPORTANT In a SIL 3 application, when you reset the GuardLogix 5580 Controller you

must also reset the 1756-L8SP Safety Partner.

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 37

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

SD Card Behavior

The controller has changed some behaviors when loading a project from the

SD card into a controller. These changes facilitate a better workflow for easier

commissioning of brand new out of box controllers. All Logix 5000 controllers

ship from the factory with firmware revision 1.x.

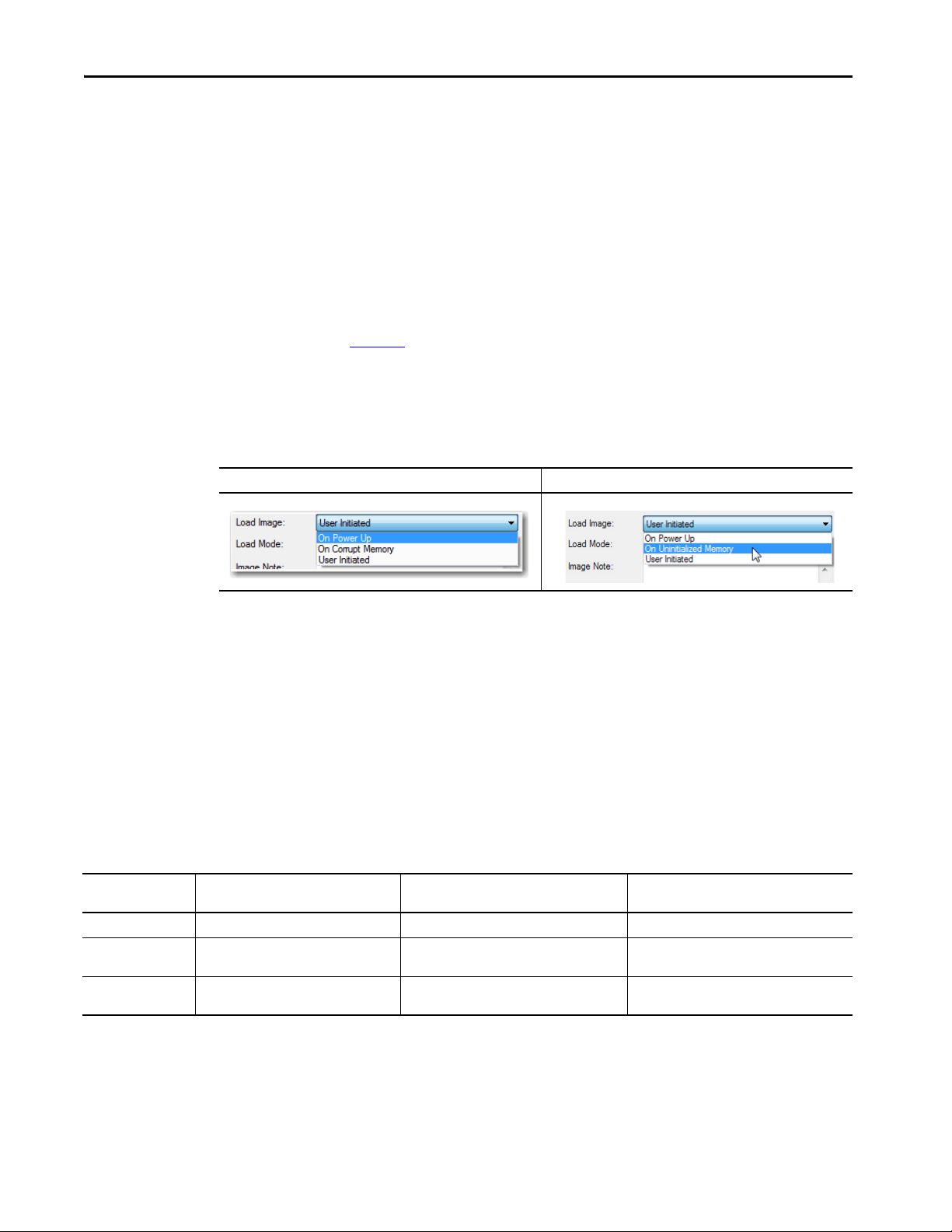

With 5580 controllers, the Load Image setting On Uninitialized Memory is

available. This setting replaces the On Corrupt Memory setting that is available

with 5570 controllers.

The general behavior is the same for both settings. The only difference is the

controller behavior when it is in the out-of-box condition, as described in

Ta b l e 6

.

You can install an SD card that uses On Uninitialized Memory in an out-of the

box controller, that is, one that uses firmware revision 1.

x. In this case, at power-

up the image loads both the controller firmware and controller application.

5570 Controllers Example 5580 Controllers Example

When you use an SD card with an image in an out-of-box controller (firmware

revision 1.x), at power-up that controller updates its firmware to the revision

stored on the card. The update happens regardless of the Load Image setting

you made when you transferred the image to the SD card.

The On Power Up, and On Initialized Memory settings also load the

controller application into an out of box controller.

This table shows what happens at power-up when you insert an SD card that

contains an image into a 5580 controller.

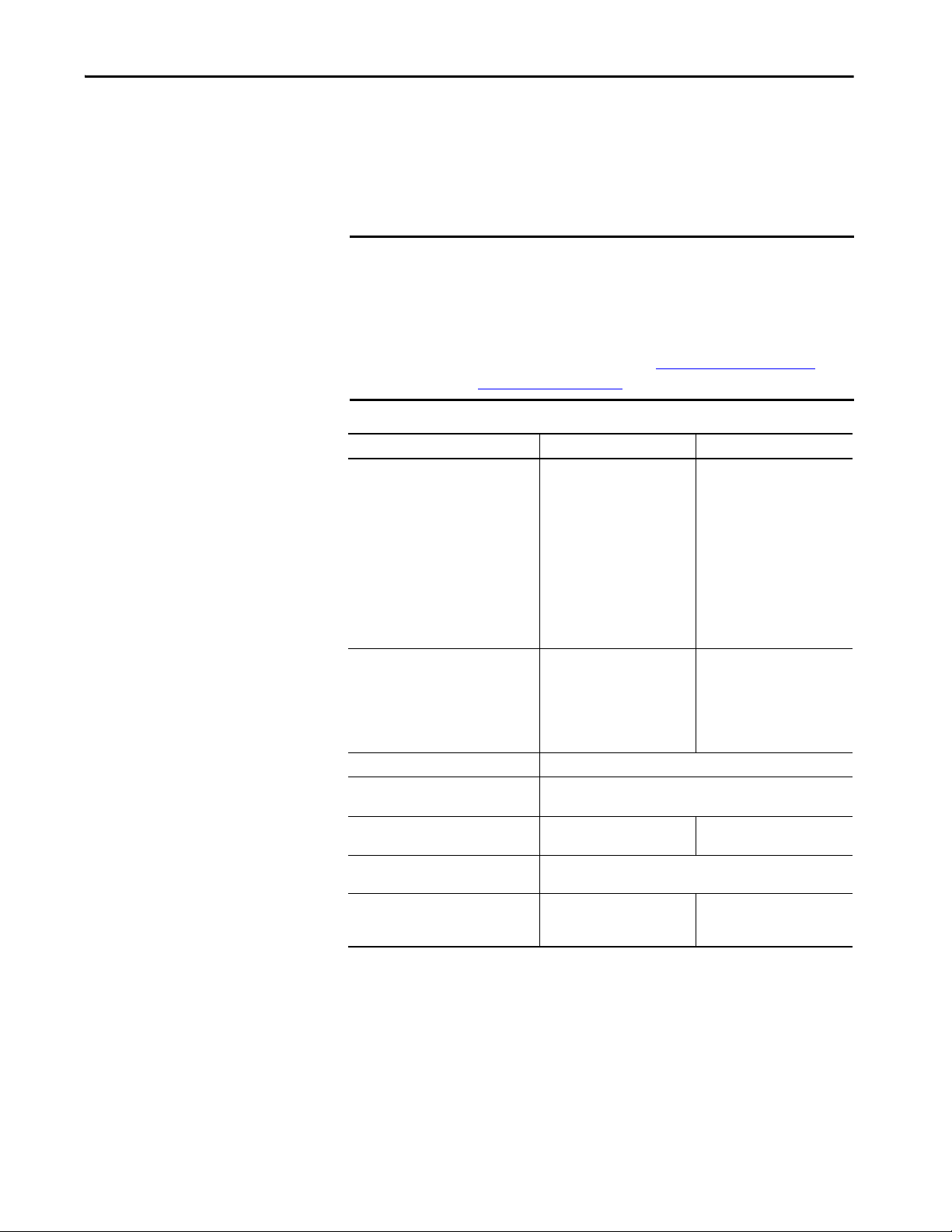

Table 6 - SD Card Settings and Controller Power-up Behavior

Image Setting Controller is in Out-of-Box Condition

User Initiated Loads Firmware Only

On Power Up Loads both Firmware and Application • Loads Firmware if there is a revision mismatch

On Uninitialized Memory Loads both Firmware and Application

(1) Indicates change in behavior from ControlLogix 5570 and older controllers.

(2) “Valid” includes the No Project condition.

(v1.x firmware)

(1)

Firmware > 1.x and Internal Nonvolatile

Memory is not Valid

Does Nothing Does Nothing

• Loads Application

(1)

• Loads Firmware if there is a revision mismatch

• Loads Application

(2)

Firmware > 1.x and Internal Nonvolatile

Memory is Valid

• Loads Firmware if there is a revision mismatch

• Loads Application

Does Nothing

(2)

38 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

Communication Options

Several communication networks are available for use. This table describes

typical network applications that are used, and lists the networks available to

support such applications.

Application Type 5570 Controllers -

Communication options • EtherNet/IP

Integrated Motion • EtherNet/IP

Time Synchronization EtherNet/IP - Available with Integrated Motion and non-motion

Control of distributed I/O • ControlNet

Produce/consume data between

controllers

Messaging to and from other devices,

including access to the controller via

Logix Designer application

(1) With Studio 5000 Logix Designer Application Version 31.00.00 or later.

Supported Networks

• ControlNet®

• DeviceNet®

• Data Highway Plus™ (DH+™)

• Remote I/O

•SynchLink™

•USB Client

• SERCOS interface

• Analog options:

– Encoder input

–LDT input

– SSI input

applications

• DeviceNet

• EtherNet/IP

• Foundation Fieldbus

•HART

• Universal remote I/O

•ControlNet

• EtherNet/IP

•ControlNet

• DeviceNet (only to devices)

• Data Highway Plus (DH+)

•DH-485

• EtherNet/IP

5580 Controllers Supported Networks

EtherNet/IP

• SERCOS interface

• Analog options:

– Encoder input

–LDT input

– SSI input

(1)

(1)

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 39

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

Communication Throughput

Unlike 5570 controllers, which shares the main core between application code

and communications, 5580 controllers run communications asynchronously

from the user application.

This implementation provides better communications throughput in both the

bandwidth and speed of data the 5580 controllers can deliver to and from, for

example, HMIs, Historians, and MES systems. It also improves the overall

application performance as the controller no longer has to task switch and

pause application execution to handle HMI or other class 3 traffic.

For 5570 and 5580 controllers, the controller runs communication

asynchronously to the application, make sure communication that is delivered

to the controller is complete before the application executes on the newly

delivered data. This applies to both data that comes into the controller and

data that goes out.

For example, if the HMI is writing a large block of recipe data to the controller,

application code can start executing on that recipe data before the data writing

process finishes. This action results in half of the current recipe and half of the

last recipe in the application space.

Traditionally, programmers have used the following techniques to control the

effects of asynchronous communications:

•UID/UIE pairs

•Periodic tasks

•Moving data with CPS instructions

The techniques all rely on controlling when the main core can switch tasks.

This helps to prevent the communications task from changing data while the

control task used it. Because the controller processes communications on an

independent core of the CPU, then UID/UIE pairs and Periodic Tasks are not

as effective in all cases.

The items that are highlighted in this table are where controller behavior

differs.

Table 7 - ControlLogix 5570 and ControlLogix 5580 Controller Behavior Differences

Tag Read/Write

Source

HMI

MSG

I/O Update Allows Allows

Produce/Consume Allows Allows

Other User Tasks Blocks Blocks

Motion Planner Allows Allows

Blocks - Stops source data values from change by communications during application execution.

Allows - Communications can change source data values during application execution.

5580 Controllers 5570 Controllers

Allows Blocks Blocks Blocks Allows Blocks

Allows Blocks Blocks Blocks Allows Blocks

UID/UIE CPS Peri odic Task

5580 Controllers 5570 Controllers 5580 Controllers 5570 Controllers

Blocks Blocks Allows Allows

Blocks Blocks Allows Allows

Blocks Blocks Allows Allows

Blocks Blocks Allows Allows

40 Rockwell Automation Publication 1756-RM100F-EN-P - October 2018

Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems Chapter 2

Build Button

Because the controllers have 32-bit data integrity, this only applies to data

structures larger than 32 bits. If word-level integrity is your primary concern,

the 32-bit data integrity does not impact your data use.

Good programming practice dictates the use of two unique words at the

beginning and the end of data. The controller validates the words to assure the

entire structure has data integrity. We recommend that the handshake data is

changed and the application code validates it every transaction before the

controller application code or higher-level system reading controller data acts

on it.

Download the Program to the Controller

The first time that you download a program, it can take longer than subsequent

downloads. These situations can affect download/compile times:

• The capability of the personal computer or laptop.

• You download the project immediately after a project import or upload,

but before Logix Designer has compiled the project once.

• You edit a User Defined Tag (UDT), Add-On Instruction (AOI), or an

object that is used in many places.

• Increased load when Logix Designer compiles and generates code.

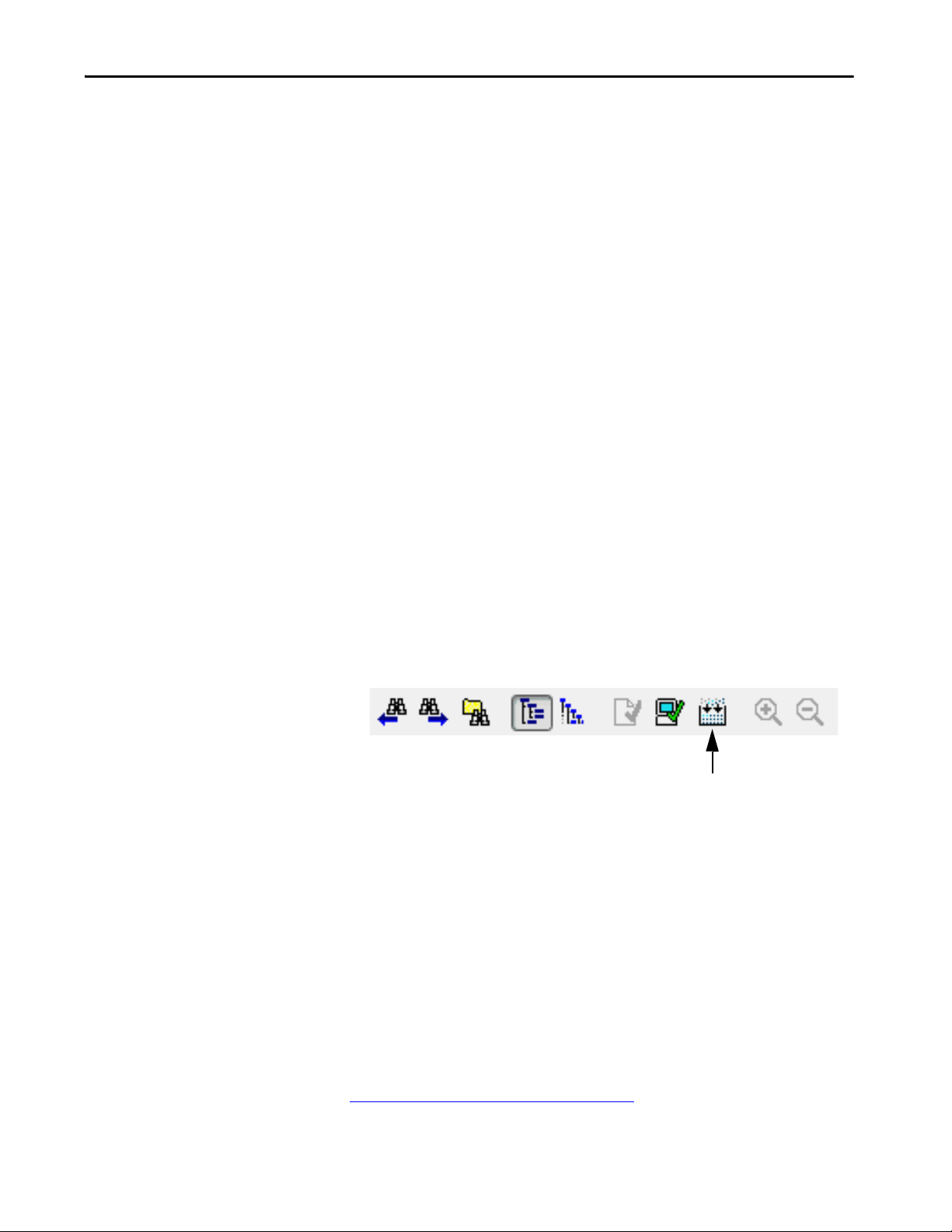

Build Button

The new Build button in Logix Designer creates binary files that are compiled

from user subroutines, and caches them in the project .ACD file.

If these files are present in the project during a download, then Logix Designer

does not have to recompile them, and saves time during the download process.

Every download requires that only the changed subroutines must be

recompiled. You can perform a build offline, save the project .ACD file, and

later distribute it to many controllers without recompilation.

This manual build step is optional. If you do not use the build button, Logix

Designer builds all necessary files when you initiate a download.

An imported project requires a complete rebuild, and extends the download

process the first time you attempt a download.

Downloading Workflow Change on page 42

download changes.

Rockwell Automation Publication 1756-RM100F-EN-P - October 2018 41

provides an explanation of the

Chapter 2 Replacement Considerations with ControlLogix 5580 and GuardLogix 5580 Systems

Downloading Workflow Change

Offline builds can save time when doing subsequent downloads.

5580 Controllers 5570 Controllers

Only changed source code is recompiled on a download. All source code is recompiled on every project download.

Mitigation

Adjust your workflow to save workstations from having to rebuild the project.

You can do offline builds, save the project file, and distribute it to other

workstations to minimize your download times.

Upload Fidelity Change

When you upload, projects that contain program parameters and aliases now

are faithfully reproduced. The uploaded Ladder Diagram source code is an